White Rodgers 1361-103, 1361-104, 1361-102 Installation Instructions

|

TYPE 1361 |

|

WHITE-RODGERS |

HYDRONIC ZONE VALVES |

|

(2 WIRE) |

||

|

||

|

INSTALLATION INSTRUCTIONS |

|

|

|

Operator: Save these instructions for future use!

FAILURE TO READ AND FOLLOW ALL INSTRUCTIONS CAREFULLY BEFORE INSTALLING OR OPERATING THIS CONTROL COULD CAUSE PERSONAL INJURY AND/OR PROPERTY DAMAGE.

These water valves provide a low cost system of zoned temperature control wherever hot water is the heating medium. In new construction, the heating piping system can be laid out to produce any number of independent temperature controlled zones by use of these valves.

In existing buildings, a variety of zone heating combinations can be obtained, depending on the particular -piping lay-outs. Each zone requires one water valve and one thermostat, but only one circulator is required for the entire system. New construction properly piped, will not require flow control valves, since the water valve itself performs this function.

Existing construction, where flow control valves have been installed, will operate quite satisfactorily without removing the existing flow control valves.

DESCRIPTION

If in “Closed” position, valve may be opened by turning dial clockwise with your thumb until word “Open” appears. When power is resumed, valve will automatically return to command of room thermostat.

This zone valve motor is intended for use with a low voltage system; do not use this zone valve with a millivolt or line voltage system. If in doubt about whether your wiring is millivolt, line or low voltage, have it inspected by a qualified heating contractor or electrician.

Do not exceed the specification ratings.

PRECAUTIONS

! CAUTION

To prevent electrical shock and/or equipment damage, disconnect electric power to system at main fuse or circuit breaker box until installation is complete.

All wiring must conform to local and national electrical codes and ordinances.

! CAUTION

To prevent injuries from scalding always drain system before unlatching valve assembly from body.

! WARNING

Do not use on circuits exceeding specified voltages. Higher voltages will damage control and could cause shock or fire hazard.

SPECIFICATIONS

All guarantees are void if these specifications are exceeded.

Maximum water temperature: 240°F (115°C) Maximum system pressure: 50 PSI Differential across valve: 15 PSI

Electrical Rating:

Valve motor: .2 Amp. Max at 25 VAC (.40 Amp.) when valve is in open position.

Auxiliary Contacts: Do not exceed 2.0 Amp. at 25 VAC (Terminals 2 and 3)

NOTE: The valve motor draws more than .2 Amp. while it is opening. For this reason, do not use more than the

recommended number of valves per transformer as shown on pages 3 and 4.

Thermostat: Use two-wire thermostat with .2 Amp. anticipator Timing: From full close to full open–Approx. 45 seconds

From full open to full close–Approx. 60 seconds

Friction loss equivalents:

3/4" valves – 2-1/2 ft. copper tubing 1" valves – 4 ft. copper tubing 1-1/4" valves – 7 ft. copper tubing

