Page 1

MICROMASTER 440

0.12 kW - 250 kW

Operating Instructions Issue 10/06

User Documentation

6SE6400-5AW00-0BP0

Page 2

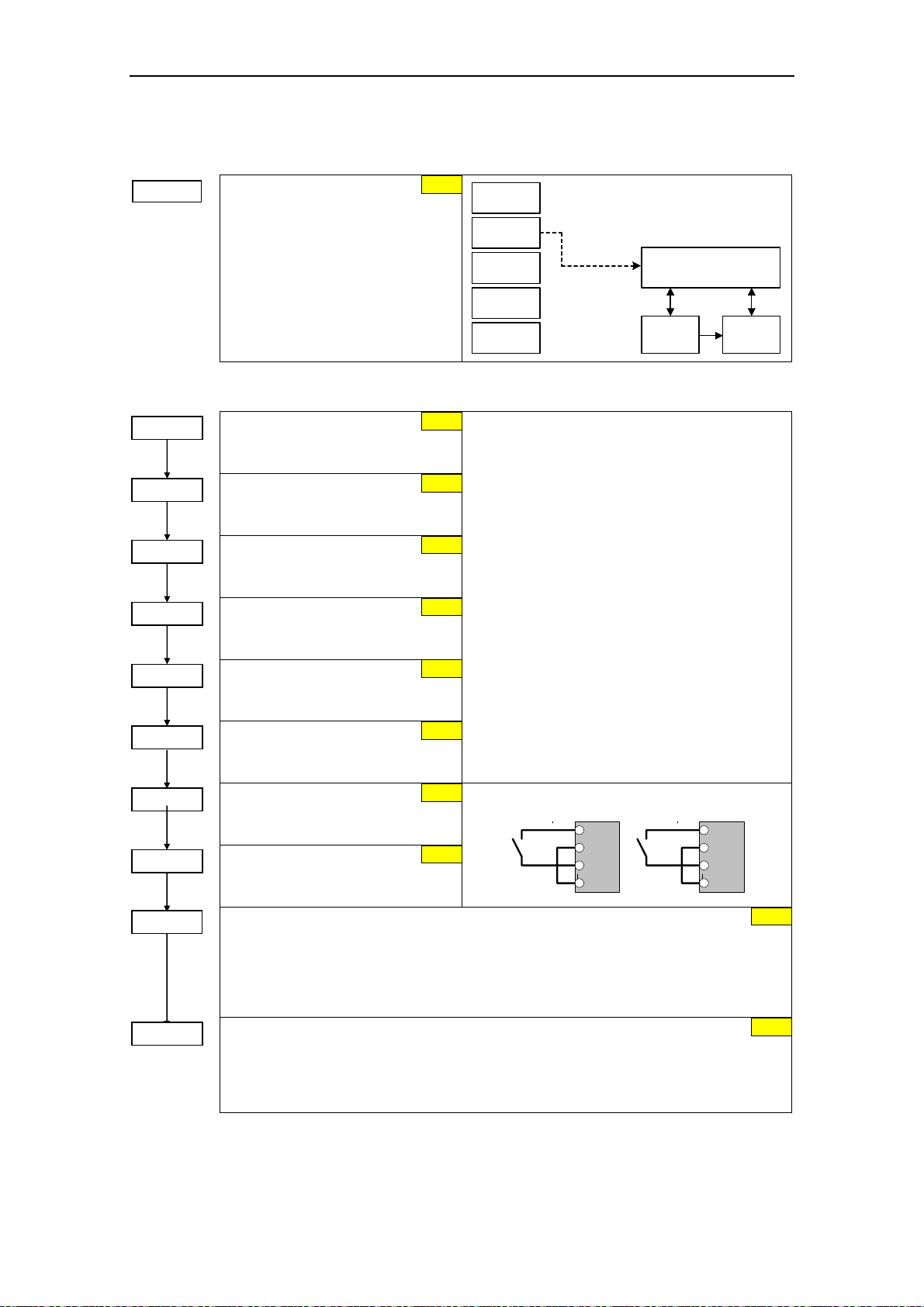

MICROMASTER 440 Documentation

Getting Started Guide

Is for quick commissioning with SDP and BOP.

Operating Instructions

Gives information about features of the

MICROMASTER 440, Installation, Commissioning,

Control modes, System Parameter structure,

Troubleshooting, Specifications and available options

of the MICROMASTER 440.

Parameter List

The Parameter List contains the description of all

Parameters structured in functional order and a

detailed description. The Parameter list also includes

a series of function plans.

Catalogues

In the catalogue you will find all the necessary

information to select an appropriate inverter, as well

as filters, chokes, operator panels and

communication options.

Page 3

Overview

1

MICROMASTER 440

0.12 kW - 250 kW

Operating Instructions

User Documentation

Installation

Functions

Troubleshooting

Specifications

Options

Electro-Magnetic

Compatibility

2

3

4

5

6

7

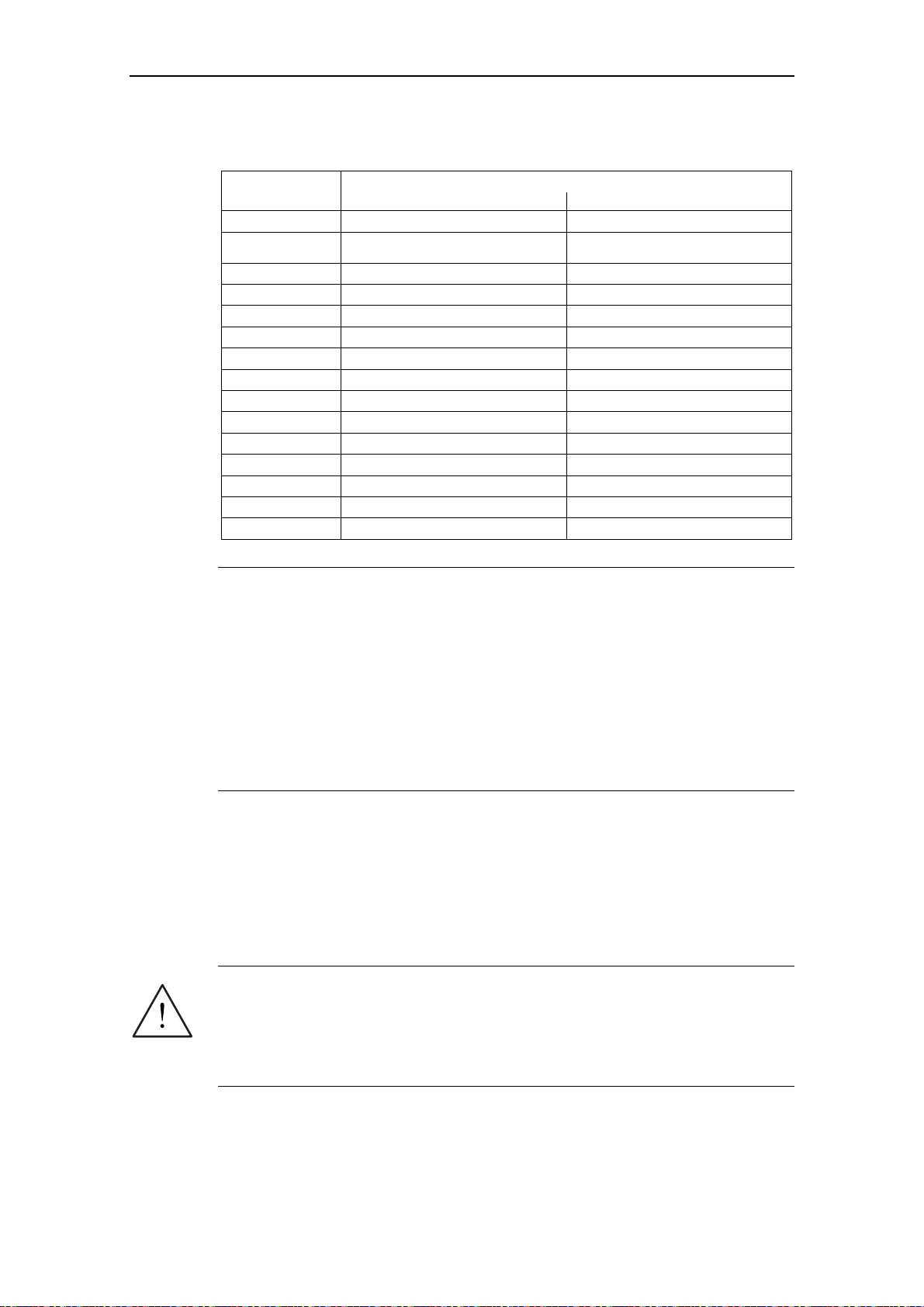

Valid for Issue 10/06

Inverter Type Software Version

MICROMASTER 440 2.1

0.12 kW - 250 kW

Appendices

Index

A

B

C

D

E

F

G

Issue 10/06

Page 4

Further information can be obtained from Internet

website:

http://www.siemens.de/micromaster

Approved Siemens Quality for Software and Training

is to DIN ISO 9001, Reg. No. 2160-01

The reproduction, transmission or use of this document,

or its contents is not permitted unless authorized in

writing. Offenders will be liable for damages. All rights

including rights created by patent grant or registration of a

utility model or design are reserved.

© Siemens AG 2001 – 2005, 2006. All Rights Reserved.

MICROMASTER® is a registered trademark of Siemens

Order number: 6SE6400-5AW00-0BP0

Other functions not described in this document may be

available. However, this fact shall not constitute an

obligation to supply such functions with a new control, or

when servicing.

We have checked that the contents of this document

correspond to the hardware and software described.

There may be discrepancies nevertheless, and no

guarantee can be given that they are completely identical.

The information contained in this document is reviewed

regularly and any necessary changes will be included in

the next edition. We welcome suggestions for

improvement.

Siemens handbooks are printed on chlorine-free paper

that has been produced from managed sustainable

forests. No solvents have been used in the printing or

binding process.

Document subject to change without prior notice.

Siemens-Aktiengesellschaft

MICROMASTER 440 Operating Instructions

4 6SE6400-5AW00-0BP0

Page 5

Issue 10/06 Foreword

Foreword

User Documentation

WARNING

Before installing and commissioning the inverter, you must read all safety

instructions and warnings carefully including all the warning labels attached to the

equipment. Make sure that the warning labels are kept in a legible condition and

replace missing or damaged labels.

Information is also available from:

Regional Contacts

Please get in touch with your contact for Technical Support in your Region for

questions about services, prices and conditions of Technical Support.

Central Technical Support

The competent consulting service for technical issues with a broad range of

requirements-based services around our products and systems.

Europe / Africa

Tel: +49 (0) 180 5050 222

Fax: +49 (0) 180 5050 223

Email: adsupport@siemens.com

America

Tel: +1 423 262 2522

Fax: +1 423 262 2589

Email: simatic.hotline@sea.siemens.com

Asia / Pazific

Tel: +86 1064 757 575

Fax: +86 1064 747 474

Email: adsupport.asia@siemens.com

Online Service & Support

The comprehensive, generally available information system over the Internet, from

product support to service & support to the support tools in the shop.

http://www.siemens.com/automation/service&support

Contact address

Should any questions or problems arise while reading this manual, please contact

the Siemens office concerned using the form provided at the back this manual.

MICROMASTER 440 Operating Instructions

6SE6400-5AW00-0BP0

5

Page 6

Definitions and Warnings Issue 10/06

Definitions and Warnings

DANGER

indicates an immanently hazardous situation which, if not avoided, will result in

death or serious injury.

WARNING

indicates a potentially hazardous situation which, if not avoided, could result in

death or serious injury.

CAUTION

used with the safety alert symbol indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate injury.

PE

= Ground

CAUTION

used without safety alert symbol indicates a potentially hazardous situation which,

if not avoided, may result in a property damage.

NOTICE

indicates a potential situation which, if not avoided, may result in an undesirable

result or state.

NOTE

For the purpose of this documentation, "Note" indicates important information

relating to the product or highlights part of the documentation for special

attention.

Qualified personnel

For the purpose of this Instruction Manual and product labels, a "Qualified

person" is someone who is familiar with the installation, mounting, start-up and

operation of the equipment and the hazards involved.

He or she must have the following qualifications:

1. Trained and authorized to energize, de-energize, clear, gro und and tag circuits

and equipment in accordance with established safety procedures.

2. Trained in the proper care and u se of protective equipment in accordance with

established safety procedures.

3. Trained in rendering first aid.

♦ PE – Protective Earth uses circuit protective conductors sized for short circuits

where the voltage will not rise in excess of 50 Volts. This connection is

normally used to ground the inverter.

♦

- Is the ground connection where the reference voltage can be the same as

the Earth voltage. This connection is normally used to ground the motor.

Use for intended purpose only

The equipment may be used only for the application stated in the manual and only

in conjunction with devices and components recommended and authorized by

Siemens.

MICROMASTER 440 Operating Instructions

6 6SE6400-5AW00-0BP0

Page 7

Issue 10/06 Safety Instructions

Safety Instructions

The following Warnings, Cautions and Notes are provided for your safety and as a

means of preventing damage to the product or components in the machines

connected. This section lists Warnings, Cautions and Notes, which apply generally

when handling MICROMASTER 440 Inverters, classified as General, Transport &

Storage, Commissioning, Operation, Repair and Dismantling & Disposal.

Specific Warnings, Cautions and Notes that apply to particular activities are

listed at the beginning of the relevant chapters and are repeated or supplemented

at critical points throughout these sections.

Please read the information carefully, since it is provided for your personal

safety and will also help prolong the service life of your MICROMASTER 440

Inverter and the equipment you connect to it.

General

WARNING

¾ This equipment contains dangerous voltages and controls potentially

dangerous rotating mechanical parts. Non-compliance with Warnings or

failure to follow the instructions contained in this manual can result in loss of

life, severe personal injury or serious damage to property.

¾ Only suitable qualified personnel should work on this equipment, and only after

becoming familiar with all safety notices, installation, operation and

maintenance procedures contained in this manual. The successful and safe

operation of this equipment is dependent upon its proper handling, installation,

operation and maintenance.

¾ Risk of electric shock. The DC link capacitors remain charged for five minutes

after power has been removed. It is not permissible to open the equipment

until 5 minutes after the power has been removed.

The following terminals can carry dangerous voltages even if the inverter is

inoperative:

♦ the power supply L/L1, N/L2, L3 resp. U1/L1, V1/L2, W1/L3

♦ the motor terminals U, V, W resp. U2, V2, W2

♦ and depending on the frame size the terminals DC+/B+, DC-, B-, DC/R+

resp. DCPS, DCNS, DCPA, DCNA

¾ HP ratings are based o n the Siemens 1LA motors and are given for

guidance only; they do not necessarily comply with UL or NEMA HP

ratings.

CAUTION

¾ Children and the general public must be prevented from accessing or

approaching the equipment!

¾ This equipment may only be use d for the purpose specified by the

manufacturer. Unauthorized modifications and the use of spare parts and

accessories that are not sold or recommended by the manufacturer of the

equipment can cause fires, electric shocks and injuries.

MICROMASTER 440 Operating Instructions

6SE6400-5AW00-0BP0

7

Page 8

Safety Instructions Issue 10/06

NOTICE

¾ Keep these operating instructions within easy reach of the equipment and

make them available to all users

¾ Whenever measuring or testing has to be performed on live equipment, the

regulations of Safety Code BGV A2 must be observed, in particular §8

“Permissible Deviations when Working on Live Parts”. Suitable electronic tools

should be used.

