Page 1

ConOx

Operating manual

Combined Conductivity and Dissolved Oxygen Sensor

ba75383e03 10/2004

Page 2

ConOx

Accuracy when

going to press

The use of advanced technology and the high quality standard of our

instruments are the result of continuous development. This may result in

differences between this operating manual and your instrument. Also, we

cannot guarantee that there are absolutely no errors in this manual.

Therefore, we are sure you will understand that we cannot accept any legal

claims resulting from the data, figures or descriptions.

26

Copyright

© Weilheim 2004, WTW GmbH

Reprinting - even as excerpts - is only allowed with the explicit written

authorization of WTW GmbH, Weilheim.

Printed in Germany.

Page 3

ConOx Contents

ConOx - List of contents

1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

1.1 Structure and function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

1.2 Instrument identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.1 Scopes of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

3.2 Getting the sensor ready for measuring . . . . . . . . . . . . . . . . . .32

4 Measuring / Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.1 Calib ra t io n . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

4.2 Measu ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

4.3 Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

5 Maintenance, cleaning, replacement . . . . . . . . . . . . . . . . . . 34

5.1 General maintenance instructions . . . . . . . . . . . . . . . . . . . . . . 34

5.2 Outside cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.3 DO module: Changing the electrolyte solution and

membrane cap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

5.4 DO module: Cleaning the electrodes . . . . . . . . . . . . . . . . . . . .38

5.5 Checking the DO module for freedom from zero-current . . . . .40

5.6 Aging of the conductivity measuring cell . . . . . . . . . . . . . . . . . .40

5.7 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6 What to do if... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.1 Error symptoms of DO measurement . . . . . . . . . . . . . . . . . . . . 42

