Page 1

Xantrex

Sun Tie XR

STXR1500

STXR2500

Installation and Operation Guide

Page 2

Sun Tie XR

Installation and Operation Guide

Page 3

About Xantrex

Xantrex Technology Inc. is a world-leading supplier of advanced power electronics and controls with products from

50 watt mobile units to one MW utility-scale systems for wind, solar, batteries, fuel cells, microturbines, and backup

power applications in both grid-connected and stand-alone systems. Xantrex products include inverters, battery

chargers, programmable power supplies, and variable speed drives that convert, supply, control, clean, and distribute

electrical power.

Trademarks

Xantrex is a registered trademark of Xantrex International.

Other trademarks, registered trademarks, and product names are the property of their respective owners and are used

herein for identification purposes only.

Notice of Copyright

Sun Tie XR Installation and Operation Guide © February 2003 Xantrex International. All rights reserved.

Disclaimer

UNLESS SPECIFICALLY AGREED TO IN WRITING, XANTREX TECHNOLOGY INC. (“XANTREX”)

(a) MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY OF ANY

TECHNICAL OR OTHER INFORMATION PROVIDED IN ITS MANUALS OR OTHER DOCUMENTATION.

(b) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSS OR DAMAGE, WHETHER DIRECT,

INDIRECT, CONSEQUENTIAL OR INCIDENTAL, WHICH MIGHT ARISE OUT OF THE USE OF SUCH

INFORMATION. THE USE OF ANY SUCH INFORMATION WILL BE ENTIRELY AT THE USER’S RISK.

Date and Revision

February 2003, Revision 1

Part Number

975-0053-01-01

Contact Information

Telephone: 360.435.8826

Fax: 360.925.5143

Email: CustomerService@xantrex.com

Web: www.xantrex.com

Page 4

About This Guide

Purpose

The Sun Tie XR Installation and Operation Guide contains information for a qualified

installer and authorized service person to install, operate and troubleshoot the Xantrex

Sun Tie XR.

Scope

The guide provides safety guidelines, installation, operation, troubleshooting, and

warranty information for the Sun Tie XR.

The guide does not provide detailed information about solar (photovoltaic or “PV”)

arrays or requirements for connecting to the utility power grid. You will need to

consult the PV array manufacturer’s guide and your local electrical utility for this

information.

Page 5

About This Guide

Organization

This guide is organized into four chapters and two appendixes:

Chapter 1, “Introduction”, outlines the main performance and safety

features of the Sun Tie XR. Reading this chapter will give you a clear

understanding of the inverter’s capabilities.

Chapter 2, “Installation”, provides information about planning for and

performing a Sun Tie XR installation.

Chapter 3, “Operation”, provides procedures for starting up the inverter

and operating the unit. It explains how to read the front panel display to

monitor the Sun Tie XR’s operation.

Chapter 4, “Troubleshooting”, for authorized service personnel only,

explains how to identify and solve problems that can occur with the

Sun Tie XR.

Appendix A, “Specifications”, provides the electrical, mechanical and

physical specifications of the Sun Tie XR.

Appendix B, “Warranty and Product Information”, contains the product’s

warranty. The appendix also explains how to return a product for service,

and to prepare for a call to Xantrex Customer Service.

Conventions Used

To reduce the risk of electrical shock and to ensure the safe installation

and operation of this product, the following safety symbols have been

placed throughout this manual to indicate dangerous conditions and

important safety instructions.

WARNING

Warnings identify conditions that could result in personal

injury or loss of life.

CAUTION

Cautions identify conditions or practices that could result in

damage to the Sun Tie XR or to other equipment.

ii 975-0053-01-01

Page 6

Note: Notes describe additional information which may add to your

understanding of how to install or use the Sun Tie XR.

Related Information

You can find more information about Xantrex Technology Inc. and its

products and services at www.xantrex.com

About This Guide

975-0053-01-01 iii

iv 975-0053-01-01

Page 7

Page 8

Contents

1

Introduction

About the Sun Tie XR- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–2

Standard Features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–3

Accessories - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–3

2

Installation

Installation Planning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–2

Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–2

Tools required - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–2

Hardware and materials required - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–2

Locating the Sun Tie XR - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–3

Routing the wires - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–3

Planning AC Connections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–4

Recommended wire sizes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–4

AC circuit breaker requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–5

Planning DC Connections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–5

Grounding Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–6

PV Array Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–7

Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–9

Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–9

Mounting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–9

Connecting DC Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–15

Connecting AC Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–16

Grounding the System - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–18

Connecting Inverters in Parallel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–21

Installing the Optional Remote Monitor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–22

3

Operation

Startup Procedure- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–2

Required Equipment - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–2

Checking the PV Array DC Voltage - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–2

Checking the AC Utility Voltage - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–3

Starting up the Sun Tie XR - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–4

Monitoring the Front Panel Display - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–5

Reading the Front Panel Display - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–6

Status Indicator Lights - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–7

Reassembling the Sun Tie XR - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–8

Page 9

Contents

Factors Affecting Sun Tie XR Performance- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–10

PV Array Factors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–10

Other Factors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–11

4

Troubleshooting

Troubleshooting the Sun Tie XR - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–2

Viewing the Status LEDs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–2

Troubleshooting Reference Table - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–5

A

Specifications

Electrical Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–2

Mechanical Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–3

Standard Features and Options - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–4

Efficiency Curve - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–5

Temperature Derating Curve- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–6

B

Warranty and Product Information

Limited Warranty - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–2

Return Material Authorization Policy - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–5

Return Procedure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–5

Information About Your System - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–6

vi 975-0053-01-01

Page 10

Important Safety Instructions

WARNING: SAVE THESE INSTRUCTIONS

This manual contains important safety instructions that should

be followed during the installation and maintenance of this

product. Specific safety instructions for installation, operation,

and troubleshooting are in their respective sections. Read and

keep this manual for future reference.

DANGER: SHOCK HAZARD

Do not remove the upper cover. Removing the upper cover should

be performed only by authorized service personnel. If you suspect

your unit is not functioning correctly, call Xantrex.

For safe installation and operation:

• All electrical work must be done in accordance with local and national electrical

codes.

• Before installing or using this device, read all instructions and cautionary markings

located in the manual, on the Sun Tie XR and on the PV array.

Page 11

Important Safety Instructions

• Do not expose this unit to rain, snow or liquids of any type without

• To reduce the chance of short circuits when installing or working with

• Remove all jewelry such as rings, bracelets, wristwatches and

• The Sun Tie XR contains more than one live circuit (the PV array and

• This product contains no user-serviceable parts. Return the unit to

• Wiring to the utility should only be done after receiving prior

• Completely cover the surface of all PV arrays with an opaque (dark)

the Rain Shield installed. The Rain Shield does not, however, make

the Sun Tie XR waterproof.

the inverter or the PV array, use insulated tools.

necklaces prior to installing this system. This will greatly reduce the

chance of accidental exposure to live circuits.

the AC line). Power may be present at more than one source even

when the circuit breakers are off.

Xantrex for maintenance.

approval from the utility company and performed only by a qualified

electrician.

material before wiring them. PV arrays produce electrical energy

when exposed to light and could create a hazardous condition.

viii 975-0053-01-01

Page 12

Introduction

Chapter 1, “Introduction”, describes the standard features and

accessories for the Sun Tie XR.

