Page 1

System Software Version 80.20.84

Book Version 3.1

November 2015

®

Xerox

Versant

User Guide

®

80 Press

Page 2

©2015 Xerox Corporation. All rights reserved. Xerox®, Xerox and Design®, FreeFlow®,

SquareFold®, CentreWare®and Versant®are trademarks of Xerox Corporation in the

United States and/or other countries.

Adobe PDF is a registered trademarks of Adobe Systems, Inc. PostScript is an Adobe

registered trademark used with the Adobe PostScript Interpreter, the Adobe page

description language, and other Adobe products.

Fiery®and EFI™are trademarks or registered trademarks of Electronics For Imaging, Inc.

GBC®and AdvancedPunch™are trademarks or registered trademarks of General Binding

Corporation.

Microsoft, Windows, Windows XP, Windows Vista, Internet Explorer, and Word are

registered trademarks of Microsoft Corporation in the United States and/or other

countries.

3-IN-ONE®and WD-40®are a registered trademarks of the WD-40 Company.

BR4005

Page 3

Table of Contents

1 Product Overview.......................................................................................1-1

Introduction...........................................................................................................................1-1

Base Configuration.............................................................................................................1-1

Print Server Overview..........................................................................................................1-2

Press Components...............................................................................................................1-2

Press Components..................................................................................................1-2

Locating the Press Serial Number....................................................................1-3

User Interface (UI).................................................................................................1-4

Features...................................................................................................................................1-5

Logon...........................................................................................................................1-5

Language...................................................................................................................1-6

Language Feature.....................................................................................1-6

Changing the Language.........................................................................1-6

Energy (Power) Saver Mode...............................................................................1-6

Energy (Power) Saver Mode Overview..............................................1-6

Low Power Mode.......................................................................................1-7

Sleep Mode..................................................................................................1-7

Exiting Energy (Power) Saver Mode...................................................1-7

Power On/Off.........................................................................................................................1-7

The Power Switches...............................................................................................1-7

Power On/Off the Press........................................................................................1-8

Power On the Press...................................................................................1-8

Power Off the Press...................................................................................1-8

Feeding and Finishing Devices.......................................................................................1-8

Feeding Devices.......................................................................................................1-9

Finishing Devices..................................................................................................1-10

Optional Performance Package...................................................................................1-14

2 Where to Find Help...................................................................................2-1

Help on the Xerox Web Site.............................................................................................2-1

Print Server Customer Documentation.......................................................................2-1

3 Paper and Media.......................................................................................3-1

Overview..................................................................................................................................3-1

Loading Media in Trays 1, 2, and 3...............................................................................3-1

Information About Loading Media in Trays 1, 2, and 3..........................3-1

Loading Paper in Trays 1, 2, and 3...................................................................3-2

User Guide

iXerox®Versant®80 Press

Page 4

Table of Contents

Loading Media in the Bypass (Tray 5).........................................................................3-5

Loading Paper in the 1-Tray High Capacity Feeder (HCF / Tray 6)..................3-8

Loading Media in the 1- or 2-Tray Oversized High Capacity Feeder (OHCF

Loading Media in the OHCF (Trays 8 and 9)..........................................................3-15

Loading Post-Process Media in Optional Finishing Devices.............................3-21

Loading Tab Stock in Trays 1, 2, and 3...........................................................3-2

Loading Transparencies in Trays 1, 2, and 3................................................3-3

Loading Pre-drilled Stock in Trays 1, 2, and 3..............................................3-4

Loading Paper in the Bypass (Tray 5).............................................................3-5

Loading Tab Stock in the Bypass (Tray 5).....................................................3-6

Loading Transparencies in the Bypass (Tray 5)..........................................3-6

Loading Pre-drilled Stock in the Bypass (Tray 5)........................................3-7

Loading Envelopes in the Bypass (Tray 5)....................................................3-7

/ Trays 6 and / or 7)...................................................................................................3-9

Postcard Bracket......................................................................................................3-9

Using the Postcard Bracket.................................................................3-10

Skew Adjustment Levers (Trays 6 and 7)....................................................3-11

Loading Paper in the Oversized High Capacity Feeder (OHCF / Trays

6 and 7).........................................................................................................3-12

Loading Tabs in the Oversized High Capacity Feeder (OHCF / Trays

6 and 7).........................................................................................................3-12

Loading Transparencies in the Oversized High Capacity Feeder

(OHCF / Trays 6 and 7)............................................................................3-13

Loading Pre-Drilled Stock into the Oversized High Capacity Feeder

(OHCF / Trays 6 and 7)............................................................................3-14

Postcard Bracket...................................................................................................3-15

Using the Postcard Bracket.................................................................3-15

Skew Adjustment Levers (Trays 8 and 9)....................................................3-17

Loading Paper in the OHCF (Trays 8 and 9)..............................................3-18

Loading Tabs in the OHCF (Trays 8 and 9)................................................3-18

Loading Transparencies in the OHCF (Trays 8 and 9)...........................3-19

Loading Pre-drilled Stock into the OHCF (Trays 8 and 9)....................3-20

4 Copy................................................................................................................4-1

Document Feeder and Glass...........................................................................................4-1

Document Feeder Tips..........................................................................................4-1

Document Glass......................................................................................................4-1

Basic Copying Steps............................................................................................................4-2

Basic Copying with the Document Feeder (DADF)...................................4-2

Basic Copying with the Document Glass......................................................4-2

Selecting Copy Options for a Third-Party Finishing Device...................4-3

Copy Feature..........................................................................................................................4-4

Xerox®Versant®80 Pressii

User Guide

Page 5

Table of Contents

Copy Feature Overview.........................................................................................4-4

Reduce/Enlarge.......................................................................................................4-4

Reduce / Enlarge (R/E).............................................................................4-4

More Reduce/Enlarge (R/E) Options..................................................4-5

Paper Supply.............................................................................................................4-5

Output Color.............................................................................................................4-6

Copy Output.............................................................................................................4-6

2 Sided Copying......................................................................................................4-7

Original Type............................................................................................................4-8

Darken/Lighten........................................................................................................4-8

Image Quality Feature.......................................................................................................4-9

Image Quality Feature Overview.....................................................................4-9

Selecting Image Quality Options.....................................................................4-9

Original Type..........................................................................................................4-10

Image Options......................................................................................................4-10

Image Enhancement.........................................................................................4-11

Color Effects...........................................................................................................4-11

Color Balance.........................................................................................................4-11

Color Shift...............................................................................................................4-12

Layout Adjustment Feature..........................................................................................4-12

Layout Adjustment Feature Overview.........................................................4-12

Selecting Layout Adjustment Options........................................................4-12

Book Copying........................................................................................................4-13

2 Sided Book Copying........................................................................................4-14

Original Size...........................................................................................................4-14

Edge Erase..............................................................................................................4-14

Image Shift............................................................................................................4-15

Image Rotation....................................................................................................4-15

Invert Image..........................................................................................................4-16

Original Orientation............................................................................................4-16

Output Format Feature...................................................................................................4-16

Output Format Feature Overview..................................................................4-16