6.2 Error symptoms of conductivity measuremen t . . . . . . . . . . . . .42

7 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

7.1 Conductivity basic module . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

7.2 Dissolved oxygen (DO) module . . . . . . . . . . . . . . . . . . . . . . . . 44

8 Wear parts and accessories . . . . . . . . . . . . . . . . . . . . . . . . . 47

27

Page 4

Overview ConOx

1 Overview

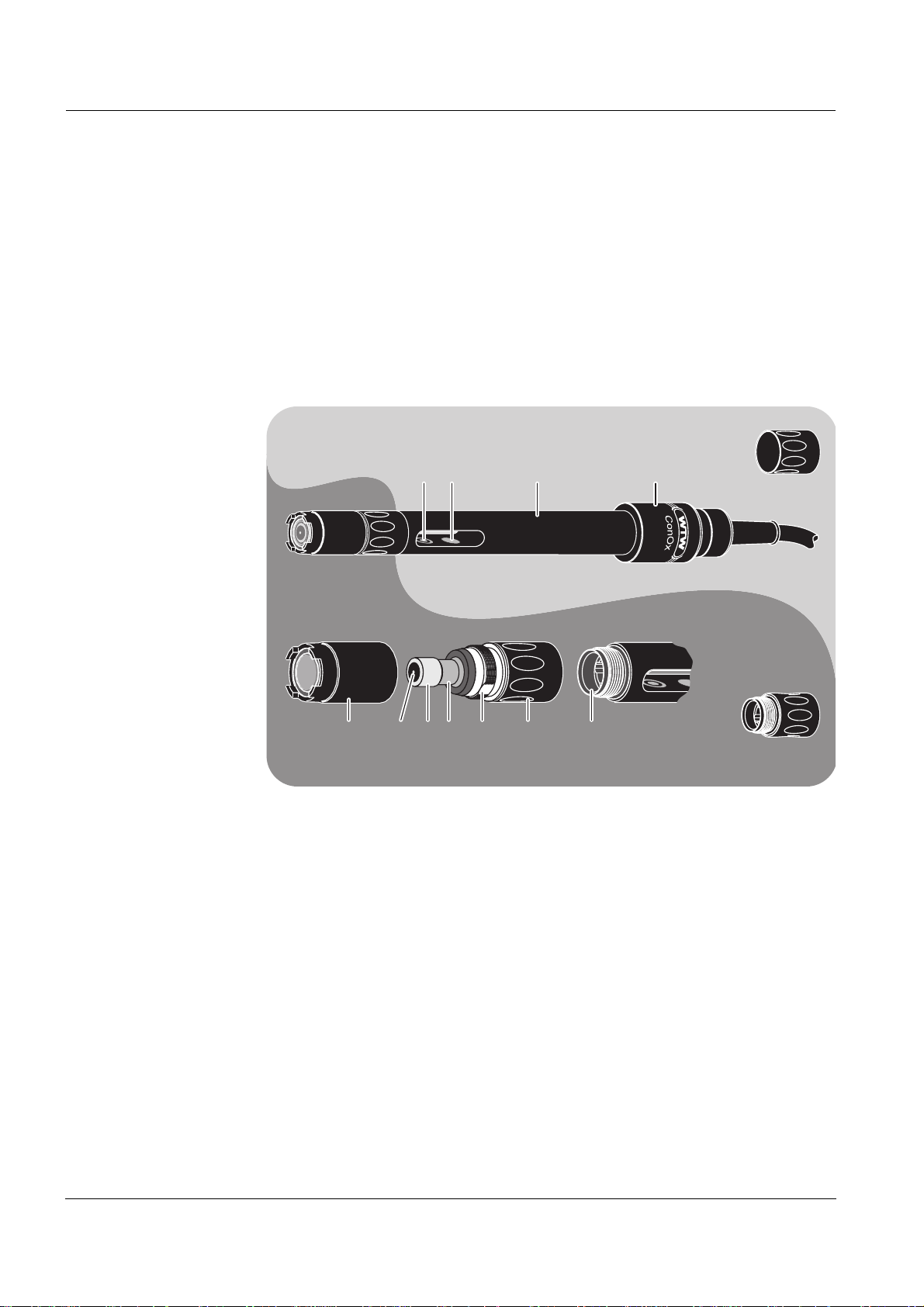

1.1 Structure and function

The ConOx is a modular sensor for conductivity , dissolved oxygen (DO) and

temperature. It consists of two basic components:

l Conductivity basic module, according to the quadripole measuring princi-

ple, with integrated temperature sensor

l Removable dissolved oxygen module, according to the galvanic measur-

ing principle

Structure of the

ConOx

Conductivity basic module

41, 2 3 5

13

78961110 12

Dissolved oxygen (DO) module

1 Voltage electrode (inside, 2x)

2 Current electrode (ring, 2x)

3 Temperature sensor in a graphite enclosure

4 Shaft

5 Connection head

6 WP 90 membrane cap (filled with electrolyte solution)

7 Gold working electrode (cathode)

8 Insulator

9 Lead counter electrode (anode)

10 Screw thread base with ventilation area

11 Cap nut

12 Plug connection

13 Closing cap for conductivity basic module

14 Closing cap for DO module

14

28

Page 5

ConOx Overview

The conductivity basic module can be used as an independent conductivity

measuring cell. For this pu rpose, unscrew the DO module and cl ose the open

plug connection with a closing cap.

The DO module is connected to the conductivity basic module via a watertight, three-pole plug connection. The conduc tivity basic module measures

the temperature, which is required for the determination of the DO content.

For this reason the DO module only works in conjuncti on with the conductivity

basic module.

Recommended

fields of

application

Conductivity basic

module

Dissolved oxygen

(DO) module

l On site measurements in rivers, lakes and wastewater

l fishfarming

l Ground water measurements

l Applications in water laboratories

1.2 Instrument identification

A series number is printed on both ConOx modules. Keep these numbers

ready if you have questions to ask the WTW service department.

The series numbers contain the following information:

The number is printed on the shaft.

12 3

03360013

The number is printed on the cap nut.

1234

0342A007

1 Manufacturing year 20... (example: 2003)

2 Calendar week of manufacturing (CW 36)

3 Sequential batch number (0013)

1 Manufacturing year 20... (example: 2003)

2 Calendar week of manufacturing (CW 42)

3 Sensor type (type A)

4 Sequential batch number (007)

29

Page 6

Safety ConOx

2Safety

This operating manual contains special instructions that must be followed

during the operation of the sensor.

Always keep this operating manual in the vicinity of the sensor.

Special user

qualifications

General safety

instructions

The membrane cap of the DO module is filled with a small amount of an

alkaline electrolyte solution. All maint enance work t hat requi res deali ng wit h

the electrolyte soluti on must only be carr ied out by persons who know how to

deal with chemicals safely.

The individual chapters of thi s operating manual use safety labels like the one

below to indicate danger:

Caution

indicates instructions t hat must b e followed pr ecisely in orde r to avoid

slight injuries or damage to the instrument or the environment.

3 Commissioning

3.1 Scopes of delivery

3.1.1 Scope of delivery of the ConOx

l ConOx combination conductivity and DO sensor,

DO module filled with electrolyte soluti on and ready to use

l 1 closing cap for conductivity basic module

l 1 closing cap for DO module

l 3 exchange membrane caps, WP 90

l Calibration and storage vessel, OxiCal

l Polishing strip, SF 300

l Electrolyte solution, ELY/G

l Cleaning solution, RL/G

l Operating manual for ConOx

Note

The membrane cap that is mounted on the DO sensor for delivery serves

mainly as a transport protection. Depending on the duration of the transport

and storage period, it may have a shortened oper ational lifetime. If the measuring system cannot be calibrated (error message on the ins trument),

please proceed according to section secti on 5.3 DO

ELECTROLYTE SOLUTION AND MEMBRANE CAP.

