Versant 3100 Press

Optional Units Manual

2nd High Capacity Feeder C1-DS

Interface Decurler Module

Inserter

High Capacity Stacker

Crease/Two-sided Trimmer

Fol der Unit

Finisher

SquareFold Trimmer

Finishing Transport

In this manual, safety instructions are preceded by the symbol . Always read and follow the instructions

before performing the required procedures.

It may be a legal offence to print currency notes, certificates of stocks and securities, or any other documents of

similar nature, regardless of whether they will be used.

If a malfunction occurs with the machine's hard disk or other storage media, any received or stored data including registered configurations may be lost. Fuji Xerox is not responsible for any direct or indirect damages arising

from or caused by such data loss.

Fuji Xerox is not responsible for any breakdown of machines due to infection of computer virus or computer hacking.

Important

1. This manual is copyrighted with all rights reserved. Under the copyright laws, this manual may not be copied

or modified in whole or part, without the written consent of the publisher.

2. Parts of this manual are subject to change without prior notice.

3. We welcome any comments on ambiguities, errors, omissions, or missing pages.

4. Never attempt any procedure on the machine that is not specifically described in this manual. Unauthorized

operation can cause faults or accidents. Fuji Xerox is not liable for any problems resulting from unauthorized

operation of the equipment.

An export of this product is strictly controlled in accordance with Laws concerning Foreign Exchange and Foreign Trade of Japan and/or the export control regulations of the United States.

Xerox, Xerox and Design, Fuji Xerox and Design, Versant as well as CentreWare are registered trademarks or trademarks of Xerox Corporation in Japan and/or other countries.

Other company names or product names are registered trademarks or trademarks of each company.

2

Optional Units Manual

Preface

Fuji Xerox Co.,Ltd.

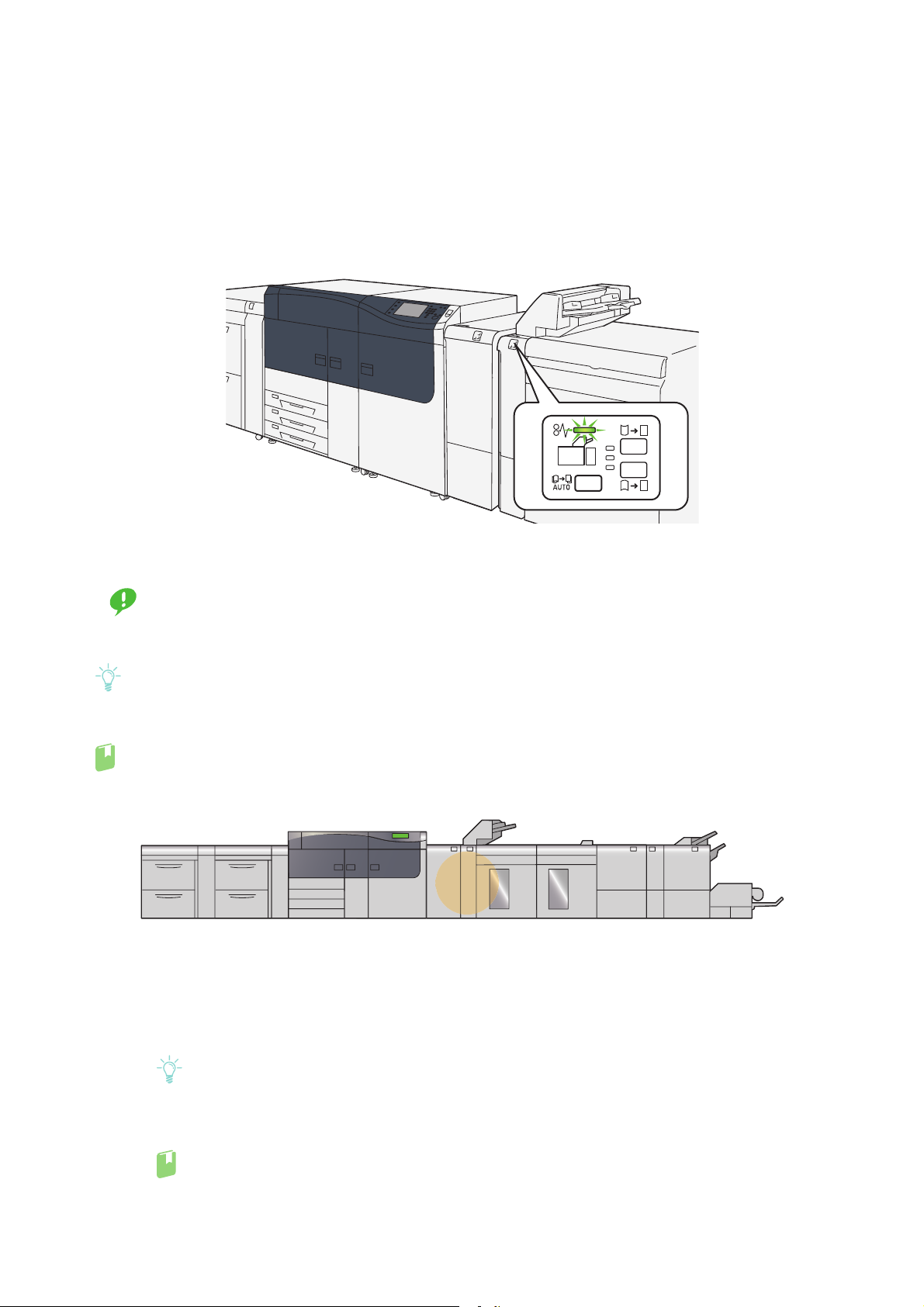

Thank you for selecting the Versant 3100 Press.

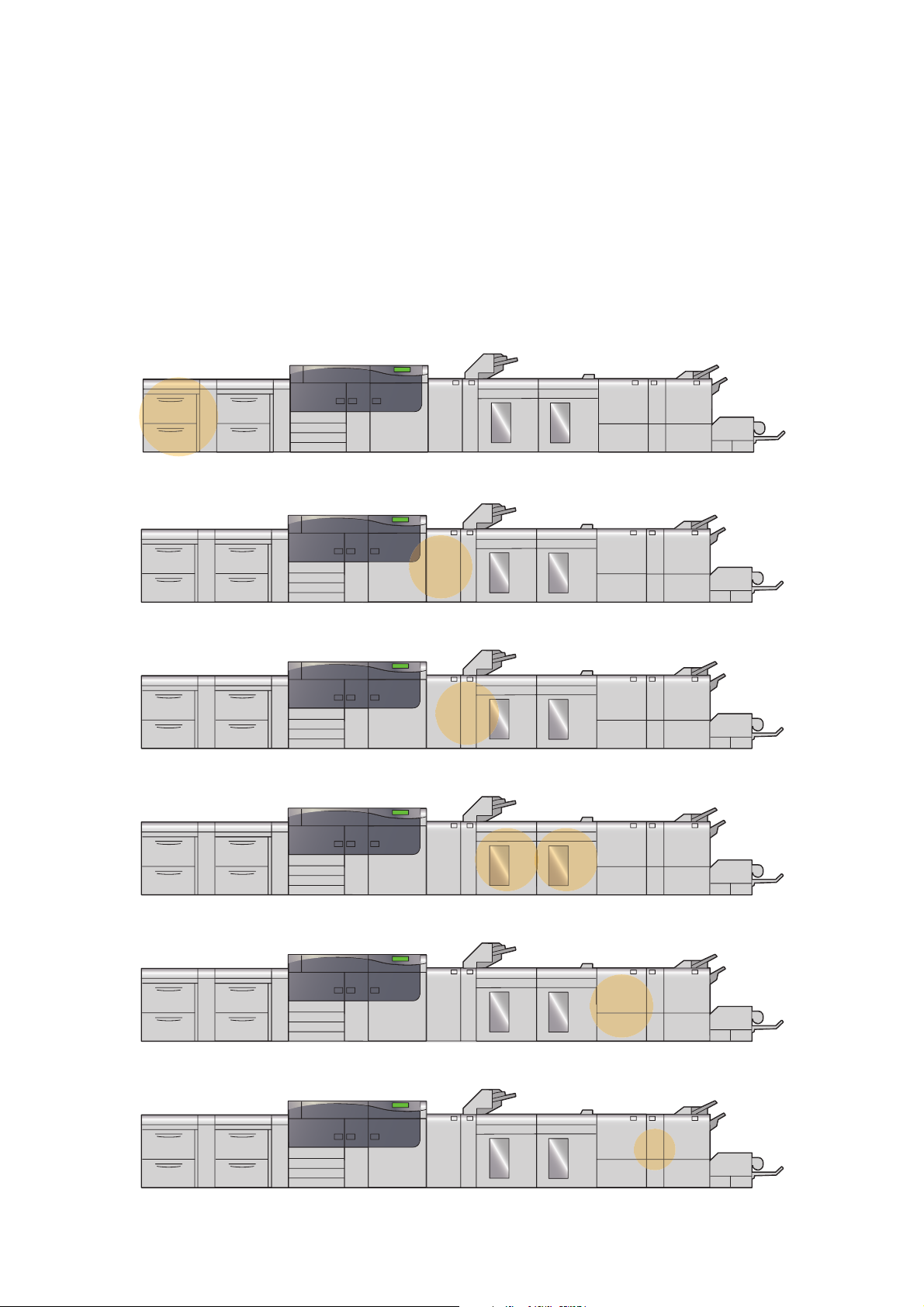

The Versant 3100 Press is a color printing system that quickly processes data from client computers and

delivers high-quality outputs. The Versant 3100 Press consists of the printer unit and a variety of optional

units as well as a Print Server.

The Versant 3100 Press offer high-speed color printing: up to 100 sheets/minute (A4) (the actual speed

depends on the size, type, and weight of paper).

This manual is intended to provide first-time users of the Versant 3100 Press with necessary information

such as operating procedures and precautions on using the optional units.

Before using the Versant 3100 Press, please read this manual thoroughly to obtain the best performance

of the Versant 3100 Press.

After reading this manual, please keep it in a safe place for further reference. It will be useful in case you

forget how to perform operations or if a problem occurs with the printer.

For information on functions and operations of the Print Server, refer to customer documentation supplied

with Print Servers.

Preface

3

Table of Contents

Preface...................................................................................................................................................................................................................................... 3

Table of Contents................................................................................................................................................................................................................. 4

Types of Manuals................................................................................................................................................................................................................. 6

Using This Manual ............................................................................................................................................................................................................... 7

Chapter 1 2nd High Capacity Feeder C1-DS...........................................................................10

1.1 Machine Components ............................................................................................................................................ 10

1.2 Paper Jams.................................................................................................................................................................. 12

1.2.1 Paper Jams in Tray ...................................................................................................................................................... 12

1.2.2 Paper Jams inside the Right Side Cover ............................................................................................................. 14

1.2.3 Paper Jams in the Paper Feeding Unit ............................................................................................................... 17

Chapter 2 Interface Decurler Module.......................................................................................18

2.1 Machine Components ............................................................................................................................................ 18

2.2 Curl Correction........................................................................................................................................................... 19

2.3 Paper Jams.................................................................................................................................................................. 21

Chapter 3 Inserter............................................................................................................................23

3.1 Machine Components ............................................................................................................................................ 23

3.2 Loading Paper............................................................................................................................................................ 25

3.3 Paper Jams.................................................................................................................................................................. 26

Chapter 4 High Capacity Stacker ...............................................................................................30

4.1 Machine Component .............................................................................................................................................. 30

4.2 Output Paper.............................................................................................................................................................. 32

4.2.1 Output Trays .................................................................................................................................................................. 32

4.2.2 Control Buttons.............................................................................................................................................................32

4.3 Paper Jams.................................................................................................................................................................. 33

Chapter 5 Crease/Two-sided Trimmer ......................................................................................40

4

Optional Units Manual

5.1 Machine Components ............................................................................................................................................ 40

5.2 Trimmer Waste Container .................................................................................................................................... 43

5.3 Paper Jams.................................................................................................................................................................. 44

Chapter 6 Folder Unit .....................................................................................................................53

6.1 Machine Components ............................................................................................................................................ 53

6.2 Output Paper.............................................................................................................................................................. 54

6.3 Paper Jams.................................................................................................................................................................. 55

Chapter 7 Finisher............................................................................................................................59

7.1 Machine Components ............................................................................................................................................ 60

7.2 Output Paper.............................................................................................................................................................. 64

7.2.1 Output Trays .................................................................................................................................................................. 64

7.2.2 Control Buttons.............................................................................................................................................................66

7.3 Staple Cartridge........................................................................................................................................................ 67

7.3.1 Replacing the Cartridge ............................................................................................................................................67

7.3.2 Staple Faults...................................................................................................................................................................69

7.3.3 Re-inserting the Staple Cartridge.......................................................................................................................... 72

7.4 Waste Container....................................................................................................................................................... 74

7.4.1 Staple Waste Container............................................................................................................................................74

7.4.2 Hole Punch Waste Container..................................................................................................................................76

7.5 Paper Jams.................................................................................................................................................................. 77

7.5.1 Paper Jams in the Finisher ....................................................................................................................................... 77

7.5.2 Paper Jams in the Saddle Stitch Unit..................................................................................................................81

7.5.3 Paper Jams in the Paper Feeding Unit ............................................................................................................... 84

Chapter 8 SquareFold Trimmer...................................................................................................85

8.1 Machine Components ............................................................................................................................................ 85

8.2 Output Paper.............................................................................................................................................................. 87

8.2.1 Output Trays .................................................................................................................................................................. 87

8.2.2 Spine-flattener Strength Adjustment Button.................................................................................................. 87

8.3 Trimmer Waste Container .................................................................................................................................... 88

8.4 Paper Jams.................................................................................................................................................................. 89

Chapter 9 Finishing Transport.....................................................................................................92

9.1 Machine Components ............................................................................................................................................ 92

9.2 Paper Jams.................................................................................................................................................................. 93

Index ...................................................................................................................................................................................................................................... 96

Table of Contents

5

Types of Manuals

Refer

The Versant 3100 Press comes bundled with the following manuals:

For information on functions and operations of the Print Server, refer to customer documentation supplied

with Print Servers.

Some of them come with manuals. The manuals for optional components describe all the necessary steps

for using the optional components and installing the software.

For details on the functions of your 3rd Vendor Finisher or GBC® AdvancedPunch™ Pro, refer to the manual

supplied with the device.

PDF Manual

The Manuals are stored as PDF files on the Versant 3100 Press Instruction Manuals CD.

Double-click "index.html" and select the language of the manual you wish to display.

Versant 3100 Press Optional Units Manual (this manual)

Describes how to replace consumables and how to clear paper jams in the optional units (High Capacity

Stacker, Finisher, and others).

Versant 3100 Press Printer Unit Manual

Describes how to load paper, how to replace consumables, how to clear paper jams, and the daily maintenance procedures for the printer unit. (These descriptions are also applied to the printer unit equipped

with Offset Catch Tray.)

Versant 3100 Press User Interface Manual

Describes the operations of the user interface (UI) for operating the printer.

The user interface allows you to confirm status of the printer, and to set the printer behavior.

Versant 3100 Press Paper Jams: Quick Access Guide

Illustrates possible paper jam areas, allowing you to quickly identify a paper jam location.

HTML Manual

Stock Library Manager Manual

Describes Stock Library Manager with which you can change the paper settings.

The manual can be viewed from the [Help] menu of Stock Library Manager.

CentreWare Internet Services Help

The help describes CentreWare Internet Services where you can change various settings of the printer

using a client computer.

Click [Help] in the upper right corner of CentreWare Internet Service window to display the help.

To display the online help for CentreWare Internet Services, users need to have the environment to connect

Important

to the Internet. The communication fee shall be borne by you.

Paper Manual

6

Versant 3100 Press Safety Notes

Provides information for using the printer safely. Read this manual before using the printer.

Optional Units Manual

Using This Manual

This manual is intended to provide first-time users of the Versant 3100 Press with necessary information

such as operating procedures and precautions on using the optional units.

Organization of This Manual

This manual identifies components as well as covers procedures to clear paper jams for each of the

optional units.