Page 13

Introduction

About the Sun Tie XR

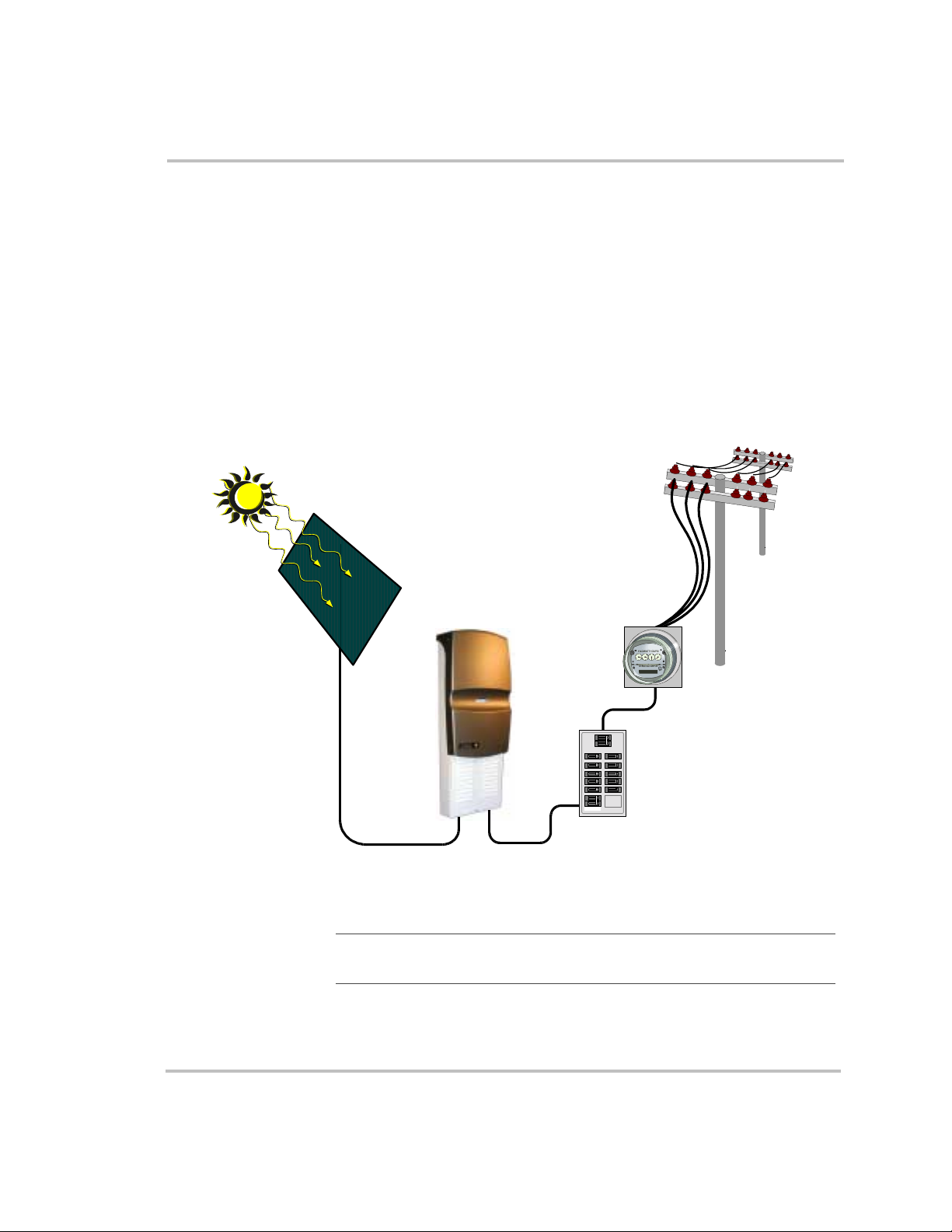

The Xantrex Sun Tie XR grid-connect solar inverter is designed to

convert a home or business into a “green” power generating station. The

Sun Tie XR converts solar electric (photovoltaic, or PV) power into

utility-grade electricity that can be used by the home or sold to the power

company. Installing the Sun Tie XR consists of mounting it to the wall

and connecting a DC source (a PV array) and the AC output to the utility.

See Figure 1-1 for a simple diagram of a typical installation. In order to

operate, the Sun Tie XR must have grid power available and connected. It

will not provide backup power.

Solar-harvested

AC power to grid

PV array

Figure 1-1

DC input voltage

Basic System Overview

Note:

Figure 1-1 is a one-line drawing intended as a system overview

only. System grounding and other electrical details are not included.

Sun Tie XR

AC output

voltage

OFF

OFF

OFF

OFF

OFF

OFF

OFF

Sun Tie

OFF

ON

OFF

ON

ON

ON

OFF

OFF

ON

ON

OFF

ON

ON

OFF

ON

ON

ON

ON

OFF

ON

ON

AC utility meter

Main utility

electrical panel

1–2 975-0053-01-01

Page 14

About the Sun Tie XR

Standard Features

All-in-one design All necessary DC input and AC output connections, disconnects and

circuit breakers are housed within the Sun Tie XR’s easily installed,

compact enclosure. A built-in LCD display panel provides easy-to-read

system status and daily cumulative energy production information. Two

status LEDs inside the unit also provide operating and troubleshooting

information.

Uses most types of

PV technology

The Sun Tie XR is designed to take advantage of most types of solar

electric technologies. The inverter allows up to 120 VDC open circuit PV

modules to be used, so it will work with both crystalline and thin film PV

modules.

Sun Sweep™

Maximum Power

Point Tracking

(MPPT)

Sun Sweep

technology that allows the Sun Tie XR to harvest the maximum amount

of energy from your solar array. No matter what PV system you choose—

single crystalline, polycrystalline or thin film—SunSweep

TM

is Xantrex’s proprietary Maximum Power Point Tracking

TM

learns your

array’s specific characteristics, maximizing its output all day, all season,

year after year.

High efficiency The high-frequency, solid-state design of the Sun Tie XR inverter is

extremely efficient. Above 500 watts, the inversion process is 90%

efficient (or greater) with a peak efficiency of 91%.

Expandable Sun Tie XR inverters may be connected in a parallel configuration for

increasing net metering capacity. The modular expandability of the

Sun Tie XR Series allows for system growth.

Meets standards and

requirements

The Sun Tie XR has complete on-board islanding protection and meets

U.S. and Canadian safety operating standards and code requirements.

Accessories

• STRM–Sun Tie XR Remote Monitor, for remote display of system

status, energy production, troubleshooting log, and resetting Wh.

• STRS–Sun Tie XR Rain Shield, required for outdoor installation.

975-0053-01-01 1–3

1–4 975-0053-01-01

Page 15

Page 16

Installation

Chapter 2, “Installation” provides information about planning for

and installing the Sun Tie XR. It contains information to help you

plan wire routes, AC and DC connections, and find a suitable

location for installation. It also discusses requirements for

grounding the Sun Tie XR and your PV array.

This chapter then provides procedures to install the Sun Tie XR,

including mounting, making DC and AC connections, and

grounding the inverter and the PV array.

Page 17

Installation

Installation Planning

Overview

Before you begin to install the Sun Tie XR you need to consider the

following:

• tools required

• hardware and materials required

• mounting location

• routes for AC and DC wiring

• AC and DC connection wire size requirements

• grounding requirements

• PV array requirements

Tools required

❐ Phillips screwdrivers ❐ level

❐ slot-head screwdrivers ❐ wire strippers

❐ open-end wrenches ❐ torque wrench

❐ socket wrench and fittings ❐ electrical tape

❐ 3/32" hex bit

❐ multimeter ❐ utility knife

❐ frequency counter (optional)

❐ pencil

Hardware and materials required

❐ wood screws and washers (supplied)

❐ metal conduit and appropriate fittings

❐ anchors for screws (material dependent)

2–2 975-0053-01-01

Page 18

Locating the Sun Tie XR

The Sun Tie XR should be installed in locations that meet the following

requirements:

Installation Planning

Vertical The UL listing for the Sun Tie XR requires it

to be mounted vertically.

Dry When the Sun Tie is mounted outdoors, attach

the optional Rain Shield (STRS) to prevent

water entering the unit.

Temperature The unit meets specifications from 32 to

113 °F (0 to 45 °C) but will operate within the

temperature extremes of most climates—from

-38 to 113 °F (-39 to 45 °C). At extreme cold

temperatures the LCD display may not

function normally and it is recommended that

an indoor-mounted Remote Monitor be used.

At temperatures above 45 °C, the unit begins

derating power. See “Temperature Derating

Curve” on page A–6.

Ground clearance The Sun Tie requires at least 36 inches (100

cm) of clearance between the bottom of the

unit and the ground.

Dust free Dust can be drawn inside and accumulate

within the unit, interfering with wiring

connections and ventilation.

WARNING: SHOCK HAZARD

Do not install the Sun Tie XR unit outdoors without the Rain

Shield. Water entering the unit could cause a dangerous

condition and cause the unit to fail. Failure due to improper

installation will void the warranty.

Routing the wires

Typical

configurations

975-0053-01-01 2–3

Determine all wire routes to and from the Sun Tie XR. Typical routing

configurations include:

• AC wiring from the Sun Tie XR to the main service panel

• DC input wiring from the PV array to the Sun Tie XR

• DC ground from the PV array to an external ground rod

Page 19

Installation

All wiring and installation methods should conform to applicable

electrical and building codes.

Conduit holes Pre-plan the wire and conduit runs. Knockouts for conduit holes are

located on the bottom of the unit. See Figure 2-9.

Acceptable wire

sizes

The DC terminal blocks in the Sun Tie XR accept up to a #6 AWG wire.

The AC circuit disconnects accept cable sizes up to #6 AWG.

For maximum safety, run AC and DC wires/cables in separate conduits.

WARNING: SHOCK HAZARD

Check for existing electrical or plumbing prior to drilling holes

in the walls.

Planning AC Connections

AC connections include all the wires and connectors between the

Sun Tie XR AC output breakers and the main utility electrical panel.

Figure 2-14 and Figure 2-15 show simplified diagrams of the entire

installation.

Recommended wire sizes

The AC output breakers accept wire sizes from #6–14 AWG. Refer to

Table 2-1 for minimum recommended wire size. The values in Table 2-1

are the minimum recommended wire sizes in conduit. Installing a large

number of wires in conduit or enclosed locations may require larger wire

sizes. Consult your local/national electrical code for more information.

