Page 1

Versant 3100 Press

Printer Unit Manual

Page 2

Microsoft product screen shots reprinted with permission from Microsoft Corporation.

In this manual, safety instructions are preceded by the symbol . Always read and follow the instructions

before performing the required procedures.

It may be a legal offence to print currency notes, certificates of stocks and securities, or any other documents of

similar nature, regardless of whether they will be used.

If a malfunction occurs with the machine's hard disk or other storage media, any received or stored data including registered configurations may be lost. Fuji Xerox is not responsible for any direct or indirect damages arising

from or caused by such data loss.

Fuji Xerox is not responsible for any breakdown of machines due to infection of computer virus or computer hacking.

Important

1. This manual is copyrighted with all rights reserved. Under the copyright laws, this manual may not be copied

or modified in whole or part, without the written consent of the publisher.

2. Parts of this manual are subject to change without prior notice.

3. We welcome any comments on ambiguities, errors, omissions, or missing pages.

4. Never attempt any procedure on the machine that is not specifically described in this manual. Unauthorized

operation can cause faults or accidents. Fuji Xerox is not liable for any problems resulting from unauthorized

operation of the equipment.

An export of this product is strictly controlled in accordance with Laws concerning Foreign Exchange and Foreign Trade of Japan and/or the export control regulations of the United States.

Xerox, Xerox and Design, Fuji Xerox and Design, Versant as well as CentreWare are registered trademarks or trademarks of Xerox Corporation in Japan and/or other countries.

Other company names or product names are registered trademarks or trademarks of each company.

2

Printer Unit Manual

Page 3

Preface

Fuji Xerox Co.,Ltd.

Thank you for selecting the Versant 3100 Press.

The Versant 3100 Press is a color printing system that quickly processes data from client computers and

delivers high-quality outputs. The Versant 3100 Press consists of the printer unit and a variety of optional

units as well as a Print Server.

The Versant 3100 Press offer high-speed color printing: up to 100 sheets/minute (A4) (the actual speed

depends on the size, type, and weight of paper).

This manual is intended to provide first-time users of the Versant 3100 Press with necessary information

such as operating procedures, daily maintenance, and precautions on using the printer unit.

Before using the Versant 3100 Press, please read this manual thoroughly to obtain the best performance

of the Versant 3100 Press.

After reading this manual, please keep it in a safe place for further reference. It will be useful in case you

forget how to perform operations or if a problem occurs with the printer.

For information on functions and operations of the Print Server, refer to customer documentation supplied

with Print Servers.

Preface

3

Page 4

Table of Contents

Preface...................................................................................................................................................................................................................................... 3

Table of Contents................................................................................................................................................................................................................. 4

Types of Manuals................................................................................................................................................................................................................. 6

Using This Manual ............................................................................................................................................................................................................... 7

Features of Versant 3100 Press...................................................................................................................................................................................... 8

Chapter 1 Before Using the Machine.......................................................................................... 9

1.1 Machine Components ...............................................................................................................................................9

1.2 Power On/Off .............................................................................................................................................................12

1.2.1 Powering On ...................................................................................................................................................................12

1.2.2 Powering Off .................................................................................................................................................................. 13

1.2.3 Main Power Switch...................................................................................................................................................... 14

1.2.4 Circuit Breaker Switch ................................................................................................................................................14

1.3 Image Printable Area and Assured Image Area.......................................................................................... 15

Chapter 2 Load and Output Paper.............................................................................................17

2.1 Paper Types ................................................................................................................................................................ 17

2.1.1 Recommended Paper.................................................................................................................................................17

2.1.2 Supported Paper........................................................................................................................................................... 18

2.1.3 Storing and Handling Paper....................................................................................................................................23

2.2 Output Paper.............................................................................................................................................................. 24

2.3 Loading Paper............................................................................................................................................................ 25

2.3.1 Loading Paper in Trays .............................................................................................................................................. 25

2.3.2 Loading paper in High Capacity Trays ............................................................................................................... 27

2.3.3 Loading paper in Bypass Tray ................................................................................................................................ 31

4

Printer Unit Manual

Page 5

Chapter 3 Problem Solving ...........................................................................................................33

3.1 Troubleshooting........................................................................................................................................................ 33

3.1.1 Printing Troubles ..........................................................................................................................................................34

3.1.2 Image Quality Trouble .............................................................................................................................................. 37

3.2 Paper Jams in the Printer Unit............................................................................................................................ 41

3.2.1 Paper Jams in the Transfer Module ..................................................................................................................... 41

3.2.2 Paper Jams in Tray ...................................................................................................................................................... 44

3.2.3 Paper Jams in the Paper Feeding Unit ............................................................................................................... 45

3.2.4 Long Paper Jam ............................................................................................................................................................ 47

3.3 Paper Jams in the Printer Output Unit ............................................................................................................ 48

3.3.1 Paper Jams in the Cooling Unit ............................................................................................................................. 48

3.3.2 Paper Jams inside the Cover................................................................................................................................... 51

3.3.3 Paper Jams in the Output Area.............................................................................................................................. 54

3.4 Paper Jams in the High Capacity Feeder C3-DS.......................................................................................... 55

3.4.1 Paper Jams in Tray ...................................................................................................................................................... 55

3.4.2 Paper Jams inside the Right Side Cover .............................................................................................................57

Chapter 4 Maintenance .................................................................................................................60

4.1 Consumables.............................................................................................................................................................. 60

4.1.1 Replacing the Toner Cartridge............................................................................................................................... 61

4.1.2 Replacing the Waste Toner Bottle ....................................................................................................................... 63

4.2 Full Width Array ........................................................................................................................................................ 65

4.3 Cleaning the Printer ................................................................................................................................................ 66

4.3.1 Cleaning Chute ............................................................................................................................................................. 68

4.3.2 Cleaning High Capacity Trays................................................................................................................................ 70

4.3.3 Cleaning the Paper Feeding Unit in the High Capacity Tray ................................................................... 72

Chapter 5 Appendix.........................................................................................................................75

5.1 Specifications............................................................................................................................................................. 75

5.2 Optional Components ............................................................................................................................................ 78

Index ...................................................................................................................................................................................................................................... 80

Table of Contents

5

Page 6

Types of Manuals

Refer

The Versant 3100 Press comes bundled with the following manuals:

For information on functions and operations of the Print Server, refer to customer documentation supplied

with Print Servers.

Some of them come with manuals. The manuals for optional components describe all the necessary steps

for using the optional components and installing the software.

For details on the functions of your 3rd Vendor Finisher or GBC® AdvancedPunch™ Pro, refer to the manual

supplied with the device.

PDF Manual

The Manuals are stored as PDF files on the Versant 3100 Press Instruction Manuals CD.

Double-click "index.html" and select the language of the manual you wish to display.

Versant 3100 Press Printer Unit Manual (this manual)

Describes how to load paper, how to replace consumables, how to clear paper jams, and the daily maintenance procedures for the printer unit. (These descriptions are also applied to the printer unit equipped

with Offset Catch Tray.)

Versant 3100 Press Optional Units Manual

Describes how to replace consumables and how to clear paper jams in the optional units (High Capacity

Stacker, Finisher, and others).

Versant 3100 Press User Interface Manual

Describes the operations of the user interface (UI) for operating the printer.

The user interface allows you to confirm status of the printer, and to set the printer behavior.

Versant 3100 Press Paper Jams: Quick Access Guide

Illustrates possible paper jam areas, allowing you to quickly identify a paper jam location.

HTML Manual

Stock Library Manager Manual

Describes Stock Library Manager with which you can change the paper settings.

The manual can be viewed from the [Help] menu of Stock Library Manager.

CentreWare Internet Services Help

The help describes CentreWare Internet Services where you can change various settings of the printer

using a client computer.

Click [Help] in the upper right corner of CentreWare Internet Service window to display the help.

6

To display the online help for CentreWare Internet Services, users need to have the environment to connect

Important

to the Internet. The communication fee shall be borne by you.

Paper Manual

Versant 3100 Press Safety Notes

Provides information for using the printer safely. Read this manual before using the printer.

Printer Unit Manual

Page 7

Using This Manual

Important

Note

Refer

This manual is intended to provide first-time users of the Versant 3100 Press with necessary information

such as operating procedures, daily maintenance, and precautions on using the printer unit.

Organization of This Manual

This manual consists of the following chapters:

Chapter 1 Before Using the Machine

Describes machine components, powering on/off the machine, and other information required before

using the machine. Please read this chapter first.

Chapter 2 Load and Output Paper

Describes sizes and types of supported paper, precautions for handling paper stocks, and how to load and

output paper. Read this chapter when loading paper.

Chapter 3 Problem Solving

Describes how to deal with paper jams, error messages, unsatisfactory print quality, or other problems.

Read this chapter when a problem occurs.

Chapter 4 Maintenance

Describes procedures for daily maintenance such as replacing Toner Cartridges or other consumables.

Chapter 5 Appendix

Describes specifications of the machine.

Conventions

This manual uses the following symbols:

Indicates important information you have to know or be reminded before operations.

Indicates supplemental information useful for operations.

Indicates references to other chapters and manuals.

< > Indicates the Control Panel, and buttons and lamps on the printer or optional units.

[ ] Indicates the names of tabs, options, buttons, menus and file names on the touch screen

display.

> Indicates the path to the touch screen. e.g. [XXX] > [XXX]

" " Indicates the names of reference sections in this manual, characters to be entered, path

names, and messages.

XXX Manual Indicates the names of the reference manuals.

Illustrations in This Manual

All illustrations contained in this manual are of the product equipped with Offset Catch Tray.

Using This Manual

7

Page 8

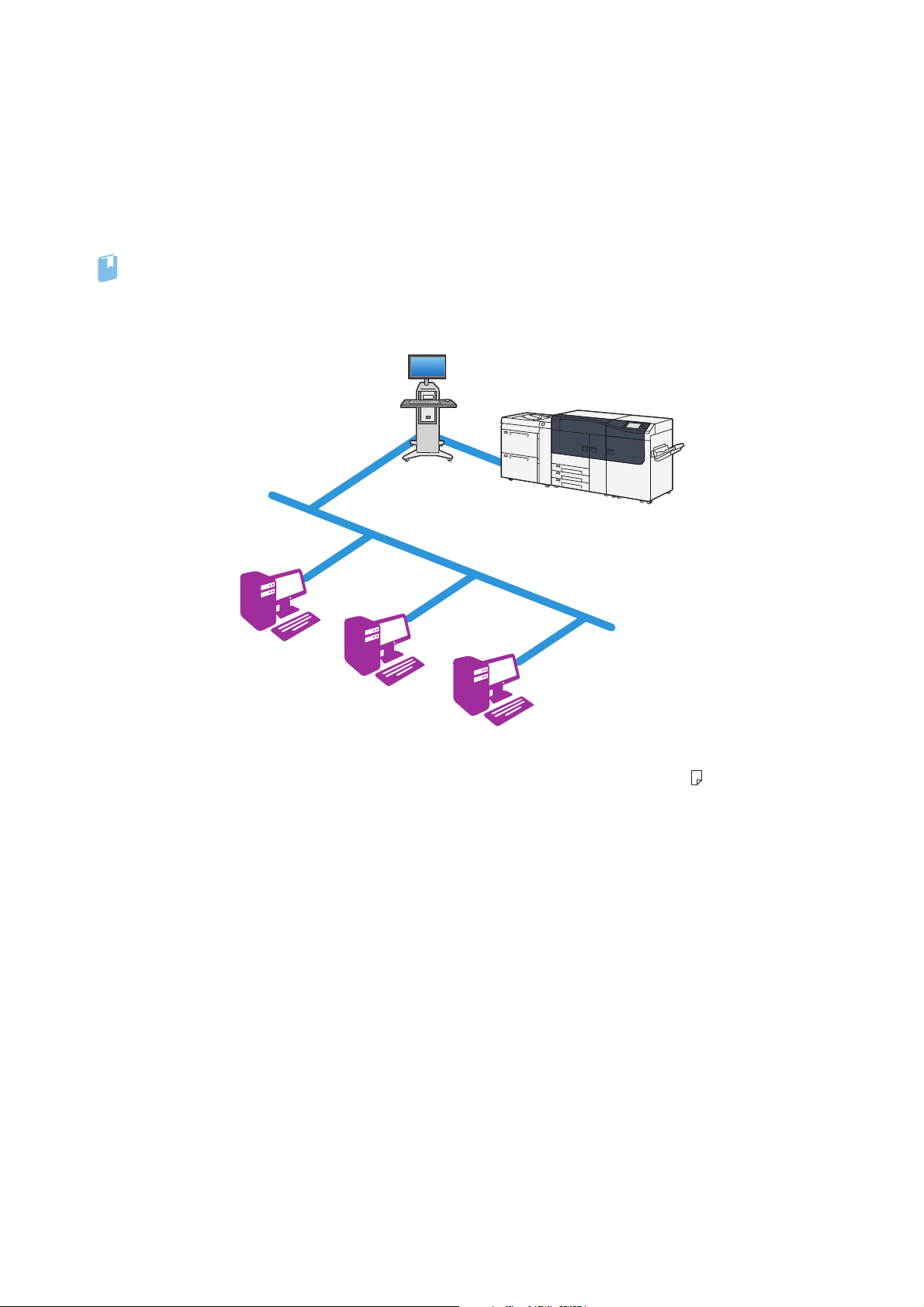

Features of Versant 3100 Press

Refer

Print Server

Client Computers

Printer

The Versant 3100 Press is a color printing system that quickly processes data from client computers and

delivers high-quality outputs.

The standard configuration consists of the Versant 3100 Press printer unit and a Print Server.

For information on the optional units other than Offset Catch Tray, refer to Optional Units Manual.

In this manual, a computer storing the software for the printer is called a "client computers".

High-speed, high-quality color printing

The Versant 3100 Press offer high-speed color printing: up to 100 sheets/minute (A4 ) (the actual speed

depends on the size, type, and weight of paper), with the image quality of 2,400 dpi.

A wide range of paper types supported, including 52 - 350 g/m2 paper, transparency, and

coated paper

The printer runs under optimal conditions for the paper type specified by the user.

8

Printer Unit Manual

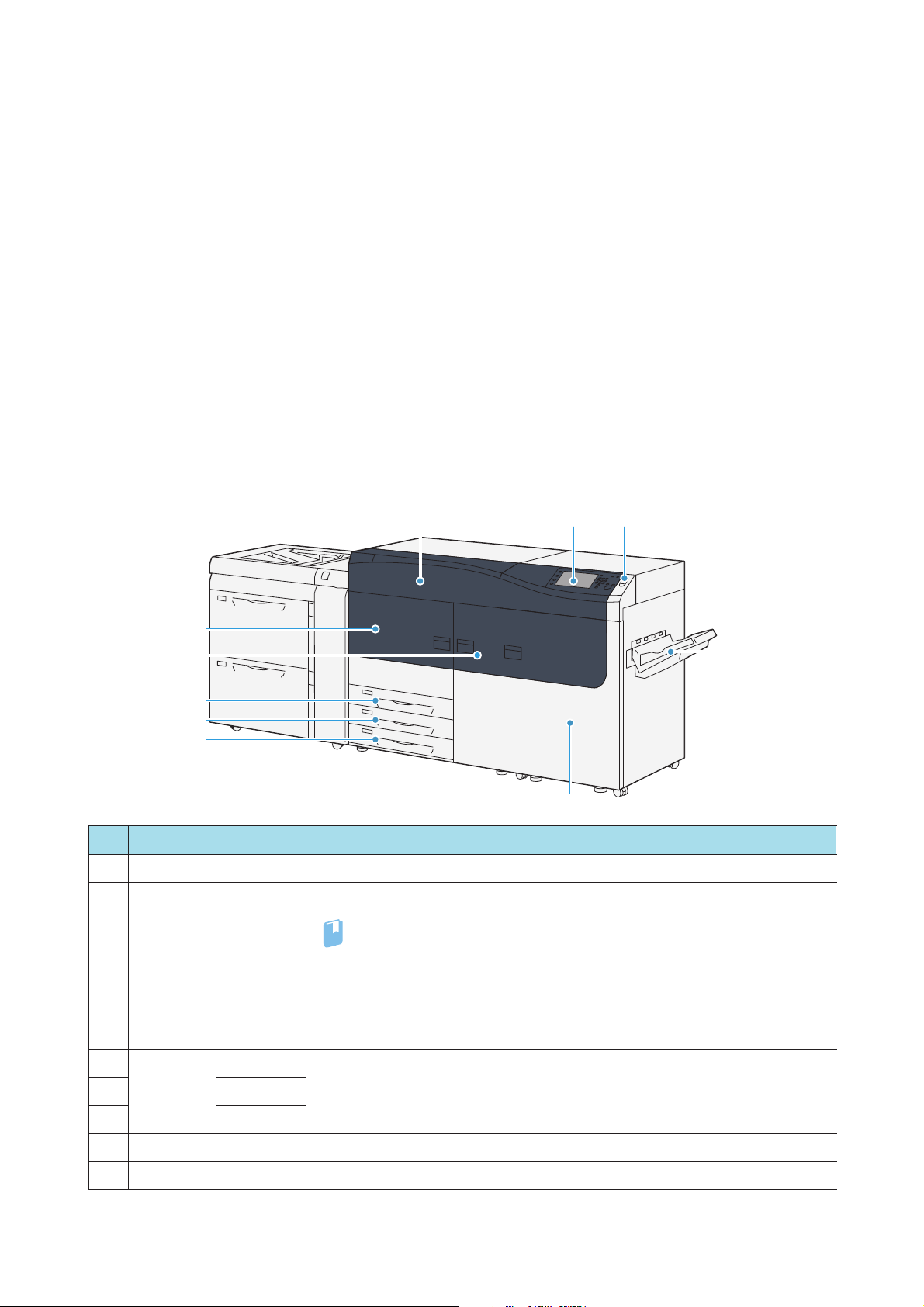

Page 9

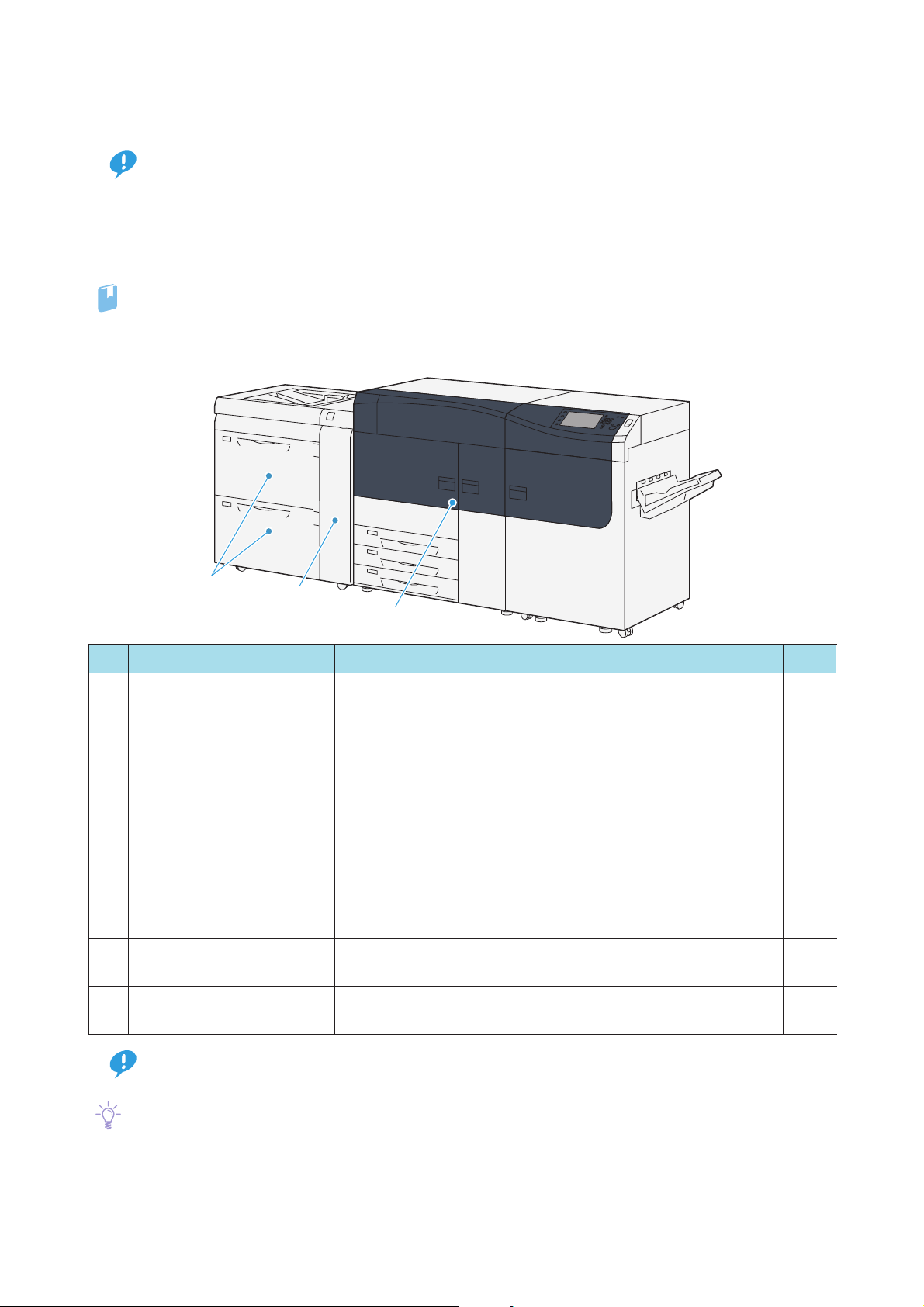

Chapter 1

9

10

5

123

4

6

7

8

1.1 Machine Components.............................................................................. 9

1.2 Power On/Off .............................................................................................12

1.3 Image Printable Area and Assured Image Area..........................15

Before Using the Machine

1.2.1 Powering On .......................................................................................................... 12

