Page 1

Welch Allyn Solarc

Light Source Menu

Operation Manual

Light Source/Illuminator

Service Manual

Models: 49500,49502,49504,49506,

HLS-24-0,HLS-24-2,HLS-24-4,HLS24-6

Copyright 1996

Welch Allyn Inc.

4341 State Street Road

P.O Box 220

Skaneateles Falls, NY 13153-0220

P/N 495621 Rev. B

Page 2

Introduction

Revision (History) Page

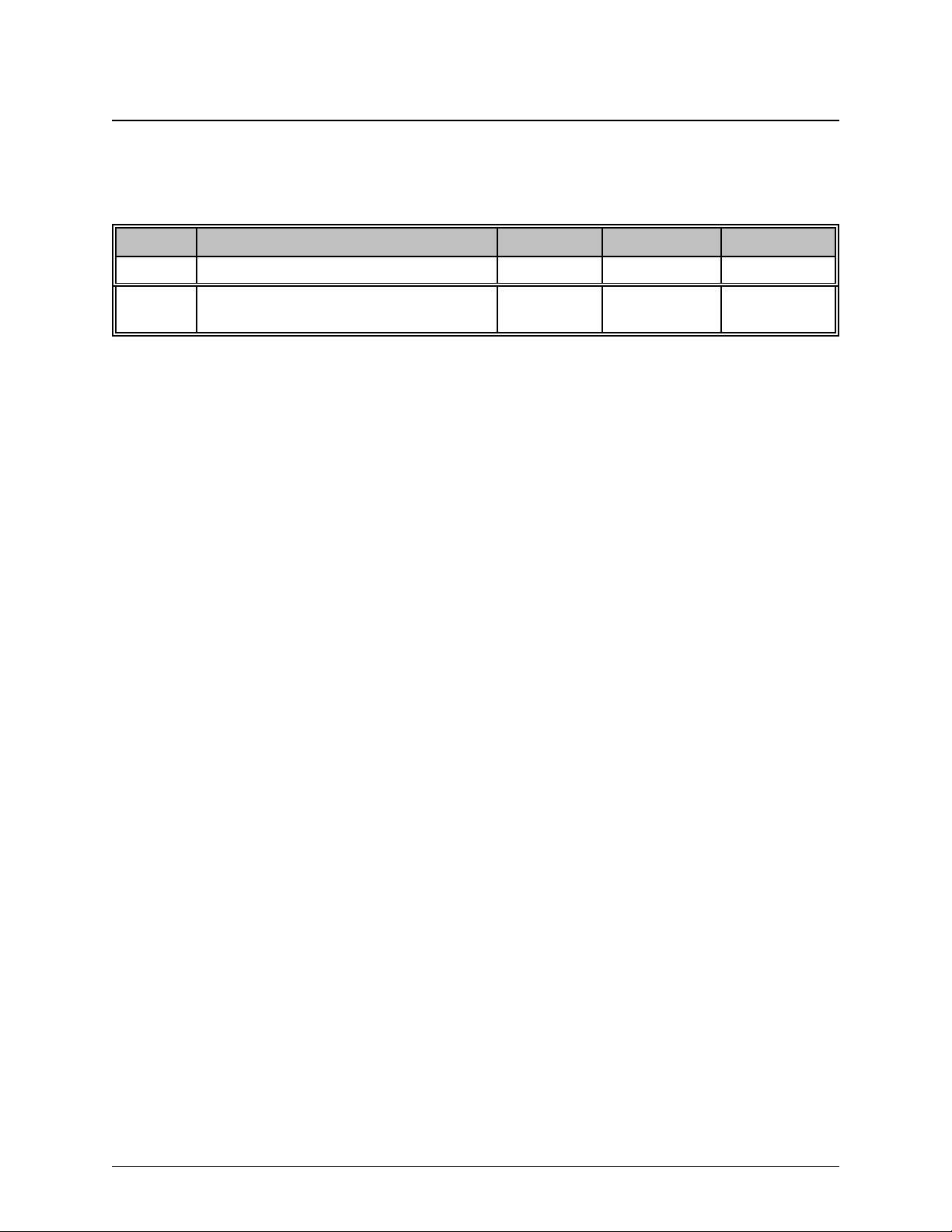

Rev. Description of Change ECN # Date Initial

A New Release 5-33806 10/10/96 JSJ

B Update, Remove section revisions,

replace fuse P/N

5-34456 1/14/97 JSJ/MD

Light Source/Illuminator Service Manual Page 2

Page 3

Introduction

To Service Personnel:

The information in this manual is subject to change without notice and

should not be construed as a commitment by Welch Allyn, Inc.

