Whirlpool 4322452 User Manual

GAS RANGES

4322452

Electrical Shock Hazard

Disconnect the gas range’s line cord plug from the wall receptacle before you

service any of the components inside the unit. Failure to do this could result in violent

electrical shock.

VOLTAGE CHECKS

When making voltage checks, be sure to observe the following precautions:

1. The floor must be dry. Water and dampness increase the chances of electrical

shock.

2. Set the voltmeter correctly for the voltage being measured.

3. Touch only the insulated parts of the meter probes.

4. Touch the component terminals, or wires, with the meter probe tips only.

5. Touch the meter probe tips only on the terminals being checked. Touching other

components could damage good parts.

PARTS QUALITY

An important step in the appliance repair procedure is the selection of FSP

(FACTORY SPECIFICATION PARTS) as replacements. Use of “fits-all,” or “look

alike” parts could result in early parts failure, safety hazard, or substandard performance of a WHIRLPOOL appliance. It could also result in an unnecessary repeat of

your repair efforts.

To be sure that the part(s) you purchase meet the exacting quality standards used to

build every new WHIRLPOOL appliance, be sure to ask for genuine FSP replacement

parts, as specified for your model. “FSP” is a registered trademark of WHIRLPOOL

CORPORATION.

You can buy your genuine FSP replacement parts from any authorized WHIRLPOOL

Parts Distributor.

WHIRLPOOL CORPORATION assumes no responsibility for

any repair made on our products by anyone other than qualified

®

TECH-CARE

Service Technicians.

®

Copyright 1998 Whirlpool Corporation, Benton Harbor, MI

ii

Table Of Contents

Page

Fundamental Properties Of Gas ............................................................................................ 1-1

Measuring Heat Energy........................................................................................................ 1-1

Fuel Types............................................................................................................................ 1-2

Characteristics Of Gas Fuels ............................................................................................... 1-4

Distribution Of Natural Gas .................................................................................................. 1-5

Distribution Of L.P. Gas........................................................................................................ 1-6

Pressure Regulators .............................................................................................................. 2-1

Functions .............................................................................................................................. 2-1

Regulator Operation ............................................................................................................. 2-2

Venting ................................................................................................................................. 2-4

Regulator Diagnostics .......................................................................................................... 2-4

Measuring Gas Pressure...................................................................................................... 2-5

The Cooktop Burner System .................................................................................................. 3-1

Gas Distribution .................................................................................................................... 3-1

Gas Valve ............................................................................................................................. 3-2

Gas Valve Orifices................................................................................................................ 3-3

Performance Check.............................................................................................................. 3-7

Burner Operation .................................................................................................................. 3-8

Air Shutter & Venturi ......................................................................................................... 3-9

Burner Head ................................................................................................................... 3-10

Flame Characteristics ..................................................................................................... 3-11

Improper Flame Diagnostics ........................................................................................... 3-15

Cleaning The Burners ..................................................................................................... 3-16

Standing Pilot Ignition System............................................................................................ 3-17

Operation ........................................................................................................................ 3-17

Relighting A Standing Pilot ............................................................................................. 3-18

Adjusting The Pilot Flame Height ................................................................................... 3-19

Cleaning The Pilot .......................................................................................................... 3-20

Electronic Ignition System .................................................................................................. 3-21

Operation ........................................................................................................................ 3-21

Conventional Burner ....................................................................................................... 3-23

Sealed Burner ................................................................................................................. 3-24

Electronic Ignition Diagnostics ........................................................................................ 3-25

Performance Check............................................................................................................ 3-26

The Oven Burner System....................................................................................................... 4-1

Standing Pilot Ignition........................................................................................................... 4-1

Lighting The Oven Pilot .................................................................................................... 4-5

Glo-Bar Ignition .................................................................................................................... 4-6

Cleaning The Oven Burner ............................................................................................. 4-11

Self-Cleaning System ......................................................................................................... 4-12

F-Code Guidelines ............................................................................................................. 4-16

Performance Check............................................................................................................ 4-17

The Self-Clean Oven Door Locking System....................................................................... 4-18

iii

Page

Natural And L.P. Gas Conversion .......................................................................................... 5-1

General................................................................................................................................. 5-1

Converting A Pressure Regulator......................................................................................... 5-2

Converting Cooktop Burners ................................................................................................ 5-2

Converting An Oven Burner ................................................................................................. 5-3

Converting An Oven Thermostat .......................................................................................... 5-3

Burner Flame Adjustment..................................................................................................... 5-4

Performance Check.............................................................................................................. 5-5

Testing The Components ....................................................................................................... 6-1

Warning Labels .................................................................................................................... 6-1

General Information.............................................................................................................. 6-2

Testing An Oven Glo-Bar Ignitor .......................................................................................... 6-3

Testing An Ignitor Switch...................................................................................................... 6-4

Testing An Oven Light Switch .............................................................................................. 6-5

Testing An Oven Temperature Sensor................................................................................. 6-6

Testing An Oven Door Latch ................................................................................................ 6-7

Testing A Gas Safety Valve ................................................................................................. 6-9

Testing The Gas Control Valves ........................................................................................ 6-10

Testing The Gas Pressure Regulator ................................................................................. 6-11

Troubleshooting Chart ........................................................................................................ 6-12

Schematic Diagrams .......................................................................................................... 6-14

Strip Circuits ....................................................................................................................... 6-16

iv

INTRODUCTION

This program is designed to teach the servicer basic skills in handling common

service procedures for gas ranges. This program does not cover the diagnosis and

repair of all range problems and components, (oven liner, wiring harness, etc.).

PROGRAM OBJECTIVE

Upon completion of this program, the participants will be able to identify the location

of major range components, as well as diagnose problems, and remove and repair

the components causing the problem.

INSTRUCTIONS

This program has the following sections:

• Fundamental Properties of Gas

• Pressure Regulators

• The Cooktop Burner System

• The Oven Burner System

• Natural And L.P. Gas Conversion

• Testing The Components

TOOLS YOU WILL NEED

Phillips Screwdriver

Long-Nosed Pliers

Adjustable Wrench

Pipe Sealer

Special Tools:

• Volt-Ohmmeter

v

— NOTES —

vi

FUNDAMENTAL PROPERTIES OF GAS

MEASURING HEAT ENERGY

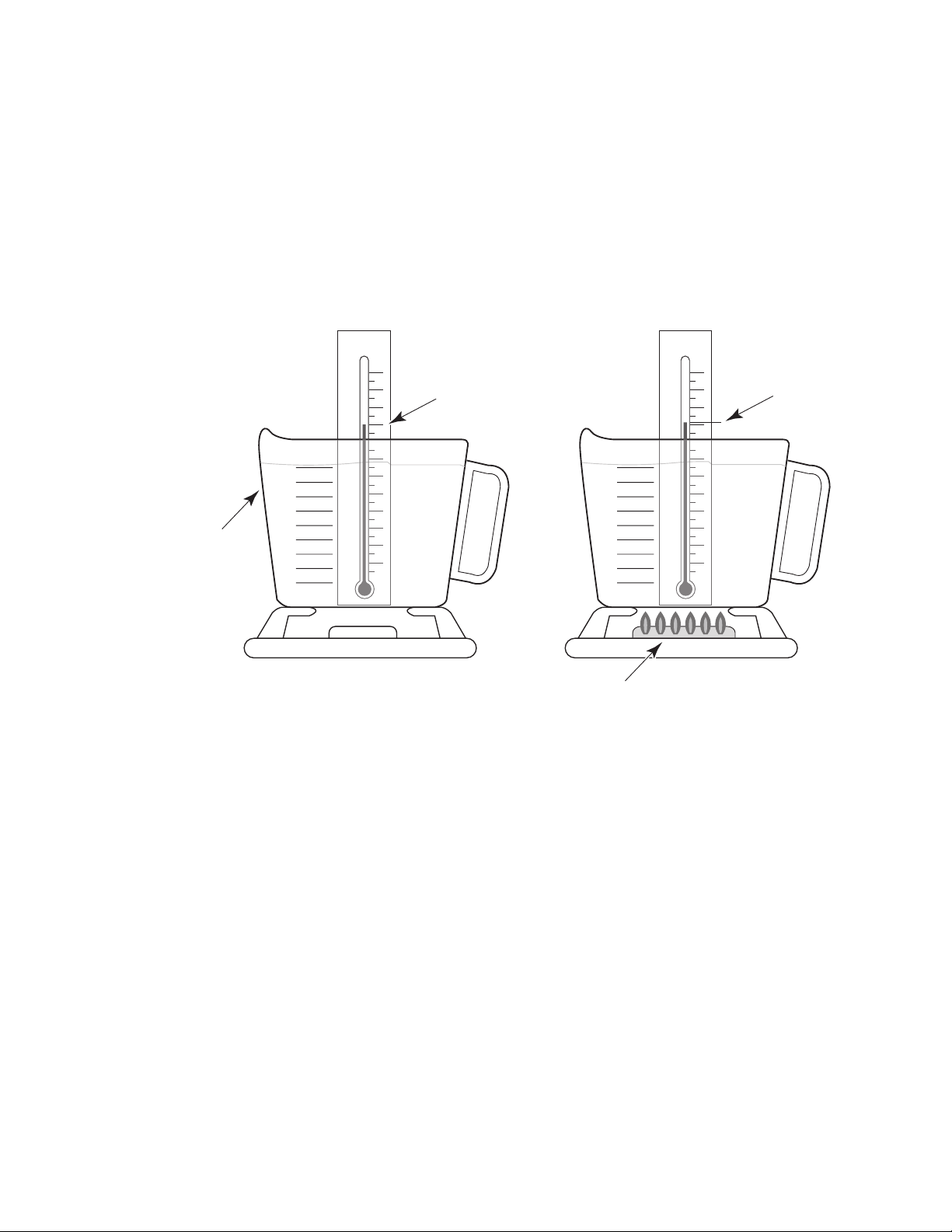

When burning a gas fuel, heat energy is produced. This heat energy is usually expressed in British

Thermal Units, or B.T.U.’s. One B.T.U. is equal to the amount of heat needed to raise one pound

of water one degree Fahrenheit (see Figure 1-1).

1 B.T.U. = the heat necessary to raise 1 lb. of water 1˚F

A wooden kitchen match will produce approximately 1 B.T.U. of heat energy.

ONE POUND

OF WATER

120

110

100

90

80

70

60

50

40

30

20

10

0

˚F

Figure 1-1

90˚F

˚F

120

110

100

90

80

70

60

50

40

30

20

10

0

91˚F

HEAT ENERGY PRODUCED

BY BURNING GAS

Page 1-1

Gas Fuels are categorized as follows:

#1 = Natural Gas

#2 = Mixed Gas

#3 = Manufactured Gas

#4 = Liquefied Petroleum Gas

#1 — NATURAL GAS

FUEL TYPES

Natural Gas

hydrocarbons, such as propane and butane. These hydrocarbons are removed by the gas

company so that only the pure natural gas properties, methane and ethane, are left.