1.2.2 Powering Off ......................................................................................................... 13

1.2.3 Main Power Switch ............................................................................................. 14

1.2.4 Circuit Breaker Switch........................................................................................ 14

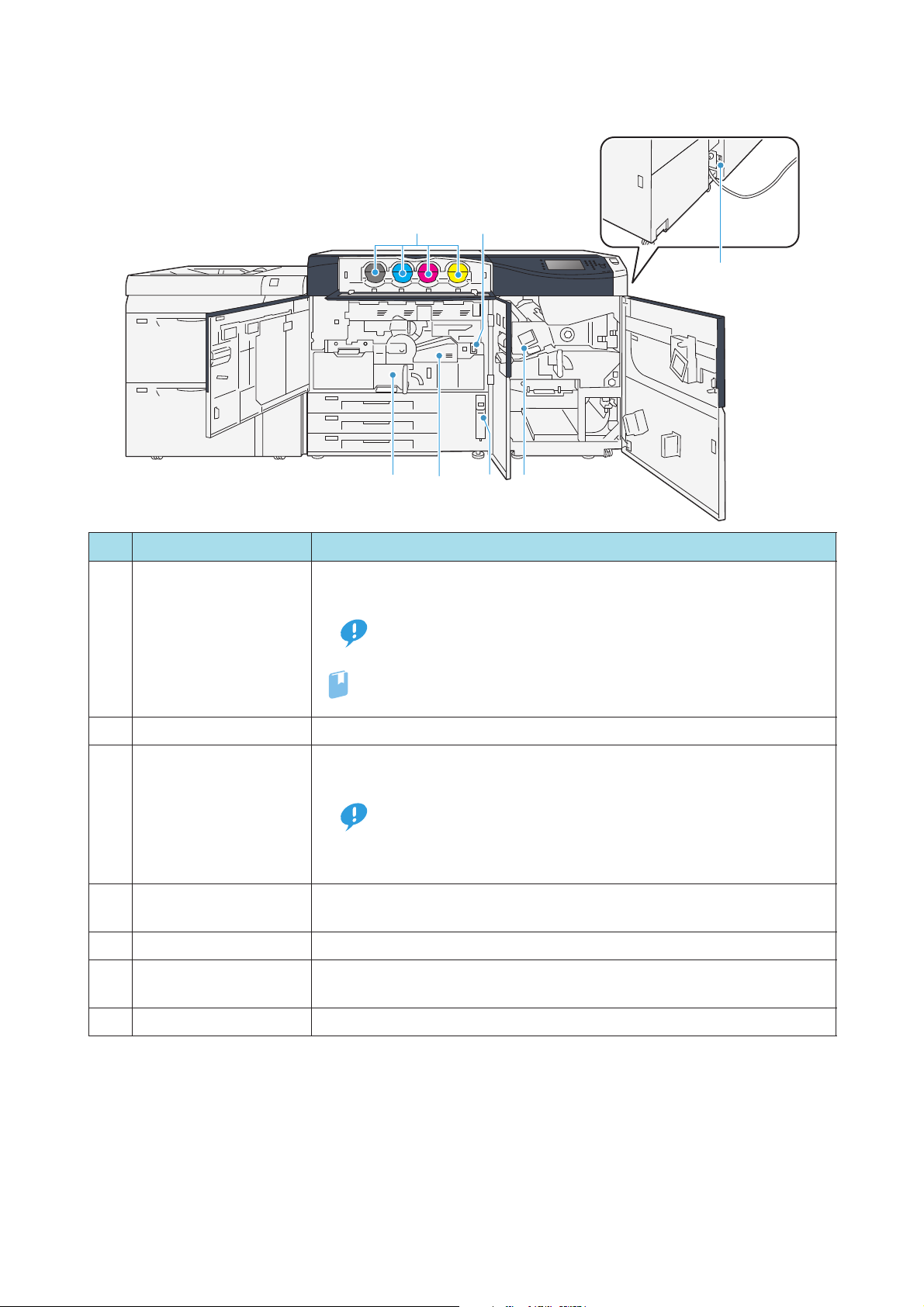

1.1

Machine Components

Front of the Machine

No. Component Description

1 Power switch Powers on/off the printer.

User interface Buttons and touch screen to operate the printer.

2

3 Toner cover Open this cover to replace Toner Cartridges.

4 Left side cover Open this cover to clear paper jams.

5 Center cover Open this cover to clear paper jams, or to replace Waste Toner Bottles.

6 Printe r Unit

Trays

7 Tray 2

8 Tray 3

9 Right side cover Open this cover to clear paper jams.

10 Offset Catch Tray Receives output sheets stacked with offset.

Tray 1 Load paper here.

Refer

Images are printed on the underside of the loaded paper.

For detailed information about the user interface, refer to User Interface Manual.

Chapter 1 Before Using the Machine

9

Page 10

Inside of the Machine

Important

Refer

Important

12

5

3

No. Component Description

4

6

The back side

7

Main power switch Switches the main power of the machine on and off. Always follow the

instructions by the system administrator.

1

2 Toner Cartridges There are Toner Cartridges, each one for Black, Cyan, Magenta, and Yellow.

Transfer Module This module transfers the toner onto paper.

Pull out this module to clear paper jams.

3

Fusing Module Fuses toner on paper.

4

5 Waste Toner Bottles Collects waste toner.

Cooling Unit This part cools the paper.

6

7 Circuit breaker switch Automatically shuts off electricity in the event of fault current or a short circuit.

The Fusing Module is extremely hot, so do not touch it.

Pull out this unit to clear paper jams.

Always switch the power off before switching the main power off.

For detailed information, refer to "1.2 Power On/Off" (p.12).

If an abrupt power shutdown of the printer due to an electrical outage or other disruption arises when the printer is in operation, do not

pull out the Transfer Module, before the power is back.

The Transfer Module must only be handled when the power is on.

10

Printer Unit Manual

Page 11

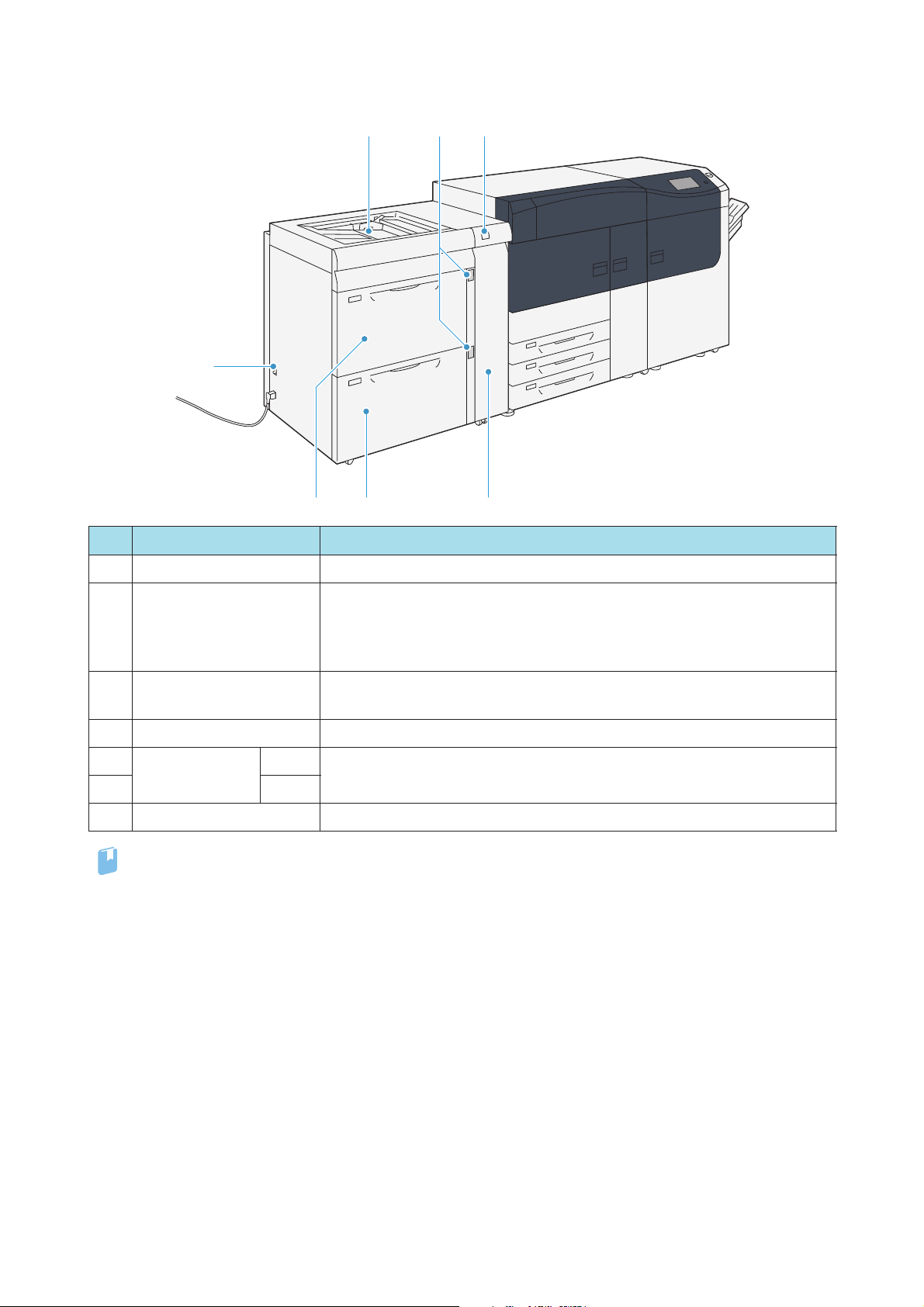

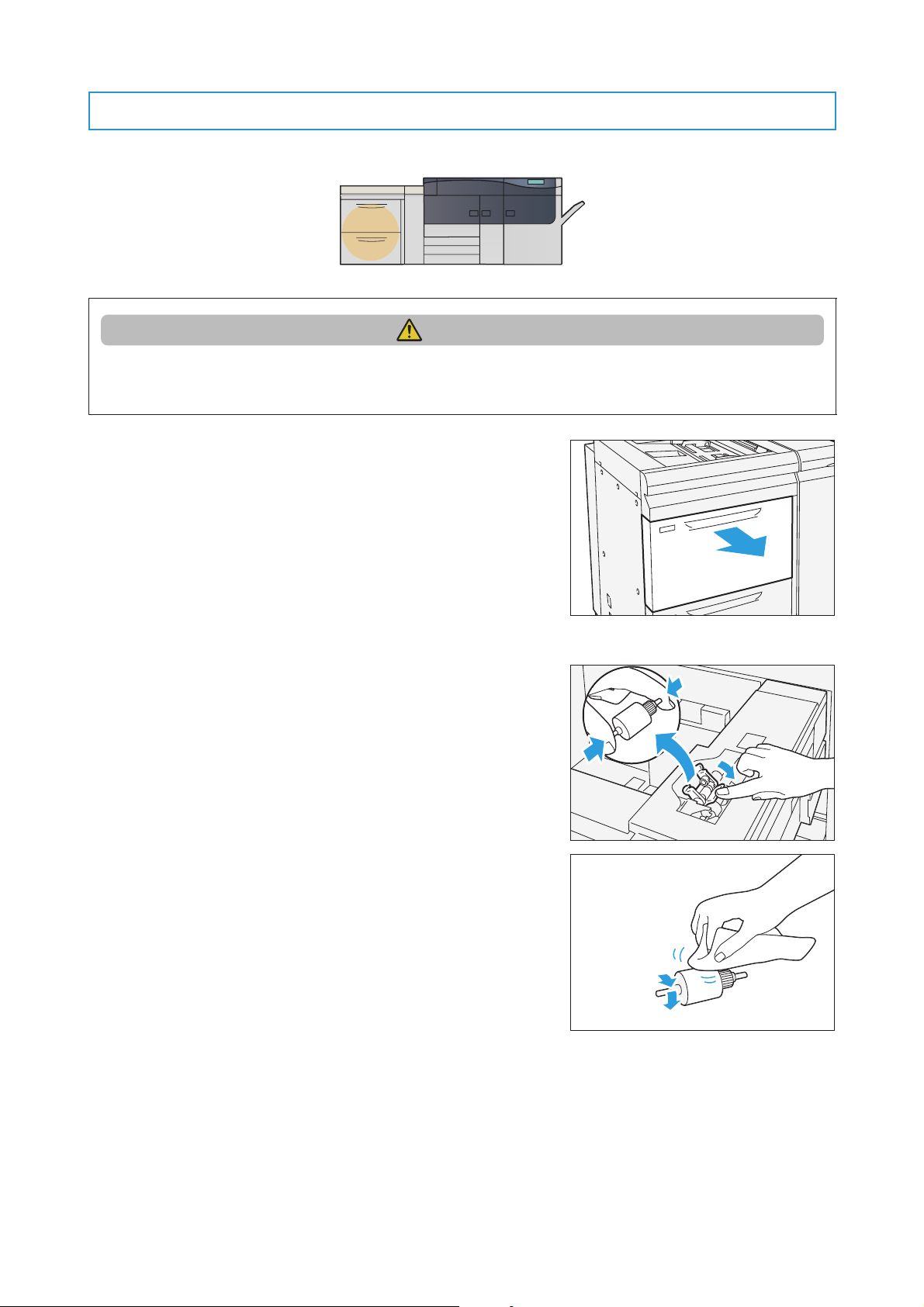

High Capacity Feeder C3-DS

Refer

12

4

3

765

No. Component Description

1 Error lamp Illuminates when a paper jam occurs.

Paper level indicator lamp The top active indicator lamp lights when the corresponding Tray is active.

2

Bypass Tray (Tray 5) Load paper here.

3

4 Circuit breaker switch Automatically shuts off electricity in the event of fault current or a short circuit.

5 High Capacity

Trays

6 Tray 7

7 Right side cover Open this cover to clear paper jams.

For detailed information about the 2nd High Capacity Feeder C1-DS, refer to "Chapter 1 2nd High Capacity

Feeder C1-DS" in the Optional Units Manual.

Tray 6 Load paper here.

The four center lamps (1=25%) indicate the amount of remaining paper.

When all of the four lamps turn off, Tray becomes empty and paper empty

indicator lamp lights.

Images are printed on the face side of the loaded paper.

Images are printed on the face side of the loaded paper.

Chapter 1 Before Using the Machine

11

Page 12

1.2

Note

Note

Refer

The printer warms up and becomes ready to print within about 5 minutes after powered on.

Switch the power off at the end of a day or if the machine is not used for a long time.

Power On/Off

The warm-up time may vary with an initial temperature of the printer.

After being inactive for a while, the printer automatically enters the Power Saver mode to reduce power

consumption. For detailed information about the Power Saver mode, refer to "1.4 Power Saver Mode" in the

User Interface Manual.

