Page 1

Version 1.0

November 2020

702P08365

Xerox

®

Versant

®

4100 Press

User Documentation

Page 2

© 2020 Xerox Corporation. All rights reserved. Xerox®, Xerox and Design®, and Versant®are trademarks of Xerox

Corporation in the United States and/or other countries.

®

Adobe

and the Adobe logo, InDesign®, Illustrator®, PageMaker®, Photoshop®, Acrobat®, Distiller®, PostScript, and the

Acrobat logo are either registered trademarks or trademarks of Adobe Systems Incorporated in the United States and/

or other countries.

Macintosh, Mac OS, Power Macintosh, TrueType, and Mac are registered trademarks of Apple Computer, Inc. in the

United States and/or other countries.

Microsoft

®

Windows 2000®, Windows XP, Windows 7, Windows 10, and Microsoft®Windows are trademarks of

Microsoft Corporation in the United States and/or other countries.

Mozilla and Firefox are trademarks of The Mozilla Foundation

PANTONE

®

, PANTONE Goe™, PANTONE MATCHING SYSTEM®, PMS®, and X-Rite PANTONE®are either registered

trademarks or trademarks of Danaher Corporation.

The CentOS Marks are trademarks of Red Hat, Inc.

Changes are periodically made to this document. Changes, technical inaccuracies, and typographic errors will be

corrected in subsequent editions.

Page 3

Table of Contents

1 Learning About.......................................................................................................................... 7

Safety. ....................... . . . . . ....................... . . ....................... . . . . . ........................ . . ....................... . . . 8

Product Symbols . . . . ....................... . . . . . ....................... . . ....................... . . . . . ........................ . .. 8

Notices and Safety................... . . ........................ . . . . ....................... . . . ....................... . . . . ..... 11

Electrical Safety . ....................... . . . . . ....................... . . . ....................... . . . . . ....................... . . ... 11

Laser Safety...................... . . ........................ . . . . ....................... . . . ....................... . . . . ............ 13

Operational Safety.. . . . . . ........................ . . ....................... . . . . . ....................... . . ..................... 13

Maintenance Information.......... . . . . ....................... . . . ....................... . . . . . ....................... . . ... 14

Consumable Information .. . . ........................ . . . ....................... . . . . ....................... . . . ............. 15

Battery Safety............... . . . ....................... . . . . . ....................... . . ........................ . . . . ............... 15

Environmental, Health, and Safety Contact Information .. . . . . . ....................... . . .................. 16

Press Overview .................. . . . . . ....................... . . ....................... . . . . . ....................... . . .................. 17

Press Components. ....................... . . . . ....................... . . . . ....................... . . . ....................... . . . . 17

PredictPrint Media Manager Overview....................... . . . . ....................... . . . . ....................... . . . . ... 25

Print Server Overview .. . . . . ....................... . . ....................... . . . . . ....................... . . ........................ . 26

Specifications . . ........................ . ........................ . . . . . ....................... . . ....................... . . . . . ........... 27

Performance Specifications .......... . . . . ........................ . . . ....................... . . . . ....................... . . . 27

Environmental Specifications .................... . . . ........................ . . . ....................... . . . . .............. 28

Getting Help .. . . ....................... . . ........................ . . . . ....................... . . . ....................... . . . . . ........... 29

Help on the Xerox Website...................... . . ....................... . . . . . ....................... . . .................. 29

Print Server Documentation ................. . . . . . ....................... . . . ....................... . . . . .................. 29

More Information................. . . . . ....................... . . . ........................ . . . ....................... . . . . ....... 29

Regulatory Information ......... . . . ........................ . . . . ....................... . . . ....................... . . . . ............ 31

Basic Regulations. . ....................... . . ....................... . . . . . ....................... . . . ....................... . . . . . 31

Copy Regulations ........................ . . . ....................... . . . . ....................... . . . . ....................... . . . . . 35

Safety Certification...................... . . . ........................ . . . . ....................... . . . ....................... . . . . 37

Safety Data Sheets ....... . . . ....................... . . . . . ....................... . . ........................ . . . . ............... 38

Recycling and Disposal............. . . ....................... . . . . . ....................... . . . ....................... . . . . ........... 39

All Countries .................. . . . . . ........................ . . ....................... . . . . . ....................... . . .............. 39

North America .. . . . . ....................... . . . ........................ . . . . ....................... . . . ....................... . . . . 39

European Union. . . ....................... . . . ....................... . . . . . ....................... . . . ....................... . . . . . 40

Other Countries..................... . . . . . ........................ . ........................ . . . . . ....................... . . ....... 40

2 Working With...........................................................................................................................41

Power On or Off ..... . . . . . ....................... . . . ....................... . . . . . ....................... . . ....................... . . . . . 42

Power Switches .................. . . ....................... . . . . . ....................... . . . ....................... . . . . ........... 42

Power On or Off the Press .. . ....................... . . ........................ . . . . . ....................... . . .............. 43

Power Saver Mode ........................ . . . . . ....................... . . ....................... . . . . . ........................ . 44

Job and Machine Status........... . . . . ....................... . . . ....................... . . . . ....................... . . . ........... 45

Job Status............... . . . . ....................... . . . ........................ . . . ........................ . . . ..................... 45

Xerox®Versant®4100 Press

User Documentation

3

Page 4

Table of Contents

Machine Status..................... . . . ........................ . . . ........................ . . . ....................... . . . . ....... 46

Paper and Media.................. . . . ....................... . . . . ........................ . . ....................... . . . . . .............. 52

Paper and Media Overview.................. . . ........................ . . . . ........................ . . ..................... 52

Supported Paper....................... . . ....................... . . . . . ....................... . . . ....................... . . . . . ... 54

Loading Paper..... . . ....................... . . . . . ....................... . . . ....................... . . . . ....................... . . . 60

Matching the Tray and Stock Information... . ........................ . . . . . ....................... . . .............. 63

Paper Feed Performance in Trays 6 and 7 ...................... . . ....................... . . . . . ..................... 64

Printing on Special Media ................ . . . . ........................ . . ........................ . . . . ...................... 69

Loading Media in Optional Devices ............. . . . . ....................... . . . ....................... . . . . ............ 86

PredictPrint Media Manager.................... . . . . ........................ . . ........................ . . . . ..................... 87

Desktop Shortcuts. ....................... . . . ....................... . . . . . ....................... . . . ....................... . . . . 87

PredictPrint Cloud Server . . ....................... . . . . . ........................ . . ....................... . . . . . .............. 88

Backing Up and Transferring the Stock Library .............. . . . ....................... . . . . ..................... 89

Stock Wizard. . ....................... . . ....................... . . . . . ....................... . . ........................ . . . . . ....... 90

Administration........ . . . ........................ . . . ........................ . . . ....................... . . . . ..................... 98

Stock Management... . . . ........................ . . . ....................... . . . . ....................... . . . . ................. 105

Tray Properties. . ....................... . . ........................ . . . . ....................... . . . ....................... . . . . . .. 113

Test Print ............ . . ....................... . . . . . ....................... . . . ....................... . . . . ........................ 116

Advanced Stock Setup . ........................ . . . . . ....................... . . ....................... . . . . . ................ 118

Paper Curl Correction ................. . . . . ....................... . . . ....................... . . . . . ....................... . . . 129

Profiles.. ....................... . . . . ....................... . . . ....................... . . . . ........................ . . . .............. 135

Alignment Profiles...... . . ........................ . . . . ....................... . . . ....................... . . . . . ................ 136

Fold Adjustments ................... . . . . ........................ . . ........................ . . . . ....................... . . . .... 144

Print Job Submission ............ . . . ....................... . . . . ........................ . . ....................... . . . . . ............ 160

Information to Know Before Printing a Job............ . . ....................... . . . . . ....................... . . . . 160

How to Submit a Print Job................ . . . ....................... . . . . ........................ . . ...................... 160

Printing from Your Computer......... . . . . . ....................... . . ....................... . . . . . ....................... 161

Printing from the EX or EX-P Print Server........ . . . ....................... . . . . ........................ . . ......... 161

Information about Printing on Tabs .. . . ....................... . . . . ........................ . . ...................... 162

Feeding Devices ....................... . . ........................ . . . . ....................... . . . ....................... . . . . ......... 163

Dual Advanced Oversized High Capacity Feeder (Trays 8 and 9) ....................... . . . . . ......... 163

Paper and Media for Trays 8 and 9... . . ....................... . . . . . ........................ . . ...................... 165

Trays 8 and 9 Specifications...... . . . . ....................... . . . ....................... . . . . ....................... . . . . . 179

Finishing Devices ..................... . ........................ . . . . . ....................... . . ....................... . . . . . ......... 180

Interface Decurler Module (IDM) ............... . . ........................ . . . . ....................... . . . ............ 180

Inserter Device.. . . . . ....................... . . . . ....................... . . . . ....................... . . . ....................... . . 185

®

AdvancedPunch™Pro.................. . . . . . ....................... . . . ....................... . . . . ................ 191

GBC

High Capacity Stacker (HCS) ...... . . . . ....................... . . . ....................... . . . . . ....................... . . . 192

Crease and Two-Sided Trimmer. . ....................... . . ........................ . . . . ........................ . . ..... 196

C/Z Folder .. . ....................... . . . . . ....................... . . ....................... . . . . . ........................ . . ........ 198

Production Ready (PR) Finishers ............. . . . ....................... . . . . . ....................... . . ................ 201

SquareFold

®

Trimmer Device............. . . . . ........................ . . . ....................... . . . . ................... 213

Job Workflows................... . . . . . ....................... . . ....................... . . . . . ........................ . ................ 221

Printing Extra-Long Sheets ................... . . ....................... . . . . . ....................... . . ................... 221

Printing Saddle-stitched Booklets with Full Bleed, Trimmed Edges, and Inserting

Preprinted Covers.................. . . . ....................... . . . . ........................ . . . ....................... . . . . ..... 222

Adjusting Booklet Fold and Staple Positions .. . ....................... . . . . ....................... . . . . .......... 225

Producing Simple Folded Sheets and Inserting Folded Sheets into a Document .............. 227

4

Xerox®Versant®4100 Press

User Documentation

Page 5

Table of Contents

Using the Inserter Device to Include Sheets or Tabs into the Printed Output. ................ . . 229

Using the GBC

®

AdvancedPunch®Pro...................... . . . ....................... . . . . ....................... . 230

Maintenance . . . ........................ . . . ....................... . . . . ....................... . . . ....................... . . . . ......... 232

General Precautions and Warnings....................... . . . ....................... . . . . . ....................... . . . . 232

Cleaning the Press ... . . . . ........................ . . . ....................... . . . . ....................... . . . .................. 232

Calibrating the Press ............. . . . . ....................... . . . ........................ . . . ........................ . . . ..... 236

Replacing Consumable Supplies ................ . . . ........................ . . . . ....................... . . . ............ 238

Tray 8 and 9 Maintenance ........... . . . . . . ....................... . . ....................... . . . . . ....................... 261

Finishing Devices Maintenance .................. . . ........................ . . . . ....................... . . . ............ 271

3 Troubleshooting................................................................................................................... 285

General Troubleshooting . . . ....................... . . . ........................ . . . ....................... . . . . ................... 286

Press Does Not Power On ... . . . . ....................... . . . ....................... . . . . ....................... . . . ......... 286

Cannot Obtain the Press Serial Number from the Machine Status Screen ................ . . . . . .. 286

Press Control Panel Is Not Working.............. . . . . ........................ . . ....................... . . . . . ......... 287

Press Does Not Complete a Print Job ................ . . . ........................ . . . ....................... . . . . ..... 287

Time Interval Between Print Jobs Is Longer Than 1 Minute ....................... . . ................... 287

Print Output Contains Corrupted Text...... . . . . ....................... . . . ........................ . . . . ............. 288

Trays Do Not Recognize the Media.............. . . . . . ....................... . . ....................... . . . . . ......... 288

Prints Are Not on Desired Paper Size ..................... . . . . . . ....................... . . ....................... . . . 288

Paper Jams or Wrinkles in the Fuser Area .............. . . . ....................... . . . . . ....................... . . . 288

Repeated Paper Misfeeds, Jams, or Wrinkles.......... . . . . . ....................... . . . ....................... . . . 289

Multiple Sheets Fed From the Same Tray....................... . . . . ....................... . . . ................... 289

Excessive Paper Curl on Printed Output .................. . . . . . ....................... . . . ....................... . . 290

Reducing Dry Ink/Toner Consumption ..... . . . . ....................... . . . ........................ . . . .............. 291

Image Quality (IQ) Troubleshooting........... . . . ....................... . . . . ....................... . . . . ................. 292

Contamination on the Back Side of Prints ..................... . . . ....................... . . . . ................... 292

Banding on Prints. . ....................... . . ....................... . . . . . ....................... . . . ....................... . . . 293

Color Nonuniformity on Prints..................... . . . ....................... . . . . ....................... . . . ........... 294

Random White or Dark Spots on Prints. . ........................ . . . . . ....................... . . ................... 294

Repeating Defects at Regular Intervals on Prints ... . . . . ....................... . . . . ....................... . . . 295

Streaks or Lines on Prints.............. . . . ....................... . . . . . ....................... . . . ....................... . . 296

Edgewear or Gloss Differential on Prints...... . . . . . ....................... . . ....................... . . . . . ......... 298

Halo or Smudges on Prints ................... . . . . . ....................... . . ....................... . . . . . ................ 298

Image Density...................... . . ....................... . . . . . ....................... . . ........................ . . . . . ..... 299

Image-on-Paper Registration .. . . . ....................... . . ........................ . . . . ....................... . . . ..... 300

Unfused Prints or Fuser Offset..................... . . ........................ . . . . ....................... . . . ........... 301

Trail-Edge Deletions .. ....................... . . ....................... . . . . . ........................ . ....................... 302

PredictPrint Media Manager Troubleshooting.............. . . . ....................... . . . . . ....................... . . . 304

Faults during the Setup Routines in the Stock Wizard ......... . . . ........................ . . . . ............. 304

Unable to Load a Stock in the Stock Wizard .......... . . . . ....................... . . . . ....................... . . . 304

Multifeeds, Misfeeds, and Paper Jams in Trays 6–9...................... . . . . . ....................... . . ..... 304

Paper Curl .... . . ....................... . . . . . ........................ . ........................ . . . . . ....................... . . ..... 306

Uneven Density or Mottle ....................... . . . . . ........................ . . ....................... . . . . . ............ 307

