Page 1

Watson-Marlow Alitea 114 pumpheads: operating instructions 1

WATSON-MARLOW MANUALS

Watson-Marlow Alitea

114 pumpheads

m-114pumphead-gb-04

Contents

1 Declaration of incorporation 2

2 Safety notes 3

3 Product specifications 4

3.1 Dimensions 4

4 Good pump installation

practice 5

4.1 General recommendations 5

4.2 Do’s and do not’s 6

4.3 Troubleshooting 6

5 Pumphead mounting 7

6 Torque requirement 8

7 Tube holder positioning 9

7.1 Tube holder repositioning 10

8 Tube loading 11

9 Flow rates and

pressure capabilities 12

10 Tubing part numbers 14

11 Trademarks 15

12 Patient-connected use: warning 15

13 Publication history 15

Page 2

Watson-Marlow Alitea 114 pumpheads: operating instructions 2

1 Declaration of incorporation

When this unit is to be installed into a machine or is to be assembled with

other machines for installations, it must not be put into service until the

relevant machinery has been declared in conformity with the Machinery

Directive 2006/42/EC.

Responsible person: Lars Eriksson, General Manager, Watson-Marlow Alitea AB,

Hammarby Fabriksvag 29-31, 120 33 Stockholm, Sweden.

Telephone +46 8 556 556 00. Fax +46 8 556 556 25.

The information in this user guide is believed to be correct at the time of publication. However, Watson-Marlow Alitea accepts no liability for errors or omissions.

Watson-Marlow Alitea has a policy of continuous product improvement, and reserves

the right to alter specifications without notice. This manual is intended for use only

with the pump it was issued with. Earlier or later models may differ. The most upto-date manuals appear on the Watson-Marlow Pumps Group website:

http://www.watson-marlow.com

114DV, 114DVP

September 2014

Page 3

Watson-Marlow Alitea 114 pumpheads: operating instructions 3

2 Safety notes

In the interests of safety, this pumphead and the tubing selected should only be

used by competent, suitably trained personnel after they have read and understood

this manual, and considered any hazard involved. If the product is used in a manner not specified by Watson-Marlow Ltd, the protection provided by the product may

be impaired.

Any person who is involved in the installation or maintenance of this equipment

should be fully competent to carry out the work. In the UK this person should also

be familiar with the Health and Safety at Work Act 1974.

There are moving parts inside the pumphead. Before opening the flip top,

ensure that the following safety directions are followed.

Ensure that the pump is isolated from the mains power.

Ensure that there is no pressure in the pipeline.

If a tube failure has occurred, ensure that any fluid in the pumphead has been

allowed to drain to a suitable vessel, container or drain.

Protective clothing and eye protection must be worn if hazardous fluids are

pumped.

Primary operator protection from rotating parts of the pump is provided by the

pumphead track.

This pump must be used only for its intended purpose.

This symbol, used on the pump or in this manual,

means: Caution, refer to accompanying documents.

This symbol, used on the pump or in this manual,

means: Do not allow fingers to contact moving parts.

114DV, 114DVP

Page 4

Watson-Marlow Alitea 114 pumpheads: operating instructions 4

3 Product specifications

114 pumpheads

This compact pumphead allows automatic tube positioning and tension in seconds,

with no need for operator adjustment to achieve high accuracy and repeated precision dosing.

For continous tubing, 1.6mm wall

Recommended for continous duty

Four-roller pumphead

Max speed: 400 rpm continous and 600 rpm intermittent

Up to 340 ml/min continuous flow and up to 510 ml/min intermittent flow

Two tube-holder positions to accept tube in bore sizes from 0.5mm to 4.8mm

Models with occlusion settings for standard or high-pressure operation

Universal drive connection for shafts from 6mm diameter to 10mm diameter

Operating temp: -10° to 45°C

This manual describes the visible rotation pumpheads, 114DV and 114DVP. For

versions without visible rotation: 114D—refer to 114DV; 114DP—refer to 114DVP.