Chapter 1 2nd High Capacity Feeder C1-DS

Chapter 2 Interface Decurler Module

Chapter 3 Inserter

Chapter 4 High Capacity Stacker

Chapter 5 Crease/Two-sided Trimmer

Chapter 6 Folder Unit

Using This Manual

7

Chapter 7 Finisher

Chapter 8 SquareFold Trimmer

Chapter 9 Finishing Transport

8

Optional Units Manual

Conventions

Note

Important

Note

Refer

Bottom

Feed direction

Front edge

Portrait

Landscape

To p

Rear edge

This manual uses the following symbols:

Indicates important information you have to know or be reminded before operations.

Indicates supplemental information useful for operations.

Indicates references to other chapters and manuals.

< > Indicates the Control Panel, and buttons and lamps on the printer or optional units.

[ ] Indicates the names of tabs, options, buttons, menus and file names on the touch screen

display.

" " Indicates the names of reference sections in this manual, characters to be entered, path

names, and messages.

XXX Manual Indicates the names of the reference manuals.

Paper

Orientation

There are two paper orientations: Long Edge Feed (LEF) and Short Edge Feed (SEF).

The figures below describe front, rear, top, and bottom edges of the paper for LEF and

SEF.

Long Edge Feed (LEF )

Long edge: landscape (width),

Short edge: portrait (height)

The front of the printer The front of the printer

The feed direction shown above works in an opposite manner for Printer Unit Trays and Inserter Tray.

Short Edge Feed (SEF )

Short edge: landscape (width),

Long edge: portrait (height)

To p

Landscape

Rear edge

Feed direction

Bottom

Illustrations in This Manual

All illustrations contained in this manual are of the product equipped with all optional units.

Front edge

Portrait

Using This Manual

9

Chapter 1

Refer

1.1 Machine Components............................................................................10

1.2 Paper Jams..................................................................................................12

For detailed information on how to load paper, refer to "2.3 Loading Paper" in the Printer Unit Manual, and

how to clean the printer, refer to "4.3 Cleaning the Printer" in the Printer Unit Manual.

2nd High Capacity Feeder C1-DS

1.2.1 Paper Jams in Tray.............................................................................................. 12

1.2.2 Paper Jams inside the Right Side Cover .................................................... 14

1.2.3 Paper Jams in the Paper Feeding Unit....................................................... 17

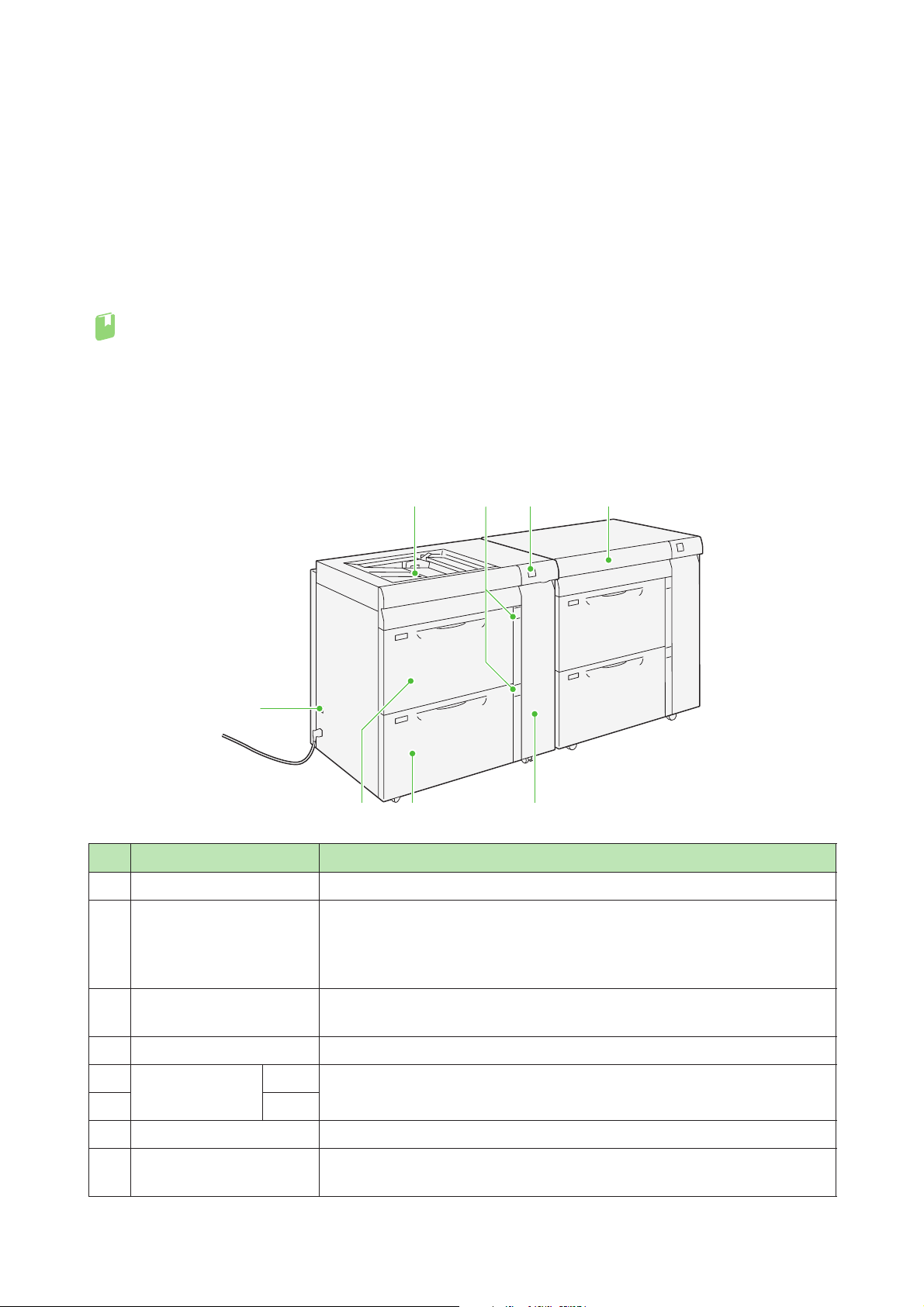

1.1

No, Component Description

Machine Components

3 8

4

12

765

10

1 Error lamp Illuminates when a paper jam occurs.

Paper level indicator lamp The top active indicator lamp lights when the corresponding Tray is active.

2

Bypass Tray (Tray 5) Load paper here.

3

4 Circuit breaker switch Automatically shuts off electricity in the event of fault current or a short circuit.

5 High Capacity

Trays

6 Tray 9

7 Right side cover Open this cover to clear paper jams.

Top cover of High Capacity

8

Feeder C3-DS

Optional Units Manual

Tray 8 Load paper here.

The four center lamps (1=25%) indicate the amount of remaining paper.

When all of the four lamps turn off, Tray becomes empty and paper empty

indicator lamp lights.

Images are printed on the face side of the loaded paper.

Images are printed on the face side of the loaded paper.

Open this cover to clear paper jams.

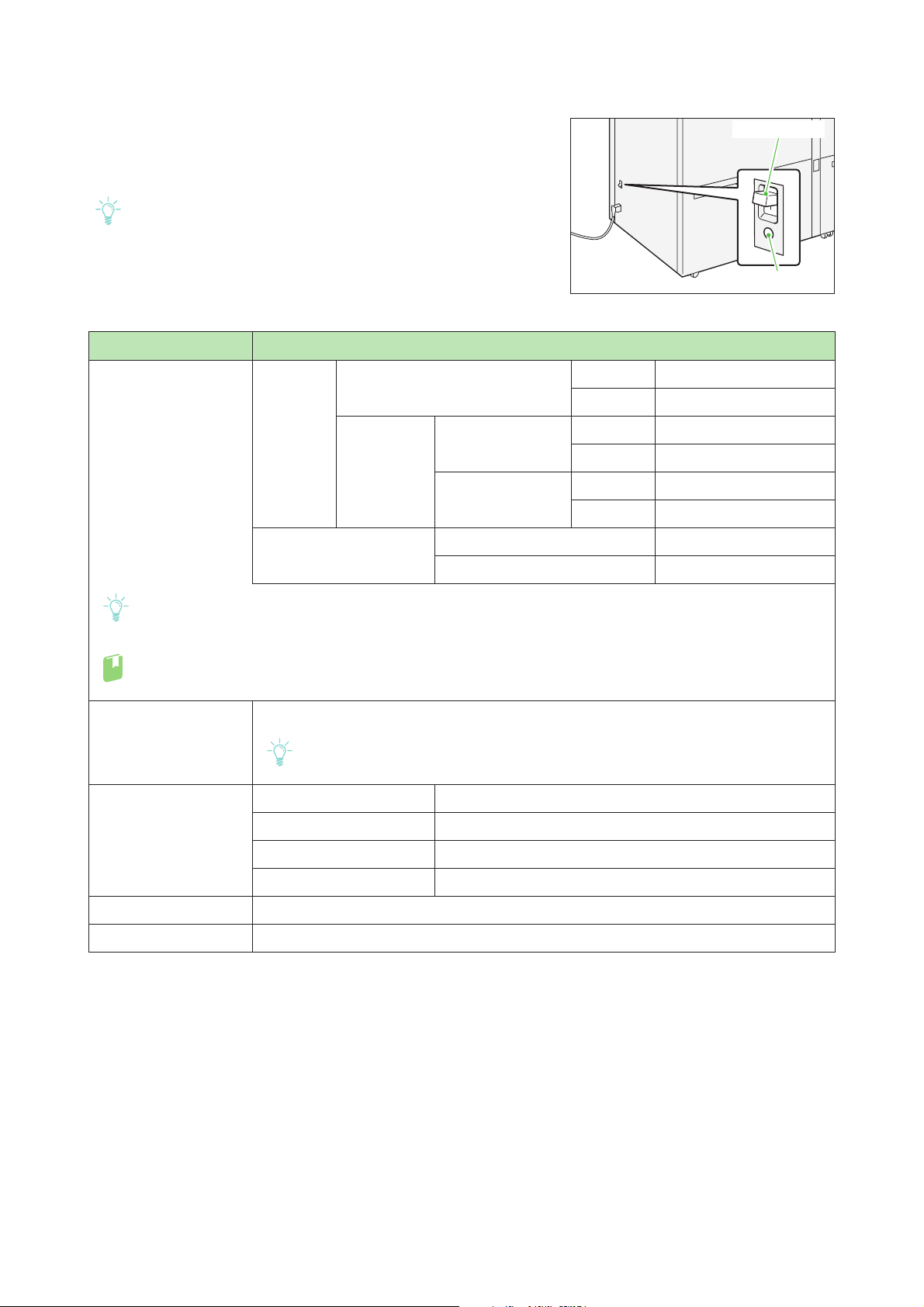

Circuit Breaker Switch

Note

Note

Refer

Note

TEST button

Breaker switch

The switch is normally in the upper position.

If the machine will be moved or unused for an extended period of

time, turn off the switch by pressing it to the lower position.

When fault current is detected, the circuit breaker is automatically turned off to discontinue the electrical flow. Do not touch

the breakers under normal condition. For information on fault

current, refer to the Safety Notes.

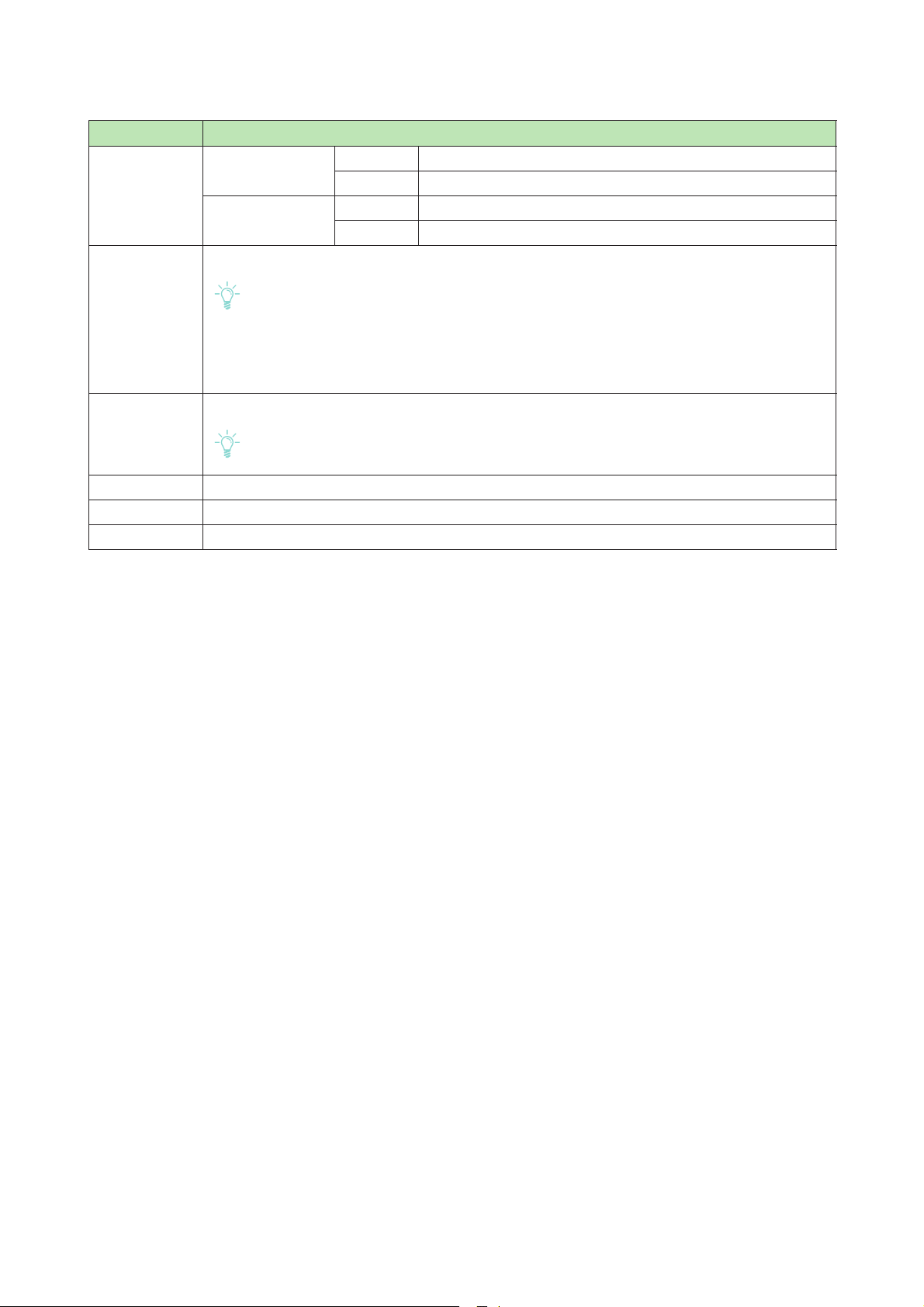

Specifications

Component Description

Paper size

Paper weight

Paper size Standard size Maximum A3, 13 x 19"

Minimum Post Card (100 x 148 mm)

Custom size Bypass Tray Height 98.0 - 330.2 mm

Width 148.0 - 660.4 mm

High Capacity Tray Height 98.0 - 330.2 mm

Width 148.0 - 488.0 mm

Paper weight Bypass Tray 52 - 300 g/m

High Capacity Tray 52 - 350 g/m

Printing on long paper can cause decreased continuous printing speed.

There is a certain limitation on how long paper can be fed and delivered.

For detailed information about the supported paper size and weight, refer to "2.1.2 Supported Paper" in

the Printer Unit Manual.

2

2

Tray capacity 2,000 sheets x 2 Trays (Maximum capacity: 4,000 sheets), Bypass Tray: 250 sheets

The values are based on Colotech+90.

Power supply

Power consumption

Power supply 100 - 120 V AC ±10%, 5 A, 50 Hz or 60 Hz

Peak 500 W

Power supply 200 - 240 V AC ±10%, 3 A, 50 Hz or 60 Hz

Peak 660 W

Dimension Width 988 x Depth 762 x Height 992 mm

Weight 222 kg (When it is installed.)

Chapter 1 2nd High Capacity Feeder C1-DS

11

1.2

Note

Refer

Paper Jams

If there is a paper jam, the printing will be canceled.

