Page 1

INDUSTRIAL HOISTS

INSTALLATION AND OPERATOR'S GUIDE

GUIDE D'INSTALLATION ET OPERATEUR

TM

Page 2

.................................1

...............................21

Page 3

Warnings and Cautions

General Safety Precautions

As you read these instructions, you will see

WARNINGS, CAUTIONS, NOTICES and NOTES.

Each message has a specific purpose. WARNINGS

are safety messages that indicate a potentially hazardous situation, which, if not avoided could result in

serious injury. CAUTIONS are safety messages that

indicate a potentially hazardous situation which, if not

avoided, could result in minor or moderate injury. A

CAUTION may also be used to alert against unsafe

practice. CAUTIONS and WARNINGS identify the

hazard, indicate how to avoid the hazard, and advise

of the probable consequence of not avoiding the hazard. NOTICES are messages to avoid property damage. NOTES are additional information to help you

complete a procedure. PLEASE WORK SAFELY!

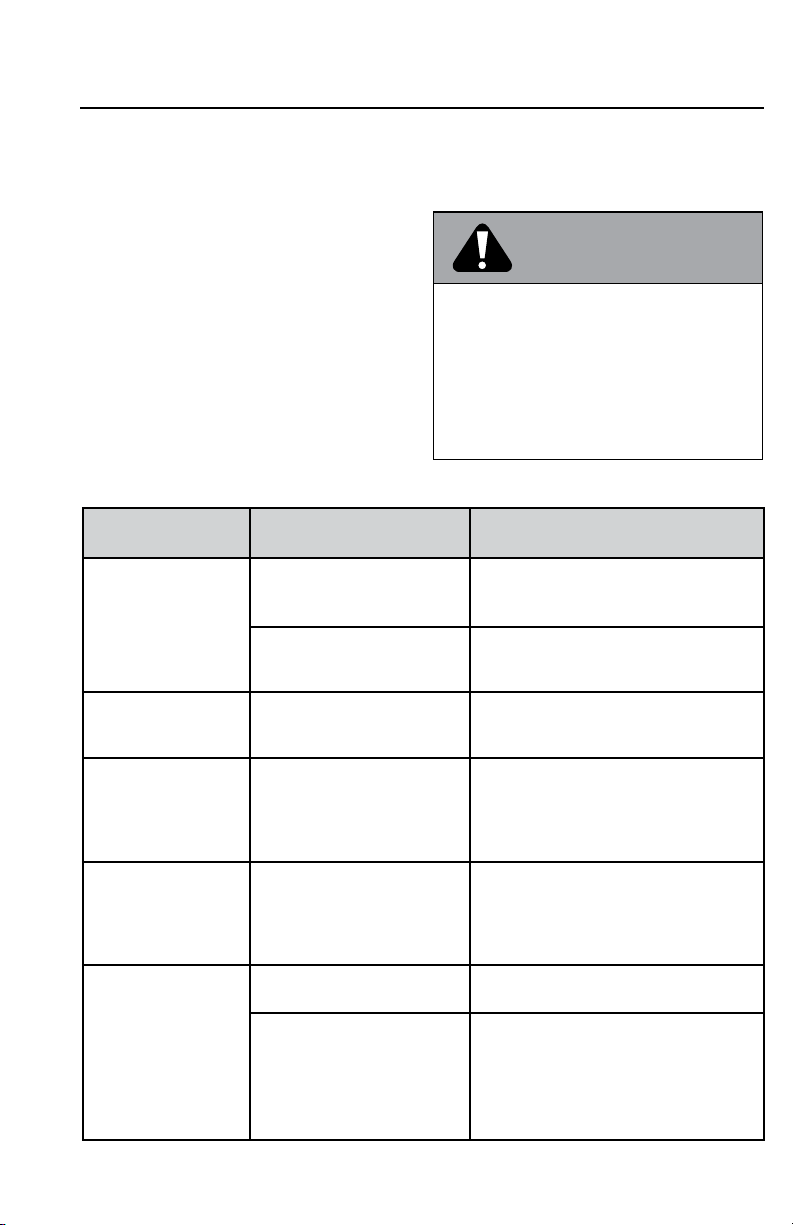

WARNING

MOVING PARTS ENTANGLEMENT

HAZARD

Failure to observe these instructions could

lead to severe injury or death.

WARNING

CHEMICAL AND FIRE HAZARD

Failure to observe these instructions could

lead to severe injury or death.

• Never operate hoist in an environment

containing explosive or combustible material.

• Always remove jewelry and wear eye

protection.

• Never lean over battery while making

connections.

• Always verify area is clear of fuel lines, fuel

tank, brake lines, electrical wires, etc. when

drilling.

• Never route electrical cables:

- Across any sharp edges.

- Through or near moving parts.

- Near parts that become hot.

• Always insulate and protect all exposed

wiring and electrical terminals.

• Always install terminal boots as directed in

installation instructions.

