Page 1

INJECTOR

®

MODEL C-1100 MODEL-V

VARIABLE SPEED

POSITIVE DISPLACEMENT INJECTOR PUMP

OPERATING MANUAL

R

Blue-White

Industries, Ltd.

5300 Business Drive

Huntington Beach, CA 92649

Phone: 714-893-8529 FAX: 714-894-9492

E mail: sales@blue-white.com or techsupport@blue-white.com

Website: www.blue-white.com

USA

Page 2

Page 2 C-1100V

TABLE OF CONTENTS

1.....Introduction .....................................................................................3

2.....Specifications ............. .............. ........................................................3

3.....Features........ .............. .............. .............. .............. .............. ..............3

4.....Unpacking.... .............. .............. .............. .............. .............. ..............3

5.....Installation ................. .............. .............. .............. .............. ..............4

5.1..Mounting location ........................... .............. .............. ..............4

5.2..Input power connections ............................... .............. ..............5

5.3..External input signal connections..............................................6

5.4..How to install the tubing and fittings.........................................8

6.....How to operate the Pump ....................... .............. .............. ..............10

6.1..Description of pump output adjustment controls .......................10

6.2..How to adjust the output - manual stroke adjustment .. ..............11

6.3..Mode 1 - Manually Adjusting the output..................... ..............11

6.4..Mode 2 - 4-20 mA input.... .............. .............. ............................12

6.5..Mode 3 - 0-10 VDC input ............... .............. .............. ..............14

6.6..Mode 4 - Frequency (Hz) input ....... .............. .............. ..............16

6.7..Measuring the pump output - Volumetric test .............. ..............18

6.8..FVS Flow Verification System ....... .............. ............................18

7.....How to maintain the Pump ...............................................................20

7.1..Routine inspection and cleaning................................................20

7.2..How to clean the pump ..... ........................................................20

7.3..500 hour service warning timer ....... .............. ............................20

Pump head and Valve exploded view drawing ..... .............. ..............21

Replacement parts drawing ...... .............. .............. .............. ..............22

Replacement parts list ............................ .............. .............. ..............23

Warranty information......................................................... ..............24

Authorized service centers ..................... .............. ............................25

Page 3

C-1100V

1.0 Introduction

Congratulations on purchasing the C-1100 Model-V Variable speed positive

displacement metering pump. The C-1100 is designed to inject chemicals

into piping systems and is capable of injecting against a high system

pressure up to 150 PSI (10.4 bar). In addition to the front mounted

mechanical flow rate adjustment, the C-1100 Model-V unit is equipped with

an external input control circuitry which allows the pumps output to be

externally controlled by either a 4-20mA input signal, a 0-10V DC input

signal or a pulsed input signal.

2.0 Specifications

Maximum Working Pressure 150 psig / 10.4 bar (most models)

Maximum Fluid Temperature 130 F / 54 C

Ambient Temperature Range 14 to 110 F / -10 to 43 C

Duty Cycle Continuous

Maximum Viscosity 1,000 Centipoise

Maximum Suction Lift up to 30 ft. water

Power Requirements 108/130Vac 60Hz 40 Watts,

Dimensions 6-1/8” H x 10-1/8” W x 9” D

Weight 12 lb.

o o

o o

208/250Vac 40Hz 40 Watts,

208/250Vac 60Hz 45 Watts

Page 3

3.0 Features

!

Double-ball, springless ceramic check valves with PVDF (Kynar) body,

TFE/P (Aflas) and Viton o-ring seals.

!

Easy access, front mounted mechanical feed rate adjustment.

!

High outlet pressure capability of 150 psig (most models).

!

400:1 adjustment turn down ratio(speed and stroke combined).

!

Digital electronic feed rate control.

!

Corrosion proof Valox housing.

!

Tamper resistant electronic control panel cover.

4.0 Unpacking

Your pump package should contain the following:

1 - Injector pump

1 - suction tube footvalve & strainer assembly

1 - ceramic tubing weight

1 - 5’ Length of clear PVC suction tubing

1 - 5’ Length of opaque LLDPE discharge tubing

1 - Injection fitting with internal back-flow check valve

1 - Mounting hardware kit

Page 4

Page 4

CAUTION: Proper eye and skin protection must be

worn when installing and servicing the pump.

C-1100V

5.0 Installation

CAUTION: Proper eye and skin protection must be

worn when installing and servicing the pump.

Note: All diagrams are strictly for guideline purposes only. Always consult

an expert before installing the pump into specialized systems. The pump

should be serviced by qualified persons only.

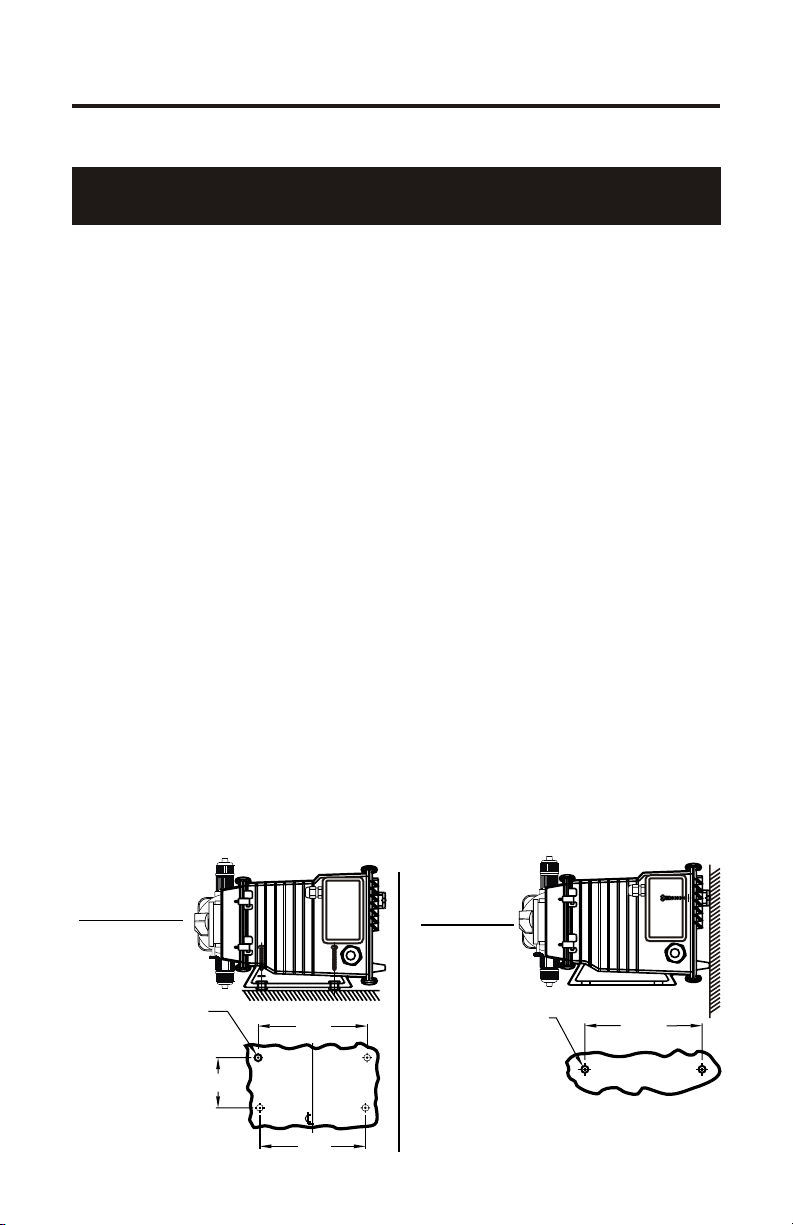

5.1 Mounting Location

Choose an area located near the chemical supply tank, chemical injection

point and electrical supply. Although the pump is designed to withstand

outdoor conditions, a cool, dry, well ventilated location is recommended.

Install the pump where it can be easily serviced.

!

Mount the pump to a secure surface or wall using the enclosed hardware.

Wall mount to a solid surface only. Mounting to drywall with anchors is not

recommended.

!

Mount the pump close to the injection point. Keep the inlet (suction) and

outlet (discharge) tubing as short as possible. Longer discharge tubing

increases the back pressure at the pump tube.

!

Your solution tank should be sturdy. Keep the tank covered to reduce

fumes. Do not mount the pump directly over your tank. Chemical fumes

may damage the unit. Mount the pump off to the side or at a lower level

than the chemical container.

!

Mounting the pump lower than the chemical container will gravity feed the

chemical into the pump. This “flooded suction” installation will aid in

priming the pump and will reduce output error due to increased suction lift.

We recommended installing a shut-off valve, pinch clamp or other means to

halt the gravity feed to the pump during servicing.

!

Be sure your installation does not constitute a cross connection with the

drinking water supply. Check your local plumbing codes.

Floor Mount

Drill .156 Dia. (5/32)

For Self-Tap Screw

#10 X 1” Phillips Steel

4 Places

3-1/2”

INJECTOR MOUNTING

Wall Mount

7-5/8”

7-3/8”

Drill .156 Dia. (5/32)

For Self-Tap Screw

#10 X 1” Phillips Steel

Note: For wall-mounting, drill & thread into

solid wood only.

8-3/16”

2 Places

Page 5

WARNING: Risk of electric shock.

