Wilbur Curtis PTT3 User Manual

Models Included:

•TCTS/T

•PTT3

CAUTION: Equipment must be installed to comply with applicable

federal, state, and local plumbing/ electrical codes having jurisdiction.

CAUTION: Follow this setup procedure before attempting to use this

unit. Failure to follow these instructions can result in injury and/or void

of warranty.

CAUTION: DO NOT connect the unit to hot water. The inlet valve is

not rated for hot water.

IMPORTANT:

After setup, run a FULL brewcycle. Place a tea

container to catch both hot water from the brewcone and dilution water from spout on the front cover.

ISO 9001:2008 REGISTERED

WILBUR CURTIS CO.

Montebello, CA 90640 For the latest information go to

www.wilburcurtis.com Tel: 800/421-6150

Wilbur Curtis Company, Inc.

Service Manual – TCT & PTT

Important Safeguards/Symbols

This appliance is designed for commercial use. Any servicing other than cleaning and preventive maintenance should be performed by an authorized Wilbur Curtis service technician.

•Do NOT immerse the unit in water or any other liquid

•To reduce the risk of fire or electric shock, do NOT open service panels. No user serviceable parts inside.

•Keep hands and other items away from hot surfaces of unit during operation.

•Never clean with scouring powders, bleach or harsh chemicals.

Symbols

WARNINGS – To help avoid personal injury

Important Notes/Cautions – from the factory

Sanitation Requirements

The Curtis G3 Brewer is Factory Pre-Set and Ready to Go… Right from the Box.

Following are the Factory Settings for the G3 Iced Tea Brewer.

•Brew Temperature = 204°F

•Brew Volume = Set to dispensing vessel requirements (2.2 liters)

Generally there will never be a reason to change the G3/Gold Cup Series default settings. However, should you need to make slight adjustments to meet your brewing needs, programming instructions are provided later in this manual.

System Requirements:

• Water Source 20 – 90 PSI. Minimum flow rate of ½ gpm (1 gpm preferred flow rate).

• Electrical: See electrical schematic on page 6.

SETUP STEPS

The unit should be level (left to right and front to back), and located on a secure counter top. Connect a water line from the water filter to the brewer.

NOTE:Awater filtration system must be used to help maintain trouble-free operation. Air must be purged from the cartridge prior to connection to equipment. In areas with extremely hard

water, we highly recommend the use of a Curtis approved water filter. For our full line of filters, please log on to www.wilburcurtis.com.

NSF International requires the following water connection:

1. Aquick disconnect or additional coiled tubing (at least 2x the depth of the unit) so that the machine can be moved for cleaning underneath.

2.In some areas an approved backflow prevention device may be required between the brewer and the water supply.

3.Waterpipeconnectionsandfixturesdirectlyconnectedtoapotablewatersupplyshallbesized, installed and maintained in accordance with federal, state, and local codes.

1.A1/4” Flare has been supplied for water line connection. Use tubing sized sufficiently to provide ½ GPM (preferred flow rate is 1gpm).

2.Connect the unit to an appropriate electrical power circuit.

3.Turn on the toggle (STANDBY/ON) switch behind the unit. The heating tank will start to fill. When the water level in the tank rises to the correct volume, the heating element will energize automatically. With

G3 tea brewers there is no danger of element burnout caused by an empty tank.

4.The heating tank will require 20 to 30 minutes to reach operating temperature (204°F). This is indicated when READY-TO-BREW is displayed on the screen.

5.Important: Run one full brewcycle, to purge the water lines and valves of air. Five seconds of dilution water at the beginning of each brewcycle is normal operation.

1

BREWING INSTRUCTIONS

1.Brewer should be ON (Confirm at rear toggle switch, then press ON/OFF button). Ready-to-Brew should be displayed on the screen.

2.Make sure tea container is correctly placed on the brew deck, centered under the brewcone.

3.Place a new filter into the brew basket. Pour leaf tea into the brew cone.

4.Slide the tilled brew cone into brew rails.

6.Select the desired BREW button and press to start brewing tea.

WARNING TO AVOID SCALDING, Do not remove the brewcone or coffee container until the UCM screen indicates that the brew cycle has finished.

