Page 1

MEDUMAT Basic

Ventilator

MEDUMAT Basic

Ventilator

Servicing and repair instructions

WM 22600

p

WM 22650

Page 2

Contents

Introduction

1.

Overview

1.1

2.

Description of ventilator

2.1

2.2

2.3

3.

Final Check

3.1

3.2

3.3

3.4

3.5

3.6

3.7

3.8

3.9

3.10

3.11

3.12

3.13

3.14

3.15

4.

Servicing

4.1

4.2

4.3

4.4

4.5

5.

Troubleshooting

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

Symbols used on the ventilator

Uses

. . . . . . . . . . . . . . . . . . . . . . . . .

Ventilation function

Patient valve

. . . . . . . . . . . . . . . . . . . . . . . . . .

Test resources required

Preparations for final check

Entering device data

Testing for leaks and checking pressure

reading

Device self-test after switching on

Functional check on alarms

Functional check on frequency setting

Functional check on

at 4.5 bar delivery pressure and

10 mbar counterpressure

Checking oxygen concentration

Functional check on pressure limit

Functional check on exhaust valve

without patient valve

Check the breath volume

Checking equipment and accessories

(system components)

Checking external condition

Documentation

Intervals and Scope

Batteries and fuses

Adjusting the pressure gauge

Storage

Disposal

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . . . . . .

. . . . .

. . . . . . . . .

. .

tidal volume

. . . . . . . . . .

. . . . . .

. . . .

. . . . . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . .

10

10

11

11

12

13

13

13

13

14

14

15

15

16

16

17

17

18

3

4

5

6

6

6

7

8

8

9

9

9

6.

Repair information and repair instructions

6.1

General

6.2

Replacing the sieve in the compressed

gas connection

6.3

Changing the foam insert in the

pressure relief valve outlet

6.4

Opening the

6.5

Closing the

6.6

Changing the batteries

6.7

Replacing the fuse

6.8

Replacing ventilation control knob

6.9

Calibration after removal of PCB,

ventilation control knob 5 and/or

pneumatic block

6.10

Replacing the alarm signalling device

6.11

Replacing two-way switch for maximum

ventilation pressure (

Basic p Basic p only)

6.12

Replacing the circuit board. . . . . . . . . 29

6.13 Replacing the pressure gauge . . . . . . . 31

6.14 Replacing the pneumatic block . . . . . . 32

6.15 Replacing the pneumatic block with

angled outlet . . . . . . . . . . . . . . . . . . 34

6.16 Replace 3/2 solenoid valve . . . . . . . . 37

6.17 Changing the Air Mix/

7. Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . 47

8. Tools and test equipment . . . . . . . . . . . . . . . 51

9. Technical data . . . . . . . . . . . . . . . . . . . . . . . 53

10. Technical Changes . . . . . . . . . . . . . . . . . . . . 56

11. Repair and inspection log. . . . . . . . . . . . . . . 57

No Air Mix switch . . . . . . . . . . . . . . 38

6.18 Replace upper part of housing/

control panel . . . . . . . . . . . . . . . . . . 39

6.19 Replacing the housing base section . . . 45

6.20 Upgrading ventilation tube . . . . . . . . . 46

7.1 List of spare parts . . . . . . . . . . . . . . . 47

7.2 Maintenance set. . . . . . . . . . . . . . . . 49

8.1 General tools. . . . . . . . . . . . . . . . . . 51

8.2 Special tools . . . . . . . . . . . . . . . . . . 51

8.3 Test equipment . . . . . . . . . . . . . . . . . 52

9.1 Pneumatics . . . . . . . . . . . . . . . . . . . 54

9.2 O2 content when using Air Mix. . . . . . 55

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . .

device

. . . . . . . . . . . . .

device

. . . . . . . . . . . . . .

. . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

MEDUMAT Basic /

. . . . . . . . . . . . .

. .

. . . .

. .

21

21

21

22

22

23

23

24

24

25

27

28

© Copyright Weinmann GmbH & Co. KG.

The content and presentation are copyright protected and may only be used by authorised Weinmann Service Partners in the

course of their service operations. The content must not be reproduced or passed on to third parties. The complete documents

must be returned on termination of the cooperation with Weinmann.

2

Page 3

Introduction

For decades, Weinmann has developed, manufactured and distributed equipment for emergency

medicine, oxygen therapy and inhalation therapy.

In 1972, Weinmann introduced the first

MEDUMAT emergency ventilator to the market.

MEDUMAT emergency ventilators are automatic

resuscitators. They are used for controlled respiration in emergency medicine, e.g. in the event of

acute ventilatory disorders, and for secondary obstructions.

The new generation of equipment, which was

especially developed to meet the requirements of

users, offers users and patients an enhanced level

of safety. An intelligent alarm system monitors the

patient's breathing and notifies the user of any malfunctions. Hence, this technology offers even greater safety and reliability during respiration.

The aim of these service and repair instructions is

to familiarise you, as a knowledgeable expert, with

the MEDUMAT in terms of function, technology

and repairs. In conjunction with the training you

have already received from Weinmann, you are

now a "trained, qualified expert" and are able to

instruct your clients correctly, rectify faults yourself,

and perform the functional checks described in the

instructions for use, as well as conduct any repairs

which may be necessary, as outlined in these service and repair instructions.

In the event of a guarantee claim, MEDUMAT should

be returned to Weinmann.

To enable us to process any guarantee or goodwill

claims, please return the consumer's proof of

purchase (invoice) together with the device.

Repairs and maintenance work must be carried out

only by Weinmann or by knowledgeable experts.

You are responsible for all repairs performed by

yourself and the warranty thereof!

Only original Weinmann spare parts should be used

for repair purposes.

Please remember:

Your customer trusts you and relies on your expertise, just as you rely on Weinmann.

Note:

The following information can be found in the description and operating instructions for MEDUMAT:

• Safety instructions

• Mounting with the wall bracket STATION MEDUMAT,

Mounting of accessories

• Operation

• Hygienic preparation

• Functional check

3

Page 4

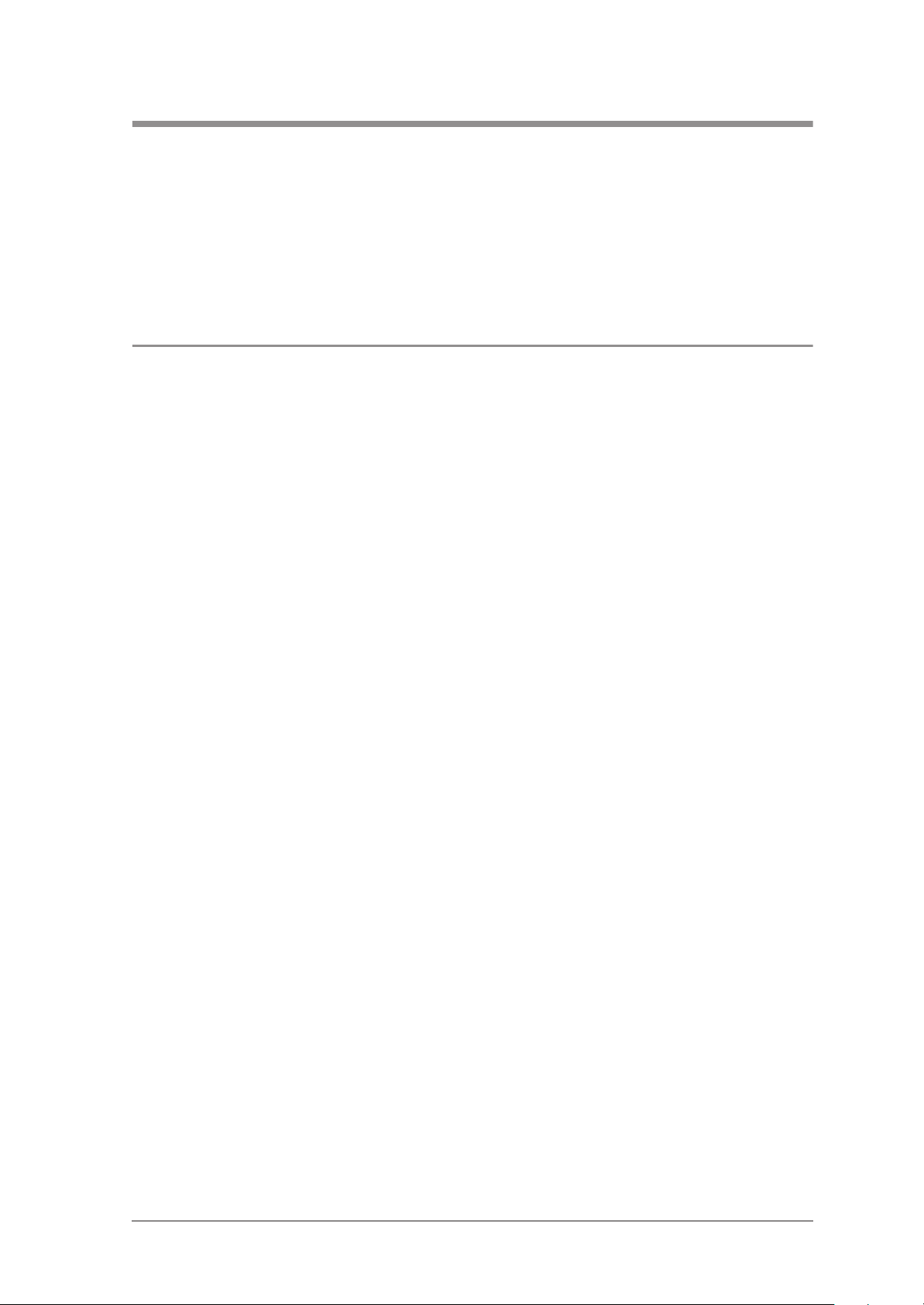

1. Overview

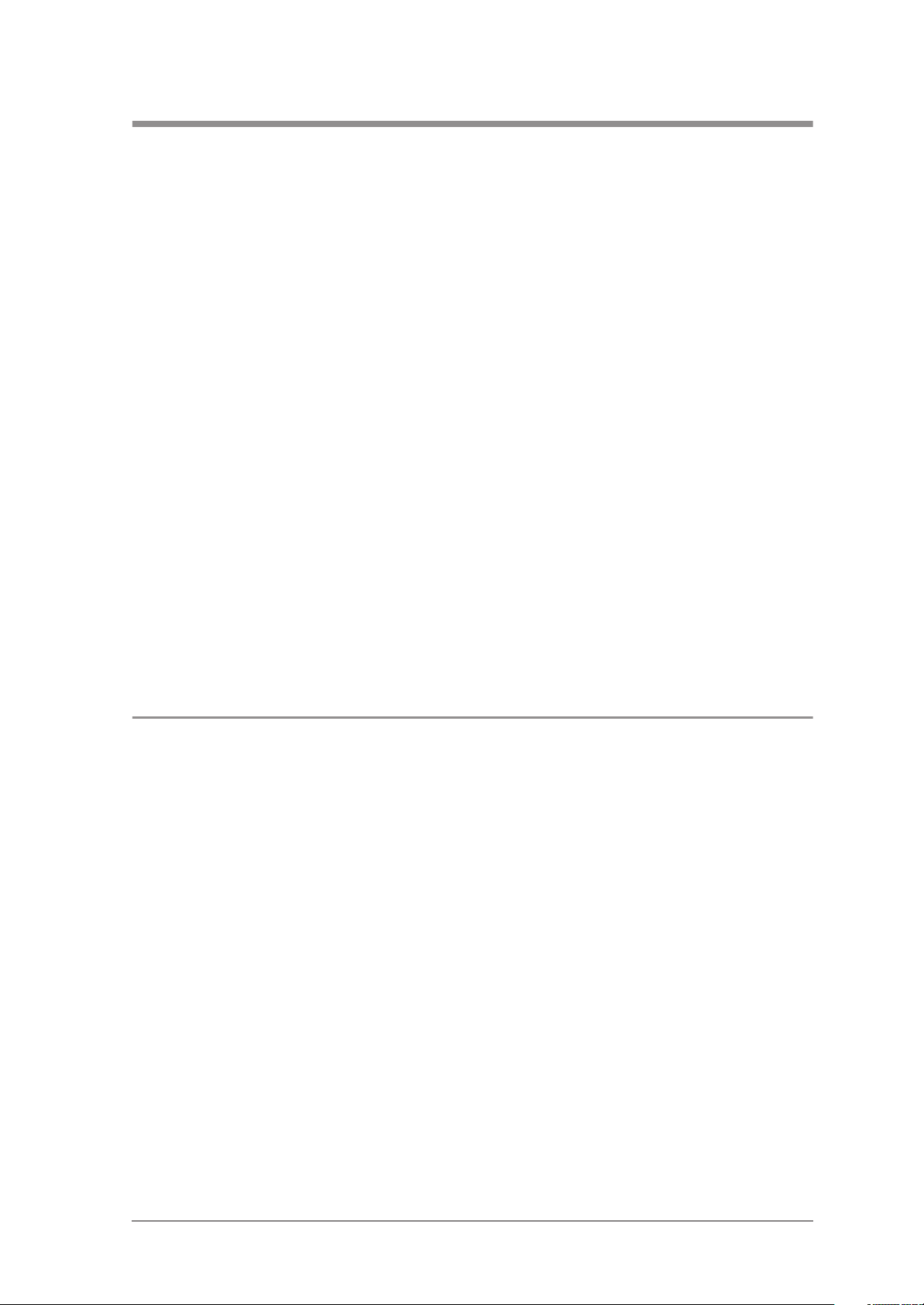

Control panel MEDUMAT Basic, Basic p

1 Ventilation pressure gauge

3 Alarm mute button2 Alarm panel

(Manometer)

9 Tumbler switch for setting max.

ventilation pressure (Basic p only)

