Page 1

Global Water

OWNER’S MANUAL

CL500 OnLine Residual

Chlorine Monitor

Global Water Instrumentation

11390 Amalgam Way

Gold River CA 95670

Phone: 800-876-1172

Fax: 847-672-9988

EMail:Globalw@globalw.com

Website:

www.globalw.com

Catalog #24420GW (2/08)

REV. 2.0

Page 2

Page 3

Table of Contents

Section Page

Specifications....................................................................................................1

1.0 Overview...........................................................................................................2

1.1 Unpacking and Inspection of the Instrument and Accessories .............2

1.2 The Display ...........................................................................................3

1.3 The Touch Pad ......................................................................................3

2.0 Safety.................................................................................................................4

2.1 Symbols Used In CL500........................................................................4

3.0 Theory of Operation........................................................................................5

4.0 Installation and Commissioning ....................................................................6

4.1 Mounting & Site Selection.....................................................................6

4.2 Plumbing ..............................................................................................7

4.3 Electrical Connections ..........................................................................8

4.3.1 Power ........................................................................................9

4.3.2 RS-485 .....................................................................................9

4.3.3 Relays.......................................................................................10

4.3.4 4-20 mA ..................................................................................10

4.3.5 RS-485/4-20 mA cable Ferrite.................................................10

4.4 Installing Reagents ..............................................................................10

5.0 Operation .......................................................................................................11

5.1 Routine Measurement .........................................................................11

5.2 Security Access Feature.......................................................................12

6.0 Instrument Calibration ................................................................................13

6.1 Slope (gain) Calibration Procedure .....................................................13

6.2 Zero (offset) Calibration Procedure ....................................................14

6.3 Restore Factory Settings ......................................................................14

7.0 Instrument Configuration (CONFIG mode)...............................................15

7.1 Setting the 4-20 mA.............................................................................15

7.2 Configuring the Error Level.................................................................16

7.3 Configuring the RS-485 Port ..............................................................16

7.4 Configuring the Alarms .......................................................................17

7.4.1 Alarm 1 ....................................................................................17

7.4.2 Alarm 2 ...................................................................................18

7.5 Enabling the Security Access...............................................................18

7.6 Extended Settings.................................................................................18

Page 4

Table of Contents (continued)

Section Page

7.7 Speed of Response...............................................................................19

7.8 LCD Backlight Brightness...................................................................19

7.9 RS- 485 Parameters..............................................................................20

7.10 Cycle Time ..........................................................................................20

7.11 Saving Configuration Settings.............................................................20

8.0 Additional Features and Options ................................................................21

8.1 Backlit LCD.........................................................................................21

8.2 RS-485 Output.....................................................................................21

8.2.1 Online SCADA........................................................................21

8.2.2 Simple Communication ...........................................................21

8.2.3 Modbus Communication..........................................................22

8.3 Remote Panel Meter.............................................................................22

8.4 Desiccant Cartridge..............................................................................22

9.0 Troubleshooting.............................................................................................23

9.1 CL500 Fault Detection.........................................................................23

9.2 Setting Flow Rate.................................................................................24

9.3 Clearing Faults.....................................................................................24

9.4 Diagnostic Chart .................................................................................25

9.5 Technical and Customer Assistance ...................................................25

10.0 Routine Maintenance.....................................................................................26

10.1 Maintenance Schedule ........................................................................26

10.2 Replacing or Installing the Reagents ...................................................28

10.3 Cuvette Change ...................................................................................29

10.4 Instrument Storage ..............................................................................29

10.5 Cleaning the CL500 ............................................................................30

11.0 Accessories and Replacement Parts List .....................................................31

12.0 Warranty .......................................................................................................32

Page 5

Specifications

Measurement Range

Accuracy

Resolution

Cycle Time

Display

Alarms

Analog Output

Communications Port

Water Pressure

Flow Rate to Waste

Operating Temperature

Wetted Materials

0 – 10.00 mg/L (PPM)

±5% of reading or ±0.03 mg/L (PPM) whichever is greater for range of

0-6.0 mg/L(PPM)

±10% of reading from 6.01-10.00 mg/L (PPM)

0.01 mg/L (PPM)

Adjustable; 110 seconds to 10 minutes (600 seconds)

Note: the system defaults to 2.5 minutes

Multi-Line Liquid Crystal Backlit Display

Two Programmable, 120-240VAC 2A Form C Relay

Powered 4-20 mA, 600 Ω drive, isolated

Bi-directional RS-485 with Modbus

Integral pressure regulator 0.34 bar(5.0 PSI) to 10.3 bar (150 PSI.)

200 – 400 ml/min.

5°C – 40°C (41°F – 104°F)

PVC, Borosilicate Glass, Reslyn (FFKM), Viton® (FKM),

Polypropylene, Stainless Steel, Acetal, Nitrile, Noryl®, Nylon

Sample Temperature Range

Power Supply

Insulation Rating

Environmental Conditions

Enclosure Rating

Regulatory Compliance

And Certifications

Shipping Weight

Shipping Dimensions

Warranty

5°C – 40°C (41°F – 104°F)

100 – 240 VAC, 47 – 63 Hz, 150VA

Double Insulated, Pollution Degree 2, Overvoltage Category II

Not recommended for outdoor use.

Altitude up to 2000 meters

Up to 95 % RH (non-condensing)

Designed to meet IP 66 /NEMA 4X

CE Approved, ETL listed to UL 61010-1-2004 &

ETL Certified to CSA 22.2 No. 61010.1 2

nd

edition dated July 2004

2.5 kg (5.5 lbs.) Reagents Shipped Separately

406 mm X 406 mm X 229 mm (16”X 16” X 9”)

1 Year from date of shipment

CL500 (2/08) Page 1

REV 2.0

Page 6

1.0 Overview

The CL500 Online Chlorine Analyzer allows for the reading of chlorine levels of process

water on-line. The CL500 has been designed to meet the design criteria specified by

Standard Methods for the Examination of Water and Wastewater (21th Edition) Method

4500-Cl G. DPD Colorimetric Method. The CL500 uses a 515nm LED as the

measurement light source.

Every effort has been made to ensure the accuracy of this manual. Due to the continuous

development and improvement of all instrumentation, there may be slight differences

between this manual and the instrument received. Therefore, no legal claims can be made

against any discrepancies herein. The latest version of the manual can be downloaded

www.globalw.com.

from

1.1 Unpacking and Inspection of the Instrument and Accessories

The table below indicates the items in the shipment.

Item Quantity

CL500 Analyzer 1

Instruction Manual 1

Mounting Kit 1

Tubing/Cuvette Kit: 8 black “B” tubes, 2 Cap Assemblies, 1 replacement cuvette 1

In-Line Strainer Kit 1

Ferrite 1

Remove the instrument from the packing carton. Carefully inspect all items to ensure that

no visible damage has occurred during shipment. If the items received do not match the

order, please immediately contact the local distributor or Global Water’s Customer

Service Department.