Welch Ally n assumes no responsibility for any errors that may appear in this

manual. If the product and/or its operation varies significantly from any

description herein, please contact the Welch Allyn Product Service

Department at 4341 State Street Road, Skaneateles Falls, New York 131530220, 1 800 669-9771, (315) 685-4445

This product has been designed to provide a high degree of safety and

reliability. However, we can not guarantee against the deterioration of

components due to aging and normal wear.

All service and repairs must be performed by authorized Welch Allyn

personnel or agents, using Welch Ally n replacement parts. Failure to do so

will invalidate the product warranty.

Authorized service centers should refer to repair specification for proper

test and device history record requirements.

Please refer to the product warranty for specific coverage.

Welch Allyn, Inc.

Medical Products

4341 State Street Road

Skaneateles Falls, New York 13153-0220

USA

1 800 669-9771

(315) 685-4445

Limited Warranty

Light Source/Illuminator Service Manual Page 3

Page 4

Introduction

49501Medical Light Source...

new, to be free of defects in material and workmanship and to perform in accordance with

manufacture' specifications when subject to normal use and service for a period of three

years from the date of purchase from Welch Allyn or an authorized agent. Welch Allyn

will either repair or replace any components found to be defective or at variance from

manufacture's specifications within this time at no cost to the customer. It shall be the

purchaser's responsibility to return the instrument directly to the authorized distributor,

agent, or service representative. This warranty does not cover the Solarc Lamp or breakage

or failure due to tampering, misuse, neglect, accidents, improper installation, modification,

shipping, or to improper maintenance, service, and cleaning procedures. This warranty

is also void if the instrument is not used in accordance with manufacture's

recommendations or if required or serviced by other than Welch Allyn or an authorized

agent. Purchase date determines warranty requirements. No other express or implied

warranty is given.

HLS24 Industrial Illuminator...

new, to be free of defects in material and workmanship and to perform in accordance with

manufacture' specifications when subject to normal use and service for a period of one year

from the date of purchase from Welch Allyn or an authorized agent. Welch Allyn will

either repair or replace any components found to be defective or at variance from

manufacture's specifications within this time at no cost to the customer. It shall be the

purchaser's responsibility to return the instrument directly to the authorized distributor,

agent, or service representative. This warranty does not cover the Solarc Lamp or breakage

or failure due to tampering, misuse, neglect, accidents, improper installation, modification,

shipping, or to improper maintenance, service, and cleaning procedures. This warranty

is also void if the instrument is not used in accordance with manufacture's

recommendations or if required or serviced by other than Welch Allyn or an authorized

agent. Purchase date determines warranty requirements. No other express or implied

warranty is given.

Welch Allyn warrants the Welc h Allyn Light Source when

Welch Allyn warrants the We lch Ally n Illuminator when

For service assistance or questions regarding this warranty, please call

Welch Allyn Medical Technical Service Department at 1 800 669-9771, or

(315) 685-4445.

Light Source/Illuminator Service Manual Page 4

Page 5

Introduction

Table of Contents

SECTION 1: General Information

Basic System Description ...............................................................7

Specifications ........................................................................8

SECTION 2: Service

Intent of Manual ......................................................................9

Required Tools .......................................................................9

Words of Caution ....................................................................10

Performance Check ..................................................................11

Calibration .........................................................................11

SECTION 3: Problem Solving

Troubleshooting .................................................................. 12-13

SECTION 4: Disassembly and Repair

Part Identification ....................................................................14

Left Housing Assy ....................................................................15

Ballast Board .......................................................................16

Power Supply .......................................................................16

Fan / Secondary Wire Harness Asy ......................................................17

Lamp Cover Safety Interlock Switch ......................................................18

