Wilbur Curtis RU-225-35 Service Manual

MODELS INCLUDED

• RU-150

• RU-225

• RU-300

• RU-600

• RU-1000

Wilbur Curtis Co., inC.

Service Manual – RU Series Automatic Urns

Important Safeguards/Symbols

This appliance is designed for commercial use. Any servicing other than cleaning and maintenance

should be performed by an authorized Wilbur Curtis service center.

• Toreducetheriskofreorelectricshock,donotopensideorbottompanel.Therearenouser

serviceable parts inside.

• All repairs should only be performed by authorized service personnel.

• Keep hands and other items away from hot parts of the unit during operation.

• Never clean with scouring powders, bleach or harsh chemicals.

Symbols:

WARNING/CAUTION – To advise about conditions that may result in property damage,

personal injury or death

IMPORTANT – Notes about proper operation

Sanitation requirements

The RU Automatic Urn is factory pre-set and ready to go… right from the carton.

Factory Settings:

WARNING: HOT

LIQUID, Scalding

may occur. Avoid

splashing.

ISO 9001:2008 REGISTERED

WILBUR CURTIS CO., INC.

6913 West Acco Street

Montebello, CA 90640-5403

For the latest information go to

www.wilburcurtis.com

Tel: 800-421-6150

Fax: 323-837-2410

• Brew Temperature = 200°F

• Brew Volume = Set to requirements of coffee liner

System Requirements

•WaterSource:20–100psi(minimumowrateof1gpm)

• Electrical: See attached schematic for standard model or visit www.wilburcurtis.com for your

model.

CAUTION: Please use the setup procedures in this manual before attempting to use the

brewer. Failure to follow the instructions can result in injury or the voiding of the warranty.

See setup procedures on page 2.

Brewing Instructions

1. Place lter in basket.

Pour coffee into lter.

Place basket into liner.

Technical Support: 800-995-0417 M-F 5:30 a.m. - 4:00 p.m. PT

2. Rotate spray head over

bed of coffee inside

lter.

Email: techsupport@wilburcurtis.com

3. Press BREW button on

control panel to begin

brewing.

INSTALLATION AND OPERATING INSTRUCTIONS

SETUP STEPS

WARNING: DO NOT place this urn closer than six [6] inches from wall. Urn must have adequate cross-ventilation.

NOTE: A water ltration system must be used to help maintain trouble-free operation. Air must

be purged from the cartridge prior to connection to equipment. In areas with extremely hard

water, we recommend the use of a Curtis approved water lter. For our full line of lters, please

log on to www.wilburcurtis.com.

1. Attach adjustable legs, threading them into

the holes beneath the four corners of the urn.

2. Place unit at counter height, on a rm, level

base, near water and power supply connections. Level it left to right and front to back by

rotating the feet on the 4 corners.

WARNING: Use the leveling legs

to level the brewer only. Do not

use them to adjust brewer height. Do not

extend them higher than necessary.

3. Install the water and coffee faucets.

4. Connect water line to inlet tting on valve. All

Curtis automatic urns are equipped with a ¼”

male are tting which must be connected

to the water supply with a ¼” copper tubing

and a ¼” are nut. Water pressure entering brewer is required to be stable and must

provide minimum of 1 gallon per minute. Use

water regulator for constant pressure. Required water pressures, 20 to 100 psi.

CAUTION: Don’t forget to close the

valve once the water jacket has lled.

8. When the water jacket has lled, turn on the

thermostat by turning the dial clockwise to

the desired setting. It will take 50 to 60 minutes for the heating tank to reach operating

temperature. On electric urns, the thermostat

indicator will light at this time.

WARNING: When you hookup an

electric urn, use the proper wire

gauge, plus 25% (see table on page 12).

Never use fuses or breakers larger than

needed.

The body of the urn must be securely

grounded with a separate grounding

conductor and never with the neutral

conductor of a single phase, 3 wire system.

Refer to the wiring diagram included with

each urn for wire gauge.