PRINCIPLE OF OPERATION

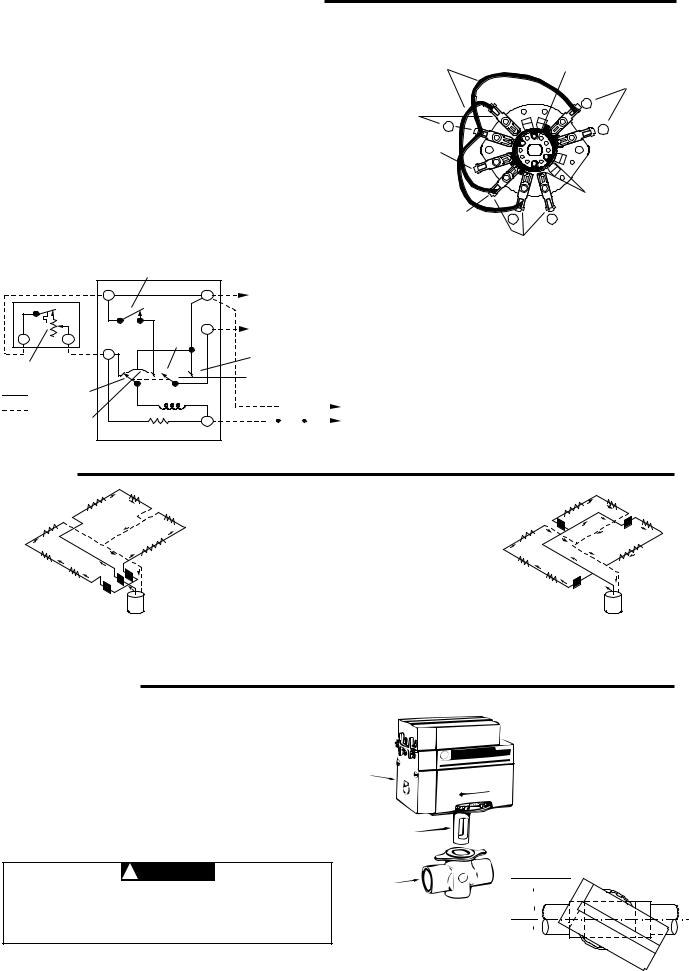

The zone valve is designed to turn in one direction, stopping every 90° in either the open or closed position, depending on thermostat demand. The motor position is controlled by a wafer switch attached to the motor shaft.

The contact arrangement of the switch is constructed so that when the shaft of the motor revolves 90° a new set of stationary and moving contacts makes, while the old set breaks. Fig.1. The schematic shows the valve in the closed position. As the

WHITE-RODGERS DIVISION

EMERSON ELECTRIC CO.

9797 REAVIS RD., ST. LOUIS, MO. 63123

(314) 577-1300, Fax (314) 577-1517

Printed in U.S.A.

9999 HWY. 48, MARKHAM, ONT. L3P 3J3

(905) 475-4653, FAX (905) 475-4625

PART NO. 37-5422B

Replaces 37-5422A

9812

PRINCIPLE OF OPERATION (CONT.)

thermostat calls for heat, the valve motor is energized by a circuit made through side “A” of the motor switch to terminal “4”. Fig. 2. (At the same time, a circuit is made through the warp switch heater.) As the valve begins to open, side “A” of the motor switch makes with a “holding” contact and then breaks from the stationary contact wired to terminal “4”. The “holding” contact provides a circuit which prevents the valve from stopping part way through its cycle if the thermostat is changed to the satisfied position. As the valve reaches the full open position, side “B” of the motor switch closes, providing a low voltage auxiliary circuit for starting the burner or circulator. At the same time side “A” of the motor switch makes a circuit through the warp switch contacts to terminal “2”. The valve does not continue to rotate since the warp switch opened its contacts before the valve reached the full open position. The warp switch heater remains energized as long as the thermostat calls for heat.

NOTE: INTERNAL PARTS AND

WIRING OF WATER VALVE.

JUMPER WIRES

▼

STATIONARY CONTACTS |

|

|

(TERMINALS 2 & COM.) |

|

▼ |

|

|

▼ |

▼ |

2 |

|

|

▼ |

|

|

|

|

(2 THRU WARP |

|

|

SWITCH CONTACTS) |

|

|

|

|

▼ |

|

|

▼ |

|

|

▼ |

COMMON

MOTOR SHAFT: Revolves in 90° intervals with each thermostat cycle.

STATIONARY CONTACTS (TERMINALS 2 & 3)

▼ 2

|

|

|

|

▼ |

|

|

|

|

3 |

|

|

▼ |

|

|

|

|

|

|

▼ |

|

|

▼ |

|

|

|

|

|

|

ROTATING BOARDS: |

|

|

|

|

Each Board makes/breaks |

|

▼ |

▼ |

|

1 set of contacts with each |

|

|

90° revolution of motor |

||

|

|

|

||

2 |

|

|

4 |

|

|

|

shaft on thermostat |

||

|

|

|

|

demand.

