Page 1

Quick Guide

1

Page 2

Contents

Daily Use 4

Display 5

Display Keys 5

Contrast Setup 6

Reset the System 6

Function Keys 7

Basic Setup; Pump Control 1 10

Signal List 10

Configuration 13

Step by Step: 14

Operation of the Pumps 15

Overview Screen for Pump Control 1 16

Screen Information: 16

Start/Stop Levels 18

Manual Operation 20

Pump Data 22

Basic Flowchart 23

2

Page 3

Introduction

Thank you for choosing the MJK Connect® or Mµ Connect® controller and

monitoring unit. MJK Connect

and put into operation. To get the full advantages of MJK Connect

Connect® MJK recommends that future users read this manual to get familiar

with all details concerning MJK Connect

®

and Mµ Connect® are easy to install, calibrate

®

and Mµ Connect®. The equipment

®

and Mµ

should be treated and used as directed by MJK Automation A/S to ensure a

stable operation and precise measurements.

Liability

MJK Automation A/S are liable to the common rules of Danish law on product liability, however, the liability is reduced to coverage of our public liability

insurance of products. To the extent where nothing else follows in lines of

invariable rules of law, we are not liable for loss of profits and working deficits

or other indirect losses.

Changes

As our products are developed continuously we reserve the right to make any

alterations without prior notice.

Trademarks & Acknowledgements

Mµ Connect

Shuttle

Expert™ is a trademark of MJK Automation A/S, Denmark.

®

VLT

is a registered trademark of Danfoss A/S.

®

, Connect®, MagFlux®, Chatter®, SuSix®, Oxix®, pHix® and

®

are registered trademarks of MJK Automation A/S, Denmark.

MJK Automation is a Xylem Brand.

®

A complete manual for Connect

, including all menus and functions, technical

specifications and more can be found on our website as pdf.

http://www.mjk.dk/downloads/downloads-products/downloads-rtu/

downloads-connect/

A complete manual for Instrument Link, including all menus and functions,

technical specifications and more can be found on our website as pdf.

http://www.mjk.dk/downloads/downloads-products/downloadsaccessories/

downloads-rtusoftware/

3

Page 4

Daily Use

This is a Quick Guide to get started with your Connect®.

The following examples in this section will show and explain how a Connect® is configured as pump controller for a wastewater pump station with 2

pumps.

In Connect® the function “Pump Control 1” is used to control the pumps

through the level in the pumping sump.

The complete manual for Connect® and Mµ Connect® can be found on

www.mjk.com.

This Quick Guide applies to Connect® with the following firmware versions:

Firmware Versions

Product Number Revision

Connect® Base Unit 844003 007-017

Connect® Display 841021 003

4

Page 5

Display

The 4 soft keys located below the display are used to navigate the menus during the daily operation of Connect®.

Display Keys

Numerical keys and soft keys are used for startup configuration and normal

operation. Which of these is decided by the installed display firmware.

The functions of the 4 soft keys are shown at the bottom of the display. The

functions of the soft keys depends on which menu or function is currently active/shown.

Symbols and current functions are described in detail in the individual menu

sections. The numerical keyboard on the right can be used for direct menu

selections and alpha-numerical typing of names and texts.

Key function Description

Left button The left button usually changes between Menu and Index (Toggle

Up/Down Arrows The arrows are labelled “Select” where you can move up and down

Right button The right button is used mainly to confirm your choice and/or to

function)

in the menus.

continue to the next screen.

5

Page 6

Contrast Setup

Configure the display contrast by pressing the two outer soft keys simultaneously as shown with the red circles to the right. Then press the up/down

arrows until you get the desired contrast.

Save the changes by pressing the 2 outer soft keys simultaneously again.

Reset the System

It is possible to reset the system and refresh all system views and key combinations by pressing all four soft keys down simultaneously. This is especially

useful in situations such as a service technician having to change the language to one he understands. A reset of the system will change the language

to the default English (GB).

Please note: A reset of the system should not be confused with the very

comprehensive Factory Settings>Restore Connect, which will erase all local

configurations and setup and replace them with the original factory settings.

