Page 1

INSTRUCTION HANDBOOK

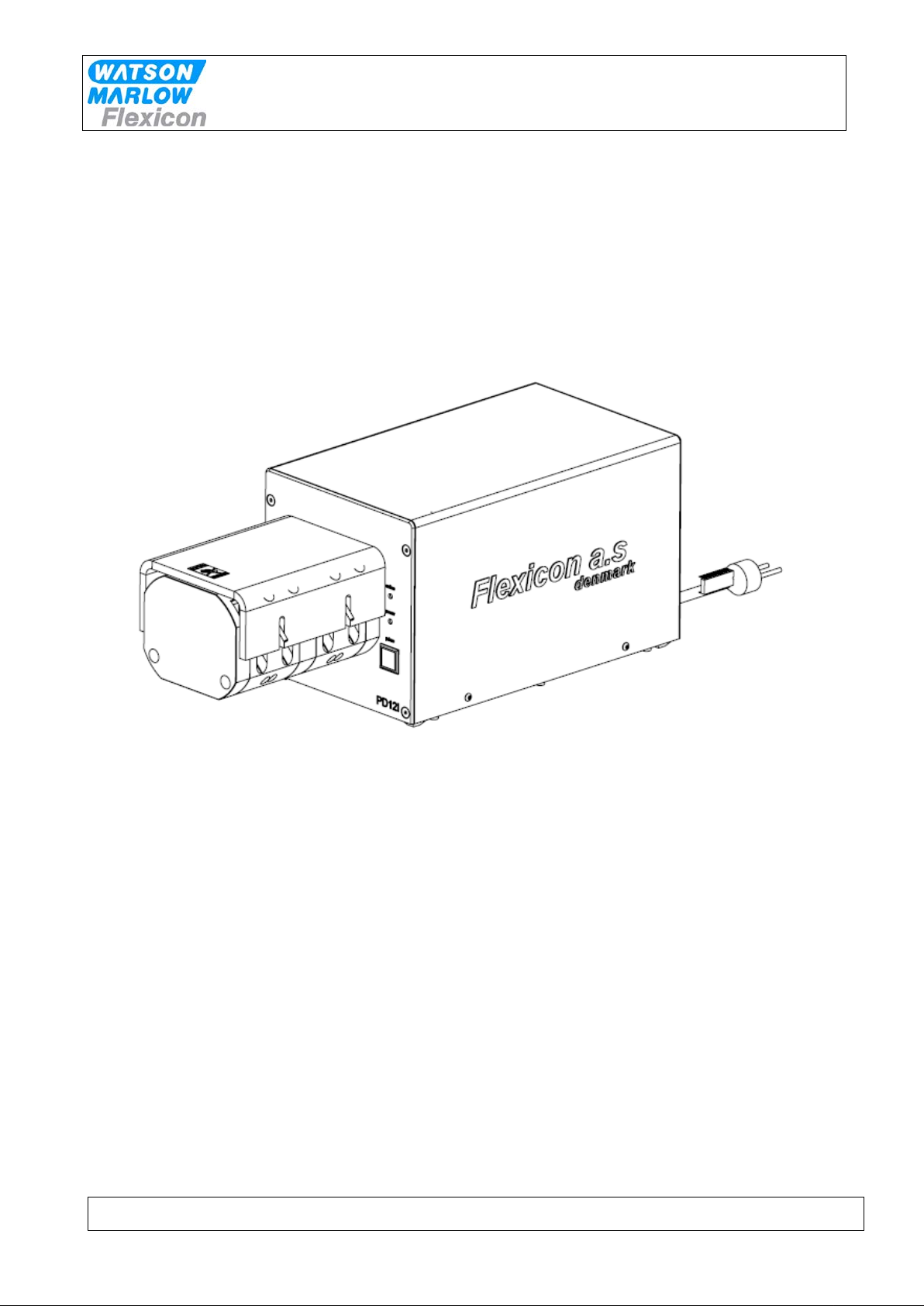

PD12IHS / PD12IDH

PD12 IHS / PD12 IDH

(example; exact model may vary)

This instruction handbook is for the daily users of the equipment.