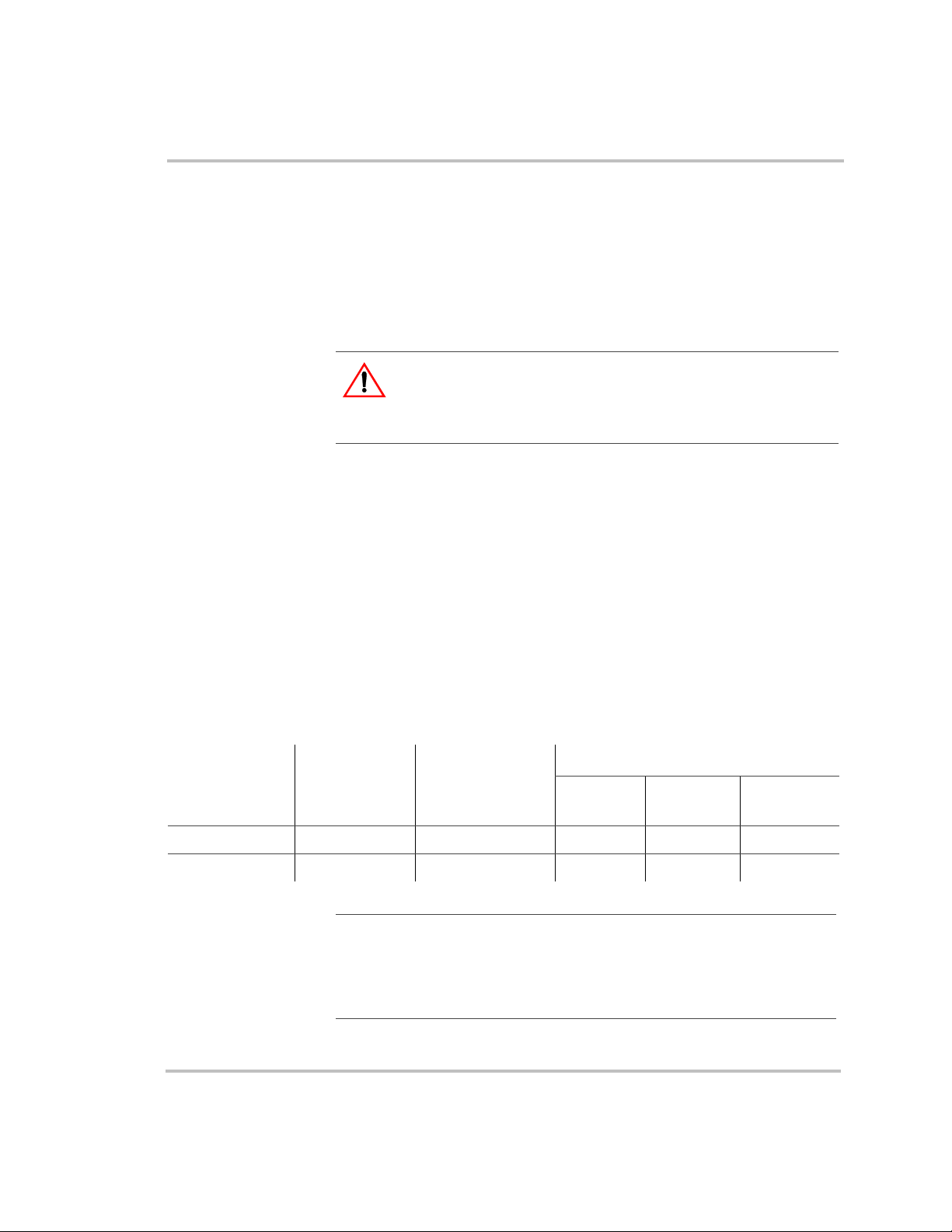

Table 2-1 Recommended minimum AC wire sizes

Minimum wire size for specified distance

AC amps

Inverter model

STXR1500 6.3 7.9 14 AWG 10 AWG 8 AWG

STXR2500 10.4 13.0 12 AWG 8 AWG 6 AWG

output per leg

Note:

NEC amps per leg

(amps x 125%)

The six-circuit combiner board is rated for 100 amps (Imp) of

0–50 ft

one way

maximum real current. Although the 20 amp fuses will theoretically

allow 120 amps to be applied, always design for a maximum of 100

amps maximum current. With appropriate fuse deratings, per NEC code,

the maximum allowed current is 16 amps for any of the six circuits.

50–100 ft

one way

100–200 ft

one way

2–4 975-0053-01-01

Page 20

Installation Planning

AC circuit breaker requirements

The main service panel must dedicate a 15 amp minimum, double pole

breaker (120/240 volts AC) to operate the Sun Tie XR.

Planning DC Connections

DC connections include all the wires and connectors between your PV

array and the Sun Tie XR’s combiner board. Figure 2-1 and Figure 2-2

show the combiner board and connection points. Figure 2-14 and Figure

2-15 show simplified diagrams of the entire installation.

Wire Sizes The DC connections are made on the combiner board inside the

Sun Tie XR. The combiner board accepts wire sizes from #6–14 AWG.

Refer to Table 2-2 for minimum recommended wire sizes.

Exceptions The values in Table 2-2 are the minimum recommended wire sizes.

Installing a large number of wires in conduit or enclosed locations may

require larger wire sizes. Consult your local or national electrical code for

more information.

NEC Restrictions The National Electrical Code (NEC) places restrictions on minimum DC

wire bending radius. A #6 AWG wire is the largest that may be used on

the Sun Tie XR when connecting to the individual fused circuits of the

combiner board.

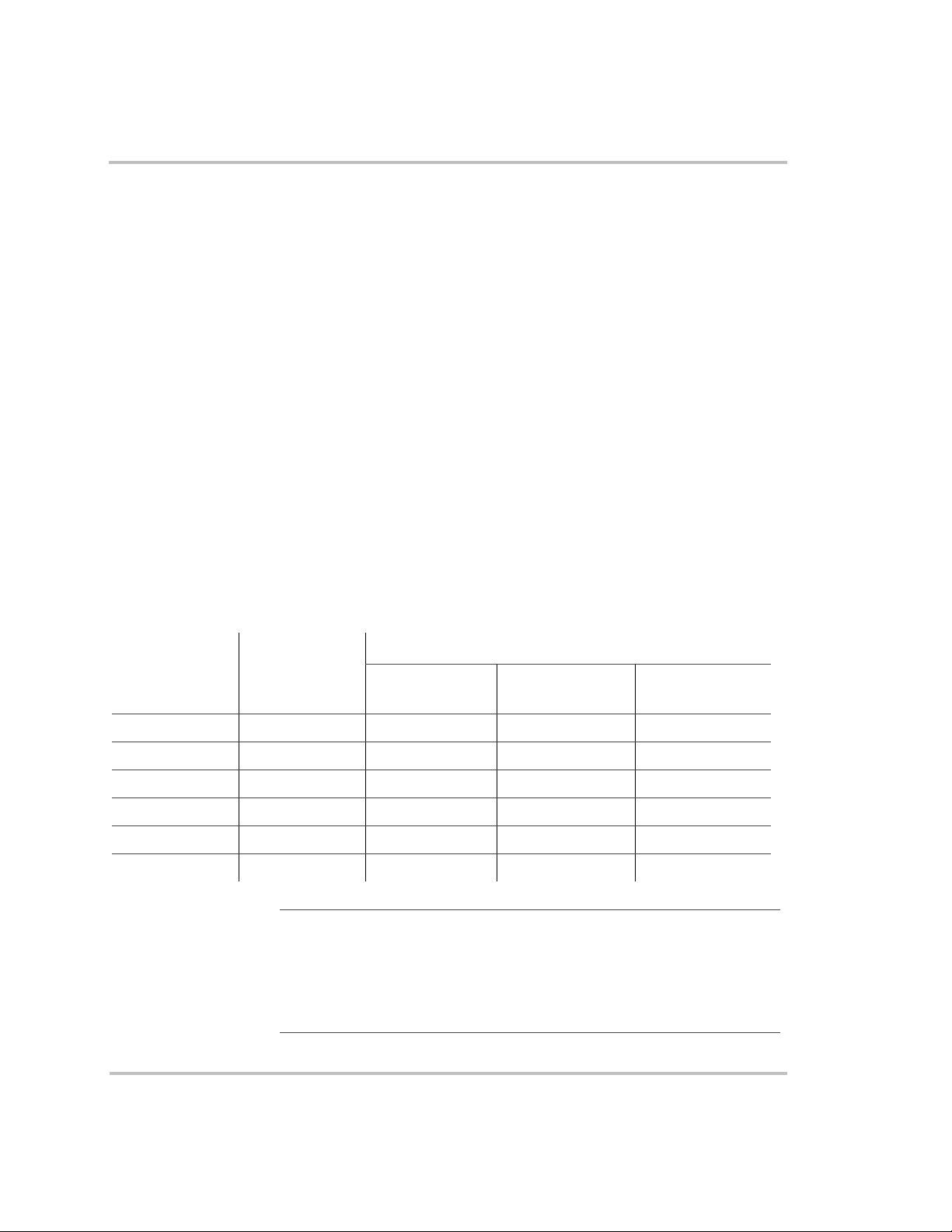

Table 2-2 Recommended minimum DC wire sizes

Minimum wire size for specified distance

DC amps (Imp)

(from PV array)

1.0 1.6 14 AWG 14 AWG 14 AWG

3.0 4.7 14 AWG 12 AWG 10 AWG

5.0 7.8 12 AWG 10 AW G 6 AWG

7.0 10.9 12 AWG 8 AWG 6 AWG

9.0 14.0 10 AWG 8 AWG Not Recommended

11.0 17.2 10 AWG 6 AWG Not Recommended

NEC amps

(amps x 156%)

Note:

For an installation requiring a two-wire run (positive and

0–25 ft

one way

25–50 ft

one way

50–100 ft

one way

negative), the PV array wires can bypass the individual fused combiner

board terminals and connect directly to the input terminals (through an

externally mounted DC fused combiner box) by using the positive and

negative bypass terminals on the combiner board. Refer to Figure 2-2

and Table 2-2 for connection and wire sizes.

975-0053-01-01 2–5

Page 21

Installation

PV Array Fuses

(F1 to F6)

Positive PV Array Fused

Terminal Connections

(1 to 6)

Negative PV Array Fused

Terminal Connections

DC conduit wiring

(from PV arrays)

Figure 2-1 Combiner board with PV array wiring to individual terminal

connections

PV array wiring (two-line

run to bypass terminals—

note polarity)

pos (+)

neg (–)

Figure 2-2 Combiner board with PV array wiring to bypass terminals

Grounding Requirements

AC grounding The Sun Tie XR must be connected to a grounded, permanent wiring

system.

2–6 975-0053-01-01

Page 22

Installation Planning

DC grounding The negative PV conductor must be bonded to the grounding system at

only one point in the system. See Figure 2-3 for the location of the Sun

Tie XR ground bar. The size for the conductor is usually based on the size

of the largest conductor in the DC system. Negative/ground bonding is

accomplished by factory-wired PVGFP breakers.

Figure 2-3 Ground bar location

PV Array Requirements

MPPT operational

window

Vo l t a g e

requirements

The Sun Tie XR is optimized to work with 4-each, 12 volt nominal

crystalline PV modules in series (48 VDC nominal), or various

combinations of amorphous, thin film PV modules. Ensure the PV array

used in the system operates within the maximum peak power tracking

(MPPT) operational window.