CAUTION: DO NOT connect this urn

to hot water. The inlet valve is not

rated for hot water.

5. Turn on water valve.

6. Hook-up electrical power to the unit (refer to

schematic for power requirements). If gas or

steam, 120V circuit is required.

7. When power is turned on, water will start owing into the water jacket. To expedite the lling

of the urn, you may use the emergency rell

valve located behind the machine.

2

CARE AND MAINTENANCE OF URN

PREVENTIVE MAINTENANCE

1. Remove the spray head from the urn and

clean it once a week. More often in heavy lime

areas.

WARNING: Switch off the power to the

unit at the circuit breaker. Turn off the

water line running to the urn.

2. Clean the faucet seat cups twice a week and

replace when cracked or leaking.

3. Periodic temperature checks and thermostat

adjustments should be made by authorized

personnel.

CLEANING

To ensure the highest quality coffee, the urn must

be cleaned daily after the last batch of coffee is

used.

Regular cleaning and preventive maintenance is

essential in keeping your coffee urn looking and

working like new.

CAUTION: Do not use cleaning products

containing chemicals that will damage stainless steel, ammonia and bleaches containing

chlorine. Never use abrasives that will scratch the

outside surface of the urn.

DAILY CLEANING INSTRUCTIONS

WARNING: These steps involve working

with very hot water.

1. After all the brewed coffee has been drawn

from the urn, run a brew cycle of fresh water.

Spray the hot water into the liner, then thoroughly brush it out with a long handled brush.

TWICE A WEEK

The coffee urn liner must be scoured twice a

week:

1. Be sure water jacket is full of water and at

brewing temperature.

2. Fill the liner with several gallons of water and

add at least 1½ ounces of coffee urn cleaning

compound. Allow this solution to remain in the

liner approximately 30 minutes. During this

time, the thermostat should be set to BOIL.

WARNING: Very hot water.

3. Scrub the inside of the liner and cover with a

long handled brush.

4. Drain all the urn cleaning solution and rinse

by running several brew cycles with the spray

head centered over the liner, draining the

rinse water between sprays.

5. Thoroughly clean the faucets.

WARNING: Never remove the faucet

when the liner has water or coffee in it.

Switch off the power to the unit at the circuit

breaker. Turn off the water line running to the

urn.

Use a long thin gauge glass brush to clean the

coffee gauge glass. Use the same brush to

clean the tting at the bottom of the liner and

the pipe connecting to the coffee faucet.

6. Leave a gallon or two of fresh water in the

liner. Drain just before brewing coffee.

7. After the unit is clean, turn on the water supply and power to the unit.

2. Drain the water off then repeat step one. Run

another brew cycle. Brush out the liner and

drain. Wipe down the liner with a clean towel.

3. If urn is not going to be used immediately, pour

a gallon or two of fresh water into the liner. Remember to drain off this water before making

another brew.

4. Wash the wire brew baskets with urn cleaner

and rinse thoroughly.