®

-CX

MODULE: CHANGING THE

30

Page 7

ConOx Commissioning

3.1.2 Scope of delivery of the conductivity basic module

l Conductivity basic module

l 1 closing cap, mounted on the conductivity basic module

l Operating manual for ConOx

3.1.3 Scope of delivery of the DO module

l DO module, filled with electrolyte solutio n and operabl e

l 1 closing cap, mounted on the DO module

l 1 exchange membrane cap, WP 90

l Polishing strip, SF 300

l Electrolyte solution, ELY/G

l Cleaning solution, RL/G

l Operating manual for ConOx

Note

The membrane cap that is mounted on the DO sensor for delivery serves

mainly as a transport protection. Depending on the duration of the transport

and storage period, it may have a shortened operati onal lifetime. If the measuring system cannot be calibrated (error message on the instr ume nt),

please proceed according t o s ection sec tion 5.3 DO

ELECTROLYTE SOLUTION AND MEMBRANE CAP.

MODULE: CHANGING THE

31

Page 8

Commissioning ConOx

3.2 Getting the sensor ready for measuring

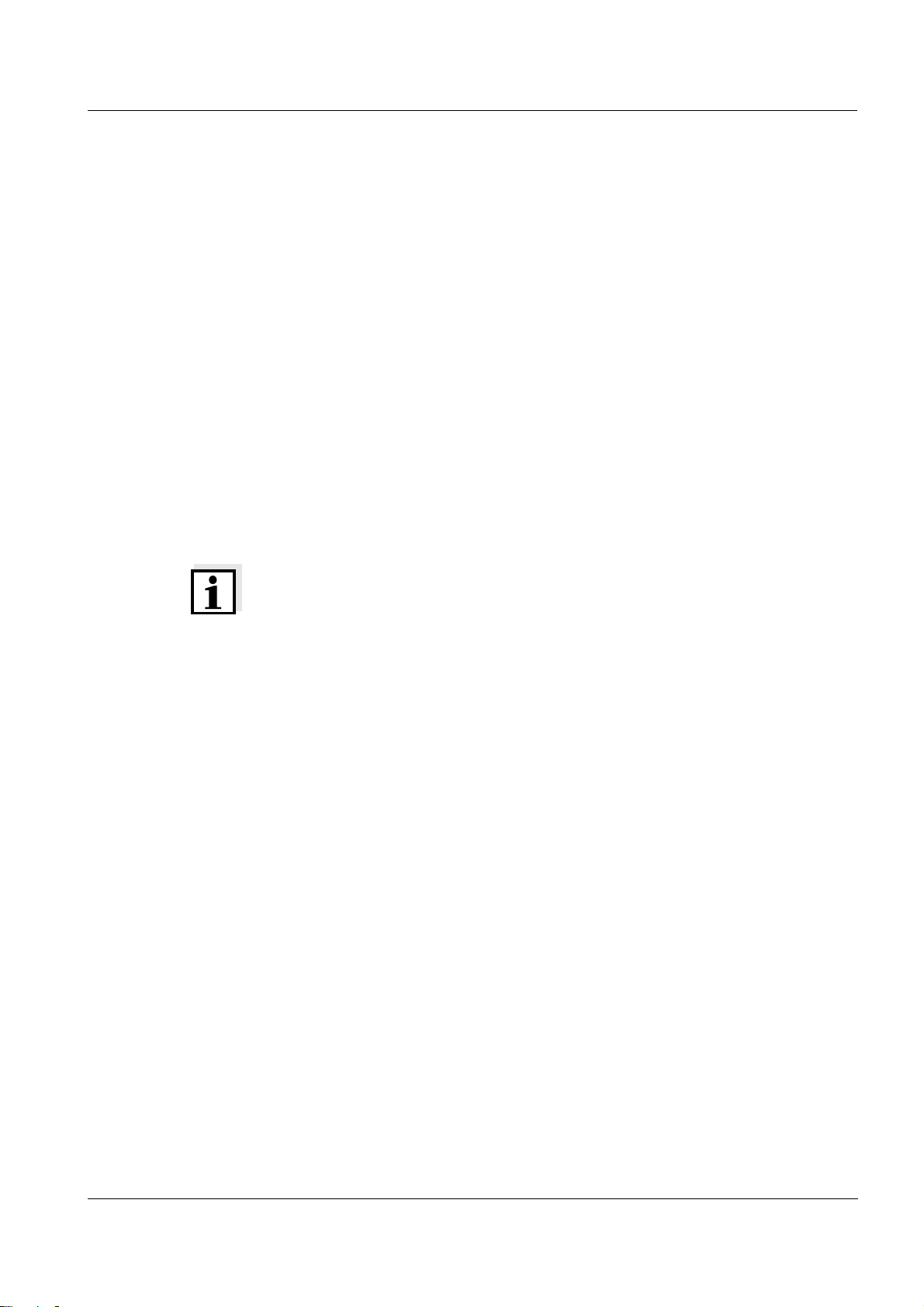

3.2.1 M easurements with the conductivity basic module

Make sure that the plug connection is tight ly closed by the closing cap. When

mounted, the closing cap (1) must be screwed on up to the stop.

