Page 1

System Software Version 100.21.44

Book Version 3.0

September 2015

702P02815

®

Xerox

Versant

User Guide

®

2100 Press

Page 2

©2015 Xerox Corporation. All rights reserved. Xerox®, Xerox and Design®, FreeFlow®,

SquareFold®, CentreWare®and Versant®are trademarks of Xerox Corporation in the

United States and/or other countries.

Adobe®PDF®is a registered trademarks of Adobe Systems, Inc. PostScript®is an Adobe

registered trademark used with the Adobe PostScript Interpreter, the Adobe page

description language, and other Adobe products.

Fiery®and EFI™are trademarks or registered trademarks of Electronics For Imaging, Inc.

GBC®and AdvancedPunch™are trademarks or registered trademarks of General Binding

Corporation.

3-IN-ONE®and WD-40®are a registered trademarks of the WD-40 Company.

BR4005

Page 3

Table of Contents

1 Product Overview.......................................................................................1-1

Press Overview.......................................................................................................................1-1

Print Server Overview..........................................................................................................1-1

Press Components...............................................................................................................1-2

Locating the Press Serial Number....................................................................1-3

Status Lights.............................................................................................................1-4

Control Panel............................................................................................................1-4

Logon.............................................................................................................1-5

Language......................................................................................................1-6

Energy Saver Mode................................................................................................1-6

Low Power Mode.......................................................................................1-7

Sleep Mode..................................................................................................1-7

Exiting Power Saver Mode.....................................................................1-7

Power On / Off.......................................................................................................................1-7

The Power Switches...............................................................................................1-7

Power On / Off the Press......................................................................................1-8

Feeding and Finishing Devices.......................................................................................1-9

Feeding Devices.......................................................................................................1-9

Oversized High Capacity Feeder (OHCF / Trays 6 and

7)...........................................................................................................1-9

Chained Oversized High Capacity Feeder (OHCF / Trays 8

and 9)..................................................................................................1-9

Bypass (Tray 5)........................................................................................1-10

Finishing Devices..................................................................................................1-10

Offset Catch Tray (OCT)......................................................................1-10

Interface Module....................................................................................1-10

GBC®AdvancedPunch™.........................................................................1-11

GBC®AdvancedPunch™Pro.................................................................1-11

High Capacity Stacker..........................................................................1-12

Standard Finisher...................................................................................1-12

Booklet Maker Finisher.........................................................................1-12

SquareFold®Trimmer Module...........................................................1-13

Standard Finisher Plus..........................................................................1-13

Third-Party Finishing Devices............................................................1-14

2 Where to Find Help...................................................................................2-1

Help on the Xerox Web Site.............................................................................................2-1

User Guide

iXerox®Versant®2100 Press

Page 4

Table of Contents

Diagnostic Tool.....................................................................................................................2-1

Stock Library Manager Online Help..............................................................................2-2

Print Server Customer Documentation.......................................................................2-2

3 Technical Specifications..........................................................................3-1

Press Specifications.............................................................................................................3-1

First Print: Out Time...............................................................................................3-2

Press Warmup Time...............................................................................................3-2

Paper Tray Information........................................................................................3-2

Throughput / Productivity Information ........................................................3-3

Paper Specifications for Trays 1-3, 5, and 6-7..........................................................3-5

Press Environmental Specifications..............................................................................3-7

4 Paper and Other Media..........................................................................4-1

Paper and Other Media Overview.................................................................................4-1

Loading Media in Trays 1, 2, and 3...............................................................................4-2

Loading Paper in Trays 1, 2, and 3...................................................................4-2

Loading Tab Stock in Trays 1, 2, and 3...........................................................4-3

Loading Transparencies in Trays 1, 2, and 3................................................4-4

Loading Pre-drilled Stock in Trays 1, 2, and 3..............................................4-5

Loading Media in the Bypass (Tray 5).........................................................................4-5

Loading Paper in the Bypass (Tray 5).............................................................4-6

Loading Tab Stock in the Bypass (Tray 5).....................................................4-6

Loading Transparencies in the Bypass (Tray 5)..........................................4-7

Loading Pre-drilled Stock in the Bypass (Tray 5)........................................4-8

Loading Envelopes in the Bypass (Tray 5)....................................................4-8

Loading Media in the OHCF (Trays 6 and 7)............................................................4-9

Postcard Bracket......................................................................................................4-9

Using the Postcard Bracket...................................................................4-9

Skew Adjustment Levers (Trays 6 and 7)....................................................4-11

Loading Paper in the OHCF (Trays 6 and 7)..............................................4-12

Loading Tabs in the OHCF (Trays 6 and 7)................................................4-12

Loading Transparencies in the OHCF (Trays 6 and 7)...........................4-13

Loading Pre-drilled Stock into the OHCF (Trays 6 and 7)....................4-14

Loading Media in the OHCF (Trays 8 and 9)..........................................................4-15

Postcard Bracket...................................................................................................4-15

Using the Postcard Bracket.................................................................4-15

Skew Adjustment Levers (Trays 8 and 9)....................................................4-17

Loading Paper in the OHCF (Trays 8 and 9)..............................................4-18

Loading Tabs in the OHCF (Trays 8 and 9)................................................4-18

Loading Transparencies in the OHCF (Trays 8 and 9)...........................4-19

Xerox®Versant®2100 Pressii

User Guide

Page 5

Table of Contents

Loading Pre-drilled Stock into the OHCF (Trays 8 and 9)....................4-20

Loading Post-Process Media in Optional Finishing Devices.............................4-21

5 Submitting a Print Job.............................................................................5-1

Setting Up and Submitting a Print Job.......................................................................5-1

How to Submit a Print Job................................................................................................5-2

Printing from Your Computer..........................................................................................5-2

Printing from the FreeFlow Print Server......................................................................5-3

Printing from the EX Print Server...................................................................................5-3

Printing on Tabs....................................................................................................................5-4

Printing Tabs from the Print Server..................................................................5-4

6 Job Status.....................................................................................................6-1

Job Status Overview............................................................................................................6-1

Job Status Area.......................................................................................................6-1

Active Jobs Tab.....................................................................................................................6-2

Completed Jobs Tab............................................................................................................6-2

7 Machine Status..........................................................................................7-1

Machine Status Overview.................................................................................................7-1

Machine Information Tab................................................................................................7-1

Faults Tab................................................................................................................................7-3

Billing Information Tab......................................................................................................7-3

Accessing Billing Information............................................................................7-3

Billing Impression Mode......................................................................................7-4

Billing Impressions Information.......................................................................7-4

Usage Counters.......................................................................................................7-5

8 Calibrating the Press................................................................................8-1

Full Width Array Overview................................................................................................8-1

Density Uniformity Adjustment.....................................................................................8-2

Adjusting Automatic Density Uniformity.....................................................8-2

Clean Fuser Assembly Information...............................................................................8-2

9 Maintenance...............................................................................................9-1

Maintenance Overview......................................................................................................9-1

Cleaning the Press ..............................................................................................................9-1

Cleaning the Exterior............................................................................................9-2

Clean Fuser Assembly...........................................................................................9-2

Cleaning the Drum Drawer Area......................................................................9-3

Cleaning the ROS Windows................................................................................9-3

Replacing Consumable Supplies....................................................................................9-3

Ordering Supplies...................................................................................................9-4