C-1100V

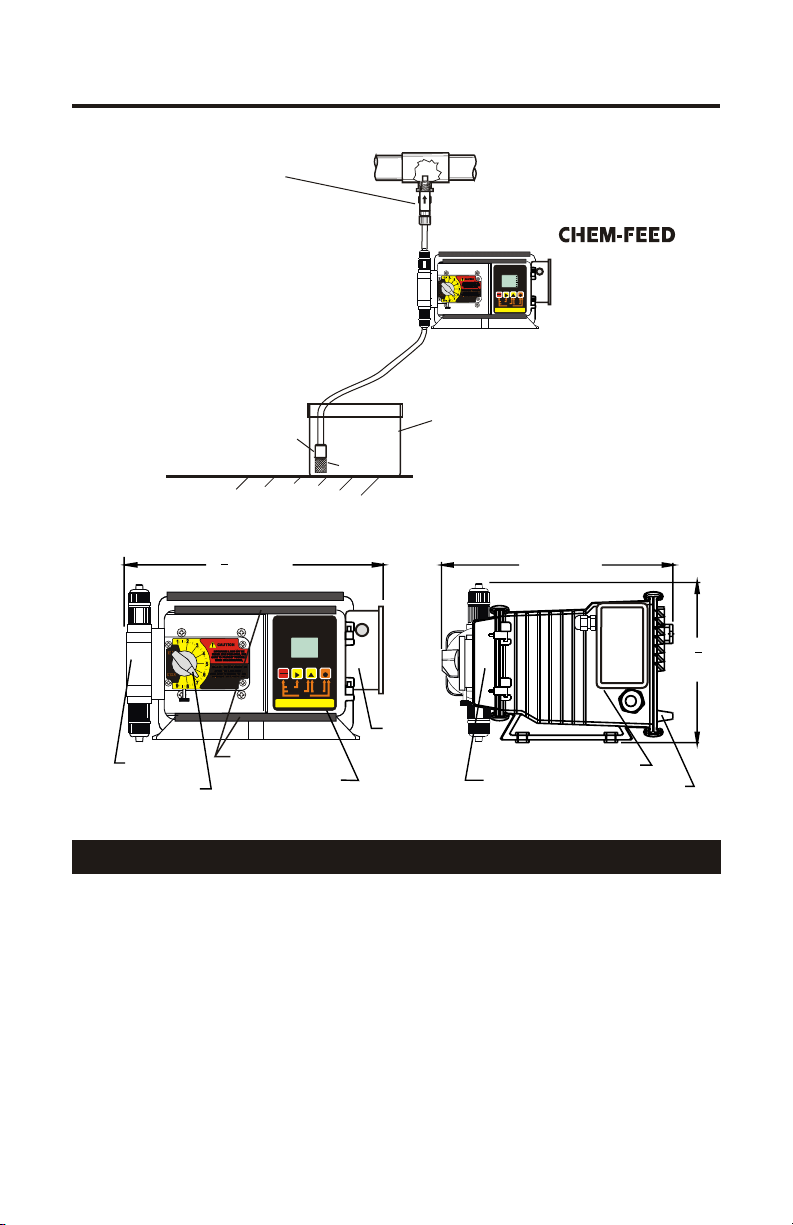

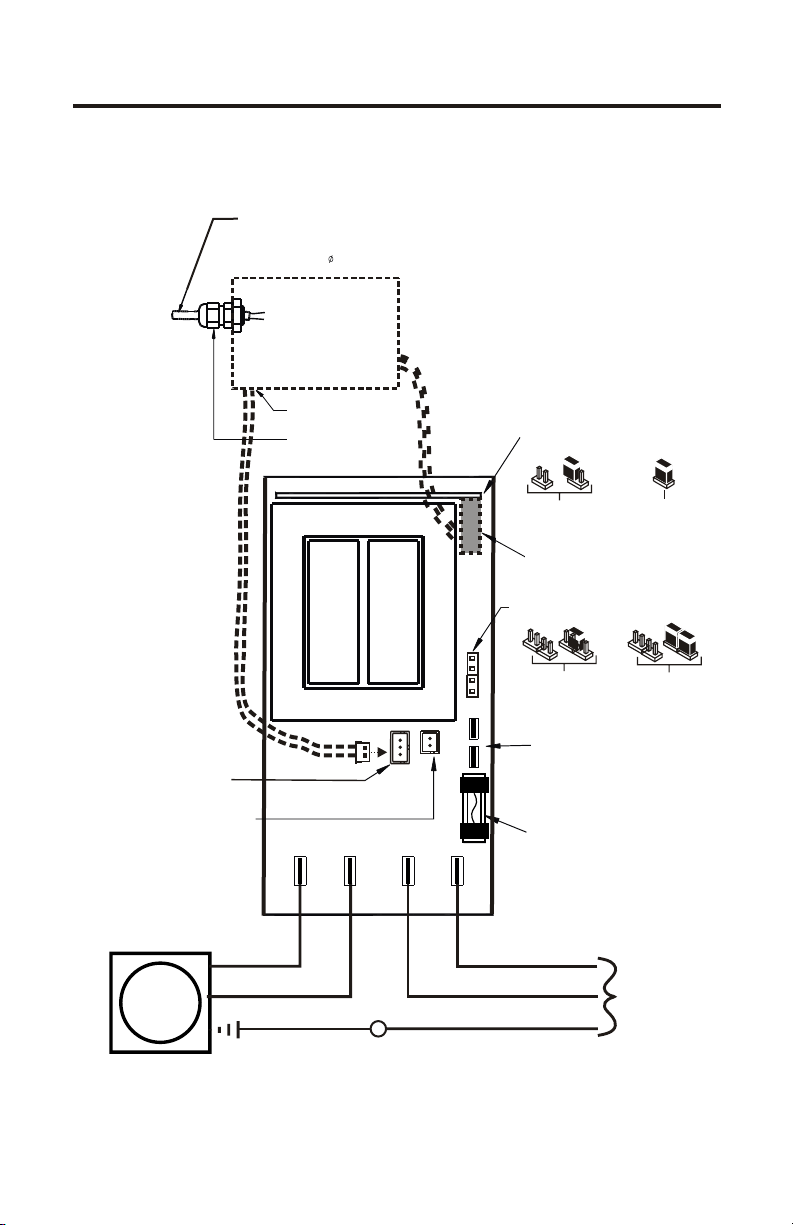

Injection / Check valve

with 1/4” and 1/2” male

pipe threads.

Mount in upward position

to prevent trapped gasses

in the injection fitting.

Pumphead

Adjustment knob

TYPICAL INSTALLATION

Ceramic Weight

1

10 IN. (267 MM)

2

Slide Clamps*

Control Panel

Discharge

Tube

Suction

Tube

Chemical

Container

Strainer

with cover

PARTS LOCATOR DRAWING

VARIABLESPEED PUMP

RUN

1

MODE

PROGRAM

VDC

mA Hz

%SPEED

STAND-BY

PRIME

1000

MINIMUM

ALARM

SERVICE

MAXIMUM

DIGIT MODE

FIELD

RUN

STANDBY

PRIME

DISPLAY

RESETSERVICE

PROGRAM

INPUTMODES

3-0-10VDC 4-PULSE(Hz)

2-4-20mA

1-MANUAL

J-Box

VARIABLESPEEDPUMP

RUN

1

MODE

PROGRAM

VDC

mA Hz

%SPEED

STAND-BY

PRIME

1000

MINIMUM

SERVICE

ALARM

MAXIMUM

DIGIT MODE

FIELD

RUN

STANDBY

PRIME

DISPLAY

RESETSERVICE

PROGRAM

INPUTMODES

3-0-10VDC 4-PULSE(Hz)

2-4-20mA

1-MANUAL

10 IN. (254 MM)

Control Cover

Page 5

®

Wall or shelf mount

away from the top of the

solution tank. Chemical

fumes can damage the

unit.

1

6

4

(159

Motor Housing

Rear Cover

IN.

MM)

5.2 Input Power Connections

WARNING: Risk of electric shock.

! Be certain to connect the pump to the proper supply voltage. Using the

incorrect voltage will damage the pump and may result in injury. The

voltage requirement is printed on the pump serial label.

! Removable resistors on the circuit board are factory preset for the correct

voltage. See page 7 Circuit Board Connections diagram for details.

! The pump is supplied with a ground wire conductor and a grounding type

attachment plug (power cord). To reduce the risk of electric shock, be

certain that the power cord is connected only to a properly grounded,

grounding type receptacle.

Note: When in doubt regarding your electrical installation, contact a

licensed electrician.

Page 6

Page 6

C-1100V

5.3 External Input Signal Connections

The C-1100V will accept any one of three different types of external input

signals; 4-20 mA , 0-10 VDC, or frequency. The 4-20mA and 0-10 VDC

loops must be powered. Two types of frequency inputs, AC sine waves

(magnetic coils type outputs) and Digital Square waves (Hall Effect signals,

contact closures), are acceptable. A jumper plug located on the circuit board

is factory pre-set for AC sine wave signals, the jumper must be repositioned when digital square wave signals are being used. See page 7,

“Hz input jumper settings”

All wiring connections are to be made inside of the junction box located on

the side of the C-1100V. A liquid-tite connector is supplied and should be

used for the external signal cable. The signal input wires are color coded to

the type of signal being used.

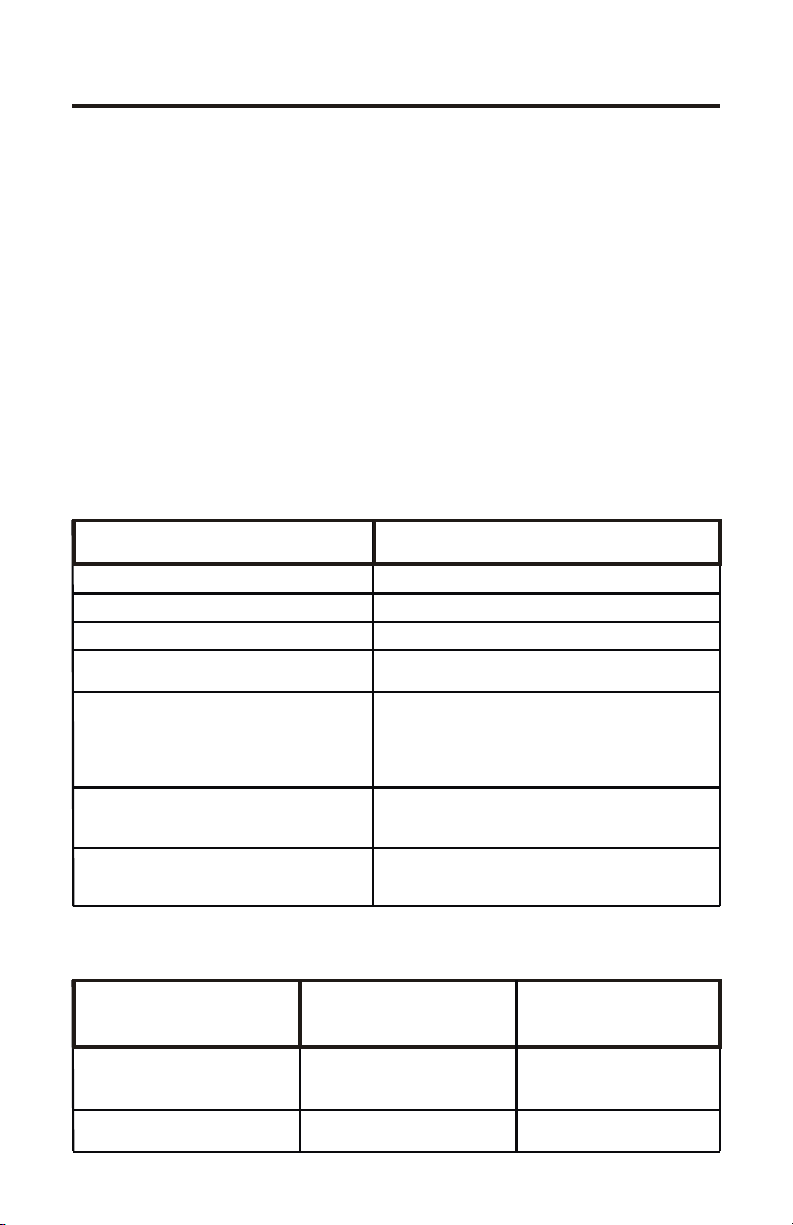

SIGNAL INPUT/OUTPUT WIRE COLOR CODES

INPUT TYPE

4-20 mA

0-10 VDC

AC sine wave, TTL, CMOS

CONTACT (10v @ 2 mA max)

HALL EFFECT, NPN

ALARM RELAY

connect 2-conductor plug to either

normally open (NO) (factory default)

or normally closed (NC) side of receptacle.