PD12IHS_PD12IDH IH EN 74-115-181 v2.00.doc Version: 2.00 Page 1 of 19

Page 2

INSTRUCTION HANDBOOK

PD12IHS / PD12IDH

Table of Contents

1

Introduction .............................................................................................................................. 3

1.1 The peristaltic principle ............................................................................................................ 3

1.2 Abbreviations in this manual .................................................................................................... 3

1.3 Symbols on the machine ......................................................................................................... 4

1.4 Caution and employee safety .................................................................................................. 4

1.5 Essential training before daily use ........................................................................................... 4

1.6 References .............................................................................................................................. 5

2 General information ................................................................................................................. 5

2.1 Unpacking and inspection ........................................................................................................ 5

2.2 Technical specifications ........................................................................................................... 5

3 Installation ............................................................................................................................... 6

4 Daily Use ................................................................................................................................. 8

4.1 Starting-up and running ........................................................................................................... 8

4.2 Placing the product container .................................................................................................. 8

4.3 Choosing tubes, y-connectors and filling nozzles ..................................................................... 9

4.4 Assembly of tubes and Y-connectors ..................................................................................... 10

4.5 Mounting of silicone tubes ..................................................................................................... 11

4.6 Dispensing ............................................................................................................................. 12

4.6.1 Prime tubes ........................................................................................................................... 12

4.6.2 Problems with drips ............................................................................................................... 12

4.6.3 Problems with hard feed ........................................................................................................ 12

5 Choice of parameters ............................................................................................................ 13

5.1 Programming principle ........................................................................................................... 13

5.1.1 Description of PD12 specific functions/parameters ................................................................ 13

Function 1 – Volume .......................................................................................................................... 13

Function 2 - Tube diameter ................................................................................................................ 13

Function 3 - Velocity .......................................................................................................................... 13

Function 4 - Acceleration/deceleration ............................................................................................... 14

Function 5 - Reversing (back suction) ................................................................................................ 14

6 Cleaning ................................................................................................................................ 15

6.1 Cleaning Frequency .............................................................................................................. 15

6.2 Preparations for cleaning ....................................................................................................... 15

6.3 Cleaning Guidance ................................................................................................................ 15

6.4 Detergents or cleaning agents ............................................................................................... 15

7 Maintenance & service .......................................................................................................... 16

7.1 Daily maintenance ................................................................................................................. 16

7.2 Service .................................................................................................................................. 16

7.3 Methods and frequency of inspections for safety functions .................................................... 16

8 Interface and change of voltage ............................................................................................. 17

8.1 PD12 interface ....................................................................................................................... 17

8.2 Connecting multiple PD12’s to flexnet ................................................................................... 18

8.3 Change of voltage ................................................................................................................. 18

9 Declaration of conformity ....................................................................................................... 19

PD12IHS_PD12IDH IH EN 74-115-181 v2.00.doc Version: 2.00 Page 2 of 19

Page 3

INSTRUCTION HANDBOOK

e.g.

As example

Fig.

Figure

Hz

Hertz

i.d.

Internal diameter

IDH

Industrial Double Head

IHS

Industrial High Speed

MC12

Flexicon Master Controller

mA

milli Ampere

msec

milli secunds

o.d.

Outer diameter

PD12

Peristaltic Dispenser

VAC

Volt Alternating Current

VDC

Volts Direct Current

PD12IHS / PD12IDH

1 Introduction

This manual covers two models.

PD12 IHS (high speed). This model fills one bottle at a time.

In the double head the tubes are mounted in pairs of 2 and via y-connectors these are joined into one

tube in order to fill one bottle at a time.

and

PD12 IDH (double head). This model fills two bottles simoultaneously.

In the double head the tubes are mounted in pairs of 2 and via y-connectors each set of tubes are

joined into one tube in order to fill two bottles simoultaneously.

In general all sections of the manual cover both models; unless clearly specified.

