Page 1

Operating Instructions

HVS 1.1 - HVS 1.2

HVS 3.2 - HVS 3.4

Sensorless

V 201203A

771079102 Manual HVS1.3-3.4 ENGLISH

Page 2

Page 3

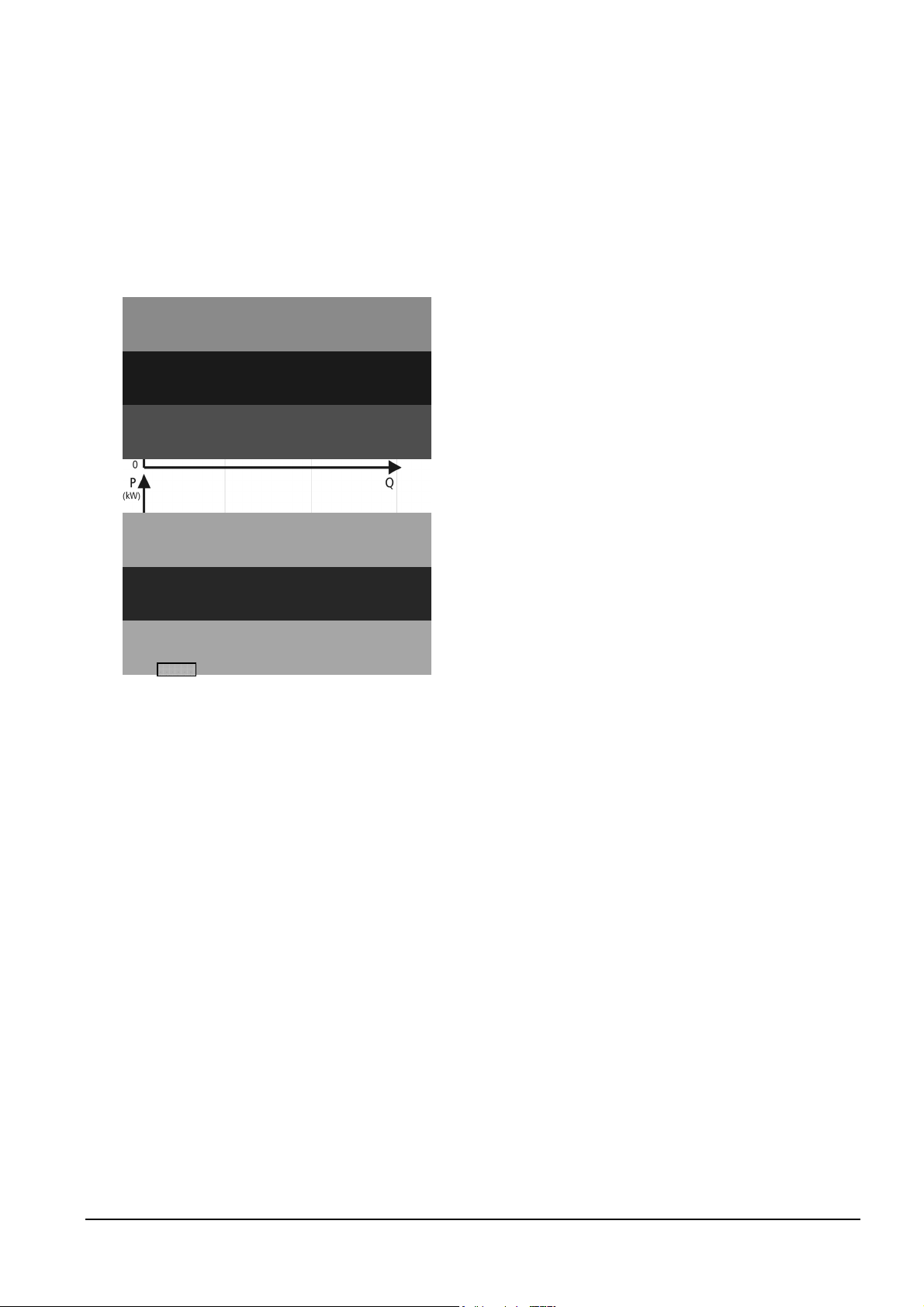

HYDROVAR sensorless

The idea is to control the pump speed

Energysavings

according to the power consumption of

the motor instead to the head of the

pump.

Each working point at a defined speed on

the curve of required pump head in the

hydraulic diagram (A,B,C) has also a

corresponding point in the electric

performance diagram (D,E,F).

Each of these points is defined by the

power consumption at the same speed.

All these points of power consumption at

different speeds results in a pretended

curve of power consumption at different

speeds.

If the controller varies the speed of the

pump at different flow values so that the

power consumption moves along this

curve and the working point of the pump

in the hydraulic diagram will also move

along the corresponding curve of pump

head but without measuring this head.

3

Page 4

Index

1. IMPORTANT SAFETY INSTRUCTIONS ................................................................................................6

2. TECHNICAL DATA - HYDROVAR SENSORLESS AND GENERAL DATA................................................8

2.1 DIMENSIONS ............................................................................................................................................9

3. HYDROVAR SENSORLESS MOUNTING............................................................................................10

3.1 MOUNTING THE HYDROVAR SENSORLESS ON THE PUMP ..........................................................................................10

3.1.1 Included components ................................................................................................................10

3.1.2 Mechanical mounting ................................................................................................................11

3.1.3 Mounting the Thermistor...........................................................................................................13

3.2 ELECTRIC INSTALLATION AND WIRING.....................................................................................................................14

3.2.1 Means of protection ..................................................................................................................14

3.2.2 Wiring the Hydrovar sensorless to the motor.............................................................................14

3.3 MAIN PART OVERVIEW .......................................................................................................................................15

3.4 CONNECTING THE POWER CABLES .........................................................................................................................16

3.4.1 Control Terminals.......................................................................................................................17

3.5 FRONT PLATE .................................................................................................................................................19

4 FUNCTION BUTTONS OF THE HYDROVAR SENSORLESS.................................................................20

5 LEARNING A SYSTEM CURVE TO ADAPT THE SYSTEM’S REQUIREMENTS......................................21

6 SETTINGS AT THE SUBMENU – PROGRAMMING DEVICE ...............................................................23

7 SETTINGS AT THE SUBMENU-PARAMETER .................................................................................................24

7.1 AUTO START .................................................................................................................................................24

7.2 SUBMENU INVERTER..........................................................................................................................................25

7.2.1 Maximum Frequency..................................................................................................................25

7.2.2 Boost .........................................................................................................................................25

7.2.3 Fixed Speed ...............................................................................................................................25

7.3 SUBMENU CONTROLLER .....................................................................................................................................26

7.3.1 Function Mode...........................................................................................................................26

7.3.2 Window Hz - Interpolation ........................................................................................................26