¾ Before installing and commissioning, please read these safety instructions and

warnings carefully and all the warning labels attached to the equipment. Make

sure that the warning labels are kept in a legible condition and replace missing

or damaged labels.

Transport & Storage

WARNING

Correct transport, storage, erection and mounting, as well as careful operation

and maintenance are essential for proper and safe operation of the equipment.

CAUTION

Protect the inverter against physical shocks and vibration during transport and

storage. Also be sure to protect it against water (rainfall) and excessive

temperatures (see Table 4-1).

Commissioning

WARNING

¾ Work on the device/system by unqualified personnel or failure to comply with

warnings can result in severe personal injury or serious damage to material.

Only suitably qualified personnel trained in the setup, installation,

commissioning and operation of the product should carry out work on the

device/system.

¾ Only permanently-wired input power connections are allowed. This equipment

must be grounded (IEC 536 Class 1, NEC and other applicable standards).

¾ Only type B ELCBs should be used with FSA to FSF. Machines with a three-

phase power supply, fitted with EMC filters, must not be connected to a supply

via an ELCB (Earth Leakage Circuit-Breaker - see DIN VDE 0160, section

5.5.2 and EN50178 section 5.2.11.1).

¾ The following terminals can carry dangerous voltages even if the inverter is

inoperative:

♦ the power supply L/L1, N/L2, L3 resp. U1/L1, V1/L2, W1/L3

♦ the motor terminals U, V, W resp. U2, V2, W2

♦ and depending on the frame size the terminals DC+/B+, DC-, B-, DC/R+

resp. DCPS, DCNS, DCPA, DCNA

¾ This equipment must not b e used as an ‘emergency stop mechanism’ (see EN

60204, 9.2.5.4)

CAUTION

The connection of power, motor and control cables to the inverter must be carried

out as shown in Fig. 2-11 on page 44, to prevent inductive and capacitive

interference from affecting the correct functioning of the inverter.

MICROMASTER 440 Operating Instructions

8 6SE6400-5AW00-0BP0

Page 9

Issue 10/06 Safety Instructions

Operation

WARNING

¾ MICROMASTERS operate at high voltages.

¾ When operating ele ctrical device s, it is impossibl e to avoid applying

hazardous voltages to certain parts of the equipment.

¾ Emergency Stop facilities according to EN 60204 IEC 204 (VDE 0113) must

remain operative in all operating modes of the control equipment. Any

disengagement of the Emergency Stop facility must not lead to uncontrolled or

undefined restart.

Certain parameter settings may cause the inverter to restart automatically

after an input power failure (e.g. automatic restart).

¾ Wherever faults occu rring in the control equipment can lead to substantial

material damage or even grievous bodily injury (i.e. potentially dangerous

faults), additional external precautions must be taken or facilities provided to

ensure or enforce safe operation, even when a fault occurs (e.g. independent

limit switches, mechanical interlocks, etc.).

¾ Motor parameters must be accurately configured for motor overload protection

to operate correctly.

¾ This equipment is cap able of providing internal motor overload protection in

accordance with UL508C section 42. Refer to P0610 and P0335, i

2

t is ON by

default. Motor overload protection can also be provided using an external PTC

or KTY84.

¾ This equipment is suitable for use in a circuit capable of delivering not more

than 10,000 (Frame Sizes A to C) or 42,000 (Frame Sizes D to GX)

symmetrical amperes (rms), for a maximum voltage of 230 V / 460 V / 575 V

when protected by an H, J or K type fuse, a circuit breaker or self-protected

combination motor controller (for more details see Appendix F).

¾ This equipment must not b e used as an ‘emergency stop mechanism’ (see EN

60204, 9.2.5.4)

Repair

WARNING

¾ Repairs on equipment may only be carried out by Siemens Serv ice, by repair

centers authorized by Siemens or by authorized personnel who are

thoroughly acquainted with all the warnings and operating procedures

contained in this manual.

¾ Any defective parts or compone nts must be replaced using parts contained in

the relevant spare parts list.

¾ Disconnect the power supply before opening the equipment for access.

Dismantling & Disposal

CAUTION

¾ The inverter’s packaging is re-usable. Re tain the packaging for future use.

¾ Easy-to-release screw and snap connectors allow you to break the unit down

into its component parts. You can then re-cycle these component parts,

dispose of them in accordance with local requirements or return them to

the manufacturer.

MICROMASTER 440 Operating Instructions

6SE6400-5AW00-0BP0

9

Page 10

Electrostatic Sensitive Devices (ESD) Issue 10/06

Electrostatic Sensitive Devices (ESD)

The device contains components which can be destroyed by electrostatic

discharge. These components can be easily destroyed if not carefully handled.

Before opening the cabinet/enclosure in which the device is located, you must

electrically discharge your body and apply the appropriate ESDS protective

measures. The cabinet/enclosure should be appropriately labeled.

If you have to handle electronic boards, please observe the following:

• Electronic boards should only be touched when absolutely nece s sary.

• The human body must be electrically discharged before touching an electronic

board.

• Boards must not come into contact with highly insulating materials - e.g. plastic

parts, insulated desktops, articles of clothing manufactured from man-made

fibers.

• Boards must only be placed on conductive surfaces.

• Boards and components should only be stored and transported in conductive

packaging (e.g. metalized plastic boxes or metal containers).

• If the packing material is not conductive, the boards must be wrapped with a

conductive packaging material, e.g. conductive foam rubber or household

aluminium foil.

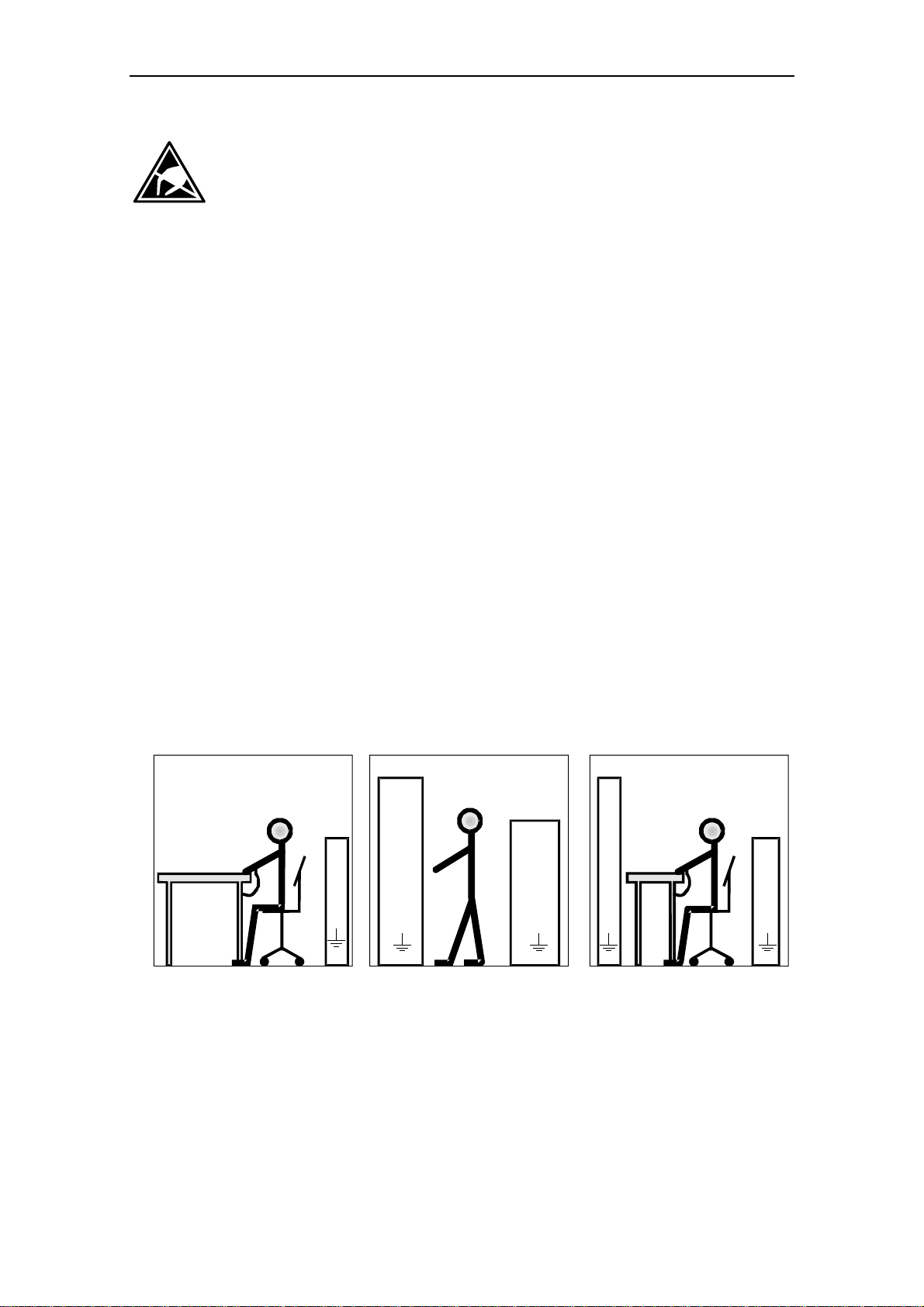

The necessary ESD protective measures are clearly shown again in the following

diagram:

• a = Conductive floor surface

• b = ESD table

• c = ESD shoes

b

c

a

d

e

f

Sitting

f f f

c

Standing Standing / Sitting

• d = ESD overall

• e = ESD chain

• f = Cubicle ground connection

d

f

a

b

c

d

e

a

MICROMASTER 440 Operating Instructions

10 6SE6400-5AW00-0BP0

Page 11

Issue 10/06 Table of Contents

Table of Contents

1 Overview................................................................................................................17

1.1 The MICROMASTER 440....................................................................................... 18

1.2 Features.................................................................................................................. 19

2 Installation............................................................................................................. 21

2.1 Installation after a Period of Storage...................................................................... 23

2.2 Ambient operating conditions ................................................................................. 24

2.3 Mechanical installation............................................................................................ 26

2.4 Electrical installation ............................................................................................... 33

3 Functions............................................................................................................... 47

3.1 Parameters ............................................................................................................. 51

3.2 Operator panels for MICROMASTER..................................................................... 70

3.3 Block diagram......................................................................................................... 74

3.4 Factory setting ........................................................................................................ 75

3.5 Commissioning ....................................................................................................... 77

3.6 Inputs / outputs ..................................................................................................... 135

3.7 Communications...................................................................................................144

3.8 Fixed frequencies (FF).......................................................................................... 167

3.9 Motorized potentiometer (MOP) ........................................................................... 170

3.10 JOG....................................................................................................................... 172

3.11 PID controller (technological controller)................................................................ 173

3.12 Setpoint channel...................................................................................................181

3.13 Free function blocks (FFB) ................................................................................... 191

3.14 Motor holding brake (MHB)................................................................................... 196

3.15 Electronic brakes .................................................................................................. 202

3.16 Automatic restart................................................................................................... 211

3.17 Flying restart.........................................................................................................213

3.18 Closed-loop Vdc control........................................................................................ 215

3.19 Positioning down ramp ......................................................................................... 219

3.20 Monitoring functions / messages.......................................................................... 221

3.21 Thermal motor protection and overload responses.............................................. 227

3.22 Power module protection...................................................................................... 232

3.23 Open-loop/closed-loop control technique.............................................................235

4 Troubleshooting.................................................................................................. 257

4.1 Troubleshooting with the SDP.............................................................................. 258

4.2 Troubleshooting with the BOP.............................................................................. 259

MICROMASTER 440 Operating Instructions

6SE6400-5AW00-0BP0

11

Page 12

Table of Contents Issue 10/06

4.3 Fault messages..................................................................................................... 260

4.4 Alarm Messages...................................................................................................260

5 MICROMASTER 440 specifications................................................................... 261

6 Options ................................................................................................................ 273

6.1 Inverter-independent options................................................................................ 273

6.2 Inverter-dependent options................................................................................... 274

7 Electro-magnetic compatibility (EMC).............................................................. 275

7.1 Electro-magnetic compatibility..............................................................................276

Appendices..............................................................................................................................281

A Changing the Operator Panel............................................................................ 281

B Removing Front Covers..................................................................................... 282

B.1 Removing Front Covers. Frame Sizes A..............................................................282

B.2 Removing Front Covers. Frame Sizes B and C ................................................... 283

B.3 Removing Front Covers. Frame Sizes D and E ................................................... 284

B.4 Removing Front Covers. Frame Size F................................................................285

B.5 Removing Front Covers. Frame Sizes FX and GX.............................................. 286

C Removing the I/O Board..................................................................................... 287

D Removing ‘Y’ Cap ............................................................................................... 288

D.1 Removing ‘Y’ Cap. Frame Size A......................................................................... 288

D.2 Removing ‘Y’ Cap. Frame Sizes B and C............................................................. 289

D.3 Removing ‘Y’ Cap. Frame Sizes D and E............................................................. 290

D.4 Removing ‘Y’ Cap. Frame Size F......................................................................... 291

D.5 Removing ‘Y’ Cap. Frame Size FX....................................................................... 292

D.6 Removing ‘Y’ Cap. Frame Size GX......................................................................293

E Removing fan ...................................................................................................... 294

E.1 Removing fan. Frame Size A................................................................................ 294

E.2 Removing fan. Frame Sizes B and C ................................................................... 295

E.3 Removing fan. Frame Size D and E.....................................................................296

E.4 Removing fan. Frame Size F................................................................................ 297

E.5 Removing fan. Frame Size F with filter................................................................. 298

E.6 Removing fan. Frame Sizes FX and GX .............................................................. 299

F Short circuit current rating (SCCR)...................................................................300

G Standards............................................................................................................ 301

H List of Abbreviations..........................................................................................302

Index .............................................................................................................................. 305

MICROMASTER 440 Operating Instructions

12 6SE6400-5AW00-0BP0

Page 13

Issue 10/06 Table of Contents

List of Illustrations

Fig. 2-1 Forming................................................................................................................................23

Fig. 2-2 Ambient operating temperature............................................................................................ 24

Fig. 2-3 Installation altitude................................................................................................................24

Fig. 2-4 Drill pattern for MICROMASTER 440...................................................................................27

Fig. 2-5 Installation dimensions for MICROMASTER 440 Frame size FX.........................................28

Fig. 2-6 Installation dimensions for MICROMASTER 440 Frame size GX ........................................29

Fig. 2-7 Options for the electronic box............................................................................................... 32

Fig. 2-8 MICROMASTER 440 Connection Terminals........................................................................37

Fig. 2-9 MICROMASTER 440 connection drawing – frame size FX.................................................. 38

Fig. 2-10 MICROMASTER 440 connection drawing - frame size GX..................................................39

Fig. 2-11 Motor and Power Connections.............................................................................................40

Fig. 2-12 Adaptation of fan voltage......................................................................................................41

Fig. 2-13 Control terminals of MICROMASTER 440............................................................................42

Fig. 2-14 Wiring Guidelines to Minimize the Effects of EMI.................................................................44