Power Switch .......................................................................18

SECTION 5: Maintenance

Preventative Maintenance ..............................................................20

Cleaning ...........................................................................20

Checking Ground Impedance ..........................................................21

Measuring Leakage Current ......................................................... 21-22

Fuse or Lamp Replacement ............................................................23

SECTION 6: Theory of Operations

Introduction .........................................................................24

Start Up Routine .....................................................................24

Power Supply .......................................................................25

Ballast Board........................................................................25

Light Source/Illuminator Service Manual Page 5

Page 6

Introduction

APPENDIX A: Schematics/Diagrams

Table of Drawings (Appendix A)

Drawing Number Description

N/A Parts Lst/Recomended Inventory

495000 ACMI Light Box Asm

495064 Right Housing Asm

495072 Internal Chassis Asm

495078 Secondary Wire Harness Asm

495102 Interconnect Diagram

A03387 Illuminator Electrical Safety Test Secification

Drawings and specs are for reference only. Consult factory for current revisions.

Light Source/Illuminator Service Manual Page 6

Page 7

General Information

Basic System Description

Model # 49501 is a medical light source which is used in conjunction with several Welch Allyn

medical instruments. This model has a built in Infrared filter to limit the heat generated by the

light. It also has an external ferrite bead built into the power cord to meet Electromagnetic

Interference (EMI) requirements, as required by medical standards.

Model HLS-24-0 is an industrial illuminator which can be used in many industrial applications.

The HLS-24-0 is also known at Welch Allyn as a 49501I (The I indicates that the unit is for

industrial use only). This instrument is identical to the 49501 medical light source with the

deletion of the Infrared filter and the Ferrite bead.

49500....Welch Allyn Light Source

100-240 VAC

50/60 Hz

U.S.A. Plug Type

49502...Welch Allyn Light Source

100-240 VAC

50/60 Hz

European Plug Type

49504...Welch Allyn Light Source

100-240 VAC

50/60 Hz

U.K. Plug Type

49506...Welch Allyn Light Source

100-240 VAC

50/60 Hz

Australian Plug Type

HLS24-0...Welch Allyn Illuminator

100-240 VAC

50/60 Hz

U.S.A. Plug type

HLS24-2...Welch Allyn Illuminator

100-240 VAC

50/60 Hz

European Plug type

HLS24-4...Welch Allyn Illuminator

100-240 VAC

50/60 Hz

U.K. Plug type

HLS24-6...Welch Allyn Illuminator

100-240 VAC

50/60 Hz

Australian Plug Type

Light Source/Illuminator Service Manual Page 7

Page 8

Section 1 General Information

Specifications

Electrical

Input Voltage: 100-240 VAC, 50-60 Hz

Input Current: 1Amp (@ 100VAC)

Output: 60VDC @.4A

Leakage Current: Less than 100 microamps

Dimensions

HxWxD: 8.2" x 3.1" x 5.2" (21cm x 8cm x 13cm)

Weight: 2.5 Pounds

Illumination System

Welch Allyn HI-Lux Lamp

Color Temperature: 5500

Lamp: 60 Volts, 24 Watts

Lamp Life: 300 hours average

Dimming System

Manual Shutter: 20% to 100%

Fiber Optic Bundle Interface

Standard ACMI Connector

K

Approvals

UL 2601-1 IEC 801-2,3,4,5

CSA C22.2 No. 601.1-M90 EN 55011

IEC 601-1 Australia AS3200

IEC 601-1-2

CE

The CE mark on this product indicates it has been tested to and conforms with the provisions noted within

the 93/42/EEC Medical Device Directive.

Declarations of Conformity are held by Welch Allyn's European Representative.

European Regulatory Manager

Welch Allyn Ltd.,

Kells Road, Navan,

County Meath, Republic of Ireland.

Tel +353 46 28122

Fax +353 46 28536

Environment

Operating: 60F (15C) to 85F (30C)

Storage: -13

F (-25 C) to 140F (60C)

Equipment Classification

Class 1, Type B, Continuous Operation

Fuses

T1.0A L250V: 1.0 A, 250 V, Time Lag (Slow-Blow), Low Breaking Capacity.