6

Page 7

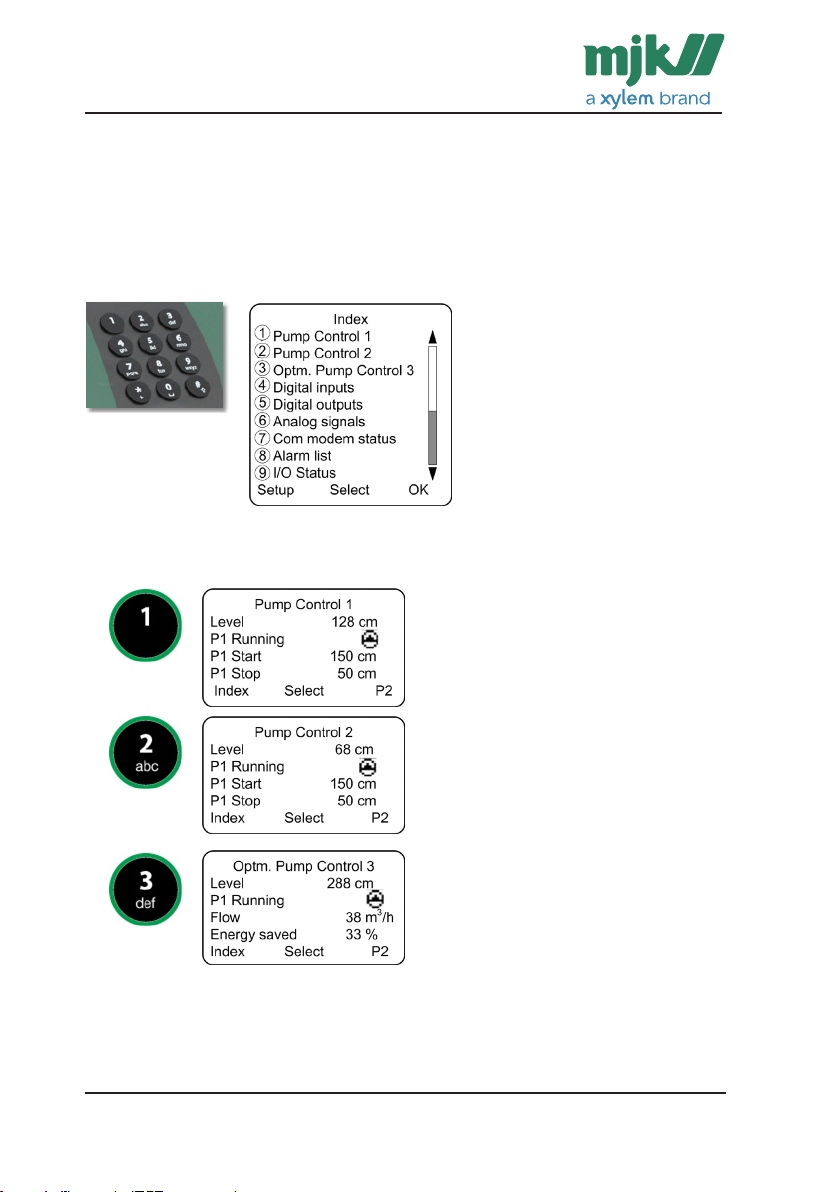

Function Keys

The daily operation of Connect

®

and Mµ Connect® is done through the built-in

function keys 1-9.

The function keys (numerical keyboard) is also used for direct menu selection

and typing names and texts.

Each function key has pre-defined views and can be customized as needed.

When selecting Index, an overview of the defined overview

screens are created. Use this

screen to make a quick switch

to the selected screen.

Function keys 1 to 3 have the following functions:

Pump Control 1. This screen is a

standard screen for Connect

®.

This screen shows current level, pump

1 operating condition and first set of

start/stop levels

Pump Control 2. This screen is a

standard screen for Connect

®

This screen shows current level, pump

1 operating condition and first set of

start/stop levels

The function keys 1 to 3 are only shown when “Create Overview Screen” in

the function menu has been done.