Selecting Output Format Options.................................................................4-17

Booklet Creation...................................................................................................4-17

Covers.......................................................................................................................4-19

Page Layout...........................................................................................................4-19

Poster........................................................................................................................4-20

Annotations...........................................................................................................4-20

Watermark..............................................................................................................4-21

Tab Margin Shift...................................................................................................4-21

User Guide

iiiXerox®Versant®80 Press

Page 6

Table of Contents

Face Up/Down Output.......................................................................................4-22

ID Card Copy.........................................................................................................4-22

Transparency Options........................................................................................4-23

Folding (optional)................................................................................................4-23

Job Assembly Feature......................................................................................................4-24

Job Assembly Feature Overview.....................................................................4-24

Build Job..................................................................................................................4-24

Sample Job.............................................................................................................4-25

Combine Original Sets.......................................................................................4-26

Delete Outside/Delete Inside..........................................................................4-26

5 Scan................................................................................................................5-1

Scan Overview.......................................................................................................................5-1

Basic Scanning......................................................................................................................5-1

Basic Scanning Procedure...................................................................................5-1

Previewing Scanned Images..............................................................................5-2

Changing Scan Settings/Options.....................................................................5-3

Canceling a Scan Job............................................................................................5-3

Stopping a Scan Job..............................................................................................5-3

Scan Options..........................................................................................................................5-4

Scan Options Overview.........................................................................................5-4

Basic Scan Options.................................................................................................5-4

Advanced Settings.................................................................................................5-5

Layout Adjustment................................................................................................5-7

E-mail Options.........................................................................................................5-8

Filing Options........................................................................................................5-10

Resolving a File Name Conflict.......................................................................5-12

E-mail.....................................................................................................................................5-13

E-mail Overview....................................................................................................5-13

E-mail Components.............................................................................................5-13

Scanning to an E-mail Address.......................................................................5-14

Network Scanning.............................................................................................................5-15

Network Scanning Overview............................................................................5-15

Network Scanning Components....................................................................5-15

Network Scanning Procedure..........................................................................5-16

Scan to PC............................................................................................................................5-16

Scan to PC Overview...........................................................................................5-16

Scan to PC Components....................................................................................5-16

How to Use the Scan to PC Feature.............................................................5-17

Using the Scan to PC Feature............................................................5-17

Xerox®Versant®80 Pressiv

User Guide

Page 7

Table of Contents

Using the Address Book to Specify a Scan to PC

Destination.....................................................................................5-17

Browsing the Network for a Scan to PC Destination................5-18

Specifying a Scan to PC Destination Using the UI

Keyboard..........................................................................................5-18

Store to Folder....................................................................................................................5-19

Store to Folder Overview...................................................................................5-19

Store to Folder Components............................................................................5-19

Using the Store to Folder Feature.................................................................5-19

Store to USB........................................................................................................................5-20

Store to USB Overview.......................................................................................5-20

Using the Store to USB Feature.....................................................................5-20

Store and Send Link Feature (Send to Folder).......................................................5-21

Store and Send Link (Send to Folder) Overview.......................................5-21

Storing and Sending a Link (Sending to Folder)......................................5-22

Store to Web Services for Devices (WSD)................................................................5-23

Store to WSD Overview.....................................................................................5-23

How to Use the Store to Web Services for Devices (WSD)

Feature...........................................................................................................5-23

Using the Store to WSD Feature......................................................5-23

Starting a Scan Job from a Network Computer.........................5-24

Starting a Scan Job from This Device.............................................5-24

6 Send from Folder (Folder / File Management)..............................6-1

Send from Folder (Folder / File Management) Overview.....................................6-1

File Options............................................................................................................................6-1

Managing Folders and Scanned Files..........................................................................6-3

How to Configure/Start a Job Flow..............................................................................6-4

Configuring/Starting a Job Flow......................................................................6-4

Using Send from Folder to Link a Job Flow Sheet to a Folder..............6-5

7 Job Flow........................................................................................................7-1

Job Flow Overview...............................................................................................................7-1

Job Flow Settings and Options.......................................................................................7-2

Overview of Job Flow Options...........................................................................7-2

Additional Job Flow Options..............................................................................7-2

Sheet Filtering Options.........................................................................................7-3

Send as E-mail Options........................................................................................7-3

Transfer via FTP (1) / Transfer via FTP (2) Options...................................7-4

Transfer via SMB (1) / Transfer via SMB (2) Options................................7-4

Print Options.............................................................................................................7-4

E-mail Notification Options................................................................................7-5

User Guide

vXerox®Versant®80 Press

Page 8

Table of Contents

Job Flow Procedures...........................................................................................................7-5

Creating a Job Flow Sheet..................................................................................7-5

Linking a Job Flow Sheet with a Folder..........................................................7-5

Starting a Job Flow Manually............................................................................7-6

Confirming/Changing a Job Flow....................................................................7-7

8 Stored Programming................................................................................8-1

Stored Programming Overview.......................................................................................8-1

Stored Programming Options.........................................................................................8-1

Stored Programming Notes and Restrictions...........................................................8-2

Stored Programming Procedures...................................................................................8-3

Creating and Saving a Job as a Stored Program.......................................8-3

Creating and Saving a Stored Program to Use with Build Job.............8-4

Deleting a Stored Program.................................................................................8-5

Naming / Renaming a Stored Program.........................................................8-5

Assigning or Changing Icons for a Stored Program..................................8-6

Running a Stored Program.................................................................................8-6

Using a Stored Program while Build Job is Running.................................8-6

9 Web Applications.......................................................................................9-1

Web Applications Overview.............................................................................................9-1

Accessing Web Applications............................................................................................9-1

10 Job Status................................................................................................10-1

Job Status Overview.........................................................................................................10-1

Job Status Area..................................................................................................................10-1

Active Jobs Tab...................................................................................................................10-1

Completed Jobs Tab.........................................................................................................10-2

11 Machine Status.....................................................................................11-1

Machine Status Overview..............................................................................................11-1

Device Information Tab..................................................................................................11-1

Faults Tab.............................................................................................................................11-2

Supplies Tab.........................................................................................................................11-3

Billing Information Tab...................................................................................................11-3

Accessing Billing Information.........................................................................11-3

Billing Impressions Information....................................................................11-3

Usage Counters....................................................................................................11-4

Tools Tab...............................................................................................................................11-5

Changing the Paper Tray Attributes..........................................................................11-6

12 How to Submit a Print Job................................................................12-1

Setup and Submit the Print Job..................................................................................12-1

Xerox®Versant®80 Pressvi

User Guide

Page 9

Table of Contents

How to Submit a Print Job.............................................................................................12-1

Printing from a Computer or Print Server................................................................12-2

Printing from a Computer.................................................................................12-2

Printing from the FreeFlow Print Server......................................................12-2

Printing from the EX Print Server...................................................................12-3

Printing on Tabs from a Print Server..........................................................................12-3

Basic Procedure for Printing on Tabs from a Print Server.....................12-3

Tips for Printing on Tabs from the EX Print Server..................................12-4

13 Press Maintenance..............................................................................13-1

Procedures for Cleaning the Press..............................................................................13-1