Light Source/Illuminator Service Manua Page 8

Page 9

Service

Intent of Manual

The purpose of this manual is to provide Welch Allyn Inc. authorized service representatives with

systematic guidelines for preventative maintenance, problem identification, and service of the

Solarc Light Source/Illuminator. We have included the theory of operation schematic diagrams,

simplified drawings, service tips and procedures to assist a trained service representative with

board-level repairs. Should you encounter problems that are beyond the scope of this manual,

please contact the Technical Service Department of Welch Allyn's Medical Products for assistance.

Required Tools for Service

1. 11/32 Nut Driver

2. Screwdriver: Phillips #1

3. Long Nose Pliers

4. Wire Cutters Xcelite 54CG

5. 1/16" Drill bit and Pin-Vise

Required Equipment:

1. Digital Volt/Ohm Meter with Leads (True RMS). Beckman model 310 or equivalent.

2. Soldering Iron

3. Solder Sucker or Desoldering Wick

4. Kepco Model MSK 10-10M Power Supply. Capable of 10 amps at 10VDC.

5. Hy-Pot Tester- Associated Research Inc. Model 35400D or Equivalent.

Light Source/Illuminator Service Manual Page 9

Page 10

Section 2 Service

Words of Caution:

High Voltage

Use caution when servicing. When servicing the unit, potentially

dangerous high voltage levels are exposed. Disconnect the

power cord whenever possible to avoid electric shock.

Static Electricity (ESD)

Adhere to standard ESD practices at all times when servicing this

equipment. Many of the electronic devices in this equipment are

static sensitive, and may suffer catastrophic or latent failure if

handled improperly.

Heat

Lamps, power supplies, and heat sinks may emit extreme

amounts of heat during and after operation. Approach and

handle these and other potentially hot components with caution.

Finished Parts

Handle all finished parts with care. The finish can be easily scratched or

damaged from poor or improper handling.

Light Source/Illuminator Service Manual Page 10

Page 11

Section 2 Service

Performance Checks

The following performance checks will help you (1) determine whether or not the system is

operating properly, and (2) isolates a problem, if there is one.

System Set Up

Make sure the system is connected as follows:

1. Be sure that power is being provided by the wall outlet.

2. Be sure that the Lamp is installed properly.

3. Be sure that the cooling fan is turning when the unit is turned on.

4. The light source should produce a bright continuous white light with no

flickering after it reaches the steady state (approx. 15-20 Sec).

If any of these conditions do not occur, see the troubleshooting section.

Calibrations

Not Applicable

Light Source/Illuminator Service Manual Page 11

Page 12

Problem Solving

Troubleshooting

Experience shows that many service calls are due to improper operator technique and poor

connections. Before taking apart the light source, make sure that setup err ors are not causing

the problem.

harness wires, connectors, and on the circuit board.

Symptom Possible Cause Procedure

When checking voltages or signals, be sure to verify signal through the

Lamp is not illumina t ed,

and the fan is running.

Lamp connector is not

connected well.

Lamp is blown.

Defective ballast

Remove lamp cover and

re-seat connector.

Verify unit functions with a

known good lamp or lamp

functions with a known

good unit.

Verify Voltage input and

output of the Ballast

board. Refer to wiring

diagram.

1KV to 2KV present at

the output during

startup.

Note: There is

Light Source/Illuminator Service Manual Page 12

Page 13

Section 3 Problem Solving

Symptom Possible Cause Procedure

Lamp not illuminat ed, fan

does not function (No

power is apparent).

Power line damaged or

disconnected.

Power is not turned "ON"

Lamp Door Interlock

switch is disengaged.

AC line fuses F1 and/or

F2 are open.

Open circuit connection.

Power supply circuit

defective.

Connect, repair, or

replace as necessary.

Turn power on.

Verify that the lamp cover

is firmly and properly in

place and that interlock

switch is functioning

properly. Verify continuity

to be sure that the switch

is working properly.

Verify and replace as

necessary.

Verify AC input through

unit to the Switching

Power Supply.

Verify DC output at J2 of

Switching Power Supply.

Light Source overheating

Other circuits loading

down power supply.

Fan Not working properly

or blocked fan ventilation

If the fuse is blown,

disconnect the plug from

J2 (Output of the

Switching Power Supply).

