Weinmann WM 22800 Service Manual

Servicing and

repair instructions

MEDUMAT Standard a

Ventilator

WM 22800

Contents

Introduction

1.

Overview

1.1

2.

Description of ventilator

2.1

2.2

2.3

2.4

2.5

2.6

3.

Final Check

3.1

3.2

3.3

3.4

3.5

3.6

3.7

3.8

3.9

3.10

3.11

3.12

3.13

3.14

3.15

4.

Servicing

4.1

4.2

4.3

4.4

4.5

5.

Troubleshooting

. . . . . . . . . . . . . . . . . . . . . . . . . . 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Symbols used on the ventilator

Uses

. . . . . . . . . . . . . . . . . . . . . . . . . 6

Ventilation function

Controlled ventilation

Assisted ventilation

Checking course of ventilation

Patient valve

. . . . . . . . . . . . . . . . . . . . . . . . . . 9

Test resources required

Preparations for final check

Entering device data

Testing for leaks and checking pressure

reading . . . . . . . . . . . . . . . . . . . . . .

Device self-test after switching on

Functional check on alarms

Checking assisted ventilation

Functional check on frequency setting

Functional check on

4.5 bar delivery pressure and 10 mbar

counterpressure . . . . . . . . . . . . . . . . .

Checking oxygen concentration

Functional check on pressure limit

Functional check on exhaust valve

without patient valve . . . . . . . . . . . . . .

Checking equipment and accessories

(system components) . . . . . . . . . . . . . .

Checking external condition

Documentation

. . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Intervals and Scope

Batteries and fuses

Adjusting the pressure gauge

Storage

Disposal

. . . . . . . . . . . . . . . . . . . . . 17

. . . . . . . . . . . . . . . . . . . . . 18

. . . . . . . . . . . . . . . . . . . . . . 19

. . . . . . . . 5

. . . . . . . . . . . . . . . . . 6

. . . . . . . . . . . . . . . 6

. . . . . . . . . . . . . . 7

. . . . . . . . . . . . . . . 7

. . . . . . . . 8

. . . . . . . . . . . . . . . . . . . 8

. . . . . . . . . . . . 9

. . . . . . . . . . 9

. . . . . . . . . . . . . . 9

10

. . . . . 10

. . . . . . . . . 11

. . . . . . . 12

. . 12

tidal volume at

. . . . . . . . . . . . . . . . . 15

. . . . . . . . . . . . . . 16

. . . . . . . . . . . . . . 17

13

. . . . . . 14

. . . . 14

14

15

. . . . . . . . 15

. . . . . . . 17

6.

Repair information and repair instructions

6.1

General

6.2

Replacing the sieve in the compressed

gas connection . . . . . . . . . . . . . . . . .

6.3

Changing the foam insert in the pressure

relief valve outlet . . . . . . . . . . . . . . . .

6.4

Opening the

6.5

Closing the

6.6

Changing the batteries

6.7

Replacing the fuse

6.8

Replacing the alarm signalling device

6.9 Replacing the potentiometer

(for setting pressure or frequency) . . . . .26

6.10 Calibration after removal of PCB or

Pot 28 (frequency) . . . . . . . . . . . . . . .28

6.11 Replacing the circuit board . . . . . . . . . 29

6.12 Replacing the pressure gauge . . . . . . . 31

6.13 Replacing the pneumatic block . . . . . . 32

6.14 Replacing the pneumatic block with

angled outlet . . . . . . . . . . . . . . . . . . .34

6.15 Changing the Air Mix/

7. Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . 44

8. Tools and test equipment . . . . . . . . . . . . . . . 48

9. Technical data . . . . . . . . . . . . . . . . . . . . . . . 50

10. Technical Changes . . . . . . . . . . . . . . . . . . . . 52

11. Repair and inspection log . . . . . . . . . . . . . . 53

No Air Mix switch . . . . . . . . . . . . . . .37

6.16 Replacing the upper housing section. . . 38

6.17 Replacing the housing base section . . . 43

7.1 List of spare parts . . . . . . . . . . . . . . . 44

7.2 Maintenance set. . . . . . . . . . . . . . . . 46

8.1 General tools. . . . . . . . . . . . . . . . . . 48

8.2 Special tools . . . . . . . . . . . . . . . . . . 48

8.3 Test equipment . . . . . . . . . . . . . . . . . 49

9.1 Pneumatics . . . . . . . . . . . . . . . . . . . 51

9.2 O2 content when using Air Mix. . . . . . 52

. . . . . . . . . . . . . . . . . . . . . 22

device

. . . . . . . . . . . . . 23

device

. . . . . . . . . . . . . . 24

. . . . . . . . . . . 24

. . . . . . . . . . . . . . . 25

. . 22

22

23

. . 25

© Copyright Weinmann GmbH & Co. KG.

The content and presentation are copyright protected and may only be used by authorised Weinmann Service Partners in the

course of their service operations. The content must not be reproduced or passed on to third parties. The complete documents

must be returned on termination of the cooperation with Weinmann.

2

Introduction

For decades, Weinmann has developed, manufactured and distributed equipment for emergency

medicine, oxygen therapy and inhalation therapy.

In 1972, Weinmann introduced the first

MEDUMAT emergency ventilator to the market.

MEDUMAT emergency ventilators are automatic

resuscitators. They are used for controlled respiration in emergency medicine, e.g. in the event of

acute ventilatory disorders, and for secondary obstructions.

The new generation of equipment, which was

especially developed to meet the requirements of

users and launched on the market in 1997, offers

users and patients an enhanced level of safety. An

intelligent alarm system monitors the patient's breathing and notifies the user of any malfunctions.

Hence, this technology offers even greater safety

and reliability during respiration.

The aim of these service and repair instructions is

to familiarise you, as a knowledgeable expert, with

the MEDUMAT in terms of function, technology

and repairs. In conjunction with the training you

have already received from Weinmann, you are

now a "trained, qualified expert" and are able to

instruct your clients correctly, rectify faults yourself,

and perform the functional checks described in the

instructions for use, as well as conduct any repairs

which may be necessary, as outlined in these service and repair instructions.

In the event of a guarantee claim, MEDUMAT should

be returned to Weinmann.

To enable us to process any guarantee or goodwill

claims, please return the consumer's proof of

purchase (invoice) together with the device.

Repairs and maintenance work must be carried out

only by Weinmann or by knowledgeable experts.

You are responsible for all repairs performed by

yourself and the warranty thereof!

Only original Weinmann spare parts should be used

for repair purposes.

Please remember:

Your customer trusts you and relies on your expertise, just as you rely on Weinmann.

Note:

The following information can be found in the description and operating instructions for MEDUMAT Standard a:

• Safety instructions:

See chapter 2.

• Mounting with the wall bracket STATION MEDUMAT,

Mounting of accessories:

See chapter 3.

• Operation of the MEDUMAT emergency ventilator:

See chapter 4.

• Hygienic preparation:

See chapter 5.

• Functional check:

See chapter 6.

