Page 1

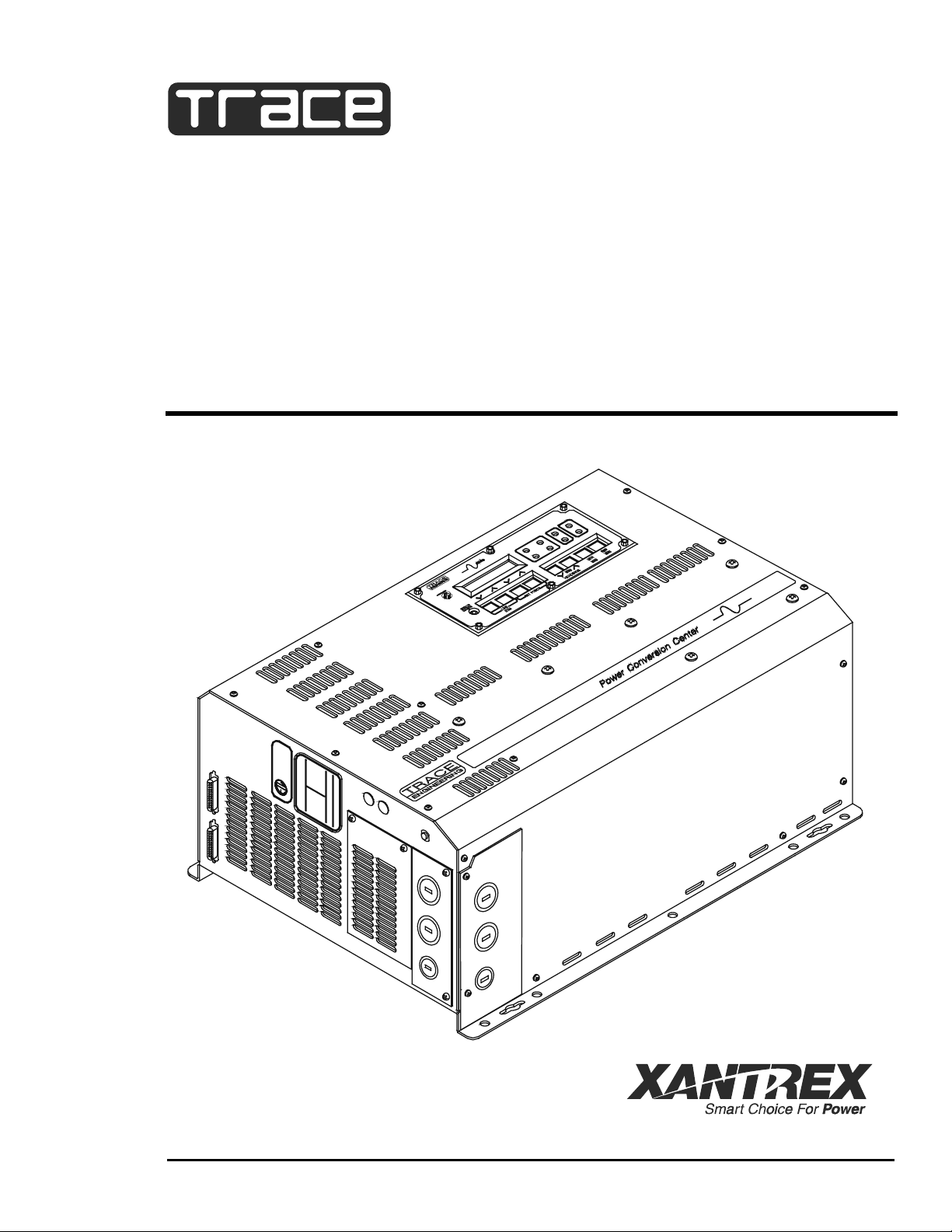

™

SW Series Inverter/Chargers

With Revision 4.01 Software

Owner’s Manual

2001 Xantrex Technology, Inc.

5916 - 195th Street N. E.

Arlington, WA 98223

Telephone: 360/435-8826

Fax: 360/435-2229

www.traceengineering.com

SW Series Inverter/Charger

Part No. 2031-5

Rev. C: February 2001

Page 2

2001 Xantrex Technology, Inc.

SW Series Inverter/Charger

5916 - 195th Street N. E.

Arlington, WA 98223

Telephone: 360/435-8826

Fax: 360/435-2229

www.traceengineering.com

Part No. 2031-5

Rev. C: February 2001

Page 3

PRODUCT MATERIALS PACKAGE

Thank you for choosing Xantrex products to meet your powering needs. W e m ake every effor t to ensure

that your inverter/charger is properly packaged for shipping including the following:

q Owner’s Manual;

q Battery Temperature Sensor (BTS);

q Red and black battery terminal covers with attaching hardware;

q Hardware package (AC access panels with screws, crimp-on terminals);

q Trace™ bumper sticker;

If any of the above listed materials are m issing f rom your pack age, or if it is uns atisf actory in any m anner,

please contact our Service department at 360-435-8826; or, fax this page explaining the discrepancy to

360-474-0616. Please provide:

Model Number: ________________________________

Serial Number: ________________________________

Comments:

Visit our web site at www.traceengineering.com for more information and answers to frequently asked

questions.

2001 Xantrex Technology, Inc.

5916 - 195th Street N. E.

Arlington, WA 98223

Telephone: 360/435-8826

Fax: 360/435-2229

www.traceengineering.com

SW Series Inverter/Charger

Part No. 2031-5

Rev. C: February 2001

Page 4

2001 Xantrex Technology, Inc.

SW Series Inverter/Charger

5916 - 195th Street N. E.

Arlington, WA 98223

Telephone: 360/435-8826

Fax: 360/435-2229

www.traceengineering.com

Part No. 2031-5

Rev. C: February 2001

Page 5

TABLE OF CONTENTS

TABLE OF CONTENTS

IMPORTANT SAFETY INSTRUCTIONS ..................................................................................................... 1

GENERAL PRECAUTIONS....................................................................................................................................1

SPECIAL NOTICES................................................................................................................ ................................2

PERSONAL PRECAUTIONS..................................................................................................................................3

INTRODUCTION .......................................................................................................................................... 5

UNIT IDENTIFICATION................................................................................................................................ 7

MODEL NUMBER...................................................................................................................................................7

CONTROLS, INDICATORS AND COMPONENTS...................................................................................... 9

CONTROL PANEL..................................................................................................................................................9

AC SIDE ...............................................................................................................................................................12

DC SIDE...............................................................................................................................................................14

INSTALLATION.......................................................................................................................................... 15

QUICK INSTALL...................................................................................................................................................16

COMPLETE INSTALL...........................................................................................................................................17

FUNCTIONAL TEST .................................................................................................................................. 31

MENU SYSTEM.......................................................................................................................................... 33

OVERVIEW ..........................................................................................................................................................33

USER MENU MAP................................................................................................................................................34

SETUP MENU MAP..............................................................................................................................................35

USER MENU ........................................................................................................................................................36

SETUP MENU ......................................................................................................................................................44

OPERATION............................................................................................................................................... 57

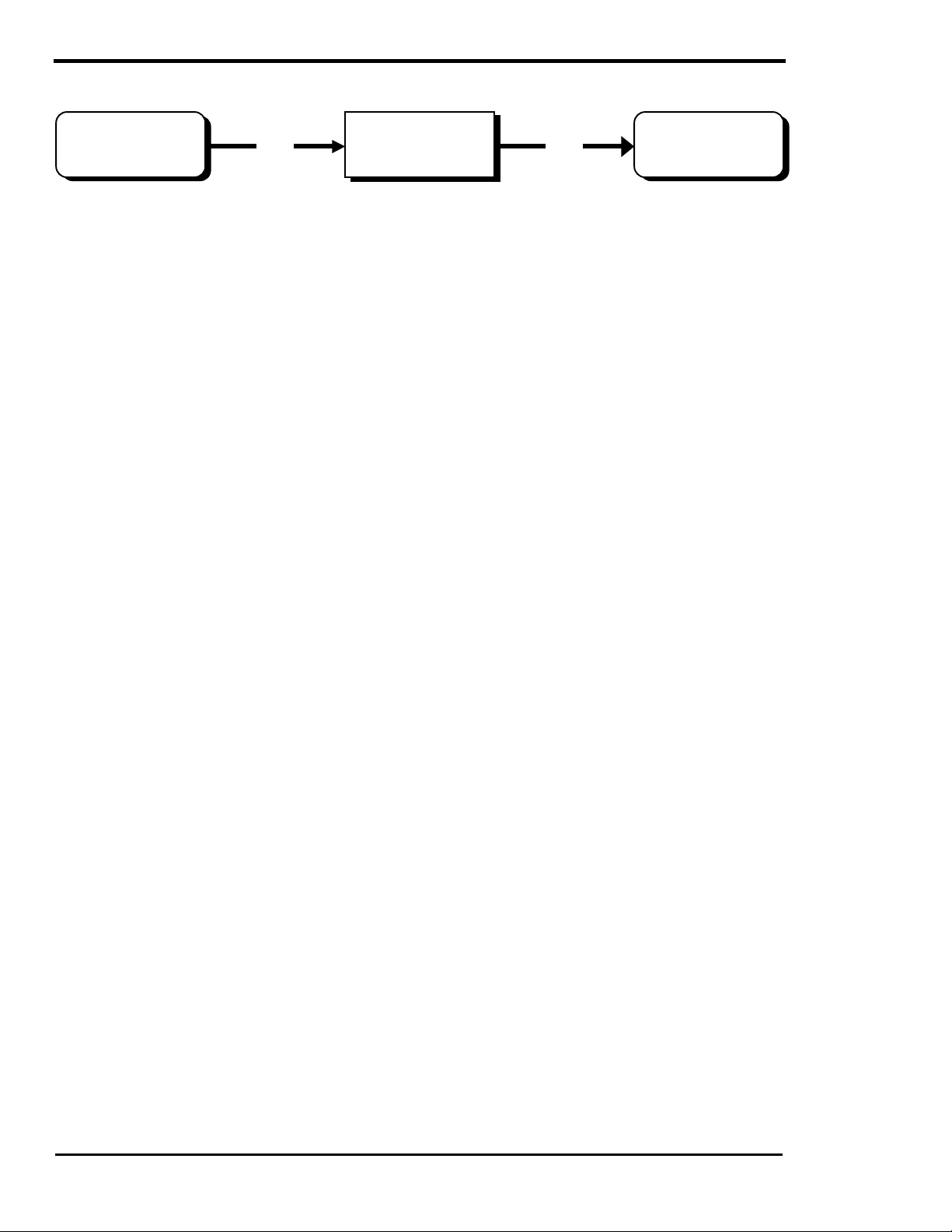

THEORY OF OPERATION...................................................................................................................................57

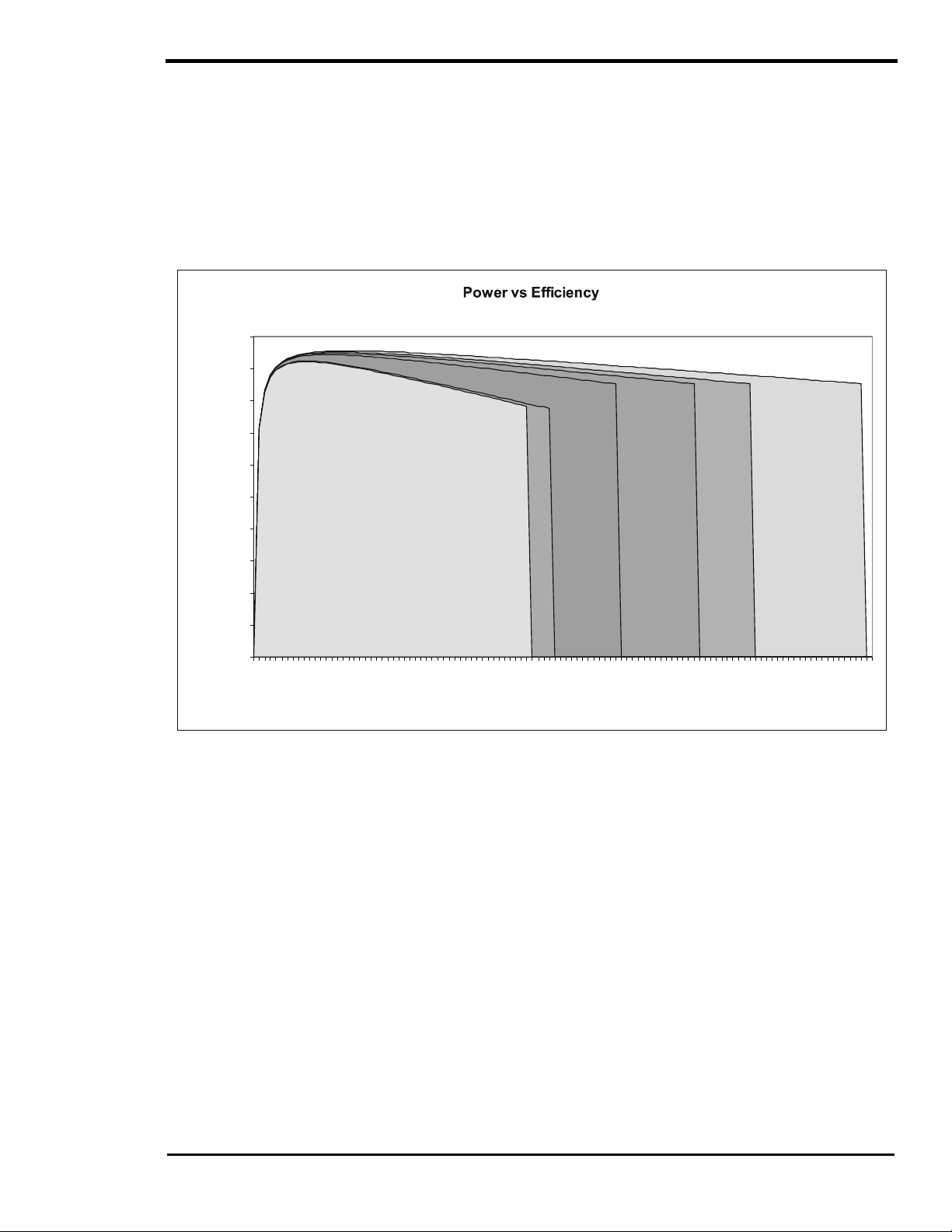

POWER VS. EFFICIENCY...................................................................................................................................59

INVERTER CAPACITY VS TEMPERATURE .......................................................................................................60

OPERATING MODES...........................................................................................................................................61

INVERTER MODE................................................................................................................................................62

CHARGER MODE................................................................................................................................................64

INVERTER/CHARGER MODE.............................................................................................................................69

GENERATOR SUPPORT MODE.........................................................................................................................71

AUTOMATIC GENERATOR CONTROL MODE ...................................................................................................73

UTILITY BACKUP MODE.....................................................................................................................................81

UTILITY INTERACTIVE MODE ............................................................................................................................83

ENERGY MANAGEMENT MODE.........................................................................................................................90

PEAK LOAD SHAVING MODE.............................................................................................................................92

IN BRIEF...............................................................................................................................................................92

LOW BATTERY TRANSFER (LBX) MODE..........................................................................................................93

USING MULTIPLE INVERTERS...........................................................................................................................95

TECHNICAL INFORMATION..................................................................................................................... 99

BATTERY TYPE...................................................................................................................................................99

BATTERY SIZING...............................................................................................................................................101

BATTERY BANK SIZING....................................................................................................................................102

BATTERY CARE AND MAINTENANCE.............................................................................................................104

BATTERY INSTALLATION.................................................................................................................................106

BATTERY HOOK-UP CONFIGURATIONS.........................................................................................................107

BATTERY CABLE INDUCTANCE......................................................................................................................110

APPLICATIONS..................................................................................................................................................111

TROUBLESHOOTING GUIDE............................................................................................................................112

INVERTER/CHARGER TERMINOLOGY............................................................................................................115

SPECIFICATIONS AND FEATURES (60 Hz Models)..................................................................................... ...118

SPECIFICATIONS AND FEATURES (50 Hz Models)..................................................................................... ...119

DIMENSIONS.....................................................................................................................................................121

INSTALLATION DIAGRAMS..............................................................................................................................121

USER SETTINGS WORKSHEETS.....................................................................................................................123

2001 Xantrex Technology, Inc.

5916 - 195th Street N. E.

Arlington, WA 98223

Telephone: 360/435-8826

Fax: 360/435-2229

www.traceengineering.com

SW Series Inverter/Charger

Part No. 2031-5

Rev. C: February 2001

Page 6

TABLE OF CONTENTS

SW Series Inverter/Charger

APPENDIX................................................................................................................................................ 128

OPTIONS........................................................................................................................................................... 128

OTHER PRODUCTS.......................................................................................................................................... 129

REFERENCE TABLES AND GRAPHS.............................................................................................................. 130

STORAGE CHECKLIST..................................................................................................................................... 133

WARRANTY/REPAIR INFORMATION .................................................................................................... 135

LIMITED WARRANTY............................................................................................................... ......................... 135

WARRANTY REGISTRATION...........................................................................................................................135

LIFE SUPPORT POLICY....................................................................................................................................135

WARRANTY OR REPAIR SERVICE REQUIRED.............................................................................................. 136

INDEX ....................................................................................................................................................... 137

2001 Xantrex Technology, Inc.

5916 - 195th Street N. E.