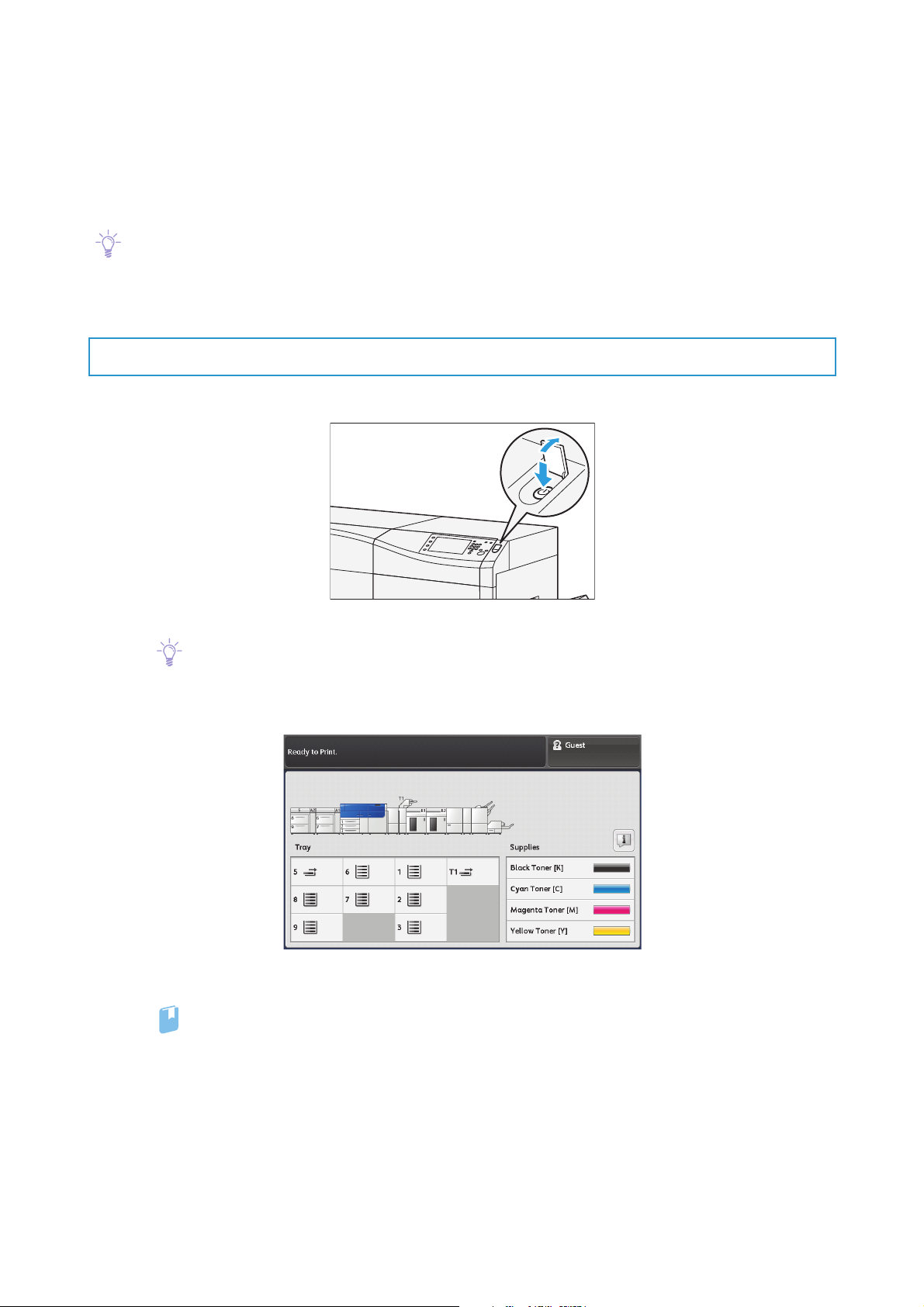

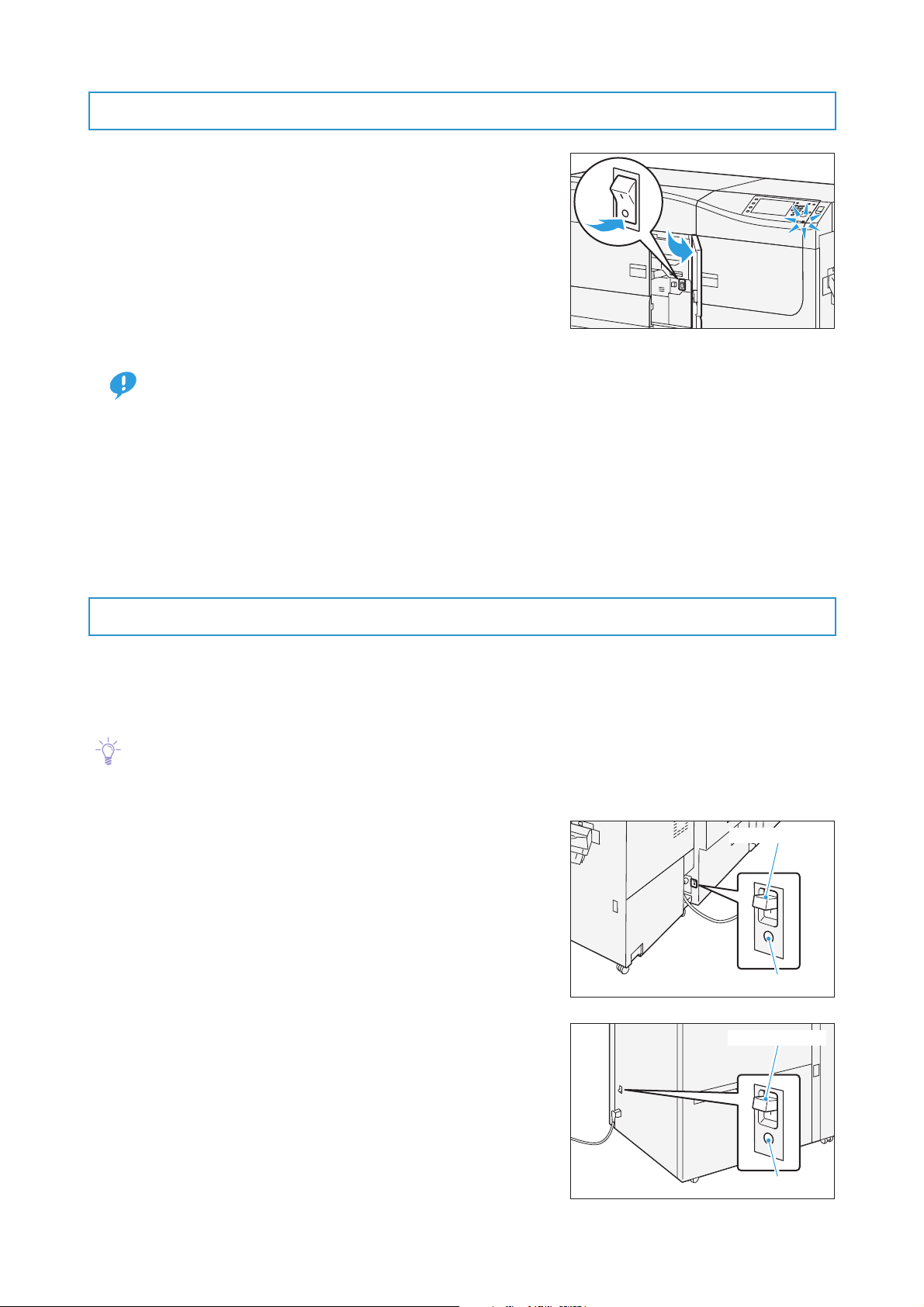

1.2.1 Powering On

1.

Press the power switch on the printer unit.

User interface will be powered on.

When powered on, the printer immediately gets started to proceed with image quality adjustment,

but it takes some time before the printer becomes ready to print.

When the printer becomes ready to print (i.e. enters the Standby mode), the message changes to "Ready

to Print."

2.

Power on your Print Server to start the Print Server.

For information on functions and operations of the Print Server, refer to customer documentation

supplied with Print Servers.

12

Printer Unit Manual

Page 13

3.

Refer

Important

Note

On Print Server, make sure the Stock Library Manager is activated.

1.2.2 Powering Off

1.

Make sure all the printing is finished and the <Data> lamp is not blinking.

2.

Shut down the Print Server.

Stock Library Manager will be closed as the Print Server is shut down.

For information on functions and operations of the Print Server, refer to customer documentation

supplied with Print Servers.

3.

Press the power switch on the printer unit.

On pressing the power switch, the printer will be turned off after the time displayed on the screen lapses.

When you switch the power off, the <Power Saver> button on the control panel may continue blinking even after the touch screen goes dark. Do not switch the main power off until the light of the

<Power Saver> button goes off. (You can turn on the printer again.)

When powering the printer on after it has been switched off, wait 10 seconds or more after the

touch screen has gone dark.

You can also switch the power off by clicking [Power Off] on CentreWare Internet Services under

[Status] tab > [General].

Chapter 1 Before Using the Machine

13

Page 14

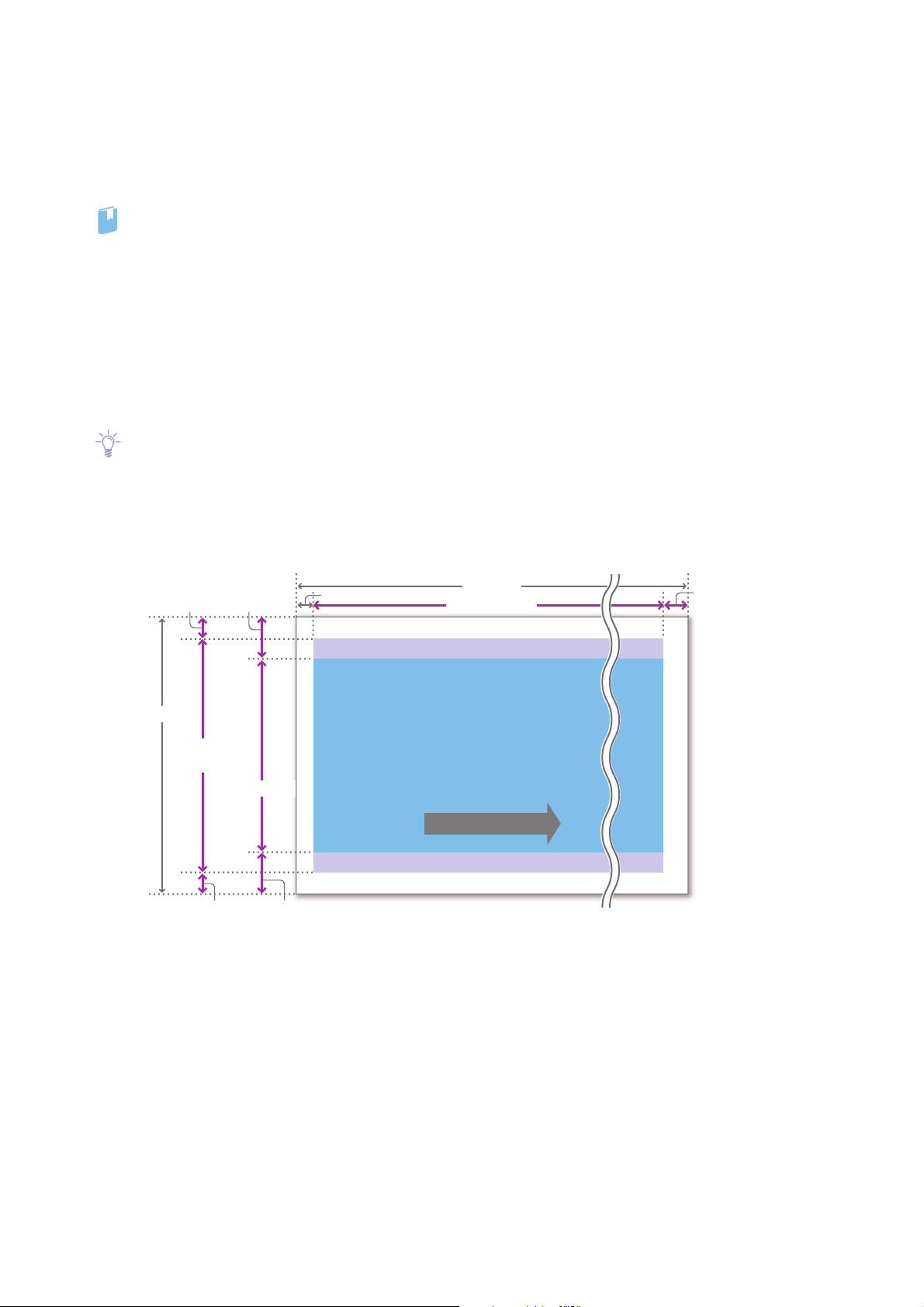

1.2.3 Main Power Switch

Note

Breaker switch

TEST button

Breaker switch

TEST button

If you turn off the main power, the power consumption can be

reduced. (but cannot be reduced to zero.)

Note that the machine needs more time to warm up if switched on

after the main power is off.

The printer may be damaged if you switch the main power off

immediately after switching the power off. Make sure the <Power

Saver> button is out and then switch off the main power.

Cooling down may take up to 60 minutes.

Switching off the main power may damage the hard disk and the memory or cause a printer malfunction,

Important

Open Machine Center Door and push the lower side of the switch to <O> (OFF).

The <Power> indicator goes out on the control panel.

The switch is normally in the upper <|> (On) position.

please adhere to the following guidelines.

Do not switch the main power off while the touch screen displays a screen or the <Power Saver> button

blinks.

Switch the main power off first when unplugging the power cord.

Do not switch off the main power immediately after switching on the main power.

1.2.4 Circuit Breaker Switch

The switch is normally in the upper position.

If the machine will be moved or unused for an extended period of time, turn off the switch by pressing it

to the lower position.

When fault current is detected, the circuit breaker is automatically turned off to discontinue the electrical

flow. Do not touch the breakers under normal condition. For information on fault current, refer to the Safety

Notes.

Printer Unit

High Capacity Feeder C3-DS

14

Printer Unit Manual

Page 15

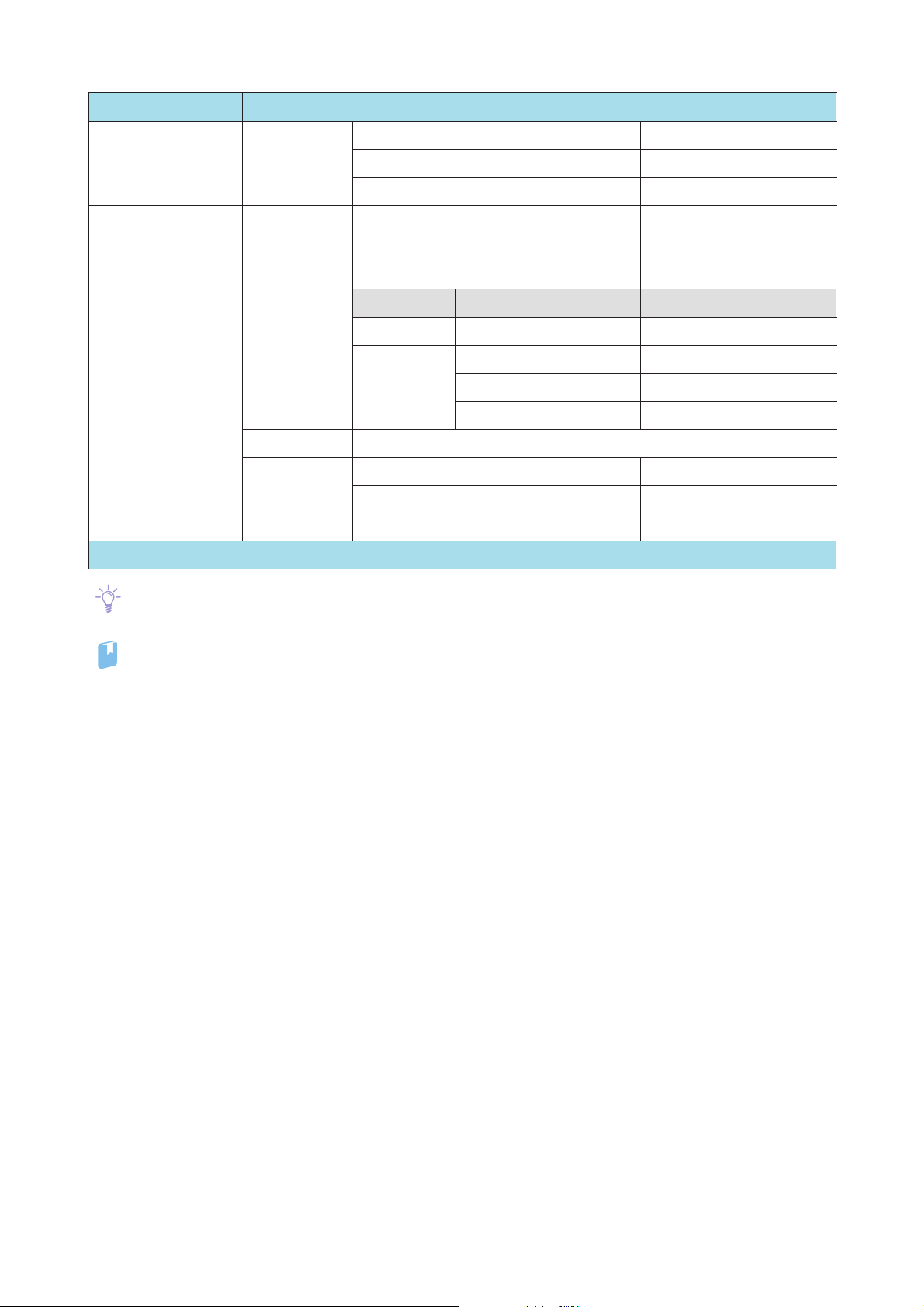

1.3

Refer

Note

Image Printable Area

Assured Image Area

Image Printable Area and Assured Image Area

The printer defines "Image Printable Area" and "Assured Image Area" for printing.

For detailed information about the supported paper size, refer to "2.1.2 Supported Paper" (p.18).

Image Printable Area

Image Printable Area is the area where the printer can print.

In the area close to boundary of printable area, image or text printed may become slightly blur but does

not give impacts if printing crop marks or color patches.

Assured Image Area

Assured Image Area is the area where Fuji Xerox assures image quality.

When an image with high area coverage is placed in the area described above, Fusing Unit jam may be

caused.

High temperature and high pressure on the Fusing Unit may cause the paper to expand or contract.

Regardless of size, there are some areas where printer cannot print on the lead, tail, top and bottom of a

paper.

Top 3.5 (2) mm 6.5 mm

330.2 mm

323.2

(326.2) mm

317.2 mm

bottom 3.5 (2) mm

6.5 mm

Rear edge 2 mm

Image Printable Area

Image Printable Area

When Bypass Tray is used for the paper feed, 172.4 mm is added in each

of the following:

Paper size: 488->660.4 mm

Assured image area: (484-A)->(656.4-A) mm

488 mm

(484-A) mm

Assured Image Area

Assured Image Area

Feed Direction

Front edge A mm

Chapter 1 Before Using the Machine

15

Page 16

Note

Refer

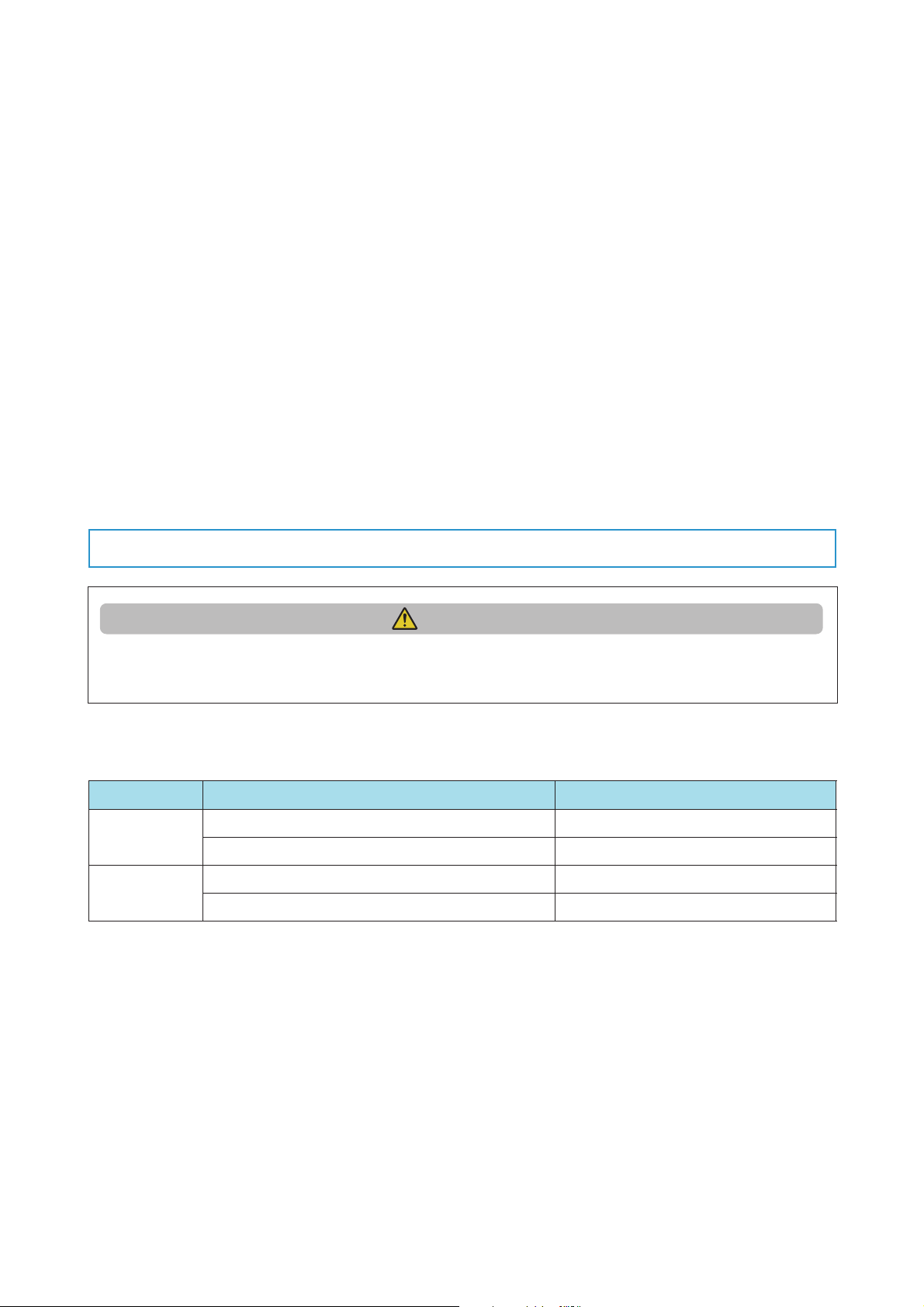

Item Size

Image printable area Maximum fed from Printer Unit Trays (1 - 3) 323.2 x 482 mm

fed from Bypass Tray (5) 326.2 x 654.4 mm

fed from High Capacity Trays (6 - 9) 326.2 x 482 mm

Assured image area Maximum fed from Printer Unit Trays (1 - 3) 317.2 x 482 mm

fed from Bypass Tray (5) 317.2 x 654.4 mm

fed from High Capacity Trays (6 - 9) 317.2 x 482 mm

Image Loss Area Front edge

Paper type Paper weight Value of lead edge A

Uncoated 52 - 350 g/m

Coated* 52 - 72 g/m

73 - 119 g/m

120 - 350 g/m

2

2

2

2

Rear edge 2 mm

Top / bottom fed from Printer Unit Trays (1 - 3) 3.5 mm

fed from Bypass Tray (5) 2 mm

fed from High Capacity Trays (6 - 9) 2 mm

*: For paper weighing 71 g/m2 or lighter, paper feed performance cannot be guaranteed.

The lead edge A is set to 4 mm as the factory default value. If you change this default setting, contact your

local Fuji Xerox representative.

For detailed information about the Register Paper Feeding Positions, refer to "4.1.8 Maintenance" in the User

Interface Manual.