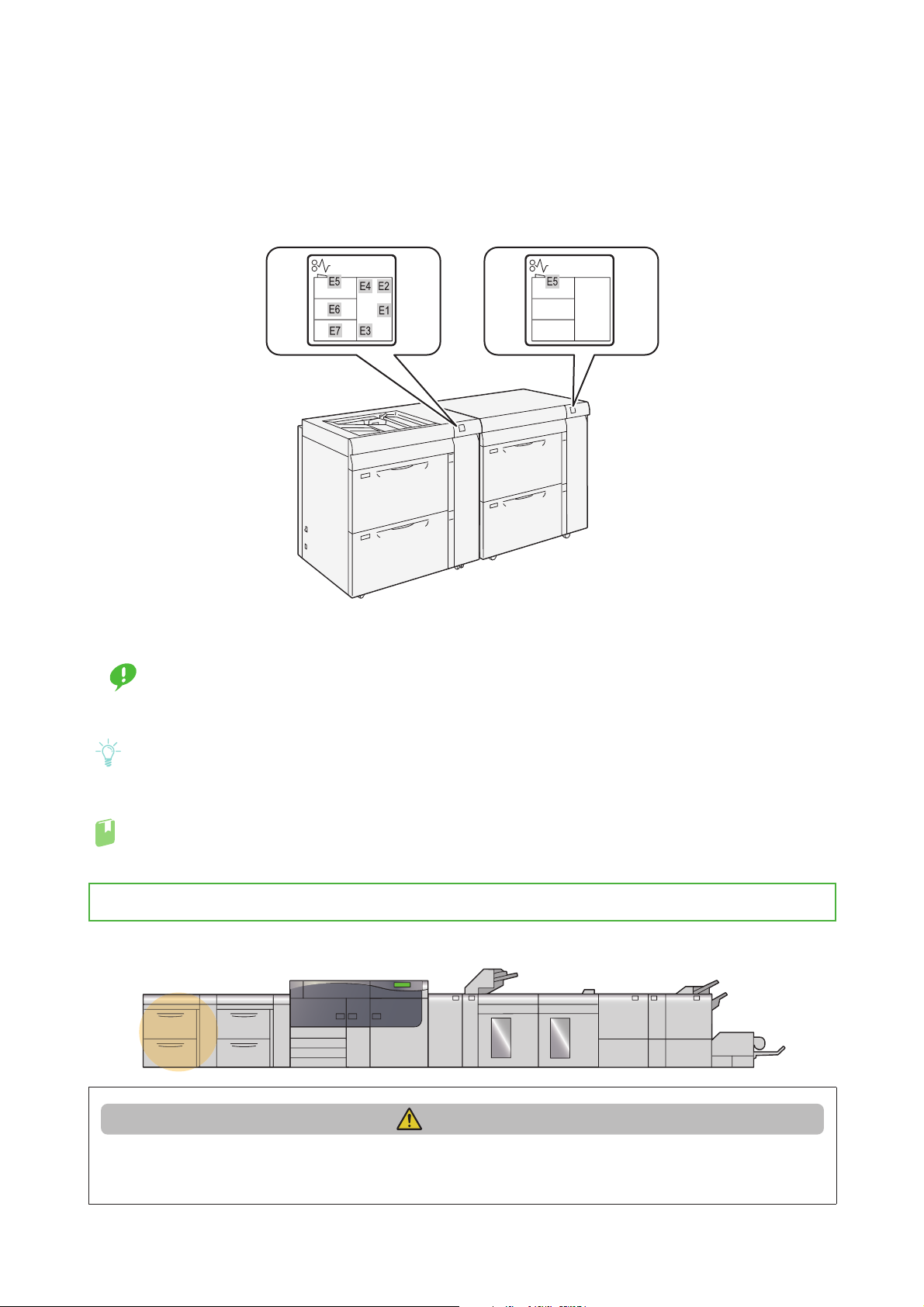

The Error Message area of the touch screen will show the affected area in red, along with the message.

Also, the error lamp on the top of the machine will illuminate.

If there is a paper jam in the following area, tap the [Faults] and the [Faults] screen will appear, explaining

how to remove jammed papers.

Remove the paper only after you are sure the printer is no longer moving.

Important

After removing jammed papers, be sure to close the cover. Leaving the cover open will not be able to continue to print jobs.

Leave the power on and proceed to remove jammed papers.

If there is still paper remaining, the paper jam message will continue to display. Make sure that there is no

jammed paper left and also no jams in other places.

For detailed information on how to regard the messages, refer to "1.2.1 Services Home" in the User Interface

Manual.

1.2.1 Paper Jams in Tray

Follow the steps below to clear paper jams in Tray.

12

CAUTION

When pulling out the Tray, do it gently. If pulled out with too much force, the Tray can hit and injure

your knees.

Optional Units Manual

1.

Note

Important

Refer

Important

Remove jammed papers.

When Lamp E5 is Lit...........................................................................................................................................................p.13

When Lamp E6 is Lit...........................................................................................................................................................p.13

When Lamp E7 is Lit...........................................................................................................................................................p.14

Solutions differ depending on where the paper jam occurs. Confirm the jammed area in the Error

Message area.

The code (E) on the upper-left part of the message indicates which error lamp on the top of the

machine is illuminating.

When Lamp E5 is Lit

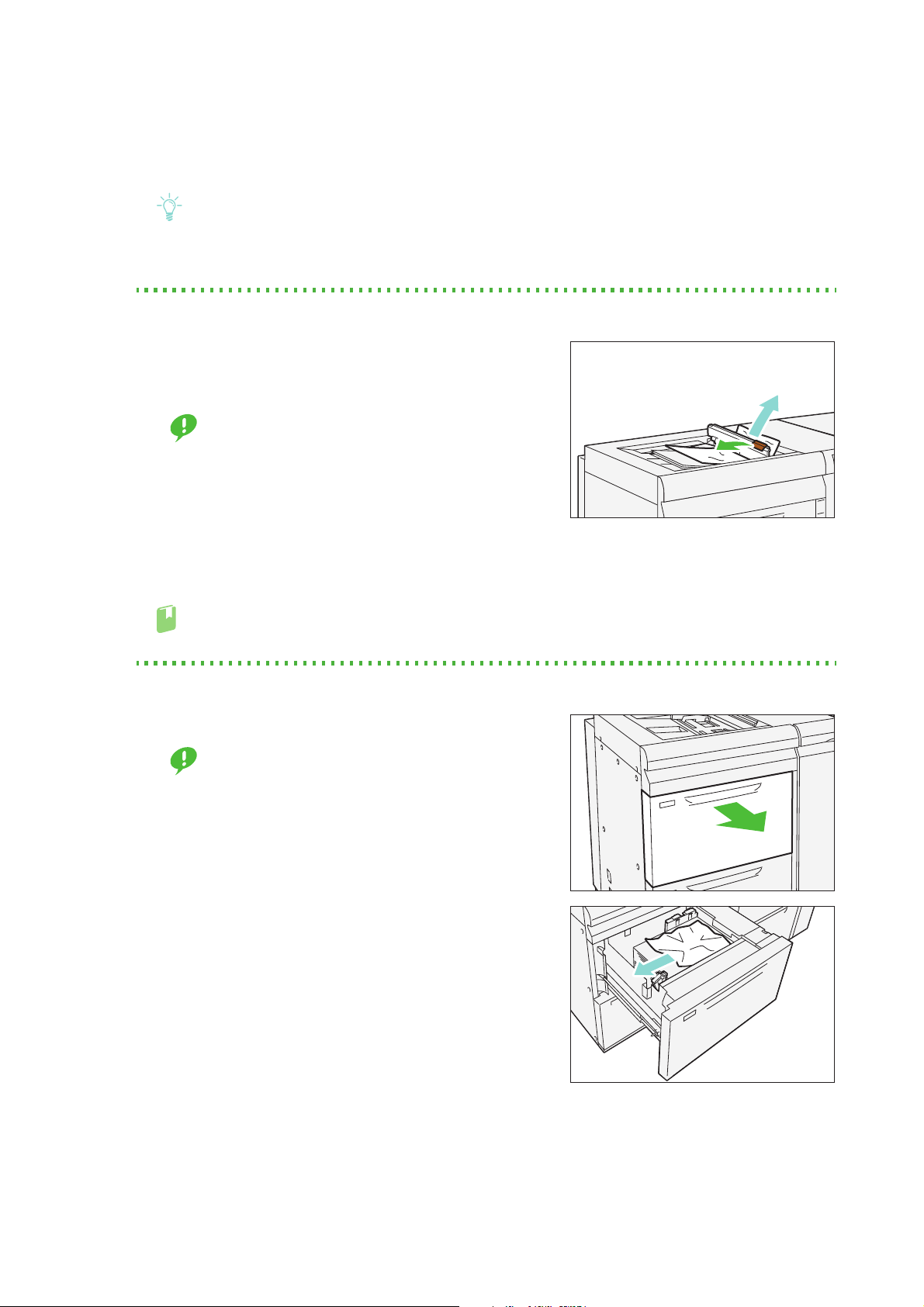

(1) Open the cover on the top of the Bypass Tray, and

remove jammed papers and all papers loaded in the

Bypass Tray.

When two or more sheets of paper are loaded,

remove all the sheets from the Tray.

(2) Close the cover.

(3) Fan the paper you removed and make sure all four

corners are aligned correctly. Then reload the paper.

If you have difficulty in removing jammed papers, open

the cover on the right side to remove the paper inside.

For detailed information on paper jams inside the right side cover, refer to "1.2.2 Paper Jams inside

the Right Side Cover" (p.14).

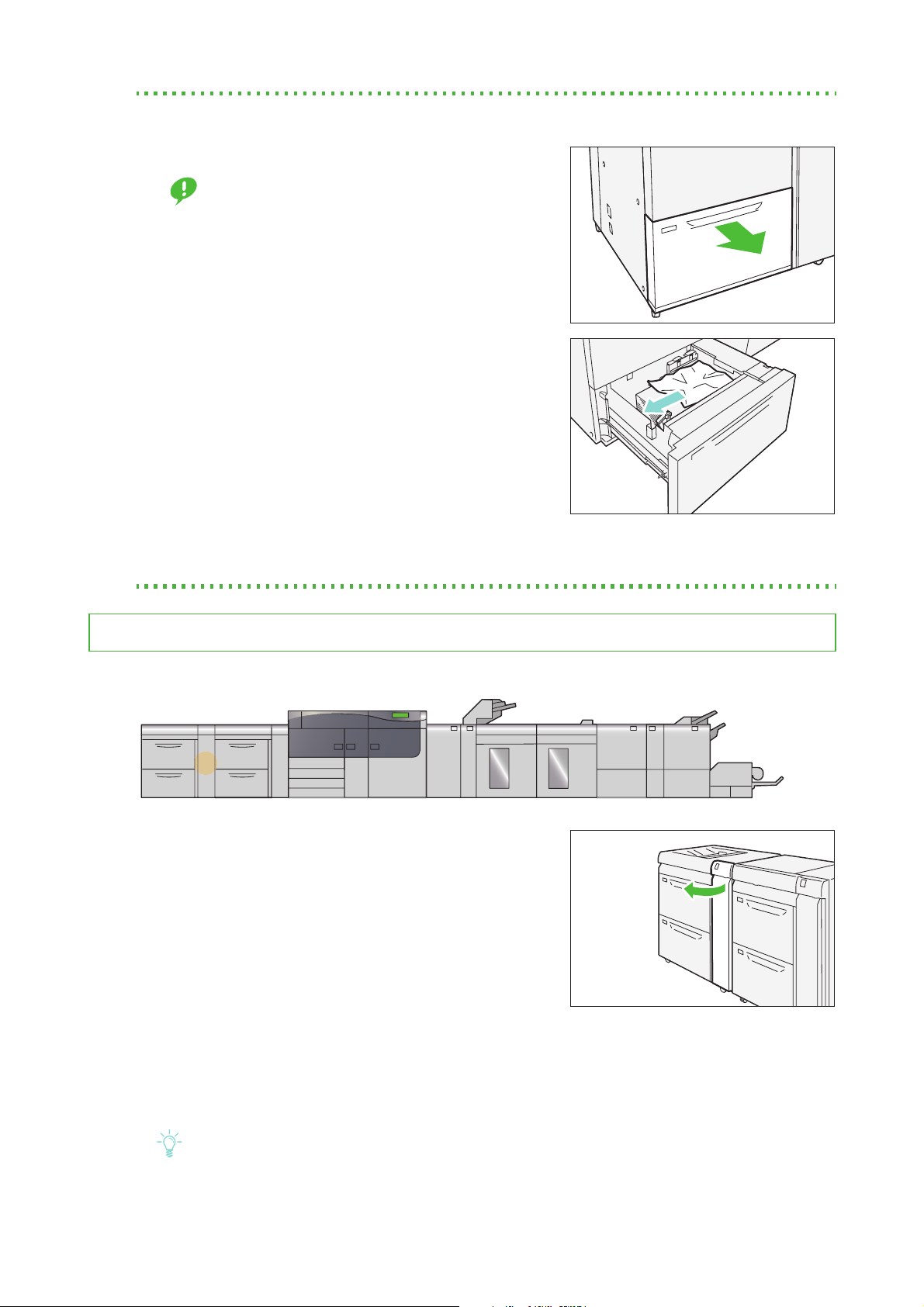

When Lamp E6 is Lit

(1) Pull out the Tray 8 toward you until it stops.

Before pulling out the Tray, make sure no paper is

jammed inside the right side cover.

(2) Remove jammed papers.

(3) Make sure the long-side and short-side paper guides are positioned to just touch the

paper, and then push the Tray into the machine.

Chapter 1 2nd High Capacity Feeder C1-DS

13

When Lamp E7 is Lit

Important

Note

(1) Pull out the Tray 9 toward you until it stops.

Before pulling out the Tray, make sure no paper is

jammed inside the right side cover.

(2) Remove jammed papers.

(3) Make sure the long-side and short-side paper guides are positioned to just touch the

paper, and then push the Tray into the machine.

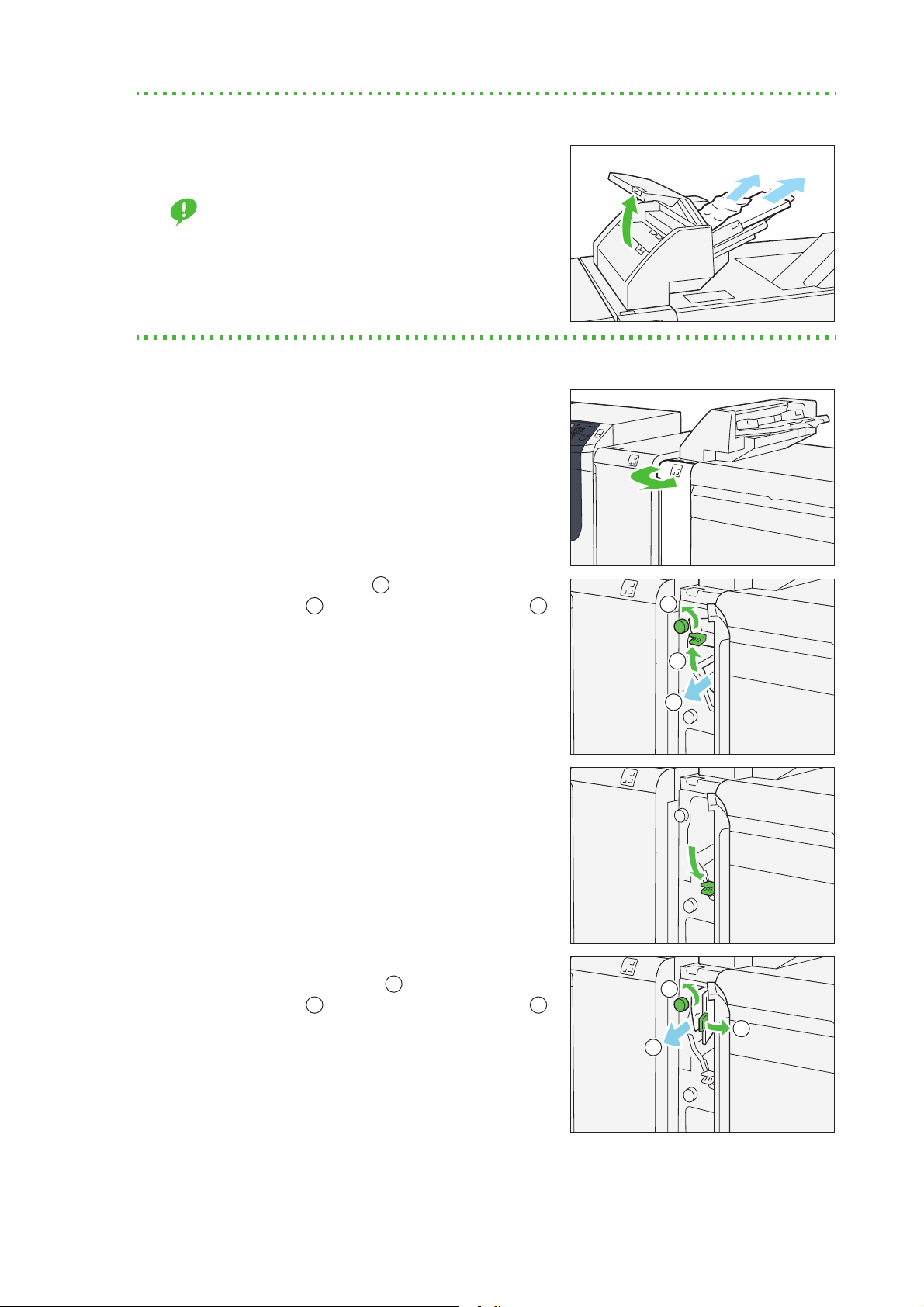

1.2.2 Paper Jams inside the Right Side Cover

Follow the steps below to clear paper jams inside the cover of the 2nd High Capacity Feeder C1-DS.