Arlington, WA 98223

Telephone: 360/435-8826

Fax: 360/435-2229

www.traceengineering.com

Part No. 2031-5

Rev. C: February 2001

Page 7

TABLE OF CONTENTS

INDEX OF FIGURES

Figure 1, Identification Label .................................................................................................................. 7

Figure 2, SW Series Inverter/Charger.................................................................................................... 9

Figure 3, Control Panel........................................................................................................................... 9

Figure 4, AC Side................................................................................................................................. 12

Figure 5, Internal Components and Indicators ..................................................................................... 13

Figure 6, Aux and Gen Control Relays................................................................................................. 14

Figure 7, DC Side................................................................................................................................. 14

Figure 8, Air Flow Intake Location........................................................................................................ 18

Figure 9, AC Input/Output Power Connection......................................................................................19

Figure 10, Warning Label..................................................................................................................... 21

Figure 11, Battery to Inverter Cable Connection .................................................................................. 24

Figure 12, Neutral-To-Ground Bond Switching: No External AC Source Connected........................... 27

Figure 13, Neutral-To-Ground Bond Switching: External AC Source Connected ................................ 28

Figure 14, Neutral-To-Ground Bond Switching: Neutral Bonded To Ground....................................... 28

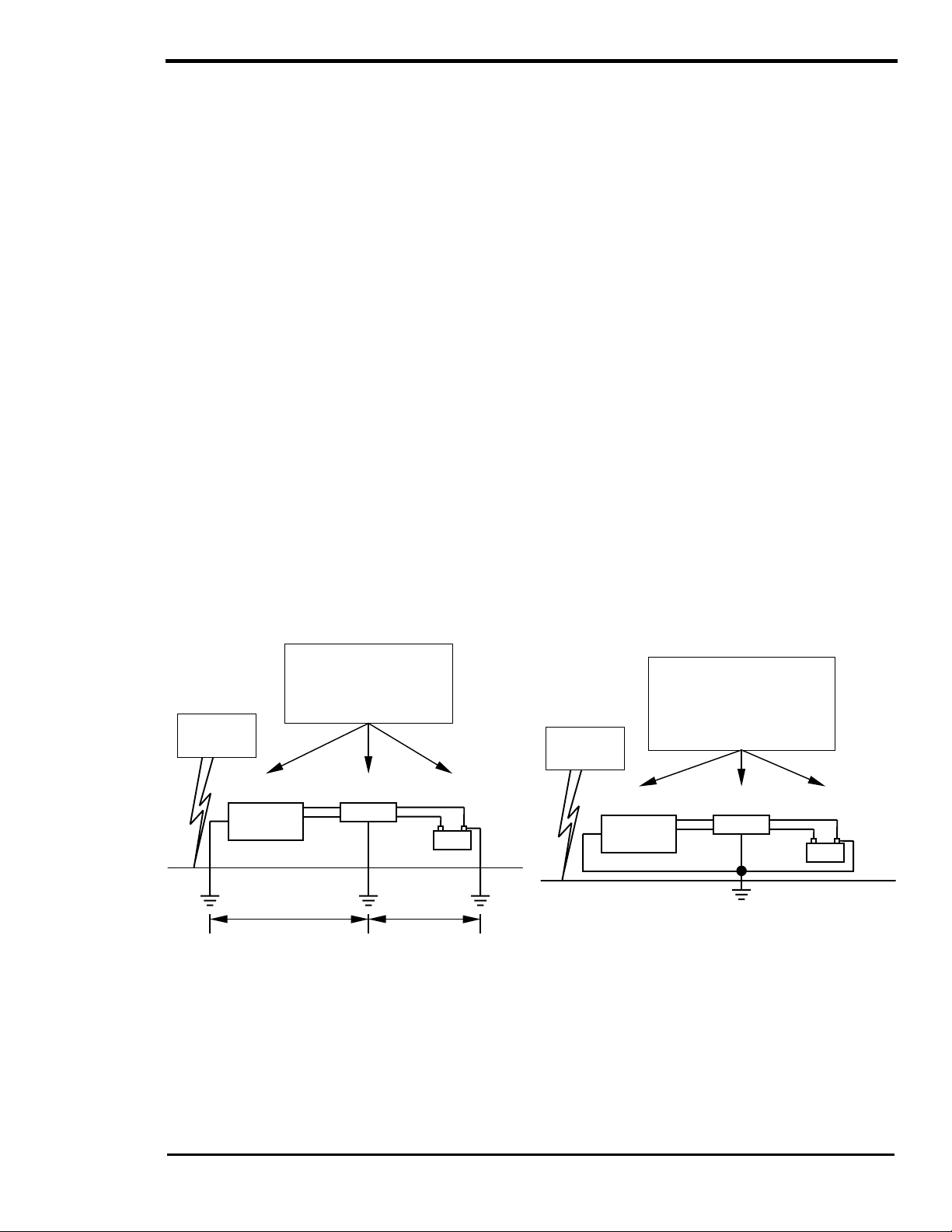

Figure 15, Multiple Point Ground System............................................................................................. 29

Figure 16, Single Point Ground System ............................................................................................... 29