Natural gas is lighter than air, and has a heat value of between 900 and 1200 B.T.U. per-cubic-foot.

is found underground. It is referred to as “wet gas,” because it contains heavy

#2 — MIXED GAS

Mixed Gas

of between 700 and 900 B.T.U. per-cubic-foot.

consists of natural and manufactured gas. It is lighter than air, and has a heat value

#3 — MANUFACTURED GAS

Manufactured Gas

of between 500 and 700 B.T.U. per-cubic-foot.

is made from coal and petroleum. It is lighter than air, and has a heat value

#4 — LIQUEFIED PETROLEUM (L.P.) GAS

Liquefied Petroleum (L.P.) Gas

of these gases are converted from a

can then be stored in a pressurized tank and easily transported. The liquid gas will return to its

gaseous state when it is released into the atmosphere. L.P. gas is heavier than air and will lay in

the lowest spot it can find when released into a room.

Propane

cubic-foot.

has a heat value of 2500 B.T.U. per-cubic-foot, and

consists of the heavy hydrocarbons “propane or butane.” Both

gaseous

to a

liquid

state by using pressure. The liquid gas

butane

a value of 3200 B.T.U. per-

Page 1-2

Category 1

Category 2

– Natural Gas –

Contains Methane & Ethane.

Sour Natural Gas

Contains Hydrogen Sulfide

Which Corrodes Copper & Brass.

It Has A Heat Valve Of

900 to 1200 B.T.U. Per-Cubic-Foot.

Specific Gravity Is 0.65 To 0.70.

Category 3

– Manufactured Gas –

Made From Coal & Petroleum.

It Has A Heat Valve Of 500 to 700

B.T.U. Per-Cubic-Foot.

Specific Gravity Is 0.38 To 0.40.

– Mixed Gas –

Contains A Mixture Of

Natural & Manufactured Gases.

It Has A Heat Valve Of 700 to 900

B.T.U. Per-Cubic-Foot.

Specific Gravity Is 0.5.

Category 4

– Liquefied Petroleum (L.P.) Gas –

Made Of Propane Or Butane.

Is Converted To A Liquid State

Under Moderate Pressure For

Easy Transportation In

Pressurized Tanks.

Propane Has A Heat Valve Of

2500 B.T.U. Per-Cubic-Foot.

Specific Gravity Is 1.53.

Gas Fuel Properties

Summary

Page 1-3

CHARACTERISTICS OF GAS FUELS

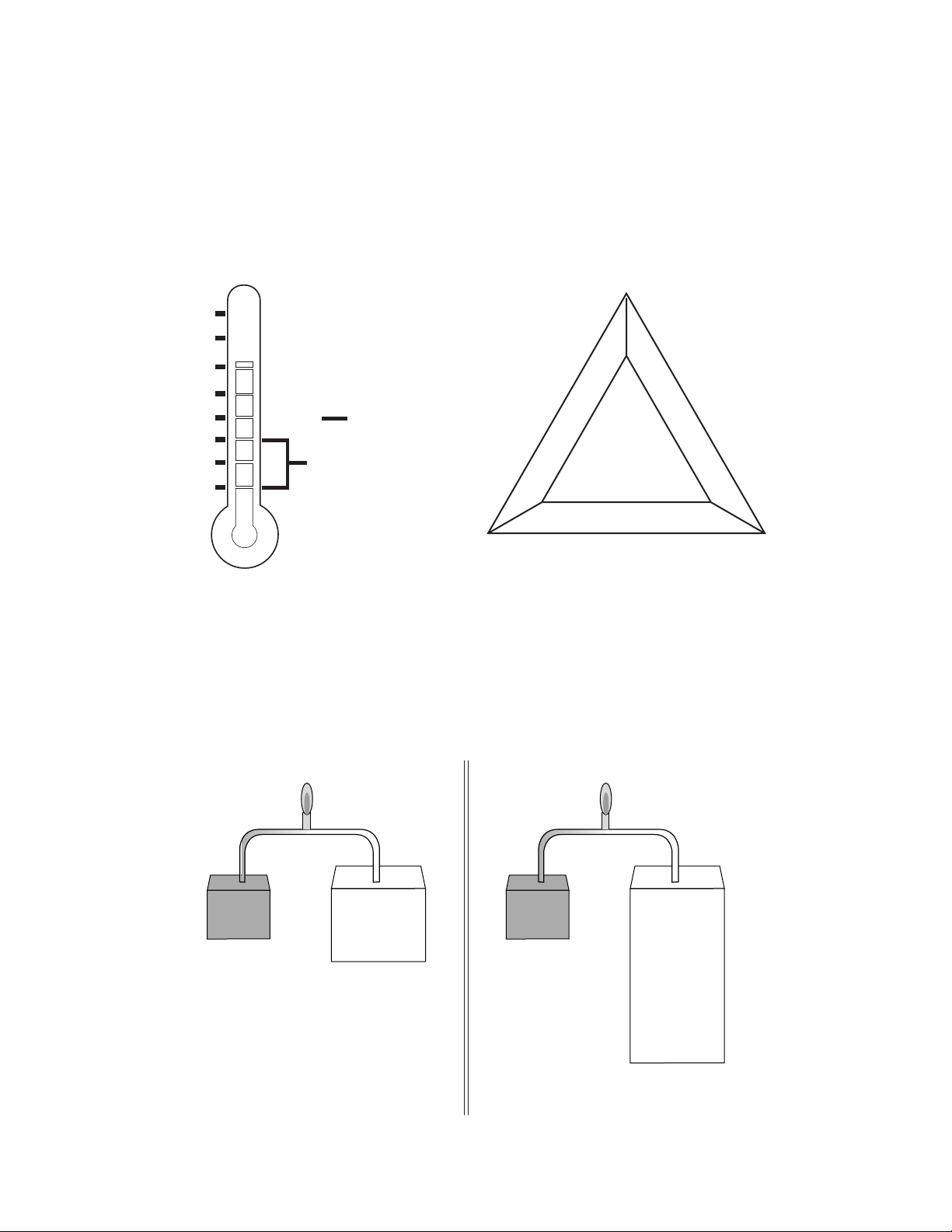

Each of the four types of gas has a specific boiling point (see Figure 1-2). The

boiling point

is

referred to as the temperature where gas turns from a liquid to a gas at atmospheric pressure. If

temperatures fall below the freezing point (32˚F), the liquid will not turn into a gas, and there will

be no flame.

By itself, gas cannot be ignited. Fuel, oxygen, and heat are necessary for combustion to occur.

Remove one of these, and combustion cannot take place (see Figure 1-3).

200

100

32

Zero

– 44

–100

– 200

– 300

Butane

Propane

FahrenheitDegrees

L.P.

Natural

Mixed

Manufactured

OXYGEN

FUEL

HEAT

THE COMBUSTION PROPERTIES

BOILING POINT OF GAS

Figure 1-2

Figure 1-3

Gases will ignite at temperatures between 900˚F and 1200˚F.

A proper mixture, or ratio, of gas and air is needed to produce a flame. If the air-to-gas ratio is not

correct, incomplete combustion, or an improper flame, will result. The ratio needed to ignite natural

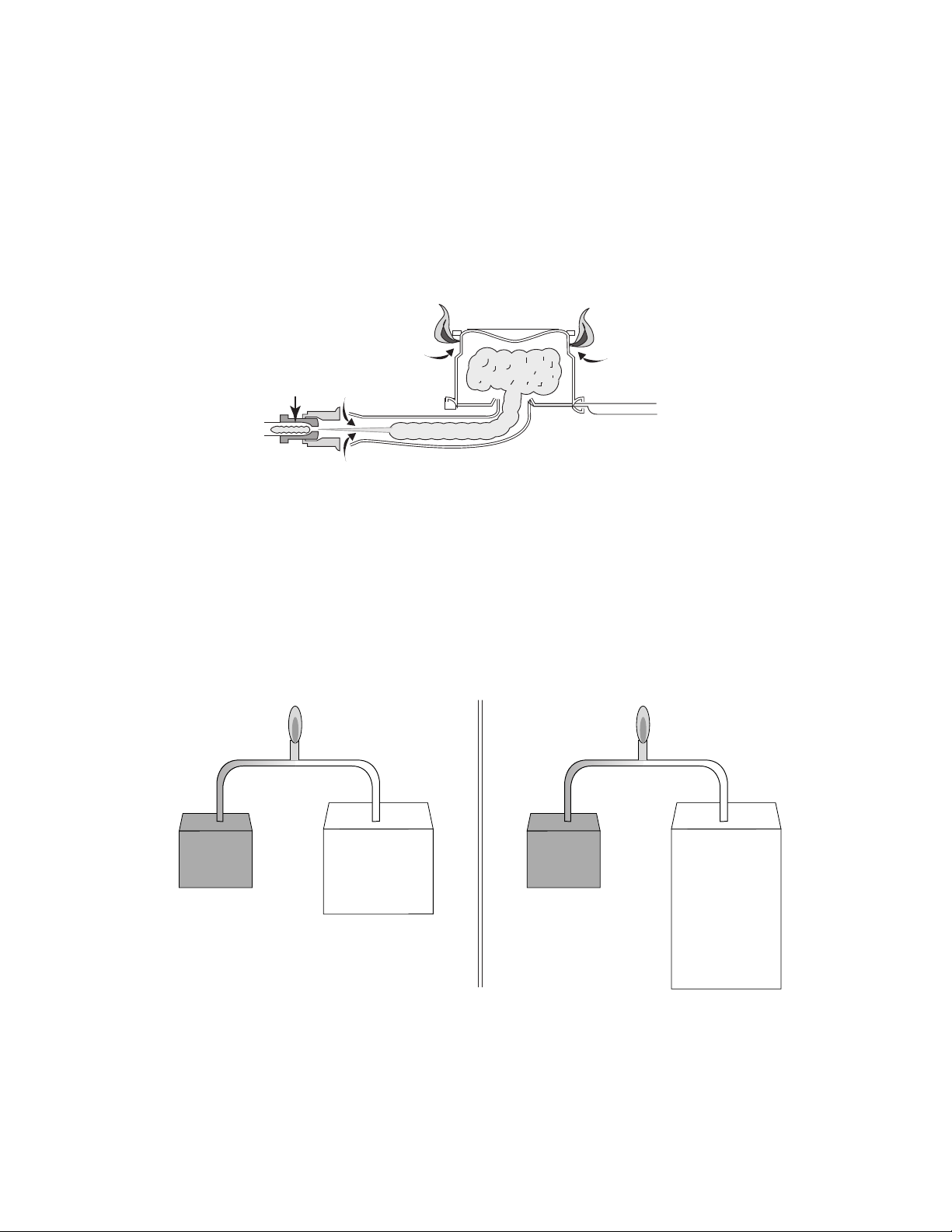

gas (10:1) is shown in Figure 1-4, and the ratio for L.P. gas (24:1) is shown in Figure 1-5.