3

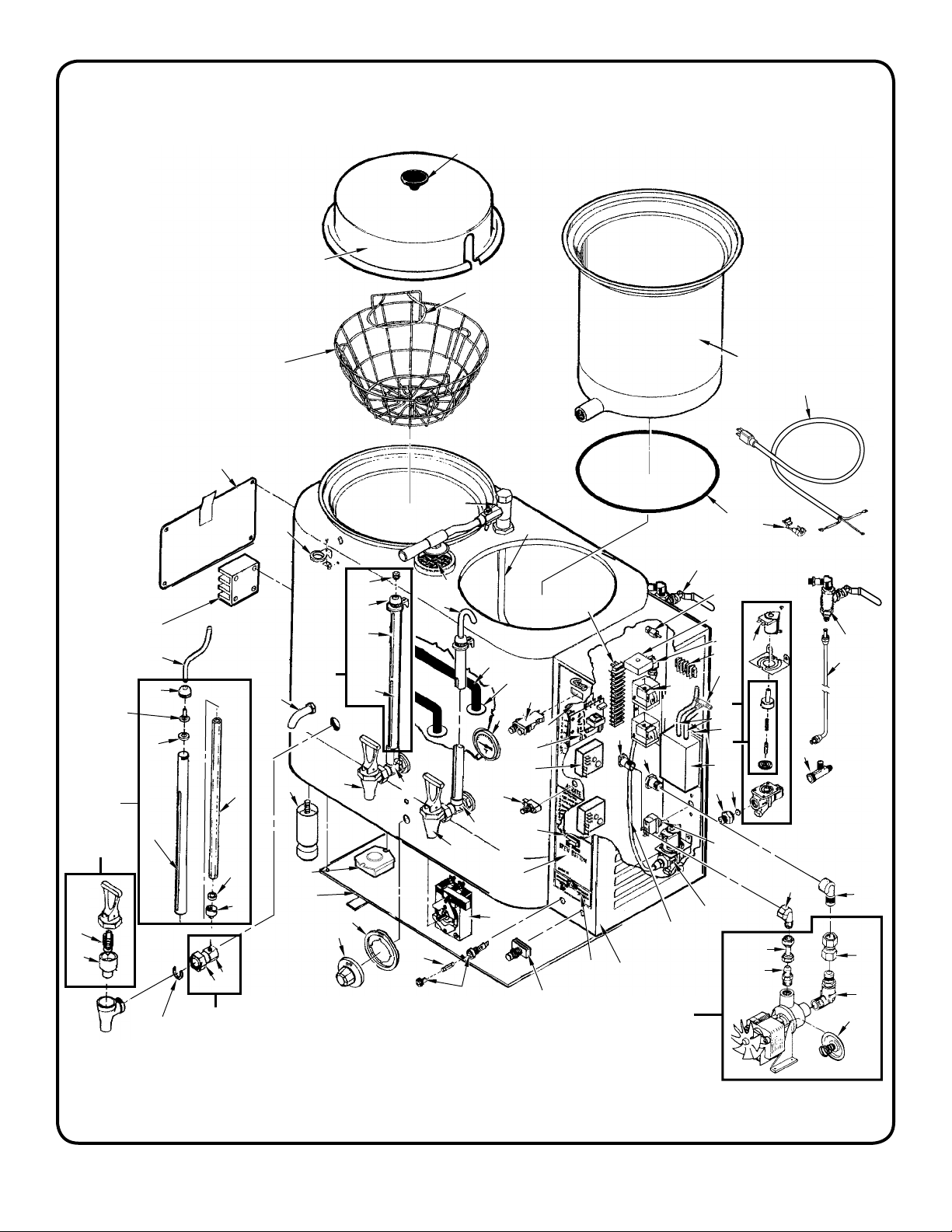

ILLUSTRATED PARTS LIST AUTOMATIC URNS,

RU-150, RU-225, RU-300, RU-600, RU-1000 ELECTRIC

1

2

2A

17

3

3A

3B

85

54

58

60

61

34

35

78

78A

78B

78C

77

76

83

84

48

36

69

61

82*

81

80

80A

80B

80C

79

80D

79A

79B

79C

71

87

70

75

73

72

74

63

63A

63B

63C

62

64

64A

64B

64C

66

15

11

56

35

65

74

67

51

50

53

41

41A

41B

91

86

86A

42

52

43

44

45

46

42

47

47A

47B

47C

27

49

21

21A

21B

21C

34

31

31A

31B

37

37A

33

32

32A

25

4

4A

4B

4C

5

8

39

40

68

11

16

20

12

35

19

13

18

14

15

38

12

29

28

6

7

8

9

9A

10

30

22

23

24

26

*82 NOT INCLUDED WITH GAUGE GLASS ASSEMBLY.

