Xantrex GT5.0-NA-240/208 UL-05, GT5.0-NA-240/208-POS UL-05, GT4.0N-NA-240/208 UL-05, GT4.0-NA-240/208 UL-05, GT4.0-NA-240/208-POS UL-05 Owners Manual

...

Grid Tie Solar Inverter

GT5.0-NA-240/208 UL-05

GT5.0-NA-240/208-POS UL-05

GT4.0N-NA-240/208 UL-05

GT4.0-NA-240/208 UL-05

GT4.0-NA-240/208-POS UL-05

GT3.3N-NA-240/208 UL-05

GT3.3-NA-240/208 UL-05

GT3.3-NA-240/208-POS UL-05

GT2.8-NA-240/208 UL-05

GT2.8-NA-240/208-POS UL-05

Owner’s Manual

Xantrex Grid Tie

Solar Inverter

Xantrex Grid Tie Solar Inverter

Owner’s Manual

About Xantrex

Xantrex Technology Inc. is a world-leading supplier of advanced power electronics and controls with products from

50 watt mobile units to one MW utility-scale systems for wind, solar, batteries, fuel cells, microturbines, and backup

power applications in both grid-connected and stand-alone systems. Xantrex products include inverters, battery

chargers, programmable power supplies, and variable speed drives that convert, supply, control, clean, and distribute

electrical power.

Trademarks

Xantrex Grid Tie Solar Inverter is a trademark of Xantrex International. Xantrex and Xanbus are registered

trademarks of Xantrex International.

Other trademarks, registered trademarks, and product names are the property of their respective owners and are used

herein for identification purposes only.

Notice of Copyright

Xantrex Grid Tie Solar Inverter Owner’s Manual © June 2007 Xantrex International. All rights reserved.

Exclusion for Documentation

UNLESS SPECIFICALLY AGREED TO IN WRITING, XANTREX TECHNOLOGY INC. (“XANTREX”)

(

A) MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY OF ANY TECHNICAL OR OTHER

INFORMATION PROVIDED IN ITS MANUALS OR OTHER DOCUMENTATION.

(

B) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSSES, DAMAGES, COSTS OR EXPENSES, WHETHER SPECIAL,

DIRECT, INDIRECT, CONSEQUENTIAL OR INCIDENTAL, WHICH MIGHT ARISE OUT OF THE USE OF SUCH INFORMATION.

T

HE USE OF ANY SUCH INFORMATION WILL BE ENTIRELY AT THE USER’S RISK; AND

(C) REMINDS YOU THAT IF THIS MANUAL IS IN ANY LANGUAGE OTHER THAN ENGLISH, ALTHOUGH STEPS HAVE BEEN

TAKEN TO MAINTAIN THE ACCURACY OF THE TRANSLATION, THE ACCURACY CANNOT BE GUARANTEED. APPROVED

X

ANTREX CONTENT IS CONTAINED WITH THE ENGLISH LANGUAGE VERSION WHICH IS POSTED AT

WWW.XANTREX.COM.

Date and Revision

June 2007 Revision C

Manual Part Number

975-0334-01-01

Product Part Numbers

864-1009 (GT5.0-NA-240/208 UL-05), 864-1011 (GT5.0-NA-240/208-POS UL-05)

864-1007 (GT4.0-NA-240/208 UL-05) 864-1010 (GT4.0-NA-240/208-POS UL-05)

864-1008 (GT4.0N-NA-240/208 UL-05)

864-1004 (GT3.3-NA-240/208 UL-05) 864-1005 (GT3.3-NA-240/208-POS UL-05)

864-1006 (GT3.3N-NA-240/208 UL-05)

864-1001 (GT2.8-NA-240/208 UL-05) 864-1002 (GT2.8-NA-240/208-POS UL-05)

Contact Information

Telephone: 1 800 670 0707 (toll free North America)

Fax: 1 360 925 5143 (direct)

Email: customerservice@xantrex.com

Web: www.xantrex.com

1 360 925 5097 (direct)

About This Manual

The purpose of this Owner’s Manual is to provide explanations and procedures for

installing, operating, maintaining, and troubleshooting the Xantrex Grid Tie Solar

Inverter™.

Scope

The manual provides safety guidelines, detailed planning and setup information. It

provides procedures for installing the inverter and information about operating

and troubleshooting the unit. It does not provide details about particular brands of

photovoltaic (PV) panels. You need to consult individual PV manufacturers for

this information.

Audience

This manual does not provide sufficient information for anyone but a qualified

installer to install this product. Installers should be electricians or technicians fully

educated on the hazards of installing electrical equipment. The monitoring and

operation information in this manual is intended for anyone who needs to operate

a GT Inverter.

Organization

This manual is organized into 6 chapters and an appendix.

Chapter 1 contains information about the features and functions of the Xantrex

Grid Tie Solar Inverter.

Chapter 2 provides information about installing the GT Inverter. It contains

information on determining a suitable location for installation, PV array

requirements, and procedures for mounting the unit.

Chapter 3 provides information about DC and AC wiring, and grounding the GT

Inverter and the PV array.

Chapter 4 contains information on starting up the Xantrex Grid Tie Solar Inverter

and performing a functional test.

Chapter 5 contains information for understanding the LCD screens and the LED

indicators.

Chapter 6 contains information about how to provide general maintenance for the

Xantrex Grid Tie Solar Inverter. It also provides information about troubleshooting

the unit.

Appendix A contains information about the specifications of the Xantrex Grid Tie

Solar Inverter.