2 mm

4 mm

3 mm

2 mm

16

Printer Unit Manual

Page 17

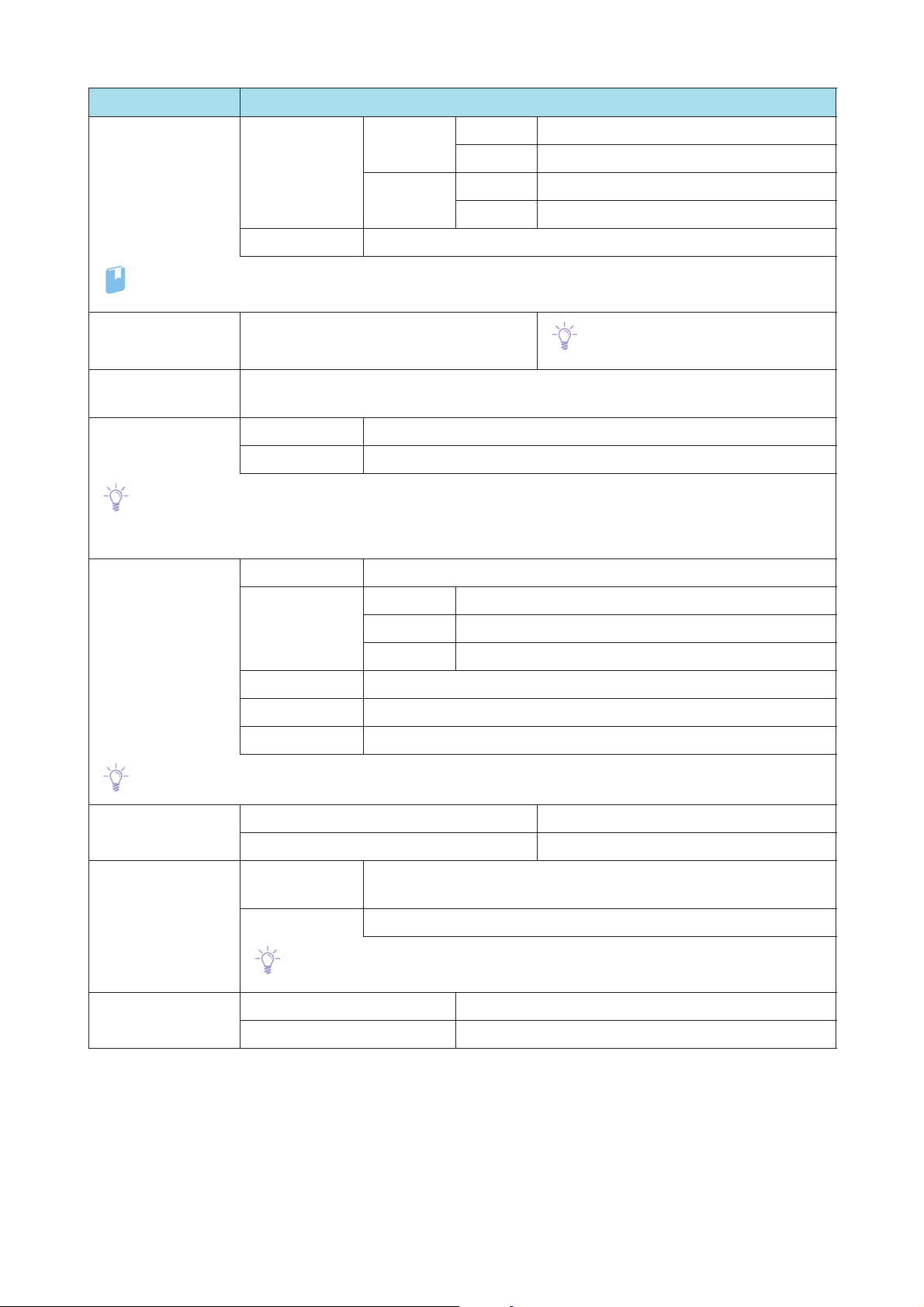

Chapter 2

WARNING

2.1 Paper Types ................................................................................................17

2.2 Output Paper..............................................................................................24

2.3 Loading Paper............................................................................................25

Load and Output Paper

2.1.1 Recommended Paper........................................................................................ 17

2.1.2 Supported Paper.................................................................................................. 18

2.1.3 Storing and Handling Paper ........................................................................... 23

2.3.1 Loading Paper in Trays...................................................................................... 25

2.3.2 Loading paper in High Capacity Trays....................................................... 27

2.3.3 Loading paper in Bypass Tray........................................................................ 31

2.1

Paper Types

2.1.1 Recommended Paper

Do not use conductive paper such as origami paper, carbonic paper or conductively-coated paper.

When paper jam occurs, it may cause short-circuit and eventually a fire accident.

Choose the paper compliant with the standards if using commercially available paper. We recommend following types of standard paper.

Type Paper name or size Paper weight

Uncoated J Paper 82 g/m

Colotech+90 90 g/m

Coated OS coated paper W 127 g/m

Colotech+ Gloss Coated 120 g/m

2

2

2

2

For available paper types other than the standard paper, refer to the Recommended Media List in Stock

Library. If you intend to use paper not included in the Recommended Media List, contact your local Fuji

Xerox representative.

Chapter 2 Load and Output Paper

17

Page 18

The printed image may fade or damaged due to moisture caused by water, rain, or vapor. For information,

Note

Refer

Note

Important

contact your local Fuji Xerox representative.

Even if you use recommended paper types, however, please note that they do not necessarily yield the

optimum print results depending on the environment where the printer is installed (room temperature,

humidity, and others), and/or on the print data.

If you are running a large print job, we recommend that you print some sample sets to check the print

quality before you continue to the remaining.

The print system fuses toner images on paper by applying heat. Therefore, a certain amount of expansion

and contraction can occur on any type of paper.

Ballpoint inks and water-color inks may hard to penetrate into the surface of printed paper.

Adhesive materials such as tapes, sticky notes, and book binding adhesives may come unglued quickly on

printed paper.

White dots or white areas may appear on the output due to paper dust, small coating pieces, or other foreign materials.

Performance of preprinted paper depends on types of preprint. Before running a job, please test preprinted

paper and ensure its output quality and running performance.

For detailed information about the Stock Library, refer to "Stock Library" in the Stock Library Manager Man-

ual.

2.1.2 Supported Paper

Below is the list of paper sizes available for printing by setting paper properties with Stock Library Manager.

If you load paper whose paper properties are different from those currently being set for the specified Tray, it

Important

can cause paper jams and image quality defects. Make sure the selected paper size, paper type, and paper

weight are all correct.

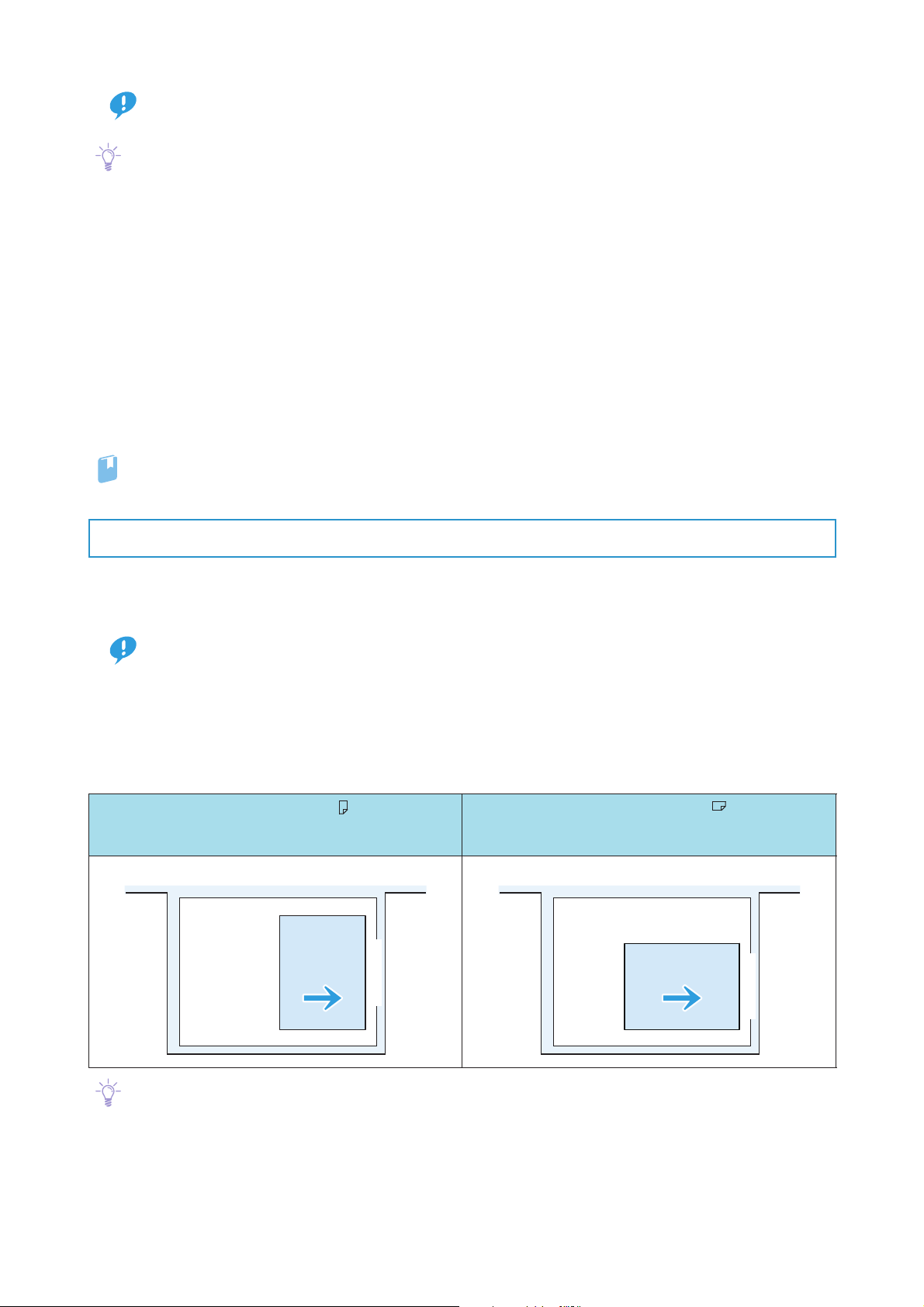

Paper Orientation

There are two paper orientations: Long Edge Feed (LEF) and Short Edge Feed (SEF).

The figures below describe front, rear, top, and bottom edges of the paper for LEF and SEF.

Long Edge Feed (LEF )

Long edge: landscape (width),

Short edge: portrait (height)

The front of the printer The front of the printer

To p

Landscape

Rear edge

Feed direction

Bottom

Front edge

Portrait

Short Edge Feed (SEF )

Short edge: landscape (width),

Long edge: portrait (height)

To p

Landscape

Rear edge

Feed direction

Bottom

Portrait

Front edge

18

The feed direction shown above works in an opposite manner for Printer Unit Trays and Inserter Tray.

Printer Unit Manual

Page 19

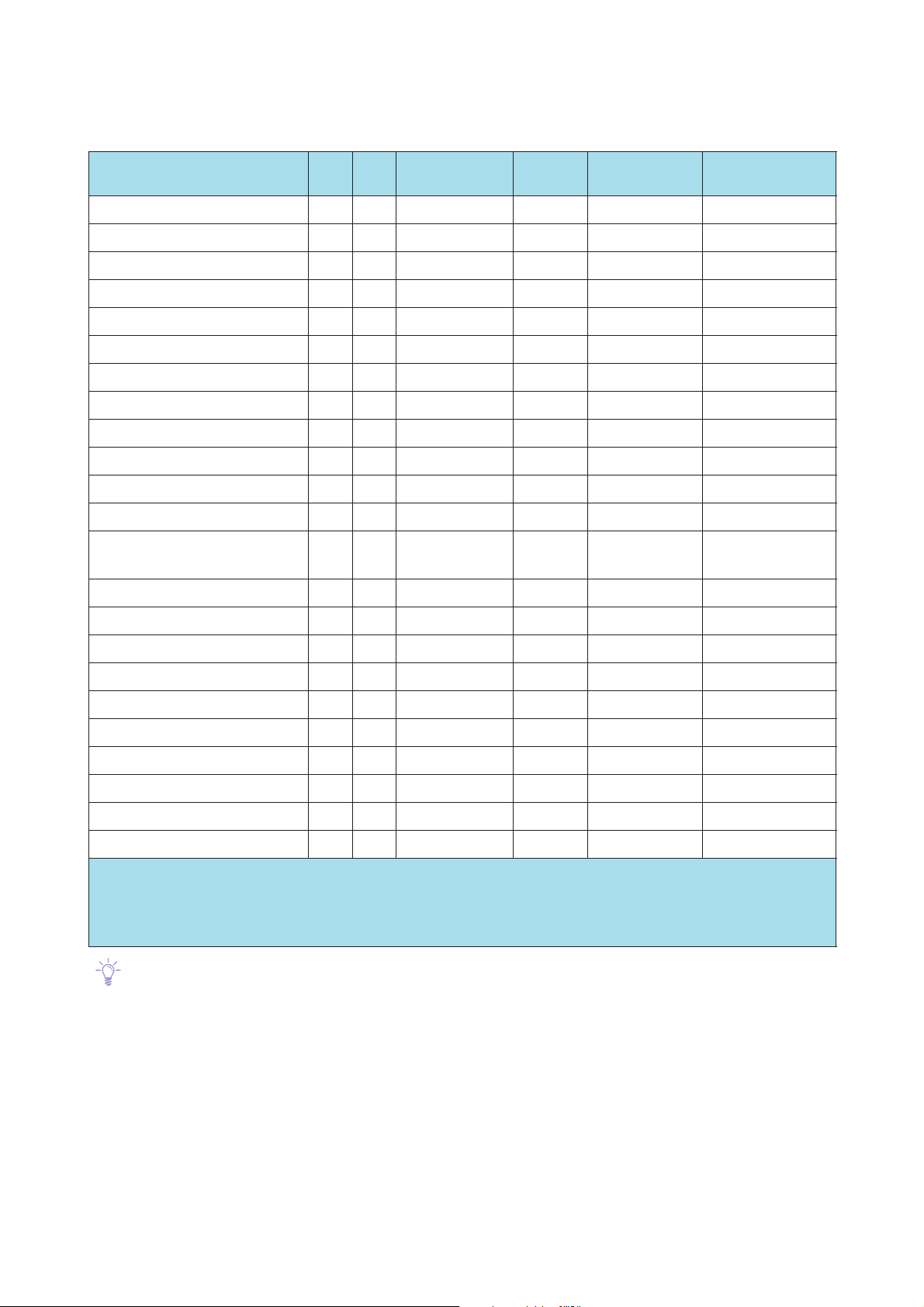

Paper Size

Note

Standard size

Size (short edge x long edge) LEF SEF

SRA3 (320 x 450mm) /

A3 (297 x 420mm) /

A4 (210 x 297mm)

JIS B4 (257 x 364 mm) /

JIS B5 (182 x 257 mm)

8K (267 x 388 mm) /

8K (270 x 390 mm) /

16K (194 x 267 mm)

16K (195 x 270 mm)

Tabloid Oversized (12 x 18") /

Tabloid (11 x 17") /

Legal (8.5 x 14") /

Foolscap (8.5 x 13")

Letter (8.5 x 11")

Printer Unit

Trays (1 - 3)

Bypass

Tray (5)

- (LEF),

(SEF)

High Capacity

Trays (6 - 9)

(LEF), * (SEF)

(LEF), * (SEF)

* (LEF), O (SEF)

Inserter Tray

(T1)

/

Quarto (8 x 10")

Executive (7.25 x 10.5")

DT Special A4 (226 x 310 mm)

DT Special A3 (310 x 432 mm) /

12.6 x 19.2" /

13 x 18" /

13 x 19" /

Postcard (100 x 148 mm) /

Postcard (4 x 6") /

: Can be automatically detected by selecting [Size] in Stock Library

/

/

(LEF), * (SEF)

(LEF), * (SEF)

/ (LEF), * (SEF)

/

/

* : Handled as non-standard size paper as it cannot be automatically detected when loaded

/ : Paper orientation cannot be selected and Stock cannot be applied

- : The stock can be applied, however, the image quality and paper feed performance cannot be guaranteed

Use Postcard Kit for paper size 181.9 mm portrait or smaller in High Capacity Trays.

Chapter 2 Load and Output Paper

19

Page 20

Custom size

Note

Refer

When you use non-standard size paper and long paper, from one of the Stock Library, select [Custom] for

[Size] to specify the paper size using [Width] and [Height].

Printer Unit Trays (1 - 3) LEF: 139.7 - 330.2 mm

SEF: 182.0 - 488.0 mm

Bypass Tray (5) LEF: 98.0 - 330.2 mm

SEF: 148.0 - 660.4 mm

High Capacity Trays (6 - 9) LEF: 98.0 - 330.2 mm

SEF: 148.0 - 488.0 mm

Inserter Tray (T1) LEF: 182.0 - 297.0 mm

SEF: 182.0 - 488.0 mm

For Bypass Tray, paper size 146.0 - 147.9 mm landscape or larger can be loaded but the image quality and

Important

paper feed performance cannot be guaranteed.

Long paper has the following restrictions:

- Only one sheet can be loaded. (Image quality and paper feed performance cannot be guaranteed when

multiple sheets are loaded.)

- The 2 sided and the printing in reverse side (changing the side to output) are not available.

- Available Paper types are [Plain], [Film], and [Recycled]. You cannot select [Matte Coated].

When GBC AdvancedPunch Pro is installed, the image quality and paper feed performance cannot be guaranteed for the papers 488.1 mm landscape or larger.

Use Postcard Kit for paper size 181.9 mm portrait or smaller in High Capacity Trays.

The printer defines "Image Printable Area" and "Assured Image Area" for printing. For detailed information

about the Image Printable Area and Assured Image Area, refer to "1.3 Image Printable Area and Assured

Image Area" (p.15).

20

Printer Unit Manual

Page 21

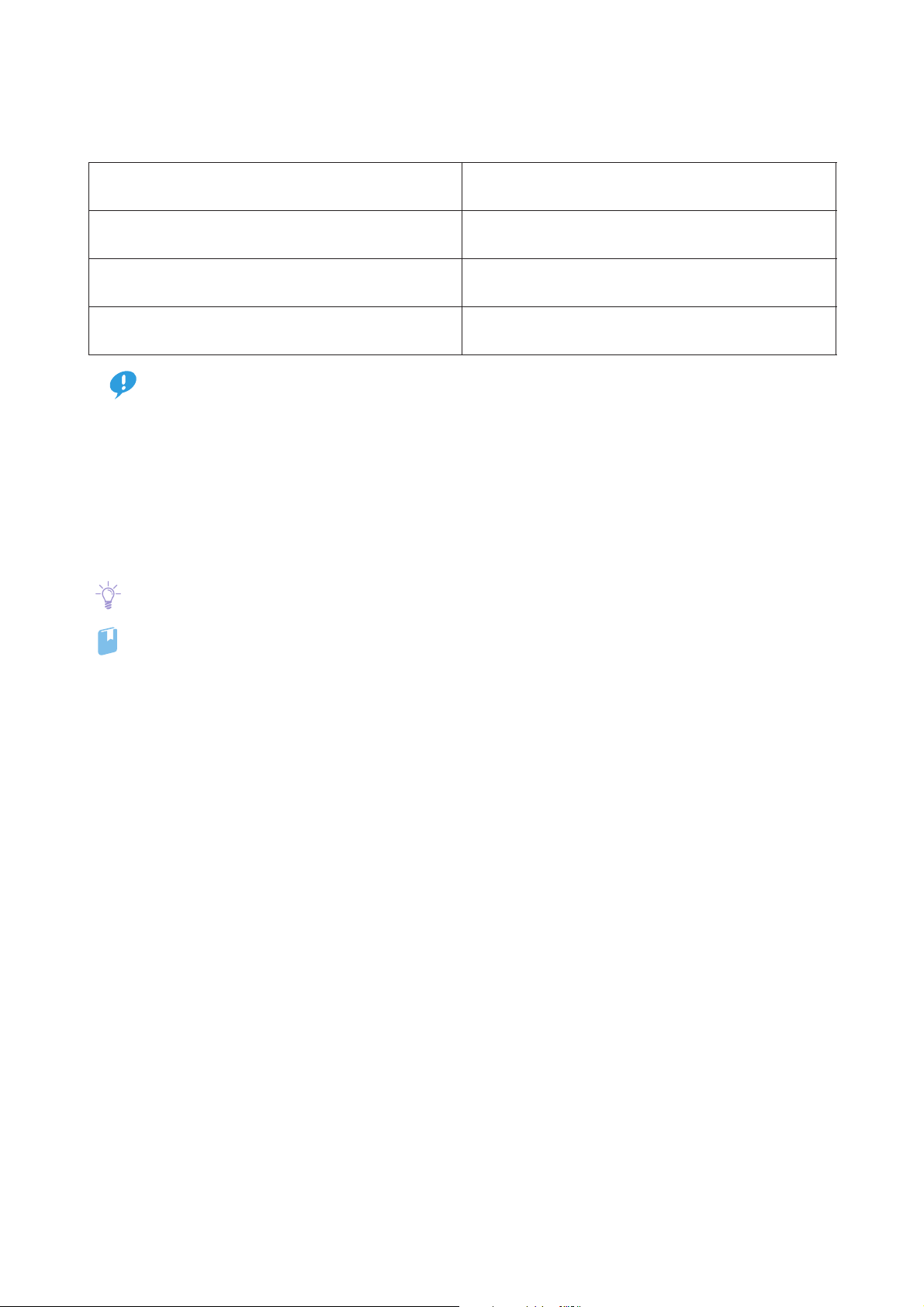

Paper Weight (g/m2)

Note

Plain

Type

Printer Unit

Trays (1 - 3)

Bypass

Tray (5)

High

Capacity

Trays (6 - 9)

Inserter

Tray (T1)

64 - 256 52 - 300 52 - 350 52 - 350

Long paper

(488.1 mm

landscape or larger)

52 - 220 (Uncoated)

72 - 220 (Coated /

Cast Coated)

Transp are ncy -- - - /

Film 64 - 256 64 - 300 64 - 350 / 72 - 220

Postcard / 106 - 300 106 - 350 / /

Textured/Embossed 106 - 256 106 - 300 106 - 350 106 - 350 /

Precut tab - Plain 64 - 256 52 - 300 52 - 350 52 - 350 /

Precut tab - Embossed 106 - 256 106 - 300 106 - 350 106 - 350 /

Full cut tab - Plain 64 - 256 52 - 300 52 - 350 52 - 350 /

Full cut tab - Embossed 106 - 256 106 - 300 106 - 350 106 - 350 64 - 105

Ordered/Sequenced - Plain 64 - 256 52 - 300 52 - 350 52 - 350 /

Ordered/Sequenced - Embossed 106 - 256 106 - 300 106 - 350 106 - 350 /

Recycled 64 - 105 64 - 105 64 - 105 64 - 105 /

Labels 106 - 256 106 - 300 106 - 350 / /

Adhesive /- - / /

Transfer Paper / 129 - 176 - / /

- : Paper weight cannot be loaded

/ : Stock cannot be applied

Paper weight 52 - 350 g/m2 can be loaded for some of the types although they are not supported; In this

Important

case the image quality and paper feed performance cannot be guaranteed. For coated paper, we only

guarantee printing on paper weighing 72 g/m

For Bypass Tray, paper weight 301 - 350 g/m2 can be loaded but the image quality and paper feed performance cannot be guaranteed.