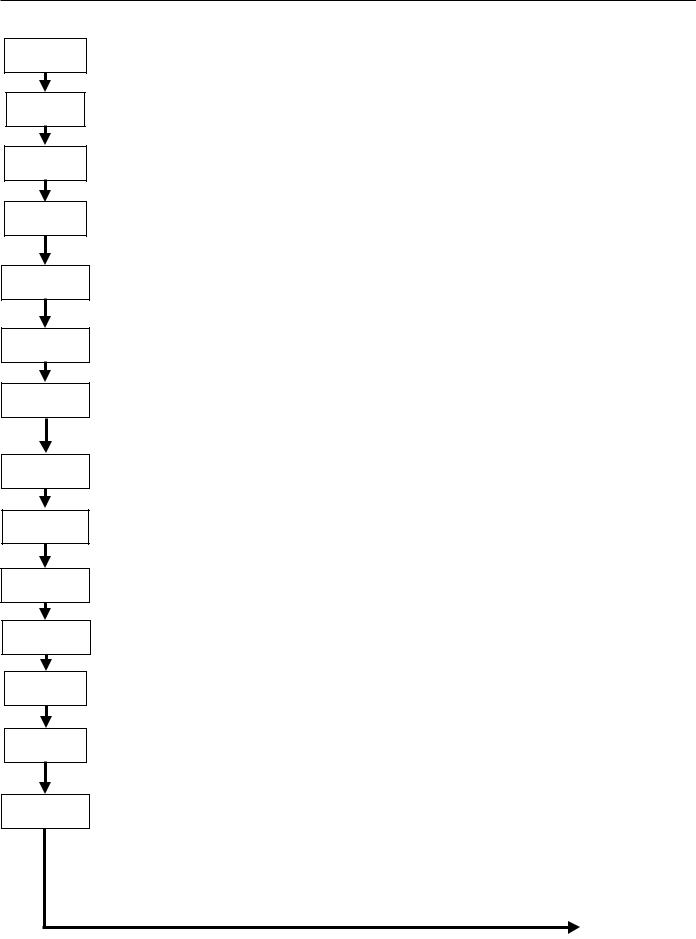

To Go Into Programming

Turn off (dark display) by pressing ON/OFF button (yellow). Press and hold BREW button 4 (green) and then press and release ON/OFF button (yellow).

Continue holding BREW button. Display will read |

, wait until |

is displayed Enter the 4 digit access code, the digits 1 4 corre- |

||||

spond to the buttons (see illustration below). |

|

|

|

|||

The default code set at the factory is 1 2 3 4. Then |

will be displayed. |

|

||||

|

|

|

|

All programming selections are performed with the three center buttons. |

|

|

|

|

|

|

The symbols below the buttons are: |

|

|

|

|

|

|

|

Scroll LEFT |

|

1 |

2 |

3 |

4 |

SELECTION or ENTER to save new parameter |

GRAY |

|

|

Scroll RIGHT |

|||||

|

|

|

|

|

|

|

SPRAYHEADS: Mentioned in this Programming guide are the words Gray and Purple. This refers to the color of the sprayhead. The current |

|

|||||

sprayhead is the purple AFS. The older version is the gray sprayhead. See the illustration at right. |

