Wavetek 395 User Manual

This area cut out to form a window

USER’S HANDBOOK

Model 395

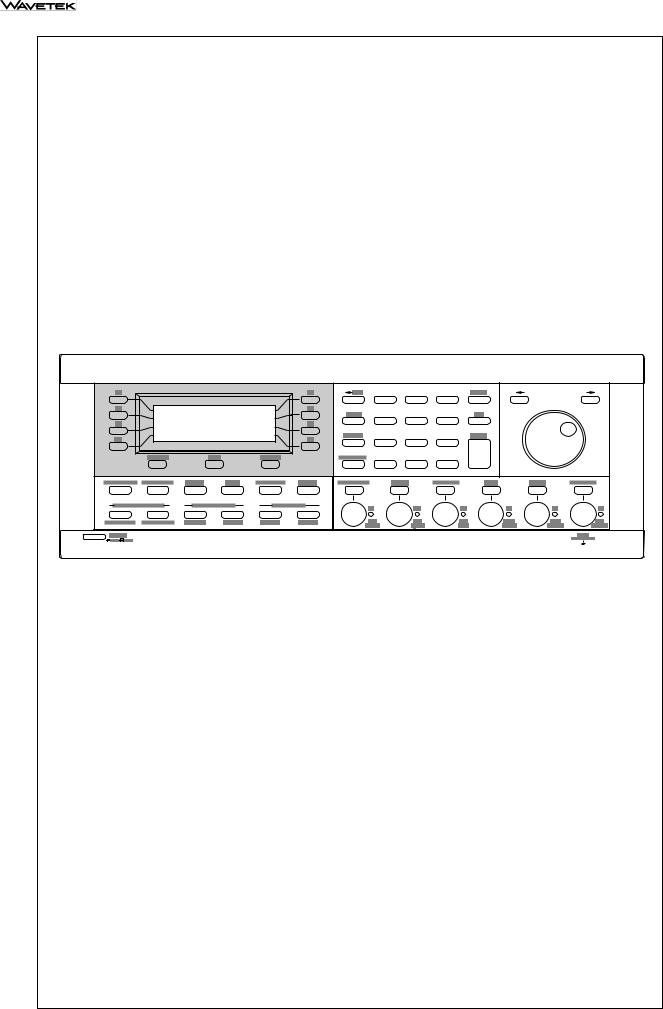

100 MHz Synthesized

Arbitrary Waveform Generator

USER'S HANDBOOK

for

THE MODEL 395

100MHz Synthesized

Arbitrary Waveform Generator

Part no. 850325 |

Issue 1.0 (April 2000) |

ISO 9002

CERTIFICATE

No. FM 29700

For any assistance contact your nearest Wavetek-Datron Sales and Service Center. Addresses can be found at the back of this handbook.

© 2000 Fluke Precision Measurement Ltd.

is a registered trademark of Fluke Precision Measurement Ltd.

is a registered trademark of Fluke Precision Measurement Ltd.

WARRANTY

Wavetek-Datron warrants that all products manufactured by Wavetek-Datron conform to published Wavetek-Datron specifications and are free from defects in materials and workmanship for a period of one (1) year from the date of delivery when used under normal operating conditions and within the service conditions for which they were furnished.

The obligation of Wavetek-Datron arising from a Warranty claim shall be limited to repairing, or at its option, replacing without charge, any product which in Wavetek-Datron’s sole opinion proves to be defective within the scope of the Warranty. In the event Wavetek-Datron is not able to modify, repair or replace non-conforming defective parts or components to a condition as warranted within a reasonable time after receipt thereof, Buyers shall be credited for their value at the original purchase price.

Wavetek-Datron must be notified in writing of the defect or nonconformity within the Warranty period and the affected product returned to Wavetek-Datron’s factory or to an authorized service center within thirty (30) days after discovery of such defect or nonconformity.

For product warranties requiring return to Wavetek-Datron, products must be returned to a service facility designated by Wavetek-Datron. Buyer shall prepay shipping charges, taxes, duties and insurance for products returned to WavetekDatron for warranty service. Except for products returned to Buyer from another country, Wavetek-Datron shall pay for return of products to Buyer.

Wavetek-Datron shall have no responsibility hereunder for any defect or damage caused by improper storage, improper installation, unauthorized modification, misuse, neglect, inadequate maintenance, accident or for any product which has been repaired or altered by anyone other than Wavetek-Datron or its authorized representative and not in accordance with instructions furnished by Wavetek-Datron.

Exclusion of Other Warranties

The Warranty described above is Buyer’s sole and exclusive remedy and no other warranty, whether written or oral, is expressed or implied. Wavetek-Datron specifically disclaims the implied warranties of merchantability and fitness for a particular purpose. No statement, representation, agreement, or understanding, oral or written, made by an agent, distributor, representative, or employee of Wavetek-Datron, which is not contained in the foregoing Warranty will be binding upon Wavetek-Datron, unless made in writing and executed by an authorized WavetekDatron employee. Under no circumstances shall Wavetek-Datron be liable for any direct, indirect, special, incidental, or consequential damages, expenses, losses or delays (including loss of profits) based on contact, tort, or any other legal theory.

EC Declaration of Conformity

WE:

Wavetek-Datron

Hurricane Way

Norwich, NR6 6JB

United Kingdom

Declare under sole responsibility that the

Model 395 100MHz Synthesized Arbitary Waveform Generator

meets the intent of Directive 89/336/EEC for Electromagnetic Compatibility and Low Voltage Directive 72/23/EEC for Product Safety. Compliance was demonstrated to the following specifications as listed in the Official Journal of the European Communities:

EMC Directive 89/336/EEC (rev 91/263/EEC. 92/31/EEC. 93/68/EEC):

EN 50081 - 1 Emissions:

EN 55011/22 Class A radiated and conducted emissions

EN 50082 - 1 Immunity:

IEC 801 - 2 Electrostatic discharge immunity

IEC 801 - 3 RF electromagnetic field immunity

IEC 801 - 4 Electrical fast transient / burst immunity

IEC 801 - 5 Power line surge immunity

Low Voltage Directive 73/23/EEC (rev 93/68/EEC):

EN 61010 - I |

Safety requirements for electrical equipment for measurement, |

|

control and laboratory use. |

Contents

SAFETY ISSUES

READ THIS ENTIRE SECTION THOROUGHLY BEFORE ATTEMPTING TO INSTALL, OPERATE OR SERVICE THE MODEL 395 100MHz SYNTHESIZED ARBITRARY WAVEFORM GENERATOR ix

Section 1 |

Introduction |

|

|

1.1 |

THE MODEL 395................................................................................... |

1-1 |

|

1.2 |

ORGANIZATION OF THIS MANUAL.................................................... |

1-2 |

|

Section 2 |

Initial Preparation |

|

|

2.1 |

THIS SECTION...................................................................................... |

2-1 |

|

2.2 |

RECEIVING AND INSPECTING SHIPMENTS..................................... |

2-1 |

|

2.3 |

RETURNING EQUIPMENT FOR REPAIR............................................ |

2-1 |

|

2.4 |

PREPARATION FOR STORAGE OR SHIPMENT ............................... |

2-2 |

|

2.5 |

LINE VOLTAGES AND FUSES ............................................................ |

2-2 |

|

2.6 |

INITIAL TURN–ON ................................................................................ |

2-4 |

|

2.7 |

ERROR MESSAGES ............................................................................ |

2-5 |

|

2.8 |

FUNCTIONAL CHECKOUT .................................................................. |

2-5 |

|

|

Continuous Mode Check........................................................................ |

2-5 |

|

|

Sweep Mode Check ............................................................................... |

2-5 |

|

|

Gated Mode Check ................................................................................ |

2-5 |

|

|

Triggered Mode Check........................................................................... |

2-6 |

|

2.9 |

OPERATOR MAINTENANCE ............................................................... |

2-6 |

|

|

2.9.1 |

Routine Maintenance ................................................................... |

2-6 |

|

2.9.2 |

Battery Replacement ................................................................... |

2-7 |

2.10 RACK MOUNTING EARS ................................................................... |

2-7 |

||

2.11 REMOTE SETUP ................................................................................ |

2-7 |

||

|

2.11.1 RS-232 ....................................................................................... |

2-7 |

|

|

2.11.2 |

IEEE-488 (Option 001).............................................................. |

2-10 |

Section 3 |

Introduction To The Model 395 |

|

|

3.1 |

OVERVIEW OF THE MODEL 395 ........................................................ |

3-1 |

|

|

Using the Model 395 .............................................................................. |