975-0334-01-01 iii

About This Manual

Conventions Used

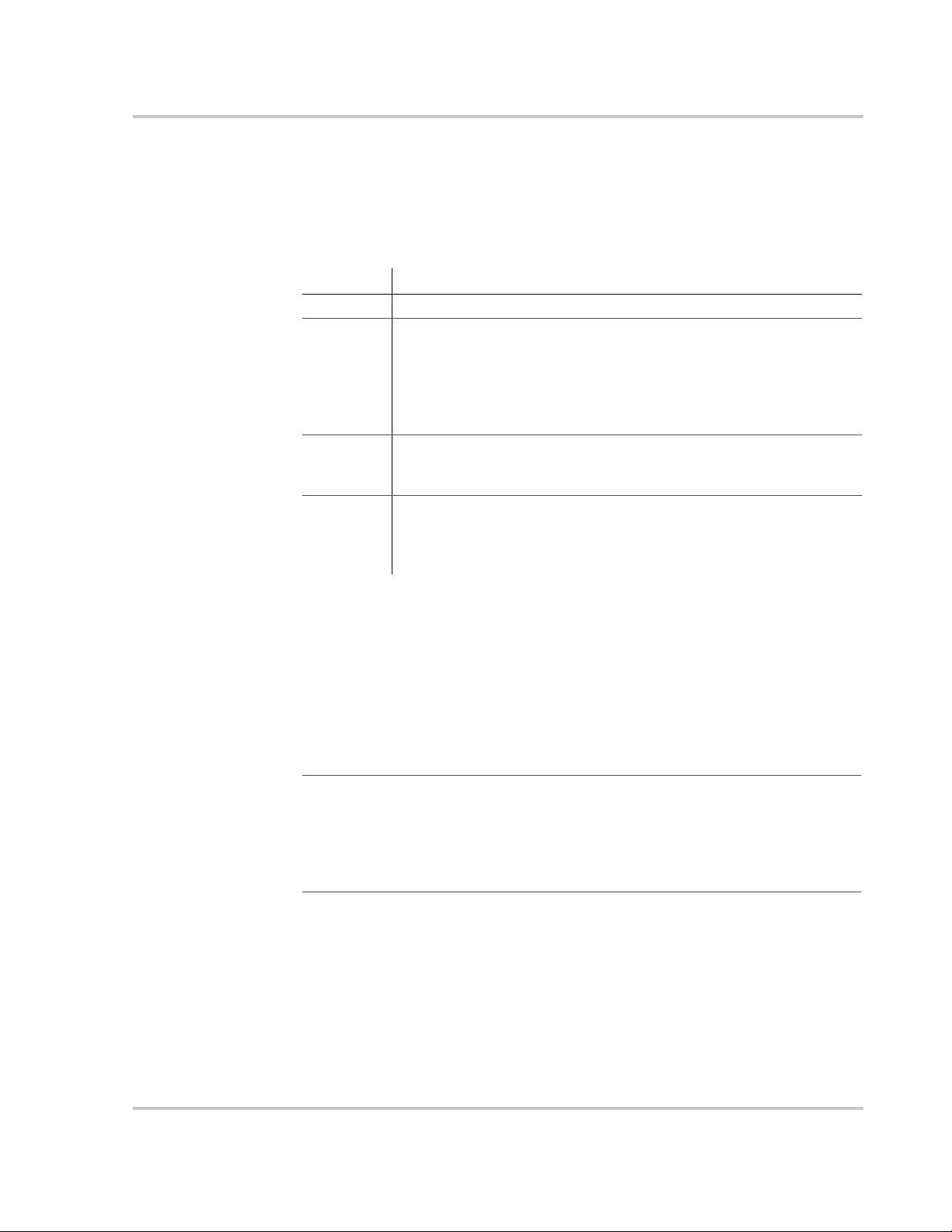

The following conventions are used in this guide.

WARNING

Warnings identify conditions that could result in personal injury or loss of life.

CAUTION

Cautions identify conditions or practices that could result in damage to the unit or other

equipment.

Important:

serious as a caution or warning.

These notes describe things which are important for you to know, but not as

Abbreviations and Acronyms

CEC California Energy Commission

CSA Canadian Standards Association

GFDI Ground Fault Detector/Interrupter

GT Gr id T i e

LCD Liquid Crystal Display

LED Light Emitting Diode

MPPT Maximum Power Point Tracking

NEC US National Electrical Code NFPA-70

PV Photovoltaic

PVGFP PV Ground Fault Protection

STC Standard Test Condition

UL Underwriters Laboratories

Va c Vo lt s A C

Vdc Volts DC

V

V

MPP

OC

Voltage at Maximum Power

Open Circuit Voltage

iv 975-0334-01-01

Symbols Used

5 min.

About This Manual

Ground

In this guide: Important information, warnings, or cautions.

On the product: Important information, warnings or cautions with further

explanation in the product guide.

Caution, risk of electric shock.

Hot surface—risk of burns.

FOR AUTHORIZED SERVICE PERSONNEL: Before opening cover,

disconnect DC and AC power and wait 5 minutes to allow internal voltages

to reach safe levels.

NOTE: there are no user-serviceable parts inside.

Refer to the operating instructions.

Related Information

You can find more information about Xantrex Technology Inc. as well as its

products and services at www.xantrex.com.

975-0334-01-01 v

vi

Important Safety Instructions

SAVE THESE INSTRUCTIONS—This manual contains important instructions that shall be followed

during the installation and maintenance of the Xantrex Grid Tie Solar Inverter.

WARNING

The following warnings identify conditions or practices that could result in personal injury or loss of life.

1. Before installing and using the GT Inverter, read all instructions and cautionary markings on the

inverter, wiring box, and all appropriate sections of this guide.

2. To reduce risk of fire hazard, do not cover or obstruct the heat sink.

3. Under some conditions, the GT Inverter heat sink can reach temperatures hot enough to cause skin

burns if accidentally touched. Ensure that the GT Inverter is located away from normal traffic areas.

4. Use only accessories recommended or sold by the manufacturer. Doing otherwise may result in a risk

of fire, electric shock, or injury to persons.

5. To avoid a risk of fire and electric shock, make sure that existing wiring is in good condition and that

wire is not undersized. Do not operate the GT Inverter with damaged or substandard wiring.

6. Do not operate the GT Inverter if it has received a sharp blow, been dropped, or otherwise damaged in

any way. If the GT Inverter is damaged, see the Warranty section.

7. Do not disassemble the GT Inverter. It contains no user-serviceable parts. See Warranty for instructions

on obtaining service. Attempting to service the GT Inverter yourself may result in a risk of electrical

shock or fire and will void the factory warranty.

8. Authorized service personnel should reduce the risk of electrical shock by disconnecting both AC and

DC power from the GT Inverter before attempting any maintenance or cleaning or working on any

circuits connected to the inverter. Turning off controls will not reduce this risk. Internal capacitors

remain charged for 5 minutes after disconnecting all sources of power.

9. Normally grounded conductors may be ungrounded and energized when a ground fault is indicated.

10. The GT Inverter must be connected to an AC equipment-grounding conductor directly and a DC

grounding electrode conductor to a single point ground.

11. The AC Neutral connection is for voltage sensing only and is not used as a current carrying conductor,

nor is it bonded to ground.

CAUTION

The following caution identifies conditions or practices that could result in damage to the unit or other

equipment.

Observe the clearance recommendations as described on page 2–7. Do not install the GT Inverter in a zeroclearance or non-ventilated compartment. Overheating may result.