When loading coated paper (coated, cast coated, matte coated), transparencies or films into the Tray

other than High Capacity Tray, make sure you load one sheet at a time.

If two or more sheets are loaded, the image quality and paper feed performance will not be not guaranteed.

Paper weight means the weight of a paper in gram per 1 square meter (g/m2).

For information on supported transparency, contact your local Fuji Xerox representative.

Transparency having a white strip on the edge is not supported.

For 2-sided print jobs where both front and back sides contain toner density, use 115 g/m2 or heavier paper.

2

or heavier.

Chapter 2 Load and Output Paper

21

Page 22

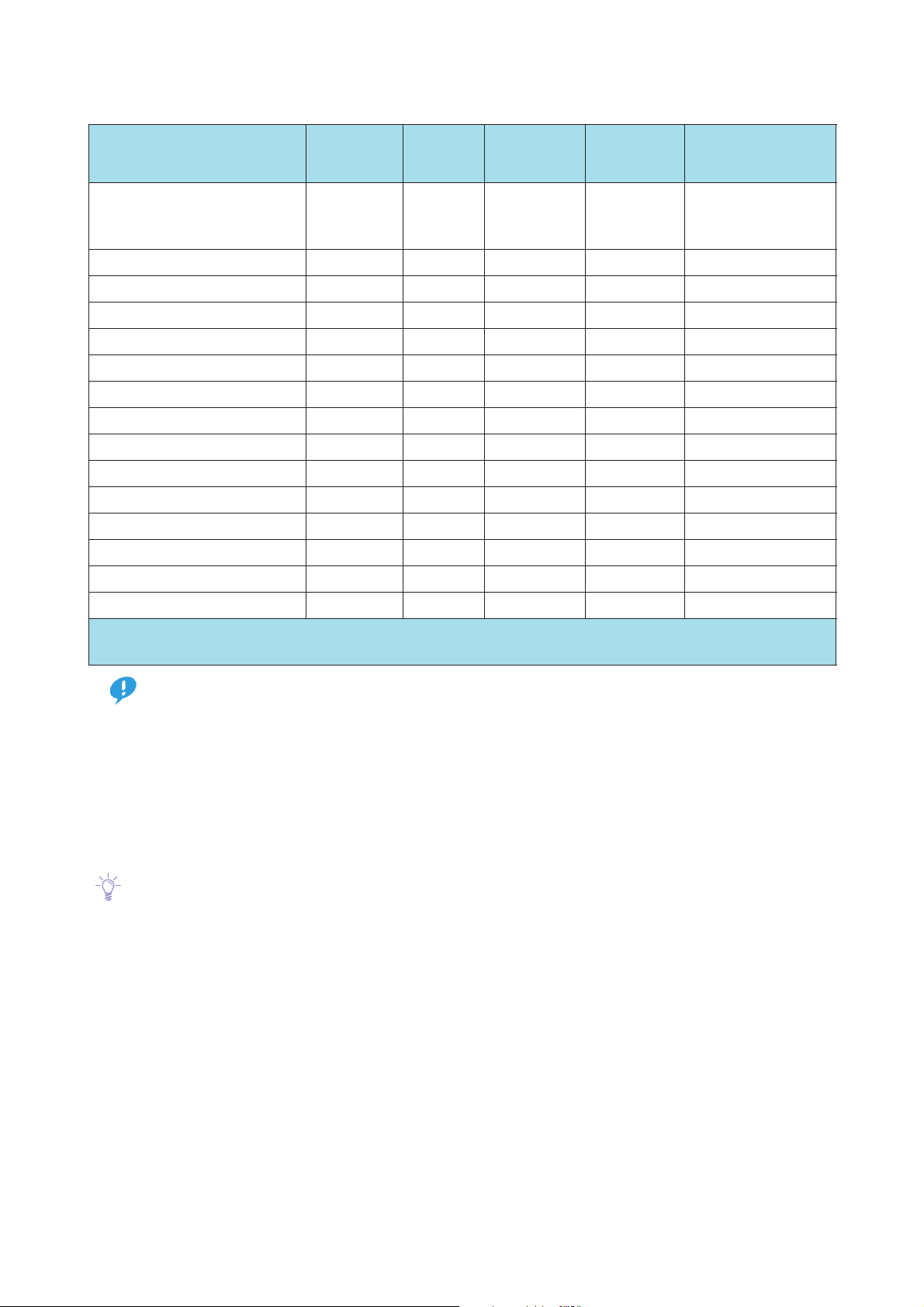

Paper Type

Note

Type Preprinted Stock (Sides 2) Coating Modulus

Plain

-

Transp are ncy ---

Film ---

Postcard *

-

Textured/Embossed **-

Precut tab - Plain

Precut tab - Embossed **

Full cut tab - Plain

-

Full cut tab - Embossed **-

Ordered/Sequenced - Plain

Ordered/Sequenced - Embossed **

Recycled

-

Labels -*-

Adhesive ---

Transfer Paper ---

Custom The same as Plain

: Can be loaded

- : Cannot be loaded

* : Can be loaded but ineffective

If you select [Matte Coated] or [Cast Coated] under [Coating], settings for [Preprinted Stock] will be disabled.

[Ordered/Sequenced] is a set of multiple papers as same as the precut tab. When you select [Ordered/

Sequenced] or [Precut tab], enter the number of papers in a set in [Modules].

When you print a set of paper consists of 5 sheets, enter "5" in [Modules], and if the paper jam occurred on

the 3rd paper of the set, the 4th, 5th, next 1st, and next 2nd papers are purged (ejected without printing),

and the 3rd paper of the next set is printed.

Unsupported Paper

Do not use the following paper. It may damage the machine.

Inkjet paper

Business-card-size paper

Folded or wrinkled paper

Damp or wavy damp paper

12 mm or more curled paper

Thermal paper, Heat-transfer paper

Window envelope

There are some unsupported papers other than the one listed above. For more information, contact your

local Fuji Xerox representative.

22

Printer Unit Manual

Page 23

2.1.3 Storing and Handling Paper

Important

Refer

Storing Paper

Paper is easy to get moist by the open air and to be deformed by the impact. Therefore, be sure to note

the following:

Store paper inside a cabinet or other dry places. Paper that has absorbed moisture can cause paper

jams and image quality defects.

After unpacking the paper, store any remaining paper in the wrapper.

Store paper flat to prevent from bending or warping.

Keep papers out of direct sunlight.

Handling Paper

Do not load a bunch of sheets that were once separate and then put together.

Do not use folded or wrinkled paper.

Do not load mixed sizes or types together into the Tray.

Fan Transparencies, films, or coated paper well before loading in a Tray. These types of paper may be

jammed or multifeed (multiple sheets transferred simultaneously). Also, setting Tray Air Assist feature

may help improving its feeding performance when using High Capacity Tray.

Paper absorbs moisture if the paper is left in a Tray for a long time under highly humid conditions. Paper

with excessive moisture may cause paper jams and image quality defects when it goes through the

machine. It is recommended to remove all such paper from the Tray, and replace it with fresh paper.

Do not use damp paper, paper left unwrapped for long periods of time, and/or paper having excessive curl.

For detailed information about the Tray Air Assist, refer to "Stock Library" in the Stock Library Manager Man-

ual.

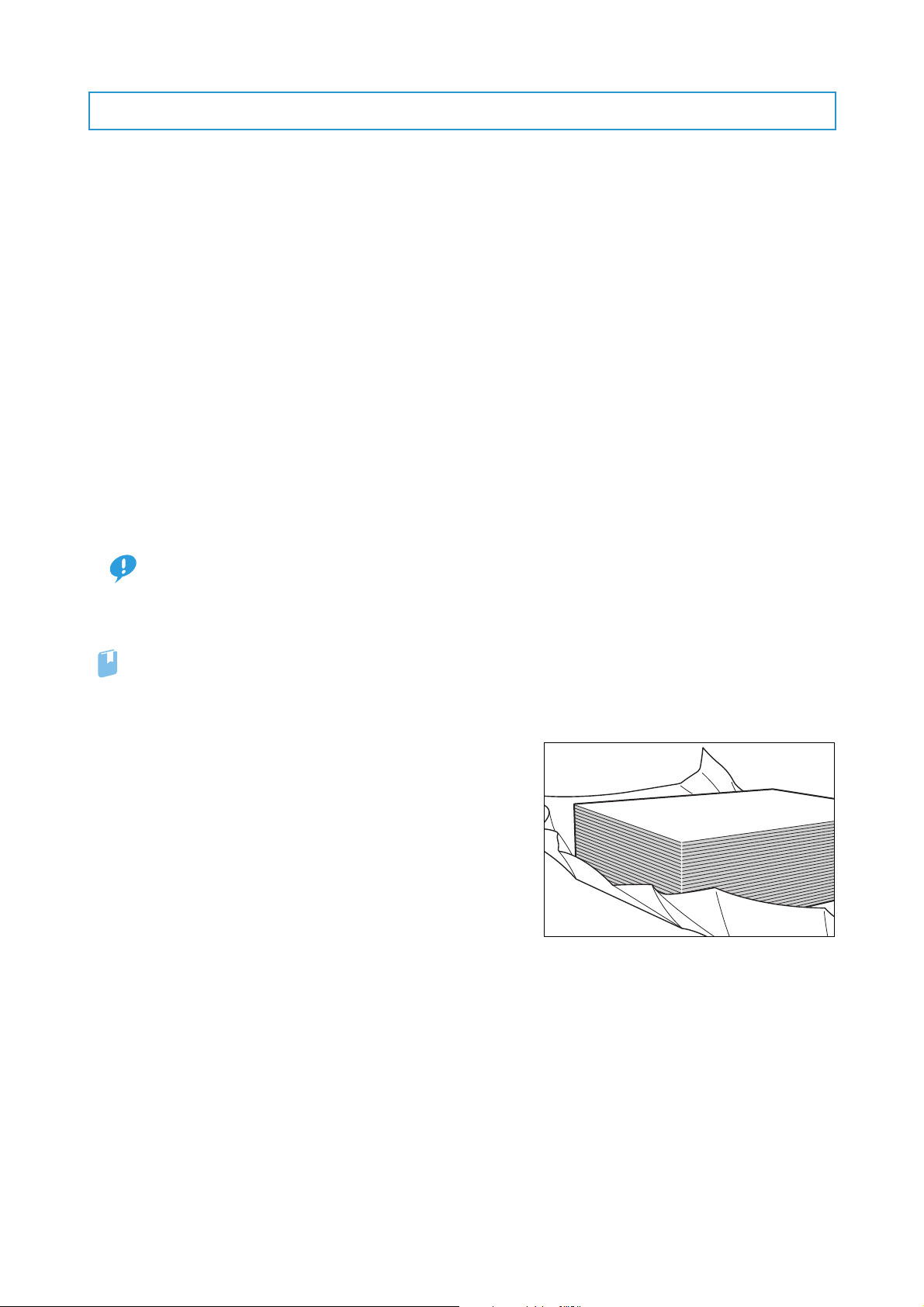

Removing Paper Dust

Edges of a paper may have paper dust or coating materials

generated during a paper cutting process.

Before loading paper in a Tray, remove paper dust and coating

materials from paper edges using a vacuum cleaner or dry

cloth.

Chapter 2 Load and Output Paper

23

Page 24

2.2

Note

Refer

Output Paper

Offsetting

When offsetting is enabled, each set of printed paper is staggered

in the output tray so that you can separate the stack easily.

Enable offsetting on Print Server.

Offsetting is disabled when:

Sheets 297.1 mm portrait or larger and 181.9 mm portrait or smaller.

Offset is performed only when the paper length (portrait) is in a range between 182 and 297 mm.

Sheets 488.1 mm landscape or larger

The Offset Catch Tray offers a capacity of 500 sheets (A4 , Colotech+90, 1-sided job). Please note, however,

the capacity may be reduced depending on the following conditions.

Size of paper, Weight of paper

Types of paper (such as coated/uncoated) and the degree to which the paper is curled

2-sided printing

Ton e r de ns i t y

When the Offset Catch Tray becomes full, the machine detects it and stops running.

For detailed information on capacities of High Capacity Stacker Output tray and Finisher Output tray, refer to

the relevant chapters describing these units in the Optional Units Manual.

Purge Function

The sheets are ejected to the Offset Catch Tray or Output tray on optional units when they are in mid-flow

being fed, before paper jam causes the machine to stop. Also, after the jammed papers are removed, the

remaining sheets in the machine are ejected to the Offset Catch Tray (or to the Output tray closer to the

printer unit if any optional units are installed).

Do not reuse the sheets ejected by the Purge function, as this may cause paper jams.

Important

24

Printer Unit Manual

Page 25

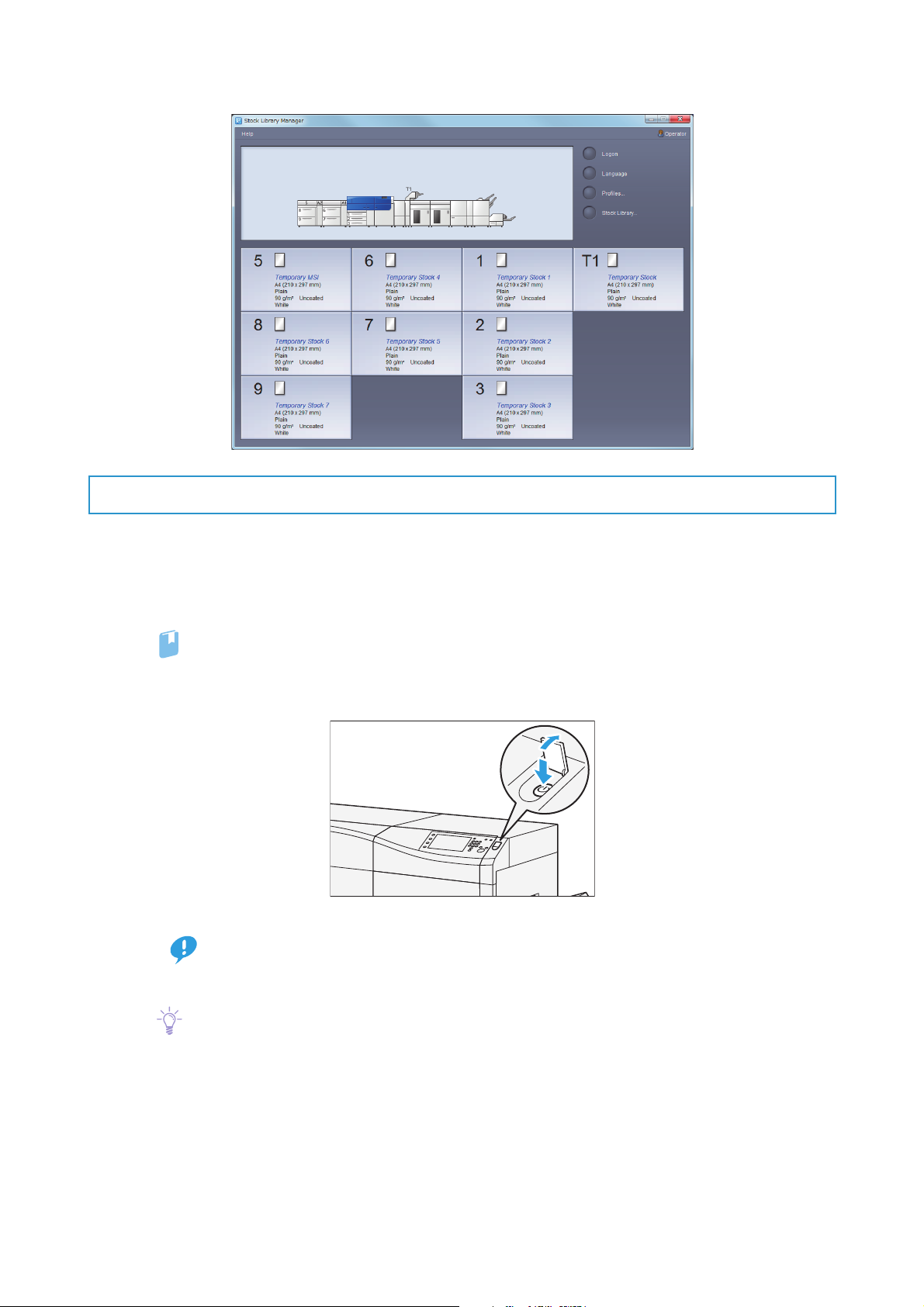

2.3

Refer

CAUTION

Loading Paper

After loading the paper, be sure to set the information of the loaded paper in [Tray Stock Properties] window on Stock Library Manager.

For detailed information on how to regard Tray settings, refer to "Tray Status Confirmation / Setting Area" in

the Stock Library Manager Manual.

When pulling out the Tray, do it gently. If pulled out with too much force, the Tray can hit and injure

your knees.

Do not place any paper or objects in the empty space of Trays. It may cause paper jams or printer malfunc-

Important

tions.

Do not load mixed types of paper in a Tray as this may cause paper jams.

While the printer is processing a job, do not pull out the Tray being used for the job.

To avoid paper jams, and to prevent the different type of paper being loaded, make sure you do not add

paper to the remaining stack of paper in the Tray. If you removed remaining paper from the Tray, load new

paper first, and then add the remaining paper over the new paper.

Paper may stick together in case of some types or the state of the paper. Fan the paper well before loading

it.