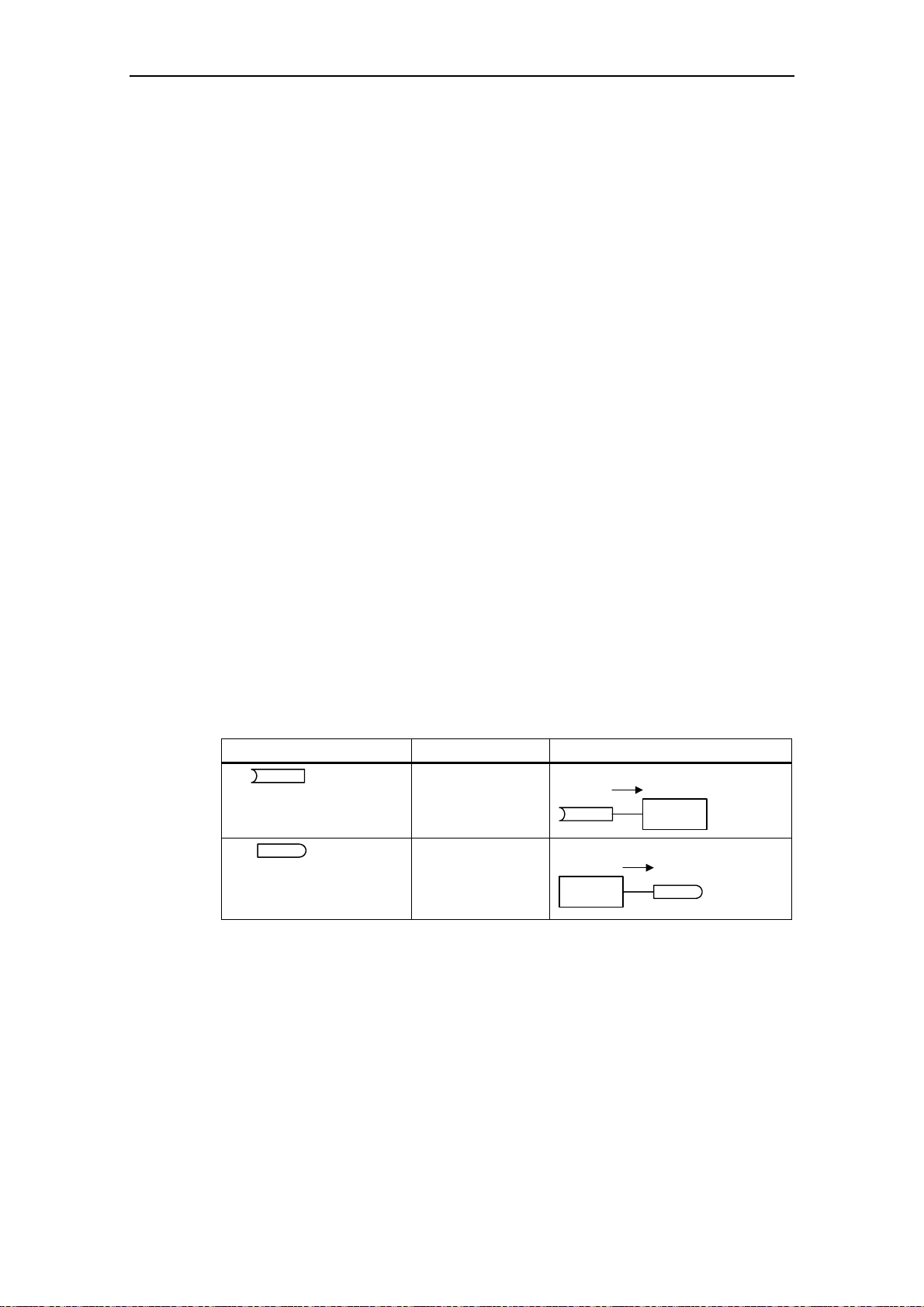

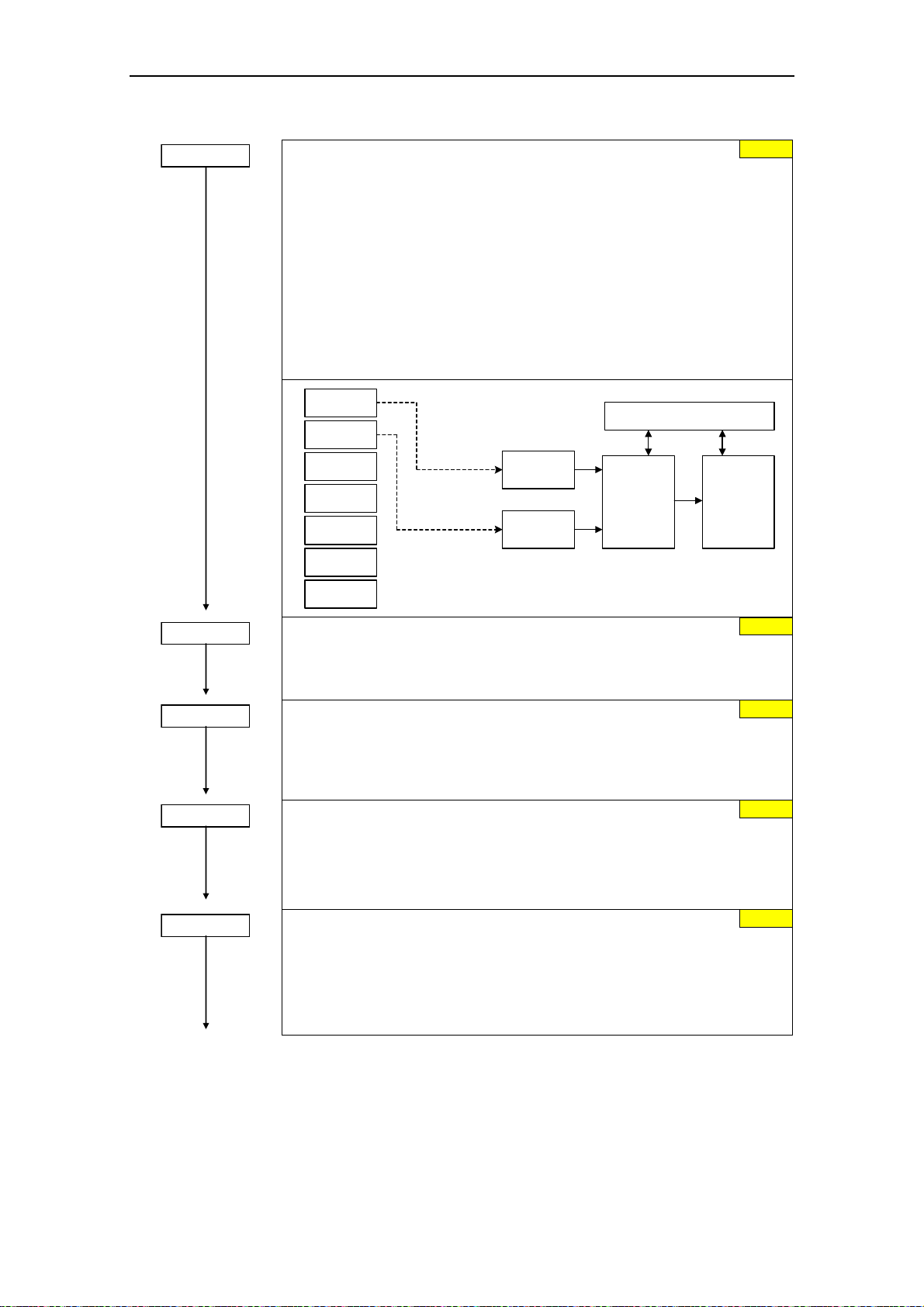

Fig. 3-1 Parameter types...................................................................................................................51

Fig. 3-2 Header line for parameter P0305.........................................................................................55

Fig. 3-3 Parameter grouping / access................................................................................................56

Fig. 3-4 Binectors ..............................................................................................................................60

Fig. 3-5 Connectors...........................................................................................................................61

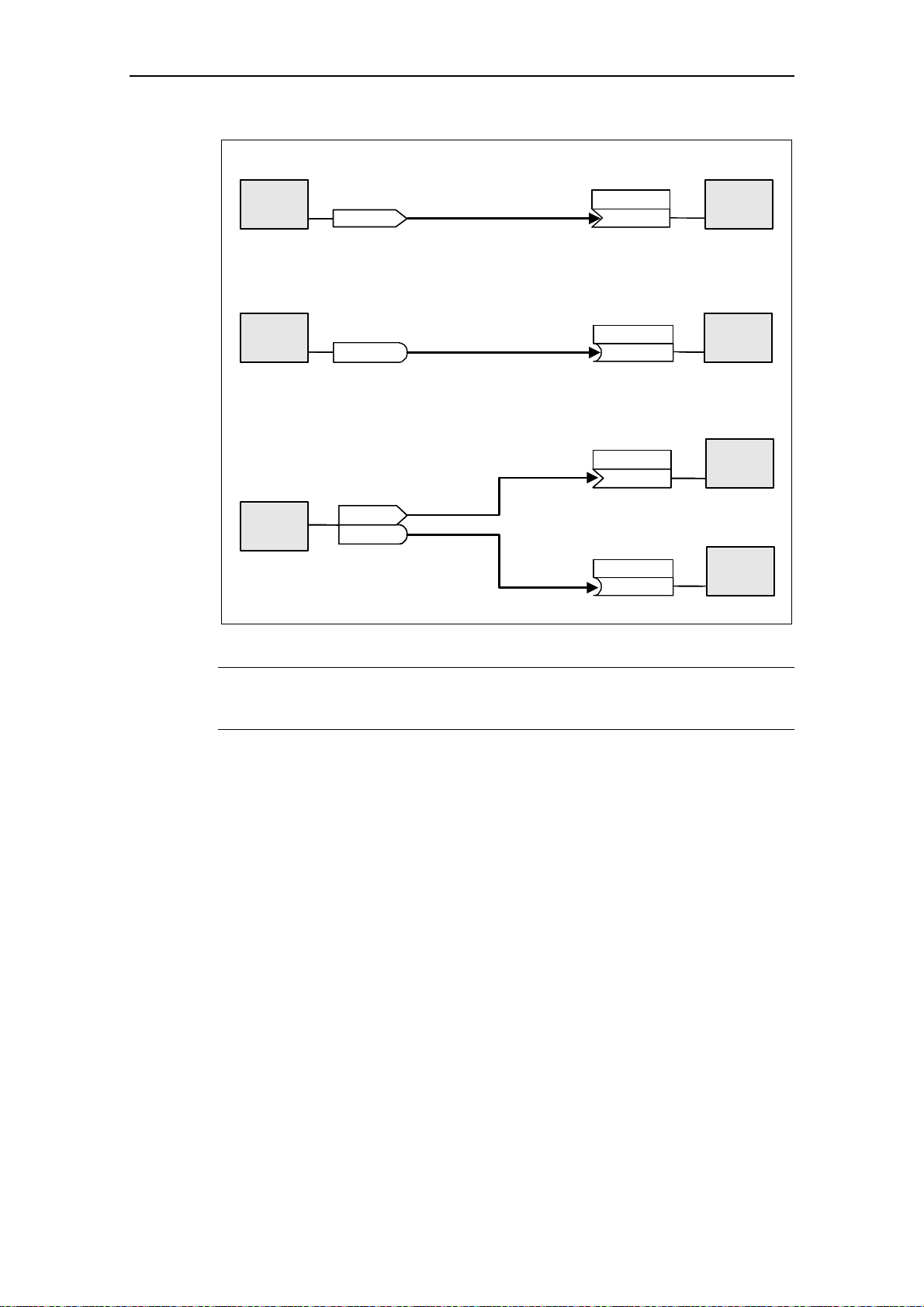

Fig. 3-6 BICO connections (examples).............................................................................................. 62

Fig. 3-7 Example: Changeover from motor 1 to motor 2....................................................................63

Fig. 3-8 Example: Changing-over between the control and setpoint (frequency) source...................63

Fig. 3-9 Copying from CDS ...............................................................................................................65

Fig. 3-10 Changing-over CDS .............................................................................................................65

Fig. 3-11 Copying from DDS ...............................................................................................................66

Fig. 3-12 Changing-over DDS .............................................................................................................67

Fig. 3-13 Normalization / de-normalization.......................................................................................... 69

Fig. 3-14 Operator panels....................................................................................................................70

Fig. 3-15 Operator panel keys.............................................................................................................72

Fig. 3-16 Changing parameters using the BOP...................................................................................73

Fig. 3-17 MICROMASTER 440 – block diagram .................................................................................74

Fig. 3-18 Status Display Panel (SDP)..................................................................................................75

Fig. 3-19 Recommended wiring for the factory setting ........................................................................76

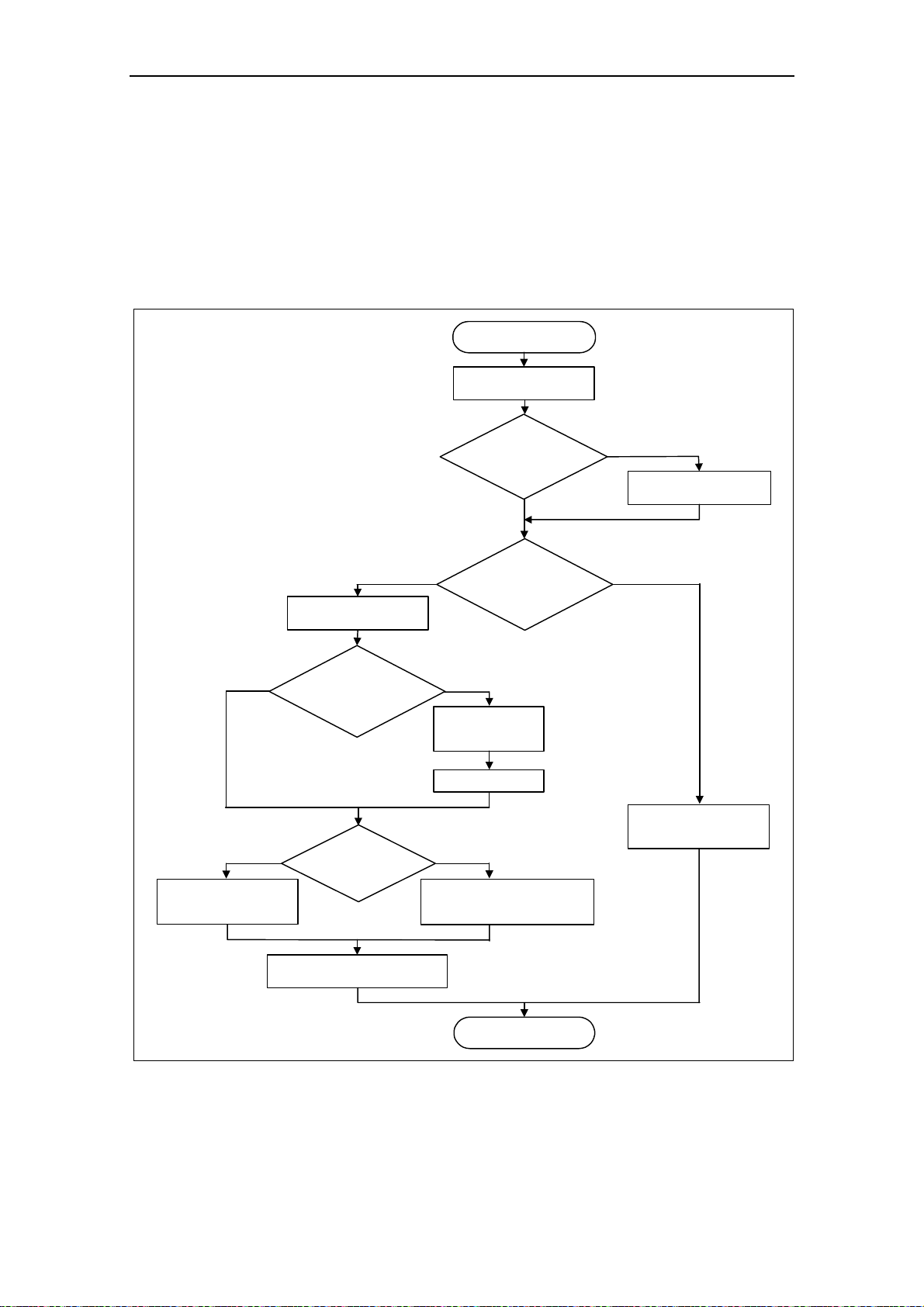

Fig. 3-20 Procedure when commissioning...........................................................................................77