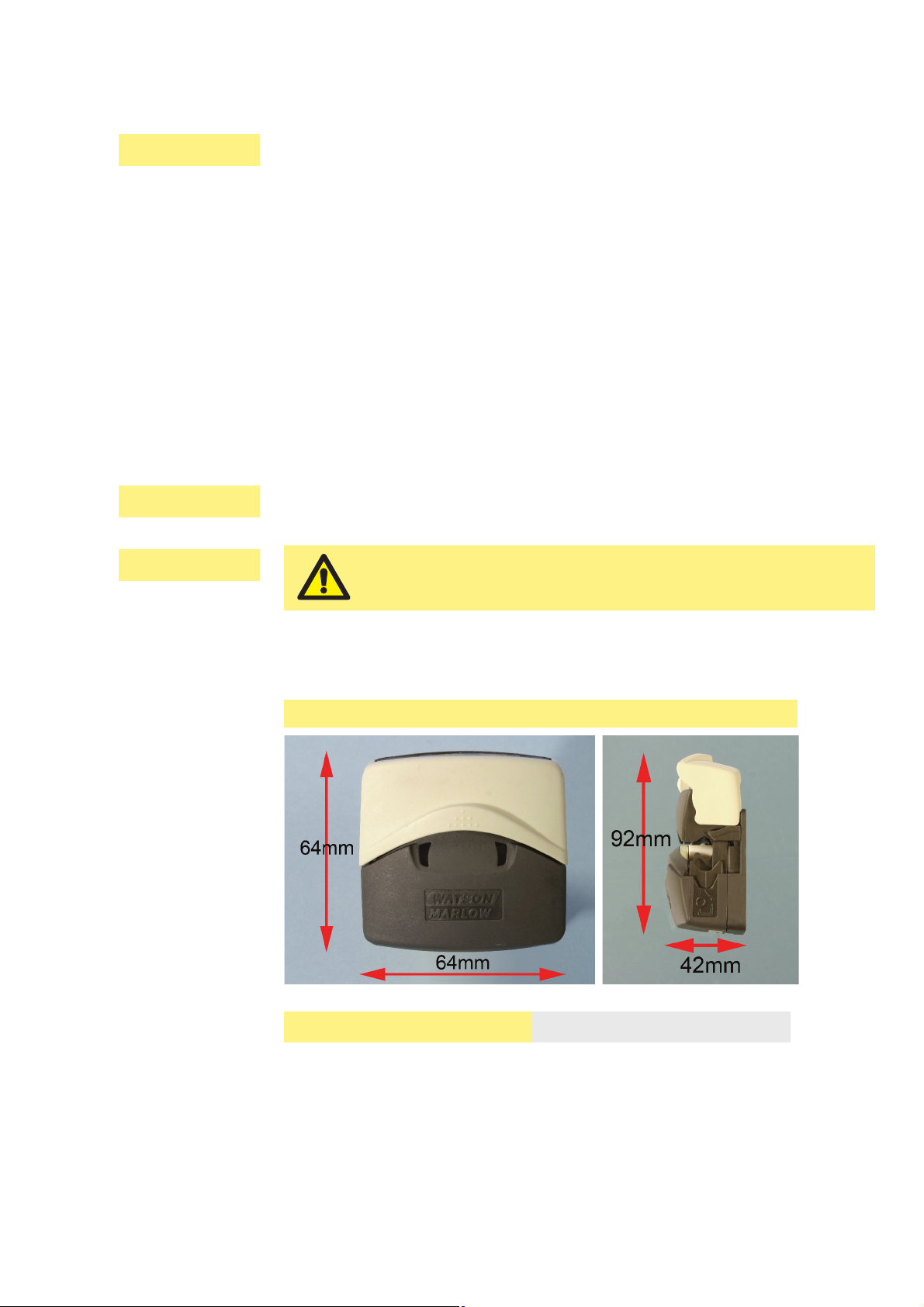

3.1 Dimensions

114 pumphead

Unit weight 0.1kg

This product does not comply with the ATEX directive

and must not be used in explosive atmospheres.

114DV, 114DVP

114D, 114DP

114DV, 114DVP

Page 5

Watson-Marlow Alitea 114 pumpheads: operating instructions 5

4 Good pump installation practice

4.1 General recommendations

A correctly engineered installation will promote long tube life.