CL500 (2/08) Page 2

REV 2.0

Page 7

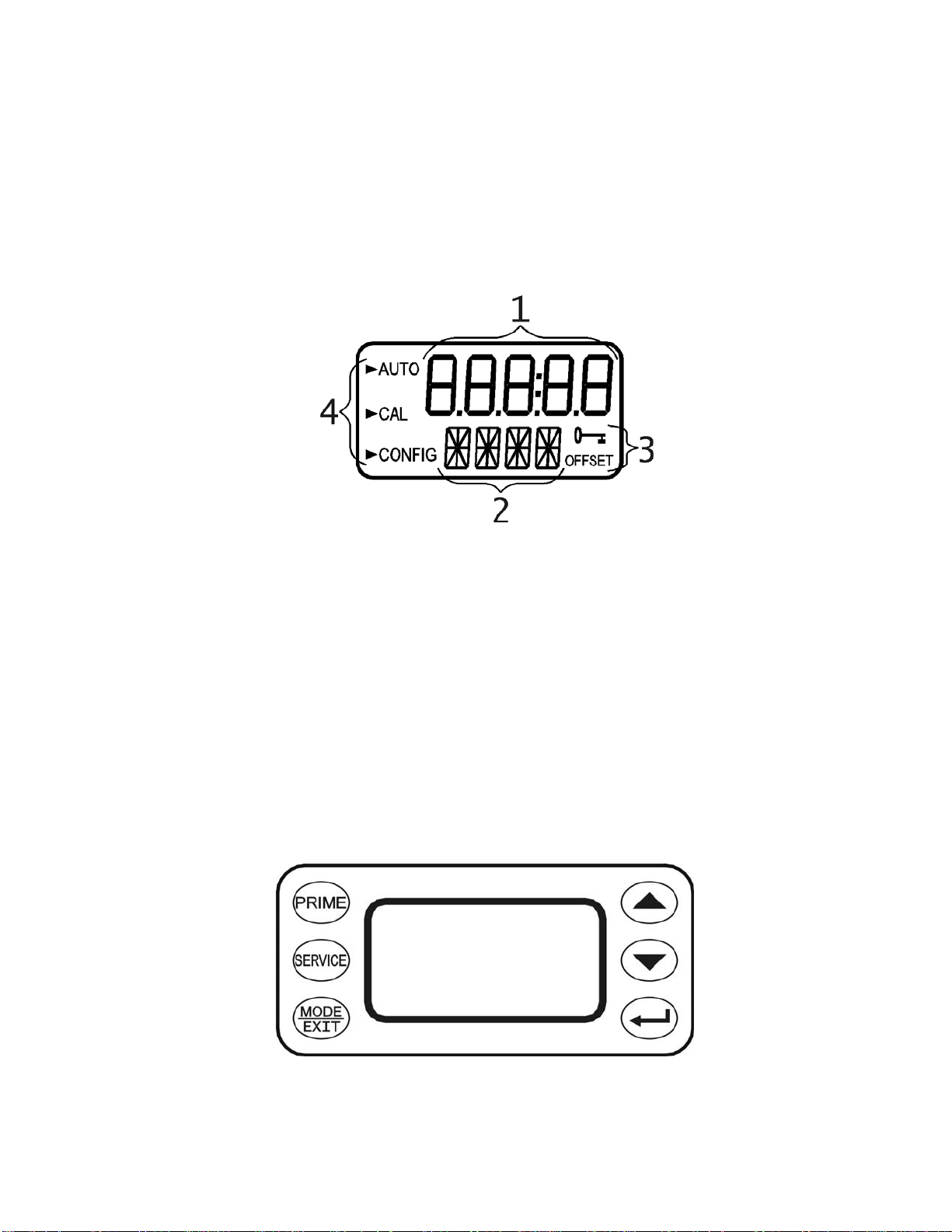

1.2 The Display

Figure 1 illustrates all the items that can appear on the display. The upper row of the

display (1) is used for reporting the chlorine levels and to provide user guidance in the

customer setting routine. The lower row of the display (2) is used to communicate error

messages (message queue) and provide user guidance. The display has two icons (3) that

are used to indicate the use of access code and offset mode. In addition, mode arrows (4)

are used to indicate the current instrument operating mode; AUTO (normal operation),

CAL (calibration) and CONFIG (configuration).

Figure 1: Display used in the instrument.

1.3 The Touch Pad Figure 2 illustrates the touch pad. The touch pad has six buttons: PRIME, SERVICE, MODE/EXIT, , S and T

The MODE/EXIT button is used to cycle between the three operational modes of the

instrument: CAL, CONFIG, and AUTO (Measurement) mode. The button enters the

option or mode that is highlighted or chosen. The S and T buttons are used to change

settings.

The PRIME and SERVICE buttons are dedicated controls. The PRIME will start 75

reagent pump pulses to prime the tubing after a change or addition of reagent bottles. The

SERVICE button will drain the instrument and hold all operations until either the

SERVICE button is pushed again or the power is reset. This button should be used while

changing the tubing, the measurement cuvette or reagent bottles.

Figure 2: The CL500 touch pad.

CL500 (2/08) Page 3

REV 2.0

Page 8

2.0 Safety

This manual contains basic instructions that must be followed during the commissioning,

operation, care and maintenance of the instrument. The safety protection provided by this

equipment may be impaired if it is commissioned and/or used in a manner not described in

this manual. Consequently, all responsible personnel must read this manual prior to

working with this instrument.

In certain instances “Notes”, or helpful hints, have been highlighted to give further

clarification to the instructions. Refer to the Table of Contents to easily find specific

topics and to learn about unfamiliar terms.

2.1 Symbols Used In CL500

Standard IEC symbols are used on the high voltage cover.

ISO 3864, No. B.3.6 Caution, risk of electric shock.

cover

This symbol indicates that hazardous voltages may be present under this

This symbol is reminding you to read the sections in the manual referring

to the electrical connections, and potential hazards.

ISO 3864, No.B3.1 Caution refer to accompanying documents.

CL500 (2/08) Page 4

REV 2.0

Page 9

3.0 Theory of Operation

The CL500 has two solenoid valves, one for sample water (FLOW) and one for draining

of the cuvette (PURGE). A third solenoid, along with four check valves forms a reagent

pump. Sample water flow is controlled by the FLOW solenoid valve. The PURGE

solenoid valve is used to empty the measurement cuvette.

The measurement chamber consists of a sample inlet, a purge drain, and an overflow. The

reagent is added below the cuvette. A green LED provides the 515 nm source lamp, a red

LED is used for sample level and flow measurement. A single detector is located 180 º

from the green LED. A replaceable glass cuvette separates the sample water from the

optical devices and maintains the measurement path length. Sample water flows in the

inlet at the bottom, through the measurement cuvette and out through overflow drain. This

flow is used to both fill the cuvette and flush the system.

The reagents consist of two replaceable bottles. One bottle has a buffer to control the pH;

the second has an indicator that contains the DPD, which produces color when chlorine is

present in the sample. The degree of color is dependant on the amount of chlorine in the

sample water.

The measurement chamber is open to view operations in the cuvette. A white LED

illuminates the chamber for a clearer view. The white LED will flash to attract attention in

the case of a warning or failure. Most warnings and failures are displayed on the screen.

During normal operation the CL500 will run through a timed cycle. A simplified cycle

will consist of the following sequences:

• Flushing – continuous sample flow

• Zeroing – no flow with cuvette full

• Purging – PURGE valve opens

• Adding Reagents – one pulse of the reagent pump

• Mixing with sample – sample flow pulses in

• Reading resulting sample – no flow with cuvette full

• Purging – PURGE valve opens to remove reacted sample

The cycle above does not describe all the actions and testing that occurs. The CPU

continuously diagnoses the entire system for correct operation and sample water flow. If

an error occurs, a message is posted to the message queue.

The reagent is added from the front, below the cuvette, by a single pulse of the reagent

solenoid. When the reagents require replacement, the PRIME button is pushed to bring

new reagents into the system. The reagent solenoid is pulsed several times to draw fluid

from the two reagent bottles and fill the tubes with new reagent. A complete prime takes

less than a minute.

The SERVICE button empties the cuvette, stops the flow of sample water, and clears any

errors. This provides a convenient way to replace reagents and the measurement cuvette. If

more extensive servicing is performed, all power to the CL500 should be removed. If the

CL500 is to be turned off, it is recommended that the instrument be placed in SERVICE

mode before removing power. This ensures that the cuvette is emptied and the flow is off.

CL500 (2/08) Page 5

REV 2.0

Page 10

4.0 Installation and Commissioning

Prior to use for the first time, one of the reagents (the indicator) will have to be mixed.

Refer to section 10.2 Replacing or Installing the Reagents.