4 Air Mix/No Air Mix switch

5 Minute volume regulator

6 Colour code

7 Recommendations for ventilation

settings

8 ON/OFF switch

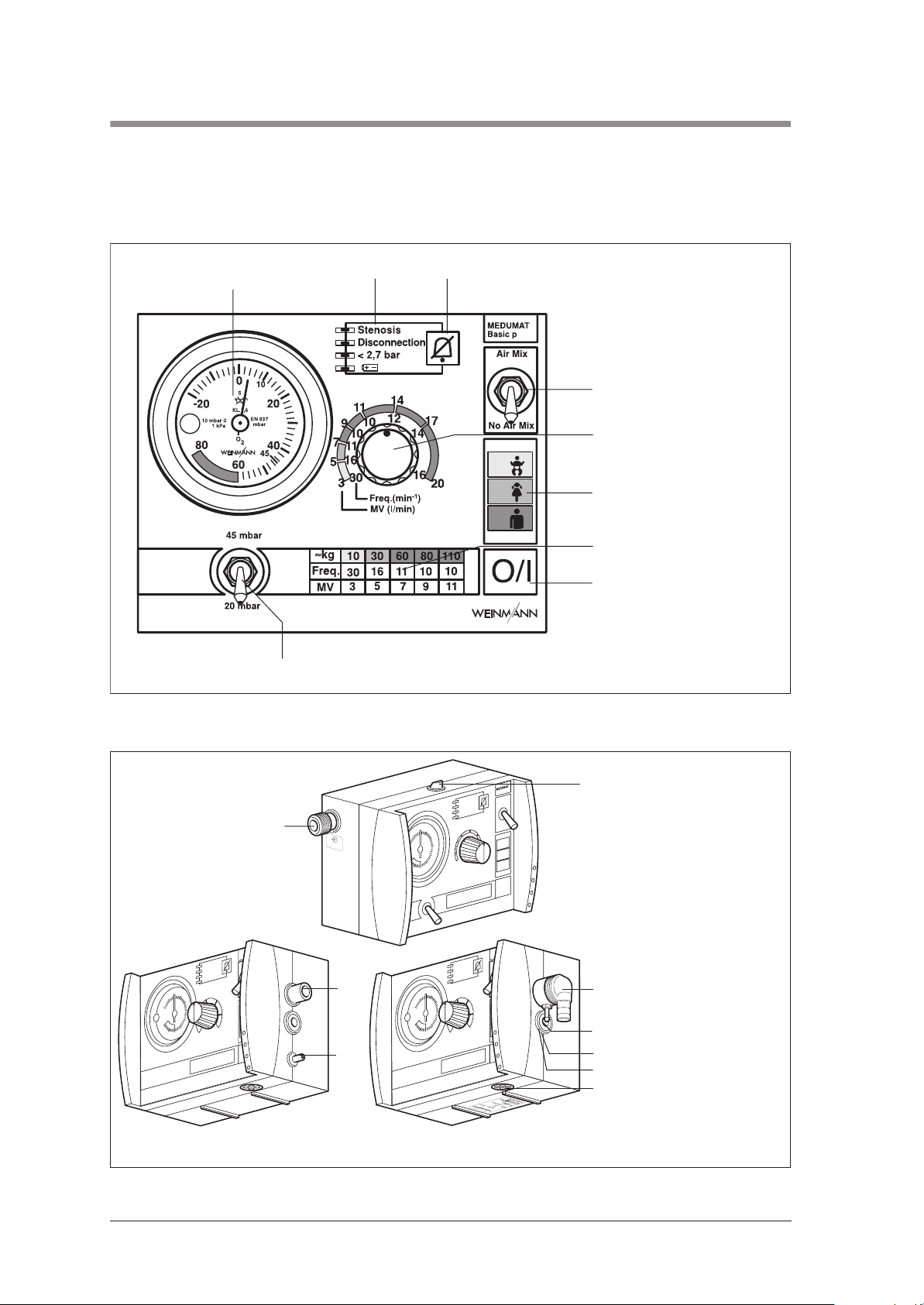

MEDUMAT Basic, Basic p connections

10 Pressure gas connection

®

T

A

M

U

D

E

M

ic

s

a

B

12

O/I

up to appliance no.: Basic 1019

Basic p 1399

13

from appliance no.: Basic 1020

p

c

i

s

a

B

/I

O

®

T

A

M

U

D

E

M

ic

s

a

B

O/I

:

:

N

S

:

p

y

T

Basic p 1400

11 Locking latch for STATION

MEDUMAT wall bracket

12 Connection for ventilation hose

13 Pressure gauge hose connection

14 Relief valve

15 Dust cover

16 Mixed air filter

4 Overview

Page 5

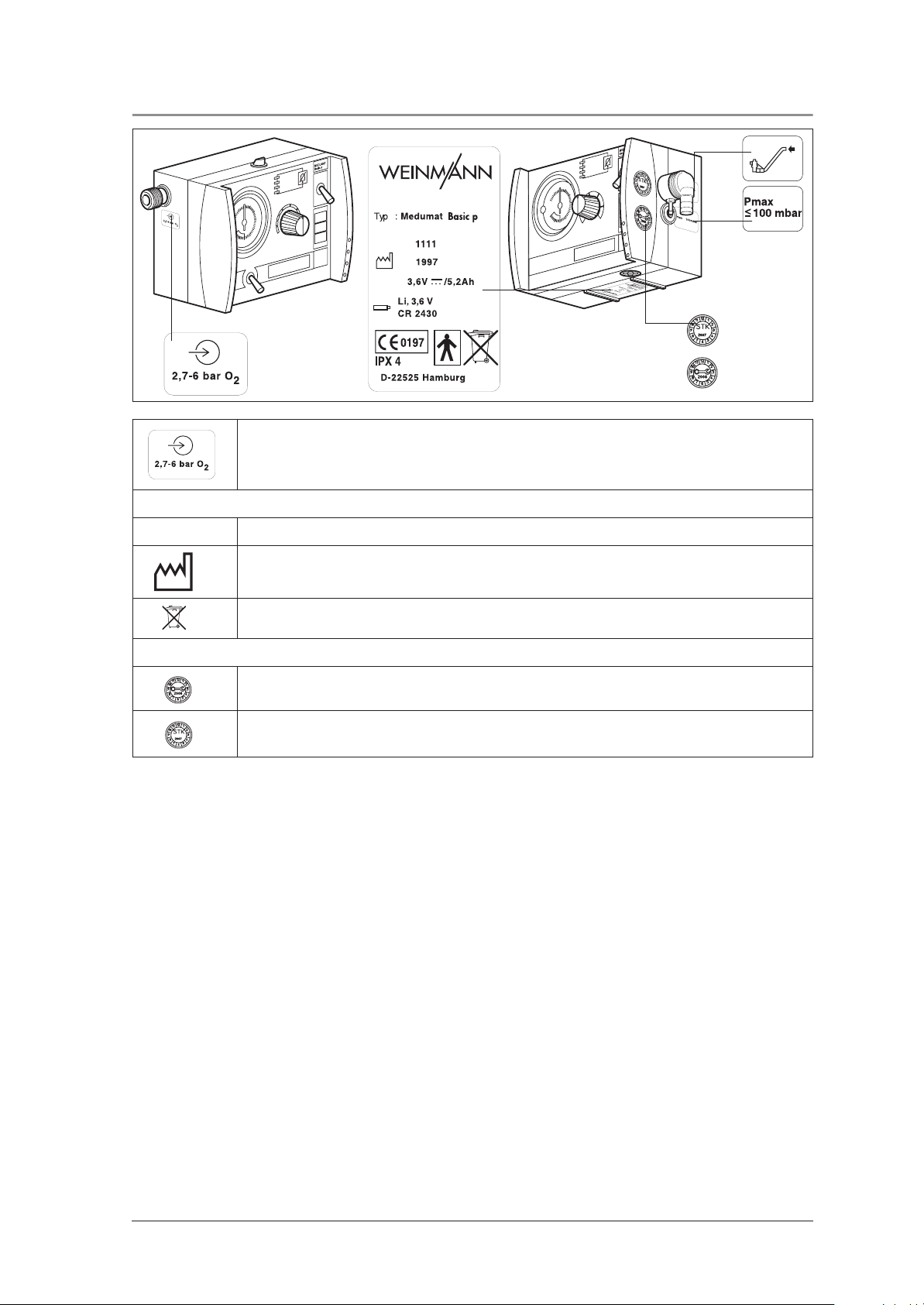

1.1 Symbols used on the ventilator

SN

SN :

O/I

:

Inlet 2,7 - 6 bar O2.

MEDUMAT Basic / Basic p device information plate

Serial number of device

Year of manufacture

Do not dispose of device in domestic waste.

Safety check and servicing label

Servicing label: indicates when the next service is due.

O/I

:

:

:

p

y

T

N

S

Safety check label (in Germany only): marks when the next safety check as per §6 of the

German law relating to users of medical devices is required.

Overview 5

Page 6

2. Description of ventilator

2.1 Uses

MEDUMAT Basic / Basic p is an automatic (short-term) ventilator.

You can use MEDUMAT Basic / Basic p:

• to revive patients at the site of an emergency

• on a longer term basis in more protracted

emergencies, e.g. fires.

You can use MEDUMAT Basic / Basic p whilst

transporting patients:

• between the various rooms and departments

of a hospital;

• between the hospital and other premises;

• in emergencies;

• when transport over a considerable distance is

planned.

2.2 Ventilation function

MEDUMAT Basic / Basic p operates within a pressure range of 2.7 to 6 bar and at a flow rate of not

less than 70 l/min O2. It has a built-in power

pack.

The gas used for ventilation is highly compressed

medical oxygen, which is reduced to the required

operating pressure by a two-stage external pressure reducer. The oxygen supply is fed in at input

valve 10.

MEDUMAT Basic / Basic p:

• is designed to provide controlled ventilation to

persons of 10 kg body weight or more;

• is used to treat respiratory arrest;

• can be preset to parameters that ensure evenly

balanced ventilation provided that the selected

maximum ventilation pressure P

is not ex-

max

ceeded.

• can be supplied with additional modules for

aspiration and oxygen inhalation. (N.B.

MEDUMAT Basic / Basic p cannot be used

as a ventilator simultaneously with these modules)

p

c

i

s

a

B

10

/I

O

The continuously adjustable ventilation settings and

the inspiration/expiration ratio of1:1.67 are regulated internally by electronic control processes.

The gas for inspiration flows along the hose and

through the patient valve and either the mask or the

tracheal tube into the patient’s airways. The patient

valve is fitted with a lip membrane that enables expired gas to be conducted away through the expiration tube.

6 Description of ventilator

Page 7

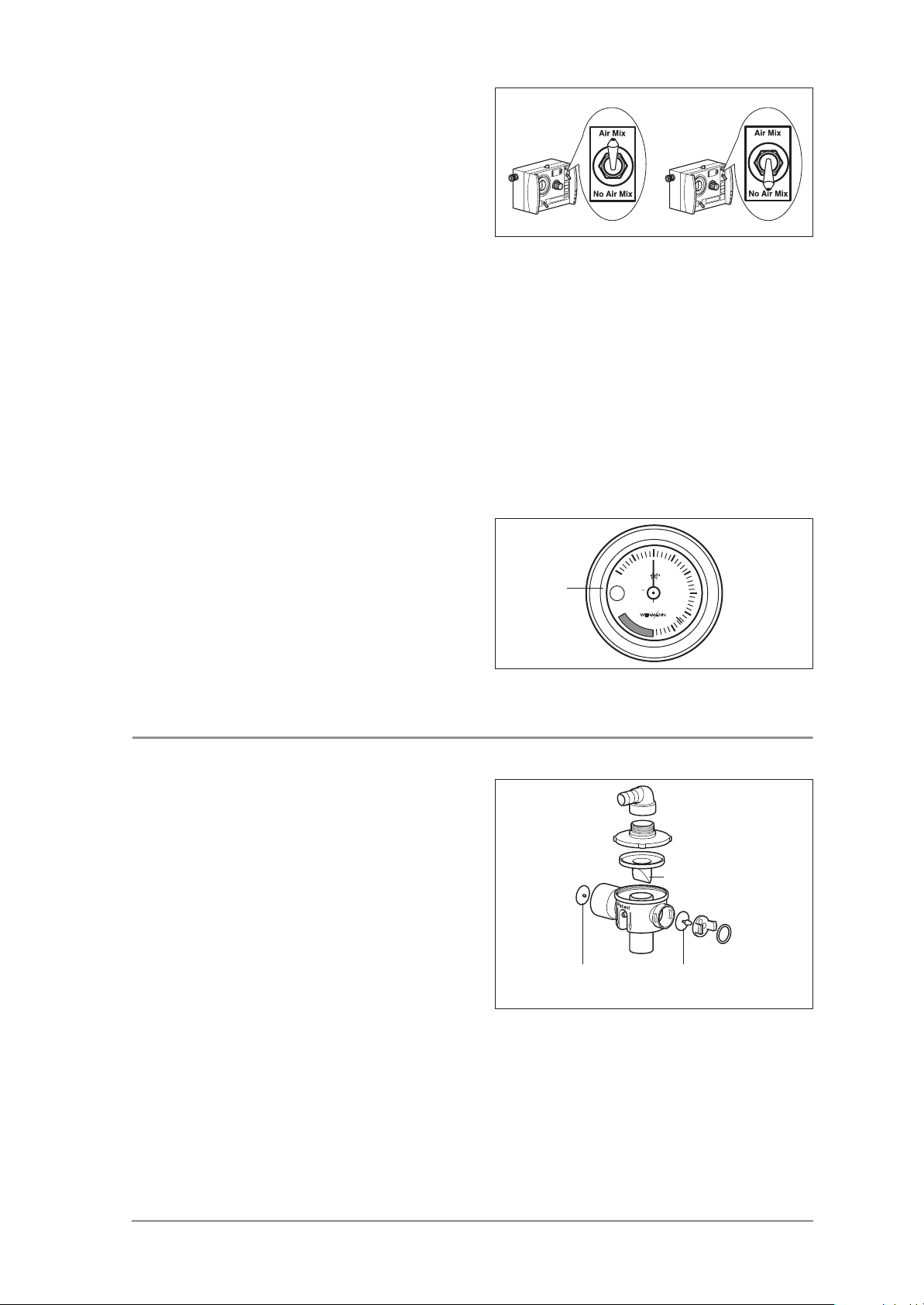

At the normal Air Mix setting, atmospheric air is admixed to give an O2-concentration of between

55% and 85% at 10 mbar ventilation pressure

(see “9.2 O2 content when using Air Mix“ on

page 55).

In certain indications and in cases where the surrounding atmosphere is contaminated, you can

switch to No Air Mix and ventilate with pure oxygen.

The injector unit is switched off when switching

from Air Mix to No Air Mix. This increases minute

volume which can result in the set pressure limit being exceeded and a stenosis alarm (Stenosis) being

triggered. In this case, set minute volume correspondingly lower.

In the opposite instance, in other words when

switching from No Air Mix to Air Mix, the injector

unit is switched on. This reduces minute volume

which can lead to the set pressure limit being un-

dershot. In this case, set minute volume correspond-

ingly higher.