Fig. 3-21 DIP switch to change-over between 50/60 Hz......................................................................79

Fig. 3-22 Mode of operation of the DIP50/60 switch in conjunction with P0100 ..................................79

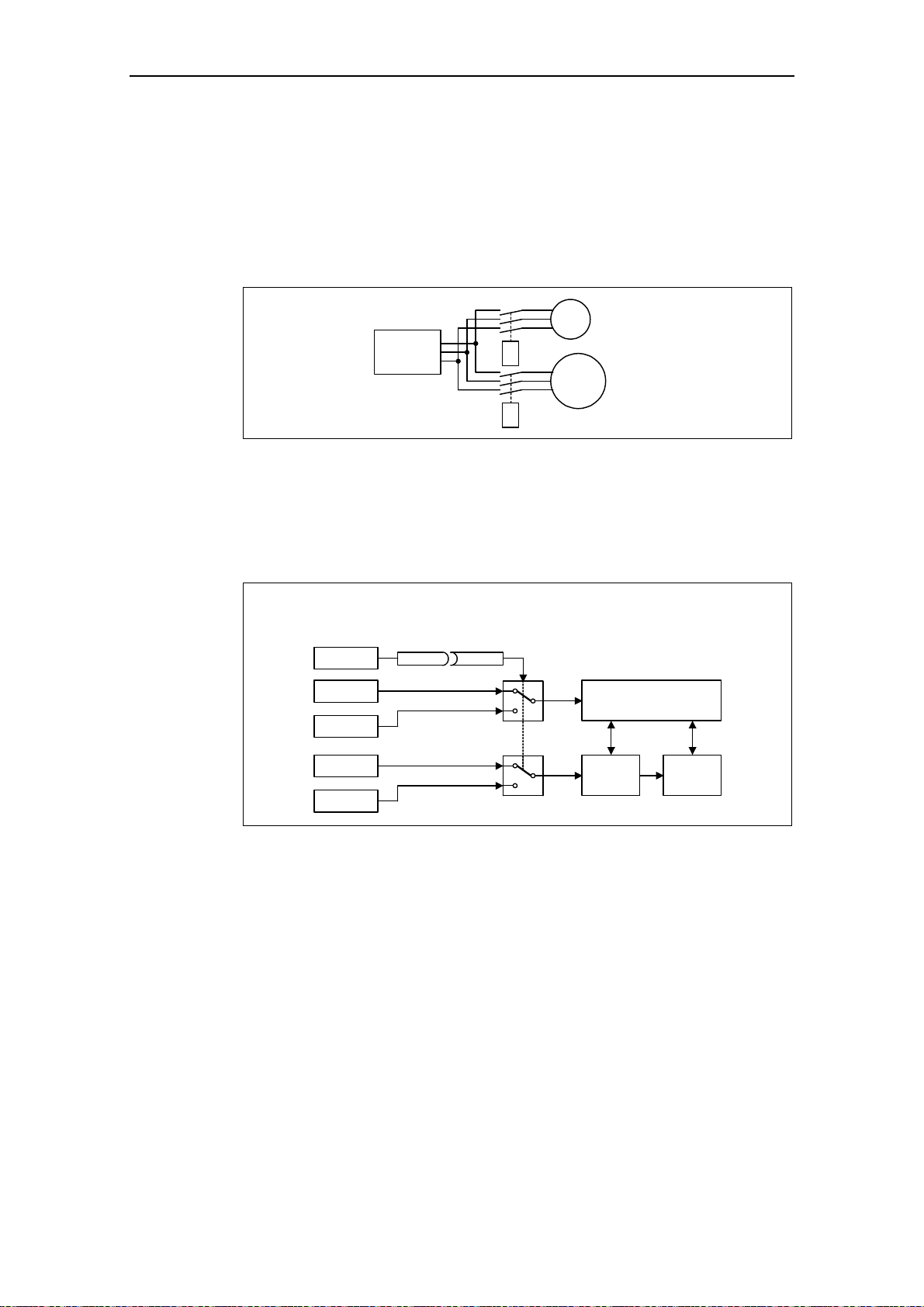

Fig. 3-23 Motor terminal box................................................................................................................80

Fig. 3-24 Star / delta circuit configurations ..........................................................................................81

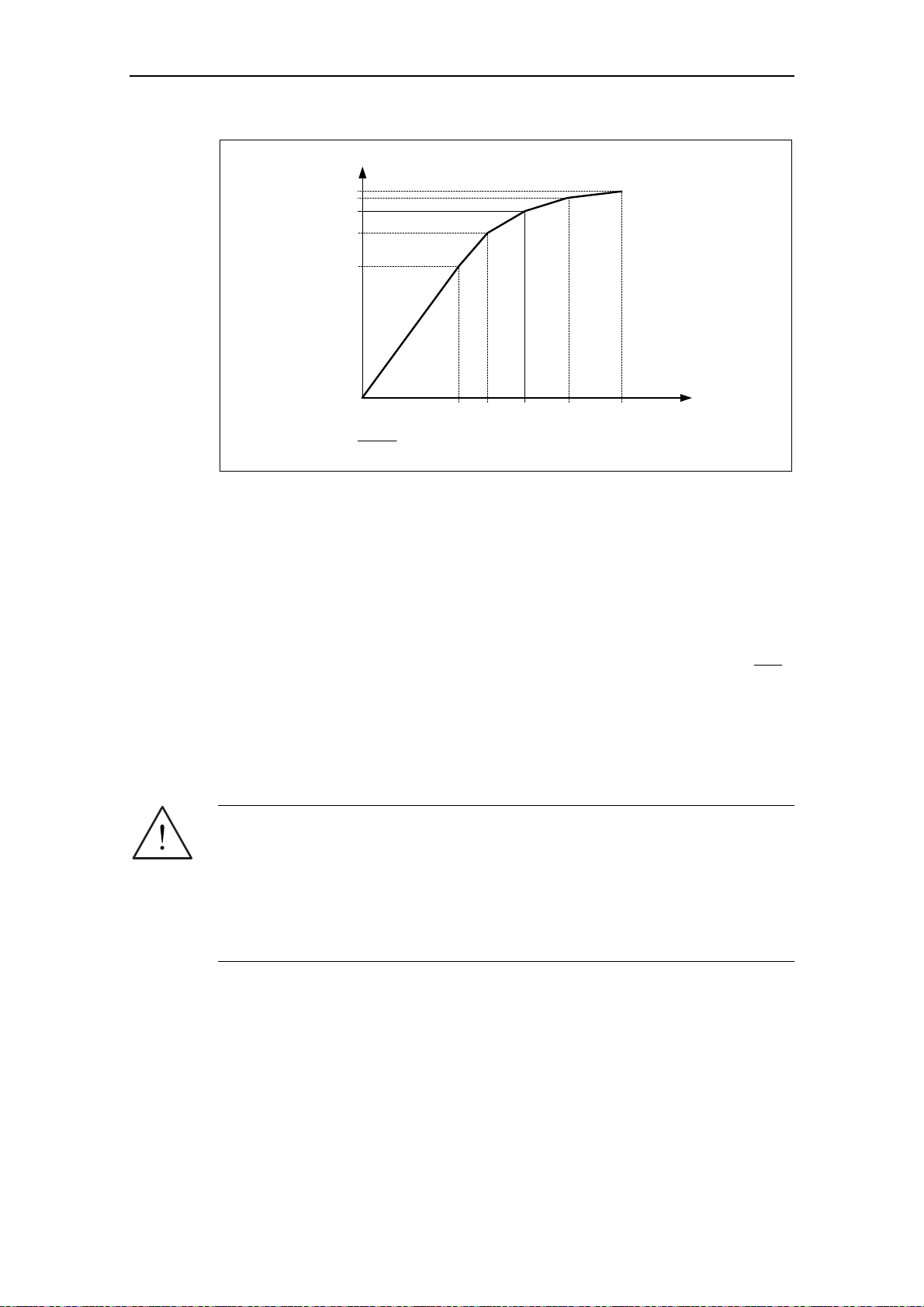

Fig. 3-25 V/f characteristic...................................................................................................................82

Fig. 3-26 Equivalent circuit diagram (ECD) .........................................................................................91

Fig. 3-27 Magnetizing characteristic....................................................................................................92

Fig. 3-28 Upread / download using AOP and PC Tools..................................................................... 132

Fig. 3-29 Digital inputs.......................................................................................................................135

Fig. 3-30 Digital outputs.....................................................................................................................138

Fig. 3-31 DIP switch and P0756 for ADC current / voltage input....................................................... 140

MICROMASTER 440 Operating Instructions

6SE6400-5AW00-0BP0

13

Page 14

Table of Contents Issue 10/06

Fig. 3-32 Connection example for ADC voltage / current input..........................................................141

Fig. 3-33 ADC channel......................................................................................................................141

Fig. 3-34 Signal output through the D/A converter channel............................................................... 142

Fig. 3-35 D/A converter channel........................................................................................................142

Fig. 3-36 Serial communication interfaces - BOP link and COM link.................................................144

Fig. 3-37 Cycle times......................................................................................................................... 147

Fig. 3-38 Serial linking of MICROMASTER (slaves) with a higher-level computer (master)..............148

Fig. 3-39 Telegram structure .............................................................................................................149

Fig. 3-40 Assignment of the address byte (ADR) ..............................................................................150

Fig. 3-41 Circulating list (Example of configuration) ..........................................................................151

Fig. 3-42 Cycle time...........................................................................................................................151

Fig. 3-43 Transmit sequence.............................................................................................................152

Fig. 3-44 USS bus topology...............................................................................................................153

Fig. 3-45 Telegram structure .............................................................................................................155

Fig. 3-46 Structure of the PKW and PZD areas................................................................................. 155

Fig. 3-47 Connecting the USS bus cable...........................................................................................164

Fig. 3-48 Connecting the RS485 terminator......................................................................................165

Fig. 3-49 Example for directly selecting FF1 via DIN1 and FF2 via DIN2.......................................... 168

Fig. 3-50 Example for selecting FF1 via DIN1 and FF2 via DIN2 using the binary-coded method.... 169

Fig. 3-51 Motorized potentiometer ..................................................................................................... 170

Fig. 3-52 JOG counter-clockwise and JOG clockwise....................................................................... 172

Fig. 3-53 Structure of the technology controller.................................................................................174

Fig. 3-54 Structure of the technological controller (PID controller) ....................................................175

Fig. 3-55 PID controller......................................................................................................................176

Fig. 3-56 Example to directly select the PID fixed frequency of fixed frequency 1 via DIN1..............178

Fig. 3-57 PID dancer roll control........................................................................................................179

Fig. 3-58 Structure of the closed-loop PID-dancer roll control...........................................................180

Fig. 3-59 Setpoint channel.................................................................................................................181

Fig. 3-60 Summation.........................................................................................................................182

Fig. 3-61 Modifying the frequency setpoint........................................................................................182

Fig. 3-62 Ramp-function generator....................................................................................................183

Fig. 3-63 Rounding off after an OFF1 command...............................................................................184

Fig. 3-64 OFF1..................................................................................................................................186

Fig. 3-65 OFF2..................................................................................................................................187

Fig. 3-66 OFF3..................................................................................................................................188

Fig. 3-67 Changing-over using the BICO parameters P0810 and P0811.......................................... 189

Fig. 3-68 Motor holding brake after ON / OFF1................................................................................. 196

Fig. 3-69 Motor holding brake after OFF2 .........................................................................................197

Fig. 3-70 Direct motor holding brake connection...............................................................................200

Fig. 3-71 Indirect motor holding brake connection............................................................................. 201

Fig. 3-72 Inter-dependency of the electronic brakes..........................................................................202

Fig. 3-73 DC braking after OFF1 / OFF3...........................................................................................203

Fig. 3-74 DC braking after external selection .................................................................................... 204

Fig. 3-75 Compound braking.............................................................................................................205

Fig. 3-76 Connecting the chopper (braking) resistor..........................................................................207

Fig. 3-77 Mode of operation of the dynamic braking..........................................................................207

MICROMASTER 440 Operating Instructions

14 6SE6400-5AW00-0BP0

Page 15

Issue 10/06 Table of Contents

Fig. 3-78 Load duty cycle – chopper resistors (MICROMASTER Catalog DA51.2)...........................208

Fig. 3-79 Increasing the level of braking energy which can be absorbed ..........................................209

Fig. 3-80 Chopper load duty cycle.....................................................................................................209

Fig. 3-81 Automatic restarts ..............................................................................................................211

Fig. 3-82 Flying restart.......................................................................................................................214

Fig. 3-83 Vdc_max controller.............................................................................................................216

Fig. 3-84 Kinetic buffering (Vdc_min controller)................................................................................. 218

Fig. 3-85 Positioning down ramp.......................................................................................................219

Fig. 3-86 Rotary or linear axis............................................................................................................220

Fig. 3-87 Shaft drive with flat belts.....................................................................................................223

Fig. 3-88 Load torque monitoring (P2181 = 1)................................................................................... 223

Fig. 3-89 Frequency/torque tolerance bandwidth ..............................................................................224

Fig. 3-90 Load torque characteristic with minimum permissible load.................................................225

Fig. 3-91 Load torque characteristic with maximum permissible load................................................225

Fig. 3-92 Load torque characteristic with minimum and maximum permissible load......................... 226

Fig. 3-93 Thermal motor protection ...................................................................................................228

Fig. 3-94 Connecting a temperature sensor to MICROMASTER.......................................................230

Fig. 3-95 PTC characteristic for 1LG / 1LA motors...........................................................................231

Fig. 3-96 KTY84 characteristic for 1LG / 1LA motors........................................................................231

Fig. 3-97 Operating ranges and characteristics of an induction motor when fed from a drive inverter236

Fig. 3-98 Slip compensation..............................................................................................................239

Fig. 3-99 Effect of V/f resonance damping ........................................................................................240

Fig. 3-100 Imax controller....................................................................................................................242

Fig. 3-101 Current Vector diagram in a steady-state condition............................................................ 243

Fig. 3-102 Changeover condition for SLVC......................................................................................... 245

Fig. 3-103 Starting and passing-through 0 Hz in closed-loop controlled operation..............................246

Fig. 3-104 P0400 and DIP switch on the pulse encoder module......................................................... 247

Fig. 3-105 Speed controller.................................................................................................................248

Fig. 3-106 Speed controller with pre-control........................................................................................250

Fig. 3-107 Speed controller with droop................................................................................................ 252

Fig. 3-108 Closed-loop speed/torque control.......................................................................................253

Fig. 3-109 Torque limits.......................................................................................................................255

List of Tables

Table 2-1 Dimensions and Torques of MICROMASTER 440...............................................................30

Table 3-1 Parameter attributes.............................................................................................................52

Table 3-2 Parameter P0700.................................................................................................................57

Table 3-3 Parameter P1000.................................................................................................................58

Table 3-4 Parameter P0719.................................................................................................................59

Table 3-5 Normalized interfaces...........................................................................................................68

Table 3-6 Normalization functions........................................................................................................68

Table 3-7 Pre-assignment of the digital inputs .....................................................................................75

Table 3-8 Example 1LA7060-4AB10....................................................................................................82