1 AMP MAX @ 125VAC (24VDC)

FLOW VERIFICATION SENSOR

MOTOR ON SIGNAL

5-20V DC open collector output

closed while motor is energized

ORANGE (+) (non-powered) & BLACK (-)

WIRE COLOR CODE

BLUE (+) (non-powered) & BLACK (-)

WHITE (+) & BLACK (-)

RED (+) & WHITE (-)

PURPLE & PURPLE

RED/WHITE (+ 20VDC)

BLACK (-)

YELLOW (signal)

BROWN (+) & BLACK (-)

PADDLEWHEEL SENSOR SIGNAL INPUT WIRING

BLUE-WHITE

PADDLEWHEEL

SENSOR TYPE

MODEL FH

HALL EFFECT SENSOR

MODEL FC

AC SINE WAVE SENSOR

PADDLEWHEEL SENSOR

WIRE COLOR CODE

RED (+)

BLACK (-)

BARE (signal)

RED (+)

BLACK (-)

PUMP INPUT

WIRE COLOR CODE

RED (+ 20VDC)

BLACK (-)

WHITE (signal)

WHITE (+)

BLACK (-)

Page 7

C-1100V

CIRCUIT BOARD CONNECTIONS

EXTERNAL INPUT CABLE

ACCEPTABLE CABLE JACKET RANGE:

YELLOW (verification sensor input)

BROWN (motor-on contact output)

PURPLE X2 (alarm relay contacts)

.118 - .255 INCH

.( 3,0 - 6,5 MM)

RED (+20VDC)

BLACK (Ground)

BLUE (4-20 mA input)

ORANGE (0-10 VDC input)

WHITE (frequency input)

Page 7

ALARM OUTPUT

(CONTACT CLOSURE)

normally open (NO)

(factory default)

TUBE FAILURE SENSOR

PROBE INPUT

2 Grey wires pump head sensors.

RED (+)

DC

MOTOR

BLACK (-)

Ground (green)

JUNCTION BOX

LIQUID-TIGHT

CONNECTOR

MOTOR

MOTOR

BLACK (-)

RED (+)

AC LINE

NEUTRAL

202

C

N

ON

PR BEO

1AMP

250VAC

AC LINE

HOT

Earth Ground (green)

Hz INPUT JUMPER SETTINGS

Located under connector

AC sine waves

Jumper Not Installed

(open - factory default)

INPUT SIGNAL CONNECTOR

Digital square waves

Jumper Installed

7 wire bundle

AC LINE VOLTAGE SETTINGS

0

1

1

0

230 VAC

1

1

One Jumper Installed

on center position

(ends open)

TS

THERMAL SWITCH

.187 push tab connectors

PROTECTOR FUSE

1 Amp, 250 Volt AC

(Littlefuse #239001

or Equivalent)

2 conductors

Two Jumpers Installed

Hot

Common

Input

Power

115 VAC

on end positions

(no open pins)

AC

Page 8

Page 8

CAUTION: Proper eye and skin protection must be

worn when installing and servicing the pump.

C-1100V

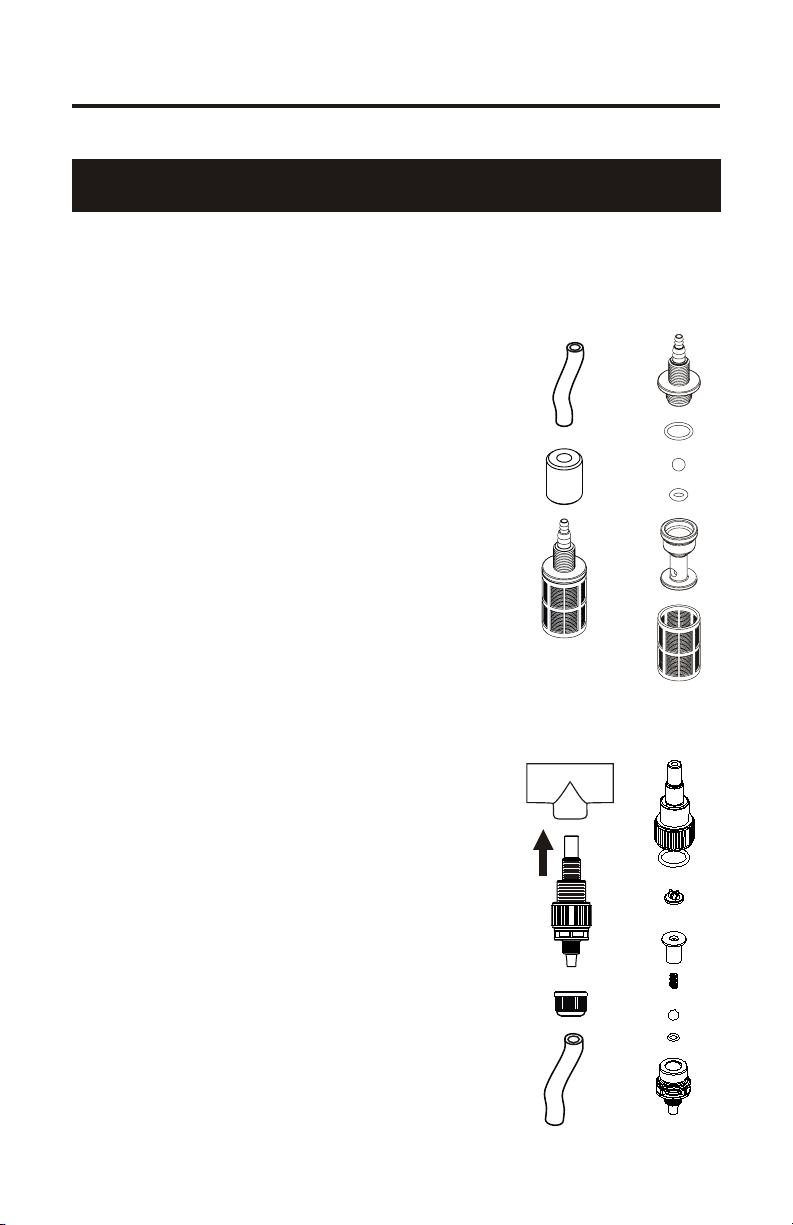

5.4 How To Install the Tubing and Fittings

CAUTION: Proper eye and skin protection must be

worn when installing and servicing the pump.

! Inlet Tubing - Locate the inlet fitting of the pump head. Remove the tube

nut. Push the clear suction tubing through the tube nut and onto the fitting

barb. Hand tighten the tube nut to secure the tubing.

! Footvalve/Strainer - Trim the inlet end

of the suction tubing so that the strainer

will rest approximately two inches from

the bottom of the solution tank. This will

prevent sediment from clogging the

strainer. Slip the ceramic weight over

the end of the suction tube. Press the

strainer’s barbed fitting into the end of

the tube. Secure the ceramic weight to

the strainer. Drop the strainer into the

solution tank.

! Outlet Tubing - Locate the outlet

fitting of the pump head. Remove the

tube nut. Push the opaque discharge

tubing through the tube nut and onto the

compression barb of the fitting. Hand

tighten the tube nut to secure the tubing.

Keep outlet tube as short as possible.

! Injection/Check Valve Fitting

Installation - The Injection/Check valve

fitting is designed to install directly into

either 1/4” or 1/2” female pipe threads.

This fitting will require periodic

cleaning, especially when injecting

fluids that calcify such as sodium

hypochlorite. See section 7.0.

Install the Injection/Check valve directly

into the piping system. To prevent

trapped gasses, install the fitting in an

upward direction. Use Teflon thread

sealing tape on the pipe threads.

Push the opaque outlet (discharge)

tubing through the tube nut and onto the

compression barb of the Injection/Check

valve fitting. Hand tighten the tube nut

to secure the tubing.