WARP SWITCH

CONTACTS

NORMALLY CLOSED

TYPE 1E/F30

5 2

THERMOSTAT

|

▼ |

|

3 |

▼ |

SIDE “A” |

|

OPEN |

4 |

POSITION |

HEAT |

|

|

|

ANTICIPATOR |

▼ |

▼ |

▼ |

|

|

||

|

▼ |

▼ |

|

INTERNAL WIRING |

SIDE “A” OF |

|

|

MOTOR |

|

|

|

|

|

|

|

EXTERNAL WIRING |

SWITCH |

|

|

|

|

|

|

|

HOLDING |

MOTOR |

1 |

|

CONTACT |

|

|

|

WARP SWITCH HEATER |

|

|

|

|

|

|

|

|

|

STATIONARY CONTACTS |

|

|

|

|

|

|

|

|

(TERMINALS 2, 4 & COM.) |

|

TO AUXILIARY CIRCUIT |

(Valve is shown in the open position) |

|||||||

(NOTE: IF SAME |

||||||||

TRANSFORMER POW- |

Fig. 1 |

|||||||

ERS BOTH THE AUXIL- |

||||||||

IARY CIRCUIT AND THE |

When the thermostat is satisfied, the circuit through the warp |

|||||||

WATER VALVE, CON- |

||||||||

NECT AUXILIARY CIR- |

switch heater is broken, allowing the heater to cool. When the |

|||||||

CUIT TO TERMINALS 1 |

||||||||

AND 3 INSTEAD OF 2 |

warp switch contacts close, the valve motor is energized, and |

|||||||

AND 3.) |

||||||||

OPEN POSITION |

drives the valve to the closed position. As the valve begins to |

|||||||

SIDE “B” |

move to the closed position, side “A” of the motor switch makes |

|||||||

SIDE “B” OF |

||||||||

the holding circuit. Then side “B” of the motor switch breaks the |

||||||||

MOTOR SWITCH |

||||||||

|

|

|

|

|

|

|

auxiliary circuit and side “A” of the motor switch makes contact |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

LINE |

“4” then breaks the holding circuit stopping the valve (in a fully |

|

|

|

|

|

|

|

|

closed position). |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

TRANSFORMER |

|

|||||||

Fig. 2

PIPING

PLAN 1

Water valves installed at the boiler header to provide a separate supply to each zone.

Fig. 3

The two most commonly used piping systems are shown below. Plan 1 is popular for new installations, while plan 2 is frequently used when converting twopipe systems.

This valve does not seal completely. A small amount of leakage through valve is permitted. The amount depends on valve size and pressure differential across closed valve. Do not use if your application requires complete seal off. Maximum leakage at rated differential is two, four or six gal. per hour for 3/4", 1" or 1-1/4" valves, respectively.

729

PLAN 2

A common main supplies all zones, with a water valve installed on the riser to each zone.

Fig. 4

INSTALLATION

ALL GUARANTEES ARE VOID IF THE VALVE IS NOT ASSEMBLED ACCORDING TO THESE INSTRUCTIONS.

1.Remove body assembly only from shipping carton. Valve head and stem should be left in carton at this time for protective purposes. Do not assemble head to body before attaching body into line.

2.Mount the valve body in the line in any desired position except upside down. CAUTION: Provide the necessary clearances for turning valve head sideways when assembling it to valve body (see fig. 5). Note that terminal end of valve head requires more clearance.

VALVE

HEAD

STEM

Clearances required for assembling valve head to valve body.

! CAUTION

BODY

Use only silicone grease, water, or soap suds on O-ring or Valve Body to facilitate assembly. Use of vaseline or

any petroleum grease or oil will cause O-ring to dete-

riorate.

Fig. 5

▼

2" MINIMUM CLEARANCE

▼ ▼

2-3/4" MINIMUM CLEARANCE

2 |

|

|

▼ |

||

! CAUTION

Be sure that bayonet lock securely latches mounting plate to body. Failure to do so could allow valve head to separate from body and result in scalding injuries and/or water damage.

3.Be sure that any excess solder, flux, or other foreign matter is thoroughly removed from the valve bore.