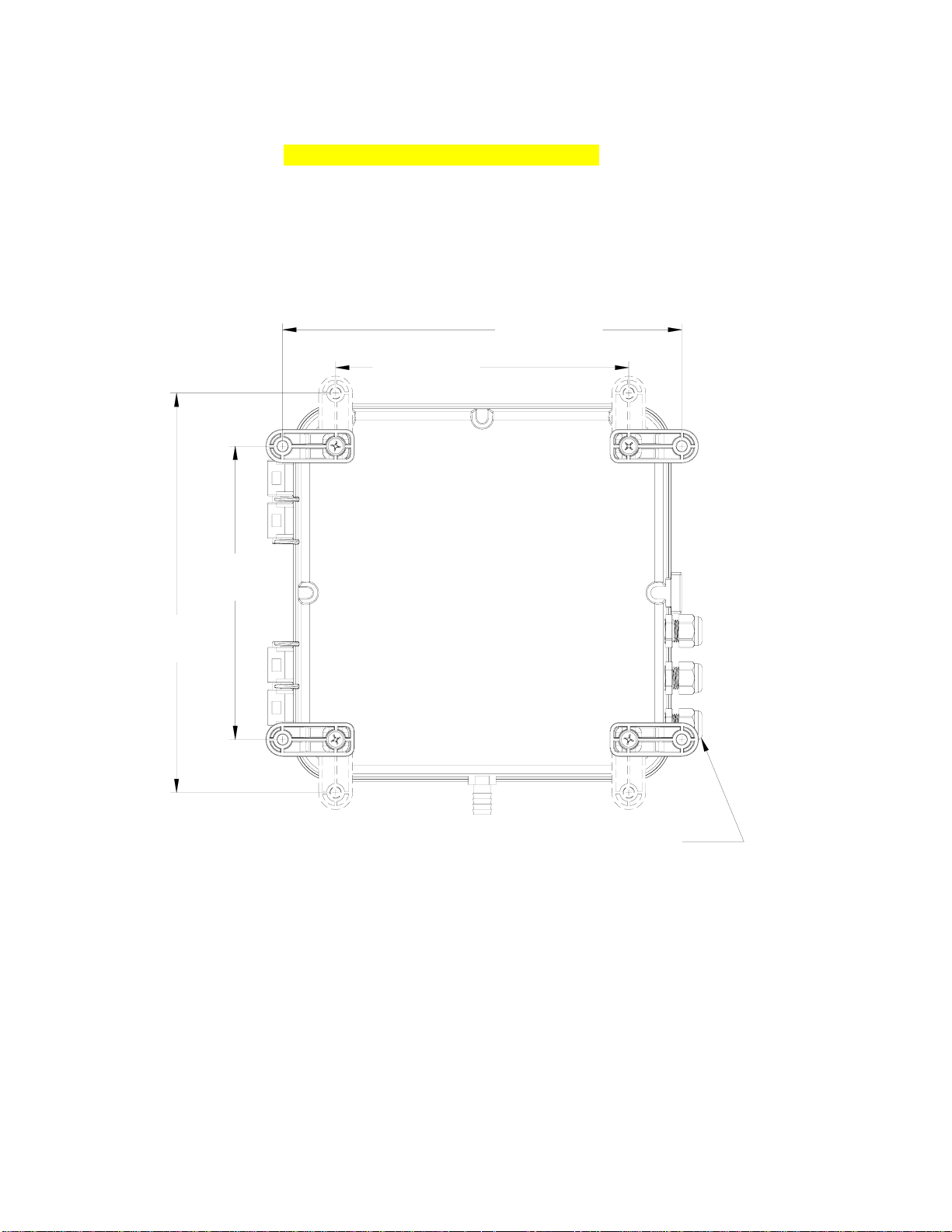

4.1 Mounting & Site Selection

The instrument is designed for wall mounting. If wall mounting is not practical, the

instrument can be mounted on any suitable level surface Choose a location that is easily

accessible for operation and service and ensure that the front display rests at eye level.

Consideration must be made the plumbing connections. The overall mounting dimensions

of the instrument are shown in Figure 3.

219.08mm

(8.625")

298.45mm

(1

1.750")

219.08mm

(8.625")

298.45mm

(11.750")

REAR VIEW

OF THE

INSTRUMENT

IT MAY BE NECESSARY TO REMOVE

THIS BULKHEAD NUT TO ACCESS THE

BOTTOM LEFT MOUNTING HOLE WITH

THE BRACKET IN THIS POSITION.

Figure 3: Overall Mounting Dimensions of the Instrument

It is critical that the instrument be mounted as close as possible to the sampling point to

ensure a quick response time (within 2-3 meters (6-10 ft) of the sampling point).

The provided mounting feet will need to be installed with the provided screws. These can

be rotated as shown above. Suggested mounting screws are up to M6 (¼”).

CL500 (2/08) Page 6

REV 2.0

Page 11

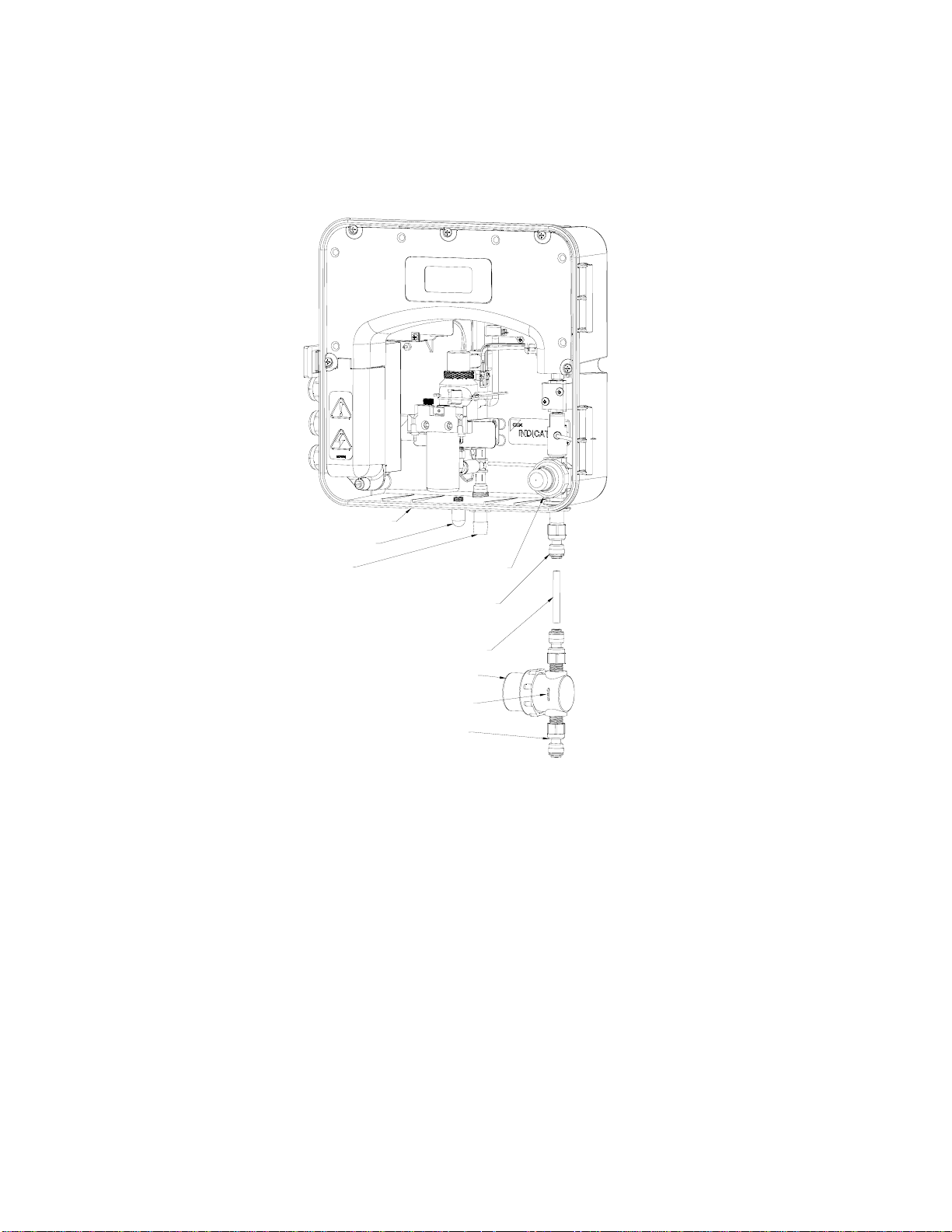

4.2 Plumbing

The recommended plumbing for the instrument is shown in Figure 4. The instrument is

designed to require very little head pressure to operate, but will need around 0.34 bar (5

PSI). The maximum pressure for proper operation should not exceed 10.3 bar (150 PSI).