FOOTVALVE/STRAINER

Suction Tubing

Ceramic

Wei ght

FootValve

Strainer

Assembly

INJECTION/CHECK VALVE

Pipe tee

Install

upward

Injection

Check valve

Tube retaining

nut

Discharge

Tubing

Page 9

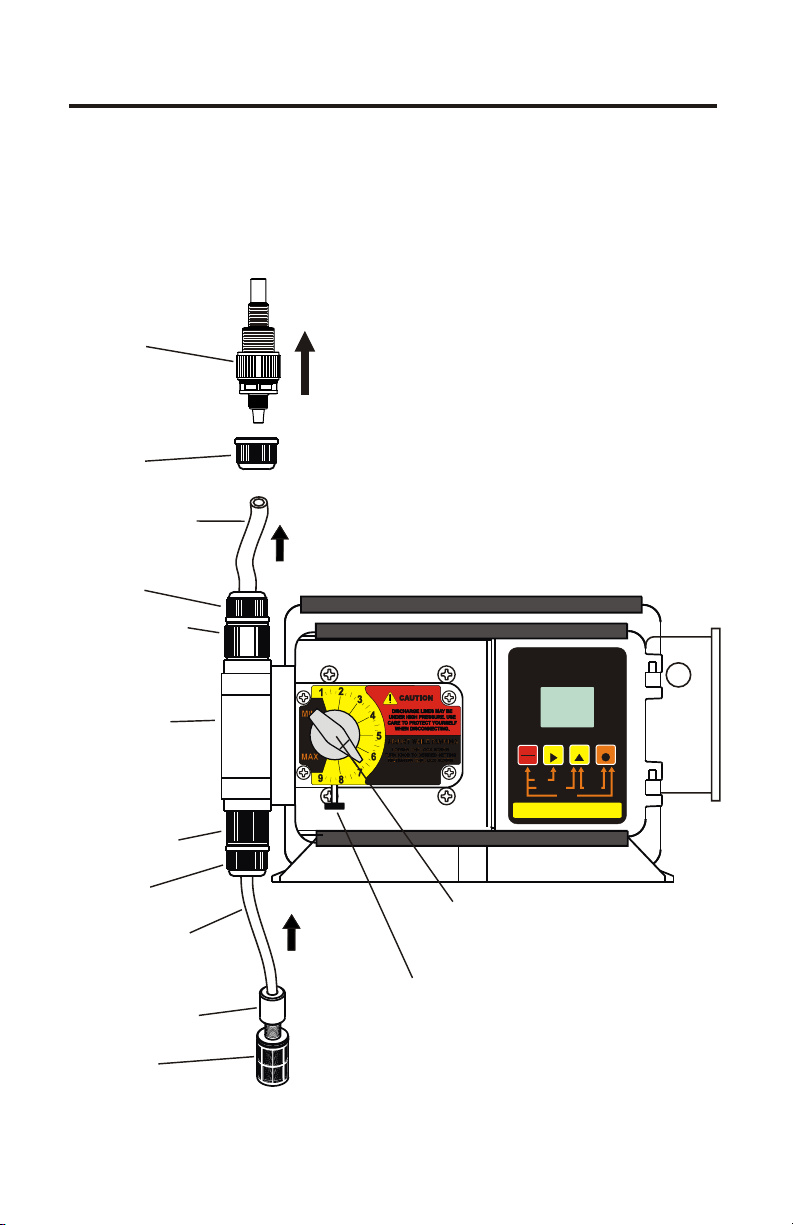

C-1100V

Page 9

Injection

Check valve

Tube Nut

Discharge Tube

(Rigid P.E.)

Tube Nut

Outlet Adapter

Pump Head

Inlet Adapter

Tube Nut

Suction Tubing

(clear PVC)

Install

upward

Manual

Stroke length

Adjustment knob

Lock Screw

VARIABLE SPEED PUMP

MODE

mA Hz

% SPEED

1000

ALARM

FIELD

RUN

STANDBY

PRIME

RESETSERVICE

PROGRAM

INPUTMODES

2-4-20mA

1-MANUAL

RUN

1

PROGRAM

VDC

STAND-BY

PRIME

MINIMUM

SERVICE

MAXIMUM

DIGIT MODE

DISPLAY

3-0-10VDC 4-PULSE(Hz)

Ceramic Weight

Footvalve

Page 10

Page 10

C-1100V

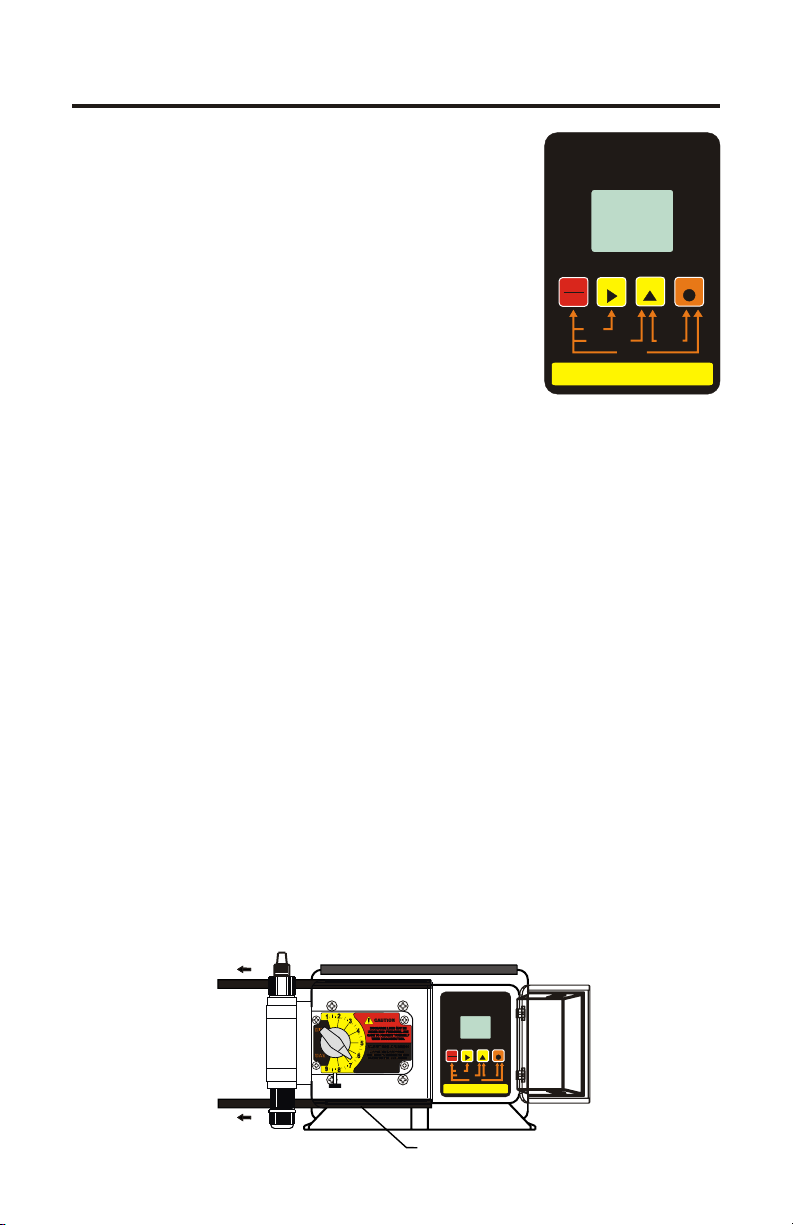

6.0 How To Operate The C-1100V

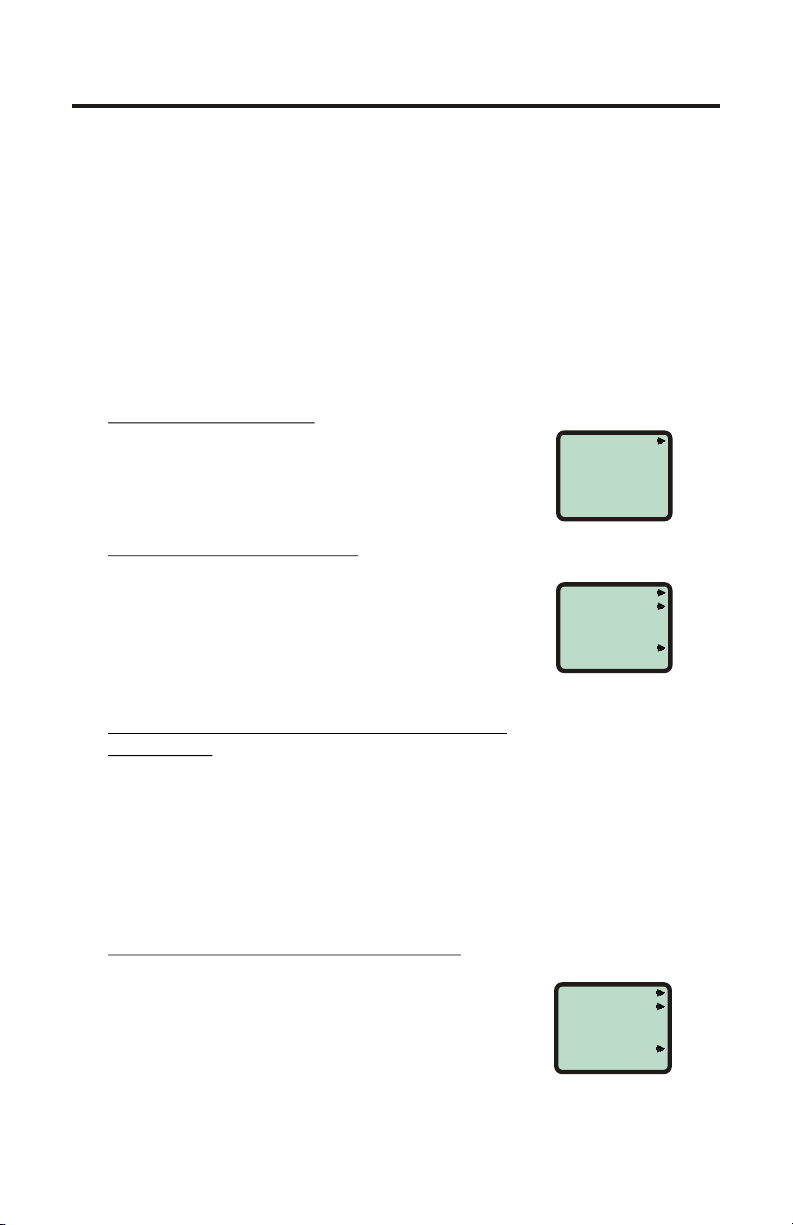

6.1 Description of Pump Output

Adjustment Controls

panel door by sliding the upper and lower slide

clamps to the left.

!

RUN/STANDBY Button -

4

Press to start and stop the pump. The ARROW

next to the word RUN will light when in the run

mode. The ARROW next to the word STAND-BY

will blink when in the stand-by mode.

4

Press to clear ALARM.

4

When pressed with the FIELD Button, initiates a 99 second prime cycle

which temporarily overrides the mode setting and runs the pump motor at

100% speed. The ARROW next to the word PRIME will blink.

4

When pressed with the DIGIT button, resets the 500 hour service warning

timer to zero.

4

When pressed with the MODE button, initiates the programming mode.

The ARROW next to the word PROGRAM will blink.

!

FIELD Button -

4

In the programming mode, selects the digit to be changed.

4

When pressed with the DIGIT button, initiates the Flow Verification

Sensor feature and allows programming the alarm delay from 1-256

seconds.

!

DIGIT Button -

4

In the programming mode, increases the selected digit.

4

When pressed with the MODE Button, toggles the display from % motor

speed to input signal value.

!

MODE Button -

4

Used to select one of four operating modes.