Table 3-9 Possible settings for parameter P0340.................................................................................88

Table 3-10 Calculated parameters .........................................................................................................89

Table 3-11 Parameters P0701 – P0706...............................................................................................136

MICROMASTER 440 Operating Instructions

6SE6400-5AW00-0BP0

15

Page 16

Table of Contents Issue 10/06

Table 3-12 Parameters P0731 – P0733 (frequently used functions / states)........................................138

Table 3-13 BOP link .............................................................................................................................145

Table 3-14 COM link.............................................................................................................................145

Table 3-15 Minimum start intervals for various baud rates...................................................................152

Table 3-16 Structural data....................................................................................................................153

Table 3-17 Thermal and electrical characteristics ................................................................................154

Table 3-18 Max. number of nodes (devices) depending on the max. data transfer rate....................... 154

Table 3-19 Task IDs (master -> drive converter)..................................................................................158

Table 3-20 Response ID (converter -> master)....................................................................................159

Table 3-21 Fault numbers for the response ID "Request cannot be executed".................................... 160

Table 3-22 Example for direct coding via digital inputs.........................................................................167

Table 3-23 Example for binary coding via digital inputs........................................................................168

Table 3-24 Mode of operation of the MOP ...........................................................................................171

Table 3-25 Selecting the motorized potentiometer...............................................................................171

Table 3-26 Correspondence between the parameters .........................................................................177

Table 3-27 Important parameters for the PID dancer roll control.......................................................... 180

Table 3-28 BICO parameters for ramp-function generator...................................................................185

Table 3-29 Examples for settings of parameter P0810.........................................................................190

Table 3-30 Possible settings for parameters P0700 and P1000........................................................... 190

Table 3-31 Free function blocks ...........................................................................................................191

Table 3-32 FFB priority table................................................................................................................194

Table 3-33 Settings for parameter P1200.............................................................................................213

Table 3-34 DC link undervoltage – shutdown threshold....................................................................... 219

Table 3-35 Partial excerpt of monitoring functions / messages............................................................222

Table 3-36 Thermal classes .................................................................................................................228

Table 3-37 General protection of the power components.....................................................................232

Table 3-38 V/f characteristic (parameter P1300)..................................................................................236

Table 3-39 Voltage boost .....................................................................................................................238

Table 3-40 Vector control versions.......................................................................................................244

Table 4-1 Inverter conditions indicated by the LEDs on the SDP.......................................................258

Table 5-1 MICROMASTER 440 Performance Ratings.......................................................................262

Table 5-2 Dimensions, required cooling air flow and tightening torques for power terminals.............264

Table 5-3 Current reduction depending on pulse frequency............................................................... 265

Table 5-4 Data for braking resistors ...................................................................................................266

Table 5-5 MICROMASTER 440 Specifications .................................................................................. 266

Table 7-1 Permissible harmonic current emissions............................................................................ 277

Table 7-2 General industrial application.............................................................................................278

Table 7-3 With filter, for industrial applications................................................................................... 278

Table 7-4 With filter, for residential, commercial and trade applications............................................. 279

Table 7-5 Compliance Table ..............................................................................................................280

MICROMASTER 440 Operating Instructions

16 6SE6400-5AW00-0BP0

Page 17

Issue 10/06 1 Overview

1 Overview

This Chapter contains:

A summary of the major features of the MICROMASTER 440 range.

1.1 The MICROMASTER 440....................................................................................... 18

1.2 Features.................................................................................................................. 19

MICROMASTER 440 Operating Instructions

6SE6400-5AW00-0BP0

17

Page 18

1 Overview Issue 10/06

1.1 The MICROMASTER 440

The MICROMASTER 440 are frequency inverters for speed and torque control of

three-phase motors. The various models available cover the performance range

from 120 W to 200 kW (for constant torque (CT), alternatively up to 250kW (for

variable torque (VT)).

The inverters are microprocessor-controlled and use state-of-the-art Insulated Gate

BipoIar Transistor (IGBT) technology. This makes them reliable and versatile. A

special pulse-width modulation method with selectable Pulse frequency pe rmits

quiet motor operation. Comprehensive protective functions provide excellent

inverter and motor protection.

With the factory default settings, the MICROMASTER 440 is suitable for many

variable speed applications. Using the functionally grouped parameters, the

MICROMASTER 440 can adapted to more demanding applications.

The MICROMASTER 440 can be used in both 'stand-alone' applications as well as

being integrated into 'Automation Systems'.

MICROMASTER 440 Operating Instructions

18 6SE6400-5AW00-0BP0

Page 19

Issue 10/06 1 Overview

1.2 Features

Main Characteristics

¾ Easy installation

¾ Easy commissioning

¾ Rugged EMC design

¾ Can be operated on IT line supplies

¾ Fast repeatable response time to control signals

¾ Comprehensive range of parameters enabling configuration for a wide range of

applications

¾ Simple cable connection

¾ Output relays

¾ Analog outputs (0 – 20 mA)

¾ 6 Isolated and switchable NPN/PNP digital inputs

¾ 2 Analog inputs:

♦ ADC1: 0 – 10 V, 0 – 20 mA and -10 to +10 V

♦ ADC2: 0 – 10 V, 0 – 20 mA

¾ The 2 analog inputs can be used as the 7

¾ BICO technology

¾ Modular design for extremely flexible configuration

¾ High switching frequencies (drive inverter specific up to 16 kHz) for low-noise

motor operation

¾ Internal RS485 interface (port)

¾ Detailed status information and integrated message functions

th

and 8th digital inputs

MICROMASTER 440 Operating Instructions

6SE6400-5AW00-0BP0

19

Page 20

1 Overview Issue 10/06

Performance Characteristics

¾ Vector Control

♦ Sensorless Vector Control (SLVC)

♦ Vector Control with encoder (VC)

¾ V/f Control

♦ Flux Current Control (FCC) for improved dynamic response and motor

control

♦ Multi-point V/f characteristic

¾ Automatic restart

¾ Flying restart

¾ Slip compensation

¾ Fast Current Limitation (FCL) for trip-free operation

¾ Motor holding brake

¾ Built-in DC injection brake

¾ Compound braking to improve braking performance

¾ Built-in braking chopper (Frame Sizes A to F) for resistor braking (dynamic

braking)

¾ Setpoint input via:

♦ Analog inputs

♦ Communication interface

♦ JOG function

♦ Motorized potentiometer

♦ Fixed frequencies

¾ Ramp function generator

♦ With smoothing

♦ Without smoothing

¾ Technology controller (PID)

¾ Parameter set switch-over

♦ Motor data sets (DDS)

♦ Command data sets and setpoint sources (CDS)

¾ Free Function Blocks

¾ DC link voltage controller

¾ Kinetic Buffering

¾ Positioning Ramp down

Protection characteristics

¾ Overvoltage/undervoltage protection

¾ Overtemperature protection for the inverter

¾ Ground fault protection

¾ Short-circuit protection

2

¾ i

t thermal motor protection

¾ PTC/KTY84 for motor protection

Options

¾ Refer to Chapter 5

MICROMASTER 440 Operating Instructions

20 6SE6400-5AW00-0BP0

Page 21

Issue 10/06 2 Installation

2 Installation

This Chapter contains:

¾ General data relating to installation

¾ Dimensions of Inverter

¾ Wiring guidelines to minimize the effects of EMI

¾ Details concerning electrical installation

2.1 Installation after a Period of Storage...................................................................... 23

2.2 Ambient operating conditions ................................................................................. 24

2.3 Mechanical installation............................................................................................ 26

2.4 Electrical installation ............................................................................................... 33

MICROMASTER 440 Operating Instructions

6SE6400-5AW00-0BP0

21

Page 22

2 Installation Issue 10/06

WARNING

¾ Work on the device/system by unqualified personnel or failure to comply with

warnings can result in severe personal injury or serious damage to material.

Only suitably qualified personnel trained in the setup, installation,

commissioning and operation of the product should carry out work on the

device/system.

¾ Only permanently-wired input power connections are allowed. This equipment

must be grounded (IEC 536 Class 1, NEC and other applicable standards).

¾ Only type B ELCBs should be used with FSA to FSF. Machines with a three-

phase power supply, fitted with EMC filters, must not be connected to a supply

via an ELCB (Earth Leakage Circuit-Breaker - see DIN VDE 0160, section 5.5.2

and EN50178 section 5.2.11.1).

¾ The following terminals can carry dangerous voltages even if the inverter is

inoperative:

♦ the power supply L/L1, N/L2, L3 resp. U1/L1, V1/L2, W1/L3

♦ the motor terminals U, V, W resp. U2, V2, W2

♦ and depending on the frame size the terminals DC+/B+, DC-, B-, DC/R+

resp. DCPS, DCNS, DCPA, DCNA

¾ Always wait 5 minutes to allow the unit to discharge after switching off before

carrying out any installation work.

¾ This equipment must not be used as an ‘emergency stop mechanism’ (see EN

60204, 9.2.5.4)

¾ The minimum size of the earth-bonding conductor must be equal to or greater

than the cross-section of the power supply cables.

¾ If the front cover (Frame Sizes FX and GX) has been removed, the fan impeller

is exposed. There is danger of injury when the fan is running.

CAUTION

The connection of power, motor and control cables to the inverter must be carried

out as shown in Fig. 2-11 on page 44, to prevent inductive and capacitive

interference from affecting the correct functioning of the inverter.

MICROMASTER 440 Operating Instructions

22 6SE6400-5AW00-0BP0

Page 23

Issue 10/06 2 Installation

2.1 Installation after a Period of Storage

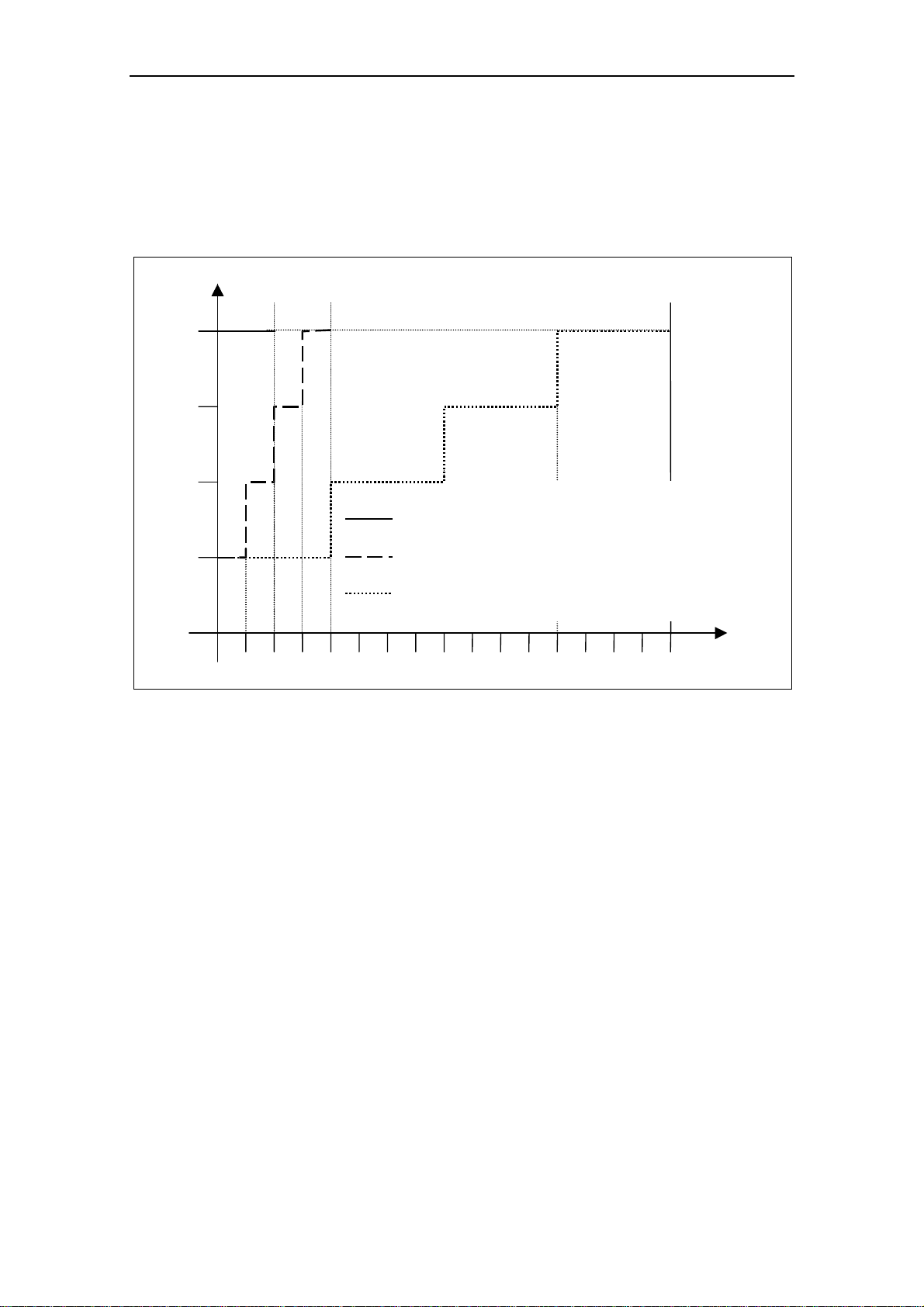

Following a prolonged period of storage, you must reform the capacitors in the

inverter.

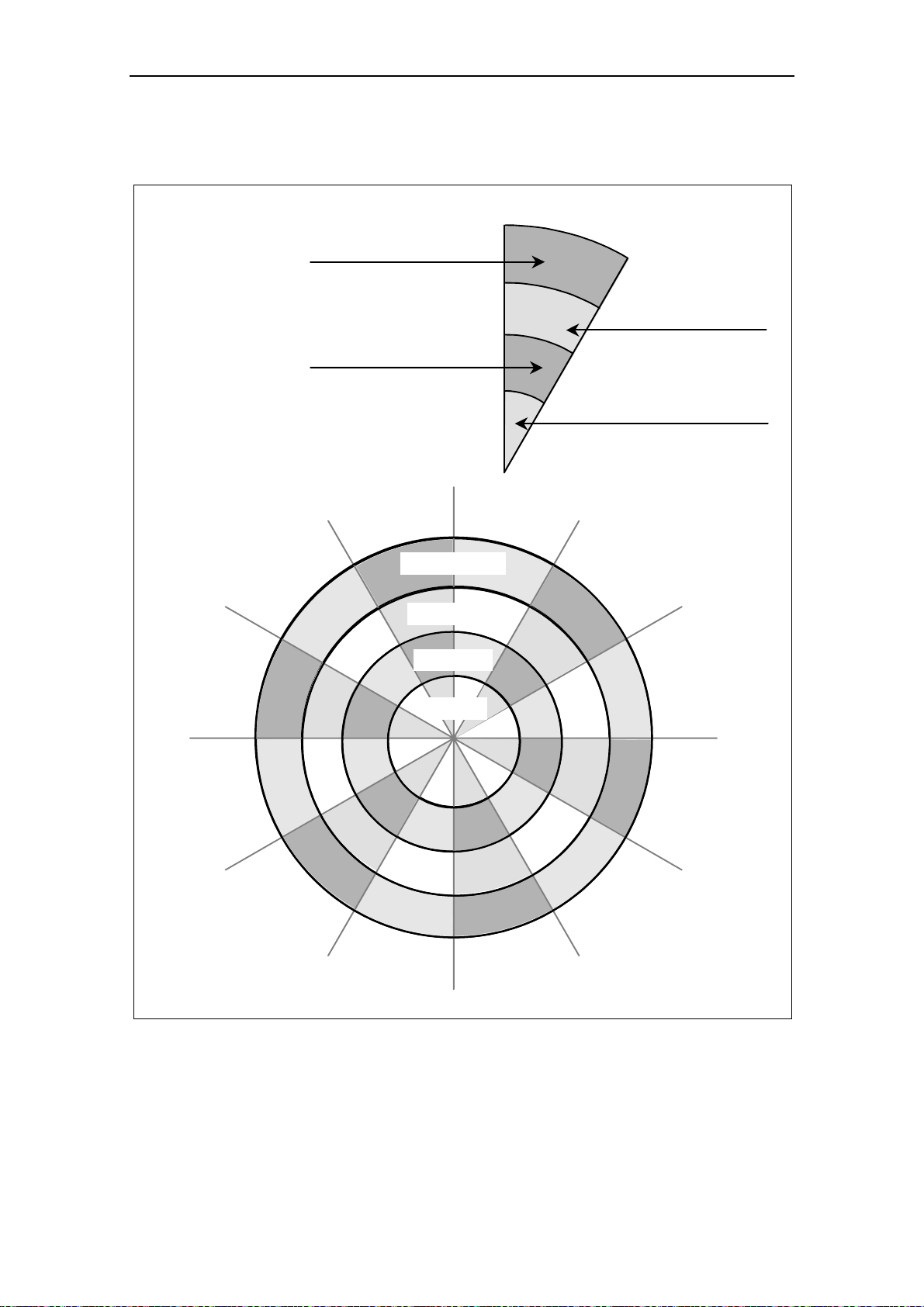

Frame Sizes A to F

Voltage

[%]

100

75

50

0,5 1

Fig. 2-1 Forming

Frame Sizes FX and GX

Reforming the capacitors can be accomplished by applying 85% of the rated input

voltage for at least 30 minutes without load.