3-1 |

|

3.2 |

NAVIGATING THE SCREENS.............................................................. |

3-1 |

|

|

3.2.1 Front Panel Keys and Screens ..................................................... |

3-1 |

|

|

3.2.2 |

Softkeys ....................................................................................... |

3-2 |

|

3.2.3 |

Extended Screens........................................................................ |

3-2 |

|

3.2.4 Changing Numeric Values ........................................................... |

3-3 |

|

|

3.2.5 |

Correcting Mistakes ..................................................................... |

3-4 |

3.3 ON-SCREEN HELP................................................................................ |

3-4 |

||

3.4 |

ERROR MESSAGES ............................................................................ |

3-5 |

|

3.5 |

INITIAL SETUP...................................................................................... |

3-5 |

|

3.6 |

MODEL 395 AS A FUNCTION GENERATOR ...................................... |

3-6 |

|

|

Example 1. Setting Up the Function Generator ............................. |

3-6 |

|

3.7 |

MODEL 395 AS AN ARBITRARY WAVEFORM GENERATOR............ |

3-10 |

|

|

Example 2 Creating an Arbitrary Waveform Using Line Draw ........ |

3-11 |

|

|

Example 3 Generating the Arb Waveform....................................... |

3-14 |

|

|

Example 4. Creating an Arb Waveform Using Waveform Insert ..... |

3-17 |

|

|

Example 5. Creating an Arbitrary Waveform Using Point Edit ........ |

3-19 |

|

3.8 |

THE MODEL 395 AS A WAVEFORM SEQUENCE GENERATOR....... |

3-22 |

|

|

Example 6 Creating a Waveform Sequence .................................. |

3-22 |

|

3.9 |

STORING AND RECALLING SETUPS................................................. |

3-24 |

|

|

Example 7. Storing and Recalling an Instrument Setup ................. |

3-24 |

|

3.10 THE MODEL 395 AS A SWEEP GENERATOR ................................. |

3-25 |

||

|

Example 8. Setting up the Sweep Generator................................. |

3-25 |

|

Contents v

3.11 |

THE MODEL 395 AS A TRIGGER GENERATOR.............................. |

3-27 |

|

Example 9 Setting up the Triggered Generator............................... |

3-27 |

3.12 |

THE MODEL 395 AS A PULSE GENERATOR .................................. |

3-31 |

|

Example 10 Setting up the Pulse Waveform.................................. |

3-31 |

|

Example 11 Setting up the Pulse Train Waveform ......................... |

3-34 |

3.13 |

THE MODEL 395 AS A NOISE GENERATOR ................................... |

3-43 |

|

Example 12 Setting Up the Signal To Noise Waveform ................. |

3-43 |

3.14 |

THE MODEL 395 AS AN AMPLITUDE MODULATION SIGNAL |

|

|

SOURCE ....................................................................................... |

3-46 |

|

Example 13 Setting Up Amplitude Modulation ............................... |

3-46 |

3.15 |

THE MODEL 395 SUMMING INPUT ................................................. |

3-48 |

|

Example 14. Setting Up Summing Input ........................................ |

3-48 |

Section 4 |

Front Panel Operation Reference |

|

||

4.1 INTRODUCTION .................................................................................... |

4-1 |

|||

4.2 FRONT PANEL....................................................................................... |

4-1 |

|||

4.3 REAR PANEL ........................................................................................ |

4-9 |

|||

4.4 REFERENCE.......................................................................................... |

4-11 |

|||

4.4.1 Amplitude ...................................................................................... |

4-11 |

|||

4.4.2 AM In (amplitude modulation And SCM) ..................................... |

4-14 |

|||

4.4.3 |

Arbitrary Waveforms .................................................................... |

4-16 |

||

4.4.3.1 Introduction.......................................................................... |

4-16 |

|||

4.4.3.2 Creating Waveforms............................................................ |

4-17 |

|||

4.4.3.3 Create From Copy .............................................................. |

4-18 |

|||

4.4.3.4 |

Modifying Waveforms ......................................................... |

4-19 |

||

4.4.4 Filter .............................................................................................. |

|

|

4-29 |

|

4.4.4.1 Introduction.......................................................................... |

4-29 |

|||

4.4.4.2 |

Mode................................................................................... |

4-29 |

||

4.4.4.3 |

Filter.................................................................................... |

4-30 |

||

4.4.5 |

Frequency .................................................................................... |

4-30 |

||

4.4.5.1 Standard Waveform Frequency ......................................... |

4-30 |

|||

4.4.5.2 |

Standard Waveform Period ................................................ |

4-30 |

||

4.4.5.3 |

Arbitrary Waveforms - Frequency / Period ......................... |

4-31 |

||

4.4.5.4 |

Sequence - Frequency/Period............................................ |

4-31 |

||

4.4.5.5 Pulse / Pulse Train Period ................................................... |

4-31 |

|||

4.4.5.6 |

Noise Clock ........................................................................ |

4-31 |

||

4.4.6 MODE ................................................................................................. |

|

|

4-32 |

|

4.4.7 OFFSET.............................................................................................. |

|

|

4-34 |

|

4.4.8 REMOTE |

............................................................................................ |

|

4-35 |

|

4.4.9 RESET................................................................................................ |

|

|

4-36 |

|

4.4.10 SEQUENCE...................................................................................... |

4-37 |

|||

4.4.11 SETUPS |

............................................................................................ |

|

4-40 |

|

4.4.12 STANDARD WAVEFORMS ............................................................. |

4-41 |

|||

4.4.12.1 Introduction........................................................................ |

4-41 |

|||

4.4.12.2 |

Sine................................................................................... |

4-42 |

||

4.4.12.3 |

Square .............................................................................. |

4-42 |

||

4.4.12.4 |

Triangle............................................................................. |

4-42 |

||

4.4.12.5 |

DC..................................................................................... |

4-42 |

||

4.4.12.6 |

Positive Ramp .................................................................. |

4-43 |

||

4.4.12. 7 |

Negative Ramp................................................................ |

4-43 |

||

4.4.12.8 |

Sin(x)/x.............................................................................. |

4-43 |

||

4.4.12.9 |

Positive Haversine............................................................ |

4-43 |

||

4.4.12.10 |

Negative Haversine ........................................................ |

4-43 |

||

4.4.12.11 |

Pulse ............................................................................... |

4-43 |

||

4.4.12.12 |

Pulse Train...................................................................... |

4-46 |

||

4.4.12.13 |

Digital Noise ................................................................... |

4-51 |

||

4.4.12.14 |

Analog Noise (White Analog Noise) ............................... |

4-52 |

||

vi Contents

4.4.12.15 Comb .............................................................................. |

4-55 |

|

4.4.12.16 Signal Plus Noise ........................................................... |

4-57 |

|

4.4.12.17 Signal Plus Comb ............................................................ |

4-60 |

|

4.4.12.18 AM / SCM ....................................................................... |

4-63 |

|

4.4.12.19 FM................................................................................... |

4-65 |

|

4.4.12.20 Arb Waveforms ............................................................... |

4-66 |

|

4.4.12.21 Sequence ....................................................................... |

4-66 |

|

4.4.13 |

Status ......................................................................................... |

4-67 |

4.4.14 |

Sum in ........................................................................................ |

4-68 |

4.4.15 Sweep ........................................................................................ |

4-69 |

|

4.4.16 |

Sync Out .................................................................................... |

4-74 |

4.4.17 |

Trigger ........................................................................................ |

4-76 |

4.4.18 |

Utility........................................................................................... |

4-77 |

4.4.19 |

Ref In / Ref Out .......................................................................... |

4-79 |

Section 5 |

Remote Operation |

|

5.1 INTRODUCTION ................................................................................... |

5-1 |

|

5.2 SCPI PRIMER ....................................................................................... |

5-2 |

|

5.2.1 |

Parameters................................................................................... |

5-3 |

5.2.2 |

Queries......................................................................................... |

5-4 |

5.2.3 |

SCPI Punctuation and Syntax...................................................... |

5-4 |

5.2.4 |

Condensed Rules:........................................................................ |

5-4 |

5.2.5 |

Text Symbols ............................................................................... |

5-5 |

5.2.6 Example Command Tree ............................................................. |

5-6 |

|

5.2.7 Example Command Table ........................................................... |

5-8 |

|

5.2.8 Example Command Syntax Diagrams......................................... |

5-8 |

|

5.3 REMOTE RS-232 SETUP ..................................................................... |

5-11 |

|

5.3.1 Hardware Setup ........................................................................... |

5-11 |

|

5.3.2 |

Instrument Setup.......................................................................... |