7

Page 8

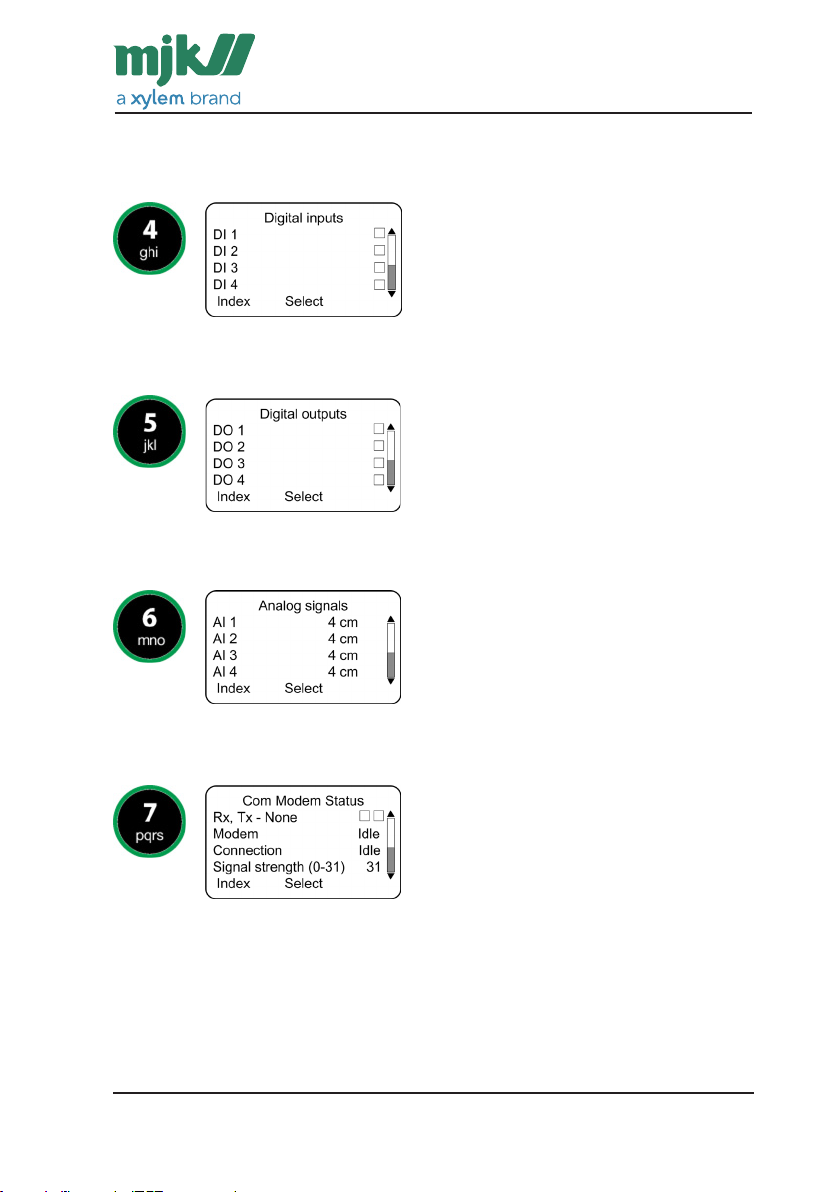

The function keys 4 to 9 have the following functions:

Function key 4. Digital Inputs

Shows status on all digital inputs.

Function key 5. Digital Outputs

Shows status on all digital outputs.

Function key 6. Analog Inputs

Shows status on all analog outputs.

Function key 7. Communication Status

Shows status on the communication. Is dependent on chosen communication

module.