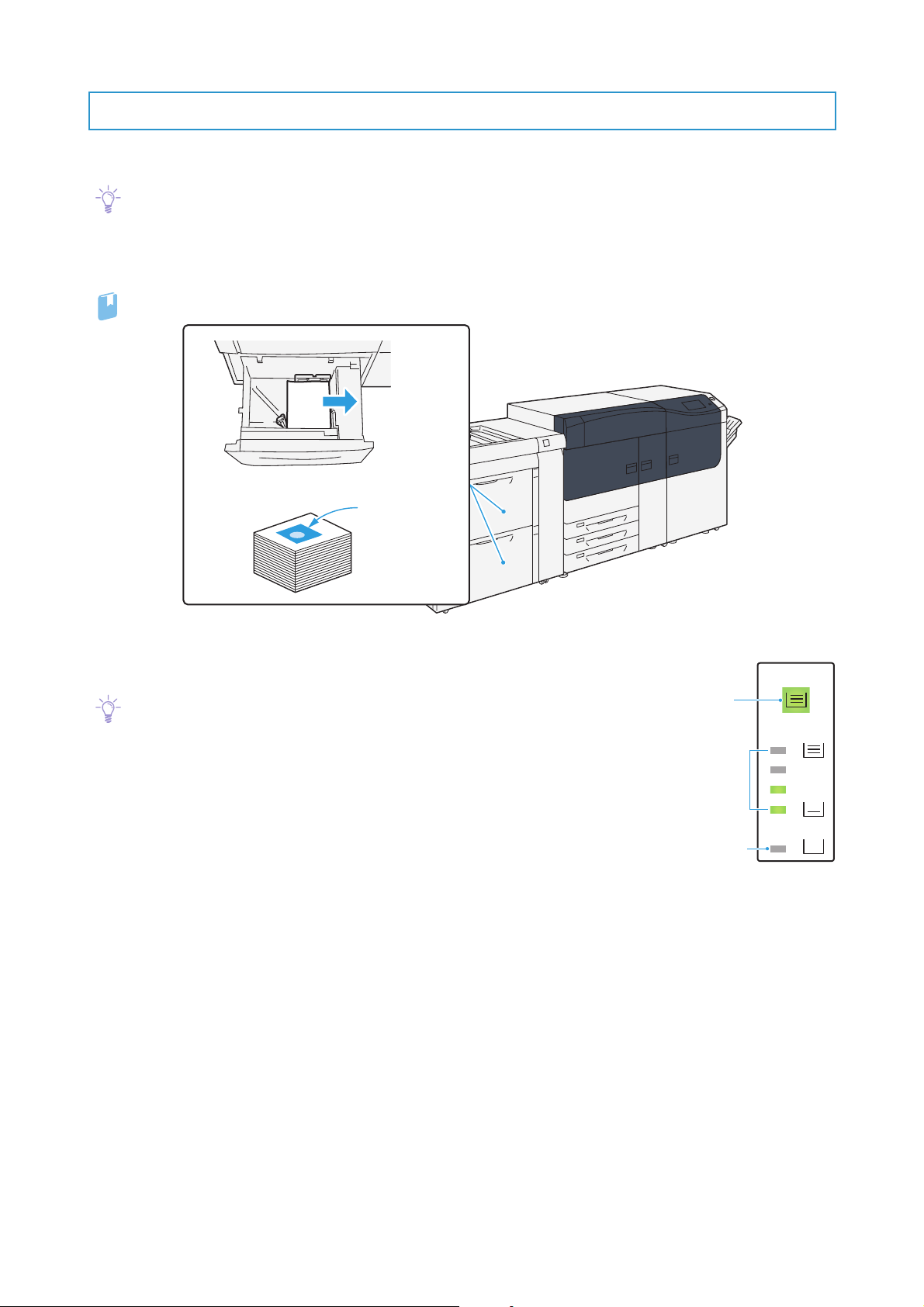

2.3.1 Loading Paper in Trays

The Trays 1, 2 and 3 are refilled in the same way.

Images are printed on the underside of the loaded paper.

Up to 550 sheets (Colotech+90) can be loaded to each Tray.

Feed Direction

Printed side

Chapter 2 Load and Output Paper

25

Page 26

1.

Important

Pull out the Tray toward you until it stops.

2.

Remove any paper remaining in the Tray.

3.

Hold the long-side paper guide by its grip and move

it to lightly contact the paper edges ( ).

4.

Hold the short-side paper guide by its grip and move

it to lightly contact the paper edges ( ).

5.

Fan the paper well and load it with the printed side

1

2

facing down, with the edges aligned in the direction

of the arrow.

Do not load paper above the maximum fill line. It

may cause paper jams or machine malfunctions.

Position the guides correctly to match the paper

size. Incorrectly positioned guides may cause misfeeding and paper jam s.

6.

Push the Tray into the machine.

The [Tray Stock Properties] window appears on the Stock Library Manager.

7.

Change the Tray settings.

Special Media Setting

Transparency

Loading side: Load sheets with the printed side facing up.

Hole punched paper

Orientation: Place the holes of paper on the left side when you face the front side of printer.

Precut tab

Orientation: Place the tabs of paper on the right side when you face the front side of printer.

26

Printer Unit Manual

Page 27

2.3.2 Loading paper in High Capacity Trays

Note

Refer

Note

Printed side

Feed Direction

Paper Empty

Active

Paper Level

The Trays 6 and 7 are refilled in the same way.

The 2nd High Capacity Feeder C1-DS (Trays 8 and 9) is also refilled in the same way.

Images are printed on the face side of the loaded paper.

Up to 2,000 sheets (Colotech+90) can be loaded to each Tray.

For detailed information about the Bypass Tray (5), refer to "2.3.3 Loading paper in Bypass Tray" (p.31).

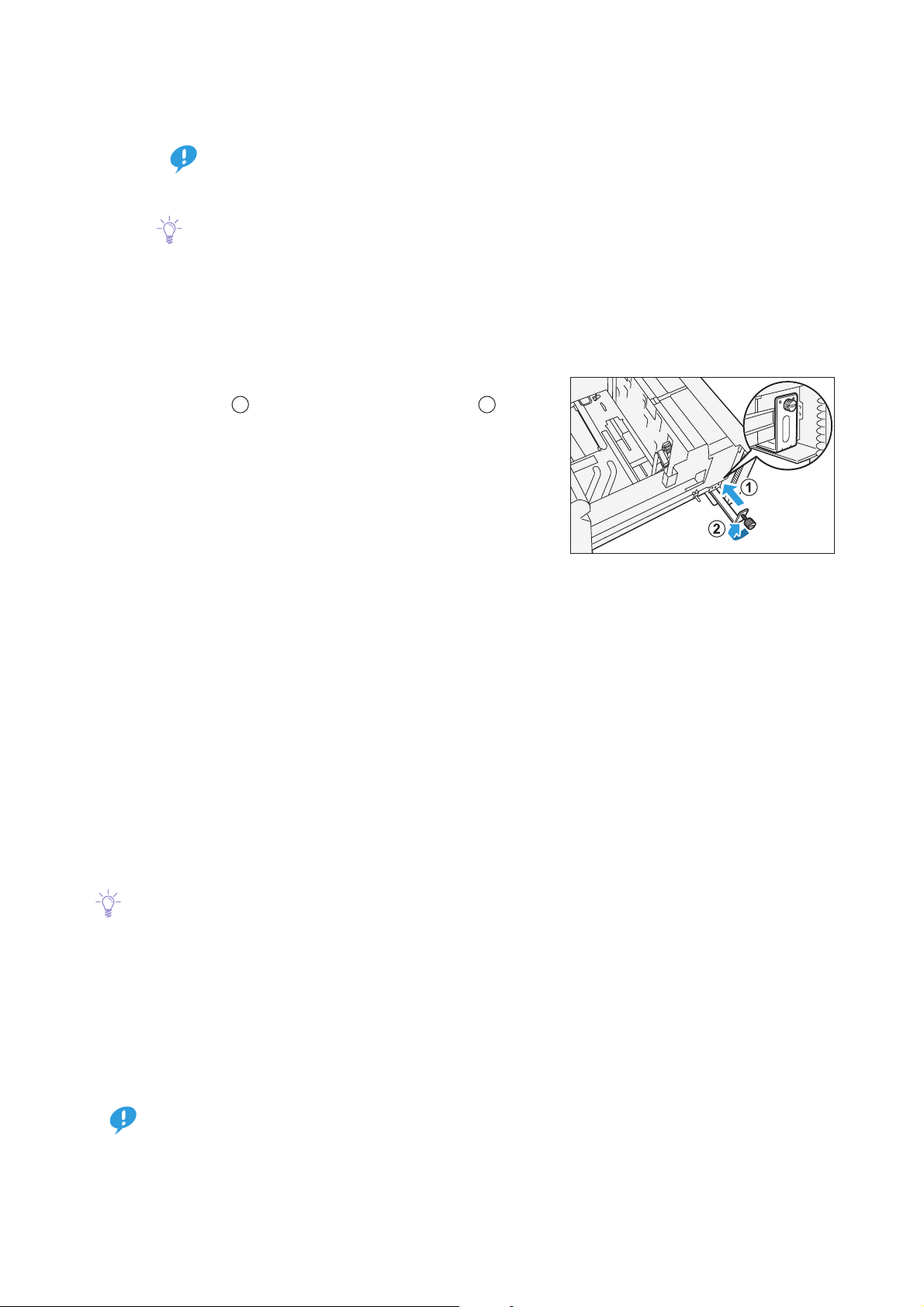

Checking Remaining Paper Level

Remaining paper level can be checked with the paper level indicator lamp.

If an incorrect level is indicated, pull out the Tray, make sure the plate is lowered, and then push the Tray into the machine slowly and firmly.

After setting the paper, it may take some time for the lamp to illuminate.

This is because the printer is raising the bottom plate or setting up the Air

Assist function, and thus not a malfunction.

The top active indicator lamp lights when the corresponding Tray is active. The

four center lamps (1=25%) indicate the amount of remaining paper. When all

of the four lamps turn off, Tray becomes empty and paper empty indicator

lamp lights.

Chapter 2 Load and Output Paper

27

Page 28

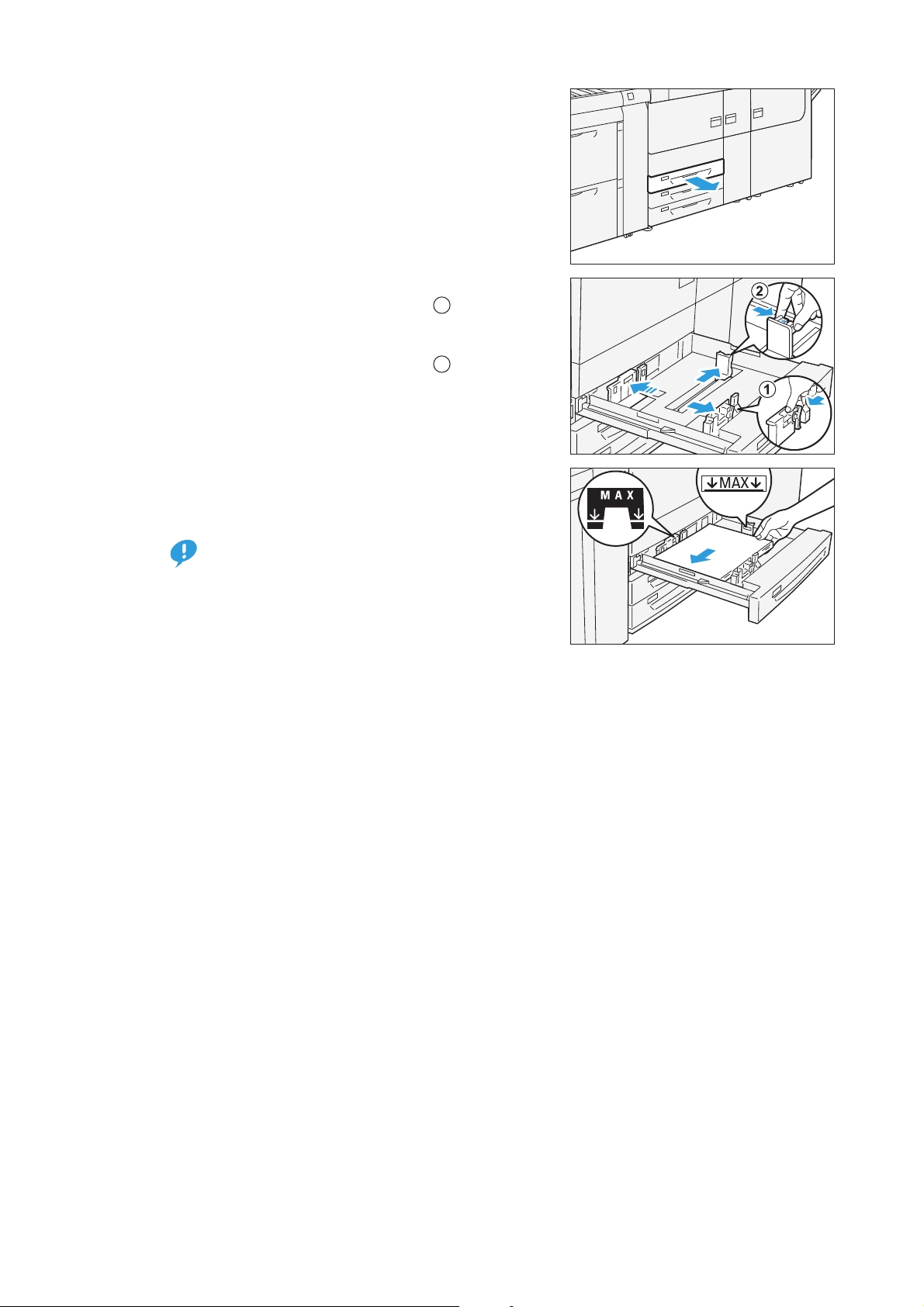

Loading Paper in a Tray

Note

Important

Important

Important

Note

2

1

The number of sheets is the value when Colotech+90 is used. Adjust the number according to the type or the

weight of the paper.

1.

Pull out the Tray toward you until it stops.

2.

Remove any paper remaining in the Tray.

3.

Fan the paper well and load about 100 to 500 sheets

with the printed side facing up, and the paper edges

aligned in the direction of the arrow ( ).

4.

Hold the long-side paper guide by its grip and move

it to lightly contact the paper edges ( ).

If the amount of the loaded paper is less than 100

sheets, the guides apply more pressure to the paper.

It may cause the paper to be distorted, leading to

paper jams.

1

5.

Load remaining sheets with the printed side facing

up, and align the paper edges in the direction of the

arrow ( ).

6.

Hold the short-side paper guide by its grip and move

it to lightly contact the paper edges ( ).

Do not load paper above the maximum fill line. It

may cause paper jams or machine malfunctions.

Position the guides correctly to match the paper

size. Incorrectly positioned guides may cause misfeeding and paper jam s.

7.

Push the Tray into the machine.

The [Tray Stock Properties] window appears on the Stock Library Manager.

In the event power is disconnected while the Tray's bottom plate is rising, the plate may not move

up when the power is recovered. In this case, pull out the Tray, make sure the plate is lowered, and

then push the Tray into the machine slowly and firmly.

When paper sheets are loaded or fed, the Tray makes a sound of supplying air. This is caused by the

Air Assist function that supplies air to coated or heavy weight paper, and not an abnormal noise.

8.

Change the Tray settings.

2

28

Postcard Setting

Attach Postcard Kit to the Tray to load paper size 181.9 mm portrait or smaller.

Postcard Kit may be purchased separately.

Below is how to load paper with the Kit, taking postcards for example.

Printer Unit Manual

Page 29

1.

Important

Important

Important

1

2

1

2

1

2

1

2

1

2

1

Pull out the Tray toward you until it stops.

2.

Remove any paper remaining in the Tray.

3.

If the Postcard Kit is supplied with the Tray, loosen

the screw ( ) on the left side of the Tray to remove

the Kit ( ).

4.

Insert the small protrusion of the Kit into the notch

to the right side of the bottom of the Tray ( ). Align

the hole of the Kit with the front Tray hole and

tighten the screw to fasten the Kit ( ).

2

1

5.

Load about 100 to 500 sheets of paper with the

printed side facing up, and align the paper edges in

the direction of the arrow ( ).

Be sure to set them in short edge feed.

The right side short edge of the set postcard will be

the lead edge.

6.

Hold the long-side paper guide by its grip and move

it to lightly contact the paper edges ( ).

If the amount of the loaded paper is less than 100

sheets, the guides apply more pressure to the paper.

It may cause the paper to be distorted, leading to

paper jams.

7.

Load remaining sheets with the printed side facing

1

2

up, and align the paper edges in the direction of the

arrow ( ).

8.

Hold the short-side paper guide by its grip and move

it to lightly contact the paper edges ( ).

Do not load paper above the maximum fill line. It

may cause paper jams or machine malfunctions.

Position the guides correctly to match the paper

size. Incorrectly positioned guides may cause misfeeding and paper jam s.

2

Chapter 2 Load and Output Paper

29

Page 30

9.

Important

Note

Note

1

2

Push the Tray into the machine.

The [Tray Stock Properties] window appears on the Stock Library Manager.

In the event power is disconnected while the Tray's bottom plate is rising, the plate may not move

up when the power is recovered. In this case, pull out the Tray, make sure the plate is lowered, and

then push the Tray into the machine slowly and firmly.

When paper sheets are loaded or fed, the Tray makes a sound of supplying air. This is caused by the

Air Assist function that supplies air to coated or heavy weight paper, and not an abnormal noise.

10.

Change the Tray settings.

11.

To remove the Postcard Kit from the Tray, loosen the screw completely and then

remove the Kit.

12.

Store the Kit in place by inserting it from the left side

of the Tray ( ) and tightening the screw ( ).

Special Media Setting

Transparency

Loading side: Load sheets with the printed side facing up.

Hole punched paper

Orientation: Place the holes of paper on the right side when you face the front side of printer.

Precut tab

Orientation: Place the tabs of paper on the left side when you face the front side of printer.

Envelope

Loading side: Load sheets with the printed side facing up.

Direction with the flap open: Place the flap of Envelope on the left side when you face the front side of

printer.

Direction with the flap closed: Place the flap of Envelope on the right or near side when you face the front

side of printer.

If envelopes are loaded with the flaps unfolded, the size will not be automatically detected as standard

size.

Fold the flaps when loading self-seal envelopes.

If you place the flap of envelope closed on this side, a failure in printing might occur on the rear edge of

papers depending on the arranged images.

30

Improving Paper Feed Precision

If print skew (misregistration of print) occurs on properly loaded paper, the problem can be solved by

switching the paper feed precision.

On other than plain paper with 220 g/m2 or less, switching the paper feed precision may cause the paper jam

Important

Printer Unit Manual

because papers may not normally be fed. Also, this function has no effect when you use the Postcard Kit.

Page 31

1.

Note

Note

Note

Refer

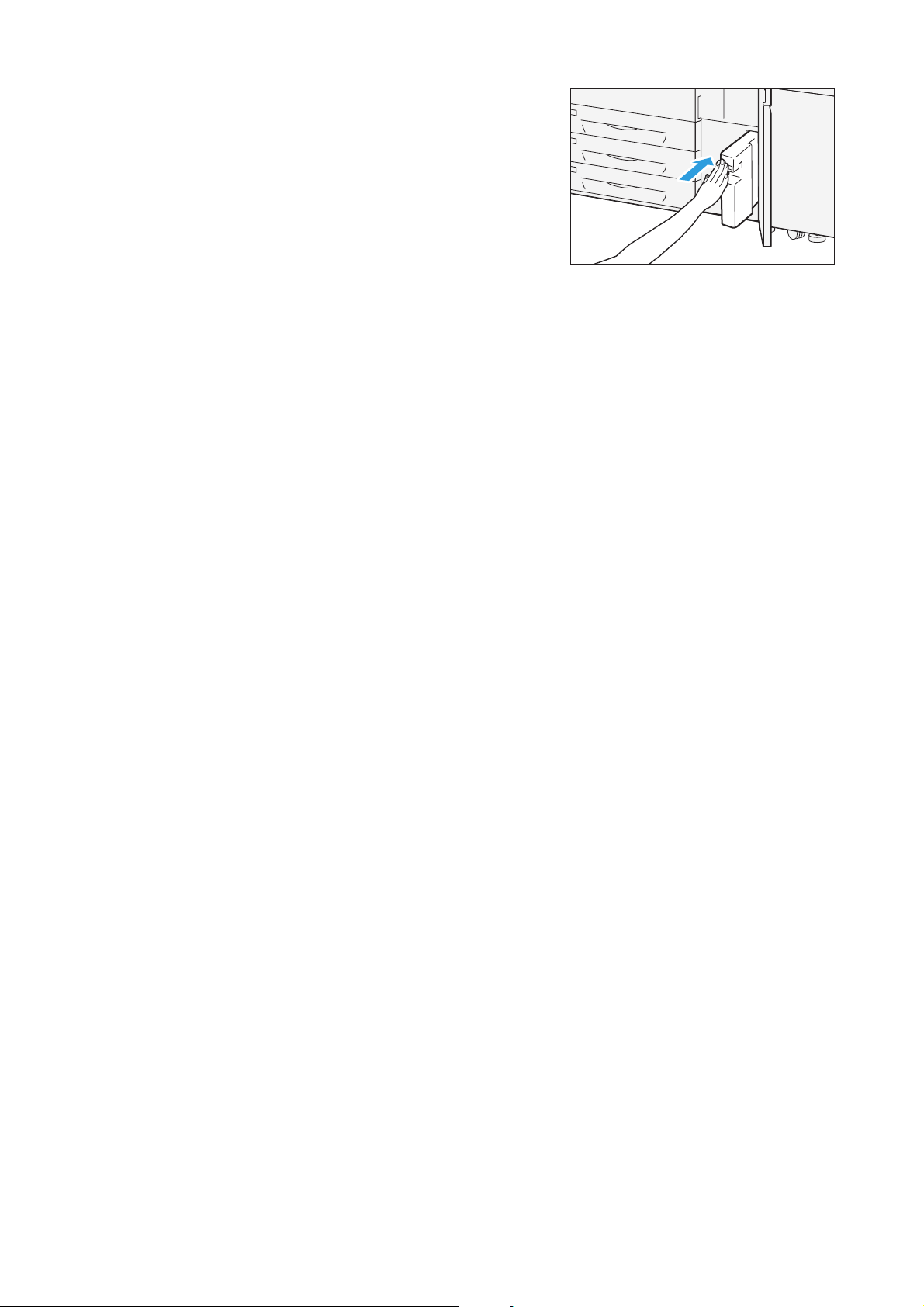

Pull out the Tray toward you until it stops.