5-11 |

5.4 IEEE-488.1 (GPIB) SETUP ................................................................... |

5-12 |

|

5.4.1 Hardware Setup ........................................................................... |

5-12 |

|

5.4.2 |

Instrument Setup.......................................................................... |

5-12 |

5.5 SCPI PROGRAMMING EXAMPLES..................................................... |

5-13 |

|

5.5.1 |

Model 395 As a Function Generator............................................ |

5-14 |

Example 1. Setting Up the Function Generator ............................. |

5-14 |

|

5.5.2 |

Model 395 as an Arbitrary Waveform Generator......................... |

5-15 |

Example 2 Creating an Arbitrary Waveform Using Line Draw ........ |

5-15 |

|

Example 3 Running the Arb Waveform .......................................... |

5-16 |

|

Example 4. Creating an Arb Waveform Using Waveform Insert ..... |

5-17 |

|

Example 5. Creating an Arbitrary Waveform Using Point Edit ........ |

5-17 |

|

5.5.3 The Model 395 as a Waveform Sequence Generator ................. |

5-19 |

|

Example 6 Creating a Waveform Sequence .................................. |

5-19 |

|

5.5.4 |

Storing and Recalling Setups....................................................... |

5-20 |

Example 7. Storing and Recalling an Instrument Setup ................. |

5-20 |

|

5.5.5 The Model 395 As a Sweep Generator ....................................... |

5-20 |

|

Example 8. Setting up the Sweep Generator................................. |

5-20 |

|

5.5.6 |

The Model 395 as a Trigger Generator ....................................... |

5-21 |

Example 9 Setting up the Triggered Generator............................... |

5-21 |

|

5.5.7 The Model 395 as a Pulse Generator.......................................... |

5-22 |

|

Example 10 Setting up the Pulse Waveform.................................. |

5-22 |

|

Example 11 Setting up the Pulse Train Waveform ......................... |

5-22 |

|

5.5.8 The Model 395 as a Noise Generator.......................................... |

5-24 |

|

Example 12 Setting Up the Signal To Noise Waveform ................. |

5-24 |

|

5.5.9 |

The Model 395 as an Amplitude Modulation Signal Source......... |

5-24 |

Example 13 Setting Up Amplitude Modulation ............................... |

5-24 |

|

5.5.10 The Model 395 and its Summing Input ...................................... |

5-25 |

|

Example 14. Setting Up Summing Input ........................................ |

5-25 |

|

Contents vii

5.6 |

SCPI COMMANDS ................................................................................ |

5-27 |

|

5.6.1 ABORT ............................................................................................... |

5-27 |

||

|

5.6.2 |

CALibration .................................................................................. |

5-27 |

|

5.6.3 |

DISPlaY........................................................................................ |

5-28 |

|

5.6.4 |

INITiate......................................................................................... |

5-29 |

|

5.6.5 MMEMory..................................................................................... |

5-29 |

|

|

5.6.6 OUTPut ........................................................................................ |

5-31 |

|

|

5.6.7 |

RESet........................................................................................... |

5-32 |

|

5.6.8 [SOURce] ..................................................................................... |

5-33 |

|

|

5.6.9 STATus ........................................................................................ |

5-44 |

|

|

5.6.10 SYSTem..................................................................................... |

5-45 |

|

|

5.6.11 TEST .......................................................................................... |

5-45 |

|

|

5.6.12 TRACe ....................................................................................... |

5-46 |

|

|

5.5.12 |

TRIGger ..................................................................................... |

5-48 |

5.7 |

IEEE 488.2 COMMON COMMANDS .................................................... |

5-50 |

|

5.8 |

HIGH SPEED BINARY WAVEFORM TRANSFER ............................... |

5-51 |

|

5.9 |

RS-232-C PROGRAMMING.................................................................. |

5-53 |

|

5.10 GPIB ERROR HANDLING AND STATUS REPORTING.................... |

5-53 |

||

5.11 RESUMING LOCAL OPERATION ...................................................... |

5-58 |

||

Appendix A |

Specifications |

Appendix B |

Menu - Quick Reference |

Appendix C |

SCPI Command - Quick Reference |

Appendix D |

Rack Ears Kit Installation |

Appendix E |

Information/Error Messages |

Appendix F |

DSO Upload |

Appendix G |

Performance Verification and Alignment Procedures |

viii Contents

SAFETY ISSUES

READ THIS ENTIRE SECTION THOROUGHLY BEFORE ATTEMPTING TO INSTALL, OPERATE OR SERVICE THE MODEL 395

General Safety Summary

This instrument has been designed and tested in accordance with the British and European standard publication EN61010: 1993/A2: 1995, and has been supplied in a safe condition.

This manual contains information and warnings that must be observed to keep the instrument in a safe condition and ensure safe operation. Operation or service in conditions, or in a manner other than specified could compromise safety. For the correct and safe use of this instrument it is essential that both operating and service personnel follow generally accepted safety procedures in addition to the safety precautions specified.

To avoid injury or fire hazard the instrument should not be switched on if it is damaged or suspected faulty, and it should not be used under damp, wet, condensing, dusty or explosive gas conditions.

Whenever it is likely that safety-protection has been impaired, the instrument must be made inoperative and be secured against any unintended operation. Qualified maintenance or repair personnel should be informed. Safety-protection is likely to be impaired if, for, example the instrument shows visible damage or fails to operate normally.

Explanation of safety related symbols and terms

DANGER |

|

Risk of Electric Shock |

The product is marked with this symbol to indicate that |

|

hazardous voltage (> 30V dc or ac pk) may be present. |

CAUTION |

|

Refer to accompanying documents |

The product is marked with this symbol when it is necessary |

|

for the user to refer to the instruction manual. |

Earth (Ground) Terminal |

Functional Earth (Ground) only, must not be used as a |

|

Protective Earth. |

WARNING Warning statements identify conditions or practices that could result in injury or loss of life

CAUTION Caution statements identify conditions or practices that could result in damage to this or other property.

WARNING

THIS INSTRUMENT CAN DELIVER A LETHAL ELECTRIC SHOCK. NEVER TOUCH ANY LEAD OR TERMINAL UNLESS YOU ARE ABSOLUTELY CERTAIN THAT NO DANGEROUS VOLTAGE IS PRESENT.

ix

Protective Earth (or Grounding)

Protection Class 1 - The instrument must be operated with a Protective Earth /Ground connected via the Protective Earth/Grounding conductor of the supply cable.

This is connected to the instrument before the line and neutral connections when the supply plug is inserted into the socket on the back of the instrument. If the final connection to the supply is made elsewhere, ensure that the ground connection is made before line and neutral.

WARNING Any interruption of the protective ground conductor inside or outside the instrument is likely to make the instrument dangerous. Intentional interruption is prohibited.

To avoid electric shock the signal connections to the instrument should be connected after the ground connection is made and disconnected before the ground connection is removed, i.e. the supply lead must be connected whenever signal leads are connected.

Do Not Operate without Covers

To avoid electric shock or fire hazard, the instrument must not be operated with covers removed. The covers protect the user from live parts and unless otherwise stated they should be removed only by suitably qualified personnel for maintenance and repair purposes.

WARNING Removing the covers may expose voltages in excess of l.5 kV pk; these may be present for up to one minute after the instrument has been disconnected from the power source; longer under fault conditions.

Safe Operating Conditions

The unit must be operated only within the manufacturers specified operating conditions. Examples of specification that must be considered are:

Ambient temperature Ambient humidity

Power supply voltage and frequency Maximum terminal voltages or currents Altitude

Ambient pollution level Exposure to shock and vibration

To avoid electric shock or fire hazard, do not apply to or subject the instrument to any condition that is outside specified range. Please refer to Appendix A of this manual for detailed Specification of the instrument and its operating conditions.

CAUTION

Direct sunlight, radiators and other heat sources should be taken into account when assessing the ambient temperature.