8

Page 9

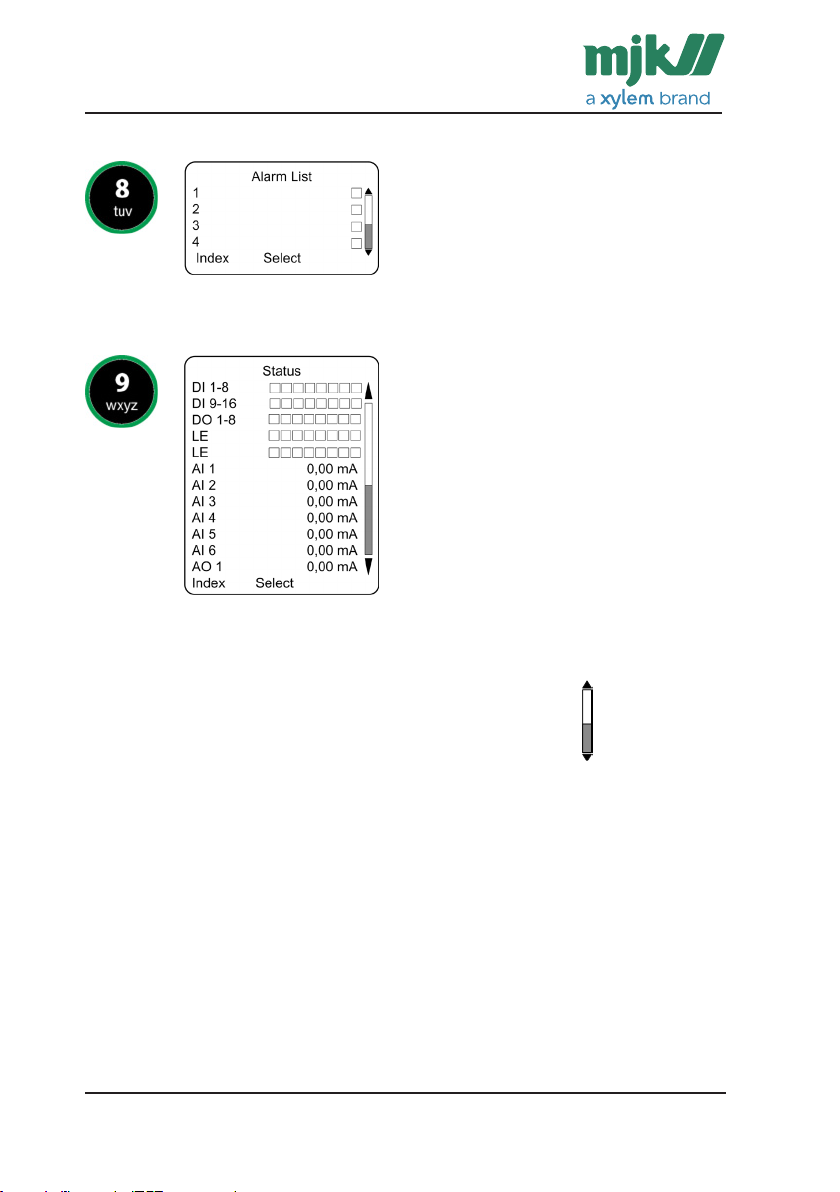

Function key 8. Alarm List

Shows status on alarms.

Function key 9. I/O Status

Shows status on all inputs/outputs and analog limits, virtual analog outputs

and logical flags (LF).

Please note: Scroll with the up/down arrows to view more.

9

Page 10

Basic Setup; Pump Control 1

This section will show and explain how a Connect® is configured as pump

controller for a wastewater pump station with 2 pumps.

The function “Pump Control 1” is used to control the pumps through the level

in the pumping sump.

The picture shows an example on 2-pump station with 2 submerged pumps.

Signal List

First step is to create a signal list to create a full overview of the signal from

the pump controller to the pumps and from the pumps to the controller.

The following table shows examples from an typical pump station.

10

Page 11

The list shows signals connected to the digital inputs in this example.

Digital

Input

DI 1 Operation P1 NO 0 sec. In use In use

DI 2 Operation P2 NO 5 sec. In use In use

DI 3

DI 4 Thermo alarm P1 NO 15 sec. Alarm

DI 5 Thermo alarm P2 NO 15 sec. Alarm

DI 6

DI 7 Klixon P1 NO 0 sec. Alarm

DI 8 Klixon P1 NO 0 sec. Alarm

DI 9

DI 10 MAN-0-AUT P1 NO Alarm

DI 11 MAN-0-AUT P1 NO Alarm

DI 12

DI 13

DI 14

DI 15

DI 16 High Level

Signal Name Relay

Function

NO Alarm

Switch

Delay Alarm /

In use

Alternation

The list shows the signals connected to the digital outputs in the example.

Digital

output

DO 1 Start/Stop P1 NO-constant 0 sec. 0 sec.

DO 2 Start/Stop P2 NO-constant 0 sec. 0 sec.

DO 3

DO 4

DO 5

DO 6

DO 7

DO 8 Joint reset of

Signal Name Relay Function Close time

(seconds on time)

NO-time controlled 1 sec. 0 sec.

thermo error

Delay

11

Page 12

Digital

Input

AI 1 Level 0 300 Level 0 sec.

AI 2 Power P1 0 10 Other Units 0 sec.

AI 3 Power P2 0 10 Other Units 0 sec.

