Xylem CL500 User Manual

Global Water

MODBUS MANUAL

For the

CL500

Online Residual

Chlorine Monitor

Global Water

Gold River CA 95670

Phone: 800-876-1172

Fax: 847-672-9988

EMail:Globalw@globalw.com

Website: www.globalw.com

Revised (3/09)

Rev. 1.3

11390 Amalgam Way

1.0 Overview

The Global Water CL500 uses a communication protocol called Modbus. A company

called Modicon, for use with their programmable controllers, developed the Modbus

protocol. Since that time Modbus has evolved into common communication protocol in

industry.

The communication method involves using a master-slave technique, in which there is one

master and several slaves. The CL500 is a slave device. Only the master can initiate

queries. These queries are directed to an individual slave device and the appropriate slave

responds with the requested data.

A broadcast message can be sent to all slaves. The slave devices do not answer these

broadcasts.

There are two transmission modes. These modes are known as RTU (Remote Terminal

Unit) and ASCII (American Standard Code for Information Interchange).

The CL500 can be setup in a network of up to 255 slave devices. Each device must have a

different address (1-255). The CL500 can be set for either RTU or ASCII mode.

CL500 Modbus (3/09)

Rev. 1.3

1

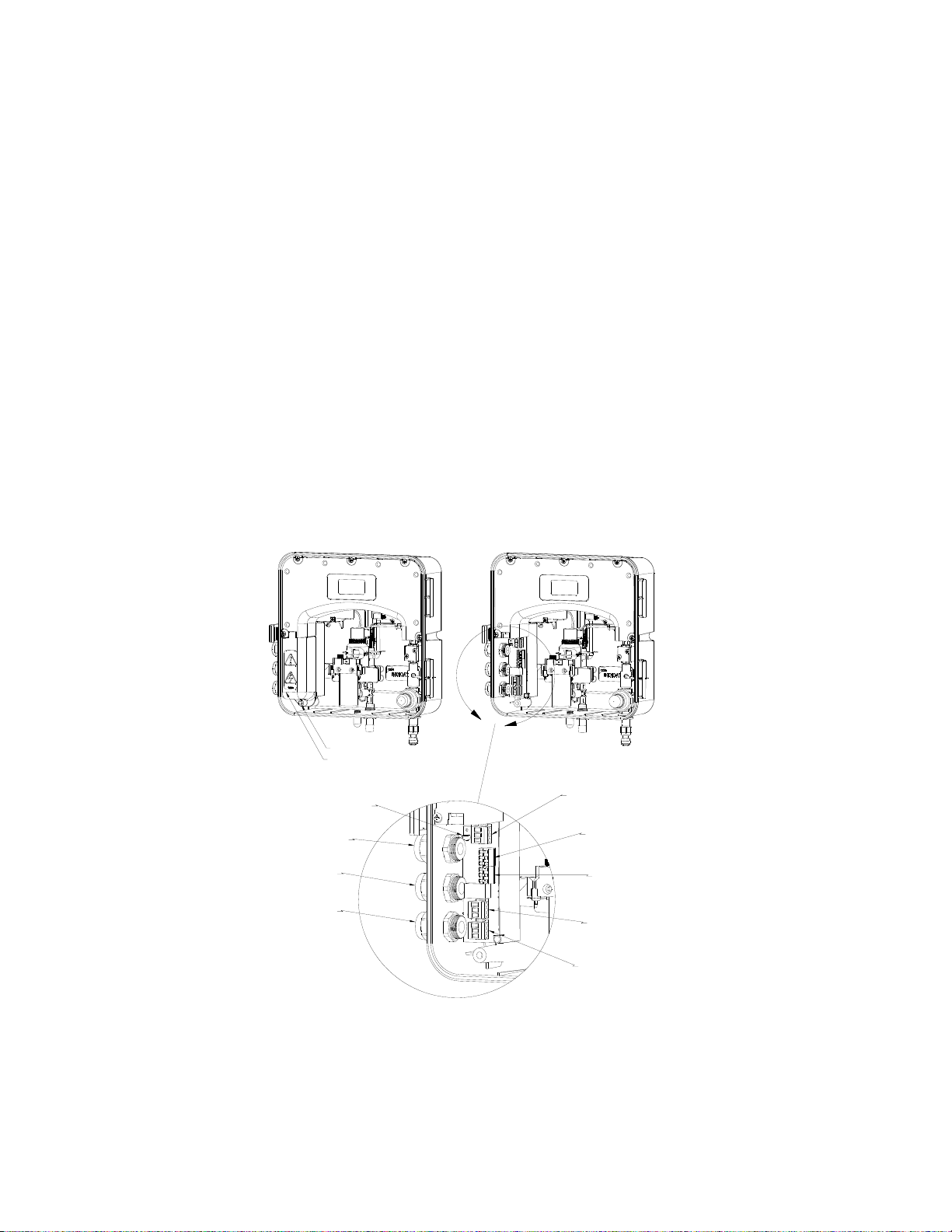

2.0 Electrical Connections

All of the electrical connections to the instrument are made at the termination area, which

is located on the portion of the instrument. The connections are labeled and are selfdescriptive (see Figure 1). Please follow all local and government recommendations and

methods for installation of electrical connections to and between the instrument and other

peripheral devices.

Plugs are inserted into cable bulkheads when shipped, to ensure a watertight seal. These

plugs should be removed and discarded as required when cabling to this connection.

The bulkhead will accept cable diameters from 5.8mm (.230 in.) up to 10 mm (.395 in.).

The terminals are designed to accept wires in the range of 14-28 AWG. All wires should

be stripped to a length of 6 mm

It is the user’s responsibility to assure that the watertight seal is maintained after the

terminal box has been wired for operation. If any of the bulkheads are not tightened

properly around a cable or plug, the ratings of the instrument will be jeopardized and there

is a possibility of creating a shock hazard.

Note: Only qualified electricians should be allowed to perform the installation of the

instrument as it involves a line voltage that could endanger life.

Captive Screw

High Voltage Cover

Power Cable

Strain Relief

Power

Bulkhead

Alarms

Bulkhead

Communication

Bulkhead

Anchor

Power

Terminal

Block

Alarm #2

Terminal

Block

Alarm #1

Terminal

Block

RS-485

Terminal

Block

4-20mA

Terminal

Block

Figure 1: Electrical Connections for the Instrument

CL500 Modbus (3/09)

Rev. 1.3

2

2.1 RS-485 Connection

The RS-485 half-duplex (2-wire) digital interface operates with differential levels that are

not susceptible to electrical interferences. This is why cable lengths up to 3000 ft can be

implemented. The last device on every bus may require a 120-ohm termination resistor to

eliminate the possibilities of signal reflection on the line. Do not run RS-485 cables in the

same conduit as power.

Ensure each instrument is not powered when connecting the RS-485 line. To prevent

damage to the instrument, ensure that power is disconnected prior to making connections.

CL500 Modbus (3/09)

Rev. 1.3

3

Loading...

Loading...