975-0334-01-01 vii

Safety

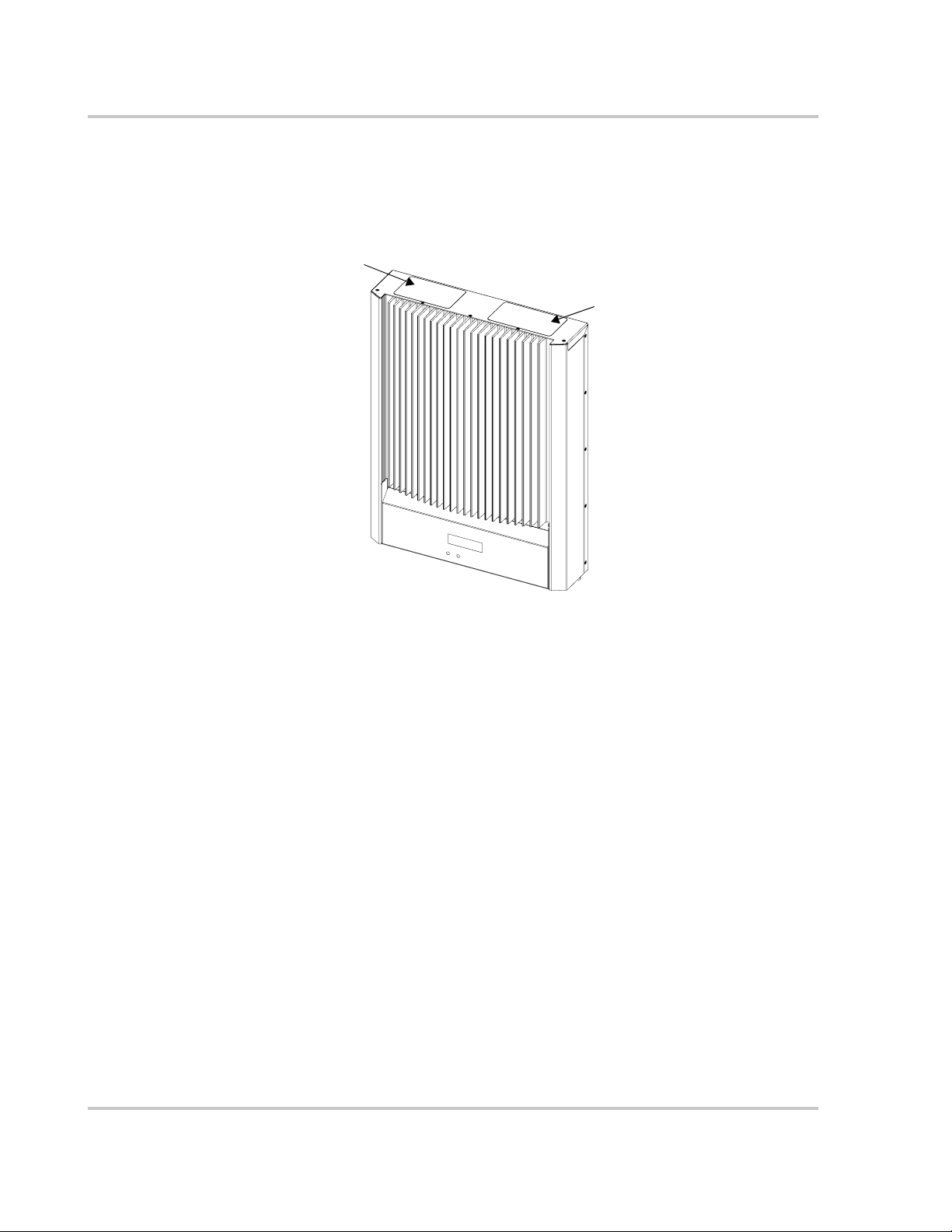

Location of Safety and Data Labels

The figure below shows the location of the safety label and the data label with model, serial number and

part number information.

Data Label

Safety Label

FCC Information to the User

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant

to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates, uses and can radiate radio frequency

energy and, if not installed and used in accordance with the instructions, may cause harmful interference to

radio communications. However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or television reception, which can

be determined by turning the equipment off and on, the user is encouraged to try to correct the interference

by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and the receiver.

• Connect the equipment to a different circuit from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

viii 975-0334-01-01

Contents

Important Safety Instructions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - vii

Location of Safety and Data Labels - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - viii

FCC Information to the User - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - viii

1

Introduction

About the Xantrex Grid Tie Solar Inverter- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–1

Standard Features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–2

Front Panel Features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–3

Wiring/Disconnect Box - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–4

2

Installation

Installation Options - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–1

Planning the Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–1

Inverter Location - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–1

PV Array Voltage and MPPT Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–3

Mounting the Inverter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–4

Dimensions and Knockout Locations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–4

Installing the Mounting Bracket - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–6

Mounting the Inverter on the Bracket - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–8

3

Wiring the Inverter

Grounding Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–1

Ground Fault Fuse - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–3

Wiring Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–4

AC Circuit Breaker Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–4

DC/AC Disconnect Switch - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–4

Accessing the Wiring Terminals - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–5

Connecting the DC Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–7

DC Wiring for Multiple Inverters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–9

Connecting the AC Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–10

DC and AC Wiring for Multiple Inverters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–11

Communications Wiring for Multiple Inverters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–12

Xanbus Network Technology - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–12

Guidelines for Routing the Network Cables - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–15

Connecting Network Cable Between Multiple Inverters - - - - - - - - - - - - - - - - - - - - - - - - - 3–15

Communications Wiring for Monitoring a Single Inverter - - - - - - - - - - - - - - - - - - - - - - - 3–15

975-0334-01-01 ix

Contents

4

Starting the Inverter

Startup Procedure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–1

Checking the PV Array DC Voltage - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–2

Checking the AC Utility Voltage - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–2

Replacing the Wiring/Disconnect Box Cover - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–2

Starting up the GT Inverter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–3

Commissioning Multiple Inverters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–3

Disconnect Test - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–5

Locating the Firmware Version Number- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–5

5

Monitoring the Inverter

Monitoring the Front Panel Display- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–1

Front Panel Display Screens and What They Mean - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–2

Startup Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–2

Normal Operation Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–4

Offline Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–6

Fault Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–8

Special Screens - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5–10

Custom Screens - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5–10

Status Indicator Lights- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–11

6

Maintenance and Troubleshooting

Factors Affecting GT Inverter Performance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–1

PV Array Factors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–1

Other Factors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–2

Performing General Maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–3

Replacing Parts - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–3

Replacing the Ground Fault Protection Fuse - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–4

Replacing the Inverter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–6

Identifying Error/Fault Conditions and Solutions- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–9

A

Specifications

Electrical Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–2

GT5.0 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–2

GT4.0 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–4

GT3.3 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–6

GT2.8 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–8

Adjustable Voltage, Frequency and Reconnection Settings - - - - - - - - - - - - - - - - - - - - - - A–10

Output Power Versus Ambient Temperature - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–11

Environmental Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–11

x 975-0334-01-01

Contents

User Display- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–11

Display Accuracy - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A–11

Mechanical Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–12

Regulatory Approvals - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–12

Warranty and Return Information - - - - - - - - - - - - - - - - - - - - - - - - - - - - -WA–1

Index - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -IX–1

975-0334-01-01 xi

xii

Introduction

1

Chapter 1 contains information about the features and functions of the

Xantrex Grid Tie Solar Inverter.