4

INDEX №PART

№

DESCRIPTION

EQUIPMENT USED ON

1 WC-3205 KNOB, LID 1/4-20 FEMALE THRD USE ON WC-5601/2/3 ALL RU URNS

2 WC-5601 LID, LINER ASSY (SC)RU-150/300 RU-150, RU-300

2A WC-5603 LID, LINER ASSY RU225/600/1000 RU-225, RU-600, RU-1000

3 WC-3302 BREW BASKET WIRE W/FLAPS RU-300 RU-150, RU-300

3A WC-3303 BREW BASKET, WIRE W/ FLAPS RU-600 RU-225, RU-600

3B WC-3304 BREW BASKET, WIRE W/ FLAPS RU-1000 RU-1000

4 WC-5700 LINER, 3 GAL RU-150 RU-150

4A WC-5706 LINER, 6 GAL RU-600 RU-225, RU-600

4B WC-5704 LINER, 3 GAL RU-300 RU-300

4C WC-5708 LINER, 10 GAL RU-1000 RU-1000

5 WC-4303 O-RING, LINER RU-150/300 RU-150, RU-300

5A WC-43076 O-RING, LINER, RU’S, 6, 10 GA RU-225, RU-600, RU-1000

6 WC-1200 CORD, 14/3 SJTO 6’ BLK W/PLUG ALL GAS, STEAM & 3Ø RU URNS

7 WC-1408 GRIP, CORD 7/8” OD ALL GAS, STEAM & 3Ø RU URNS

8 WC-806 VLVE, 1/4” BR. BALL ASSY EMERGENCY REFILL RU’S ALL RU URNS

9 WC-53104 TUBE ASSY, 1/4x14.50 ER W/NUTS RU-150/300 RU-150, RU-300

9A WC-53105 TUBE ASSY, 1/4x17.00 ER W/NUTS RU-225/600 RU-225, RU-600

9B WC-53109 TUBE ASSY, 1/4” ER W/NUTS RU-1000 RU-1000

10 WC-2705 TEE, 1/4 X 1/4 FLARE X 3/8 NPT PLATED ALL RU URNS

11 WC-3217 KNOB, ELECTRIC THERMOSTAT RU ALL RU URNS

12 WC-801 VALVE, INLET BRASS .50 GPM 120V 10W RU/WB ALL RU URNS

13 WC-3700 KIT, INLET VAL. REP. USE ON WC-801/801R/885/890/858 ALL RU URNS

14 WC-813 FLOW WASHER, .5GPM .5” S45 ALL RU URNS

15 WC-3220 BEZEL, THERMOSTAT ELECTRIC URN’S ALL RU URNS

16 WC-3011 TERMINAL STRIP, 4-S ALL RU URNS (BEFORE 1/29/13)

17 WC-3305 FLAP, WIRE BASKET RU150/300 (2 REQUIRED) RU-150 & RU-300

18 WC-37166 KIT, AIR PUMP RU’S ALL RU URNS

19 WC-5843 BRACKET, AERATOR PUMP RU ALL RU URNS

20 WC-3600 TEE, CONNECTOR 3/16 POLYPROPYLENE RU-150 & RU-225

21 WC-38570 LABEL, INSTRUCTION PANEL RU150/RU-300 RU-150 & RU-300 (AFTER 1/29/13)

21A WC-38571 LABEL, INSTRUCTION PANEL RU225/RU-600 RU-225 & RU-600 (AFTER 1/29/13)

21B WC-38574 LABEL, INSTRUCTN PANEL RU1000 RU-1000 (AFTER 1/29/13)