1000 BTU Heat

1 cu.ft.

Gas

Natural Gas (10:1)

10 cu. ft. Air To 1 cu.ft. Gas

10 cu.ft.

Figure 1-4

Air

Figure 1-5

1000 BTU Heat

1 cu.ft.

Gas

L.P. Gas (24:1)

24 cu. ft. Air To 1 cu.ft. Gas

24 cu.ft.

Air

Page 1-4

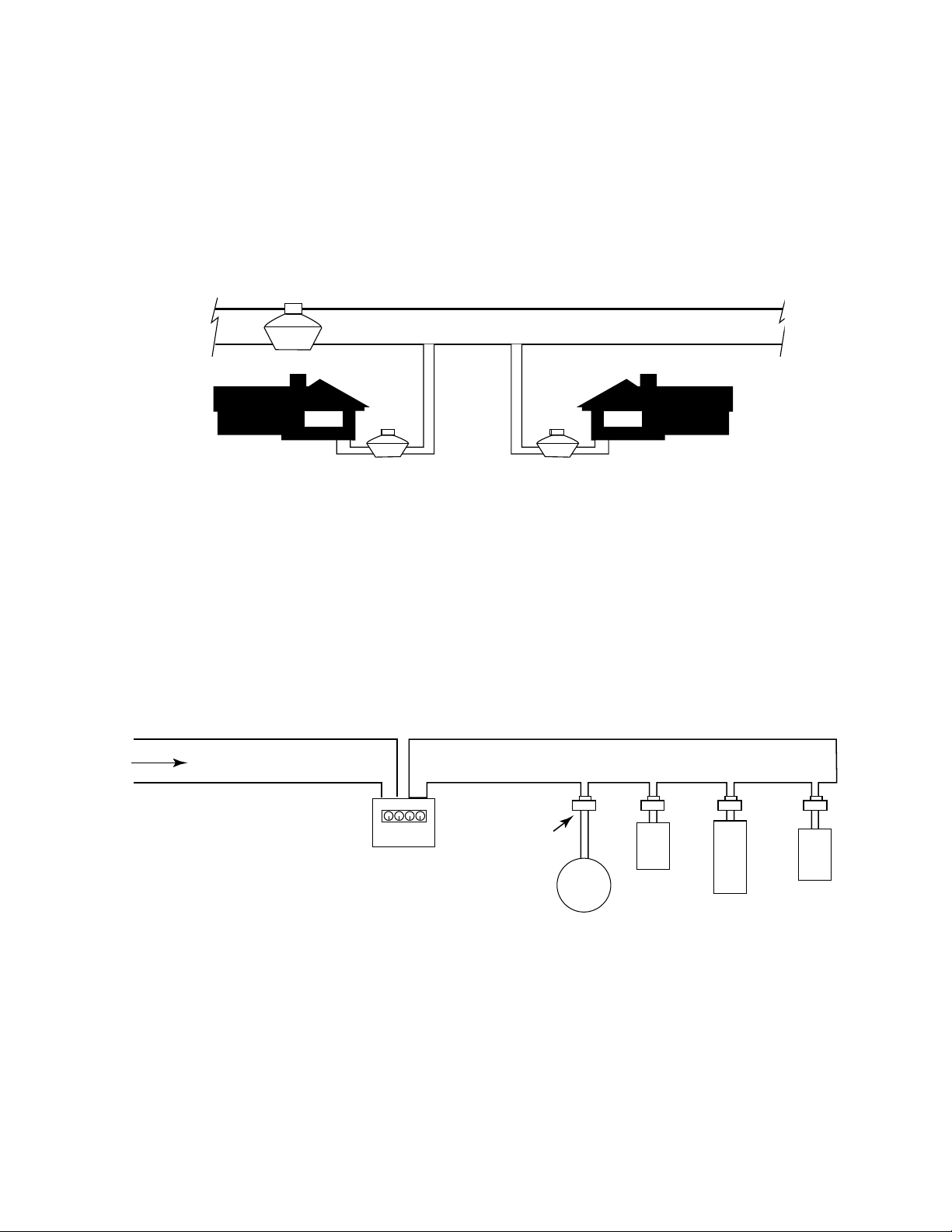

DISTRIBUTION OF NATURAL GAS

Utility companies send natural gas through underground pipes, called “mains.” The gas in these

mains is pressurized at between 25 and 60 pounds-per-square-inch (psi).

Branches carry the pressurized gas to the various buildings, and are connected to gas meters.

The meters decrease the main’s gas pressure to 7 inches water column pressure (1/4 pounds) for

use by the appliances inside the buildings (see Figure 1-6).

DISTRIBUTION

REGULATOR

25 To 60 Pounds Pressure “Main”

SERVICE

REGULATOR

7" WCP (1/4 Pound Pressure)

SERVICE

REGULATOR

Figure 1-6

A gas piping system is able to supply gas to all of the appliances in a building at one time. Ranges

generally operate on gas pressure rated at 4 inches water column pressure. Each appliance

usually has its own pressure regulator to more accurately meet the designed requirements (see

Figure 1-7).

Gas Main 25 - 60 Pounds

Gas Meter

(Service Regulator)

Appliance

Regulator

7" WCP (1/4 Pound)

In-House Gas Supply Line

4

"

Range

Furnace

Water

Heater

Dryer

Figure 1-7

Page 1-5

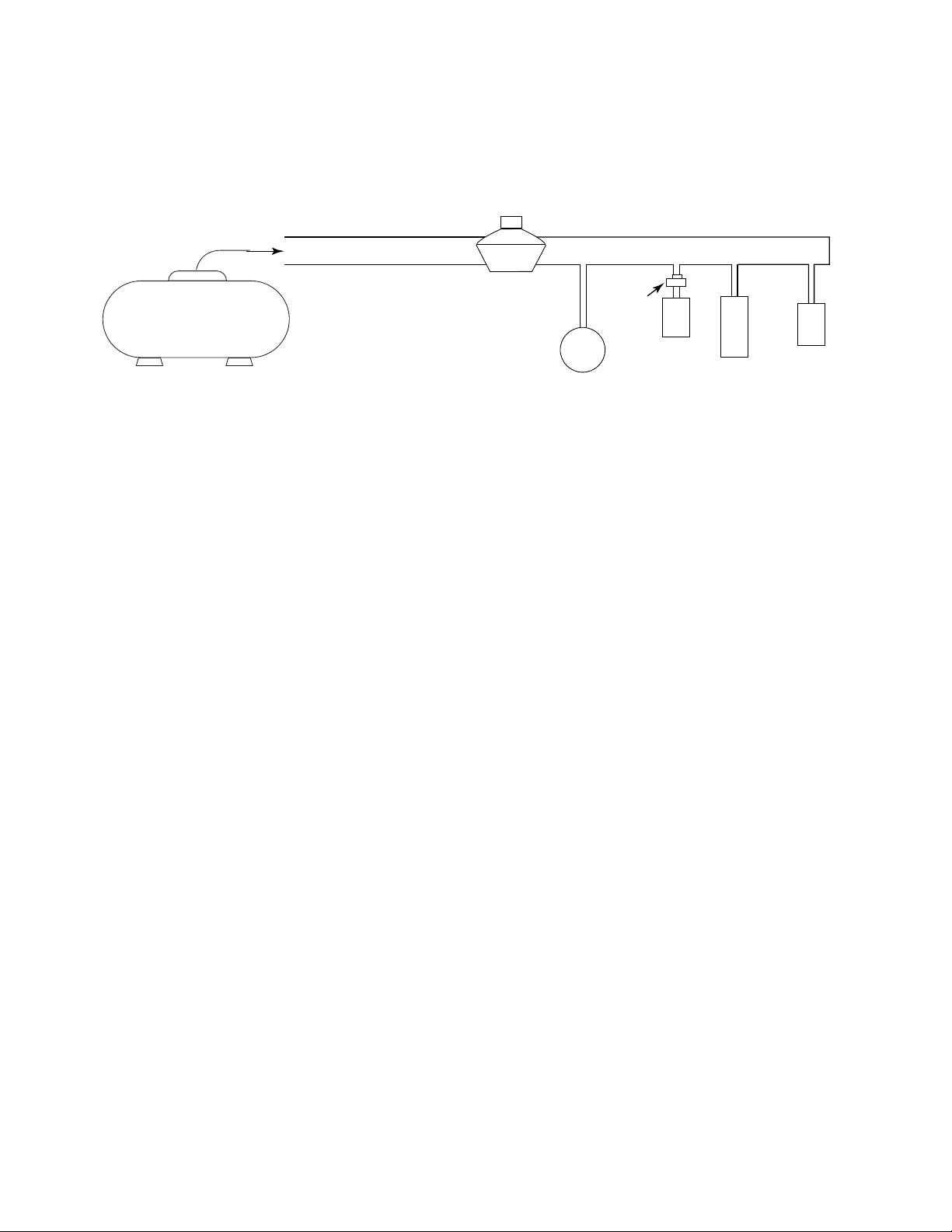

DISTRIBUTION OF L.P. GAS

For Liquid Propane (L.P.) gas, appliances generally operate on gas pressure rated at between 10

and 12 inches water column pressure. Each appliance usually has its own pressure regulator to

more accurately meet the designed requirements (see Figure 1-8).

10

" - 12"

L.P. Gas Main 28" WCP (1 lb.)

WCP In-House Gas Supply Line

L.P. Gas Tank

Figure 1-8

Service

Regulator

Water

Heater

10

"

Appliance

Regulator

Range

Furnace

Dryer

Page 1-6

PRESSURE REGULATORS

FUNCTIONS

A

Gas Pressure Regulator

• Reduces higher incoming gas pressure to a desired lower outgoing gas pressure.

• Maintains a steady, even flow of gas as it leaves the regulator.