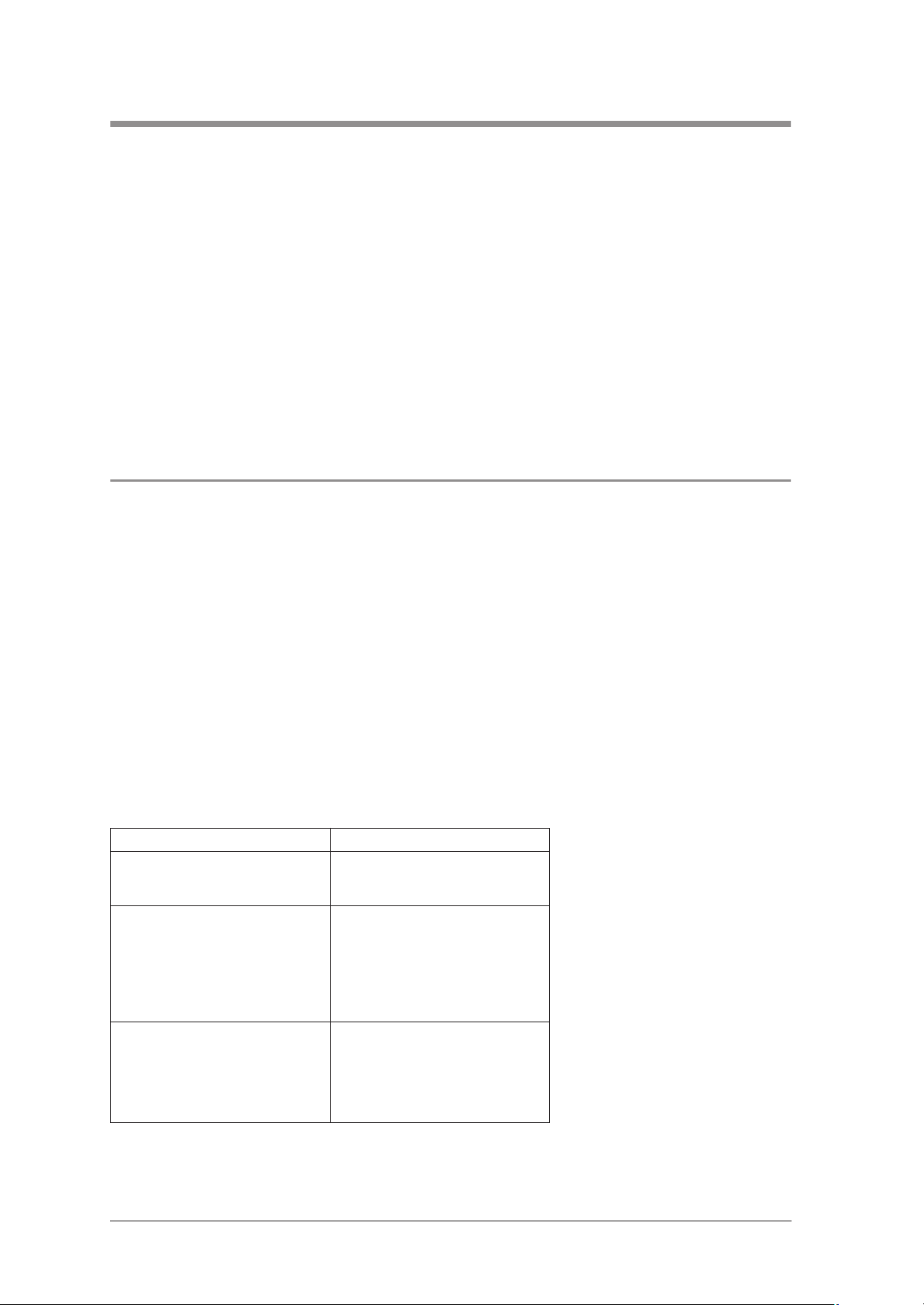

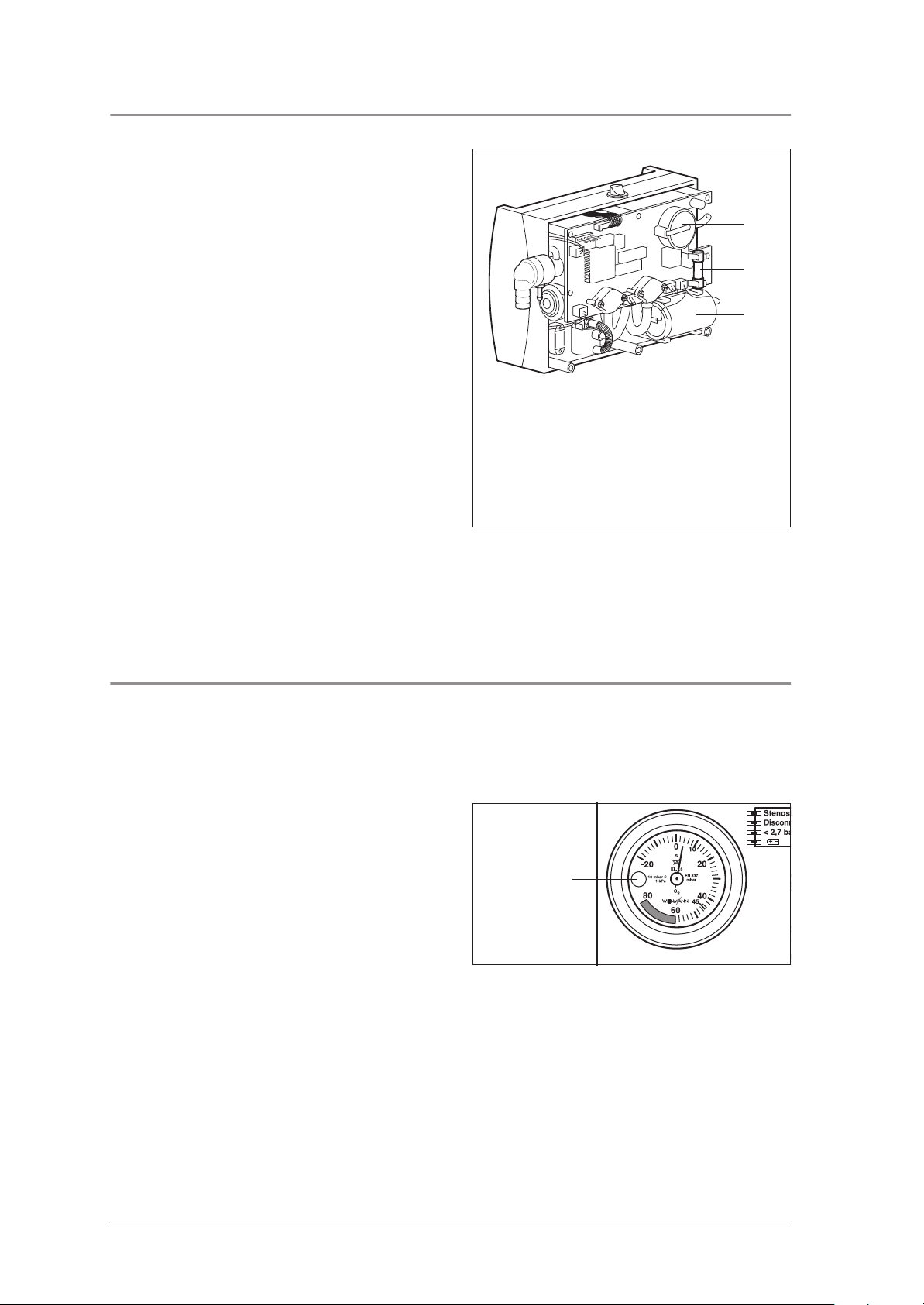

You can check the course of the ventilation on pressure gauge 1.

/I

O

0

10

S

1

-20

80

10 mbar =

1 kPa

20

KL.1,6

EN 837

mbar

O

2

40

45

60

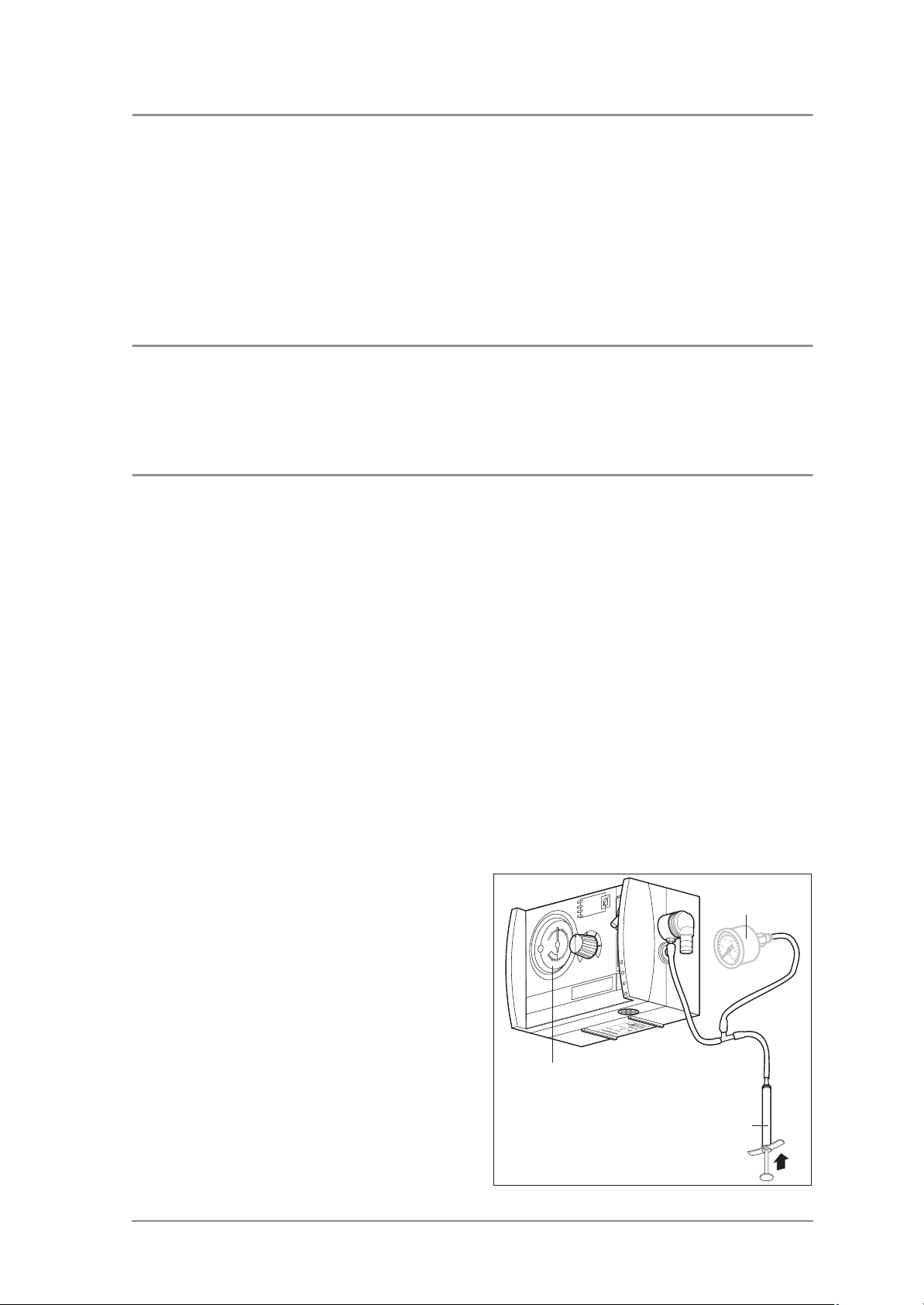

2.3 Patient valve

The gas for inspiration is channelled into the patient’s airways through the patient valve.

This valve is designed to enable spontaneous breathing

in case of equipment failure.

Diaphragm for

exspirations arm

Lip membrane

Diaphragm for

spontaneous

breathing arm

Description of ventilator 7

Page 8

3. Final Check

After any repair and maintenance work, the device

must be subjected to the following final check in

accordance with the Test Instructions WM 22671

and Test Record.

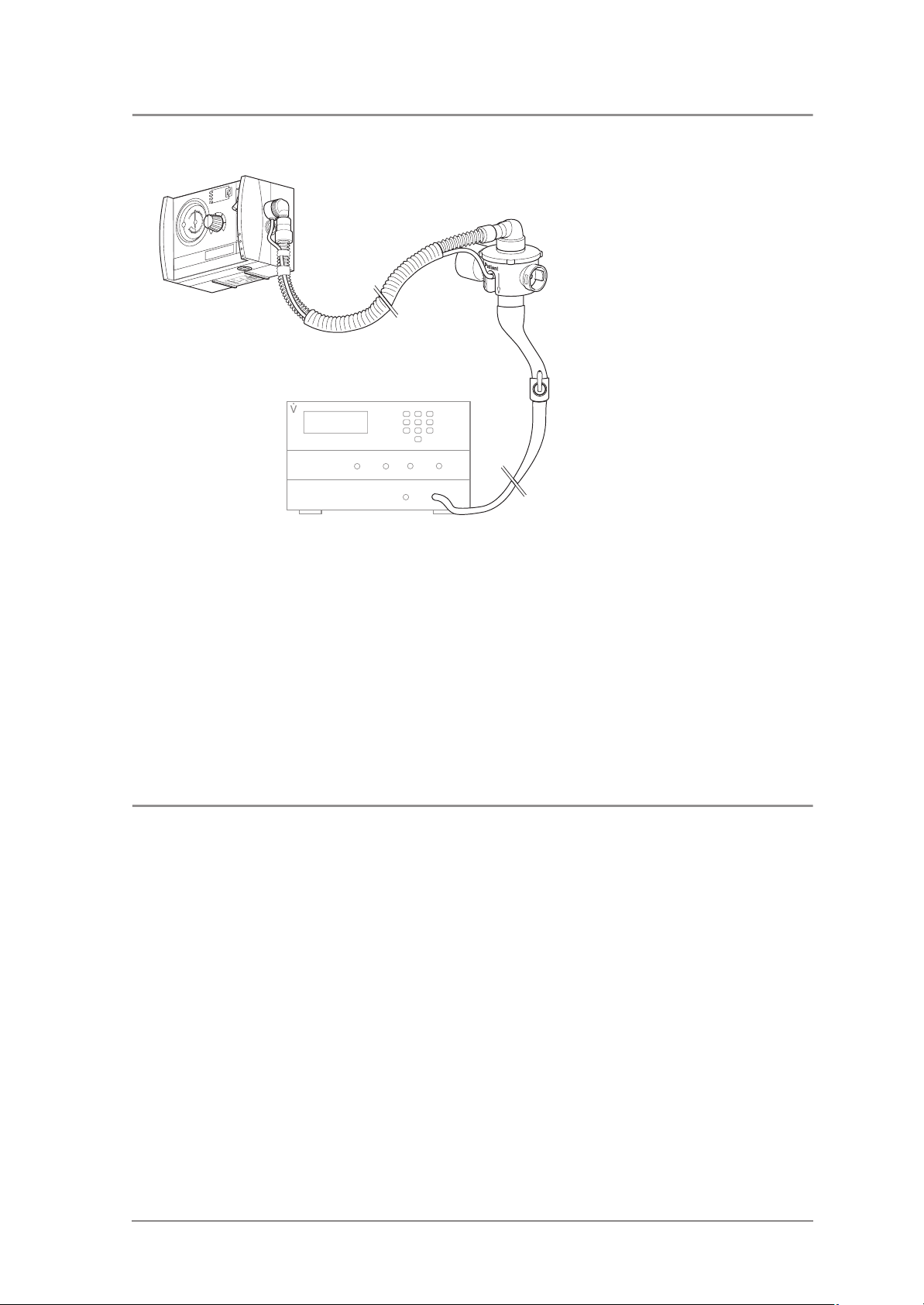

Note:

For a final check on the MEDUMAT Basic /

Basic p you must connect the respiration tube and

the patient valve.