The pump may be set up so that the direction of rotor rotation is clockwise or counter-clockwise, whichever is convenient. Please note, however, that tube life will be

greater if the rotor rotates clockwise; and that performance against pressure will be

maximised if the rotor rotates counter-clockwise.

Peristaltic pumps are self-priming and self-sealing against backflow. No valves are

required in inlet or discharge lines, except as described below. Valves in the process

flow must be opened before the pump operates. Users are advised to fit a pressure

relief device between the pump and any valve on the discharge side of the pump to

protect against damage caused by accidental operation with the discharge valve

closed.

114DV, 114DVP

Page 6

Watson-Marlow Alitea 114 pumpheads: operating instructions 6

4.2 Do’s and do not’s

Do not build a pump into a tight location without adequate airflow around the pump.

Do keep delivery and suction tubes as short and direct as possible - though ideally

not shorter than 0.5m - and follow the straightest route. Use bends of large radius:

at least four times the tubing diameter. Ensure that connecting pipework and fittings

are suitably rated to handle the predicted pipeline pressure. Try to avoid pipe reducers and lengths of smaller bore tubing than the pumphead section, particularly in

pipelines on the suction side. Any valves in the pipeline (not usually needed with

a self-priming peristaltic pump) must not restrict the flow. Any valves in the flow line

must be open when the pump is running.

Do use suction and delivery pipes equal to or larger than the bore of the tube in the

pumphead. When pumping viscous fluids use pipe runs with a bore several times

larger than the pump tube.

Do ensure that on longer tube runs at least 0.5m of smooth bore flexible tubing is

connected to the inlet and discharge port of the pumphead to help to minimise

impulse losses and pulsation in the pipeline. This is especially important with viscous

fluids and when connecting to rigid pipework.

Do site the pump at or just below the level of the fluid to be pumped if possible.

This will ensure flooded suction and maximum pumping efficiency.

Do keep the pumphead track and all moving parts clean and free from contamination and debris.

Do run at slow speed when pumping viscous fluids. Flooded suction will enhance

pumping performance in all cases, particularly for materials of a viscous nature.

Do recalibrate after changing pump tubes, fluid, or any connecting pipework. It is

also recommended that the pump is recalibrated periodically to maintain accuracy.

Tube selection: The chemical compatibility lists published in Watson-Marlow publications are guides. If in doubt about the compatibility of a tube material and the

duty fluid, request a Watson-Marlow tube sample card for immersion trials.

4.3 Troubleshooting

If the pump runs but there is little or no flow, make the following checks:

Check that the tube is in the pumphead.

Check that fluid is supplied to the pump.

Check that the tube is not split or burst.

Check for any kinks or blockages in the lines.

Check that any valves in the lines are open.

Check that the correct wall-thickness tube is being used.

Check direction of rotation.

114DV, 114DVP

114DV, 114DVP

Page 7

Watson-Marlow Alitea 114 pumpheads: operating instructions 7

5 Pumphead mounting

Lift the flip top until fully open.

Mount the pumphead on its supporting plate through the holes indicated below,

using two Allen-key headed M4 screws, length equal to 5mm + the thickness of

the mount. Tighten them to a maximum of 0.5Nm.

Drive shafts 8mm in diameter are recommended, but shafts from 6mm diameter to

10mm diameter are acceptable.

114DV, 114DVP

Page 8

Watson-Marlow Alitea 114 pumpheads: operating instructions 8

0.3

0.25

0.2

0.15

0.1

0.05

0

Nm

Tube bore

0.5

Torque requirement, 1.6mm wall tube

0.8

1.6

2.4

3.2 4.0 4.8

Required torque depends on many parameters. The chart above includes standard

materials, direction, occlusion setting, pressure and running temperature.

Starting torques are approximately the above figures x 2.

Assess your application’s torque requirement from the top of the arrows if all the

parameters listed are those requiring more torque, as shown in the graph below, or

to be sure to have sufficient torque for all conditions; use the bottom of the arrows

if all the parameters listed are those requiring less torque, as shown in the graph

below.