To avoid injury to hands or fingers:

• Always keep hands clear of rope, hook loop,

and hook during installation, operation and

when spooling in or out.

• Always use extreme caution when handling

hook and rope during spooling operations.

• Always use supplied hook strap whenever

spooling rope in or out, during installation,

and during operation.

• Always disconnect all wires from battery,

before beginning work.

• Always disconnect negative terminal first and

reconnect negative terminal last.

WARNING

FALLING OR CRUSHING HAZARD

Failure to observe these instructions could

lead to severe injury or death.

• Never use hoist to lift or move persons.

• Always use the size of rope specified in the

product data sheet.

1

1

Page 4

General Safety Precautions

CAUTION CAUTION

MOVING PARTS ENTANGLEMENT

HAZARD

Failure to observe these instructions could

lead to minor or moderate injury.

General Safety:

• Always know your hoist. Take time to fully

read this Installation and Operations Guide

in order to understand your hoist and its

operation.

• Never operate this hoist if you are under 16

years of age.

• Never operate this hoist when under the

influence of drugs, alcohol or medication.

• Never exceed hoist or rope rated capacity.

Double line using a snatch block to reduce

hoist load.

Installation Safety:

• Always choose a mounting location that is

sufficiently strong to withstand the maximum

lifting capacity of your hoist.

• Always use factory approved mounting

hardware, components, and accessories.

• Always use grade 5 or better mounting

hardware.

• Never weld mounting bolts.

• Always use care when using longer bolts

than those supplied from factory. Bolts

that are too long can damage the base

and/or prevent the hoist from being mounted

securely.

• Always mount the hoist and attach the hook

to the rope’s end loop before connecting the

electrical wiring.

• Always spool the rope onto the drum in the

direction specified by the drum rotation label

and/or documentation. This is required for

the automatic brake to function properly.

• Always prestretch wire rope and respool

under load before use. Tightly wound wire

rope reduces chances of “binding”, which can

damage the rope.

MOVING PARTS ENTANGLEMENT

HAZARD

Failure to observe these instructions could

lead to minor or moderate injury.

Hoisting Safety:

• Always inspect, rope, hook, and slings

before operating hoist. Damaged

components must be replaced before

operation. Protect parts from damage.

• Always report any malfunction, unusual

performance, or damage to the hoist.

• Never leave remote control plugged into

hoist when rigging or when the hoist is not

being used.

• Never hook rope back onto itself. This

damages the rope.

• Always remove any element or obstacle that

may interfere with safe operation of the hoist.

• Always take time to use appropriate rigging

techniques for a hoist lift.

• Never hoist with less than 5 wraps of rope

around the drum, the rope could come loose

from the drum.

• Never touch rope or hook while in tension or

under load.

• Never touch rope or hook while someone

else is at the control switch or during hoisting

operation.

• Always stand clear of rope and load and

keep others away while hoisting.

• Always be aware of stability of vehicle and

load during hoisting. Alert all bystanders of

any unstable condition.

• Always keep remote control lead clear of the

drum, rope and rigging. Inspect for cracks,

pinches, frayed wires or loose connections.

Replace remote control if damaged.

• Always pass remote control through a

window to avoid pinching lead in door when

using remote inside a vehicle.

• Never swing or twist loads.

• Never leave suspended load unattended.

2

Page 5

WARNING CAUTION

CUT AND BURN HAZARD

Failure to observe these instructions could

lead to minor or moderate injury.

To avoid injury to hands and fingers:

• Always wear heavy leather gloves when

handling wire rope.

• Never let rope slip through your hands.

• Always be aware of possible hot surface

at hoist motor, drum or rope during or after

hoist use.

• Never mount controller in an area where it

may be used as a step or where tools will be

hung or placed on it.

• Always avoid damage to terminals located

on top surface of the enclosure.

• Always keep tools and other electrically

conductive equipment away from terminals

at all times.

General Safety Precautions

MOVING PARTS ENTANGLEMENT

HAZARD

Failure to observe these instructions could

lead to minor or moderate injury.

• Always use a hook with a latch

• Always insure hook latch is closed and not

supporting load.

• Never apply load to hook tip or latch. Apply

load only to the center of hook.

• Never use a hook whose throat opening has

increased, or whose tip is bent or twisted.

WARNING

Failure to observe these instructions could

lead to property damage, severe injury, or

death.

• Never exceed the maximum recommended

hydraulic pressure or flow for any of the

components used.

• Always connect the hoist to the hydraulic

system as shown in the hydraulic schematic.

• Always use the correct type of control valve

as shown in the hydraulic schematic.

• Always Stand clear of hydraulic lines

during operation.

• Always install hydraulic components

in accordance with manufacturer’s

recommendations.

NOTICE

AVOID HOIST AND EQUIPMENT

DAMAGE

• Never “jog” rope under load. Shock loads

can momentarily exceed capacity of rope and

hoist.

• Never use hoist to secure a load during

transport.

• Never submerge hoist in water.

• Always store the remote control in a

protected, clean, dry area.