If the final check reveals faults or deviations from

the specified values, you must not use the

We recommend you to keep the following parts in

stock:

• Replacement seals for device connections;

• Replacement dust filter;

• Lip diaphragm for patient valve;

• Diaphragm for spontaneous breathing leg;

• Diaphragm for expiration leg;

• O–Ring 1145/118.

MEDUMAT Basic / Basic p.

3.1 Test resources required

• Flowmeter, PF 300 (imtmedical), RT 200 (Timeter), EKU VIP (EKU Elektronik) or comparable testing

device

• Functional check test set WM 15335

• Adjustable orifice, e.g. ball valve, internal diameter ≥ 10 mm

• Oxygen concentration measuring device, 0 – 100 % ± 1 %,

e.g. Type Oxycontrol WM 13550

• Set: hose with injector WM 15359

• Pressure gauge 0 - 13 bar, class 1.6

• Pressure gauge 0 - 160 mbar, class 1.6

• Set, supply test Medumat / Modules WM 15440

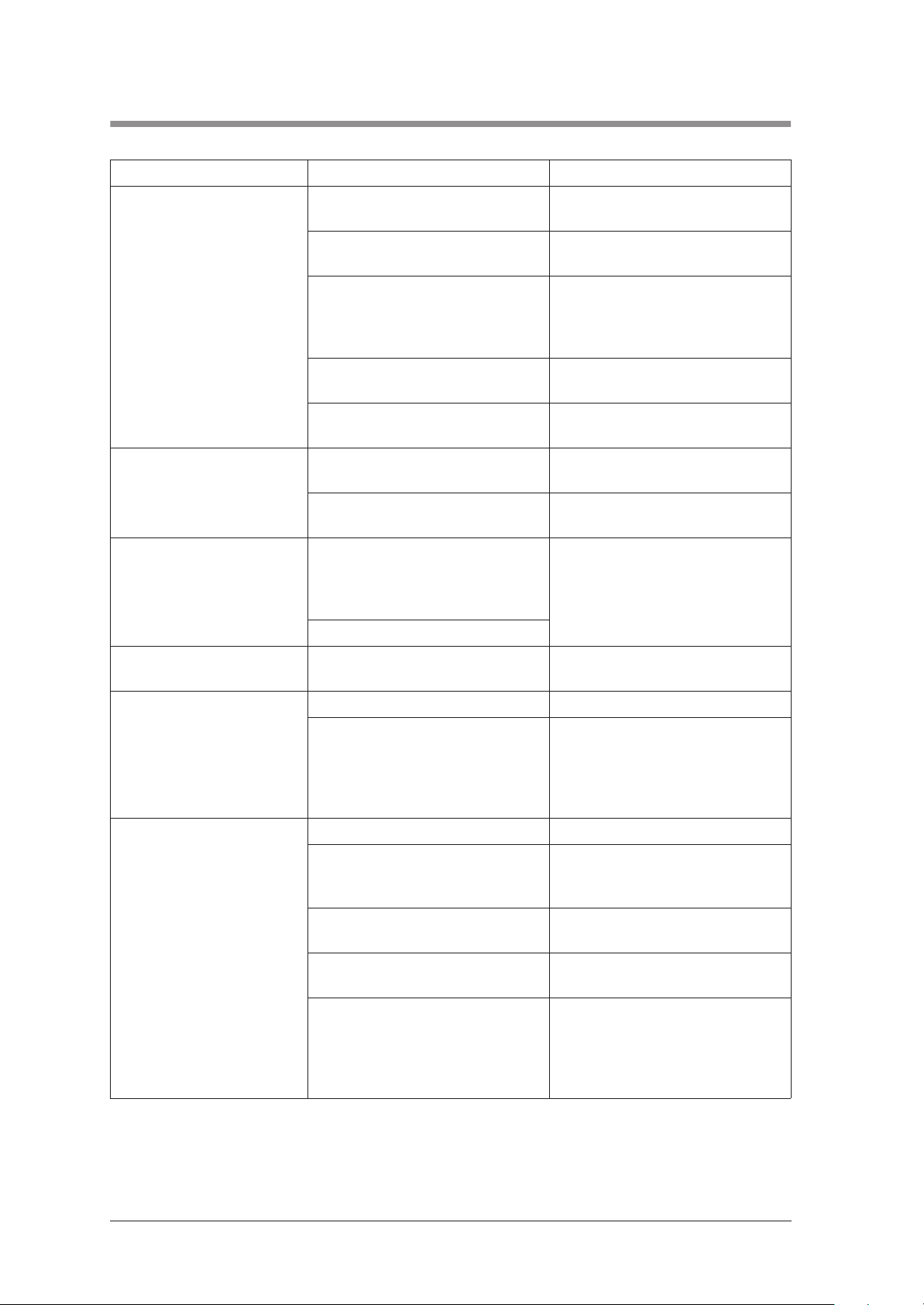

Default settings for flow meter PF300

Settings Values

Default settings:

– Type of gas

– Gas standardization

Trigger settings:

– Type of ventilation

– Source

– Start

– End

– Delay

– Base flow rate

Units and measured values:

– P high

– P diff

– Rate

– Vti

– O

2

Air/02 auto

STP

Adult

Internal HF

Flow rate ≥ 3.0 l/min

Flow rate ≤ 3,0 l/min

60 ms

disabled

bar

mbar

1/min or b/min

ml

%

If you have a comparable testing device, contact WEINMANN’s Technical Support department to have the

setting parameters calibrated.

8 Final Check

Page 9

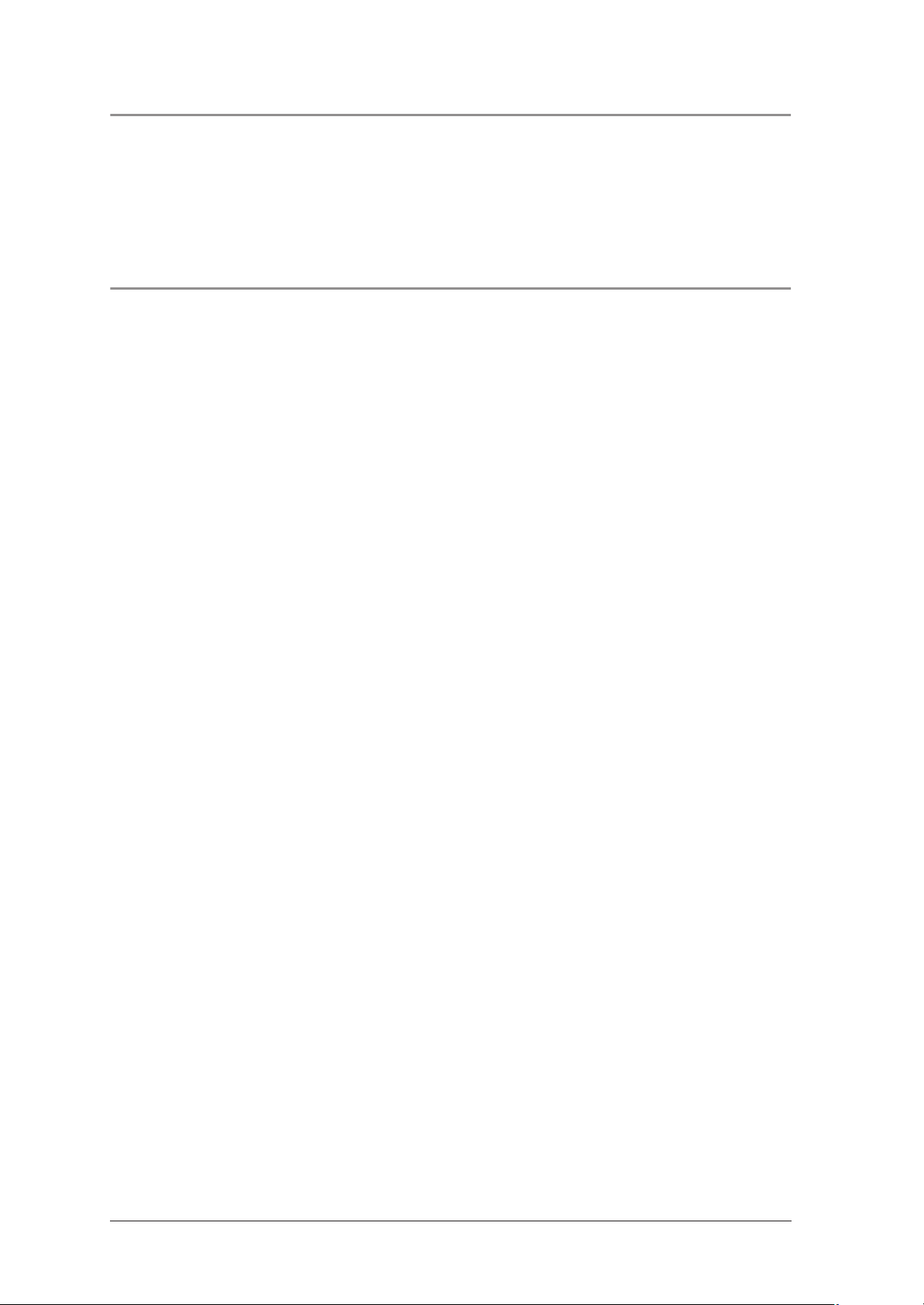

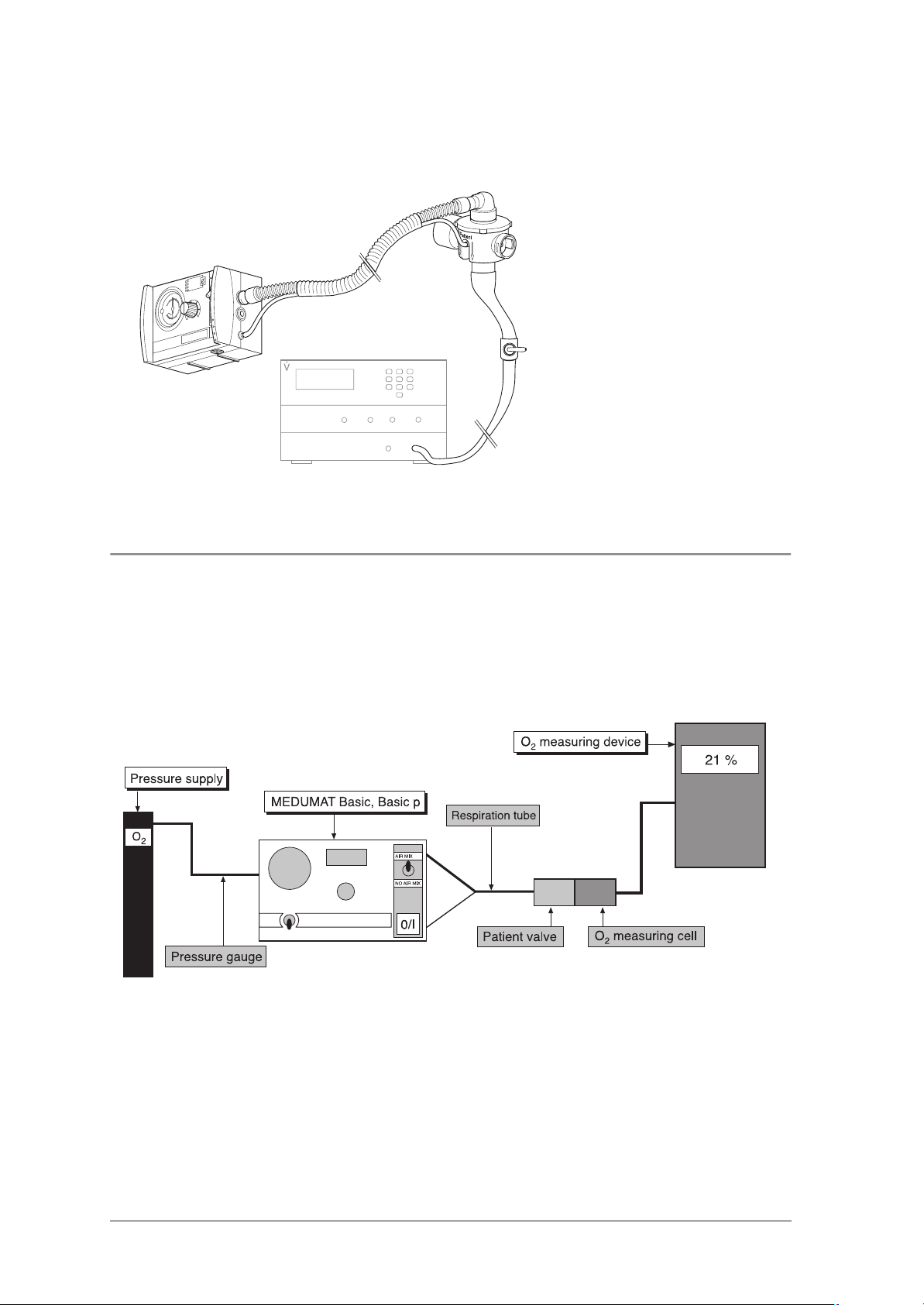

3.2 Preparations for final check

1. Connect MEDUMAT Basic / Basic p to pressure supply 4.5 – 6 bar of cylinder system.

2. Connect respiration tube and pressure measurement tube to MEDUMAT Basic / Basic p.

3. Set MEDUMAT Basic / Basic p with switch in position No Air Mix to Freq. = 30 min-1, MV = 3 l/min

and P

= 45 mbar.

max

4. Start check.

3.3 Entering device data

• Enter the device number and date of manufacture in the Test Record.

3.4 Testing for leaks and checking pressure reading

3.4.1 Testing for leaks on the inlet side

• With device switched off, apply pressure of 6 bar to inlet side and shut off outlet pressure.

• Set lever to No Air Mix.

Requirement: The pressure drop must be less than 0.2 bar/min.

• Set lever to Air Mix.

Requirement: The pressure drop must be less than 0.2 bar/min.

3.4.2 Testing for leaks in pressure measurement segment

• Apply pressure of 60 mbar to pressure measurement segment of MEDUMAT Basic / Basic p.

• During the measurement, a traction force of approx. 3 N must be applied manually to the elbow outlet.

Requirement: The pressure drop must be less than 2 mbar/min.

3.4.3 Checking pressure reading

®

T

A

M

U

D

E

1. Attach T-connector with injector (WM 15359)

to pressure measurement connection 13.

2. Connect test pressure gauge 0 - 100 mbar or

Timeter to free end of T-connector (pressure

gauge/volumetric flowmeter not supplied with

device).