Factors affecting torque requirement

Pumpsil

CW

Standard occlusion

High temperature

CCW

Bioprene

+Pressure occlusion

Low temperature

More torque

Less torque

6 Torque requirement

114DV, 114DVP

Page 9

Watson-Marlow Alitea 114 pumpheads: operating instructions 9

7 Tube holder positioning

The pumphead can be adjusted to accommodate 1.6mm wall tubing in sizes from

0.5mm bore to 4.8mm bore.

Inner position, for small tubing Outer position, for large tubing

With the smaller bore tubes of 0.5mm, 0.8mm and 1.6mm the inner position must

be used to prevent the risk of tube slipping through the clamps and wandering

across the rollers causing premature tube rupture.

With the larger bore tubes of 4.0mm and 4.8mm the outer position must be used to

prevent the flow rate being excessively reduced.

For tubing bores of 2.4mm and 3.2mm either setting may be used, as appropriate

for the application. The inner setting will clamp the tube harder, reducing tube slip

but has the potential to marginally reduce flow rate. The outer setting will optimise

flow rate but the risk of tube slip is increased.

114DV, 114DVP

Tube holder position

Tube bore size 0.5mm 0.8mm 1.6mm 2.4mm 3.2mm 4.0mm 4.8mm

Inner

Outer

Page 10

Watson-Marlow Alitea 114 pumpheads: operating instructions 10

To change from the large tube to the small tube setting

Switch off the pump before changing the tube holder position. Use a pointed

device such as a ball-point pen to reposition the lower tube holders on both sides

of the pumphead.

Press down and slightly away from the front of the pumphead, as shown in the

first picture above.

Maintain the angled downward pressure and push away from the front of the

pumphead. The jaw clicks into a new position.

Release the pressure. The jaw rises into its correct alignment. If it does not

rise, repeat the procedure, being sure to maintain downward pressure until

release.

Adjust the tube holder on the other side of the pumphead in the same way.

To change from the small tube to the large tube setting

Carry out the procedure described above, but pushing towards the front of the

pumphead.

Lift the flip top until fully open.

Place the pointed device pointing

down into the small depression pictured here.

Note: The pictures on the previous page show the tube holders’ correct positions for

small and large tubing. If a tube holder is not vertical relative to the body of the

pumphead, it is wrongly positioned. Follow the instructions above to reposition it.

7.1 Tube holder repositioning

114DV, 114DVP

Page 11

Watson-Marlow Alitea 114 pumpheads: operating instructions 11

8 Tube loading

Lift the flip top until fully open.

Select enough tube length for the curve of the pump track. Place the tube

between the rotor rollers and the track, pressed against the pumphead inner

wall. The tube must not be twisted or stretched against the rollers.

Lower the flip top until it clicks into its fully closed position. The track closes

automatically and the tube is stretched correctly as it does so.

Click!

Switch off the pump before tube loading.

Check that the tube holders on both sides of the pumphead are correctly set for the

size of tube you are using.

114DV, 114DVP

Page 12

Watson-Marlow Alitea 114 pumpheads: operating instructions 12

9 Flow rates and pressure

capabilities

Pumping conditions

For precise and repeatable performance it is important to determine flow rates under

operating conditions for each new piece of tubing.

114 pumpheads’ flow rates are the same whether rotating clockwise (cw) or counter-clockwise (ccw). Their pressure capabilities vary depending on rotation sense.

114, cw and ccw rotation:

Flow rates, ml/min

Tube bore

size

0.5mm 0.8mm 1.6mm 2.4mm 3.2mm 4.0mm 4.8mm

ml/rev 0.02 0.04 0.14 0.29 0.47 0.67 0.85

30 rpm 0.7 1.3 4.2 8.7 14 20 25.5

60 rpm 1.4 2.6 8.4 17.5 28.5 40.5 51

100 rpm 2.2 4.3 14 29 47.5 67 85

190 rpm 4.3 8.2 26.5 55 90.5 128 160

200 rpm 4.6 8.6 28 58 95 135 170

350 rpm 8.0 15 49 100 165 235 300

400 rpm 9.1 17 56 115 190 270 340

600 rpm 13.5 26 84 175 285 405 510

Flow rate tests were carried out using water at zero suction pressure and Bioprene

tubing, with the pumphead rotating cw. Actual flow rates achieved may vary because

of changes in temperature, viscosity, inlet and discharge pressures, system configuration and tubing performance against time. Flow rates may also vary due to normal manufacturing tolerances of the tubing.