Introduction 3

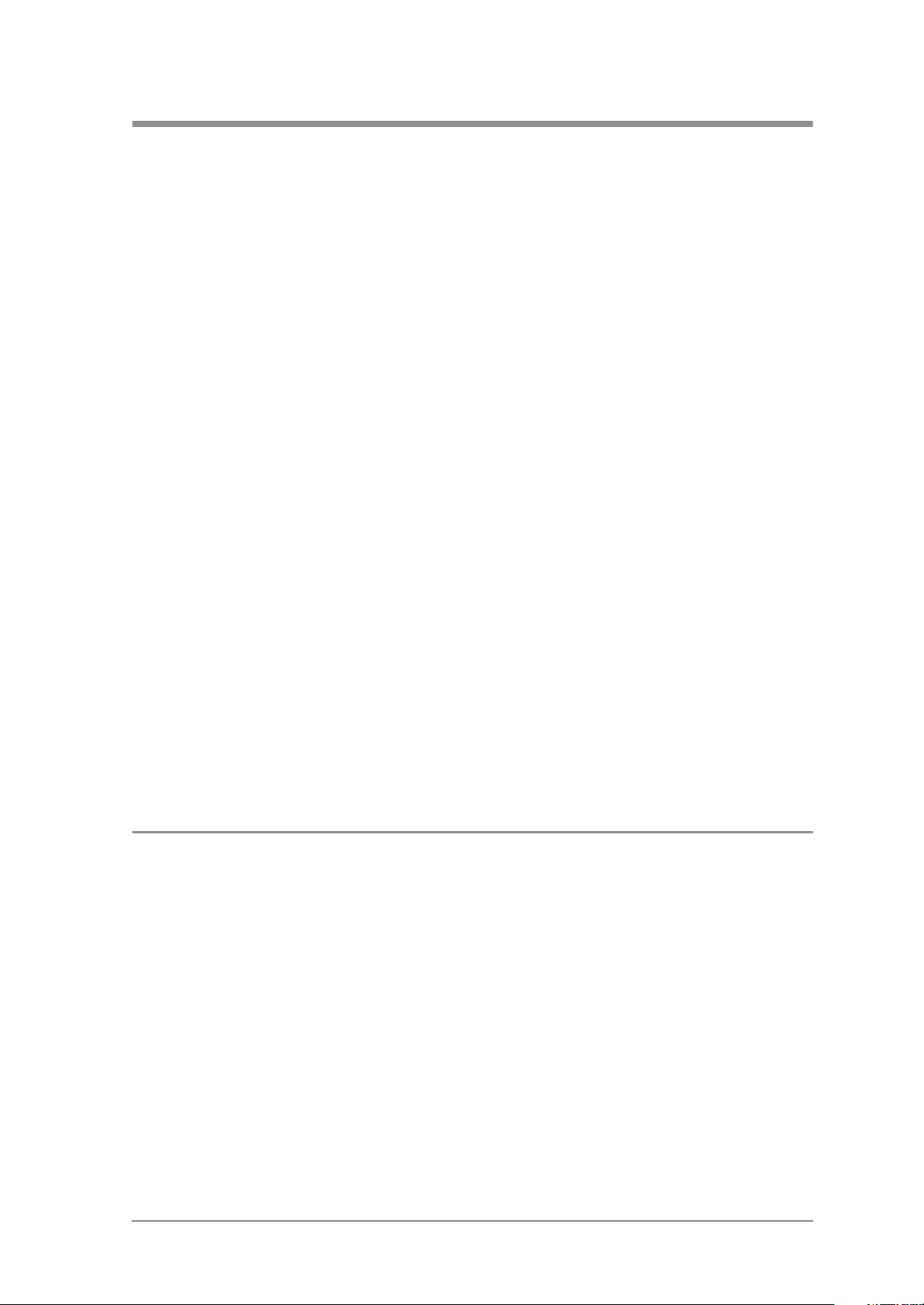

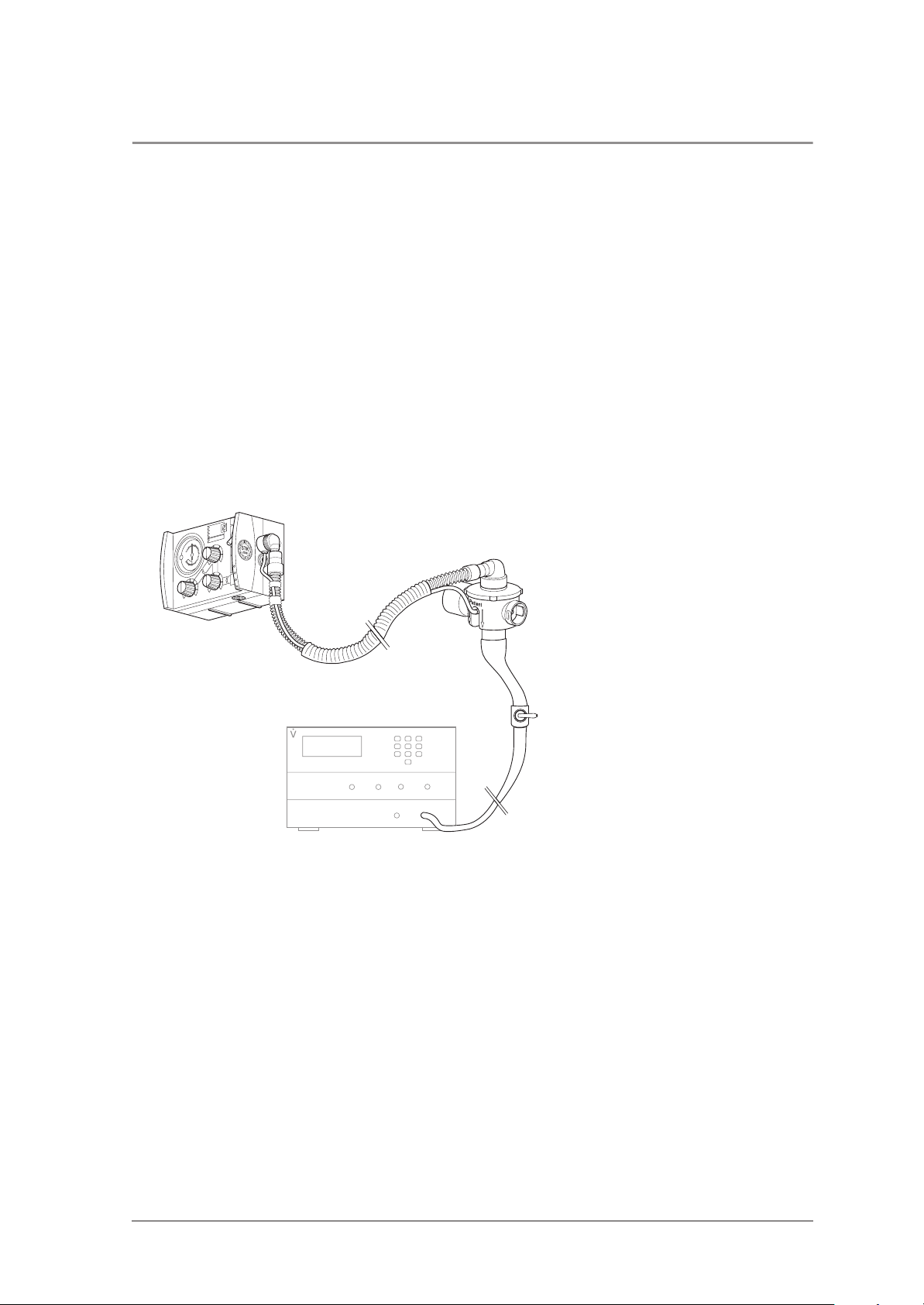

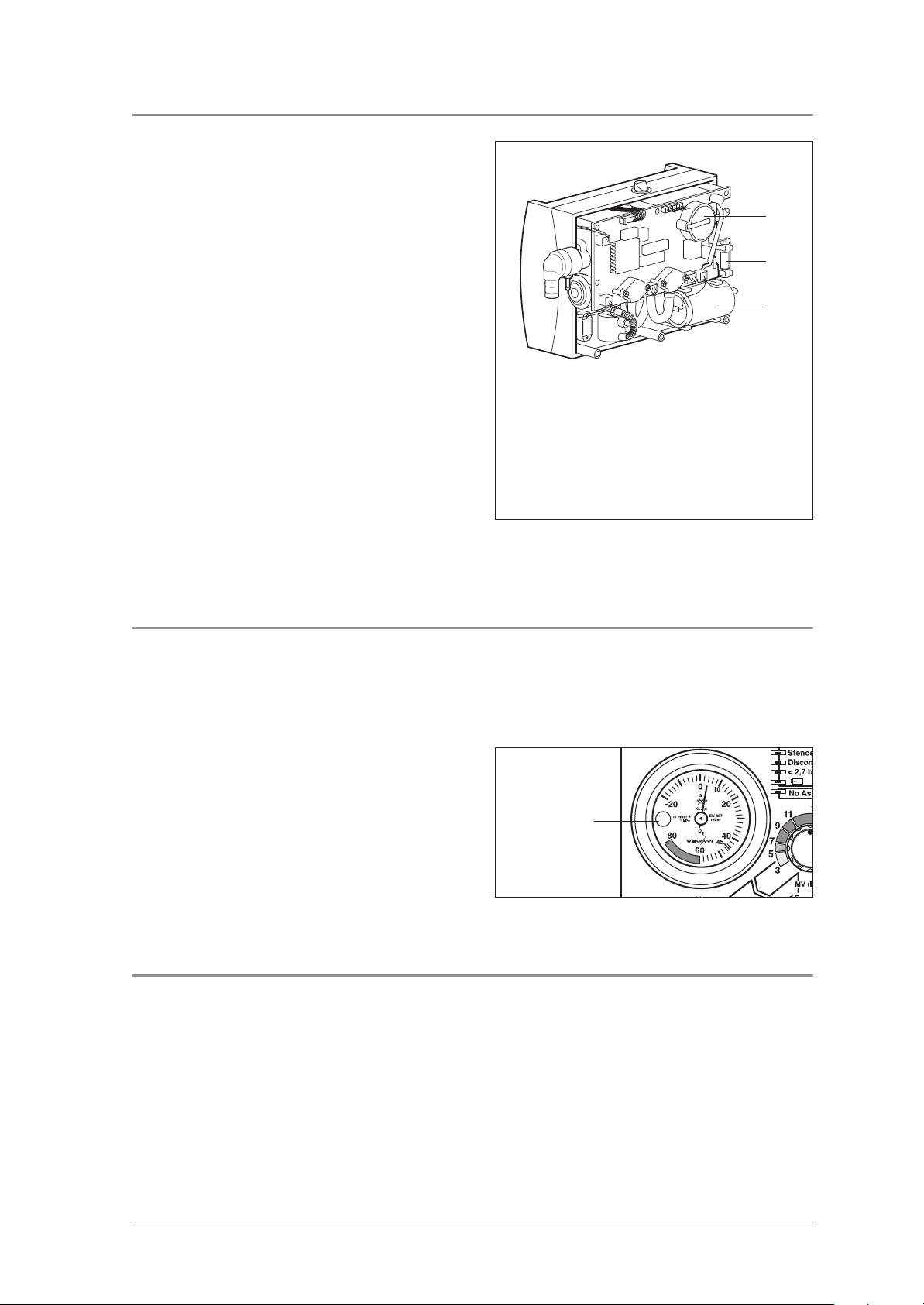

1. Overview

Control panel MEDUMAT Standard a

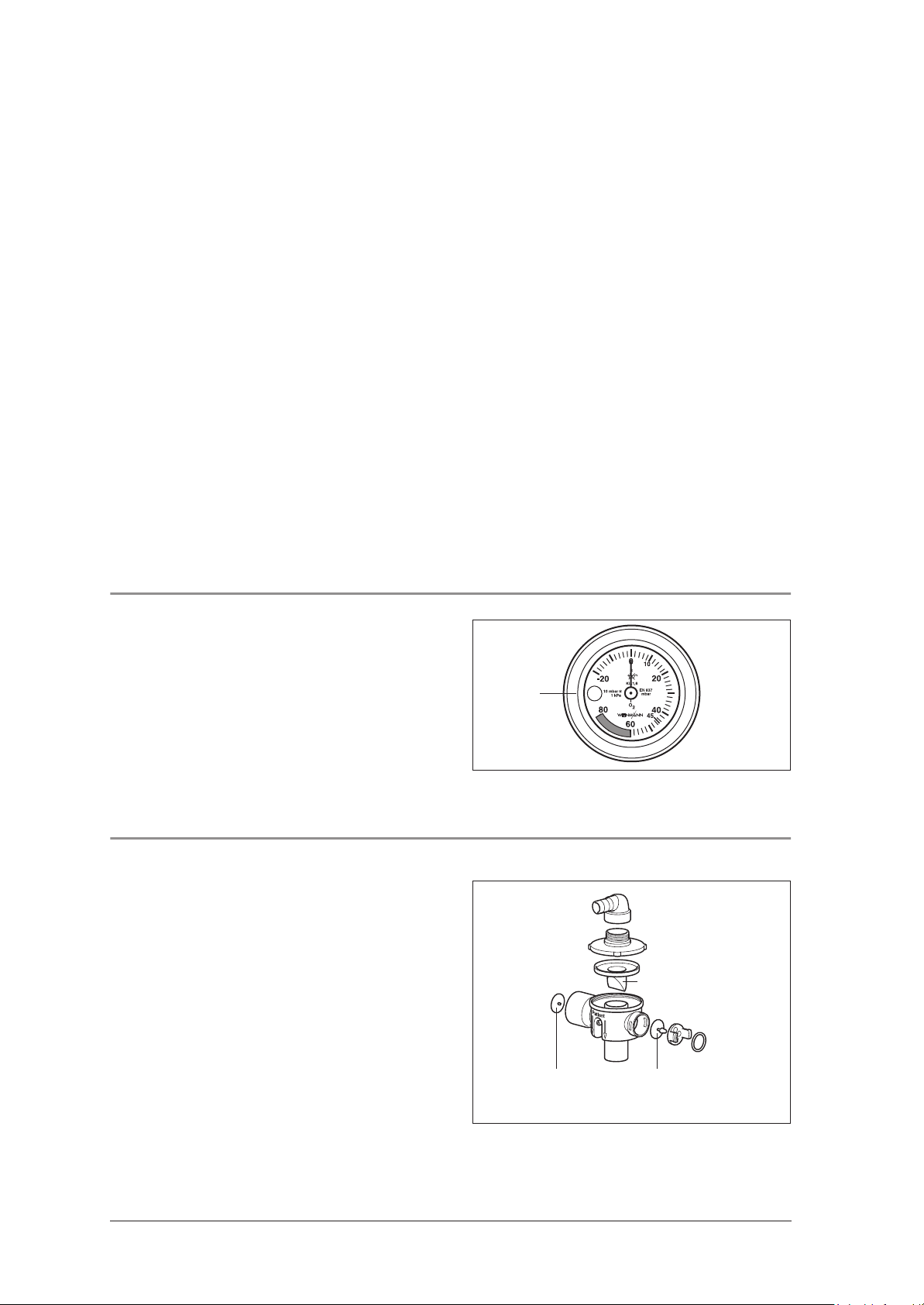

1 Ventilation pressure gauge

(Manometer

10 Max. ventilation pressure regulator

3 Alarm acknowledgement2 Alarm panel

4 Air Mix/No Air Mix switch

5 Minute volume regulator

6 ON/OFF switch

assisted ventilation

7 Colour code

8 Ventilation frequency regulator

9 ON/OFF switch

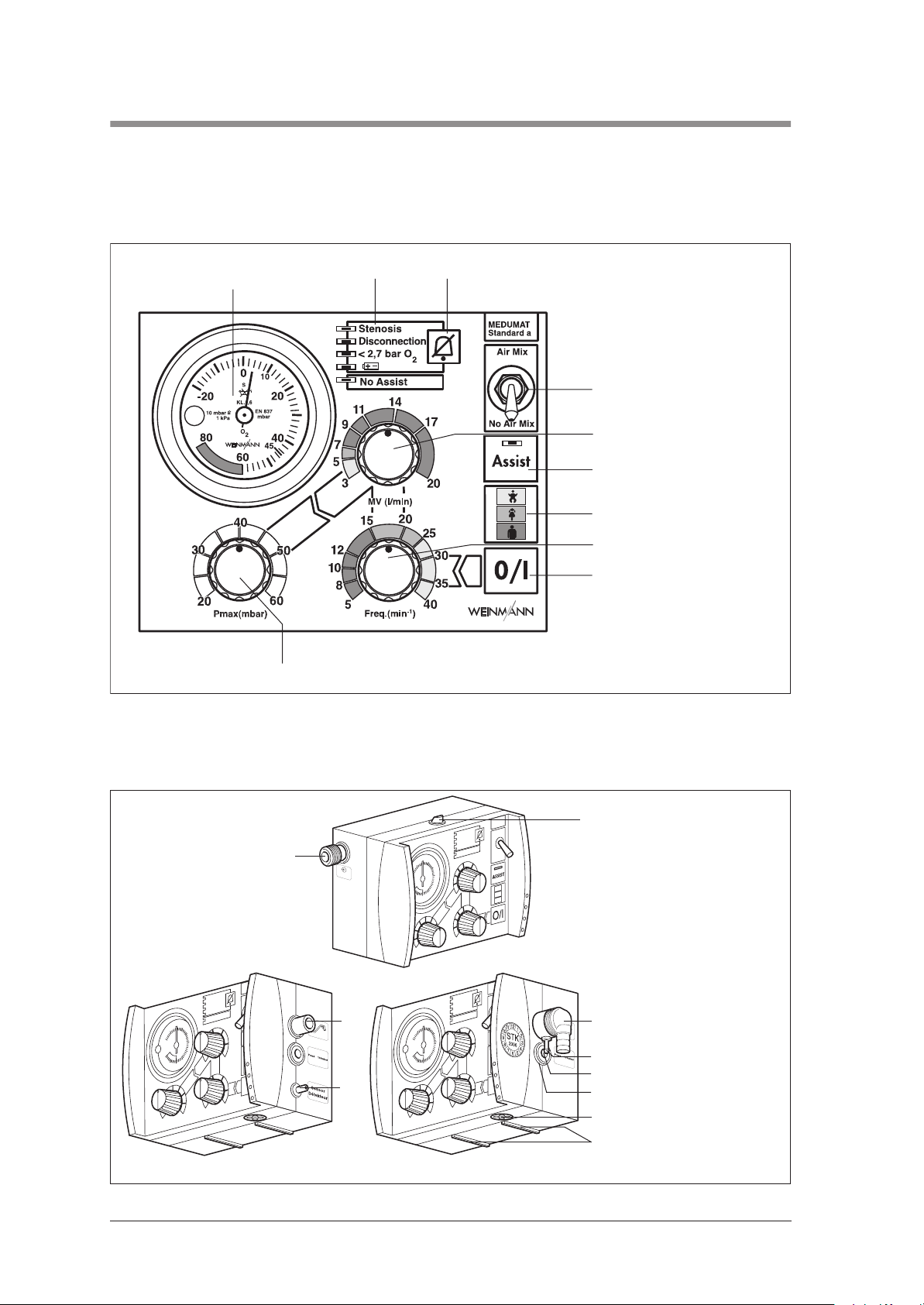

MEDUMAT Standard a connections

11 Pressure gas connection

13

O/I

up to appliance no. 1669 from appliance no. 1669

14

O/I

12 Catch for STATION MEDUMAT

wall mounting

13 Connection for ventilation hose

14 Pressure gauge hose connection

15 Relief valve

16 Dust cover

17 Mixed air filter

12 Catch for STATION MEDUMAT

wall mounting

4 Overview

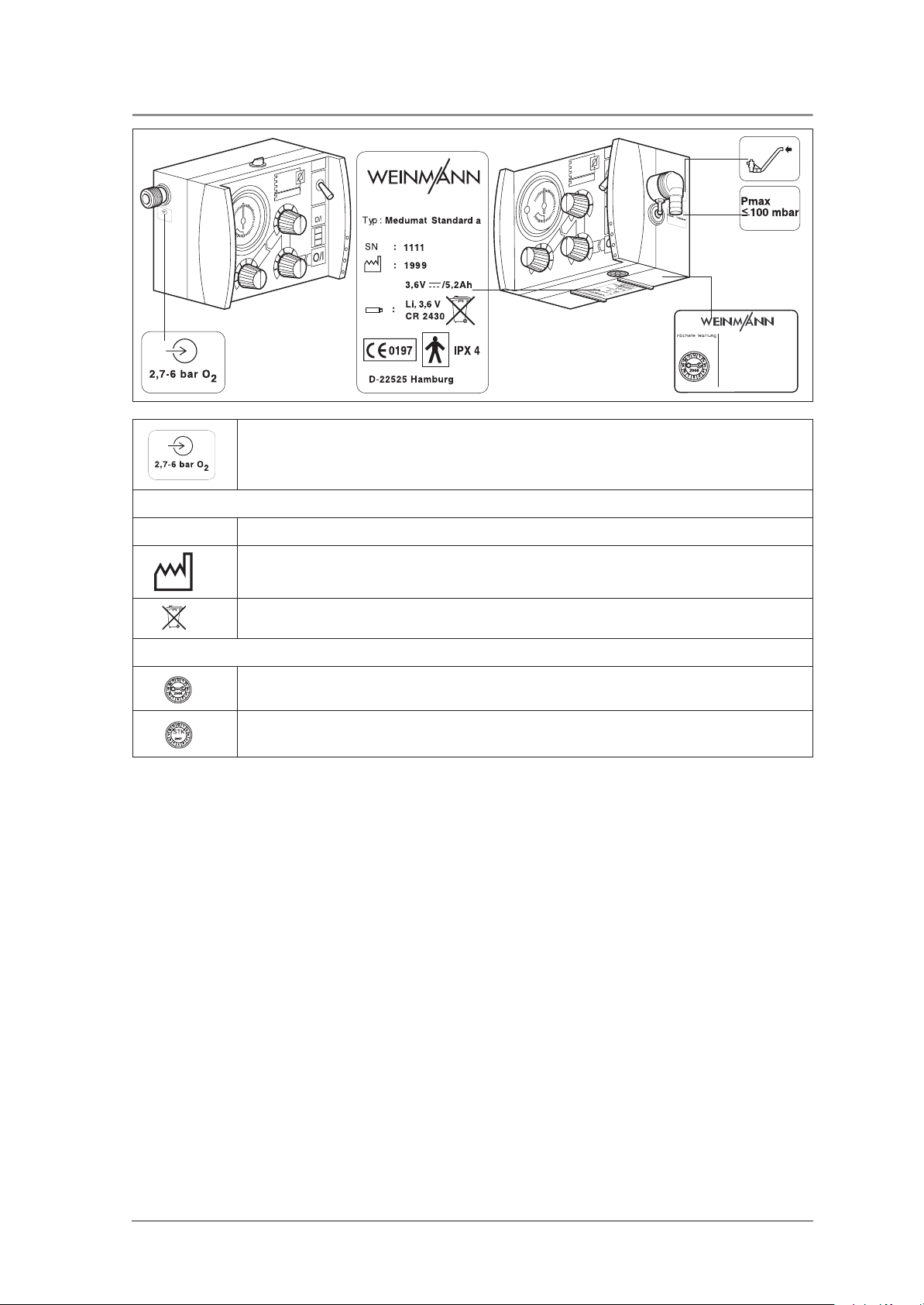

1.1 Symbols used on the ventilator

Inlet 2,7 - 6 bar O2.

MEDUMAT Standard a device information plate

SN

Serial number of device

Year of manufacture

Do not dispose of device in domestic waste.

Safety check and servicing label

Servicing label: indicates when the next service is due.

Safety check label (in Germany only): marks when the next safety check as per §6 of the

German law relating to users of medical devices is required.

Overview 5

2. Description of ventilator

2.1 Uses

MEDUMAT Standard a is an automatic (short-term) ventilator.