3. Use injector to create a pressure of 55 mbar

as shown on the test pressure gauge.

Requirement: Respiration pressure reading must not

deviate from set value by more than ≤≤≤≤ 1.5 mbar.

Pressure gauge

M

c

i

s

a

B

/I

O

:

:

N

S

:

p

y

T

Test pressure

gauge

Injector

Final Check 9

Page 10

3.5 Device self-test after switching on

1. Apply approx. 4.5 bar to the inlet.

2. Switch on MEDUMAT Basic / Basic p at pushbutton 8 O/I.

Requirement: The self-test is activated: all 4 LEDs light up together and a brief signal tone sounds.

3.6 Functional check on alarms

3.6.1 Stenosis alarm check up to appliance no.: Basic 1019; Basic p 1399

• Set MEDUMAT Basic / Basic p to the Air Mix setting at f = 30/min, MV = 3 l/min and

p

= 45 mbar. Close patient valve outlet.

max

Note: Over-response of needle is normal.

Requirement: The stenosis alarm must be activated after two respiration cycles.

• Set MEDUMAT Basic / Basic p to the No Air Mix setting at f = 30/min, MV = 3 l/min and

p

= 45 mbar. Close patient valve outlet.

max

Note: Over-response of needle is normal.

Requirement: The stenosis alarm must be activated after two respiration cycles.

3.6.2 Stenosis alarm check from appliance no.: Basic 1020; Basic p 1400

• Set MEDUMAT Basic / Basic p to the Air Mix setting at f = 30/min, MV = 3 l/min and

p

= 45 mbar. Close patient valve outlet.

max

Note: Over-response of needle is normal.

MEDUMAT Basic / Basic p briefly switches to expiration if the maximum ventilation pressure is exceeded, but then tries to continue inspiration in the same inspiration phase.

If the maximum ventilation pressure is exceeded for a second time during the same inspiration phase,

the unit finally switches to expiration and vents the patient tube system completely. The next inspiration

begins with the following ventilation stroke according to the frequency selected.

Requirement: The stenosis alarm must be activated after two respiration cycles.

• Set MEDUMAT Basic / Basic p to the No Air Mix setting at f = 30/min, MV = 3 l/min and

p

= 45 mbar. Close patient valve outlet.

max

Note: Over-response of needle is normal.

Requirement: The stenosis alarm must be activated after two respiration cycles.

3.6.3 Test alarm mute button

• Immediately after first alarm tone sounds, press button 3 alarm acknowledgement.

Requirement: The alarm tone must be suppressed immediately. The alarm sounds again after approx.

1 min (or immediately, if parameters are changed).

3.6.4 Disconnection alarm check

• Open patient valve outlet.

Requirement: The disconnection alarm must be activated after two respiration cycles.

3.6.5 Pressure alarm check

• Shut off pressurised gas connection of MEDUMAT Basic / Basic p (2.7 - 6.0 bar).

Requirement: The pressure alarm must be activated.

10 Final Check

Page 11

3.7 Functional check on frequency setting

Connect respiration tube to 10 mbar orifice and to volumetric flowmeter.

®

T

A

M

U

D

E

M

c

asi

B

Patient valve with

/I

O

:

:

N

S

:

p

y

T

Volumetric flowmeter

tube system

Orifice 10 mbar

open

1. Run MEDUMAT Basic / Basic p in position No Air Mix, Freq. = 16 min

Requirement: The measured frequency must be 16 ± 2 min

-1

.

2. Run MEDUMAT Basic / Basic p in position No Air Mix, Freq. = 10 min

Requirement: The measured frequency must be 10 ± 2 min

-1

.

3. Run MEDUMAT Basic / Basic p in position No Air Mix, Freq. = 30 min

Requirement: The measured frequency must be 30 ± 2 min

-1

.

-1

and MV = 20 l/min.

-1

and MV = 11 l/min.

-1

and MV = 3 l/min.

3.8 Functional check on tidal volume at 4.5 bar delivery pressure and 10 mbar counterpressure

1. Run MEDUMAT Basic / Basic p in position No Air Mix, Freq. = 16 min-1 and MV = 20 l/min.

Requirement: Tidal volume must be 1250 ± 190 ml.

Switch MEDUMAT Basic / Basic p to position Air Mix.

Requirement: Tidal volume must be 1250 ± 190 ml.

2. Run MEDUMAT Basic / Basic p in position No Air Mix, Freq. = 10 min-1 and MV = 11 l/min.

Requirement: Tidal volume must be 1100 ± 170 ml.

Switch MEDUMAT Basic / Basic p to position Air Mix.

Requirement: Tidal volume must be 1100 ± 170 ml.

Final Check 11

Page 12

3. Run MEDUMAT Basic / Basic p in position No Air Mix, Freq. = 30 min-1 and MV = 3 l/min.

Requirement: Tidal volume must be 100 ± 20 ml.

Switch MEDUMAT Basic / Basic p to position Air Mix.

Requirement: Tidal volume must be 100 ± 20 ml.

Patient valve with

tube system

®

T

A

M

U

D

E

M

c

i

s

a

B

I

/

O

Volumetric flowmeter

Orifice set to

10 mbar

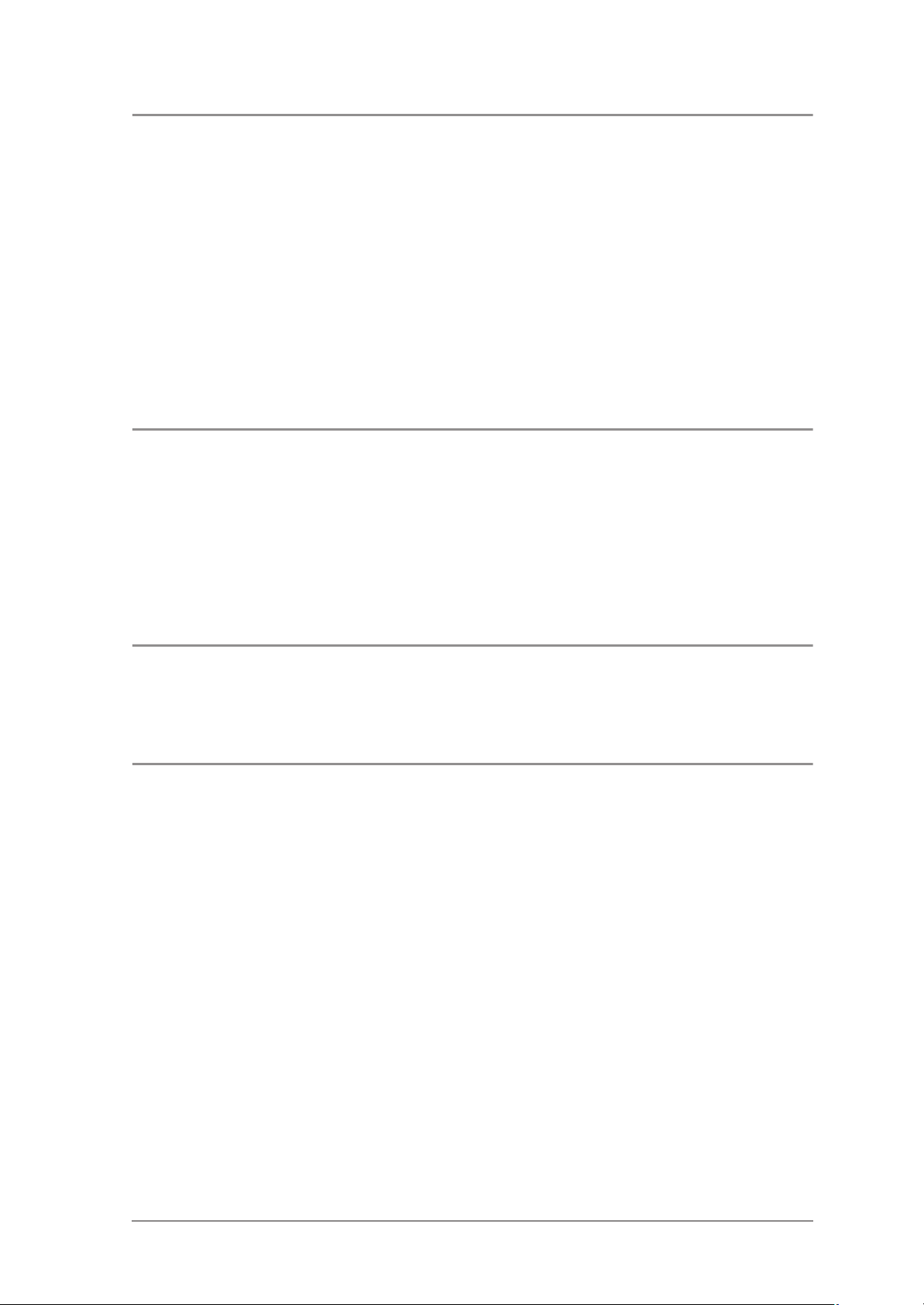

3.9 Checking oxygen concentration

1. Run MEDUMAT Basic / Basic p in position Freq. = 10 min-1 and MV = 11 l/min with 100 % O2.

2. Check O2 concentration in position No Air Mix.

Requirement: The O

concentration must be greater than 98 %.

2

3. Check O2 concentration in position Air Mix.

Requirement: The O

concentration must lie between 50 % and 65 %.

2

12 Final Check

Page 13

3.10 Functional check on pressure limit

1. Connect respiration tube to test bag.

2. Set MEDUMAT Basic / Basic p to No Air Mix, Freq. = 11 min-1 and MV = 7 l/min.

3. Applies to MEDUMAT Basic / Basic p Basic p only

Set pressure limit to 20 mbar.

Requirement: The pressure limit must respond at 20 ± 5 mbar and trigger the stenosis alarm.

4. Applies to MEDUMAT Basic / Basic p Basic and MEDUMAT Basic / Basic p Basic p

Set pressure limit to 45 mbar.

Requirement: The pressure limit must respond at 45 ± 5 mbar and trigger the stenosis alarm.

3.11 Functional check on exhaust valve without patient valve

1. Run MEDUMAT Basic / Basic p in position f = 10 min

2. Connect patient valve to device outlet with expiration outlet closed, without lip diaphragm and with test

bag.

Requirement: The test bag is completely inflated in one inspiration stroke. The respiration device can then

be heard to exhaust.

-1

and MV = 11 l/min.

3.12 Check the breath volume

See “Check the breath volume” in the description and operating instructions for MEDUMAT.

3.13 Checking equipment and accessories (system components)

• Respiration tube with patient valve undamaged and in working order

• Functional check test set in working order

• Pressure reducer in working order

• O2 cylinder within test deadline; valve in working order

• Portable system complete and in working order

• Medical products book present

• Operating instructions present

Final Check 13

Page 14

3.14 Checking external condition

• Check external condition of device.

Requirement: No mechanical damage to housing.

Device labels with operating information are legible.

Sealing sleeves are properly seated.

Pressure gauge zero reading is correct.

Connecting thread G3/8 is undamaged and functions smoothly.

All rotary knobs are self-locking against inadvertent readjustment.

3.15 Documentation

• Document points 4. to 13. in the Test Record, along with test date and tester number.

14 Final Check

Page 15

4. Servicing

N.B.

Always remember to carry out a technical safety check of the ventilator after every repair.

MEDUMAT Basic / Basic p must be serviced regularly.

We recommend having all maintenance work, servicing and repairs carried out either by the manufacturer

Weinmann or by a qualified agent expressly authorised by that company.

4.1 Intervals and Scope

Every 2 years:

Every 2 years, you must subject the device (including patient valve and tube system) to a technical safety check

and maintenance.

The servicing and inspection may also be carried out by the manufacturer Weinmann.

The following points should be observed:

• Check that the equipment is complete

• Visual check for:

– physical or mechanical damage

– correct markings on controls

– damage to all external hoses

• Replacement of worn components/

compulsory change parts (see “7.2 Maintenance set” on page 49);

• Check of system components: portable system, oxygen supply fittings, secretion suction

system, hose connections etc.

• Check test bag.

• Repeat testing of aluminium oxygen bottles

WM 1821 and WM 3621 by the Technical

Testing Association. The specified testing date

is stamped on the shoulder of the bottle.

• Final check in accordance with Test Instructions/

Test Report STK WM 22671 (see „3. Final Check“

on page 8 and see “11. Repair and inspection

log” on page 57).

Every 4 years:

• Servicing of the fittings in the oxygen supply system (e.g. pressure reducer) either by the manufacturer or

by a qualified agent expressly authorised by him.

Every 10 years:

• Repeat testing of the conventional steel or aluminium oxygen bottles by the Technical Testing Association.

The specified testing date is stamped on the shoulder of the bottle.

Servicing 15

Page 16

4.2 Batteries and fuses

MEDUMAT Basic / Basic p is fitted with two batteries which must always be changed together:

A button cell CR2430 17 supplies the electronics

with auxiliary power if the capacity of the main

battery 19 is exhausted. This means that an alarm

can still be activated in the event of sudden failure

of the main battery. The device switches to expiration.

As a general rule, the capacities of the batteries

are designed in such a way that under normal usage conditions, they do not need to be changed

during the 2-year servicing intervals. Within the

context of the prescribed 2-year servicing, the batteries are replaced completely.

We recommend that the batteries be changed

only by the manufacturer Weinmann or by authorised specialists explicity authorised by them, since

special precautions must be taken to protect the

electronics (see “6.6 Changing the batteries” on

page 23)).

17

18

19

17:Button cell for auxiliary power

18:Fuse to prevent internal short-circuiting

19:Lithium battery 3.6 V for main power to

MEDUMAT Basic / Basic p

For information on replacing the fuse, see Section

„6.7 Replacing the fuse“ on page 24.