Mode 1 - Manual Adjustment (external input disabled)

Mode 2 - 4-20mA input

Mode 3 - 0-10VDC input

Mode 4 - Frequency (Hz) input

- Open the control

VARIABLE SPEED PUMP

% SPEED

RUN

STANDBY

PRIME

RESET SERVICE

2 - 4-20mA

1-MANUAL

MODE

VDC

mA Hz

1000

ALARM

SERVICE

DIGIT MODE

FIELD

PROGRAM

INPUT MODES

3 - 0-10VDC 4- PULSE (Hz)

RUN

1

PROGRAM

STAND-BY

PRIME

MINIMUM

MAXIMUM

DISPLAY

VARIABLESPEED PUMP

1

MODE

VDC

mA Hz

%SPEED

1000

ALARM

SERVICE

DIGIT MODE

FIELD

RUN

STANDBY

PRIME

DISPLAY

RESETSERVICE

PROGRAM

INPUTMODES

3-0-10VDC 4-PULSE (Hz)

2-4-20mA

1-MANUAL

SLIDE CLAMP

RUN

PROGRAM

STAND-BY

PRIME

MINIMUM

MAXIMUM

Page 11

C-1100V

Page 11

6.2 How to adjust the output- manual stroke adjustment The

Pump flow rate can be adjusted within a range of 5% -100% of maximum

output (20:1 turndown ration) by means of a mechanical, cam type

mechanism. The mechanism adjusts the pump’s stroke length to an infinite

number of settings within the flow range.

ø Note: The pump’s output will reduce due to increased system pressure,

increased suction lift, and increased fluid viscosity. The pump must be oversized to allow for these factors. Sizing the pump to allow adjustment within

the midrange is preferred to maintain accuracy. Consult the factory for

individual pump model output curve data.

To adjust the pump’s output:

1. With the pump running, loosen the lock screw.

2. Turn the adjustment knob to the desired setting.

3. Re-tighten the lock screw.

6.3 OPERATING MODE 1 - Output adjusted

manually -

In this mode, the pump’s motor speed is adjusted

manually using the front panel touch pad. The motor

speed can be adjusted from 0-100%. To adjust the

speed:

4

Set the pump for mode 1. Press the MODE button

until MODE 1 is shown on the LCD display. The

%SPEED icon will light. The large 3-DIGIT LCD

will indicate the currently programmed percentage of

speed.

4

Enter the programming mode. At the same time,

press the RUN/STANDBY button and the MODE

button. A blinking ARROW will point to the word

PROGRAM indicating the program mode has been

activated.

4

Press the FIELD button to select the digit to program.

The digit will blink when selected.

4

Press the DIGIT button to change the selected digit.

4

Repeat until all digits are programmed.

4

To exit the programming mode, press the

RUN/STANDBY button and the MODE button at the

same time. The arrow next to the word PROGRAM will

disappear.

[

NOTE: If while in the program mode no buttons are

pressed within 20 seconds, the circuitry will automatically return to the run mode, without saving changes.

RUN MODE 1

1

MODE

% SPEED

100

PROGRAM MODE 1

constant speed % setting

1

MODE

% SPEED

000

RUN

PROGRAM

STAND-BY

PRIME

MINIMUM

MAXIMUM

RUN

PROGRAM

STAND-BY

PRIME

MINIMUM

MAXIMUM

Page 12

Page 12

6.4

OPERATING MODE 2 - Output adjusted

by 4-20 mA input signal

-

In this mode, the pump’s motor speed is adjusted

automatically based on the value of the 4-20 mA input

signal. Any motor speed can be assigned to either the

minimum or maximum milliamp input values.

However, the programmed minimum mA value

must be less than the programmed maximum mA

value. The ALARM and SERVICE icons will blink

if the programming is in error. To assign the minimum

and maximum motor speed and the minimum and

maximum mA input signal values:

4

Set the pump for mode 2. Press the MODE button

until MODE 2 is shown on the LCD display. The

%SPEED or mA icon will light depending on the

current display setting. The large 3-DIGIT LCD will

indicate the current motor speed or the current mA

input value.

4

Enter the programming mode. At the same time,

press the RUN/STANDBY and MODE buttons. A

blinking ARROW will point to the word PROGRAM

indicating the program mode is activated. A blinking

ARROW will point to the word MINIMUM indicating

the minimum value is ready to be programmed. The %

SPEED icon will blink indicating the percentage of

speed is ready to be programmed.

4

Enter the motor speed at the minimum mA input

signal value. Press the FIELD button to select the

digit to program. The digit will blink when selected.

4

Press the DIGIT button to change the selected digit.

4

Repeat until all digits are programmed.

4

Press the mode button. The % SPEED icon will stop

blinking and the mA icon will blink indicating the

minimum mA value is ready to be programmed. The

currently programmed minimum value is shown on

the 3-DIGIT LCD.

4

Enter the minimum mA input signal value. Note: this

value must be less than the maximum mA input signal

value. Press the FIELD button to select the digit to

program. The digit will blink when selected.

4

Press the DIGIT button to change the selected digit.

4

Repeat until all digits are programmed.

4

Press the mode button. The Ma icon will stop blinking

and the % SPEED icon will blink. The ARROW next

to the word MAXIMUM will blink indicating the

C-1100V

RUN MODE 2

RUN

2

MODE

mA

04.0

PROGRAM MODE 2

% speed at the minimum input

MODE

% SPEED

000

PROGRAM MODE 2

minimum input value

MODE

mA

04.0

PROGRAM

STAND-BY

PRIME

MINIMUM

MAXIMUM

RUN

2

PROGRAM

STAND-BY

PRIME

MINIMUM

MAXIMUM

RUN

2

PROGRAM

STAND-BY

PRIME

MINIMUM

MAXIMUM

Page 13

C-1100V

4

maximum value is ready to be programmed. The

currently programmed maximum motor speed value is

shown on the 3-DIGIT LCD.

4

Enter the motor speed at the maximum mA input

signal value. Press the FIELD button to select the

digit to program. The digit will blink when selected.

4

Press the DIGIT button to change the selected digit.

4

Repeat until all digits are programmed.

4

Press the mode button. The % SPEED icon will stop

blinking and the mA icon will blink indicating the

maximum mA value is ready to be programmed. The

currently programmed maximum value is shown on

the 3-DIGIT LCD.

4

Enter the maximum mA input signal value. Note: this

value must be greater than the minimum mA input

signal value. Press the FIELD button to select the digit

to program. The digit will blink when selected..

4

Press the DIGIT button to change the selected digit.

4

Repeat until all digits are programmed.

4

Press the mode button. Programming is complete.

4

To exit the programming mode, press the

RUN/STANDBY button and the MODE button at the

same time. The PROGRAM arrow will disappear.

Page 13

PROGRAM MODE 2

% speed at the maximum input

RUN

2

MODE

%SPEED

100

PROGRAM MODE 2

maximum input value

MODE

mA

20.0

PROGRAM

STAND-BY

PRIME

MINIMUM

MAXIMUM

RUN

2

PROGRAM

STAND-BY

PRIME

MINIMUM

MAXIMUM

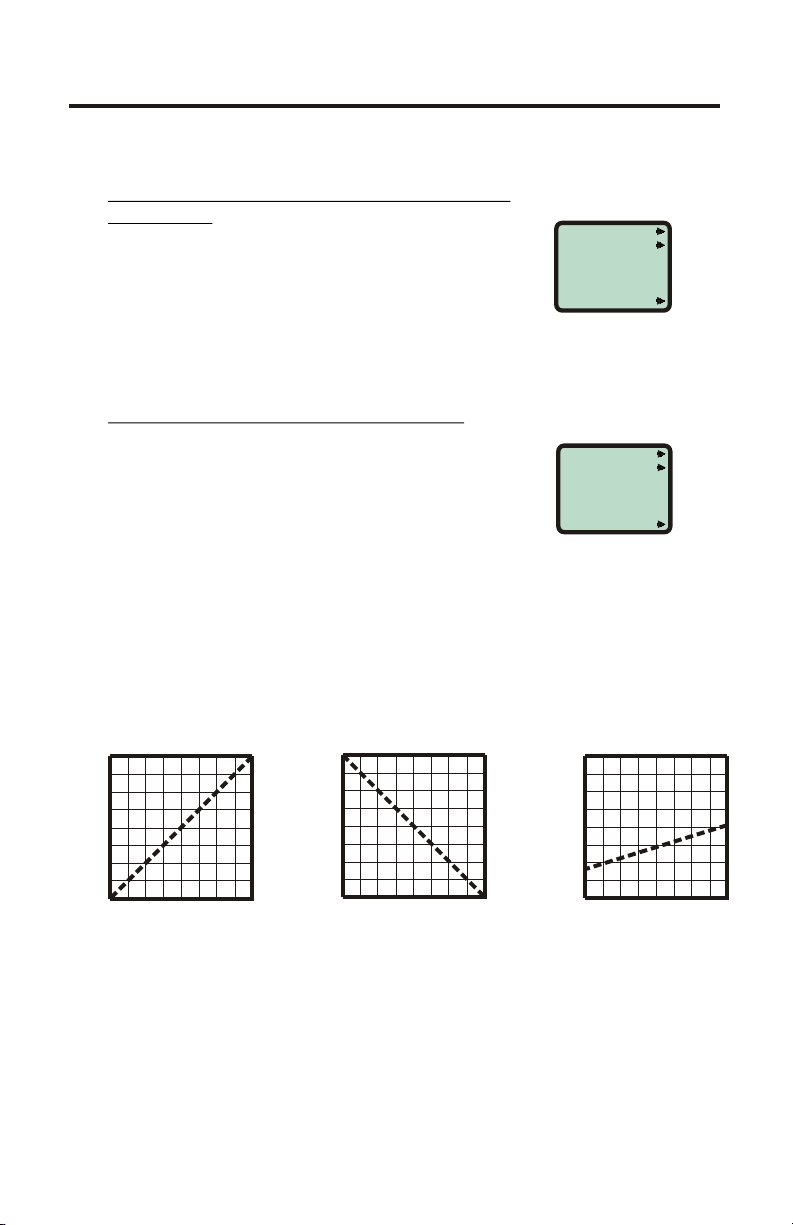

Example 1

4 mA = 0% OUTPUT

20 mA = 100% OUTPUT

100

75

50

25

Pump Motor Speed (%)

0

6

8

4

10

Milliamp input (mA)

MODE 2 PROGRAMMING EXAMPLES

Example 2

4 mA = 100% OUTPUT

20 mA = 0% OUTPUT

100

75

50

25

Pump Motor Speed (%)

0

6

8

16

20

18

14

12

4

Milliamp input (mA)

16

20

18

14

12

10

Example 4

4 mA = 20% OUTPUT

20 mA = 50% OUTPUT

100

75

50

25

Pump Motor Speed (%)

0

6

8

4

10

Milliamp input (mA)

16

20

18

14

12

Page 14

Page 14

6.5

OPERATING MODE 3 - Output adjusted

by 0-10VDC input signal

-

In this mode, the pump’s motor speed is adjusted

automatically based on the value of the 0-10VDC

input signal. Any motor speed can be assigned to

either the minimum or maximum DC input signal

values. However, the programmed minimum VDC

value must be less than the programmed maximum

VDC value. The ALARM and SERVICE icons will

blink if the programming is in error. To assign the

minimum and maximum motor speed and the

minimum and maximum VDC input signal values:

4

Set the pump for mode 3. Press the MODE button

until MODE 3 is shown on the LCD display. The %

SPEED or VDC icon will light depending on the

current display setting. The large 3-DIGIT LCD will

indicate the current motor speed or the VDC input

value.