1.

Open the right side cover of the 2nd High Capacity

Feeder C1-DS.

2.

Remove jammed papers.

When Lamp E1 is Lit...........................................................................................................................................................p.15

When Lamp E2 is Lit...........................................................................................................................................................p.15

When Lamp E3 is Lit...........................................................................................................................................................p.16

When Lamp E4 is Lit...........................................................................................................................................................p.16

14

Solutions differ depending on where the paper jam occurs. Confirm the jammed area in the Error

Message area.

The code (E) on the upper-left part of the message indicates which error lamp on the top of the

machine is illuminating.

Optional Units Manual

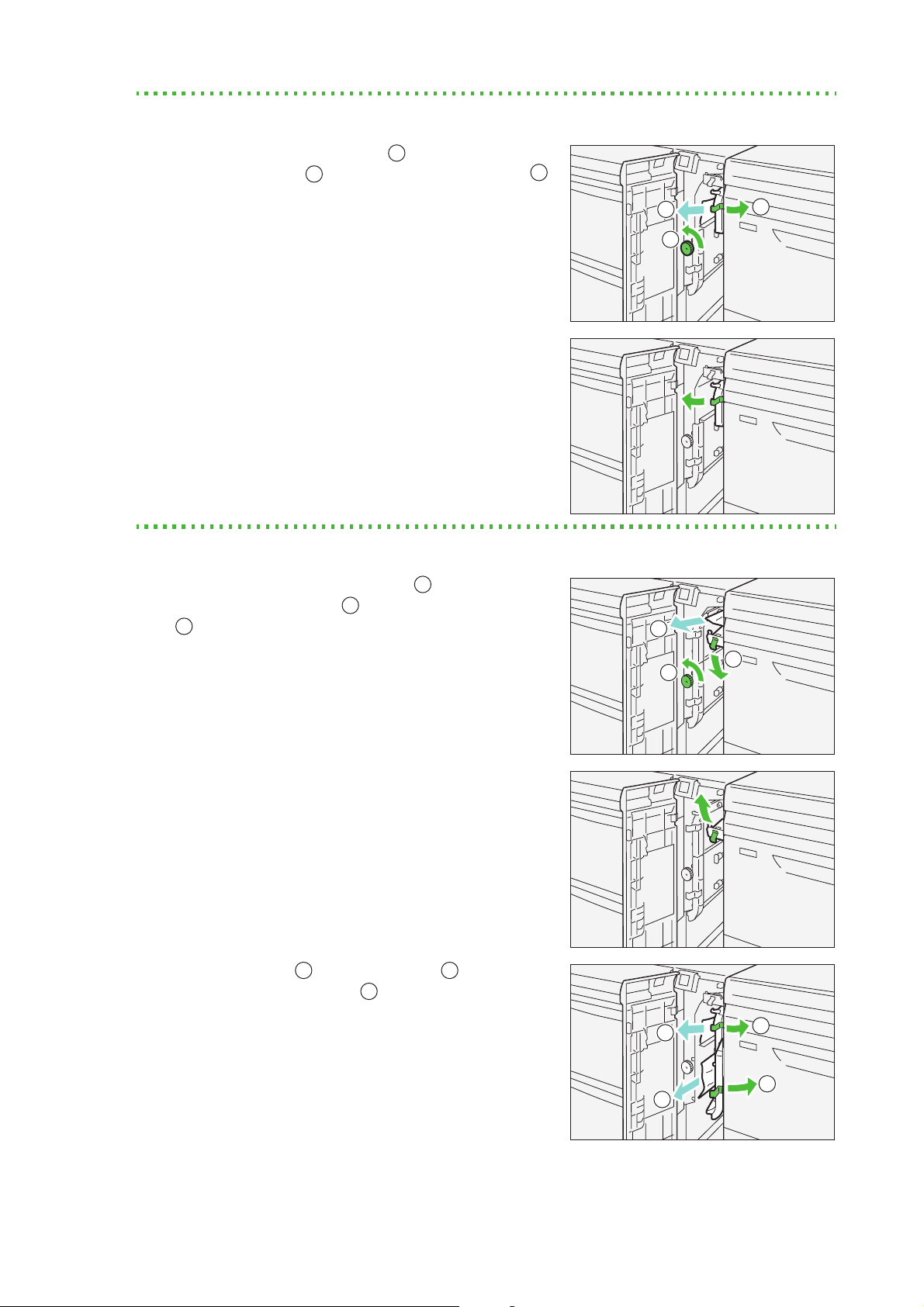

When Lamp E1 is Lit

2

1

3

1

3

1

2

3

1

3

1

2

3

3

1

3

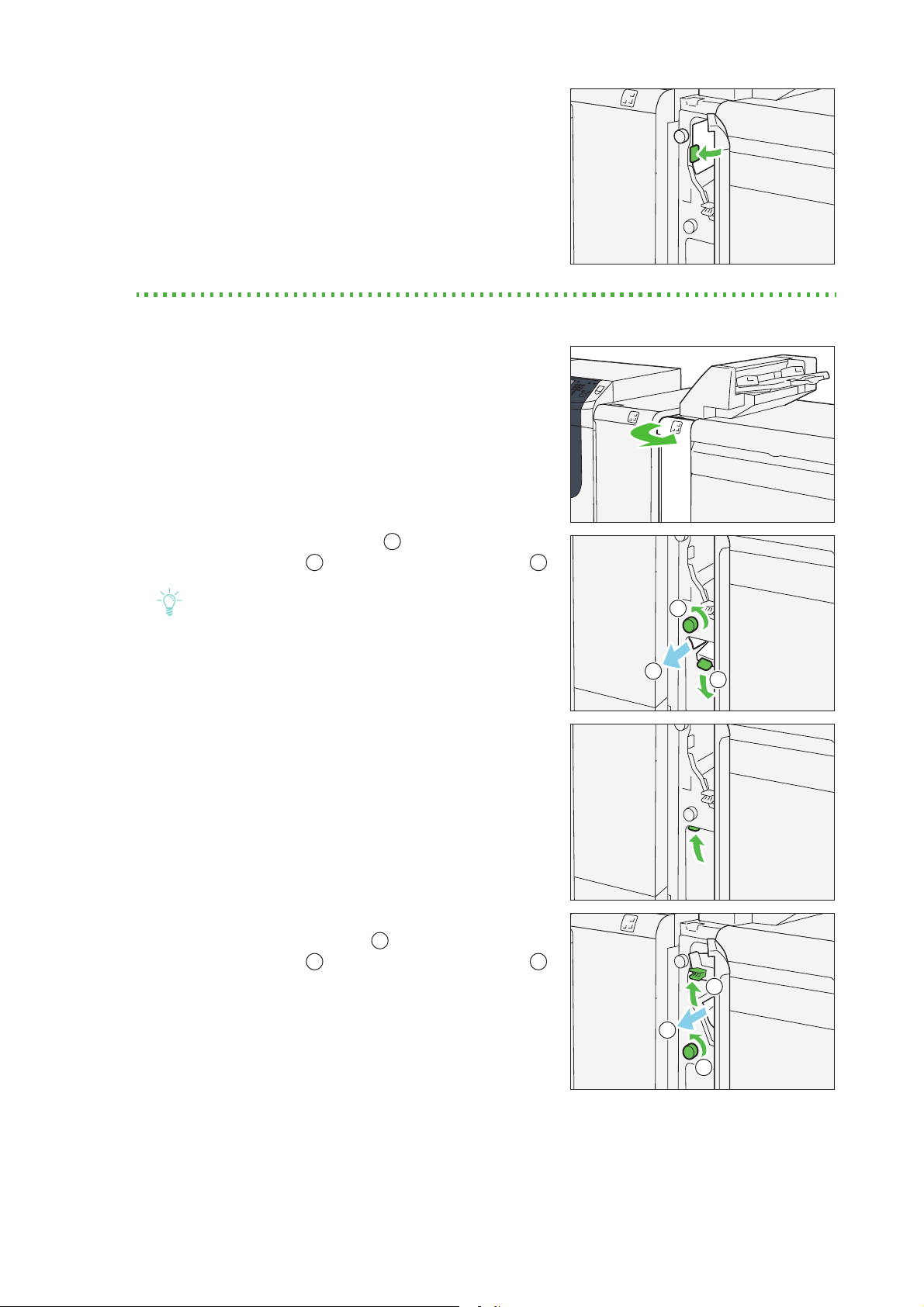

(1) Open lever "1a" to the right ( ) and turn knob "1c"

counterclockwise ( ). Remove jammed papers ( ).

2

(2) Return lever "1a" to its original position.

When Lamp E2 is Lit

(1) Open lever "1d" to downward ( ) and turn knob

"1c" counterclockwise ( ). Remove jammed papers

2

().

(2) Return lever "1d" to its original position.

(3) Open lever "1a" ( ) and lever "1b" ( ) to the right.

2

Remove jammed papers ( ).

Chapter 1 2nd High Capacity Feeder C1-DS

15

(4) Return levers "1a" and "1b" to their original positions.

1

2

3

1

3

1

2

3

3

When Lamp E3 is Lit

(1) Open lever "1b" to the right ( ) and turn knob "1c"

counterclockwise ( ). Remove jammed papers ( ).

2

(2) Return lever "1b" to its original position.

When Lamp E4 is Lit

(1) Open lever "1d" downward ( ) and turn knob "1c"

counterclockwise ( ). Remove jammed papers ( ).

2

1

(2) If you have difficulty in removing jammed papers,

loaded in the Bypass Tray, open the top cover and

remove them.

16

Optional Units Manual

(3) Return lever "1d" to its original position.

Note

Important

1

2

3

1

2

3

1

2

3.

Close the cover.

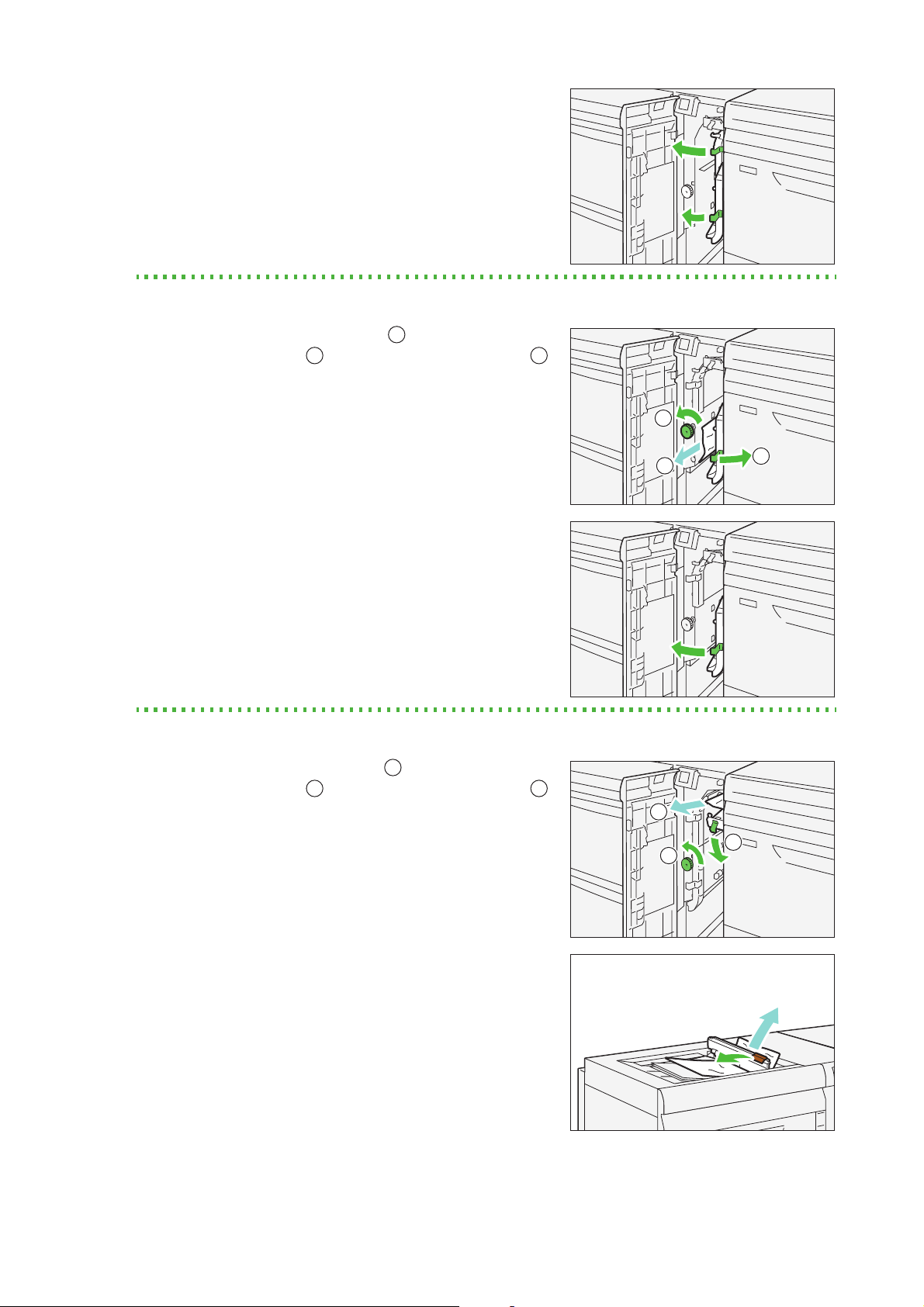

1.2.3 Paper Jams in the Paper Feeding Unit

Follow the steps below to clear paper jams in the paper feeding unit.

The "E5" error lamp of the High Capacity Feeder C3-DS will illuminate.

1.

Pull out the top cover of the High Capacity Feeder

C3-DS toward you until it stops.

Before pulling out the Tray, make sure no paper is

jammed inside the right side cover.

2.

Open lever "2a" to the right ( ) and lever "2b"

upward ( ). Remove jammed papers

3.

Return levers "2a" ( ) and lever "2b" ( ) to their

1

()

2

original positions.

.

4.

Close the cover.

Chapter 1 2nd High Capacity Feeder C1-DS

17

Chapter 2

Note

2

1

3

2.1 Machine Components............................................................................18

2.2 Curl Correction...........................................................................................19

2.3 Paper Jams..................................................................................................21

Interface Decurler Module

2.1

No. Component Description

1

2

Machine Components

Error lamp Illuminates when a paper jam occurs.