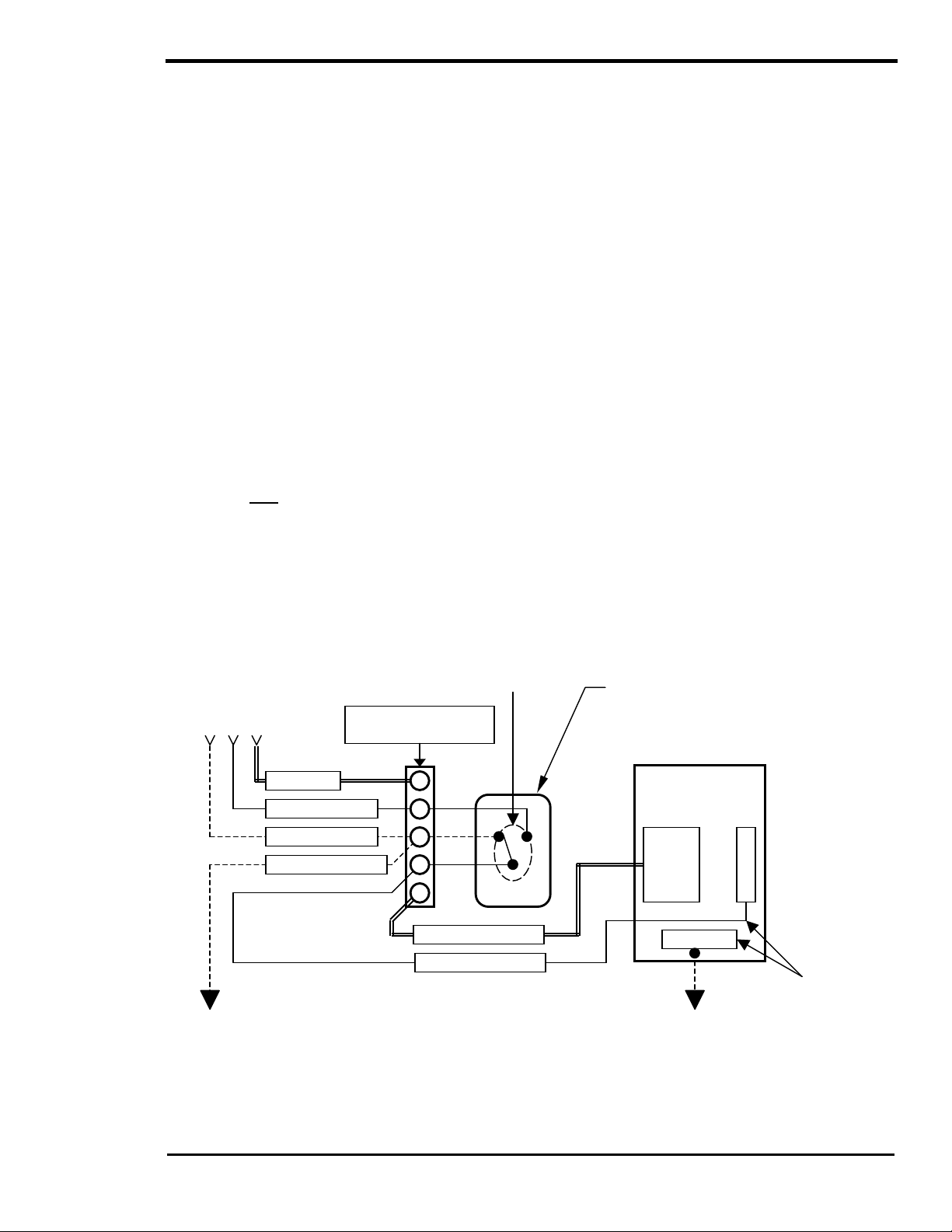

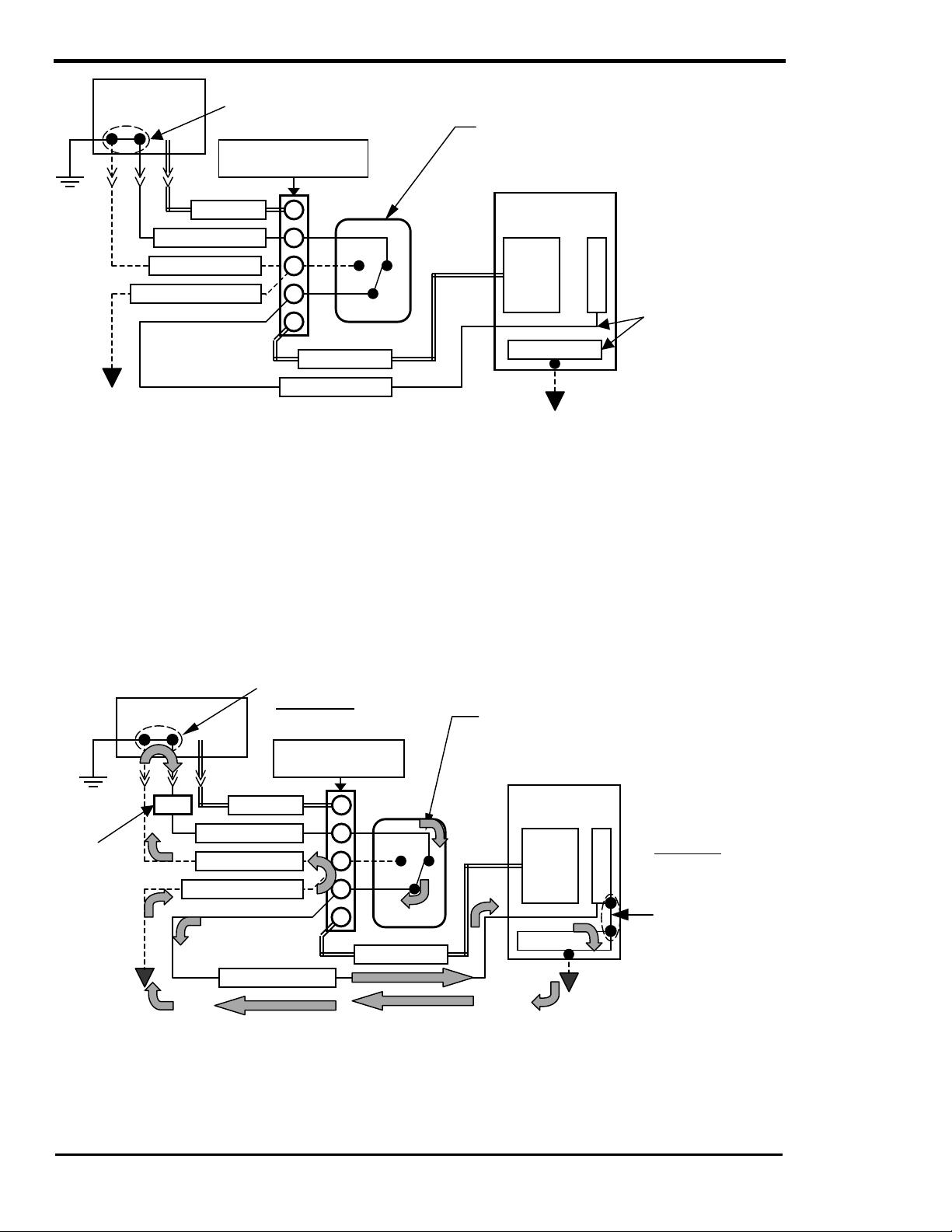

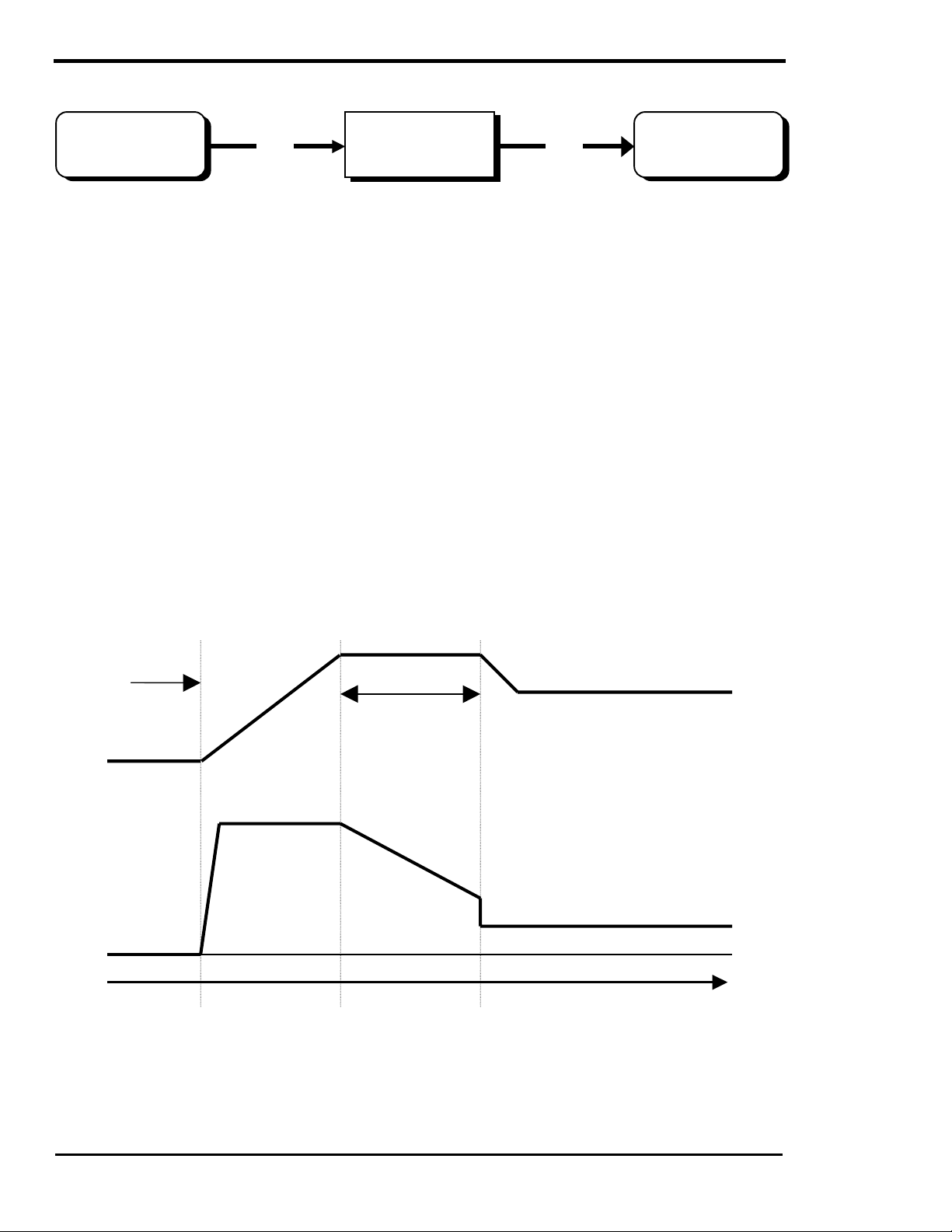

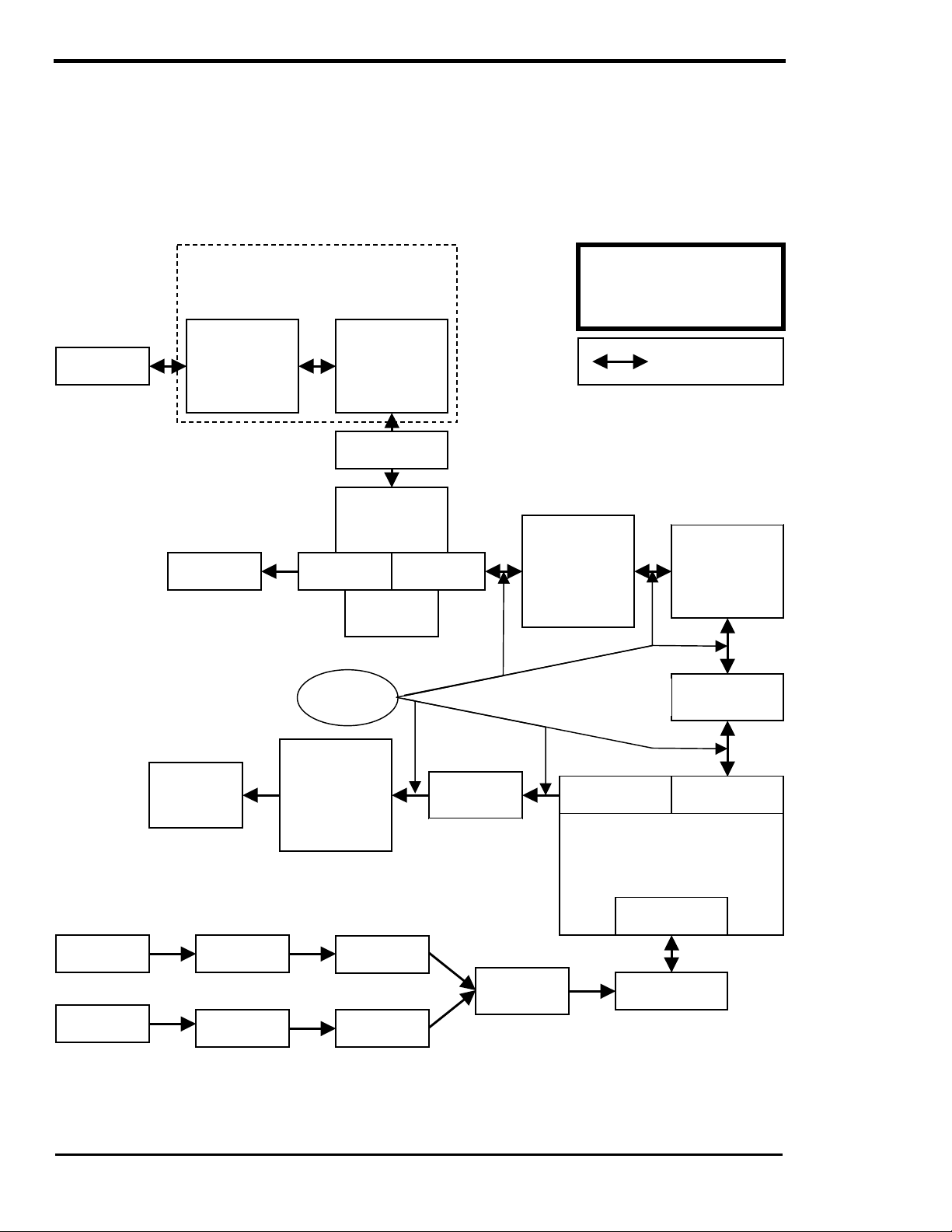

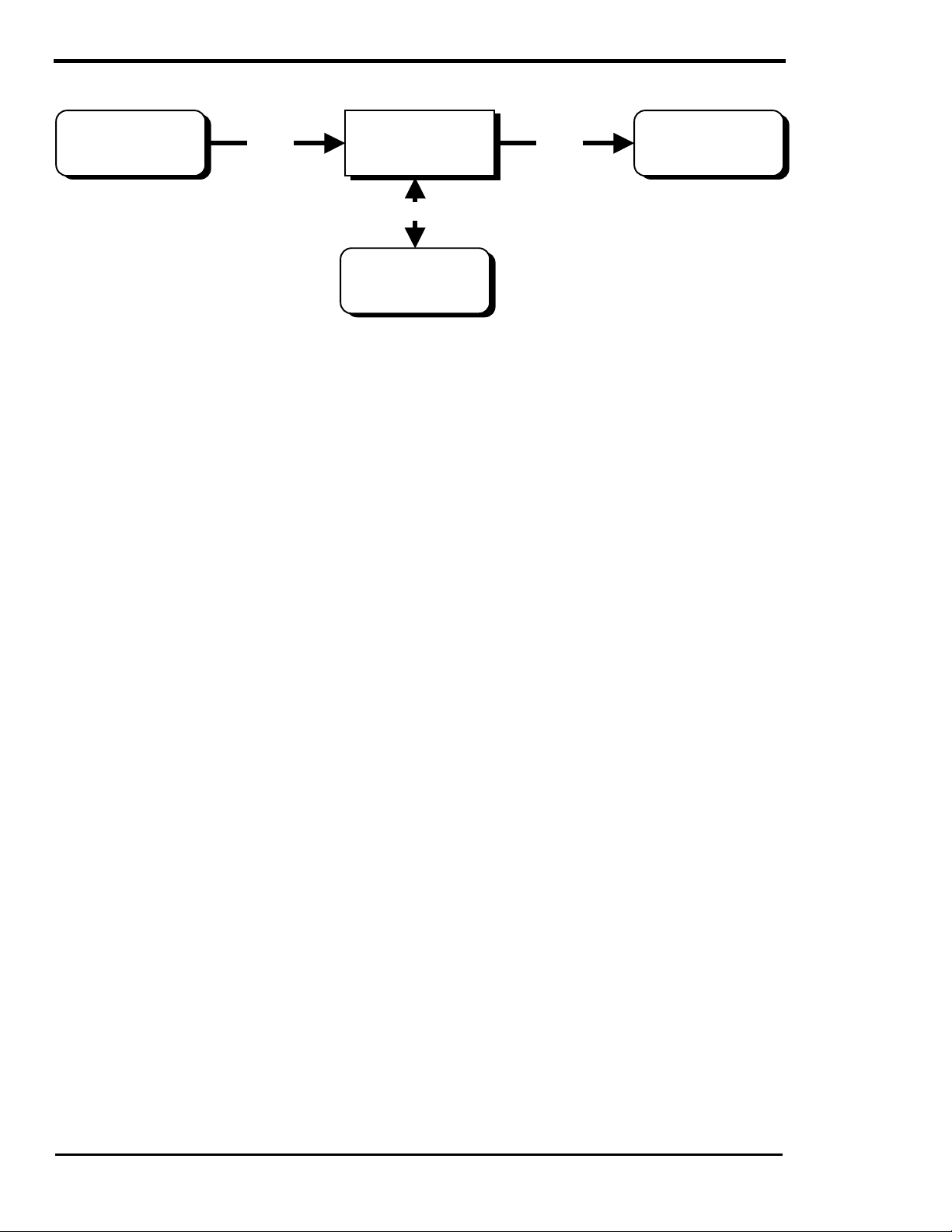

Figure 17, Trace™ SW Series Inverter Simple Block Diagram ........................................................... 57

Figure 18, Trace™ SW Series Inverter Output Waveform................................................................... 58

Figure 19, Trace™ SW Series Efficiency Curves.................................................................................. 59

Figure 20, Inverter Capacity vs. Temperature...................................................................................... 60

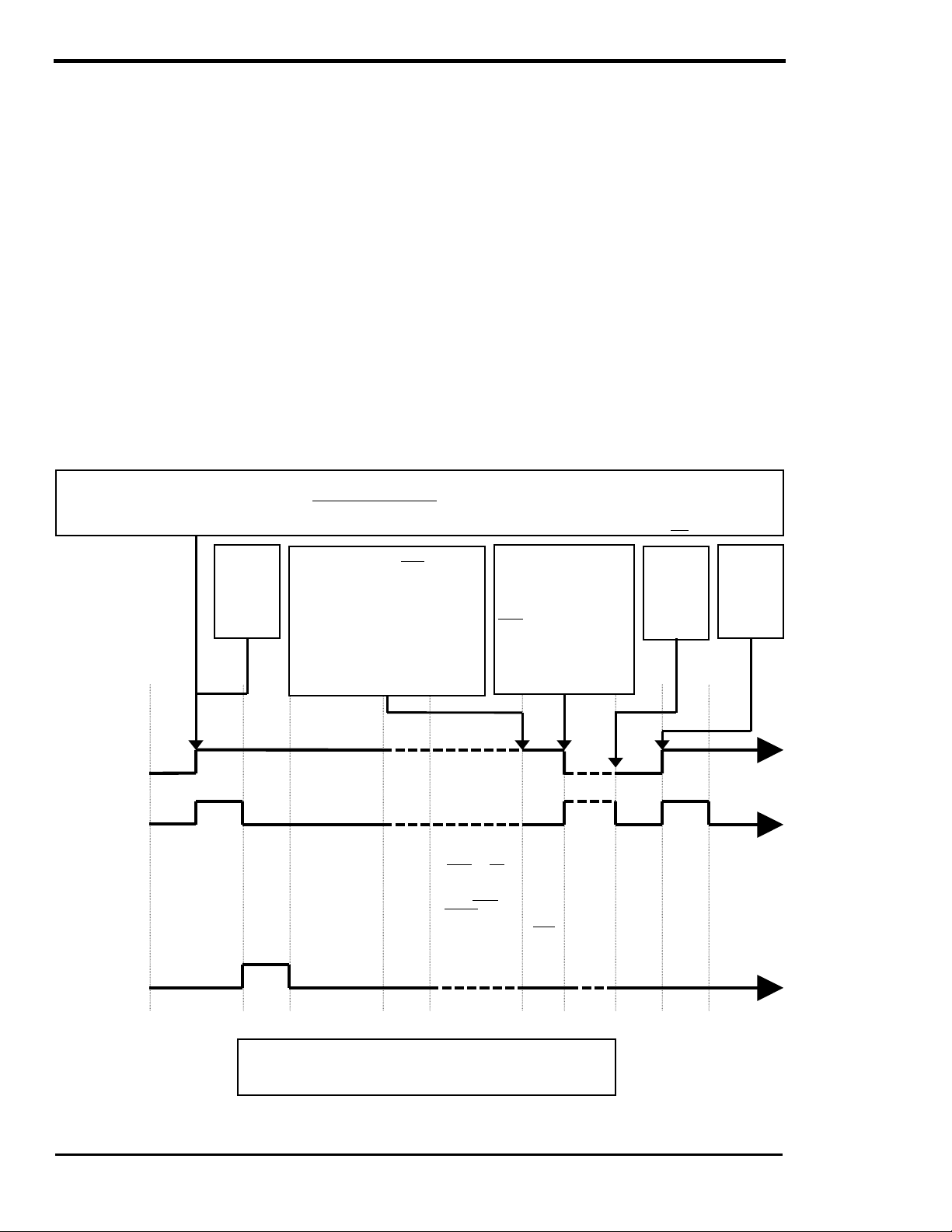

Figure 21, Three-Stage Battery Charging ............................................................................................ 64

Figure 22, BTS (Battery Temperature Sensor) .................................................................................... 65

Figure 23, Two Wire Start Wiring Diagram .......................................................................................... 76

Figure 24, Three Wire Start Wiring Diagram (HONDA Type) .............................................................. 77

Figure 25, Three Wire Start Wiring Diagram (ONAN Type)................................................................. 77

Figure 26, Relay RY7 and RY8 Sequence...........................................................................................78

Figure 27, Selling Power From A DC Charging Source; Hypothetical Time Of Day Oper. History...... 85

Figure 28, Selling Power Stored In The Batteries; Hypothetical Time Of Day Operational History...... 86

Figure 29, Utility Interactive Line-Tie System With Battery Backup Flow Diagram.............................. 88

Figure 30, Overvoltage Protection for Battery ...................................................................................... 89

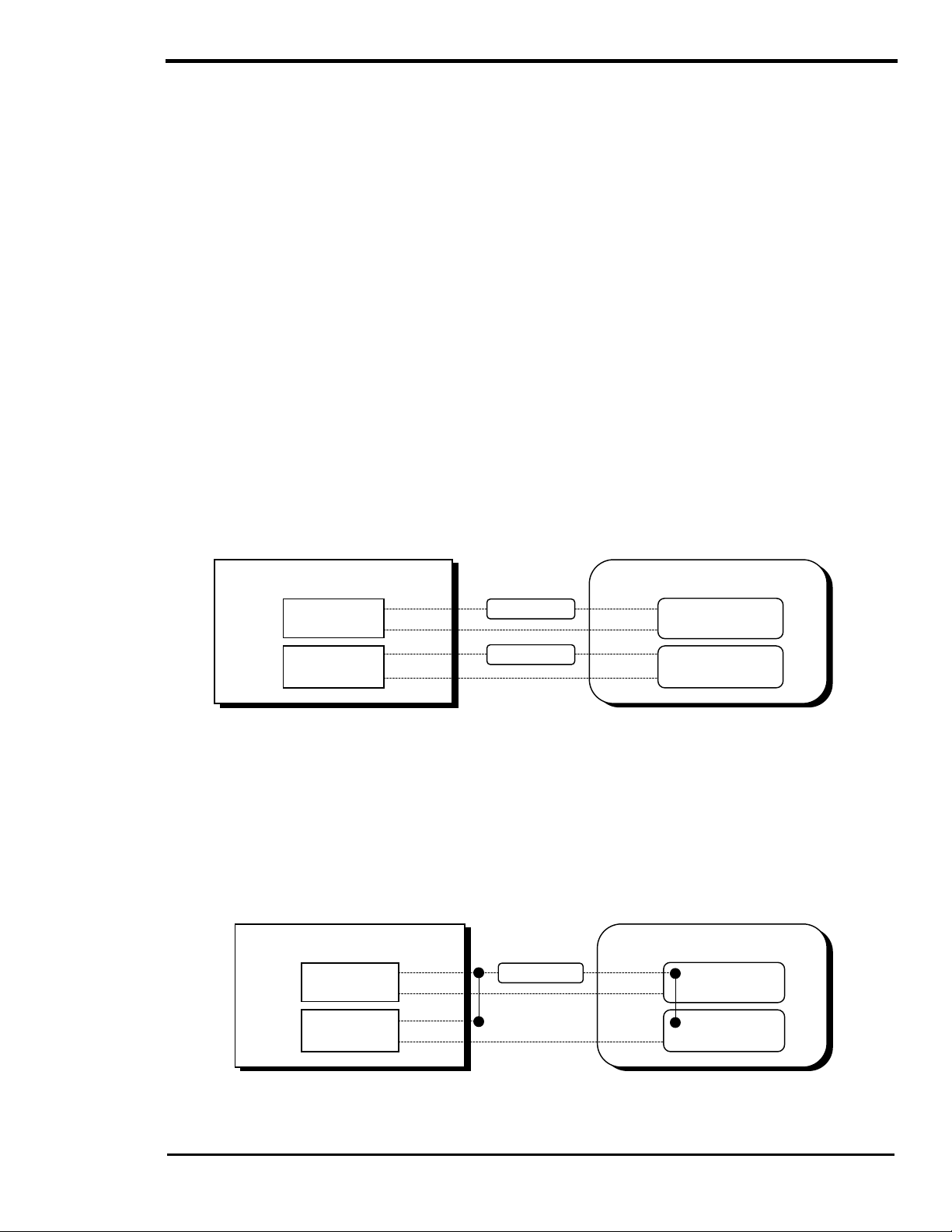

Figure 31, Series Configuration: 6-Volt Battery Wiring....................................................................... 107

Figure 32, Series Configuration: 12-Volt Battery Wiring..................................................................... 107

Figure 33, Parallel Configuration: 12-Volt Battery Wiring................................................................... 108

Figure 34, Series-Parallel Configuration: 6-Volt Battery Wiring.......................................................... 109

Figure 35, Series-Parallel Configuration: 12-Volt Battery Wiring........................................................ 109

Figure 36, AC Waveforms.................................................................................................................. 116

Figure 37, SW Series Dimensions: With AC Access Covers – Showing Knockout Sizes................. 120

Figure 38, Installation Diagram, 120 VAC, 1 Phase, Grid Connected, Generator Backup ................ 121

Figure 39, Installation Diagram, 240 VAC, 3 Wire, Grid Connected, Generator Backup................... 122

Figure 40, AWG Wire Size................................................................................................................. 131

2001 Xantrex Technology, Inc.

5916 - 195th Street N. E.

Arlington, WA 98223

Telephone: 360/435-8826

Fax: 360/435-2229

www.traceengineering.com

SW Series Inverter/Charger

Part No. 2031-5

Rev. C: February 2001

Page 8

TABLE OF CONTENTS

SW Series Inverter/Charger

INDEX OF TABLES

Table 1, AC Input and Output Wiring Connections .............................................................................. 19

Table 2, Minimum Recommended Battery Cable Size vs. Cable Length............................................. 22

Table 3, Battery Cable To Maximum Breaker/Fuse Size .....................................................................23

Table 4, Charging Setpoints For Common Battery Types.................................................................... 67

Table 5, Typical Wattage Of Common Appliances ............................................................................ 101

Table 6, Battery Charging: Charging Setpoints.................................................................................. 104

Table 7, Battery State of Charge Voltage........................................................................................... 105

Table 8, Battery Cable Inductance .....................................................................................................110

Table 9, Power Consumption Of Common Appliances...................................................................... 130

Table 10, AWG to Metric Wire Conversion Chart .............................................................................. 130

Table 11, Minimum Recommended Battery Cable Size vs. Cable Length......................................... 131

Table 12, Battery Cable to Maximum Breaker/Fuse Size................................................................... 131

Table 13, Recommended Minimum AC Wire Sizes (75° C)............................................................... 132

Table 14, Knockout/Hole Size To Conduit Size Required.................................................................. 132

Table 15, Safety Ground Wire Sizes.................................................................................................. 132

2001 Xantrex Technology, Inc.

5916 - 195th Street N. E.

Arlington, WA 98223

Telephone: 360/435-8826

Fax: 360/435-2229

www.traceengineering.com

Part No. 2031-5

Rev. C: February 2001

Page 9

IMPORTANT SAFETY INSTRUCTIONS

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS!

This manual contains im portant safety and operating instructions as prescribed by UL Standards for the

Trace™ SW Series Inverter/Chargers for use in residential and commercial applications. This manual

specifically covers products with the revision 4.01 software.

The 120 VAC/60 Hertz models of the SW Series Inverter/Chargers are ETL listed to UL Standard 1741

(Draft), Static Inverters and Charge Controllers for use in Photovoltaic Systems. The 12 and 24 VDC,

120 VAC/60 Hertz models of the SW Ser ies Inverter/Char gers ar e ETL lis ted to UL stan dard 458, Pow er

Converters/Inverters and Power Converter/Inverter Systems for Land Vehicles and Marine Craft.

The 120 VAC/60 Hertz models of the SW Series Inverter/Chargers are also ETL listed to Canadian

Standard CSA - C 22.2 No. 107.1 - M1, Commercial and Industrial Power Supplies.

The following Model Numbers of the SW Series Invert er/Chargers listed above comp ly with the following

EU directives:

• 89/336/EEC, “Council Directive of 3 May 1989 on the approximation of the laws of Member States

relating to Electromagnetic compatibility” (EMC)

• 73/23/EEC, “Council Directive of 19 February 1973 on the harmonization of the laws of Mem ber

States relating to electrical equipment for use within certain voltage limits” (LVD)

SW2612E SW4548AHC SW4548EPV SW2612A

SW2612EHC SW4548EHC SW2612AHC SW3048AHC SW4548E3PH

SW3024E

SW3048E

SW3048A SW3024EHC SW3048E SW4548E SW4548A

SW3048EHC SW3024E SW3048EPV SW3048E3PH

SW3024AHC SW3024A SW3048APV SW4548APV

SW3048E

The compliance of the above mentioned products with the Directives is confirmed through the

application of the following essential requirements:

Emissions and Immunity Safety

EN 50091-1

EN 50091-2 and

EN 60950

NOTE: To achieve compliance to EN50091-1, Conducted RF emissions, product mus t not be

connected to AC mains. Compliance is assured for off-grid applications only.

As the manufacturer we declare under our sole responsibility that the above mentioned products comply

with the above named directives.

GENERAL PRECAUTIONS

1. Before using the SW Series Inverter/Charger, read all instructions and cautionary markings on:

(a) the inverter/charger; (b) the batteries and; (c) all appropriate sections of this manual.

WARNING - To reduce risk of injury, charge only deep-cycle lead acid, lead antimony, lead calcium,

gel cell, absorbed glass mat, or NiCad/NiFe type rechargeable batteries. Other types of batteries

may burst, causing personal injury and damage.