You can use MEDUMAT Standard a:

• to revive patients at the site of an emergency

• on a longer term basis in more protracted

emergencies, e.g. fires.

You can use MEDUMAT Standard a whilst transporting patients:

• between the various rooms and departments

of a hospital;

• between the hospital and other premises;

• in emergencies;

• when transport over a considerable distance is

planned.

2.2 Ventilation function

MEDUMAT Standard a operates within a pressure

range of 2.7 to 6 bar and at a flow rate of not less

than 70 l/min O2. It has a built-in power pack.

MEDUMAT Standard a:

• is used for controlled ventilation of persons

with a body weight of about 10 kg upward,

or for assisted ventilation from about 15 kg

body weight;

• is used to treat respiratory arrest;

• can be preset to parameters that ensure evenly

balanced ventilation provided that the selected

maximum ventilation pressure P

ceeded;

• can be supplied with additional modules for

aspiration and oxygen inhalation. (N.B.

MEDUMAT Standard a cannot be used as a

ventilator simultaneously with these modules)

is not ex-

max

The gas used for ventilation is highly compressed

medical oxygen, which is reduced to the required

operating pressure by a two-stage external pressure reducer. The oxygen supply is fed in at input

valve 11.

The continuously variable ventilation frequency

and the inspiration/expiration ratio of 1:1.67 for

controlled ventilation are controlled by electronic

control routines within the device.

Regardless of the ventilation mode selected, the

patient is free to use the patient valve to take a

spontaneous breath between ventilation cycles. In

that case the patient draws the air for breathing

from the surroundings.

The gas for inspiration flows along the hose and

through the patient valve and either the mask or the

tracheal tube into the patient’s airways. The patient

valve is fitted with a lip membrane that enables expired gas to be conducted away through the expiration tube.

11

6 Description of ventilator

At the normal Air Mix setting, atmospheric air is admixed to give an O2-concentration of between

55% and 85% at 10 mbar ventilation pressure

(see „9.2 O2 content when using Air Mix“ on

page 52).

In certain indications and in cases where the surrounding atmosphere is contaminated, you can

switch to No Air Mix and ventilate with pure oxygen.

The injector unit is switched off when switching

from Air Mix to No Air Mix. This increases minute

volume which can result in the set pressure limit being exceeded and a stenosis alarm (Stenosis) being

triggered. In this case, set minute volume correspondingly lower.

In the opposite instance, in other words when

switching from No Air Mix to Air Mix, the injector

unit is switched on. This reduces minute volume

which can lead to the set pressure limit being un-

dershot. In this case, set minute volume correspond-

ingly higher.