The solar array connected to the Sun Tie XR should have a minimum of

50 volts DC open-circuit in full sunlight conditions. Crystalline solar

arrays configured for 48 volts DC nominal will have an open-circuit

voltage of around 84 volts DC in full sunlight. The MPPT software

controls the output of the solar modules, under loaded conditions, in the

42–85 volts DC range (full inverter output power occurs between 52–85

VDC for the STXR1500 and between 52–75 VDC for the STXR2500).

Other array voltages will either not operate the inverter, may cause

damage, or will not allow maximum harvest of the sun’s energy.

Ground bar

(connect to solid earth ground)

975-0053-01-01 2–7

Page 23

Installation

Note:

batteries.

The MPPT algorithm does not work with wind power or

CAUTION

Although the nominal voltage range suggests that you can use

strings of five modules in series, this is not safe for the unit, as

the PV array may exceed the inverter’s maximum input

(120 VDC).

WARNING: SHOCK HAZARD

Whenever a PV array is exposed to sunlight, a shock hazard

exists at the output cables or exposed terminals. To reduce the

risk of shock during installation, cover the array with an opaque

(dark) material before making any connections.

2–8 975-0053-01-01

Page 24

Installation

Overview

Installation steps There are four main steps in the installation of the Sun Tie XR:

1. Mounting the unit

2. Making the DC connections from the PV array to the Sun Tie XR

3. Making the AC connections from the service utility panel to the

Sun Tie XR

4. Grounding the PV array

This section also discusses two installation options: connecting inverters

in parallel and connecting the Remote Monitor.

WARNING: FIRE, SHOCK and ENERGY HAZARDS

Before installing the Sun Tie XR, read all instructions and

cautionary markings located in this manual, on the PV array,

and on the main service panel.

Installation

Mounting

Surfaces for

mounting

The Sun Tie XR must be mounted to a flat, vertical surface such as

wallboard or wood siding. Installation onto wallboard or concrete

requires the use of anchors to properly hold the screws.

WARNING: SHOCK HAZARD

Before drilling holes to mount the Sun Tie XR, ensure there are

no electrical wires or plumbing in this area. Since this unit is

installed close to the utility entrance or meter, there may be a

high concentration of electrical wire in the area.

CAUTION

The Sun Tie XR weighs approximately 35 pounds. Always use

proper lifting techniques during installation to prevent personal

injury.

975-0053-01-01 2–9

Page 25

Installation

To mount the Sun Tie XR:

1. Locate the area where the Sun Tie XR is to be installed. Installing it

as close to the utility service panel as possible is recommended. The

bottom of the unit must be at least 36 inches from the floor or ground

when mounted.

2. Using a level, place the mounting bracket up to the wall (in a

horizontal position) and mark the area for the three screws, as shown

in Figure 2-4. To achieve the 36-inch height from the bottom of the

Sun Tie XR to the ground, mount the bracket 70 inches from the

ground.

3. If required, remove the bracket and drill the holes using a #10 (0.193

diameter) drill bit. Drill appropriately sized holes for anchors when

installing on non-wood surfaces.

4. Mount the bracket to the wall using the screws and washers provided.

If mounting to a surface other than wood, use the appropriate screws

and anchors.

5. Place the Sun Tie XR’s rear lip, located on the back top of the

enclosure, over the bracket and ensure it is seated properly, as shown

in Figure 2-5.

6. Remove the lower external cover to access the internal circuit breaker

panel by removing the screw on each side of the cover with a 3/32

hex bit, as shown in Figure 2-6.

7. Remove the internal breaker panel by removing the screws in the

breakers and the breaker cover grounding screw. Lift the panel until

the lower locking tabs are free, then gently pull the inner cover

outward, as shown in Figure 2-7. Save the screws for reinstallation.

8. After the unit is correctly seated on the upper bracket, locate the two

screw holes in the bottom (back) area of the enclosure and mark these

locations on the wall, as shown in Figure 2-5 and Figure 2-8. Remove

the Sun Tie XR (if required).

9. Drill two pilot holes (as above, if required).

10. Reinstall the Sun Tie XR to the bracket and secure the bottom of the

unit with the wood screws and washers provided (or appropriate

screws and anchors for non-wood surfaces) and tighten.

"

"

Note:

supplied.

2–10 975-0053-01-01

Mounting hardware for surfaces other than wood is not

Page 26

Installation

Wall bracket, screws,

and washers (supplied)

Figure 2-4 Bracket mounting

9 41/64"

4 13/16"

Enclosure

mounted on

wall bracket

19/64"

26 21/32"

Mount 70 inches (minimum) from ground

Sun Tie XR enclosure lip

onto bracket

8 55/64"

Screw

holes

3.20"

Figure 2-5 Enclosure mounting

975-0053-01-01 2–11

Page 27

Installation

Upper cover

Remove screws

(one on each side)

External breaker cover

(remove during

installation)

Figure 2-6 External cover components

2–12 975-0053-01-01

Page 28

Remove breaker

screws

Lift up and pull

forward to remove

Locking tabs

remove breaker cover

grounding screw

Figure 2-7 Inner breaker cover

Installation

PV combiner board

Internal mounting

holes

Figure 2-8 Mounting holes

975-0053-01-01 2–13

Page 29

Installation

10

3

3

8

3

2

(2X)

1

(2X)

8

3

8

3

4

1

3

8

3

4

8

1

5

2

5

7

8

7

8

8

3

8

4

3

1

8

7

8

1

2

3

10

8

front of inverter

all dimensions are in inches

1

3

4

5

1

8

5

2

8

Figure 2-9 Bottom hole conduit locations (bottom view)

2–14 975-0053-01-01

Page 30

Installation

Connecting DC Wiring

Fuse requirements The combiner board in the Sun Tie XR accepts up to six individual PV

array circuits (positive and negative wires). Each circuit on the combiner

board contains a fuse to protect against over-current. Always replace this

fuse with one of the same type and rating (GBB, 20 amp maximum,

ceramic type, 0.25" x 1.25"). The combiner board is rated for 100 amps

maximum input.

Combiner board

location

Wiring procedure Before connecting DC wiring, refer to Figure 2-10.

PV array wiring to

terminal block

(note polarity)

+

–

The combiner board PV array input connection block is located in the

lower left-hand section of the Sun Tie XR unit.

PVGFP (ganged)

100 amp DC breaker

PVGFP (ganged)

1 amp DC breaker

PV array

100 amp DC breaker

L1 15 amp AC breaker

(ganged)

L2 15 amp AC breaker

(ganged)

L2 breaker AC

connection

L1 breaker AC

connection

Ground bar

Figure 2-10 Electrical component location and PV array DC connection points

To wire the PV array to Sun Tie XR:

1. Install the DC conduit from the PV arrays to the bottom of the

Sun Tie XR, through one of the knockout holes, as shown in Figure 2-

9. Metal conduit is highly recommended.

2. Route the wires from the PV array(s) through the conduit and into the

lower section of the Sun Tie XR enclosure, as shown in Figure 2-8.

Note:

If you are using more than one PV sub-array, label the positive

and negative wire pairs appropriately (such as PV 1, PV 2, and so on).

3. Connect the positive (+) wire from the #1 array to the PV PLUS 1

terminal on the combiner board. Check that the wire is in the proper

location and tighten the screw.

975-0053-01-01 2–15

Page 31

Installation

4. Connect the negative (–) wire from the PV array to the PV MINUS 1

(leftmost) terminal. Check that the wire is in the proper location and

tighten the screw.

5. Repeat this procedure for each PV array circuit, connecting the #2 PV

positive wire to the terminal labeled PV PLUS 2, and so on.

The PV arrays do not have to connect in the order marked on the

board (this is just for reference). All PV array positives on the

combiner board are joined together AFTER the fuse.

6. Repeat this procedure for each PV array circuit, connecting the #2 PV

negative wire to the PV MINUS 2 terminal, and so on.

The PV arrays do not have to connect in the order marked on the

board (this is just for reference). All PV array negatives on the

combiner board are electrically tied together.

7. Torque wires according to the following values.

Wire Size (AWG) Torque (in-lb)

14–10 AWG 35

8 AWG 40

Connecting AC Wiring

AC HOT wiring is connected to the Sun Tie XR’s L1 and L2 breakers,

and the ground wire connects to the ground bar. All AC wiring is located

in the lower section of the Sun Tie XR.

Note:

meter, or to dual meters, where one meter indicates power used and the

second meter indicates power sold (power supplied back to the utility).

The installer and utility must determine the proper components to

install.

4–6 AWG 45

2–1/0 AWG 50

WARNING: SHOCK HAZARD

AC utility wiring to the Sun Tie XR unit is performed directly

at the main breaker panel. This should be done only by a

qualified utility installer or electrician with prior utility

company approval.

The Sun Tie XR can be connected to a single bidirectional

2–16 975-0053-01-01

Page 32

Installation

WARNING: SHOCK HAZARD

Before wiring the Sun Tie XR, ensure the main 120/240 volt

breaker in the main utility breaker box is switched off. Switch

this breaker on only after all wiring is completed as instructed

in the procedures.

To wire the main utility panel to the Sun Tie XR:

1. Run conduit from the main utility breaker panel to the lower section

of the Sun Tie XR. Run the two HOT wires (L1 and L2) and ground

through the conduit and into the Sun Tie XR’s lower section. Metal

conduit is highly recommended.

2. Install or use existing double-pole 15-amp circuit breaker (or two

single-pole 15-amp breakers, ganged) in the main utility breaker

panel.

3. Connect the L1 HOT wire (black) from the 15-amp, double-pole

breaker installed in the main breaker panel, to the breaker labeled L1

in the Sun Tie XR. Refer to Figure 2-11.

4. Connect the L2 HOT wire (red) from the remaining 15-amp, doublepole breaker installed in the main breaker panel, to the breaker

labeled L2 in the Sun Tie XR.

5. Connect the ground wire (green or bare copper) from the ground bar

in the main breaker panel, to the ground bar in the lower section of the

Sun Tie XR.