2. Do not expose invert er/charger to rain, snow or liquids of any type. The inverter is designed f or indoor

mounting only. Protect the inverter from splashing if used in vehicle applications.

2001 Xantrex Technology, Inc.

5916 - 195th Street N. E.

Arlington, WA 98223

Telephone: 360/435-8826

Fax: 360/435-2229

www.traceengineering.com

SW Series Inverter/Charger

Part No. 2031-5

Rev. C: February 2001

Page

1

Page 10

IMPORTANT SAFETY INSTRUCTIONS

SW Series Inverter/Charger

3. Use of battery cable or custom attachm ent not recom mended or sold by Xantrex Tec hnology Inc. for

the SW Series Inverter/Charger may result in a risk of fire, electric shock, or injury to persons.

4. Do not disassem ble the inverter/charger. T ak e it to a qualif ied service c enter when servic e or repair is

required. Incorrect re-assembly may result in a risk of electric shock or fire.

5. To reduce risk of electric shock , disconnect all wiring bef ore attempting any maintenanc e or cleaning.

Turning off the inverter will not reduce this risk. Solar m odules produce power when expos ed to light.

Cover them with opaque material before servicing any connected equipment.

WARNING – RISK OF EXPLOSIVE GASSES

(a) WORKING IN VICINITY OF A LEAD ACID BATTERY IS DANGEROUS. BATTERIES

GENERATE EXPLOSIVE GASES DURING NORMAL BATTERY OPERATION. FOR THIS

REASON, IT IS OF UTMOST IMPORTANCE THAT EACH TIME BEFORE SERVICING

EQUIPMENT IN THE VICINITY OF THE BATTERY, YOU READ THIS MANUAL AND

FOLLOW THE INSTRUCTIONS EXACTLY.

(b) To reduce risk of batter y explosion, follow the instructions in this manual and those publis hed

by the battery manufacturer as well as manufactur er of any additional equipment us ed in the

vicinity of the battery. Review all cautionary markings on these products.

SPECIAL NOTICES

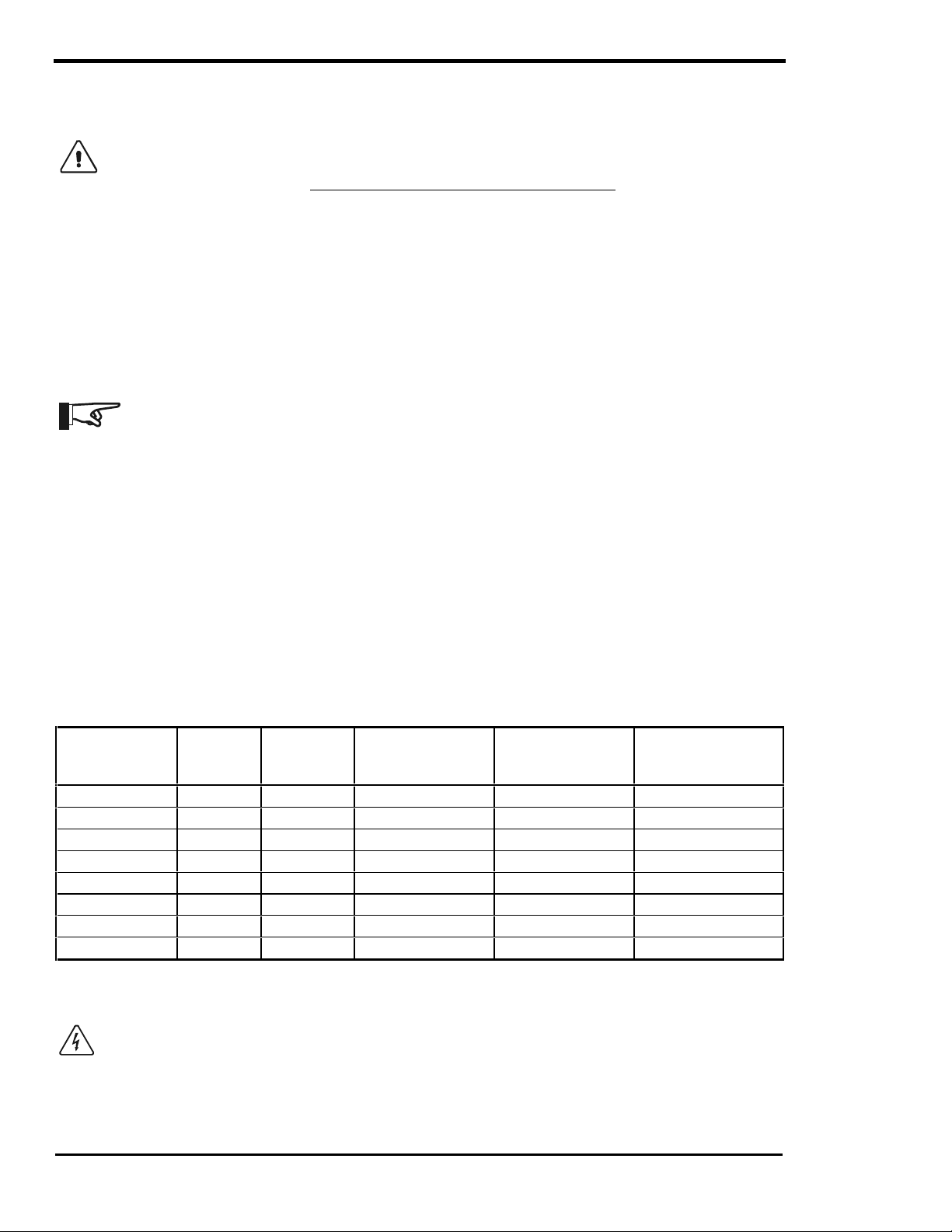

1. Tools required to make AC and DC wiring connections: Wire strippers; 1/2" (13MM) open-end or

socket wrench; Phillips #2 screwdriver; flat blade 1/4" (6MM) screwdriver.

2. No terminals or lugs are required for hook-up of the AC wiring. AC wiring must be copper wire and

rated for 75°C or higher. The maximum wire size for the AC terminals is #6 AWG (4.11 mm diameter).

Battery cables must be rated for 75°C or higher. Crimped and sealed copper ring ter minal lugs with a

5/16 hole should be used to connect the battery cables to the DC terminals of the inver ter/charger.

Soldered cable lugs are also acceptable.

3. Torque all AC wiring connections to 20 inch-pounds. T orque all DC cable connections to 10-15 footpounds. Avoid dropping metal tools onto the batteries. A s hort-circuit could result in a spar k, fire or

possible explosion.

4. T his inverter /c harger is designed for use with a battery supply with a nominal voltage that matches the

last two digits of the model number (e.g., 12 Volt with an SW2512).

5. For instructions on mounting, see the MOUNTING section on page 17 of this manual.

NOTE: Do not use the keyhole mounting slots for permanent ins tallations. F or battery installation

and maintenance refer to the battery manufacturer’s instructions.

6. No AC or DC disconnects are provided as an integral part of this inverter. Both AC and DC

disconnects must be pr ovided as part of the s ystem installation. Refer to the INSTALLATION section

beginning on page 15 for more information.

7. No overcurrent protection for the battery supply is provided as an integral part of this inverter.

Overcurrent protection of the battery cables must be provided as part of the system ins tallation. Refer

to the INSTALLATION section beginning on page 15 and the DC DISCONNECT AND

OVERCURRENT PROTECTION section on page 23 for more information.

8. No over current protection for the AC output wiring is provided as an integral part of this inverter.

Overcurrent protection of the AC output wiring m ust be provided as part of the system installation. Refer to

the INSTALLATION section on page 15 and the AC WIRING section on page 18 for more information.

9. The AC output neutral conductor and DC negative conductors are not connected (bonded) to the

inverter chassis. Both the input and output conductors are isolated from the enc losur e and eac h other.

System grounding, if required by sections 690-40, and 690-42 of the National Electric Code,

ANSI/NFPA 70-1996, is the responsibility of the system installer. All installations m ust comply with

local and national electrical codes and standards.

Page

2

2001 Xantrex Technology, Inc.

5916 - 195th Street N. E.

Arlington, WA 98223

Telephone: 360/435-8826

Fax: 360/435-2229

www.traceengineering.com

Part No. 2031-5

Rev. C: February 2001

Page 11

IMPORTANT SAFETY INSTRUCTIONS

10. GROUNDING INSTRUCTIONS - This inverter/battery charger should be connected to a grounded,

permanent wiring system. For m ost installations, the negative battery conductor should be bonded to

the grounding system at one (and only one point) in the system. All installations should com ply with

national and local codes and ordinances. Refer to the SYSTEM GROUNDING section on page 26 for

more information.

PERSONAL PRECAUTIONS

1. Someone should be within range of your voice or close enough to come to your aid when you work

near batteries.

2. Have plenty of fresh water and soap nearby in case battery acid contacts skin, clothing, or eyes.

3. Wear complete eye protection and clothing protection. Avoid touching eyes while working near

batteries. Wash your hands when done.

4. If battery acid contacts skin or clothing, wash immediately with soap and water. If acid enters eye,

immediately flood eye with running cool water for at least 15 minutes and get medical attention immediately.

(a) Baking soda neutralizes lead acid battery electrolyte.

(b) Vinegar neutralizes spilled NiCad and NiFe battery electrolyte.

(c) Keep a supply on hand in the area of the batteries.

5. NEVER smoke or allow a spark or flame in vicinity of a battery or generator.

6. Be extra cautious to reduce the risk of dropping a metal tool onto batteries. It could short-circuit the

batteries or other electrical parts that may result in a spark which could cause an explosion.

7. Remove personal m etal items such as rings, brac elets, necklaces , and watches when working with a

battery. A battery can produce a short-c ircuit current high enough to weld a ring or the like to metal,

causing severe burns.

8. NEVER charge a frozen battery.

9. If necessary to remove the battery, make s ure all accessories are off. Then, rem ove the grounded

terminal from the battery first.

10. If a remote or automatic generator

control system is used, disable the automatic starting circuit and/or

disconnect the generator from its starting battery while perform ing maintenanc e to prevent accidental

starting.

11. Provide ventilation to outdoors from the battery compartment. The battery enclosure should be

designed to prevent accumulation and conc entration of hydrogen gas in “pockets” at the top of the

compartment. Vent the batter y compartment from the highest point. A sloped lid c an also be used to

direct the flow to the vent opening location.

12. Clean battery terminals. Be careful to keep corrosion from coming in contact with eyes.

13. Study all the battery manufacturer’s specif ic precautions, s uch as rem oving or not rem oving cell caps

while charging and recommended rates of charge.

14. For flooded lead acid batteries, add distilled water in each cell until the battery acid reaches the level

specified by the battery manufacturer. This helps purge excessive gas fumes from the cells. Do not

overfill. For a battery without cell caps, carefully follow the manufacturer’s recharging instructions.

2001 Xantrex Technology, Inc.

5916 - 195th Street N. E.

Arlington, WA 98223

Telephone: 360/435-8826

Fax: 360/435-2229

www.traceengineering.com

SW Series Inverter/Charger

Part No. 2031-5

Rev. C: February 2001

Page

3

Page 12

IMPORTANT SAFETY INSTRUCTIONS

SW Series Inverter/Charger

Page

4

2001 Xantrex Technology, Inc.

5916 - 195th Street N. E.

Arlington, WA 98223

Telephone: 360/435-8826

Fax: 360/435-2229

www.traceengineering.com

Part No. 2031-5

Rev. C: February 2001

Page 13

INTRODUCTION

INTRODUCTION

Congratulations! You are the proud owner of the finest inverter on the market today - and one very

complex piece of equipment. T he Trace™ Sine wave (SW Series) Inverter/Charger has many features

and capabilities previously either non-existent, or found only in separate products.

With proper installation, the inverter will operate satisf actor ily for many applications str aight out of the box ,

using the factory default settings. To fully utilize the inverter's generator interactive, or utility interactive

capabilities, it is necessary to understand the way the inverter operates and then tailor its operation via the

Control Panel and the USER and SETUP menu systems. This manual will provide the necessary

information. However, it is recom mended that you consult with your authorized dealer to ensure correct

installation and maximum utilization of the numerous featur es of this produc t. If you do not understand any

aspect of installation, contact your authorized Xantrex dealer/installer for assistance.

If you intend to operate the inverter in a utility interactive mode, in which power will be sold to the utility,

you must contact the local utility office and get their approval. T he utility may require additional inf or mation

that may not be included in this manual. Please contact your authorized Xantrex dealer/installer for

assistance.

As a minimum , you should read the sections of the manual that relate to your type of installation. The

MENU SYSTEM section, beginning on page 33, explains how to make changes to the inverter’s

user/setup menus. T he OPERATION section, beginning on page 57, explains how the inverter works in

each of its different operating modes. Focus on the operating modes that relate best to your type of

installation and make the appropriate selections and adjustm ents. Installation diagrams are provided for

many of the various applications. This m enu system provides contro l of the inverter, allows features to be

enabled, and allows setting of operating parameters.

This is a long manual and much of it is fairly technical. Throughout this m anual terms may be used that

are unfamiliar, see the INVERTER/CHARGER TERMINOLOGY glossary on page 115 for clarification. If

you are an insomniac, properly used, this manual is guaranteed to provide several good nights of sleep.

Note: This manual is specific to the REVISION 4.01 software. Some featur es disc ussed may not

be included in previous software revisions provided in inverters manufactured before March

1996.

You can verify that the inverter is using REVISION 4.01 software by checking under the TRACE

ENGINEERING (3) m enu heading. The second menu item should read REVISION 4.01. If your inverter

includes a previous software version, please contact your authorized Xantrex dealer r egarding upgrade

options.

2001 Xantrex Technology, Inc.

5916 - 195th Street N. E.

Arlington, WA 98223

Telephone: 360/435-8826

Fax: 360/435-2229

www.traceengineering.com

SW Series Inverter/Charger

Part No. 2031-5

Rev. C: February 2001

Page

5

Page 14

INTRODUCTION

SW Series Inverter/Charger

Page

6

2001 Xantrex Technology, Inc.

5916 - 195th Street N. E.