User Guide

iiiXerox®Versant®2100 Press

Page 6

Table of Contents

Checking the Status of Consumables.............................................................9-5

Replacing the Bypass Tray Feed Rolls for the OHCF (Trays 6 and

7).........................................................................................................................9-5

Replacing the Feed Rolls for the OHCF (Trays 6 and 7)...........................9-7

Replacing a Dry Ink / Toner Cartridge.........................................................9-11

Replacing the Dry Ink / Toner Waste Bottle..............................................9-12

Replacing a Drum Cartridge............................................................................9-13

Replacing the Suction Filter.............................................................................9-16

Removing the Fuser Module............................................................................9-18

Replacing the Stripper Finger Assembly........................................9-22

Replacing the Pressure Roll Assembly............................................9-23

Replacing the Pressure Roll Cleaning Pad Assembly................9-24

Installing the Fuser Module.............................................................................9-24

Extending Fuser Life..............................................................................9-27

Changing the Fuser Width ID ..........................................................9-28

10 Problem Solving....................................................................................10-1

Locating the Press Serial Number...............................................................................10-1

Calling for Service..............................................................................................................10-1

Basic Troubleshooting.....................................................................................................10-2

General Problems..............................................................................................................10-2

Image Quality Problems.................................................................................................10-8

Fault Codes........................................................................................................................10-12

Fault Codes - Press............................................................................................10-12

Fault Codes - Oversized High Capacity Feeder (Trays 6 and

7)...................................................................................................................10-15

Fault Codes - Oversized High Capacity Feeder (Trays 8 and

9)...................................................................................................................10-18

Fault Codes - Interface Module...................................................................10-20

Fault Codes - GBC AdvancedPunch............................................................10-21

Fault Codes - GBC AdvancedPunch Pro....................................................10-22

Fault Codes - High Capacity Stacker..........................................................10-22

Fault Codes - Standard Finisher / Booklet Maker Finisher................10-23

Fault Codes - SquareFold Trimmer Module.............................................10-25

Fault Codes - Standard Finisher Plus.........................................................10-27

Paper Jams........................................................................................................................10-28

Information about Paper Jams...................................................................10-28

Paper Jams Inside the Press..........................................................................10-29

Clearing Jams in Transfer Drawer (Area 2)................................10-29

Clearing Jams in the Output Module (Areas 3, 4 and

5)......................................................................................................10-31

Paper Jams in Trays 1-3..................................................................................10-34

Xerox®Versant®2100 Pressiv

User Guide

Page 7

Table of Contents

Paper Jams in the Bypass (Tray 5)..............................................................10-34

Paper Jams When the Bypass is Installed on Trays 6 and

7........................................................................................................10-34

Paper Jams When the Bypass is Installed on Trays 8 and

9........................................................................................................10-35

OHCF Jam Clearance (Trays 6 and 7).......................................................10-37

Clearing OHCF Jams (Trays 6 and 7)...........................................10-37

Paper Jams inside OHCF Trays 6 and 7.......................................10-37

OHCF (Trays 6 and 7) Paper Jams at Lever 1a and Knob

1c......................................................................................................10-38

OHCF (Trays 6 and 7) Paper Jams at Lever 1b and Knob

1c......................................................................................................10-39

OHCF (Trays 6 and 7) Paper Jams at Lever 1d and Knob

1c......................................................................................................10-39

Hints and Tips..................................................................................................................10-41

Tips for Extending Fuser Life.........................................................................10-41

Preventing Fuser Damage..............................................................................10-41

Fuser Paper Width Information.....................................................10-41

11 Chained (Second) Oversized High Capacity Feeder (OHCF

/ Trays 8 and 9)...................................................................................11-1

OHCF (Trays 8 and 9) Overview...................................................................................11-1

OHCF (Trays 8 and 9) Specifications...........................................................11-2

Loading Media in the Chained OHCF (Trays 8 and 9).......................................11-2

OHCF (Trays 8 and 9) Maintenance..........................................................................11-3

Replacing the Bypass Tray Feed Rolls for the OHCF (Trays 8 and

9)......................................................................................................................11-3

Replacing the OHCF Feed Rolls for the OHCF (Trays 8 and

9)......................................................................................................................11-5

OHCF (Trays 8 and 9) Problem Solving....................................................................11-8

Fault Codes - Oversized High Capacity Feeder (Trays 8 and

9)......................................................................................................................11-8

OHCF (Trays 8 and 9) Jam Clearance.......................................................11-11

Clearing OHCF (Trays 8 / 9) Jams.................................................11-11

Paper Jams When the Bypass is Installed on Trays 8 and

9........................................................................................................11-11

Paper Jams Inside the OHCF (Trays 8 and 9)...........................11-13

OHCF (Trays 8 and 9) Paper Jams at Lever 1a and Knob

1c......................................................................................................11-13

OHCF (Trays 8 and 9) Paper Jams at Lever 1b and Knob

1c......................................................................................................11-14

OHCF (Trays 8 and 9) Paper Jams at Lever 1d and Knob

1c......................................................................................................11-14

User Guide

vXerox®Versant®2100 Press

Page 8

Table of Contents

12 Interface Module.................................................................................12-1

Interface Module Overview...........................................................................................12-1

Control Panel.........................................................................................................12-2

Paper Path..............................................................................................................12-3

Auto Decurl Presettings.....................................................................................12-3

Manual Decurl Buttons......................................................................................12-3

Problem Solving.................................................................................................................12-4

Fault Codes - Interface Module......................................................................12-4

Interface Module Jam Clearance..................................................................12-5

Clearing Jams...........................................................................................12-5

Paper Jams at Lever 1a........................................................................12-5

Paper Jams at Lever 2a........................................................................12-6

Paper Jams at Lever 2b........................................................................12-7

13 GBC AdvancedPunch..........................................................................13-1

GBC AdvancedPunch Overview...................................................................................13-1

GBC AdvancedPunch Specifications............................................................13-1

GBC AdvancedPunch Components............................................................................13-2

GBC AdvancedPunch Operation Controls..................................................13-2

Status Indicators on the GBC AdvancedPunch.......................................13-2

Punch Dies..............................................................................................................13-3

GBC AdvancedPunch Procedures................................................................................13-4

Changing the Punch Die...................................................................................13-4

Pre-Punch Job Checkpoints..............................................................................13-5

Loading Tab Stock with the GBC AdvancedPunch.................................13-6

GBC AdvancedPunch Maintenance...........................................................................13-6

Emptying the Punch Container......................................................................13-6

GBC AdvancedPunch Problem Solving.....................................................................13-7

Fault Codes - GBC AdvancedPunch..............................................................13-7

GBC AdvancedPunch General Problems.....................................................13-7

GBC AdvancedPunch Jam Clearance...........................................................13-8

Clearing Jams in the AdvancedPunch............................................13-8

14 GBC AdvancedPunch Pro..................................................................14-1

AdvancedPunch Pro Overview......................................................................................14-1

AdvancedPunch Pro Specifications...............................................................14-2

AdvancedPunch Pro Components..............................................................................14-3

Operation Controls..............................................................................................14-3

Punch Chip Container.........................................................................................14-3

Punch Modes.........................................................................................................14-3

AdvancedPunch Pro User Display Panel...................................................................14-4