12

Before screwing on the closing cap, check the following points:

l The sealing (2) must be clean and evenly positioned in the groove.

l The plug connection and the inside of the closing cap must be clean.

Screwing on the

DO module

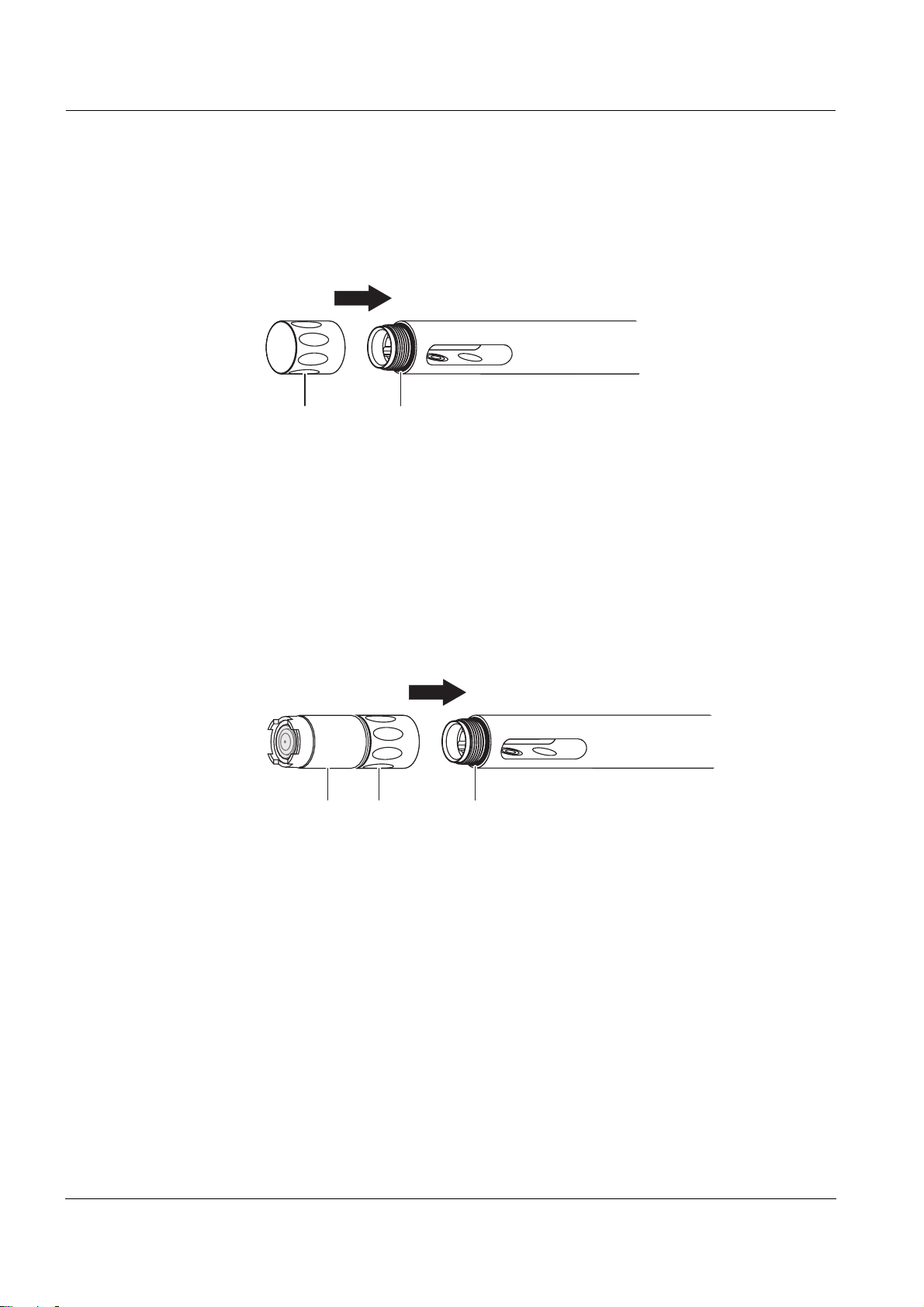

3.2.2 M easurements with the combination sensor

Make sure that the DO module and conductivity basic module are screwed

together tightly. When mounted, the cap nut of the DO module has to be

screwed on up to the stop.

21 3

Before screwing on the DO module, check the following points:

l The sealing (3) must be clean and evenly positioned in the groove.

l The plug connection must be dry on both sides.