CAUTION

Before connecting the instrument to the supply, ensure that the rear panel AC supply voltage selector is set to the appropriate voltage, either 115V or 230V and that correctly rated fuses are fitted (see below)

Fuse Requirements

To avoid fire hazard the fuse arrangement shown in the table below must be followed. Additionally the supply network must be fused at a maximum of 16 A and in the UK, a 5 A fuse should be fitted in the power cord plug.

x

Power Input Fuse

Supply (Line) |

Fuse Action |

Fuse Rating |

Wavetek-Datron |

Manufacturer |

|

Voltage |

|

UL/CSA |

Part No. |

& Type No. |

|

|

|

|

|

|

|

115 VAC |

T |

1 A |

2400-05-0029 |

BUSSMAN MDL 1 |

|

Time delay |

|||||

|

|

|

|

||

|

|

|

|

|

|

230 VAC |

T |

500 mA |

2400-05-0010 |

BUSSMAN MDL 1/2 |

|

Time delay |

|||||

|

|

|

|

||

|

|

|

|

|

The Power Cord and Power Supply Disconnection

The power supply disconnect device is the ON / OFF switch on the rear panel of the instrument. The ON / OFF switch should be readily accessible whilst the instrument is in operation. If this operating condition cannot be satisfied, it is essential that either the power cord plug or a separate power disconnecting device be readily reached and accessible to the operator.

To avoid electric shock and fire hazard, ensure that the power cord is not damaged and is adequately rated against power supply network fusing. If the power plug is to be the accessible disconnecting device, the cord must not be longer than 3 metres.

Connection to Instrument Terminals

Ensure that the instrument is correctly Earthed (Grounded) via its power cord before and whilst any other connection is made.

Installation Category I

Measurement and/or guard terminals are designed for connection at Installation (Over voltage) Category I. To avoid electric shock or fire hazard the instrument terminals must not be connected directly to the mains power supply or any other source of voltage or current that might temporarily exceed the peak ratings of the instrument

WARNING To avoid injury or loss of life, do not connect or disconnect signal leads while they are connected, or suspected of being, connected to a hazardous voltage or current source (internal or external to the instrument).

Maintenance and Repair

Local or national safety regulations and rules for the prevention of accidents and hazard must be observed in all work performed. The unit must be disconnected from all signal sources and then the power supply before the removal of covers. Any adjustment, parts replacement, maintenance or repair should be carried out only by authorised WavetekDatron technical personnel.

WARNING For continued protection against injury and fire hazard it is essential that only manufacturer supplied parts be used to replace parts relevant to safety. Safety tests must be performed after the replacement of parts relevant to safety.

Ventilation and Dust

The instrument relies on forced air cooling via a fan and ventilation slots. Adequate ventilation can usually be achieved by positioning on a level surface and by leaving a 75 mm (3" gap) around the instrument. Care should be taken to avoid restricting the airflow to or from the fan at the rear/sides of the instrument as damage may result from overheating.

Cleaning

Ensure the instrument signal and then power leads are disconnected prior to cleaning. Use only a damp, lint free cloth to clean facia and case parts.

Observe any additional safety instructions or warnings given in this manual.

xi

100 MHz Synthesized Arbitrary Waveform Generator model 395 |

|

|

7 |

8 |

9 |

4 |

5 |

6 |

1 |

2 |

3 |

0 |

• |

+ /- |

Model 395, 100 MHz Synthesized Arbitrary Waveform Generator |

||

Introduction |

Section 1 |

|

|

|

|

1.1 THE MODEL 395

Wavetek-Datron’s Model 395 100-MHz synthesized arbitrary waveform generator delivers high-speed performance in both bench-top and ATE applications. The Model 395 combines the capabilities of a synthesized arbitrary waveform generator, synthesized function generator, pulse generator, noise generator, sweep generator, and trigger generator. As a modulation source, the Model 395 provides real-time AM and SCM, and synthesized AM, SCM and FM.

The Model 395’s 1mHz to 100 MHz clock generates arbitrary (user-defined) waveforms with 12 bits of vertical resolution (4096 points: -2048 to +2047) and up to 256K points of horizontal memory for simulating “real-world” non-standard signals. At clock rates of 50 MHz or below, Model 395 uses direct digital synthesis (DDS) that provides highfrequency resolution (up to 10 digits). Model 395 is an excellent signal source for a wide range of applications, including in-circuit testing of semiconductors, communication testing requiring complex pulse patterns, and performance characterization testing of electrical devices.

Create arbitrary waveforms using the Model 395’s front panel by using point-by-point, copy, or line edit modes. Also, use the RS-232 interface or optional GPIB (IEEE-488.2, SCPI compatible) interface to upload waveforms. Wavetek-Datron’s WaveForm DSP software tool makes waveform creation, modification, and uploading easy over the GPIB interface. The Direct DSO Upload, part of Option 001 IEEE-488 Interface, allows transfer of waveforms captured with a digital storage oscilloscope directly into the Model 395.

Another capability, Sequence, allows up to four waveforms to be linked in a sequence with advancement from one waveform to the next conditional upon waveform repeat (loop) counts and trigger signals.

In addition to complex arbitrary waveforms, Model 395 provides a number of synthesized standard waveforms including sine waves to 40 MHz, square waves to 50 MHz, and triangle waves to 10 MHz.

The built-in pulse generator generates pulses with programmable parameters that include rate, width, delay, and rise/fall times. Pulse train allows you to create a series of up to 10 independently programmable pulses each with their own level, width, delay, rise/fall times.

Noise functions provide analog noise, digital noise, signal-plus-noise, comb, and comb- plus-noise.

Sweep allows frequency sweeps from 1mHz to 20 MHz in one continuous band and include seven sweep modes, as well as linear or logarithmic spacing.

The Model 395 allows real-time AM and SCM modulation of both standard and arbitrary waveforms.

For non-continuous operation, the Model 395 provides triggered and gated modes. Triggered mode includes programmable burst counts from 1 to 1,048,575 counts. Trigger sources include an internal trigger rate generator, manual trigger key, trigger input BNC, and remote trigger command.

Model 395 is designed to provide an MTBF in excess of 10,000 hours, thus the Model 395 is extremely reliable. The easy-to-use calibration procedure can be performed entirely from the front panel in less than fifteen minutes without removing the instrument cover.

Introduction 1-1

1.2 ORGANIZATION OF THIS MANUAL

Installation and Preparation For Use

Section 2 tells you how to set up and check out the Model 395 before you use it. It also familiarizes you with the physical setup of the unit.

Introduction To The Model 395

Section 3 describes the fundamentals of front panel operation using a series of examples.

Operation Reference

Section 4 provides detailed explanations for every function and feature of the Model 395.

Remote Operation

Section 5 provides an introduction to the set up and operation of the Model 395 from remote sources using the standard RS-232 or optional IEEE–488.2 interfaces. It also contains the Model 395’s SCPI remote command set and IEEE-488.2 Common Commands.

Specifications

Appendix A, located at the rear of this manual, contains the detailed specifications for the Model 395.

Menu Quick Reference

Appendix B contains quick reference diagrams of the Model 395’s menu structure.

SCPI Quick Reference

Appendix C contains quick reference diagrams of the Model 395’s SCPI command tree. The SCPI information is presented as a “Primer”. This appendix also contains the SCPI required Conformance Information.

Rack Adapter Instructions

Appendix D contains instructions for mounting the Model 395 in an instrument rack.

DSO Upload

Appendix F contains instructions on DSO uploading to the Model 395. Plus, appendix F describes how to create and load DSO driver files for DSOs not included in the unit’s firmware.

Verification and Alignment Procedures

Appendix G contains both the verification test procedure and alignment procedure for the Model 395.

1-2 Introduction

Initial Preparation |

Section 2 |

|

|

2.1 THIS SECTION

This section contains:

Receiving and Inspecting Shipments;

Returning Equipment For Repair;

Preparation For Storage or Shipment;

Preparation For Use;

Initial Turn on;

Functional Checkout;

Routine Maintenance.

2.2 RECEIVING AND INSPECTING SHIPMENTS

Use the following steps to inspect a shipment of Wavetek-Datron equipment.

1.Inspect the shipment. If the shipment is damaged have the driver describe the box damage and list shortages on the delivery bill.

If you find unreported shortages or damage, notify the shipper before further unpacking.

2.After unpacking the boxes. Save all of the packing material.

3.Inspect the equipment for damage. Inspect it carefully, regardless of the condition of the shipping boxes.

4.If necessary, file a damage claim. If any damage is found, call the shipper within 10 days and start the claim process.

5.Call Wavetek-Datron. Call Wavetek-Datron’s Customer Service department and tell them that the equipment arrived damaged.

2.3RETURNING EQUIPMENT FOR REPAIR

Use the following steps if you should ever need to return the Model 395 to Wavetek-

Datron for repair.

1.Save the packing material. Always return the equipment to Wavetek-Datron in its original packing material and boxes. If you use inadequate packing material, you will have to pay to repair any shipping damage. Carriers will not pay claims on incorrectly packed equipment.

2.Call Wavetek-Datron for a Return Authorization. Wavetek-Datron’s customer service representative will ask for the name of the person returning the equipment. Plus, the representative will ask for your telephone number, company name, equipment type and serial number, and a description of the problem.