Xerox®Versant®2100 Pressvi

User Guide

Page 9

Table of Contents

Layout of the User Display Panel..................................................................14-4

User Display Panel Overview...........................................................................14-4

Messages on the User Display Panel...........................................................14-5

Settings on the User Display Panel...............................................................14-5

Information on User Display Panel..............................................................14-6

Die Sets.................................................................................................................................14-7

Die Set Configuration.........................................................................................14-7

Pin Numbering.........................................................................................14-7

Pin Removal Table for US Paper Sizes............................................14-8

Pin Removal Table for ISO Paper Sizes...........................................14-9

Die Stop Position...............................................................................................14-10

Die Stop Position Guide for US Paper Sizes...............................14-10

Die Stop Position Guide for ISO Paper Sizes.............................14-11

Available Die Sets for the AdvancedPunch Pro.....................................14-11

AdvancedPunch Pro Procedures...............................................................................14-13

Pre-Punch Job Checkpoints...........................................................................14-14

Changing Settings on the AdvancedPunch Pro....................................14-14

Changing Die Sets in the AdvancedPunch Pro (Removing /

Installing)...................................................................................................14-15

Die Set Procedures............................................................................................14-17

Removing Pins from a Die Set........................................................14-17

Adding Pins to a Die Set...................................................................14-18

Changing the Die Stop Position.....................................................14-19

AdvancedPunch Pro Maintenance...........................................................................14-20

Ordering Supplies for the AdvancedPunch Pro......................................14-20

Cleaning the Exterior of the AdvancedPunch Pro................................14-21

Emptying the Punch Container....................................................................14-21

Die Set Maintenance.......................................................................................14-22

Lubricating Die Set Pins (without a Felt Pad)...........................14-22

Lubricating Die Set Pins (with a Felt Pad)..................................14-22

AdvancedPunch Pro Problem Solving.....................................................................14-23

Fault Codes - GBC AdvancedPunch Pro....................................................14-23

AdvancedPunch Pro General Problems.....................................................14-24

Die Set End of Life............................................................................................14-24

Clearing Paper Jams in the AdvancedPunch Pro..................................14-25

15 High Capacity Stacker (HCS)...........................................................15-1

HCS Overview......................................................................................................................15-1

HCS Introduction.................................................................................................15-1

Identifying the HCS Components.................................................................15-2

HCS Control Panel..................................................................................15-3

User Guide

viiXerox®Versant®2100 Press

Page 10

Table of Contents

HCS Top Tray............................................................................................15-3

Unloading the Stacker Tray / Cart.................................................................15-3

HCS Media Guidelines.......................................................................................15-4

Problem Solving.................................................................................................................15-4

Fault Codes - High Capacity Stacker............................................................15-4

HCS Jam Clearance.............................................................................................15-5

Jam Clearance Tips................................................................................15-5

HCS Entrance Jams (E1, E2, and E3)...............................................15-6

HCS Transport Jams (E4, E5, and E6).............................................15-6

HCS Top Tray Jam (E7).........................................................................15-7

HCS Exit Jam (E8)...................................................................................15-8

Hints and Tips for Using the HCS..................................................................15-9

Loss of Power.........................................................................................................15-9

16 Standard Finisher / Booklet Maker Finisher...............................16-1

Overview of the Finishers...............................................................................................16-1

Standard Finisher Versus Booklet Maker Finisher...................................16-1

Finisher Components..........................................................................................16-2

Manual Decurling Feature on the Finisher................................................16-3

Fold Feature............................................................................................................16-4

Fold Types..................................................................................................16-4

Loading Paper or Tabs in the Post-Process Inserter (Tray

T1)...................................................................................................................16-5

Specifications......................................................................................................................16-6

Finisher Specifications.......................................................................................16-6

Optional C / Z Folder Specifications.............................................................16-9

Finisher Maintenance......................................................................................................16-9

Finisher Consumable Supplies........................................................................16-9

Replacing the Basic Staple Cartridge........................................................16-10

Replacing the Booklet Staple Cartridge...................................................16-11

Replacing the Staple Waste Container.....................................................16-12

Emptying the Punch Waste Container......................................................16-13

Finisher Problem Solving.............................................................................................16-14

Problem Solving Overview.............................................................................16-14

Fault Codes - Standard Finisher / Booklet Maker Finisher................16-14

Finisher Jam Clearance...................................................................................16-17

Paper Jams in the Post-Process Inserter (Tray T1)..................16-17

Paper Jams Inside the Finisher Left Cover.................................16-17

Paper Jams Inside the Finisher Right Cover..............................16-20

Paper Jams at the Optional C / Z Folder.....................................16-23

Paper Jams at Finisher Top Tray....................................................16-27

Xerox®Versant®2100 Pressviii

User Guide

Page 11

Table of Contents

Paper Jams at Finisher Stacker Tray.............................................16-27

Paper Jams at the Booklet Maker Tray.......................................16-28

Stapler Faults......................................................................................................16-29

Staple Jams in the Basic Staple Cartridge.................................16-29

Reinserting the Basic Staple Cartridge........................................16-31

Staple Jams in the Booklet Maker Cartridge............................16-32

17 SquareFold Trimmer Module...........................................................17-1

SquareFold Trimmer Module Overview....................................................................17-1

SquareFold Trimmer Module Specifications.............................................17-2

Identifying the Module Components.......................................................................17-2

Main Components...............................................................................................17-2

Module Paper Path..............................................................................................17-3

Module Control Panel.........................................................................................17-4

Square Fold Feature.........................................................................................................17-4

Square Fold Options............................................................................................17-5

Accessing the Square Fold Options...............................................................17-6

Trimmer Feature................................................................................................................17-6

Trimmer Options..................................................................................................17-6

Trim Guidelines.....................................................................................................17-7

Hints and Tips.....................................................................................................................17-9

Printing Full-Page Images on Booklets........................................................17-9

Follow These Tips..............................................................................................17-10

Problem Solving...............................................................................................................17-10

Fault Codes - SquareFold Trimmer Module.............................................17-10

SquareFold Trimmer Module Jam Clearance.........................................17-12

Jam Clearance Overview...................................................................17-12

Clearing Jams........................................................................................17-12

Clearing E1 / E2 Jams.........................................................................17-13

Clearing E3 Jams..................................................................................17-14

18 Standard Finisher Plus........................................................................18-1

Standard Finisher Plus Overview.................................................................................18-1

Specifications for the Standard Finisher Plus........................................................18-2

Finisher Module Specifications......................................................................18-2

Optional C / Z Folder Specifications.............................................................18-3

Finishing Transport Specifications................................................................18-4

Finisher Module.................................................................................................................18-4

Finisher Module Main Components.............................................................18-4

Fold Feature............................................................................................................18-5

Fold Types...............................................................................................................18-6

User Guide

ixXerox®Versant®2100 Press

Page 12

Table of Contents

Finishing Transport...........................................................................................................18-7

Standard Finisher Plus Maintenance.........................................................................18-9

Problem Solving...............................................................................................................18-13

Loading Paper or Tabs in the Post-Process Inserter (Tray

T1)...................................................................................................................18-7

Finishing Transport Main Components.......................................................18-7

Finishing Transport Status Indicators..........................................................18-8

Standard Finisher Plus Consumable Supplies...........................................18-9

Replacing the Basic Staple Cartridge...........................................................18-9