Image Registration, Perpendicularity, Skew, and Magnification ... . ........................ . . . . . ..... 308

Unfused Dry Ink or Toner on Output ..................... . . . . ....................... . . . . ....................... . . . 311

Edge Damage........... . . . ........................ . . . ....................... . . . . ....................... . . . .................. 312

Fold Adjustment ...... . . . . ........................ . . . ....................... . . . . ....................... . . . .................. 313

Xerox®Versant®4100 Press

User Documentation

5

Page 6

Table of Contents

Smear 208 mm from the Lead Edge...................... . . ....................... . . . . . . ....................... . . . 314

Trail Edge Deletions .... . . . . ....................... . . . ....................... . . . . . ....................... . . ................ 315

PredictPrint Media Manager Default Settings....................... . . . . ....................... . . . ............ 315

Paper Jams . . . ....................... . . . . ....................... . . . ........................ . . . ........................ . . . ............ 324

Paper Jam Information . . . . ....................... . . . . . ....................... . . ........................ . . . . ............. 324

Clearing Jams in Area 2 ............. . . . . ....................... . . . ....................... . . . . . ....................... . . . 324

Clearing Jams in Areas 3, 4, and 5........... . . ....................... . . . . . ........................ . . ............... 328

Paper Jams in Trays 1-3 ............. . . . . ....................... . . . ....................... . . . . . ....................... . . . 335

Paper Jams in the Bypass (Tray 5)...................... . ........................ . . . . . ....................... . . ..... 337

Jam Clearance of OHCF ................... . . . ....................... . . . . ........................ . . . ..................... 338

Fault Information . . . ........................ . . ....................... . . . . . ....................... . . ....................... . . . . . . . 343

Obtaining Fault Information from the Press Touch Screen .... . . . . . ....................... . . ............ 343

Fault Messages ....... . . . ....................... . . . . ........................ . . ....................... . . . . . ................... 345

Trays 8 and 9 Troubleshooting ...................... . . ....................... . . . . . ........................ . . ............... 347

Trays 8 and 9 Troubleshooting ................... . . ........................ . . . . ....................... . . . ............ 347

Troubleshooting Finishing Devices ............. . . . . . ....................... . . ....................... . . . . . ................ 354

Interface Decurler Module Troubleshooting...................... . . ....................... . . . . . ................ 354

Inserter Module Troubleshooting . . . ....................... . . . . ....................... . . . . ....................... . . . 357

High Capacity Stacker Troubleshooting............... . . . . ....................... . . . ....................... . . . . . . 363

Crease and Two-Sided Trimmer Troubleshooting................... . . . . ....................... . . . ........... 373

C/Z Folder Troubleshooting ..................... . . . . ....................... . . . ........................ . . . .............. 388

Production Ready Finishers Troubleshooting......................... . . . ....................... . . . . ............ 394

®

SquareFold

Trimmer Troubleshooting. . ........................ . . . . ....................... . . . ................... 418

Troubleshooting Help.................... . . . ........................ . . . . ....................... . . . ....................... . . . . ... 424

Locating the Press Serial Number ....................... . . . . ....................... . . . ....................... . . . . . .. 424

Calling for Service ....................... . . . ....................... . . . . ....................... . . . . ....................... . . . 424

4 For Administrators................................................................................................................ 427

6

Xerox®Versant®4100 Press

User Documentation

Page 7

1

Learning About

This chapter contains:

• Safety........ . . . ........................ . . . ....................... . . . . ....................... . . . . ....................... . . . .................... 8

• Press Overview . . . . . ........................ . . ....................... . . . . . ....................... . . . ....................... . . . . ........... 17

• PredictPrint Media Manager Overview....... . . . ....................... . . . . ........................ . . ........................ . 25

• Print Server Overview ............ . . ....................... . . . . . ....................... . . . ....................... . . . . .................. 26

• Specifications ..... . . ....................... . . . . . ....................... . . . ....................... . . . . ........................ . . .......... 27

• Getting Help .......... . . ....................... . . . . . ........................ . . ....................... . . . . . ....................... . . ....... 29

• Regulatory Information.............. . . . ........................ . . . ....................... . . . . ....................... . . . . ............ 31

• Recycling and Disposal...................... . . . ........................ . . . ........................ . . . ....................... . . . . ..... 39

Xerox®Versant®4100 Press

User Documentation

7

Page 8

Learning About

Safety

Your press and the recommended supplies have been designed and tested to meet strict safety

requirements. Attention to the following information ensures the continued safe operation of your

®

Xerox

PPrroodduucctt SSyymmbboollss

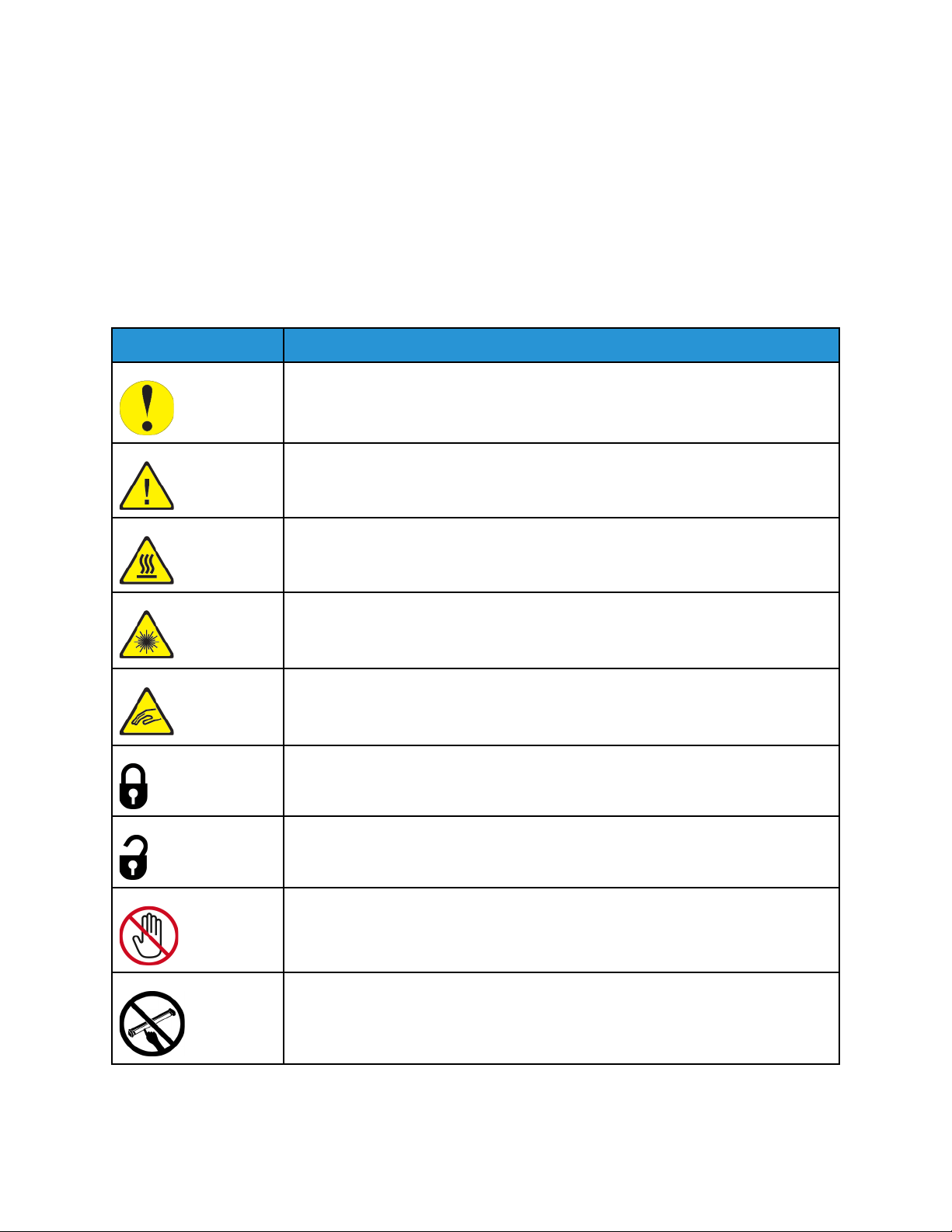

This product uses a variety of symbols; refer to the following table for a list of these symbols and their

definitions.

Press.

Symbol Name and Definition (if required)

Caution

This symbol indicates a mandatory action to take in order to avoid damage to

these areas.

Warning

This symbol alerts users to areas where there is the possibility of personal injury.

Hot Warning

This symbol alerts users to areas where there are heated surfaces which should not

be touched.

Laser Warning

This symbol indicates a laser is being used and alerts the user to refer to the

appropriate safety information.

Pinch Hazard

This warning symbol alerts users to areas where there is the possibility of personal

injury.

Lock

Unlock

Do Not Touch

Do Not Touch the Drum Cartridge

To avoid damage, do not touch the surface of the Drum Cartridge.

8

Xerox®Versant®4100 Press

User Documentation

Page 9

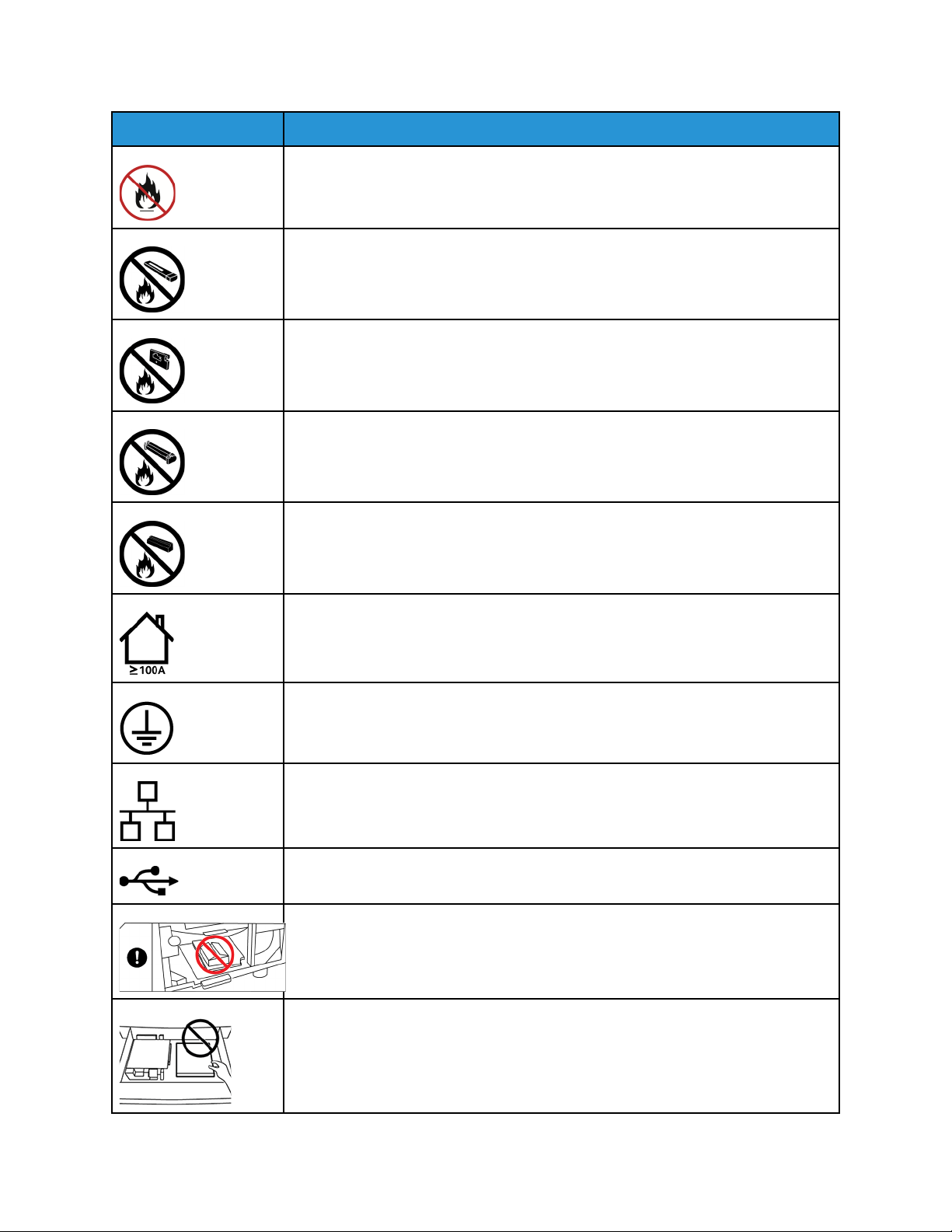

Symbol Name and Definition (if required)

Do Not Dispose into an Open Flame or Incinerate

Do Not Incinerate the Toner Cartridge

Always refer to the recycling instructions for your region or marketplace for correct

disposal information and procedures.

Do Not Incinerate the Toner Waste Bottle

Always refer to the recycling instructions for your region or marketplace for correct

disposal information and procedures.

Do Not Incinerate the Drum Cartridge

Always refer to the recycling instructions for your region or marketplace for correct

disposal information and procedures.

Learning About

Do Not Incinerate the Second Bias Transfer Roll

Always refer to the recycling instructions for your region or marketplace for correct

disposal information and procedures.

Flicker Label with 100 Amp Current

This symbol indicates usage only in premises that have a service current capacity

equal to or greater than 100 Amps per phase.

Ground, Common, or Earth Terminal

LAN

Local Area Network

USB

Universal Serial Bus

Keep Area Clear

Do not store any objects in this location.

Keep Area Clear

Do not store any objects in this location.