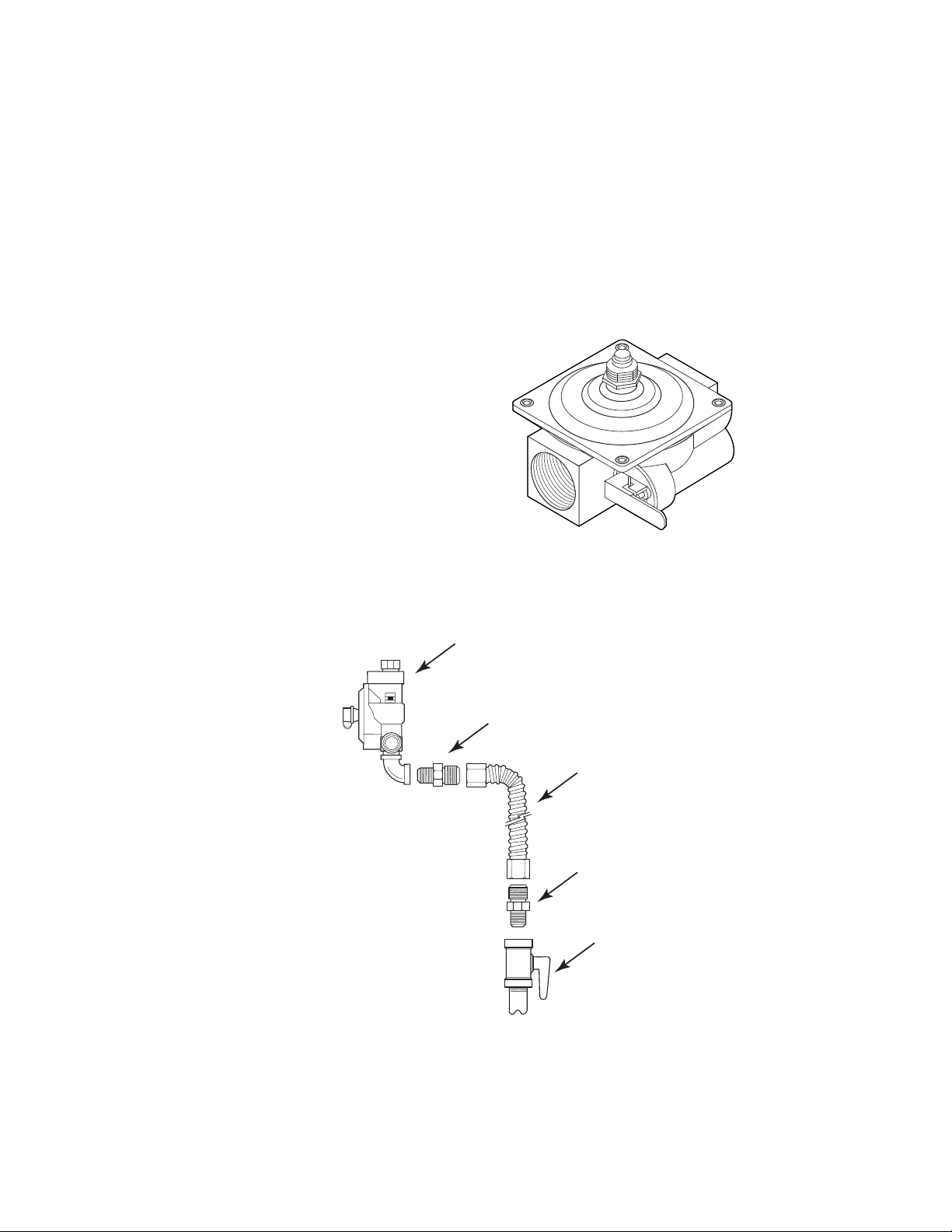

The

Appliance Pressure Regulator

for the particular application (see Figure 2-1). This is the final stage of gas regulation. It controls

gas at a lower pressure and flow rate.

Appliance Pressure Regulator

It is recommended that the pressure regulator be connected to a manual gas shutoff valve, via a

flexible line (depending on local codes), so that it will be easy to shut off the gas supply to the range

before servicing it (see Figure 2-2).

is a mechanical device that performs the following two functions:

is used to further reduce the gas pressure to the desired level

N

N

Figure 2-1

Figure 2-2

Pressure

Regulator

Fitting

Flexible

Gas Line

Fitting

Manual Gas

Shutoff Valve

Page 2-1

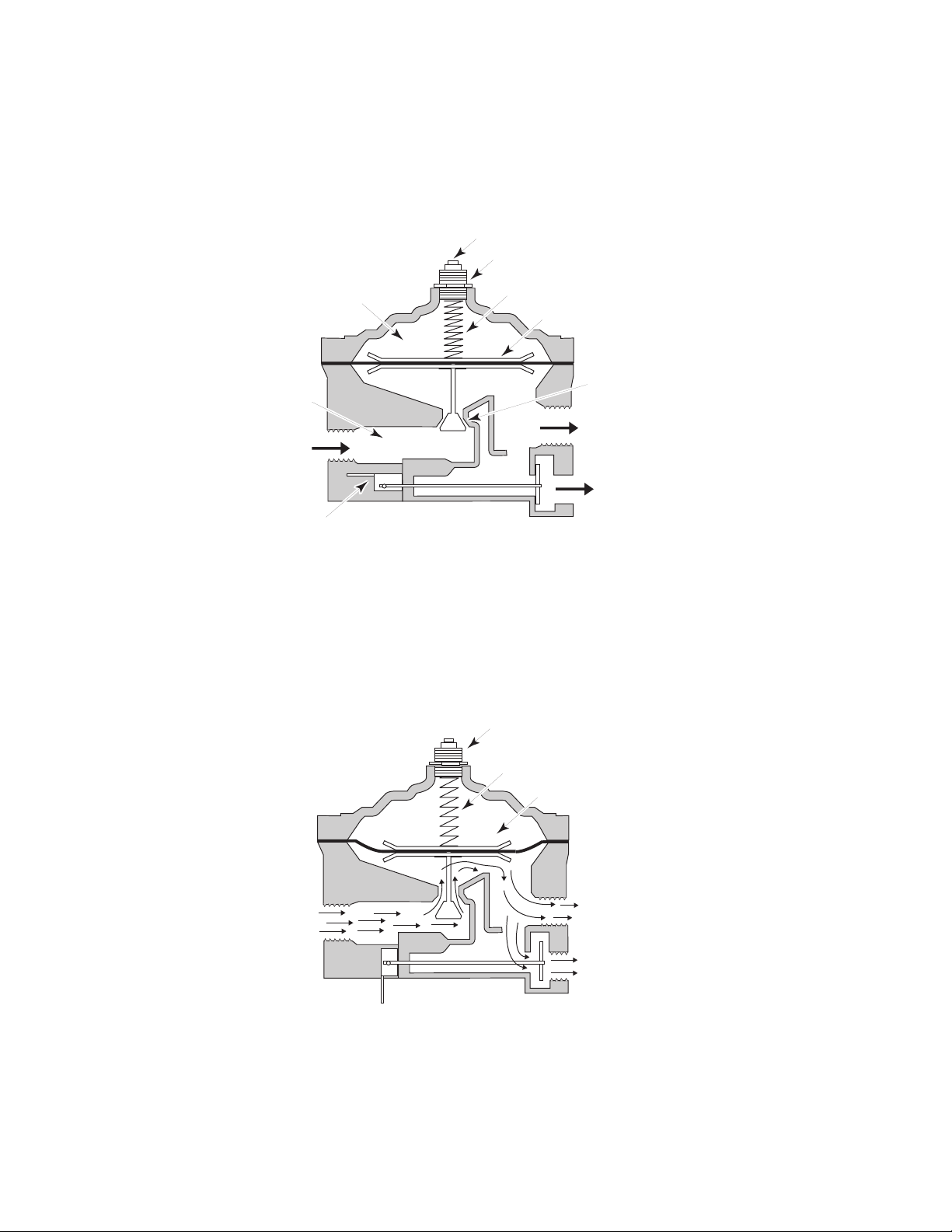

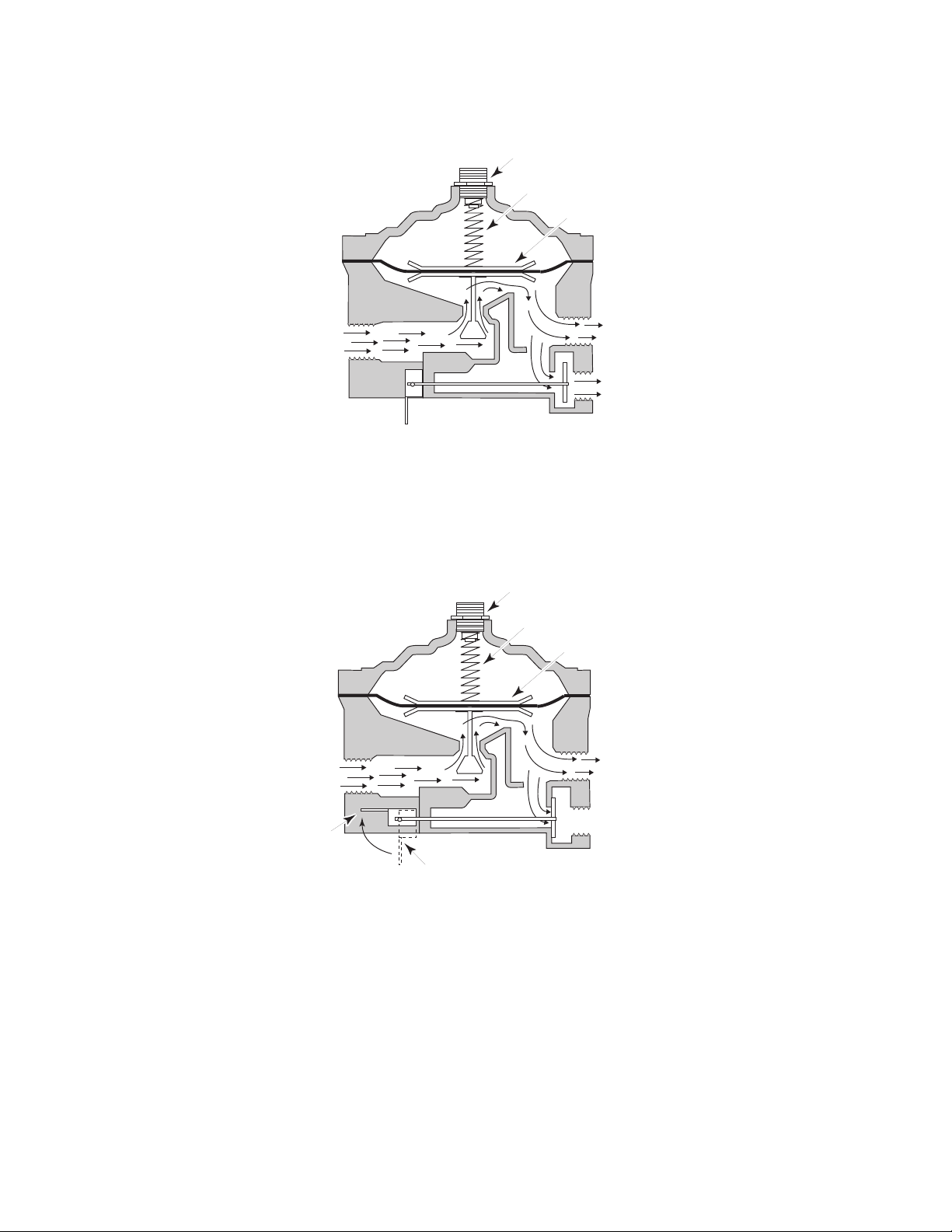

REGULATOR OPERATION

The pressure of the gas coming into the pressure regulator pushes against a spring-loaded

diaphragm, forcing it upward. The diaphragm spring puts pressure on the diaphragm. In order to

control the flow rate, the diaphragm has a tapered plug suspended from it to restrict or increase

the gas flow pressure (see Figure 2-3).