Replacing the Staple Waste Container.....................................................18-10

Emptying the Punch Waste Container......................................................18-12

Fault Codes - Standard Finisher Plus.........................................................18-13

Paper Jams in the Finisher Module............................................................18-14

Paper Jams in the Post-Process Inserter (Tray T1)..................18-14

Paper Jams Inside the Finisher Left Cover.................................18-15

Paper Jams Inside the Finisher Right Cover..............................18-17

Paper Jams at the Optional C / Z Folder.....................................18-21

Paper Jams at the Finisher Output Area....................................18-25

Paper Jams in the Finishing Transport......................................................18-27

Paper Jams in Area 1..........................................................................18-27

Paper Jams in Area 2..........................................................................18-28

Paper Jams in Area 3..........................................................................18-28

Paper Jams in Area 4..........................................................................18-29

Stapler Faults......................................................................................................18-30

Staple Jams in the Standard Staple Cartridge.........................18-31

Reinserting the Basic Staple Cartridge........................................18-32

Xerox®Versant®2100 Pressx

User Guide

Page 13

1

Product Overview

Press Overview

The Xerox®Versant®2100 Press is a full color / black and white, auto-duplex press that

operates at a speed of 100 prints per minute (when printing on 8.5 x 11 inch / A4 paper).

The system configuration consists of the Oversized High Capacity Feeder (OHCF / Trays

6 and 7), the print engine with internal feeding trays (Trays 1-3), and an embedded

Control Panel and touch screen (the user interface). A print server is also part of the

configuration, which includes the Stock Library Manager application used for stock and

tray setup and print job submission. An Offset Catch Tray can be attached to the print

engine or various optional inline finishing devices with the Interface Module are offered.

Print Server Overview

The print server networked with your press accepts, processes, and manages document

files for job submission to the press.

One of two print servers may be used with your press:

• Xerox®FreeFlow®Print Server

• Xerox®EX Print Server, Powered by Fiery

The print server contains the Stock Library Manager application. Refer to the Stock

Library Manager > Help for information on how to set up stocks, custom profiles, and

paper trays used by the press.

Note

For detailed information on your specific print server, refer to the customer

documentation that was delivered with it.

User Guide

®

1-1Xerox®Versant®2100 Press

Page 14

Product Overview

Press Components

1 Oversized High Capacity Feeder (OHCF / Trays 6 and 7)

One OHCF is part of the configuration. The feeder includes two drawers (Trays 6 and

7) that hold 2,000 sheets each. The right portion of the feeder is the J Transport area.

2 Bypass Tray

An optional Bypass tray (Tray 5) can be installed on top of the OHCF to allow for

additional feeding options. Otherwise, the system does not come with this feeding

tray.

3 Print Engine

The press includes the 4 dry ink / toner and drum cartridges, transfer belt and fuser /

ROS system, Full Width Array calibration feature, decurler, registration and paper path,

and paper inverter.

4 Control Panel and Touch Screen

An embedded Control Panel on the top panel of the press consists of buttons, a touch

screen and a keypad for logging on / off, setting job features, printing reports, and

viewing supply, job and press status.

5 Dry Ink / Toner Cover

Open this cover to access and replace the dry ink / toner cartridges.

6 Left Front Door

Open this door to access the registration area and paper handling drawer to clear paper

jams. This area also includes the Transfer Drawer and Xerographic Drawer for replacing

customer replaceable units (CRUs).

Xerox®Versant®2100 Press1-2

User Guide

Page 15

Product Overview

7 Center Front Door

Open this door to access the decurler area and fuser assembly.

8 Right Front Door

Open this Output Module door to access the exit / inverter area, the cooling belt and

full width array.

9 Paper Trays 1, 2, and 3

These internal trays of the print engine feed standard size paper.

10 Offset Catch Tray (OCT)

If there are no inline finishing devices attached to the system, the Offset Catch Tray

can be installed for holding print output.

11 Interface Module

12 High Capacity Stacker

The Interface Module and optional finishing devices, such as the High Capacity

Stacker, are not part of the base configuration.

When the Offset Catch Tray is removed, and any of the optional finishing devices are

attached, the Interface Module is required to provide decurling and paper height

adjustment between the print engine and the attached finishing device.

Locating the Press Serial Number

The press serial number can be accessed from either the press control panel or by locating

the serial number plate on the inside frame of the first feeder tray (Tray 1).

1. Press the Machine Status button on the press control panel.

2. From the Machine Status screen, ensure that the Machine Information tab is

displayed.

The press serial number is displayed under General Information.

3. If there is a loss of power and it is not possible to access the Machine Status screen,

the press serial number can also be found on the inside frame of the press near the

Paper Tray 1 drawer:

a) At the press, fully open Paper Tray 1.

User Guide

1-3Xerox®Versant®2100 Press

Page 16

Product Overview

b) At the left of the feeder tray, on the press frame, locate the plate with the serial

number (SER#).

Status Lights

There are three status lights on the press directly below the Control Panel. From right

to left, they are:

• Main Power Status LED -steady green indicates main power to the system is on

• Error Status LED - steady orange indicates the press is experiencing faults and / or

errors

• Data Transmission Status LED - flashing green indicates that the transmission of an

incoming print job is in process

Control Panel

The embedded Control Panel on the press includes an LCD touch screen, keypad and

feature buttons. The touch screen displays instructions, faults, and informational

messages. Select the Control Panel buttons to log in, perform job setup functions, and

view job, press, and supply statuses.

1 Home button

Displays the main menu. Provides access to view the supplies and trays available on

the press and the status of consumables.

2 Tools button

Displays the Tools mode screen. For the operator, select the Tools icon to view billing

information and to perform press calibration such as Full Width Array color uniformity

adjustments.

3 Job Status button

Use to check the progress of active jobs and detailed information about completed

jobs or pending jobs. This area also allows you to delete a job (cancel printing) and to

pause jobs.

4 Machine Status button

Use to check the press configuration, the software version, the press billing meter and

counter information, and to access and print job history or error reports.

Xerox®Versant®2100 Press1-4

User Guide

Page 17

Product Overview

5 Touch Screen

Directly touch the screen to select and set features. Displays instructional and

informational messages, fault clearance procedures and general press information.

6 Log In / Out button

Use to log in and out of Administrator mode or Authentication mode with user ID and

password.

7 Language button

Use to select a different language for the touch screen options.

8 Power Saver button

Use this button if the press has been inactive and the touch screen is dark (system is

in Energy Saver mode). This button manually exits the system from Energy Saver mode;

it does not place the press in Energy Save mode.

9 Numeric Keypad

Use to enter alphanumeric characters. The ‘C’ Cancel Entry cancels the previous entry

made on the numeric keypad.

10 Clear All button

Use this button to return all selections to the same state as when the press was powered

on. Press once to clear a current entry. Press twice to return to default settings.

11 Stop button

Press to stop and pause the print job in progress.

12 Cancel Entry button

Use this button to cancel the previous entry made on the numeric keypad.

13 Start button

Press to start and print a selected report from the print engine. Also used by the

Customer Service Engineer during diagnostic routine procedures.

14 Press Status Lights

The three indicator lights that identify: data transmission in progress, the press is

experiencing an error, and main power is on.