4.With valve body mounted in the line, remove the head assembly from the carton, and carefully wipe stem with a soft cloth to remove any dust or grit.

! CAUTION

to prevent injuries from scalding always drain system before unlatching valve assembly from body.

5.The valve head may now be assembled to the valve body. With valve head positioned as shown in figure 5, insert valve stem into valve bore, push downward, and turn valve head until it locks to valve body.

6.Support piping with a pipe hanger on each side of valve. The valve is now ready to be wired.

WIRING

All wiring should be done according to local and national electrical codes

For best connections, use #18 Thermostat wire. #16 will also work satisfactorily.

Make connections to screw terminals according to wiring diagram.

NOTE: To check motor operation without thermostat connected, jumper 2 and 4 to open valve; remove jumper to close valve.

If the boiler manufacturer recommends a wiring diagram, follow his instructions. If none are available, the following diagrams show suggested circuits for Type 1361 Water Valves in conjunc-

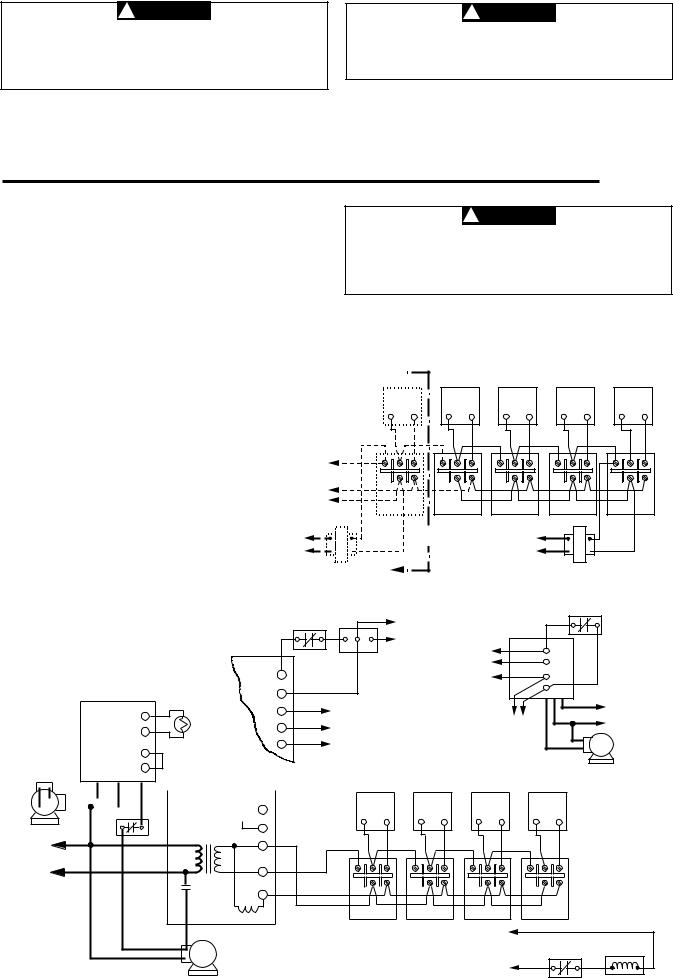

DIAGRAM FOR SYSTEMS WHERE BURNER AND CIRCULATOR OPERATION IS INDEPENDENT OF THERMOSTAT

Fig. 6 Using Type 1361 Zone Valve

! CAUTION

Do not attempt to wire two or more zone valves in parallel to operate from a single thermostat. (If valves are wired in parallel, the motors may run continuously, due to feedback between the motor holding circuits.)

tion with two-wire thermostat (.2 Amp. anticipator) and other related controls.

A 40 VA transformer will handle up to four (4) water valves. A 20 VA transformer will handle a maximum of two (2) 1361 series valves.