Vent (Through

Hole In Cap)

Cap

Tension

Spring

Diaphragm

Valve Seat & Valve

(Tapered Plug)

Gas Outlet

To Cooktop

Burners

Gas Outlet

To Oven

Burners

Lower Chamber

Gas Inlet

Manual Gas

Shutoff Valve

To Oven Burner

Upper Chamber

Figure 2-3

As the gas pressure against the diaphragm drops, the tension from the spring pushes the

diaphragm downward, moving the tapered plug away from the valve seat, allowing more gas

pressure to flow to the burners (see Figure 2-4). Additional gas may then flow into the regulator,

pushing the diaphragm back up, thus restricting the flow of gas pressure into the passage way, and

the cycle can repeat. In this way, the diaphragm and tapered plug maintain a constant gas pressure

level to the burners.

Gas Inlet

Cap (In Natural Gas

Position)

Tension

Spring

Diaphragm

Gas Outlet

To Cooktop

Burners

Gas Outlet

To Oven

Burners

Figure 2-4

Page 2-2

The amount of spring tension applied to the diaphragm determines the output pressure of the

regulator (see Figure 2-5).

Cap (L.P. Position)

Tension Spring

Diaphragm

Gas Outlet

Gas Inlet

To Cooktop

Burners

Gas Outlet

To Oven

Burners

Figure 2-5

A manual gas shutoff on some pressure regulators will allow the gas to be turned off to the oven

burners during service to allow gas flow to the cooktop to remain on. The gas to the oven burners

is turned off by moving the manual shutoff lever in the direction shown in Figure 2-6.

Gas Inlet

Manual Shutoff

Lever

CLOSED POSITION

Cap (L.P. Position)

Tension Spring

Diaphragm

Gas Outlet

To Cooktop

Burners

Gas Outlet

To Oven

Burners

Manual Shutoff

Lever

OPEN POSITION

Figure 2-6

Page 2-3

VENTING

Pressure regulators contain an air vent in the upper chamber to allow a free flow of air in and out

of the chamber during operation (see Figure 2-7). The vent’s secondary purpose is to safely control

the flow of gas to the atmosphere (200cc-per-hour or 7 BTU-per-hour) in case the diaphragm

ruptures. If the vent is partially or completely plugged, the regulator will become sluggish. It can

also become fixed in the high or low position, depending on which position the diaphragm was in

when it became plugged.

Vent (Through

Hole In Cap)

Cap

Figure 2-7

REGULATOR DIAGNOSTICS

Common causes for regulator failure are:

A. Ruptured diaphragm.

B. Broken or worn valve.

C. Debris accumulating around the valve seat.

D. Restricted (plugged) vent.

E. Internal corrosion due to water in the L.P. gas system. Keep the tank full to prevent this

from occurring.

As a safety feature, the regulator will “lock-up” and restrict all gas flow during any situation that

applies extreme pressure to the incoming gas supply line. The pressure regulator can be unlocked

by removing the cap, and pushing down on the diaphragm with the eraser end of a pencil.

Usually the appliance regulator is replaced rather than serviced, since it has few replaceable or

serviceable parts, and is a relatively inexpensive device.

Page 2-4

MEASURING GAS PRESSURE

Gas pressure is measured in

Inches of Water Column Pressure (WCP)

. It takes 28" WCP to

equal one pound per-square-inch (PSI).

In most locations, natural gas pressure entering the home is regulated to 7 inches water column.

L.P. gas is regulated between 10 and 12 inches water column. The appliance regulator reduces

the incoming pressure to the required amount for the appliance. The model/serial plate on the gas

range (see Figure 2-8) provides information about the proper water column pressure. Whirlpool

ranges operate on 4 inches water column on natural gas, and 10 inches WCP on L.P.

it becomes necessary to measure these pressures, two instruments are available: a manometer,

and a magnehelic gauge.

WHIRLPOOL, U.S.A., BENTON HARBOR, MI 49022

THIS UNIT IS FACTORY ADJUSTED FOR NAT. GAS BUT

MAY BE USED WITH LP/PROPANE OR NAT. GAS

MODEL:

SERIAL:

120V 60 HZ 10A

SFV360BEEW-E

TGENG006

BTU RATINGS RF LF RR LR BAKE BROILER

9500 9500 6500 7500 16500 10000

4" WC NAT.

8500 8500 5500 6500 15500 9000

10" WC LP

Figure 2-8

When it becomes necessary to measure these pressures, there are two instruments available that

you can use: a manometer and a magnehelic gauge.

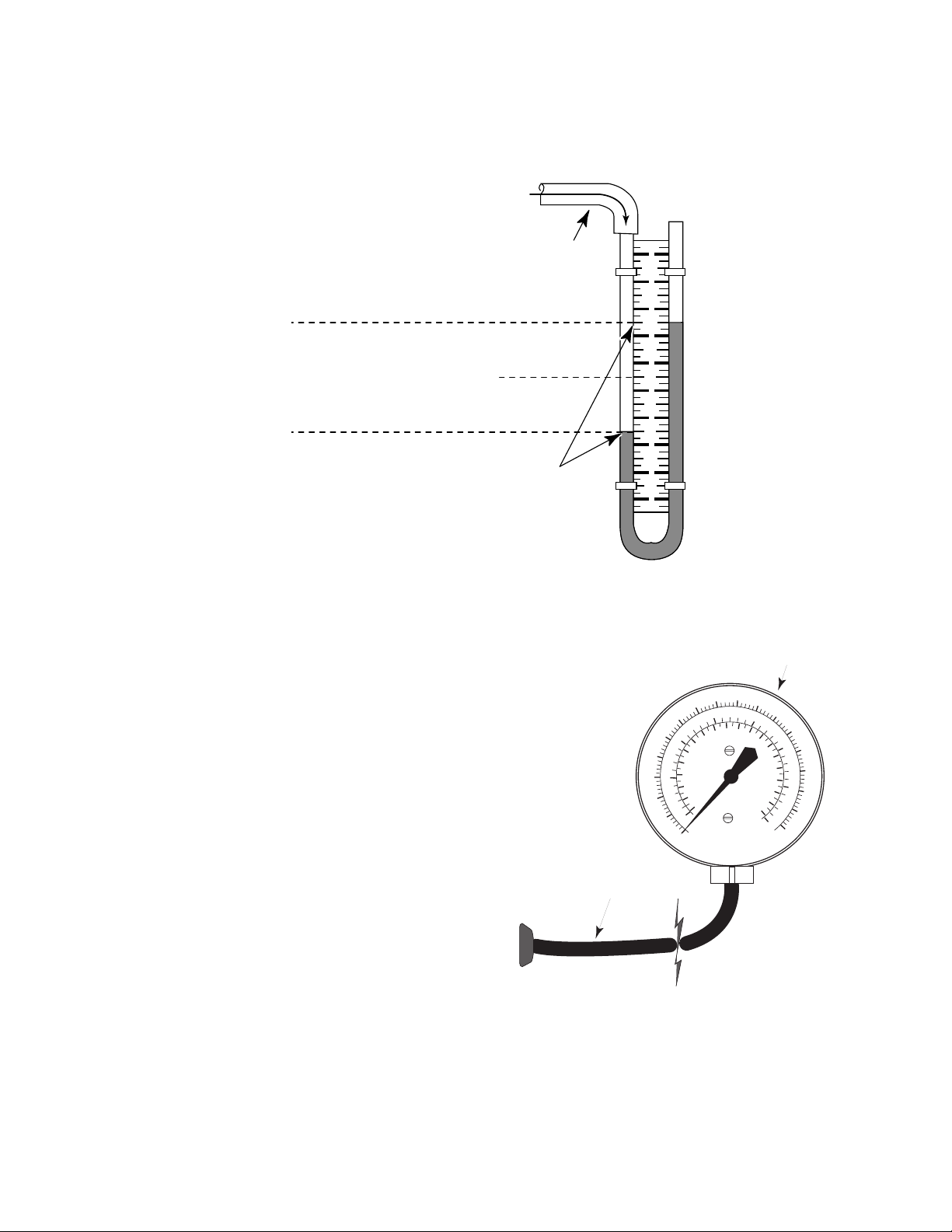

A manometer is basically a U-shaped tube with a scale, marked in inches of water column. To

prepare and use the manometer, use the following steps:

1. Check the appliance model/serial plate and note the gas pressure

rating.

2. Turn off the gas pressure to the range.

Hose

3. Prepare the manometer by filling the U-shaped tube with water so

that both sides of the tube fill to the

zero

point (see Figure 2-9).

NOTE: Use a little food coloring in the water to help make reading

the meter easier.

4. Connect the tubing that is supplied with the manometer over one

end of the manometer.

5. Remove a burner from the appliance and place the free end of the

tubing over the burner orifice.

6. Turn on the gas supply to the range.

Balanced

Water Columns

4

3

2

1

0

1

2

3

4

7. Turn on the gas valve to the orifice being tested and light at least

one other burner to serve as a load.

Figure 2-9

Page 2-5

8. Observe the movement of the water in the manometer. The gas pressure is read by adding

the water movement in both legs of the tube, as shown in Figure 2-10. It should measure within

the pressure rating stated on the rating plate.

Incoming

Gas Flow

Hose

4

3

2

Total Change In

Water Column =

4.00 IN. W.C.

2.00 IN.

2.00 IN.

1

0

1

2

3

New Water

4

Levels

Figure 2-10

The Magnehelic gauge (see Figure 2-11) can also help measure gas pressure. This type of gauge

is easier and faster to use that a manometer.

To use the gauge:

l. Check the appliance model/serial plate and note

the gas pressure rating (see Figure 2-8 on the

previous page ).

2. Turn off the gas pressure to the range.

3. Remove a burner from the appliance and place

the free end of the tubing over the burner orifice.

4. Turn on the gas supply to the range.

5. Read the gas pressure directly from the scale of

the gauge. It should measure within the pressure

rating stated on the rating plate. Some gauges

have numerous scales on the dial face. Read the

water column pressure scale when taking the

measurement.

2

5

1

Rubber Hose

Magnehelic Gauge

4

15

3

10

8

4

0

O

0

U

N

I

N

C

H

0

20

12

20

C

.

E

Q

S

S

P

R

E

R

E

E

S

T

A

O

W

F

K

S

I

L

L

O

A

P

C

A

S

Figure 2-11

5

6

25

7

16

30

8

.