PURPLE |

|||||

|

|

|

|

|

|

|

2

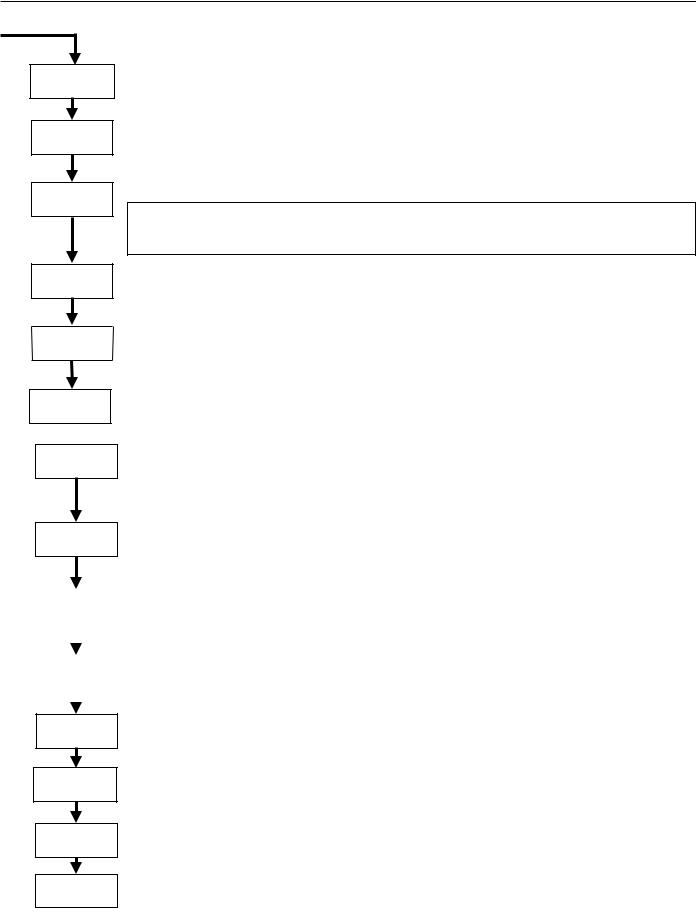

Programming

Program Menus

Tea Recipes

Tea By Volume

Tea By Time

Tea Dilut Delay

Tea Dilut Volume

Tea Dilut Time

Program Menus screen. Press > button, to show the next menu item.

Tea Recipes (Factory set to Standard Tea Purple)

Press to Select. Press < or > to scroll through recipes: Standard Gray, Standard Purple, Tropical Gray, Tropical Purple, 76/308 Gray or 76/308 Purple. Press to set.

*Tea by Volume: Press to select, Display will now show Push START To Begin... Press the BREW button then hot water starts running, when desired volume is reached press BREW button again to stop the flow. Now the volume has been set. Pressing > button will display the subsequent menu features.

*Tea by Time (Factory set to 5:52)

Press to select. By pressing < or > buttons, you can increase and decrease time. Press to set minutes and seconds. Units with the half batch option, the Half Batch brew button is factory set at for half the brew time (2:56).

*Tea Dilution Delay (Factory set to 0:30)

Press to Select. Press < or > buttons, to add or decrease time. Press to set.

*Tea Dilution Volume: Press to Select, Display will now show Push START To Begin... Press the BREW button and water will flow, when desired volume is reached press BREW button again to stop the flow. Now the volume has been set. Press > to display subsequent menu features.

*Dilution Time (Factory set to 4:05)

Press to Select. By pressing < or > buttons, you can increase and decrease time. Press to set minutes and seconds.

Tea Dilut Stir

Tea Pulse Brew

Tea Fast Brew

Tea Half Batch

Tea Drip-Out

Temperature

Energy Save Mode

Tea Dilution Stir (Factory set to ON).

Press to Select. Press < or > buttons, to toggle between OFF and ON. Press to set.

Tea Pulse Brew (Factory set to OFF).

Press to Select. Press < or > to select ON, OFF or D. D is a manual adjust from 1 to 20 pulses with an ON time from 5 to 150 seconds and an OFF time from 5 to 150 seconds.

Tea Fast Brew (Factory set to OFF).

Press to Select, press < or > to choose ON or OFF. Selecting ON will start hot water spraying in the brewcone first and then 1 minute later the dilution water will start to flow.

Tea Half Batch (Factory set to OFF).

Press to Select. Press < or > buttons, to toggle between OFF and ON. Press to set.

Tea Drip-Out (Factory set to OFF)

Press to Select. Press < or > to adjust time. Settings are OFF, up to 15 minutes, at one minute increments.

Temperature (Factory set to 204ºF)

Press to Select. Press < or > to increase or decrease setting. Temperature range, from 170ºF to 208ºF in 2 degree increments.

Energy Save Mode (Factory set to OFF)

Press to Select, < or > ON, OFF or ON 140ºF , to set. When in ON, unit will automatically shut off 4 hours from last brew. When feature is OFF, unit does not have the energy saving mode.