Replace the blown fuse,

and reapply power. Verify

DC output at J2. If no

voltage is present or fuse

is again blown, replace

Switching Power supply.

Verify correct voltages at

the input and output of the

power supply

diagram 495102).

voltages are within

specification, then replace

motor/secondary wire

harness assembly.

(See wiring

If all

Light Source/Illuminator Service Manual Page 13

Page 14

y

p

About This Section:

This section describes how to remove and replace major sub assemblies of the

49501 (Medical Version) and 40501I (Industrial Version) Solarc Light Source.

Disassembl

and Re

air

Note:

reference on the Parts List to determine the correct part number.

Refer to the "Bubble Number" on each drawing and the cross

Part

Number

106087 PHPS 6-32 X.500 495000 4

495080 PLUG, SCREW 495000 10

Description Drawing

#

Bubble

#

Start up

order Qty

20

50

Light Source/Illuminator Service Manual Page 14

Page 15

Section 4 Disassembly and Repair

Left Housing Assy Disassembly

1. Remove the tw o screw plugs:

___

through the center of the plug w ith a 1/16 drill in a pin vise

Drill

and pull straight up.

2. Remove the Bottom Housing:

___

Loosen

thumb screw on the back of the unit and slide the

assembly towards the back of the unit.

3. Lamp Replacement Label:

___

off Label and discard.

Peel

4 Fan Guard:

___

Unscrew

the two screws on the left side directly over the AC

Power inlet that hold the fan guard in place. Only remove these

two screws.

5. Light Attenuator Assembly:

___

Unscrew

the two screws that hold Light Attenuator Control

Assembly, and remove the pan head screw, that was under the

attenuator control, from the left housing.

6. Left Housing Assembly:

___

Unscrew

the two side screws that hold the right and left

housings together. The left hous ing will now come off. Make sure

to hold the switch and t he AC power inlet down.

Light Source/Illuminator Service Manual Page 15

Page 16

Section 4 Disassembly and Repair

Ballast Board Replacement

1. Lamp:

___

Remove

the lamp from the lamp holder, and disconnect the

lamp socket.

2. Wire Tie:

___

the tie wrap that holds the black and white wires t hat lead

Cut

to the ballast board and lift the metal chassis off t o one side.

3. Ballast PCB:

___

Unscrew

board in place. Lift the board up and

the four Phillips head screws that hold the ballast

unplug

secondary wire

harness connector from the ballast board.

4. Lamp Wires:

___

Desolder

the Black and White wires from the ballast board.

5. Reassembly:

___

Reassemble

the wires under the chassis plate. The chassis plate should be

between the right housing and the insulator. Be sure to place the

ballast board insulator in its original position.

Power Supply Replacement

1. Insulator Sheet:

___

out insulator along side the PCB.

Pull

2. Wire Harness:

___

Unplug

PCB. It is the plug closest to t he fan.

___

Unplug

ground wire from the power supply board.

in reverse order taking care to not pinch any of

the secondary wire harness from the power supply

the primary wire connector and the green/yellow

3. Reassembly:

___

Reassemble

back into its original position.

supply board is

Light Source/Illuminator Service Manual Page 16

in reverse order. Be sure to put the insulator

that the new power

seated

Make sure

into the right housing.

Page 17

Section 4 Disassembly and Repair

Fan / Secondary Wire Harness Replacement

The fan comes as part of the secondary wire harness assembly; therefore, the

*

entire secondary wire harness assembly must be replaced.

1. Power Supply PCB:

___

Remove

the power supply board and the ballast board as

described in earlier in section 4 of this document. Do Not desolder

the black and white wires from the ballast board as described in

the ballast board section .

2. Fan/Fan Guard:

___

Unscrew

the remaining two screws that hold the fan to the

right housing. Taking care to remember how the ground wire is

connected and routed.

3. Wire Tie:

___

the w ire tie that holds the secondary wiring harness to t he

Cut

Black & White wires leading from the ballast board.

4. Ground Wire:

___

Unscrew

11/32 nut driver, and lift off the top two ring terminals. See detail

"A"of drawing 495072 for proper assembly of ground wires to the

chassis ground stud.