1.1 The peristaltic principle

PD12 operates with a peristaltic dispenser head (tube pump), where the liquid only comes into

contact with the flexible tube, the tube connections and the filling nozzle. The tubes are usually made

of silicone, but other materials can also be used.

The dispenser head is designed in such a way that sterilized tubes can be mounted in the head

without affecting the sterility.

The dispenser head is self-priming, and the dispenser head itself can stand to be run dry (not

recommended for the sake of the tubes).

The dispenser head on PD12 works with four parallell tubes which are squeezed by rollers mounted

on ball bearings. The rollers in are offset in order to eliminate pulsation.

1.2 Abbreviations in this manual

PD12IHS_PD12IDH IH EN 74-115-181 v2.00.doc Version: 2.00 Page 3 of 19

Page 4

INSTRUCTION HANDBOOK

PD12IHS / PD12IDH

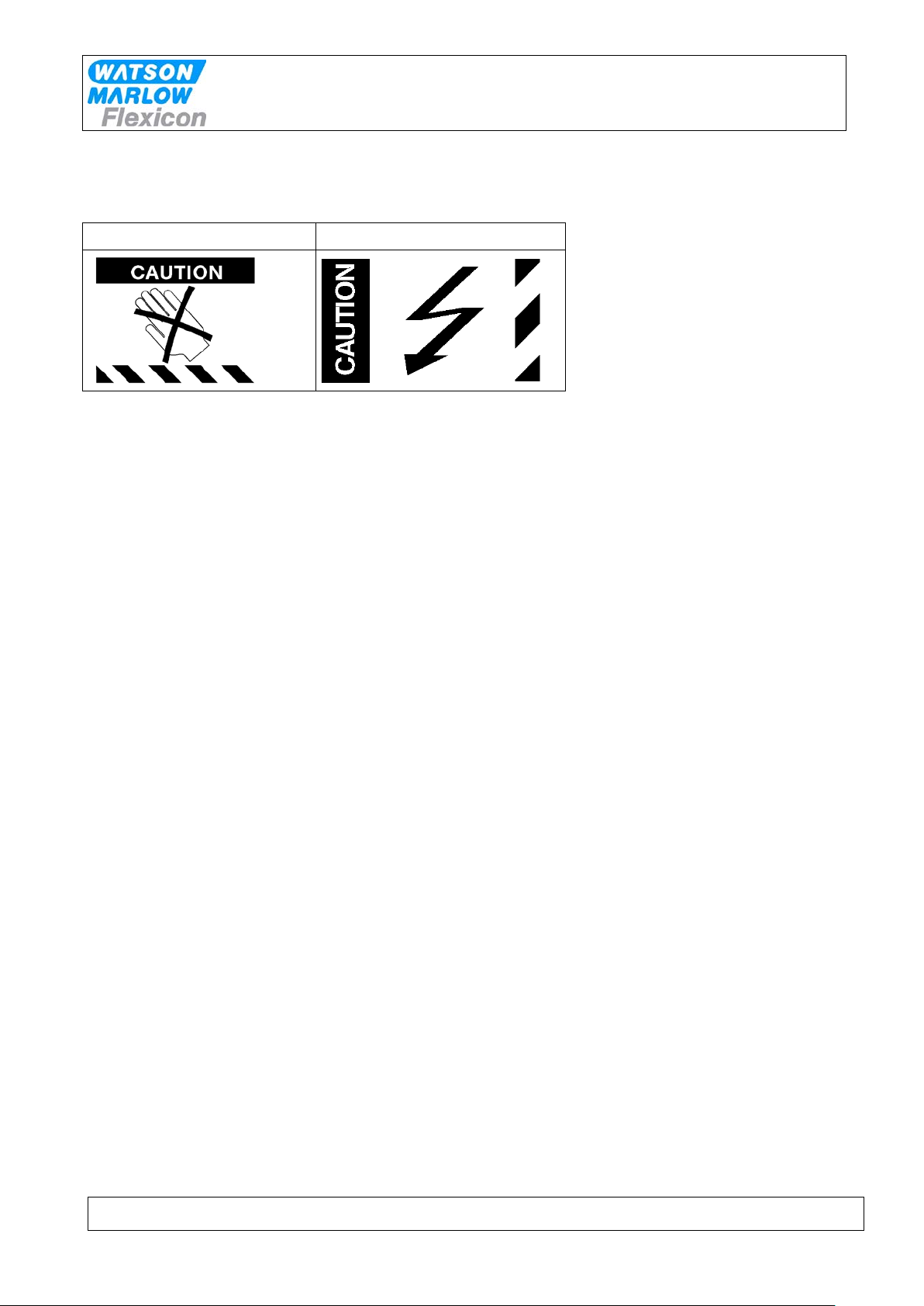

1.3 Symbols on the machine

Warning against touching Warning against high voltage

Fig. 1 – Symbols

1.4 Caution and employee safety

This manual should be read before using the PD12.

It is strongly advised that

- Any kind of maintenance or cleaning of the machine not is carried out while power is

connected

- Unauthorised / non-trained personnel should not open the cover of the electrical parts

- The machine is placed in such a way that it is not exposed to high humidity, high temperatures

or other abnormal operating environment.

- The machine is not to be used in explosion hazardous environments.

- When operating the machine make sure that the dispenser heads are closed and that safety

cover is placed above.

- The machine should be used for dosing and filling of liquid fluids, only.

A peristaltic dispenser head is not suitable for viscous products; see section 4.3

1.5 Essential training before daily use

Read the section with Daily Use, thoroughly before using the machine.

Protective equipment and protective devices are installed:

The machine is equipped with a safety cover which protects the operator from hazards; the