In the ON 140ºF position, temperature goes down to 140ºF. if unit has not brewed in 4 hours. This feature will save energy by maintaining a lower temperature in the tank during periods of non operation.

* On units with the half batch option, the half batch brew button may be independently set.

Continued on Page 4

3

Programming

Brew Count Odom

Brew Count Total

Cold Brew Lock

Master Reset

Brew Count Odom.

Press to Select, Shows total gallons and total brew cycles on the unit. Press ex or Reset Brew Count Total.

Brew Count Total

Press to Select, Shows total gallons and total brew cycles on the unit. Cannot be reset.

Cold Brew Lock (Factory set to 5º F)

Press to select, < or > to select desired setting (CBL 5, 15 or OFF), to set.

The Cold Brew Lock feature allows the brewer to brew at three different temperature levels from the actual set point. The first setting is within 5 degrees of set point, next is within 15 degrees of set point, OFF is within 30 degrees of set point for the Ready to Brew message, however it will brew at any temperature.

Master Reset

Press to displayAre You Sure? Then < for Yes, > for No. When Master Reset is used, the all of the menu selections in the UCM return to factory defaults.

Service Call

Access Code

Banner Name

P-Maintenance

Service Call (Phone number Factory set to 1-800-000-0000)

Press to display number and change number or < to move place and EX to exit when complete. This number will be displayed during a Heating system SENSOR ERROR or during a WATER ERROR.

Access Code (Factory set to 1 2 3 4)

Press to display number and change number, (the number can be changed 1 to 4) or < to move place and ex to exit when complete.

Banner Name (Factory set to CURTIS)

Press to display letters and change letters or < to move place and EX to exit when complete

This feature allows up to 14 letters to be programmed for company name or regional name. Programming all blanks disables Banner Name. If programmed, Banner Name is displayed every 5 sec. on and off.

P-Maintenance (Factory set to OFF)

Press to Select, Set gallons brewed to indicate P-Maintenance. Press < or > to adjust from Off to 3000 gallons.

Press to exit.

|

|

Beeper On/Off (Factory set to ON) |

|

Beeper On/Off |

|||

Press to display ON or OFF. Pressing either < or > toggles between on and off. to set. When ON, this feature |

|||

|

|

allows you to hear a short beep each time a button is pressed. |

|

|

|

||

|

|

Quality Timer (Factory set to OFF) |

|

|

|

||

Quality Timer |

|||

Press to Select. By pressing < or > buttons, you can increase and decrease time. Setting range is from 0 to 10 |

|||

|

|

hours in 1 hour increments. Press to set. Expired time indicated by audio alarm and flashing “Quality Timer”. |

|

|

|

||

|

|

|

|

Display Brew

Time

Display Messages

Model Select

Exit

Display Brew Time (Factory set to ON)

Press to Select. Pressing < or > toggles between ON and OFF.

Display Messages (Factory set to ON)

Press to display ON or OFF. Pressing either < or > toggles between on and off. This feature allows the operator to select the message “Rinse Server Before Brewing”. This will be displayed any time the unit is not brewing.

Model Select (Factory set to 1/Half Batch)

Press to Select. Pressing < or > toggles between 1/Half Batch and 3-Batch.

Exit

Press to select, exits program mode and returns unit to operation. Pressing > returns you to Tea Recipes.