Air Mix

No Air Mix

O/I

Air Mix

No Air Mix

O/I

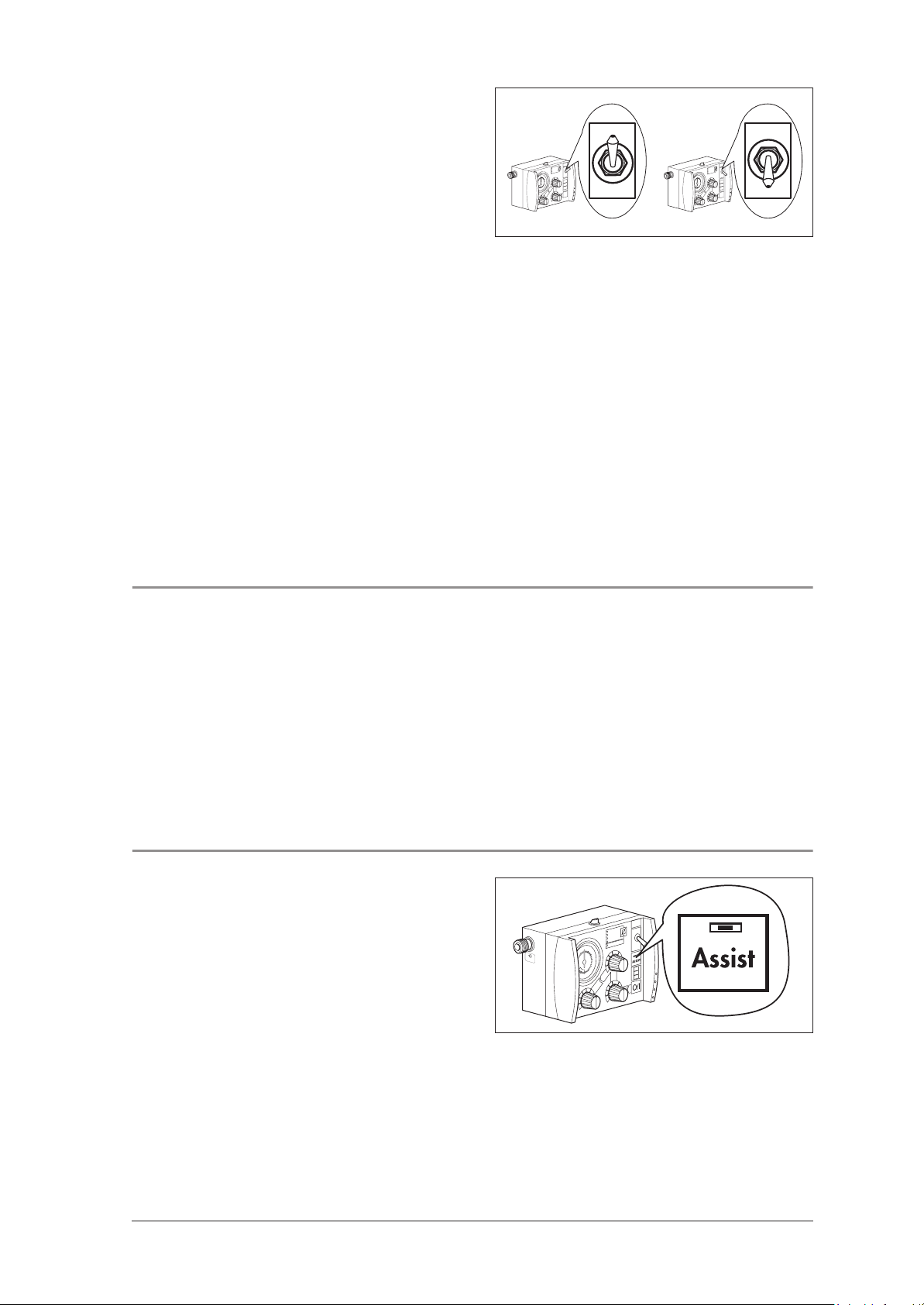

2.3 Controlled ventilation

After switching on, MEDUMAT Standard a is automatically in the controlled ventilation mode. This

means that the intubated patient receives mandatory

ventilation cycles which depend on the ventilation

values set on the device.

Mandatory ventilation cycle: it is not the patient, but

the device which determines the time of the next

breath.

2.4 Assisted ventilation

In addition to the controlled ventilation mode the

MEDUMAT Standard a provides an assisted

ventilation mode.

Once you switch on the assisted ventilation mode

by pressing the Assist button, a green LED flashes

to indicate that this mode is operating.

Triggered ventilation cycle: the patient can trigger a

ventilation cycle by making an effort to breathe.

Description of ventilator 7

Within a time window of 40 % of expiration, the

patient can now start a triggered ventilation cycle.

To do this the patient must create a flow of at least

5 l/min by making their own efforts to breathe.

If the patient’s efforts to breathe are not sufficient to

trigger a cycle, the patient automatically receives

a mandatory ventilation cycle at the end of the time

window, thereby ensuring compliance with the set

minute ventilation.

This function allows the device ventilation cycles to

be synchronised with the patient’s own efforts to

breathe.

Between mandatory ventilation cycles the patient

has the opportunity to breathe ambient air via the

patient valve.

If the patient does not trigger the device, an alarm

is set off. The patient then receives controlled ventilation.

IPPV: Intermittent Positive Pressure Ventilation

(= controlled ventilation).

2.5 Checking course of ventilation

You can check the course of the ventilation on pressure gauge 1.

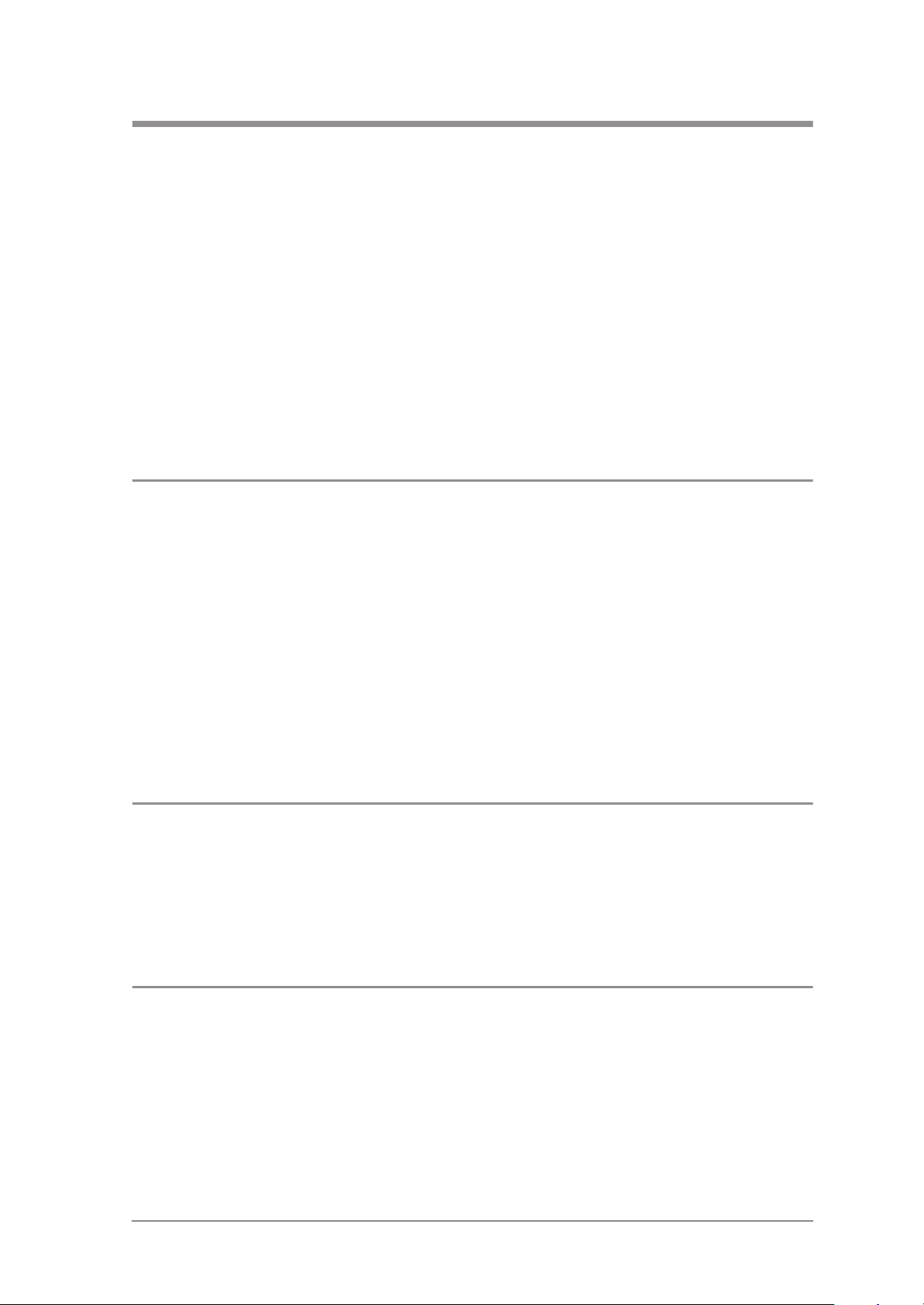

2.6 Patient valve

The gas for inspiration is channelled into the patient’s airways through the patient valve.