5. Thermal Cut Off:

___

Loosen

lamp holder assembly, and remove the sensor.

6. Harness:

___

Remove

7. Reassembly:

___

Reassemble

thermal compound

of the new temperature sensor before it is installed. See detail

"A"of drawing 495072 for

chassis ground stud.

grommets are positioned properly.

the top nut on the chassis ground stud, using an

the screw that holds the temperature sensor to the

the Secondary Wiring Harness assembly.

in reverse order.

(Note)

(M11047) needs to be

proper assembly of ground wires

Make sure

that the thermal cut out wire

A small amount of

applied to

the flat side

to the

Light Source/Illuminator Service Manual Page 17

Page 18

Section 4 Disassembly and Repair

Lamp Cover Safety Interlock Switch:

1. Safety Switch Assy:

___

Unscrew

the two Phillips head screws that hold the switch

assembly to the chassis. K eep the outside insulators.

2. Primary Wires:

___

Disconnect

the primary w ires from the switch, and remove the

switch.

3. Reassembly:

___

Reassemble

in reverse order. Make sure to reinstall the two

insulators that were removed in step #1. Refer to wiring diagram

for wiring of the switch.

Power Switch Replacement

1. Left Housing:

___

Remove

left housing assembly as described in the left

housing disassembly section.

2. Power Switch removal:

___

Unplug

remove

the four quick connect terminals from the switch and

defective swit ch.

3. Power Switch replacement:

___

Reassemble

the switch to the four quick connect terminals.

The switch should be set into the right housing w ith the "0" closest

to the internal chassis plate.

Light Source/Illuminator Service Manual Page 18

Page 19

Section 4 Disassembly and Repair

Replacement of the Primary Wiring Harness

1. Left Housing:

___

Remove

left housing assembly as described earlier in sect. 4.

2. Wire Ties:

___

the two wire ties that hold the harness to the internal

Cut

chassis plate.

3. Ground Wire:

___

Unscrew

11/32 nut driver, and

the two nuts on the chassis ground lug using an

remove

the primary ground wire.

4. Removal of the Interlock Switch:

___

Unscrew

the two Phillips head screws that hold the interlock

safety sw itch assembly to the chassis. Keep the out side insulators.

5. Removal of the defective wiring harness:

___

Pull

off the quick connect terminals that attach the defective

wiring harness to the power switch and to the interlock safety

switch, Remov e t he defective wiring harness.

6. Reassembly of the primary wire harness assembly:

___

Reassemble

in reverse order. Refer to wiring diagram for

wire connections.

Light Source/Illuminator Service Manual Page 19

Page 20

Maintenance

Preventative Maintenance

The purpose of preventative maintenance is to pro-actively reduce or eliminate future problems.

Keeping the Solarc Light Source in good operating condition ensures that it will perform reliably and

safely. Every six to twelve months, you should:

* Check power cable for wear.

* Ensure that, during use, the light source receives adequate ventilation.

* Ensure that the ball detent is still functioning properly.

Visual Inspection

Check for anything out of the ordinary. For instance:

- Does the light source make too much noise?

- Are there any loose parts inside the box?

- Is the power switch working properly?

- Do all components connect/disconnect easily?

- Are the ventilation holes free of obstructions?

CLEANING

Refer to Operating Manual, Welch Allyn Part Number 495003.

Light Source/Illuminator Service Manual Page 20

Page 21

Section 5 Maintenance

Check Ground Continuity

1. Disconnect the power cord from the Solarc Light Source.

2. Verify the impedance between the ground pin of the IEC detachable gr ound cord and the thumb

screw meets the requirements as outlined on drawing A03387 in Appendix. A).

Measuring Leakage Current

To check the Chassis Leakage Current:

1. Connect the light source to a leakage tester (refer to figure 5-1), and measure leakage current

on leakage meter. Ensure that leakage is less than 100 microamperes.

2. Open ground line, and ensure leakage current is less than 100 microamperes.

3. Reverse line polarity, and ensure that leakage current is less than 100 microamperes.

4. With reversed polarity, open ground line and ensure leakage is less than 100 microamperes.

CAUTION: The meter must be suitably insulated and

capable of withstanding the power line voltage.