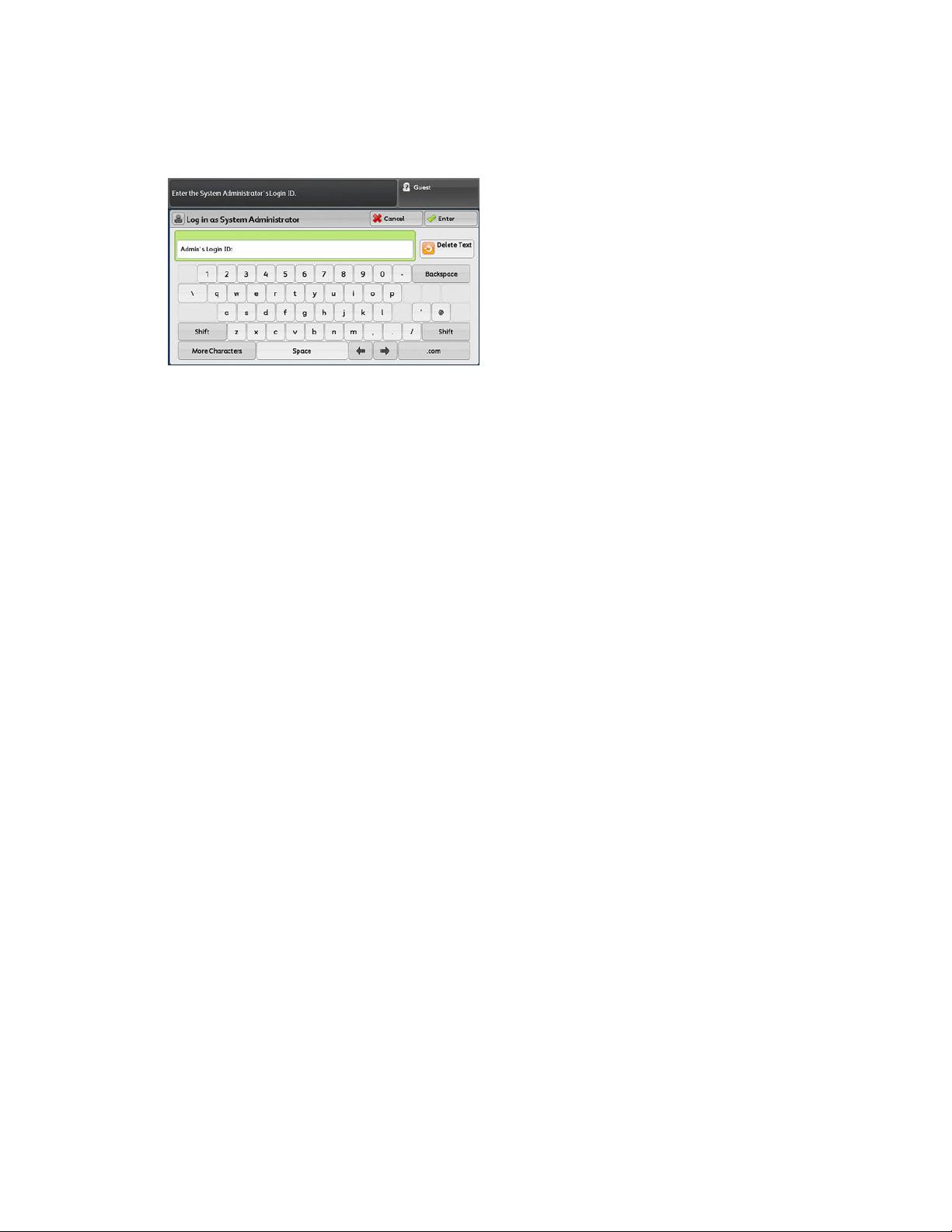

Logon

There are two logon levels:

• Guest / Operator: This is the default logon user. You are automatically logged on as

Guest.

1-5Xerox®Versant®2100 Press

User Guide

Page 18

Product Overview

• Administrator: This logon level is required to customize the system and network

defaults for your press and to customize particular print jobs by setting, or changing

parameters for certain features. Press the Guest button (or the Log in button on the

Control Panel) to access the Login screen.

Note

Refer to the System Administration Guide for more information on the Administrator

features.

Language

Note

The number of languages available on your system depends on what was installed during

the initial installation process.

Selecting a particular Language button immediately changes the language. No

confirmation is required.

Changing the Language

1. Press the Language button on the press Control Panel.

The Language window displays on the touch screen.

2. Select the desired language from the list and select Save. The language on the screen

changes to the new language and closes the Language window.

3. Select the Cancel button to return to the main screen.

Energy Saver Mode

The Energy Saver feature allows the press to enter a reduced power consumption mode

when all print jobs have completed and there are no jobs currently processing. There

are two energy saving modes: Low Power and Sleep.

By default, the press automatically enters the Low Power mode after 15 minutes of

inactivity. After 60 minutes of inactivity, the press then enters Sleep mode. These time

intervals for both modes can be changed by the system administrator.

Xerox®Versant®2100 Press1-6

User Guide

Page 19

Product Overview

Here are two examples:

• If Low Power Mode is set to 15 minutes and Sleep Mode is set to 60 minutes, Sleep

Mode activates after 60 minutes of total inactivity, not 60 minutes after Low Power

Mode begins.

• If Low Power Mode is set to 15 minutes and Sleep Mode is set to 20 minutes, Sleep

Mode activates 5 minutes after Low Power Mode begins.

Low Power Mode

In this mode, the power to the Control Panel and fuser unit is lowered to save power.

The display goes out and the Energy Saver button on the Control Panel lights. To use

the press, select the Energy Saver button. The Energy Saver button is no longer lit,

indicating that the Energy Saver feature is canceled.

Sleep Mode

In this mode, the power is lowered more than in the Low Power mode. The display goes

out and the Energy Saver button on the Control Panel lights. To use the press, select the

Energy Saver button. The Energy Saver button is no longer lit, indicating that the Energy

Saver feature is canceled.

Exiting Power Saver Mode

The press exits Power Saver mode either by pressing the Power Saver button on the

press Control Panel or when receiving print data for an incoming job to be printed.

Power On / Off

The Power Switches

There are three power switches involved with the press:

• The Breaker switch located at the rear of the press. Initially check to make sure this

switch is set to On when the press is shipped.

User Guide

1-7Xerox®Versant®2100 Press

Page 20

Product Overview

• The Main Power switch located inside the Center Front Door. This switch is used

mainly by the Xerox Service Representative when servicing the press. In rare problem

solving cases, you may be directed to power off the press with this switch.

• The Power On / Off button located on the right side of the Control Panel. This button

is the primary way for you to switch on or off the press. It is used by the operator as

workflow requires.

Use the Power On / Off button to power ON or power OFF the press.

Important

Always use the Power On / Off button first, and then power off the Main Power Switch.

Power On / Off the Press

To switch on the press:

• Check that the Main Power switch behind the Center Front Door is On and then press

the Power On / Off button on top of the print engine to the ON position. The Ready

Indicator light displays green.

A screen message advises of a short wait while the fuser warms up and the press runs

a system check. You can set features for a job during this time and the printing process

will start automatically when the press is ready.

To switch off the press:

• Press the Power On / Off button on the print engine.

Note

Allow the press to remain off for a minimum of 10 seconds before switching on the

power again.