Page 6

WARN Industrial Hoists

What is a Hoist?

WARN Industries produces a large family of hoists

and winches. But what makes a hoist different

than a winch?

Hoists and winches look alike. Both consist of a

motor, a rotating drum with wire rope, reduction

gears, a base, and usually an electrical control

system. However, hoists and winches are used for

different purposes.

Hoists are used to lift a load into the air while

winches are used to pull a load horizontally across

the ground. Because a load that is suspended

in the air creates unique hazards, hoists are

engineered to higher safety standards. And unlike

winches, the operator of a hoist may not unwind

cable by “free spooling” or disengaging the motor

from the gear train.

Mechanical Brake

The mechanical brake generates heat when

loads are lowered and the wire rope is powered

out. Care must be taken to avoid overheating the

mechanical brake.

With heavier loads allow more time for the brake

to cool between uses.

Whine or chatter associated with a new

mechanical brake is normal and typically

disappears with use.

OVERHEATING THE MECHANICAL BRAKE

MAY RESULT IN PERMANENT DAMAGE TO,

OR FAILURE OF, THE BRAKE. REPLACE ANY

DAMAGED BRAKE COMPONENTS BEFORE

RESUMING USE OF THE HOIST.

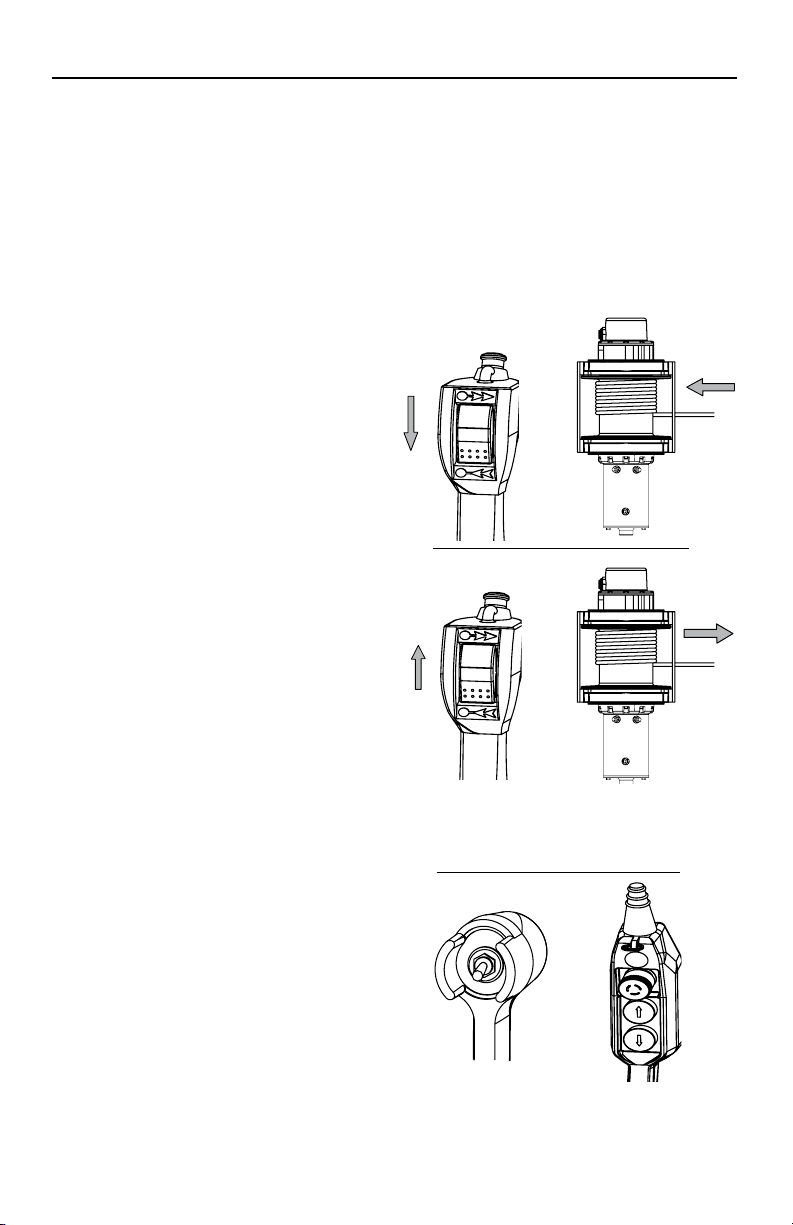

Remote Control

Switch operation

Do not leave the remote plugged into the hoist

when not in use. Leaving the remote plugged in

may result in unexpected activation of the hoist

and/or battery drain.

line in (raise load)

line out (lower load)

Heavy duty water

resistant remote

control pendant

Standard remote

control pendant

4 77

CE remote control

pendant features a

locking emergency

stop button.

Page 7

WARN Industrial Hoists

Pre-Install Checklist

1 Check to see that you have received the

following:

• The hoist

• The controller

• The remote control pendant

• The hoist mounting hardware

2 Upon removing hoist from packaging, check

for damage including bent or cracked tie rods,

tie bars, or housings. Correct any damage

before installing hoist.