4

Enter the programming mode. At the same time,

press the RUN/STANDBY and MODE buttons. A

blinking ARROW will point to the word PROGRAM

indicating the program mode is activated. A blinking

ARROW will point to the word MINIMUM indicating

the minimum value is ready to be programmed. The %

SPEED icon will blink indicating the percentage of

speed is ready to be programmed.

4

Enter the motor speed at the minimum VDC input

signal value. Press the FIELD button to select the

digit to program. The digit will blink when selected.

4

Press the DIGIT button to change the selected digit.

4

Repeat until all digits are programmed.

4

Press the mode button. The % SPEED icon will stop

blinking and the VDC icon will blink indicating the

minimum VDC value is ready to be programmed. The

currently programmed minimum value is shown on

the 3-DIGIT LCD.

4

Enter the minimum VDC input signal value. Note:

this value must be less than the maximum VDC input

signal value. Press the FIELD button to select the digit

to program. The digit will blink when selected.

4

Press the DIGIT button to change the selected digit.

4

Repeat until all digits are programmed.

4

Press the mode button. The VDC icon will stop

blinking and the % SPEED icon will blink. The

ARROW next to the word MAXIMUM will blink

C-1100V

RUN MODE 3

RUN

3

MODE

00.0

PROGRAM MODE 3

% speed at the minimum input

MODE

% SPEED

000

PROGRAM MODE 3

minimum input value

MODE

00.0

VDC

VDC

PROGRAM

STAND-BY

PRIME

MINIMUM

MAXIMUM

RUN

3

PROGRAM

STAND-BY

PRIME

MINIMUM

MAXIMUM

RUN

3

PROGRAM

STAND-BY

PRIME

MINIMUM

MAXIMUM

Page 15

C-1100V

indicating the maximum value is ready to be programmed. The currently programmed maximum

motor speed value is shown on the 3-DIGIT LCD.

4

Enter the motor speed at the maximum VDC input

signal value. Press the FIELD button to select the

digit to program. The digit will blink when selected.

4

Press the DIGIT button to change the selected digit.

4

Repeat until all digits are programmed.

4

Press the mode button. The % SPEED icon will stop

blinking and the VDC icon will blink indicating the

maximum VDC value is ready to be programmed. The

currently programmed maximum value is shown on

the 3-DIGIT LCD.

4

Enter the maximum VDC input signal value. Note:

this value must be greater than the minimum VDC

input signal value. Press the FIELD button to select

the digit to program. The digit will blink when

selected.

4

Press the DIGIT button to change the selected digit.

4

Repeat until all digits are programmed.

4

Press the mode button. Programming is complete.

4

To exit the programming mode, press the

RUN/STANDBY button and the MODE button at the

same time. The PROGRAM arrow will disappear.

Page 15

PROGRAM MODE 3

% speed at the maximum input

RUN

3

MODE

% SPEED

100

PROGRAM MODE 3

maximum input value

MODE

10.0

VDC

PROGRAM

STAND-BY

PRIME

MINIMUM

MAXIMUM

RUN

3

PROGRAM

STAND-BY

PRIME

MINIMUM

MAXIMUM

Page 16

Page 16

6.6

OPERATING MODE 4 - Output adjusted

by frequency (Hz) input signal

-

In this mode, the pump’s motor speed is adjusted

automatically based on the frequency (Hz) of the input

signal. Any motor speed can be assigned to either the

minimum or maximum Hz input signals. However,

the programmed minimum Hz value must be less

than the programmed maximum Hz value. The

ALARM and SERVICE icons will blink if the

programming is in error. To assign the minimum and

maximum motor speed and the minimum and

maximum Hz input signal values:

4

Set the pump for mode 4. Press the MODE button

until MODE 4 is shown on the LCD display. The %

SPEED or Hz icon will light depending on the current

display setting. The large 3-DIGIT LCD will indicate

the current motor speed or the Hz input value.

4

Enter the programming mode. At the same time,

press the RUN/STANDBY and MODE buttons. A

blinking ARROW will point to the word PROGRAM

indicating the program mode is activated. A blinking

ARROW will point to the word MINIMUM indicating

the minimum value is ready to be programmed. The %

SPEED icon will blink indicating the percentage of

speed is ready to be programmed.

4

Enter the motor speed at the minimum Hz input

signal value. Press the FIELD button to select the

digit to program. The digit will blink when selected.

4

Press the DIGIT button to change the selected digit.

4

Repeat until all digits are programmed.

4

Press the mode button. The % SPEED icon will stop

blinking and the Hz icon will blink indicating the

minimum Hz value is ready to be programmed. The

currently programmed minimum value is shown on

the 3-DIGIT LCD.

4

Enter the minimum Hz input signal value (to the

nearest 10 Hz). Note: this value must be less than the

maximum Hz input signal value. Press the FIELD

button to select the digit to program. The digit will

blink when selected.

4

Press the DIGIT button to change the selected digit.

4

Repeat until all digits are programmed.

4

Press the mode button. The Hz icon will stop blinking

and the % SPEED icon will blink. The ARROW next

to the word MAXIMUM will blink indicating the

C-1100V

RUN MODE 4

RUN

4

MODE

000

PROGRAM MODE 4

% speed at the minimum input

MODE

% SPEED

000

PROGRAM MODE 4

minimum input value

MODE

000

PROGRAM

Hz

STAND-BY

PRIME

MINIMUM

MAXIMUM

RUN

4

PROGRAM

STAND-BY

PRIME

MINIMUM

MAXIMUM

RUN

4

PROGRAM

Hz

STAND-BY

PRIME

MINIMUM

MAXIMUM

Page 17

C-1100V

maximum value is ready to be programmed. The

Currently programmed maximum motor speed value is

shown on the 3-DIGIT LCD.

4

Enter the motor speed at the maximum VDC input

signal value. Press the FIELD button to select the

digit to program. The digit will blink when selected.

4

Press the DIGIT button to change the selected digit.

4

Repeat until all digits are programmed.

4

Press the mode button. The % SPEED icon will stop

blinking and the Hz icon will blink indicating the

maximum Hz value is ready to be programmed. The

currently programmed maximum value is shown on

the 3-DIGIT LCD.

4

Enter the maximum Hz input signal value (to the

nearest 10 Hz). Note: this value must be greater than

the minimum Hz input signal value. Press the FIELD

button to select the digit to program. The digit will

blink when selected.

4

Press the DIGIT button to change the selected digit.

4

Repeat until all digits are programmed.

4

Press the mode button. Programming is complete.

4

To exit the programming mode, press the

RUN/STANDBY button and the MODE button at the

same time. The PROGRAM arrow will disappear.

Page 17

PROGRAM MODE 4

% speed at the maximum input

RUN

4

MODE

%SPEED

82.5

PROGRAM MODE 4

minimum input value

MODE

620

PROGRAM

STAND-BY

PRIME

MINIMUM

MAXIMUM

RUN

4

PROGRAM

Hz

STAND-BY

PRIME

MINIMUM

MAXIMUM

MODE 4 PROGRAMMING EXAMPLES

Example 1

0Hz=0%OUTPUT

1000 Hz = 100% OUTPUT

100

75

50

25

Pump Motor Speed (%)

0

0

600

200

400

Frequency input (Hz)

800

1000

Example 2

0 Hz = 100% OUTPUT

1000 Hz = 0% OUTPUT

100

75

50

25

Pump Motor Speed (%)

0

200

0

400

Frequency input (Hz)

600

800

1000

Example 3

0 Hz = 10% OUTPUT

270 Hz = 75% OUTPUT

100

75

50

25

Pump Motor Speed (%)

0

200

0

400

Frequency input (Hz)

600

800

1000

Page 18

Page 18

C-1100V

6.7 Measuring the Pump’s Output - Volumetric Test.

This volumetric test will take into account individual installation factors

such as line pressure, fluid viscosity, suction lift, etc. This test is the most

accurate for measuring the injector’s output in an individual installation.

1. Be sure the Injection Fitting and Footvalve/Strainer is clean and working

properly.

2. Fill a large graduated cylinder with the solution to be injected.

3. With the pump installed under normal operating conditions, place the

suction tubing with the Footvalve/Strainer installed in the graduated

cylinder.

4. Run the pump until all air is removed from the suction line and the solution

enters the discharge tubing. If the pump does not easily prime, remove the

discharge tubing from injection fitting until the pump primes. Re-connect

the discharge tubing to the injection fitting.

5. Remove the suction tubing from the graduated cylinder and refill the

graduated cylinder if necessary. Note the amount of solution in the graduated cylinder.

6. Place suction tubing with the Footvalve/Strainer installed back into the

graduated cylinder.

7. Run the injector for a measured amount of time. A longer testing time will

produce more accurate results.

8. Remove the suction tubing from the graduated cylinder. Measure the

amount of chemical injected.

6.8 FVS - Flow Verification System The C-

1100V is equipped with a Flow Verification System which is designed to

stop the pump and provide a contact closure output in the event the sensor

does not detect chemical during pump operation. This could indicate a

clogged injection fitting, empty chemical solution tank, loose tubing

connection, etc.

To allow the pump to clear any gasses that may have accumulated during

stopper operation (such as with chlorine), an alarm delay time value from 1256 seconds must be programmed (An alarm delay value of 000 seconds

disables the FVS system). The pump will stop, and the alarm mode

activated, if no pulses are received by the pump and the alarm delay time

period has ended. Press the STAND-BY button twice to clear the alarm and

restart the pump. The Flow Verification Sensor is sold as an optional

accessory.

- (sensor sold separately)

Page 19

OPERATING

FLOW RANGE

(ml/min)

C-1100V

Page 19

Confirm the FVS flow range - The Flow

Verification Sensor (FVS) will only function

within its operating range. Sensor model FV100-6V has an operating range of 30-300

ml/min (1-10 oz/min). If the pump’s output is

less than 30 ml/min (0.5 ml/sec), the sensor

will not detect chemical and a signal will not

be sent to the pump.