Cleaning the Press Overview...........................................................................13-1

Cleaning the Exterior..........................................................................................13-1

Cleaning the Document Cover and Glass..................................................13-1

Cleaning the Document Feeder Rollers.......................................................13-3

Cleaning the Drum Drawer Area....................................................................13-4

Cleaning the ROS Windows.............................................................................13-4

Cleaning the Fuser Assembly..........................................................................13-5

Procedures for Replacing Consumables...................................................................13-6

Replacing Consumable Supplies....................................................................13-6

Ordering Supplies.................................................................................................13-6

Checking the Status of Consumables..........................................................13-7

Replacing a Dry Ink/Toner Cartridge............................................................13-8

Replacing the Dry Ink/Toner Waste Bottle................................................13-9

Replacing a Drum Cartridge.........................................................................13-10

Replacing the Suction Filter..........................................................................13-12

14 Press Problem Solving.........................................................................14-1

Locating the Press Serial Number...............................................................................14-1

Calling for Service..............................................................................................................14-1

Press Troubleshooting.....................................................................................................14-2

Basic Troubleshooting Information..............................................................14-2

General Problems.................................................................................................14-2

Image Quality Problems...................................................................................14-7

Fault Codes........................................................................................................................14-10

Press Fault Codes...............................................................................................14-10

Fault Codes - High Capacity Feeder (Tray 6) .........................................14-19

Fault Codes - Oversized High Capacity Feeder (Trays 6 and / or

7)...................................................................................................................14-20

Fault Codes - Oversized High Capacity Feeder (Trays 8 and

9)...................................................................................................................14-22

User Guide

viiXerox®Versant®80 Press

Page 10

Table of Contents

Paper Jams........................................................................................................................14-35

Fuser Hints and Tips......................................................................................................14-45

Fault Codes - Business Ready (BR) Finisher and Optional Booklet

Maker...........................................................................................................14-25

Fault Codes - Interface Module / Interface Cooling Module...........14-26

Fault Codes - GBC AdvancedPunch............................................................14-27

Fault Codes - GBC AdvancedPunch Pro....................................................14-28

Fault Codes - High Capacity Stacker (HCS).............................................14-28

Fault Codes - Standard Finisher / Booklet Maker Finisher................14-29

Fault Codes - SquareFold Trimmer Module.............................................14-31

Fault Codes - Standard Finisher Plus.........................................................14-33

Paper Jams Overview.......................................................................................14-35

Information about Paper Jams...................................................................14-35

Jam Recovery Offset Feature.......................................................................14-35

Setting Up the Jam Recovery Offset Feature...........................14-36

Paper Jams in the Document Feeder........................................................14-37

Document Feeder Jams.....................................................................14-37

Document Jams Under the Document Feeder Belt...............14-39

Press Paper Jams...............................................................................................14-40

Paper Jams Inside the Press............................................................14-40

Paper Jams in Trays 1-3.....................................................................14-41

Paper Jams in the Bypass (Tray 5)..............................................................14-42

Paper Jams in the Standalone Bypass (Tray 5)........................14-42

Paper Jams When the Bypass is Installed on Trays 6 and

7........................................................................................................14-42

Paper Jams When the Bypass is Installed on Trays 8 and

9........................................................................................................14-43

Extending Fuser Life.........................................................................................14-45

Preventing Fuser Damage..............................................................................14-45

Fuser Paper Width Information...................................................................14-46

15 Press Technical Data...........................................................................15-1

Press Specifications..........................................................................................................15-1

General Press Specifications............................................................................15-1

First Print-Out Time.............................................................................................15-2

Press Warm-up Time...........................................................................................15-2

Document Feeder Specifications...................................................................15-2

Paper Tray Information.....................................................................................15-3

Throughput / Productivity Information .....................................................15-3

Copy Specifications.............................................................................................15-5

Scan Specifications.............................................................................................15-7

Xerox®Versant®80 Pressviii

User Guide

Page 11

Table of Contents

Paper Specifications.........................................................................................................15-8

Environmental Specifications....................................................................................15-10

16 1-Tray High Capacity Feeder (HCF / Tray 6), Letter-Size / A4

Only..........................................................................................................16-1

High Capacity Feeder (HCF) Overview......................................................................16-1

Loading Paper in the 1-Tray High Capacity Feeder (HCF / Tray 6)...............16-1

HCF Problem Solving........................................................................................................16-2

Fault Codes - High Capacity Feeder (Tray 6) ...........................................16-2

Clearing Paper Jams in the HCF (Tray 6)....................................................16-4

Clearing HCF Paper Jams in the Lower Left Cover..................................16-4

HCF Specifications............................................................................................................16-5

17 1- or 2-Tray Oversized High Capacity Feeder (OHCF / Trays

6 and 7)..................................................................................................17-1

Overview of the Oversized High Capacity Feeder (Trays 6 and 7) ...............17-1

Loading Media in the OHCF (Trays 6 and 7)..........................................................17-2

OHCF Maintenance (Trays 6 and 7)..........................................................................17-2

Consumable Supplies for the OHCF (Trays 6 and 7)..............................17-2

Replacing the OHCF Bypass Tray Feed Rolls (Trays 6 and 7)..............17-2

Replacing the OHCF Feed Rolls (Trays 6 and 7).......................................17-3

OHCF Problem Solving (Trays 6 and 7)....................................................................17-6

Fault Codes - Oversized High Capacity Feeder (Trays 6 and / or

7)......................................................................................................................17-6

OHCF Jam Clearance (Trays 6 and 7)..........................................................17-8

Clearing OHCF Jams (Trays 6 and 7)..............................................17-8

Paper Jams When the Bypass is Installed on Trays 6 and

7..........................................................................................................17-8

Paper Jams Inside the OHCF Trays (6 and 7).............................17-9

OHCF Paper Jams at Lever 1a and Knob 1c (Trays 6 and

7)......................................................................................................17-10

OHCF Paper Jams at Lever 1b and Knob 1c (Trays 6 and

7)......................................................................................................17-11

OHCF Paper Jams at Lever 1d and Knob 1c (Trays 6 and

7)......................................................................................................17-11

OHCF Specifications (Trays 6 and 7)......................................................................17-13

18 Chained (Second) Oversized High Capacity Feeder (OHCF

/ Trays 8 and 9)...................................................................................18-1

OHCF (Trays 8 and 9) Overview...................................................................................18-1

OHCF (Trays 8 and 9) Specifications...........................................................18-2

Loading Media in the Chained OHCF (Trays 8 and 9).......................................18-2

OHCF (Trays 8 and 9) Maintenance..........................................................................18-3

User Guide

ixXerox®Versant®80 Press

Page 12

Table of Contents

OHCF (Trays 8 and 9) Problem Solving....................................................................18-8

Replacing the Bypass Tray Feed Rolls for the OHCF (Trays 8 and

9)......................................................................................................................18-3

Replacing the OHCF Feed Rolls for the OHCF (Trays 8 and

9)......................................................................................................................18-4

Fault Codes - Oversized High Capacity Feeder (Trays 8 and

9)......................................................................................................................18-8