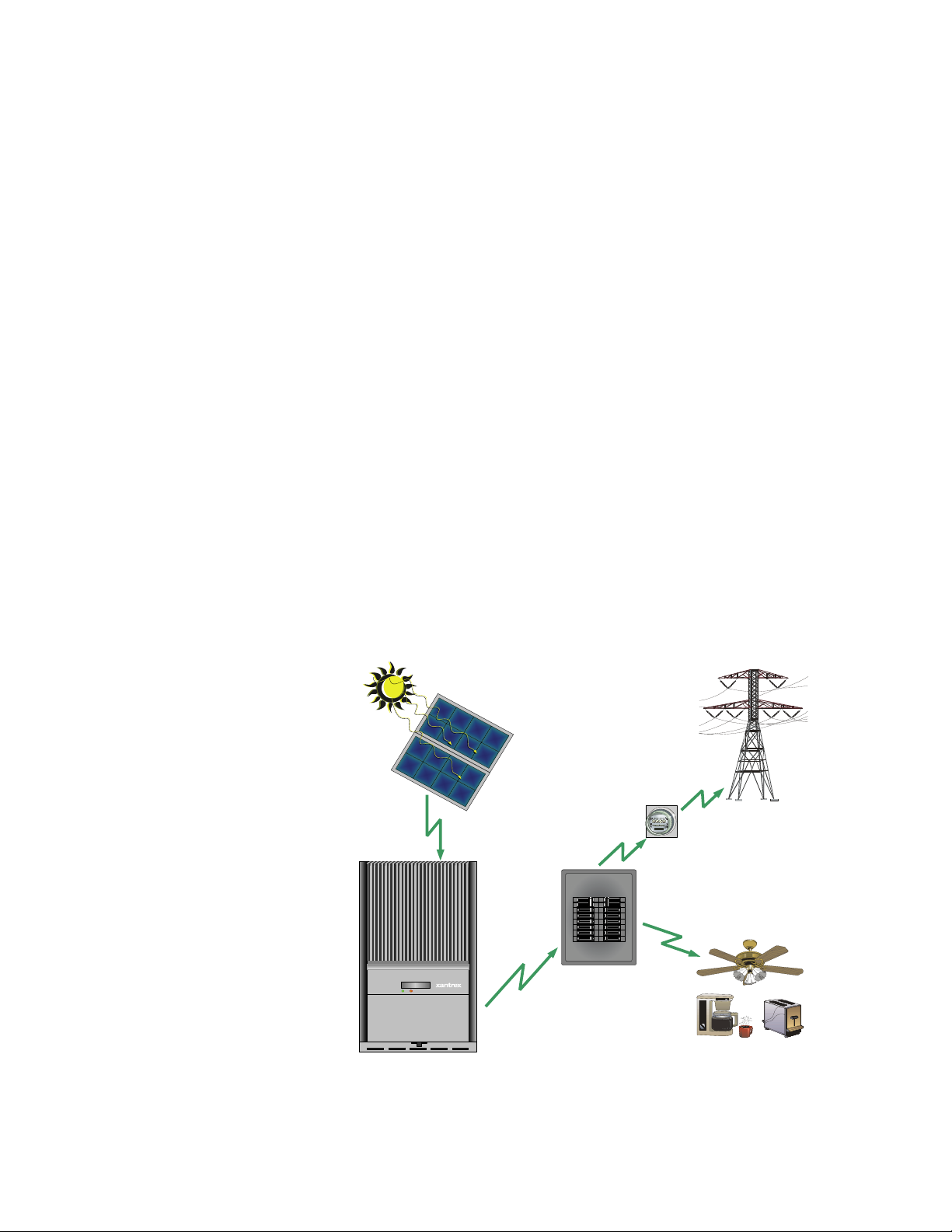

About the Xantrex Grid Tie Solar Inverter

The Xantrex Grid Tie Solar Inverter (GT Inverter) is designed to convert solar

electric (photovoltaic or PV) power into utility-grade electricity that can be used

by the home or sold to the local power company.

Installing the GT Inverter consists of mounting it to the wall and connecting the

DC input to a PV array and the AC output to the utility. See Figure 1-1 for a

simple diagram of a typical installation.

In order to operate, the GT Inverter must have grid power available and connected.

It will not provide backup power if the AC grid fails.

Figure 1-1

Photovoltaic (PV)

Panels - PV Array

Harvested

solar energy

Grid Tie Inverter

GT Inverter

Basic System Overview

DC converted

to AC

Xantrex

Utility

Meter

Utility Grid

Surplus p ower routed

to Utility Grid

Power ro uted

to loads

Main Utility

Service Panel

Loads

Introduction

PV compatibility The GT Inverter is designed to take advantage of solar modules configured as high

voltage PV string arrays—single crystalline, poly crystalline, or thin film—with

an input voltage Maximum Power Point range (depending on inverter model) of

195 to 550 Vdc, 240 to 550 Vdc, 240 to 480, or 200 to 400 Vdc. See “Electrical

Specifications” on page A–2 for more information.

Utility grid

compatibility

The GT Inverter can operate on either 240 V or 208 V nominal grid voltage. The

inverter senses the phase-to-phase voltage and automatically changes the power

limit value for each grid voltage. The disconnect thresholds (see “Adjustable

Voltage, Frequency and Reconnection Settings” on page A–10) remain the same

because both nominal voltages have the same 120 Vac phase-to-neutral

thresholds.

Maximum Power

Point Tracking

(MPPT)

The GT Inverter uses Xantrex proprietary Maximum Power Point Tracking

(MPPT) technology to harvest the maximum amount of energy from the solar

array. Xantrex MPPT learns your array’s specific characteristics, maximizing its

output at all times.

High efficiency The high-frequency, solid-state design of the GT Inverter is extremely efficient.

See Appendix A, “Specifications” for the efficiency ratings of each model.

GT4.0N and

GT3.3N models

Positive-ground

models

The GT4.0N and GT3.3N models feature higher efficiency ratings over a narrower

input voltage maximum power point range.

Xantrex offers positive-ground models (designated by the -POS suffix in the

model name) designed to work with positive-grounded PV arrays. Some brands of

PV modules require positive grounded arrays for increased power harvest.

Although most PV modules work fine with negative-ground GT Inverter models,

the installer must confirm the PV array grounding type with the module

manufacturer before installing the inverter.

Expandable Multiple GT Inverters may be networked together for increased net metering

capacity or future system growth. All models have adjustable voltage and

frequency disconnect settings and can be aggregated above 30 kW on a single

point-of-common-coupling (PCC). See “Adjustable Voltage, Frequency and

Reconnection Settings” on page A–10.

Communications

protocol

The GT Inverter uses the Xanbus

communicate with multiple units connected within the system. For more

®

communications protocol, enabling it to

information, see “Xanbus Network Technology” on page 3–12.

Standard Features

The GT Inverter has the following standard features:

• Sealed inverter section protecting power electronic components;

• Liquid Crystal Display (LCD) providing easy-to-read system status and daily

cumulative energy production information;

• Two LED indicator lights providing status and ground fault indication;

• Wiring/disconnect box providing protection for all AC and DC connections

and eliminating exposed “live” wiring if the inverter is removed.

1–2 975-0334-01-01

WARNING: Shock hazard

The 600 volt DC/AC disconnect in the wiring/disconnect box meets NEC Article 690. It is

a non-serviceable component and shall remain in place. Separating the inverter and

wiring/disconnect box, or removing the wiring/disconnect box cover can expose

energized conductors. PV input circuits in the wiring box ahead of the switch remain

energized even when the switch is in the “off” position—hazardous voltage will still be

present on the DC input (PV) terminals under the clear plastic insulation barrier inside the

wiring/disconnect box.