Arlington, WA 98223

Telephone: 360/435-8826

Fax: 360/435-2229

www.traceengineering.com

Part No. 2031-5

Rev. C: February 2001

Page 15

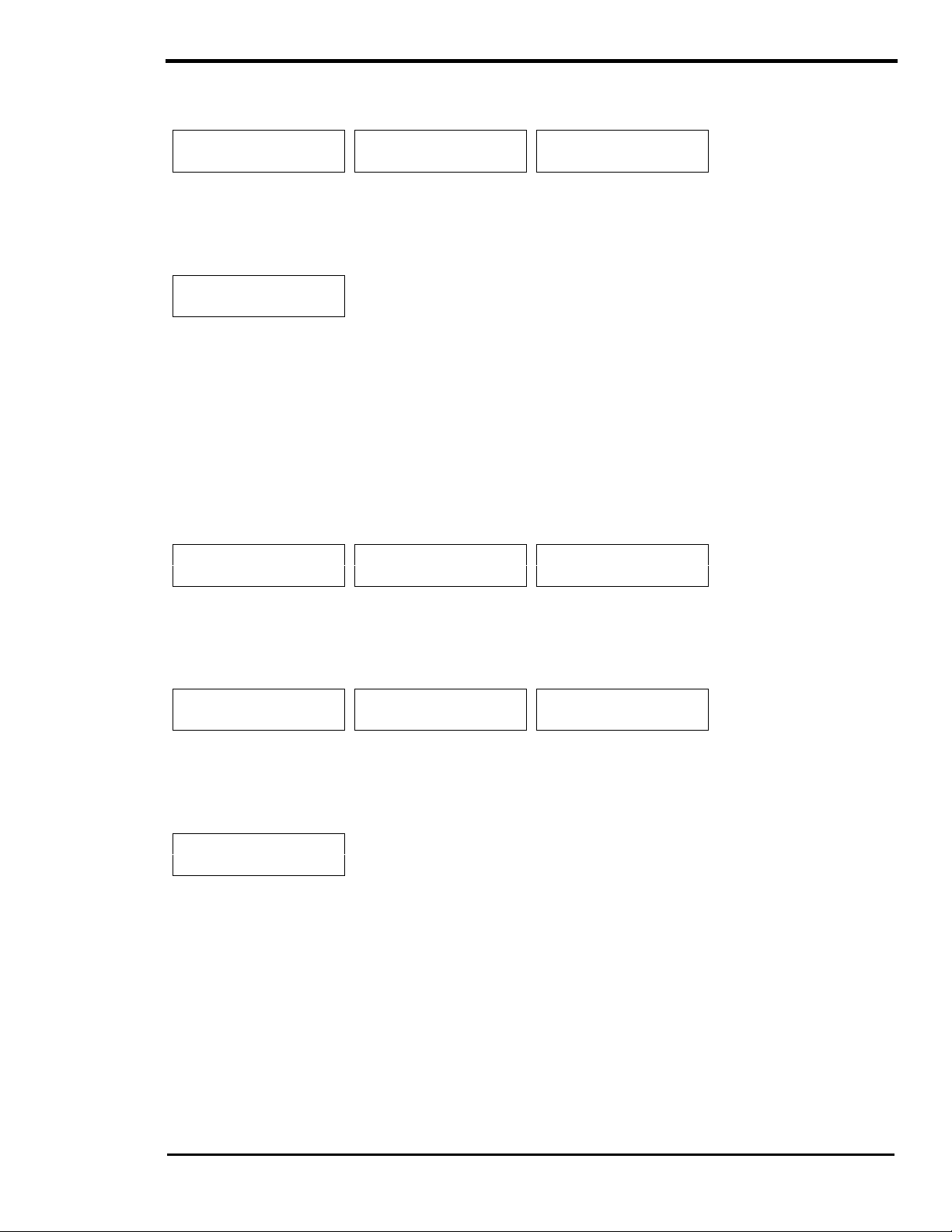

UNIT IDENTIFICATION

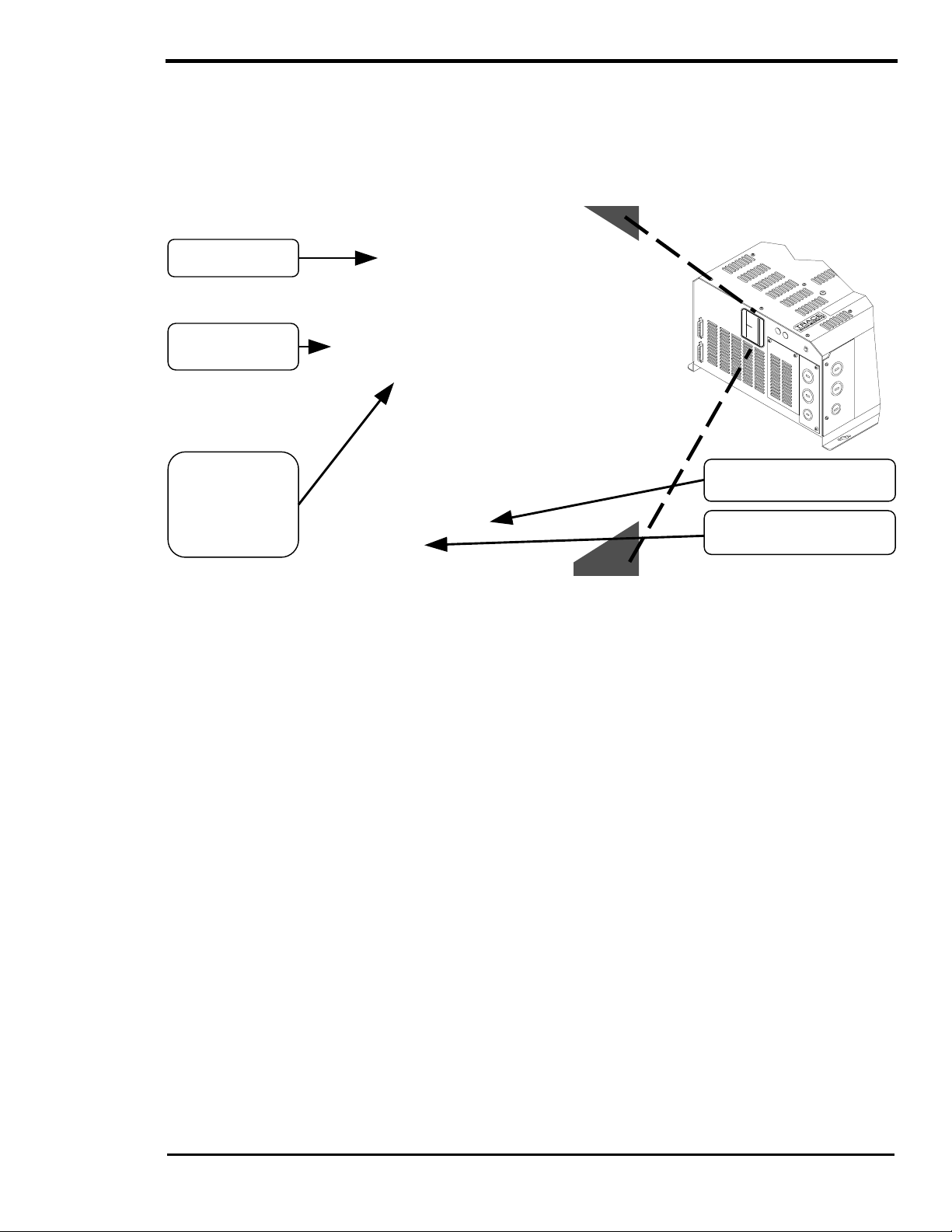

UNIT IDENTIFICATION

This section describes the marking and location of the model and serial numbers for SW Series

Inverter/Chargers. Use this section to determine the type and model of your inverter/charger. The unit

identification label on the left side panel of the inverter/charger will show the serial number, model number,

listings, ratings, and date of manufacture.

Model Number

DC Input Voltage

Operating Range

AC Input/Output

Phase,

Quarter and Year of

Manufacture

Waveform,

Frequency and

Voltage

Product Code and Serial

Number

Figure 1, Identification Label

MODEL NUMBER

The Model Number of your inverter determines the different features your unit m ay have. Consider the

following unit with a SW4024 model number:

SW 40 24 *

Model Power Nominal DC

Voltage

Model: The first letter(s) (SW) indicate the model, in this case the SW Series.

Power: The first and second positions in the model num ber indicate the continuous AC power output in

hundreds of VA (Volt-Amps). Power levels available s tart at 2500 up to 5500 Volt-Amps with different DC

voltages. In the example above, 40 would stand for a 4000 VA (4 kVA), continuous-output inverter.

Input/Output DC Voltage: The number (24) following the power rating indicates an inverter/charger that

is designed to convert 24 VDC input to an AC voltage

output, and charge 24 VDC batteries when powered

by the same AC voltage. Available DC voltages are 12, 24 and 48 volt models.

AC Voltage/Options

Input/Output AC Voltage/Options: The letter following the power rating indicates what AC voltage and

frequency or particular option this inverter/charger is specifically designed to provide. No letter after the

DC voltage number indicates an AC voltage of 120 VAC/60 Hz and requires the s ame AC voltage and

frequency (120 VAC/60 Hz) to charge the inverter batteries. Available voltages range from 105 to 240

VAC at 50 or 60 Hz.

See the SPECIFICATIONS AND FEATURES section, on page 118, for the different models available.

2001 Xantrex Technology, Inc.

5916 - 195th Street N. E.

Arlington, WA 98223

Telephone: 360/435-8826

Fax: 360/435-2229

www.traceengineering.com

SW Series Inverter/Charger

Part No. 2031-5

Rev. C: February 2001

Page

7

Page 16

UNIT IDENTIFICATION

SW Series Inverter/Charger

Page

8

2001 Xantrex Technology, Inc.

5916 - 195th Street N. E.

Arlington, WA 98223

Telephone: 360/435-8826

Fax: 360/435-2229

www.traceengineering.com

Part No. 2031-5

Rev. C: February 2001

Page 17

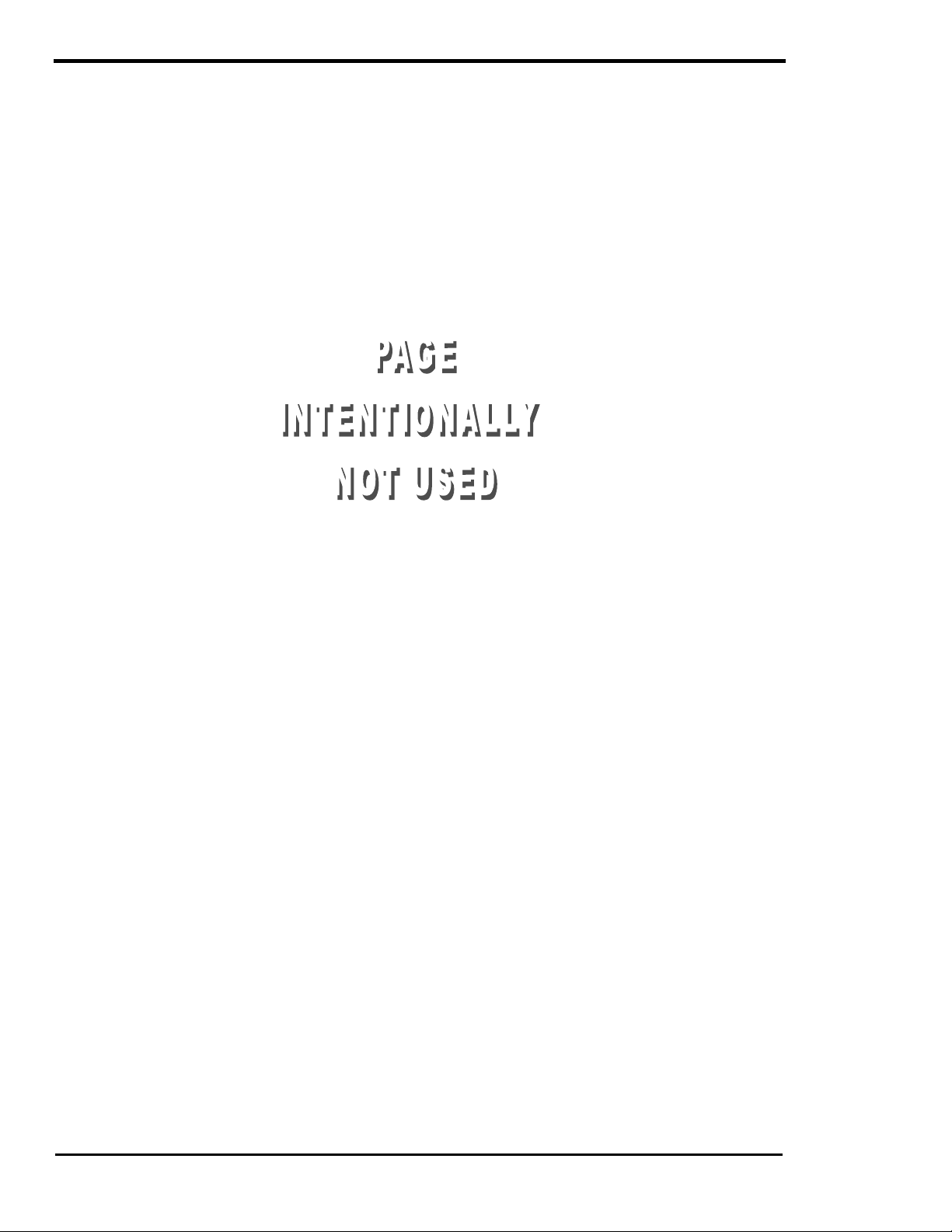

CONTROLS, INDICATORS AND COMPONENTS

CONTROLS, INDICATORS AND COMPONENTS

The SW Series Inver ter/Chargers have an integral, full f unction Control Panel with LED status indicators.

The following components are als o included: inverter/charger circ uit breaker; battery tem perature sensor

(BTS) port, remote port, and a stacking port.

Stacking Interface

Remote Interface

Control Panel

AC Side

DC Side

BTS Sensor Input

Circuit Breaker

Figure 2, SW Series Inverter/Charger

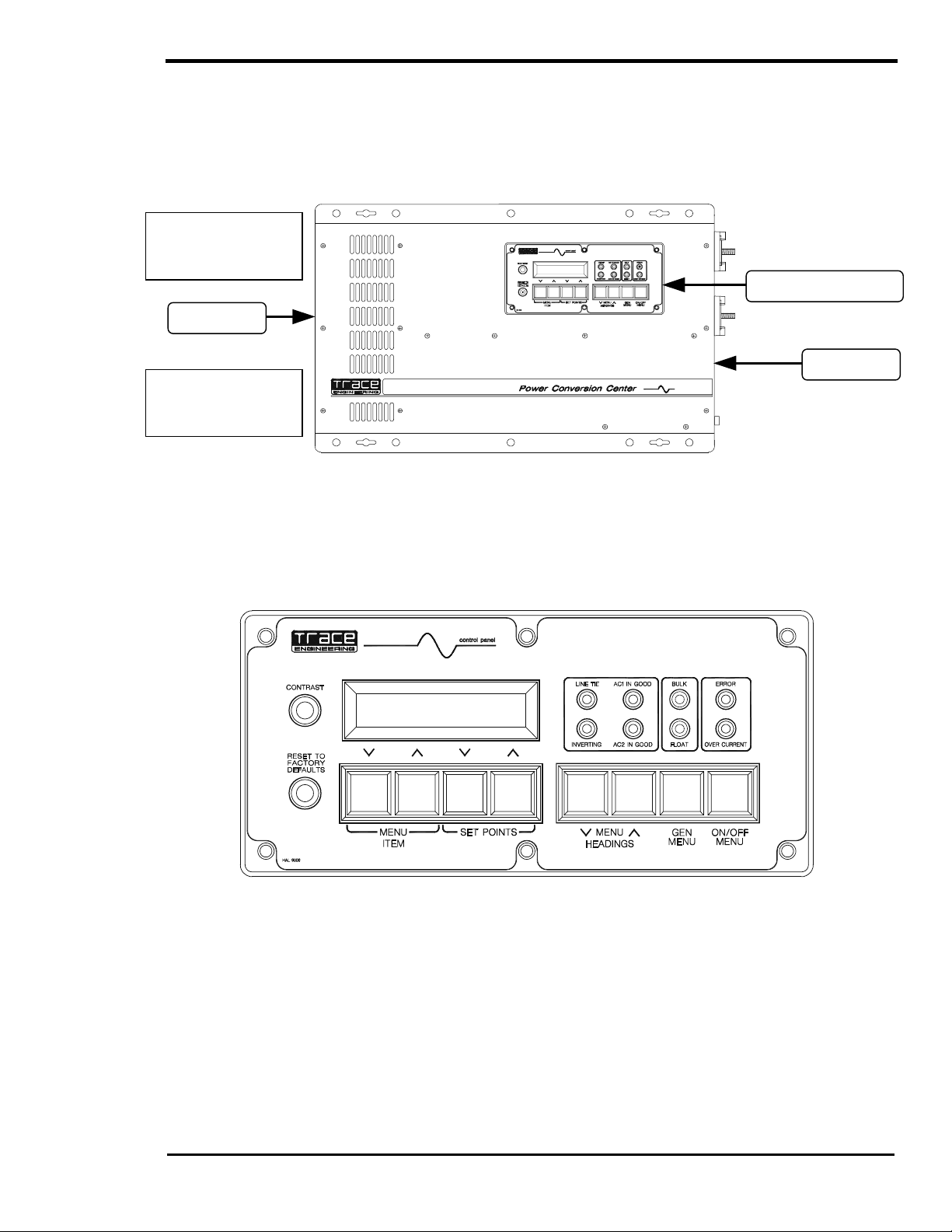

CONTROL PANEL

The Control Panel, on the front of the SW Series Inverter/Charger, provides the controls and displays

needed to adjust, control and monitor the oper ation of the unit. T he contr ol panel is operational whenever

DC power is applied to the inverter DC input terminals.

Figure 3, Control Panel

Eight pushbuttons are used to select the various menus, menu items and oper ating setpoint values f or the

unit, including the ability to turn the inverter on and off. A Liquid Crystal Display (LCD) presents the various

system settings and data as selected by the operation of the MENU BUTTONS on the control panel. Eight

LED indicators are provided to show the operating condition of the inverter, battery charger, AC inputs and

self-protection systems.

DISPLAY

The Liquid Crystal Display (LCD) displays data as selected by the menu buttons. Refer to the USER

MENU, beginning on page 36, and the SETUP MENU, beginning on page 44, for specific information on

the Menu Items, functions and display information.

2001 Xantrex Technology, Inc.

5916 - 195th Street N. E.

Arlington, WA 98223

Telephone: 360/435-8826

Fax: 360/435-2229

www.traceengineering.com

SW Series Inverter/Charger

Part No. 2031-5

Rev. C: February 2001

Page

9

Page 18

CONTROLS, INDICATORS AND COMPONENTS

SW Series Inverter/Charger

CONTRAST CONTROL

The CONTRAST adjustm ent enables you to adjust the contrast of the LCD display screen to accomm odate

changing lighting conditions. Less contrast is usually preferable in brighter lighting conditions.

RESET TO FACTORY DEFAULTS BUTTON

The RESET TO FACTORY DEFAULTS button returns all of the inver ter settings (exc ept for the TIME OF

DAY settings) to the factory default values. The def ault values will be re-entered only when this button is

pushed from a spec ific m enu item in the USER MENU. You must first select the TRACE ENGINEERING

(3) menu heading and then go to the first menu item, which will display “PRESS RESET NOW FOR

DEFAULTS”. Once this reset button is pressed from this menu item, you must reprogram all settings

required by your installation into the inverter.

Removing DC power from the inverter will also return the inverter to the factory default values

(including the TIME OF DAY settings). You must then reprogram the inverter with the required settings

for proper operation of your system. Recording your settings on the USER SETT INGS W ORKSHEET, in

the TECHNICAL INFORMATION section of this manual, will make the reprogramming of the inverter

much easier.

The reset button is also used to re-synchronize the remote control (SW RC) display if the charac ters bec om e

jumbled. Pressing the reset button anywhere in the menu s ystem ( except the PRESS RESET NOW FOR

DEFAULTS menu item) will re-synchronize the display, but the default values will not be reset.

MENU BUTTONS

ON/OFF MENU BUTTON (Red)

Pressing the red ON/OFF MENU button at any time will take you directly to the SET INVERTER menu

item of the INVERTER MODE (1) menu heading. There are four options available from this m enu item.

The first letter of the selec ted item will be underlined. Pressing the red ON/OFF MENU button will move

the cursor one position to the right, selecting the next item. You can also use the SET POINT S buttons to

move either right or left.

GEN MENU BUTTON (Green)

Pressing the green GEN MENU button at any time will display the SET GENERATOR menu item of the

GENERATOR MODE (2) menu heading. There are four options available from this menu. The f irst letter

of the selected item will be underlined. Pres sing the green GEN MENU button will move the cursor one

position to the right, selecting the next item. You can also us e the SET POINTS buttons to move either

right or left.

MENU ACCESS/ADJUSTMENT BUTTONS (Black)

The MENU HEADING buttons are used to move either up or down through the selection of menu

headings. Once a menu heading is selected, the MENU ITEM buttons are used to move up or down

through the list of related menu items. The SET POINTS buttons change the value of a parameter or

select a mode, for the selected menu item.

LED STATUS INDICATORS

The Control Panel features eight colored LED indicators that identify the various operating conditions of

the inverter. Unless otherwise indicated, the LED’s will be "solid" in appearance, when illuminated.

LINE TIE (Yellow)

Selecting SELL from the GRID USAGE menu item under the INVERTER SET UP (9) menu heading will

enable sell mode. This should only be done with utility connected systems and after you have received the

approval of the local utility. This mode allows excess power to be sent into the utility grid.

INVERTING (Yellow)

The inverter is operational and AC output is available. If this LED is blinking, the inverter is in the search

mode and is looking for an AC load greater than the SET SEARCH WATTS setting.

Page

10

2001 Xantrex Technology, Inc.

5916 - 195th Street N. E.