Light Source/Illuminator Service Manual Page 21

Page 22

Section 5 Maintenance

LEAKAGE CURRENT TEST SET-UP

When the light source is used in conjunction with other accessories, it may be necessary to measure

the leakage current level of the entire set-up. A typical system setup is shown in Figure 5-1. Using a

standard leakage tester, this set-up will allow the overall sy stem leakage current to be measured. If this

value exceeds 100 microamps (or whatev er the maxi mum req uirements ar e for a particular region), an

isolation transformer should be used.

Figure 5-1: Typical Current Leakage Test Set-Up

Light Source/Illuminator Service Manual Page 22

Page 23

Section 5 Maintenance

FUSE REPLACEMENT

1. Turn the power switch OFF and disconnect the power cord from the light source.

2. Open fuse drawer located as part of the power cord receptacle.

3. Remove fuse by pulling it out firmly.

4. Check fuse condition. Replace if blown. Replacement fuse:

250V, 1.0 Amps. 5 x 20mm , Slow-Blow.

unqualified fuse may fail prematurely.

Use WA fuse only! An

5. T h is system has two fuses. Be certain to check the condition

of both fuses.

Fuse Replacement Figure 5-2

LAMP REPLACEMENT

Refer to users manual 495002 for full detail.

1. Turn the power switch OFF and disconnect the power cord from the light source.

2. Wait a minimum of 5 minutes to allow the lamp to cool.

3. Remove the lamp cover on the bottom of the Light Source by unscrewing the thumb screw on

the back of the light source.

NOTE: Removing the cover will automatically cut off power to the Light Source.

4. Slide black connector off the lamp.

5. Remove the lamp assembly by pulling against the spring action and pulling up.

6. Acquire new replacement lamp assembly.

7. Reseat the new lamp assembly. Be sure that the pin on the lamp is properly seated into the

slot on the lamp bracket.

8. Slide black connector on to lamp.

9. Secure lamp cover.

10. Reconnect system to verify lamp operation and power interlock switch is closed.

Light Source/Illuminator Service Manual Page 23

Page 24

Introduction

Theory of Operation

Model # 49501 is a

medical instruments. This model has a built in Infrared filter to limit the heat generated by the

light. It also has an external ferrite bead built into the power cord to meet Electromagnetic

Interference (EMI) requirements. This light source should only be used by qualified medical

personnel.

Model HLS-24-0 is an industrial illuminator which can be used in many industrial applications.

The HL S-24-0 is also known at Welch Allyn as a 49501I (The I indicates that the unit is for

industrial use only). This instrument is identical to the 49501 medical light source with the

deletion of the Infrared filter and the Ferrite bead.

Start up Routine (Lamp Ignition)

Upon turning the power switch to the "ON" position lamp ballast will ignite the lamps for an

approximate warm-up phase of 15 seconds. Once this warm-up phase is complete, the the lamps

will be warmed up, and the system will be ready for use.

Note: The fiber bundle must be in place to stabilize light output. Do not toggle the power switch

ON and OFF . Doing so will dramatically shorten lamp life. The lamp will not restart for 5-10

Seconds after power down.

medical light source

which is used in conjunction with several Welch Allyn

Light Source/Illuminator Service Manual Page 24

Page 25

Section 6 Theory of Operation

Power Supply

UNIVERSAL INPUT, SWITCHING AC TO DC MEDICAL GRADE POWE R SUPPLY

The power supply accepts an input voltage of 100-240 VAC, 50-60 Hz, single phase. The primary

circuit provides adequate control of leakage current, which is limited to 35 microamperes maximum.

The primary side of the power supply rectifies the AC vol tage and converts it to a high voltage DC lev el.

This DC vol tage is connected to the i solation transformer through a sw itching dev ice, typical ly a mosfet.

The mosfet is triggered by a high frequency clock circuit, typically at a 30-50 KHz rate. The

secondary side of this transformer provides isolation between primary and secondary circuits. The

secondary voltage i s rectified and filtered to pr ovide a + 15 VDC output vol tage at 5.3 amps. The output

voltage is regulated to 2%, with peak-to-peak noise of 150mV. The output is fully protected against

short circuit and output overload. Short circuit protection is a cycling type power limit with automatic

recovery after fault.