If the lamp is blinking, you must first clear the paper jam.

Decurl button Press this button to correct the curl.

This function is to correct the curl while sheets are being printed.

3 Cover Open this cover to clear paper jams.

The Interface Decurler Module is required when connecting a paper discharge unit to the printer unit.

Specifications

Item Specification

Power supply

Power consumption

Dimensions Width 340 x Depth 725 x Height 992 mm

Weight 40 kg

Power supply 100 - 240 V AC±10% 100 V 2.5 A, 50 Hz or 60 Hz

240 V 1 A, 50 Hz or 60 Hz

Peak 250 W

18

Optional Units Manual

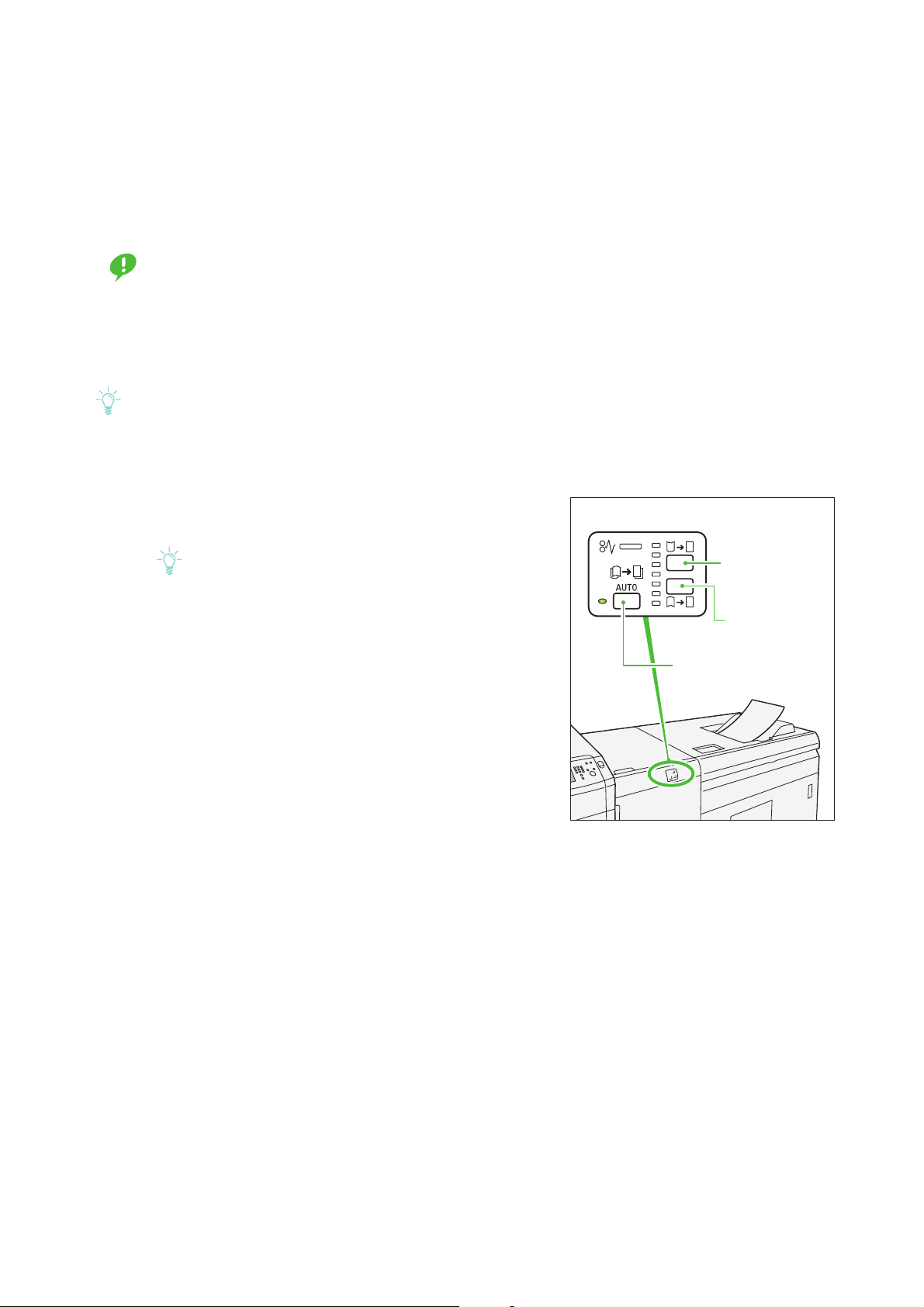

2.2

Important

Note

Note

Upward curl

correction button

<AUTO> button

Downward

curl correction button

Curl Correction

By pressing decurl buttons, you can correct the paper curl caused by heat and pressure.

As far as the printer is powered on, the decurl buttons function regardless of whether the printer is running

or idle.

This curl correction function is intended to be used during printing. Fine adjustment according to the characteristics of each paper can be made by using Stock Library.

For detailed information on how to regard the Stock Library, refer to "Stock Library" in the Stock Library

Manager Manual.

Since paper curl can easily cause stapling problems, make sure you always check the curl direction of output paper to properly correct paper curl.

If you correct curl while the printer is running, the new mode is applied to the sheet delivered immediately

after the button is pressed.

1.

Check the curl direction of output paper.

2.

Make sure a decurl button lamp is lit and press the

button.

When feeding paper in "AUTO" mode, the lamps illuminate briefly to indicate the direction and level of

correction as paper curl is corrected. Use these lamps

as a guide when correcting paper curl manually.

Chapter 2 Interface Decurler Module

19

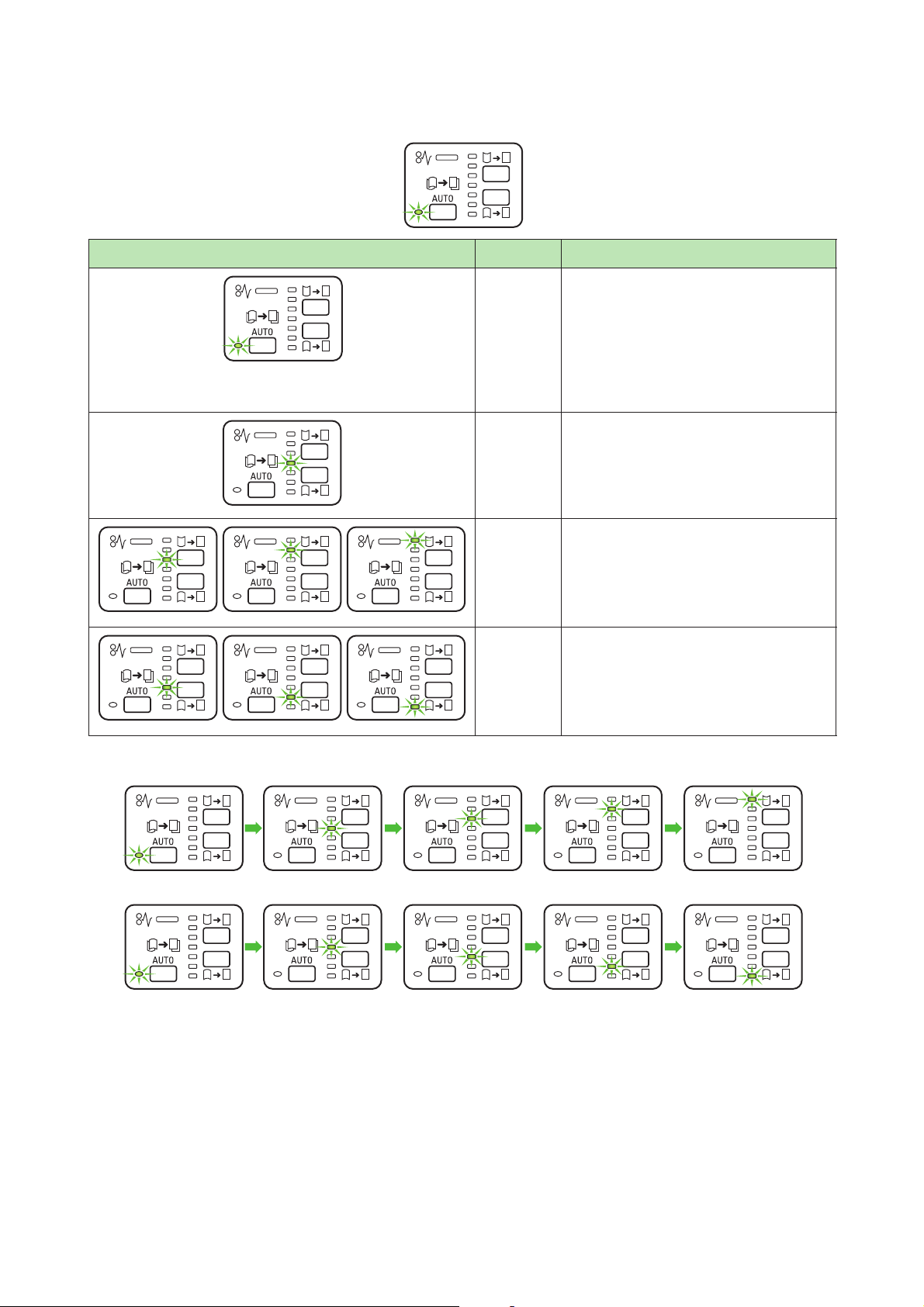

Curl correction modes and functions of the decurl buttons

Press the <AUTO> button to switch to the "AUTO" mode.

Indicator Mode Function

AUTO Automatically corrects paper curl.

No rmally i t is recomm ended to sel ect this

mode.

The module selects the optimal curl

adjustment method, depending on the

size and delivery orientation of the

printed output.

OFF The machine will not perform the curling

correction to straighten the curled

printed output.

Upward

Curling

Downward

Curling

Select this when the printed output print

is curled upwards, in order to apply

upward curl correction.

The correction level is indicated by the

lamp, with the top being the highest.

Select this when the printed output is

curled downwards, in order to apply

downward curl correction.

The correction level is indicated by the

lamp, with the bottom being the lowest.

Pressing the upward curl correction button changes correction levels as follows.

Pressing the downward curl correction button changes correction levels as follows.

20

Optional Units Manual

2.3

Note

Refer

Refer

E1

E2

E3

Paper Jams

If there is a paper jam, the printing will be canceled.

The Error Message area of the touch screen will show the affected area in red, along with the message.

Also, the error lamp on the top of the machine will illuminate.

If the lamp is blinking, you must first clear the paper jam.

If there is a paper jam in the following area, tap the [Faults] and the [Faults] screen will appear, explaining

how to remove jammed papers.

Remove the paper only after you are sure the printer is no longer moving.

Important

After removing jammed papers, be sure to close the cover. Leaving the cover open will not be able to continue to print jobs.

Leave the power on and proceed to remove jammed papers.

If there is still paper remaining, the paper jam message will continue to display. Make sure that there is no

jammed paper left and also no jams in other places.

For detailed information on how to regard the messages, refer to "1.2.1 Services Home" in the User Interface

Manual.

Follow the steps below to clear paper jams in the Interface Decurler Module.

1.

Open the cover of the Interface Decurler Module.

If the jammed long paper is lying across more than one unit, refer to "3.3.4 Long Paper Jam" in the

Printer Unit Manual.

Chapter 2 Interface Decurler Module

21

2.

Important

Note

1

2

3

2

3

1

2

1

2

Open lever "1a" downward ( ) and turn knob "1b"

1

counterclockwise ( ). Remove jammed papers ( ).

Make sure you turn the knob 10 times or more.

When removing the jammed paper, carefully

remove it by gently pulling it out.

The jammed paper may be hidden behind the upper

covering.

3.

Return lever "1a" to its original position.

4.

If you have difficulty in removing jammed papers,

open lever "1c" upward ( ) and remove jammed

papers ( ).

5.

Return lever "1c" to its original position.

6.

Close the cover.

22

Optional Units Manual

Chapter 3

Note

Refer

1

3

2

4

3.1 Machine Components............................................................................23

3.2 Loading Paper............................................................................................25

3.3 Paper Jams..................................................................................................26

Inserter

3.1

No. Component Description

1 Inserter Tray (Tray T1) Load paper to be used for separators or covers sheets.

2

Machine Components

Error lamp Illuminates when a paper jam occurs.

If the priority unit lamp is blinking, you must first clear the paper jam.

Decurl button Use this button if paper curl still persists after setting the curl correction level to the

highest (or the lowest) on the Interface Decurler Module. Steps to correct paper curl is

the same as those for the Interface Decurler Module. This button, however, provides

3

4 Cover Open this cover to clear paper jams.

The Inserter can be only attached to the Interface Decurler Module.

you with three correction levels only: OFF, upward and downward.

For information about the Curl Correction in the Interface Decurler Module, refer to "2.2 Curl Correction" (p.19).

Chapter 3 Inserter

23

Specifications

Note

Item Specification

Paper size Standard size Maximum A3, 13 x 19"

Minimum JIS B5

Custom size Height 182.0 - 330.2 mm

Width 148.0 - 488.0 mm

Paper weight 52 - 350 g/m

2

Note

Make sure you use Bypass Tray when using the combination of the following paper types

and Saddle Stitch / Bi-fold, because the combination can cause misalignment of folding

positions and wrinkle:

Coated Paper weighing 127 g/m2 or lighter

Blank sheets (unprinted paper) weighing 80 g/m2 or lighter

Tray capacity 250 sheets

The values are based on Colotech+90.

Power supply Supplied from the Interface Decurler Module

Dimensions Width 700 x Depth 725 x Height 1,228 mm (The width of the paper feeding unit is 165 mm.)