Arlington, WA 98223

Telephone: 360/435-8826

Fax: 360/435-2229

www.traceengineering.com

Part No. 2031-5

Rev. C: February 2001

Page 19

CONTROLS, INDICATORS AND COMPONENTS

AC1 IN GOOD (Green)

Indicates that AC power is present at the AC HOT IN 1 and NEUTRAL IN 1 input terminals. T his input is

intended for utility power. When an AC sourc e is connected to the input term inals, it will s tart to blink slowly

(once a second) to show the AC voltage has been detected. After the inverter has connected to the AC

source, the LED will be solid. If the LED starts to blink during operation, utility power has been dropped.

AC2 IN GOOD (Green)

Indicates that AC power is present at the AC HOT IN 2 and NEUTRAL IN 2 input terminals. T his input is

intended for generator power. When an AC source is connected to the input ter minals, it will start to blink

slowly (once a second) to show the AC voltage has been detected. After the inverter has connected to the

AC source, the LED will be solid. If the LED starts to blink during operation, generator power may have been

dropped.

This LED will also blink slowly (once a second) when the automatic generator control system is enabled.

When the generator has star ted, it will continue to blink slowly until the generator has been connected. If the

generator does not successfully start, the AC 2 IN GOOD LED w ill stop blinking and the red ERROR LED will

turn on. The ERROR CAUSES (5) menu heading will indicate a GENERATOR SYNC ERROR condition.

BULK (Yellow)

This indicator will be on to indicate the inverter is in the Bulk or Absor ption char ge s tage. This indicator will

go off and the FLOAT indicator will illuminate when the battery voltage has been held near the SET BULK

VOLTS DC setting for the time period determined by the SET ABSORPTION TIME setting from the

BATTERY CHARGING (10) menu heading.

If the EQ mode is selec ted from the SET GENERATOR menu item under the GENERATOR MODE (2)

menu heading, the BULK LED will slowly blink while the charger completes the equalization process.

FLOAT (Green)

This indicator will be on when the battery voltage has reached the Float Stage of the charging proc ess. It

will now regulate the charging process to the SET FLOAT VOLTS DC setting from the BATTERY

CHARGING (10) menu heading. The SET FLOAT VOLTS DC setting provides a maintenance c harge to

the battery until another Bulk Charge Cycle is initiated or the AC sourc e is disconnected. If a generator is

manually controlled and powering the battery charger, the FLOAT indicator will com e on to indicate that

the generator should be turned off, since the battery is now fully charged.

This indicator is also used to indicate the r egulation setpoint when the inverter is operating as an Utility

Interactive Inverter (SELL mode). The indicator will blink s lowly to indicate the battery is regulated to the

SET BATTERY SELL VOLTS DC setting from the BATTERY SELLING (17) menu heading, and the

indicator will be “solid” to indicate the battery is regulated to the SET FLOAT VOLTS DC setting from the

BATTERY CHARGING (10) menu heading.

ERROR (Red)

Indicates that an operating error has occur red (refer to the ERRO R CAUSES (5) menu heading f or a list

of possible causes). T o reset the inverter, pres s the red ON/OFF MENU button and then select OFF and

then ON with the SET POINTS buttons or by pressing the red button several times.

This indicator will blink slowly to indicate that the AC source f requency is not well-adjusted (3 to 7 hertz

from nominal). You can use the LED blink to help adjust the AC source frequenc y. Once the frequency is

within 3 hertz of your nominal frequency, the LED will turn off.

OVERCURRENT (Red)

The load requirement has ex ceeded the inverter’s maximum output AC am ps. A sustained overcurrent

condition will require a manual reset by pressing the red ON/OFF MENU button and then selecting OFF

and then ON with the SET POINTS buttons or by pressing the red button several times. Momentary

flashing of the red OVERCURRENT indicator means that the inverter has reac hed it max imum output AC

amps and has automatically reset itself. This may occur during motor startups and is acceptable.

2001 Xantrex Technology, Inc.

5916 - 195th Street N. E.

Arlington, WA 98223

Telephone: 360/435-8826

Fax: 360/435-2229

www.traceengineering.com

SW Series Inverter/Charger

Part No. 2031-5

Rev. C: February 2001

Page

11

Page 20

CONTROLS, INDICATORS AND COMPONENTS

SW Series Inverter/Charger

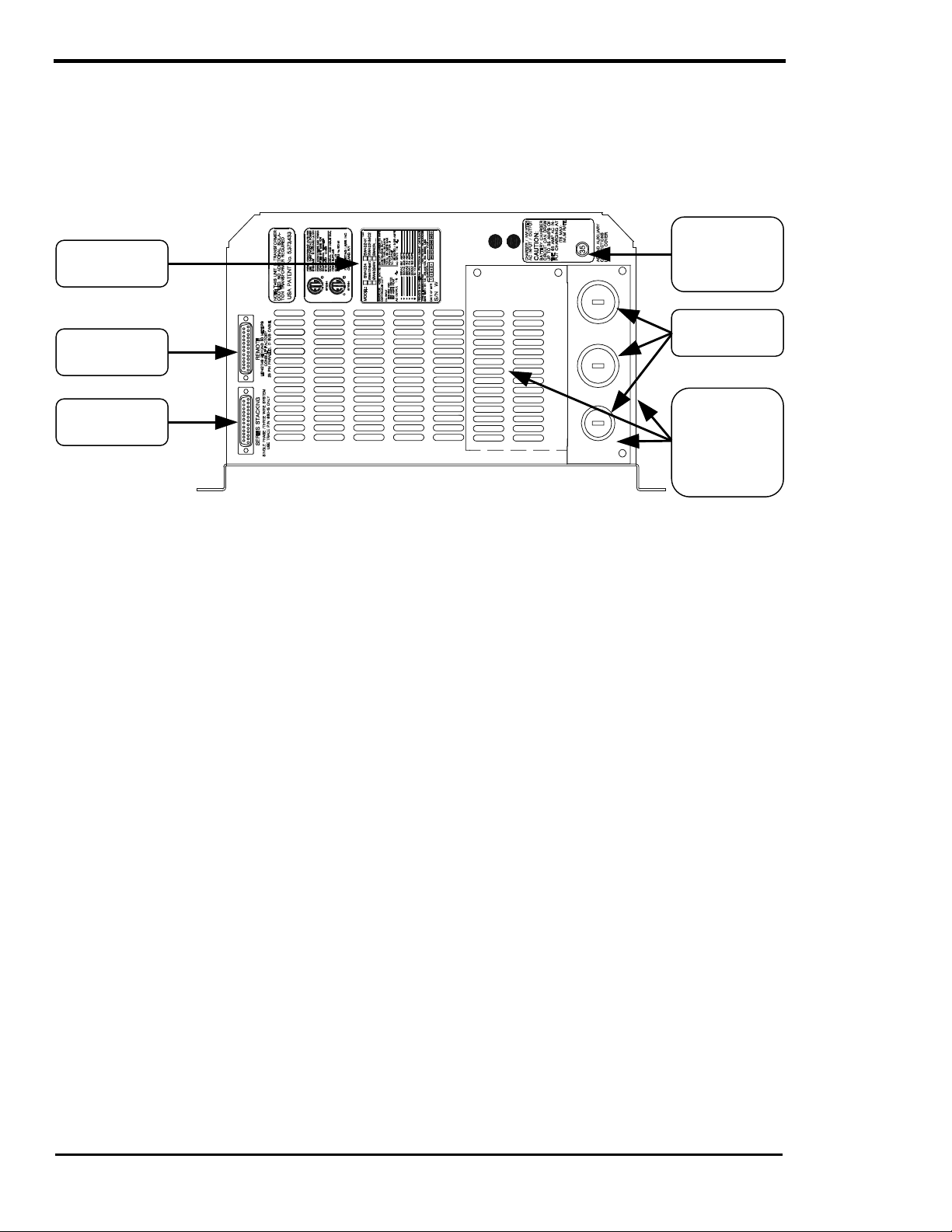

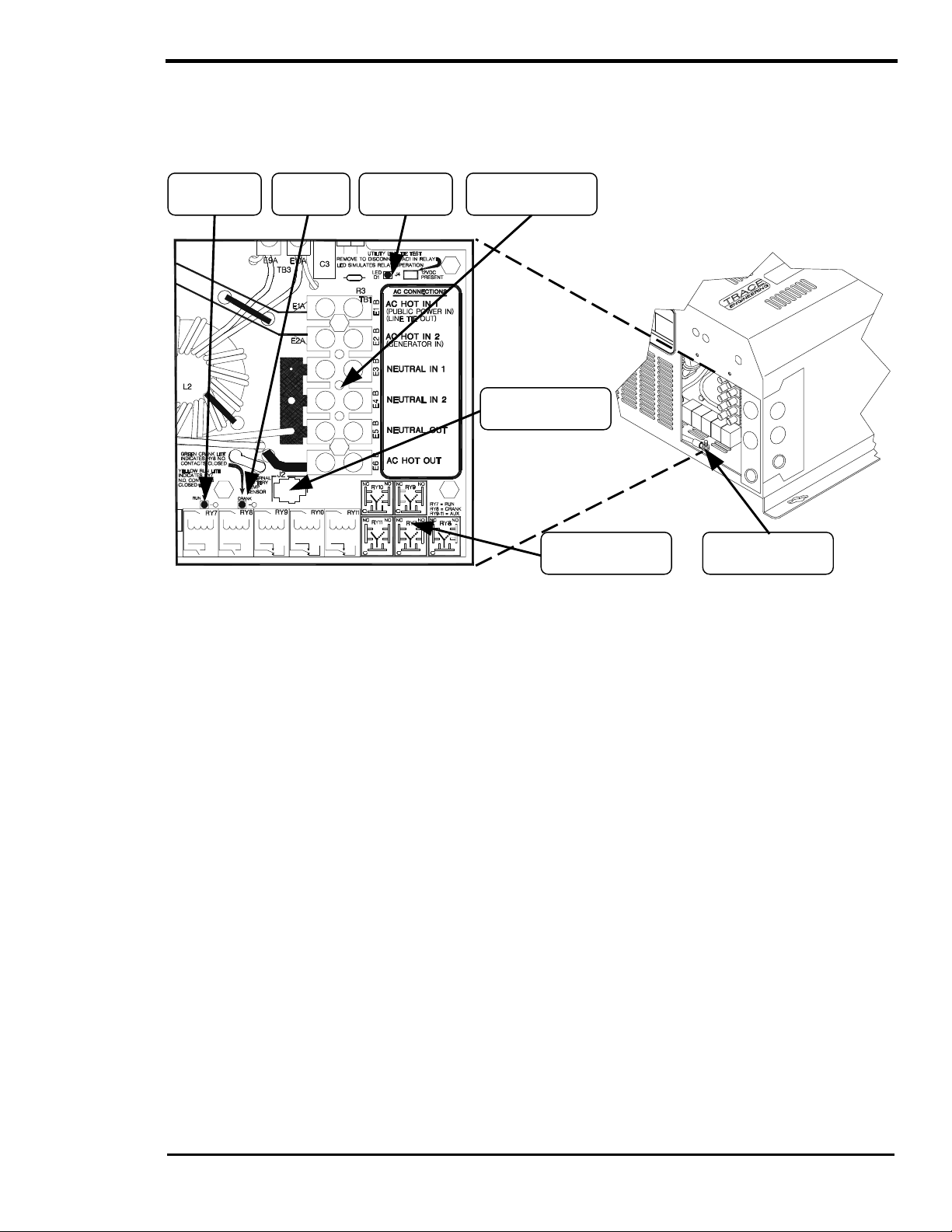

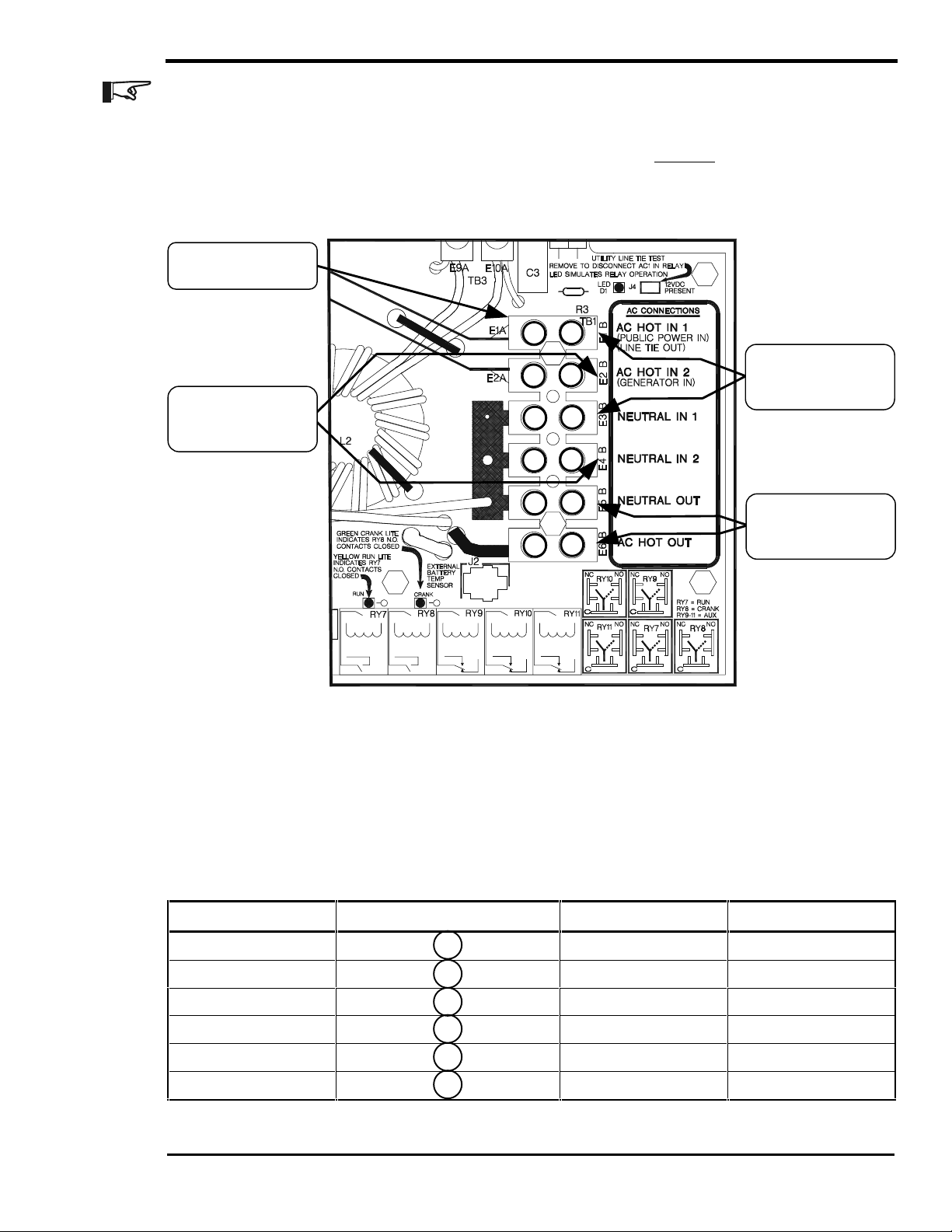

AC SIDE

Figure 4 shows the components located on the AC side of the inverter. T he rem ovable AC Acc ess Panels

cover and protect the Internal Components and Indicators, such as the AC Terminal Block, BTS

Connection, LED status indicators (for the AC1 and Gen Control relays) and the Aux and Gen Control

relay terminals. Refer to the INSTALLATION section beginning on page 15, for all wiring connections.

Inverter/

Identification

Label

Remote

Port

Charger

Circuit Breaker

Knockouts

(Also On Side}

Stacking

Port

Three

Removable

Access Panel

(One Panel on

Side)

Figure 4, AC Side

REMOTE PORT

The SW Series Inverter/Charger can be controlled remotely from the unit by plugging in a Sine wave

Remote Control (SWRC) or Sine wave Communications Adapter (SWCA).

The SWRC remote control is a full function, programmable remote control with backlit LCD which

duplicates the functions of the integral Control Panel.

The SWCA serial communications interf ace adapter allows for rem ote setup, adjustment, m onitoring and

troubleshooting of SW Series Inverter/Chargers from a personal computer and allows modem access

monitoring over long distances.

See the APPENDIX, OPTIONS section, starting on page 128, for a com plete description of the SW RC

Remote Control and SWCA Serial Communications Adapter.