The maximum allowable fluid temperature is 40°C (104°F).

ONLINE CHLORINE MONITOR

CABINET VENT

DRAIN CONNECTION

ACCEPTS 12,7 MM

(1/2") I. D. TUBING

INLINE T-STRAINER

PRESSURE

REGULATOR

WATER INLET

ACCEPTS 6,35 MM

(1/4") O. D. TUBING

1/4" OD PE TUBING

NOTE DIRECTION OF ARROW

IF NECESSARY, CHANGE

THE INLET FITTING HERE

Figure 4: Recommended Plumbing for the Instrument

The supplied T-strainer should always be used to prevent clogging of the instrument. ¼”

quick connect fittings are supplied on the T strainer. If a pipe fitting change is required,

this adaptation should be made at the T-strainer, not the instrument. Opaque tubing is

recommended be used if the tubing will be exposed to sunlight, to prevent algae growth.

Please note that the supplied connectors are compatible with ¼” O.D. semi-rigid or rigid

tubing.

The instrument is equipped with an internal cabinet drain (vent) to prevent damage in the

event of a tubing failure.

The drain tubing connects to a hose barb. The rated tubing size is ½” ID tubing. It is

recommended that opaque tubing be used to prevent algae growth. Keep this tubing as

short as possible. This drain must be kept open to the atmosphere.

CL500 (2/08) Page 7

REV 2.0

Page 12

The fluid waste from drain connection of this instrument contains reagents

diluted with large quantities of sample water. Global Water Instrumentation

recommends that operators check with local authorities concerning proper

disposal of waste fluids.

A ½ “ ID tubing can be placed over the cabinet vent to redirect accidental

spills of reagent to a suitable container.

4.3 Electrical Connections

All of the electrical connections to the instrument are made at the termination area which

is located on the left side of the instrument. Remove the high voltage cover by loosening

the captive screw. Refer to figure 5. The connections are labeled and are self-descriptive

(see Figure 5). Please follow all local and government recommendations for installation

of electrical connections to and between the instrument and other peripheral devices.

Bulkhead

Communication

Bulkhead

Captive Screw

High Voltage Cover

Power Cable

Strain Relief

Anchor

Power

Bulkhead

Alarms

Power

Terminal

Block

Alarm #2

Terminal

Block

Alarm #1

Terminal

Block

RS-485

Terminal

Block

4-20mA

Terminal

Block

Figure 5: Electrical Connections for the Instrument

CL500 (2/08) Page 8

REV 2.0

Page 13

Plugs are inserted into the RS-485 and 4-20mA cable bulkheads when shipped, to ensure a

watertight seal. These plugs should be removed and discarded when cabling to either of

these connections.

The power cable bulkhead will accept cable diameters from 5.8mm (.230 in.) up to 10 mm

(.395 in.). All terminals are designed to accept wires in the range of 14-28 AWG. All

wires should be stripped to a length of 6 mm (¼”). A strain relief strap is provided to

reduce tension on the power terminals.

It is the user’s responsibility to assure that a watertight seal is maintained after the CL500

has been wired for operation. If any of the bulkheads are not tightened properly around a

cable or plug, the ratings of the instrument will be jeopardized and there is a possibility of

creating a shock hazard.

Only qualified electricians should be allowed to perform the installation of the

instrument as it involves a line voltage that could endanger life.

4.3.1 Power

The instrument is equipped with 100-240 VAC, 47-63 Hz power supplies requiring

150VA; please verify that the line voltage falls within these specifications. It is

recommended that a circuit breaker be placed prior to the power connection to

allow for service. For safety it is recommended that the connection be less than 2

meters (six feet) from the instrument. While making connections, refer to Figure 5.

The CL500 is intended for cord connection with a three wire non-locking

grounded power cord; however ridged or flexible conduit connections can be used.

A power cord can be purchased separately from the factory (Catalog No. 00-302).

The CL500 is not supplied with a power cord. If the CL500 is to be used in the

U.S. or Canada the power cord must be UL Listed & CSA Certified. Please consult

all local electrical codes for proper connection.

The connection block is marked N for Neutral and L for line the third symbol

indicates a secure earth ground. The green removable terminal block is suitable for

wire gauges 18 to 12 AWG.

4.3.2 RS-485

The RS-485 half-duplex (2-wire) digital interface operates with differential levels

that are not susceptible to electrical interferences. This is why cable lengths up to

3000 ft can be implemented. The last device on each bus may require terminating

with a 120 ohm resistor to eliminate signal reflection on the line. Do not run RS485 cables in the same conduit as power. Set-up of the RS-485 is covered in 7.3

Configuring the RS–485 Port

To prevent damage to the instrument, ensure that power is disconnected prior to

making connections. For ease of connecting, remove the plug-in terminal block.

Connections are labeled beside this termination on the PC board.

The recommended cable is 22 AWG shielded twisted pair. The grey terminal block

is removable to assist in making connections.

CL500 (2/08) Page 9

REV 2.0

Page 14

4.3.3 Relays

The Alarm 1 and Alarm 2 relays are mechanical relays rated at 240 VAC 2A.

Please note that the relays are labeled NO (Normally Open), NC (Normally

Closed) and C (Common). As these alarms are configured fail-safe, the normal

condition is with power applied to the CL500 and in a non-alarm condition.

Operation of these alarms is covered in section 7.4 Configuring the Alarms.

The lever operated terminal blocks are rated for wire gauges 28-14.

4.3.4 4-20 mA

The 4-20 mA output is driven by a 15 VDC power source and can drive recorder

loads up to 600 ohms. Transformer isolation is provided on the CL500. Do not run

4-20 mA cables in the same conduit as power. Operation of this output is covered

in section 7.1 Setting the 4-20 mA.

To prevent damage to the instrument, and for general safety ensure that power is

disconnected to the CL500 prior to making any connections. Polarities of the

connections are labeled beside this termination on the PC board.

The recommended cable is 22 AWG shielded twisted pair. To prevent ground

loops, connect the shield at either the CL500 or at its destination, but not both.

The grey terminal block is removable to assist in making connections.

4.3.5 RS-485/4-20 mA cable Ferrite

To meet IEC requirements for RF radiated immunity a clamp-on type ferrite is

supplied in the accessory kit. It should be placed on the RS-485 or 4-20 mA cable

outside, as close as possible to the CL500. If both outputs will be used, an

additional ferrite will be needed and can be ordered from Global Water

Instrumentation Catalog number 24560GW.

4.4 Installing Reagents

The CL500 will require that two reagents be installed prior to operation. These are a

buffer and an indicator. Be sure the correct, prepared reagents are on hand as different

reagents are required to read Free than Total chlorine residual. For reagent preparation

refer to section 10.2 Replacing and Installing the Reagents.

CL500 (2/08) Page 10

REV 2.0

Page 15

5.0 Operation

The CL500 Online Chlorine Analyzer allows for the measurement of the chlorine of

process water on-line. The chlorine value of the process water is usually reported in

milligrams per Liter (mg/L), these units are equivalent to Parts Per Million (PPM).