3 Make sure the environment surrounding hoist

and controller is free of :

• Combustible vapors

• Chemical fumes

• Oil vapors

• Corrosive material

4 Make sure that the air temperature

surrounding the hoist and controller stays

within 120° F (49° C) and -20° F (-29° C).

5 Make sure that the mounting structure can

withstand the full rated pull of the hoist.

6 Make sure that the hoist boom or lift structure

will not deform under twice the full rated load

of the hoist.

Mounting the Hoist

Use the supplied fasteners whenever possible or

SAE Grade 5 (8.8 metric) bolts of the same thread

size. Both tie rods or tie bars must be in place.

Flat washers and lock washers should be used

between the bolt heads and mounting surface.

For thru bolt drum supports:

There should be 1 to 4 threads protruding

above the square nut. Bolts that are too long

may damage drum supports while bolts that are

too short will not provide adequate strength.

Flat washers and lock washers should be used

between bolt heads and mounting surface.

For threaded drum supports:

Bolts that are too long may damage the drum

supports and/or fail to anchor the hoist tightly.

Bolts that are too short will not provide adequate

strength. The length of the bolt must allow it to

extend between 15/16 inch (24 mm) and 1-3/8

inch (35 mm) into the base of the hoist.

1 Make sure that the mounting surface is flat

within +/-0.020 in. (0.50 mm). If the surface

is not flat, use shim stock as needed to avoid

straining the hoist.

2 Torque all mounting bolts to the recommended

values on the product data sheet.

3 Use the mounting hole locations provided on

the product data sheet.

Page 8

WARN Industrial Hoists

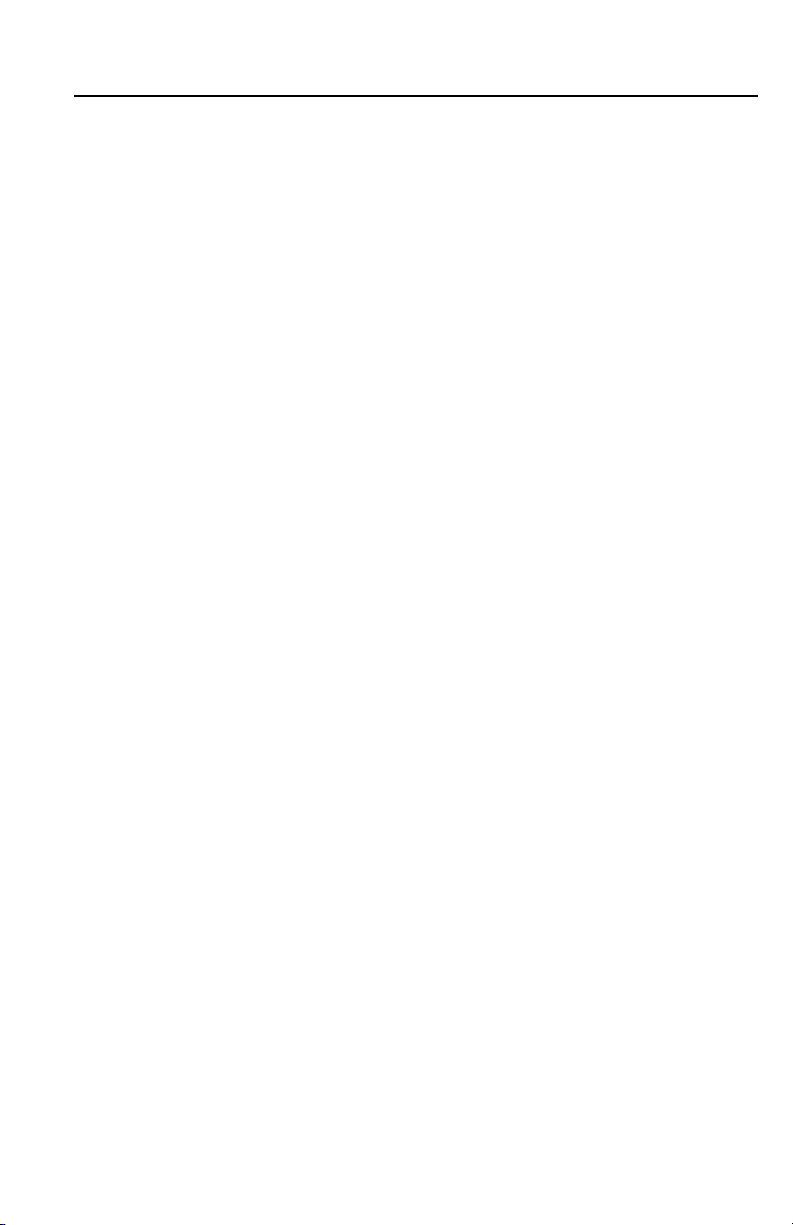

5.25 in (133 mm)

Foot print

of controller

cover

6.7 in (170 mm)

4.6 ni (116 mm)

Mounting the Controller (Electric Hoists)

1 Remove the screws holding cover to controller

bracket.