6. Ensure all connections are correctly wired and properly torqued.

7. Torque wires according to the following values.

Wire Size Torque (in-lb)

14–10 AWG 35

8 AWG 40

6 AWG 45

975-0053-01-01 2–17

Page 33

Installation

L1

240 VAC

L2

Ground bar

Figure 2-11 240 VAC connection points

Grounding the System

PV grounding The Sun Tie XR is designed to have all PV positive, negative and ground

conductors connected inside its access area. The PV equipment ground

should be connected to the Sun Tie XR ground bar. This ground bar must

also be connected to the main utility breaker panel’s ground bar and to the

house grounding rod according to the NEC requirements. Verify that there

is an AC ground/neutral bond in the main utility breaker panel and that no

other ground/neutral bonds exist in the system.

Lightning

protection

Recommended

additional

grounding

To protect the equipment from lightning damage, use a single-point

grounding system. In this system, all ground lines terminate at the same

point. This point normally is the main utility ground installed by the

utility company to provide a ground for the house wiring. This ground

usually consists of a copper rod driven 6 to 8 feet into the earth, as shown

in Figure 2-12.

Xantrex recommends that if the inverter is more than 8 feet from the

utility ground rod, a second ground rod should be added (Reference NEC

250.56) and bonded to the same point (Reference NEC 250.58) to

minimize the impedance to ground and maximize system protection.

2–18 975-0053-01-01

Page 34

Solar

Array

Connect all

array frames

together and

ground

DC Wiring

(and ground)

Sun Tie Unit

Ground

Bar

AC Wiring

Main Utility

Breaker Panel

Ground

Bar

AC

Wiring

Utility

Meter

AC

Wiring to

Utility

Installation

Array

Ground

Wire

*Optional Array Ground Wire

*

NOTE

: An optional array ground wire

may be required in many states as an

additional permanent ground p ath in

the event the inverter is removed for

service. Check your local codes for

grounding requirements.

Sun Tie

Ground

Rod

Utility

Ground

Wire

Figure 2-12 Typical roof mount installation grounding

Required additional

grounding

If the PV array is located a considerable distance (over 100 feet) from the

Sun Tie XR, then an additional ground rod must be installed close to the

PV array for the most reliable lightning protection, as shown in Figure 2-

13. The grounded frame of the PV array provides a direct route to

dissipate lightning strikes through the closest ground rod. Please

reference NEC 2002 250.53 – “Grounding Electrode System

Installations” and NEC 2002 250.70 – “Methods of Grounding and

Bonding Conductor Connections to Electrodes” for specific grounding

requirements.

Note:

Always refer to your local codes for wiring and grounding

requirements, which may differ from the information given in this

manual.

Bonded Neutral Wire

Utility

Ground

Rod

975-0053-01-01 2–19

Page 35

Installation

> 100 feet (30 m)

Solar

Array

Ground

Frame to

Pole

Array Ground

Wire

DC Wiring

(and ground)

Ground

Bar

Buried Copper Wire Buried Copper Wire

Array Ground Rod Utility Gr ound Rod

Sun Tie Ground Rod

Figure 2-13 Long distance grounding

SOV

LIGHTNING

A

15 A

L1

15 A

L2

GROUND

BAR

NOTES:

INSTALLER CONNECTIONS REQUIRED

(A)

AT POINTS

INVERTER ENCLOSURE.

THE UTILITY METER MAY BE A

BI-DIRECTIONAL METER OR DUAL

METERS .

OBTAIN UTILITY COMPANY APPROVAL

BEFORE INSTALLING.

AND

ARRESTOR

(OPTION)

L1

L2

INVERTER

G

G

Main

Breakers

G

L2

L1

Sun-Tie

Breakers

MAIN SERVICE PANEL

(B)

TO THE

ST Unit

Sun Tie Ground Wire

+

–

NEUTRAL

GROUND

Main Utility

Breaker Panel

Ground

AC Wiring

Bar

STXR UNIT

PV GROUND FAULT

BREAKERS (OPTION)

100 A

100 A

+

–

1 A

L2

L1

UTILITY METER

N

Buried copper wi re if second ground rod is used

Utility

Meter

AC

Wiring

Bonded Neut ral Wire

Utility Gr ound Wire

PV COMBINER BO ARD

– +

20 A

–

20 A

–

20 A

–

20 A

–

20 A

–

20 A

–

L1

L2

N

+

+

–

+

+

–

+

+

–

+

+

–

+

+

–

+

+

B

UTILITY

GRID

AC

Wiring to

Utility

PV

ARRAYS

Extra Ground Rod

Only Required on

Long Runs > 1 00

feet (30 m).

Figure 2-14 Simplified electrical wiring diagram

2–20 975-0053-01-01

Page 36

SOV

LIGHTNING

A

L1

L2

NOTES:

INSTALLER CON NECTIONS REQUIRED AT P OINTS

THE INVERTER ENCL OSURE.

THE UTILITY METER MAY BE A BI-DIRECTIO NAL METER OR DUAL

METERS MA Y BE USED.

OBTAIN UTILITY COMPAN Y APPROVAL BEFORE INSTALLING.

ARRESTOR

(OPTION)

15 A

15 A

L1

L2

G

G

Breakers

G

L2

L1

MAIN SERVICE PANEL

(A)

AND

(B)

Main

Sun-Tie

Breakers

INVERTER

TO

GROUND

NEUTRAL

STXR UNIT

+

–

BYPASS TERMINALS

PV GROUND FAULT

BREAKERS (OPTION)

100 A

+

–

1 A

L1

UTILITY METER

Installation

PV ARRAY

EXTERNAL

COMBINER BOARD

–

+

PV COMBINER BOARD

+

–

20 A

+

–

20 A

100 A

L2

N

+

–

20 A

+

–

20 A

+

–

20 A

+

–

20 A

+

–

Extra Ground Rod

B

Only Required on

Long Runs > 100

feet (30 m).

L1

UTILITY

L2

GRID

N

975-S00-003A

Figure 2-15 Simplified electrical wiring diagram (using PV bypass terminals)

Connecting Inverters in Parallel

Reasons and

requirements

Connecting AC and

DC wiring

975-0053-01-01 2–21

Sun Tie XR inverters may be connected in a parallel configuration to

harvest additional energy from the sun. In this configuration, a separate

solar array is required for each Sun Tie XR unit. The output of each Sun

Tie XR feeds a dual-pole 15-amp circuit breaker (L1 and L2) in the main

utility breaker panel.

The procedure for wiring the additional Sun Tie XR is exactly the same as

previously described for the AC and DC wiring. Additional Sun Tie XR

inverters can be added in the future as required.

An example of a parallel configuration is shown in Figure 2-16.

Note:

If you are combining two Sun Tie XR inverters into a single

dual-pole breaker (30 amp, for example), you will need to size the AC

wires and conduit to the larger breaker. If this breaker trips, it will also

shut down both inverters. For these reasons, we do not recommend

using a single dual-pole breaker.

Page 37

Installation

PV ARRAY

SOV

LIGHTNING

ARRESTOR

(OPTION)

15 A

L1

15 A

L2

G

MAIN UTILITY PANEL

Main

Breakers

L2

15 A

15 A

L1

L2

15 A

15 A

L1

NEUTRAL

GROUND

15 A

L1

15 A

L2

G

House Ground

(Ground Rod)

L1

L2

N

UTILITY

GRID

L2

UTILITY METER

N

L2

L1

L1

Sun-Tie XR

Breakers

(Dual-Pole)

Sun-Tie XR

Breakers

(Dual-Pole)

Neutral/Ground

Bond

Figure 2-16 Parallel Sun Tie XR configuration

L1

L2

SOV

INVERTER

LIGHTNING

ARRESTOR

(OPTION)

L1

L2

INVERTER

SUN TIE XR #1

PV GROUND FAULT

BREAKERS (OPTION)

+

–

SUN TIE XR #2

+

–

100 A

+

–

1 A

PV GROUND FAULT

BREAKERS (OPTION)

100 A

PV COMBINER BOARD

+

–

20 A

+

–

20 A

100 A

+

–

20 A

+

–

20 A

+

–

20 A

+

–

20 A

+

–

PV ARRAY

PV COMBINER BOARD

– +

20 A

+

–

20 A

100 A

+

–

1 A

+

–

20 A

+

–

20 A

+

–

20 A

+

–

20 A

+

–

Installing the Optional Remote Monitor

Remote Monitor

function

2–22 975-0053-01-01

The optional Remote Monitor provides additional functions which are not

directly available on the front panel LCD display. It can be mounted in a

more accessible location such as the garage, kitchen, living room, and so

on. Refer to the “Sun Tie XR Series Remote Monitor Installation and

Operator’s Guide” (part number 975-0032-01-02) for installation details.