machine will not run unless the safety cover is placed.

Always respect the symbols on the machine.

Cleaning must be performed as described in section 6.

PD12IHS_PD12IDH IH EN 74-115-181 v2.00.doc Version: 2.00 Page 4 of 19

Page 5

INSTRUCTION HANDBOOK

Buttons:

PD12IHS / PD12IDH

1.6 References

- MC12 manual

2 General information

2.1 Unpacking and inspection

Please check that all ordered items have been received and that no items are damaged during

transport. In case of any defects or omissions, please contact W-M Flexicon or your supplier

immediately.

2.2 Technical specifications

Dimensions:

Length: 525 mm

Width: 200 mm

Height: 208 mm (incl. Feet)

Fig. 2 – Dimensions

online

Lights when communicating with MC12.

power

Lights when the machine is on.

prime

Pushbutton for tube priming

Fig. 3 - Buttons on PD12

PD12IHS_PD12IDH IH EN 74-115-181 v2.00.doc Version: 2.00 Page 5 of 19

Page 6

INSTRUCTION HANDBOOK

PD12IHS / PD12IDH

Other:

Weight: 13 kg

Motor: High Torque Step Motor MST341B02

PD12 Power consumption: max 150 Watt

Mains: 110/230 VAC earthed, 50/60 Hz

3 Installation

PD12 must be placed on a stable bedplate. All electrical connections are on its rear.

2

3

1

Fig. 4 - Connections

The cable with plug (1) is connected to an earthed switch.

The communication cable from MC12 (type 3) comes fitted with two 4-pin DIN plugs. One is

connected to the "net 1" socket (2) on the PD12, and the other plug is connected to the "net" socket

on MC12.

The terminator supplied with MC12 (4-pin blind DIN plug) is connected to the "net 2" (3) socket on

PD12.

Should the system be operating more than one PD12, the "net 2" socket (3) is to be connected to the

"net 1" socket (2) on the next PD12 by a communication cable (type 3). The terminator is connected

to the last PD12 on the line.

PD12 is now ready to be switched on and to be programmed from the MC12.

If the PD12 is one of several filling stations in a system, none of the stations may have the same

address and it must therefore be changed.