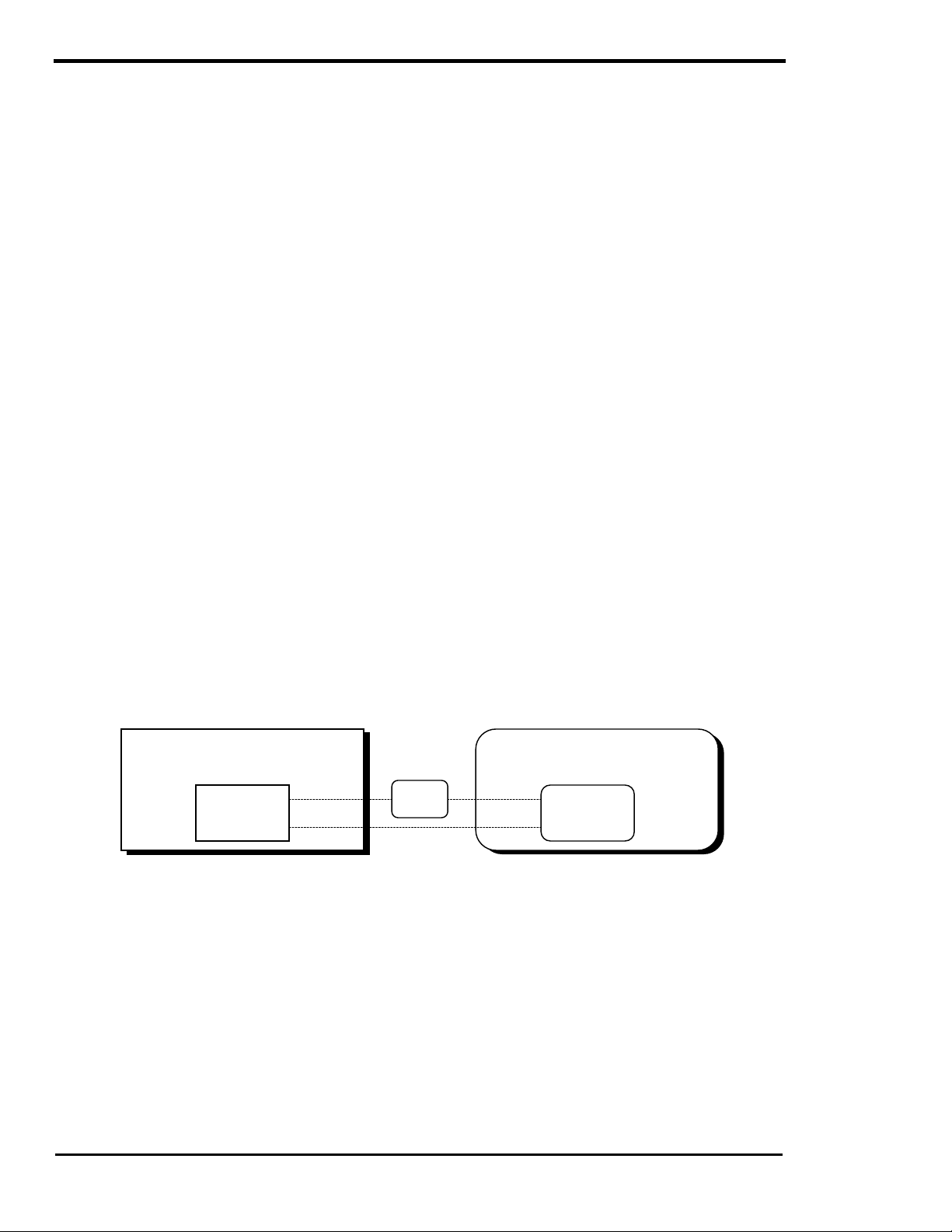

STACKING PORT

The stacking port allows multiple SW Series Inverter/Chargers to be used in the same system. The

inverters can be used in a “SERIES” configuration to operate 240 Vac loads and to connect to

120/240 Vac power systems. A series stacking interface cable (SWI) is required to connect the series

stacking ports of the inverters. This port is als o used to c onnect two units in a “PARALLEL” configur ation.

The parallel stacking inter face cable (SWI/PAR) allows two inverters to be connected to provide twice the

continuous and surge capability at the same AC voltage. See the U SING MULTIPLE INVER TERS section

on page 95 for more information.

INVERTER/CHARGER CIRCUIT BREAKER

This circuit break er protects the unit’s internal wiring while the unit is inverting or charging. It is not used

for the pass-through current. This is not a branch-circuit rated breaker, separate output breakers are

required. Press the breaker to reset (to reset on 48-volt units, move the breaker handle to the ON

position).

Page

12

2001 Xantrex Technology, Inc.

5916 - 195th Street N. E.

Arlington, WA 98223

Telephone: 360/435-8826

Fax: 360/435-2229

www.traceengineering.com

Part No. 2031-5

Rev. C: February 2001

Page 21

CONTROLS, INDICATORS AND COMPONENTS

INTERNAL COMPONENTS AND INDICATORS

Additional components and indicators ar e located behind three removable AC Access Panels located on

the AC Side of the unit. They include the AC Terminal Block , BTS Connector, three LED indicators and

the Aux and Gen Control Relay Connectors.

RY7 (Yellow)

LED

RY8 (Green)

LED

AC1 Relay

(Red) LED

Figure 5, Internal Components and Indicators

LED INDICATORS

AC

Terminal Block

BTS

Connector

Aux and Gen Control

Relay Connectors

AC

Safety Ground

Three LED indicators allow visual indication of operation of the RY7, RY8 and AC1 relays.

RY7 (Yellow) LED

Allows visual indication of relay RY7 operation. During the automatic generator control sequence, the

LED will be on to show that RY7 is closed (engaged) from the N.O. to the COM contacts, and will be

off when RY7 is opened (disengaged).

RY8 (Green) LED

Allows visual indication of relay RY8 operation. Dur ing the automatic generator control sequenc e, the

LED will be on to show that RY8 is closed (engaged) from the N.O. to the COM contacts, and will be

off when RY8 is opened (disengaged).

AC1 RELAY (Red) LED

Allows visual indication of AC1 relay operation. The LED will be on when the AC1 relay is closed

(engaged). This LED along with the test-jumper adjacent to the LED is used by utilities to perform

voltage and frequency tests to qualify the SW Series Inverter/Charger for line-tie applications.

BTS PORT

The battery temperature sensor (BTS) can be connected (plugged in) at the RJ-11 four-conductor

connector, located on the AC Circuit Board. T he BTS provides information that enables the three-stage

standby battery charger to “fine tune” the battery charge voltages for better charging per form anc e, greater

efficiency and longer battery life.

AC TERMINAL BLOCK

A six position terminal block is provided to m ak e the AC connec tions. T he term inal block is located on the

AC Circuit Board. The terminal block is used to hardwire all AC input and output connections.

2001 Xantrex Technology, Inc.

5916 - 195th Street N. E.

Arlington, WA 98223

Telephone: 360/435-8826

Fax: 360/435-2229

www.traceengineering.com

SW Series Inverter/Charger

Part No. 2031-5

Rev. C: February 2001

Page

13

Page 22

CONTROLS, INDICATORS AND COMPONENTS

SW Series Inverter/Charger

AC SAFETY GROUND

The AC Safety Ground is used to connect the inverter chassis to the AC Grounding System.

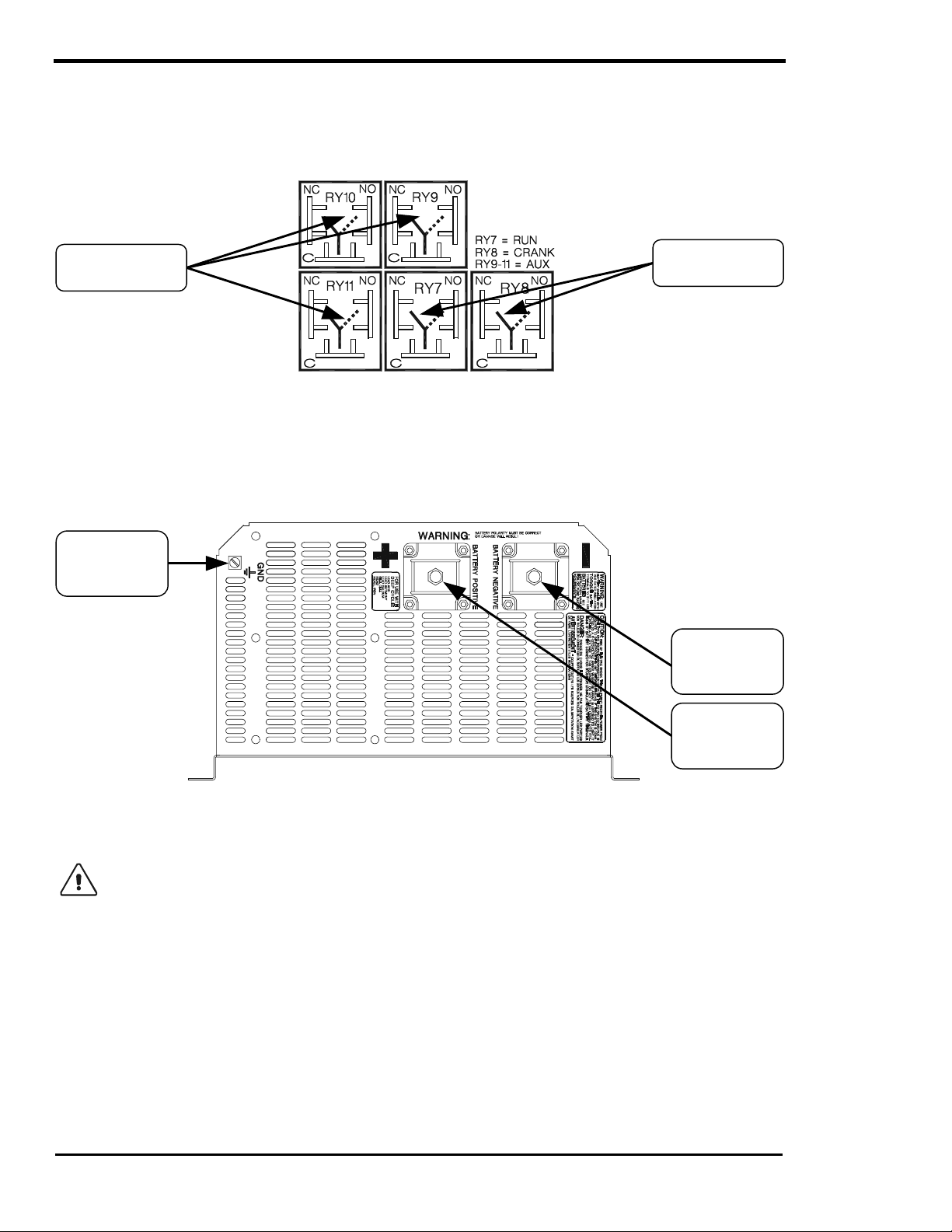

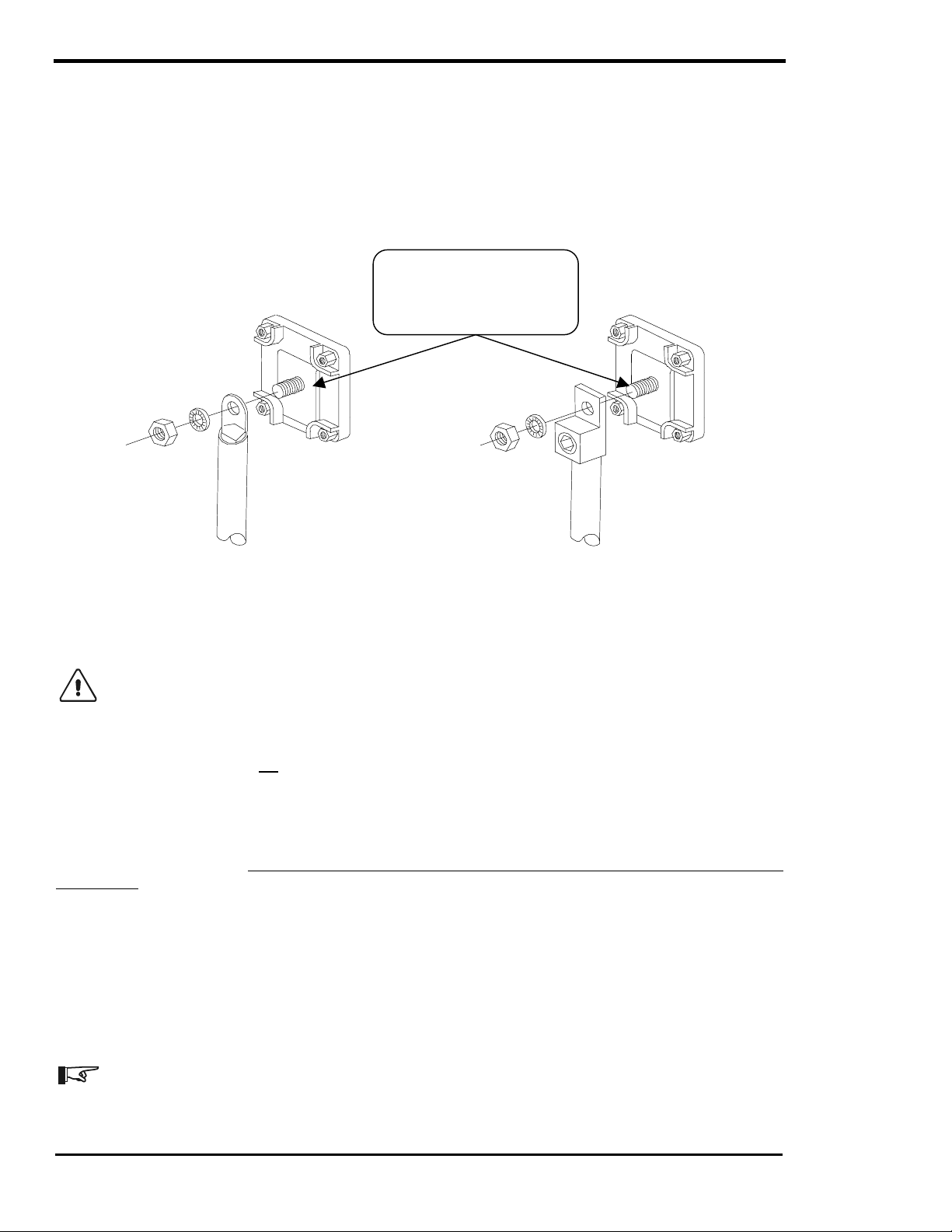

AUXILIARY AND GENERATOR CONTROL RELAY CONNECTORS

Auxiliary Control

Relay Connectors

Generator Control

Relay Connectors

Figure 6, Auxiliary and Generator Control Relay Connectors

DC SIDE

Figure 5 shows the components located on the DC side of the inverter. Refer to the INSTALLATION

section for the battery wiring connections to the Battery Terminals and the DC Ground.

DC

(Equipment)

Ground

Battery

Terminal

(-)

Battery

Terminal

(+)

Figure 7, DC Side

BATTERY TERMINALS

Caution: Before connecting the battery cables to the inverter, ver ify the correct battery voltage

and cable polarity using a voltmeter. The inverter is not reverse polarity protected. If the

positive terminal of the battery is co nnected to the negative terminal of the inverter and

vice versa, severe damage will result. If necessary, color- code the cables with colored tape or

heat shrink tubing: RED for positive (+); BLACK for negative (-) to avoid polarity problems.

DC (EQUIPMENT) GROUND

This connection is used to connect the exposed chassis of the inverter to the DC grounding system. The

terminal accepts wires from #14 AWG to #2 AWG.

Page

14

2001 Xantrex Technology, Inc.

5916 - 195th Street N. E.

Arlington, WA 98223

Telephone: 360/435-8826

Fax: 360/435-2229

www.traceengineering.com

Part No. 2031-5

Rev. C: February 2001

Page 23

INSTALLATION

INSTALLATION

This section is very important, since it tells you how to properly install your SW Series Inverter/Charger.

It becomes very frustrating when your inverter system does not perform properly, simply because car e

was not taken during installation. Please read this entir e section carefully. You will save time and avoid

common mistakes.

This section also describes the requirements and recommendations for installing the SW Series

Inverter/Charger. In the U.S., the National Electrical Code (NEC) def ines the standards for both the AC

and DC wiring in residential, commerc ial and RV applications. It will list the requirement for wire sizes,

overcurrent protection and installation m ethods and r equirem ents. T here ar e still m any other variables not

covered by the NEC. Most are determined by the level of automatic operation, the am ount of external AC

and DC power to be controlled and the loads to be operated.

The NEC standards and regulations are described here in general for your convenience, and are not

represented as comprehensive or complete. For comprehensive and complete official standards and

regulations, write the address listed below:

NFPA - National Fire Protection Association

National Electrical Code Handbook

1 Batterymarch Park,

PO Box 9101

Quincy, MA 02269-9101

617-770-3000.

Before beginning the installation of the SW Series Inverter/Charger , read all instructions. Disconnect all

sources of AC and DC power to prevent accidental shoc k. Disable and sec ure all AC and DC disconnec t

devices and automatic generator starting devices.

All installations should meet all local codes and standards and be performed by qualified

personnel such as a licensed electrician. Although the DC electrical system may be “low voltage”,

significant hazards may be present, particularly from s hort circuits of the battery system. Inver ter systems

by their nature involve power from multiple sour ces (inverter, gener ator, utility, batteries, solar arr ays etc.)

that add hazards and complexity that can be very challenging.

After you have finished installing your unit, continue with the FUNCTIONAL TEST section on page 31.

This Functional Tes t should be completed prior to configuring your unit’s Menu System for your specific

operation.

2001 Xantrex Technology, Inc.

5916 - 195th Street N. E.

Arlington, WA 98223

Telephone: 360/435-8826

Fax: 360/435-2229

www.traceengineering.com

SW Series Inverter/Charger

Part No. 2031-5

Rev. C: February 2001

Page

15

Page 24

INSTALLATION

SW Series Inverter/Charger

QUICK INSTALL

This section provides ins tallers, licensed electrical contractors, and k nowledgeable laymen the essential

steps to quickly install the Trace™ SW Series Inverter/Charger. If you haven’t had experience with the SW

Series Inverter/Charger, you are urged to skip this s ection and read the entire INSTALLATION section

before installing the inverter/charger.

MOUNTING

Mount the unit securely in a clean, dry, properly ventilated enclosure. Do not mount the unit in the sam e

enclosure as vented or maintenance-free type vented batteries. Bolt the unit securely. Allow adequate

clearance to allow access to the indicators or controls.

DC CABLING

1. Connect an appropriate sized cable from the positive batter term inal (or batter y bank) to the inverter’s

positive (red) terminal. See T able 12 in the Appendix to determ ine the proper size c able and length of

run needed to use with your inverter model and for your specific application. The National Electric

Code (NEC) requires the use of a DC fuse or disconnect with this cable. See Table 12 in the Appendix

to determine the correct fuse or breaker to use.

2. Connect an appropriate sized cable from the negative battery terminal to the negative (black ) inverter

terminal. Torque all term inals to 10-15 foot-pounds. NOT E: A 'snap' caused by charging the internal

capacitors may occur when first connecting the cable. This can be avoided by first removing the DC

fuse or opening the disconnect in the positive battery cable.

3. Connect a cable from the inverter’s DC Chassis Ground to the system ground.

AC IN CABLING

1. See Table 13 in the Appendix to determine the appropriate AC wire size.

2. Remove the knock out from the inverter chas sis and install a strain relief or conduit in which to route

the AC cabling in and out.

3. Connect the black wire from the hot side of the AC power to the terminal labeled AC HOT IN 1 (AC

HOT IN 2 if a generator is the AC source) on the inverter.