2.

Slide the switch on top of the long-side paper guide

to the right side until it stops.

To return the switch to its original position, slide it to

the left side until it stops.

3.

If the paper feeding does not improve after Step 2.,

slide the switch on the front right side toward the

rear side until it stops.

To return the switch to its original position, slide it

toward you until it stops.

4.

Push the Tray into the machine.

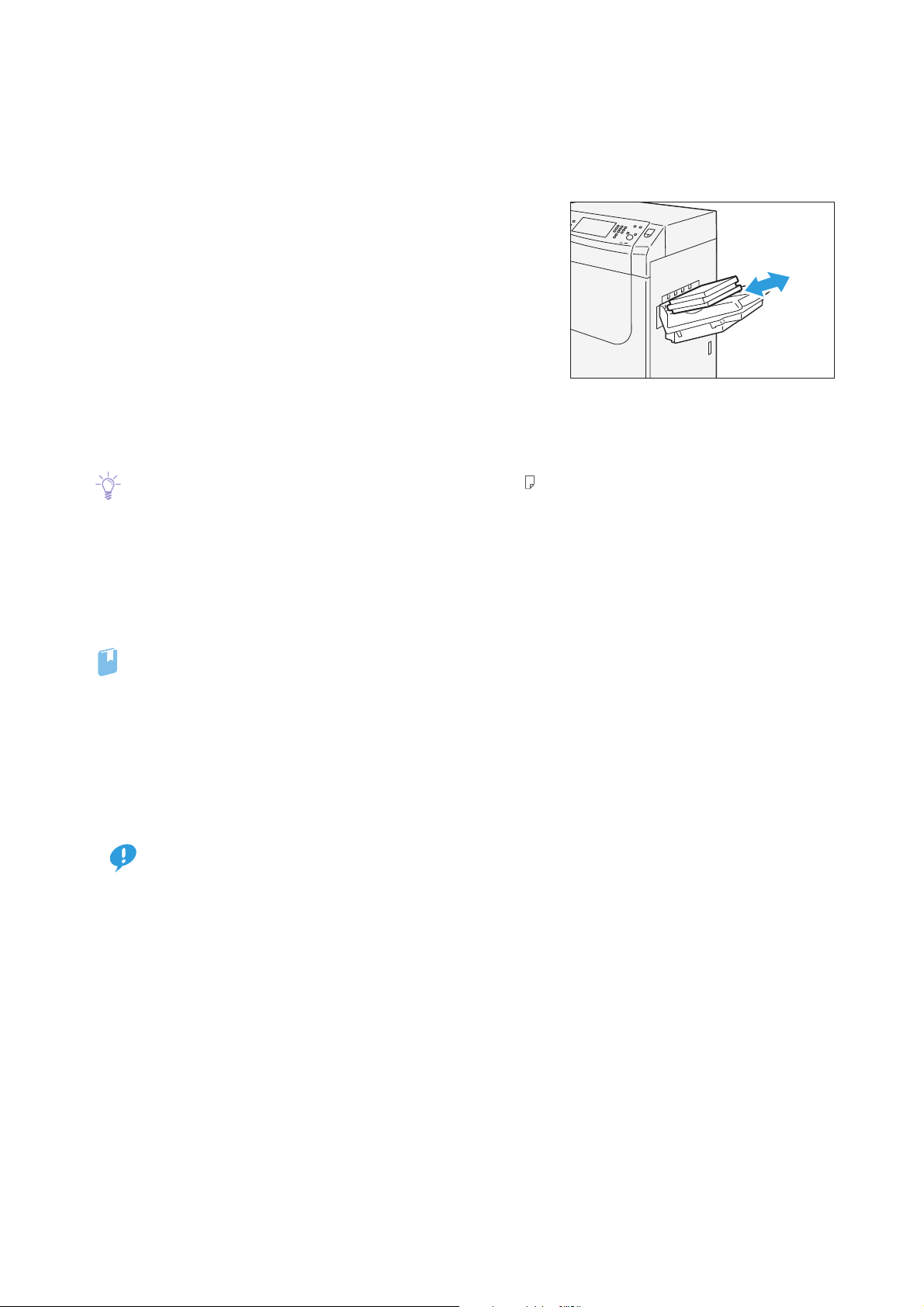

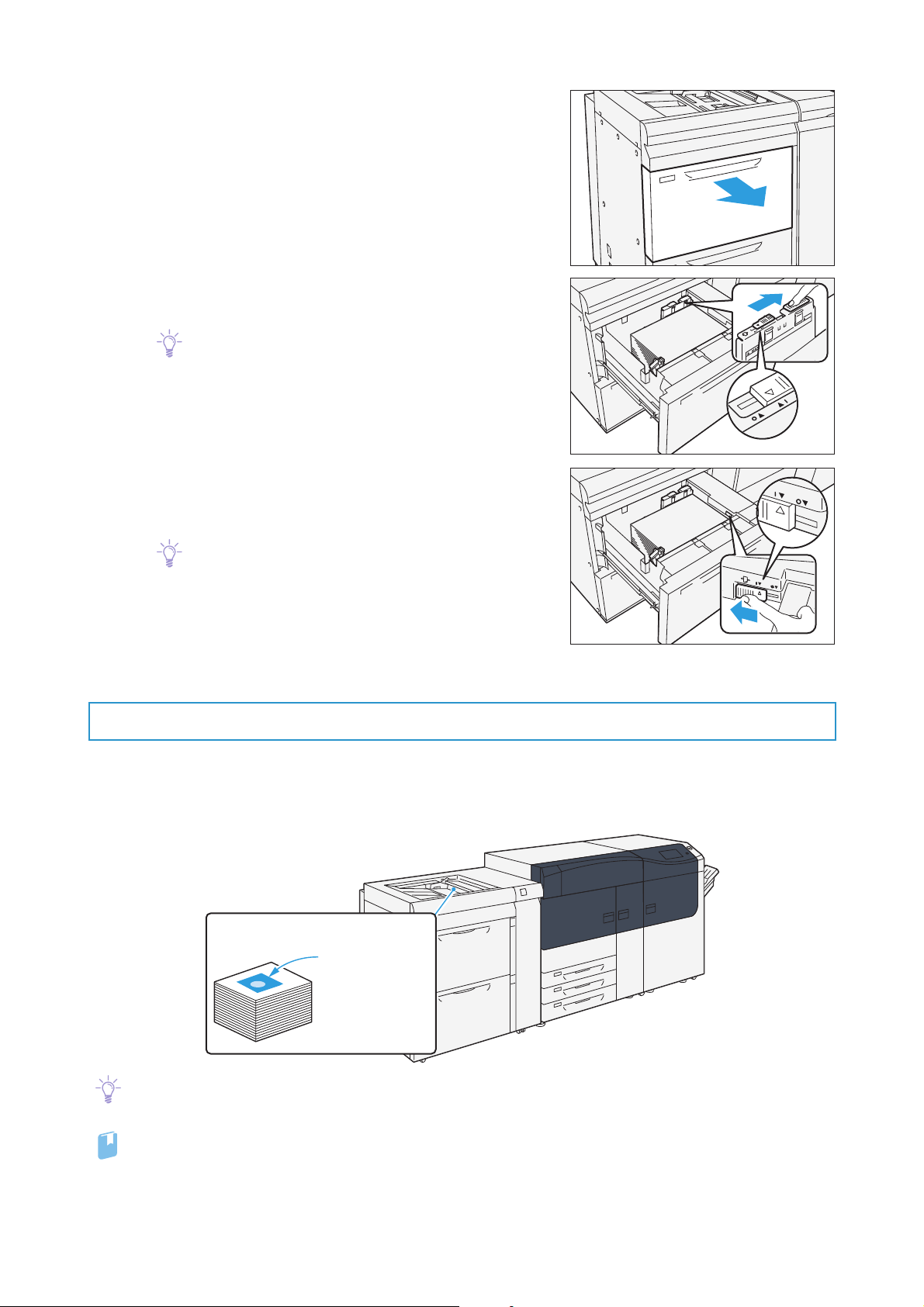

2.3.3 Loading paper in Bypass Tray

Types of paper unavailable in the Trays or High Capacity Trays can be loaded in Bypass Tray (5).

Images are printed on the face side of the loaded paper.

Up to 250 sheets (Colotech+90) can be loaded.

Printed side

If any paper remains in the Tray, remove the paper first, and put the paper and the new paper together, and

then load all of the paper into the Tray at once.

For detailed information on the paper available in Bypass Tray, refer to "2.1.2 Supported Paper" (p.18).

Chapter 2 Load and Output Paper

31

Page 32

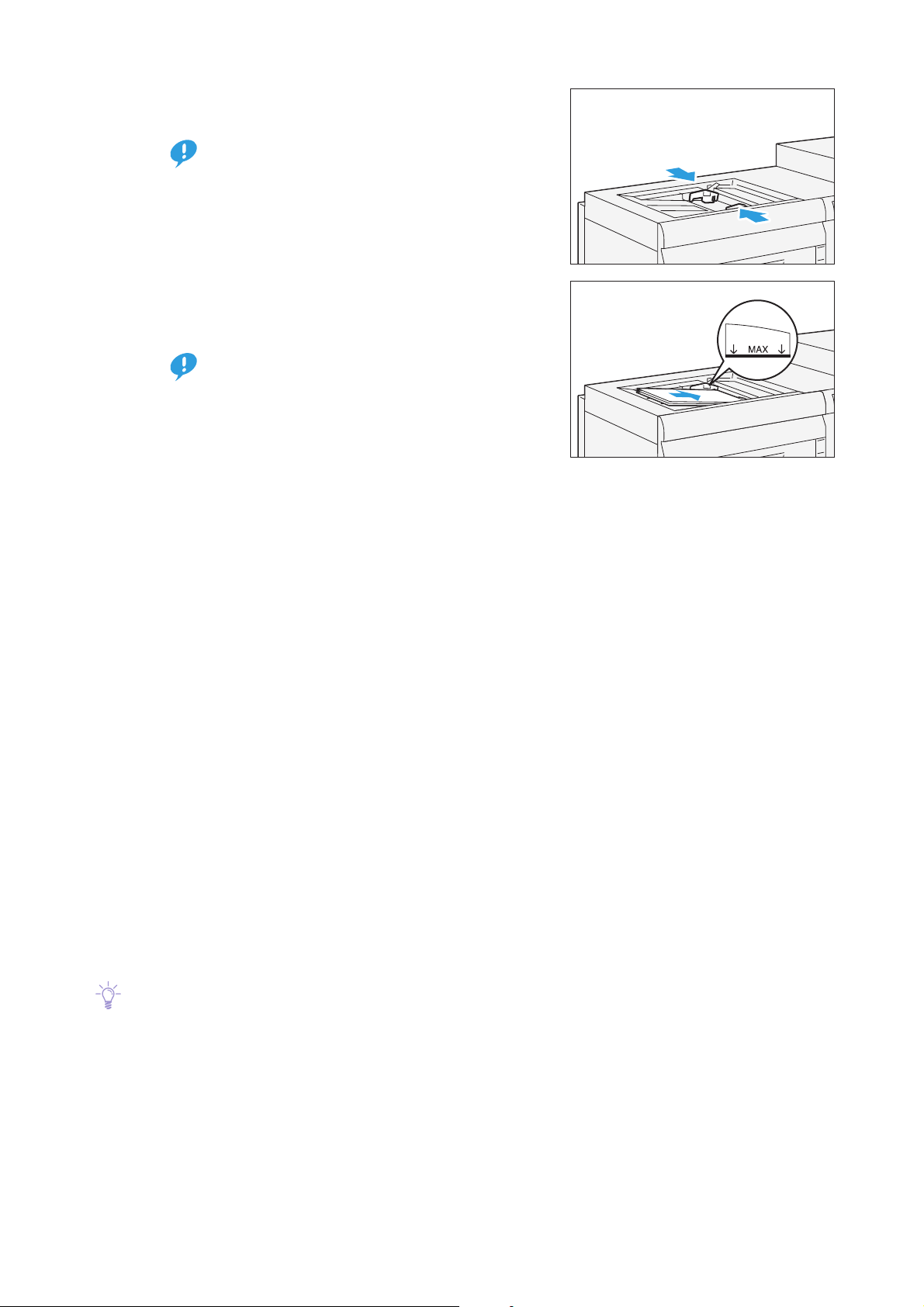

1.

Important

Important

Note

Hold the center of the paper guides and slide them to

the desired paper size.

If the distance between the guides is too long or short

relative to the paper, paper jams may occur.

2.

Fan the paper well and insert it along the paper

guide all the way until it touches the back, with the

printed side facing up.

Do not load paper above the maximum fill line. It

may cause paper jams or machine malfunctions.

3.

When loading a non-standard size paper, slightly move the paper guides to the desired

paper size.

Special Media Setting

Transparency

Loading side: Load sheets with the printed side facing up.

Hole punched paper

Orientation: Place the holes of paper on the right side when you face the front side of printer.

Precut tab

Orientation: Place the tabs of paper on the left side when you face the front side of printer.

Postcard

Orientation: SEF

Envelope

Loading side: Load sheets with the printed side facing up.

Direction with the flap open: Place the flap of Envelope on the left side when you face the front side of

printer.

Direction with the flap closed: Place the flap of Envelope on the right or near side when you face the front

side of printer.

If envelopes are loaded with the flaps unfolded, the size will not be automatically detected as standard

size.

Fold the flaps when loading self-seal envelopes.

If you place the flap of envelope closed on this side, a failure in printing might occur on the rear edge of

papers depending on the arranged images.

32

Printer Unit Manual

Page 33

Chapter 3

3.1 Troubleshooting........................................................................................33

3.2 Paper Jams in the Printer Unit............................................................41

3.3 Paper Jams in the Printer Output Unit ............................................48

3.4 Paper Jams in the High Capacity Feeder C3-DS ..........................55

Problem Solving

3.1.1 Printing Troubles.................................................................................................. 34

3.1.2 Image Quality Trouble...................................................................................... 37

3.2.1 Paper Jams in the Transfer Module............................................................. 41

3.2.2 Paper Jams in Tray.............................................................................................. 44

3.2.3 Paper Jams in the Paper Feeding Unit....................................................... 45

3.2.4 Long Paper Jam ................................................................................................... 47

3.3.1 Paper Jams in the Cooling Unit..................................................................... 48

3.3.2 Paper Jams inside the Cover .......................................................................... 51

3.3.3 Paper Jams in the Output Area..................................................................... 54

3.4.1 Paper Jams in Tray.............................................................................................. 55

3.4.2 Paper Jams inside the Right Side Cover .................................................... 57

3.1

Follow the procedures shown in this chart to solve problems.

For troubles concerning the job processing and solutions to them, refer to customer documentation supplied with Print Servers.

Troubleshooting

The printer does not work properly.

No

A message is displayed.

No

The image quality is poor.

No

Having network troubles.

No

If the error is not resolved even after following the above procedure, contact your local Fuji Xerox

representative.

Yes

Yes

Yes

Yes

"3.1.1 Printing Troubles" (p.34)

An error code is displayed.

"8.2 Error Messages" in the User Interface Manual.

Paper is jammed.

"3.2 Paper Jams in the Printer Unit" (p.41)

"3.3 Paper Jams in the Printer Output Unit" (p.48)

"3.4 Paper Jams in the High Capacity Feeder C3-DS" (p.55)

"3.1.2 Image Quality Trouble" (p.37)

"8.1 IPv4 and IPv6 Connection Problems"

in the User Interface Manual.

Chapter 3 Problem Solving

33

Page 34

3.1.1 Printing Troubles

Refer

Refer

Refer

When paper jams or any other troubles with the printer unit occurs, follow the procedures shown in the

touch screen. If the machine does not work properly after taking the procedure, contact your local Fuji

Xerox representative.

Troubles with the Printer Unit

Symptom Cause Remedy

Power switch is on, but

printer is not turned on

"1.2 Power

On/Off"

(p.12)

The <Error> indicator is

blinking

The <Error> indicator is lit Is there a paper jam? Follow the instruction displayed and remove

Is the emergency main power switch

in the

<|>

(ON) position?

Is the circuit breaker switch in the

"ON" (upper position)?

The printer unit or optional units may

be having trouble.

The hard disk may not be recognized. Switch off the printer and then on again.

Is any cover open? Follow the instructions displayed to solve the

Is any massage shown, suggesting

the replacement of consumables?

Is any error massage shown? Follow the instructions displayed to solve the

Press the main power switch to the

position.

Press the circuit breaker switch to the "ON"

(upper position).

Switch off the printer and then on again.

Confirm that the power to the High Capacity

Feeder C3-DS and optional unit is on.

jammed papers.

problem.

Follow the instructions displayed to solve the

problem.

problem.

If an error code such as "016-450" is displayed,

check the error code list and solve the problem.

<|>

(ON)

The touch screen is too

dark

"8.2 Error Messages" in the User

Interface Manual.

Is the <Power Saver> button lit? The printer is in the Power Saver mode.

Press the <Power Saver> button on the control

panel to exit the Power Saver mode.

"1.4 Power Saver Mode" in the

User Interface Manual.

34

Printer Unit Manual

Page 35

Refer

Refer

Refer

Symptom Cause Remedy

Unable to print Is the message "Machine Cooling in

The printer is in cooling mode. Please wait.

Progress" displayed on the touch

screen?

Is any of below happening?

The power was left OFF for a long

It may take time to start printing as image

quality adjustment is in progress.

time.

A job was sent right after the printer

returned from the Sleep mode.

A job with large volume was sent.

Does the loaded paper correspond

with the stock set with Stock Library

Load the corresponding paper and print the

job again.

Manager?

Troubles with the Trays

"2.3 Loading Paper" (p.25)

Symptom Cause Remedy

Unable to insert or

remove the Tray

Did you open a cover or turn the

power switch off during printing?

Do not forcibly insert or remove the Tray. Turn the power

switch off. In a few seconds, switch on the power.

When the printer is ready to receive data, insert or

remove the Tray.

"1.2.1 Services Home" in the User

Interface Manual.

Stock Library Manager Manual

Indicated paper level

is wrong

Tray bottom plate

does not move up

(High Capacity

Trays)

Is there extra paper or any object

placed in a space in the Tray?

Placing extra paper or anything in the space may cause

the printer to recognize incorrect paper size or paper

level or to malfunction. Make sure nothing is placed in

the space.

Is paper loaded correctly? First remove all the paper from the Tray, and then

reload it correctly. Slide the long-side and short-side

paper guides to just touch the edges of the paper. Push

the Tray into the machine slowly and firmly.

Is any paper sheet stuck at the

exit of the Tray?

Was power supply disconnected

while the bottom plate was rising?

Remove jammed papers and push the Tray into the

machine slowly and firmly.

If yes, the bottom plate may fail to move up when the

printer is powered on again.

In this case, pull out the Tray, make sure the plate is

lowered, and then push the Tray into the machine

slowly and firmly.

Is there extra paper or any object

placed in a space in the Tray?

Placing extra paper or anything in the space may cause

the printer to recognize incorrect paper size or paper

level or to malfunction. Make sure nothing is placed in

the space.

Is the paper curled? Turn over or flatten the curled paper, or replace with

uncurled paper.

Do not use 12 mm or more curled paper.

Is the loaded paper different from

what is set on the Stock Library?

Change the stock settings to match the loaded paper.

Load the same paper set on the Stock Library.