Xerox®Versant®4100 Press

User Documentation

9

Page 10

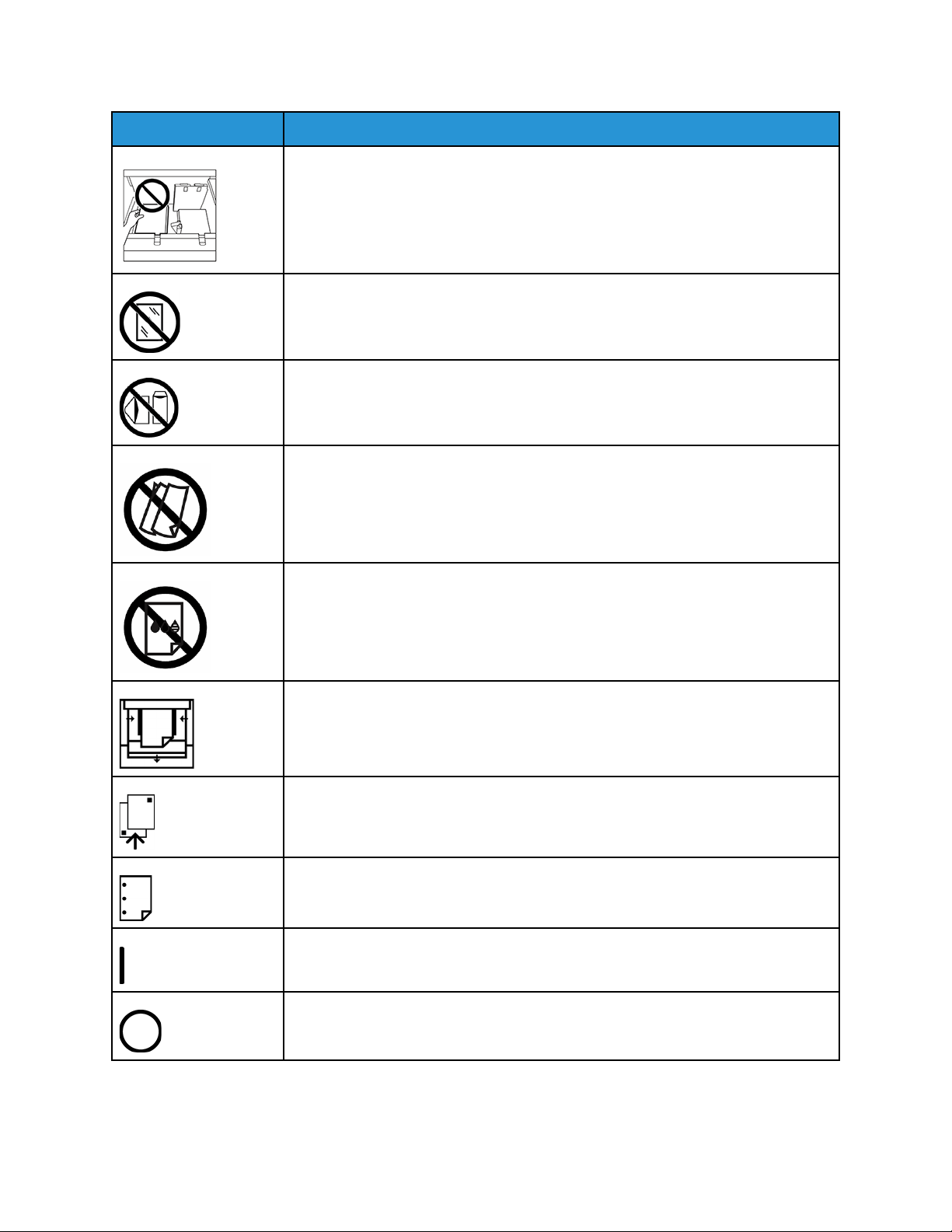

Learning About

Symbol Name and Definition (if required)

Keep Area Clear

Do not store any objects in this location.

Do Not Use Transparencies with a White Strip or Overhead Projector Sheets

with a White Strip

Do Not Use Open Envelopes

Do Not Use Folded, Creased, Curled, or Wrinkled Paper

Do Not Use Ink Jet Paper

Tray Guides Must Touch Media

Load Postcards in the Indicated Direction

Load Hole-punched Paper as Indicated

On

This symbol indicates the main power switch is in the ON position.

Off

10

This symbol indicates the main power switch is in the OFF position.

Xerox®Versant®4100 Press

User Documentation

Page 11

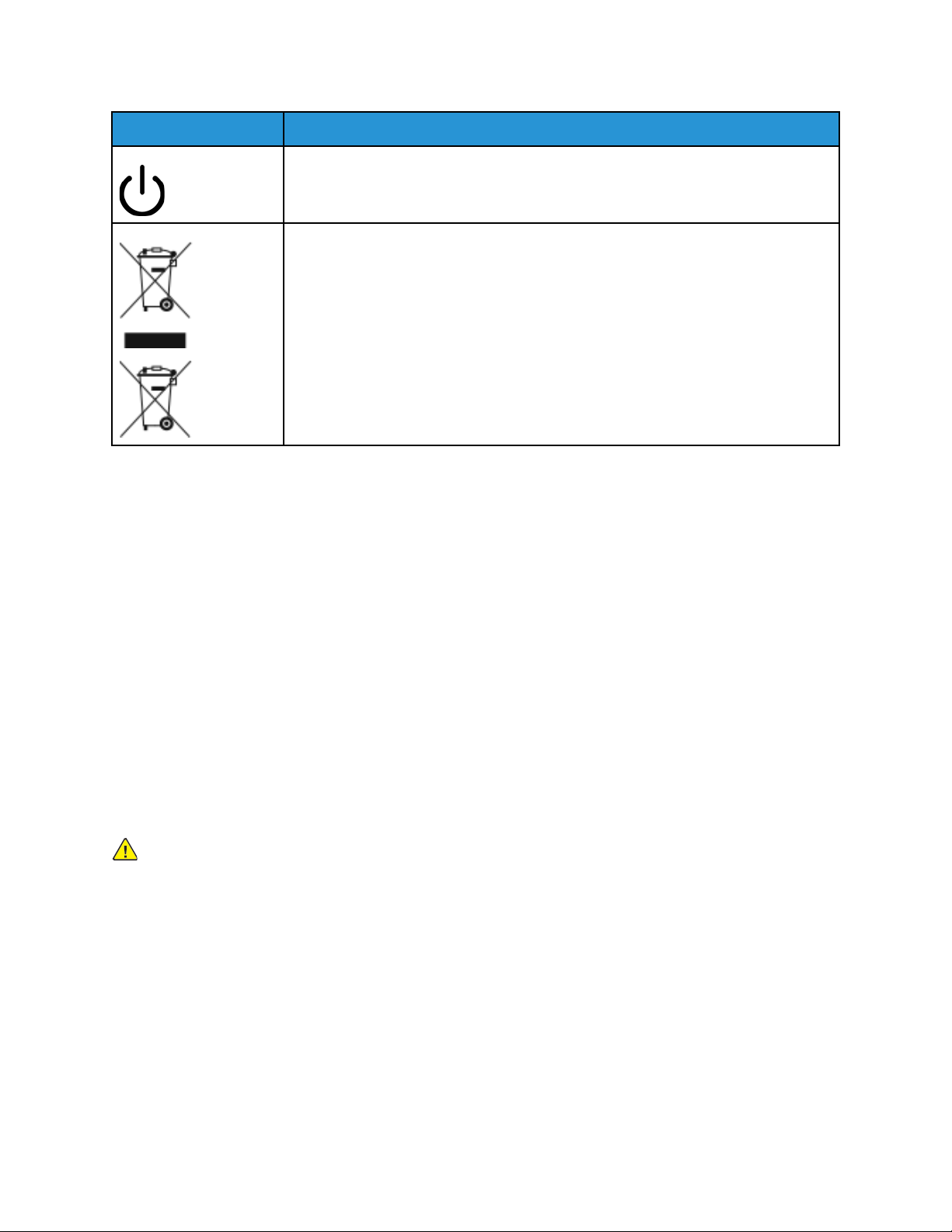

Symbol Name and Definition (if required)

Standby

This symbol indicates the secondary power switch is in the Standby position.

Do Not Dispose in Normal Household Waste Stream

• Application of this symbol is confirmation that you should not dispose of items,

such as Customer Replaceable Units (CRUs), in the normal household waste

stream. You must dispose of these items in compliance with agreed national

procedures.

• This symbol often accompanies batteries and indicates that used electrical and

electronic products and batteries should not be mixed with general household

waste.

• For more information about collection and recycling, please contact your local

municipality, your waste disposal service, or the point of sale where you

purchased the items.

NNoottiicceess aanndd SSaaffeettyy

Learning About

Carefully read the following instructions before operating your press. Refer to these instructions to

ensure the continued safe operation of your press.

Your Xerox

requirements include safety agency evaluation and certification, and compliance with

electromagnetic regulations and established environmental standards.

The safety and environment testing and performance of this product have been verified using Xerox

materials only.

Unauthorized alterations, which can include the addition of new functions or connection of external

devices, can affect the product certification. For more information, contact your Xerox representative.

®

press and supplies are designed and tested to meet strict safety requirements. Safety

EElleeccttrriiccaall SSaaffeettyy

GGeenneerraall GGuuiiddeelliinneess

WARNING: Read the following warnings.

• Do not push objects into slots or openings on the press. Touching a voltage point or shorting out a

part could result in fire or electric shock.

• Do not remove the covers or guards that are fastened with screws unless you are installing

optional equipment and are instructed to do so. Switch off the press when performing these

installations. Disconnect the power cord when removing covers and guards for installing optional

equipment. Except for user-installable options, there are no parts that you can maintain or service

behind these covers.

®

EEmmeerrggeennccyy PPoowweerr OOffff

The following are hazards to your safety:

Xerox

®

Versant®4100 Press

User Documentation

11

Page 12

Learning About

• The power cord is damaged or frayed.

• Liquid is spilled into the press.

• The press is exposed to water.

• The press emits smoke, or the surface is unusually hot.

• The press emits unusual noise or odors.

• The press causes a circuit breaker, fuse, or other safety device to activate.

If any of these conditions occur, do the following:

1. Turn off the printer immediately.

2. Disconnect the power cord from the electrical outlet.

3. Call an authorized service representative.

PPoowweerr CCaabbllee aanndd EElleeccttrriiccaall SSuuppppllyy

• Use the power cords that are supplied with your press.

• Do not remove or modify the power cord.

• The electrical outlet must be near the printer and must be easily accessible.

• Plug the power cable directly into a properly grounded electrical outlet. Ensure that each end of

the cable is connected securely. If you do not know if an outlet is grounded, ask an electrician to

check the outlet.

WARNING: To avoid risk of fire or electrical shock, do not use extension cords, power

strips, or power plugs. Always adhere to national and local building, fire, and electrical

codes regarding length of cord, conductor size, grounding, and protection.

• Do not use a ground adapter plug to connect the press to an electrical outlet that does not have a

ground connection terminal.

• The electrical supply for the press must meet the requirements stated on the data plate located

on the rear of the press. If necessary, consult your local electricity provider or a licensed

electrician.

• Do not place the press in an area where people can step on the power cable.

• Do not place objects on the power cable.

• Do not plug or unplug the power cable while the power switch is in the On position.

• If the power cable becomes frayed or worn, replace it.

• To avoid electrical shock and damage to the cable, grasp the plug when unplugging the power

cable.

DDiissccoonnnneecctt DDeevviiccee

The power cable is the disconnect device for this equipment. To remove all electrical power from the

machine, disconnect the power cable from the electrical outlet.

12

Xerox®Versant®4100 Press

User Documentation

Page 13

Learning About

LLaasseerr SSaaffeettyy

NNoorrtthh AAmmeerriiccaa LLaasseerr SSaaffeettyy

This product complies with safety standards and is certified as a Class 1 Laser product under the

Center for Devices and Radiological Health (CDRH) of the United States Food and Drug

Administration (FDA) implemented regulations for laser products. This product complies with FDA

performance standards for Laser products except for deviations pursuant to Laser Notice No. 50

dated June 24, 2007. These regulations apply to laser products marketed in the United States. The

label on the Production Press indicates compliance with CDRH regulations and must be attached to

laser products marketed in the United States. This product does not emit hazardous laser radiation.

Laser Warning: Use of controls or adjustments or performance of procedures other than those

specified herein may result in hazardous exposure of laser light.

Since radiation emitted inside this product is completely confined within the protective housing and

external covers, the laser beam cannot escape from the Production Press during any phase of the user

operation.

This product contains laser warning labels. These labels are intended for use by the Xerox Service

Representative and are placed on or near panels or shields that require special tools for removal. Do

not remove any of the panels. There are no operator serviceable areas in these covers.

EEuurrooppeeaann UUnniioonn ((EEUU)) LLaasseerr SSaaffeettyy

This product complies with IEC safety standard EN 60825-1: 2014.

The equipment complies with laser product performance standards set by governmental, national,

and international agencies as a Class 1 Laser Product. It does not emit hazardous radiation as the

beam is totally enclosed during all phases of customer operation and maintenance.

WARNING: Use of controls or adjustments or performance of procedures other than those

specified herein may result in hazardous radiation exposure.

If you need additional safety information about the product or Xerox supplied materials, you can

email request to EHS-Europe@xerox.com.

OOppeerraattiioonnaall SSaaffeettyy

Your Xerox equipment and supplies were designed and tested to meet strict safety requirements.

These include safety agency examination, approval, and compliance with established environmental

standards.

Your attention to the following safety guidelines will help ensure the continued safe operation of your

Press:

• Do not remove any trays when the Press is printing.

• Do not open the doors when the Press is printing.

• Keep hands, hair, neckties, and so on, away from the exit and feed rollers.

• Covers, which require tools for removal, protect the hazard areas within the Press. Do not remove

the protective covers.

®

Xerox

Versant®4100 Press

User Documentation

13

Page 14

Learning About

• Do not attempt to remove paper that is jammed deeply inside the Press. Switch off the Press

promptly and contact your local Xerox representative.

• To avoid a tip hazard, do not push or move the device with all of the paper trays extended.

• Do not place the Press in locations susceptible to vibrations.

• For optimum performance, use the Press at the Altitude specified in Environmental Specifications

section of the User Documentation.

• Use the materials and supplies specifically designed for your Press. The use of unsuitable materials

may result in poor performance of the Press and possibly a hazardous situation.

• Follow all warnings and instructions that are marked on or supplied with the Press.

• Place the Press in a room that provides adequate space for ventilation and servicing.

• Place the Press on a level, solid surface, not on a thick pile carpet, that has adequate strength to

support the weight of the Press.

• Do not attempt to move the Press. A leveling device that was lowered when your Press was

installed may damage the carpet or floor.

• Do not set up the Press near a heat source.

• Do not set up the Press in direct sunlight.

• Do not store or operate the Press in an extremely hot, cold, or humid environment.

• Do not set up the Press in line with the cold air flow from an air conditioning system.

• Do not place containers of coffee or other liquid on the Press.

• Do not block or cover the slots and openings on the Press.

• Do not attempt to override any electrical or mechanical interlock devices.