Position the DO module (1) on the conductivity basic module and carefully

and with slight pressure turn it until th e guidi ng nib on the DO module locks

in place in the corresponding groove on the conductivity basic module.

Subsequently tighten the cap nut (2) up to the stop. The thread onl y snatches

if the DO module was correctly positioned.

32

Page 9

ConOx Measuring / Operation

Unscrewing the

DO module

Unscrew the cap nut and remove the DO module from the conducti vity basic

module.

Caution

Inappropriate handling can lead to the release of electrolyte solution.

When unscrewing the DO module only turn the cap nut (not the

membrane cap!).

3.2.3 Preparing the measuring operation

Connect the sensor to th e measur ing i nstr ument. The sen sor is immediatel y

ready to measure. It is not necessary to polarize the DO module.

4 Measuring / Operation

4.1 Calibration

To calibrate for DO measurements, use the OxiCal®-CX calibration and

storage vessel. If the A 325/K or A 325/S armoring is used, you have to

remove the protective hood and fixing nut of the armoring first.

Minimum

approach flow for

DO measurements

When determining the cell constant, observe the respective minimum

immersion depth with the closing cap or D. O. module screwed on (important:

the temperature sensor must be submersed). The minimum immersion

depths are given in chapter 7 T

ECHNICAL DATA.

Note

Please read the course of the calibration in the operating man ual of the measuring instrument.

4.2 Measuring

Please always observe the required minimum immersion depth and the

minimum approach flow that is important for DO measurements (see

chapter 7 T

The minimum flow can be provided in different ways, e. g.:

l The flow of the water to be measured is sufficient (aeration tank, water

pipe, stream)

l Slowly pull the sensor through the water by hand (lake, container), or

l Use a flow aid, e. g. a magnet ic st irr er wit h s tirr ing dev ic e or a batt ery s tir-

rer (see chapter 8 W

ECHNICAL DATA).

EAR PARTS AND ACCESSORIES)

Note

When using the BR 325 battery stirrer, please make sure that the protective

pipe already has the groove in the area of the conductivity basic module ( from

the year of manufacture, 2004).

33

Page 10

Maintenance, cleaning, replacement ConOx

4.3 Storage

Always store the sensor with the DO module in the calibration vessel at a

temperature of 0 to +50 °C. Make sure that the sponge in the calibration vessel is always moist.

Storage in th e

calibration vessel,

®

OxiCal

-CX

12

Moisten the sponge:

l Remove the cap (1).

l Take out the sponge (2), wet it, then slightly squeeze it out.

l Reinsert the sponge and close the calibration vessel with the cap.

5 Maintenance, cleaning, replacement

5.1 General maintenance instructions

For your safety Note the following safety instru ctions when handling elect rolyte and cleaning

solutions:

Caution

The ELY/G electrolyte solution irritates eyes and skin. When dealing

with the ELY/G electrolyte solution, observe the following points:

l During working activities, always wear suitable protective gloves

and protective goggles/face shield.

l If it comes into contact with the ski n, rinse thoroughly with water and

immediately change contaminated clothing.

l If it comes into contact with the eyes, rinse thoroughly with water

and consult a doctor.

l Follow the safety datasheet.

34

Page 11

ConOx Maintenance, cleaning, replacement

Caution

The RL/G cleaning solution irritates eyes and skin. When dealing with

the RL/G cleaning solution, observe the following points:

l During working activities, always wear suitable protective gloves

and protective goggles/face shield.

l If it comes into contact with the ski n, rinse thoroughly with water and

immediately change contaminated clothing.

l If it comes into contact with the eyes, rinse thoroughly with water

and consult a doctor.

l Follow the safety datasheet.

Caution

Before all maintenance activities, disconnect the sensor from the

instrument.

Note

Information on how to order wear parts and maintenance means can be

found in chapter 8 W

EAR PARTS AND ACCESSORIES.

Maintenance

activities on the

DO module

Cleaning agents

For better handling, l eave the DO modul e screwed on the conduc tivi ty basi c

module. Thus, you can better immerse the sensor head in the electrolyte or

cleaning solution and the plug connection remains prot ected against

damage.

5.2 Outside cleaning

Contamination Cleaning procedure

Lime sediments Immerse in acetic acid for 1 minute ( vol ume

share = 20 %)

Fat/oil Clean with warm water that contains

washing-up liquid

After cleaning, thoroughly rinse with deionized water and recalibrate if

necessary.

35

Page 12

Maintenance, cleaning, replacement ConOx

5.3 DO module: Changing the electrolyte solution and

membrane cap

Caution

Before starting to work with the sensor, please note the GENERAL

MAINTENANCE INSTRUCTIONS on page 34.