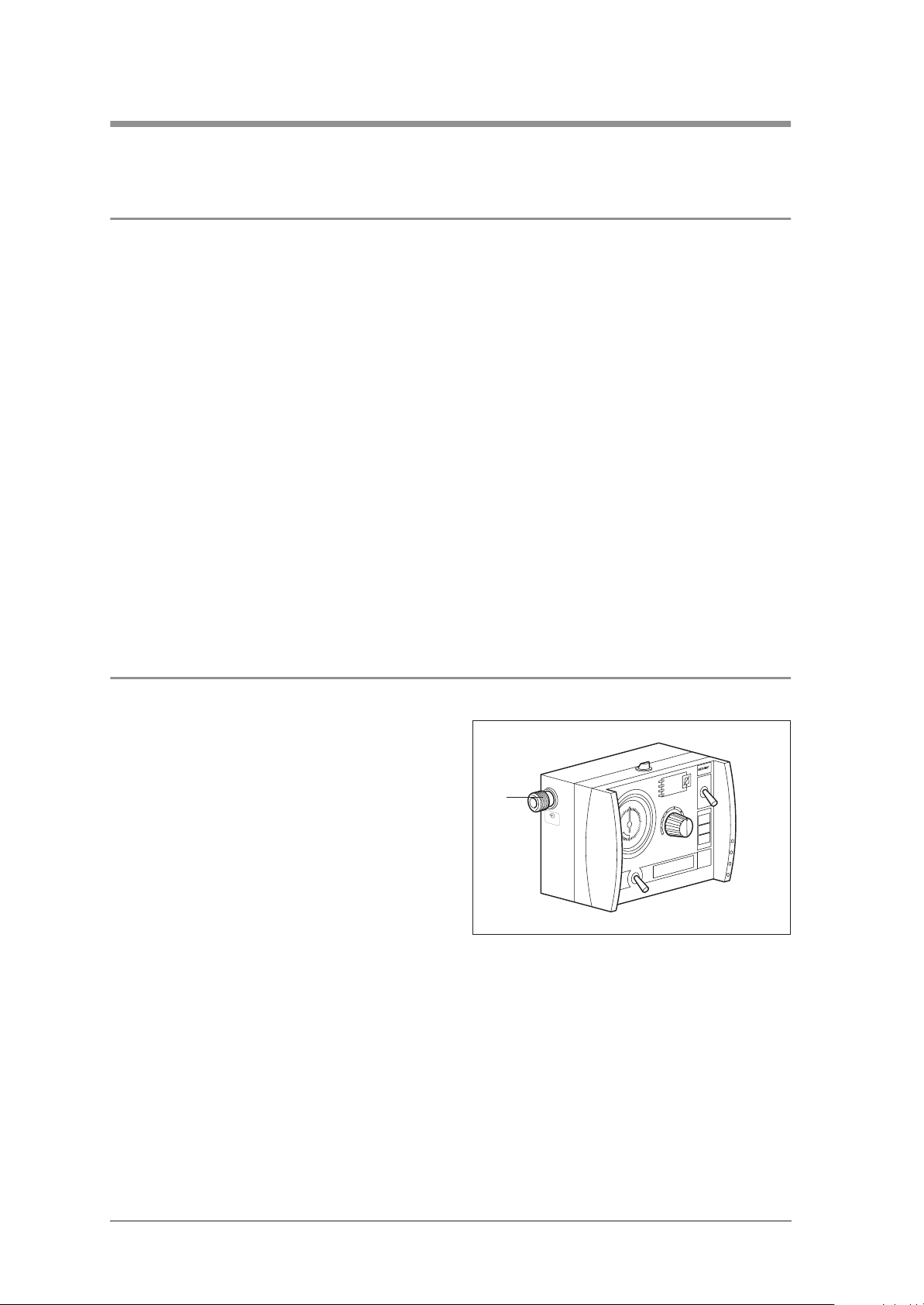

4.3 Adjusting the pressure gauge

In the idle state, with MEDUMAT Basic / Basic p deactivated and the oxygen cylinder closed, the needle of

the pressure gauge must point precisely to “0”.

To adjust the needle, proceed as follows:

1. Carefully lever out the plastic cover of the adjusting screw.

2. Adjust the needle with the adjusting screw

using a small screwdriver.

3. Re-insert the plastic cover.

Adjusting screw

16 Servicing

Page 17

4.4 Storage

If you are not intending to use MEDUMAT Basic / Basic p for a long period, we recommend the following

storage precautions:

1. Clean and disinfect the ventilator (see

“5. Hygienic preparation” of the description

and operating instructions for MEDUMAT).

2. Store MEDUMAT Basic / Basic p in a dry

place.

4.5 Disposal

Do not dispose of the unit with domestic waste. For proper waste disposal of the equipment, please

contact an approved and certified waste disposal site for electronic goods. Ask your Environmental

Officer or town council for the address.

Important note!

Remember that the ventilator still requires servicing

at the stipulated intervals even when in storage,

otherwise it cannot be used when removed from

storage.

Servicing 17

Page 18

5. Troubleshooting

Defect Cause of defect Elimination

Battery failure

Fuse is defective

MEDUMAT Basic / Basic p

Basic, Basic p cannot be

switched on

Ribbon cable to front membrane

faulty or not connected

On/Off switch faulty

Circuit board faulty

Replace both batteries

(chap. 6.6, page 23)

Replace the fuse (chap. 6.7,

page 24)

Check plug-in connectors X7 and

cable (chap. 6.12, page 29);

If necessary replace top of housing

(chap. 6.18, page 39)

If necessary replace top of housing

(chap. 6.18, page 39)

Replace circuit board (chap. 6.12,

page 29)

MEDUMAT Basic / Basic p

Basic, Basic p cannot be

switched off

MEDUMAT Basic / Basic p

Basic, Basic p is functioning

but without any displays

MV too high

MEDUMAT Basic / Basic p

Basic, Basic p:

MV not correct

MEDUMAT Basic / Basic p

Basic only:

MV not correct

User error

On/Off switch 8 faulty

Pressure gauge hose on

MEDUMAT Basic / Basic p Basic,

Basic p or on patient valve slipped

off

Kink in pressure gauge hose

Measured without 10 mbar

counterpressure

Measuring device not calibrated Calibrate measuring device

Spindles in pneumatic block out of

adjustment

Inlet pressure > 6 bar Adjust system to below 6 bar

Patient valve not in order

Adjustment knob incorrectly set

Air Mix/No Air Mix switch 4 faulty

Leak in pneumatic block

Keep switch 8 depressed for at least

2 seconds

If necessary replace top of housing

(chap. 6.18, page 39)

Check pressure gauge hose

Set to 10 mbar counterpressure

Replace pneumatic block (chap.

6.14, page 32)

or replace pneumatic block with

angled outlet (chap. 6.15,

page 34)

Check diaphragms and O-ring,

replace if necessary (Chapter 6.8 of

Operating Instructions)

Reset adjustment knob (chap. 6.9,

page 25)

Replace switch (chap. 6.17,

page 38)

Replace pneumatic block (chap.

6.14, page 32)

or replace pneumatic block with

angled outlet (chap. 6.15,

page 34)

18 Troubleshooting

Page 19

Defect Cause of defect Elimination

Incorrect setting selected on device

Pressure gauge not reading “0”

Patient valve not in working order

Patient valve or test bag incorrectly

connected

MV not correct See defect “MV not correct”

Pressure limit (P

) incorrect

max

Tube connections in device faulty

Pressure sensor on circuit board

faulty

Potentiometer for frequency faulty

Pressure measurement connection

blocked

Two-way switch 9 45 mbar/

20 mbar faulty (for

MEDUMAT Basic / Basic p Basic p)

LEDs do not light up

Alarms (visual and acoustic)

faulty

Incorrect indication

(Stenosis/Disconnection)

No alarm (visual + acoustic) Circuit board faulty

Alarm acknowledgement pressed Wait for 30 – 120 s

No acoustic alarm

Alarm sensor faulty

No stenosis alarm Valve unit membrane leaking

Pressure sensor faulty

Alarm < 2,7 bar despite

existence of pressure

Tube connections in device faulty

Make correct setting (Chapter 6.5 of

Operating Instructions)

Adjust (chap. 4.3, page 16) or

replace pressure gauge (chap.

6.13, page 31)

Check diaphragms and O-ring, if

necessary replace (Chapter 6.8 of

Operating Instructions)

Check tube connections and bag

Check tubes and replace if

necessary (chap. 6.14, page 32)

Replace circuit board (chap. 6.12,

page 29)

Replace pneumatic block (chap.

6.14, page 32)

or replace pneumatic block with

angled outlet (chap. 6.15,

page 34)

Replace (chap. 6.10, page 27)

Replace switch (chap. 6.17,

page 38)

Replace top of housing (chap. 6.18,

page 39)

Check settings, check tube

connection to patient valve

(Chapter 6.8 of Operating

Instructions)

Replace circuit board (chap. 6.12,

page 29)

Replace alarm sensor (chap. 6.10,

page 27)

Check that valve membrane is

properly seated

Replace circuit board (chap. 6.12,

page 29)

Check tubes and replace if

necessary (chap. 6.14, page 32)

Alarm Battery failing

Leak at pressure inlet

Elbow connector in device loose or

faulty

Leaks in tubes in device

Replace both batteries (chap. 6.6,

page 23)

Check (chap. 6.19, page 45)

Check tubes and replace if

necessary (chap. 6.14, page 32)

Troubleshooting 19

Page 20

Defect Cause of defect Elimination

Leak in pressure sensor on

circuit board

Air Mix/No Air Mix switch 4

faulty

Leak in pneumatic block

O2 concentration not correct

Frequencies incorrect

Test bag is not sufficiently

inflated during functional

check, disconnection alarm

No stenosis alarm when

patient valve is closed during

functional check, see

“Functional check on tidal

volume” (chap. 3.8,

page 11)

Replace circuit board (chap. 6.12,

page 29)

Replace switch (chap. 6.17,

page 38)

Replace circuit board (chap. 6.14,

page 32)

Measuring device not calibrated Calibrate measuring device

Incorrect measurement sequence Check No Air Mix first, then Air Mix

Air Mix/No Air Mix switch 4 faulty

Replace switch (chap. 6.17,

page 38)

Replace pneumatic block (chap.

6.14, page 32)

Pneumatic block faulty

or replace pneumatic block with

angled outlet (chap. 6.15,

page 34)

Adjustment knob out of adjustment

Reset adjustment knob (chap. 6.9,

page 25)

Replace pneumatic block (chap.

Spindles (MV + frequency in

MEDUMAT Basic / Basic p Basic)

out of adjustment

6.14, page 32)

or replace pneumatic block with

angled outlet (chap. 6.15,

page 34)

Ventilation parameters wrongly

selected

Correct ventilation parameters

Patient valve not working properly Check lip membrane

Pressure gauge hose not fitted Fit pressure gauge hose

Patient valve not working properly Check lip membrane

20 Troubleshooting

Page 21

6. Repair information and repair instructions

6.1 General

Repairs to MEDUMAT Basic / Basic p should be carried out only at an ESD workstation!

• Please follow the safety instructions for

MEDUMAT Basic / Basic p on page 6 of the

description and operating instructions.

• All handling of the device pre-supposes a

precise knowledge of and compliance with

the description and operating instructions and

the service and repair instructions.

• Please carry out only the repairs described in

these service and repair instructions. Otherwise, perfect functioning of the

MEDUMAT Basic / Basic p cannot be guaranteed.

• Please ensure that your hands and workplace

are clean when carrying out repairs.

• After each repair, please perform a functional

check (see “3. Final Check” on page 8).

• When you replace components or individual

parts, please use original Weinmann parts only.

• When ordering the housing base section 28,

please specify the device model, year of construction and device number.

• Note:

The item numbers used in the following text

match the item numbers in the spare parts list

on page 47 and the overview on page 4.

6.2 Replacing the sieve in the compressed gas connection

Tools required:

• Slotted screwdriver,

• Tweezers.

1. Unscrew the slotted screw at the compressed

gas connection 10.

2. Using the tweezers, remove the sieve set 62.

3. Carefully insert a new sieve set 62 into the

compressed gas connection.

4. Screw the slotted screw back into the compressed gas connection.

62

Repair information and repair instructions 21

Page 22

6.3 Changing the foam insert in the pressure relief valve outlet

Tools required:

• Tweezers.

1. Use tweezers to remove foam insert 15.

2. Place a new foam insert 15 in the outlet.

6.4 Opening the device

Tools required:

15

• Crosstip screwdriver, size 2.

1. Carefully place the device on a non-slip surface and unscrew the 6 screw 40 the rear panel of the device.

2. Pull off the housing base section 28 and fold it

away.

3. Next, loosen the connecting tube 46 from the

oxygen inlet by pushed back the sleeve on the

angular bush 29 and pulling out the tube.

40

up to appliance no.:

Basic 1019; Basic p 1399

29

46

28

from appliance no.:

Basic 1020; Basic p 1400

40

22 Repair information and repair instructions

Page 23

6.5 Closing the device

Tools required:

• Crosstip screwdriver, size 2.

1. Push the connecting hose 46 into the angular

bush 29 as far as it will go.

2. Place the housing base section 28 onto the upper housing section.

Take care to ensure that none of the lines are

pinched and that the twistlock 11, the

grommets 39 and the angled outlet or the pressure measurement connection 13 are correctly

seated.

3. Next, secure the housing base section using

the 6 screws 40.

4. Perform a functional check (see “3. Final

Check” on page 8).

28

29

46

11 11

angled outlet

13

39 39

up to appliance no.:

Basic 1019; Basic p 1399

6.6 Changing the batteries

Tools required:

• Crosstip screwdriver, size 2.

1. Open the device (see “6.4 Opening the device” on page 22).

2. The main battery 19 can be removed by lifting

the battery out of its holder and then pulling

connector X1 from the circuit board.

3. To remove the button cell 17, gently lift up the

plus contact and pull the button cell out sideways with your other hand.

4. Insert the new batteries by proceeding in the

reverse order.

Make sure that the wires for the main battery are

not pinched and that the button cell is inserted

with correct polarity!

5. Close the device (see “6.5 Closing the

device” on page 23).

6. Perform a functional check (see “3. Final

Check” on page 8).

40

28

from appliance no.:

Basic 1020; Basic p 1400

40

17

X1

19

Remember that used batteries must not be disposed of with your domestic waste. Used batteries should be

taken to a collection point in your area, or to a specialist dealer.

Repair information and repair instructions 23

Page 24

6.7 Replacing the fuse

Tools required:

• Crosstip screwdriver, size 2.

1. Open the device (see “6.4 Opening the device” on page 22).

2. Pull out the defective fuse 18 upwards.

3. Carefully press a new fuse 18 into the holder.

4. Close the device (see “6.5 Closing the

device” on page 23).

5. Perform a functional check (see “3. Final

Check” on page 8).

6.8 Replacing ventilation control knob

Tools required:

18

• Crosstip screwdriver, size 2,

• L-handled socket wrench 10 mm,

• Special tool WM 22829 from special tool set WM 15349,

• Calibration device WM 22836.

1. Remove the faulty ventilation control knob 5.

To do so, proceed as follows:

– Turn the control knob 35 as far as it will go

to the left, so that you have a reference

point when reassembling later.

– Prise off the cover 34.

– Hold the control knob with the special tool

and undo the nut with a tubular socket span-

ner (10 mm).

– Pull the control knob 35 off.

2. Attach the new control knob 35:

– Push the control knob 35 onto the spindle

almost as far as it will go.

– Turn the knob until the white line points to

the lowest MV value.

– Hold the knob with the special tool and

tighten the nut to secure it.

3. Check the control knob 35 readings: at the left

stop the white line must point to the lowest MV

value, at the right stop it must point to the highest value. If this is not the case, slacken the nut

and align the control knob correctly.

4. Place the cover 34 on the control knob 35.

5. Perform calibration (see “6.9 Calibration after

removal of PCB, ventilation control knob 5

and/or pneumatic block” on page 25).