Page 38

Installation

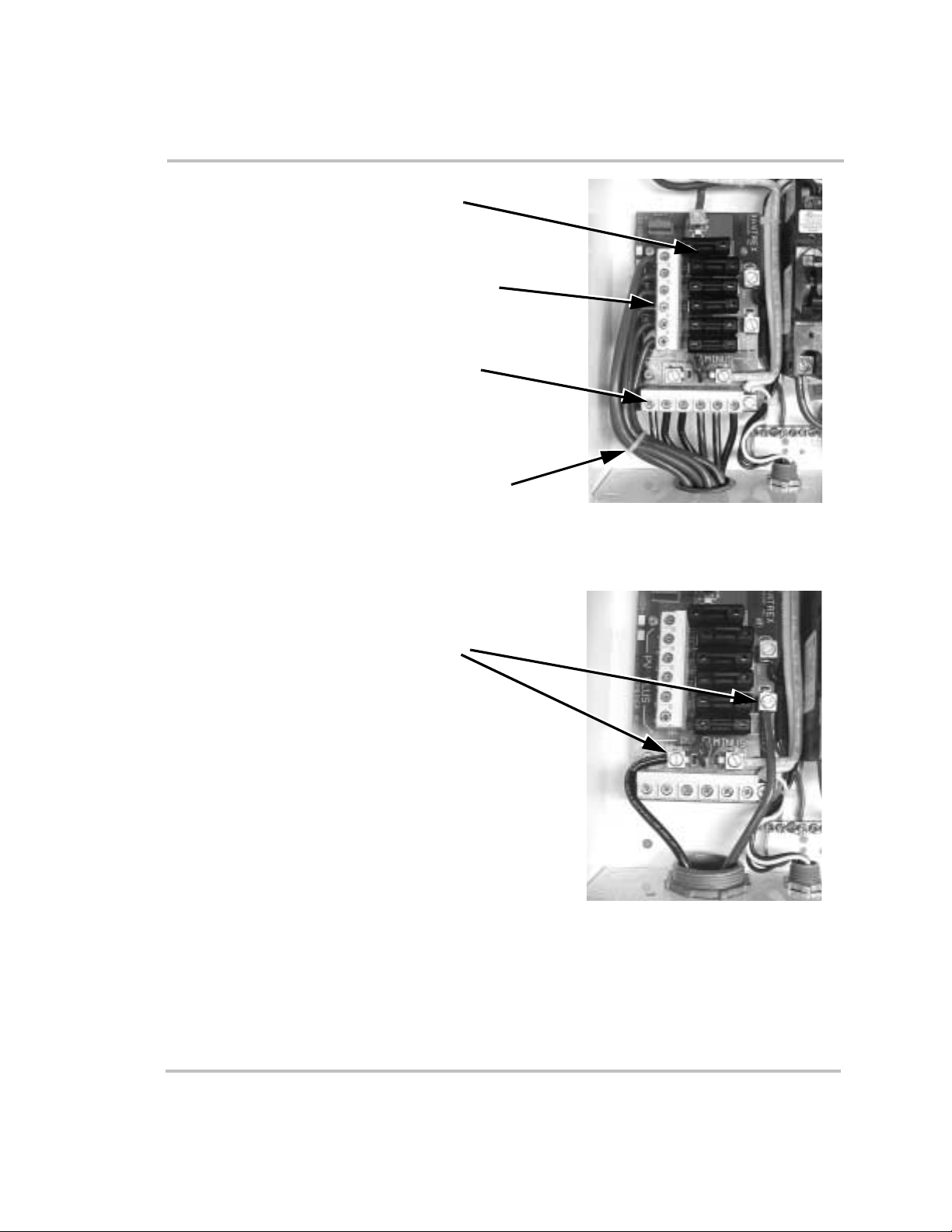

To wire the Remote Monitor to the Sun Tie XR:

1. Route the Remote Monitor’s six-conductor cable separate from the

other wiring to prevent noise and interference from being introduced

into the data cable. Refer to Figure 2-17 and Figure 2-18. The

connector is located in the upper right-hand section of the wiring

compartment.

CAUTION

When routing the Remote Monitor cable, do not use a metal

conduit. Metal conduit may induce noise in the remote cable

and cause scrambled data to appear on the display.

2. Run the cable through one of the lower knockouts (with a strain relief

installed) and plug it into the Remote Monitor port.

3. Recheck all wiring and reinstall the panels and the Rain Shield (if

used).

CAUTION

The P.C. com. port next to the Remote Monitor port is not

enabled. Connecting a computer to this port may result in

damage to the inverter or the computer.

Remote Monitor port (located

on top of wiring access

compartment)

Figure 2-17 Location of optional Remote Monitor port

975-0053-01-01 2–23

Page 39

Installation

Route Remote Monitor

cable away from AC

and DC wires

Remote Monitor

connection

CPU board (cover

removed for clarity)

Figure 2-18 Remote Monitor connection and cable

2–24 975-0053-01-01

Page 40

Operation

Chapter 3, “Operation” provides procedures for starting up and

operating the Sun Tie XR. It also explains the messages that appear

on the front panel display. The chapter ends with information about

factors that affect how much power the Sun Tie XR can gather from

the PV array and deliver to the utility grid.

Page 41

Operation

Startup Procedure

Starting up the Sun Tie XR requires several steps. You will need to:

1. Check the PV array DC voltage.

2. Check the AC utility voltage.

3. Start up the Sun Tie by switching on the DC and AC circuit breakers

inside the unit.

4. Reassemble the Sun Tie XR and replace the external covers.

Required Equipment

You will need the following equipment to help you start up the

Sun Tie XR:

❐ AC voltmeter (or multimeter)

❐ DC voltmeter (or multimeter)

❐ Frequency counter (optional)

WARNING: SHOCK HAZARD

Hazardous voltages present from two sources. Use extreme

caution during startup procedure. Before applying power to the

Sun Tie XR, ensure all AC and DC wiring is correct.

Checking the PV Array DC Voltage

To check the PV array DC voltage:

1. Uncover the PV arrays and expose them to full sunlight. The sunlight

must be intense enough to produce the required output voltage.

2. Measure the PV array open circuit DC voltage across the DC positive

(+) and negative (–) terminals as shown in Figure 3-1. This voltage

must be greater than 50 volts DC for 5 minutes minimum to start the

inverter.

Note:

voltages from 100–120 volts. Crystalline solar modules will produce

open circuit voltages at 75–85 volts (four modules wired in series). An

open circuit voltage of 50 volts or more is required for 5 minutes to start

the inverter. The 5-minute time delay is required by safety standards.

3. Switch on the PVGFP and DC breakers.

Some thin film modules (amorphous) may produce open circuit

3–2 975-0053-01-01

Page 42

> 50 VDC

Startup Procedure

AC

VOLTS

DC

VOLTS

+

Figure 3-1 PV array DC voltage test

Checking the AC Utility Voltage

Note:

applications. For commercial applications where only 208 VAC is

available, the Sun Tie XR may be installed with the appropriate use of a

buck-boost transformer.

To check the AC utility voltage:

1. Switch on the main 240 V breakers in the building’s electrical service

The Sun Tie XR is designed primarily for residential

panel.

–

2. Ensure all circuit breakers located in the Sun Tie XR unit are in the

off (down) position.

3. Using an AC voltmeter, measure the AC open circuit utility voltage

between L1 and L2, as shown in Figure 3-2. Ensure this voltage is

approximately 240 volts AC. The inverter operates with a line-to-line

voltage (L1 to L2) ranging from 211–264 volts AC.

4. Switch on the ganged 15 amp Sun Tie XR circuit breakers located in

the main electrical service panel. This applies the utility-supplied

240 volts AC to the Sun Tie XR unit.

975-0053-01-01 3–3

Page 43

Operation

240 VAC

Figure 3-2 AC voltage test

Starting up the Sun Tie XR

To start up the inverter:

1. Switch on the 100-amp DC circuit breaker located in the Sun Tie XR

unit. This breaker supplies the DC power from the PV array to the

Sun Tie unit. Refer to Figure 3-3, item 1.

2. Switch on the 1 and 100 amp (ganged) PVGFP breakers. These

breakers open when 1 amp or greater is detected in the DC negativeto-ground line; indicating a ground fault condition. Refer to Figure 3-

3, item 2.

AC

VOLTS

Connect to

L2 terminal

Connect to

L1 terminal

DC

VOLTS

3. Switch on the double-pole 15 amp AC circuit breakers located in the

Sun Tie XR unit. These breakers provide the Sun Tie XR-produced

power to the utility and provide the necessary utility voltage and

frequency to the inverter. This means the inverter will not produce an

AC output if utility voltage is not present on its output. Refer to

Figure 3-3, item 3.

3–4 975-0053-01-01

Page 44

Startup Procedure

2

1

3

Figure 3-3 Startup sequence

Monitoring the Front Panel Display

During startup During startup, the inverter’s front panel LCD display shows the first four

messages described in “Reading the Front Panel Display”.

During waiting

period

During operation When the five-minute wait protection timer stops, the Sun Tie XR begins

When the five-minute timer begins, the inverter displays the countdown

timer status meter.

selling power, indicated by the power output reading in the display. The

array “Wh” values will increase slowly, depending on the array size and

sunlight intensity.

Note:

The values in the front panel LCD display are calibrated at the

factory. The calibration is not user-adjustable.

975-0053-01-01 3–5

Page 45

Operation

Front panel

LCD display

Figure 3-4 Front panel display location

Reading the Front Panel Display

During startup During startup, the Sun Tie XR will display several messages on its front

panel LCD display. These messages appear in the following order.

Message Display Duration

XANTREX TECH INC.

STXR2500

(or “STXR1500”)

Enhanced with

Sun Sweep

CPU Rev = x.x

LCD Rev = x.x

244 vac 74 vdc

Start in 300 sec

3–6 975-0053-01-01

8 seconds

Cycles with the Lifetime Energy and Time Online

messages for five minutes. See “After startup”.

Page 46

Startup Procedure

After startup After the 300-second countdown timer and during normal operation, the

Sun Tie will display four messages that repeat every minute.

Display

Message (with

sample data)

duration

(seconds) Description

54 mppt 74 vdc

2500 W 12123 Wh*

244 vac 74 vdc

2500 W 12123 Wh*

Lifetime Energy

10.000kWh

Time Online

Today 00:00:00

0 – 8 Message 1 shows the inverter’s

DC regulation voltage for

maximum power production,

DC input voltage, power output,

and energy harvested today.

8 – 16 Message 2 shows AC input

voltage, DC input voltage, the

power output and energy

harvested today.

16 – 24 Repeats message 1.

24 – 28 Repeats message 2.

28 – 32 Message 3 shows the amount of

energy produced since

installation and startup.

32 – 40 Repeats message 1.

40 – 48 Repeats message 2.

48 – 56 Repeats message 1.