Initial Preparation 2-1

2.4 PREPARATION FOR STORAGE, SHIPMENT OR OPERATION

Packaging

If possible, always use the original shipping container. However, when using packing materials other than the original, use the following guidelines:

Wrap the Model 395 in plastic packing material.

Use a double-walled cardboard shipping container.

Protect all sides with shock absorbing material (minimum of 2 inch thick material) to prevent movement of the Model 395 within the container.

Seal the shipping container with approved sealing tape.

Mark “FRAGILE” on all sides, top, and bottom of the shipping container.

Storage

The Model 395 should be stored in a clean, dry environment. In high humidity environments, protect the Model 395 from temperature variations that could cause internal condensation. The following environmental conditions apply to both shipping and storage;

Temperature |

–20°C to +70°C |

Relative Humidity (sea level) |

Less than 95% at 11°C to +30°C. |

Altitude |

Less 15,000 feet (4570 meters). |

Vibration |

Less than 2g. |

Shock |

Less than 40g. |

Operation

The Model 395 should be operated on a flat surface or in an equipment rack within its envoronmental specifications. All air vents should be clear of obstructions.

Signal connections should not be made to external hazardous voltages.

WARNING

THIS INSTRUMENT CAN DELIVER A LETHAL ELECTRIC SHOCK. NEVER

TOUCH ANY LEAD OR TERMINAL UNLESS YOU ARE FIRST

ABSOLUTELY CERTAIN THAT NO DANGEROUS VOLTAGE IS PRESENT.

SEE THE SAFETY ISSUES SECTION AT THE FRONT OF THIS MANUAL.

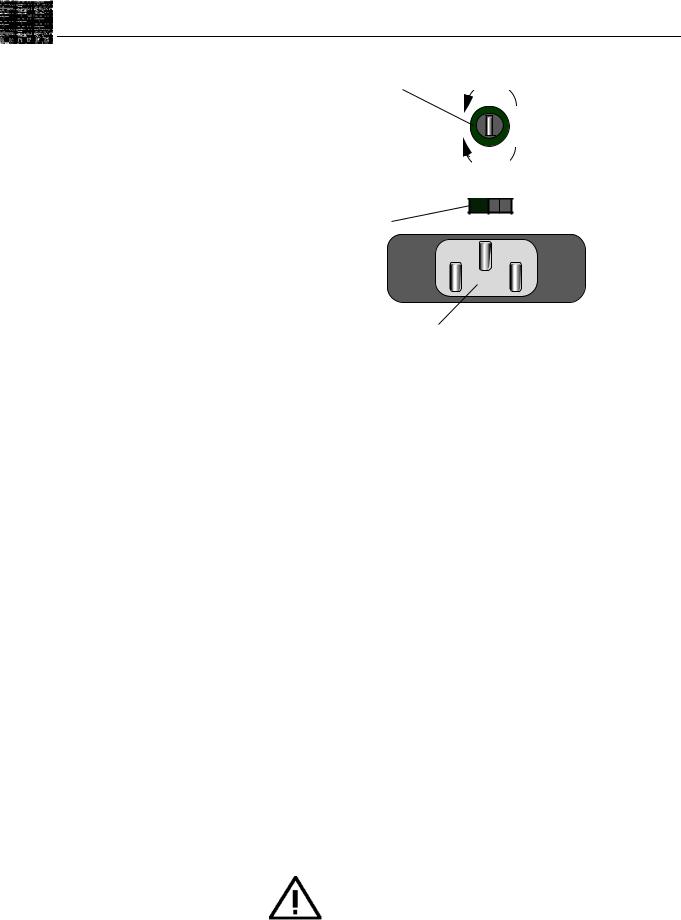

2.5 LINE VOLTAGES AND FUSES

The Model 395 accepts a primary input voltage of either 90 to 132 Vac or 198 to 252 Vac, 50/60 Hz. Wavetek-Datron ships the Model 395 set for the line voltage and with the proper fuse for the destination country. Figure 2-1 illustrates the location of the line voltage switch and fuse holder.

2-2 Initial Preparation

Fuse Holder |

Remove |

Install

230 115

230 115

Line Voltage

Selector

Power Connector

Figure 2-1. Line Voltage Switch and Fuse Holder

To change the line voltage, disconnect the power cord from the Model 395. Slide the Line Voltage Selector (figure 2-1) to the desired line voltage: left for 230VAC, and right for 115VAC. Refer to table 2-1 for voltage ranges for each voltage position. Also check that the fuse is the correct rating; see the following procedure.

To change the fuse, perform the following steps:

1.Disconnect the power cord from the instrument. Remove the fuse from the fuse holder.

Table 2-1. Line Voltage and Fuse Selection

Supply (Line) |

Fuse Action |

Fuse Rating |

Wavetek-Datron |

Manufacturer |

|

Voltage |

|

UL/CSA |

Part No. |

& Type No. |

|

|

|

|

|

|

|

115 VAC |

T |

1 A |

2400-05-0029 |

BUSSMAN MDL 1 |

|

Time delay |

|||||

|

|

|

|

||

|

|

|

|

|

|

230 VAC |

T |

500 mA |

2400-05-0010 |

BUSSMAN MDL 1/2 |

|

Time delay |

|||||

|

|

|

|

||

|

|

|

|

|

2.Compare the ampere rating on the fuse to the ampere ratings given in table 2-1. If the fuse is blown, replace it by sliding the new fuse back into the fuse holder.

If the fuse is not blown and has the right rating, keep it. If the fuse has the wrong rating, place the new fuse into the fuse holder.

3.Connect the ac line cord supplied to the power connector at the rear of the unit and power source.

CAUTION IN THE EVENT OF FAILURE OF ANY FUSE, CONTACT THE SERVICE CENTER IMMEDIATELY. SEE THE SAFETY ISSUES SECTION AT THE FRONT OF THIS MANUAL.

Initial Preparation 2-3

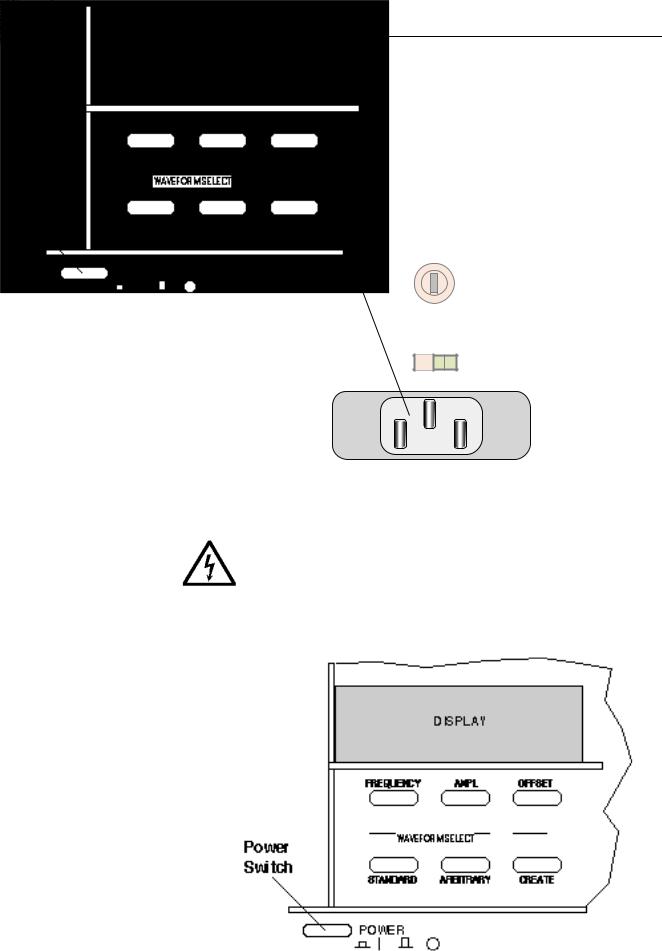

2.6 INITIAL TURN–ON

WARNING

The Model 395 is equipped with a three-wire power cable. When connected to a grounded AC power receptacle, this cable grounds the instrument. Do not use extension cords or AC adapters without a ground.

1.Connect the power cable supplied to the power connector on the Model 395 rear panel; see figure 2-2.

Power Connector

Figure 2-2. Power Connector

WARNING

ANY INTERRUPTION OF THE PROTECTIVE EARTH/GROUND CONDUCTOR INSIDE OR OUTSIDE THE INSTRUMENT IS LIKELY TO MAKE THE INSTRUMENT DANGEROUS. SEE THE SAFETY ISSUES SECTION AT THE FRONT OF THIS MANUAL.