Storage period less than 1 year:

Storage period 1 to 2 years:

Storage period 2 to 3 years:

Storage period 3 and more years:

2468

No action necessary

Prior to energizing, connect to

voltage for one hour

Prior to energizing, form

according to the curve

Prior to energizing, form

according to the curve

Time t [h]

MICROMASTER 440 Operating Instructions

6SE6400-5AW00-0BP0

23

Page 24

2 Installation Issue 10/06

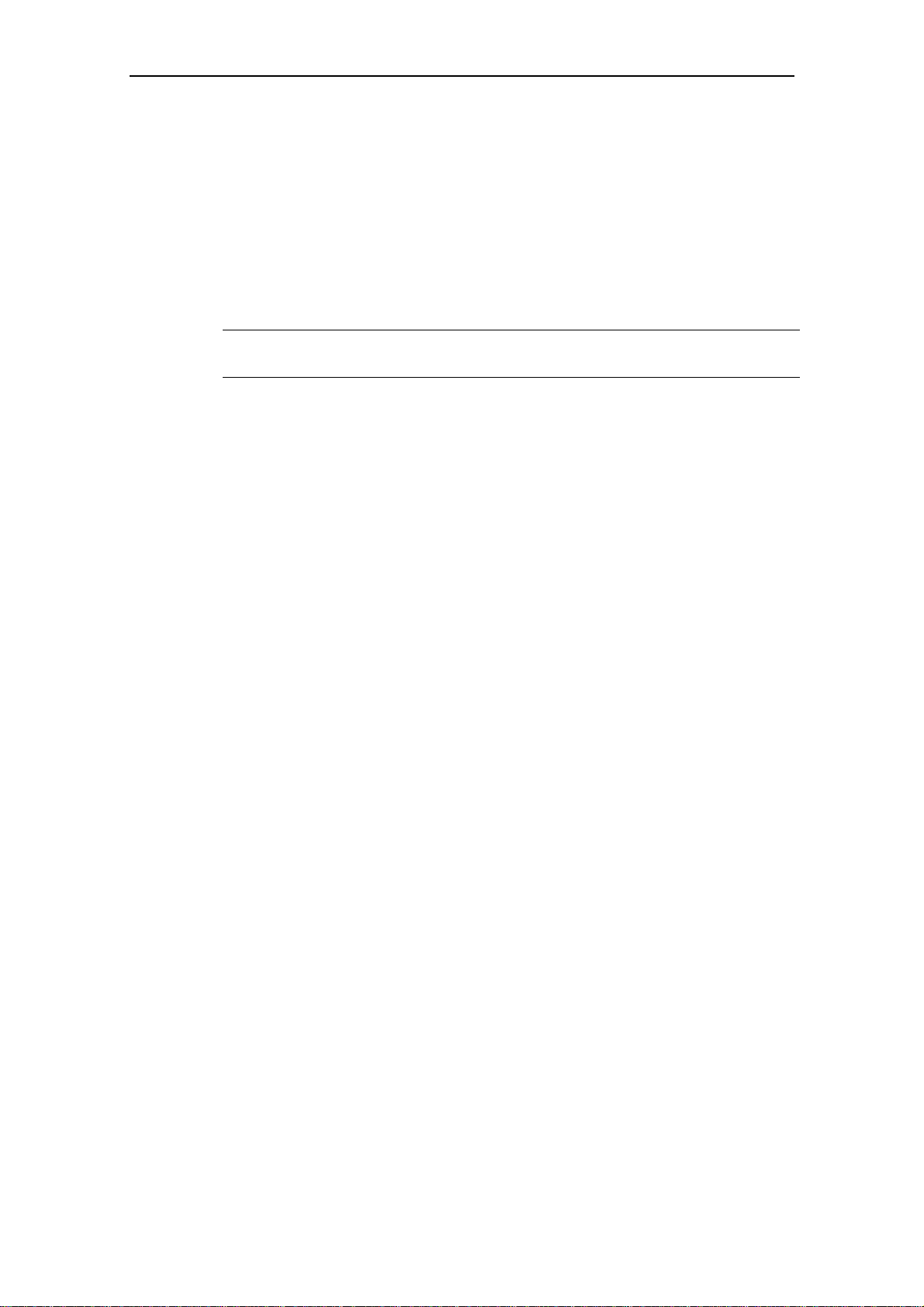

2.2 Ambient operating conditions

Temperature

Frame Sizes A to F: Frame Sizes FX and GX:

Permissible output current

[%]

100

75

Permissible output current

[%]

100

95

90

50

constant torque

-10

25

0

variable torque

10

20 30

40

50

Ambient temperatur e

Fig. 2-2 Ambient operating temp erature

Humidity Range

Relative air humidity ≤ 95 % Non-condensing

Altitude

If the inverter is to be installed at an altitude > 1000 m or > 2000 m above sea

level, derating will be required:

Permissible output current

100

%

85

80

[°C]

60

Frame Sizes

FX and GX

Frame Sizes

A to F

85

0203010 40

Permissible input voltage

100

%

80

77

[°C]

50 55

45

Ambient temper at u r e

01000

Instal l at i on altitud e in m above sea level

2000

3000 4000

01000

Installation altitude in m above sea level

2000

3000 4000

Fig. 2-3 Installation altitude

Shock and Vibration

Do not drop the inverter or expose to sudden shock. Do not install the inverter in an

area where it is likely to be exposed to constant vibration.

Mechanical strength to EN 60721-33

¾ Deflection: 0.075 mm (10 ... 58 Hz)

¾ Acceleration: 9.8 m/s

2

(> 58 ... 200 Hz)

Electromagnetic Radiation

Do not install the inverter near sources of electromagnetic radiation.

MICROMASTER 440 Operating Instructions

24 6SE6400-5AW00-0BP0

Page 25

Issue 10/06 2 Installation

Atmospheric Pollution

Do not install the inverter in an environment, which contains atmospheric pollutants

such as dust, corrosive gases, etc.

Water

Take care to site the inverter away from potential water hazards, e.g. do not install

the inverter beneath pipes that are subject to condensation. Avoid installing the

inverter where excessive humidity and condensation may occur.

Installation and cooling

CAUTION

The inverters MUST NOT be mounted horizontally.

The inverters can be mounted without any clearance at either side. When mounting

inverters one above the other, the specified environmental conditions must not be

exceeded.

Independent of this, these minimum distances must be observed.

¾ Frame Size A, B, C above and below 100 mm

¾ Frame Size D, E above and below 300 mm

¾ Frame Size F above and below 350 mm

¾ Frame Size FX, GX above 250 mm

below 150 mm

in front 40 mm (FX), 50 mm (GX)

No equipment that could have a negative effect on the flow of cooling air should be

installed in this area. Make sure that the cooling vents in the inverter are positioned

correctly to allow free movement of air.

MICROMASTER 440 Operating Instructions

6SE6400-5AW00-0BP0

25

Page 26

2 Installation Issue 10/06

2.3 Mechanical installation

WARNING

¾ To ensure the safe operation of the equipment, it must be installed and

commissioned by qualified personnel in full compliance with the warnings laid

down in these operating instructions.

¾ Take particular note of the general and regional installation and safety

regulations regarding work on dangerous voltage installations (e.g. EN 50178),

as well as the relevant regulations regarding the correct use of tools and

personal protective equipment (PPE).

¾ The mains input, DC and motor terminals, can carry dangerous voltages even

if the inverter is inoperative; wait 5 minutes to allow the unit to discharge after

switching off before carrying out any installation work.

¾ The inverters can be mounted without any clearance at either side. When

mounting inverters one above the other, the specified environmental

conditions must not be exceeded. Independent of this, these minimum

distances must be observed.

• Frame Size A, B, C above and below 100 mm

• Frame Size D, E above and below 300 mm

• Frame Size F above and below 350 mm

• Frame Size FX, GX above 250 mm

below 150 mm

in front 40 mm (FX), 50 mm (GX)

¾ If the front cover (Frame Sizes FX and GX) has been removed, the fan

impeller is exposed. There is danger of injury when the fan is running.

¾ IP20 protection is only against direct contact, always use these products within

a protective cabinet.

4

Removing from transport pallet (only for frame sizes FX and GX)

During transport, the inverter is fastened on the transport pallet with the aid of two

iron brackets.

WARNING

Note that the center of gravity of the inverter is not in the middle of the unit. When

lifting the pallet, the unit can therefore suddenly change position and swing to the

side.

1. Fasten the hoisting crane cable to the hoisting eyes on the inverter (2 eyes,

see Fig. 2-9 and Fig. 2-10).

2. Remove the two retaining bolts at the top of the front cover.

3. Unscrew the bolts in the iron brackets on the transport pallet and lift the

inverter off the pallet.

4. Once installation has been completed and the inverter connected, fasten the

two retaining bolts for the front cover at the bottom side of the door.

MICROMASTER 440 Operating Instructions

26 6SE6400-5AW00-0BP0

Page 27

Issue 10/06 2 Installation

Frame Sizes A to F

Frame Size A

55 mm

2.2"

160 mm

6.30"

Ø 4.5 mm

0.17"

Frame Size B Frame Size C

Ø 5.5 mm

Ø 4.8 mm

0.19"

138 mm

5.43"

174 mm

6.85"

0.22"

174 mm

6.85"

Frame Size D Frame Size E Frame Size F

Ø 17.5 mm

0.68"

486 mm

19.13"

Ø 17.5 mm

0.68"

616.4 mm

24.27"

Ø 15 mm

0.59"

204 mm

8.03"

810 mm

31.89"

with

filter

1110 mm

43.70"

235 mm

9.25"

235 mm

9.25"

Fig. 2-4 Drill pattern for MICROMASTER 440

300 mm

11.81"