2 Mount the controller in an upright or vertical

orientation so that water will not collect in the

cover.

3 Mount controller in a location free of excessive

vibration. Use lock washers to prevent

mounting nuts from loosening.

4 Mount controller so it is protected from

damage by tools or heavy objects.

5 The controller can be mounted in a location

exposed to the weather; but it should be

protected from the possibility of damage from

tools or heavy objects.

6 Use the mounting dimensions shown.

FIRE HAZARD

Failure to observe these instructions could

lead to severe injury or death.

• Never mount controller in an area where it

may be used as a step or where tools will be

hung or placed on it.

• Always avoid damage to terminals located

on top surface of the enclosure.

• Always keep tools and other electrically

conductive equipment away from terminals

at all times.

WARNING

Mounting dimensions for typical controller

6 75

Page 9

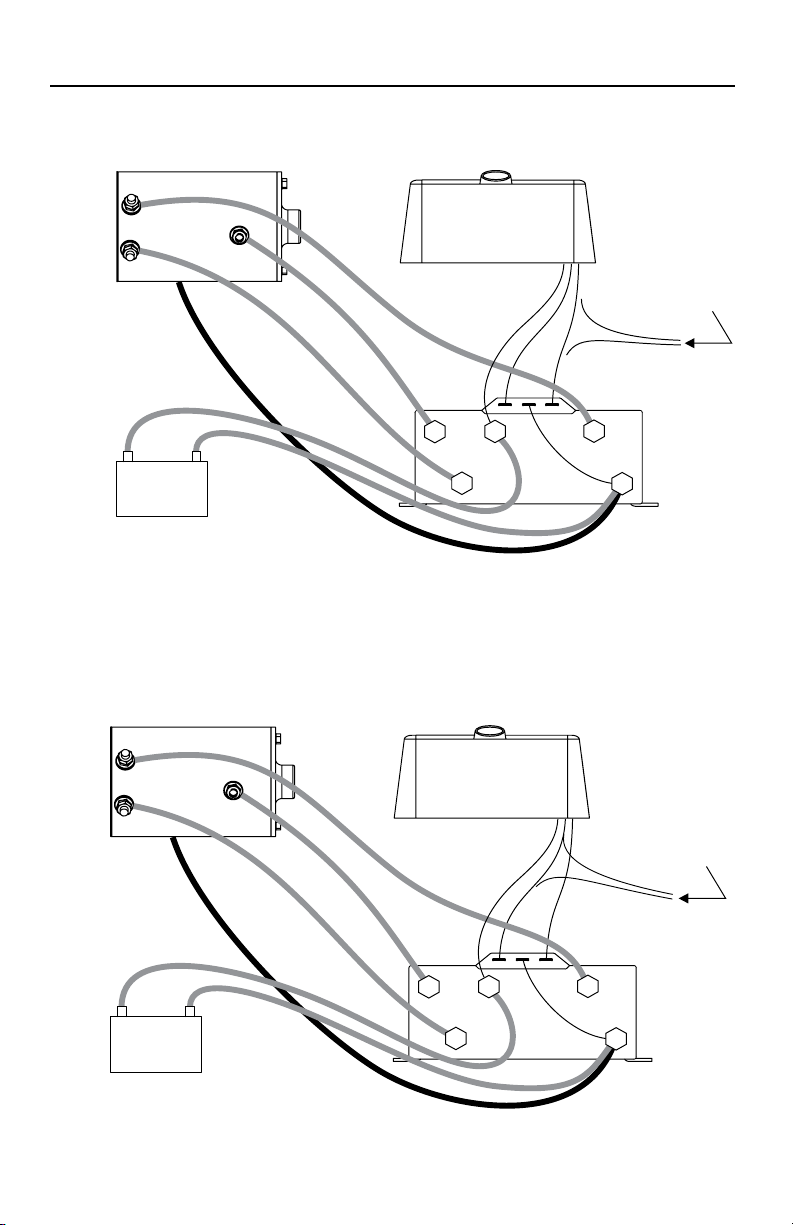

Electric Cable Connections

See illustrations on following page.

Connection guidelines:

• Use #2 gauge battery cable for all power

connections. Excess cable length can

result in a voltage drop causing poor hoist

performance.

• Minimize cable length where possible. When

cables longer than 10 feet (3m) are needed,

use size #0 cable.

• Route cables along protected areas to avoid

wear and damage.

• Use insulating boots on all exposed terminal

connections to prevent electrical shorting.

Slide terminal boots onto cables before

connecting cables to terminals.

• Use splice connectors to attach the motor

thermal-switch wires.

• Connect the F1, F2, A and ground cables

as shown for clockwise models. For

counterclockwise models, the F1 controller

terminal must be connected to the F2 motor

terminal, and the F2 controller terminal must

be connected to the F1 motor terminal.