7.3.3 Window Fx - Function mode ......................................................................................................26

7.3.4 Shift – Function mode................................................................................................................ 26

7.3.5 Accel high..................................................................................................................................27

7.3.6 Decel high..................................................................................................................................27

7.3.7 Accel Low ..................................................................................................................................27

7.3.8 Decel Low. .................................................................................................................................27

7.4 SUBMENU REFERENCE CURVE ..............................................................................................................................28

7.4.1 Reference Curve.........................................................................................................................28

7.4.2 Power / Frequency .....................................................................................................................28

7.4.3 Coefficients A / B / C .................................................................................................................. 28

7.5 SUBMENU TEST-RUN .........................................................................................................................................29

7.5.1 Start Test Run ............................................................................................................................29

7.5.2 Enable Test Run .........................................................................................................................29

7.5.3 Test Frequency...........................................................................................................................29

7.5.4 Boost Test Run...........................................................................................................................29

7.6 SUBMENU ECONOMY ........................................................................................................................................30

7.6.1 Currency ....................................................................................................................................30

7.6.2 Rated Power ..............................................................................................................................30

7.6.3 Costs / kWh................................................................................................................................30

7.6.4 Clear Savings .............................................................................................................................30

4

Page 5

7.7 MODE CONTROLLER .......................................................................................................................................... 31

7.8 SWITCH INTERVAL.............................................................................................................................................31

7.9 SET PASSWORD................................................................................................................................................31

7.10 LEARNING .................................................................................................................................................31

7.11 DEFAULT .................................................................................................................................................31

7.12 SUBMENU DIAGNOSIS – “READ ONLY” PARAMETERS ..............................................................................................32

7.12.1 Pump Runtime .........................................................................................................................32

7.12.2 Pump Address..........................................................................................................................32

7.12.3 Error memory...........................................................................................................................32

7.12.4 Software Version .....................................................................................................................32

8 CONTROLLER MENU OF THE PROGRAMMING DEVICE ..................................................................33

8.1 CONTROLLER MENU CONFIGURATION ....................................................................................................................33

8.1.1 Automatic connection to the programming device....................................................................33

8.1.2 Software Version .......................................................................................................................33

8.2 SUBMENU ADDRESS ..........................................................................................................................................34

8.2.1 Change of pump address...........................................................................................................34

9 POSSIBLE ERROR MESSAGES .........................................................................................................35

9.1 OVERHEATING – MOTOR ....................................................................................................................................35

9.2 OVERVOLTAGE .................................................................................................................................................35

9.3 UNDERVOLTAGE ............................................................................................................................................... 35

9.4 OVERLOAD .................................................................................................................................................35

9.5 OVERHEATING OF THE HEAT SINK..........................................................................................................................36

9.6 ERROR POWER MEASUREMENT.............................................................................................................................36

9.7 ADDITIONAL INTERNAL PROCESSOR ERROR MESSAGES: ..............................................................................................36

10 POSSIBLE INDICATIONS OF THE LED ON THE HYDROVAR SENSORLESS...................................................37

11 MAINTENANCE .........................................................................................................................................38

5

Page 6

1. Important safety instructions

Read and follow the operating instructions

and safety instructions carefully before

starting operations! All modifications must be

done by qualified technicians!

In addition to the instructions contained in these operating instructions please pay

attention to universal safety and accident prevention regulations.

Warns that failure to observe the precaution may cause electric shock.

Warns that failure to observe the precaution may cause personal injury

or damage to property.

The HYDROVAR sensorless has to be disconnected from the power supply before any work

can be carried out in the electrical or mechanical part of the system.

Installation, maintenance and repair work may only be carried out by trained, skilled and

qualified personnel.

Unauthorised modifications or changes to the system make all guarantees null and void.

When in operation the motor can be stopped by remote control, where by the HYDROVAR

sensorless and the motor remain under voltage. For safety reasons, the unit must be

disconnected from the power supply when carrying out work on the machinery as locking

out the equipment by switching off the release mechanism or set value cannot prevent

accidental starting of the motor.

When the HYDROVAR sensorless is connected to power supply, the

components of the power unit as well as certain components of the master

control unit are also connected to the power supply.

Touching these components seriously endangers life!

Before removing the HYDROVAR sensorless cover the system must be

disconnected from the power supply. After switching off the power supply

wait at least 5 minutes before starting work on or in the HYDROVAR

sensorless (the capacitors in the intermediate circuit have to be discharged

by the installed discharge resistors first).

Voltages of up to 400 volts are possible (if there are faults it can be higher).

6

Page 7

All work carried out when the HYDROVAR sensorless is open may only be

performed by qualified authorised staff.

Furthermore, care must be taken not to short circuit the neighbouring

components when connecting the external control wires and that open

cable ends which are not in use are insulated.

The HYDROVAR sensorless contains electronic safety devices which switch

off the control element in the event of faults, whereby the motor has zero

current but remains energised and comes to a halt. The motor can also be

halted by mechanical blocking. If it is switched off electronically the motor

is disconnected from the mains voltage through the electronics of the

HYDROVAR sensorless but is not potential-free in the circuit.

In addition voltage fluctuations, especially power failures can cause the

system to switch off itself.

Repair of faults can cause the motor to start up again.

The system may only be put into operation when it has been earthened. In addition,

equipotential bonding of all pipes must be ensured.

The operating instructions have to be read, understood and followed by the operating

personnel. We point out that we accept no liability for damage and operating disorders

which are the result of non-compliance with the operating instructions.

NOTICE!

High voltage tests of the inverter or the motor may damage the

electronic components! Hence bridge before the in- and outgoing

terminals L -N -- U- V-W.

To avoid incorrect metering by capacitors incorporated in the

electronic part isolate the motor from the HYDROVAR sensorless.

Preliminary Inspection

Visual Inspection

Upon delivery, check the integrity of the packaging.

After you have removed the external packaging, visually inspect the converter to make sure

it has suffered no damage during transport. If any damage is visible, inform your

distributor within 8 days from the delivery date.

Handling and Storage

The product must be lifted and handled carefully.

During transport and storage, protect the converter from humidity and mechanical damage

caused by impacts, falls, etc...

ATTENTION:

Dispose of all packing materials and the unit in accordance with local regulations.