22 WC-2405 ELBOW, 1/2 FLARE x 1/2 NPT ALL RU URNS

23 WC-2609 SWIVEL, 1/2” TUBE X 1/2 NPT ALL RU URNS

24 WC-2504 ELBOW, 1/2 NPT X 1/2 NPT ALL RU URNS

25 WC-1037 PUMP, WATER W/FITTINGS 120VAC ALL RU URNS

26 WC-3702 KIT, WATER PUMP SEAL RU’S USE ON WC-1000 ALL RU URNS

27 WC-37165 KIT, THERMOSTAT WC-500A/501A ALL RU URNS

28 WC-2605 CONNECTOR, 3/8 FLARE X 3/8 NPT ALL RU URNS

29 WC-2608 SWIVEL, 3/8 TUBE x 3/8 NPT ALL RU URNS

30 WC-2403 ELBOW, 3/8 FLARE x 3/8 NPT PLATED GEN USE ALL RU URNS

31 WC-5808 DOOR, CONTROL BOX LOUVER, RU-225/600 RU-225, RU-600

31A WC-5807 DOOR, LOUVER ACB RU150/300 RU-150, RU-300

31B WC-5809 DOOR, CONTROL BOX LOUVER RU-1000 RU-1000

32 WC-5322 TUBE ASSY, 1/4x20.00 WI W/NUTS RU-225, RU-600

32A WC-5321 TUBE ASSY, 1/4x17.00 WI W/NUTS RU-150, RU-300

33 WC-2929P FITTING, 1/2 NIPPLE/NUT PLATED ALL RU URNS

34 WC-300 POWER BLOCK 3-STA 175A 600V RU’S ALL RU URNS

35 WC-5307 TUBE, 3/16 ID x 3/32W SILICONE GEN USE ALL RU URNS

36 WC-522 THERMO., HI LIMIT HEATER CONTROL DPST 277V 40A ALL RU URNS

37 WC-402

37A WC-403

1,2

RELAY, HOLDING 120V COIL 10A RU’S ALL RU URNS (BEFORE 1/29/13)

1,2

RELAY HOLDING 120V 3 POLE 6.6A RES.@240V RU-1000 (BEFORE 1/29/13)