OHCF (Trays 8 and 9) Jam Clearance.......................................................18-10

Clearing OHCF (Trays 8 / 9) Jams.................................................18-10

Paper Jams When the Bypass is Installed on Trays 8 and

9........................................................................................................18-10

Paper Jams Inside the OHCF (Trays 8 and 9)...........................18-12

OHCF (Trays 8 and 9) Paper Jams at Lever 1a and Knob

1c......................................................................................................18-12

OHCF (Trays 8 and 9) Paper Jams at Lever 1b and Knob

1c......................................................................................................18-13

OHCF (Trays 8 and 9) Paper Jams at Lever 1d and Knob

1c......................................................................................................18-14

19 Business Ready (BR) Finisher and Optional Booklet

Maker......................................................................................................19-1

Business Ready (BR) Finisher Overview....................................................................19-1

Identifying the BR Finisher Components................................................................19-2

BR Finisher Maintenance...............................................................................................19-2

Consumable Supplies for the BR Finisher...................................................19-2

Replacing Staples in the Main Stapler Unit...............................................19-3

Replacing Staples in the Booklet Maker.....................................................19-3

Emptying the Hole Punch Waste Container..............................................19-4

Problem Solving for the BR Finisher...........................................................................19-5

Fault Codes - Business Ready (BR) Finisher and Optional Booklet

Maker..............................................................................................................19-5

Clearing Jams in the BR Finisher at Position 3a......................................19-6

Clearing Jams in the BR Finisher at Position 3c.......................................19-7

Clearing Jams in the BR Finisher at Position 3d......................................19-8

Clearing Jams in the BR Finisher at Position 4.........................................19-8

Clearing Jams in the Booklet Tray.................................................................19-9

BR Finisher Specifications...........................................................................................19-10

20 Interface Module / Interface Cooling Module.........................20-1

Overview of the Interface Module / Interface Cooling Module......................20-1

Module Overview...............................................................................................................20-2

Module Control Panel.........................................................................................20-2

Paper Path through the Module....................................................................20-3

Paper Curl Settings on the Module...............................................................20-3

Xerox®Versant®80 Pressx

User Guide

Page 13

Table of Contents

Auto Decurl Presettings........................................................................20-3

Manual Decurl Buttons........................................................................20-3

Internal Spectrophotometer (Interface Cooling Module)...................20-4

Problem Solving for the Interface Module / Interface Cooling

Module........................................................................................................................20-5

Fault Codes - Interface Module / Interface Cooling Module..............20-5

Jam Clearance on the Interface Module / Interface Cooling

Module...........................................................................................................20-6

Clearing Module Jams..........................................................................20-6

Paper Jams at Lever 1a........................................................................20-6

Paper Jams at Lever 2a........................................................................20-7

Paper Jams at Lever 2b........................................................................20-8

21 GBC AdvancedPunch..........................................................................21-1

GBC AdvancedPunch Overview...................................................................................21-1

GBC AdvancedPunch Specifications............................................................21-1

GBC AdvancedPunch Components............................................................................21-2

GBC AdvancedPunch Operation Controls..................................................21-2

Status Indicators on the GBC AdvancedPunch.......................................21-2

Punch Dies..............................................................................................................21-3

GBC AdvancedPunch Procedures................................................................................21-4

Changing the Punch Die...................................................................................21-4

Pre-Punch Job Checkpoints..............................................................................21-5

Loading Tab Stock with the GBC AdvancedPunch.................................21-6

GBC AdvancedPunch Maintenance...........................................................................21-6

Emptying the Punch Container......................................................................21-6

GBC AdvancedPunch Problem Solving.....................................................................21-7

Fault Codes - GBC AdvancedPunch..............................................................21-7

GBC AdvancedPunch General Problems.....................................................21-7

GBC AdvancedPunch Jam Clearance...........................................................21-8

Clearing Jams in the AdvancedPunch............................................21-8

22 GBC AdvancedPunch Pro..................................................................22-1

AdvancedPunch Pro Overview......................................................................................22-1

AdvancedPunch Pro Specifications...............................................................22-2

AdvancedPunch Pro Components..............................................................................22-3

Operation Controls..............................................................................................22-3

Punch Chip Container.........................................................................................22-3

Punch Modes.........................................................................................................22-3

AdvancedPunch Pro User Display Panel...................................................................22-4

Layout of the User Display Panel..................................................................22-4

User Display Panel Overview...........................................................................22-4

User Guide

xiXerox®Versant®80 Press

Page 14

Table of Contents

Die Sets.................................................................................................................................22-7

AdvancedPunch Pro Procedures...............................................................................22-13

AdvancedPunch Pro Maintenance...........................................................................22-20

AdvancedPunch Pro Problem Solving.....................................................................22-23

Messages on the User Display Panel...........................................................22-5

Settings on the User Display Panel...............................................................22-5

Information on User Display Panel..............................................................22-6

Die Set Configuration.........................................................................................22-7

Pin Numbering.........................................................................................22-7

Pin Removal Table for US Paper Sizes............................................22-7

Pin Removal Table for ISO Paper Sizes...........................................22-9

Die Stop Position...............................................................................................22-10

Die Stop Position Guide for US Paper Sizes...............................22-10

Die Stop Position Guide for ISO Paper Sizes.............................22-11

Available Die Sets for the AdvancedPunch Pro.....................................22-11

Pre-Punch Job Checkpoints...........................................................................22-14

Changing Settings on the AdvancedPunch Pro....................................22-14

Changing Die Sets in the AdvancedPunch Pro (Removing /

Installing)...................................................................................................22-15

Die Set Procedures............................................................................................22-17

Removing Pins from a Die Set........................................................22-17

Adding Pins to a Die Set...................................................................22-18

Changing the Die Stop Position.....................................................22-19

Ordering Supplies for the AdvancedPunch Pro......................................22-20

Cleaning the Exterior of the AdvancedPunch Pro................................22-21

Emptying the Punch Container....................................................................22-21

Die Set Maintenance.......................................................................................22-22

Lubricating Die Set Pins (without a Felt Pad)...........................22-22

Lubricating Die Set Pins (with a Felt Pad)..................................22-22

Fault Codes - GBC AdvancedPunch Pro....................................................22-23

AdvancedPunch Pro General Problems.....................................................22-24

Die Set End of Life............................................................................................22-24

Clearing Paper Jams in the AdvancedPunch Pro..................................22-25

23 High Capacity Stacker (HCS)...........................................................23-1

High Capacity Stacker (HCS) Overview....................................................................23-1

High Capacity Stacker (HCS) Components.............................................................23-2

Identifying the Main HCS Components.....................................................23-2

HCS Control Panel................................................................................................23-2

HCS Top Tray..........................................................................................................23-3

Unloading the HCS Stacker Tray / Cart.......................................................23-3

Xerox®Versant®80 Pressxii

User Guide

Page 15

Table of Contents

HCS Problem Solving........................................................................................................23-4

Fault Codes - High Capacity Stacker (HCS)...............................................23-4

HCS General Problems.......................................................................................23-5

HCS Jam Clearance.............................................................................................23-5