Hot Warning: Be careful when working in areas identified with this warning symbol. These

areas may be very hot and should not be touched.

If you need any additional safety information concerning the Press or materials, contact your Xerox

representative.

OOzzoonnee IInnffoorrmmaattiioonn

This product produces ozone during normal operation. The ozone is heavier than air, and the quantity

is dependent on print volume. Install the system in a well-ventilated room.

For more information, refer to Facts about ozone and Fact about ventilation at www.xerox.com/EHS or

www.xerox.com/EHS-eu.

MMaaiinntteennaannccee IInnffoorrmmaattiioonn

Do not carry out any maintenance on this product which is not described in the customer

documentation.

WARNING: Do not use aerosol cleaners. Aerosol cleaners can be explosive or flammable when

used on electromechanical equipment.

Use supplies and cleaning materials only as directed.

Do not remove the covers or guards that are fastened with screws. Customer service items are not

14

Xerox®Versant®4100 Press

User Documentation

Page 15

Learning About

located behind these covers.

Note: Your Xerox Production Press is equipped with an power saving device to conserve power

when the Production Press is not in use. The Production Press can be left on continuously.

Hot Warning: The metallic surfaces in the fuser area are hot. Use caution when you remove

paper jams from this area and avoid touching any metallic surfaces.

VVaaccuuuumm CClleeaanneerr UUssee ffoorr DDrryy IInnkk//TToonneerr SSppiillllss

Use a broom or a wet cloth to wipe off spilled dry ink/toner. Sweep slowly to minimize generation of

dust during clean up. Avoid using a vacuum. If a vacuum must be used, the unit should be designed

for combustible dusts (for example, explosion rated motor and non-conductive hose).

CCoonnssuummaabbllee IInnffoorrmmaattiioonn

WARNING: Use of non-Xerox supplies is not recommended. The Xerox Warranty, Service

Agreement, and Total Satisfaction Guarantee do not cover damage, malfunction, or

degradation of performance caused by use of non-Xerox supplies, or the use of Xerox supplies

not specified for this Production Press. The Total Satisfaction Guarantee is available in the

United States and Canada. Coverage can vary outside these areas. For more details, contact

your Xerox representative.

WARNING: When handling cartridges such as ink or fuser, avoid skin or eye contact. Eye

contact can cause irritation and inflammation. Do not attempt to disassemble the cartridge.

This can increase the risk of skin or eye contact.

Store all consumables in accordance with the instructions given on the package or container.

Keep all consumables away from the reach of children.

Never throw dry ink/toner, print cartridges, or dry ink/toner containers into an open flame.

For information on Xerox

• For the United States or Canada: www.xerox.com/recycling

• For Europe and other markets: www.xerox.com/recycling-eu

®

supplies recycling programs, go to:

BBaatttteerryy SSaaffeettyy

One or more circuit boards in this printer contain a lithium battery.

Do not attempt to repair or replace the lithium battery. If there is a problem with the battery, contact

an authorized service representative to correct the problem.

The lithium battery in this printer contains Perchlorate material. For information about the special

handling procedures associated with Perchlorate material, refer to www.dtsc.ca.gov/hazardouswaste/

perchlorate.

WARNING: If the battery on a circuit board is installed incorrectly, there is a risk of explosion.

Xerox

®

Versant®4100 Press

User Documentation

15

Page 16

Learning About

EEnnvviirroonnmmeennttaall,, HHeeaalltthh,, aanndd SSaaffeettyy CCoonnttaacctt

IInnffoorrmmaattiioonn

For more information on Environment, Health, and Safety in relation to this Xerox®product and

supplies, contact the following:

• United States and Canada: 1-800-ASK-XEROX (1-800-275-9376)

• Email request to Europe: EHS-Europe@xerox.com.

• Web address: www.xerox.com/environment or www.xerox.com/environment_europe.

16

Xerox®Versant®4100 Press

User Documentation

Page 17

Learning About

Press Overview

The Xerox®Versant®4100 Press is a full color or black and white, auto-duplex press that operates at a

speed of 100 prints per minute, when printing on 8.5 x 11 inch or A4 paper.

The system configuration consists of the Advanced Oversized High Capacity Feeder (Trays 6 and 7),

the print engine with internal feeding trays (Trays 1-3), and an embedded Control Panel and touch

screen (the user interface). A print server is also part of the configuration, which includes the

PredictPrint Media Manager application used for stock and tray setup, and print job submission. An

Offset Catch Tray can be connected to the press or other optional inline finishing devices are

available.

Note: With the exception of the Offset Catch Tray, all other finishing devices require the

Interface Decurler Module.

The press includes the 4 dry ink/toner and drum cartridges, transfer belt and fuser or ROS system, Full

Width Array calibration feature, decurler, registration and paper path, and paper inverter.

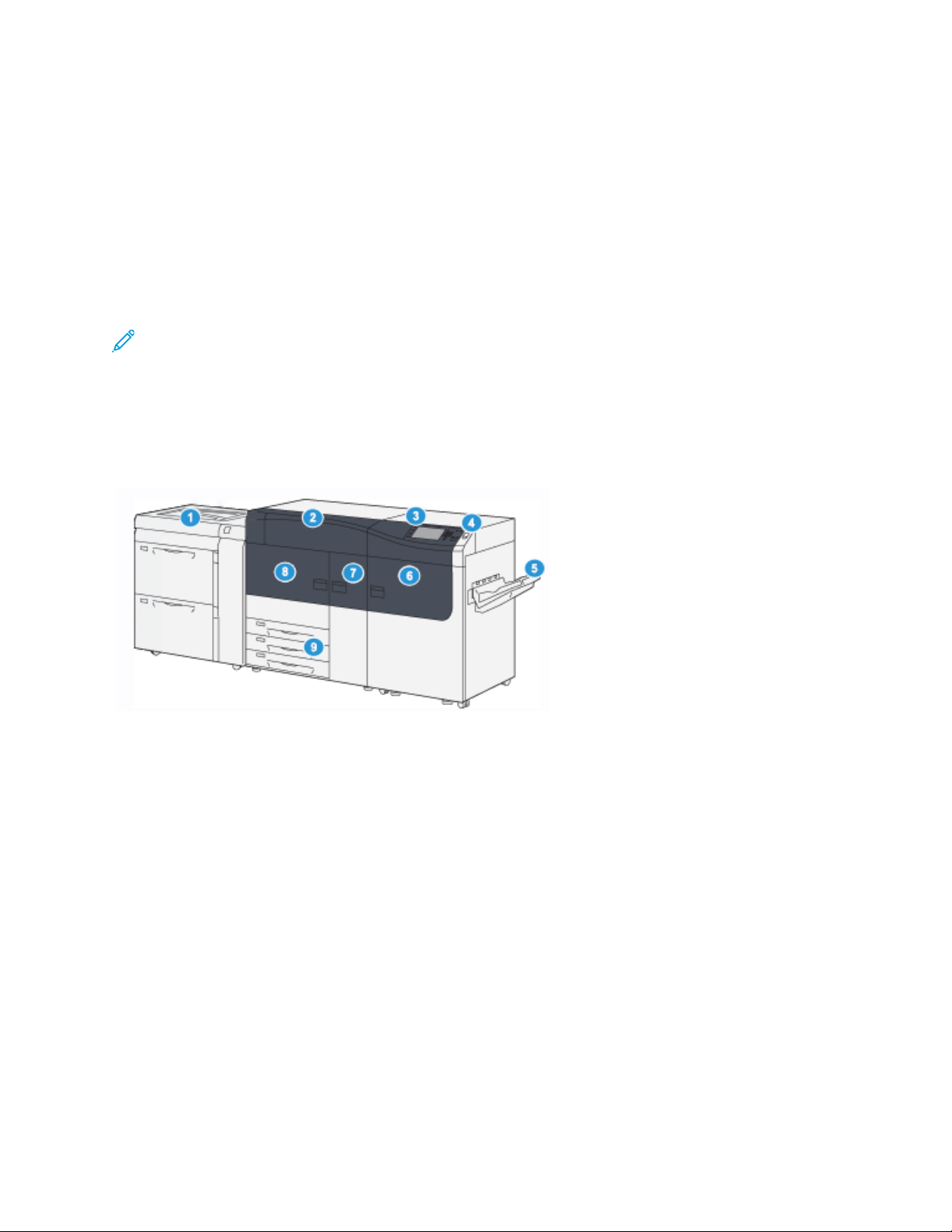

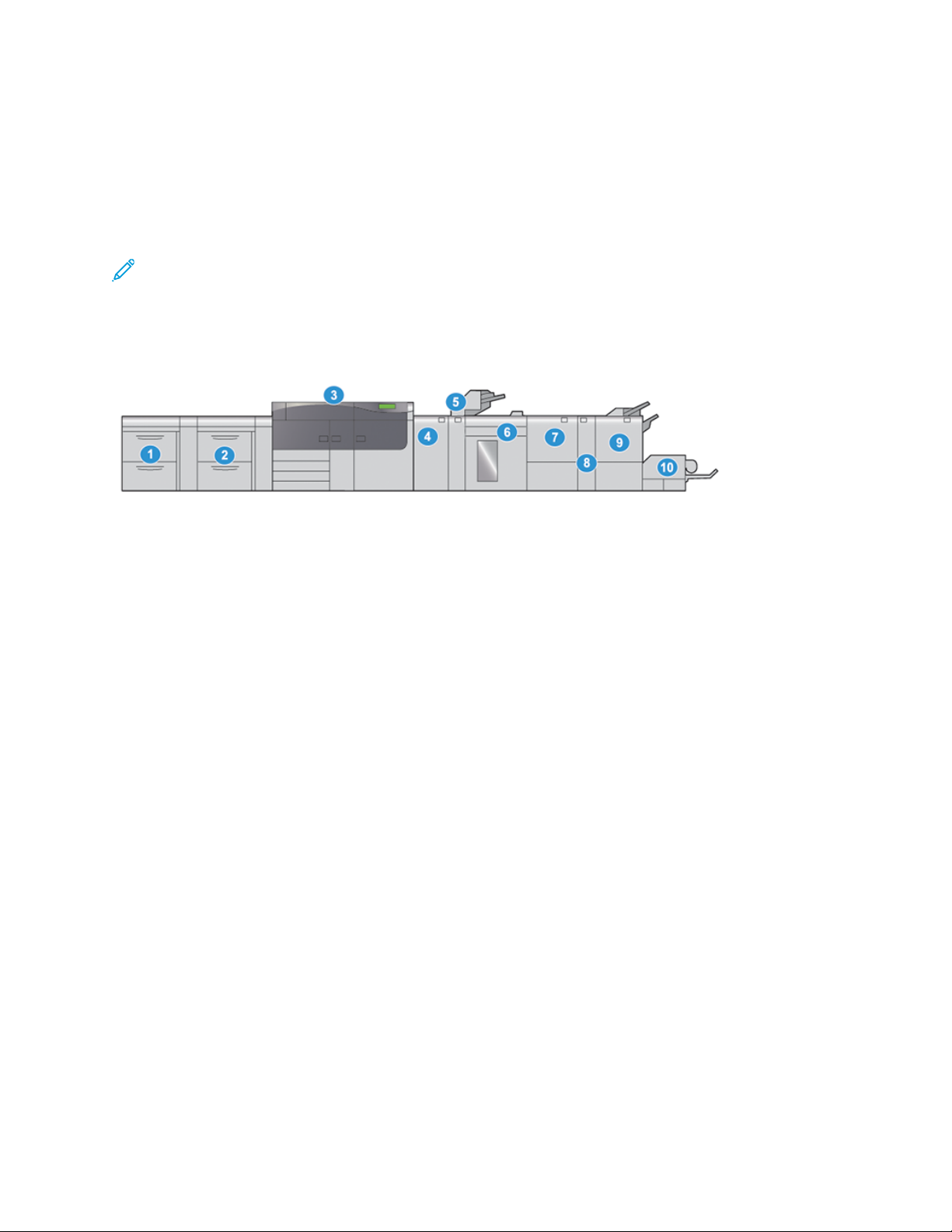

PPrreessss CCoommppoonneennttss

1. Advanced Oversized High Capacity Feeder

(Trays 6 and 7), with Tray 5 (Bypass)