Readings above 10.00 mg/L are outside the range of this instrument. Although the CL500

may display above 10.0 mg/L, these readings will not be within the stated accuracy. As

the reagents degrade due to aging, readings above 10.0 mg/L may decrease in value.

5.1 Routine Measurement

First, ensure that all plumbing and electrical connections are complete before continuing.

The following steps describe how to measure the value of chlorine of a sample using this

instrument:

1. Apply power to the instrument and allow the unit to warm up (typically 45 minutes to

one hour on initial commissioning).

2. When a continuous process stream is flowing through the instrument, the instrument

will display the measured chlorine level of the sample by displaying it on the LCD

screen. In addition, the equivalent signal is provided on the analog (4-20 mA) output,

or the digital (RS-485) output, depending on the options selected.

During normal operation, the instrument will have the arrow beside AUTO highlighted

with the current scale displayed on the lower row of the display and the measured reading

on the upper row of the display (see illustration below).

The screen depicted below indicates that the system has just been started or just entered

AUTO mode from Service mode and no readings have been taken yet.

Please note that calibrations will not be allowed until a reading is posted.

CL500 (2/08) Page 11

REV 2.0

Page 16

5.2 Security Access Feature

The instrument is equipped with a security access code feature that can be activated in the

configuration mode. If the security feature is enabled, the screen shown in the illustration

below will appear when the MODE/EXIT button is pressed.

The security code (333) must be entered to gain access to CAL or CONFIG menus.

Notice that the first number in the code is flashing. The flashing indicates that this is the

number to be changed. Use the S or T arrows to select the first of the three numbers in

the code and then press the button to accept the first number of the code. Now enter the

second number in the code. Proceed as with the first number followed by . Then repeat

the process for the third number in the access code, and finish with the button.

If the valid access code has been selected, the instrument will be directed to the calibration

mode. If the wrong access code is selected, the instrument will return to the AUTO mode.

Refer to section 7.5 Enabling the Security Access for more information.

CL500 (2/08) Page 12

REV 2.0

Page 17

6.0 Instrument Calibration

The instrument was tested prior to leaving the factory. Since it operates from a predetermined calibration curve, no calibration is required.

Calibration can easily be performed if required. The method is by comparison against

another instrument, such as a laboratory or hand held photometer.

There are two points of calibration. The slope or gain and the zero (offset). To perform the

zero the instrument must be plumbed to a sample of known chlorine free water such as deionized water for a zero adjustment.

6.1 Slope (gain) Calibration Procedure

It is important that the chlorine level be quite stable to use this method. The comparison

will be made against a trusted measurement such as a chlorine photometer,

spectrophotometer, or an amperometric titration.

1. Obtain a grab sample of the flow.

2. Measure the value of the sample with one of the methods shown above.

3. On the CL500, press the MODE/EXIT button once. The screen is shown below.

4. Press to enter the calibration adjustment.

5. The screen will show the current reading on the CL500. Using the S & T buttons

adjust the reading to agree with the laboratory method or portable photometer.

6. Press to accept the calibration adjustment and return to AUTO measurement

mode.

There is a limit to the size of the change that can be made to a current

reading. The upper limit is the current reading times 1.5. The lower limit is

the current reading divided by 1.5.

Ensure a reading is posted to the display before calibrating to avoid a nOnE

error.

CL500 (2/08) Page 13

REV 2.0

Page 18

6.2 Zero (offset) Calibration Procedure

Generally this calibration is only required if readings are expected to be below 1 mg/L or

if it is required by a regulatory authority. To perform this calibration, the water supply to

the CL500 must be changed to chlorine free water such as de-ionized water. This chlorine

free water must be run through the instrument for at least 5 minutes prior to using the

following procedure.

1. On the CL500, press the MODE/EXIT button once. The screen is shown

below.

2. Press either the S or Tbuttons to get the following screen.

3. Press to enter the zero calibration screen.

4. The screen will show the current reading on the CL500. Since there is no

chlorine, the only reading may be a slight offset due to the absorbance of the

reagents. There should be no pink color developed.

5. Press to perform a Zero calibration. When the calibration has completed the

instrument will return to AUTO measurement mode automatically.

There is a limit of ±0.20 mg/L total adjustment available. A ZERO Cal.

greater than this will cause a CAL warning and no calibration will have

occurred. Enter SERVICE mode to clear this error.

6.3 Restore Factory Settings

If the CL500 displays a CAL error or the calibration was incorrectly performed, it may be

desired to restore the factory calibration. All factory defaults including factory

configurations can be reset by holding down the S button and then pressing and releasing

the button then releasing the S button.

CL500 (2/08) Page 14

REV 2.0

Page 19

7.0 Instrument Configuration (CONFIG mode)

The instrument has been designed to provide the ability to customize the instrument

according to needs at any time during normal operation. This mode has been split into

sub-menus to facilitate instrument configuration. This section describes how to use each

of the sub-menus to configure the instrument. While in the configuration mode, the

instrument has a time-out feature that automatically returns the system operation to the

AUTO mode after a fifteen (15) minute period of no button pushes.

Enter the CONFIG mode of the instrument by pressing the MODE/EXIT button until the

arrow beside CONFIG is illuminated, then press the ↵ button.

To exit the CONFIG mode, press the MODE/EXIT button.

7.1 Setting the 4-20 mA Output

The first configuration selection is 4-20 for the 4-20 mA output. Select the either On or

OFF using the S and T buttons. Once the desired output has been set, press the button

to accept it. The next prompts will depend on the output selected.

If the 4-20 mA output was turned On, prompts to set the 4 mA (4MA) and 20 mA

(20MA) chlorine limits will be displayed. There will also be a menu to adjust the error

level (ERLV). The first prompt will be the chlorine limit assigned to the 4 mA output

level:

Select the chlorine level to assign to the 4MA using the S and T buttons.

Once the desired level has been set, press the button to accept it.

The 4MA can be set higher than 20MA level to invert the output current if

required. This may be required to control a dosing pump.

CL500 (2/08) Page 15

REV 2.0

Page 20

The next prompt will be the chlorine level assigned to the 20MA. Select the chlorine level

using the S and T buttons. Once the desired level has been set, press the button to

accept it.

7.2 Configuring the Error Level

In case of an error in the CL500, the 4-20 mA reading can be used to indicate a problem

by sending the current to either 4.00 mA, 2.00 mA or 0 mA. The factory default setting is

OFF. Select the desired ERLV by using the S and T buttons then press the button to

accept the desired error response.

7.3 Configuring the RS–485 Port

The instrument is equipped with an RS 485 port which operates in Simple bus, a

proprietary communication) or Modbus. Prompts will appear for setting the baud rate, the

address and the Modbus transmission mode (RTU or ASCII).

Select the correct baud rate (1200, 2400, 4800, 9600, or 19200) for operation of the I/O

port by pressing the S or T buttons to change the displayed baud rate.

CL500 (2/08) Page 16

REV 2.0

Page 21

Press the button to continue on and select the desired instrument address using the S or

T buttons. Once the selection is satisfactory, press the button.

To use the Modbus mode, select ASCII or RTU. Refer to the Modbus Manual available

from Global Water Instrumentation or online at

7.4 Configuring the Alarms

Two relays are provided that are designed to operate as two independent programmable

alarms or as a system problem alarm. Please note that changes to alarms will not be

recognized until the start of the next cycle. Two settings must be selected to fully program

each alarm:

1. The alarm function (HI, LO, OFF or Error)

2. The alarm set point (level at which the alarm activates)

These items are described below:

www.globalw.com.

Alarm Function: The alarms can either be turned OFF or selected to operate in one of

three different manners:

1. HI alarm: the relay changes state when the measured chlorine level is higher than the

programmed alarm level (set point).