2.Press the “POWER” On/Off switch in to turn the unit on (figure 2-3).

Figure 2-3. Power Switch

2-4 Initial Preparation

2.7 ERROR MESSAGES

Some front panel entries may cause error or information messages to appear on the display.

2.8 FUNCTIONAL CHECKOUT

The functional checkout provides a quick method of verifying the Model 395 operation. The only test equipment required is an oscilloscope (Tektronix 2445 - dual channel or equivalent), and the appropriate cables and loads.

Continuous Mode Check

1.Connect the Model 395 to the primary power source. Leave all cables disconnected. See Initial Turn-On in this section.

2.Turn on the Model 395 by pushing in the POWER switch.

At power on, the Model 395 displays its start up screen (figure 2-4).

Wavetek

Model 395

(for assistance,

press HELP)

Figure 2-4. Model 395 Start Up Screen

3.Press the RESET key, and from the Instrument Reset screen press F3 to reset all parameters. Then press F8 to confirm reset.

4.Press the MAIN OUT key to turn on the Main Output. Main Out indicator remains on.

5.Press the SYNC OUT key. From the Sync Output Setup screen, press F2 twice to turn the Sync Output on (“output: on”).

Observe: Scope displays a 1Vp sine wave at 1kHz (Main Out must be terminated into 50Ω).

Sweep Mode Check

Press the MODE key. From the Mode screen, press F2 “sweep.”

Observe: Scope displays a sweep of the frequency from 1kHz to 10 kHz.

Gated Mode Check

Press the MODE key. From the Mode screen, press F3 “gated.” Press the STANDARD key, and then rotate the knob; select the softkey to select “triangle.”

This check uses the Model 395’s internal trigger source which is programmed to 5 ms.

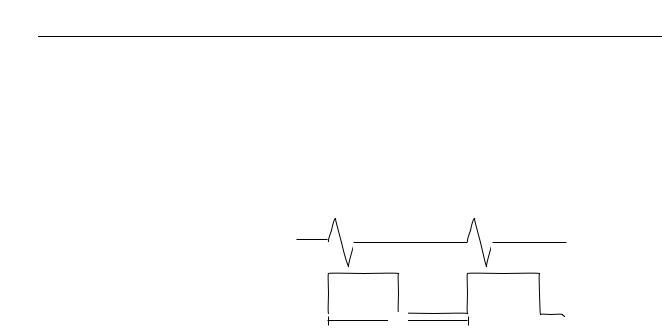

Observe: Scope displays a gated waveform; see below:

1ms

5ms

Initial Preparation 2-5

Triggered Mode Check

Press the MODE key. From the Mode screen, press F4 “trig’d.”

This check uses the Model 395’s internal trigger source which is programmed to 5 ms.

Observe: Scope displays a triggered waveform with a count of 1; see below:

5ms

This completes the functional test. Remove all cables and test equipment.

2.9OPERATOR MAINTENANCE

2.9.1Routine Maintenance

No tools or equipment are required for routine maintenance. Cleaning materials required are listed below:

Description |

National Stock Number |

Cotton Cheesecloth |

8305-00-267-3015 |

|

CCC-C-440, Type II, |

|

Class 2 (81349) |

Mild Liquid Detergent |

None |

Routine maintenance for the Model 395 is limited to routine tasks such as listed below;

Cleaning, using cloth moistened with detergent

Dusting,

Wiping,

Checking for frayed cables,

Storing items not in use,

Covering unused receptacle,

Checking for loose screws.

Perform these routine tasks as required.

2-6 Initial Preparation

2.9.2 Battery Replacement

The Model 395 contains an internal battery for the unit’s internal memory. Its replacement should only be carried out by a suitably qualified technician. Measure the battery voltage when performing calibration of the unit (approximately every 12 months); refer to paragraph 4.3, figure 4-7 and table 4-6 item 6. The battery should measure between +3.2 Vdc and +2.7 Vdc. Replace the battery when it measures +2.7 Vdc or below to avoid loosing Arb waveforms, stored settings, “last setup,” and all remote setup parameters.

WARNING

This instrument uses an internal battery containing more than 0.2 grams of Lithium. Do not charge or short this battery. A hazard of explosion and or contamination exists.

CAUTION Always replace the battery with one of the same type: Panasonic BR- 2/3A

To replace the battery. This task should only be undertaken by a suitably qualified technician.

1.Turn off the Power and disconnect the power cable.

2.Remove the two screws; one on each side of the cover.

3.Slide the cover back.

4.Remove the battery.

5.Remember, removing the battery will loose Arb waveforms, stored settings, “last setup," and all remote setup parameters.

6.Install the new battery. Be sure to match the polarity on the battery with the polarity indicator on the battery holder.

2.10RACK MOUNTING EARS

The Model 395 can be rack mounted using the optional mounting ears (Option 004).

Installation instructions are in appendix D of this manual.

2.11REMOTE SETUP

2.11.1RS-232

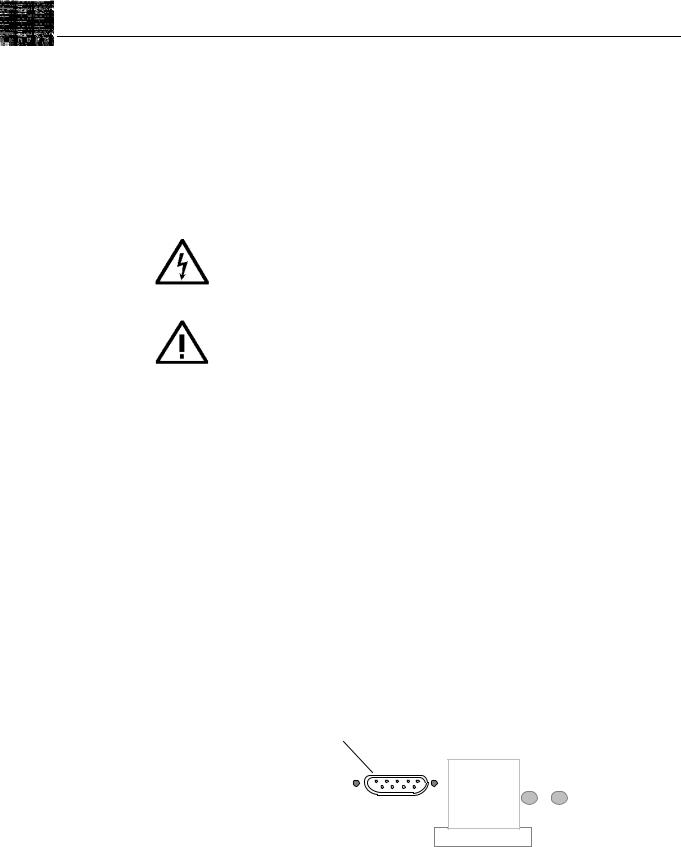

To connect the Model 395 to a computer via RS-232, use the provided RS-232 cable. For information on RS-232 remote programming, refer to section 5 of this manual. Note that the 0 V connection on the RS–232 connector is internally connected to the floating analog common and not ground.

RS-232

Connector

|

CAL ENABLE |

RS-232 |

BATTERY |

|

TEST |

|

NORM - CAL |

|

Cal Sticker |

|

BAT GND |

Figure 2-5. RS-232-C Connector

Initial Preparation 2-7

Standard RS-232 Connection

The Model 395 is configured as a DCE , and uses a 9-pin female connector (DB-9). The standard connection will be to a DTE ( generally a computer) with a standard 9-pin male connector (DB-9). This connection can be made using the 9-pin female to 9-pin male cable (P/N 6001-00-0061) included with the Model 395. If the DTE uses a male DB-25, the connection can be made using the 25-pin female to 9-pin male adapter (P/N 2100- 02-0328 ) included with the Model 395. After connections are made, both the Model 395 and the DTE must be configured to have the same baud rate and data format. The data format for the model 395 is 8-bits, no parity, one stop bit. Refer to section 5.3 for the Model 395 RS-232 setup.

Non-Standard RS-232 Connection

Because the Model 395 is configured as a DCE, connection to a device configured other than a standard DTE may require a special cable. Some knowledge of the RS-232 is beneficial to insuring a proper connection. The pin assignments for the model 395 and for a standard DTE (an AT comm port), are given in Table 2-2 .