7

Page 8

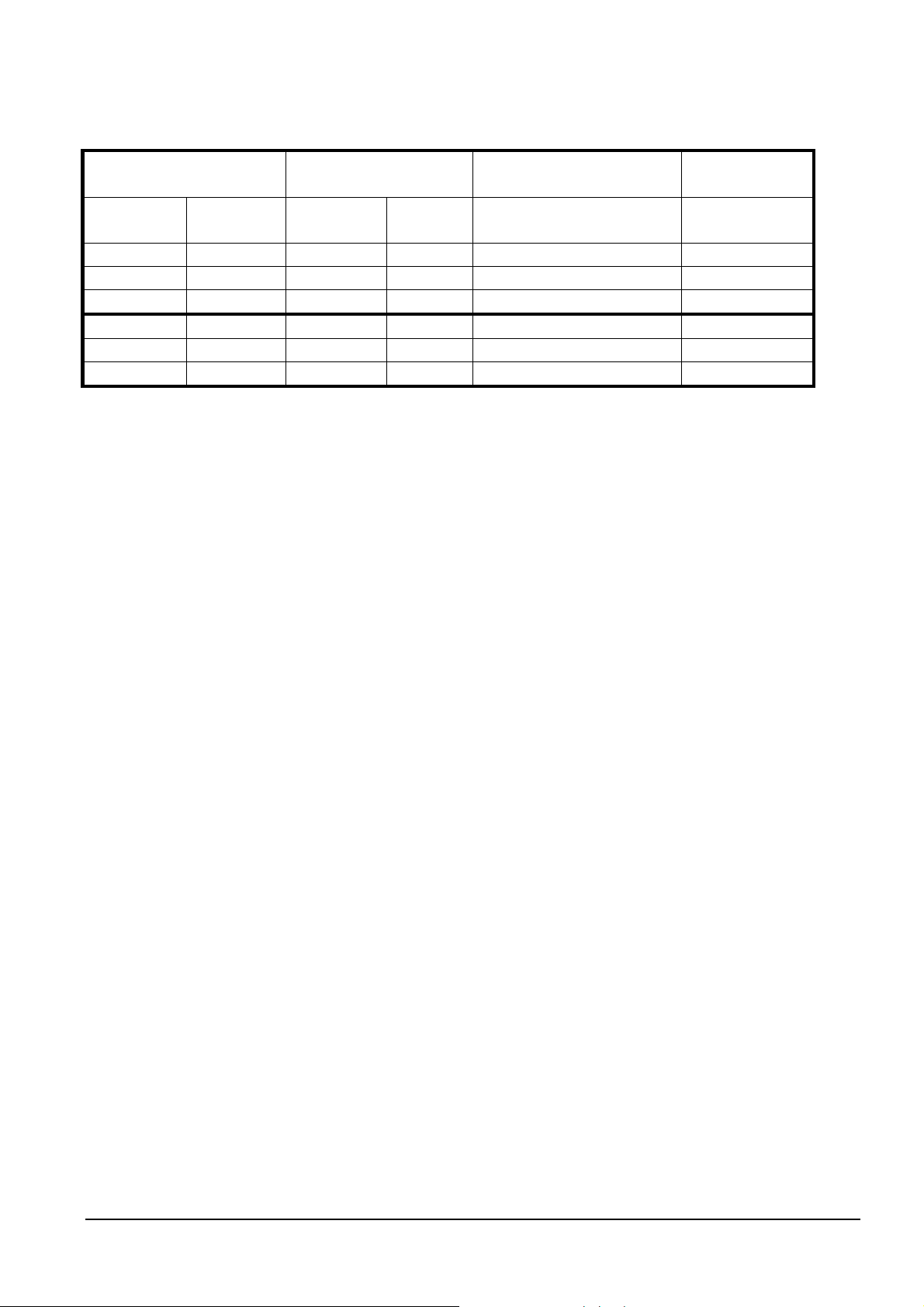

2. Technical Data - Hydrovar sensorless and General Data

HYDROVAR

sensorless

Type

HVS

Rated

output

Hydrovar sensorless

output to the Motor

Voltage Max.

current

Supply Voltage (Uin) Prefuse

min.

Mains frequency

[A] Ampere

48-62 [Hz]

1.1 1,1 kW 3x0-Uin 4,8 A 1x220-240V ±15% 10

1.15 1,5 kW 3x0-Uin 7,0 A 1x220-240V ±15% 16

1.2 2,2 kW 3x0-Uin 10,0 A 1x220-240V ±15% 20

3.2 2,2 kW 3x0-Uin 5,7 A 3x380-460V ±15% 10

3.3 3 kW 3x0-Uin 7,3 A 3x380-460V ±15% 13

3.4 4 kW 3x0-Uin 9 A 3x380-460V ±15% 16

Output voltage: 3x 0...Uin VAC / 0-70 Hz

(depends on the input voltage)

Min. frequency: 0 – max. frequency

Electrical efficiency: > 95%

Protection against: Short circuit, over- and undervoltage, overheating of the

electronics (overload) and additional external protective functions

via PTC (motor temperature) and low water switch.

A mains filter is fitted to ensure interference immunity.

The Hydrovar sensorless complies with the general EMC provisions and has been tested

according to the following standards:

• Disturbance voltage: EN 55011

• EMC – Immunity: EN 61000-4-3 and ENV 50204

• Electrostatic discharge: EN 61000-4-2

Ambient temperature: 5° C ... + 40°C

Storage temperature: -25° C ... + 55° C

(+70°C during max. 24 hours.)

Humidity: rH max. 50% at 40°C, unlimited

rH max. 90% at 20°C, max. 30 days per year

Condensation not permitted !

Air pollution:

The air may contain dry dust as found in workshops where

there is no excessive quantity of dust due to machines.

Excessive amounts of dust, acids, corrosive gases, salts etc.

are not permitted

Altitude: max. 1000m above sea level

At sites over 1000 m above sea level, the maximum output

power is derated by 1% for every additional 100m.

If the installation site is higher than 2000 m above sea level,

please contact your local distributor.