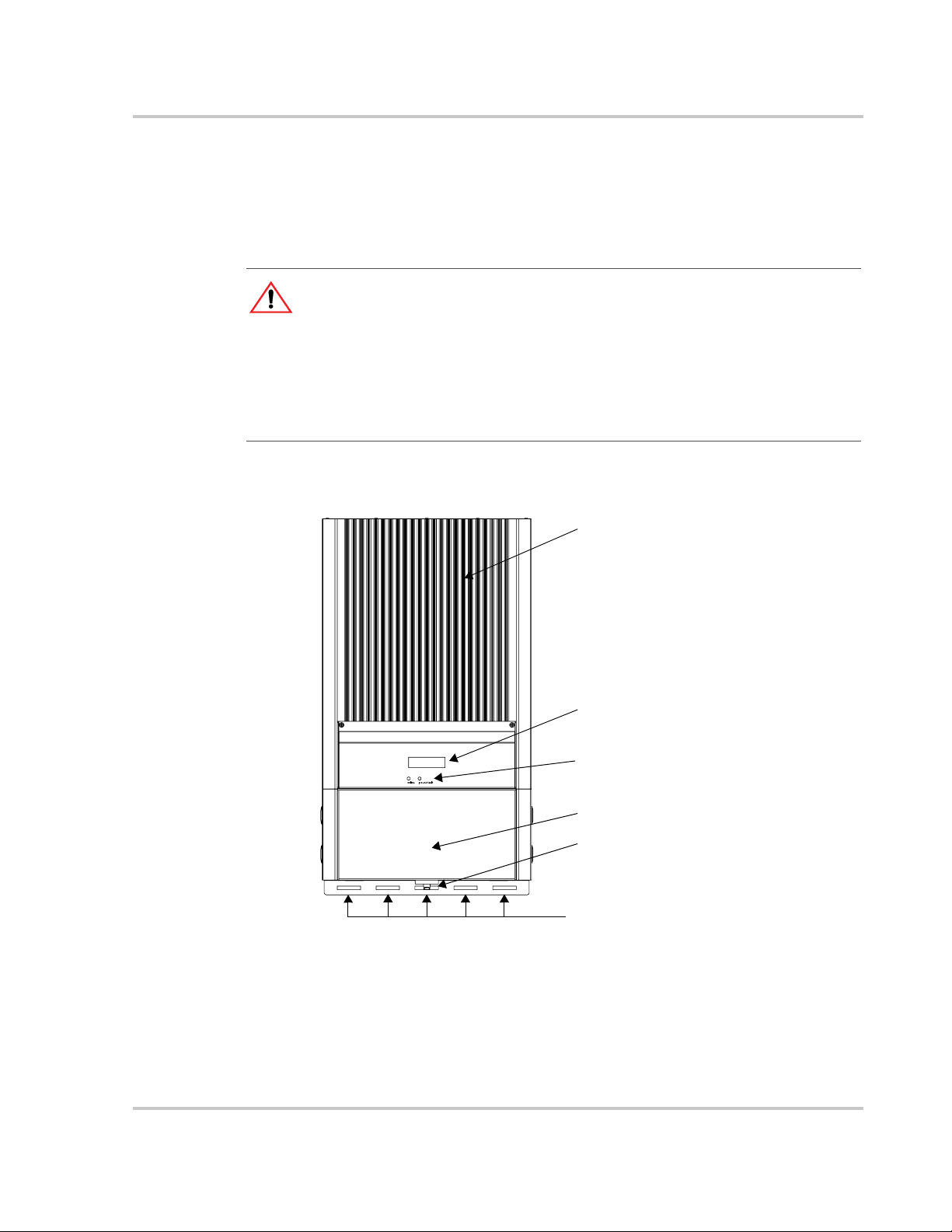

Front Panel Features

About the Xantrex Grid Tie Solar Inverter

The wiring/disconnect box has been designed to be physically mated to the

electronics section of the GT Inverter at the factory, but remains in place as a

non-serviceable item in the event that the inverter electronics section is ever

required to be removed. The inverter and wiring/disconnect box together form

an NEMA 3R enclosure to allow outdoor installation.

Heat sink

LCD

LED indicator lights

Wiring/disconnect box

DC/AC disconnect switch

Mounting slots

Figure 1-2

975-0334-01-01 1–3

Main Features of the GT Inverter

Introduction

Wiring/Disconnect Box

The wiring/disconnect box is standard for all North American models of the GT

Inverter. The wiring/disconnect box provides a location for making AC, DC and

ground connections. It also contains the DC/AC (PV array/utility) disconnect

switch. When used with the GT Inverter, the DC/AC disconnect switch is 600V

AC and DC rated and is identified on the outside by an illustration showing the

open and closed switch positions. The switch is lockable, and meets NEC Section

690 requirements as a means of disconnect.

In jurisdictions where the local utility requires that the AC disconnect be capable

of being locked in the open position by its service personnel, this disconnect

switch can also serve as a lockable isolating device.

Important:

electrical code requirement. Regulatory approval is based on the wiring/disconnect box

always being attached to the inverter during operation. Any attempt to remove this box

will invalidate the approvals and create an electrical hazard.

In North America and other locations the wiring/disconnect box is an

1–4 975-0334-01-01

2

Chapter 2 provides information about installing the GT Inverter. It contains

information on determining a suitable location for installation, PV array

requirements, and procedures for mounting the unit.

Installation Options

The GT Inverter may be installed as a single inverter for a single PV array of one

to three PV strings. Only GT5.0 models can accept three PV strings. An external

fuse box may be required when three PV strings are connected.

The GT Inverter can also be installed in a multiple inverter configuration. If

multiple inverters are used, each inverter must be wired to an independent PV

array.

Communications between inverters can be enabled by installing network cabling

to the inverter RJ-45 ports. See “Connecting Network Cable Between Multiple

Inverters” on page 3–15.

Installation

Planning the Installation

Ensure that you have obtained all permits required by local authorities or utilities

before beginning installation.

Inverter Location

WARNING: Burn hazard

Do not install in a location where people can accidentally come into contact with the front

of the inverter. High temperatures can be present on the face of the inverter, causing a

potential burn hazard.

In extreme conditions, the GT Inverter chassis can reach temperatures over 70° C

(158° F), which can cause skin burns if accidentally touched. Ensure that the GT Inverter

is located away from normal traffic areas.

Installation

Inverter failure due to improper installation will void the inverter warranty.

Consider the following when determining where to install the inverter.

Indoor/

Outdoor

Orientation

• The GT Inverter uses a Type 3R-rated enclosure (vertical mount only)

that can be mounted indoors or outdoors. (Type 3R enclosures are

intended for outdoor use primarily to provide a degree of protection

against falling rain; and to be undamaged by the formation of ice on the

enclosure.)

• While the 3R-rated enclosure protects the GT Inverter from moisture,

outdoor installations should be located away from lawn sprinklers and

other sources of spray.

• A sun shade is recommended for outdoor installations. In bright sun

conditions, when the GT Inverter is at or near full output with an

ambient temperature above 40 °C (104 °F), shading the unit will help

increase inverter performance. A sun shade can also protect the inverter

from dust, debris, and birds. The sun shade should be made from an

opaque material to provide shade for the heat sink. It should be large

enough and positioned so that it shades the heat sink when the inverter

is operating at full power—usually a four-hour time period centered

around noon. Ensure the shade is installed according to the minimum

clearances specified on page 2–7.

• The GT Inverter must be mounted vertically on a wall or pole.

• Do not mount the GT Inverter horizontally.

• If mounting the inverter indoors on a south-facing wall, ensure the wall

is insulated to reduce the amount of heat absorbed by the inverter.

Unless walls are properly insulated, avoid mounting the inverter

indoors on any wall that is directly exposed to the sun.