• Make sure all electrical connections are

clean and tight.

• It is recommended that a power-cut off

switch be installed in an easily accessible

location. This will provide power shut-off

during servicing and act as an added safety

feature. Use a 300 amp switch.

• It is recommended that a 300 amp circuit

breaker be installed in the positive (+) cable

near the battery to protect against short

circuits.

WARN Industrial Hoists

WARNING

CHEMICAL AND FIRE HAZARD

Failure to observe these instructions could

lead to severe injury or death.

• Never route electrical cables:

- Across any sharp edges.

- Through or near moving parts.

- Near parts that become hot.

Page 10

WARN Industrial Hoists

Series wound motor

F2

A

F1

+

_

ground cable

Controller cover

white

A

+

F1

black

23

of motor cut in here

X

green

1

brown

Battery

Connections for series-wound DC motors (3 terminals)

Drum rotation: Clockwise viewed from motor end.

Series wound motor

F2

A

F1

+

_

ground cable

Controller cover

white

A

+

F1

green

23

1

wires from bottom

of motor cut in here

X

black

Controller

brown

_

Thermal switch

wires from bottom

Controller

F2

_

Thermal switch

F2

Battery

Connections for series-wound DC motors (3 terminals)

Drum rotation: Counter clockwise viewed from motor end.

8 73

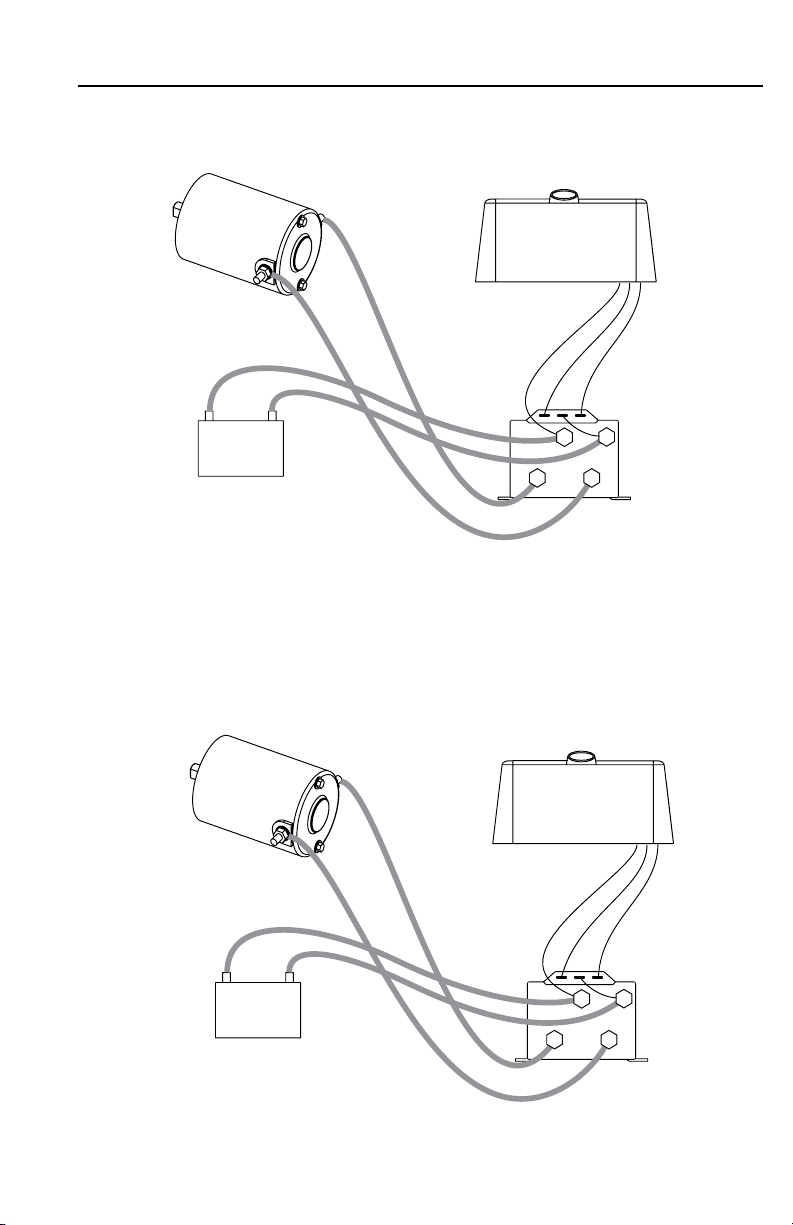

Page 11

WARN Industrial Hoists

#1

#2

Permanent

Controller Cover

magnet motor

white

green

black

3

2

1

_

+

#2

#1

+

Battery

_

Controller

Connections for permanent-magnet DC motors (2 terminals)

Drum rotation: Clockwise viewed from motor end.