Weight 45 kg

24

Optional Units Manual

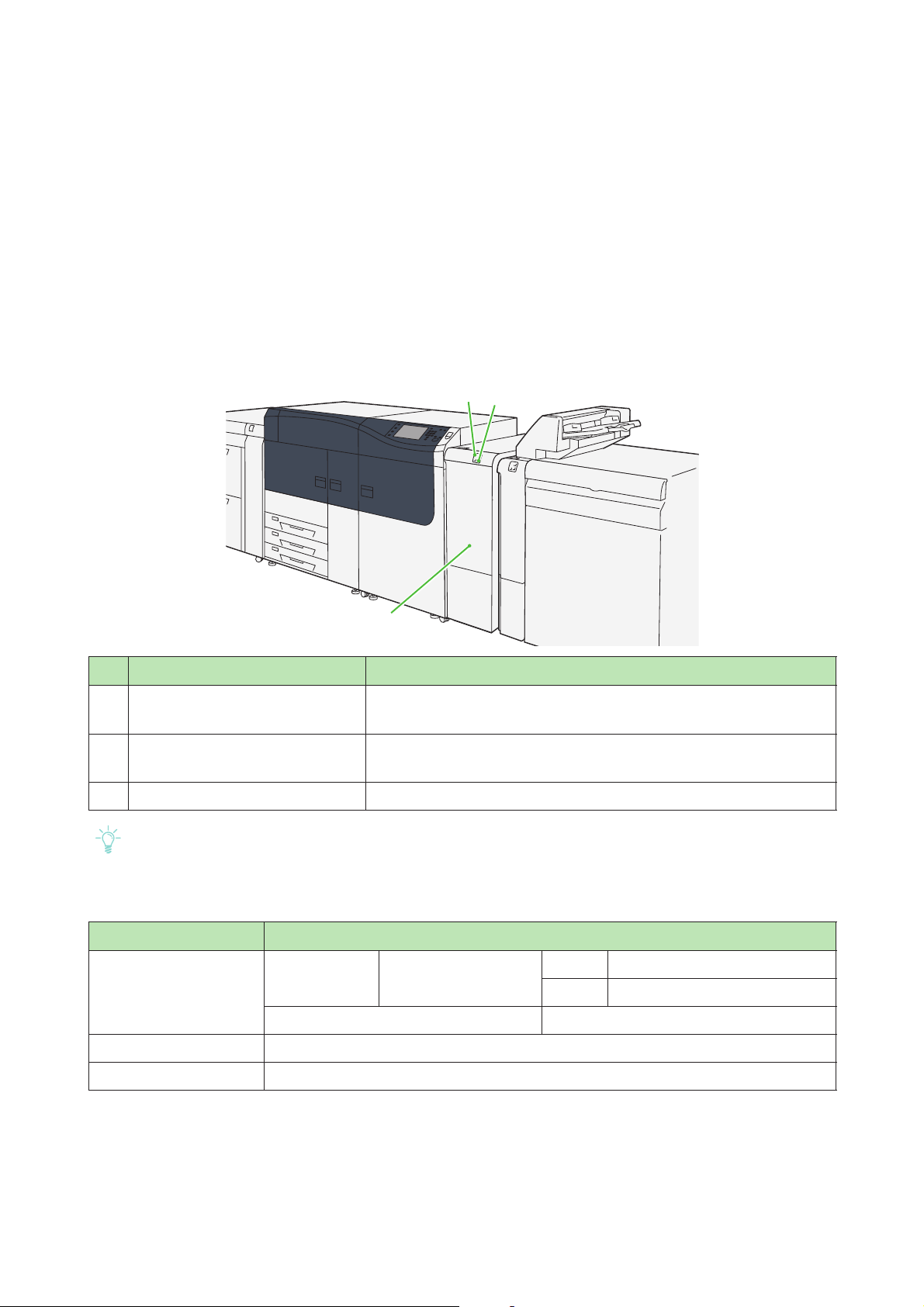

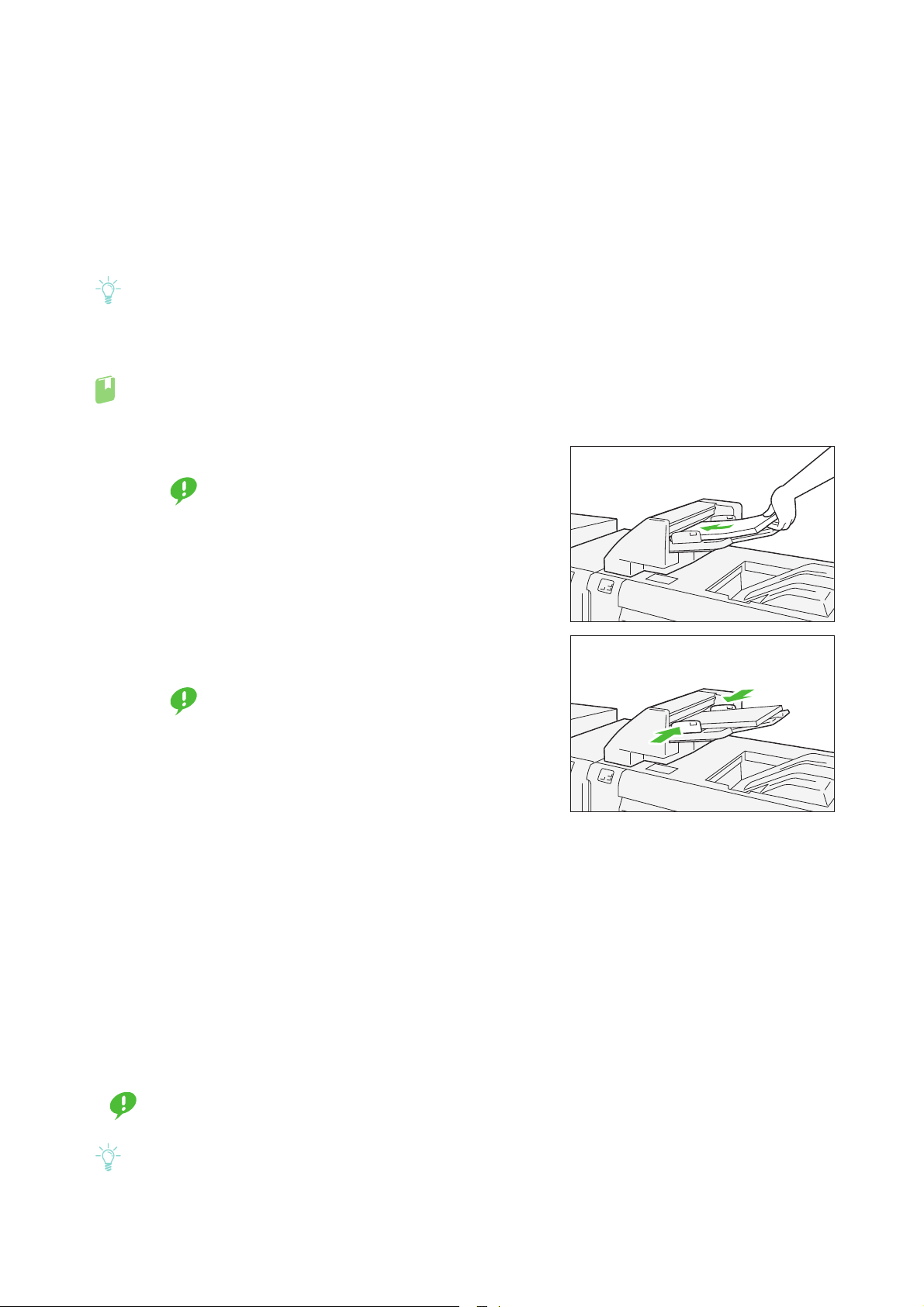

3.2

Note

Refer

Important

Important

Important

Note

Load paper to be used for separators or covers sheets (blank or printed sheets).

The Inserter Tray is used for feeding separator or cover sheets. These sheets are not printed by the

machine.

Up to 250 sheets (Colotech+90) can be loaded.

1.

Loading Paper

If any paper remains in the Tray, remove the paper first, and put the paper and the new papertogether,

and then load all of the paper into the Tray at once.

Saddle Stitch / Bi-fold can be performed only when using paper of the same size as main paper (paper

sheets delivered from the printer unit).

For detailed information about the supported paper size and weight, refer to "2.1.2 Supported Paper" in the

Printer Unit Manual.

Load the paper, neatly aligning all edges.

Do not load paper above the maximum fill line. It

may cause paper jams or machine malfunctions.

2.

Hold the center of the paper guides and slide them to

the desired paper size.

Slide the guides gently to just touch the edges of the

paper. If the distance between the guides is too long

or short relative to the paper, paper jams may occur.

Special Media Setting

Hole punched paper

Orientation: Place the holes of paper on the right side when you face the front side of the Inserter.

Precut tab

Orientation: Place the precut tab of paper on the left side when you face the front side of the Inserter.

Purge Function

The printer stops printing when paper runs out. When this happens, sheets of paper being fed are delivered to the optional unit's output tray.

Do not reuse the sheets ejected by the Purge function, as this may cause paper jams.

You can also set so that purging does not occur when paper runs out.

For detailed information, refer to "4.1.8 Maintenance" in the User Interface Manual.

Chapter 3 Inserter

25

3.3

Note

Refer

Note

Refer

E1

E2

E3

Paper Jams

If there is a paper jam, the printing will be canceled.

The Error Message area of the touch screen will show the affected area in red, along with the message.

Also, the error lamp on the top of the machine will illuminate.

If the priority unit lamp is blinking, you must first clear the paper jam.

If there is a paper jam in the following area, tap the [Faults] and the [Faults] screen will appear, explaining

how to remove jammed papers.

Remove the paper only after you are sure the printer is no longer moving.

Important

After removing jammed papers, be sure to close the cover. Leaving the cover open will not be able to continue to print jobs.

Leave the power on and proceed to remove jammed papers.

If there is still paper remaining, the paper jam message will continue to display. Make sure that there is no

jammed paper left and also no jams in other places.

For detailed information on how to regard the messages, refer to "1.2.1 Services Home" in the User Interface

Manual.

Follow the steps below to clear paper jams in the Inserter.

1.

Remove jammed papers.

When Lamp E1 is Lit...........................................................................................................................................................p.27

When Lamp E2 is Lit...........................................................................................................................................................p.27

When Lamp E3 is Lit...........................................................................................................................................................p.28

26

Solutions differ depending on where the paper jam occurs. Confirm the jammed area in the Error

Message area.

The code (E) on the upper-left part of the message indicates which error lamp on the top of the

machine is illuminating.

If the jammed long paper is lying across more than one unit, refer to "3.3.4 Long Paper Jam" in the

Printer Unit Manual.

Optional Units Manual

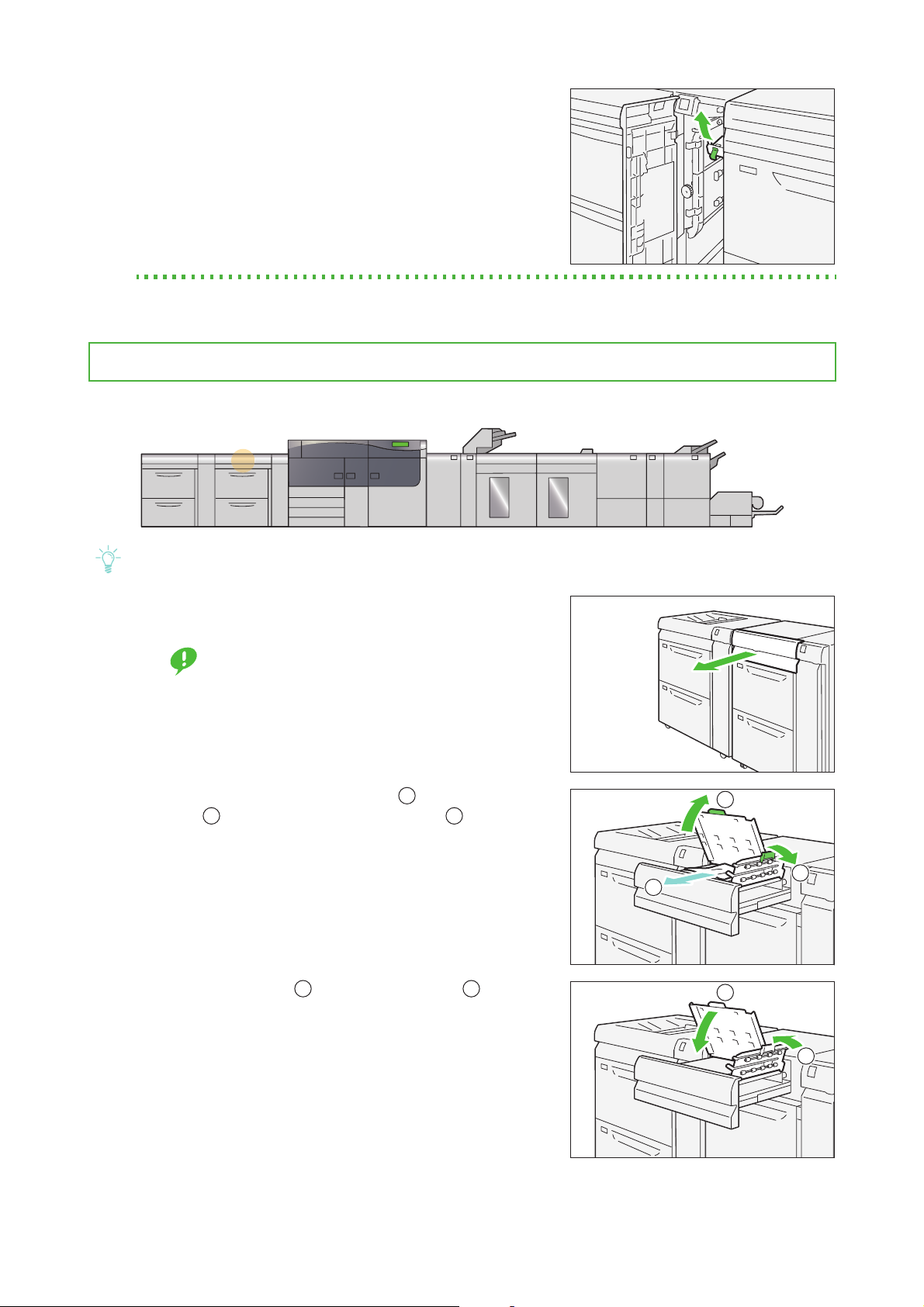

When Lamp E1 is Lit

Important

1

2

3

1

3

1

2

3

3

(1) Open the cover, and remove jammed papers and all

paper loaded in the Tray.

When two or more sheets of paper are loaded,

remove all sheets.

(2) Fan the paper you removed and make sure all four

corners are aligned correctly. Then reload the paper.

(3) Push the cover to close it.

When Lamp E2 is Lit

(1) Open the cover of the Inserter.

(2) Open lever "1a" upward ( ) and turn knob "1b"

counterclockwise ( ). Remove jammed papers ( ).

2

(3) Return lever "1a" to its original position.

(4) If you have difficulty in removing jammed papers,

open lever "1c" to the right ( ) and turn knob "1b"

counterclockwise ( ). Remove jammed papers ( ).

2

1

Chapter 3 Inserter

27

(5) Return lever "1c" to its original position.

Note

1

2

3

1

3

1

2

3

1

3

(6) Close the cover.

When Lamp E3 is Lit

(1) Open the cover of the Inserter.

(2) Open lever "1d" downward ( ) and turn knob "1e"

counterclockwise ( ). Remove jammed papers ( ).

2

The jammed paper may be hidden behind the upper

covering.

(3) Return lever "1d" to its original position.

(4) If you have difficulty in removing jammed papers,

open lever "1a" upward ( ) and turn knob "1e"

counterclockwise ( ). Remove jammed papers ( ).

2

28

Optional Units Manual

(5) Return lever "1a" to its original position.

Refer

(6) Close the cover.

2.

Check the curl direction of jammed paper, and correct paper curl.

For information about the Curl Correction, refer to "2.2 Curl Correction" (p.19).

Chapter 3 Inserter

29

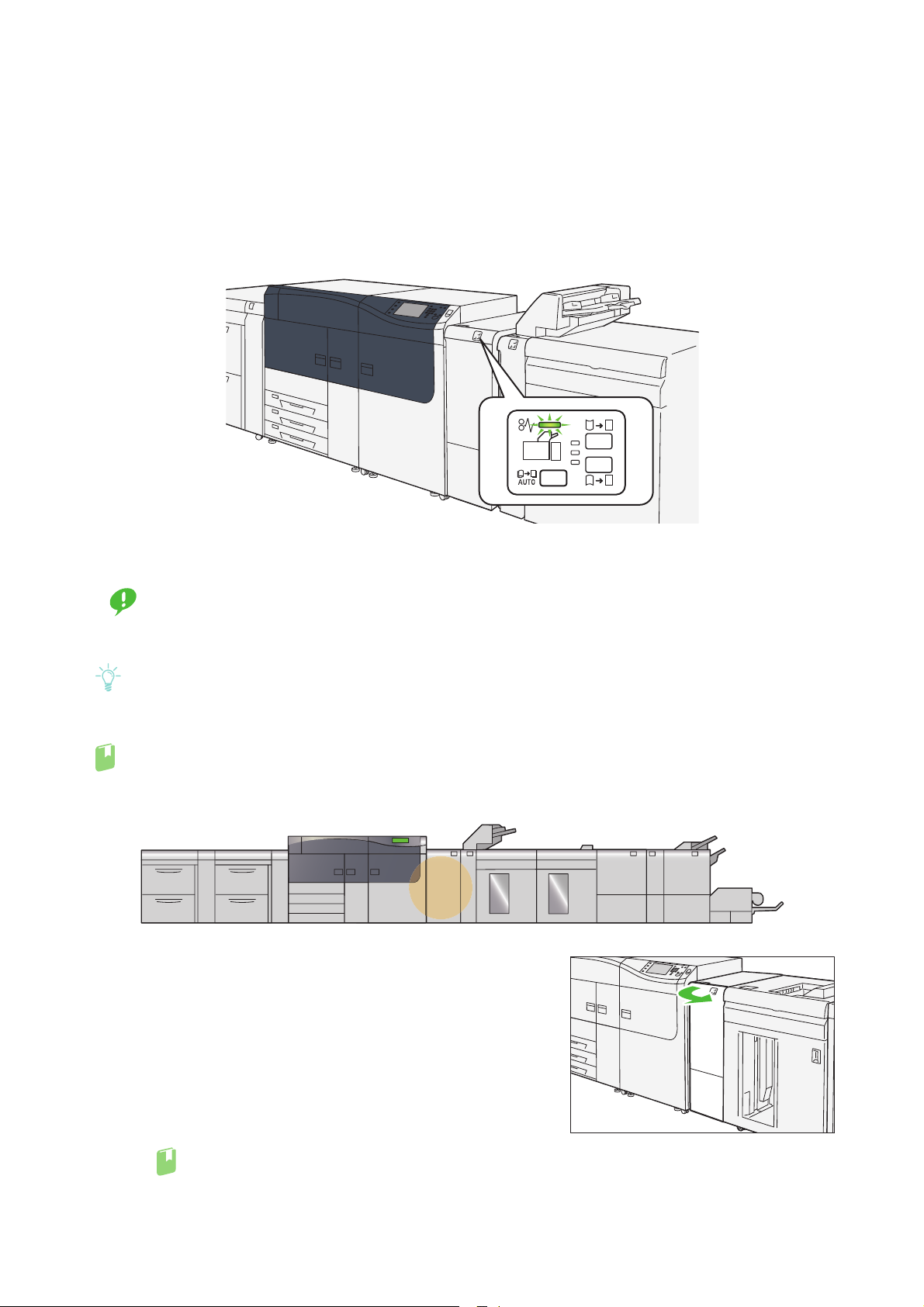

Chapter 4

Note

2

3

7

4

5

6

8

1

4.1 Machine Component..............................................................................30

4.2 Output Paper..............................................................................................32

4.3 Paper Jams..................................................................................................33

High Capacity Stacker

4.2.1 Output Trays.......................................................................................................... 32

4.2.2 Control Buttons.................................................................................................... 32

4.1

Machine Component

No. Component Description

1 Error lamps Illuminates when a paper jam occurs.

2 Sample button Press this button to output a sample sheet to the output tray.

3 Paper eject button Press this button to stop printing and remove paper.

4 Output tray Receives output sheets. Sample sheets are delivered here.

Circuit breaker switch

5

(back side)

6 Top cover Open this cover to clear paper jams.

Stacker tray (stacker cart) Press the paper eject button to output sheets by moving paper onto the stacker

7

8 Lower cover Open this cover to take out paper.

The installed first and second High Capacity Stackers are the same one.