HCS Jam Clearance Overview............................................................23-5

HCS Entrance Jams (E1, E2, and E3)...............................................23-6

HCS Transport Jams (E4, E5, and E6).............................................23-6

HCS Top Tray Jam (E7).........................................................................23-7

HCS Exit Jam (E8)...................................................................................23-8

Information about Paper Curl and the HCS..............................................23-8

HCS Specifications............................................................................................................23-9

24 Standard Finisher / Booklet Maker Finisher...............................24-1

Standard Finisher / Booklet Maker Finisher Overview........................................24-1

Manual Decurling Feature on the Finisher..............................................................24-3

Folding Feature on the Finisher...................................................................................24-4

Folding Overview..................................................................................................24-4

Fold Types...............................................................................................................24-4

Loading Paper / Tabs in the Post-Process Inserter (Tray T1)............................24-5

Finisher Maintenance......................................................................................................24-6

Finisher Consumable Supplies........................................................................24-6

Replacing the Basic Staple Cartridge...........................................................24-6

Replacing the Booklet Staple Cartridge......................................................24-7

Replacing the Staple Waste Container........................................................24-8

Emptying the Punch Waste Container......................................................24-10

Finisher Problem Solving.............................................................................................24-11

Problem Solving Information.......................................................................24-11

Fault Codes - Standard Finisher / Booklet Maker Finisher................24-11

Jam Clearance in the Finisher......................................................................24-13

Paper Jams in the Post-Process Inserter (Tray T1)..................24-13

Paper Jams at Finisher Top Tray....................................................24-14

Paper Jams at Finisher Stacker Tray.............................................24-14

Paper Jams at the Booklet Maker Tray.......................................24-15

Paper Jams at Lever 1a and Knob 1c...........................................24-15

Paper Jams at Lever 1d.....................................................................24-16

Paper Jams at Lever 1b.....................................................................24-17

Paper Jams at Lever 3b and 3d......................................................24-18

Paper Jams at Lever 3e and Knob 3c...........................................24-19

Paper Jams at Lever 3g and Knob 3f...........................................24-19

Paper Jams at Lever 4b and Knob 3a..........................................24-20

Paper Jams at the Optional C / Z Folder.....................................24-21

User Guide

xiiiXerox®Versant®80 Press

Page 16

Table of Contents

Stapler Faults......................................................................................................24-25

Stapler Faults Overview.....................................................................24-25

Staple Jams in the Basic Staple Cartridge.................................24-26

Staple Jams in the Booklet Maker Cartridge............................24-27

Reinserting the Basic Staple Cartridge.....................................................24-28

Specifications for the Standard Finisher / Booklet Maker Finisher.............24-30

Standard / Booklet Maker Finisher Specifications...............................24-30

C / Z Folder Specifications.............................................................................24-33

25 SquareFold Trimmer Module...........................................................25-1

SquareFold Trimmer Module Overview....................................................................25-1

SquareFold Trimmer Module Specifications.............................................25-2

Identifying the Module Components.......................................................................25-2

Main Components...............................................................................................25-2

Module Paper Path..............................................................................................25-3

Module Control Panel.........................................................................................25-4

Square Fold Feature.........................................................................................................25-4

Square Fold Options............................................................................................25-5

Trimmer Feature................................................................................................................25-5

Trimmer Options..................................................................................................25-6

Trim Guidelines.....................................................................................................25-6

Square Fold / Trimming Procedures...........................................................................25-8

Selecting the Square Fold / Trimming Options for Network Print

Jobs.................................................................................................................25-8

Selecting the Square Fold / Trimming Options for Copy

Jobs.................................................................................................................25-8

Hints and Tips.....................................................................................................................25-9

Printing Full-Page Images on Booklets........................................................25-9

Follow These Tips..............................................................................................25-10

Problem Solving...............................................................................................................25-10

Fault Codes - SquareFold Trimmer Module.............................................25-10

SquareFold Trimmer Module Jam Clearance.........................................25-12

Jam Clearance Overview...................................................................25-12

Clearing Jams........................................................................................25-12

Clearing E1 / E2 Jams.........................................................................25-13

Clearing E3 Jams..................................................................................25-14

26 Standard Finisher Plus........................................................................26-1

Standard Finisher Plus Introduction..........................................................................26-1

Standard Finisher Plus Components..........................................................................26-1

Standard Finisher Plus Main Components.................................................26-1

Finisher Module....................................................................................................26-2

Xerox®Versant®80 Pressxiv

User Guide

Page 17

Table of Contents

Finisher Module Main Components................................................26-2

Folding Feature and Types..................................................................26-3

Post-Process Inserter (Tray T1)..........................................................26-3

Finishing Transport..............................................................................................26-3

Finishing Transport Main Components.........................................26-3

Finishing Transport Status Indicators............................................26-4

Standard Finisher Plus Maintenance.........................................................................26-4

Consumable Supplies for the Standard Finisher Plus............................26-4

Finisher Module Maintenance Procedures................................................26-5

Standard Finisher Plus Problem Solving...................................................................26-5

Fault Codes - Standard Finisher Plus............................................................26-5

Paper Jam Procedures for the Finisher Module.......................................26-7

Paper Jams in the Finisher Module.................................................26-7

Paper Jams in Areas 4b and 4c.........................................................26-8

Paper Jams in the Finishing Transport........................................................26-8

Paper Jams in Area 1.............................................................................26-8

Paper Jams in Area 2.............................................................................26-9

Paper Jams in Area 3..........................................................................26-10

Paper Jams in Area 4..........................................................................26-11

Standard Finisher Plus Specifications....................................................................26-12

Finisher Module Specifications....................................................................26-12

C / Z Folder Specifications.............................................................................26-15

Finishing Transport Specifications.............................................................26-15

User Guide

xvXerox®Versant®80 Press

Page 18

Table of Contents

Xerox®Versant®80 Pressxvi

User Guide

Page 19

1

Product Overview

Introduction

The Xerox®Versant®80 Press is a full color/black and white, auto-duplex copier/printer

that operates at a speed of 80 prints per minute (when printing on 8.5 x 11 inch/A4

paper).