2. Dry Ink/Toner Cover

3. Control Panel and Touch Screen

4. Power Button

5. Offset Catch Tray (OCT)

6. Right Front Door

7. Center Front Door

8. Left Front Door

9. Paper Trays 1, 2, and 3

®

Xerox

Versant®4100 Press

User Documentation

17

Page 18

Learning About

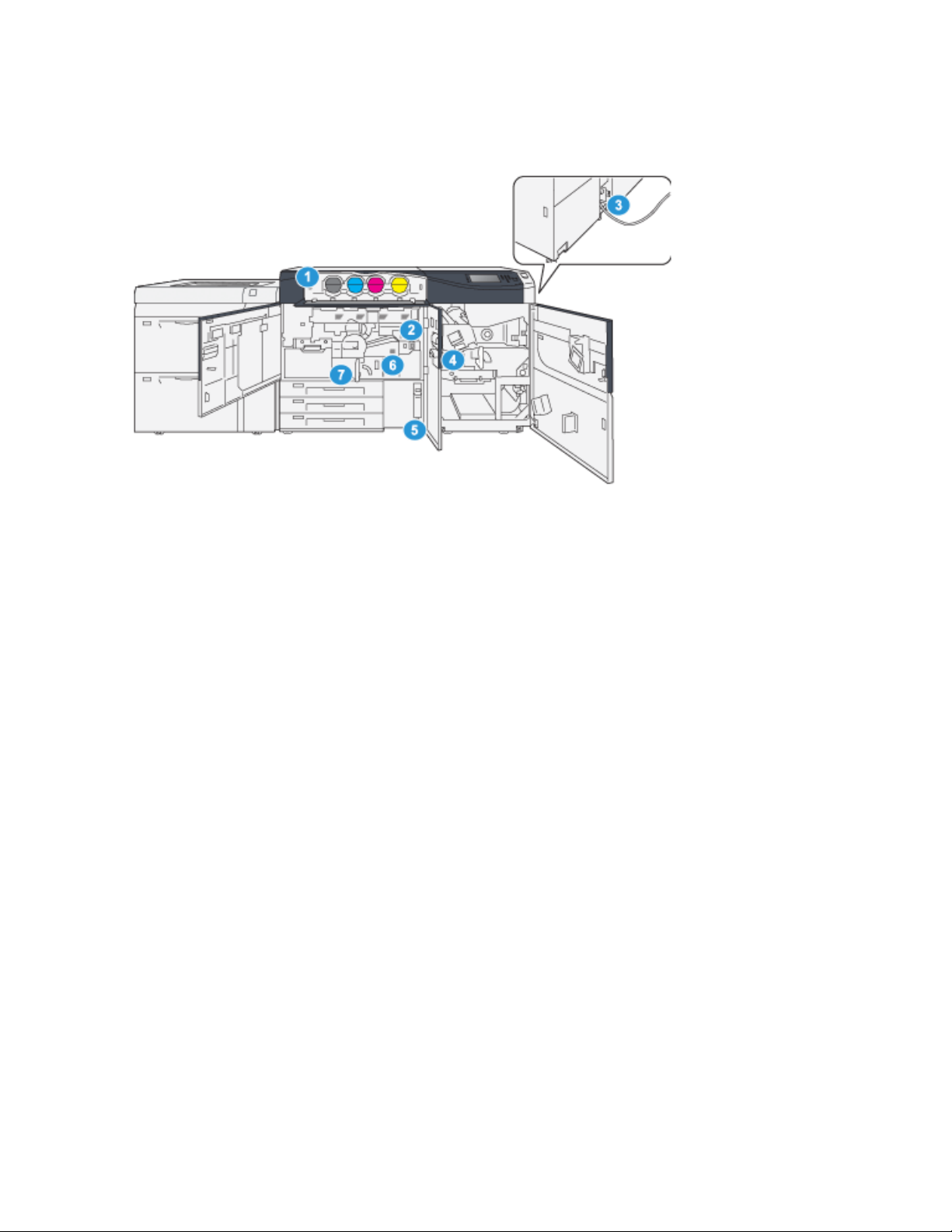

IInntteerrnnaall CCoommppoonneennttss

1. Dry Ink/Toner Cartridges

2. Main Power Switch

3. Circuit Breaker Switch (on rear of press)

4. Paper Cooling Module

5. Dry Ink/Toner Waste Bottle

6. Fuser Module

7. Transfer Module

18

Xerox®Versant®4100 Press

User Documentation

Page 19

Learning About

LLooccaattiinngg tthhee PPrreessss SSeerriiaall NNuummbbeerr

The press serial number can be accessed from the User Interface (UI) or by locating the serial number

plate on the inside frame of the first feeder tray (Tray 1).

1. Press the Machine Status button on the UI.

2. From the Machine Status screen, ensure that the Machine Information tab is displayed.

The press serial number is displayed under General Information.

3. If there is a loss of power and it is not possible to access the Machine Status screen, the press

serial number can also be found on the inside frame of the press near paper Tray 1:

a. At the press, fully open paper Tray 1.

b. At the left of the feeder tray, on the press frame, locate the plate with the serial number

(SER#).

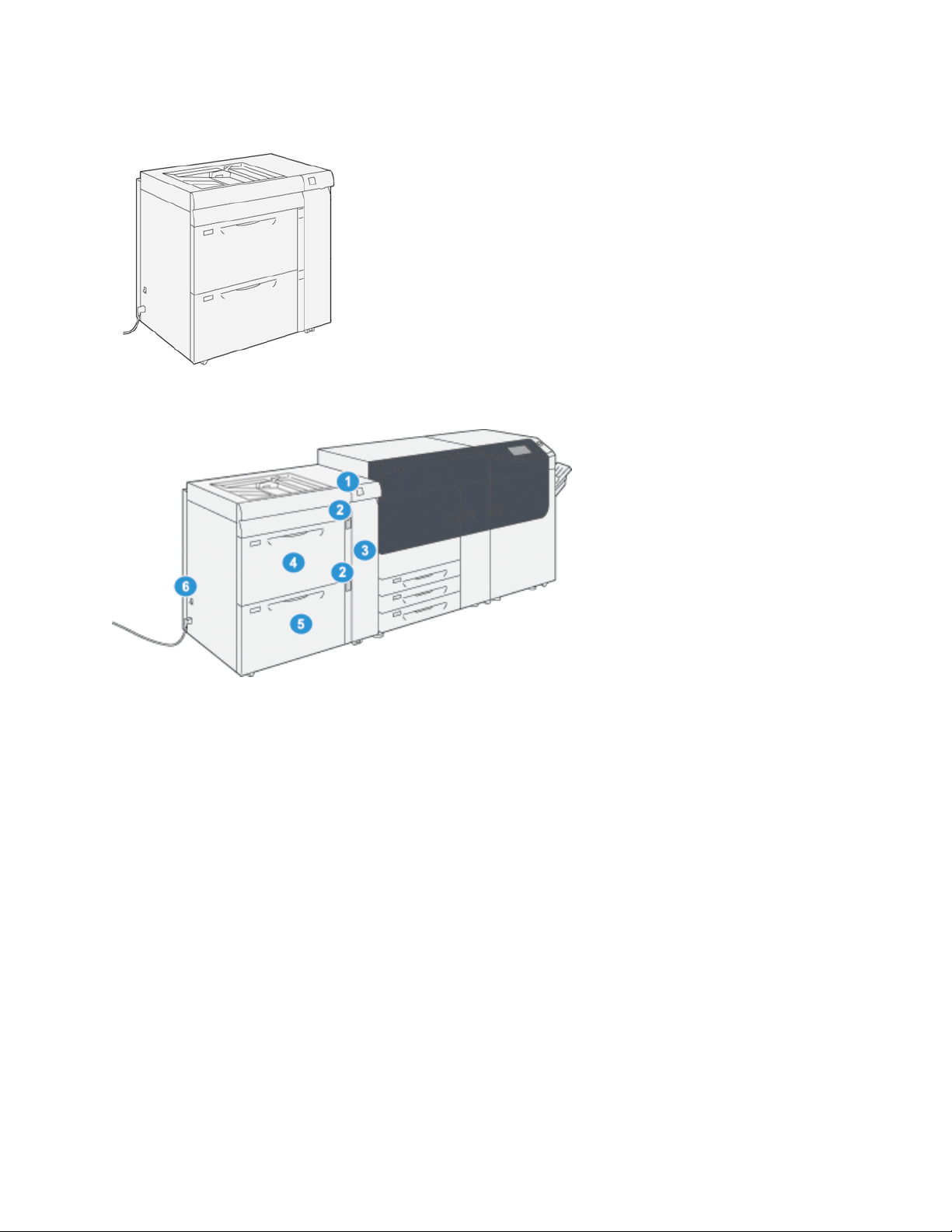

AAddvvaanncceedd OOvveerrssiizzeedd HHiigghh CCaappaacciittyy FFeeeeddeerr ((TTrraayyss 66 aanndd 77))

Tip: The Advanced Oversized High Capacity Feeder is part of the standard press configuration.

The Advanced Oversized High Capacity Feeder contains Trays 6 and 7. These trays feed a variety of

stock sizes, including standard, heavyweight, and large-sized stocks up to 330 x 488 mm (13 x 19.2

in.) in size and weighing between 52 g/m

uncoated stock.

Note: For Versant®4100 Press, the Advanced Oversized High Capacity Feeder (Trays 6 and 7)

includes the Tray 5 (Bypass). It is a part of the standard press configuration.

The following illustration show the Trays 6 and 7 with the Tray 5 (Bypass).

2

and 400 g/m2. Each tray holds 2,000 sheets of coated and

Xerox

®

Versant®4100 Press

User Documentation

19

Page 20

Learning About

Trays 6 and 7 with Tray 5

Trays 6 and 7 Components

1. Paper Jam and Error Indicator Panel

2. Paper Level Indicators

3. Feeder Front Cover

20

Xerox®Versant®4100 Press

User Documentation

4. Tray 6

5. Tray 7

6. Circuit Breaker Switch

Page 21

Learning About

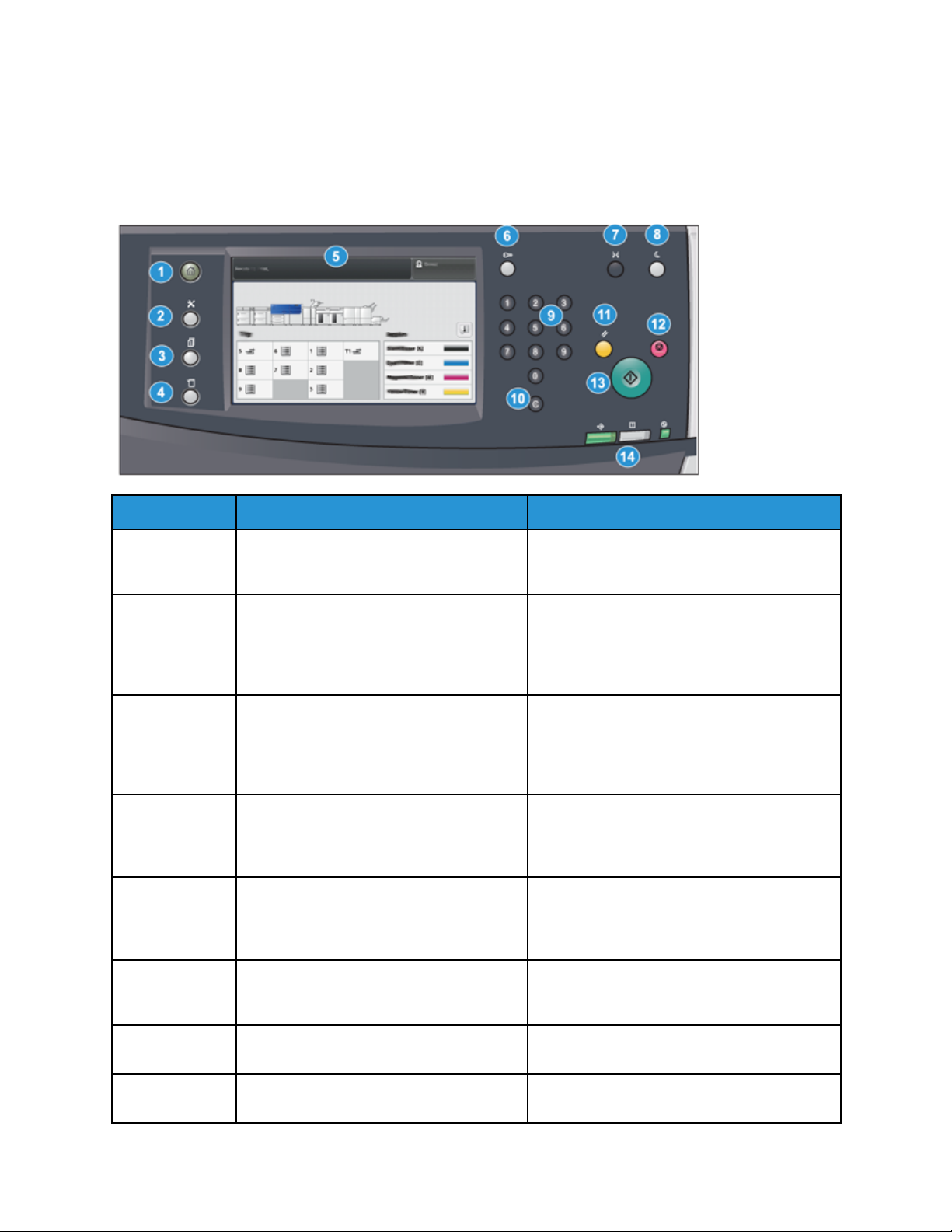

CCoonnttrrooll PPaanneell

The embedded Control Panel on the press includes an LCD touch screen, keypad and feature buttons.

The touch screen displays instructions, faults, and informational messages. Select the Control Panel

buttons to log in, perform job setup functions, and view job, press, and supply statuses.

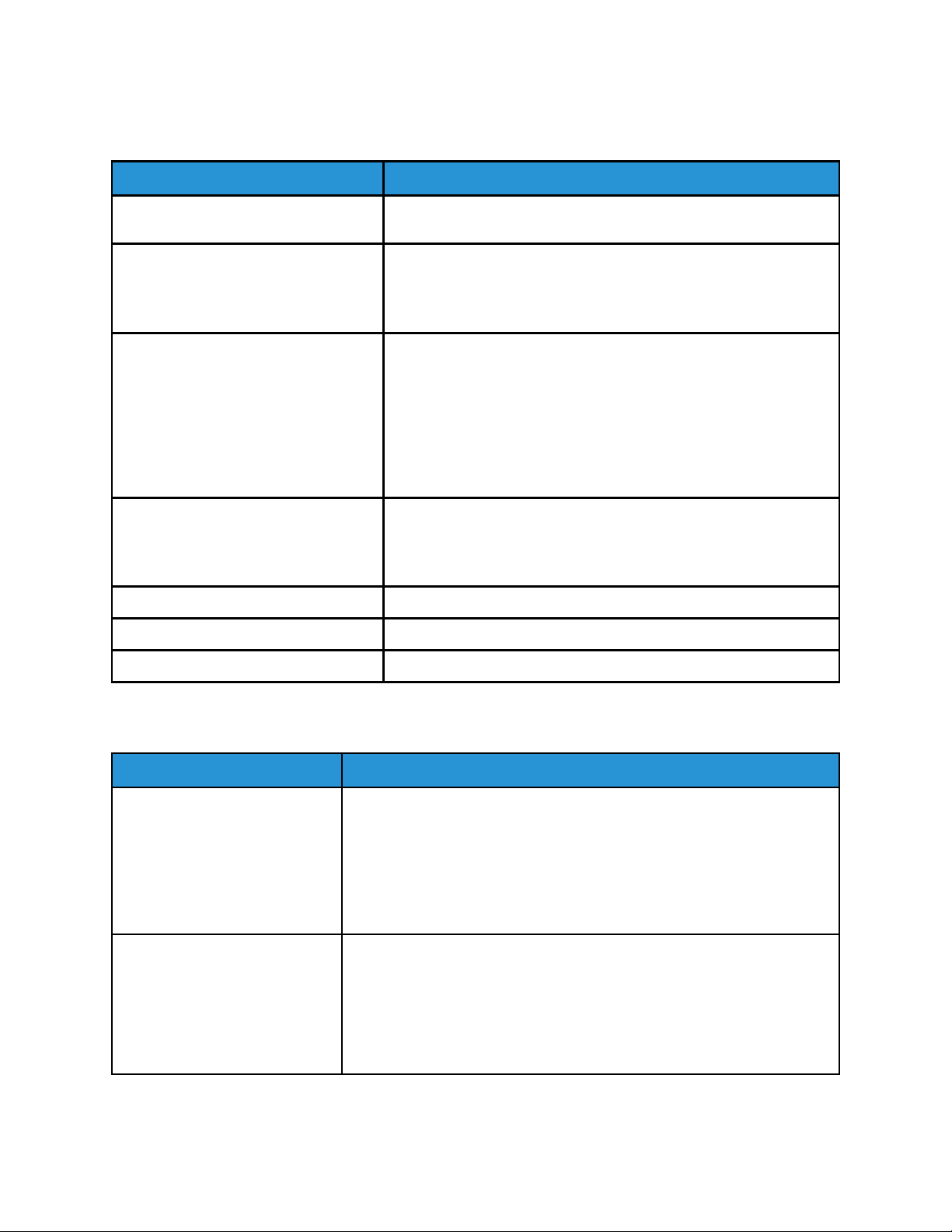

Item Number Name

1 Home button Displays the main menu. Provides access to

2 Tools button Displays the Tools mode screen. For the

3 Job Status button Use to check the progress of active jobs and

4 Machine Status button Use to check the press configuration, the

5 Touch Screen Directly touch the screen to select and set

Description

view the supplies and trays available on the

press and the status of consumables.

operator, select the Tools icon to view billing

information and to perform press calibration

such as Full Width Array color uniformity

adjustments.

detailed information about completed jobs or

pending jobs. This area also allows you to

delete a job (cancel printing) and to pause

jobs.

software version, the press billing meter and

counter information, and to access and print

job history or error reports.

features. Displays instructional and

informational messages, fault clearance

procedures and general press information.