The patient valve is designed so that even in the

event of failure of the MEDUMAT Standard a,

spontaneous breathing is possible regardless of

which ventilation mode you selected.

1

Lip membrane

8 Description of ventilator

Diaphragm for

expiration arm

Diaphragm for

spontaneous

breathing arm

3. Final Check

After any repair and maintenance work, the device

must be subjected to the following final check in

accordance with the Test Instructions WM 22805

and Test Record.

Note:

For a final check on the MEDUMAT Standard a

you must connect the respiration tube and the patient valve.

If the final check reveals any faults or deviations

from the specified values, you must not use the

MEDUMAT Standard a.

We recommend you to keep the following parts in

stock:

• Replacement seals for device connections;

• Replacement dust filter;

• Lip diaphragm for patient valve;

• Diaphragm for spontaneous breathing arm;

• Diaphragm for expiration arm;

• O-ring 1145/118.

3.1 Test resources required

• Oxygen concentration measuring device,Type Oxycontrol WM 13550

• Volumetric flowmeter, Type RT 200 (Timeter) or Type EKU VIP – Ventilator

• Functional check test set WM 15382

• Adjustable orifice, e.g. ball valve, internal diameter ≥ 10 mm

• Set: hose with injector WM 15359

• Pressure gauge 0 - 6.3 bar, class 1.6

• Pressure gauge 0 - 100 mbar, class 1.6

• Set, supply test Medumat / Modules WM 15440

3.2 Preparations for final check

1. Connect MEDUMAT Standard a to test equipment.

2. Set MEDUMAT Standard a with switch in position No Air Mix to Freq. = 40 min-1, MV = 5 l/min and

P

= 60 mbar.

max

3.3 Entering device data

• Enter the device type, device number and date of manufacture in the Test Record.

Final Check 9

3.4 Testing for leaks and checking pressure reading

3.4.1 Testing for leaks on the inlet side

• With device switched off, apply pressure of 6 bar to inlet side and shut off outlet pressure.

• Set lever to No Air Mix.

Requirement: The pressure drop must be less than 0.2 bar/min.

• Set lever to Air Mix.

Requirement: The pressure drop must be less than 0.2 bar/min.

3.4.2 Testing for leaks in pressure measurement segment

• Apply pressure of 60 mbar to pressure measurement segment of Medumat.

• During the measurement, a traction force of approx. 3 N must be applied manually to the elbow outlet.

Requirement: The pressure drop must be less than 2 mbar/min.

3.4.3 Checking pressure reading

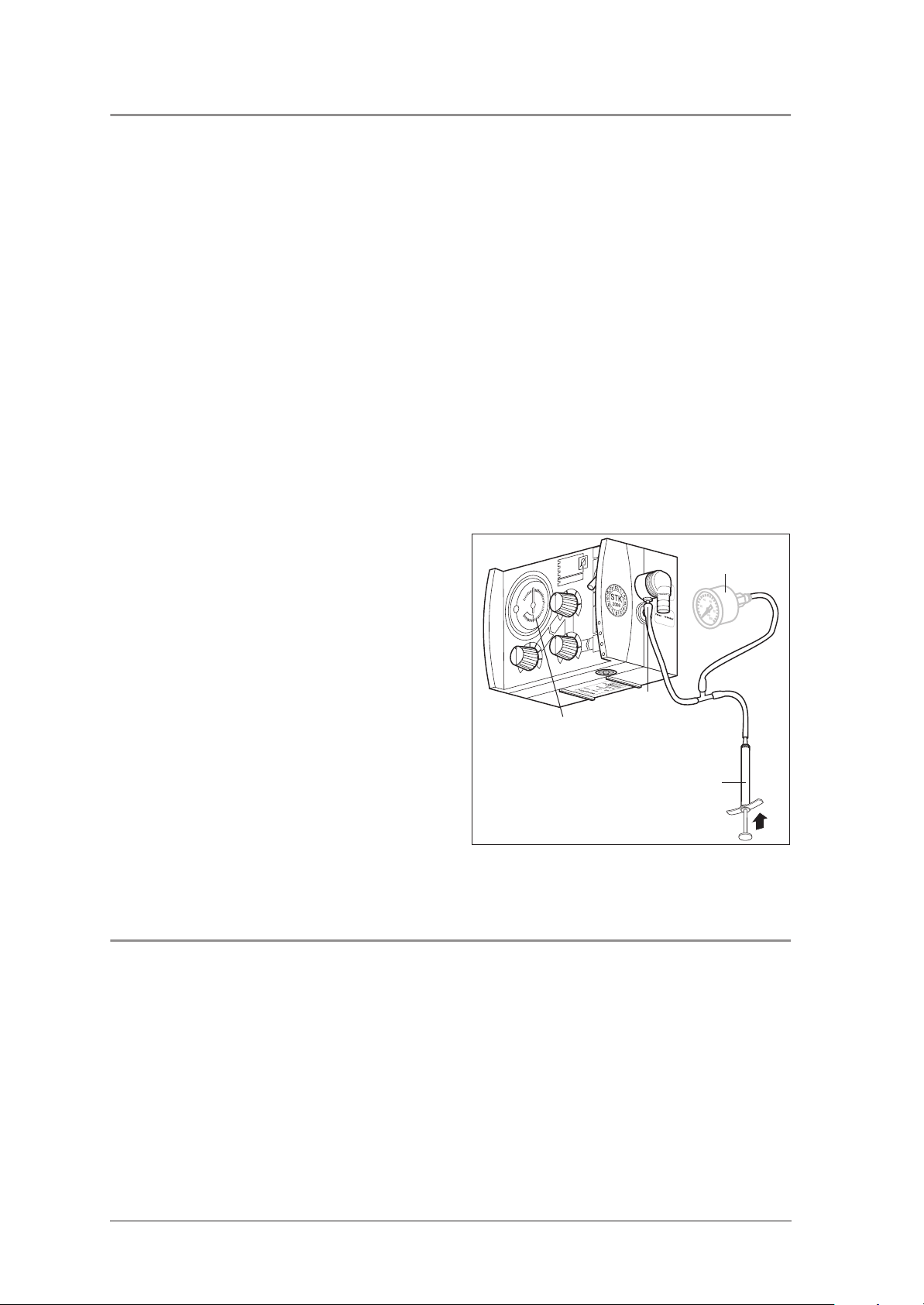

1. Attach T-connector with injector (WM 15359)

to pressure measurement connection 14.

2. Connect test pressure gauge 0 - 100 mbar or

Timeter to free end of T-connector (pressure

gauge/volumetric flowmeter not supplied with

device).

3. Use injector to create a pressure of 55 mbar

as shown on the test pressure gauge.

Requirement: Respiration pressure reading must not

deviate from set value by more than ≤≤≤≤ 1.5 mbar.

3.5 Device self-test after switching on

Pressure gauge

O/I

Test pressure

gauge

:

SN :

:

p

y

T

14

Injector

1. Apply approx. 4.5 bar to the inlet.

2. Switch on MEDUMAT Standard a.

Requirement: The self-test is activated: all 6 LEDs light up together and a brief signal tone sounds.

10 Final Check

3.6 Functional check on alarms

3.6.1 Stenosis alarm check up to appliance no. 1799

• Set MEDUMAT Standard a to the Air Mix setting at f = 40/min, MV = 3 l/min and p

= 60 mbar.

max

Close patient valve outlet.

Note: Over-response of needle is normal.

Requirement: The stenosis alarm must be activated after two respiration cycles.

• Set MEDUMAT Standard a to the No Air Mix setting at f = 40/min, MV = 3 l/min and p

= 60 mbar.

max

Close patient valve outlet.

Note: Over-response of needle is normal.

Requirement: The stenosis alarm must be activated after two respiration cycles.

3.6.2 Stenosis alarm check from appliance no. 1800

• Set MEDUMAT Standard a to the Air Mix setting at f = 40/min, MV = 3 l/min and p

Close patient valve outlet.