Base Configuration

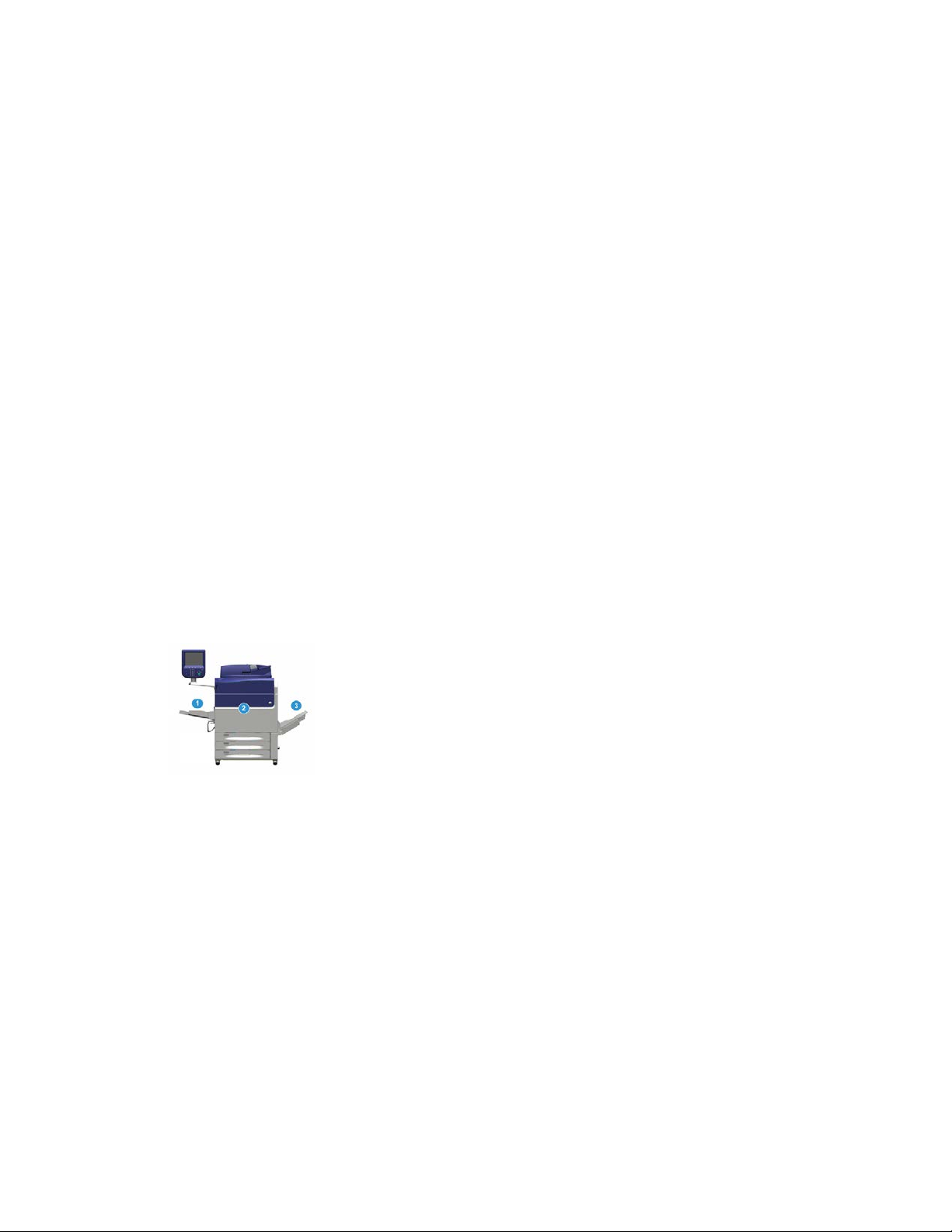

The system base system configuration consists of the following components:

1. Bypass Tray

Other optional feeding devices are available.

2. Color Press

3. Offset Catch Tray

Other optional finishing devices are available.

4. Print Server (not shown)

Choice of one of three print servers is available.

User Guide

1-1Xerox®Versant®80 Press

Page 20

Product Overview

Print Server Overview

The print server networked with your press accepts, processes, and manages document

files for job submission to the press.

One of the following print servers may be used with your press:

• Xerox®FreeFlow®Print Server

• Xerox®EX 80 Print Server, Powered by Fiery

• Xerox®EX-P 80 Print Server, Powered by Fiery

Note

For detailed information on your specific print server, refer to the customer

documentation that was delivered with it. Documentation may also be downloaded

from www.xerox.com by searching for the press and selecting the Support link.

®

®

Press Components

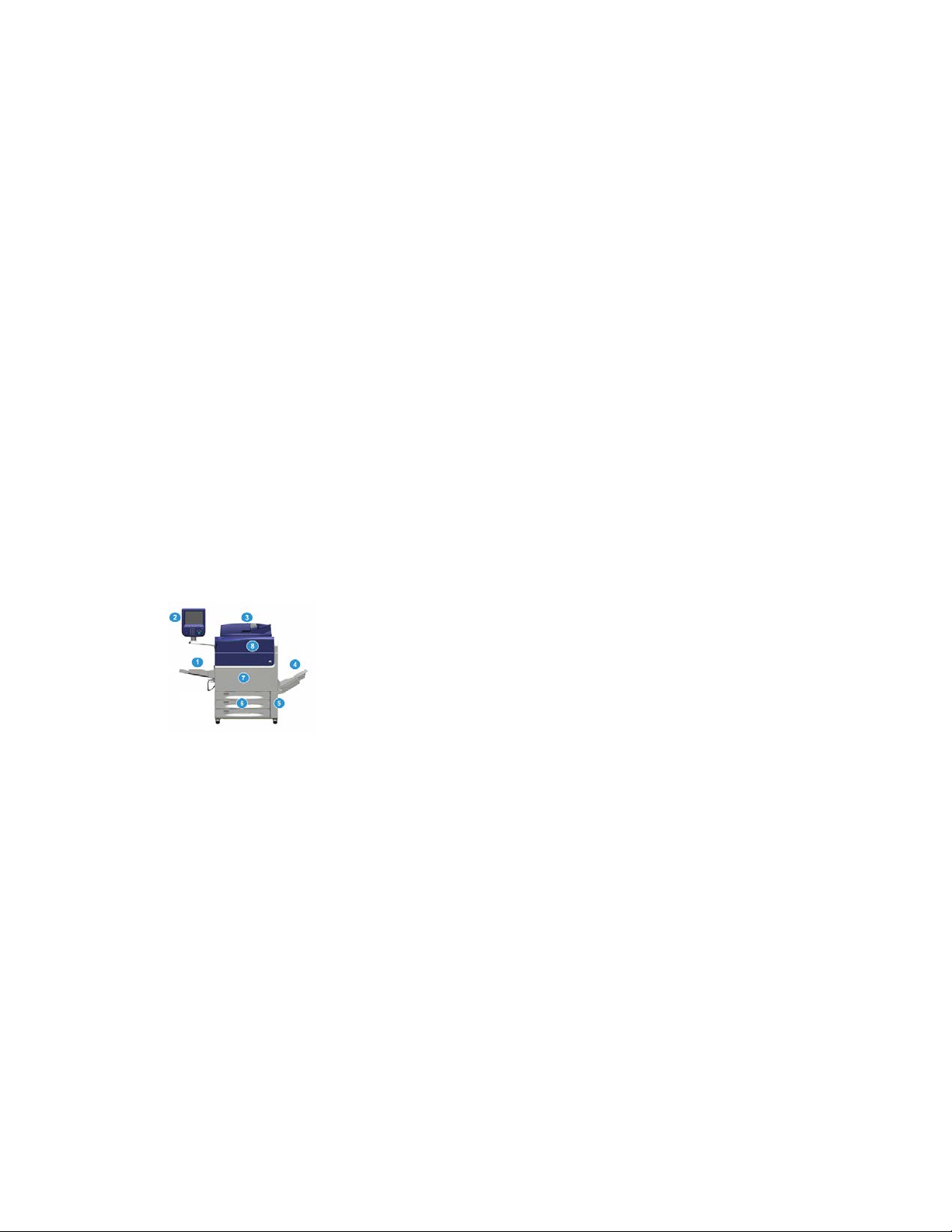

Press Components

1 Bypass Tray

The Bypass Tray is also called Tray 5 or Multisheet Inserter; the tray accommodates

all types of stock in various sizes and weight ranges.