Chapter 3 Problem Solving

35

Page 36

Symptom Cause Remedy

Tray 5 - 9 are not

displayed on the

touch screen

Indicated paper level

is wrong (High

Capacity Trays)

Are the main unit and the High

Capacity Feeder C3-DS

connected?

Is the Tray inserted correctly? Pull out the Tray, make sure the plate is lowered, and

Make sure the devices are securely connected.

then push the Tray into the machine slowly and firmly.

It may take some time for the printer to indicate the

paper level. This is because the printer is raising the

bottom plate or setting up the Air Assist function, and

thus not a malfunction.

Troubles Concerning the Paper

Symptom Cause Remedy

Paper jams or wrinkles

on paper occurs

frequently (problems

in how the paper is

loaded)

Are the paper and Tray settings

correct?

Are the paper guides set correctly? Load the paper correctly, and align the paper guides

Is paper exceeding the maximum

fill line in the Tray?

Please check if the set stock setting (size, type, weight

etc.) and the paper match.

Refer

with the paper.

Load paper in the Tray so that it does not exceed the

maximum fill line.

Stock Library Manager Manual

Paper jams or wrinkles

on paper occurs

frequently (problems

with the paper itself)

Are the special media loaded with

correct orientation?

Are there any torn pieces of paper

or foreign objects left in the

printer?

Is unsupported paper loaded in

the Tray?

Is the paper finely cut out? Some types of paper may not be cut correctly. Load

Is any folded or wrinkled paper

loaded in the Tray?

Is the paper damp? Replace with fresh paper that has just been unpacked.

Are edges or holes of the loaded

paper sheets neatly aligned?

Is the paper curled? Turn over or flatten the curled paper, or replace with

Is paper curl correction properly

configured?

Load the media in correct direction.

Refer

Check for jammed or torn paper, or any other objects

in the parts where paper often jams.

Replace with supported paper.

the paper after fanning it.

Remove folded or wrinkled paper sheets, or replace

with new paper.

Replace paper having irregular edges or holes.

uncurled paper.

Do not use 12 mm or more curled paper.

Perform curl correction.

"2.3 Loading Paper" (p.25)

36

Printer Unit Manual

Page 37

3.1.2 Image Quality Trouble

Refer

If the image quality of a printed document is poor, identify the symptom in the following table to perform

the remedy.

If image quality does not improve even after performing the remedy, contact your local Fuji Xerox representative.

Symptom Cause Remedy

Color density is less than desired. Output characteristics has

Tone jumping or tonal defect appears.

Colors do not match the previously

printed samples.

Printing is faint (rough, smudged,

unclear).

been changed by the

changes in environment or

conditions.

The paper is damp. Replace paper.

The Fusing Module may be

dirty.

There is a possibility of

transfer defect.

The drum cartridge has

deteriorated or is damaged.

The toner is old. Clean the toner on a regular basis.

Correct the print quality with Full Width

Array.

Refer

Clean the Fusing Module on a regular basis.

Refer

Specify each item for [Advanced Stock

Setup] on Stock Library.

Refer

Contact your local Fuji Xerox representative

to replace the Drum Cartridge.

Refer

"3.3.2 Full Width Array" in the

User Interface Manual.

"3.3.1 Clean Fusing Unit" in the

User Interface Manual.

"Stock Library" in the Stock

Library Manager Manual.

"4.1.8 Maintenance" in the User

Interface Manual.

There is no toner left in the

toner cartridge.

Black dots are printed. The Fusing Module may be

dirty.

The drum cartridge has

deteriorated or is damaged.

Black or colored lines are printed. The Fusing Module may be

dirty.

The drum cartridge has

deteriorated or is damaged.

Replace the toner cartridge with a new one.

Clean the Fusing Module on a regular basis.

"3.3.1 Clean Fusing Unit" in the

User Interface Manual.

Contact your local Fuji Xerox representative

to replace the Drum Cartridge.

Clean the Fusing Module on a regular basis.

Refer

Contact your local Fuji Xerox representative

to replace the Drum Cartridge.

"3.3.1 Clean Fusing Unit" in the

User Interface Manual.

Chapter 3 Problem Solving

37

Page 38

Symptom Cause Remedy

Feed Direction

Dirt appears at equal intervals. The paper path is dirty. Print a few pages to remove the dirt.

The Fusing Module may be

dirty.

The drum cartridge has

deteriorated or is damaged.

White dots appear in black filled areas. The paper is unsuitable. Load suitable paper.

The Fusing Module may be

dirty.

The drum cartridge has

deteriorated or is damaged.

The toner is old. Clean the toner on a regular basis.

Printed toner smudges when rubbed

with your finger.

Toner is not fused.The paper is soiled

with toner.

The paper is damp. Replace paper.

The paper setting is

unsuitable.

Clean the Fusing Module on a regular basis.

Refer

Contact your local Fuji Xerox representative

to replace the Drum Cartridge.

Clean the Fusing Module on a regular basis.

Refer

Contact your local Fuji Xerox representative

to replace the Drum Cartridge.

Refer

Load the paper type and paper weight

correctly.

"3.3.1 Clean Fusing Unit" in the

User Interface Manual.

"3.3.1 Clean Fusing Unit" in the

User Interface Manual.

"4.1.8 Maintenance" in the User

Interface Manual.

38

The entire paper area is printed black. The drum cartridge has

deteriorated or is damaged.

High-voltage power supply

may have malfunctioned.

Nothing is printed. Multifeed (multiple sheets

transferred simultaneously)

occurs.

Power supply or highvoltage power supply may

have malfunctioned.

Printer Unit Manual

Contact your local Fuji Xerox representative

to replace the Drum Cartridge.

Contact your local Fuji Xerox representative.

Fan the paper well and load it again.

Contact your local Fuji Xerox representative.

Page 39

Symptom Cause Remedy

Feed Direction

White areas or white or colored stripes

appear.

The entire output is faint. Multifeed (multiple sheets

Paper becomes wrinkled. The paper is unsuitable. Replace paper.

The paper is damp. Replace paper.

The paper is unsuitable. Load suitable paper.

Fan the paper well and load it again.

transferred simultaneously)

occurs.

Paper has been added to

the paper loaded.

The paper is damp.

Text is blurred. The paper is unsuitable. Replace paper.

Paper has been added to

the paper loaded.

The paper is damp.

White or color patches appear

vertically.

The Fusing Module may be

dirty.

The drum cartridge has

deteriorated or is damaged.

No toner remains in the

toner cartridge.

Clean the Fusing Module on a regular basis.

Refer

Contact your local Fuji Xerox representative

to replace the Drum Cartridge.

Replace the toner cartridge with a new one.

"3.3.1 Clean Fusing Unit" in the

User Interface Manual.

Chapter 3 Problem Solving

39

Page 40

Symptom Cause Remedy

Text or images are printed at an angle. Paper guides in the Trays

are not in the right position.

Prints on the front and back side of the

paper are off-center.

Alignment (registration

adjustment) is not properly

set.

Place the long-side and short-side paper

guides in the right position.

Create an alignment profile to correct the

misregistration.

Refer

"Profiles" in the Stock Library

Manager Manual.

40

Printer Unit Manual

Page 41

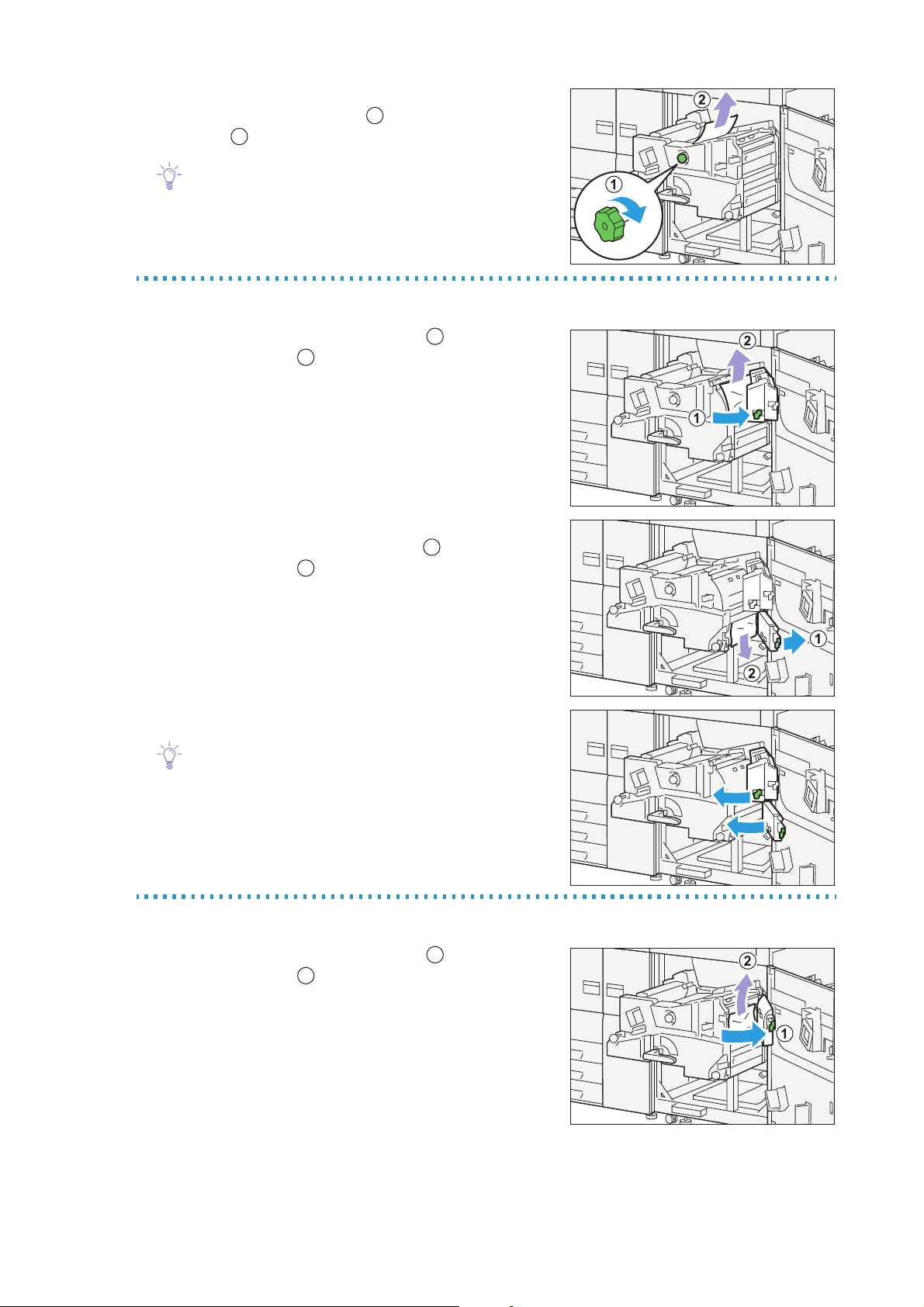

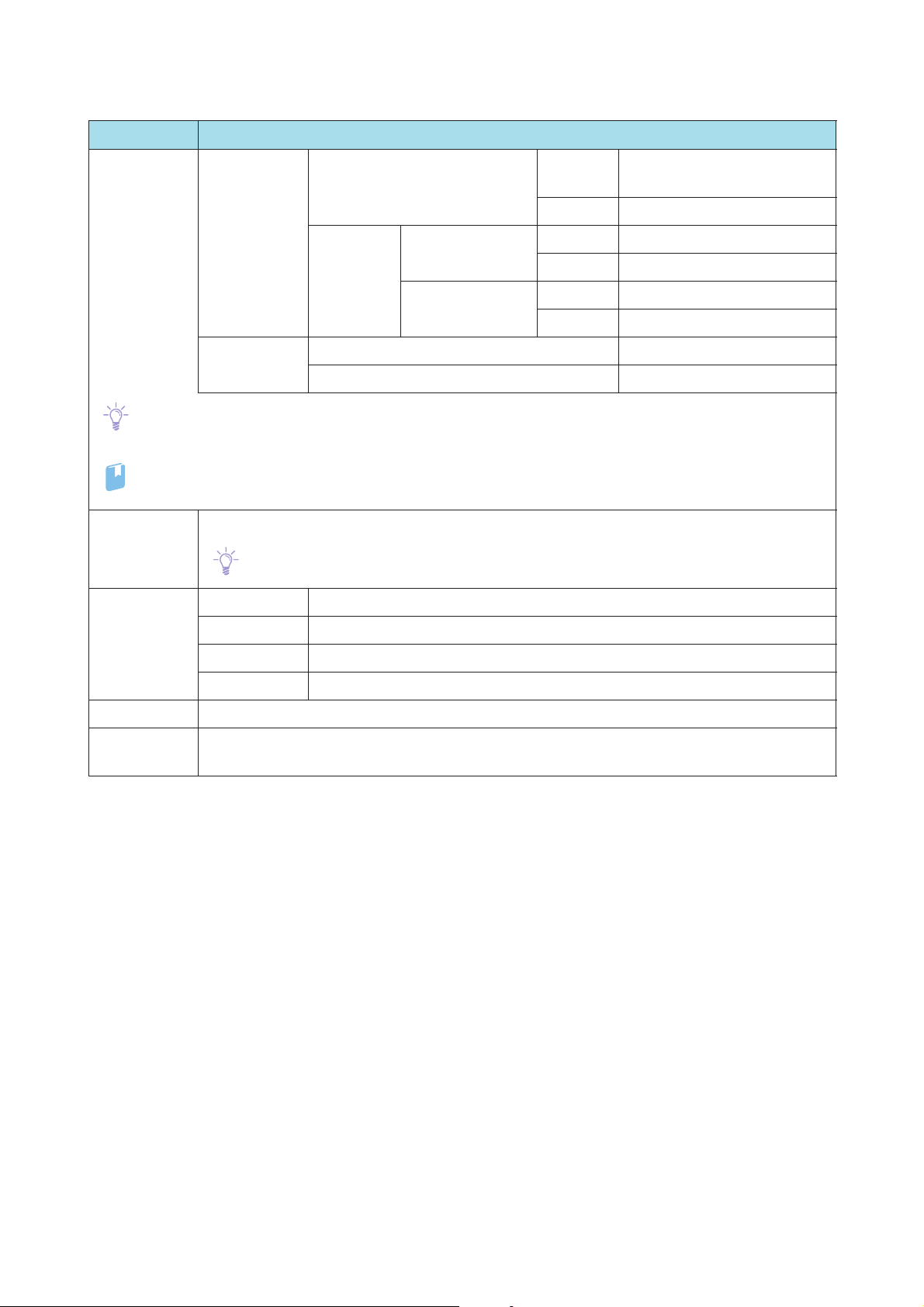

3.2

Refer

Important

Note

Paper Jams in the Printer Unit

If there is a paper jam, the printing will be canceled.

The Error Message area of the touch screen will show the affected area in red, along with the message.

If there is a paper jam in the following area, tap the [Faults] and the [Faults] screen will appear, explaining

how to remove jammed papers.

For detailed information on how to regard the messages, refer to "1.2.1 Services Home" in the User Interface

Manual.

CAUTION

Do not attempt to remove a paper jammed inside the printer, particularly a paper wrapped around a

Fusing Unit or a heat roller. Otherwise, it may cause injuries or burns. Switch off the product

promptly immediately and contact your local Fuji Xerox representative.

Always follow all warning instructions marked on or supplied with this printer.

To avoid the risk of burn injuries and electric shock, never touch the area with the "High Temperature" or "High Voltage" marks on.

Remove the paper only after you are sure the printer is no longer moving.

After removing jammed papers, be sure to close the cover. Leaving the cover open will not be able to continue to print jobs.

Leave the power on and proceed to remove jammed papers.

If there is still paper remaining, the paper jam message will continue to display. Make sure that there is no

jammed paper left and also no jams in other places.

3.2.1 Paper Jams in the Transfer Module

Follow the steps below to clear paper jams in the Transfer Module.

CAUTION

When pulling out the Transfer Module, do it gently. If pulled out with too much force, the module can

hit and injure your knees.

Chapter 3 Problem Solving

41

Page 42

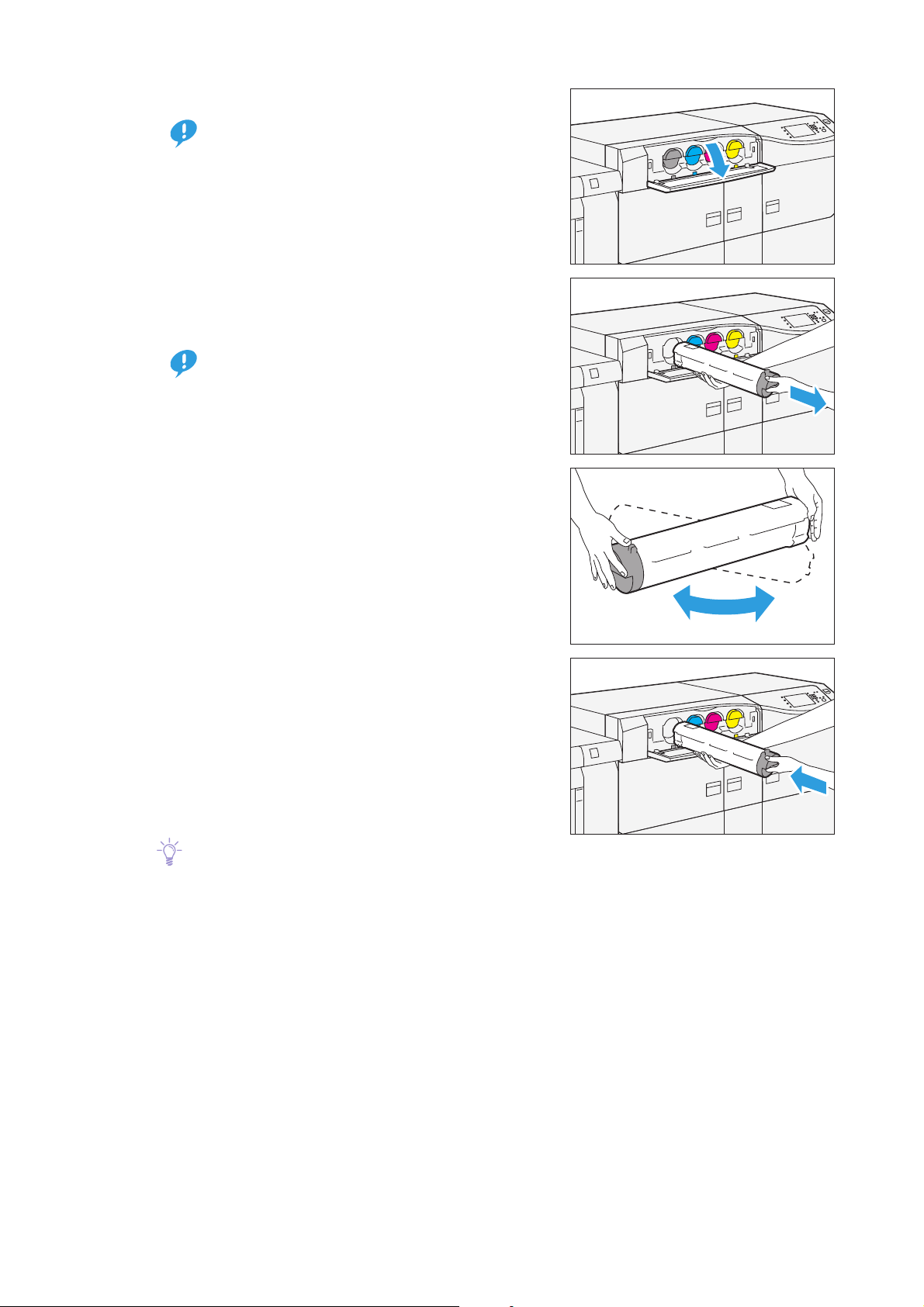

1.

Important

Note

Important

Note

Open the left side and center covers of the printer

unit.

2.

Turn lever "2" in the unlocking direction (toward the

opened-lock mark).

3.

Grip lever "2" and gently pull out the Transfer Module

toward you until it stops.

If the paper is curled and caught in the Transfer Module, stop

pulling when the jammed paper is visible, and then continue to

pull it out while holding down the paper with a hand.

4.

Remove jammed papers.

Paper Jams at Area "2a" ...................................................................................................................................................p.42

Paper Jams at Lever "2b"..................................................................................................................................................p.43

Paper Jams at Area "2c"....................................................................................................................................................p.43

Paper Jams at Lever "2d" / "2e" ......................................................................................................................................p.43

Paper Jams at Lever "2f"...................................................................................................................................................p.44