MICROMASTER 440 Operating Instructions

6SE6400-5AW00-0BP0

27

Page 28

2 Installation Issue 10/06

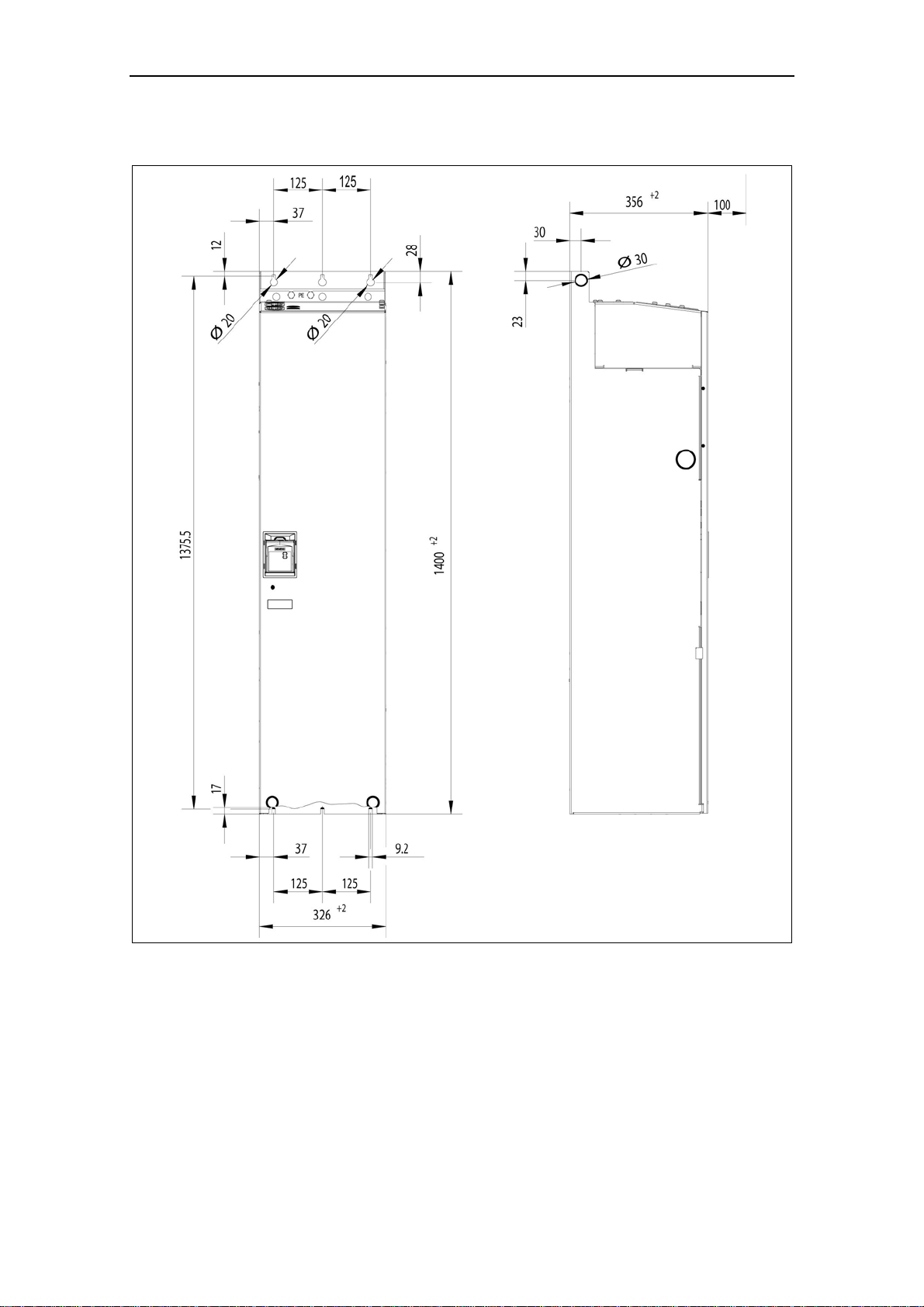

Frame Size FX

Fig. 2-5 Installation dimensions for MICROMASTER 440 Frame size FX

MICROMASTER 440 Operating Instructions

28 6SE6400-5AW00-0BP0

Page 29

Issue 10/06 2 Installation

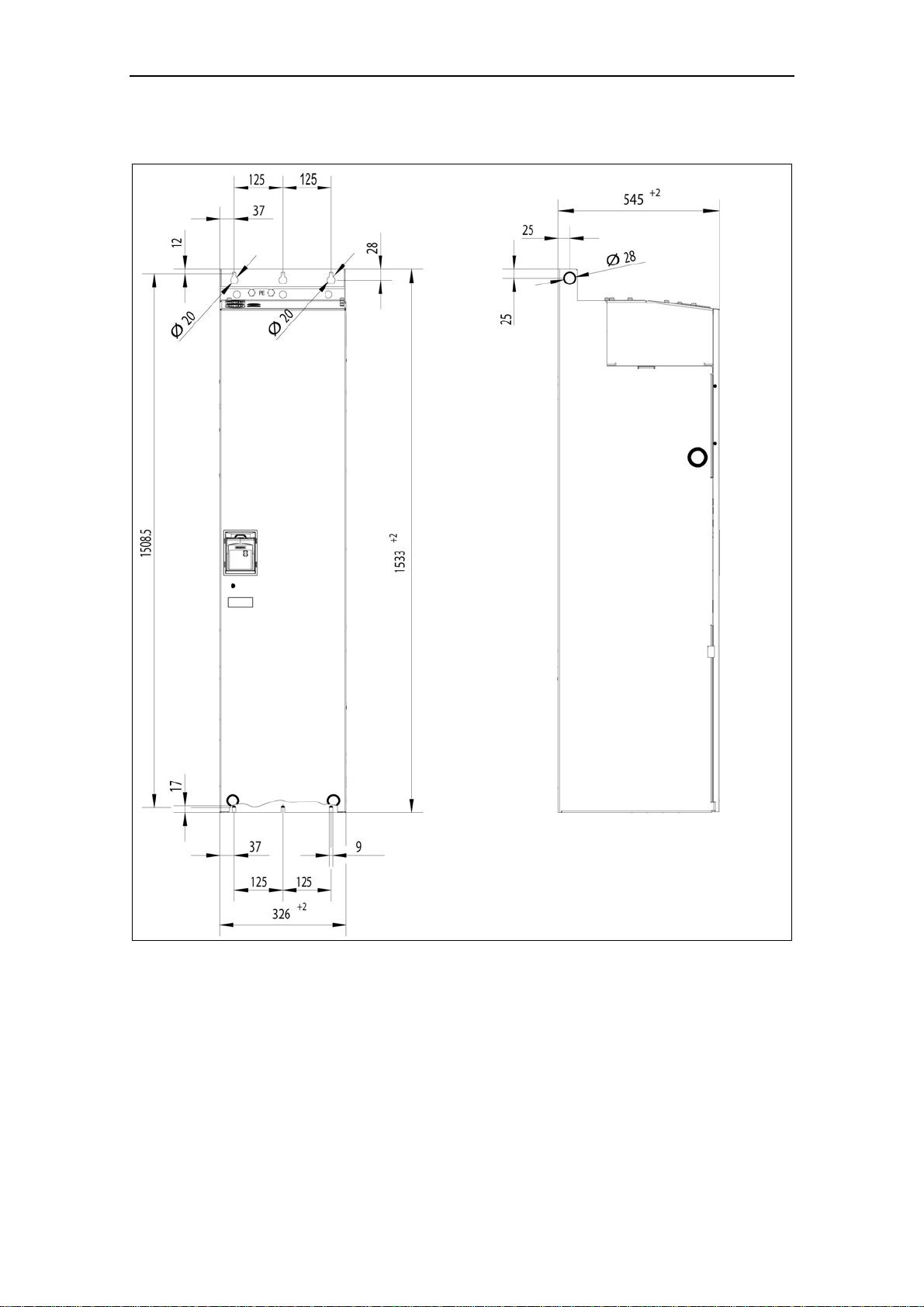

Frame Size GX

Fig. 2-6 Installation dimensions for MICROMASTER 440 Frame size GX

MICROMASTER 440 Operating Instructions

6SE6400-5AW00-0BP0

29

Page 30

2 Installation Issue 10/06

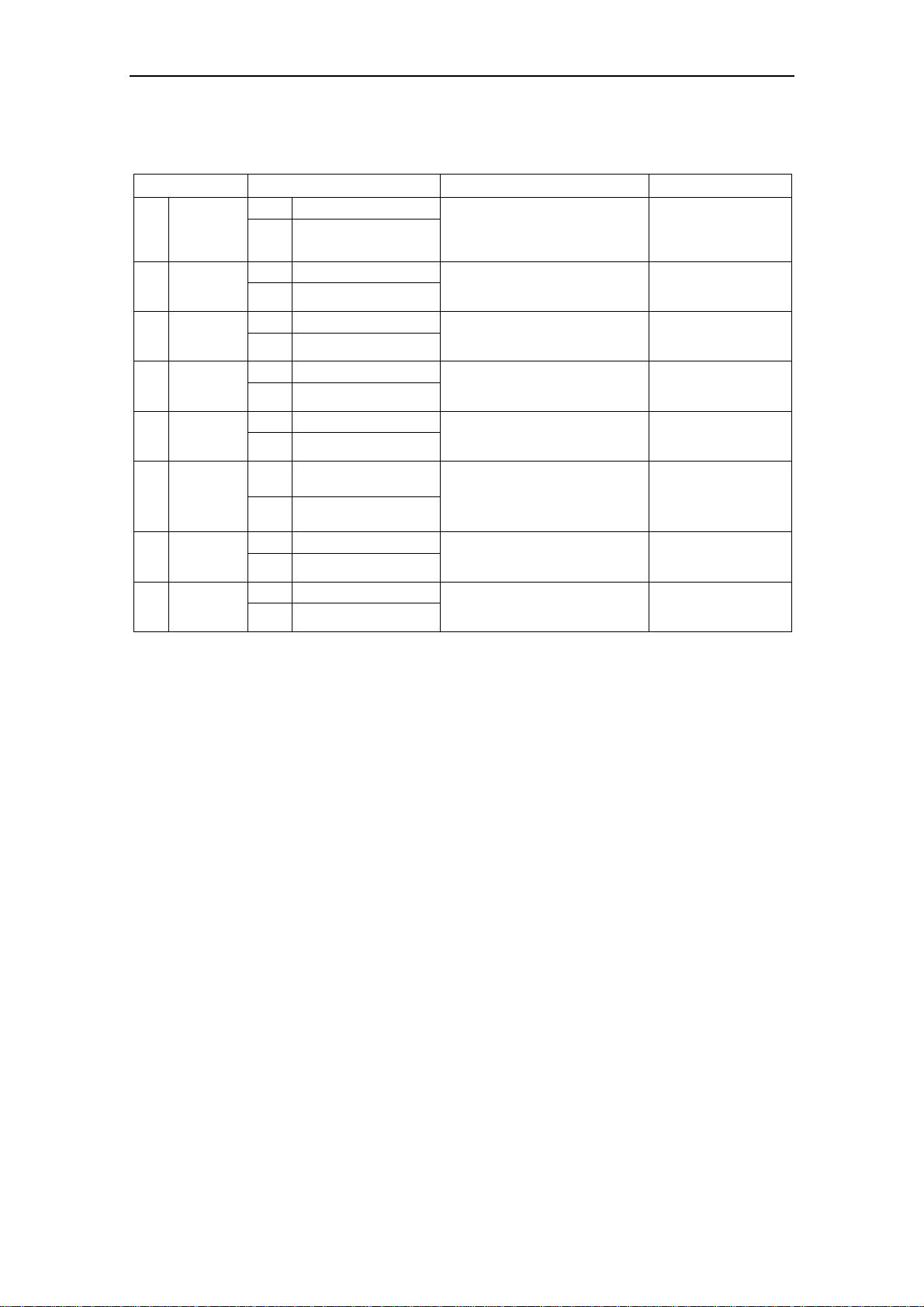

Table 2-1 Dimensions and Torques of MICROMASTER 440

Frame-Size Overall Dimensions Fixing Method Tightening Torque

2 M4 Bolts

4 M4 Nuts

4 M4 Washers or fitting on a

standard rail

4 M4 Bolts

4 M4 Nuts

4 M4 Washers

4 M5 Bolts

4 M5 Nuts

4 M5 Washers

4 M8 Bolts

4 M8 Nuts

4 M8 Washers

4 M8 Bolts

4 M8 Nuts

4 M8 Washers

4 M8 Bolts

4 M8 Nuts

4 M8 Washers

6 M8 Bolts

6 M8 Nuts

6 M8 Washers

6 M8 Bolts

6 M8 Nuts

6 M8 Washers

2,5 Nm

with washers fitted

2,5 Nm

with washers fitted

2,5 Nm

with washers fitted

3,0 Nm

with washers fitted

3,0 Nm

with washers fitted

3,0 Nm

with washers fitted

13 Nm +30 %

with washers fitted

13 Nm +30 %

with washers fitted

A

B

C

D

E

F

FX

GX

Width x

Height x

Depth

Width x

Height x

Depth

Width x

Height x

Depth

Width x

Height x

Depth

Width x

Height x

Depth

Width x

Height x

Depth

Width x

Height x

Depth

Width x

Height x

Depth

mm 73 x 173 x 149

inch 2,87 x 6,81 x 5,87

mm 149 x 202 x 172

inch 5,87 x 7,95 x 6,77

mm 185 x 245 x 195

inch 7,28 x 9,65 x 7,68

mm 275 x 520 x 245

inch 10,82 x 20,47 x 9,65

mm 275 x 650 x 245

inch 10,82 x 25,59 x 9,65

350 x 850 mm x 320

mm

height with filter 1150

13,78 x 33,46 x 12,60

inch

height with filter 45,28

mm 326 x 1400 x 356

inch 12,80 x 55,12 x 12,83

mm 326 x 1533 x 545

inch 12,80 x 60,35 x 21,46

MICROMASTER 440 Operating Instructions

30 6SE6400-5AW00-0BP0

Page 31

Issue 10/06 2 Installation

2.3.1 Mounting onto standard rail, Frame Size A

Mounting the inverter onto a 35 mm standard rail (EN 50022)

Release Mechanism

1. Locate the inverter on the mounting rail using

the upper rail latch

Upper

rail latch

Lower

rail latch

Removing the Inverter from the rail

1. To disengaged the release mechanism of the inverter, insert a screwdriver into

the release mechanism.

2. Apply a downward pressure and the lower rail latch will disengage.

3. Pull the inverter from the rail.

2. Using a flat blade screwdriver, press the

release mechanism downwards and engage

the inverter into the lower rail latch.

MICROMASTER 440 Operating Instructions

6SE6400-5AW00-0BP0

31

Page 32

2 Installation Issue 10/06

2.3.2 Installing communication options and/or pulse encoder evaluation module

Sizes A to F

NOTE

When installing the following options – PROFIBUS module, DeviceNet module,

CANopen option module and/or pulses encoder evaluation module, the mounting

depth of the drive inverter is increased!

Please refer to the relevant Operating Instructions for the actual procedure.

Sizes FX and GX

The front cover of the MICROMASTER 440 is designed so that the control module

(normally the SDP) is almost flush with the opening in the front cover.

If more than one option is to be installed in the electronic box, it is necessary to

position the entire electronic box further to the rear

Installing the options

¾ Remove the front cover:

• Unscrew two screws at the bottom side of the front cover.

• Lift front cover up and out.

¾ Remove retaining screws on the electronic box.

¾ Screw on electronic box in correct installation position as shown in Fig. 2-7

¾ Install additional options.

¾ Reinstall front cover.

Fig. 2-7 Options for the electronic box

Installation position 2

Installation position 1

Standard installation

Standard installation

Installation position 1

Installation position 2

MICROMASTER 440 Operating Instructions

32 6SE6400-5AW00-0BP0

Page 33

Issue 10/06 2 Installation

2.4 Electrical installation

WARNING

The inverter must always be grounded.

¾ To ensure the safe operation of the equipment, it must be installed and

commissioned by qualified personnel in full compliance with the warnings laid

down in these operating instructions.

¾ Take particular note of the general and regional installation and safety

regulations regarding work on dangerous voltage installations (e.g. EN 50178),

as well as the relevant regulations regarding the correct use of tools and

personal protective gear.

¾ Never use high voltage insulation test equipment on cables connected to the

inverter.

¾ The mains input, DC and motor terminals, can carry dangerous voltages even

if the inverter is inoperative; wait 5 minutes to allow the unit to discharge after

switching off before carrying out any installation work.

¾ If the front cover (Frame Sizes FX and GX) has been removed, the fan

impeller is exposed. There is danger of injury when the fan is running.

CAUTION

The control, power supply and motor leads must be laid separately. Do not feed

them through the same cable conduit/trunking.

MICROMASTER 440 Operating Instructions

6SE6400-5AW00-0BP0

33

Page 34

2 Installation Issue 10/06

2.4.1 General

WARNING

The inverter must always be grounded. If the inverter is not grounded correctly,

extremely dangerous conditions may arise within the inverter which could prove

potentially fatal.

Operation with ungrounded (IT) supplies

Filtered

The use of filtered MICROMASTER 4 drives on unearthed mains supplies is not

permitted.

Unfiltered

In the case of non-grounded networks, the 'Y' capacitor of the device must be

made ineffective. The procedure is described in Appendix D.

If the MICROMASTER is to remain in operation in non-grounded networks when a

ground fault occurs during the input or output phase, an output reactor must be

installed.

Operation with Residual Current Device (Frame Sizes A to F)

If an RCD (also referred to as ELCB or RCCB) is fitted, the MICROMASTER

inverters will operate without nuisance tripping, provided that:

¾ A type B RCD is used.

¾ The trip limit of the RCD is 300 mA.

¾ The neutral of the supply is grounded.

¾ Only one inverter is supplied from each RCD.

¾ The output cables are less than 50 m (screened) or 100 m (unscreened).

NOTE

The residual current operated circuit-breakers used must provide protection against

direct-current components in the fault current and must be suitable for briefly

suppressing power pulse current peaks. It is recommended to protect the

frequency inverter by fuse separately.

The regulations of the individual country (e.g. VDE regulations in Germany)

and the regional power suppliers must be observed!

MICROMASTER 440 Operating Instructions

34 6SE6400-5AW00-0BP0

Page 35

Issue 10/06 2 Installation

2.4.2 Power and motor connections

WARNING

The inverter must always be grounded.

♦ Isolate the mains electrical supply before making or changing connections to

the unit.

♦ Ensure that the inverter is configured for the correct supply voltage:

MICROMASTERS must not be connected to a higher voltage supply.

♦ When synchronous motors are connected or when coupling several motors in

parallel, the inverter must be operated with V/f control characteristic (P1300 =

0, 2 or 3).

CAUTION

After connecting the power and motor cables to the proper terminals, make sure

that the front covers have been replaced properly before supplying power to the

unit!

NOTICE

♦ Ensure that the appropriate circuit-breakers/fuses with the specifie d current

rating are connected between the power supply and inverter (see chapter 5,

Tables 5-5).

♦ Use Class 1 60/75

o

C copper wire only (for UL compliance). For tightening

torque see Table 5-2.