Note

The mounting location for the Bypass tray varies when optional feeding devices are

added to the machine configuration.

2 User Interface (UI)

The User Interface (UI) consists of the touch screen and control panel with the buttons

and keypad.

3 Duplex Automatic Document Feeder (DADF)

Automatically feeds 1- and 2-sided original documents. A maximum of 250 two-sided

documents can be scanned at one time.

Xerox®Versant®80 Press1-2

User Guide

Page 21

Product Overview

4 Offset Catch Tray (OCT)

This tray receives the completed print job. Output print sheets can be offset for easy

separation. The maximum capacity of the OCT is determined by the tray sensor as well

as stock weight, but is approximately 500 sheets of 24 lb. (90 gsm) paper.

Note

Offsetting per set in the stack continues up to the point when the tray reaches the

maximum height or weight allowed.

5 Dry Ink/Toner Waste Bottle Door

Open this door to access the waste bottle when replacement of the bottle is required.

6 Trays 1-3

Trays 1, 2, and 3 accommodate a variety of paper sizes and weights; refer to the

Technical Specifications chapter for detailed information.

7 Front Door

Open this door to clear paper jams and to replace various Customer Replaceable Units

(CRUs).

8 Dry Ink/Toner Cover

Open this cover to access and replace the dry ink/toner cartridges.

Locating the Press Serial Number

The press serial number can be accessed from either the press User Interface or from

the serial number plate which is located on the inside frame of Tray 1.

1. Press the Machine Status button on the User Interface.

2. From the Machine Status screen, ensure that the Device Information tab is displayed.

The press serial number is displayed under Device Serial Information near the bottom

of the screen.

3. If there is a loss of power and it is not possible to access the Machine Status screen,

the press serial number can also be found on the inside frame of the press near the

Paper Tray 1 drawer:

a) At the press, fully open Tray 1.

b) At the left of the tray, on the press frame, locate the plate with the serial number

(SER#).

User Guide

1-3Xerox®Versant®80 Press

Page 22

Product Overview

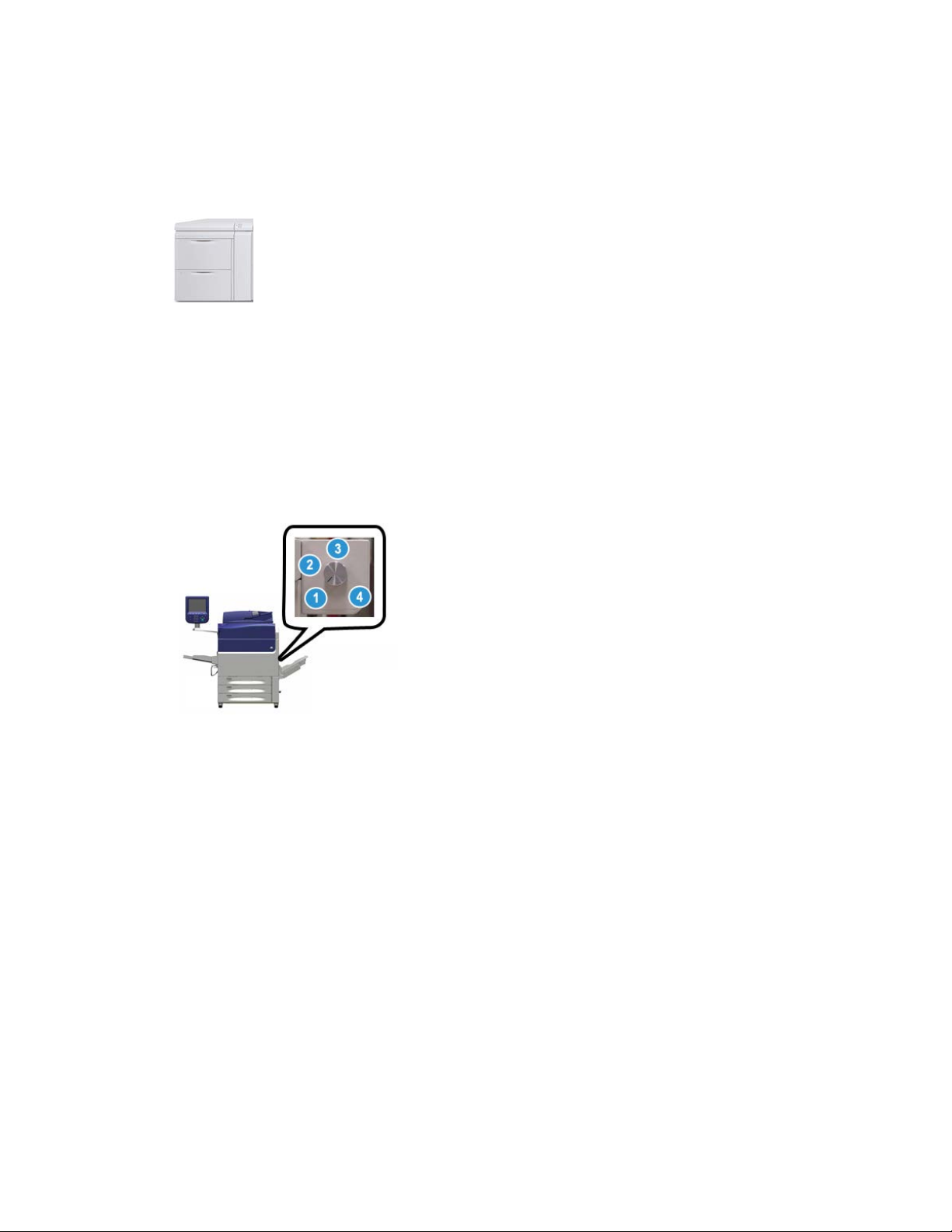

User Interface (UI)

1 Touch Screen

Directly touch the screen to select and set features. Displays instructional and

informational messages, fault clearance procedures and general press information.

2 Home button

Press this button to display the main window. Provides access to features such as Copy,

E-Mail, and Network Scanning, just to name a few features. Other features may be

available depending on your marketplace.

3 Services

This button lights when the main power is on.

4 Job Status button

Use to check the progress of active jobs and detailed information about completed

jobs or pending jobs. This area also allows you to delete a job (cancel printing or copying)

and pause jobs.

5 Machine Status button

Use to access the Tools feature, check the press configuration, the software version,

the press billing meters and counter information, and to access and print job history

or error reports.

6 Log In/Out button

Use to log in and out of Administrator mode or Authentication mode with user ID and

password.

7 Energy / Power Saver button

Use this button if the press has been inactive and the touch screen is dark (system is

in Energy Saver mode). This button manually exits the system from Energy Saver mode;

it does not place the press in Energy Save mode.