#2

#1

Permanent

magnet motor

Controller Cover

white

black

green

3

2

1

_

+

#2

#1

+

Battery

_

Controller

Connections for permanent-magnet DC motors (2 terminals)

Drum rotation: Counter clockwise viewed from motor end.

Page 12

WARN Industrial Hoists

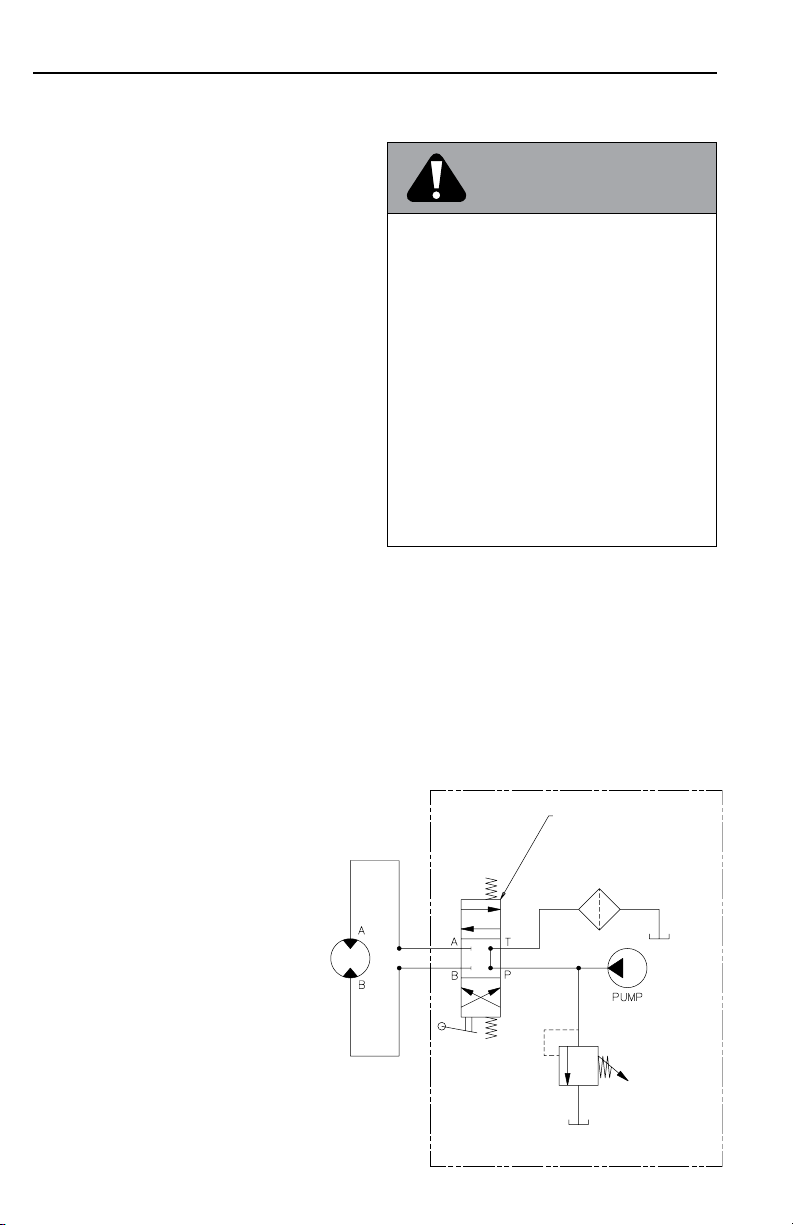

Hydraulic Hoists: General Information

NOTE: The hydraulic system diagram and

component descriptions are provided for general

reference. Consult a knowledgeable hydraulics

representative for specific recommendations on

component selection, interconnection, layout, and

best practice.

The pressure rating of the hoist motor is

determined by a) the maximum allowable

pressure at the motor inlet port and b) the

maximum allowable pressure drop across the

motor. Pressure drop is defined as the difference

between the inlet port pressure and the outlet

port pressure at the hoist motor. Exceeding the

maximum inlet pressure may damage the hoist

motor. Exceeding the maximum pressure drop

may cause failure of hoist components.

Failure to observe these instructions could

lead to property damage, severe injury, or

death.

• Never exceed the maximum recommended

hydraulic pressure or flow for any of the

components used.

• Always connect the hoist to the hydraulic

system as shown in the hydraulic schematic.

• Always use the correct type of control valve

as shown in the hydraulic schematic.

• Always Stand clear of hydraulic lines

during operation.

• Always install hydraulic components

in accordance with manufacturer’s

recommendations.

WARNING

The recommended operating temperature range

of the hydraulic motor is 100ºF to150ºF (38ºC

to 66ºC). The maximum operating temperature

range is -6ºF to 180ºF (-21ºC to 82ºC). Do NOT

exceed the flow rating of the hydraulic motor.

See the product data sheet for specific hydraulic

specifications.

Installation Final

Check:

• Recheck mounting hardware for

loose bolts, etc…

• Be sure all hydraulic system

components and connections

are correct.