30

Optional Units Manual

Automatically shuts off electricity in the event of fault current or a short circuit.

cart.

Circuit Breaker Switch

Note

Note

Breaker switch

TEST button

The switch is normally in the upper position.

If the machine will be moved or unused for an extended period of

time, turn off the switch by pressing it to the lower position.

When fault current is detected, the circuit breaker is automatically turned off to discontinue the electrical flow. Do not touch

the breakers under normal condition. For information on fault

current, refer to the Safety Notes.

Specifications

Item Specification

Tray capacity Output tray 500 sheets

Stacker tray 5,000 sheets

The values are based on a paper less than 80 g/m2.

Paper size Output tray Standard size Maximum A3, 13 x 19"

Minimum Postcard (100 x 148 mm)

Custom size Height 98.0 - 330.2 mm

Width 148.0 - 660.4 mm

Stacker tray Standard size Maximum A3, 13 x 19"

Minimum JIS B5

Custom size Height 203.0 - 330.2 mm

Width 182.0 - 488.0 mm

Paper weight Output Tray 52 - 350 g/m

Stacker tray 52 - 300 g/m

Power supply

Power supply 100 - 240 V AC±10% 100 V 1.5 A, 50 Hz or 60 Hz

Power consumption

Peak 150 W

Dimensions Width 800 x Depth 725 x Height 1,042 mm

Weight 155 kg

2

2

240 V 0.8 A, 50 Hz or 60 Hz

Chapter 4 High Capacity Stacker

31

4.2

Refer

Output tray

Stacker tray

Output Paper

4.2.1 Output Trays

The High Capacity Stacker has two output trays: the stacker tray

and the output tray.

Unnecessary sheets purged by Purge function are ejected to the

output tray.

Which output tray to be used is specified on your Print Server.

For detailed information on how to regard the method of

specification, refer to customer documentation supplied with

Print Servers.

For detailed information about the Purge function, refer to

"2.2 Output Paper" in the Printer Unit Manual.

4.2.2 Control Buttons

Sample Button

Press this button to output a sample sheet to the output tray.

Paper Eject Button

Press this button to stop printing and remove paper.

Sample button

Paper eject button

32

Optional Units Manual

4.3

Note

Refer

Paper Jams

If there is a paper jam, the printing will be canceled.

The Error Message area of the touch screen will show the affected area in red, along with the message.

Also, the error lamp on the top of the machine will illuminate.

If there is a paper jam in the following area, tap the [Faults] and the [Faults] screen will appear, explaining

how to remove jammed papers.

Remove the paper only after you are sure the printer is no longer moving.

Important

After removing jammed papers, be sure to close the cover. Leaving the cover open will not be able to continue to print jobs.

Leave the power on and proceed to remove jammed papers.

If there is still paper remaining, the paper jam message will continue to display. Make sure that there is no

jammed paper left and also no jams in other places.

For detailed information on how to regard the messages, refer to "1.2.1 Services Home" in the User Interface

Manual.

Follow the steps below to clear paper jams in the High Capacity Stacker.

1.

Remove jammed papers.

When Lamp E1 is Lit...........................................................................................................................................................p.34

When Lamp E2 is Lit...........................................................................................................................................................p.34

When Lamp E3 is Lit...........................................................................................................................................................p.35

When Lamp E4 is Lit...........................................................................................................................................................p.36

When Lamp E5 is Lit...........................................................................................................................................................p.37

When Lamp E6 is Lit...........................................................................................................................................................p.37

When Lamp E7 is Lit...........................................................................................................................................................p.38

When Lamp E8 is Lit...........................................................................................................................................................p.39

Chapter 4 High Capacity Stacker

33

Note

Solutions differ depending on where the paper jam occurs. Confirm the jammed area in the Error

Refer

1

2

1

Message area.

The code (E) on the upper-left part of the message indicates which error lamp on the top of the

machine is illuminating.

If the jammed long paper is lying across more than one unit, refer to "3.3.4 Long Paper Jam" in the

Printer Unit Manual.

When Lamp E1 is Lit

(1) Open the top cover of the High Capacity Stacker.

(2) Open lever "1b" upward ( ) and remove jammed

papers ( ).

2

(3) Return lever "1b" to its original position.

(4) Close the cover.

When Lamp E2 is Lit

(1) Open the top cover of the High Capacity Stacker.

34

Optional Units Manual

(2) Open lever "1b" upward ( ) and turn knob "1a"

1

3

2

1

1

3

2

1

3

counterclockwise ( ). Remove jammed papers. ( )

2

3

(3) Return lever "1b" to its original position.

(4) Close the cover.

When Lamp E3 is Lit

(1) Open the top cover of the High Capacity Stacker.

(2) Open lever "1b" upward ( ) and turn knob "1a"

counterclockwise ( ). Remove jammed papers ( ).

2

(3) Return lever "1b" to its original position.

Chapter 4 High Capacity Stacker

35

(4) Open lever "2b" upward ( ) and turn knob "2c"

3

1

2

1

3

1

2

1

2

counterclockwise ( ). Remove jammed papers ( ).

2

(5) Return lever "2b" to its original position.

(6) Close the cover.

When Lamp E4 is Lit

(1) Open the top cover of the High Capacity Stacker.

(2) Open lever "2a" downward ( ) and remove jammed

papers( ).

(3) Return lever "2a" to its original position.

(4) Close the cover.

36

Optional Units Manual

When Lamp E5 is Lit

3

1

2

1

2

3

(1) Open the top cover of the High Capacity Stacker.

(2) Open lever "2b" upward ( ) and turn knob "2c"

counterclockwise ( ). Remove jammed papers ( ).

(3) Return lever "2b" to its original position.

(4) Close the cover.

When Lamp E6 is Lit

(1) Press the paper eject button.

(2) Make sure the lower cover is unlocked and then open

it.

Chapter 4 High Capacity Stacker

37

(3) Pull out the stacker cart slowly and remove jammed

1

2

1

papers.

(4) Push the stacker cart back into its original position.

(5) Close the cover.

When Lamp E7 is Lit

(1) Remove any paper coming out at the exit of the out-

put tray.

(2) Open the top cover of the High Capacity Stacker.

(3) Open lever "1b" upward ( ) and remove jammed

papers ( ).

2

(4) Return lever "1b" to its original position.

38

Optional Units Manual

(5) Open lever "2a" downward ( ) and remove jammed

Refer

1

2

1

1

2

3

1

2

papers ( ).

2

(6) Return lever "2a" to its original position.

(7) Close the cover.

When Lamp E8 is Lit

(1) Open the top cover of the High Capacity Stacker.

(2) Open lever "3b" upward ( ) and turn knob "3a"

clockwise ( ). Remove jammed papers( ).

3

(3) Return lever "3b" to its original position.

(4) Close the cover.

2.

Check the curl direction of jammed paper, and correct paper curl.

For information about the Curl Correction, refer to "2.2 Curl Correction" (p.19).

Chapter 4 High Capacity Stacker

39

Chapter 5

Note

Note

1

2

4

3

Only the GX Print Server model supports the crease feature.

5.1 Machine Components............................................................................40

5.2 Trimmer Waste Container.....................................................................43

5.3 Paper Jams..................................................................................................44

Crease/Two-sided Trimmer

5.1

No Component Description

1

Machine Components

Error lamp Illuminates when a paper jam occurs.

If the priority unit lamp is blinking, you must first clear the paper jam.

Waste full lamp This lamp starts lighting when it is time to empty the waste container, and blink

2

3 Upper cover Open this cover to clear paper jams.

4 Lower cover Open this cover to dispose of the paper scraps.

The Crease/Two-sided Trimmer can be only attached to the Finisher.

40

Optional Units Manual

when the waste container becomes full.

Specifications

Note

Item Specification

Two-sided Trim Paper size Standard size Maximum A3, 13 x 19"

Minimum A4, Letter (8.5 x 11")

Custom size Height 194.0 - 330.2 mm

Width 210.0 - 488.0 mm

(trim and crease: - 386.0 mm)

Paper weight Uncoated 52 - 350 g/m

Coated 106 - 350 g/m

Trimming size| 6 - 25 mm

Setting a head-to-toe trimming area size of 7 mm or less

may cause damage of the trimmed edges.

Crease (with Creaser) Paper size Standard size Maximum A3, 13 x 19"

Minimum JIS B5

Custom size Height 182.0 - 330.2 mm

Width 210.0 - 488.0 mm

(trim and crease: - 386.0 mm)

2

Paper weight 60 - 350 g/m

(with Saddle Stitch / Bi-Fold)

2

2

Note

157 g/ m2 or heavier when not using Saddle Stitch / Bi-Fold. You may also apply

crease to paper weighing 156 g/m

you can fold the output paper sheets easily by hand along the crease lines) cannot be guaranteed.

If wrinkles occur around crease lines on output sheets when you are using Saddle

Stitch / Bi-Fold, set [Crease Pressure] to a lower value in Stock Library Manager.

For information on [Crease Pressure], refer to "Profiles" in the Stock Library Man-

ager Manual.

Number of lines 1 - 5

Note

When the paper size is less than 279 mm landscape, or is 450 mm landscape or

larger, the number of crease lines is limited to up to three.

Power supply

Power supply 100 - 240 V AC±10% 100 V 4 A, 50 Hz or 60 Hz

Power consumption

Peak 100 V 400 W

Dimensions Width 605 x Depth 725 x Height 992 mm

Weight with Creaser 128 kg

without Creaser 118 kg

2

or lighter, but the crease quality (i.e., whether

240V 2 A, 50 Hz or 60 Hz

240V 480W

Chapter 5 Crease/Two-sided Trimmer

41

Trimmed and Creased Areas

Note

194.0 - 330.2 mm (trim)

182.0 - 330.2 mm (crease)

Trim

A

B

Feed direction

Crease

210 - 488 mm

386 mm or smaller (trim and crease)

a: 12 mm or larger

b - e: 25 mm or larger

A=B: 6 - 25 mm

a

e (*)bcd

(*) If this size, measured from the leading edge of paper sheet, is less than 45 mm, printing cannot occur.

And, if this size, measured from the leading edge of paper sheet, is equal to 62 mm or less, paper feed

performance cannot be guaranteed.

Limitation on Color Density of Color Paper

Darker color paper is not suitable for trim. (It can cause paper jam.)

We have evaluated the following paper types and verified that they work with trim:

Xerox Symphony (Yellow, Blue, Pink, Green)

We have evaluated the following color densities:

The same is also applied to paper sheet having no margin around its top edge.

Xerox Symphony

0%

10%

20%

30%

40%

50%

60%

70%

80%

90%

100%

Trim can be done

Trim cannot be done

42

Optional Units Manual

5.2

Important

When it is time to empty the Waste Container, the waste full lamp starts lighting. This indicates you need

to empty the container. (You can do this while the printer is running.)

After that, the message appears on the Error Message area telling you that the Waste Container is full.

At this point, the waste full lamp changes from lighting to blinking.

1.

2.

3.

Trimmer Waste Container

Open the lower cover of the Crease/Two-sided Trimmer.

Pull out Waste Container.

Discard all waste.

Be sure to dispose of it entirely. If some waste or

scraps remain, the container will become full before

the message appears again, causing machine malfunctions.

Make sure there is no waste left inside, especially, beneath the

frame that is located behind the container.

Use the poker to remove any waste left inside.

4.

Return the Waste Container to its original position.

5.

Close the cover.

Chapter 5 Crease/Two-sided Trimmer

43

5.3

Note

Refer

E1 E2 E3

E4 E5 E6

E7

Paper Jams

If there is a paper jam, the printing will be canceled.

The Error Message area of the touch screen will show the affected area in red, along with the message.

Also, the error lamp on the top of the machine will illuminate.

If the priority unit lamp is blinking, you must first clear the paper jam.

If there is a paper jam in the following area, tap the [Faults] and the [Faults] screen will appear, explaining

how to remove jammed papers.

Remove the paper only after you are sure the printer is no longer moving.

Important

After removing jammed papers, be sure to close the cover. Leaving the cover open will not be able to continue to print jobs.

Leave the power on and proceed to remove jammed papers.

If there is still paper remaining, the paper jam message will continue to display. Make sure that there is no

jammed paper left and also no jams in other places.

For detailed information on how to regard the messages, refer to "1.2.1 Services Home" in the User Interface

Manual.

Follow the steps below to clear paper jams in the Crease/Two-sided Trimmer.

1.

Open the upper cover of the Crease/Two-sided Trimmer.

44

Optional Units Manual

2.

Note

Refer

Note

1

2

4

3

1

4

1

2

1

Remove jammed papers.

When Lamp E1 is Lit...........................................................................................................................................................p.45

When Lamp E2 is Lit...........................................................................................................................................................p.46

When Lamp E3 is Lit...........................................................................................................................................................p.47

When Lamp E4 is Lit...........................................................................................................................................................p.48

When Lamp E5 is Lit...........................................................................................................................................................p.48

When Lamp E6 is Lit...........................................................................................................................................................p.49

When Lamp E7 is Lit...........................................................................................................................................................p.50

When the Lamp Does Not Go Out................................................................................................................................p.51

Solutions differ depending on where the paper jam occurs. Confirm the jammed area in the Error

Message area.

The code (E) on the upper-left part of the message indicates which error lamp on the top of the

machine is illuminating.

If the jammed long paper is lying across more than one unit, refer to "3.3.4 Long Paper Jam" in the

Printer Unit Manual.

When Lamp E1 is Lit

(1) Open lever "1a" downward ( ), lever "1b" down-

ward ( ) and lever "1d" upward ( ). Remove

2 3

jammed papers ( ).

The jammed paper may be hidden behind the upper

covering.

(2) If you have difficulty in removing jammed papers,

turn knob "1c" clockwise ( ) and remove jammed

papers ( ).

2

(3) Return levers "1a", lever "1b" and lever "1d" to their

original positions.

Chapter 5 Crease/Two-sided Trimmer

45

When Lamp E2 is Lit

1

2

2

1

2

1

2

1

2

(1) Turn knob "2" counterclockwise to align the mark on

the knob with the unlock position (a mark resembling an open padlock).

(2) Open lever "1a" downward ( ) and lever "1b" down-

1

ward ( ).