56 – 60 Message 4 shows how long the

Sun Tie has been online since it

last started.

*If the inverter is disconnected due to a line condition, this display will

show one of the following messages:

• AC NOT PRESENT

•AC MAINS LOW

• AC MAINS HIGH

• FREQUENCY FAULT

Status Indicator Lights

The Sun Tie XR is equipped with two status indicator lights (LEDs)

above the circuit breakers inside the wiring compartment. These light

during operation to indicate the inverter’s current status. For information

about reading these lights, see Chapter 4, “Troubleshooting”.

975-0053-01-01 3–7

Page 47

Operation

Reassembling the Sun Tie XR

Once the Sun Tie XR is operating normally and producing power, you

need to replace the panels and covers that were removed during

installation and startup.

WARNING: SHOCK HAZARD

Before reattaching covers, remove AC power at the utility

panel and cover the PV arrays.

To reassemble the Sun Tie XR:

1. Replace the circuit breaker panel, as shown in Figure 3-5.

a) Install the circuit breaker (inner) panel by sliding it into place

under the top cover and fitting its two locking tabs into the slots

on the bottom of the Sun Tie XR.

b) Secure the front panel to the circuit breaker with the four screws.

c) Replace the breaker cover grounding screw.

2. Replace the external cover by positioning the external cover in place

as shown in Figure 3-6 and installing a screw in each side.

Note:

a lock through the hole at the bottom front of the external cover and the

main chassis.

3. Install the Rain Shield if the Sun Tie XR is located outdoors, as

To prevent tampering or unauthorized access to the unit, install

shown in Figure 3-7.

• Place the Rain Shield onto the Sun Tie XR enclosure.

• Secure it with the four screws provided (two each side).

3–8 975-0053-01-01

Page 48

Figure 3-5 Circuit breaker cover and screws

Startup Procedure

Replace screws in

the circuit breakers

replace breaker cover

grounding screw

Replace screws

(one on each side)

Lock hole

Figure 3-6 Outer cover and screws

975-0053-01-01 3–9

Page 49

Operation

Replace screws

(two on each side)

Rain Shield

Figure 3-7 Rain Shield and screws

Factors Affecting Sun Tie XR Performance

This section describes several factors that will affect the amount of power

that a properly installed and operating Sun Tie XR can produce.

PV Array Factors

PV array ratings PV arrays are rated at ideal factory conditions, such as specified

illumination (1000 W/m

temperature (25 °C/77 °F), which seldom reflect real-world installations.

This is called the STC (Standard Test Condition) rating and is the figure

that appears on the PV module nameplate label.

Expected

performance

3–10 975-0053-01-01

Because of several unavoidable environmental factors, you can expect

your PV array to produce around 60% to 70% of its peak STC-rated

output for a properly designed and installed PV system.

2

), spectrum of the light and specified

Page 50

Temperature and

reduced output

Factors Affecting Sun Tie XR Performance

PV array temperature affects the output of the entire system. As the

temperature on the array surface heats up, its energy output goes down.

Roof-mounted arrays also collect the heat generated by the roof surface

(or trapped under the array) and will produce less output than polemounted arrays, which allow greater air circulation behind the panels.

Note:

electronic circuits from overheating and possible damage in high heat

conditions. For maximum output in hot climates, mount the Sun Tie XR

in a shaded location with good air flow.

Angle of the sun The angle of the sun in relation to the PV array surface—the array

orientation—can dramatically affect the PV array output. The array

energy output will vary depending on the time of day and time of year as

the sun’s angle in relation to the array changes. Sunlight output decreases

as the sun approaches the horizons (such as in winter in North America)

due to the greater atmospheric air mass it must penetrate, reducing both

the light intensity that strikes the array’s surface and spectrum of the light.

In general, you can expect only four to six hours of direct sunlight per

day.

Partial shade Shading of only a single module of the array will reduce the output of the

entire system. Such shading can be caused by something as simple as the

shadow of a utility wire or tree branch on part of the array’s surface. This

condition, in effect, acts like a weak battery in a flashlight, reducing the

total output, even though the other batteries are good. However, the

output loss is not proportionate to shading.

The Sun Tie XR is designed to maximize its energy production in all of

the above situations using its MPPT algorithm.

The Sun Tie XR will reduce its energy output to protect its

Other Factors

Other factors that contribute to system losses are:

• Dust or dirt on the array

• Fog or smog

• Mismatched PV array modules, with slight inconsistencies in

performance from one module to another.

• Inverter efficiency

• Wire losses

• Utility grid voltage

For additional information and technical notes concerning PV array

performance, please visit our Web site at www.xantrex.com.

975-0053-01-01 3–11

3–12 975-0053-01-01

Page 51

Page 52

Troubleshooting

Chapter 4, “Troubleshooting” describes how to view the status

indicator lights (LEDs) inside the Sun Tie XR and use them to

troubleshoot the unit. It also provides troubleshooting information

with suggestions for solving the problems that the lights may

indicate.

Page 53

Troubleshooting

Troubleshooting the Sun Tie XR

Viewing the Status LEDs

Inverter status

LEDs

To aid in troubleshooting the Sun Tie XR, there are two red and green

lights (LEDs) inside the unit. The LEDs light to indicate the inverter’s

status according to the troubleshooting reference table on page 4–5.

Viewing the status LEDs inside the unit should only be performed by an

authorized service person. If you suspect your unit is not functioning

correctly, call Xantrex.

WARNING: SHOCK HAZARD

Do not remove the upper cover. Dangerous voltages exist in the

upper cover area.

To view the status LEDs:

1. Remove the Rain Shield (if installed) by removing the four screws

(two from each side) securing it to the housing as shown in Figure 4-

1. Set the screws aside in a safe place.

2. Remove the lower external panel by removing the two screws on

either side of the panel as shown in Figure 4-1. Set the screws aside in

a safe place.

3. Locate the red and green LEDs. They should be visible through the

upper edge of the circuit breaker cover (see Figure 4-2).

4. Refer to the troubleshooting reference table on page 4–5 for the LED

status indications.

Note:

that duplicates the function of the status LEDs inside the unit. For

troubleshooting the Sun Tie XR, we recommend using the Remote

Monitor.

4–2 975-0053-01-01

The optional Remote Monitor (STRM) has a two-color LED

Page 54

Remove screws

(two on each side)

Remove screws

(one on each side)

Figure 4-1 Rain Shield and lower panel removal

Troubleshooting the Sun Tie XR

975-0053-01-01 4–3

Page 55

Troubleshooting

Red LED

Green LED

Mode connection

(factory set—

do not adjust)

Test adjustment

(factory set—

do not adjust)

LEDs are located

above the circuit

breakers

Figure 4-2 Status LEDs location (with circuit breaker cover removed)

CAUTION

The P.C. com. port next to the status LEDs is not enabled.

Connecting a computer to this port may result in damage to the

inverter or the computer.

4–4 975-0053-01-01

Page 56

Troubleshooting Reference Table

Problem Cause Remedy

Troubleshooting Reference Table

Inverter CPU does not

illuminate the red or

green LEDs and does

not operate in sufficient

sunlight,

or the display reads “AC

Mains Not Present” or

the VDC reading is 0.

The inverter CPU only

illuminates the red LED.

The green LED never

illuminates in a flashing

or solid mode,

or the display reads “AC

Mains Not Present” or

the VDC reading is 0.

The inverter illuminates

the red LED upon

startup and goes into a

flashing green mode.

The flashing green LED

continues for over 5

minutes and never

illuminates solid.

PVGFP, AC or DC breakers

are switched off.

No AC grid or DC array

voltage is present.

20 amp fuses on combiner

board are missing or open.

The inverter does not

recognize any AC input

signal.

Inverter does not recognize

the appropriate DC signal.

The inverter recognizes the

AC grid is present, but grid

voltage or frequency are not

within the appropriate

tolerances.

Turn on breakers in the sequence described in the

operation section.

Check AC connections and ensure 240 VAC is

present at the inverter’s AC disconnect. Check

DC connections and ensure 50–125 VDC is

present on the inverter’s disconnect.

Install combiner board fuses. Check PV array for

short circuits or improper sizing for the 20 amp

fuse.

Ensure the inverter AC disconnect is switched

on. Check the AC voltage at the inverter and

ensure AC voltage is present. Check source of

the AC voltage.

Check the DC voltage on the positive and

negative input terminals. The DC voltage must

be 50 volts or greater open circuit to initiate

inverter operation. Check for incorrectly wired

PV arrays or try again on a day with brighter

sunlight intensity.

Check the AC voltage and frequency with a

multimeter/frequency meter. Wait for grid power

to return to acceptable voltage and/or frequency.

Notify the utility company that the voltage or

frequency is outside of the appropriate

boundaries.

The inverter CPU

illuminates a solid green

LED momentarily, then

flashes a red LED.

975-0053-01-01 4–5

The inverter recognizes the

AC grid and DC array

voltages and attempts to

start selling power. The PV

panels are not producing

sufficient power for the

inverter to operate at a

stable DC voltage.

Check the DC input voltage at the inverter’s

positive and negative input terminals. The PV

array is not producing enough power. Wait for

sunlight intensity to increase and ensure the

panels produce sufficient voltage for inverter

initialization.

Page 57

Troubleshooting

Problem Cause Remedy

100 amp DC breaker

trips.

Current from the array

exceeds the DC input

breaker rating.

A lightning strike hit near

the PV array.

Open 20 amp combiner

board fuse(s).

A short to ground exists in

the DC array wiring.

Array is producing current

in excess of the fuse rating.

PVGFP breaker trips. A ground fault exists in the

DC array wiring.

Check array size and ensure the DC input does

not exceed the breaker rating.

Check lightning arrestor, breakers, panels,

diodes, DC wire insulation and other components

for damage. Replace any damaged components

and reset the breaker.