4

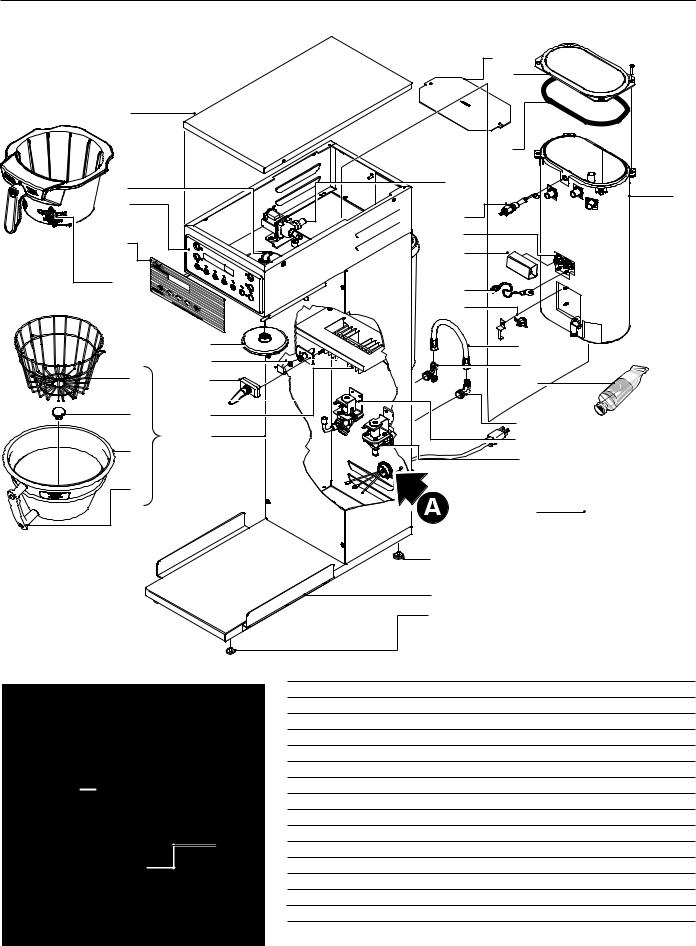

Illustrated Parts TCT |

|

|

|

|

|

|

|

|

18A |

|

|

|

|

18 |

6 |

|

|

|

|

|

|

|

|

19 |

7 |

|

|

34 |

20 |

8 |

|

|

22 |

|

|

|

|

||

|

|

|

|

|

9 |

|

|

23 |

|

|

|

24 |

|

|

|

|

|

|

|

5 |

|

|

25 |

|

5B |

|

|

|

|

|

|

26 |

|

|

|

|

|

|

|

|

10 |

|

|

29 |

1 |

32 |

|

|

28 |

11 |

|

|

21 |

|

2 |

12 |

|

|

13A |

5A |

14 |

|

|

31A |

3 |

|

|

|

30 |

|

|

|

|

|

4 |

|

|

|

|

|

|

|

|

27 |

|

|

|

16 |

|

|

|

|

17 |

|

|

|

|

16A |

|

|

ITEM |

PART Nº |

DESCRIPTION |

|

33 |

13 |

|

31 |

15 |

|

|

|

A |

1 |

WC-3301 |

BASKET, WIRE 7.00 DIA. USE WITH WC-3311 (OPTNL) |

2 |

WC-3647 |

STRAINER BT-10 BREWCONE (EXCEPT PARADISE) |

2A |

WC-8532 |

STRAINER, TROPICALBREWCONE |

3 |

WC-3320 |

BREW CONE W/HANDLE 8.8” D W/STRNR (OPTIONAL) |

4 |

WC-3201 |

HANDLE, BREW CONE BLACK FOR WC-3320 |

5 |

WC-3398 |

BREW CONE,ASSY STD TEANON-METALW/BLU GUARD |

5A |

WC-3358 |

BREWCONE W/WC-3320, WC-3301 & WC-3647 (OPTNL) |

5B |

WC-3399 |

BREWCONE,ASSYTROPICALTEANON-MTLW/YELGRD |

6 |

WC-58117 |

COVER, TOP BREWER |

7 |

WC-2977-101K |

KIT,SPRAYHEAD FITTING PLASTIC |

8 |

WC-37189* |

UCM KIT, LABEL& OVERLAY 120V TCTS/T |

8A |

WC-37338 |

KIT, UCM & OVERLAY W/HALF BATCH BREW TCTS |

8B |

WC- 729-104 |

CONTROLMODULE, (UCM) 220VAC TEA/COMBO |

9 |

WC-39398* |

LABEL, UCM PANELTCT/PTT GT3 W/O FAUCET CURTIS |

9A |

WC-39628 |

LABEL, UCM PANELW/HALF BATCH W/O FAUCET |

5

Loading...

Loading...