EIA STANDARD RS-232-C specifies the electrical characteristics and pinouts of a serial communication standard for connecting “Data Terminal Equipment” (DTE) to “Data Communication Equipment” (DCE). A DTE is usually a device such as a terminal, computer, or printer, that is the final destination of data. A DCE is usually a device that converts data to another form and passes it through such as a modem. Because RS-232 signal lines defined as outputs on a DTE are inputs on a DCE and vise versa, connection of a DTE to a DTE or a DCE to a DCE requires a special cable with many of the lines interchanged. Generally a “Null Modem” cable will have the correct lines interchanged.

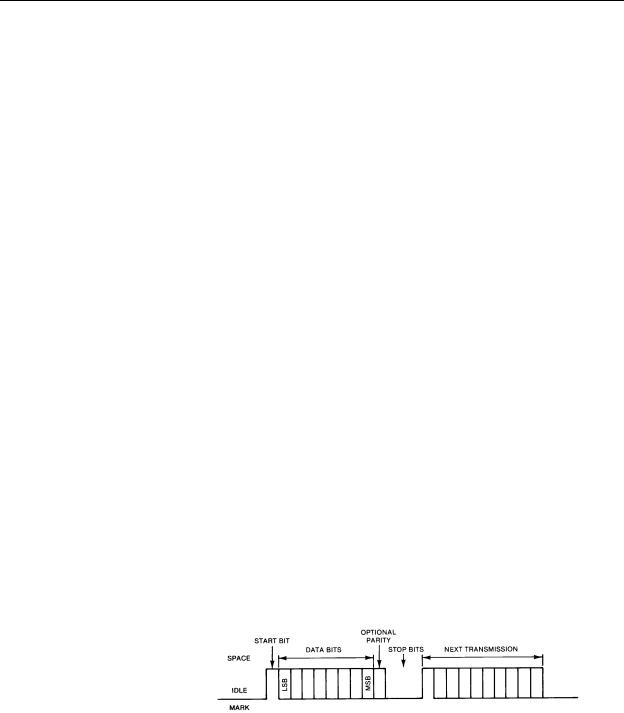

With RS-232-C, data is transferred serially between two devices using a voltage of +3 to +25 Vdc to represent a zero ( space ), and a voltage of -3 to -25 Vdc to represent a one ( mark ). Only two lines are required to transfer data, transmit and receive. When no data is being transferred, these lines will be at a mark state. To transmit a byte, the transmitting device first sends a start bit , a space, to synchronize the receiver. Then, the data bits are sent LSB first (eight bits for 395). Some devices follow the data bits with a parity bit (not 395). At the end there is up to 2 stop bits (395 uses one stop bit) that are at the mark state.

The rate at which the bits are transferred is called baud rate and is in bits per second. The baud rate must be set the same for both devices. The 395 has seven different baud rates ranging from 1200 to 57.6K.

Handshaking is a communication between the two devices to control the transfer of data to insure no data is lost when the data is transferring faster than a device can process it. Handshaking can be accomplished in two ways, software or hardware. Software handshaking is done using XON / XOFF protocol (not supported by 395), which sends control characters over the data lines to control the flow.

2-8 Initial Preparation

Hardware handshaking uses additional lines ( DSR, DTR, RTS, CTS) to signal when the device is ready to receive data. These handshake lines use +3 to +25 Vdc to indicate a true, and -3 to -25 to indicate a false condition. When a DTE is ready to communicate, it drives the DTR line true. The DCE (395) will respond by driving the DSR line true. Then the DTE will drive RTS true when it is ready to receive data and the DCE will drive CTS true when it is ready to receive data.

Table 2-2a. Model 395 RS-232 Connections (DB-9)

Pin |

|

Name |

Direction |

Description |

1 |

|

DCD |

OUT |

Carrier Detect |

2 |

|

RxD |

IN |

Receive Data |

3 |

|

TxD |

OUT |

Transmit Data |

4 |

|

DTR |

IN |

Data Terminal Ready |

5 |

|

GND |

COMMON |

Signal Ground |

6 |

|

DSR |

OUT |

Data Set Ready |

7 |

|

RTS |

IN |

Request To Send |

8 |

|

CTS |

OUT |

Clear To Send |

9 |

|

NC |

- - - |

No Connection |

|

|

|

||

|

|

Table 2-2b. Standard DTE RS-232 Connections |

||

|

|

|

|

|

Pin |

|

Name |

Direction |

Description |

DB-9 DB-25 |

|

|

||

|

|

|

|

|

1 |

8 |

DCD |

IN |

Carrier Detect |

2 |

3 |

RxD |

IN |

Receive Data |

3 |

2 |

TxD |

OUT |

Transmit Data |

4 |

20 |

DTR |

OUT |

Data Terminal Ready |

5 |

7 |

GND |

COMMON |

Signal Ground |

6 |

6 |

DSR |

IN |

Data Set Ready |

7 |

4 |

RTS |

OUT |

Request To Send |

8 |

5 |

CTS |

IN |

Clear To Send |

9 |

22 |

RI |

IN |

Ring Indicator |

|

|

|

|

|

The Model 395 RS-232 signal names are defined below. A positive voltage above +3Vdc is defined as a logic ‘0’ or ‘ON’. A negative voltage below -3 Vdc is defined as a logic ‘1’ or ‘OFF’.

DCD |

Internally connected to pins 4 (DTR) and 6 (DSR) in the model 395. A logic ‘0’ |

|

signifies that the 395 is ready for communication. See notes for DTR. |

TxD |

Serial data output from Model 395. |

RxD |

Serial data input to Model 395. |

DTR |

Signal from a DTE that indicates it is ready for communication. This signal is |

|

internally connected to pins 1 (DCD) and 6 (DSR). Upon receipt of a logic ‘0’, |

|

the DCD and DSR are driven to logic ‘0’ thus signaling that the 395 is ready for |

|

communication. |

GND |

Connected to internal signal ground. This should be connected to a ground point |

|

on the device that the 395 is going to communicate with for proper error free |

|

operation. |

Initial Preparation 2-9

DSR |

Internally connected to pins 1 (DCD) and 4 (DTR) in the model 395. A logic ‘0’ |

|

signifies that the 395 is ready for communication. See notes for DTR. |

RTS |

A logic ‘0’ on this pin indicates that the device that is connected to the 395 is ready |

|

to receive data. When handshaking is disabled, this line is ignored by the 395. |

|

The length of time that the 395 will wait before aborting transmission can be set |

|

in the RS-232 setup screen (see section 5). The Model 395 will respond to a logic |

|

‘1’ with a transmission latency of one character. |

CTS |

A logic ‘0’ indicates that the Model 395 is ready to receive data. When |

|

handshaking is enabled, this line is driven to logic ‘1’ when the 395 receive buffer |

|

is about 2/3 full. Data will continue to be stored in the buffer until it is full. This |

|

line will be driven to a logic ‘0’ when the buffer drops below 2/3 full. To prevent |

|

data loss, this line should be connected and recognized by the other device. |

|

NOTES: |

|

Although communication can be accomplished using only the Transmit |

|

and Receive lines, it is recommended that the ground and handshake |

|

lines are connected so no data is lost due to the high transfer rates |

|

possible with the Model 395. |

|

Software handshaking ( XON / XOFF ) is not supported by the Model |

|

395. |

|

The Model 395 data format is 8 data bits, no parity, 1 stop bit. |

2.11.2 IEEE-488 (Option 001)

To connect the Model 395 via the IEEE-488 interface to a computer or digital storage oscilloscope, DSO, (figure 2-6), use a standard IEEE-488 bus cable [Wavetek-Datron part number 630364 (1 metre) or 630366 (2 metres)]. For more information on remote programming using IEEE-488, refer to section 5 of this manual.

CAL ENABLE

BATTERY

TEST

NORM - CAL

Cal Sticker

BAT GND

IEEE-488

Connector

Figure 2-6. IEEE-488 Connector

Note that the 0 V connection on the IEEE-488 connector is internally connected to the floating analog common and not ground.

2-10 Initial Preparation

Introduction To The Model 395 |

Section 3 |

|

|

|

|

3.1 OVERVIEW OF THE MODEL 395

The Model 395, 100 MHz Synthesized Arbitrary Waveform Generator, produces a variety of standard, pulse, noise, and user-defined (Arbitrary) waveforms. In addition, the Model 395 allows linking of up to four arbitrary waveforms to form a Sequence. Plus, the Model 395 triggers, sweeps, and modulates all waveforms. Also, sum an external signal with the generator’s internal signal.

The Model 395 stores up to 100 Arbitrary waveforms in battery-backed memory.

Complete instrument setups can be stored and recalled.