38 WC-102 SW, TOG NON-LIT SPST 15A 125/6A 250VAC RESIST. ALL RU URNS

1

OLDER UNITS

2

ITEMS 37 AND 37A, AFTER 1/29/13 SEE ITEMS 45, 45A, 45B

5

INDEX №PART

№

DESCRIPTION

EQUIPMENT USED ON

39 WC-5502-01 KIT, PRB, ASSY WATER LVL W/HEX FITTING, O-RNG & NUT ALL RU URNS

40 WC-405R-101 TIMER, AGITATION 90-260 VAC 30 SEC ALL RU URNS

40A WC-405R TIMER, AG. 120V 50/60HZ W/WIRES & BRKT RU’S ALL RU URNS

41 WC-304

1

TERMINAL STRIP, 14-S(RU1,6) RU-225, RU-600, RU-1000

41A WC-3031 TERMINAL STRIP 12-S RU-150, RU-300

41B WC-3021 TERMINAL STRIP, 6-S(GM,CRA) RU-1000

42 WC-3737 KIT, BREW SWITCH 120V RU’S ALL RU URNS

43 WC-58021 BRACK., WTR LVL. CONT. RU-150/225/300/600/1000 ALL RU URNS

44 WC-608-101K KIT, LIQUID LEVEL CONTROL BOARD RETROFIT ALL RU URNS

45 WC-603-101K-RU KIT, RET. TIMER, BREW SELECTOR 120V RU-300 W/1/2BB SEE NOTE

NOTE: 120V RU URNS BUILT BEFORE JAN. 2013

45A WC-603-101 TIMER, BREW SELECTOR 120V 2-20 MIN GEM-120A/RU’S SEE NOTE

NOTE: 120V RU URNS (EXCEPT RU-1000) BUILT JAN. 2013 AND AFTER

45B WC-603-102 TIMR., BRW. SELT. 120V 2-20 MIN W/FULL & 1/3 BTCH OPT SEE NOTE

NOTE: 120V RU-1000 URNS BUILT BEFORE JAN. 2013

45C WC-622-101K-RU KIT, RETROFIT BREW TIMER FULL & 1/3 BATCH 220V RU SEE NOTE

NOTE: 208/220V RU URNS BUILT BEFORE JAN. 2013

45A WC-622-101 TIMER, BREW SELECTOR 220V 2-20 MIN GEM-120A/RU’S SEE NOTE

NOTE: 208/220V RU URNS (EXCEPT RU-1000) BUILT JAN. 2013 AND AFTER

45B WC-622-102 TIMER, BRW SEL. 220V 2-20 MIN W/FULL & 1/3 BTCH OPT SEE NOTE

NOTE: 208/220V RU-1000 URNS BUILT BEFORE JAN. 2013

46 WC-101 SWITCH, ON/OFF NON-LIT SPST MOMENT. 3/6A 250/120V ALL RU URNS

47 WC-3903 LABEL, INSTRUCT’S PANEL CURTIS RU-600 RU-600

47A WC-3900 LABEL, INSTRUCTION PANEL RU150 RU-150

47B WC-3901 LABEL, INSTRUCTION PANEL RU225 RU-225

47C WC-3902 LABEL, INSTRUCT’S PANEL CURTIS RU-300 RU-300

47D WC-3904 LABEL, INSTRUCT’S PANEL CURTIS RU1000 RU-1000

48 WC-3528 LEG, 4” ADJUSTABLE 3/8-16 THRD ITALIAN STYLE ALL RU URNS

49 WC-100 SW, RES-STOP N.C.NON-LIT SP MOMENT 10/15A 250/120V ALL RU URNS

50 WC-1501 FUSE, HOLDER ASSY W/5A FUSE ALL RU URNS

51 WC-1500 FUSE, 5 AMP ALL RU URNS

52 WC-511 THERMOMETER, DIAL RU’S ALL RU URNS

53 WC-5313 TUBE, SPRAYARM ASSY W/NUTS RU-300 RU-300, RU-150

53A WC-5314 TUBE, SPRAYARM ASSY W/NUTS RU-600 RU-225, RU-600

53B WC-5315 TUBE, SPRAYARM ASSY W/NUTS RU-1000 RU-1000

54 REFER TO VALVE CORE & SPRAY ARM ON PAGE 8

56 WC-5800 RING, STEAM ALL RU URNS

58 WC-2007 BRACKET, GAUGE GLASS GEM-3 ALL RU URNS

60 WC-2003 CAP, PLUG VENTED 44 ALL RU URNS

61 WC-2002 CAP, SHIELD W/CLEAN OUT ALL RU URNS

62 WC-2030 GLASS, GAUGE 13” RU-225, RU-600

63 WC-2108 GAUGE GLASS ASSEMBLY 13” USE ON RU-225 RU-225, RU-600

63A WC-2104 GAUGE GLASS ASSEMBLY 10” RU-150

63B WC-2105 GAUGE GLASS, ASSY 11” USE ON RU-150/300 RU-150, RU-300

63C WC-2113 GAUGE GLASS, ASSY 19” RU-1000

64 WC-2017 SHIELD, GAUGE GLASS 13” RU-225, RU-600

64A WC-2104 SHIELD, GAUGE GLASS 10” RU-150

64B WC-2014 SHIELD, 11” GAUGE GLASS RU-300

64C WC-2022 SHIELD, 19” GAUGE GLASS 1/8 NPT RU-1000

65 WC-1900 VALVE, GAUGE SHIELD SHUT-OFF 1/8 NPT ALL RU URNS

66 WC-1800L FAUCET, “S” SERIES LOCKING 1-1/32-14 UNS ALL RU URNS

70 WC-1805 SEAT CUP, “S” FAU USE ON WC-1800/B/LB/D/DL/L/WC-1803 ALL RU URNS

71 WC-3705 KIT, FAUCET S SERIES NONLOCK USE ON WC-1800 ALL RU URNS

72 WC-1906 C’ RING .917 X .760 X .090 TT-3 TC’S ALL RU URNS

1

OLDER UNITS

BEFORE

1/29/13

6

Loading...

Loading...