N

I

35

9.8

Page 2-6

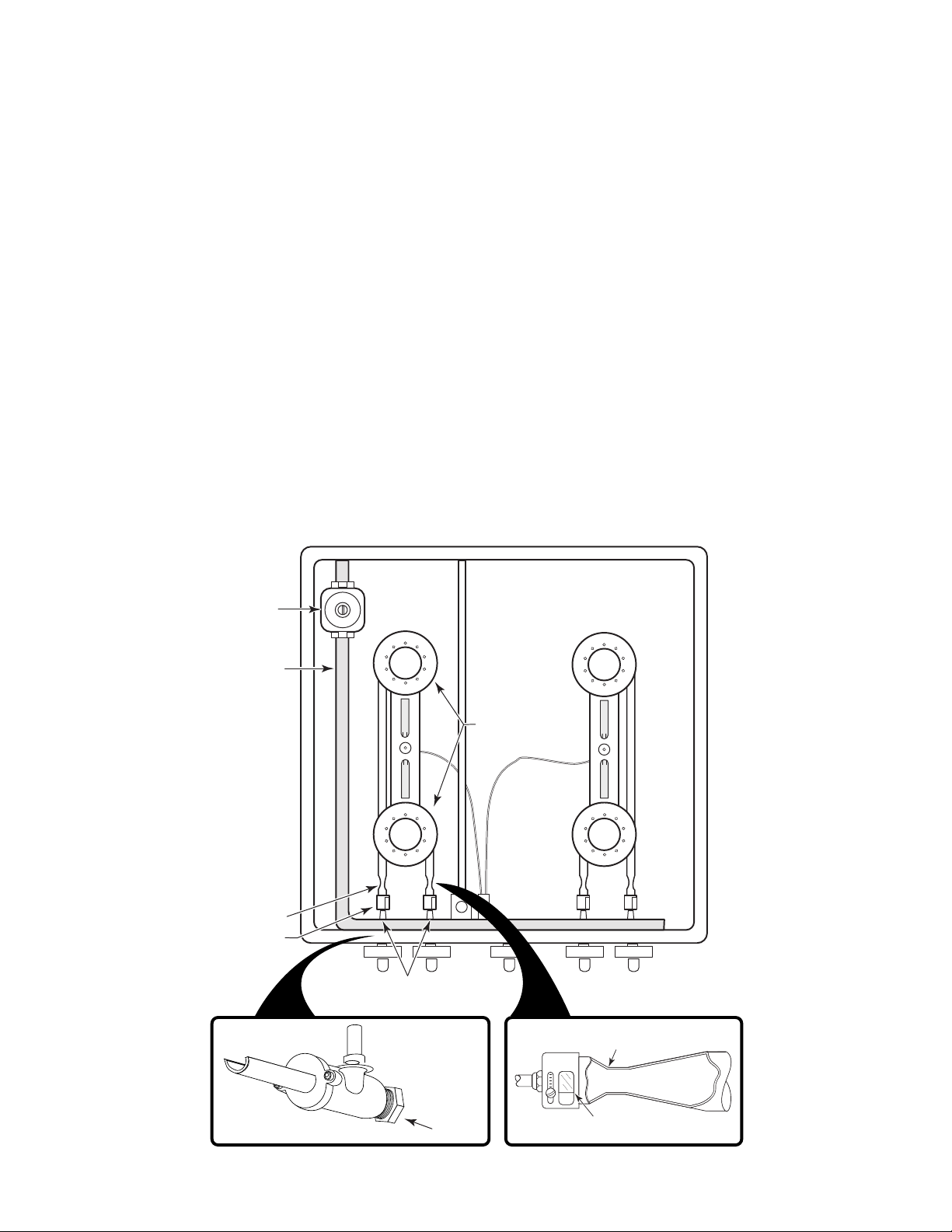

THE COOKTOP BURNER SYSTEM

GAS DISTRIBUTION

After gas passes through the gas pressure regulator, it enters the gas manifold for distribution to

the cooktop burners, or the oven safety valve. The components that provide the safe distribution

and operation of the cooktop burner system (see Figure 3-1) will be discussed in this section.

GAS MANIFOLD—After gas passes through the appliance gas pressure regulator, it enters a

manifold. A manifold is simply a formed pipe through which the incoming gas is distributed to each

of the burner valves.

GAS VALVE—The gas valve controls the gas flow to the individual burners. The valves on all

Whirlpool ranges are push-to-turn types to keep them from being turned on accidentally. When the

valve is turned on, gas flows through the valve and out an orifice.

ORIFICE—The orifice is a special fitting at the outlet of the valve that controls the amount of gas

released through the valve. The orifice controls the gas flow and directs it into the venturi and air

shutter assembly.

AIR SHUTTER & VENTURI—From the orifice, the gas flows through an air shutter into the venturi,

and finally to the burner head, where it exits a series of small holes, called “ports,” and is ignited

by the pilot flame, or spark.

Gas Pressure

Regulator

Gas Manifold

Venturi

Air Shutter

Gas Valves

& Orifices

Burner

Heads

Figure 3-1

Venturi

Gas Valve

Orifice

Page 3-1

Adjustable Air Shutter

GAS VALVE

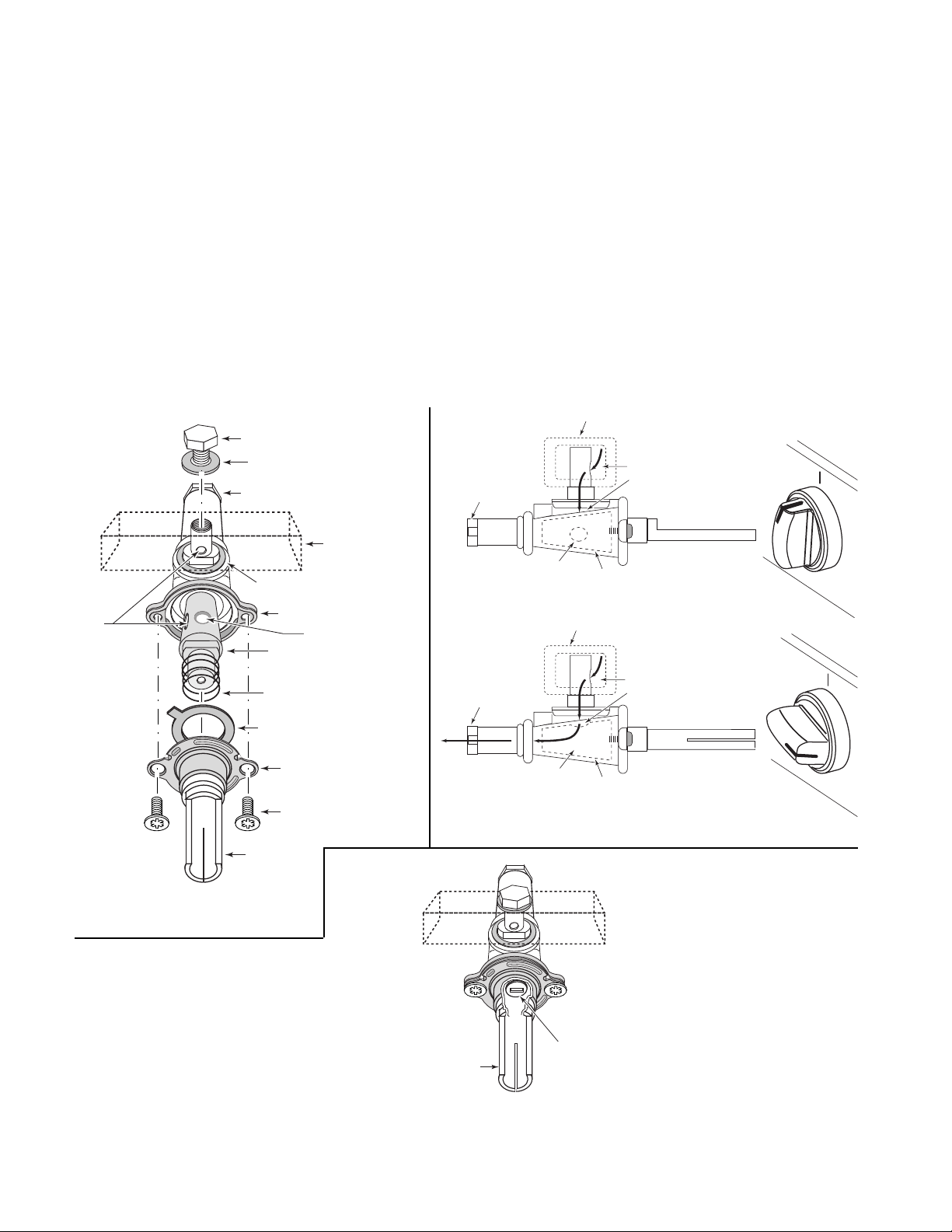

A typical Whirlpool gas valve and its component breakdown is shown in Figure 3-2. The gas valves

are used to control the gas flow to the top burners. The gas valves are usually mounted to the top

of the manifold pipe with a screw and rubber washer. The gas valve housing contains a hollow gas

control seat. As the valve stem is rotated, the hole in the seat rotates to align with the hole in the

top of the valve housing (see Figure 3-3). Gas from the manifold then flows through the holes to

the orifice.

There are two types of gas valves used, depending on the model of the range. The first type of valve

goes from closed to completely open by manually rotating the valve stem from 0˚ to 90˚. The second

type of valve has a stem rotation of 220˚.

The 220˚ gas valve has a

low flame adjustment screw

that is located inside the shaft of the valve

stem (see Figure 3-4). To adjust the control, use a small screwdriver, and turn the control until the

desired flame is produced.

Manifold

Mounting Screw

Gas From Manifold

Enters Here And Is

Stopped Here

Gas Control Seat

Gas From Manifold

Flows Through Hole

In Seat To Orifice

Gas Control Seat

Figure 3-3

OFF

On

OFF

Gas

Openings

Rubber Washer

Orifice

Rubber Washer

Gas Valve Housing

Gas “On” Position

Gas Control Seat

Spring

Detent Collar

Stem Housing

Screw

Gas Manifold

Pipe

Orifice

Gas Inlet Hole

OFF POSITION

Manifold

Orifice

Gas Inlet Hole

ON POSITION

Figure 3-2

Stem

Stem

Figure 3-4

Page 3-2

220˚ Rotation

Gas Valve

Low Flame

Adjustment Screw

GAS VALVE ORIFICES

An orifice is an opening used to control the direction and amount of gas that is discharged to a

burner. Orifices are available in different sizes and shapes and can be removed and replaced

without replacing the valve.