PD12IHS_PD12IDH IH EN 74-115-181 v2.00.doc Version: 2.00 Page 6 of 19

Page 7

Address

1 2 3 4 5 6 7 8 9

10

11

12

13

14

15

16

SW1

1 0 1 0 1 0 1 0 1 0 1 0 1 0 1

0

SW2

1 1 0 0 1 1 0 0 1 1 0 0 1 1 0

0

SW3

1 1 1 1 0 0 0 0 1 1 1 1 0 0 0

0

SW4

1 1 1 1 1 1 1 1 0 0 0 0 0 0 0

0

Change of address is performed via a dip-switch

placed underneath the PD12. This change may

only be carried out when the machine is turned

off at the main isolator.

Addresses between 1 and 16 may be chosen,

and the table below shows the various

combinations.

Address "1" is the factory setting of PD12.

This can be changed – see below.

Dip-switch settings:

INSTRUCTION HANDBOOK

PD12IHS / PD12IDH

PD12IHS_PD12IDH IH EN 74-115-181 v2.00.doc Version: 2.00 Page 7 of 19

Page 8

INSTRUCTION HANDBOOK

Flexicon

Pump Head

Preferred Placement

of container

Normal Placement

of container

Suction side Pressure side

Dispenser head

PD12IHS / PD12IDH

4 Daily Use

4.1 Starting-up and running

Installation section must be carried out before this chapter can be performed.

4.2 Placing the product container

In order to build up adequate pressure, it is recommendable to place the product container at the

same level as dispenser head or preferably above the dispenser head level. Placing the container

higher than dispenser head level provides positive product support and may reduce the calibration

interval. It is also recommended to place the container as close as possible to the dispenser on

suction side.

Fig. 5 - placing the product container

PD12IHS_PD12IDH IH EN 74-115-181 v2.00.doc Version: 2.00 Page 8 of 19

Page 9

INSTRUCTION HANDBOOK

Connector

< 1.00

0,6

0,5

2,4

1.00 – 2.00

1,0

0,8

2,4

2.00 – 3.40

1,6

1,2

3,6

3.40 –14.0

3,2

1,6

3,6

14.0–24.0

4,5

3,2

5,9

24.0 – 44.0

6,0

4,8

7,2

44.0 – 70.0

8,0

6,0

9,5

>70.0 ml

8,0*

8,0

12,4

Connector

< 0.50

0,6

0,5

2,4

0.50 – 1.00

1,0

0,8

2,4

1.00 – 1.70

1,6

1,2

3,6

1.70 – 7.00

3,2

1,6

3,6

7.00 – 12.0

4,5

3,2

5,9

12.0 – 22.0

6,0

4,8

7,2

22.0 – 35.0

8,0

6,0

9,5

>35.0 ml

8,0*

8,0

12,4

* use non-return valve

PD12IHS / PD12IDH

4.3 Choosing tubes, y-connectors and filling nozzles

The filling is carried out by the PD12 which is controlled by the MC12.

The capacity is based on the volume to be dispensed, however a lot of factors can influence on the

obtainable capacity; e.g. choice of tubes and type of product.

These aspects must be considered before choosing the filling settings.

Tubes must be selected according to the application and volume to be filled. Use the table shown

below for choice of tubes according to minimum volume to be filled.

PD12 can operate with different tube dimensions chosen according to the volume to be dispensed.

The tubes are designated by their internal diameters (i.d.) in millimetres. This value is always used as

designation for the individual tube, and this is also the value to be entered in function 2 at the MC12

master controller.

In order to obtain stable and good results, the choice of tubing can be made according to the following

guidelines:

PD12 IHS

Volume

ml

* use non-return valve

Nozzle

mm i.d.

Tubing

mm i.d.

Y-

o.d.

PD12 IDH

Volume

ml

Nozzle

mm i.d.

Tubing

mm i.d.

Y-

o.d.

PD12IHS_PD12IDH IH EN 74-115-181 v2.00.doc Version: 2.00 Page 9 of 19

Page 10

INSTRUCTION HANDBOOK

this.

PD12IHS / PD12IDH

The filling time for a volume of 10.0 ml with a Ø3.2 ID tube is 0.8 seconds with dispenser running in

high speed i.e. 400 in rpm and 100 in acceleration.