2. LO alarm: the relay changes state when the measured chlorine level is lower than the

programmed alarm level (set point).

3. Error alarm: If there is a system fault or problem the alarm will change states.

Alarm Set Point: The level at which an alarm activates is called the alarm set point. On

the instrument, the alarm set point is designated as “S/P”. The set point is adjustable to

any valid chlorine level over the range of the instrument in steps of 0.01 mg/L. This

setting is not available if the Error function is chosen

7.4.1 Alarm 1 Alarm 1 Function: The ALM1 is displayed and the display indicates the current

function of alarm 1 (HI, LO, OFF, or Error). Use the S or T buttons to cycle

through and select the desired function. Press the button to accept the selection.

If the alarm was turned OFF, a prompt will appear to set up alarm 2 (go to section

7.4.2).

CL500 (2/08) Page 17

REV 2.0

Page 22

Alarm 1 Set Point: This prompt is used to select the set point for this alarm; this

is indicated by “S/P” shown on the lower row of the display. Select the desired

alarm level by using the S and T buttons. Once the desired set point has been

set, press the button to accept it.

7.4.2 Alarm 2

Repeat the procedure listed in section 7.4.1 to set up the parameters for alarm 2. If

a selection was made to turn the alarm OFF, the next selection for the speed of

response RESP is shown.

Due to the cyclic nature of the CL500, relay chatter is not an issue. There is no

need for alarm delays or hysteresis.

7.5 Enabling the Security Access

The instrument is equipped with a security access. If this option is turned on, the user is

required to input the access code into the instrument to get to any mode other than AUTO.

The only code is 333. This code may not be changed. See section 5.2 for more

information on this security feature. The security key icon will be visible and flashing on

the display whenever the access option is selected using the S or T buttons. (On or

OFF).

7.6 Extended Settings

The last few settings are grouped together to prevent them from being adjusted by

accident. To gain access to the extended settings, select On using the S or T buttons and

press the button.

CL500 (2/08) Page 18

REV 2.0

Page 23

7.7 Speed of Response

The speed of response for both displayed and output values of mg/L can be adjusted in

this menu. Although the default setting is 1, thirty-one (0-30) response speeds are

available. The higher the number selected, the slower the response will be. A high

number could be used to ignore minor process variations in a slow changing process. A

low number is used where a rapid response is desirable

Select the desired speed of response using the S and T buttons. Press the button to

accept it.

To avoid reading air and other anomalies, select the slowest speed (30). Select the fastest

response (0) where monitoring of rapid changes is needed.

7.8 LCD Backlight Brightness

The LCD backlight brightness may need to be adjusted. This is of particular interest if

multiple instruments are located in the same area and it is desired for the entire group to

have the same appearance. Ten levels are available. The default brightness is 8.

Change the brightness by pressing the S or T button. When the desired brightness has

been selected, press the button.

CL500 (2/08) Page 19

REV 2.0

Page 24

7.9 RS-485 Parameters

These menus will only appear if the RS-485 is enabled (see 7.3). The default is 8 Bit, no

(nOnE) Parity, 1 Stop Bit. Make selections using the S and T buttons then press the

button to move to the next menu.

7.10 Cycle Time

The cycle time can be changed using this menu. Please note that changing this menu

will directly affect the volume of reagent that will be consumed. The default is set to

150 seconds (2 ½ minutes). Using this setting the reagents will last 30 days. Make

selections using the S and T buttons then press the ↵ button to move to exit to AUTO

mode. Allowable setting is from 110 to 600 seconds (10 minutes).

Reagents have a 30 day life after being mixed.

7.11 Saving Configuration Settings

If extended settings are set to OFF, pressing the button will save all settings and the

CL500 will automatically return to the normal AUTO mode of the instrument.

If extended settings are set to On, after the last menu of the extended settings, pressing the

button will save all settings and the CL500 will automatically return to the normal

AUTO mode of the instrument.

The CONFIG menu may be used at any time to reset or change any of the parameters.

The CONFIG menu may be exited at any point in the menu by using the MODE/EXIT

key. Any features that have been modified will be saved.

CL500 (2/08) Page 20

REV 2.0

Page 25

8.0 Additional Features and Options

8.1 Backlit LCD

The backlit LCD allows for easier readability of the LCD display in low light or no light

conditions. The backlight is intended for continuous operation. The brightness is

adjustable from a menu in the CONFIG mode.

8.2 RS-485 Outputs

The CL500 has the capability to operate in three different RS-485 modes. Included is a

mode for interfacing into the online software package (section 8.2.1 below), a simple

communication mode and Modbus communications. All modes will automatically

configure and do not require any changes or selections

8.2.1 Online SCADA(Catalog # 19783GW)

The CL500 can operate as a small SCADA system with an optional PC software

package. This system allows for an interface with a combination of TB500’s or

CL500’s, totaling up to 255 units, for the purpose of data logging. This system will

interface directly with common database and spreadsheet software.

8.2.2 Simple Communication

The CL500 can provide basic communications over simple programs such as the

Hilgraeve HyperTerminal that is included with most Microsoft Windows

packages. The user could also use Visual Basic or other programs. The default

communication parameters are 8 bits, no parity and 1 stop bit. These can be

changed in the Extended CONFIG menus 7.9 RS-485 Parameters.

The master computer will send out:

• Byte #1 the attention character “:” in ASCII or 3A Hex

• Byte #2 the address of the CL500 being queried

• Byte #3 & 4 CR LF or 0D 0A in hex

The CL500 will respond with:

• The same attention character “:” in ASCII or 3A Hex

• The address of the CL500

• The Reading

• The Unit (mg/L)

A sample communication would look like this:

(Master computer requesting a report from address #1) :1 CRLF

(CL500 set to address #1 Response) :001 0.0249mg/L

CL500 (2/08) Page 21

REV 2.0

Page 26

8.2.3 Modbus Communication

Modbus protocol communication manual is available Cat. #24569GW. This

manual is available free online at www.globalw.com.

8.3 Remote Panel Meter (Catalog # 19609GW)

The remote panel meter allows for remote indication of the mg/L reading using the 4-20

mA loop of the CL500. No external power is required, as the meter is run off of the 4-20

mA source of the CL500.

8.4 Desiccant Cartridge Option (Catalog #09944GW)

An optional desiccant cartridge kit can be purchased for use in applications where

condensation on the glass cuvette may compromise accuracy. The desiccant changes color

from blue to pink when expended. Instructions for replacement are included with the kit.

CL500 (2/08) Page 22

REV 2.0

Page 27

9.0 Troubleshooting

9.1 CL500 Fault Detection

The CL500 performs continuous diagnostic monitoring. In the CL500, there are 4 severity

levels of fault detection. Level 4, 3 & 2 will allow normal operation, but warn of the

problem. Level 1 is an instrument failure and the instrument will not operate. Any faults

are displayed in a queue form in the bottom row of the LCD.

A level 4 fault is simply a screen indication that one of the alarm levels has been

activated. This fault level will not affect the 4-20 mA and will only affect the alarm

activated. The sample back light blinks at a rate of once every 4 seconds.

A level 3 fault indicates a failure or a problem that usually can be corrected by the

operator. Refer to the chart below. If any of these errors occur, the instrument will still

display readings and probably will operate correctly. These faults will self-clear when the

problem is corrected. If any of these faults occur, they will affect the 4-20mA and any

alarm set for fault detection (Error). The sample back light blinks at a rate of once every

2.5 seconds.