Note: Over-response of needle is normal.

MEDUMAT Standard a briefly switches to expiration if the maximum ventilation pressure is exceeded,

but then tries to continue inspiration in the same inspiration phase.

If the maximum ventilation pressure is exceeded for a second time during the same inspiration phase,

the unit finally switches to expiration and vents the patient tube system completely. The next inspiration

begins with the following ventilation stroke according to the frequency selected.

Requirement: The stenosis alarm must be activated after two respiration cycles.

• Set MEDUMAT Standard a to the No Air Mix setting at f = 40/min, MV = 3 l/min and p

Close patient valve outlet.

Note: Over-response of needle is normal.

Requirement: The stenosis alarm must be activated after two respiration cycles.

= 60 mbar.

max

= 60 mbar.

max

3.6.3 Alarm acknowledgement check

• Immediately after first alarm tone sounds, press button 3 (alarm acknowledgement).

Requirement: The alarm tone must be suppressed immediately.

3.6.4 Disconnection alarm check

• Open patient valve outlet.

Requirement: The disconnection alarm must be activated after two respiration cycles.

3.6.5 Pressure alarm check

• Shut off pressurised gas connection of Medumat (2.7 - 6.0 bar).

Requirement: The pressure alarm must be activated.

Final Check 11

3.7 Checking assisted ventilation

Connect ventilation tube with patient valve to test bag.

1. Set MEDUMAT Standard a to MV 8 l/min, Air Mix, f = 8 /min and P

= 60 mbar.

max

2. Switch on Assist button 6, green LED in button flashes.

3. Wait for two inspiration phases.

Requirement: The visual alarm No Assist is actuated (flashing yellow light in alarm field 2).

The acoustic alarm does not cut in until one minute has elapsed.

4. Simulate inspiration impulses (negative pressure) by squeezing the test bag several times before the next

inspiration.

During simulation the pointer must swing into the negative sector and reach at least -0.8 mbar.

Requirement: The yellow No Assist LED must go out on inspiration.

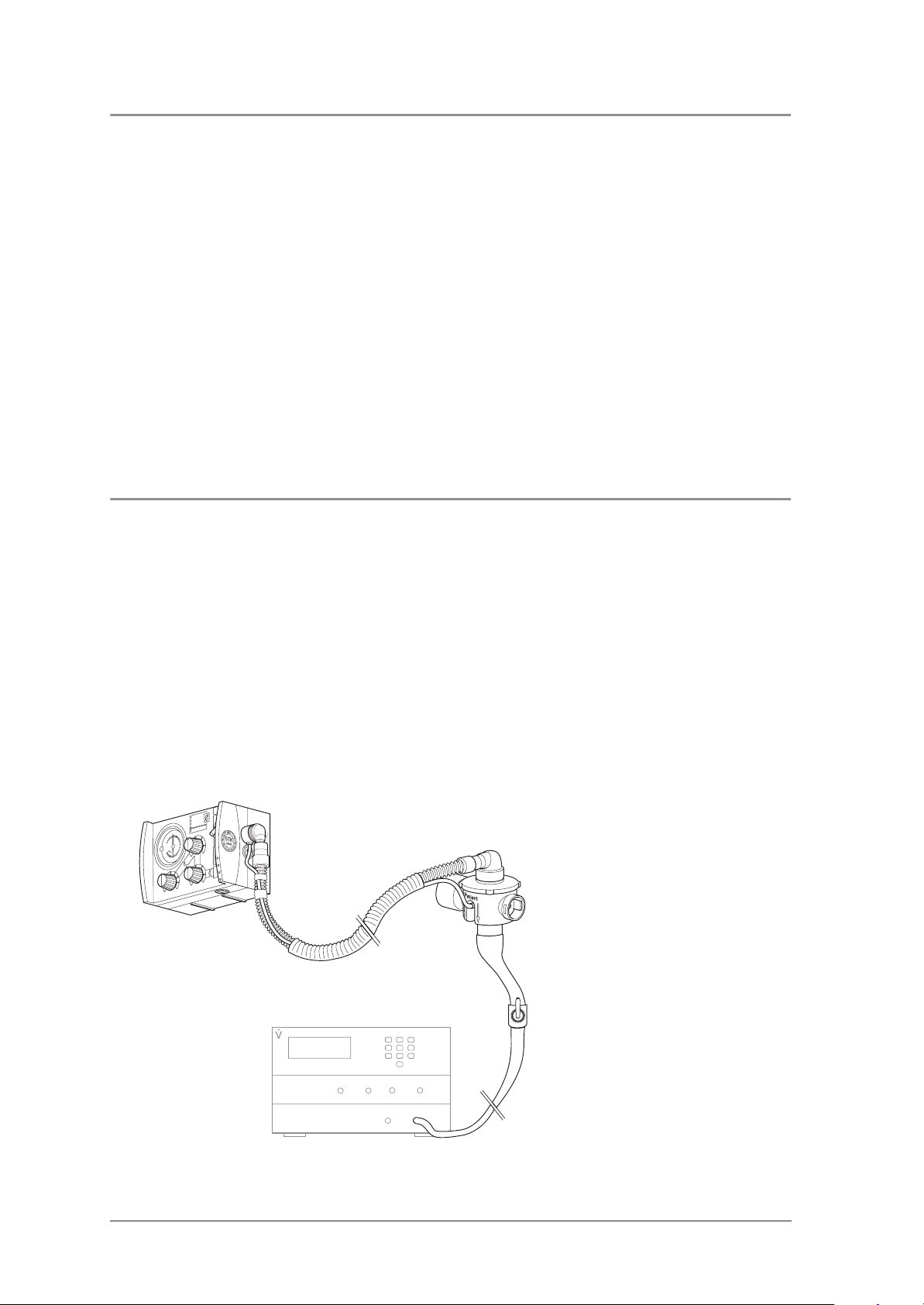

3.8 Functional check on frequency setting

Connect respiration tube to 10 mbar orifice and to volumetric flowmeter, then set MEDUMAT Standard a to

MV = 11 l/min

1. Run MEDUMAT Standard a in position No Air Mix, Freq. = 5 min-1.

Requirement: The measured frequency must be 5 ± 1 min

-1

.

2. Run MEDUMAT Standard a in position No Air Mix, Freq. = 15 min-1.

Requirement: The measured frequency must be 15 ± 2 min

-1

.

3. Run MEDUMAT Standard a in position No Air Mix, Freq. = 25 min-1.

Requirement: The measured frequency must be 25 ± 2 min

-1

.

4. Run MEDUMAT Standard a in position No Air Mix, Freq. = 40 min-1.

Requirement: The measured frequency must be 40 ± 2 min.

O/I

Patient valve with

tube system

Volumetric flowmeter

Orifice 10 mbar

open

12 Final Check

3.9 Functional check on tidal volume at 4.5 bar delivery pressure and 10 mbar counterpressure

1. Run MEDUMAT Standard a in position No Air Mix, Freq. = 15 min-1 and MV = 20 l/min.

Requirement: Tidal volume must be 1300 ± 200 ml.

Switch MEDUMAT Standard a to position Air Mix.

Requirement: Tidal volume must be 1300 ± 200 ml.

2. Run MEDUMAT Standard a in position No Air Mix, Freq. = 15 min-1 and MV = 11 l/min.

Requirement: Tidal volume must be 730 ± 110 ml.

Switch MEDUMAT Standard a to position Air Mix.

Requirement: Tidal volume must be 730 ± 110 ml.

3. Run MEDUMAT Standard a in position No Air Mix, Freq. = 40 min-1 and MV = 5 l/min.

Requirement: Tidal volume must be 125 ± 25 ml.

Switch MEDUMAT Standard a to position Air Mix.

Requirement: Tidal volume must be 125 ± 25 ml.