Temperature

Ground

Clearance

Distance

Debris free

• Ensure that the GT Inverter is mounted in a location where the ambient

temperature range is -25 to +65 °C (-13 to +149 °F).

• Above 40 °C (104 °F), the GT Inverter may derate power output.

See“Output Power vs. Ambient Temperature” on page A–11 and

“Environmental Specifications” on page A–11.

• At extreme cold temperatures, the front panel LCD may not function

normally.

• Outdoors, the GT Inverter requires at least 100 cm (39 inches) of

clearance between the bottom of the unit and the ground.

• To minimize resistance and resulting power loss, ensure that wire

lengths between the PV array and the GT Inverter and between the

inverter and the main utility service panel are kept to a minimum.

• Maximum distances will depend on wire gauges used and PV array

output voltages.

• Excessive debris (such as dust, leaves, and cobwebs) can accumulate

on the unit, interfering with wiring connections and ventilation. Do not

install in a location where debris can accumulate (under a tree, for

example).

2–2 975-0334-01-01

PV Array Voltage and MPPT Requirements

WARNING: Shock hazard

Whenever a PV array is exposed to sunlight, a shock hazard exists at the output wires or

exposed terminals. To reduce the risk of shock during installation, cover the array with an

opaque (dark) material before making any connections, and always test for voltage before

touching exposed wiring or devices.

Planning the Installation

MPPT operational

window

The MPPT software maximizes the output energy of solar arrays as long as the

operating voltage is within the MPPT operational window of the inverter. Ensure

that the open circuit voltage (V

) of the PV array is within the MPPT operational

oc

window. See “Input voltage, Maximum Power Point Range” in Appendix A,

“Specifications” for the MPPT operational window of each GT Inverter model.

Effects of array voltages outside of the MPPT operational window are shown in

Table 2-1 .

Table 2-1

Voltage Effect of Array Voltage Inverter Mode

V

< Lower limit of MPPT range Inverter not operating. Off-line

oc

V

MPP

(V

oc

V

MPP

V

MPP

and absolute maximum V

V

MPP

(or V

Voltage

requirements

MPPT Operational Window

< Lower limit of MPPT range

> Lower limit of MPPT range)

within MPPT range Maximum harvest of solar energy. On-line (MPPT window)

between upper limit of MPPT range

oc

> absolute maximum Voc

> absolute maximum Voc)

oc

The maximum power point voltage (V

Operating voltage shifts to lower limit of

MPPT range; the array is not at its

maximum power point.

Does not allow maximum harvest of solar

energy.

Inverter stops delivering power and shuts

down. Inverter may be damaged.

) of a string connected to the GT

MPP

On-line (low power)

On-line (power derating)

Off-line (shutdown)

Inverter should preferably be above the lower limit of the MPPT range for that

model. If it is below the lower limit of the MPPT range, the inverter continues to

operate, but it regulates the PV voltage to the lower limit of the MPPT range.

Because the array is not operating at its maximum power point, this may result in

lower than expected energy harvest. If V

is below the lower limit of the MPPT

oc

range, the inverter remains off-line and does not deliver power.

CAUTION: Equipment damage

To prevent damage to the inverter, the array voltage must never exceed 600 Voc (open

circuit voltage) under any condition.

975-0334-01-01 2–3

Installation

The short circuit current (Isc) rating of the array at any temperature must not

exceed the I

rating of the inverter. For maximum solar energy harvest, it is

sc

recommended that the effective power output of the array be matched with the

input power capacity of the inverter.

Guidelines for Matching PV Array Size to Xantrex Grid Tie Solar Inverter Input

• Consider the expected Voc of the string under all possible conditions. The

panel manufacturer provides a V

°C (77 °F). Ensure that the V

25

does not exceed 600 Vdc. Panel voltage increases in cold temperatures—the

panel manufacturer should be able to provide a coefficient of voltage increase

per degree.

• The NEC also has required temperature/voltage deratings that must be used;

these can be found in Article 690 of the NEC. You need to determine the

coldest temperatures expected on the site, and size the array strings

accordingly. To prevent inverter damage, the array’s maximum DC voltage in

the coldest expected temperature, with both manufacturer coefficient and

NEC derating, must not exceed 600 Vdc.

• Panel voltage decreases in high temperatures. This will affect the panels’ V

and V

. Again, the manufacturer’s coefficient must be used with the highest

oc

expected temperature to determine the minimum V

rating per panel, but it is usually rated at

oc

rating at the coldest ambient temperature

oc

and Voc.

MPP

MPP

Note:

The GT PV array sizing tool is available at www.xantrex.com.