The same volume can be obtained with Ø4.8 ID tube in 0.55 seconds for the same parameters.

The contrast here is outweighed by the fact that Ø3.2 ID tube will in this case yields better accuracy

than the option of using Ø4.8 ID. But as it is indicated the capacity will be higher with Ø4.8 tube since

filling time is shorter.

The above mentioned example should be considered as guidance only, and adjustments should be

done for the individual applications.

4.4 Assembly of tubes and Y-connectors

Before mounting the tubes in the dispenser head

the tubes must be ass embled with a Y-connector.

When the Y-connector has been assembled,

mount the tubes in the dispenser head, as shown

in 4.5

Each set of tubes and y-connector must be assembled as

PD12 IHS

PD12 IHS (high speed). This model fills one

bottle at a time.

In the double head the tubes must be

mounted in pairs of 2 and via y-connectors

these are joined into one tube.

PD12 IHS

PD12 IDH (double head). This model fills two

bottles simoultaneously.

In the double head the tubes must be

mounted in pairs of 2 and via y-connectors

each set of tubes are joined into one tube.

PD12IHS_PD12IDH IH EN 74-115-181 v2.00.doc Version: 2.00 Page 10 of 19

Page 11

INSTRUCTION HANDBOOK

1

2

3

Mount the correct tube lock (1) on its dowel pin and place the tubes.

Now mount the tube bridge in its tracks and engage the two locking pins.

PD12IHS / PD12IDH

4.5 Mounting of silicone tubes

PD12 is equipped with tube bridges and tube locks. The tube locks ensure that the mounted tubes do

not slide through the dispenser head when running.

The tube bridge retains the tube and performs the necessary pressure on the tubes.

Open the dispenser head by tipping each of the two locking pins up and lift the tube bridge

Figure 4-1 Removing the tube bridge

It is important that the tubes are situated in the two notches (2+3).

The Y-connector must be situated at the opposite side of the tube lock.

Figure 4-2 Mounting of silicone tubes

NB! Never leave the dispenser mounted with tubes overnight.

At least tip the locking pins up in order not to retain the tube in pressure.

PD12IHS_PD12IDH IH EN 74-115-181 v2.00.doc Version: 2.00 Page 11 of 19

Page 12

INSTRUCTION HANDBOOK

PD12IHS / PD12IDH

4.6 Dispensing

4.6.1 Prime tubes

When the tubes and Y-connectors have been assembled and mounted in the dispenser head, the

tubes must be primed; priming tubes have the purpose of filling the tubes with the product.

First, place the product container.

Hold a collecting bowl under the filling nozzle(s) press the prime button.

Check that the tubes are free of bubbles and that the end of the tubes on the suction side, are under

the liquid surface. The suction tubes must not have contact with the container body.

4.6.2 Problems with drips

During filling drips can cause incorrect filling volumes and that the area underneath the filling nozzle

becomes contaminated. If drips occur the following can be tried:

choose a smaller filling nozzle

decrease speed

increase acceleration

use reversion

mount a non-return v alve

4.6.3 Problems with hard feed

When dispensing with small tubes, counter pressure on the pressure side of dispenser head might

constitute inaccuracy and instability in filling (hard feed). In some cases the problem can be resolved

by using a larger tube on the pressure side (after Y-connector).

PD12IHS_PD12IDH IH EN 74-115-181 v2.00.doc Version: 2.00 Page 12 of 19

Page 13

INSTRUCTION HANDBOOK

Value

Option

Min

Max

0.01

9999.9

ml. or gram

Tube Sizes

Max. Velocity

Max. acceleration

0.5 - 0.8 – 1.2 – 1.6

400

100

3.2

400

100

4.8 - 6.0 – 8.0

400

100

PD12IHS / PD12IDH

5 Choice of parameters

5.1 Programming principle

The actual programming will be made on the MC12; however some parameters are PD12 specific.

5.1.1 Description of PD12 specifi c functions/parameters

The functions below affect filling and calibration.