Class of protection: IP55

8

Page 9

∅

∅

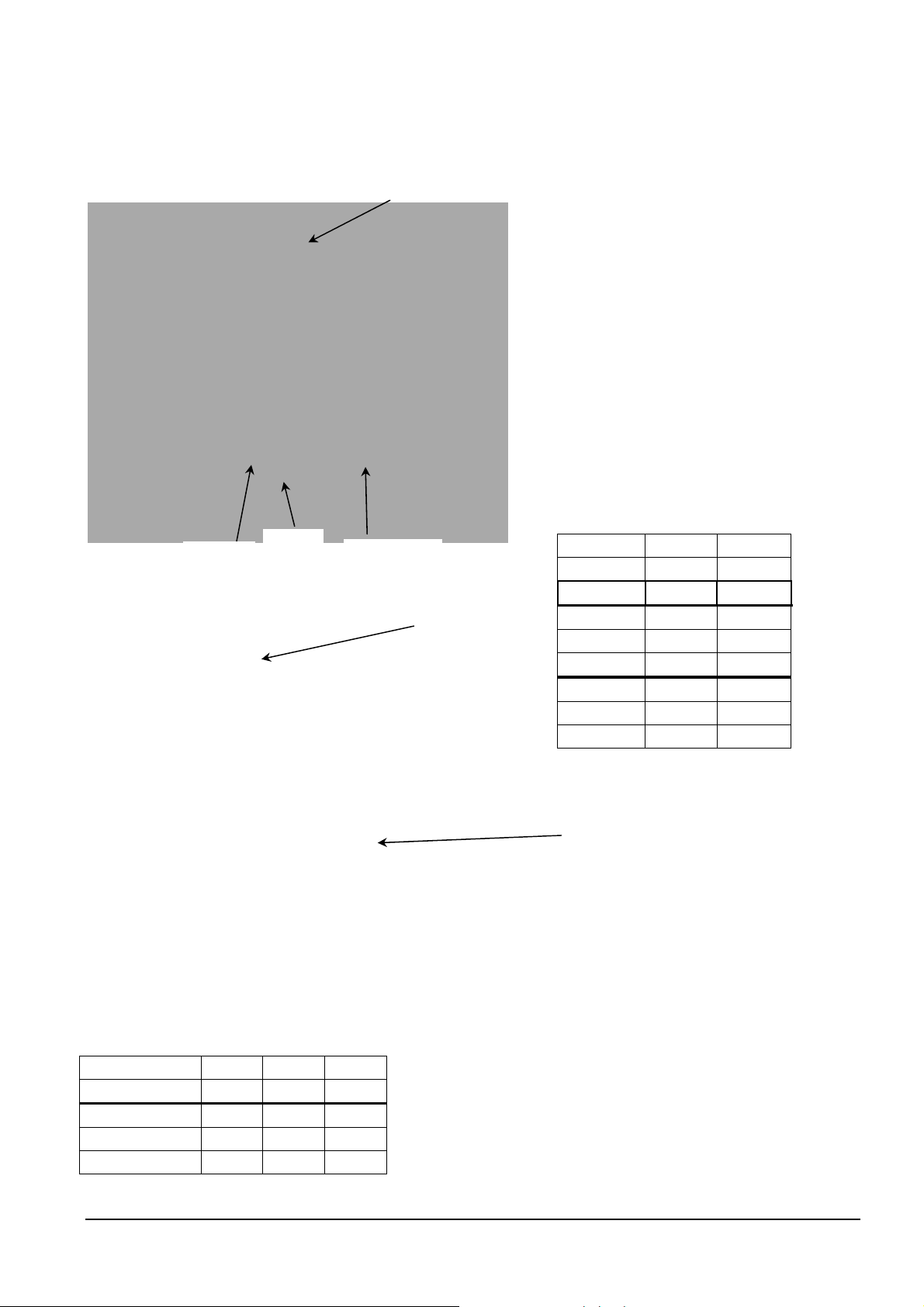

2.1 Dimensions

HVS 1.1:

closing cap

HVS 1.15/1.2/3.2/3.3/3.4

12

7

cable

gland

closing cap

Type: WM-Kit

Weight Weight

[Kg] [Kg]

HVS 1.1 2,00 1

HVS 1.15 4,70 1

HVS 1.2 4,70 1

HVS 3.2 4,70 1

HVS 3.3 4,70 1

HVS 3.4 4,70 1

cable entries

2x for M20

2x for M16

3x for M12

Dimensions for Hydrovar sensorless with wall mounting unit

Type High Wide Deep

[mm] [mm] [mm]

HVS1.1 235 155 155

HVS1.15-1.2 235 155 155

HVS3.2-3.4 265 195 195

9

Page 10

p

3. HYDROVAR sensorless mounting

3.1 Mounting the HYDROVAR sensorless on the pump

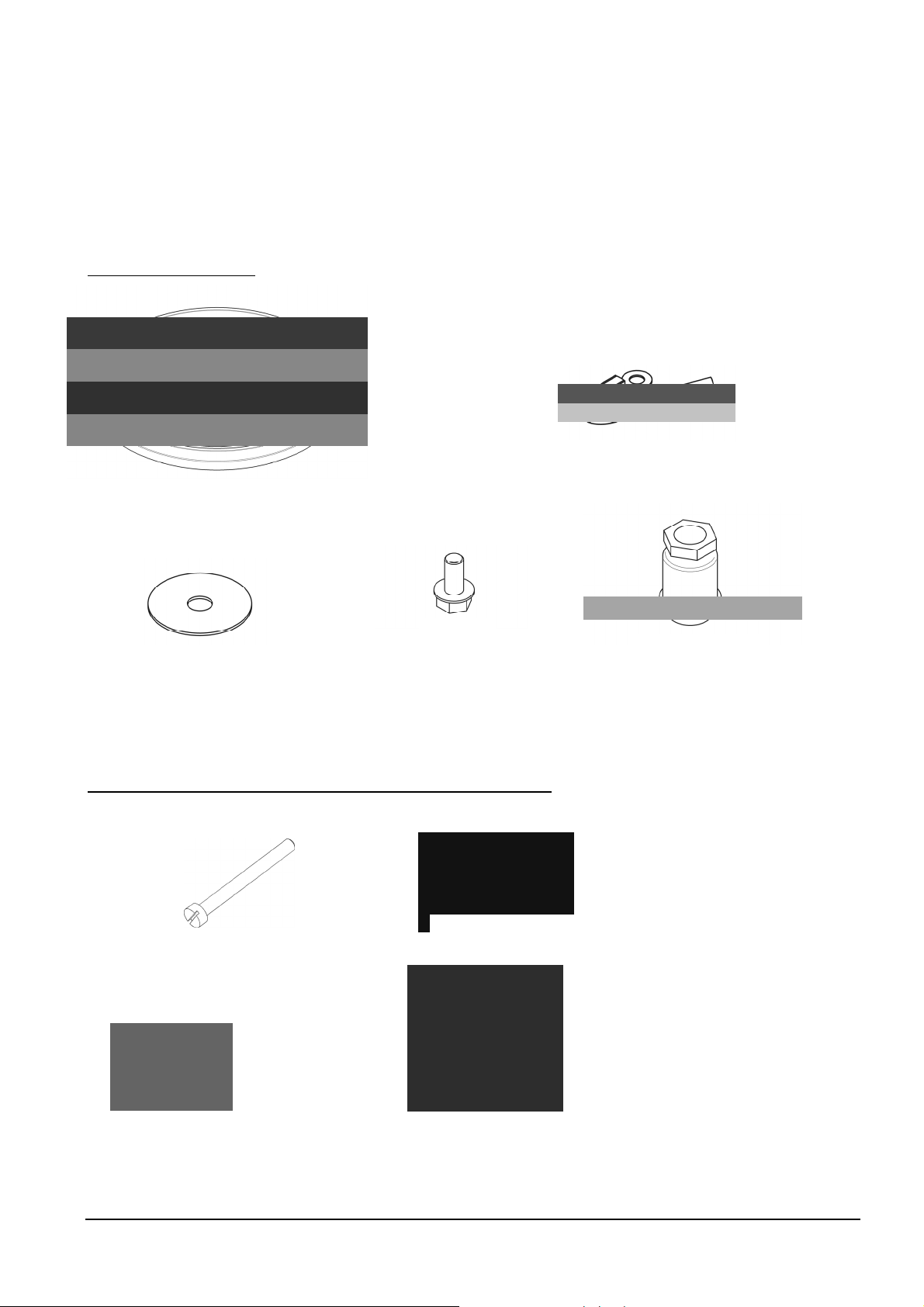

3.1.1 Included components

Variant for HVS 1.1:

mounting and distance ring

screw

washer

Variant for HVS 1.15/HVS 1.2/HVS 3.2/HVS 3.3/HVS 3.4:

thermistor

cable gland

screw M5x50

thermistor

cable gland

mounting clam

10

Page 11

sensorless

3.1.2 Mechanical mounting

Variant for HVS 1.1

Hydrovar

1. Remove the motor fan cover from

your 3-phase motor by removing the

mounting screws.

2. Put the mounting and distance ring

(1) between the fan cover and the

Hydrovar sensorless and fix them

together with the screw (3) by using

the included washer (2).

3. Use the fan cover screws to mount

(1) mounting

and distance

ring

the fan cover/Hydrovar sensorless

combination to the motor

motor fan

cover

(2) washer

(3) screw

CAUTION!:

Don’t forget the washer between the screw and the motor fan cover!

11

Page 12

Variant for HVS 1.15/HVS 1.2/HVS 3.2/HVS 3.3/HVS 3.4:

Screws with

Gasket

4 screws

M5x50

Centre bit

4 mounting

clamps

CAUTION!

Don’t forget the gaskets

for the 3 screws.

Ensure that there is no

water on the unit before you

open the cover.

Connection

Motor conduit box

Thermistor

Mounting ring

CAUTION!

If you use a motor with plastic fan cover, you have to

a mounting ring.

use

Mounting:

Remove the 3 screws holding the HVS

cover.

Place the centre bit in the HVS fan cover.

Place the HVS fan cover on the motor.

Hang the 4 clamps by the motor fan

cover and fix them with the 4 screws.

Mount the cover with the 3 screws.

12

Page 13

3.1.3 Mounting the Thermistor

Variant A:

Motor

Thermistor

Terminal block

Rubber gasket

Cover of the

conduit box

Variant B:

Thermistor

Open the cover of the conduit box and remove also the terminal block inside.

Fix the Thermistor (Variant A or B)

Electrical connection of the motor cables

13

Page 14

3.2 Electric installation and wiring

NOTICE!

All installations and maintenance have to be performed by

trained and qualified personnel with proper tools!!

WARNING!

In case of a failure, disconnect and lockout electrical power and wait

five minutes for capacitor discharge before servicing the Hydrovar

sensorless.

3.2.1 Means of protection

Ask your power supply company which means of protection are required.

Applicable: AC and DC current-operated circuit breaker (FI), TN systems, protective

circuits.

When using a FI protection switch, make sure that it also releases in the event of

a DC fault, use for each Hydrovar sensorless a separate FI-switch!

3.2.2 Wiring the Hydrovar sensorless to the motor

Remove the 3 screws holding the top of the Hydrovar sensorless. Carefully lift the top,

loose the earth screw and put the Hydrovar sensorless cover aside.

Now you can see the 2 main parts:

(1) control card with all terminals for the control signals and the RS485 interface

(2) main card with all power components and terminals for power supply and motor

14

Page 15

)

3.3 Main part overview

HVS 1.1:

Motor

connections

Cable

introduction for

motor cable

(at least

11,5mm)

Cable introduction for control

cable (at least 5mm)

HVS 1.15/HVS 1.2/HVS 3.2/HVS 3.3/HVS 3.4:

control card (1

control card (1)

main supply

connections

main board (2)

Cable gland

(for power

supply 5-10mm)

main board (2)

main supply

connections

motor

connections

cable introduction for

control cable

15

Page 16

3.4 Connecting the power cables

a) motor cable:

Locate the motor connections inside the Hydrovar sensorless. Connect wires to the

terminals and rout the cable through the cable gland.

You must take a motor cable at least Ø 11.5mm if you want protection IP55. (only HVS 1.1)

The earth-wire of the cable has to be fixed with the screws with the earth-symbol to the

cooling body of the Hydrovar sensorless.

b) Connections in the conduit box

The connection of the motor cable depends on the type of the motor and can be done in

star or delta connection:

(you have to use the connection for a motor voltage of 3x230V shown on the motor label)

Star-connection

Delta-connection

c) supply cable

The main power cable is connected to the terminals labelled L1, N for the 230 VAC, single

phase unit; or L1, L2, L3 for the 3x400VAC, three phase unit.

16

Page 17

Control terminals

terminals of the

RS485 interface

control terminals

HVS 1.1

Power supply 220V

HVS 1.15, 1.2

HVS 3.2, 3.3, 3.4

3.4.1 Control Terminals

All external used cables have to be shielded. Do not connect the mass of the electronic

components to other higher potentials.

All electronic ground and GND of the RS 485-interface are connected internal.

For external off/on and low water, switch contacts suitable for <10 V are necessary.

The control cable must be at least Ø 5mm.

If unshielded control cables are used, signal interference may occur and interfere

with the function of the inverter.

17

Page 18

Control-Terminals:

12

max. 500mA/125V

11

10

NC

CC

NC

Error relay – X2/10 and

X2/11 is closed if there is an

error or no power supply

Motor Thermistor

Internal Power measurement

External ON/OFF

Fixed Speed

Electronic Ground

+5 V

2

X

3

X

9

8

7

6

5

4

3

2

1

4

+ 5V SIO

GND

3

2

SIO +

1

SIO -

White wire

Black wire

Red wire

RS 485 Interface

Internal connected to

Power measurement

X2/3 is used for internal

power measurement

To run with Fixed Speed

close X2/2 and X2/3

Connect X3/1-2-3 to

Master / Slave unit

18

Page 19

3.5 Front plate

HVS 1.1-1.2:

HVS 3.2/3.3/3.4:

connection of the programming device

indication LED

START / +

STOPP / -

19

Page 20

4 Function buttons of the HYDROVAR SENSORLESS

CAUTION!

Before you start the system, the pump has to be filled and all wiring and

piping has to be done!

The Hydrovar sensorless is delivered with the following settings as default:

Learning: enabled – allows to learn a reference curve

Auto Start: enabled – after power supply automatic start

Other possibilities to use the push buttons of the Hydrovar sensorless:

START – Press ▲ button (if Autostart is disabled, the pump can be started by

pressing the ▼ button and then the ▲ button at the first start up or after a

power supply failure) or

STOP - Press the ▼ button.