Using the Model 395

This section introduces front panel operation of the Model 395. Included in this section are a series of examples demonstrating the features of the unit. Section 4 contains reference information about Model 395 operation. Section 5 describes the SCPI remote programming commands, RS-232 operation, and optional IEEE 488 operation. Section 5 also contains a series of SCPI language remote programming examples demonstrating the unit’s features; these examples are the remote programming equivalent of the examples in this section.

Appendix B of this manual contains a front panel screens quick reference, while appendix C contains SCPI commands quick reference.

3.2NAVIGATING THE SCREENS

3.2.1Front Panel Keys and Screens

Pressing front panel keys display screens with program parameters relative to the key pressed. Change program parameters by using softkeys (F1 through F8), or change numeric values using the keypad or knob. For example, press the FREQUENCY key to display the Frequency screen; see figure 3-1.

Introduction To The Model 395 3-1

FREQUENCY

STANDARD FREQUENCY |

|

1.000000000 kHz |

|

freq |

period |

Figure 3-1. Frequency Screen

Try pressing the TRIG IN key or MODE key to display their screens.

3.2.2 Softkeys

The Model 395 front panel softkeys (F1 through F8) allow you to select items from the screen (figure 3-2).

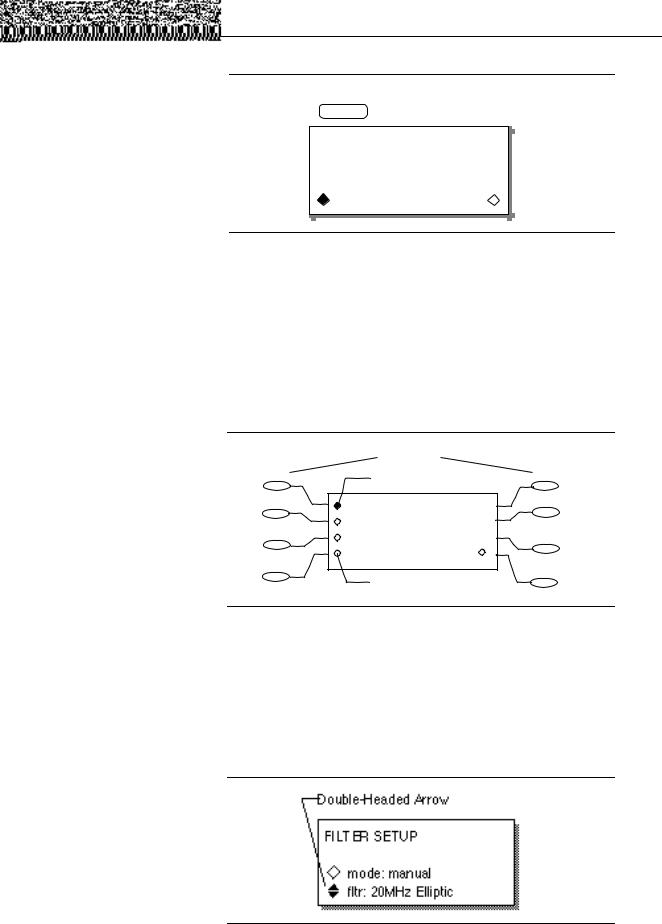

Diamonds on the screen identify selectable screen items. Hollow diamonds identify deselected items. Filled diamonds denote selected items. For example, press MODE and then press F3 to select the “gated” mode (figure 3-2). Default items are initially displayed with filled-in diamonds (like continuous in figure 3-2).

|

|

Softkeys |

|

F1 |

Selected Item |

F5 |

|

F2 |

continuous |

F6 |

|

|

sweep |

|

|

F3 |

gated |

|

F7 |

F4 |

trig'd, |

cnt:0000001 |

|

|

|

F8 |

|

|

Unselected Item |

||

|

|

||

Figure 3-2. Softkeys (Mode Screen)

3.2.3 Extended Screens

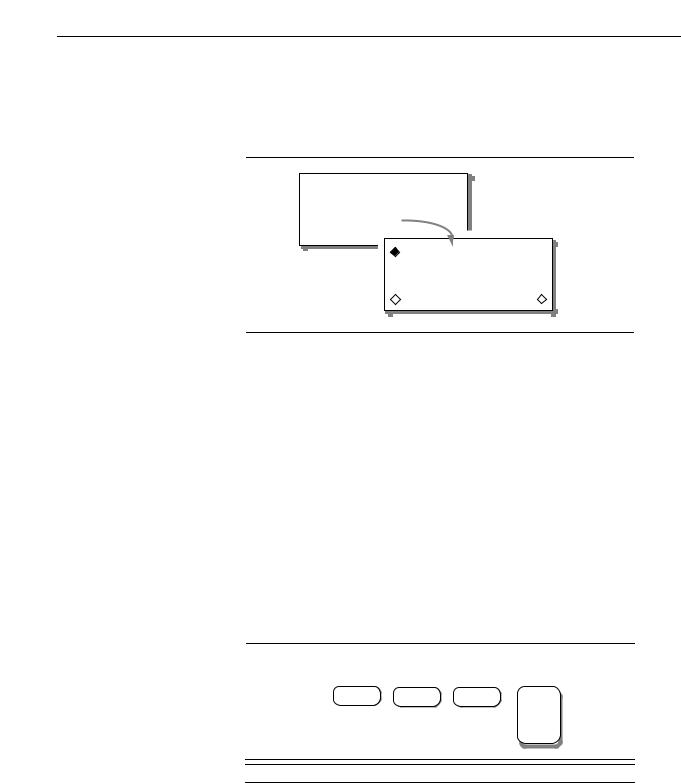

Double-Headed Arrows

Double-headed arrows on the screen indicate additional screen items can be accessed by using the knob or the cursor keys. See figure 3-3. Also, items next to double-headed arrows also can be selected by using the softkey.

Figure 3-3. Double-Headed Arrow (Filter Screen)

3-2 Introduction To The Model 395

… Ellipsis

An ellipsis (three dots following screen text) indicates additional screens will follow when selected. For example, press the Waveform Edit’s CREATE key and check out “create blank …,” see figure 3-4.

CREATE NEW WAVEFORM (avail mem: 64512)

create blank …

create blank …  create from copy …

create from copy …

CREATE: "wv2_____" |

|

size: 1024 |

|

(max: 64512) |

|

cancel |

create |

Figure 3-4. “Ellipsis” (Create Screen)

3.2.4 Changing Numeric Values

The Model 395 allows you to change numeric values using the numeric keypad or knob. The screen displays modifiable values with the “cursor” starting under the most significant digit. For example, try pressing the OFFSET key.

With the Keypad

To enter values using the keypad, press the numeric key. The Model 395 accepts the value when the Enter key is pressed.

The Model 395 accepts values in three basic formats: Integer (10), floating point (10.0), and exponential (1 exp 1).

For example, to change the frequency to 50 kHz using the exponential format, enter the value by pressing these keys:

5 |

EXP |

4 |

ENTER |

50.00000000 kHz

Using the Knob

The front panel knob also can be used to change numeric values. When using the knob, values are always changed starting from the digit over the cursor. To modify a value using the knob, place the cursor under the desired digit, and rotate the knob to change the value. Clockwise rotation increases the value; and counterclockwise rotation decrease the values.

For example, to use the knob to set the frequency to 50.35 kHz, press the FREQUENCY key to display the Standard Frequency screen; see figure 3-5. Note: the number of digits shown on the frequency screen depends on the selected waveform.

Introduction To The Model 395 3-3

STANDARD FREQUENCY |

|

50.00000000 kHz |

|

freq |

period |

Figure 3-5. Knob Example

Use the right “cursor” key to move the cursor over three digits.

3X

50.00000000 kHz

Rotate the knob clockwise until the frequency reads 50.35000000 kHz.

50.35000000 kHz

3.2.5 Correcting Mistakes

If you make a mistake while entering a value from the front panel, you can make corrections by using the CLEAR key or the BSP (Backspace) key.

Use the CLEAR key to erase the entire value. Pressing ENTER, rotating the knob, or pressing a cursor key, restores the original value providing a value has not been entered via the keypad.

When using the keypad to enter values, press the ¨ BSP (backspace) key to erase the digits to the left of the cursor. Then use the keypad to enter the correct value.

3.3 ON-SCREEN HELP

The Model 395 includes on-screen help for the current screen. To access a Help screen, press the HELP “button;” see figure 3- 6. Rotate the knob or use the cursor keys to display additional help lines. Press the HELP key a second time to return to the operation screen.

3-4 Introduction To The Model 395

Loading...

Loading...