2 |

2 |

5 |

4 |

2 |

2 |

5 |

4 |

2 |

2 |

5 |

4 |

2 |

2 |

5 |

4 |

2 |

2 |

5 |

4 |

|

|

1 |

3 |

|

|

1 |

3 |

|

|

1 |

3 |

|

|

1 |

3 |

|

|

1 |

3 |

|

|

|

ADDITIONAL |

|

|

|

|

|

HOT |

|

|

|

|

|

|

|

|

||

|

|

|

|

ZONES |

|

|

|

|

|

|

LINE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

N |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TRANSFORMER |

|

|

|

|

||

DIAGRAM FOR SYSTEMS WHERE INTERNAL TRANSFORMER OF RELAY CONTROL SUPPLIES POWER

FOR ZONE VALVES 750 MV HIGH LIMIT GAS VALVE

Alternate Wiring for using |

|

HIGH LIMIT |

|

|

750 MV |

|

|

|

|

TH |

|

PG |

POWER |

TYPE 8A02A-1 |

|

|

|

|

|

GENERATOR |

|

|

||||

750 Mv. Gas Valve |

|

|

|

|

|

|

|

|

|

|

TH PG |

|

1 |

Z-L2 |

|

||

TYPE 8A03A-2 |

|

|

|

TO ZONE |

MUST BE N.E.C. |

|||

|

|

|

|

|

|

CLASS 1 WIRING |

||

|

|

|

|

|

VALVES |

2 |

T2 |

|

|

|

MUST BE N.E.C. |

|

|

|

|||

|

|

|

|

|

{3 |

|

|

|

|

V1 |

CLASS 1 WIRING |

|

|

|

T1-V1 |

|

|

TYPE 668 OIL |

V2 |

|

|

|

|

|

V2-L1 |

|

BURNER CONTROL |

|

|

|

|

|

|

|

|

|

|

|

|

MUST BE N.E.C. |

|

|

||

|

|

|

|

|

|

HOT |

||

|

1 |

1 |

|

|

CLASS 1 WIRING |

|

||

|

|

|

|

|

|

|

LINE |

|

F |

|

|

|

|

|

TO 24 VOLT |

|

|

TYPE 956 |

|

|

|

|

|

|

|

|

FLAME DETECTOR |

2 |

2 |

|

TO ZONE VALVES |

GAS VALVE |

|

N |

|

F |

|

3} |

|

|

|

|

|

|

|

3 |

|

Alternate Connections |

|

|

|||

T |

|

|

|

|

YELLOW |

|

||

|

|

|

|

For Type 8A02A Relay |

|

|||

|

|

|

|

|

|

|||

|

|

|

|

|

|

CIRCULATOR |

||

T |

|

|

|

|

|

|

|

|

IGNITION |

|

|

|

|

|

|

|

MOTOR |

TRANS. |

|

|

|

|

|

|

|

|

TYPE 8A03A-2 |

|

|

|

|

|

|

|

|

|

WHITE |

BLACK |

|

|

|

|

|

|

|

ORANGE |

|

RELAY CONTACTS |

|

|

V1 |

||

|

|

|

|

|

|

|||

|

|

HIGH LIMIT |

||||||

|

|

|

|

|

|

|||

|

|

|

|

(24V OR 750 MV) |

|

|

|

|

BURNER |

|

|

V2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MOTOR |

|

TRANSFORMER |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WHITE |

|

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

N |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LINE |

|

|

2 |

2 |

5 |

4 |

2 |

2 |

5 |

4 |

2 |

2 |

5 |

4 |

2 |

2 |

5 |

4 |

|

BLACK |

|

|

|

||||||||||||||||

|

|

2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

HOT |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

3 |

|

|

1 |

3 |

|

|

1 |

3 |

|

|

1 |

3 |

|

for Oil-fired |

ORANGE |

VOLTAGE) |

3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Fig. 7 Diagram |

|

RELAY |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CONTACTS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(LINE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

System using |

|

|

RELAY COIL |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

|

|

|

|

|

8A03A-2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Fig. 7a Diagram for |

|

|

MUST BE N.E.C. |

|

|

24 VAC |

||||||||||

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

Gas-Fired System |

|

|

CLASS 1 WIRING |

HIGH LIMIT |

GAS VALVE |

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3 |

|

|

|

|

|

3

CIRCULATOR MOTOR

Loading...

Loading...