Reduce the flow rates quoted by 10% if using Pumpsil tubing.

Recommended tubing

114DV: Bioprene, Marprene, Pumpsil, STA-PURE PCS and STA-PURE PFL

(formerly CHEM-SURE).

114DVP: Bioprene, Marprene, Pumpsil, STA-PURE PCS, STA-PURE PFL

(formerly CHEM-SURE), PVC and Neoprene.

114DV, 114DVP

114DV

114DVP

Page 13

Watson-Marlow Alitea 114 pumpheads: operating instructions 13

Marprene tubing, 1.6mm wall, 100 rpm, CCW rotation

Pressure tests were carried out using water at constant delivery pressure. Actual

pressures achieved may vary because of actual tube dimensions, changes in temperature, viscosity, system configuration and tubing performance against time.

Direction of rotation

CCW: The pressure / flow curves above show performance in counter clockwise

rotation. This direction is recommended for pressure applications.

CW: Clockwise rotation optimizes the pump performance regarding tube life and

required torque. Clockwise rotation is recommended for low or no pressure applications. Suction performance and flow are the same as for CCW rotation.

Pressure and flow performance curves

Marprene tubing, 1.6mm wall, 100 rpm, CCW rotation

114DV

114DVP

114DV, 114DVP

suction (bar) pressure (bar)

0123 54

Flow rate: ml/min

0

20

40

70

80

100

10

30

50

60

90

-0.5 -0.3 0-0.1-0.2-0.4

0.8 x 1.6

1.6 x 1.6

4.8 x 1.6

4.0 x 1.6

3.2 x 1.6

2.4 x 1.6

114DV, standard occlusion

suction (bar) pressure (bar)

0123 54

Flow rate: ml/min

0

20

40

70

80

100

10

30

50

60

90

-0.5 -0.3 0-0.1-0.2-0.4

0.8 x 1.6

1.6 x 1.6

4.8 x 1.6

4.0 x 1.6

3.2 x 1.6

2.4 x 1.6

114DVP, +Pressure occlusion

Page 14

Watson-Marlow Alitea 114 pumpheads: operating instructions 14

10 Tubing part numbers

1.6mm wall tubing for 114 pumpheads

mm # Marprene Bioprene Pumpsil

0.5 112 902.0005.016 933.0005.016 913.A005.016

0.8 13 902.0008.016 933.0008.016 913.A008.016

1.6 14 902.0016.016 933.0016.016 913.A016.016

2.4 902.0024.016 933.0024.016 913.A024.016

3.2 16 902.0032.016 933.0032.016 913.A032.016

4.0 933.0040.016

4.8 25 902.0048.016 933.0048.016 913.A048.016

mm # Tygon E3603* Neoprene*

0.8 13 920.0008.016

1.6 14 E3603.016.16 920.0016.016

3.2 16 E3603.032.16 920.0032.016

4.0 E3603.040.16

4.8 25 E3603.048.16 920.0048.016

mm # STA-PURE PCS STA-PURE PFL

1.6 14 960.0016.016 965.0016.016

3.2 16 960.0032.016 965.0032.016

4.8 25 960.0048.016 965.0048.016

114DV, 114DVP

* Recommended for 114DVP +Pressure pumpheads only

Page 15

Watson-Marlow Alitea 114 pumpheads: operating instructions 15

11 Trademarks

Bioprene, LoadSure, Marprene, Pumpsil and Watson-Marlow are trademarks

of Watson-Marlow Limited.

Tygon is a trademark of Saint Gobain Corporation

STA-PURE PFL and STA-PURE PCS are trademarks of W.L.Gore and Associates.

12 Warning not to use pumps in

patient-connected applications

Warning These products are not designed for use in, and should not be used for

patient-connected applications.

13 Publication history

m-114pumphead-gb-03.qxp: Watson-Marlow 114 pumphead.

Revised 09 14.

114DV, 114DVP

114DV, 114DVP

114DV, 114DVP

Loading...

Loading...