General

information

WTW delivers the DO module ready to use (see section 3). The electrolyte

solution and the membrane cap must only be replaced if:

l a calibration error occurs and the membrane is heavily contaminated

l the membrane is damaged

l the electrolyte solution is exhausted.

Changing the electrolyte solution and membrane cap

Unscrew the membrane cap.

Caution:

Electrolyte solution!

Rinse the sensor head with

deionized water.

For disposal of the membrane

cap and electrolyte solution,

see section 5.7.

Carefully rub and dry the

counter electrode with a lintfree paper towel.

RL/G H O

Immerse the sensor head including the counter electrode

in RL/G cleaning solution.

Allow to react for 1 to 3 minutes.

36

Thoroughly rinse the sensor

head with deionized water.

2

Water the counter electrode in

deionized water for at least

10 minutes.

Page 13

ConOx Maintenance, cleaning, replacement

ELY/G

Carefully shake off the drops

of water.

ELY/G

Thoroughly rinse the sensor

head with electrolyte solution.

Fill a new membrane cap with

ELY/G electrolyte solution.

Ventilation area

points upwards

Hold the sensor inclined and

screw on the membrane cap

fingertight using a paper towel. Excess electrolyte solut ion

is forced out of the ventilation

area.

Remove any air bubbles by

carefully tapping the membrane cap. Additionally, you

can prevent air bubbles by

throwing the first filling away

and refilling the membrane

cap.

4mm

Check the filling:

Inspect the face surface. No

air bubbles may be present

within the dashed circle. Air

bubbles outside this area do

not interfere.

Note

For measurements under high pressure the filling must be completely free of air bubbles.

Readiness to measure The DO module is ready for operation after approx. 30 to 50 min-

utes. Subsequently calibrate the sensor for DO measurements.

Note

If you want to measure very low DO concentrations (< 0.5 % saturation), we recommend to let the sensor rest overnight and then

calibrate it.

37

Page 14

Maintenance, cleaning, replacement ConOx

5.4 DO module: Cleaning the electrodes

Caution

Before starting to work with the sensor, please note the GENERAL

MAINTENANCE INSTRUCTIONS on page 34.

General

information

Cleaning the electrodes

Unscrew the membrane cap.

Caution:

For disposal of the membrane

cap and electrolyte solution,

see section 5.7.

Electrolyte solution!

Cleaning is only required in cases of slopes too small or too large (sensor

cannot be calibrated) that cannot be resolved by changing the membrane cap

and electrolyte solution.

Rinse the sensor head with

deionized water.

SF 300

Using the rough side of the

wet SF 300 polishing strip,

polish off any contamination

from the gold working electrode using light pressure.

Caution:

ventional sandpaper or glassfiber brushes.

Do not use any con-

Rinse the sensor head with

deionized water.

38

Wipe the counter electrode

with a lint-free paper towel

and carefully remove any

loose white deposits.

RL/G

Immerse the sensor head including the counter electrode

in RL/G cleaning solution.

Allow to react for 1 to 3 minutes.

Page 15

ConOx Maintenance, cleaning, replacement

H O

2

Thoroughly rinse the sensor

head with deionized water.

ELY/G

Fill a new membrane cap with

ELY/G electrolyte solution.

Water the counter electrode in

deionized water for at least

10 minutes.

Remove any air bubbles by

carefully ta pp ing the membrane cap. Additionally, you

can prevent air bubbles by

throwing the first filling away

and refilling the membrane

cap.

Carefully shake off the drops

of water.

ELY/G

Rinse the sensor head with

electrolyte solution.

Ventilation area

points upwards

Hold the sensor inclined and

screw on the membrane cap

fingertight using a paper towel. Excess electrolyte soluti on

is forced out of the vent il ation

area.

4mm

Check the filling:

Inspect the face surface. No

air bubbles may be present

within the dashed circle. Air

bubbles outside this area do

not interfere.

39

Page 16

Maintenance, cleaning, replacement ConOx

Note

For measurements under high pressure the filling must be completel y free of

air bubbles.

Readiness to

measure

After approx. 30 to 50 minutes, the sensor is ready for operation. Subsequently calibrate the sensor.

Note

If you want to measure ver y l ow DO concen trati ons (< 0.5 % saturation), we

recommend to let the sensor rest overnight and then calibrate it.

5.5 Checking the DO module for freedom from zero-current

The DO module is free from zero-current. Checking the module for fr eedom

from zero-current is only necessary in the case of malfunctions that cannot

be remedied by exchanging the e lectrolyte soluti on and membrane cap or by

cleaning the electrodes.

There are two possibilities to check the DO module for freedom from zerocurrent:

l Measurement in a nitrogen atmosphere (recommended method)

l Measurement in a sodium sulfite soluti on according to DIN EN 25814/

ISO 5814.

Caution

If you check the sensor according to DIN EN 25814/ISO 5814, do not

leave the sensor in the sodium sulfite soluti on for more than 2 minutes.