Check all DC array wiring for improper wiring

or exposed wires.

Check array size and ensure the DC input current

does not exceed the fuse rating.

Check all PV array wiring for improper wiring,

exposed wires, or short circuits.

4–6 975-0053-01-01

Page 58

Specifications

Appendix A contains the electrical and mechanical specifications

for the Sun Tie XR. These include the AC output ranges and

characteristics, operating temperature ranges, dimensions, and

weight. Appendix A also lists standard features, options, and

regulatory information for the Sun Tie XR.

Page 59

Specifications

Electrical Specifications

AC output voltage 240 VAC

AC output voltage range 211–264 VAC

Continuous AC output at

32–113 °F (0–45 °C)

Efficiency (peak) 91%

AC output characteristics Current source

Frequency 60 Hz (+0.5 Hz, -0.7 Hz)

Wakeup DC voltage 50 VDC

Input voltage (nominal) 48 VDC (4 nominal 12 VDC PV modules in series)

Absolute maximum PV

open circuit voltage

(Voc)

Sunsweep

voltage range

DC voltage range for

full-rated VA

AC output waveform Sine wave, high frequency PWM controlled

Total harmonic distortion

(current)

Nighttime tare loss 5 W

Minimum array size

(STC rating)

TM

MPPT

1500 VA (STXR1500), 2500 VA (STXR2500)

120 VDC

42–85 VDC

52–85 VDC (STXR1500), 52–75 VDC (STXR2500)

less than 5% at rated power

480 W

A–2 975-0053-01-01

Page 60

Mechanical Specifications

Mechanical Specifications

Specified temperature

range

Enclosure type Outdoor, rainproof (with Rain Shield), powder-coated aluminum

Inverter dimensions

(H × W × D)

Shipping dimensions

(H × W × D)

Weight (inverter only) 35 lb (15.9 kg)

Weight (shipping) 40 lb (18 kg)

Mounting Vertical wall mount only

Operating: -38 to 113 °F (-39 to 45 °C)

Listed to: 32 to 113 °F (0 to 45 °C)

enclosure, fully screened

33.25

" × 13.25" × 5.3" (83.1 cm × 33.8 cm × 13.25 cm )

37.75

" × 15.75" × 9.5" (94.4 cm × 39.4 cm × 23.8 cm )

975-0053-01-01 A–3

Page 61

Specifications

Standard Features and Options

Feature Description

PV ground fault

protection system

PV combiner board with

6 fused inputs, 20 amps

maximum per input

Lightning arrestorcombined AC/DC

protection

Rain Shield Optional STRS protective Rain Shield (required for outdoor installation),

STRM—remote meter Optional remote display with user-resettable Wh meter, tech menu, and

Forced air cooling Standard forced-air AC brushless fan (eight-speed, thermally controlled)

Islanding protection Active islanding protection with over/under AC voltage and frequency

User display Dynamic backlit alphanumeric liquid crystal display with system AC/DC

AC disconnect Standard double-pole, 15 amp, 240 VAC branch-rated circuit breaker

DC disconnect Standard single-pole, 100 amp, DC-rated circuit breaker

Listings UL Listed to UL1741–1999 (first edition) and cUL Listed to CSA C22.2

Standard

Standard

Standard

which makes the Sun Tie XR a rainproof Type 3R enclosure.

dynamic user display. Includes 50 foot (15.2 m) cable.

detection

voltages, power, energy, and time online details

No. 107.1-95

NEC 690 building code requirements for PV may be met with the

standard ground fault protection (PVGFP) system.

A–4 975-0053-01-01

Page 62

Efficiency Curve

100.00%

90.00%

80.00%

70.00%

60.00%

50.00%

Efficiency

40.00%

30.00%

20.00%

10.00%

0.00%

Efficiency Curve

0.00 500.00 1000.00 1500.00 2000.00 2500.00

AC Power Output

Figure A-1

Sun Tie XR efficiency curve

975-0053-01-01 A–5

Page 63

Specifications

Temperature Derating Curve

3000

2500

2000

1500

Power Output (Watts)

1000

500

0

0 10203040506070

Temperature (C)

Figure A-2

Sun Tie XR2500 temperature derating curve*

*from our testing, these are the expected output characteristics to 60 °C

with Rain Shield installed. Thermal characteristics are enhanced if the

unit is installed indoors with no Rain Shield attached.

A–6 975-0053-01-01

Page 64

Warranty and Product

Information

Appendix B contains warranty and return procedure information for

the Sun Tie XR.

Page 65

Warranty and Product Information

Limited Warranty

What does this warranty cover? This Limited Warranty is provided

by Xantrex Technology, Inc. ("Xantrex") and covers defects in

workmanship and materials in your Xantrex Sun Tie XR. This warranty

lasts for a Warranty Period of two (2) years from the date of purchase at

point of sale to you, the original end user customer.

This Limited Warranty is transferable to subsequent owners but only for

the unexpired portion of the Warranty Period.

What will Xantrex do? Xantrex will, at its option, repair or replace

the defective product free of charge, provided that you notify Xantrex of

the product defect within the Warranty Period, and provided that Xantrex

through inspection establishes the existence of such a defect and that it is

covered by this Limited Warranty.

Xantrex will, at its option, use new and/or reconditioned parts in

performing warranty repair and building replacement products. Xantrex

reserves the right to use parts or products of original or improved design

in the repair or replacement. If Xantrex repairs or replaces a product, its

warranty continues for the remaining portion of the original Warranty

Period or 90 days from the date of the return shipment to the customer,

whichever is greater. All replaced products and all parts removed from

repaired products become the property of Xantrex.

Xantrex covers both parts and labor necessary to repair the product, and

return shipment to the customer via a Xantrex-selected non-expedited

surface freight within the contiguous United States and Canada. Alaska

and Hawaii are excluded. Contact Xantrex Customer Service for details

on freight policy for return shipments outside of the contiguous United

States and Canada.

How do you get service? If your product requires troubleshooting or

warranty service, contact your merchant. If you are unable to contact your

merchant, or the merchant is unable to provide service, contact Xantrex

directly at:

Phone:360.435.8826

Fax:360.925.5143

Email:customerservice@xantrex.com

B–2 975-0053-01-01

Page 66

Limited Warranty

Direct returns may be performed according to the Xantrex Return

Material Authorization Policy described in your product manual. For

some products, Xantrex maintains a network of regional Authorized

Service Centers. Call Xantrex or check our website to see if your product

can be repaired at one of these facilities.

In any warranty claim, dated proof of purchase must accompany the

product and the product must not have been disassembled or modified

without prior written authorization by Xantrex.

Proof of purchase may be in any one of the following forms:

• The dated purchase receipt from the original purchase of the product

at point of sale to the end user, or

• The dated dealer invoice or purchase receipt showing original

equipment manufacturer (OEM) status, or

• The dated invoice or purchase receipt showing the product exchanged

under warranty

What does this warranty not cover? This Limited Warranty does not

cover normal wear and tear of the product or costs related to the removal,

installation, or troubleshooting of the customer's electrical systems. This

warranty does not apply to and Xantrex will not be responsible for any

defect in or damage to:

a) the product if it has been misused, neglected, improperly

installed, physically damaged or altered, either internally or

externally, or damaged from improper use or use in an unsuitable

environment;

b) the product if it has been subjected to fire, water, generalized cor-

rosion, biological infestations, or input voltage that creates operating conditions beyond the maximum or minimum limits listed

in the Xantrex product specifications including high input voltage

from generators and lightning strikes;

c) the product if repairs have been done to it other than by Xantrex

or its Authorized Service Centers (hereafter "ASCs");

d) the product if it is used as a component part of a product

expressly warranted by another manufacturer;

e) the product if its original identification (trade-mark, serial num-

ber) markings have been defaced, altered, or removed.

975-0053-01-01 B–3

Page 67

Warranty and Product Information

Disclaimer

Product

THIS LIMITED WARRANTY IS THE SOLE AND EXCLUSIVE WARRANTY PROVIDED BY

XANTREX IN CONNECTION WITH YOUR XANTREX PRODUCT AND IS, WHERE

PERMITTED BY LAW, IN LIEU OF ALL OTHER WARRANTIES, CONDITIONS,

GUARANTEES, REPRESENTATIONS, OBLIGATIONS AND LIABILITIES, EXPRESS OR

IMPLIED, STATUTORY OR OTHERWISE IN CONNECTION WITH THE PRODUCT,

HOWEVER ARISING (WHETHER BY CONTRACT, TORT, NEGLIGENCE, PRINCIPLES OF

MANUFACTURER'S LIABILITY, OPERATION OF LAW, CONDUCT, STATEMENT OR

OTHERWISE), INCLUDING WITHOUT RESTRICTION ANY IMPLIED WARRANTY OR

CONDITION OF QUALITY, MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE. ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE TO THE EXTENT REQUIRED UNDER APPLICABLE LAW TO

APPLY TO THE PRODUCT SHALL BE LIMITED IN DURATION TO THE PERIOD

STIPULATED UNDER THIS LIMITED WARRANTY.

IN NO EVENT WILL XANTREX BE LIABLE FOR ANY SPECIAL, DIRECT, INDIRECT,

INCIDENTAL OR CONSEQUENTIAL DAMAGES, LOSSES, COSTS OR EXPENSES

HOWEVER ARISING WHETHER IN CONTRACT OR TORT INCLUDING WITHOUT

RESTRICTION ANY ECONOMIC LOSSES OF ANY KIND, ANY LOSS OR DAMAGE TO

PROPERTY, ANY PERSONAL INJURY, ANY DAMAGE OR INJURY ARISING FROM OR AS

A RESULT OF MISUSE OR ABUSE, OR THE INCORRECT INSTALLATION, INTEGRATION

OR OPERATION OF THE PRODUCT.

Exclusions

If this product is a consumer product, federal law does not allow an