O/I

Patient valve with

tube system

Volumetric flowmeter

Orifice set to

10 mbar

Final Check 13

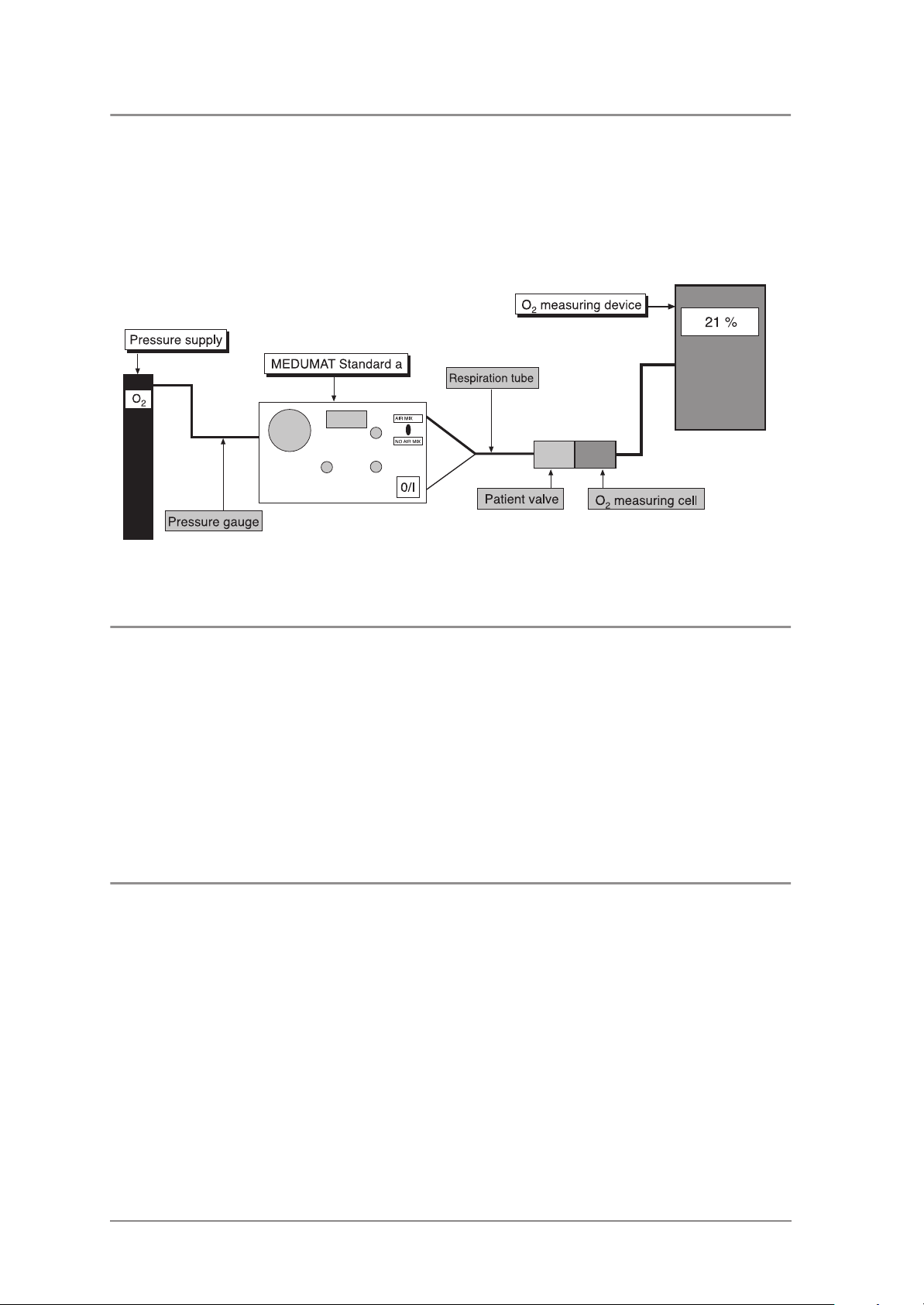

3.10 Checking oxygen concentration

1. Run MEDUMAT Standard a in position Freq. = 10 min-1 and MV = 11 l/min with 100 % O2.

2. Check O2 concentration in position No Air Mix.

Requirement: The O

3. Check O2 concentration in position Air Mix.

Requirement: The O

concentration must be greater than 98 %.

2

concentration must lie between 50 % and 65 %.

2

3.11 Functional check on pressure limit

1. Connect respiration tube to test bag.

2. Set MEDUMAT Standard a to No Air Mix, Freq. = 8 min-1 and MV = 9 l/min.

3. Set pressure limit to 20 mbar.

Requirement: The pressure limit must respond at 20 ± 5 mbar and trigger the stenosis alarm.

4. Set pressure limit to 60 mbar.

Requirement: The pressure limit must respond at 60 ± 5 mbar and trigger the stenosis alarm.

3.12 Functional check on exhaust valve without patient valve

1. Run MEDUMAT Standard a in position f = 8 min-1 and MV = 7 l/min.

2. Connect patient valve to device outlet with expiration outlet closed, without lip diaphragm and with test

bag.

Requirement: The test bag is completely inflated in one inspiration stroke. The respiration device can then

be heard to exhaust.

14 Final Check

3.13 Checking equipment and accessories (system components)

• Respiration tube with patient valve undamaged and in working order

• Functional check test set in working order

• Pressure reducer in working order

• O2 cylinder within test deadline; valve in working order

• Support plate complete and in working order

• Medical products book present

• Operating instructions present

3.14 Checking external condition

• Check external condition of device.

Requirement: No mechanical damage to housing.

Device labels with operating information are legible.

Sealing sleeves are properly seated.

Pressure gauge zero reading is correct.

Connecting thread G3/8 is undamaged and functions smoothly.

All rotary knobs are self-locking against inadvertent readjustment.

3.15 Documentation

• Document points 4 to 14 in the Test Record, along with test date and tester number.

Final Check 15

4. Servicing

N.B.

Always remember to carry out a technical safety check of the ventilator after every repair.

MEDUMAT Standard a must be serviced regularly.

We recommend having all maintenance work, servicing and repairs carried out either by the manufacturer

Weinmann or by a qualified agent expressly authorised by that company.

4.1 Intervals and Scope

Every 2 years:

Every 2 years, you must subject the device (including patient valve and tube system) to a technical safety check

in accordance with §6 of the Regulations for Users.

The servicing and inspection may also be carried out by the manufacturer Weinmann.

The following points should be observed:

• Check that the equipment is complete

• Visual check for:

– physical or mechanical damage

– correct markings on controls

– damage to all external hoses;

• Replacement of worn components/

compulsory change parts (see “7.2 Maintenance set” on page 46);

• Check of system components: transport platforms, oxygen supply fittings, secretion suction

system, hose connections etc.

• Check test bag.

• Repeat testing of aluminium oxygen bottles

WM 1821 and WM 3621 by the Technical

Testing Association. The specified testing date

is stamped on the shoulder of the bottle;

• Final check in accordance with Test Instructions/

Test Report STK WM 22805

(see “3. Final Check” on page 9 and see “11. Repair and inspection log” on page 53.

Every 4 years:

• Servicing of the fittings in the oxygen supply system (e.g. pressure reducer) either by the manufacturer or

by a qualified agent expressly authorised by him.

Every 10 years:

• Repeat testing of the conventional steel or aluminium oxygen bottles by the Technical Testing Association.

The specified testing date is stamped on the shoulder of the bottle.

16 Servicing

4.2 Batteries and fuses

MEDUMAT Standard a is fitted with two batteries

which must always be changed together:

A button cell CR2430 18 supplies the electronics

with auxiliary power if the capacity of the main

battery 20 is exhausted. This means that an alarm

can still be activated in the event of sudden failure

of the main battery. The device switches to expiration.

As a general rule, the capacities of the batteries

are designed in such a way that under normal usage conditions, they do not need to be changed

during the 2-year servicing intervals. Within the

context of the prescribed 2-year servicing, the batteries are replaced completely.

We recommend that the batteries be changed

only by the manufacturer Weinmann or by authorised specialists explicity authorised by them, since

special precautions must be taken to protect the

electronics (see “6.6 Changing the batteries” on

page 24).

18

19

20

18: Button cell for auxiliary power

19: Fuse to prevent internal short-circuiting

20: Lithium battery 3.6 V for main power to

MEDUMAT Standard a

4.3 Adjusting the pressure gauge

In the idle state, with MEDUMAT Standard a deactivated and the oxygen cylinder closed, the needle of the

pressure gauge must point precisely to “0”.

To adjust the needle, proceed as follows:

1. Carefully lever out the plastic cover of the adjusting screw.

2. Adjust the needle with the adjusting screw

using a small screwdriver (e.g. watchmaker’s

screwdriver).

3. Re-insert the plastic cover.

Adjusting screw

4.4 Storage

If you are not intending to use MEDUMAT Standard a for a long period, we recommend the following storage

precautions:

1. Clean and disinfect the ventilator (see

“5. Hygienic preparation” of the description

and operating instructions for MEDUMAT).

2. Store MEDUMAT Standard a in a dry place.

Important note!

Remember that the ventilator still requires servicing

at the stipulated intervals even when in storage,

otherwise it cannot be used when removed from

storage.

Servicing 17

Loading...

Loading...