Xerox®Versant®2100 Press1-8

User Guide

Page 21

Product Overview

Feeding and Finishing Devices

Available with your press is a variety of optional feeding and finishing devices. These

devices are briefly introduced on the following pages. Refer to the sections at the end

of this guide for specific information on each feeder or finisher.

Feeding Devices

Oversized High Capacity Feeder (OHCF / Trays 6 and 7)

Tip

The Oversized High Capacity Feeder (OHCF / Trays 6 and 7) are part of the standard

press configuration.

The Oversized High Capacity Feeder (OHCF) contains two trays, Trays 6 and 7 and feeds

a variety of stock sizes, including standard, heavyweight, and oversized stocks up to 13

x 19.2 in. / 330 x 488 mm in size and weighing between 52 gsm and 350 gsm. Each tray

holds 2,000 sheets of coated and uncoated stock.

Chained Oversized High Capacity Feeder (OHCF / Trays 8 and 9)

A second, chained Oversized High Capacity Feeder (OHCF) may be added to the system

to extend the paper capacities by providing two additional trays. This second, chained

OHCF is referred to as Trays 8 and 9, and it feeds a variety of stock sizes, including

standard, heavyweight, and oversized stocks up to 13 x 19.2 in. / 330 x 488 mm in size

and weighing between 52 gsm and 350 gsm. Each tray holds 2,000 sheets of coated

and uncoated stock.

1-9Xerox®Versant®2100 Press

User Guide

Page 22

Product Overview

Bypass (Tray 5)

The Bypass Tray, also called Tray 5, is an optional feeding device that is installed on top

of the Oversized High Capacity Feeder.

Important

When the system configuration includes only one OHCF (Trays 6 and 7), then the Bypass

Tray is installed on top of it. If the system configuration includes an second, chained

OHCF (Trays 8 and 9), then the Bypass Tray is installed on top of the second OHCF (Trays

8 and 9).

The Bypass Tray accommodates a weight range of 52 to 300 gsm and media size of

3.86 x 5.75 inches (98 x 146 mm) to 13 x 19.2 inches (330.2 x 488 mm). The Bypass

Tray holds a maximum of 280 sheets of 20 lb. / 75 gsm plain paper.

The Bypass Tray accepts envelopes, postcards and transparencies.

Finishing Devices

Offset Catch Tray (OCT)

The Offset Catch Tray installed at the end of the print engine receives the completed

print job. Output print sheets can be offset for easy separation. The maximum capacity

of the tray is 500 sheets of 24 lb. (90 gsm) paper.

Interface Module

Important

The Interface Module is required with any inline finishing devices installed with the

system.

Xerox®Versant®2100 Press1-10

User Guide

Page 23

Product Overview

The Interface Module provides communication, an aligned paper path between the

print engine and the attached finishing device, and cooling and decurling of the paper

as it exits the print engine.

GBC®AdvancedPunch

™

The GBC AdvancedPunch may be attached to a variety of optional finishing accessories.

It provides another level of finishing by allowing you to punch holes in 8.5 x 11 in. / A4

documents that support a variety of binding styles. Punch types include 19-hole to a

maximum of 32-hole for 8.5 x 11 in. media. A4 media supports punch types 21-hole to

a maximum of 47-hole.

GBC®AdvancedPunch™Pro

The GBC AdvancedPunch Pro may be attached to a variety of optional finishing

accessories and provides all the same capabilities as the GBC AdvancedPunch.

User Guide

1-11Xerox®Versant®2100 Press

Page 24

Product Overview

The AdvancedPunch Pro also provides additional capabilities such as the following:

• A bigger range of media sizes and types

• LEF and SEF punching

• 2-up punching (double punch) on large sheets

• Quick-change die sets that can be interchanged without any tools

• All die sets include an Identification Label providing the user with the hole pattern

and name

Information on this device can be found later in this guide. Information can also be

found on the customer documentation CD that came with the accessory, or it can be

downloaded from www.xerox.com.

High Capacity Stacker

The High Capacity Stacker (HCS) is an optional finishing device that provides production

stacking and offsetting capabilities of up to 5,000 sheets to a cart in the Stacker Tray.

Shorter runs of up to 500 sheets can be sent to the stacker’s Top Tray.

Standard Finisher

This finisher provides a wide range of finishing / folding options. It includes a basic inline

punch, stapler, built-in decurler and interposer.

Note

The Standard Finisher is shown here with the required Interface Module and with the

optional C / Z Folder.

Booklet Maker Finisher

This finisher provides a wide range of finishing/folding options that include a basic inline

punch, stapler, a booklet unit with saddle-stitching and bifold finishing.

Xerox®Versant®2100 Press1-12

User Guide

Page 25

Product Overview

Note

The Booklet Maker Finisher is shown here with the required Interface Module to the left

and the optional C / Z Folder and GBC finisher to the right.

SquareFold®Trimmer Module

The SquareFold Trimmer Module is an optional finishing device that is used in conjunction

with a finishing device that contains a booklet maker (with or without the C / Z Folder).

The SquareFold Trimmer Module flattens the spine of the booklet and trims the face of

the booklet.

Note

The SquareFold Trimmer Module is shown here with the required Interface Module and

the required Booklet Maker Finisher.

Standard Finisher Plus

The Standard Finisher Plus includes the same features and functions as the Standard

Finisher but also serves as an interface to transfer paper between the print engine and

any third-party, Document Finishing Architecture (DFA) device attached to the press.

Note

The Standard Finisher Plus requires the Interface Module.

User Guide

1-13Xerox®Versant®2100 Press

Page 26

Product Overview

Third-Party Finishing Devices

Additional third-party, Document Finishing Architecture (DFA) devices are also available

for your press. Information on these DFA devices can be obtained by contacting your

Xerox sales representative.

Xerox®Versant®2100 Press1-14

User Guide

Page 27

2

Where to Find Help

Help on the Xerox Web Site

For technical product support, Xerox supplies, customer documentation, and answers to

frequently-asked questions, go to www.xerox.com. You will find the latest documentation

and the knowledge base under Support & Drivers. Use the Contact link for specific

contact information / telephone numbers in your area.

Note

Be sure to periodically check this website for the latest information on your product.

It may be helpful to know your press serial number before calling for support. The press

serial number is shown on the Machine Information tab: Machine Status > Machine

Information.

Diagnostic Tool

A Customer Diagnostic Tool CD is provided with your system. It provides you with the

information needed to identify and resolve image quality issues or faults the press may

be experiencing, and includes the procedures on how to replace customer-accessible

press components.

This tool is the first step you can use in isolating a problem or specific fault code and

the resolution associated with it.

2-1Xerox®Versant®2100 Press

User Guide

Page 28

Where to Find Help

Stock Library Manager Online Help

At the top of the print server window contains a Help area from which you can locate

information on how to use the print server’s job and print management features.

There is also Help from within the Stock Library Manager application on the print server.

Use this Online Help to learn how to manage stocks used by the press and to select

advanced settings that resolve paper curl, offsetting, paper misfeeds, registration and

fold adjustments.

From the Stock Library Manager window, select Help from the top left of the screen. An

About menu and Help menu are available:

• Select the About menu to learn the software version installed.

• Select the Help menu to access all of the Stock Library Help topics such as Tray

Properties, Stock information, how to add stock, and more.