If the value of the parameter is changed during filling or calibration, the new value will not be applied

until the start of the next filling or calibration.

Please note that if parameters are changed during filling a new calibration is reccomended.

Function 1 – Volume

Value: ml

Function 1 informs the system of the volume to be filled.

The entered value must be between 0.01 and 9999.9.

PD12 IHS:

When entering a volume of e.g. 100 ml, this will be shared among the double heads into 2 x 50 ml.

PD12 IDH:

When entering a volume of e.g. 100 ml, this will trigger each head to fill 100 ml.

Function 2 - Tube diameter

Value: Inside diameter of the tube in mm.

Drive type Tube inside diameter in mm

PD12 0.5 0.8 1.2 1.6 3.2 4.8 6.0 8.0

Function 3 - Velocity

Value: Revolutions per minute (rpm).

Velocity range depends on tube size applied.

Range:

PD12IHS_PD12IDH IH EN 74-115-181 v2.00.doc Version: 2.00 Page 13 of 19

Page 14

INSTRUCTION HANDBOOK

Tube Sizes

Max. Velocity

Max. acceleration

0.5 - 0.8 – 1.2 – 1.6

400

100

3.2

400

100

4.8 - 6.0 – 8.0

400

100

PD12IHS / PD12IDH

The fastest filling will be carried out at the highest velocity setting but the velocity should always be

adjusted to suit the characteristics of the product and to reduce splashing or foaming.

Function 4 - Acceleration/deceleration

Value: An integral number.

This function offers a choice of values between 1 and 200 dependent on the tube size and drive;

1 = slowest, 200 = fastest.

Function 5 - Reversing (back suction)

Value: An integral number.

After each filling the dispenser head can be set to perform a small back suction to prevent dripping.

The back suction can be set at values between 0 and 10.

0 = no back suction

10 = maximum back suction

The value has no relation to any other parameters and is solely a number of degrees of a rotor turn.

Consequently, the volume that is sucked back will depend on the tube diameter.

For other program possibilities; see the MC12 manual.

PD12IHS_PD12IDH IH EN 74-115-181 v2.00.doc Version: 2.00 Page 14 of 19

Page 15

INSTRUCTION HANDBOOK

Cleaning of parts

May

autoclaved

Can be cleaned

alcohol 70%

Can be cleaned with

wiped off with dry a cloth

Stainless steel

AISI304

Stainless steel

AISI316L

Anodized aluminium

Silicone tubes /

X**

times

PD12IHS / PD12IDH

6 Cleaning

6.1 Cleaning Frequency

As PD12 is not in direct contact with the dispensed product, daily cleaning might not be necessary.

Cleaning might be determined by local sop’s and cleaning validations; but must never be with

detergents more potent than the ones below.

6.2 Preparations for cleaning

Before cleaning the machine:

Turn off the power

Remove the tubebridge

Remove the tubes

6.3 Cleaning Guidance

Correct cleaning of the PD12 is carried out by washing it off with water or detergents, using a lint-free

firmly wrung cloth or lint-free paper towel; subsequently the machine is wiped off with a dry cloth.

6.4 Detergents or cleaning agents

Normal cleaning agents such as tepid/medium hot water, ethyl alcohol (ethanol) 70% and may be

used all over the machine.

The PD12 consists of stainlees steel and anodized aluminium, and can be cleaned in several ways:

made of:

Y-connectors

Examples:

Flexicon silicone tubes can be autoclaved

MC12 has a membrane-type keypad. The keypad is sealed and flat and can be cleaned with

alcohol or water.

**Recommendation:

Keep a log on the cleaning in order to keep a sense of perspective.

be

X X X

X X X

X X X

Max 10

with ethyl

X X

water and afterwards

PD12IHS_PD12IDH IH EN 74-115-181 v2.00.doc Version: 2.00 Page 15 of 19

Page 16

INSTRUCTION HANDBOOK

PD12IHS / PD12IDH

7 Maintenance & service

7.1 Daily maintenance

PD12 does not require any special daily maintenance, such as lubrication or the like.