Mounting the Inverter

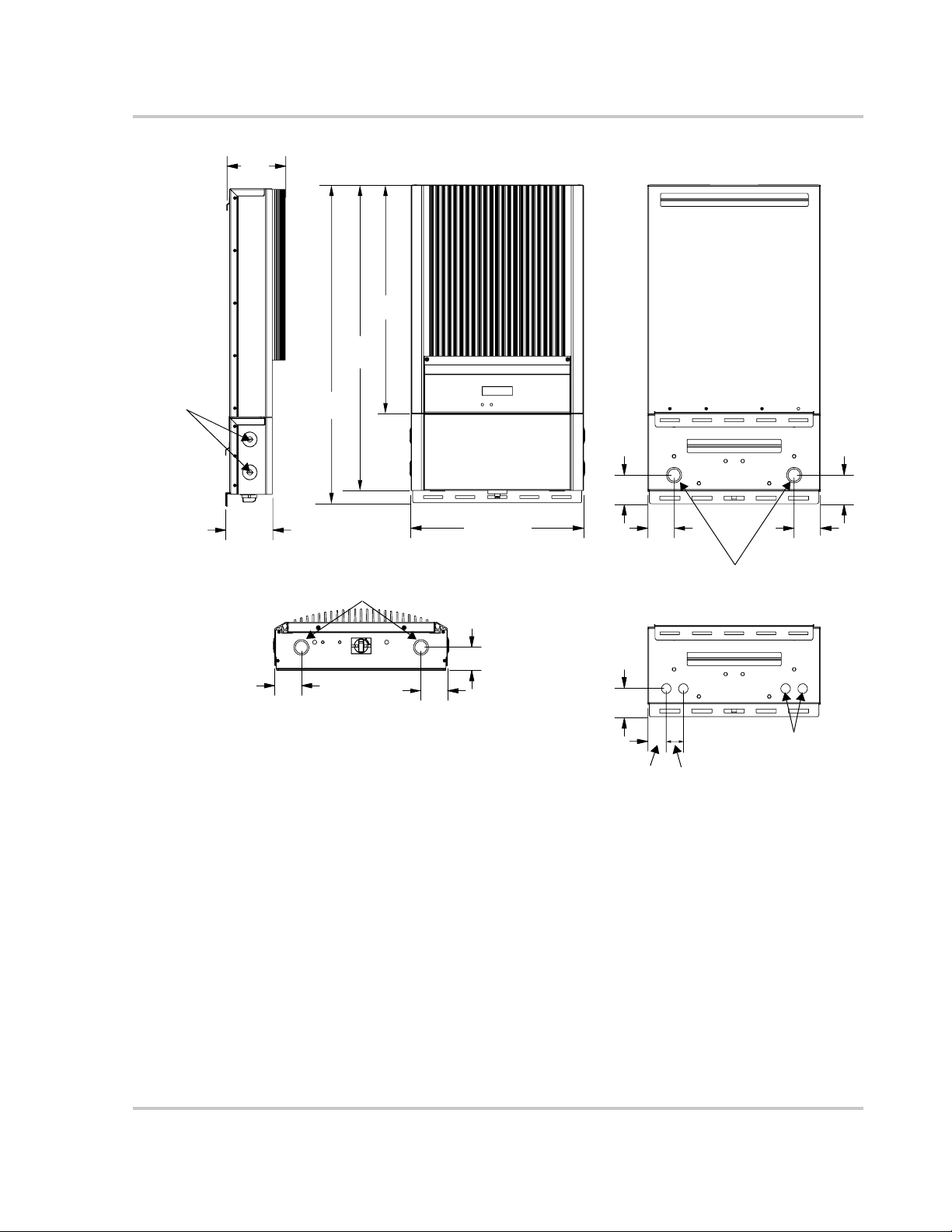

Dimensions and Knockout Locations

Inverter dimensions and knockout locations are shown in Figure 2-1.

Four 27 or 35 mm (1 or 1-3/8 inch) dual knockouts are provided on the back and

bottom of the unit to accommodate wiring. -POS models have four 22 mm

(7/8 inch) knockouts on the back of the wiring/disconnect box.

Four 27 mm (1 inch) conduit holes on the sides of the wiring/disconnect box (two

on each side) are filled with plastic plugs (thread size Pg 21). These plugs can be

removed to insert conduit nipples as required for multiple inverter installations.

Side conduit holes may be used to accommodate network communication cables

connected between multiple inverters.

Important:

knockouts provided for conduit entry.

Do not drill, cut, or punch holes in the wiring/disconnect box. Use only the

2–4 975-0334-01-01

27 mm (1")

conduit holes

with threaded

caps, both

sides

137

(5

3/8)

726

(28

9/16)

699

(27

550

(21

1/2)

5/8)

65.2 (2

Mounting the Inverter

9/16)

Figure 2-1

110

(4

5/16)

403 (15 7/8)

Dual 35 mm or 27 mm

(1 3/8" or 1") knockouts

52 (2)

7/16)

62 (2

279 (11)

All measurements in mm (inches).

GT Inverter Dimensions and Knockout Locations

Dual 35 mm or 27 mm

(1 3/8" or 1") knockouts

-POS Model Rear Knockouts

63.5 (2 ½)

41.5 (1 5/8) 40 (1 9/16)

279 (11)

61.5

7/16)

(2

22 mm (7/8")

knockouts

975-0334-01-01 2–5

Installation

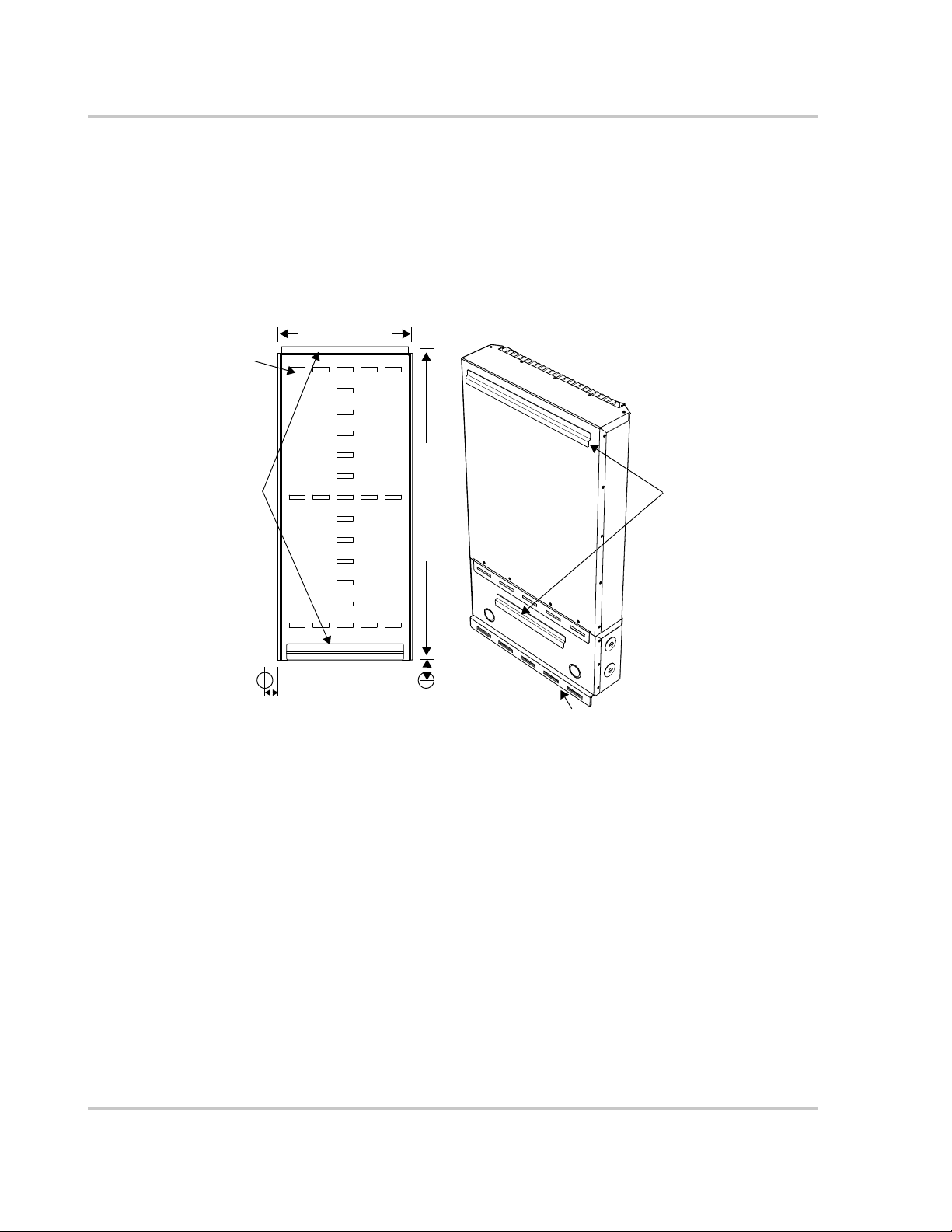

Installing the Mounting Bracket

Secure the mounting bracket to a vertical structure or surface. The GT Inverter

mounting hooks attach to the flanges on the mounting bracket. Mounting bracket

dimensions are shown in Figure 2-2.

If mounting more than one inverter, install each mounting bracket at least 150 mm

(6 inches) apart to provide enough space for the inverters to hang side by side.

Mounting bracket Back side of the inverter

253 (10)

Rectangular slots × 25:

8 × 30 (5/16 × 1

3/16)

Mounting flanges

All measurements

in mm (inches).