6 Log In / Out button Use to log in and out of Administrator mode

or Authentication mode with user ID and

password.

7 Language button Use to select a different language for the

touch screen options.

8 Power Saver button Use this button if the press has been inactive

and the touch screen is dark (system is in

Xerox®Versant®4100 Press

User Documentation

21

Page 22

Learning About

Item Number Name

9 Numeric Keypad Use to enter alphanumeric characters. The

10 Cancel Entry button Use this button to cancel the previous entry

11 Clear All button Use this button to return all selections to the

12 Stop button Press to stop and pause the print job in

13 Start button Press to start and print a selected report. Also

14 Press Status Lights The three indicator lights that identify: data

Description

Power Saver mode). This button manually

exits the system from Power Saver mode; it

does not place the press in Energy Save

mode.

‘C’ Cancel Entry cancels the previous entry

made on the numeric keypad.

made on the numeric keypad.

same state as when the press was powered

on. Press once to clear a current entry. Press

twice to return to default settings.

progress.

used by the Customer Service Engineer

during diagnostic routine procedures.

transmission in progress, the press is

experiencing an error, and main power is on.

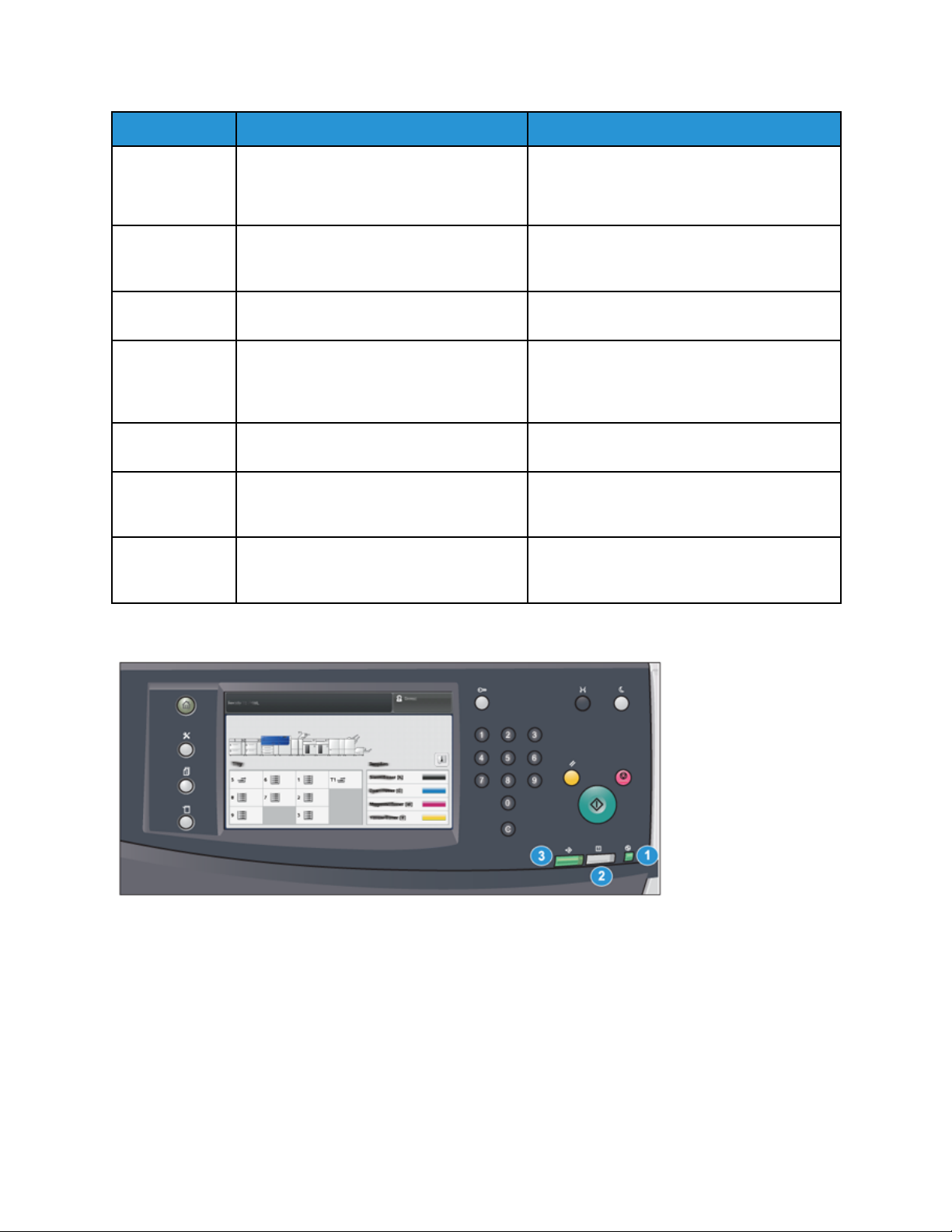

Status Lights

There are three status lights on the press directly below the Control Panel. From right to left, they are:

22

Xerox®Versant®4100 Press

User Documentation

Page 23

Item

Number Name

1 Main Power Status LED This is a steady green light indicating

2 Error Status LED This is a steady orange light indicating

3 Data Transmission Status LED This is a flashing green light indicating

Description

the main power to the system is on.

the press is experiencing faults and

errors.

that the transmission of an incoming

print job is in process.

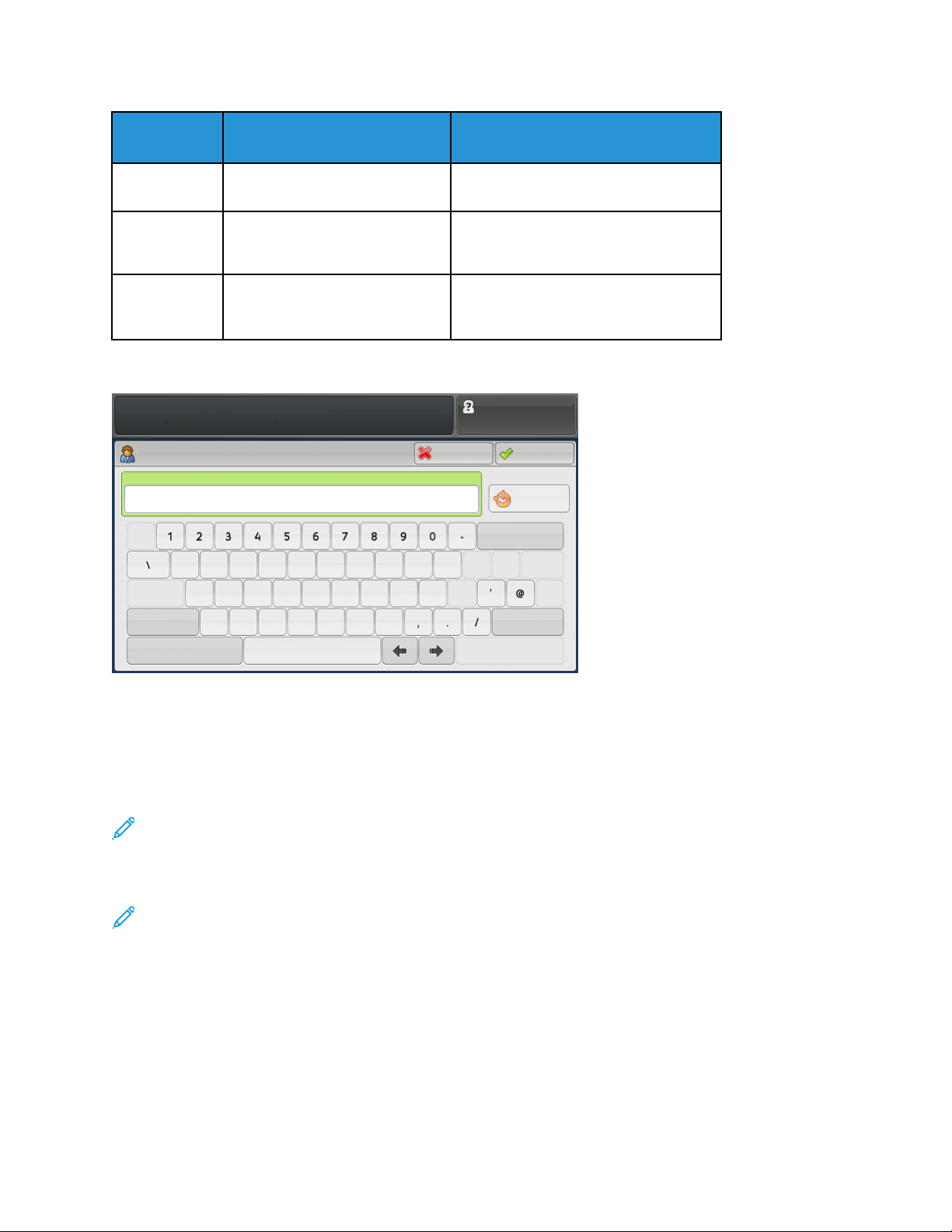

Login

Learning About

There are two login levels:

• Guest or Operator: This is the default login user. You are automatically logged in as Guest.

• Administrator: This login level is required to customize the system and network defaults for your

press and to customize particular print jobs by setting or changing parameters for certain features.

Press the Guest button or the Log in button on the Control Panel to access the Login screen.

Note: Refer to the System Administrator Guide for more information on the Administrator

features.

Language

Note: The number of languages available on your system depends on what was installed

during the initial installation process.

Selecting a particular Language button immediately changes the language. No confirmation is

required.

Changing the Language

1. Press the Language button on the press Control Panel.

The Language window displays on the touch screen.

®

Xerox

Versant®4100 Press

User Documentation

23

Page 24

Learning About

2. Select the desired language from the list and select Save.

The language on the screen changes to the new language and closes the Language window.

3. Select the Cancel button to return to the main screen.

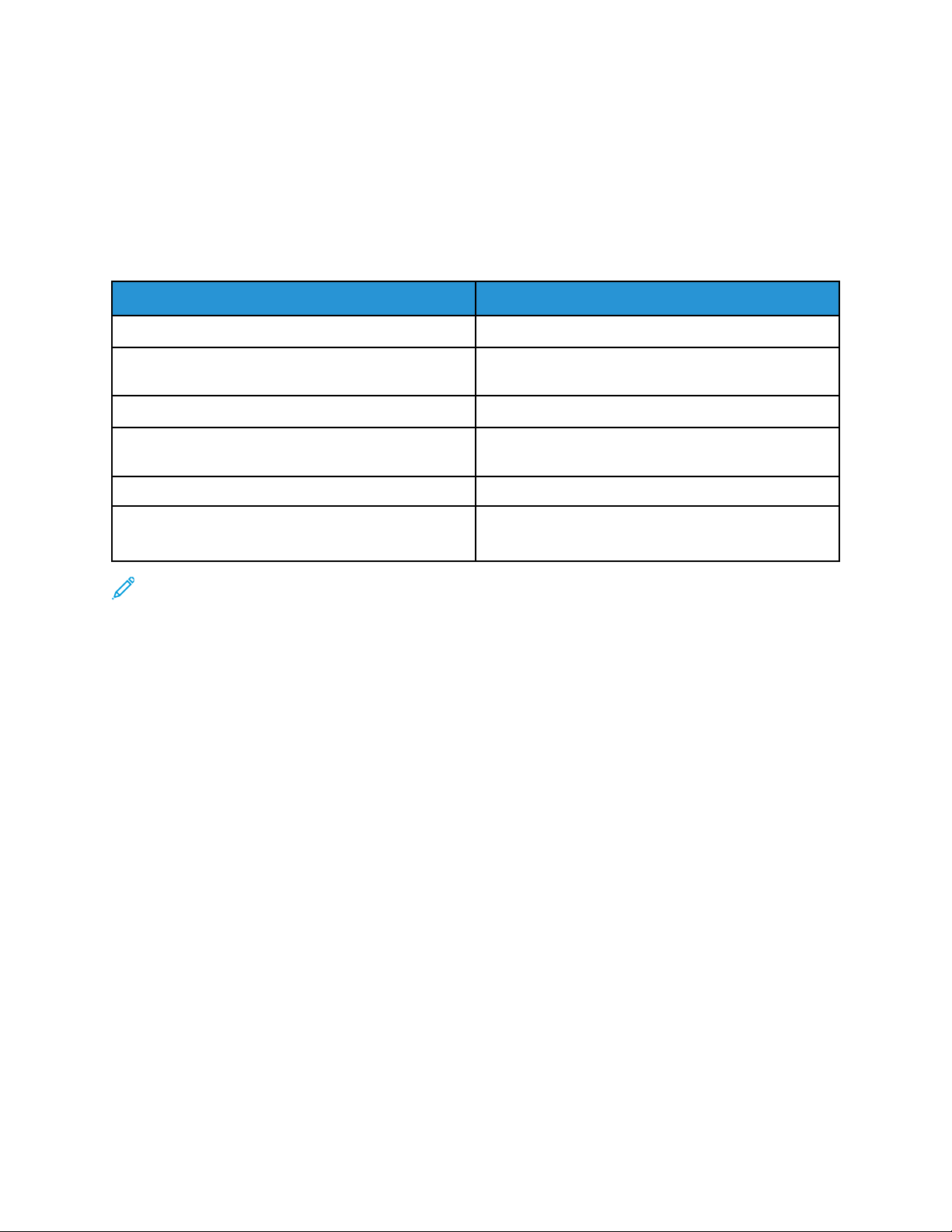

FFuullll SSyysstteemm CCoonnffiigguurraattiioonn

Note: Full system configurations will vary depending on which optional devices are attached to

the press. For detailed information about an optional device, refer to the appropriate device

chapter in this guide.