7.2 Service

Should service be needed, please contact W-M Flexicon or your local supplier.

7.3 Methods and frequency of inspections for safety functions

Safety functions should be tested once a year:

Tube Bridge

Remove the safety cover on the tube bridge and press PRIME.

The machine must not start if the safety cover is not present.

Keep a log and read the previous log recordings to present an overview of the machines state.

After testing the safety functions the results must be recorded in the log.

PD12IHS_PD12IDH IH EN 74-115-181 v2.00.doc Version: 2.00 Page 16 of 19

Page 17

INPUT FOR START SIGNAL

+5 - 50 VDC, min. 100 msec. positive-edge-trigged.

STATUS OUTPUT, MAX. +24 VDC, 100 MA.

Pin 4 is grounded via an open collector during filling.

INPUT FOR DISABLING.

+5 - 50 VDC. if this pin is activated, the drive will be disabled (no dispensing).

STATUS OUTPUT, MAX. +24 VDC, 100 MA.

Pin 4 is grounded via an open collector during filling.

STATUS OUTPUT, MAX. + 24 VDC, 100 MA.

Pin 5 is complementary to pin 4.

8 Interface and change of volta ge

8.1 PD12 interface

INSTRUCTION HANDBOOK

PD12IHS / PD12IDH

1

2

3

4

1 = External 1:

PIN 1:

PIN 2: OUTPUT, +24 VDC, MAX. 500 MA.

PIN 3: GROUND.

PIN 4:

PIN 5: STATUS OUTPUT, MAX. +24VDC, 100 mA Pin 5 is complementary to pin 4.

2 = External 2:

PIN 1:

PIN 2: OUTPUT, +24 VDC, MAX. 500 MA.

PIN 3: GROUND.

PIN 4:

PIN 5:

3 = Net 1

4 =Net 2

PD12IHS_PD12IDH IH EN 74-115-181 v2.00.doc Version: 2.00 Page 17 of 19

This socket is reserved for (RS-485) network communication.

This socket is reserved for (RS-485) network communication.

Page 18

BLUE

YEL/GR.

BROWN

WHITE

BLACK

BROWN

NET plug on MC12/

MC12P

1

16

1

16

BLUE

YEL/GR.

BROWN

BLUE

YEL/GR.

BROWN

WHITE

BLACK

BROWN

WHITE

BLACK

BROWN

LINE

EARTH

NEUTRAL

1

16

4

3

1

2

Drive 1 Drive 2 Drive 3

Connection of PD12P's in Flexnet

8.2 Connecting multiple PD12’s to flexnet

INSTRUCTION HANDBOOK

PD12IHS / PD12IDH

8.3 Change of voltage

The PD12 can be converted to accept another supply voltage.

The conversion can be made inside the machine by moving the cables of the transformer clamps.

PD12IHS_PD12IDH IH EN 74-115-181 v2.00.doc Version: 2.00 Page 18 of 19

Page 19

INSTRUCTION HANDBOOK

DS EN/ISO 12100

Safety of machinery - Basic concepts, general

principles of design

DS/EN 60204

Safety of machinery – Electrical equipment of

machines

2006/42/EC

On the approximation of the laws of the Member

States relating to machinery

2006/95/EC

On the harmonization of the laws of Member

for use within certain voltage limits

2004/108/EC

On the approximation of the laws of the Member

States relating to electromagnetic compatibility

Ringsted, Denmark

9 Declaration of conform ity

We Watson-Marlow Flexicon A/S

Frejasvej 2-6

DK-4100 Ringsted

Declare on our sole responsibility that the product:

Peristaltic dispenser: PD12 I HS / PD1 2 IDH

Model: 61-154-014

To which this declaration relates is in conformity with the following standard(s):

PD12IHS / PD12IDH

According to the provisions in the Directives:

States relating to electrical equipment designed

January 2011

Signature:

Jørn Jeppesen, Development Manager

PD12IHS_PD12IDH IH EN 74-115-181 v2.00.doc Version: 2.00 Page 19 of 19

Loading...

Loading...