Danger of sensor poisoning!

Test criterion The DO module is OK if the measuring instrument displays < 1 % DO

saturation after 2 minutes.

5.6 Aging of the conductivity measuring cell

Normally, the conductivity measuring cel l does not age. Special measuring

media (e.g. strong acids and ly es, organic solvents) or too high temperatures

shorten the operational lifeti me considerably or damage the measuring cell.

The warranty does not cover cases where such conditions cause failure or

mechanical damage.

40

Page 17

ConOx Maintenance, cleaning, replacement

5.7 Disposal Caution

The ELY/G electrolyte solution irritates eyes and skin. When dealing

with the ELY/G electrolyte solution, observe the following points:

l During working activities, always wear suitable protective gloves

and protective goggles/face shield.

l If it comes into contact with the ski n, rinse thoroughly with water and

immediately change contaminated clothing.

l If it comes into contact with the eyes, rinse thoroughly with water

and consult a doctor.

l Follow the safety datasheet.

Conductivity basic

module, DO

module and

membrane cap

Electrolyte

solution

For disposal, unscrew the membrane cap from the DO module. Then rinse

the entire sensor and the membrane cap with water.

We recommend to dispose of the conductivity basic module and the DO

module without membrane cap as electronic waste. The membrane cap may

be disposed of with the household refuse.

Disposal according to the safety data sheet.

41

Page 18

What to do if... ConOx

6 What to do if...

6.1 Error symptoms of DO measurement

Error symptom Cause Remedy

The sensor is in the air

and the display shows

0.0 mg/l or 0 % O

The sensor cannot be

calibrated

2

– No connection between

measuring instrument and sensor

– Cable defective

– No electrolyte in the membrane

cap

– Contaminated membrane cap

– Electrolyte depleted

– Check connection between

measuring instrument and sensor

– Replace and refill the membrane

cap (see section 5.3)

– Replace and refill the membrane

cap (see section 5.3)

Subsequently, wait for 30 to

50 min and recalibrate.

The sensor still cannot

be calibrated after

changing the electrolyte

and membrane cap

Incorrect temperature

display

Mechanical damage to

the sensor

– Contaminated electrodes or

sensor toxification

– membrane cap not screwed on

tight enough

– The temperature sensor of the

conductivity basic module was not

immersed deep enough in the

measuring solution

– Temperature sensor defective

– Clean the electrodes (see

section 5.4)

– Screw membrane cap tighter

– Observe the minimum immersion

depth

– Return the sensor

– Return the sensor

6.2 Error symptoms of conductivity measurement

Error symptom Cause Remedy

No temperature or conductivity display

– No connection between

measuring instrument and sensor

– Cable defective

– Check connection between

measuring instrument and sensor

Measurement delivers

implausible conductivity

values

Incorrect temperature

display

42

– Incorrect cell constant adjusted at

the measuring instrument

– Measuring range exceeded

– Contamination in the area of the

electrodes

– Electrodes damaged

– The temperature sensor was not

immersed deep enough in the

measuring solution

– Temperature sensor defective

– Check / correct the cell constant

– Observe the application range

– Clean the sensor (see

section 5.2).

– Return the sensor

– Observe the minimum immersion

depth

– Return the sensor

Page 19

ConOx Technical data

7 Technical data

7.1 Conductivity basic module

General features Measuring principle Four-electrode measurement

Cell constant 0.475 cm

-1

±1.5 %

Temperature sensor integrated NTC 30 (30 k

Dimensions

(in mm)

Weight approx. 135 g (without DO module, with 1.5 m cable)

Materials Shaft Epoxy

– Connection head POM

– Closing cap PVC

Plug connection for

DO module

Conductivity electrodes Graphite

PEEK

W/ 25 °C)

Thermistor enclosure Graphite

Connection cable Lengths 1.5 / 3 / 6 / 10 / 15 / 20 m

Diameter 6 mm

Connector for DO

module

Smallest allo w e d

bend radius

Plug type Socket, 8 pins

Plug type 3-pole, watertight plug connection with cap

Permanent bend: 80 mm

Single time or short time bend:50 mm

nut, reverse polarity protected, contacts

gold-plated

43

Page 20

Technical data ConOx

Pressure

resistance

Measurement

conditions

Storage

conditions

Sensor with closed plug

IP 68 (3 x 105Pa or 3 bar)

connection

Cable plug IP 67 (when plugged in)

The ConOx meets the requirements according to article 3(3) of the

97/23/EC directive ("Pressure equipment directive").