4. Connect the white wire from the neutral side of the AC power source to the terminal labeled

NEUTRAL IN 1 (NEUTRAL IN 2 if a generator is the AC source) on the inverter.

5. Connect the green wire from the ground of the AC power source to the AC Ground Terminal of the

inverter/charger.

AC OUT CABLING

1. Connect the black wire between the terminal m arked AC HOT OUT to the hot bus of your AC load

center or AC sub-panel.

2. Connect the white wire from the term inal marked NEUTRAL OUT to the neutral bus of your AC load

center or sub-panel.

3. Connect the AC Ground Terminal of the inverter to the safety ground bus of the AC load center or

sub-panel.

WRAP UP

1. Secure all wiring with wire ties or other non-conductive fasteners to pr event chafing or damage. Use

strain-reliefs, grommets, or conduits to prevent dam age to the wiring where it passes through any

apertures. Tighten all connections to the correct torque (AC Connections at 20 inch-pounds; DC

Connections at 10-15 foot-pounds).

2. Make a final check of all wiring, then reconnect to the AC power source.

3. Turn the inverter ON and check inverter operation (See the FUNCTIONAL TEST section on page 31).

Page

16

2001 Xantrex Technology, Inc.

5916 - 195th Street N. E.

Arlington, WA 98223

Telephone: 360/435-8826

Fax: 360/435-2229

www.traceengineering.com

Part No. 2031-5

Rev. C: February 2001

Page 25

INSTALLATION

COMPLETE INSTALL

UNPACKING

Before beginning, unpack the inverter/charger; record the

serial number on the inside cover of this booklet and on the

warranty card. Right now, please do the following:

• Verify that you have everything listed on the Packaging

Materials sheet. If any items are missing, please call

Customer Service at (360) 435-8826.

• Save your “proof-of-purchase”, You will need the “proof-of-

purchase” to obtain warranty service.

• Keep the original carton and packing materials. If you

need to return your inverter for service, you should ship it

in the original carton. It is also the best way to keep the

inverter safe if it needs to be moved.

LOCATION

Inverters are sophisticated electronic devices and should be treated ac cordingly. Treat the inverter as you

would any fine piece of electronic equipment. W hen selec ting the location for the inverter , don't think of it

in the same terms as the other interf acing equipm ent, e.g. batter ies, diesel generators, motor generators,

washing machines etc. It is a highly com plex micropr ocessor c ontrolled device. There ar e nearly 500,000

silicon junctions in its output devices and integrated circuits. The crystal oscillator runs at 4 megahertz.

The drive circuitry timing is acc urate to a thousandth of a second. Genetically speaking, it is a cous in to

stereo equipment, television sets or computer s. T he us e of c onf ormal-coated circuit boards, plated c opper

bus bars, powder coated metal components , and stainless steel fasteners impr oves tolerance to hostile

environments. However, in a corrosive or condensing environment (one in which humidity and/or

temperature change cause water to f orm on com ponents) all the ingredients for electrolysis are pres ent water, electricity and metals. In a corrosive or condensing environment, the life expectancy of the

inverter is indeterminate and the warranty is voided.

Caution: Install the inverter in a dry, protected loc ation away from sources of high temperature

and moisture. Exposure to saltwater is particularly destructive and potentially hazardous.

Locate the inverter as close to the batteries as pos sible in order to keep the battery cable length short.

Do not locate the inverter direc tly above the batteries or in the same compartment as vented batteries.

Batteries generate hydrogen sulfide gas, which is very corrosive to electronic equipm ent and everything

else. They also generate hydrogen and oxygen. If these gases accumulate, an arc caused by the

connecting of battery cables or the switching of a relay could ignite the mix ture. Mounting the inverter in a

ventilated enclosure with sealed batteries is acceptable.

Ensure the inverter is located in an area that prevents insects and rodents from entering the inverter , as

the inverter can provide a warm habitat in a cold environment. This m a y involve installing the inverter in an

enclosure and include mesh screens or nets over any openings to ensure the unit is kept well ventilated.

This inverter can create RFI (Radio Frequency Interference). Keep this in mind when determining the

placement of the inverter. You should locate the inverter as far away as possible from any electronic

devices that may be susceptible to RFI.

MOUNTING

UL Standard 1741 (draft) requires that the inverter be m ounted on a vertical surfac e (on a wall) and that

the keyhole slots not be used as the only method of mounting. The purpose of the wall mounting

requirement is to orient the inverter so that its bottom c over, which has no holes, will not allow burning

material to be ejected in case of an internal fire.

2001 Xantrex Technology, Inc.

5916 - 195th Street N. E.

Arlington, WA 98223

Telephone: 360/435-8826

Fax: 360/435-2229

www.traceengineering.com

SW Series Inverter/Charger

Part No. 2031-5

Rev. C: February 2001

Page

17

Page 26

INSTALLATION

SW Series Inverter/Charger

Use 1/4" minimum diameter bolts for mounting. The m ounting must be capable of supporting twice the

weight of the inverter in order to com ply with UL 1741. If this unit is used in a mobile applic ation (i.e. RV,

Boat) secure the inverter to a shelf or deck to prevent m ovem ent. Place flexible washer s on the m ounting

screws or bolts between the shelf or deck and the inverter chassis to reduce vibration.

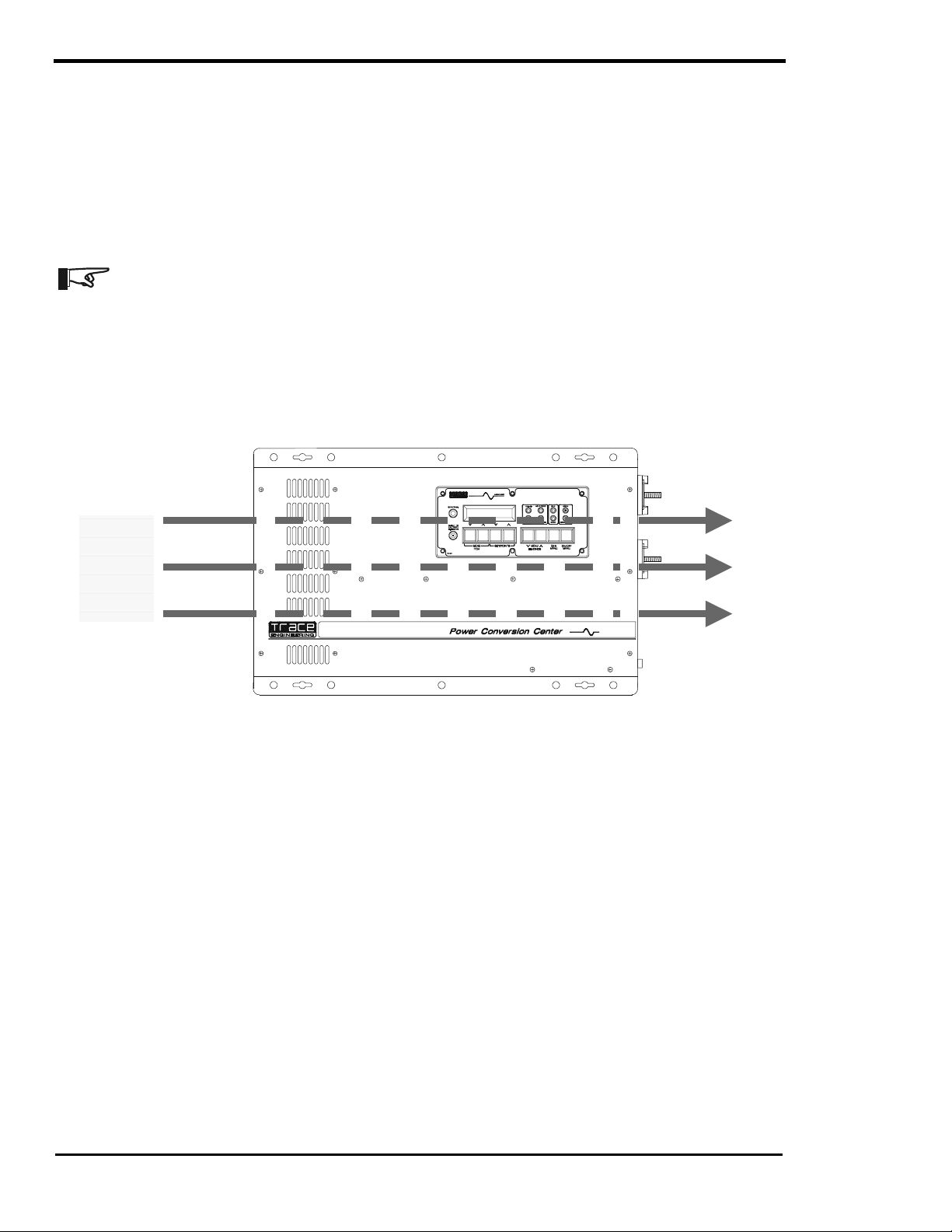

VENTILATION

Installation of the inverter in a properly ventilated enclosure is neces sary for eff icient operation of the unit.

The inverter’s thermal shutdown point will be reached sooner than normal in a poorly ventilated

environment and will result in a lower peak power output, reduced surge capability, and potentially shorter

inverter life.

Note: Do not operate the inverter in a closed-in area or restrict ventilation in any way.

Testing has shown that the volume of the enclosure is not as important as the overall ventilation. A

minimum airspace clearance of 1½ inches around the top and bottom and 3 inches of c learanc e at the lef t

and right sides of the inverter will provide adequate ventilation. Because the top and bottom of the SW

Series chassis is not vented, clearanc e between the enclosure and the top of the inverter is not critical. A

fresh air intake port s hould be provided directly to the left side and an exhaust port on the right side will

allow cool outside air to flow through the inverter and back out of the enclosure.

Top

Left

(AC Side)

Right

(DC Side)

AIR

FLOW

Bottom

Figure 8, Air Flow Intake Location

AC WIRING

This section describes AC wiring requirements and recommendations; including AC connections; wire

sizing; overcurrent devices; GFCIs; external r elays; hookup procedure; and neutral-to-ground switching.

Your local electrical code and the National Electrical Code (NEC) def ine the standards for AC ins tallation

wiring, but there are still many installation variables to be considered. Consult the local code and the NEC

for the proper wire sizes, connectors and conduit. All installations should meet all local codes and

standards and be performed by qualifie d personnel such as a licensed electrician.

AC INPUT AND OUTPUT CONNECTIONS

A six position terminal block is provided to m ak e the AC connec tions. T he term inal block is located on the

left-hand side of the inverter, enclosed under a cover plate (See INTERNAL COMPONENTS AND

INDICATORS on page 13 for location.). The term inal block can accept up to # 6 AWG str anded wire and

is used to hardwire all AC connections. For 120 VAC inverters, we recom mend 6 AWG (THHN) wire for

full utilization of the inverter’s 60 amp AC pass through capability. The code requires that disconnect

switches be provided in the AC input and output wiring circuits. AC circuit breaker s in an AC load center

can be used to meet this requirem ent. The wiring both in and out of the inverter mus t also be protected

from short circuits and overloads by a fuse or circuit breaker. Typically, a 60 amp circuit breaker will

protect #6 AWG wiring. Consult your local code for more information and for other wire sizes.

Page

18

2001 Xantrex Technology, Inc.

5916 - 195th Street N. E.

Arlington, WA 98223

Telephone: 360/435-8826

Fax: 360/435-2229

www.traceengineering.com

Part No. 2031-5

Rev. C: February 2001

Page 27

INSTALLATION

Note: The three neutral terminals are common to each other and can be used in any combination or

order. In a residential application, it is often easier to only connect one AC neutral wire to the inverter and

make the other neutral connections at a central point such as in the AC load center, etc. In mobile

installations, the AC system must have the neutral physically isolated from the gr ound throughout the load

distribution powered by the inverter. The SW Series Inverter/Charger does not include neutral to ground

switching for the AC electrical system. This must be done externally from the inverter. See the NEUTRAL-

TO-GROUND BOND SWITCHING (RV AND MARINE APPLICATIONS) section on page 27 for more

information.

AC Terminal Block

(TB1)

1b

1a

AC IN 1

2b

AC IN 2

From

Generator Power

2a

3a

4a

3b

4b

From

Utility Power

5b

5a

AC OUT

To

6a

6b

AC Loads

Figure 9, AC Input/Output Power Connection

Before making any AC connections, make sure that the inverter is disconnected from the battery (or

battery bank). Feed the wires through conduit fittings located on the left s ide or left bottom side of the

inverter. (Note: Conduit fittings must be purchased separately and are required by code to comply with

residential and commercial installations).

The AC wiring both in and out of the inverter must also be protected from short circuits and overloads by a fuse

or circuit breaker. Consult the NEC or your local code for more information and for other wire sizes. Table 13 on

page 132 gives suggestions for wire sizing. Follow the wiring guide on the circuit board inside the cover plate

(see Figure 9, above). Connect the AC wiring as follows (from front to back when wall mounted):

Table 1, AC Input and Output Wiring Connections

AC CONNECTIONS AC TERMINAL BLOCK # WIRE COLOR PURPOSE

AC HOT IN 1 1b Black (Hot) Utility Power

NEUTRAL IN 1 3b White (Neutral) Utility Power

AC HOT IN 2 2b Black (Hot) Generator

NEUTRAL IN 2 4b White (Neutral) Generator

AC HOT OUT 6b Black or Red (Hot) AC Loads

NEUTRAL OUT 5b White (Neutral) AC Loads

2001 Xantrex Technology, Inc.

5916 - 195th Street N. E.

Arlington, WA 98223

Telephone: 360/435-8826

Fax: 360/435-2229

www.traceengineering.com

SW Series Inverter/Charger

Part No. 2031-5

Rev. C: February 2001

Page

19

Page 28

INSTALLATION

SW Series Inverter/Charger

AC INSTALLATION GUIDELINES

The following steps are a basic guideline f or installation and connection of the AC wiring into and out of

the inverter.

1. Disconnect the inverter from the battery bank (if already connected), by either removing the DC s ide

fuse, or opening the DC disconnect. Then r emove the AC wiring com partm ent cover from the front of

the inverter by removing the two screws on the cover.

2. If conduit will be utilized (consult code, it may be required in your installation), determine which

knockout(s) will be utilized and remove them f rom the inver ter. Using appropriate c onduit connector s,

fasten the conduit to the inverter. Feed all AC wiring through the conduit and into the inverter AC

terminal block. Be s ure to leave yourself sever al ex tra inc hes of wire to work with. Rem ember that you

need at least two sets of three conductor wiring, one for AC Hot, Neutral, and Ground into the inverter,

and another for AC Hot, Neutral and Ground out of the inverter to the loads. Torque all AC term inals

to 10 to 15 inch-pounds.

3. Connect the Hot (black) and Neutral (white) wires from the AC source(s) to the appropriately labeled

terminals in the AC term inal block. The Safety Ground (green) should be connected to the terminal

stud labeled “AC Ground” bolted to the chassis. Repeat the procedure for the AC wiring going to the

AC sub-panel which will power the loads, except connect these wires to the terminals labeled AC HOT

OUT.

4. Ins pect all wiring for proper installation and then replace the access c over using the two screws to

secure it.

IMPORTANT PRECAUTION

The AC output of the inverter must at no time be connected directly to utility power or a generator.

This condition can be far wors e than a short circ uit. If the inverter survives this c ondition, it will s hut down

until corrections are made. Connection to a utility or generator must be only done internally by the

inverters built-in relays. This allows the inverter to f irst synchronize to the other AC sourc es waveform,

preventing damage. Connect the utility or generator to the provided input terminals AC HO T IN 1 or AC

HOT IN 2 respectively.

When the inverter output is connected directly to an external source, the inverter will shut down and

indicate an error on the control panel. Checking the ERROR CAUSES menu heading will show a YES for

the AC SOURCE WIRED TO OUTPUT menu item. Either determine the source of the AC or call a

qualified electrician to correct the situation.

EXTERNAL TRAN SFER RELAYS

It is not acceptable to switch the AC input from one AC source to another while the inverter is

connected. This applies whether the inverter is in battery charging mode or inverter mode. Switching the

AC input from one source to another can result in a loss of synchronization that can cause a severe

overcurrent condition that is far worse than short circuiting the inverter. Two separate AC inputs are

provided to eliminate the need for use of external transfer r elays. If a transfer relay is used, it must provide

a center “OFF” position (“break before make”) that causes a los s of input power to the inverter f or a period

of at least 100 milliseconds. This will allow the inverter to disconnect from the original AC input and then

re-synchronize to the new AC source although the same AC input terminal is being used. During the

transition period, the inverter will have to operate the load while it re-synchronizes to the new AC sour ce

(about a thirty-second period at the minimum). Most tr ansfer relays will switch too fast for the inverter to

detect - and will cause the inverter to lose synchronization with the AC source. This is indicated by the

inverter shutting down upon transfer and the red overcurrent LED indicator flashing or turning on.

Manually, hand operated transfer switches may be acceptable since the transfer time c an be slow enough

for the inverter to detect. The switch must go through a center “off” position. They are often used to switch

from one generator to another. Since the inverter has a separate AC input for a utility grid, a transfer

switch is not required to switch from the utility grid to a back-up generator. The inverter will not allow the

generator to be connected to the utility - if both are available, the generator will be disc onnected and the

inverter will connect to the utility on AC HOT IN 1.

Page

20

2001 Xantrex Technology, Inc.

5916 - 195th Street N. E.

Arlington, WA 98223

Telephone: 360/435-8826

Fax: 360/435-2229

www.traceengineering.com

Part No. 2031-5

Rev. C: February 2001

Page 29

INSTALLATION

120 VAC GROUND FAULT INTERRUPT OUTLETS (GFI’S)

Xantrex has tested the following 120 VAC GFI’s and found them to work satisfactorily with our inverters:

LEVITON 6599

PASS & SEYMOR 1591 4A957

ACE Hardware ACE 33238

WARNING LA BEL

A warning label is provided to inform all per sonnel that an inverter is installed in your electrical system.

This label should be installed at the electric al panel that is being powered by the inverter. Be cautious until

the inverter is disconnected from your electrical system.

!

Figure 10, Warning Label

2001 Xantrex Technology, Inc.