SENSOR

MODEL

NUMBER

FV-100-6V

FV-200-6V

FV-300-6V

FV-400-6V

FV-500-6V

FV-600-6V

OPERATING

FLOW RANGE

(ml/min)

30-300

100-1000

200-2000

300-3000

500-5000

700-7000

Install the FVS Flow Sensor - The Flow Verification Sensor (FVS) should

be installed on the outlet (discharge) side of the pump head valve. The

sensor includes a PVC tubing insert, located inside the sensor’s female

thread connection, that is designed to seal the sensor onto the pump head

inlet adapter. Thread the sensor onto the pump head until the tubing insert is

snug against the pump head inlet fitting - do not over-tighten.

Connect the red/white, black, and white wires from the sensor to the red,

black, and yellow wires located in the pump’s junction box. See page 7.

FVS Sensor

Insert Tubing Seal

Outlet Adapter

VARIABLESPEED PUMP

RUN

1

MODE

PROGRAM

VDC

mA Hz

%SPEED

STAND-BY

PRIME

1000

MINIMUM

ALARM

SERVICE

MAXIMUM

DIGIT MODE

FIELD

RUN

STANDBY

PRIME

DISPLAY

RESETSERVICE

PROGRAM

INPUTMODES

3-0-10VDC 4- PULSE (Hz)

2-4-20mA

1-MANUAL

Contact Closure Alarm Output - A contact closure output (relay) is

provided with the FVS system. The relay can be configured for normally

open (factory default) or normally closed operation by properly positioning

the connector plug on the circuit board (see page 7).

Page 20

Page 20

CAUTION: Proper eye and skin protection must be

worn when installing and servicing the pump.

C-1100V

7.0 How to Maintain the Pump

CAUTION: Proper eye and skin protection must be

worn when installing and servicing the pump.

7.1 Routine Inspection and Maintenance

The pump requires very little maintenance. However, the pump and all

accessories should be checked regularly. This is especially important when

pumping chemicals. Inspect all components for signs of leaking, swelling,

cracking, discoloration or corrosion. Replace worn or damaged components

immediately.

Cracking, crazing, discoloration and the like during the first week of

operation are signs of severe chemical attack. If this occurs, immediately

remove the chemical from the pump. Determine which parts are being

attacked and replace them with parts that have been manufactured using

more suitable materials. The manufacturer does not assume responsibility

for damage to the pump that has been caused by chemical attack.

7.2 How to Clean the Pump

The pump will require occasional cleaning, especially the Injection fitting,

the Footvalve/Strainer, and the pump head valves. The frequency will

depend on the type and severity of service.

]

Inspect and replace the pumphead valves as required.

]

When changing the diaphragm, the pump head chamber and pump head

cover should be wiped free of any dirt and debris.

]

Periodically clean the injection/check valve assembly, especially when

injecting fluids that calcify such as sodium hypochlorite. These lime

deposits and other build ups can clog the fitting, increase the back pressure

and interfere with the check valve operation. See page 8.

]

Periodically clean the suction strainer. See page 8.

]

Periodically inspect the air vents located under the motor housing and in

the back on the rear housing cover. Clean if necessary.

7.3 500 Hour Service Warning Timer

The pump is equipped with a service warning timer. After approximately

500 hours of accumulated running time, the SERVICE icon will light. This is

a reminder that the pump should be inspected and maintenance performed if

necessary.