Conductivity measuring

mS/cm ... 2 S/cm

1

range

Temperature range 0 ... 50 °C

Max. allowed overpressure 3 x 10

5

Pa (3 bar)

Depth of immersion min. 6 cm (with closing cap)

min. 8 cm (with DO module)

max. 20 m (depending on the cable length)

Operating position any

Approach flow not required

®

Recommended storing

method

in the OxiCal

ened)

-CX calibration vessel (moist-

or dry (without DO module)

Storage temperature 0 ... 50 °C

Characteristic data

on delivery

Temperature responding

behavior

Precision of the temperature

(99 % of the final value display after)

t

99

<20s

±0.3K

sensor

7.2 Dissolved oxygen (DO) module

General features Measuring principle Membrane covered galvanic sensor

Temperature compensation

Dimensions

(in mm)

IMT compensation

(calculated by the measuring instrument)

44

Weight approx. 20 g (filled with electrolyte)

Page 21

ConOx Technical data

Materials Working electrode Gol d

Counter electrode Lead

– Membrane cap

POM

– Cap nut

Membrane FEP, 13

µm

– Sensor head Epoxy, PEEK

– Plug connection PEEK

Screw thread base Stainless steel 1.4571

Seals FPM (Viton)

Closing cap POM

Plug connection Plug type 3-pole, watertight plug connection with cap nut,

reverse polarity protected, contacts gold-plated

Pressure

resistance

Sensor with closed plug

connection

IP 68 (3 x 10

5

Pa or 3 bar)

The DO module meets the requirements according to article 3(3) of the 97/

23/EC directive ("Pressure equipment directive").

Measurement

conditions

Measuring ranges at

20 °C

0 ... 50 mg/l DO

0 ... 600 % DO satu ra tion

0 ... 1250 mbar DO partial pressure

Polarization time mi n. 30 ... 50 min after changing the electrolyt e,

it is not necessary to con nect the sensor to t he

measuring instrument for polarization

Storage

conditions

Temperature range 0 ... 50 °C

5

Max. allowed overpres-

3 x 10

Pa (3 bar)

sure

Depth of immersion with

conductivity basic module

min. 8 cm

max. 20 m (depending on the cable length of

the conductivity basic module)

Operating position any

Approach flow > 3 cm/s at 10 % measurement accuracy

10 cm/s at 5 % measurement accuracy

18 cm/s at 1 % measurement accuracy

®

Recommended storing

method

in the OxiCal

ened)

-CX calibration vessel (moist-

Storage temperature 0 ... 50 °C

45

Page 22

Technical data ConOx

Characteristic data

on delivery

Pin assignment

Zero signal < 0.1 % of the saturation value

Response time at 20 °Ct

Oxygen own consumption

(90 % of the final value display after) < 10 s

90

(95 % of the final value display after) < 16 s

t

95

(99 % of the final value display after) < 60 s

t

99

0.008

µg·h

-1

(mg/l)

-1

at 20 °C

Drift approx. 3 % per month in the operating condi-

tion

Working life min. 6 months with one electrolyte filling

Conductivity basic moduleDO module

Current electrode 2

4

Voltage electrode 2

Plug connection:

AE

GE GE

GE

AE

Cod

AE

Shield

2

Voltage electrode 1

5

Current electrode 1

3

Counter electrode

8

Working electrode

6

Cod

NTC

30 kΩ

Shield+

wire

Plug from the front:

1

NTC

NTC

7

2

5

7

4

1

8

3

6

46

Page 23

ConOx Wear parts and accessories

8 Wear parts and accessories

Wear parts and

maintenance

Description Model Order no.

Set of exchange membrane caps (3 pieces) WP 90/3 202 725

means

Electrolyte solution ELY/G 205 217

Cleaning solution for lead counter electrode RL/G 205 204

Polishing film SF 300 203 680

Accessory kit, comprising:

ZBK 325 202 706

– 3 exchange membrane caps, WP 90

– Polishing strip, SF 300

– Electrolyte solution, ELY/G

– Cleaning solution, RL/G

Spare parts set, comprising:

ACC/CX 401 080

– 1 closing cap for conductivity basic

module

– 1 closing cap for DO module

– O-ring grease for the sealings of the

closing caps

®

– Sponge + lid for OxiCal

-CX

– Sealing for plug connection

Accessories Description Model Order no.

®

Calibration and storage vessel OxiCal

-CX 205 400

Magnetic stirrer Oxi-Stirrer 300 203 810

Stirring accessory - p rovi des a constant, de-

RZ 300 203 824

fined flow of the sensor, in conjunction with

the Oxi-Stirrer 300

Plastic armoring with protective hood A 325/K 903 830

Steel armoring with protective hood A 325/S 903 831

Special protective hood against fish biti ng -

SK-325 201 580

only in conjunction with A 325/K or A 325/S

Battery stirrer fo r depth measurements - only

BR 325 203 826

in conjunction with A 325/K or A 325/S

Note

For further accessories, refer to the WTW catalog or the Internet.

47

Page 24

Wear parts and accessories ConOx

48

Loading...

Loading...