The following illustration shows an example of a full system configuration with optional devices

attached. This is only one example.

1. Dual Advanced Oversized High Capacity

Feeder (Trays 8 and 9)*

2. Advanced Oversized High Capacity Feeder

(Trays 6 and 7), with Tray 5 (Bypass)

3. Press

4. Interface Decurler Module (IDM)*

5. Inserter*

* Numbers 1 and 4-10 indicate optional devices.

6. High Capacity Stacker*

7. Crease and Two-sided Trimmer*

8. C/Z Folder*

9. Production Ready (PR) Booklet Maker

Finisher*

10. SquareFold

®

Trimmer*

24

Xerox®Versant®4100 Press

User Documentation

Page 25

Learning About

PredictPrint Media Manager Overview

PredictPrint Media Manager is a hardware and software solution for Xerox®Production Presses that

provides simple, step-by-step guidance through setup routines for printing optimization. With the

Stock Wizard feature of PredictPrint Media Manager, and with the use of a handheld barcode

scanner, you can do the following:

• Program the paper trays with specific stock properties for a job

• Perform print engine adjustments to optimize print performance for the stock

• Complete Calibration and Profiling for the stock to maximize image quality and color output

For Versant Presses, the PredictPrint Media Manager application is on the EX or EX-P Print Server,

powered by Fiery

application manages the stocks that the press uses. The PredictPrint Media Manager application

connects to the PredictPrint Cloud server when a barcode is scanned, and retrieves all of the stock

properties and recommended setup routines.

®

. With the help of PredictPrint Cloud Server, the PredictPrint Media Manager

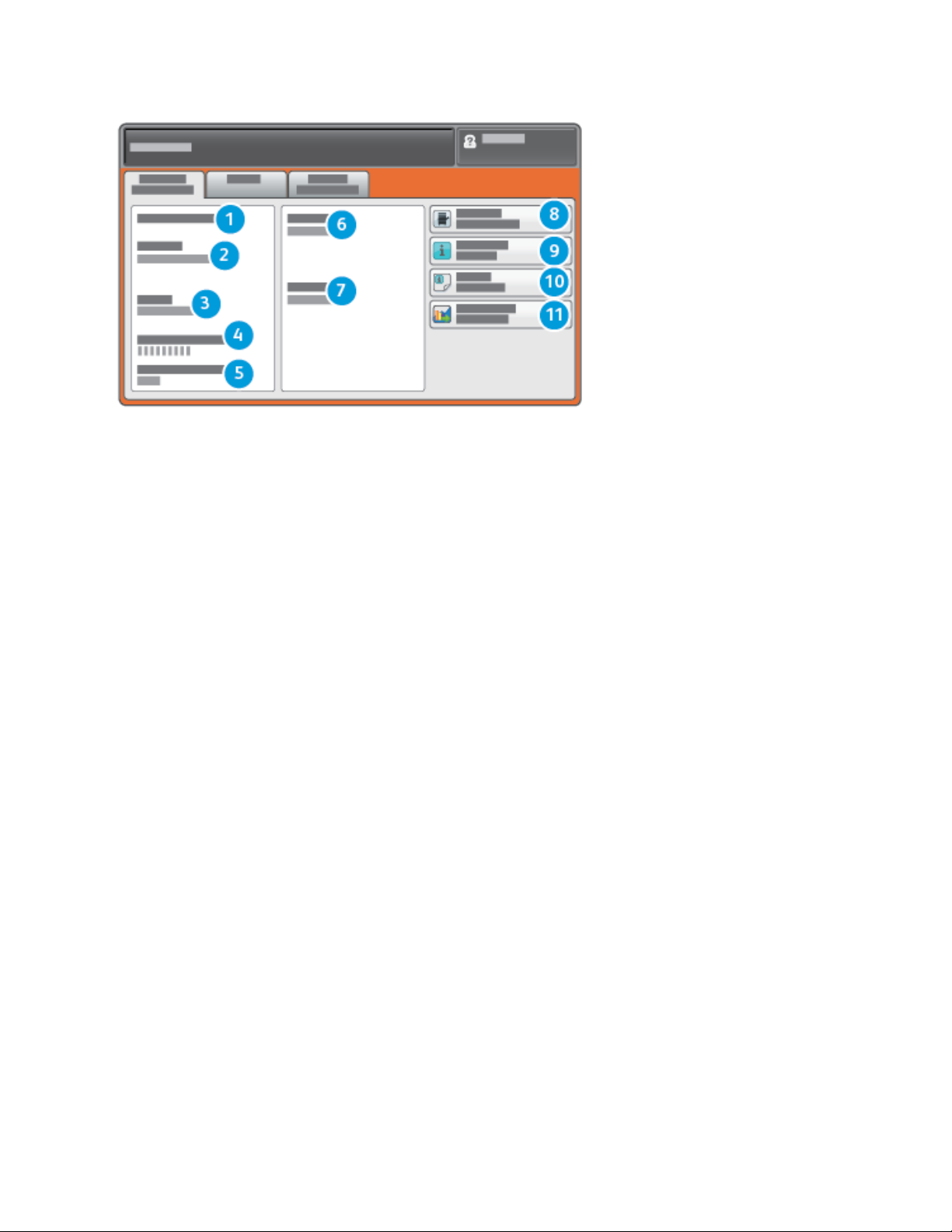

1. Main Menu

2. Login (for Administrator access)

3. Trays

4. Profiles

For more information on PredictPrint Media Manager, refer to PredictPrint Media Manager.

5. Stock Library

6. Stock Wizard

7. Display screen

Xerox

®

Versant®4100 Press

User Documentation

25

Page 26

Learning About

Print Server Overview

The Production Press is configured with a digital print server, the Xerox®EX or EX-P Print Server,

Powered by Fiery

®

.

One of the following print servers can be used with your press:

• Xerox

®

EX 4100 Print Server, Powered by Fiery

• Xerox®EX-P 4100 Print Server, Powered by Fiery

®

®

The print server accepts, processes, and manages document files for job submission to the press.

The PredictPrint Media Manager application is installed on the print server. For information on setting

up stocks and custom profiles, and paper trays that the press uses, refer to PredictPrint Media

Manager.

Note: For detailed information on your specific print server, refer to the customer

documentation that was delivered with it.

26

Xerox®Versant®4100 Press

User Documentation

Page 27

Specifications

Learning About

Feature

Rated Speed 100 pages per minute of Letter (8.5 x 11 in.) or A4 paper size (full

Print Modes Two print modes are supported and are specified at the print

Maximum Printable Area

Printing Resolution

Paper Size Ranges For information, refer to Paper Size Ranges.

Description

color or black only)

server:

• 4 Color Mode: Cyan, Magenta, Yellow, Black (CMYK)

• Black and White Mode (Grayscale)

• Default Border: 4 mm on the leading edge and 2 mm on the

remaining sides

• Print Image Quality Assurance Area: 317 mm x 482 mm (12.48

x 18.98 in.)

• For Trays 1, 2 or 3: 323 x 482 mm (12.72 x 18.98 in.)

• Tray 5 (Bypass): 326 x 482 mm (12.83 x 18.98 in.)

• Advanced High Capacity Feeder (Trays 6 and 7): 326 x 482 mm

(12.83 x 18.98 in.)

• Print Engine Imaging Resolution: 2400 x 2400 dots-per-inch

(dpi)

• Print Server Raster-Image-Processing (RIP) Resolution (print

server to print engine): 1200 x 1200 dpi

Paper Tray Information For information, refer to Paper Tray Information.

Productivity Information For information, refer to Press Productivity Information.

PPeerrffoorrmmaannccee SSppeecciiffiiccaattiioonnss

Feature

Press Warmup Time The press warmup times vary depending on the current state or mode of

Time of First Print Out of Press This is the minimum time from when the press receives a job from the

Description

the press. Warmup times are listed as follows:

• From a cold start (power on or power saver mode), less than 5 minutes

• From Sleep Mode or Power Saver, less than 5 minutes

• From Standby Mode, less than 1 minute

• When switching print modes (such as from black only to full color),

approximately 2 minutes

print server to the time when the trail edge of the first print passes

through the press exit sensor.

• From a cold start (power on or power saver), the system takes less

than 5 minutes to start printing

• From standby mode, the system usually takes less than 1 minute to

the start printing

Xerox®Versant®4100 Press

User Documentation

27

Page 28

Learning About

EEnnvviirroonnmmeennttaall SSppeecciiffiiccaattiioonnss

The press enters the Power Saver mode after 15 minutes of inactivity. The factory default time of 15

minutes can be changed when you are logged in as the administrator. For more information, refer to

the System Administrator Guide.

For the press system to operate, the temperature and relative humidity of the room where the press is

located needs to be within the minimum and maximum allowable temperature and relative humidity

limits.

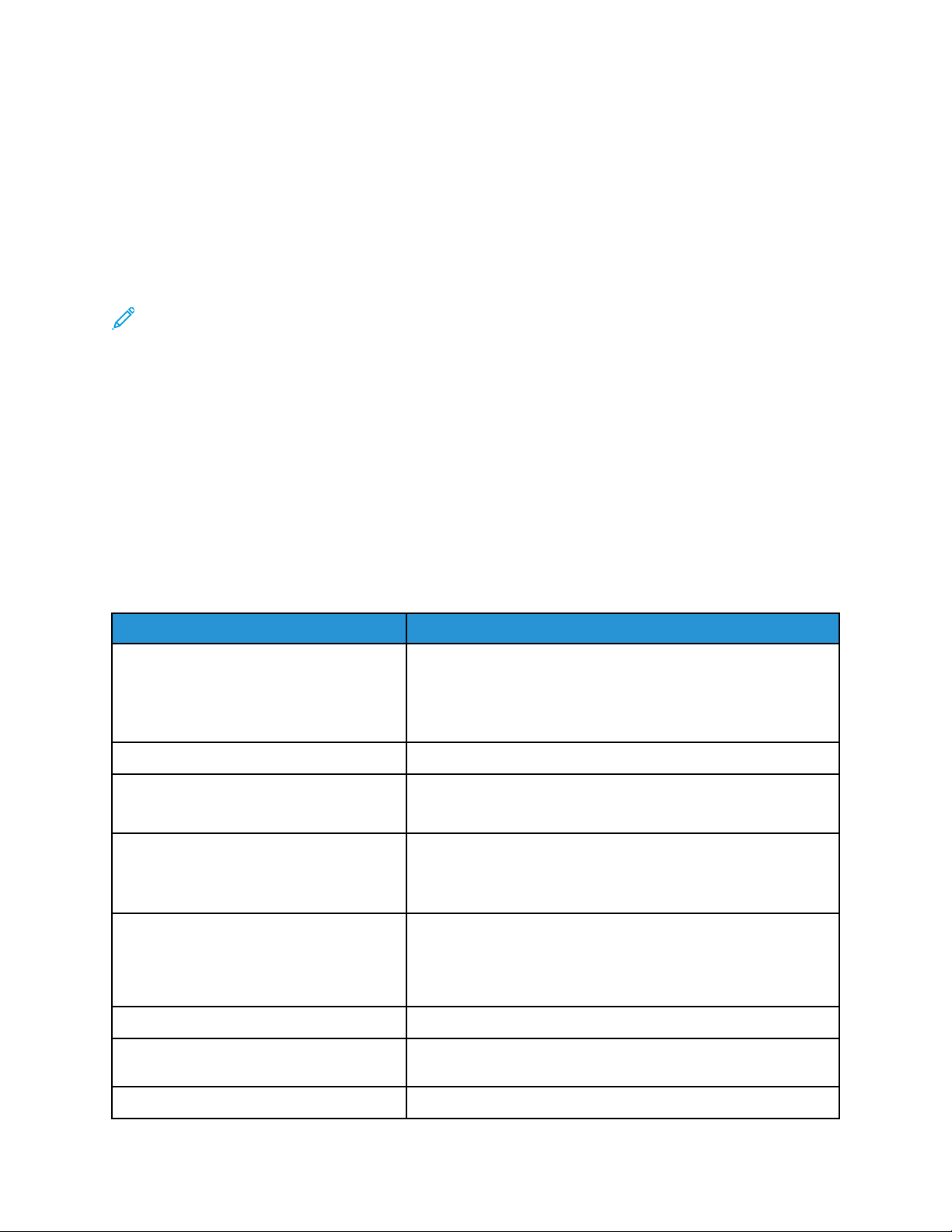

Operating Environment

Required Temperature Range 10–32° C (50–90° F)

Ambient temperature for optimal image quality and

paper handling performance

Required Relative Humidity Range 15%–85% Relative Humidity (RH)

Relative humidity for optimal image quality and

paper handling performance

Altitude (above sea level) 0–2500 meters (0–8200 feet)

Sound Pressure Levels

Versant 4100 Press

20–24° C (68–76° F)

45% RH

• Running: 65 dBA

• Standby: 40.8 dBA

Note: The press can operate outside of this range, but the performance cannot be guaranteed.

28

Xerox®Versant®4100 Press

User Documentation

Page 29

Learning About

Getting Help

HHeellpp oonn tthhee XXeerrooxx WWeebbssiittee

For technical support, Xerox supplies, customer documentation, and answers to frequently-asked

questions, go to www.xerox.com. Find the latest documentation and online support under Customer

Support→All Support and Drivers. Use the Contact Us link for specific contact information and

telephone numbers in your area.

Note: Periodically check the website for the latest information on your press.

It is helpful to know your press serial number before calling for support. The press serial number is

shown on the Machine Information tab: Machine Status→Machine Information.