Both buttons are located on the front plate of the Hydrovar sensorless

• Set Frequency for constant speed

For changing the speed without the external programming device, you have to do the

following:

1.) Press button ▼ to stop pump

2.) Press the ▲ and ▼ buttons together for more than 10 sec, the colour of the LED

changes to orange after 5 seconds and after further 5 seconds the LED changes to

orange fast flashing.

3.) Now you can change the speed of the pump by using the button ▲ (higher

frequency) or ▼ (lower frequency).

(If the external programming device is connected with HYDROVAR SENSORLESS, the

power as well as the frequency is shown on the display and you can also change the

frequency with the ▲ and ▼

buttons of the programming device.)

4.) When you have selected the right frequency, don’t press a button for 5 seconds and

that speed is saved automatically. Also after power supply fault the pump will run on

this speed.

5.) Press the ▲ and ▼ buttons together for 5 seconds the pump will stop.

If you have stored system points the HYDROVAR SENSORLESS start with automatic

mode.

20

Page 21

5 Learning a System Curve to adapt the system’s requirements

CAUTION!

The learning of the system’s required curve depends on the saved system points. It is

necessary to start at flow=0 and to save at least four system points up to a maximum

of 12 points.

Before you start the system, the pump has to be filled and all wiring and

piping has to be done!

Learning:

Before you start to learn, it is important that the motor was running with constant speed

to reach the operation temperature. Then you can choose between learning the first point

and select one of the pre programmed reference curves (only by using the external

programming unit) or learn 3 up to 12 points to run along the optimum system curve.

a) Using one of the pre programmed reference curves 2...7

1.) connect the external programming device to select your favourite reference curve

2.) Stop the pump while pressing the button ▼ on the HYDROVAR SENSORLESS.

3.) Press the ▲ and ▼ buttons together for 5 sec, the colour of the LED

changes from green to orange. The pump is now ready to learn.

4.) Set now the first system point at flow=0. You can change the speed of the pump

by using the button ▲ (higher frequency) or ▼ (lower frequency).

Check the difference pressure on an important point of the system to set the

required frequency.

On the display of the programming device, you can see the power and the

frequency.

5.) To save the learned point press the ▲ and ▼ buttons together, until the

LED will begin to start fast flashing. The Hydrovar sensorless stops automatically.

This saved point is now the min. point of your selected reference curve, but it can be used

for all other reference curves also.

21

Page 22

b) Learning a complete system curve = reference curve 0 [Default]

(no external programming device required)

1.) Stop the pump while pressing the button ▼ on the HYDROVAR SENSORLESS.

2.) Press the ▲ and ▼ buttons together for 5sec, the colour of the LED

changes from green to orange. The pump is now ready to learn.

3.) Set now the first system point at flow=0. You can change the speed of the pump

by using the button ▲ (higher frequency) or ▼ (lower frequency).

Check the difference pressure on an important point of the system to set the required

frequency.

If external programming device is connected with HYDROVAR SENSORLESS, you can see

the power and the frequency on the display.

4.) To save the learned point press the ▲ and ▼ buttons together, until the

LED will begin to start fast flashing.

5.) Increase now the flow of the pump up to 20-30% of the maximum flow.

Increase also the frequency by using the button ▲ (higher frequency) or ▼ (lower

frequency) to reach the required value.

6.) To save this point press the ▲ and ▼ buttons together (-> 4.)

Learn now the next points up to the maximum flow.

7.) To save the last system point and to end the learning mode you have to press the ▲ and

▼ button together after setting the last frequency, until the pump stops automatically

and the LED starts shining green.

Now the required system curve is stored.

8.) If “Autostart” function is disabled start the automatic mode by pressing button ▲. The

Hydrovar sensorless increases now the speed till it reaches the right point depending

on the system curve.

With the programming device you are now able to change ramps and windows for a better

controlling.

22

Page 23

6 Settings at the Submenu – Programming Device

You are always able to connect the programming device to HYDROVAR SENSORLESS.

The LED will change the colour to orange, when connection was successful.

POWER X.X %

SPEED X.X Hz

POWER SAVING

X.XX KW

TOTAL SAVINGS

XX.XX EUR

The actual Power [%] and the actual output

frequency [Hz] are displayed.

Shows the actually saved energy [kW]

Shows the whole saved energy costs

(in EUR / USD / GBP / CHF)

General for operating with the external programming device:

With Í and Î you can select the different parameters in the menu.

To enter a submenu, press the Ð button. To leave the submenu, you have to press the

buttons Í or Î for longer than 3 sec.

With Ï or Ð you can change the parameters.

Each change in the settings is saved after leaving this parameter with the buttons

Í or Î.

When you have changed a parameter and you leave it, the LCD shows you the following

message

SAVE

PARAMETER

SUBMENU

PARAMETER

PASSWORD

0000

NOTICE!

The Password protection prevents untrained personnel from accidentally changing the

base settings

PASSWORD

0066

Hold the Î button down to reach the next display

for about 2 sec.

From the 1

st

display, press the Î button to reach

Then press the Ð button and the display will change to

Press the Ï button until you reach the number 0066

23

Page 24

7 Settings at the Submenu-Parameter

IMPORTANT!

Before entering the secondary menu these instructions must be read

carefully to prevent incorrect settings which will cause malfunction.

Parameter settings on the end of the manual with the number of the side and place for the

changing Parameters.

7.1 Auto start

Auto Start

Enabled

Autostart Enabled means that the pump starts again automatically after an interruption of

the power supply (power failure).

If Autostart Disabled is set, the pump has to be restarted manually after a power failure,

by pressing Ð and Ï.

You can select between Ð Disabled and Ï Enabled

24

Page 25

7.2 Submenu Inverter

Submenu

Inverter

To enter this menu you have to press the Ð button, to

leave the menu, press the Îbutton longer than 3 sec.

7.2.1 Maximum Frequency

Max. Frequency

50.0 Hz

Attention: Settings higher than 50 Hz may overload the motor!

Settings of 10% above nominal frequency cause 33% more power consumption!

Possible setting between min. 40 and max. 70 Hz.

7.2.2 Boost

B O O S T

5.0 %

Setting of the motor starting voltage in % of rated voltage.

Settings of 0...25% of maximum output voltage are possible. However, care should

be taken that settings are kept as low as possible so that the motor does not

become thermally overloaded.

The stated value determines the course of the

U/f-curve.

7.2.3 Fixed Speed

FIXED SPEED

30.0 HZ

This speed is activated if the Digital Input (X2-2/3) is closed

or

if it is a single pump and there is ERROR POWERMEASURE detected.

This speed should be set to maintain a minimum flow (e.g. night consumption)

The energy savings are also activated with the Fixed Speed.

This speed is to run the motor with constant speed.