5

35

34

(Two-way switch only on Basic p)

24 Repair information and repair instructions

Page 25

6.9 Calibration after removal of PCB, ventilation control knob 5 and/or pneumatic block

The ventilation control knob 5 controls an EPROM on the printed circuit board of the MEDUMAT Basic /

Basic p. To ensure correct setting of the minute ventilation, the EPROM must be calibrated after every removal

of the PCB, the control knob 5 or the pneumatic block.

Tools required:

• Crosstip screwdriver, size 2

• Calibration device WM 22836.

1. Remove the back of the housing. To do so:

– Place the device on a non-slip surface and

unscrew the 6 screws 40 from the back of the

device.

– Pull off the lower part of the housing 28 and

swing it out of the way.

up to appliance no.:

Basic 1019; Basic p 1399

2. Now detach the connecting tube 46 from the

oxygen inlet by pushing back the angular

bush 29 and pulling out the tube.

3. Switch the calibration device off at the toggle

switch. The Status LED is not on.

4. Connect the power cord of the calibration

device to connector X6 on the circuit board of

the MEDUMAT Basic / Basic p.

5. Switch on the MEDUMAT Basic / Basic p.

You must hear the valve switch.

6. Switch on the calibration device at the toggle

switch. The Status LED lights up.

7. Press the bottom button Start/Stop on the cal-

ibration device. When it is pressed, all the

LEDs on the calibration device light up.

29

46

40

X6

S

28

40

from appliance no.:

Basic 1020; Basic p 1400

46

p

/

t

ic

a

s

a

m

B

u

6

1

d

a

/

e

5

d

r

M

a

d

n

a

t

0

1

4

1

/

7

1

0

3

Repair information and repair instructions 25

Page 26

8. As soon as you release the Start/Stop button,

communication between the devices is automatically established. While this is happening,

the LEDs 5/16, 17/14 and Start/Stop flash.

Once the Start/Stop LED stay on continuously

and LEDs 5/16 and 17/14 have gone out,

communication is established. The solenoid

valve of the MEDUMAT Basic / Basic p does

not switch any more.

9. Turn the ventilation control knob 5 on

MEDUMAT to the setting MV=5,

frequency=16.

10. Press the middle button on the calibration

device. The corresponding LED 5/16 must

light up.

11. Turn the ventilation control knob 5 on

MEDUMAT to the setting MV=17,

frequency=14.

12. Press the middle button on the calibration

device. The corresponding LED 17/14 must

light up.

13. Press the bottom button Start/Stop on the calibration device. All LEDs except Status go out.

You must hear the solenoid valve of the

MEDUMAT Basic / Basic p switching.

14. Switch off the calibration device at the toggle

switch.

15. Disconnect the calibration device from the

MEDUMAT.

16. Close the device (see “6.5 Closing the

device” on page 23).

17. Perform a functional check (see “3. Final

Check” on page 8).

18. Turn MEDUMAT Basic / Basic p off.

26 Repair information and repair instructions

Page 27

6.10 Replacing the alarm signalling device

Tools required:

• Crosstip screwdriver, size 2,

• Crosstip screwdriver, size 1.

1. Open the device (see “6.4 Opening the

device” on page 22).

2. Up to appliance no.: Basic 1019; Basic p 1399

Pull the pressure measurement connection 13

upwards out of the housing wall.

3. Pull the connector X5 from the circuit board.

42

4. Unscrew both screws 42.

5. Remove the defective alarm signalling

23

device 23.

6. Insert the new alarm signalling device 23.

7. Secure the alarm signalling device using the

two screws 42.

up to appliance no.:

Basic 1019; Basic p 1399

8. Push the connector X5 onto the contacts on the

circuit board.

9. Up to appliance no.: Basic 1019; Basic p 1399

Push the pressure measurement connection 13

42

into the wall of the housing.

10. Close the device (see “6.5 Closing the

device” on page 23).

23

11. Perform a functional check (see “3. Final

Check” on page 8).

from appliance no.:

Basic 1020; Basic p 1400

13

X5

X5

Repair information and repair instructions 27

Page 28

6.11 Replacing two-way switch for maximum ventilation pressure (MEDUMAT Basic / Basic p Basic p only)

Tools required:

• Crosstip screwdriver, size 2,

• Special socket spanner SW8 WM 22826.

1. Open the device (see “6.4 Opening the

device” on page 22).

2. The main battery 19 can be removed by lifting

the battery out of its holder and then pulling

connector X1 from the circuit board.

Pull on the connector only, not on the lead!

3. Turn the MEDUMAT Basic / Basic p round.

4. Unscrew the cap 27 from the two-way switch 9.

5. Unscrew the nut with the special socket spanner.

X1

19

6. Detach connector X3 from the PCB.

7. Remove the toggle switch 26.

8. Insert a new toggle switch 26 so that the red

wire points to the wall of the housing. This is the

only way to guarantee that the switch toggles

correctly.

9. Turn the MEDUMAT around and secure the

toggle switch firmly by tightening the nut.

10. Push the connector X3 onto the PCB contacts.

11. Connect the battery connector X1 to the PCB

and place the battery 19 in its holder.

12. Close the device (see “6.5 Closing the

device” on page 23).

13. Turn the MEDUMAT Basic / Basic p round.

14. Screw the cap 27 onto the toggle switch.

15. Perform a functional check (see “3. Final

Check” on page 8).

27 9

X1

19X326

27

28 Repair information and repair instructions

Page 29

6.12 Replacing the circuit board

Tools required:

• Crosstip screwdriver, size 2,

• Side nippers,

• Cable tie,

• Calibration device WM 22836.

1. Open the device (see “6.4 Opening the

device” on page 22).

2. Remove the battery 19 by lifting it out of its

holder and then pulling connector X1 from the

circuit board.

Only pull on the connector, not on the lead!

3. Pull connectors X2, X5, X4 (and also connector

X3 in Basic p) from the circuit board.

4. Release the flat cable from the locking

device X7: To do so, pull the upper part of the

locking device upwards. You can then pull out

the cable.

5. Carefully pull the tube 52 from the sensor B2.

6. Using side nippers, cut through the cable

tie 53 at the tube 47.

X7

X2

X5

X4

X1

19

X3

(Basic p only)

7. Carefully pull the tube 47 from the sensor B1.

If the tube cannot be pulled off, you may cut

through it (e.g. using a scalpel).

In such cases, the tube must be replaced (as

explained in step 9.

8. Unscrew the two screws 41 and remove the

defective circuit board 22.

9. If you have cut through the tube 47 under

point 7., please replace it as follows:

– Using side nippers, cut through the cable

tie 53 at the distributor.

– Pull off the tube.

– Slide a new tube 47 onto the distributor and

secure with a cable tie.

B252 47 B153

22

41

53

(Basic p only)

47

Repair information and repair instructions 29

Page 30

10. Replace the alarm signalling device (see

“6.10 Replacing the alarm signalling device”

on page 27).

11. Place the new circuit board 22 onto the spacer

brackets. The points of the spacer brackets

snap into the circuit board.

Make sure that no leads are beneath the circuit

board, where they may be pinched.

12. Secure the circuit board with the two short

screws 41.

13. Slide the tube 52 onto the sensor B2.

14. Slide the tube 47 onto the sensor B1 and secure it there with a cable tie.

15. Push the connectors X2, X5, X4 (and also connector X3 in the Basic p) onto the contacts of

the circuit board.

16. Connect the connector X1 of the battery to the

circuit board and insert the battery 19 into the

holder. Avoid pinching the battery cables.

17. Place the flat cable into the locking device X7:

To do so, pull the upper part of the locking

mechanism upwards, slide the cable into it,

and press the upper part down again.

18. Perform calibration (see “6.9 Calibration after

removal of PCB, ventilation control knob 5

and/or pneumatic block” on page 25).

19. Close the device (see “6.5 Closing the

device” on page 23).

20. Perform a functional check (see “3. Final

Check” on page 8).

X7

X2

X5

X4

52 47

X1

19

X3

(Basic p only)

30 Repair information and repair instructions

Page 31

6.13 Replacing the pressure gauge

Note: The pressure gauge is identical to the respiratory pressure meter described in the instructions for use.

Tools required:

• Crosstip screwdriver, size 2,

• Open-ended spanner SW 7,

• If necessary, side nippers,

• If necessary, cable tie.

1. Open the device (see “6.4 Opening the

device” on page 22).

2. Unscrew the circuit board (see „6.12 Replacing

the circuit board“ on page 29, steps 2. to 9.).

The tubes 52 and 47 may be left on the circuit

board.

3. Release the pressure gauge tube 51 by

pushing back the sleeve of the swivel screw

connection 33 and pulling out the tube.

51

33

4. Using an open-ended spanner (SW 7),

unscrew the swivel screw connection 33 from

the pressure gauge 1.

5. Using your fingers, press the pressure gauge 1

out of its holder.

Tip:

You will find the pressure gauge easier to remove

if you dribble a small amount of spirit between

the pressure gauge and the holder.

6. Wet a new pressure gauge 1 with a small

amount of spirit and press it into the holder.

Take care to install the gauge in the right position,

so that it is easy to read.

7. Screw the swivel screw connection 33 onto the

pressure gauge.

8. Push the pressure gauge tube 51 into the angular bush as far as it will go.

9. Secure the circuit board (see „6.12 Replacing

the circuit board“ on page 29, steps 11. to

18.).

10. Close the device (see “6.5 Closing the

device” on page 23).

11. Perform a functional check (see “3. Final

Check” on page 8).

1

51

(only

Basic p)

47

52

Repair information and repair instructions 31

Page 32

6.14 Replacing the pneumatic block

Tools required:

• Crosstip screwdriver, size 2,

• L-handled socket wrench 10 mm,

• Special tool WM 22829 from special tool set WM 15349,

• If necessary, side nippers,

• If necessary, cable tie,

• Calibration device WM 22836.

1. Remove the ventilation control knob 5. To do

so, proceed as follows:

– Turn the control knob 35 as far as it will go

to the left, so that you have a reference

point when reassembling later.

– Lift off the lid 34.

– Using the special tool, hold the control knob

steady and loosen the nuts with an L-handled

socket wrench (10 mm).

– Pull off the control knob 35.

2. Open the device (see “6.4 Opening the

device” on page 22).

5

35

34

(Two-way switch only on Basic p)

3. Unscrew the circuit board (see „6.12 Replacing

the circuit board“ on page 29, steps 2. to 9.).

You can leave the pressure measurement tube 47

attached to the circuit board.

4. Release the pressure tube 48 by pushing back

the sleeve of the inlet and pulling out the tube.

5. Pull the ventilation tube 45 from the pneumatic

block 24.

6. Pull the suction connector 43 from the pneumatic block 24.

7. Carefully pull the defective pneumatic block

upwards out of the housing.

8. Pull off the two grommets 39.

9. Take a new pneumatic block 24 and push the

grommets written side first onto the connection 12

and the valve 14.

39

39

43

48

(Basic p

only)

Pressure

measurement tubes

45+54

12

14

32 Repair information and repair instructions

Page 33

10. Insert the new pneumatic block into the

housing.

Make sure,

– That you push the rocker and the spindle

through the corresponding holes in the housing

– That no tubes or leads are underneath the

pneumatic block where they may be

pinched

– That the grommets are positioned correctly

in the housing wall (the housing wall must

be in the groove)

– That the pneumatic block is resting on the

four rubber buffers.

11. Slide the suction connector 43 and the ventilation tube 45 with the spring 54 onto the corresponding connections on the pneumatic

block 24 as far as they will go.

12. Slide the pressure tube 48 into the inlet of the

pneumatic block as far as it will go.

48

(Basic p

only)

13. Secure the circuit board (see „6.12 Replacing

the circuit board“ on page 29, steps 11. to

17.).

14. Turn the MEDUMAT Basic / Basic p round.

15. Attach the control knob 35. To do so, proceed

as follows:

– Slide the control knob 35 onto the spindle

as far as it will go.

– Turn the knob until the white line points to

the lowest value.

– Hold the knob steady with the special tool

and screw it down.

16. Check the display on the control knob 35:

when the knob is turned to the left stop the

white line must point to the lowest MV value,

when it is turned to the right stop the line must

point to the highest value. If this is not the case,

loosen the nuts and align the control knob 35.

17. Perform calibration (see “6.9 Calibration after re-

moval of PCB, ventilation control knob 5 and/or

pneumatic block” on page 25).

18. Close the device (see “6.5 Closing the

device” on page 23).

19. Turn the MEDUMAT Basic / Basic p round.

43 45+54

35

(Two-way switch only in Basic p)

Repair information and repair instructions 33

Page 34

20. Place the lid 34 on the knob 35.

21. Perform a functional check (see “3. Final

Check” on page 8).

35

5

34

(Two-way switch only on Basic p)

6.15 Replacing the pneumatic block with angled outlet

The pneumatic block with angled outlet is fitted as standard to MEDUMAT Basic / Basic p Basic from appliance No. 1020 and to MEDUMAT Basic / Basic p Basic p from appliance No. 1400 onward. Old

appliances should be converted not later than the 6-year service.

Tools required:

• Crosstip screwdriver, size 2,

• L-handled socket wrench 10 mm,

• Special tool WM 22829 from special tool set WM 15349,

• If necessary, side nippers,

• If necessary, cable tie,

• Special pliers WM 22928,

• Calibration device WM 22836.

1. Remove the ventilation control knob 5. To do

so, proceed as follows:

– Turn the control knob 35 as far as it will go

to the left, so that you have a reference

point when reassembling later.

– Lift off the lid 34.

– Using the special tool, hold the control knob

steady and loosen the nuts with an L-han-

dled socket wrench (10 mm).

– Pull off the control knob 35.

2. Open the device (see “6.4 Opening the

device” on page 22).

3. Unscrew the circuit board (see „6.12 Replacing

the circuit board“ on page 29, steps 2. to 9.).

You can leave the pressure measurement tube 47

attached to the circuit board.

35

5

34

(Two-way switch only on Basic p)

34 Repair information and repair instructions

47

Page 35

4. Pull the ventilation tube 45 from the pneumatic

block 24.

5. Pull the suction connector 43 from the pneumatic block 24.

6. Release the pressure tube 48 by pushing back

the sleeve of the inlet and pulling out the tube.

7. For devices with an angled connector:

Detach pressure measurement tube 50 from the

tube connector on pneumatic block 24.

8. Carefully pull the defective/old pneumatic

block upwards out of the housing.

9. Pull off the grommet 39 from the pneumatic

block 24.

For conversion of appliances up to No. 1019

(Basic) or 1399 (Basic p): go to step 10..

For replacement in appliances from No. 1020

(Basic) or 1400 (Basic p) onward: go to step 13..