AI 4

AI 5

AI 6

AI 7

Signal Name Scaling Scaling

20 mA

Unit Average

Analog

limits

AI 1 High In use High Level alarm XX 5 sec. In use

AI 1 Low Not in use AI 1 LA 0 0 Not in use

AI 2 High In use High Level alarm P1 0 0 Not in use

AI 2 Low Not in use AI 2 LA 0 0 Not in use

AI 3 High In use High Level alarm P2 0 0 Not in use

AI 3 Low Not in use AI 3 LA 0 0 Not in use

AI 4 High Not in use AI 4 HA 0 0 Not in use

AI 4 Low Not in use AI 4 LA 0 0 Not in use

AI 5 High Not in use AI 5 HA 0 0 Not in use

AI 5 Low Not in use AI 5 LA 0 0 Not in use

AI 6 High Not in use AI 6 HA 0 0 Not in use

AI 6 Low Not in use AI 6 LA 0 0 Not in use

In use

Not in use

Signal Name Setpoint Delay Call

12

Page 13

Configuration

Next step is to configure the Connect® based on the shown signal list. In the

function menu, choose Pump Control 1 and setup the specific menu items as

described in the signal list.

Go to Functions Menu and choose Pump Control 1, which contains the following items:

• Number of Pumps: Number of pumps in the wasterwater pump station.

• Measurement: The analog input on which the level transmitter is mounted

on and scaling and signal name.

• Pumps Setup

• Start/Stop levels: start and stop levels for current number of pumps.

• Control Word: 16-bit control word for intelligent pump controlling.

• Additional Functions with:

• Flow calculation

• Setpoint displacement

• Depth pumping

• Create Overview Screen: Connect will setup the screen 1 with the entered

information on overview screen 1.

13

Page 14

Step by Step:

The display shows the setup like this

Select Functions Menu Select Pump Control 1 Select In use

Enter 2 and OK Enter 2 and OK

14

Page 15

Operation of the Pumps

This section is based on the function “Pump Control 1” which is the most

used Pump function.

Function Key 1 is the screen used for the pump control and will

typically be the same screen as in the Connect when working on the

station.

Please note that the pre-defined view described here can be customized to

your needs.

Select Function Key 1 for the daily use of the pump control 1.

Overview display 1 is standard and located in the function section Pump

Control 1. The most current pump information is displayed here: Actual level,

in use/not in use and the start/stop levels of the pump.

Note: If you leave Connect® with this setup, this will be the first you see on

the pump station at next visit.

15

Page 16

Overview Screen for Pump Control 1

By pressing the right key below the display (P2), the display changes to a

similar one for Pump 2. The key will then change name to P3 - P4, depending

on how many pumps have been created in the function Pump Control 1.

Navigate with the up/down arrows below Select. Arrow down will select the

first/top line, another arrow down will select the second line, etc.

Note: There can be discrepancies from this screen if lines have been added/

changed by the user.

Screen Information:

Text line Description

Pump Control 1 This is the name of the function. You can change this to for example

Level Shows the current level in the pumping sump.

P1 Running The operation status of the pump. This is shown as text and icons.

P1 Start The start level of the pump is changed here. Select the line and

P1 Stop The stop level of the pump is changed here. Select the line and

Index Switch between the functions menu and the overview screens.

Select Use up/down arrows to scroll in the current screen and selecting a

P2 Use the right key below the display to change to a similar view for

the name of the pump station

See below list.

enter the desired start level on the display with the numerical keyboard. Save with OK.

enter the desired stop level on the display with the numerical keyboard. Save with OK.

line or function.

Pump 2. The key will then change name to P3 - P4, depending on

how many pumps have been created in the function Pump Control

1.

16

Page 17

Operation status of

Icon Description

Pump

P1 Running Digital output when the pump is in use and the

P1 stopped Digital output when the pump has stopped and

P1 error Digital output when the pump is in use and the

P1 Blocked Digital output when the pump is not in use.

feedback signal is ok.

the feedback signal is missing.

feedback signal is missing.

17

Page 18

Start/Stop Levels

How to change a start or stop level:

Press Function key 1 to enter the overview screen for Pump Control 1.

Use the arrow keys

under the display to

click down and select

the line P1 Start.

You can now press the arrow down and change the stop level the same

way as you changed the start level.

Use the arrow keys

under the display to

click down and select

the line P1 Stop.