25

Page 26

7.3 Submenu Controller

Submenu

Controller

To enter this menu you have to press the Ð button, to

leave the menu, press the Îbutton longer than 3 sec.

7.3.1 Function Mode

Function Mode

Enabled / Disabled

Enabled: Function Mode activated, control along a calculated system curve

Disabled: Interpolation (Point to Point control) – only for special applications

7.3.2 Window Hz - Interpolation

7.3.3 Window Fx - Function mode

7.3.4 Shift – Function mode

Required Settings 0....1,5 Hz

Settings to high: oscillation is possible

This function activate an increase and decrease of speed around the actual system

point.

Window

2 Hz

Window Fx

2 %

Shift

0.0 Hz

Window, if function mode is disabled

Window, if Function Mode is enabled

Oscillation of the learned system curve, if Function

mode is enabled

26

Page 27

Time setting will influence the control of the pump and SHOULD NOT BE CHANGED at

normal operation. Possible settings for each ramp 0,05 - 1000 sec.

7.3.5 Accel high

Accel. High

10 Sec

Excessively fast running up time may overload the

inverter.

7.3.6 Decel high

Decel. High

10 Sec

Excessively slow running down time tends to generate over pressure.

Excessively fast running down time tends to cause

oscillation or hunting or can cause an error

(OVER VOLTAGE) during pump down of the pump.

7.3.7 Accel Low

Accel. Low

70 Sec

Excessively fast running up time tends to cause

oscillation.

7.3.8 Decel Low.

Decel. Low

70 Sec

A too fast setting leads to oscillation.

27

Page 28

7.4 Submenu Reference Curve

Submenu

Reference Curve

To enter this menu you have to press the Ð button, to

leave the menu, press the Îbutton longer than 3 sec.

7.4.1 Reference Curve

Reference Curve

0 - 7

This parameter allows selecting different pre programmed curves.

0... Learned curve with 3 up to 12 system-points

1... previous learned system curve

2... Selection A

3... Selection B

4... Selection C

5... Selection D

6... Selection E

7... Selection F

By using reference curve 2...7 it is only necessary to

learn one point at zero flow. You are also able to

change the reference curve while pump is running to

find the best suitable curve.

The different curves depending on the type of pump

and the duty point.

Change the curve by pressing Ï or Ð

7.4.2 Power / Frequency

POWER xxx

FREQ xx.x HZ

This parameter allows only the control of the learned points.

Check the learned points by using Ï and Ð.

(Learned points 1-12)

7.4.3 Coefficients A / B / C

These coefficients define the actual reference curve 0-7.

To change the coefficients it is necessary to know a special password.

A changing without knowledge about pump curve and power will produce a

malpractice of the pump.

COEFF A / B / C

x.xxx

Change value using Ï and Ð. Press the Î button

to save and change to next coefficient.

28

Page 29

7.5 Submenu Test-Run

Submenu

Testrun

To enter this menu you have to press the Ð button, to

leave the menu, press the Îbutton longer than 3 sec.

7.5.1 Start Test Run

Start Test Run

Ï + Ð

After starting this test run, the pump will speed up with the fasten ramp 1 to the set

speed and then will ramp down with the fasten ramp 2.

By simultaneously pressing Ï + Ð a test run will be

released even if the test cycle is not set.

7.5.2 Enable Test Run

Enable Test Run

100 h

the last stop for 20 seconds with the set speed.

Deactivating test run: Set 0 hours, by using Ï and Ð.

Repeating the test run: Select the test run and set the desired hours using the Ï

button.

Adjustable between 1...100 hours.

The test run starts the pump at the set time after

7.5.3 Test Frequency

Test Frequency

30.0 Hz

Frequency for manual and automatic test run.

Can be set from 0 Hz up to 70 Hz.

7.5.4 Boost Test Run

BOOST Test Run

10.0 %.

Start voltage in % of rated voltage in order to ensure

that the motor starts safely.

29

Page 30

7.6 Submenu Economy

Submenu

Economy

To enter this menu you have to press the Ð button, to

leave the menu, press the Îbutton longer than 3 sec.

7.6.1 Currency

CURRENCY

Change the currency using Ï or Ð.

EUR

This parameter allows you to change between EUR / USD / GBP / CHF.

This function is only important to show the right cost savings.

7.6.2 Rated Power

RATED POWER

Xx KW

To measure the correct energy savings it is necessary to input the maximum

power rate of the unit.

Maximum Power Rate of the used Hydrovar

sensorless

7.6.3 Costs / kWh

Input the correct energy costs for 1 kWh.

7.6.4 Clear Savings

COSTS / KWH

Xx EURO

CLEAR SAVING

Ï and Ð

Energy costs per kWh

Press both buttons to reset the actual energy saving to

0.

30

Page 31

7.7 Mode Controller

MODE

Single pump

Single

Select with the Ï and Ð “Single” (Single pump) or “Master-Slave” (up to 4 pumps).

7.8 Switch Interval

Switch Interval

0024

Adjustable between 0 (de activated) and 250 hours.

For changing the MASTER pump

7.9 Set Password

Set Password

0066

7.10 Learning

Learning

Enabled / Disabled

7.11 Default

Default

Ï + Ð

The pre-set password can be changed if necessary

with the Ï and Ð buttons.

Enabled – you allow to learn system points

Disabled – Learn mode is deactivated

To load DEFAULT – PARAMETER, press buttons Ï + Ð

together, till the timer is run down.

31

Page 32

7.12 Submenu Diagnosis – “read only” Parameters

Submenu

Diagnosis

To enter this menu you have to press the Ð button, to

leave the menu, press the Îbutton longer than 3 sec.

7.12.1 Pump Runtime

Pump Runtime

0000 Std.

Shows the running hours of the pump.

7.12.2 Pump Address

Pump-Address

1

This window shows the adjustment of the pump

address (only readable).

7.12.3 Error memory

The last three error messages are always saved in an internal memory. The

error signals can not be deleted!

Last Error

Shows the last error

........................

2nd Error

Shows the Error before the last error

........................

3rd Error

Shows the Error before Error 2

........................

7.12.4 Software Version

Software

CP – VOG: 004

This parameter shows you the used software version

of the HYDROVAR SENSORLESS.

32

Page 33

8 Controller menu of the programming device

To reach the controller menu, you have to press Î on the controller for longer than 3 sec.,

when the

1st display POWER X.X %

SPEED X.X Hz

is shown. Then the display will change to

Address 01

P1:run

P1 ...Master run ... HVS running

P2 ...Slave disabled ... HVS is not ready / extern on /off

P. ... not active stop ... HVS is ready, but not running

Error ... Error message or no supply voltage

Then press Í on the controller to change to

The actual values are displayed.