10. Remove connection 13 for the pressure measurement tube from the upper part of the housing.

24

50

39

13

43

48

(Basic p

only)

Pressure

measurement tubes

45+54

11. Pull tube 49 off the T-piece and replace it with

the new tube 50 (use WM 22967!).

12. Route the tube so that it is below the valve insert locator and the alarm unit 23 and run it

along the inside wall of the housing.

13. Take a new or replacement pneumatic

block 24 and push the grommet 39 written side

first onto the valve 14.

14. Insert the new pneumatic block into the

housing and push tube 50 onto the pneumatic

block.

49

up to appliance no.:

Basic 1019; Basic p 1399

50

23

39

24

14

Repair information and repair instructions 35

Page 36

15. Now take the swivelling angled connector

and push it onto the connector of the pneumatic block. To fit the swivelling angled connector

properly into the upper housing section, lift the

pneumatic block slightly and push it over the

outer wall of the housing.

Make sure,

– That you push the rocker and the spindle

through the corresponding holes in the

housing

– That no tubes or leads are underneath the

pneumatic block where they may be

pinched

– That the grommet is positioned correctly in

the housing wall (the housing wall must be

in the groove)

– That the pneumatic block is resting on the

four rubber buffers.

For conversion: go to step 16..

For replacement: go to step 18..

16. Where present: If you have a device that you

have converted to a swivelling angled connector, you must insert sealing plug WM 22809

with O-ring 5-1.2 WM 1145/90 into the upper part of the housing where the pressure sensor tube was previously fitted.

17. Remove the “Sensor” plate from the housing.

18. Slide the suction connector 43 and the ventilation tube 45 with the spring 54 onto the corresponding connections on the pneumatic

block 24 as far as they will go.

19. Slide the pressure tube 48 into the inlet of the

pneumatic block as far as it will go.

20. Secure the circuit board (see „6.12 Replacing

the circuit board“ on page 29, steps 11. to

17.).

43

48

(Basic p

only)

45+54

21. Slide the tube 52 onto the sensor B2.

22. Turn the MEDUMAT Basic / Basic p round.

36 Repair information and repair instructions

B252 47

Page 37

23. Attach the control knob 35. To do so, proceed

as follows:

– Slide the control knob 35 onto the spindle

as far as it will go.

– Turn the knob until the white line points to

the lowest value.

– Hold the knob steady with the special tool

and screw it down.

24. Check the display on the control knob 35:

when the knob is turned to the left stop the

white line must point to the lowest MV value,

when it is turned to the right stop the line must

point to the highest value. If this is not the case,

loosen the nuts and align the control knob 35.

25. Perform calibration (see “6.9 Calibration after re-

moval of PCB, ventilation control knob 5 and/or

pneumatic block” on page 25).

26. Close the device (see “6.5 Closing the

device” on page 23).

27. Turn the MEDUMAT Basic / Basic p round.

28. Place the lid 34 on the knob 35.

29. Perform a functional check (see “3. Final

Check” on page 8).

35

5

34

(Two-way switch only on Basic p)

6.16 Replace 3/2 solenoid valve

Tools required:

• Crosstip screwdriver, size 2,

• 10 mm socket wrench,

• Special tool WM 22829 from set WM 15349

• If necessary, side nippers

• If necessary, cable tie

• Special pliers WM 22928

• Calibration device WM 22836

• Crosstip screwdriver, size 0

1. Open the device (see “6.4 Opening the

device” on page 22).

2. Remove the pneumatic block (see “6.15 Replacing the pneumatic block with

angled outlet” on page 34).

Repair information and repair instructions 37

Page 38

3. Undo the two mounting screws and remove

3/2 solenoid valve 64.

4. Replace the seal. Ensure that the seal is positioned correctly.

5. Screw new 3/2 solenoid valve 64 tight.

6. Refit the pneumatic block (see “6.15 Replacing the pneumatic block with angled outlet” on

page 34).

7. Close the device (see “6.5 Closing the

device” on page 23).

8. Perform a functional check (see “3. Final

Check” on page 8).

6.17 Changing the Air Mix/No Air Mix switch

Tools required:

• Crosstip screwdriver, size 2,

• L-handled socket wrench 10 mm,

• Open-ended spanner SW 17,

• Special tool WM 22829 from special tool set WM 15349,

64

• If necessary, side nippers,

• If necessary, cable tie,

• Vice with protective jaws,

• Calibration device WM 22836.

1. Up to appliance no. 1019 (Basic) or 1399

(Basic p):

Remove the pneumatic block from the housing

(see „6.14 Replacing the pneumatic block“ on

page 32, steps 1. to 7.).

From appliance no. 1020 (Basic) or 1400

(Basic p):

Remove the pneumatic block from the housing

(see „6.15 Replacing the pneumatic block with

angled outlet“ on page 34, steps 1. to 8.).

2. Clamp the pneumatic block in a vice with protective jaws.

3. Unscrew the rocker using an open-ended

spanner (SW 17).

4. Screw in a new rocker 25 with the seal.

Take care to ensure the correct installation

position:

The rocker must drop automatically into its end

position. It must not become stuck in an intermediate position.

25

38 Repair information and repair instructions

Page 39

Note:

The rocker will tend to drop into the lower

position.

5. Up to appliance no. 1019 (Basic) or 1399

(Basic p):

Re-install the pneumatic block (see „6.14 Replacing the pneumatic block“ on page 32,

steps 10. to 20.).

From appliance no. 1020 (Basic) or 1400

(Basic p):

Re-install the pneumatic block (see „6.15 Replacing the pneumatic block with

angled outlet“ on page 34, steps 14. to 28.).

6. Perform a functional check (see “3. Final

Check” on page 8).

6.18 Replace upper part of housing/control panel

Tools required:

• Crosstip screwdriver, size 2,

• Crosstip screwdriver, size 1,

• L-handled socket wrench 10 mm,

• Special tool WM 22829 from special tool set WM 15349,

• Special socket spanner 8 mm WM 22826,

• Flat nose pliers,

• Side nippers,

• Cable tie,

• Calibration device WM 22836.

Remove upper part of housing

1. Remove the ventilation control knob 5. Please

proceed as follows:

– Twist the control knob 35 to the left limit so

that you have a reference point when you

come to re-assemble it.

– Lift off the lid 34.

– Using the special tool, hold the control knob

steady and loosen the nuts with an L-han-

dled socket wrench (10 mm).

– Pull off the control knob 35.

2. Basic p only:

– Unscrew the cap 27 from the two-way

switch 9.

– Unscrew the nut with the special socket

spanner.

35

5

34

(Two-way switch only on Basic p)

27 9

Repair information and repair instructions 39

Page 40

3. Open the device (see “6.4 Opening the

device” on page 22).

4. Remove the circuit board (see „6.12 Replacing the circuit board“ on page 29, steps 2. to

9.).

The pressure measuring tube 47 may be left on

the circuit board.

5. Basic p only: remove the toggle switch 26.

6. Pull the ventilation tube 45 with the spring 54

from the pneumatic block 24 and the filter holder.

7. Pull the suction connector 43 from the pneumatic block 24 and the filter holder.

8. Release the pressure tube 48 by pushing back

the sleeve of the inlet and pulling out the tube.

48

26

(Basic p

only)

47

9. Carefully pull the pneumatic block upwards

out of the housing.

10. For devices with an angled connector:

Detach pressure measurement tube 50 from the

tube connector on pneumatic block 24.

11. Release the pressure gauge tube 51 by

pushing back the sleeve of the swivel screw

connection 33 and pulling out the tube.

12. Using your fingers, press the pressure gauge 1

out of the pressure gauge holder.

Tip:

You will find the pressure gauge easier to remove

if you dribble a small amount of spirit between

the pressure gauge and the holder.

13. Press the pressure gauge holder out of the

housing.

14. Take locking latch 11 out of the housing wall.

15. For conversion up to appliance No. 1019 (Basic)

or 1399 (Basic p):

Pull the pressure measurement connection 13

upwards out of the housing wall.

16. Unscrew both the screws 42 and remove the

alarm signalling device 23.

Filter holder

up to appliance no.:

Basic 1019; Basic p 1399

24

50

Filter holder

from appliance no.:

Basic 1020; Basic p 1400

11

43 45+54

43 45+54

234213

48

26

(Basic p

only)

47

51

33

1

40 Repair information and repair instructions

Page 41

17. For conversion up to appliance No. 1019 (Basic)

or 1399 (Basic p):

The pressure measuring tube 49 is secured to

the housing with a cable tie. Cut through the

cable tie with side nippers and remove the

tube or pull the tube off upwards the housing

with the cable tie.

up to appliance no.:

Basic 1019; Basic p 1399

49

18. Remove the filter insert:

– Pull the filter cap 55 out of the housing wall.

– Using a screwdriver, press out the pin 61.

– Take the valve insert 57 out of the recepta-

cle in the housing e.g. by tilting it with a

small screwdriver then pulling it out with flat

nose pliers.

19. Finally, remove the four rubber buffers 38.

from appliance no.:

Basic 1020; Basic p 1400

61

55

57

50

21

If you are not replacing the control panel, continue

at “Fit upper part of housing“.

Replace control panel

1. Remove upper part of housing (see above).

2. Push a screwdriver against the metal panel

from the inside until control panel 65 comes

loose.

3. Remove adhesive residues completely from the

upper part of the housing.

38

65

Repair information and repair instructions 41

Page 42

4. Pass the ribbon cable of new control panel 65

through the slot in the upper part of the housing

and glue on control panel 65.

p

ic

Bas

Fit upper part of housing

1. If your MEDUMAT Basic / Basic p is not to be

updated (straight connection on pneumatic

block), you will first have to file away a semicircle for the pressure measurement

connection 13.

2. Push the pressure gauge mounting 21 into the

new upper housing section 20.

3. Wet the rubber buffers 38 with a little spirit and

insert them.

4. Install the filter insert:

– Insert O-ring 60 in the corresponding

groove in the valve insert.

– Check that the membrane 59 is lying flush

and smooth against the valve insert 57.

– Press the valve insert, membrane first, into

the filter holder.

After installing, make sure that the valve insert

is lying straight in the holder.

– Take the pin 61 in your hand. The pin has a

notched side and a smooth side. Press the

pin with the smooth side forwards into the

small hole on the top of the filter holder until

it is flush with the holder. The pin holds the

valve insert in position.

– Push the filter cap 55 into the housing wall.

5. Wet the pressure gauge 1 with a small amount

of spirit and press it into the holder.

Observe the installation position so that the display remains clearly legible.

6. Push the pressure gauge tube 51 into the swivel screw connection 33 as far as it will go.

7. Place the pressure gauge tube 51 and the

pressure measuring tube 49/50 into the housing as illustrated.

8. For conversion up to appliance No. 1019 (Basic)

or 1399 (Basic p):

Secure the pressure measuring tube 49 to the

middle spacer with a cable tie.

up to appliance no.:

Basic 1019; Basic p 1399

11

O/I

65

61

59

57

60

55

51

33

1

9. Push locking latch 11 into the housing wall.

Remember that the slanted surface needs to be

pointing towards the device base later.

42 Repair information and repair instructions

49 Middle spacer

Page 43

from appliance no.:

Basic 1020; Basic p 1400

11

50

51

33

1

10. Basic p only:

– Insert the toggle switch 26 so that the red

wire points to the wall of the housing. This is

the only way to ensure the switch toggles

correctly.

– Turn the MEDUMAT round and secure the

toggle switch by tightening the nut.

11. Insert the alarm signalling device 23 and secure it with the screws 42.

12. For conversion up to appliance No. 1019 (Basic)

or 1399 (Basic p):

Push the connection 13 into the housing wall.

13. Insert the new pneumatic block 24 into the

housing.

Make sure that

– the connector X2 (on the long cable) is be-

side the connection 12.

– you push the rocker and the spindle through

the corresponding holes in the housing.

– no tubes or leads are underneath the pneu-

matic block where they may be pinched.

– the grommet 39 is positioned correctly in the

housing wall (the housing wall must be in

the groove).

– the pneumatic block is resting on the four

rubber buffers.

from appliance no.:

Basic 1020; Basic p 1400

up to appliance no.:

Basic 1019; Basic p 1399

24

X2

12

39

26

(Basic p only)2342

26

(Basic p only)234213

Repair information and repair instructions 43

Page 44

14. Make the tube connections:

– Push the suction connector 43 onto the rear

nozzle of the filter holder and onto the connection on the pneumatic block 24.

– Using the ventilation tube 45 with the

spring 54, connect the front nozzle of the filter holder to the pneumatic block 24.

– Make sure that all the tube ends are pushed

on to the limits.

15. Slide the pressure tube 48 into the inlet of the

pneumatic block as far as it will go.

16. Slide pressure measurement tube 50 onto the

tube connection of the angled outlet.

17. Secure the circuit board (see „6.12 Replacing

the circuit board“ on page 29, steps 11. to

17.).

18. Turn the MEDUMAT Basic / Basic p round.

19. Secure the ventilation control knob 5. Please

proceed as follows:

– Push the control knob 35 onto the spindle

just short of the limit.

– Twist the knob until the white line is pointing

to the lowest value.

– Hold the knob steady with the special tool

and screw it down.

20. Check the display on the control knob 35:

when turned to the left stop, the white line must

point to the lowest MV value.

If this is not the case, loosen the nuts and align

the control knob 35.

21. Perform calibration (see “6.9 Calibration after re-

moval of PCB, ventilation control knob 5 and/or

pneumatic block” on page 25).

22. Close the device (see “6.5 Closing the

device” on page 23).

23. Place the lid 34 on the knob 5.

24. Basic p only:

Carefully screw the cover 27 onto the two-way

switch 9.

25. Perform a functional check (see “3. Final

Check” on page 8).

48

50

43 45+54Filter holder

35

(Two-way switch only in Basic p)

35

5

34

52

44 Repair information and repair instructions

(Two-way switch only on Basic p)

Page 45

6.19 Replacing the housing base section

Tools required:

• Crosstip screwdriver, size 2,

• Open-ended spanner SW 13,

• Open-ended spanner SW 22,

• Special locknut tool G 3/8 WM 22827 and special spanner SW 17 WM 22828 from the special

tool set WM 15349,

• Vice with protective jaws.

1. Open the device (see “6.4 Opening the

device” on page 22).

2. Screw the special locknut tool onto the compressed gas connection 10.

3. Clamp the special locknut tool in a vice.

4. Tighten the nuts of the special locknut tool

against the pressure connection using an

open-ended spanner (SW 22).

5. Unscrew the angular bush 29 using an openended spanner (SW 13).

6. Using the special spanner (SW 17), loosen the

nut 30 and unscrew it.

7. Pull out the plate 31 upwards.

8. Remove the housing base section 28.

9. Remove rubber buffer 37 from the old device.

10. Place a new housing base section 28 on the

compressed gas connection 10.

11. Slide the plate 31 on the inside of the housing

onto the connection.

12. Tighten the nut 30 on the inside of the

connection.