In the Contents area, topics are displayed to the right of the book icons. Selecting a

book icon expands the view and provides selections to subtopics. The right and left arrow

buttons advance forward or backward one topic at a time using the same order as

displayed on the Contents tab.

Print Server Customer Documentation

• The FreeFlow Print Server features are documented in the Online Help system from

the Help menu shown on the main print server window. Additional FreeFlow Print

Server user documentation can be found at www.xerox.com.

• The EFI Print Server Help menu on the Command WorkStation window is designed

to provide information on specific work flows when using the Command WorkStation.

Additional user documentation supplied by EFI is available to you from www.xerox.com

under the Support and Drivers link.

Xerox®Versant®2100 Press2-2

User Guide

Page 29

3

Technical Specifications

Press Specifications

Rated Speed

100 pages per minute of Letter (8.5 x 11 in.) / A4 paper size (full color or black only)

Print Modes

Two print modes are supported and are specified at the print server:

• 4 Color Mode (CMYK)

• Black and White Mode (Greyscale)

Maximum Printable Area

• Default Border: 2 mm on all sides

• Adjustable Border: 0.5 mm up to 400 mm on all sides

• Print Image Quality Assurance Area: 12.48 x 18.98 in. / 317 mm x 482 mm

• For Trays 1, 2 or 3: 12.72 x 18.98 in. / 323 x 482 mm

• Bypass (Tray 5): 12.83 x 18.98 in. / 326 x 482 mm

• For the OHCF (Trays 6 and 7): 12.83 x 18.98 in. / 326 x 482 mm

Paper Size Ranges

• Minimum:

- Trays 1-3: 5.51 x 7.17 in. / 140 x 182 mm

- Bypass (Tray 5): 3.86 x 5.75 in. / 98 x 146 mm

- Trays 6 and 7: 3.86 x 5.75 in. / 98 x 146 mm

• Maximum:

- Trays 1-3: 13 x 19.2 in. / 330.2 x 488 mm

User Guide

3-1Xerox®Versant®2100 Press

Page 30

Technical Specifications

- Bypass (Tray 5): 13 x 19.2 in. / 330.2 x 488 mm

- Trays 6 and 7: 13 x 19.2 in. / 330.2 x 488 mm

Printing Resolution

• Print Engine Imaging Resolution: 2400 x 2400 dpi

• Print Server RIP Resolution (print server to print engine): 1200 x 1200 dpi

First Print: Out Time

First Print: Out Time is the minimum time from when the press receives a job from the

print server to the time when the trail edge of the first print passes through the press

exit sensor.

From standby mode, the system usually takes less than 1 minute to the start printing

• From a cold start (power on or power saver), the system takes less than 5 minutes to

start printing

Press Warmup Time

The press warmup times vary depending on the current state / mode of the press. Warmup

times are listed as follows:

• From a cold start (either power on or power saver mode), less than 5 minutes

• From Sleep Mode / Power Saver, less than 5 minutes

• From Standby Mode, less than 1 minute

• When switching print modes (such as from black only to full color), approximately 2

minutes

Paper Tray Information

Trays 1, 2 and 3

When the press is first installed, the tray size setting for Trays 1 and 3 are set at 8.5 x

11 inches or A4 (LEF). The tray size setting for Tray 2 is set at 11 x 17 inches or A3 (SEF).

When the Stock Library Manager is installed on the print server, the default for all trays

is Letter (8.5 x 11 inches). At the Stock Library Manager, the operator can then set those

trays to different stock size settings.

The specifications for each tray are:

• Maximum of 550 sheets of 24 lb. (90 gsm) uncoated paper; 28-80 lb. cover (105-120

gsm) coated stock

• Paper weight range of 18 lb. Bond to 95 lb. Cover (64 gsm to 256 gsm)

• Paper sizes starting at 5.51 x 7.17 in. / 140 x 182 mm to a maximum of 13 x 19.2 in.

/ 330.2 x 488 mm

Xerox®Versant®2100 Press3-2

User Guide

Page 31

Technical Specifications

• Stock types include transparencies, heavyweight, coated and uncoated, predrilled,

and tabs

• Loading paper Long Edge Feed (LEF) / portrait or Short Edge Feed (SEF) / landscape

(dependent on the actual paper size)

• Auto size detection capability

• Automatically adjusts the tray position in the front and back based on the paper size;

this is done once the tray is closed

Oversized High Capacity Feeder (Trays 6 and 7)

The specifications for each tray are:

• Maximum of 2,000 sheets of 24 lb. (90 gsm) uncoated paper; 2,100 sheets of 82 gsm

and 2,300 sheets of 64 gsm

• Paper weight range of 52 to 350 gsm

• Stock types include transparencies, heavyweight, coated and uncoated, predrilled,

and tabs. Transparencies perform best when printed from Trays 6 and 7

• If using the optional Postcard bracket, minimum size is 4 x 6 inches / 101.6 x 152.4

mm

Note

For more information on the optional Postcard bracket, refer to the Paper and Media

section of this guide.

Bypass (Tray 5)

• Maximum of 250 sheets of 24 lb. (90 gsm) uncoated paper; 28 lb. to 110 lb. cover

(106-300 gsm) coated stock

• Paper weight range of 52 gsm (uncoated) to 300 gsm (coated)

• Stock types include transparencies, heavyweight, coated and uncoated, predrilled,

and tabs

Throughput / Productivity Information

Process and print speed is based on simplex (1-Sided) / duplex (2-Sided) mode, paper

type, paper weight, paper size and feeding tray.

Table 1: Trays 1, 2 and 3 in LEF Feed Direction

Prints Per MinuteSimplex / DuplexPaper WeightPaper Type

100 ppm / 50 ppmSimplex / Duplex64 to 256 gsm8.5 x 11 / A4 uncoated

and coated

and Transparencies

User Guide

40 ppmSimplex106 to 256 gsm8.5 x 11 / A4 Labels

3-3Xerox®Versant®2100 Press

Page 32

Technical Specifications

coated and coated

coated and coated

Table 2: Trays 1, 2 and 3 in SEF Feed Direction

coated

coated

and coated

Prints Per MinuteSimplex / DuplexPaper WeightPaper Type

80 ppmSimplex106 to 176 gsm8.5 x 11 / A4 Tab un-

80 ppmSimplex177 to 256 gsm8.5 x 11 / A4 Tab un-

Prints Per MinuteSimplex / DuplexPaper WeightPaper Type

80 ppm / 40 ppmSimplex / Duplex64 to 256 gsm8.5 x 11 uncoated and

60 ppm / 30 ppmSimplex / Duplex64 to 256 gsmA4 uncoated and

60 ppm / 30 ppmSimplex / Duplex64 to 256 gsm8.5 x 14 / B4 uncoated

and coated

coated and coated

uncoated

and Transparencies

and Transparencies

Table 3: Bypass (Tray 5)