Message Description of Fault Corrective Action

MA 4-20 mA enabled & loop open Check 4-20 mA wiring or turn off 4-

CAL Calibration invalid –not accepted Recalibrate if needed

WATR No water flowing Check water flow

FAST Intake water flow too fast Set flow rate (see section 9.2)

SLOW Sample cuvette filling too slowly Set flow rate (see section 9.2)

PURG Sample cuvette has slow purge Check drain lines

NPRG Sample cuvette not purging Check drain lines

ISOL Problem with intake solenoid Check wiring, check for clogged solenoid

PSOL Problem with purge solenoid Check wiring, check for clogged solenoid

RGNT Problem with reagent Check reagent and lines

GLAS Dirty cuvette Replace or clean cuvette

WCAL Water Level Calibration Invalid Clear fault (see section 9.3)

REPL Reagents Expired Replace reagents and press PRIME

Level 3 (Self-Clearing) fault conditions

20mA if not used

A level 2 fault indicates a severe problem that will usually require technical assistance

from Global Water’s customer service (see section 9.5). The queued display will show

POST. If this fault occurs it will affect the 4-20mA and any alarm set for fault detection

(Error). The sample back light blinks at rate of once every 1 second.

CL500 (2/08) Page 23

REV 2.0

Page 28

A level 1 fault is a system fault. This is NOT a problem that the operator can correct, and

the unit must be returned to the factory for service (see section 9.5). These failures consist

of failures in the CPU, A/D, EEPROM or other devices internal to the instrument. The

queued display will show FAIL, the upper display is a five digit code. If this fault occurs,

it will affect the 4-20mA and any alarm set for fault detection (Error). The instrument will

not operate with this fault. The sample back light blinks at rate of once every 0.4 seconds.

If any fault condition occurs, the message indicating the fault will be shown on the lower

row of the display.

9.2 Setting Flow Rate

The flow rate on the CL500 was factory adjusted and should not need adjustment.

Installation variances may affect the flow. The optimal flow rate through the CL500 may

be adjusted if needed. The flow is adjusted by removing regulator vinyl cap and turning

the adjustment screw on the pressure regulator. Refer to figure 4. To assist in this

adjustment follow the procedure shown below:

1. Press the SERVICE button.

2. Wait for the display to read HOLd, then press Mode/ Exit.

3. Display will show FLOW with the number 0. Press either the S or T button.

4. CL500 will drain, and then pulse in water while a count is displayed on the screen.

5. The display will show one of three messages HI, LO or Good.

The flow test determines if the flow rate is suitable for proper operation. Loosen the

locking nut then adjust the pressure regulator using a coin or a large flat blade

screwdriver. Press either the S or T button while in the FLOW routine to display a new

flow rate. Please note that only ¼ turn incremental adjustments should be made to the

regulator on each attempt.

If the message is LO, turn the regulator control clockwise. If the message is HI, turn the

regulator counterclockwise. If the message is Good, no adjustment is required. Tighten the

locking nut after adjustment and replace the regulator vinyl cap. To return to normal

operation, press the ↵ button.

9.3 Clearing Faults

Every time SERVICE mode is exited, all faults are cleared. If the original fault or a new

fault occurs, it will be posted.

CL500 (2/08) Page 24

REV 2.0

Page 29

9.4 Diagnostic Chart

Symptom Cause Cure

Lower display shows MA 4-20 mA loop open Check wiring. See sections

4.3.4 and 7.2

Lower display shows FAIL Major system fault Refer to section 9.1

Readings are erratic (1) Bubbles in solution

(2) Debris in flow

(1) See above

(2) Install T strainer at inlet

Readings are lower than expected (1) Condensate or leaky

measurement cuvette

(2) Measurement cuvette

dirty

(3) Reagents bad or expired

(4) Buffer reagent not being

dispensed

Upper display flashes Sample Over-Range Check sample. Sample may be

Upper display shows nOnE while

attempting to calibrate

9.5 Technical and Customer Assistance

If for any reason assistance is needed regarding this instrument please do not hesitate to

contact Global Water’s Customer Service Department:

No current reading displayed Wait for CL500 to post a

Global Water Instrumentation

11390 Amalgam Way

Gold River CA 95670

Phone: (800) 876-1172

Fax: (847) 672-9988

Email:

www.globalw.com

globalw@globalw.com

(1) Install desiccant cartridge

kit

(2) Replace or clean cuvette

(3) Replace reagents

(4) Check buffer lines and

check valves.

too high to read.

reading

CL500 (2/08) Page 25

REV 2.0

Page 30

10.0 Routine Maintenance

10.1 Maintenance Schedule

The recommended schedule is shown below. It is important to replace the reagents on a

monthly basis to get reliable accurate readings from the CL500.

The CL500 is shipped with one CL500 Tubing/Cuvette kit, Cat. #09950GW. The kit

consists of the following:

Qty Part

2 “A” Cap Assemblies

8 “B” Pump Tubes

1 Cuvette

Cap Assembly "A"

Figure 6: Reagent Tubing Set

The drawing above shows one complete reagent tubing set (check valves not included in

kit). Two complete sets are used in the CL500; one for the buffer and one for the indicator.

The supplied kit is intended to last for one year. Additional kits can be ordered from your

local Global Water Instrumentation distributor or representative. It is recommended to

keep one kit on hand at all times.

Generally, all “B” tubes should be replaced on a three month basis. If the CL500 is

operated in an ambient temperature above 27 ° C (81° F), the “B” tubes should be changed

every two months. The “A” Cap Assemblies and the cuvette should be replaced annually.

Every Month

1. The reagent required for operating this instrument must be changed on a monthly

basis (with a 2.5 minute cycle time).

2. The external strainer should be checked and cleaned if necessary

3. The glass cuvette should be inspected. Check for excessive debris on the inside

surface of the glass. It is suggested to keep a spare cuvette to replace when required.

The old cuvette may be cleaned, if possible, for future replacement.

Flushing the System

It is recommended that the tubings replacements be timed with reagent replacement. Press

the SERVICE button to stop the water flow. Remove old reagents and discard. Place the

inlet tubings in a small container of clean water. Press SERVICE to return to operation

mode, press PRIME and then to flush the system with water. Remove the inlet tubings

from the water Press PRIME and then to remove most of the water.

CL500 (2/08) Page 26

REV 2.0

Check Valve

Flow

Tube"B"

Page 31

After a PRIME the CL500 will perform a water calibration (WCAL). It will

take a few minutes to complete this procedure.

3 Month Tubing Replacement

The “B” tubings need replacement more often due to the fact that they are subject to wear

from the reagent “Pump”. The check valves should not need to be replaced and should be

saved. Please note that the check valves are directional and that the “IN” side is smaller in

diameter (see drawing).

Steps:

1 Flush the system as described above to reduce personal contact with the reagents.

2 Press SERVICE to stop the flow of sample water and drain the cuvette.

3 Remove and retain the thumb screw on top of the pump; pull the pump hammer and

spring up and out of the way. There is no need to completely remove the hammer and

spring.

4 Working on one reagent side at a time. Replace the “B” (black) tubing between optics

inlet and the check valve OUTLET. Discard the old “B” tubing.

5 Ensure the check valve is placed into its seat.

6 Repeat steps 4 & 5 for the other reagent.

7 Replace the hammer and spring back into place and secure with the thumb screw.

8 Check the drawing on the following page to ensure correct installation.

9 Return to operation as described.

Annual Tubing Replacement

Once a year, complete the 3 Month Tubing Replacement as above, and then follow the

steps below:

1. Replace the two “A” Cap Assemblies.

2. Turn the knurled top on the optics system counterclockwise (as viewed for the top)

until the cuvette just “pops” out, but do not remove the top.

3. When the cuvette “pops” out, move the retaining o-ring & remove the cuvette. You

may need a stiff wire such as a bent paper clip to grasp the cuvette. Retain this cuvette

for future use if it can be cleaned.

4. Install the new cuvette by pushing it firmly in place and turning the knurled top

clockwise until the cuvette is held securely.

5. Check the drawing on the following page to ensure correct installation.

6. Return to operation as described.

Return to Normal Operation

Press the SERVICE button to return sample flow to the system. Check for leaks. If a leak

occurs press SERVICE again, repair leak and try again. Once the system is operating

correctly, return or replace reagents and press PRIME and then one time to restart

reagent flow. The system will automatically return to normal operation.