(3) Turn knob "1c" clockwise ( ) and remove jammed

papers ( ).

2

1

(4) Return levers "1a" and lever "1b" to their original posi-

tions.

(5) If you have difficulty in removing jammed papers,

open lever "1d" upward ( ) and lever "2a" to the left

().

46

Optional Units Manual

(6) Turn knob "2b" counterclockwise ( ) and remove

Note

1

2

2

1

2

1

jammed papers ( ).

(7) Return levers "1d" and lever "2a" to their original

positions.

When Lamp E3 is Lit

(1) Turn knob "2" counterclockwise to align the mark on

the knob with the unlock position (a mark resembling an open padlock).

(2) Open lever "2c" downward ( ) and remove jammed

papers ( ).

2

The jammed paper may be hidden behind the upper

covering.

1

(3) Return lever "2c" to its original position.

Chapter 5 Crease/Two-sided Trimmer

47

When Lamp E4 is Lit

Note

1

2

3

2

1

2

1

2

3

3

1

2

1

(1) Open lever "2c" downward ( ), lever "2d" upward

( ) and lever "2e" to the right ( ).

(2) Turn knob "2f" clockwise ( ) and remove jammed

papers ( ).

2

Grasp the leading edge of the jammed sheet, and pull

out the sheet to remove it.

1

3

1

If you have difficulty in removing the jammed paper

sheet, grasp the top edge at the inner side (right side) of

the sheet, and pull out the sheet to remove it.

(3) Return levers "2e" ( ), lever "2d" ( ) and lever "2c"

1

2

( ) to their original positions.

When Lamp E5 is Lit

(1) Open lever "3a" to the right ( ), lever "3b" to the

2

left ( ).

48

Optional Units Manual

(2) Turn knob "3c" clockwise ( ) and remove jammed

1

2

1

2

1

2

1

2

4

3

4

1

2

2

papers ( ).

2

1

(3) Turn knob "2f" counterclockwise ( ) and remove

jammed papers ( ).

(4) Return levers "3a" and lever "3b" to their original posi-

tions.

When Lamp E6 is Lit

(1) Open lever "3a" to the right ( ), lever "4b" down-

ward ( ) and lever "4c" to the right ( ). Remove

2 3

1

jammed papers ( ).

(2) Turn knob "4d" counterclockwise ( ) and remove

1

jammed papers ( ).

Chapter 5 Crease/Two-sided Trimmer

49

(3) Open lever "4a" to the right ( ) and turn knob "2f"

Note

Important

2

3

1

3

2

1

1

1

2

counterclockwise ( ). Remove jammed papers

2

1

().

Hold lever "4a" while turning knob "2f".

(4) Turn knob "3c" clockwise ( ) and remove jammed

papers ( ).

2

(5) Return levers "3a", lever "4b" and lever "4c" to their

original positions.

When Lamp E7 is Lit

(1) Open lever "3a" to the right ( ) and turn knob "2f"

counterclockwise ( ).

Make sure you turn the knob 5 times or more.

2

1

(2) Pull out the Trimmer Waste Container and then

replace it back again -- repeat this step continuously

three times or more.

50

Optional Units Manual

(3) Return lever "3a" to its original position.

1

2

1

When the Lamp Does Not Go Out

(1) Remove the supplied poker (stick) that is inside the

cover.

(2) Open lever "3a" to the right ( ) and open lever "3d"

to the right ( ).

2

(3) Use the poker to sweep waste around the Trimmer

Unit into the Trimmer Waste Container.

(4) If you have difficulty sweeping waste into the Trim-

mer Waste Container, you can use the poker to

gather waste and then remove the waste by hand.

(5) Return levers "3a" and lever "3d" to their original positions.

Chapter 5 Crease/Two-sided Trimmer

51

(6) Make sure there is no waste left inside, especially, beneath the frame that is located

Refer

Refer

behind the container.

Use the poker to remove any waste left inside.

For information about the container, refer to "5.2 Trimmer Waste Container" (p.43).

3.

Close the cover.

4.

Check the curl direction of jammed paper, and correct paper curl.

For information about the Curl Correction, refer to "2.2 Curl Correction" (p.19).

52

Optional Units Manual

Chapter 6

Refer

Note

6.1 Machine Components............................................................................53

6.2 Output Paper..............................................................................................54

6.3 Paper Jams..................................................................................................55

Folder Unit

6.1

No. Component Description

1 Tri-fold output tray Receives output sheets.

2 Tri-fold output tray button Press this button to open the tri-fold output tray.

Machine Components

2

1

For detailed information about the Fold Adjustment, refer to "Profiles" in the Stock Library Manager Manual.

Specifications

Item Specification

Z-Fold Half Sheet Paper size A3, Tabloid (11 x 17"), 8K, JIS B4

Paper weight 60 - 90 g/m

Tri-fold Paper size A4, Letter (8.5 x 11")

Paper weight 60 - 90 g/m

Tray capacity 30 sheets

The values are based on Colotech+90.

Power supply

Power consumption

Dimensions Width 235 x Depth 726 x Height 992 mm

Weight 55 kg

Power supply 100 - 240 V AC±10% 100 V 1 A, 50 Hz or 60 Hz

Peak 100 V 100 W

2

(Uncoated)

2

(Uncoated)

240V 0.5 A, 50 Hz or 60 Hz

240 V 120 W

Chapter 6 Folder Unit

53

6.2

Output Paper

Tri-fold Output Tray

C-Fold or Z-Fold jobs can be delivered to this tray only.

Tri-fold Output Tray Button

When you press the button, the lamp begins to flash. When the tri-fold

output tray is unlocked (the button lamp illuminates), pull out the trifold output tray.

Tri-fold Output Tray Button

Tri-fold output tray

54

Optional Units Manual

6.3

Note

Refer

E1 E2 E3

E4 E5 E6

E7

E10

E11

E12 E8 E9

Paper Jams

If there is a paper jam, the printing will be canceled.

The Error Message area of the touch screen will show the affected area in red, along with the message.

Also, the error lamp on the top of the Finisher will illuminate.

If the priority unit lamp is blinking, you must first clear the paper jam.

If there is a paper jam in the following area, tap the [Faults] and the [Faults] screen will appear, explaining

how to remove jammed papers.

Remove the paper only after you are sure the printer is no longer moving.

Important

After removing jammed papers, be sure to close the cover. Leaving the cover open will not be able to continue to print jobs.

Leave the power on and proceed to remove jammed papers.

If there is still paper remaining, the paper jam message will continue to display. Make sure that there is no

jammed paper left and also no jams in other places.

For detailed information on how to regard the messages, refer to "1.2.1 Services Home" in the User Interface

Manual.

Follow the steps below to clear paper jams in the Folder Unit.

1.

Open the cover of the Folder Unit.

Chapter 6 Folder Unit

55

2.

Note

Refer

2

3

1

3

3

2

1

1

3

Remove jammed papers.

When Lamp E10 is Lit ........................................................................................................................................................p.56

When Lamp E11 is Lit ........................................................................................................................................................p.56

When Lamp E12 is Lit ........................................................................................................................................................p.57

Solutions differ depending on where the paper jam occurs. Confirm the jammed area in the Error

Message area.

The code (E) on the upper-left part of the message indicates which error lamp on the top of the

machine is illuminating.

If the jammed long paper is lying across more than one unit, refer to "3.3.4 Long Paper Jam" in the

Printer Unit Manual.

When Lamp E10 is Lit

(1) Open lever "2a" upward ( ) and lever "2b" to the

2

left ( ). Remove jammed papers ( ).

1

(2) Return levers "2a" and lever "2b" to their original posi-

tions.

When Lamp E11 is Lit

(1) Open lever "2g" to the right ( ) and turn knob "2c"

counterclockwise ( ). Remove jammed papers

2

().

56

Optional Units Manual

(2) Return lever "2g" to its original position.

3

2

1

1

3

3

2

1

1

2

3

When Lamp E12 is Lit

(1) Pull out tri-fold output tray "2d".

(2) Open lever "2e" to the right ( ) and turn knob "2c"

counterclockwise ( ). Remove jammed papers

2

().

(3) Return lever "2e" to its original position.

(4) If you have difficulty in removing jammed papers,

open lever "2f" to the right ( ) and turn knob "2c"

counterclockwise ( ). Remove jammed papers

().

Chapter 6 Folder Unit

57

(5) Return lever "2f" to its original position.

Refer

(6) Return the tri-fold output tray "2d" to its original

position.

3.

Close the cover.

4.

Check the curl direction of jammed paper, and correct paper curl.

For information about the Curl Correction, refer to "2.2 Curl Correction" (p.19).

58

Optional Units Manual

Chapter 7

Note

In this manual, "Finisher D6", "Finisher D6 Plus" and" Finisher D6 with Booklet Maker" may be collectively called "Finisher".

7.1 Machine Components............................................................................60

7.2 Output Paper..............................................................................................64

7.3 Staple Cartridge........................................................................................67

7.4 Waste Container.......................................................................................74

7.5 Paper Jams..................................................................................................77

Finisher

7.2.1 Output Trays.......................................................................................................... 64

7.2.2 Control Buttons.................................................................................................... 66

7.3.1 Replacing the Cartridge.................................................................................... 67

7.3.2 Staple Faults .......................................................................................................... 69

7.3.3 Re-inserting the Staple Cartridge ................................................................. 72

7.4.1 Staple Waste Container.................................................................................... 74

7.4.2 Hole Punch Waste Container ......................................................................... 76

7.5.1 Paper Jams in the Finisher .............................................................................. 77

7.5.2 Paper Jams in the Saddle Stitch Unit ......................................................... 81

7.5.3 Paper Jams in the Paper Feeding Unit....................................................... 84

Chapter 7 Finisher

59

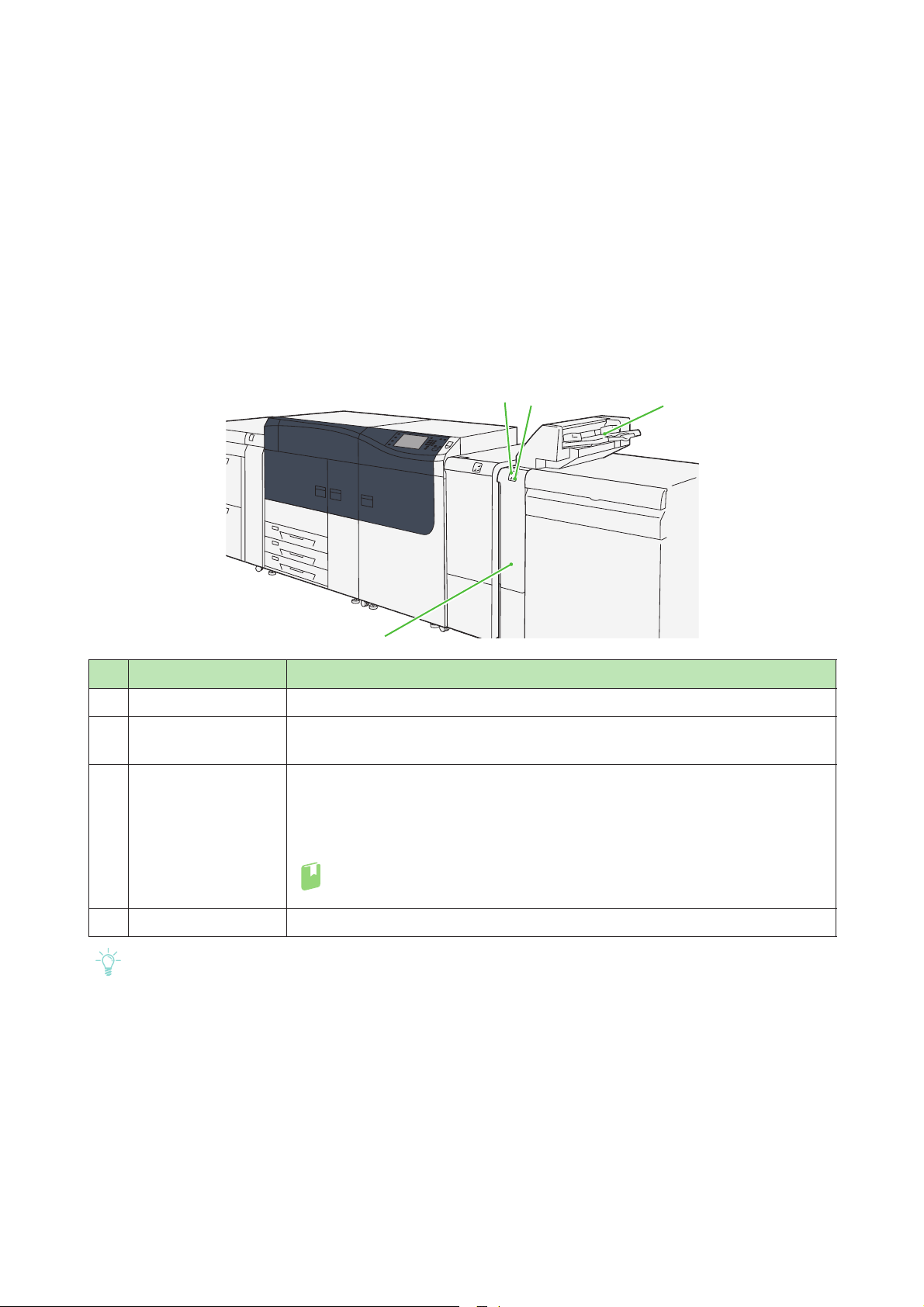

7.1

Refer

12

3

4

6

5

7

8

9

10

Machine Components

No Component Description

Error lamp Illuminates when a paper jam occurs.

1

2 Output tray Receives output sheets.

3 Finisher tray Receives output sheets.

4 Booklet tray* Receives output sheets.

Booklet output button* Press this button to move delivered booklets to a place where they can be

5

Cover Open this cover to clear paper or staple jams, replace Staple Cartridge, or

6

7 Staple Waste Container Collects waste from the stapler.

Staple cartridge for side

8

stitch

Staple cartridges for saddle

9

stitch*

10 Hole Punch Waste Container Collects waste from the puncher.

* Finisher D6 with Booklet Maker

If the priority unit lamp is blinking, you must first clear the paper jam.

removed.

remove hole punch waste.

Contains staples for side stitch.

Contains staples for saddle stitch.

There are two staple cartridges.

60

For detailed information about the Fold Adjustment, refer to "Profiles" in the Stock Library Manager Manual.

Optional Units Manual

Specifications

Note

Item Specification

Tray type Output tray collate / stack

Finisher tray collate (offsetting supported) /stack (offsetting supported)

Booklet tray collate / stack

Paper size Output tray Standard size Maximum A3, 13 x 19"

Minimum Postcard (100 x 148 mm)

Custom size Height 98.0 - 330.2 mm

Width 148.0 - 660.4 mm

Finisher tray Standard size Maximum A3, 13 x 19"

Minimum A5

Custom size Height 148.0 - 330.2 mm

Width 148.0 - 488.0 mm

Booklet tray Standard size Maximum A3, 13 x 19"

Minimum JIS B5

Custom size Height 182.0 - 330.2 mm

Width 257.0 - 488.0 mm

Paper weight Output tray 52 - 350 g/m

Finisher tray 52 - 350 g/m

Booklet tray 60 - 350 g/m

Tray capacity Output tray 500 sheets

Finisher tray

A4 3,000 sheets (Finisher D6 Plus and Finisher D6 with

(without staples)

JIS B4 or larger 1,500 sheets

Mix stack 350 sheets

Finisher tray

A4 200 sets or 3,000 sheets (Finisher D6 Plus and

(with staples)

JIS B4 or larger 100 sets or 1,500 sheets

Booklet tray 20 sets

2

2

2

Booklet Maker: 2,000 sheets)

Finisher D6 with Booklet Maker: 2,000 sheets)

The values are based on Colotech+90.

"Mix stack" means a set of paper sheets where larger sheets are placed over smaller ones (for example, A4

over JIS B5, or JIS B4 over A4).

The booklet tray capacity is 16 sets if one set consists of 17 or more sheets.

Staple Capacity 100 sheets

Note

The values are based on Colotech+90.

65 sheets (Larger than A4 / Letter (8.5 x 11")).