Page 21

C-1100V

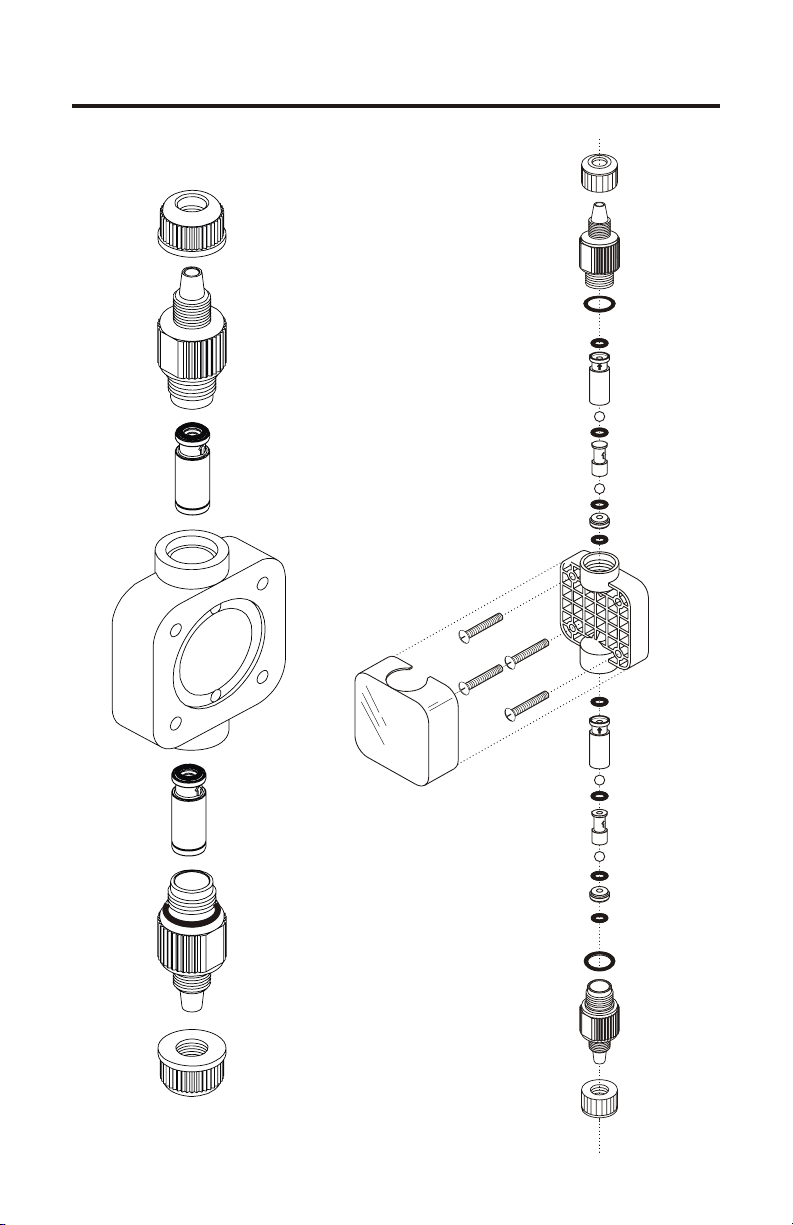

PUMP HEAD AND VALVE EXPLODED VIEW

Page 21

Page 22

Page 22 C-1100V

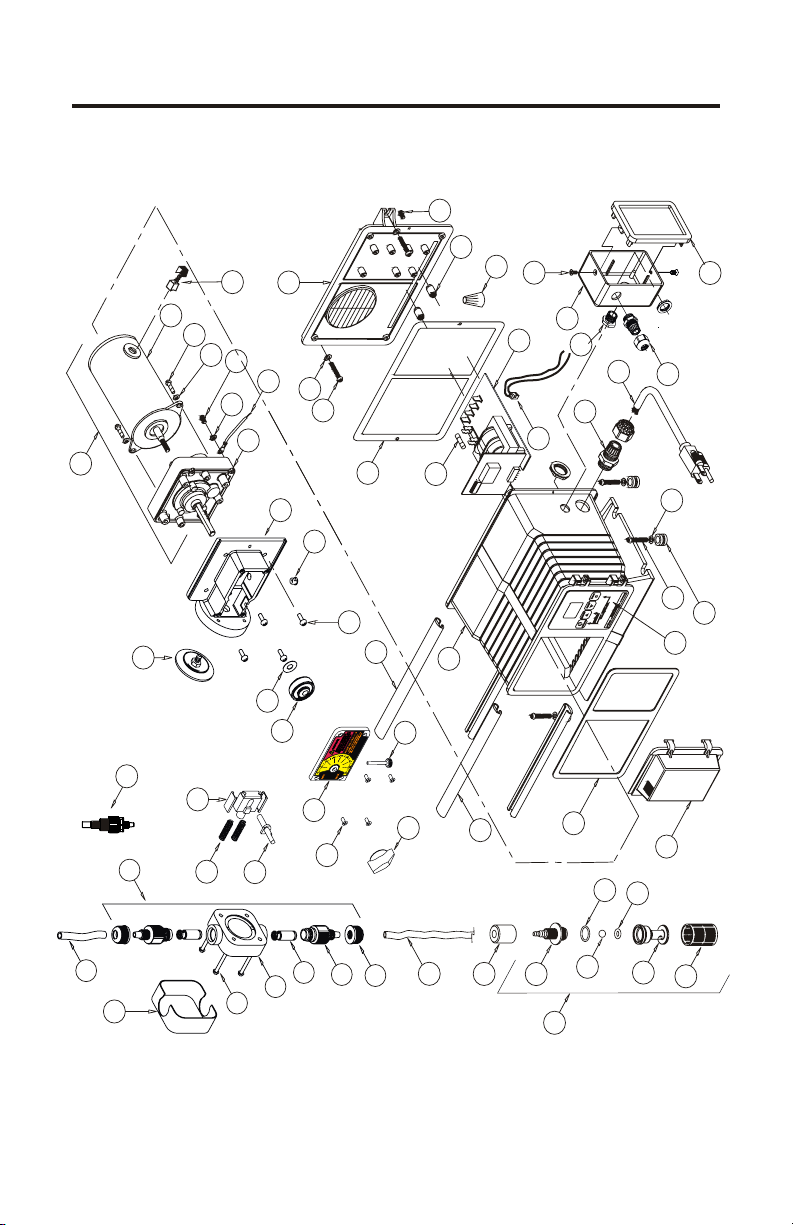

Replacement Parts Drawing

63

61

60

41

62

40

39

38

37

36

35

34

42

33

52

51

59

32

31

30

48

55

49

67

66

56

64

53

65

54

57

52

51

46

68

50

29

28

69

20

16

17

15

19

14

25

18

23

12

13

11

24

22

10

47

9

8

45

44

5

3

4

6

7

2

1

Page 23

PARTS LIST

Page 23C-1100V

Item Part No Description Qty

1 C-345S Screen, FootValve, P.P. 1

2 90002-214 Body, FootValve, PVDF 1

3 2-108A O-ring, FootValve, Aflas 1

2-108E O-ring, FootValve, E.P. 1

4 C-385C Ball, FootValve, Ceramic 1

5 90003-014 O-ring, FootValve, Viton 1

90003-015 O-ring, FootValve, E.P. 1

6 90002-215 Adapter, FootValve, PVDF 1

7 C-340E FootValve, C-340E, EP 1

C-340A FootValve, C-340V, Vit/Aflas1

8 C-346 Ceramic weight, C-346 1

9 C-334-6 Tubing Suction 3/8 x 5 FT 1

10 C-330-6 Tube Nut, .37T, P.P. 2

11 C-560-6V Adapter S/A .37T Viton 2

C-560-6E Adapter S/A .37T EP 2

C-560-6S Adapter S/A .37T Sil 2

12 K-568-4A Cartridge Valve S/A 2

13 C-535 P/Head Noir Molded, P.P. 1

14 C-504HD Screw 10-32 x 1.25 4

15 C-535FC Cover P/Head, 1

16 C-535A6-6 Kit P/Head, 37T Vit/Afl, P-P 1

C-535A6-6E Kit P/Head, 37T E.P. P-P 1

17 C-334-6-10 Tubing D/Charge, 3/8 x 10’ 1

18 C-1505N Offset Cam #1 .125” 1

R-1505N Offset Cam #2 .055” 1

C-1505N-3 Offset Cam #3 .187” 1

C-1505N-4 Offset Cam #4 .100” 1

19 C-1514N Return Spring 2

20 C-1513N Stirrup with slide bearings 1

22 C-1502 Dial Knob 1

23 90011-168 Screw #6 x .62 PH oval ‘A’ 4

24 C-1519N Thumb Screw 6-32 x 1.125 1

25 71000-363 Cover Cam S/A C-1100 1

28 C-1507A Drive Cam S/A #1 .125” 1

R-1507A Drive Cam S/A #2 .055” 1

C-1507-3A Drive Cam S/A #3 .187” 1

C-1507-4A Drive Cam S/A #4 .100” 1

29 A-031 Spacer, Rotor 1

30 C-624N Screw 10-32 x .50 PHL 4

31 90008-138 Plug .312 Hole Black 1

32 76001-183 Motor Mount, Large Dia 1

33 C-406VT-15N Diaphragm 2.0 Vit/TFE 1

C-406T-15N Diaphragm 2.0 EP/TFE 1

34 C-618N-14 Gearbox, 14 RPM 1

C-618N-30 Gearbox, 30 RPM 1

Item Part No Description Qty

C-618N-45 Gearbox, 45 RPM 1

C-618N-60 Gearbox, 60 RPM 1

C-618N-125 Gearbox, 125 RPM 1

C-618N-250 Gearbox, 250 RPM 1

35 90011-078 Washer, Ground, #8 Star 1

36 90010-222 Lead Wire, ground, Green 1

37 90011-024 Screw 8-32 x .25 SL ST 1

38 90011-074 Washer, #8 split-lock 2

39 90011-023 Screw, motor, 8-32 x .50 2

40 90010-244 Motor, 24V DC 1

41 C-1814N-4 Brush kit, (2 pc.) 24V DC 1

42 70002-255 G/motor, 14 Rpm, 24VDC 1

70002-256 G/motor, 30 Rpm, 24VDC 1

70002-257 G/motor, 45 Rpm, 24VDC 1

70002-258 G/motor, 60 Rpm, 24VDC 1

70002-259 G/motor, 125 Rpm, 24VDC 1

70002-260 G/motor, 250 Rpm, 24vDC 1

44 90002-191 Door, Controls Cover 1

45 90006-579 Gasket, Front, Neoprene 1

46 90012-245 Label Timer w/ Ext. Input 1

47 76000-999 Slide Clamp, Front 2

48 76001-000 Slide Clamp, Rear 2

49 76001-253 Enclosure, w/ Ext. Input 1

50 90003-559 Mounting Feet, Rubber 4

51 90011-091 Screw, #10 X 1.0” Phil 6

52 90011-094 Washer, #10 Stainless 6

53 71000-175 Power Cord, 220v50hz, 1

71000-177 Power Cord, 230v60hz, 1

54 70000-589 Connector Liq-tite .375 1

55 90010-235 Fuse, 1A, 250VAC 1

56 A-023N-V-115Circuit board, 115V 1

A-023N-V-230Circuit board, 220V/230V 1

57 90010-246 Wire set w/plug, alarm relay 1

59 90006-580 Gasket, Back Plate 1

60 90010-036 Wire Nut, Blue 2

62 71000-489 Enclosure Back w/Gasket 1

63 90011-044 Screw 6-32 x .37 2

64 90007-515 Bushing, J-Box, Alum. 1

65 90008-199 Connector Liq-tite .187 1

66 76001-254 Junction Box, Input, Valox 1

67 90011-129 Screw, 6-32 X .25 SS 2

68 71000-133 Cover, J-Box w/Gasket, 1

69 A-014N-6A Inj. Valve .37od, ½ lb spring 1

C-395N-6A Inj. Valve .37od, 6lb spring 1

Page 24

Page 24

LIMITED WARRANTY

Your new pump is a quality product and is warranted to be free of defects as set

down in this policy. All parts, including rubberized goods, and labor are covered

under warranty for 90 days from the date of purchase. Used peristaltic pump

tube assemblies are not warranted. Parts, excluding rubberized goods, are

covered under warranty for 12 months from the date of purchase.

Warranty coverage does not include damage to the pump that results from

misuse, carelessness, abuse or alteration. Only the repair or the replacement of

the pump is covered. Blue-White Industries does not assume responsibility for

any other loss or damage.

Warranty status is determined by the pump’s serial label and the sales invoice or

receipt. The serial label must be on the pump and the pump must be

accompanied by the sales invoice or receipt to obtain warranty coverage. The

warranty status of the pump will be verified by Blue-White or a factory

authorized service center.

Please be advised; injection and metering devices are not intended as a means of

treating water to render it suitable for human consumption. When used as

hypochlorinators, they are meant to destroy bacteria and algae contamination,

before it’s removal by filtration. Acid and soda injectors are used for PH control

(balance). Blue-White injectors are factory tested with water only for pressure

and performance. Installers and operators of these devices must be well

informed and aware of the precautions to be taken when injecting various

chemicals -especially those considered hazardous or dangerous.

Should it become necessary to return an injector for repair or service, you must

attach information regarding the chemical used as some residue may be present

within the unit which could be a hazard to service personnel.

Blue-White Industries will not be liable for any damage that may result by the

use of chemicals with their injectors and it’s components. Thank you.

C-1100V

PROCEDURE FOR IN WARRANTY REPAIR

Carefully pack the pump to be repaired, include the foot strainer and

injection/check valve fitting. Enclose a brief description of the problem as well

as the original invoice or sales receipt showing the date of purchase. The receipt

will be returned with the unit. Prepay all shipping costs. COD shipments will

not be accepted. Warranty service must be performed by the factory or an

authorized service center. Damage caused by improper packaging is the

responsibility of the sender.

Page 25

C-1100V

Page 25

AUTHORIZED SERVICE CENTERS

ARKANSAS American Pump

BT Environmental, Inc 7580-A W. Tennessee St. NORTH CAROLINA

Bill Thomason Tallahassee, FL 32304 Southern Industrial Sales

225 Castleberry Street 904-575-9618 1903 Herring Avenue

Hot Springs, AR 71902 Wilson, NC 27893

501-624-3837 919-237-2500

CALIFORNIA (NORTHERN) Del Ray Beach, FL 33444

Howard E. Hutching co.

(Repair Center)

7190 Penryn Plaza

Penryn, CA 95663 814-838-2034

Pool-Tech, Inc. 904-432-9929

3471 Mt. Diablo Blvd.

Lafayette, CA 94549

415-284-1400

Swimco Electric Co. Rapid City, SD 57702

753 Camden Avenue 605-343-7716

Campbell, CA 95008

408-378-2607

CALIFORNIA (SOUTHERN) Pompano Beach, FL 33060

Blue-White Industries

(Repair Center)

5422 Business Drive

Huntington Bch. CA 92649

714-893-8529

COLORADO

Denver Winpump

655 Depew Street

Lakewood, CO 80214-2494

303-233-1121

CONNECTICUT

Cronin-Cook & Associates

24 West Road

Vernon, CT 06066

203-875-0544

FLORIDA

AAA Electric Motor Services

1131 N.E. 45th Street

Ft. Lauderdale, FL 33334

305-772-7501

All American Pool & Patio

2021 Curry Ford Road

Orlando, FL 32806

407-898-8722

Rice Pump & Motor Repair

5788 N. Powerline Road

Ft. Lauderdale FL 33309

305-776-6049

Del Ray Electric

11 N.E. 2nd Avenue

407-278-3976

Jerry Lee Chemical Co.

3407 W. Old Fairfield Drive

Pensacola, FL 32505

Picard Chemical

1670 S. Congress Avenue

W. Palm Beach, FL 33406

407-965-3434

V.J. Mini & Son, Inc.

1581 N. Dixie Highway

305-946-0920

ILLINOIS

Mullarkey Associates

(Repair Center)

12346 S. Keeler Ave. 13700 Hwy. 90 West

Alsip, IL 60658 San Antonio, TX 78245

708-597-5558 512-677-8400

MARYLAND EGCO Industries

Century Pool Service, Inc 8505 Director Row

5020 Nicholson Court, #201 Dallas, TX 75247

Kensington, MD 20895 214-631-6885

301-231-8999

NEVADA Robert Shelton

Swim-In Enterprises, Inc. 1011 Oakmead Drive

1314 S. Main Street Arlington, TX 76011

Las Vegas, NV 89104 817-640-6188

702-384-4223

NEW YORK

Sherwood Specialties, Inc.

412 Smith Street

Rochester, NY 14608

716-546-1211

PENNSYLVANIA

Armor Electric, Inc.

1425 Selinger Avenue

Erie, PA 16505

SOUTH DAKOTA

Son-Aqua Distributing

Jim Robinson

2447 W. Main Street

TENNESSEE

Rock City Machine

307 3rd Avenue South

Nashville, TN 37201

615-244-1371

TEXAS

Alamo Water Refiners

Miracle Water Cond. Co.

Page 26

Page 26

C-1100V

This page blank

Page 27

C-1100V

Page 27

This page blank

Page 28

R

Blue-White

Industries, Ltd.

5300 Business Drive

Huntington Beach, CA 92649

Phone: 714-893-8529 FAX: 714-894-9492

E mail: sales@blue-white.com or techsupport@blue-white.com

Website: www.blue-white.com

# 80000-387 Rev. 3/8/2006

USA

Loading...

Loading...