Operation with long cables

All inverters will operate at full specification with cable lengths as follows:

Frame Sizes A to F FX and GX

screened 50 m 100 m

unscreened 100 m 150 m

Using the output chokes specified in catalogue DA 51.2, the following cable leng t hs

are possible for the appropriate frame sizes:

Supply Voltage 200 V …

240 V ± 10%

Frame Sizes A … F A … B C D … F FX, GX A … C D … F FX, GX C D … F

screened 200 m 150 m 200 m 200 m 300 m 100 m 200 m 300 m 100 m 200 m

unscreened 300 m 225 m 300 m 300 m 450 m 150 m 300 m 450 m 150 m 300 m

CAUTION

If using output chokes operation is only permissible with a pulse frequency of

4 kHz. Make shure that the automatic pulse frequency reductions are disabled.

Coercing required parameter adjusting: P1800 = 4 kHz , P0290 = 0 or 1.

380 V … 400 V ± 10 % 401 V … 480 V ± 10 % 500 V … 600 V

± 10%

MICROMASTER 440 Operating Instructions

6SE6400-5AW00-0BP0

35

Page 36

2 Installation Issue 10/06

Access to the power and motor terminals

Access to the power supply and motor terminals is possible by removing the front

covers (See Fig. 2-8 to Fig. 2-10). See also Appendix B.

After removing the front covers and exposing the terminals, complete power and

motor connections as shown in Fig. 2-11.

Connection of braking unit (only for framesize FX and GX)

A passage opening for access to the intermediate circuit connections has been

provided on the top side of the inverter. It is possible to connect an external braking

unit (refer to Catalog DA65.11 or DA65.10) to these terminals. The position is

shown in Fig. 2-9 and Fig. 2-10.

The maximum cross section of connections is 50 mm², but only provided the

crimped area of cable shoes on the equipment side is provided with a heatshrinkable sleeve. This measure is important to ensure that air gaps and creep

distances are observed.

MICROMASTER 440 Operating Instructions

36 6SE6400-5AW00-0BP0

Page 37

Issue 10/06 2 Installation

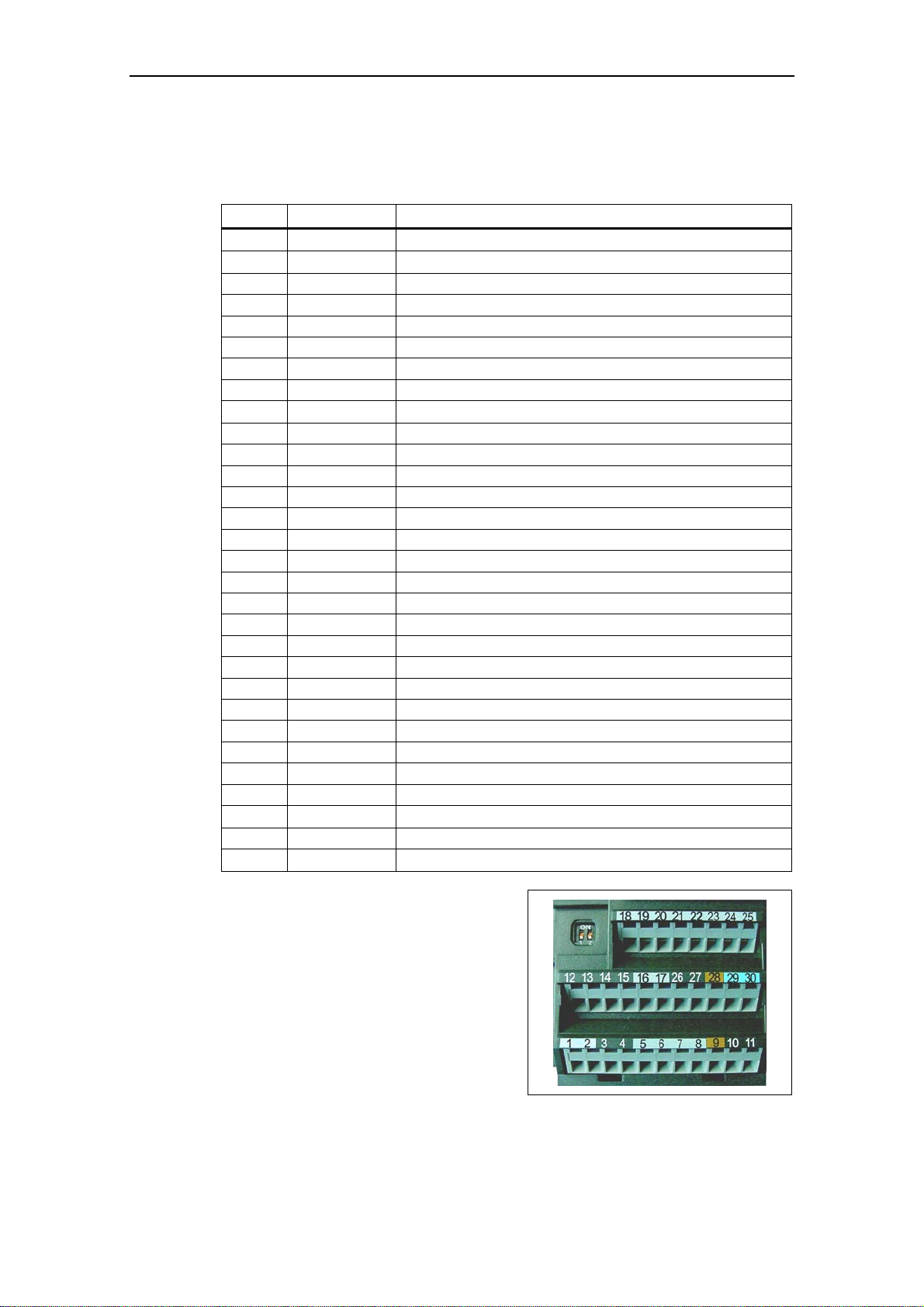

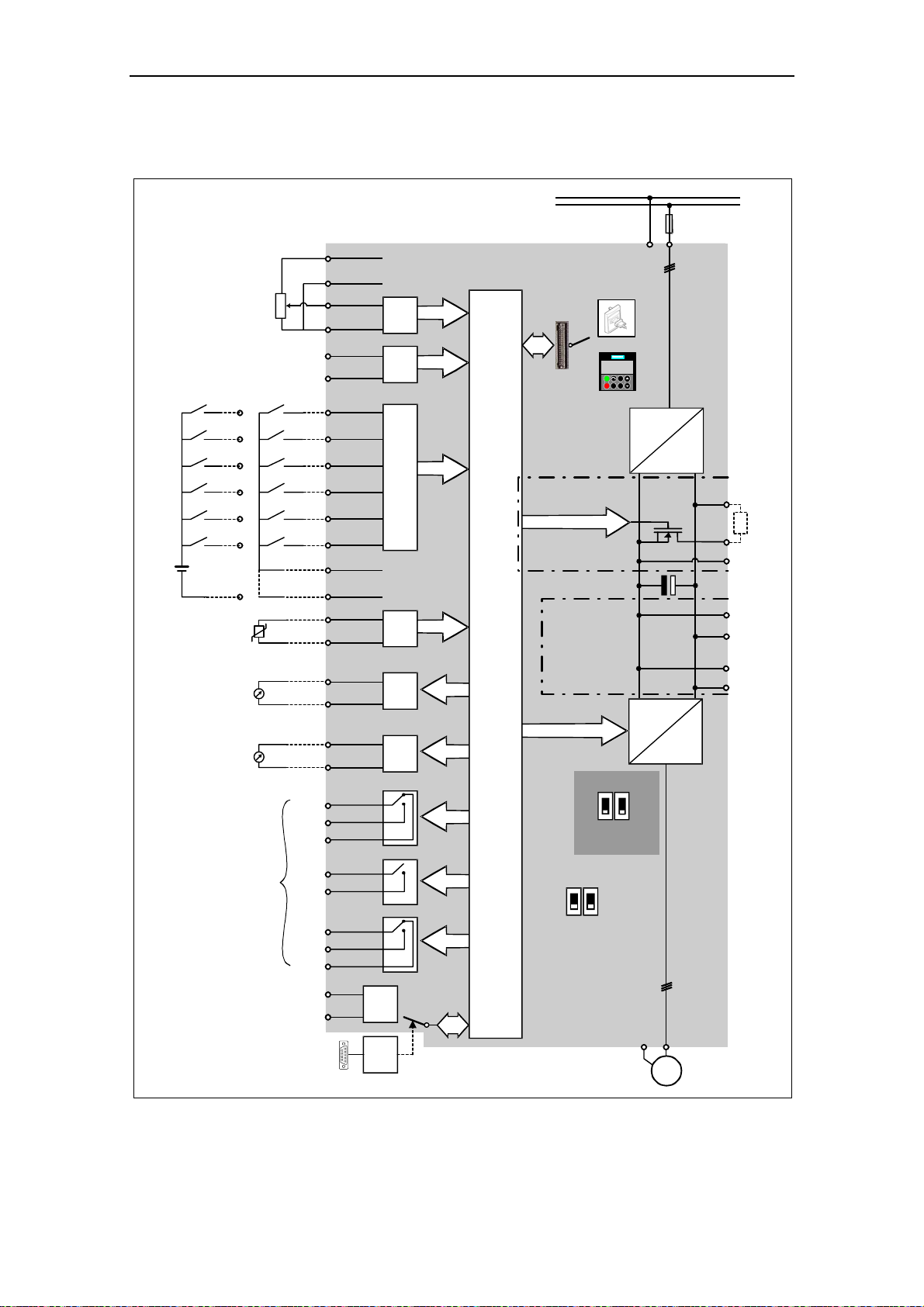

Fig. 2-8 MICROMASTER 440 C onnection Terminals

MICROMASTER 440 Operating Instructions

6SE6400-5AW00-0BP0

37

Page 38

2 Installation Issue 10/06

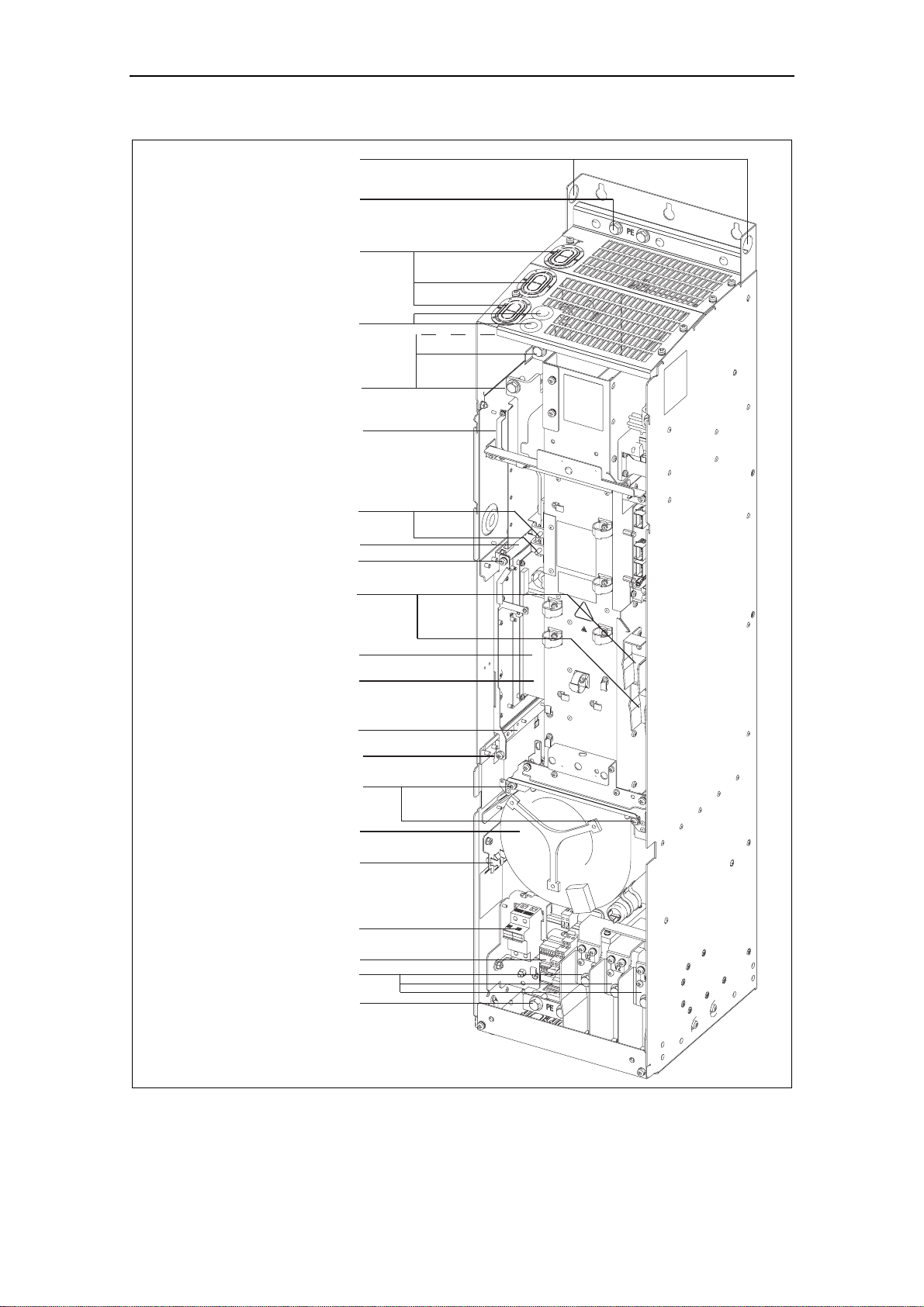

Hoisting eyes

Shield connection

Mains cable PE

Cable opening for

mains conection

U1/L1, V1/L2, W1/L3

Cable opening DCPA, DCNA

for connection of an

external braking unit

Mains cable

Phase U1/L1, V1/L2, W1/L3

Connection to

Y-Capacitor

Connection DCPA, DCNA

for external braking unit

Top adjustment rail

Top retaining screw

Connection for dv/dt filter

DCPS, DCNS

Status Display Panel

Elektronic box

Bottom adjustment rail

Bottom retaining screw

Fan screws

Fan

Shield connection

control leads

Fan fuses

Transformer adaption

PE Shield connection

Motor cable

Phase U2, V2, W2

Motor cable

Fig. 2-9 MICROMASTER 440 conn ection drawing – frame size FX

MICROMASTER 440 Operating Instructions

38 6SE6400-5AW00-0BP0

Page 39

Issue 10/06 2 Installation

Hoisting eyes

Shield connection

Mains cable PE

Cable opening for

mains conection

U1/L1, V1/L2, W1/L3

able opening DCPA, DCNA

for connection of an

external braking unit

Phase U1/L1, V1/L2, W1/L3

Connection DCPA, DCNA

for external braking unit

Connection for dv/dt filter

Status Display Panel

Bottom adjustment rail

Bottom retaining screw

Mains cable

Connection to

Y-Capacitor

Top adjustment rail

Top retaining screw

DCPS, DCNS

Elektronic box

Fan screws

Fan

Shield connection

control leads

Fan fuses

Transformer adaption

Motor cable

Phase U2, V2, W2

PE Shield connection

Motor cable

Fig. 2-10 MICROMASTER 440 conn ection drawing - frame size GX

MICROMASTER 440 Operating Instructions

6SE6400-5AW00-0BP0

39

Page 40

2 Installation Issue 10/06

Frame Sizes A to F

L3

L2

L1

N

Fuse

L3

L2

L1

Fuse

Contactor

Contactor

Single Phase

Optional

line choke

PE

Three Phase

Optional

line choke

PE

Optional

Filter

PE

Optional

Filter

PE

MICROMASTER

L/L1

U

V

N/L2

W

PE

MICROMASTER

L3

U

L2

V

L1

W

PE

1)

1)

Motor

Motor

1) with and with out filter

Frame Sizes FX and GX

L3

L2

L1

Optional