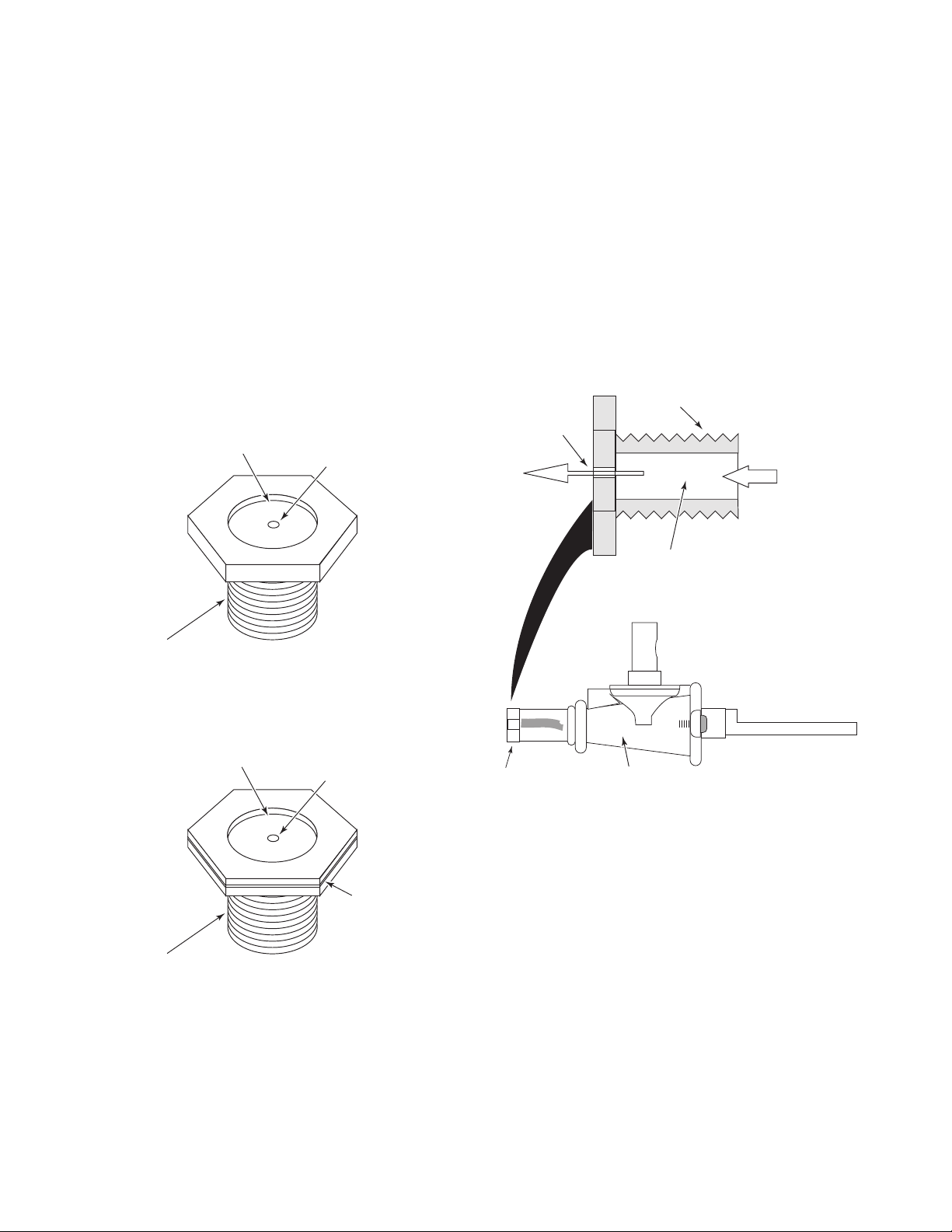

PLUG-TYPE ORIFICES

The cooktop burner orifice uses a

plug-type

orifice, as shown in Figure 3-5. The orifice is generally

constructed of brass, and consists of a threaded seat, a chamber, and a metered hole. The

threaded seat allows the orifice to be securely fastened to the burner valve. The chamber is used

as a passageway to allow gas to flow through the orifice opening. The orifice is used to control, or

limit, the amount of gas going to the burner. This type of orifice is not adjustable.

Natural Gas

Orifice Drill Size No.

(Stamped On Top)

Threaded Seat

55

Orifice

Orifice Opening

Gas Flow

Out

Threaded Seat

Gas Flow

In

Chamber

L.P. Gas

Orifice Drill Size No.

(Stamped On Top)

Threaded Seat

65

Orifice

L.P. Gas

Identification

Notch In Orifice Cap

Orifice

Gas Valve

Figure 3-5

Page 3-3

L.P. AND NATURAL GAS ORIFICES

The actual size and configuration of each orifice depends on several factors. The most important

factor, however, is the type of gas that will be used by the gas range system. The two most

frequently used types are:

liquefied petroleum (L.P.)

gas, and

natural

gas.

L.P. gas is generally heavier than natural gas and has a higher heat output.

For example, when one cubic foot of L.P. gas is burned, it gives off approximately 2,500 B.T.U. of

heat, while one cubic foot of natural gas will yield only 1,000 B.T.U. Since the heat density of L.P.

gas is higher than natural gas, it takes less cubic feet of L.P. gas to produce the same amount of

heat. An L.P. orifice will always be smaller than a natural gas orifice with an equivalent B.T.U. rating

(see the following “Orifice Specifications Chart” ). It is also important to remember that much more

air is needed with the L.P. gas system (24 cu. ft.) than with the natural gas system (10 cu. ft.). The

identification color location on the valve is shown in Figure 3-6.

Orifice Specifications Chart

SUGGESTED IDENT.

DRILL SIZE COLOR STAMPING BTU RATING

1.45 MM BRASS NAT 9,500

#65 BRASS L.P. 8,500

#55 BLACK NAT 7,500

#68 BLACK L.P. 6,500

1.2 MM NICKEL NAT 6,500

.7 MM NICKEL L.P. 5,500

#54 BRASS NAT 9,000

#66 BRASS L.P. 8,000

1.85 MM – NAT 12,500

#60 – L.P. 11,500

Identification

Color

Figure 3-6

Page 3-4

UNIVERSAL ORIFICE—OVEN APPLICATION

Gas From

L.P. Insert

Gas

Through

Cap Is

Blocked

L.P. Position

Cap Rests

Against

L.P. Insert

L.P. Insert

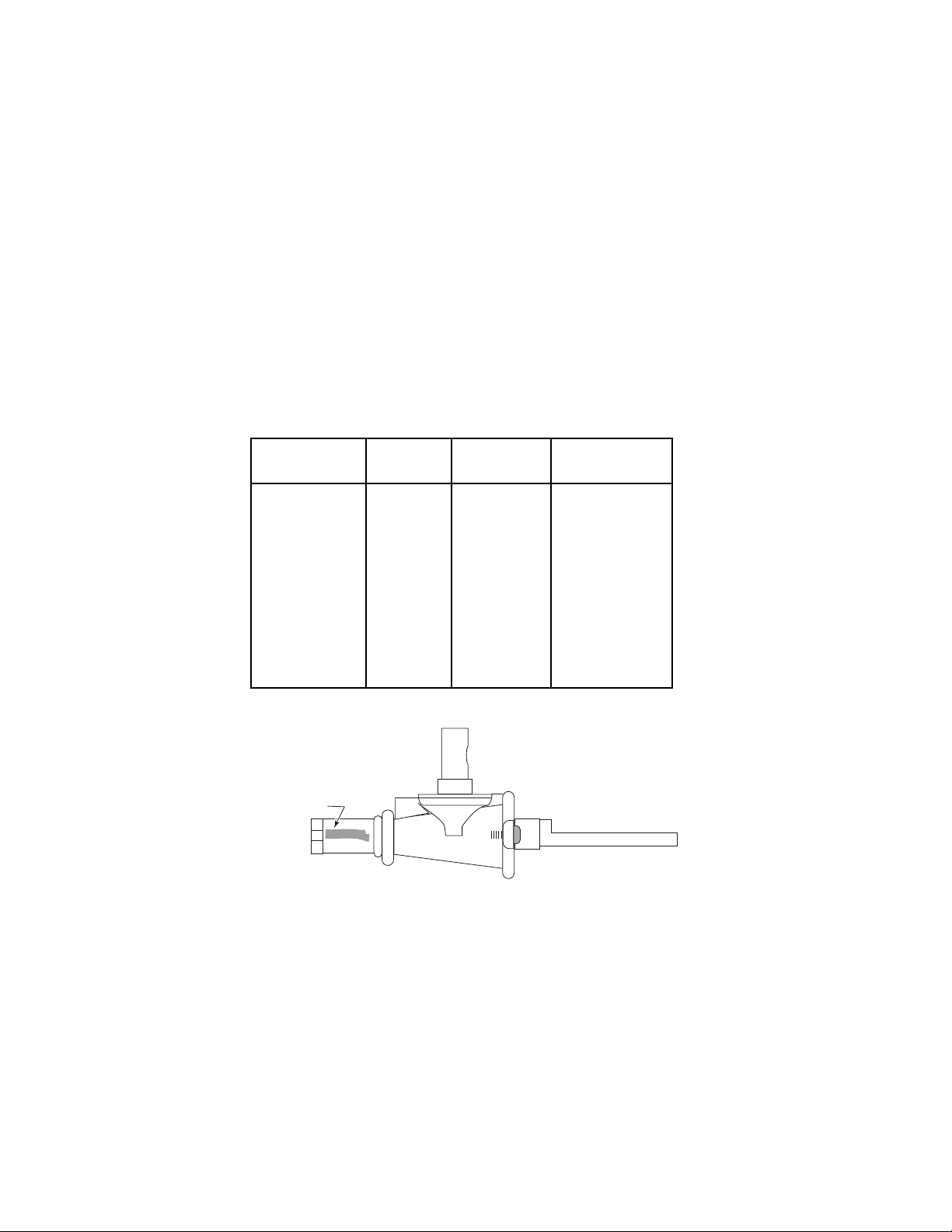

Gas cooking systems for both L.P. gas and natural gas

can be used without changing orifices by using a

sal

orifice.

The universal orifice consists of an L.P. gas insert that is

threaded into a cap orifice. This insert is actually an

orifice itself. When natural gas is used, the cap is in the

position shown in Figure 3-7. Gas enters through both

the cap and the insert. The amount of gas leaving the

orifice is controlled by the size of the cap orifice.

When L.P. gas is used, the cap is tightened down

2-1/2 turns so that it rests against the L.P. insert,

closing off the spacing between the two (see Figure

3-8). The amount of gas leaving the orifice is now

controlled by the size of the L.P. insert.

univer-

Natural Gas Position

Cap Orifice

Gas Flow

Cap

Insert

Gas Flow

Figure 3-7

Figure 3-8

Page 3-5

GAS VALVE ORIFICE DIAGNOSTICS

A gas valve orifice is often a source for gas range problems. Some of the problems that arise with

an orifice are as follows:

1. The orifice may become clogged from dirt, or slag in the gas lines. The result will be an overrestricted gas flow, causing the mixture to become too “lean”. This means that not enough gas

will be mixed with air in the burner for efficient burning to occur.

2. The orifice may become cross-threaded when it is installed and allow one of three conditions

to occur:

a) The orifice may not be aligned correctly with the venturi tube so that the gas flows straight

into the burner, causing inefficient burning.

b) The orifice may not be secured because of the cross-threading, causing a small gas leak.