The actual pump-address is shown

8.1 Controller menu Configuration

Submenu

Configuration

To enter this menu you have to press the Ð button, to

leave the menu, press the Îbutton longer than 3 sec.

8.1.1 Automatic connection to the programming device

Auto Connecting

Enabled

! Only valid for programming device!

Auto connecting enabled: after plug in the programming device, it changes

automatically to the inverter menu. During this auto connection the programming

device is looking for a valid address and “SCAN CONNECTION” is shown on the

display.

Auto connecting disabled: there is no automatic connecting with the pump (choose

the address)

Auto connecting will be saved after leaving the submenu Configuration

8.1.2 Software Version

Software:

Software: VOGREM-XXX

In the second line of the display, there is shown the

version of the software of the programming device

and also the date of programming of this software.

33

Page 34

8.2 Submenu address

Submenu

Address

To enter this menu you have to press the Ð button, to

leave the menu, press the Îbutton longer than 3 sec.

8.2.1 Change of pump address

Address Change

00--> 00 *

To change the address it is not necessary to cut the interface connection to other

HYDROVAR SENSORLESSS.

On the left side there is shown the address of the HYDROVAR SENSORLESS, which

you want to select (select the address by using the buttons Ï or Ð). On the right

side, you can select a new address also with the buttons Ï and Ð. You only can

select an address, which is not used in the pump group!

To change between left and right side, press button Í or Î. The star shows the

actual used side.

If you have selected mode “MASTER-SLAVE” it is important that each Hydrovar

sensorless has it’s own address from 01 to 04

To save the new selected address press both buttons (Í and Î) together for 2 sec.

If it was successfully you will see the same address on both sides.

To leave the submenu press the Î key for 3 sec.!

Addresses from 01 to 04 can be set in this

parameter.

34

Page 35

9 Possible Error messages

You have to connect the programming unit to read the error message on the display.

After the cause has been remedied, the malfunction has to be reset by cutting off the

power supply for >30 seconds.

The last 3 error messages are saved in SUBMENU DIAGNOSIS

9.1 Overheating – Motor

XXX

Error-Mot-Temp

Possible causes: insufficient cooling, ambient temperature is too high or motor

overloaded.

9.2 Overvoltage

XXX

Error-Overvolt

Possible causes: Check mains supply, supply voltage too high, peak voltage owing to

switch heavy loads on the network, or RAMP 2 is to fast! Find the cause and take

countermeasures (e.g. network filter, RC-elements).

9.3 Undervoltage

XXX

Error-Undervolt

Possible cause: Check mains supply, faulty fuse or phase unsymmetry.

9.4 Overload

XXX

Error Overload

Possible causes: false data settings or the pump is working at a capacity significantly in

excess of its performance data.

Ramp 1 to fast

Max. frequency to high

Boost to low

35

Page 36

9.5 Overheating of the heat sink

XXX

Error KK-Temp

The thermal sensor, mounted on the cooling body of the HYDROVAR SENSORLESS

indicates over temperature.

Possible causes: insufficient cooling, ambient temperature is too high or motor

overloaded.

9.6 Error Power measurement

XXX

Error Powermeas

No detected signal from the power measurement.

Possible causes: wrong connection on the control card

9.7 Additional internal processor Error messages:

ERROR 1 :

ERROR 2 : Not used

ERROR 3 : Processor RAM error

ERROR 4 : Not used

ERROR 5 : Processor ROM error

ERROR 6 : Watchdog error

ERROR 7 : Timer error (quartz)

ERROR 8 : Programme error

These ERROR signals are acknowledged by disconnecting the power supply for

> 30 seconds.

If the error signal should appear again, contact customer service and provide a

detailed description of the error.

EEPROM-ERROR

(corresponding data block malfunction)

36

Page 37

10 Possible indications of the LED on the HYDROVAR SENSORLESS

.) Green shining ⇒ Motor stopped

(via external stop with terminals X2/4; X2/5

or the unit is stopped with the ▼ button on the front

plate)

.) Green slow flashing ⇒ Inverter is active, but the motor has stopped

.) Green fast flashing ⇒ Motor runs

.) Orange/green flashing ⇒ connected external programming device

.) Orange shining ⇒ LEARNING – change speed with the buttons ▲ and ▼,

or the external programming device is connected and the

pump is stopped with the button ▼ on the Hydrovar

sensorless or with the external release input (terminals

X2/4 and X2/5).

.) Orange fast flashing ⇒ EMERGENCY MODE - speed can be changed with the

buttons ▲ and ▼

.) Red shining ⇒ error signalling (type of the Error is shown on the

display of the external programming device)

.) Red flashing ⇒ signalling of a fatal error (HYDROVAR SENSORLESS has

to be disconnected from the power supply!)

37

Page 38

24 25 26 27 29

29

27 27

26 26 26

11 Maintenance

The Hydrovar sensorless control unit does not require special maintenance.

However, the cooling fan and the vent should be freed of dust occasionally.

Fur further information, please ask your distributor!

12 Parameter

POWER

SPEED

POWER

SAVING

TOTAL

SAVINGS

SUBMENU

PARAMETER

SUBMENU

DIAGNOSIS

Seite 33

PASSWORD AUTOSTART

SUBMENU

INVERTER

SUBMENU

CONTROLLER

FUNCTION

MODE

SUBMENU

REFERENCE

CURVE

REFERENCE

CURVE

WINDOW HZ

PUMP

RUNTIME

PUMP

ADDRESS

MAX.

FREQUENCY

LAST ERROR 2ND ERROR 3RD ERROR SOFTWARE

BOOST FIXED SPEED

38

Page 39

31 32 32 32 32 32

31 31 31 31

30 30 30 30

29 29 29 29 29

27 27 28 28 28 28

SUBMENU

TESTRUN

START TEST

RUN

POWER FREQ. PASSWORD 2 COEFF A COEFF B COEFF C

WINDOW Fx SHIFT ACCEL HIGH DECEL HIGH ACCEL LOW DECEL LOW

SUBMENU

ECONOMY

30

CURRENCY RATED POWER COSTS/KWH CLEAR

ENABLE TEST

RUN

MODE

CONTROLLER

TEST

FREQUENZY

SWITCH

INTERVAL

BOOST TEST

RUN

SET

PASSWORD

SAVINGS

LEARNING DEFAULT

Order no.

HYDROVAR

SENSORLESS

Pump

Note:

Date / Name

39

Page 40

XYLEM WATER SOLUTIONS AUSTRIA GMBH

Ernst-Vogel Strasse 2

2000 Stockerau

Österreich

Telefon: +43 (0) 2266 / 604

Telefax: +43 (0) 2266 / 65311

e-mail: info.austria@xyleminc.com

web: www.xylemaustria.com

Xylem Water Solutions Austria GmbH reserves the right to make modifications without prior notice.

© 2012 Xylem, Inc

Loading...

Loading...