PPrriinntt SSeerrvveerr DDooccuummeennttaattiioonn

The EX or EX-P Print Server Help menu on the Command WorkStation window is designed to provide

information on specific workflows when using the Command WorkStation. Additional user

documentation supplied by EFI Fiery is available from www.xerox.com in the Support and Drivers link

for your press.

MMoorree IInnffoorrmmaattiioonn

Refer to the following sources for more information about your press and its capabilities.

Resource Location

Other documentation for your printer Print Server Documentation: For more information, refer to the

documentation, such as USB, that shipped with the print server.

After installation is complete, it is recommended that you or

your System Administrator print the print server documentation

for later reference www.xerox.com/VERSANT_4100docs.

PredictPrint Media Manager Cloud Server Go to https://www.xerox.com/predictprintmedia.

Recommended Media List United States: www.xerox.com/rmlna

Europe: www.xerox.com/rmleu

Technical support information for your

printer; including online technical support,

Online Support Assistant, and print driver

downloads.

Information Pages To print from the control panel, press the Machine Status

Go to www.xerox.com/VERSANT_4100support.

button, then touch Machine Information.

To print from the CentreWare

then on the Online Support, click Connect.

®

Internet Services, click Support,

Order supplies for your printer Go to www.xerox.com/office/VERSANT_4100supplies.

Local sales and Technical Customer

Support

Printer registration Go to www.xerox.com/register.

Go to www.xerox.com/office/worldcontacts.

Xerox®Versant®4100 Press

User Documentation

29

Page 30

Learning About

It is recommended that you print all customer documentation and keep it close to the machine.

Note: For the latest documentation updates for your Xerox Digital Press, go to www.xerox.com/

VERSANT_4100docs or www.xerox.com/VERSANT_4100support.

Before you contact Xerox for support, ensure that you have the serial number of your Xerox press. To

locate the press serial number, refer to Locating the Press Serial Number.

30

Xerox®Versant®4100 Press

User Documentation

Page 31

Learning About

Regulatory Information

BBaassiicc RReegguullaattiioonnss

Xerox®has tested this printer to electromagnetic emission and immunity standards. These standards

are designed to mitigate interference caused or received by this printer in a typical office

environment.

Changes or modifications to this device not specifically approved by the Xerox

the user's authority to operate this equipment.

FFCCCC RReegguullaattiioonnss iinn tthhee UUSSAA

This product has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the Federal Communications Commission (FCC) Rules. These limits are

designed to provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a residential area is

likely to cause harmful interference in which case the user will be required to correct the interference

at his or her own expense.

Changes or modifications to this equipment not specifically approved by the Xerox

void the user’s authority to operate this equipment.

®

Corporation may void

®

Corporation may

To maintain compliance with FCC regulations, shielded cables must be used with this equipment.

Operation with non-approved equipment or unshielded cables is likely to result in interference to radio

and TV reception.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two

conditions:

1. This device may not cause harmful interference, and

2. This device must accept any interference received, including interference that may cause

undesired operation.

Responsible Party: Xerox

Address: 800 Phillips Road, Webster, NY 14580

®

Corporation

CCaannaaddaa

This Class A digital apparatus complies with Canadian ICES-003 and ICES-001.

Cet appareil numérique de la classe A est conforme à la norme NMB-003 et NMB-001 du Canada.

This device complies with Industry Canada’s license-exempt RSSs. Operation is the subject to the

following two conditions:

1. This device may not cause interference, and

2. This device must accept any interference, including interference that may cause undesired

operation of the device.

Le présent appareil est conforme aux CNR d’Industrie Canada applicables aux appareils radio

®

Xerox

Versant®4100 Press

User Documentation

31

Page 32

Learning About

exempts de licence. L’exploitation est autorisée aux deux conditions suivantes:

1. l’appareil ne doit pas produire de brouillage, et

2. l’utilisateur de l’appareil doit accepter tout brouillage radioélectrique subi, même si le brouillage

est susceptible d’en compromettre le fonctionnement.

There are operational restrictions for License-Exempt Local Area Network (LE-LAN) devices: the device

for operation in the band 5150-5250 MHz is only for indoor use to reduce the potential for harmful

interference to co-channel mobile satellite systems.

Il y a des restrictions opérationnelles pour dispositifs de réseaux locaux exempts de licence (RL-EL): les

dispositifs fonctionnant dans la bande 5 150-5 250 MHz sont réservés uniquement pour une

utilisation à l’intérieur afin de réduire les risques de brouillage préjudiciable aux systèmes de satellites

mobiles utilisant les mêmes canaux.

This transmitter must not be co-located or operating in conjunction with any other antenna or

transmitter. This equipment must be installed and operated with a minimum distance of 20

centimeters between the radiator and your body.

Cet émetteur ne doit pas être Co-placé ou ne fonctionnant en même temps qu’aucune autre antenne

ou émetteur. Cet équipement devrait être installé et actionné avec une distance minimum de 20

centimètres entre le radiateur et votre corps.

EEuurrooppeeaann UUnniioonn aanndd EEuurrooppeeaann EEccoonnoommiicc AArreeaa CCoommpplliiaannccee

The CE mark applied to this product indicates compliance to applicable EU

Directives. You can find the full text of the EU Declaration of Conformity in www.

xerox.com/environment_europe.

EEuurrooppeeaann UUnniioonn LLoott 44 IImmaaggiinngg EEqquuiippmmeenntt AAggrreeeemmeenntt

Xerox®has agreed to design criteria for energy efficiency and environmental performance of our

products that are in scope of the European Union (EU) Energy Related Products Directive, specifically

the Lot 4 - Imaging Equipment.

In scope products include Household and Office equipment that meet the following criteria:

• Standard monochrome format products with a maximum speed less than 66 A4 images per

minute.

• Standard color format products with a maximum speed less than 51 A4 images per minute.

32

Xerox®Versant®4100 Press

User Documentation

Page 33

To learn more about Go to

Learning About

• Power Consumption and Activation Times

• Default Power Saver Settings

• Benefits of purchasing ENERGY STAR

qualified products

• Environmental Benefits of Duplex

Printing

• Benefits of using lighter paper weights

(60 g/m

• Cartridge disposal and treatment

• Xerox participation in sustainability

initiatives

2

) and Recyclability

User Documentation or Systems Administrators Guide

www.xerox.com/VERSANT_4100docs

®

www.energystar.gov

www.xerox.com/environment or www.xerox.com/

environment_europe

Environmental Benefits of Duplex Printing

Most Xerox®products have duplex printing, also known as 2-sided printing, capability. This enables

you to print on both sides of the paper automatically, and therefore helps to reduce the use of

valuable resources by reducing your paper consumption. The Lot 4 Imaging Equipment agreement

requires that on models greater than or equal to 40 ppm color or greater than or equal to 45 ppm

monochrome the duplex function has been auto-enabled, during the setup and driver installation.

Some Xerox models below these speed bands may also be enabled with 2-sided printing settings

defaulted on at the time of install. Use of the duplex function will reduce the environmental impact

of your work. However, you must require simplex or 1-sided printing, you can change the print

settings in the print driver.

Paper Types

You can use this product to print on both recycled and virgin paper, approved to an environmental

stewardship scheme, which complies with EN12281 or a similar quality standard. Lighter weight

paper (60 g/m

2

), which contains less raw material and thus saves resources per print, can be used in

certain applications. We recommend you to check if this is suitable for your printing needs.

ENERGY STAR

The ENERGY STAR program is a voluntary scheme to promote the development and

purchase of energy-efficient models, which help to reduce environmental impact.

Details on the ENERGY STAR program and models qualified to ENERGY STAR can be

found at the following website: www.energystar.gov.

The ENERGY STAR and ENERGY STAR mark are registered United States trademarks.

The ENERGY STAR Imaging Equipment Program is a team effort between United States,

European Union, Japanese governments, and the office equipment industry to promote energyefficient copiers, printers, fax, multifunction printers, personal computers, and monitors.

Reducing product energy consumption helps combat smog, acid rain, and long-term changes to

the climate by decreasing the emissions that result from generating electricity.

For more information on energy or other related topics, go to:

• www.xerox.com/environment or

• www.xerox.com/environment_europe

Xerox

®

Versant®4100 Press

User Documentation

33

Page 34

Learning About

Power Consumption and Activation Time

The amount of electricity that a device consumes depends on the way the device is used. This device

is designed and configured to enable you to reduce your electricity usage.

Power Saver modes are enabled on your device to reduce energy consumption. After the last print,

the device goes to Ready mode. In this mode, the device can print again immediately. If the device is

not used for a specified period, the device goes to Low Power mode, then to Sleep mode. In these

modes, to enable reduced-power consumption, only essential functions remain active. The device

takes longer to produce the first print after it exits the Power Saver modes than it takes to print in

Ready mode. This delay is the result of the system waking up and is typical of most imaging devices

on the market.

To save power, you can enable Auto Power Off mode on your device. If Auto Power Off mode is

enabled, you can configure the mode as follows:

• Always Allowed: The device powers off automatically after the specified time, and the cumulative

Low Power mode and Sleep mode time outs have elapsed.

• Allowed ONLY When the Conditions are Met: The device automatically powers off only after

time outs have elapsed. The device also powers off if USB Drive, and Wired and Non-Wired

Network are not activated.

To change the Power Saver settings, refer to the User Documentation at www.xerox.com/VERSANT_

4100docs. For more details, contact your System Administrator or refer to the System Administrator

Guide.

To enable Auto Power Off mode, contact your System Administrator. For details, refer to the System

Administrator Guide at www.xerox.com/VERSANT_4100docs.

To learn more about Xerox participation in sustainability initiatives, go to:

• www.xerox.com/environment or

• www.xerox.com/environment_europe

Default Power Saver Settings

This device is ENERGY STAR

Equipment. The Low-Power mode time can be configured up to 30 minutes. The default value is 15

minutes. The Sleep mode time can be configured up to 30 minutes. The default value is 30 minutes.

Sleep mode begins after the configured time of inactivity rather than time after Low-Power mode.

To change the Default Power Saver settings, contact your System Administrator, or refer to the

System Administrator Guide at www.xerox.com/VERSANT_4100docs.

Note: Changing the default Power Saver activation times can result in an overall higher energy

consumption of the device. Before you turn off Power Saver modes or set a long activation

time, consider the increase in device power consumption.

®

qualified under the ENERGY STAR Program Requirements for Imaging

EEuurraassiiaann EEccoonnoommiicc UUnniioonn CCoommpplliiaannccee

The EAC mark applied to this product indicates certification for use on the markets of

the Member States of the Customs Union.

34

Xerox®Versant®4100 Press

User Documentation

Page 35

Learning About

TTuurrkkeeyy RRooHHSS RReegguullaattiioonn

In compliance with Article 7(d), we hereby certify “it is in compliance with the EEE regulation EEE

yönetmeliğine uygundur.” (Compliant with EEE Regulations).

UUkkrraaiinnee RRooHHSS CCoommpplliiaannccee

Обладнання відповідаєвимогам Технічного регламенту щодо обмеження

використання деяких небезпечних речовин в електричному та електронному

обладнані, затвердженого постановою Кабінету Міністрів України від 3 грудня 2008 № 1057

(The equipment complies with requirements of the Technical Regulation, approved by the Resolution

of Cabinet of Ministry of Ukraine as of December 3, 2008, in terms of restrictions for the use of

certain dangerous substances in electrical and electronic equipment.)

CCooppyy RReegguullaattiioonnss

UUnniitteedd SSttaatteess

Congress, by statute, has forbidden the reproduction of the following subjects under certain

circumstances. Penalties of fine or imprisonment can be imposed on those guilty of making such

reproductions.

1. Obligations or Securities of the United States Government, such as:

• Certificates of Indebtedness

• National Bank Currency

• Coupons from Bonds

• Federal Reserve Bank Notes

• Silver Certificates

• Gold Certificates

• United States Bonds

• Treasury Notes

• Federal Reserve Notes

• Fractional Notes

• Certificates of Deposit

• Paper Money

• Bonds and Obligations of certain agencies of the government, such as FHA and so on

• Bonds. United States Savings Bonds can be photographed only for publicity purposes for the

campaign of the sale of such bonds

• Internal Revenue Stamps. If it is necessary to reproduce a legal document on which there is a

canceled revenue stamp, this can be done provided the reproduction of the document is

performed for lawful purposes

®

Xerox

Versant®4100 Press

User Documentation

35

Page 36

Learning About

• Postage Stamps, canceled or uncanceled. For philatelic purposes, Postage Stamps can be

photographed, provided the reproduction is in black and white and is less than 75% or more

than 150% of the linear dimensions of the original document

• Postal Money Orders

• Bills, Checks, or Drafts of money drawn by or upon authorized officers of the United States

• Stamps and other representatives of value, of whatever denomination, which have been or

can be issued under any Act of Congress

• Adjusted Compensation Certificates for Veterans of the World Wars

2. Obligations or Securities of any Foreign Government, Bank, or Corporation

3. Copyrighted materials, unless permission of the copyright owner has been obtained or the

reproduction falls within the fair use or library reproduction rights provisions of the copyright law.

Further information of these provisions can be obtained from the Copyright Office, Library of

Congress, Washington, D.C. 20559. Ask for Circular R21.

4. Certificate of Citizenship or Naturalization. Foreign Naturalization Certificates can be

photographed.

5. Passports. Foreign Passports can be photographed.

6. Immigration papers

7. Draft Registration Cards

8. Selective Service Induction papers that bear any of the following Registrant information:

• Earnings or Income

• Court Record

• Physical or mental condition

• Dependency status

• Previous military service

• Exception: United States military discharge certificates can be photographed

9. Badges, Identification Cards, Passes, or Insignia carried by military personnel, or by members of

the various Federal Departments, such as FBI, Treasury, and so on, unless the head of such

department or bureau orders a photograph.

Reproducing the following items is prohibited in certain states:

• Automobile Licenses

• Driver Licenses

• Automobile Certificates of Title

The above list is not all-inclusive, and no liability is assumed for its completeness or accuracy. If there

is doubt, consult your attorney.

For more information about these provisions, contact the Copyright Office, Library of Congress,

Washington, D.C. 20559. Ask for Circular R21.

36

Xerox®Versant®4100 Press

User Documentation

Page 37

Learning About

CCaannaaddaa

Parliament, by statute, has forbidden the reproduction of the following subjects under certain