148 mm

coated and coated

52 ppm / 26 ppmSimplex / Duplex64 to 256 gsm11 x 17 / A3 uncoated

50 ppm / 24 ppmSimplex / Duplex64 to 256 gsm12 x 18 / SRA3 un-

50 ppm / 24 ppmSimplex / Duplex64 to 256 gsm13 x 19.2 coated and

32 ppmSimplex106 to 256 gsm8.5 x 11 / A4 Labels

25 ppmSimplex106 to 256 gsm8.5 x 14 / B4 Labels

Prints Per MinuteSimplex / DuplexPaper WeightFeedDirectionPaper Type

70 ppm / 35 ppmSimplex / Duplex52 to 300 gsmPostal card 148 x

70 ppm / 35 ppmSimplex / Duplex52 to 300 gsmLEF8.5 x 11 / A4 un-

and coated

coated

60 ppm / 30 ppmSimplex / Duplex52 to 300 gsmSEF8.5 x 11 uncoated

50 ppm/ 25 ppmSimplex / Duplex52 to 300 gsmSEFA4 uncoated and

Xerox®Versant®2100 Press3-4

User Guide

Page 33

Technical Specifications

Prints Per MinuteSimplex / DuplexPaper WeightFeedDirectionPaper Type

50 ppm / 25 ppmSimplex / Duplex52 to 300 gsmSEF8.5 x 14 / B4 un-

coated and coated

44 ppm / 22 ppmSimplex / Duplex52 to 300 gsmSEF11 x17 / A3 un-

coated and coated

41 ppm / 21 ppmSimplex / Duplex52 to 300 gsmSEF12 x 18 / SRA3

coated and uncoated

40 ppm / 20 ppmSimplex / Duplex52 to 300 gsmSEF13x19.2coatedand

uncoated

Paper Specifications for Trays 1-3, 5, and 6-7

Note

Always refer to the Recommended Media List (RML) for a comprehensive list of supported

media. The RML can be accessed from the Stock Library Manager application, and can

also be downloaded from http://www.xerox.com/.

User Guide

3-5Xerox®Versant®2100 Press

Page 34

Technical Specifications

Weight (gsm)TraysPaper SizePaper Type

Plain paper (coated & uncoated)

Drilled paper (coated & uncoated)

B5 SEF / LEF

A4 SEF / LEF

A4 Cover SEF / LEF

DT Special A4 SEF / LEF

B4 SEF

A3 SEF

SRA3 SEF

DT Special A3 SEF

4 x 6 in. SEF

7.25 x 10.5 in. SEF / LEF

8 x 10 in. SEF / LEF

8.46 x 12.4 in. SEF

8.5 x 11 in. SEF/LEF

8.5 x 13 in. SEF / LEF

8.5 x 14 in. SEF

9 x 11 in. SEF / LEF

11 x 15 in. SEF

11 x 17 in. SEF

12 x 18 in. SEF

12.6 x 19.2 in. SEF

13 x 18 in. SEF

16-kai (TFX) SEF / LEF

16-kai (GCO) SEF / LEF

Pa-kai (TFX) SEF

pa-kai (GCO) SEF

Trays 1 - 3

Trays 5, 6 and 7

52 to 256

52 to 350

coated)

Embossed (coated & uncoated)

Government-Legal SEF / LEF

DT Special A4 SEF / LEF

DT Special A3 SEF

Envelopes

8.5 x 13 in.

215.9 x 330.2 mm

8.90 x 12.20 in.

226.0 x 310.0 mm

12.20 x 17.00 in.

310.0 x 432.0 mm

Square SEF / LEF

8.5 x 11 in. / A4 LEFLabels (coated & uncoated)

Trays 1 - 3

Trays 5, 6 and 7

Trays 5, 6 and 7

Trays 5, 6 and 7

Trays 5, 6 and 7

Trays 5, 6 and 7rectangle 3 x 10 SEF

Trays 1 - 3

Trays 5, 6 and 7

64 to 105All TraysRecycled paper (coated & un-

106 to 256

106 to 350

---All Trays8.5 x 11 in. (A4) LEFTransparency

106 to 350Trays 5, 6 and 7Postcard (coated and uncoated)

---Trays 1 -3

---Trays 1 -3

---Trays 1 -3

106 to 256

106 to 350

Xerox®Versant®2100 Press3-6

User Guide

Page 35

Technical Specifications

Weight (gsm)TraysPaper SizePaper Type

163All Trays9 x 11 in. LEFTabbed Inserts

Press Environmental Specifications

The press enters the Power Saver mode after 15 minutes of inactivity on the press. The

factory default time of 15 minutes can be changed when logged on as the Administrator.

For more information, refer to the System Administration Guide.

The temperature and relative humidity of the room where the press is located must be

within the minimum and maximum allowable temperature and relative humidity limits

for the press system to operate correctly.

Ambient Temperature

The operating temperature range is 10° to 32° Celsius (50° F to 90° F)

Relative Humidity

The required humidity range is 15% to 85% (relative humidity) - (RH) J zone (Dew

condensation is inhibited)

Altitude

The press functions at the elevation of 0 to 2,500 meters (0 to 8,200 feet)

User Guide

3-7Xerox®Versant®2100 Press

Page 36

Technical Specifications

Xerox®Versant®2100 Press3-8

User Guide

Page 37

4

Paper and Other Media

Paper and Other Media Overview

This section describes how to load specific stocks into the various feeder trays.

Before loading paper, consider the following:

• To define attributes for a stock, add a new stock to the Stock Library, or assign a stock

to a paper tray for the print job, access the Stock Library Manager on the print server.

If you have restricted access, contact your System Administrator.

Note

The Stock Library Manager is an application that is loaded onto the print server and

is used to manage the stocks and paper trays for your press. By default, the Stock

Library feature is available to both the operator and system administrator modes.

Your System Administrator may restrict user access to change or add stocks. When

you are loading paper, the Stock Library Manager application opens the Tray

Properties window for that tray and you can view or change the stock assigned to

that tray.

• The press supports the ability to pull different stock sizes and paper types from various

trays and assemble them as part of a single job. To select multiple paper trays and

insert different papers within one job, program this custom job at the print server

using features such as special pages.

• The press supports Automatic Tray Switching, which allows a job to switch

automatically from an empty tray to a full tray containing the same size paper,

orientation and stock type. Refer to the System Administrator Guide for how to enable

this feature and prioritize the order of trays to search on and use.

4-1Xerox®Versant®2100 Press

User Guide

Page 38

Paper and Other Media

Loading Media in Trays 1, 2, and 3

Trays 1, 2, and 3 are identical. Each tray has a capacity of 550 sheets of 20 lb. / 75 gsm

paper. Stock can be LEF or SEF, landscape or portrait.

Note

Each feeder tray has a stock loading label. When loading media into the tray, refer to

the labels on the inside panel of the feeder tray for the correct orientation of that stock

type.

Loading Paper in Trays 1, 2, and 3

From the Stock Library Manager on the print server, set the stock type, weight and size

settings for the tray. At the press, check that the stock loaded in the paper tray matches

the paper tray attributes programmed.

Note

A paper jam may occur if a tray is opened while it is being used to feed stock.

1. Select the appropriate paper stock for your print job.

2. Pull out the tray slowly until it stops.

3. Open the ream of paper with the seam side facing up.

4. Fan the sheets before loading them into the tray.

5. Load and align the edge of the paper against the left edge of the tray.

Paper can be loaded either in the LEF / portrait or SEF / landscape direction.

6. Adjust the paper guides by pressing in the guide release and carefully moving the

Edge Guide until it lightly touches the edge of the material in the tray.

Do not load materials above the MAX line located on the rear Edge Guide.

7. Gently push in the tray until it comes to a stop.