Tubes may darken due to contact with the reagent. This condition does not

affect the performance of these parts.

CL500 (2/08) Page 27

REV 2.0

Page 32

CAP ASSEMBLY "A"

THUMB

SCREW

PUMP

HAMMER

AND SPRING

REAGENT

PUMP

ASSY

INLET

CHECK

VALVES

INLET

CHECK VALVE DETAIL

Figure 7: Reagent Tubing Installation

10.2 Replacing or Installing the Reagents

FLOW

KNURLED TOP

OPTICS SYSTEM

CAP ASSEMBLY "A"

CUVETTE

RETAINING

O-RING

`

OUTLET

Reagent kits are available from Global Water Instrumentation for Free Chlorine and for

Total Chlorine Refer to section 11.0 Replacement Parts and Accessories for the

appropriate Catalog numbers. There are two reagents required, and supplied in each kit;

the buffer

and the indicator.

The buffer and indicator reagents are provided as dry reagents and require the addition of

deionized water. You will need to have at least 1 liter of deionized water on hand prior to

preparing the solutions. Allow about ½ hour time to prepare the reagents.

Use caution while preparing. These reagents are caustic and can burn skin

and stain clothing. The use of protective gloves, clothing and eye protection is

highly recommended.

Buffer Reagent Preparation

Add about 400 ml of deionized water into the buffer bottle. Cap tightly and shake

vigorously until the powder is fully dissolved. When fully dissolved add enough deionized

water to bring the volume in the bottle up to the fill line.

CL500 (2/08) Page 28

REV 2.0

Page 33

Indicator Reagent Preparation

Add about 400 ml of deionized water into the indicator bottle. Cap tightly and shake

vigorously until the powder is dissolved. Remove the cap and add the contents of the DPD

powder bottle (small brown bottle). Cap and shake to fully dissolve the powder. When

fully dissolved add enough deionized water to bring the volume in the bottle up to the fill

line.

Once mixed the reagents have a expected life of 30 days. Write the mixing

date on the reagent bottle labels in the area provided. Dispose of expired

reagents correctly.

To replace the reagents, press the SERVICE button; this will empty the cuvette and stop

any flow of water. Remove the cap on both bottles replace with the blue cap supplied with

the CL500. Be sure to replace the reagents in the correct location as labeled on the inside

of the CL500. The buffer is installed on the left and the indicator is installed on the right

side. The suction tube for both reagents will reach the bottom of the bottles.

To complete the replacement procedure, press the PRIME button. This will draw enough

of each reagent to completely prime the tubes and replace any old solution. The system

will automatically return to normal operation after it has primed.

Use caution when changing the reagents as they are caustic. These reagents

will stain clothing and anything they contact. After changing the reagents,

operators should wash their hands.

10.3 Cuvette Change

As recommended in section 10.1 Maintenance Schedule the cuvette should be inspected at

monthly intervals and replaced when needed.

To replace the cuvette, press the SERVICE key. When HOLD shows on the

screen, the system is ready.

The cuvette is spring loaded to allow for removal. Leave the cuvette retainer

(O-ring) in place while loosening top.

Loosen the knurled top until the cuvette pops out. Pull the cuvette retainer down to allow

for cuvette removal. Remove and replace or clean cuvette. Reverse the procedure to

replace. To avoid damage do not over tighten the knurled top. Press the SERVICE key to

return the system to normal sample flow and check for leaks.

10.4 Instrument Storage

If the CL500 is relocated or will be inactive for more than 48 hours, remove the reagents.

Flush the reagent system as describe in 10.1 Maintenance Schedule. Place the instrument

in Service mode to drain the system then remove power by disconnecting the mains power

plug. It is usually a good idea to disconnect or shut off the source water.

CL500 (2/08) Page 29

REV 2.0

Page 34

10.5 Cleaning the CL500

Flush the system as mentioned in section 10.1 Maintenance Schedule. When the flushing

is finished, press the SEVICE button wait until the display reads HOLd.

As a mater of safety, always disconnect any power source to the CL500 prior to

attempting any cleaning. It is recommended that the source water is also shut off.

Isopropyl alcohol (rubbing alcohol) on a soft cotton cloth works very well in removing

reagent stains from plastic parts, the key pad and the display. Use care when cleaning

around electrical components. Do not use any harsh cleaning agents as these may cause

damage to the instrument components.

Ensure that the system is dry prior to applying power.

CL500 (2/08) Page 30

REV 2.0

Page 35

11.0 Accessories and Replacement Parts List

The items shown below are recommended accessories and replacement parts.

Accessory Catalog Number

J.A.W. Reagent Kit – Free Chlorine 30 day supply 09951GW

J.A.W. Reagent Kit – Total Chlorine 30 day supply 09952GW

J.A.W. Reagent Kit – Free Chlorine 60 day supply 09953GW

J.A.W. Reagent Kit – Total Chlorine 60 day supply 09954GW

J.A.W. Reagent Kit – Free Chlorine 12 month supply 09955GW

J.A.W. Reagent Kit – Total Chlorine 12 month supply 09956GW

Operating Manual CL500 24420GW

Tubing/Cuvette Kit 09950GW

Replacement Cuvette 25018GW

Check Valve Set 25017GW

Ferrite for 4-20mA or RS-485 24560GW

To order any accessory or replacement part, please contact the Global Water’s Customer

Service Department. If for any reason technical assistance is needed regarding this

instrument, please do not hesitate to contact the Global Water’s Service Department.

Global Water Instrumentation

11390 Amalgam Way

Gold River CA 95670

Phone: (800) 876-1172

Fax: (847) 672-9988

Email: globalw@globalw.com

www.globalw.com

CL500 (2/08) Page 31

REV 2.0

Page 36

12.0 Warranty

Global Water Instrumentation., as vendor, warrants to the original purchaser of this

instrument that it will be free of defects in material and workmanship, in normal use and

service, for a period of one year from date of delivery to the original purchaser. Global

Water Instrumentation’s, obligation under this warranty is limited to replacing, at its

factory, the instrument or any part thereof. Parts, which by their nature are normally

required to be replaced periodically, consistent with normal maintenance, specifically

reagent, desiccant, sensors, electrodes, tubing and fuses are excluded. Also excluded are

accessories and supply type items.

Original purchaser is responsible for return of the instruments, or parts thereof, to Global

Water Instrumentation’s factory. This includes all freight charges incurred in shipping to

and from Global Water Instrumentation’s factory.

Global Water Instrumentation is not responsible for damage to the instrument, or parts

thereof, resulting from misuse, environmental corrosion, negligence or accident, or defects

resulting from repairs, alterations or installation made by any person or company not

authorized by Global Water Instrumentation

Global Water Instrumentation assumes no liability for consequential damage of any kind,

and the original purchaser, by placement of any order for the instrument, or parts thereof,

shall be deemed liable for any and all damages incurred by the use or misuse of the

instruments, or parts thereof, by the purchaser, its employees, or others, following receipt

thereof.

Carefully inspect this product for shipping damage, if damaged, immediately notify the

shipping company and arrange an on-site inspection. Global Water Instrumentation

cannot be responsible for damage in shipment and cannot assist with claims without an

on-site inspection of the damage.

This warranty is given expressly and in lieu of all other warranties, expressed or implied.

Purchaser agrees that there is no warranty on merchantability and that there are no other

warranties, expressed or implied. No agent is authorized to assume for Global Water

Instrumentation any liability except as set forth above.

Global Water Instrumentation

11390 Amalgam Way

Gold River CA 95670

Phone: (800) 876-1172

Fax: (847) 672-9988

Email:

www.globalw.com

globalw@globalw.com

CL500 (2/08) Page 32

REV 2.0

Loading...

Loading...