The last digit in the

start level is now selected. Enter the new

start level by using the

numerical keyboard on

the right.

The last digit in the

stop level is now selected. Enter the new

stop level by using the

numerical keyboard on

the right.

When the new value

has been entered, save

the value in Connect®

with OK.

When the new value

has been entered, save

the value in Connect®

with OK.

18

Page 19

If you need to change the start/stop levels on the next pumps, press once

more on the down arrow from Stop Level P1.

Now P2 will be displayed in the lower right corner. Press the right soft key

under P2 and the screen will change to Pump 2.

Repeat the procedure as described above.

By pressing the right soft key again, you will toggle between the number of

pumps chosen for Pump Control 1.

Note: It is a prerequisite that Pump Control has been set up and “Create

Overview Screen” has been carried out.

If you have chosen a higher stop level than start level, the function will

change from emptying to filling.

19

Page 20

Manual Operation

How to start or stop a pump manually:

Click the Function

Key 1 to show the

overview screen for

Pump Control 1.

The pump is now stopped and will not start until the start level has been

reached again and it is the pump’s turn in the alternation.

Note: Only one pump can be started, provided that the level in the pump

sump is above the stop level.

Use the up/down arrows

to select line 2, which

shows the operation

status. press “Operate”

button to enter the Pump

1 menu.

If you wish to start a

pump, use the arrow

keys to go down and select the Start Pump line

and click OK.

20

Page 21

If you wish to stop a pump in use, use the up/down arrows to select Stop

Pump and press OK.

If you need to start or stop one of the next pumps, press once more on the

down arrow from Stop Level P1.

Now P2 will be displayed in the lower right corner. Press the right soft key

below P2 and the screen will change to Pump 2.

Repeat the procedure as described above.

There are 4 views and icons of the Pump Status.

Operation status

Icon Description

of Pump

P1 Running Digital output when the pump is running and the feed-

P1 Stopped Digital output when the pump has stopped and the feed-

P1 Error

P1 Blocked Digital output when the pump is not in use.

back signal is ok.

back signal is missing.

Digital output when the pump is in use and the feedback

signal is missing.

Note: By pressing the right soft key again, you will toggle between the

number of pumps chosen for Pump Control 1.

It is a prerequisite that Pump Control has been set up and “Create Overview

Screen” has been carried out.

Scroll with the arrow keys to see more information.

21

Page 22

Pump Data

The overview screen View Data provides a full overview of operation data for

the pump.

In this view, View Data is selected and an overview screen of pictures for the

selected pump’s data is shown.

You can choose between 3 different data screens.

Totals Today Yesterday

Text line Description

Pump 1 This is the name of the function. You can change it to e.g. the

P1 Total/Today/

Yesterday Cnt.

P1 Total/Today/

Yesterday tim.

P1 Volume/Total/

Today/ Yesterday

Status Go back to the main screen for Pump Control 1

Select Up/down arrows are used to scroll up and down in the current

Next Change to next pump data screen.

pump number or any individual name.

Count values (number of starts) for the selected pumps.

The counter is connected to the selected DO for the pump. The

counter is shown as totals, today values (since midnight) and as

yesterday values

Time values (on-time) for the selected pumps. The counter is connected to the selected DO for the pump.

The counter is shown as totals, today values (since midnight) and

as yesterday values.

Volume values (number of units) for the selected pump. The counter is connected to the selected pump.

The counter is shown as totals, today values (since midnight) and

as yesterday values.

screen and select a line or function.

Note: It is a prerequisite that Pump Control has been set up and “Create

Overview Screen” has been carried out.

22

Page 23

Basic Flowchart

23

Page 24

Liability

DK: +45 45 56 06 56

NO: +47 69 20 60 70

SE: +46 53 31 77 50

NL: +31 251 672171

USA: +1 847 482 8655

AUS: +61 3 9758 8533

MJK Automation A/S

MJK Automation A/S are liable to the common

rules of Danish law on product liability, however,

the liability is reduced to coverage of our public liability insurance of products. To the extent where

nothing else follows in lines of invariable rules of

law, we are not liable for loss of profits and working deficits or other indirect losses.

Changes

As our products are developed continuously, we

reserve the right to make any alterations without

prior notice.

EN 6.05 Connect QG 1210

24

Loading...

Loading...