Ballast Board

The ballast board is a power supply used to operate the 24 watt Welch Allyn miniature arc lamp. The

nature of arc lamps require a ballast which limits the current, and therefore the power, in the lamp.

There are three states of the operation of the ballast: ignition, warm-up, and steady state. In ignition

the ballast provides the lamp with a train of ignition pulses between 6 and 7 kV. Once the lamp is

ignited the ballast conducts current at a very low impedance, which constitutes the warm-up phase.

Once it warms up, the impedance changes to a higher steady state value.

Light Source/Illuminator Service Manual Page 25

Page 26

Appendix A

Light Source/Illuminator Service Manual Page 26

Page 27

Parts List / Recommended Inventory

Part No. Description Drawing # Bubble # Rec. Inv.

106100-8 PHPS 6-32 X .63 LG 495000 1 20

106102-2 FHPS 4-40 X .375 LG 495000 3 20

106100-13 PHPS 6-32 X.500 495000 4 20

495059 LAMP REPLACEMENT LABEL 495000 5 25

495063-1 HOUSING, LEFT 495000 9 1

495080 PLUG, SCREW 495000 10 50

095100 LAMP, 24W MINIATURE ARC 495000 11 5

106132-5 4-40 X .750 PH TR MS SS 495000 14 10

495086-501 ACMI ATTENUATOR ASSY 495000 15 0

495055-502 MOUNTING BASE ASSY 495000 16 2

495061-1 LABEL, ETL W/CE 495000 17 5

495062-0 LABEL MODEL NUMBER 495000 18 5

495111 DIELECTRIC FILTER 495000 19 5

328043-1 RETAINING RING-LENS 495000 20 5

106106-2 #4 INTRNL TOOTH LKWSHR 495064 1 20

106103-27 FLAT WASHER 495064 2 20

790043 4-40 HEX NUT 495064 4 10

106102-2 FHPS 4-40 X .375 LG 495064 6 20

106124-13 #2 X 1/4 SCREW-PLASTITE 495064 7 20

495067 FAN GUARD 495064 8 0

495068 BALLAST 24W UNREGULATED 495064 10 5

880031 POWER SUPPLY 40 WATT 495064 11 5

495069-1 HOUSING, RIGHT 495064 15 1

495070 INSULATOR, POWER SUPPLY 495064 16 5

495071 INSULATOR, BALLAST 495064 17 5

Light Source/Illuminator Service Manual Page 27

Page 28

Parts List / Recommended Inventory

Part No. Description Drawing # Bubble # Rec. Inv

495066 LAMP HOLDER 495064 22 0

106132-3 4-40 X 1" PH TR MS SS 495064 23 10

106132-5 4-40 X .750 PH TR MS SS 495064 24 10

M31426 .032DIA ENERGIZED ROSIN S 495064 25 1

106113-6 #4-40 SOCKET SET SCREW 495064 27 20

495065 LAMP SPRING 495064 28 0

M30373 LOCTITE 425 ASSURE THDLOC 495064 30 1

106132-4 6-32 X .3125 TRUSS HEAD

SCREW

495076 CHASSIS, INTERNAL 495072 1 0

455508 LABEL, PROTECTIVE EARTH

Ground

495073 GROMMET .126 ID X.06 X.25 495072 3 10

495064 31 10

495072 2 15

.

495077 PRIMARY WIRE HARNESS 495072 5 1

747187 #8-32 HEX-NUT 495072 8 10

483412 #8 EXTERNAL LOCKWASHER 495072 9 4

761077-1 TIE WRAP 495072 10 50

495074 INSULATING PLATE 495072 12 0

451534 SCREW PHP #4-40 X1.0 495072 13 20

495075 BALLAST SIDE CONN ASSY C1 495072 15 5

495078-1 SECONDARY WIRE HARNESS 495078 NA 1

488307-9 FUSE NA NA 20

495079-501 BOTTOM HOUSING ASSY NA NA 1

Light Source/Illuminator Service Manual Page 28

Page 29

Page 30

Page 31

Page 32

Page 33

Page 34

Loading...

Loading...