The mixture will again be too lean, and inefficient burning will occur.

c) The orifice size may be incorrect. If a conversion is made from natural to L.P. gas, the orifice

must be changed to maintain the desired heat output. The orifice size may also be too small

due to a high consumption rate, so that the burner cannot meet its maximum B.T.U. output.

If it becomes necessary to clean an orifice, there are three methods that can be used:

1. Blowing forced air into the chamber.

2. Using a mild solvent and soaking the orifice for 15 to 30 minutes (the orifice can then be blown

out and reinstalled).

3. Using a drill bit to clean the orifice. The bit is inserted into the orifice, then, using a slow in and

out motion, the debris can be removed. A chart on page 3-4 shows the proper drill bit size to

use for a particular orifice.

Page 3-6

PERFORMANCE CHECK

1. Remove the gas valves.

2. Remove the orifices.

Page 3-7

BURNER OPERATION

To understand how a burner operates, it is important to understand the following terms (see Figure

3-9):

Gas:

Primary Air:

Secondary Air:

Air/Gas Ratio:

The fuel used by the burner, either natural or L.P.

The air mixed with the gas in order to make the gas combustible.

The supplemental, or ambient air, surrounding the flame.

Comparison of amounts of fuel gas and air to act as primary and

secondary air.

Secondary Air

Gas

Primary Air

Primary Air

Figure 3-9

For proper operation, a burner needs the correct amount of gas mixed with the correct amount of

air, referred to as the “air/gas ratio.” A correct air/gas ratio will result in a flame that is stable without

yellow tips. The ratio depends upon the fuel gas type being used. Ten cubic feet of air are needed

to completely burn one cubic foot of natural gas (10 to 1 ratio) and twenty-four cubic feet of air are

needed to completely burn one cubic foot of L.P. gas (24 to 1 ratio). (See Figure 3-10).

When broken down, 70% to 80% of the total air required is mixed with the gas as primary air. The

remaining 20% to 30% is pulled into the flame as secondary air.

1000 BTU Heat

1 cu.ft.

Gas

Natural Gas

10 cu. ft. Air To 1 cu.ft. Gas

10 cu.ft.

Air

Figure 3-10

1000 BTU Heat

1 cu.ft.

Gas

L.P. Gas

24 cu. ft. Air

To 1 cu.ft. Gas

24 cu.ft.

Air

Page 3-8

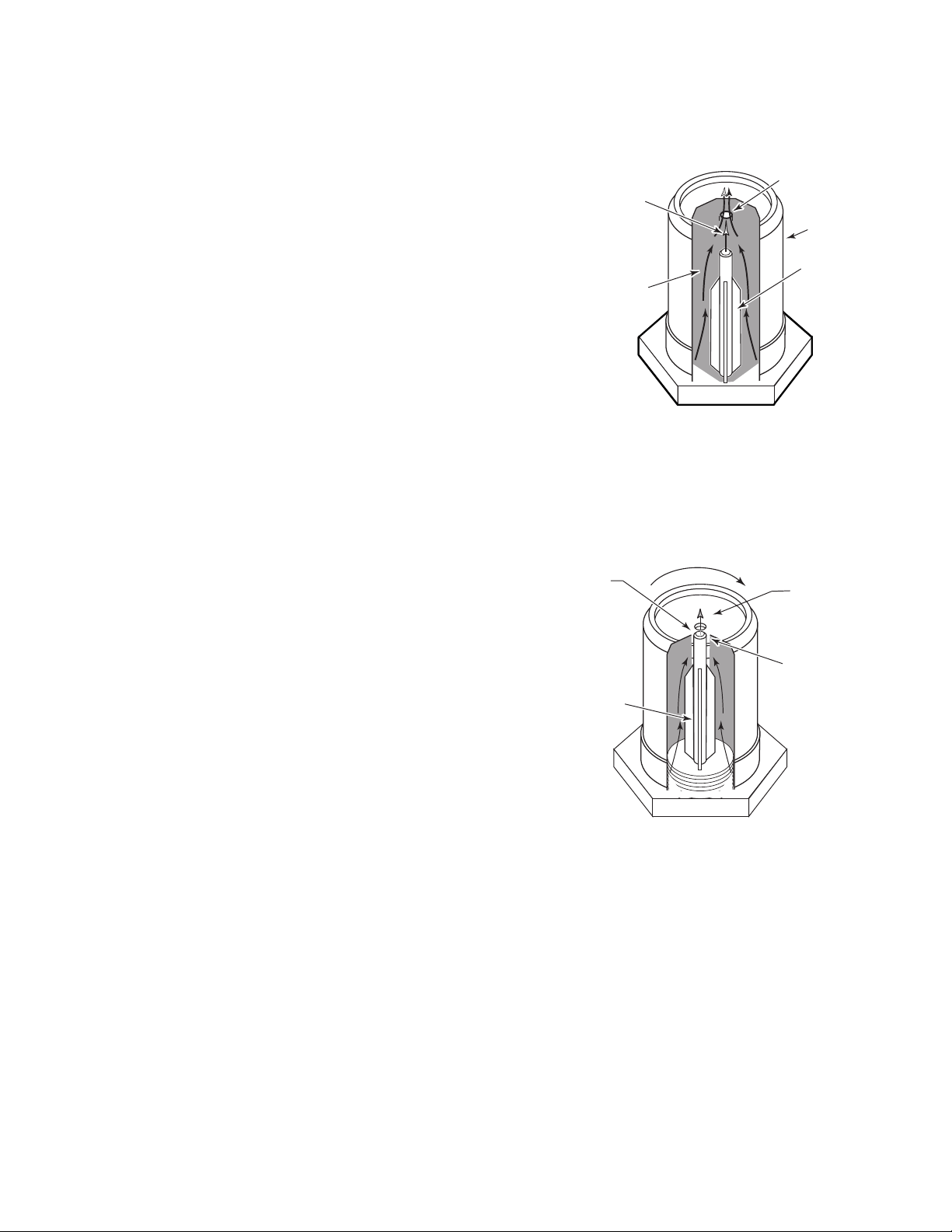

The

Cooktop Burner Assembly

controls the combustion of gas and directs its flame (see Figure

3-11). Burners are manufactured from galvanized steel and have common component parts:

1. An

2. A

Air Shutter

Venturi

to provide a pathway for gas to flow to the burner from the orifice. Air enters the

to control the amount of primary air to be mixed with the gas.

burner through the venturi tube, and is used as a pathway for gas, as well as an area for gas

and air to be mixed together for combustion.

3. A

Burner Head

to provide an exit for gas so it can be ignited. The exits are normally holes,

or slots, called “burner ports.”

Burner Head

Figure 3-11

Venturi

Air Shutter

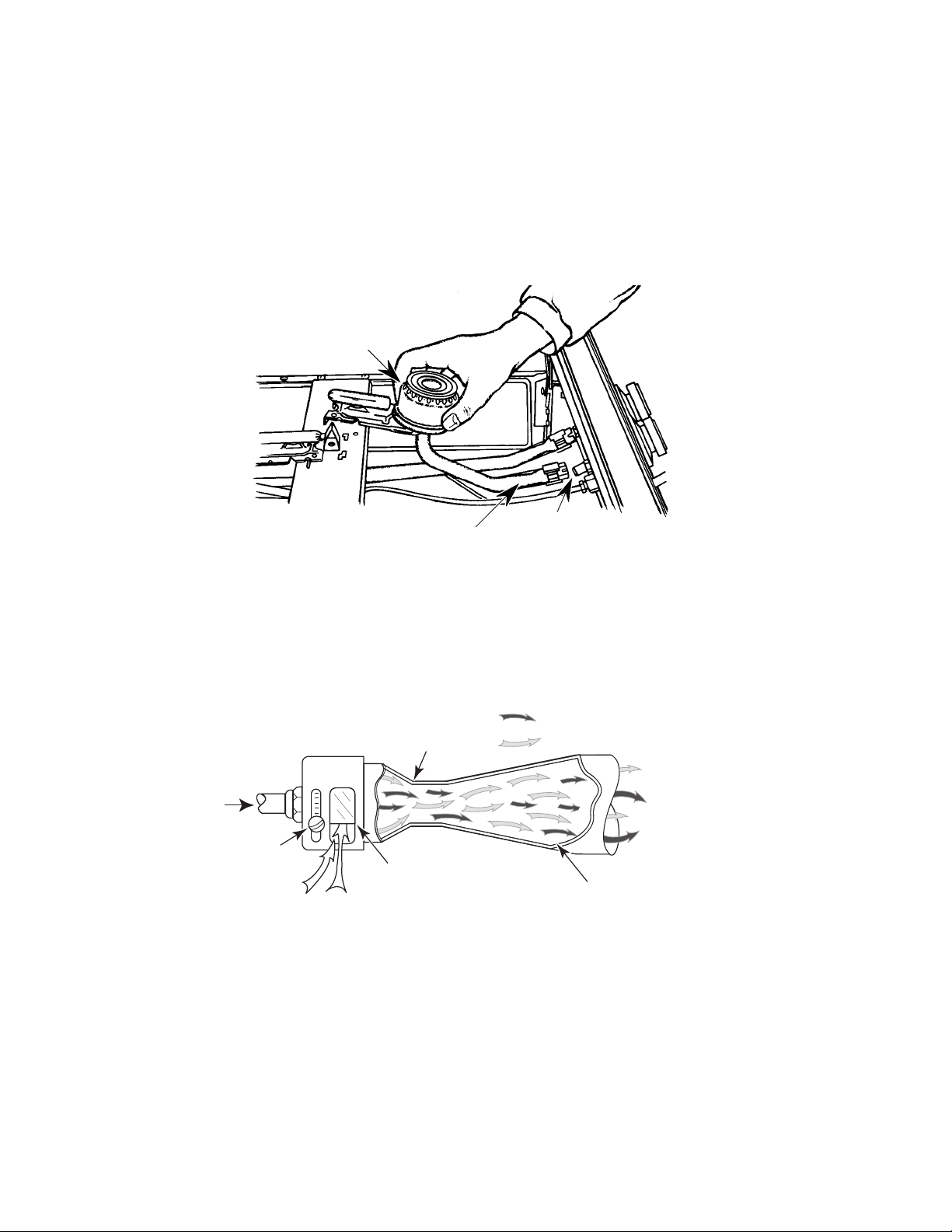

AIR SHUTTER & VENTURI

An inlet for primary air is provided before the gas supply reaches the burner port. This inlet is called

an “air shutter” (see Figure 3-12). The air shutter is adjustable to allow a better adjustment of the

air-gas mixture needed for combustion, and results in more efficient combustion.

Gas Inlet

Adjustment

Screw

Venturi

(Constricting

Area)

Adjustable

Air Shutter

Primary Air

= Gas

= Air

Expanding

Area

Mixed Air &

Gas Outlet

Figure 3-12

Page 3-9

Loading...

Loading...