8 Clear All button

Use this button to return all selections to the same state as when the press was powered

on. Press once to clear a current entry. Press twice to return to default settings.

9 Stop button

Press to stop and pause the print or copy job in progress.

Xerox®Versant®80 Press1-4

User Guide

Page 23

Product Overview

10 Start button

Use this button to perform certain functions, such as scanning/copying a document or

printing a selected report from the print engine. This button is also used by the Customer

Service Engineer (CSE) during diagnostic routine procedures.

11 Interrupt button

Use this button to suspend a copy or print job in progress and have the machine stop

to process another job. During the Interrupt mode, the Interrupt button lights. Pressing

the Interrupt button again exits the Interrupt mode and resumes the suspended job.

12 Numeric Keypad

Use to enter alphanumeric characters. The C (Cancel) Entry cancels the previous entry

made on the numeric keypad.

13 Language button

Use to select a different language for the touch screen options.

14 Help button

Displays the Help System; this feature may not be available in all marketplaces.

Features

Logon

There are two logon levels:

• Guest/Operator: This is the default logon user. You are automatically logged on as

Guest.

• Administrator: This logon level is required to customize the system and network

defaults for your press and to customize particular print jobs by setting, or changing

parameters for certain features. Press the Guest button (or the Log in button on the

Control Panel) to access the Login screen.

Note

Refer to the System Administration Guide for more information on the Administrator

features.

User Guide

1-5Xerox®Versant®80 Press

Page 24

Product Overview

Language

Language Feature

Note

The number of languages available on your system depends on what was installed during

the initial installation process.

Selecting a particular Language button immediately changes the language. No

confirmation is required.

Changing the Language

1. Press the Language button on the press User Interface

The Language window displays on the touch screen.

2. Choose one of the following:

• Select the desired language from the list, and select Save. The language on the

screen changes to the new language and closes the Language window.

• Select the Cancel button to return to the main screen.

Energy (Power) Saver Mode

Energy (Power) Saver Mode Overview

The Energy (Power) Saver feature allows the press to enter a reduced power consumption

mode when all print jobs have completed and there are no jobs currently processing.

There are two energy saving modes: Low Power and Sleep.

By default, the press automatically enters the Low Power mode after 1 minute of

inactivity. After 1 minute of inactivity, the press then enters Sleep mode. These time

intervals for both modes can be changed by the system administrator.

Here are two examples:

• If Low Power Mode is set to 15 minutes and Sleep Mode is set to 60 minutes, Sleep

Mode activates after 60 minutes of total inactivity, not 60 minutes after Low Power

Mode begins. In other words, Sleep Mode activates 45 minutes after the Low Power

Mode begins.

• If Low Power Mode is set to 15 minutes and Sleep Mode is set to 20 minutes, Sleep

Mode activates 5 minutes after Low Power Mode begins.

Xerox®Versant®80 Press1-6

User Guide

Page 25

Product Overview

Low Power Mode

In this mode, the power to the User Interface (UI) and fuser unit is lowered to save

power. The display goes out and the Energy Saver button on the UI lights. To use the

press, press the Energy Saver button. The Energy Saver button is no longer lit, indicating

that the Energy Saver feature is canceled.

Sleep Mode

In this mode, the power is lowered more than in the Low Power mode. The display goes

out and the Energy Saver button on the UI lights. To use the press, press the Energy

Saver button. The Energy Saver button is no longer lit, indicating that the Energy Saver

feature is canceled.

Exiting Energy (Power) Saver Mode

The press exits Energy (Power) Saver mode by doing one of the following:

• Pressing the Power / Energy Saver button on the press UI,

• Receiving print data for an incoming job to be printed, or

• Programming and performing a copy or scan job.

Power On/Off

The Power Switches

There are three power switches involved with the press:

• The Breaker switch located at the rear of the press. Initially check to make sure this

switch is set to On when the press is shipped.

• The Main Power switch located inside the Front Door. This switch is used mainly by

the Xerox Service Representative when servicing the press. In rare problem solving

cases, you may be directed to power off the press with this switch.

User Guide

1-7Xerox®Versant®80 Press

Page 26

Product Overview

• The Power On/Off button located on the top of the press near the Document Feeder.

This button is the primary way for you to switch on or off the press. It is used by the

operator as workflow requires.

Use the Power On/Off button to power ON or power OFF the press.

Important

Always use the Power On/Off button first, and then power off the Main Power Switch.

Power On/Off the Press

Power On the Press

1. Check that the Main Power switch behind the Front Door is On.

2. Press the Power On/Off button on top of the press to the ON position.

The Ready Indicator light displays green.

A screen message advises of a short wait while the fuser warms up and the press runs

a system check. You can set features for a job during this time and the printing process

will start automatically when the press is ready.

Power Off the Press

Important

Always power off the Power Switch first and then power off the Main Power Switch.

1. Press the Power On/Off button on the top of the press to Off.

Wait until the lights on UI stop blinking, as this allows the fuser to begin cooling.

2. Switch Off the Main Power switch behind the Front Door.

Note

Allow the press to remain off for a minimum of 10 seconds before switching on the

power again.

Feeding and Finishing Devices

Available with your press is a variety of optional feeding and finishing devices. These

devices are briefly introduced on the following pages. Refer to the sections at the end

of this guide for specific information on each feeder or finisher.

Xerox®Versant®80 Press1-8

User Guide

Page 27

Product Overview

Feeding Devices

Bypass (Tray 5)

The Bypass Tray, also called Tray 5, is part of the base system configuration. The

mounting location for the Bypass tray varies when optional feeding devices are added

to the machine configuration:

• If the system configuration includes either the 1-Tray HCF (Letter-size / A4) or the

1-Tray OHCF (Tray 6), then the Bypass (Tray 5) is installed above the feeding device.

• If the system configuration includes one 2-Tray OHCF (Trays 6 and 7), then the

Bypass Tray is installed on top of it.

• If the system configuration includes a second, chained OHCF (Trays 8 and 9), then

the Bypass Tray is installed on top of the second OHCF (Trays 8 and 9).

The Bypass Tray accommodates a weight range of 52 to 300 gsm and media size of

3.86 x 5.75 inches (98 x 146 mm) to 13 x 19.2 inches (330.2 x 488 mm). The Bypass

Tray holds a maximum of 280 sheets of 20 lb. / 75 gsm plain paper. The Bypass Tray

accepts envelopes, postcards and transparencies.

High Capacity Feeder (HCF), 1 Tray

The 1-tray High Capacity Feeder (HCF), also known as Tray 6, provides a 2,000-sheet,

letter-size (8.5 x 11 in. / A4) paper source.

Note

Only letter-size (8.5 x 11 in.) / A4 paper, Long Edge Feed (LEF) can be used in this tray.

1- or 2-Tray Oversized High Capacity Feeder (OHCF / Trays 6 and 7)

The Oversized High Capacity Feeder (OHCF) is available in a 1-tray or 2-tray option.

The OHCF feeds a variety of stock sizes, including standard and oversized stock up to

13 x 19.2 in./330.2 x 488 mm and weighing between 52 gsm and 350 gsm. Each tray