Figure 2-2

13 (1/2) from side of bracket

to knockout center

Mounting Bracket and GT Inverter

579 (22 3/4)

38 (1 1/2) from

bottom of bracket

to knockout center

Mounting hooks

Mounting slots for

securing the inverter

2–6 975-0334-01-01

Clearance Requirements

For optimal and safe operation, ensure there is adequate clearance around the

inverter. If the minimum clearances in Table 2-2 are not met, rated power may not

be achieved.

Mounting the Inverter

Surfaces for Mounting

Table 2-2

Location Minimum Clearance

Above 300 mm (12 inches)

Below:

•Inverter

• Bracket

In front 300 mm (12 inches) minimum. 910 mm (36 inches) are recommended for

On sides

Inverter Clearance Requirements

Outdoors:

• 100 cm (39 inches)

• 110 cm (43 inches)

For indoor installations, there is no clearance

requirement between the bottom of the

inverter and the ground.

easy access for reading the display, avoiding accidental contact with hot

surface, and servicing the inverter.

Units can be mounted side by side with no clearance between them, but

150 mm (6 inches) of clearance around the outside edges of the outermost

two units is recommended. In hot climates, some clearance between units

may be needed to prevent thermal derating.

The inverter extends

below the bracket by

approximately 100 mm

(4 inches)

The GT Inverter can be mounted to a vertical surface such as wallboard, wood

siding, concrete wall, or pole assembly. Ensure the mounting surface or structure

can support the weight of the inverter (26 kg/58 lb) as well as the associated

wiring and conduit. Installation onto wallboard requires either the use of a

supporting material such as plywood or securing the mounting screws to

supporting wall studs.

Important:

• Local codes may impose additional mounting requirements in earthquake or other

high-risk areas.

• No mounting hardware is supplied with the GT Inverter. It is recommended to use

6 mm (¼ inch) diameter fasteners. However, because mounting surfaces can vary,

installers must select appropriate hardware for each installation.

975-0334-01-01 2–7

Installation

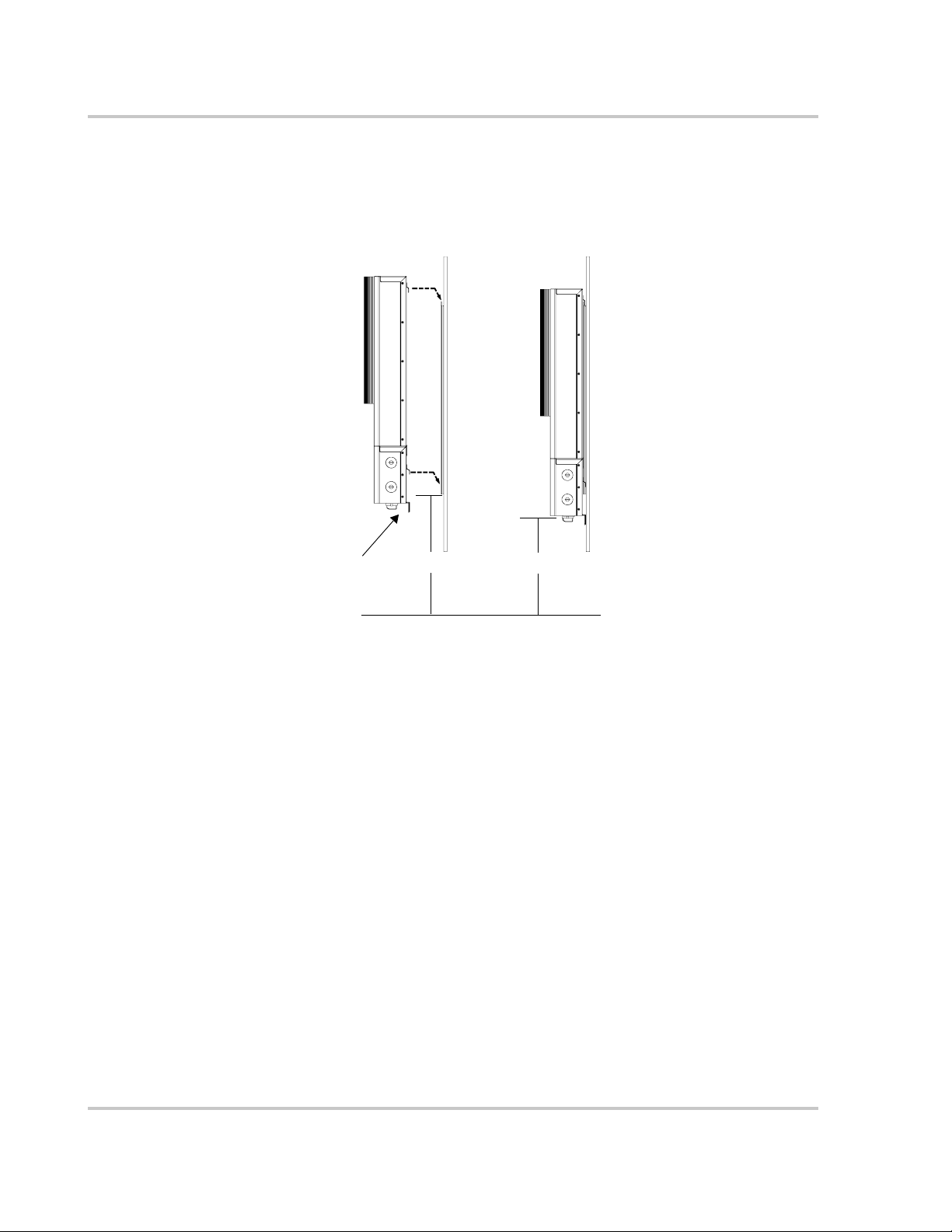

Mounting the Inverter on the Bracket

Place the inverter’s mounting hooks over the flanges on the bracket. Ensure the

inverter is seated properly, then secure the bottom of the inverter with appropriate

screws or anchors through the mounting slots.

Flange with

mounting slots

Figure 2-3

110 cm (43")

Ground/floor

100 cm (39")

Ground clearance

required for outdoor

installation

Placing the Inverter on the Mounting Bracket

2–8 975-0334-01-01

Wiring the Inverter

3

Chapter 3 provides information about DC and AC wiring, and grounding

the GT Inverter and the PV array.

This chapter does not provide sufficient information for anyone but a

qualified installer to install this product. Installers should be electricians or

technicians fully educated on the hazards of installing electrical equipment.

Grounding Requirements

AC Grounding The GT Inverter must be connected to the AC ground from the utility via the GT

Inverter ground bar.

PV Grounding The PV array (frame) ground should be connected to the GT Inverter ground bar.

The size for the conductor is usually based on the size of the largest conductor in

the DC system.

A DC grounding electrode conductor may be required by the Authority Having

Jurisdiction (AHJ). Use the GT Inverter ground bar for this connection (see

Figure 3-2 on page 3–3).

CAUTION: Equipment damage

Provide adequate clearance for grounding wires inside the GT Inverter wiring box. Ensure

that the bare copper grounding wire is more than ½ inch clear of the DC/AC interconnect

circuit board.

Two ¼-inch (7 mm) knockouts in the bottom of the wiring box are intended for

routing the ground conductors to the ground bar. See Figure 3-1.

Loading...

Loading...