• Be sure all hydraulic connections

are secure.

• Check motor rotation: The drum

should rotate in the direction

indicated by the drum rotation

label on top of the drum support.

If drum rotates in opposite direction,

recheck hydraulic and electrical

connections.

MOTOR

HYDRAULIC FLUID: The hydraulic fluid used

with the hoist must be an extreme pressure,

anti-wear hydraulic oil with oxidation and

corrosion inhibitors. It must contain a foam

suppressant, and have a viscosity rating of

100-300 SUS at 60ºF to 115ºF (15ºC to 46ºC).

The recommended nominal filtration level is 10

microns or finer.

Hydraulic Schematic

CONTROL VALVE

3-POSITION, 4-WAY,

SPRING RETURN

(CYLINDER SPOOL)

CUSTOMER SUPPLIED

COMPONENTS

10 71

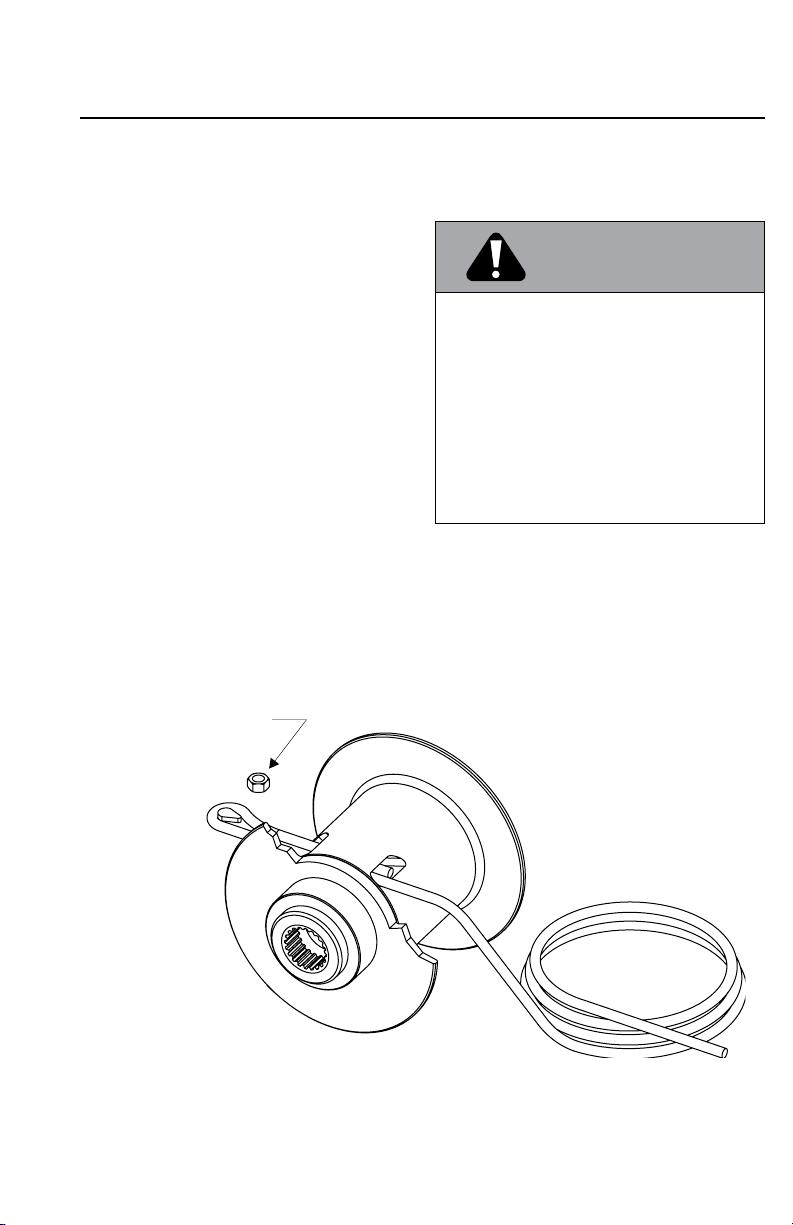

Page 13

WARN Industrial Hoists

hex nut 7/16 in. (11 mm)

Installing the Wire Rope

1 Insert rope though slot in drum as shown.

2 Form a loop and reinsert end into slot. The

“live” or load carrying portion of rope must be

closest to drum flange.

3 Insert the wedge or hex nut (7/16 in.) supplied

with the hoist into loop and pull live end of rope

to seat the wedge or hex nut into slot. The end

of the rope must remain visible in the slot as

shown. The wedge locks the rope in the slot.

4 With end of rope securely installed, carefully

wind rope evenly onto drum. Keep rope under

tension at all times.

5 Always maintain a minimum of five (5) wraps

of rope on the drum. Fewer wraps may cause

the end of the rope to pull free of the drum and

drop the load.

CAUTION

Failure to observe these instructions

could lead to moderate injury and property

damage.

• Always install rope in the direction specified

on the drum rotation label, or brake will not

function.

• Always use rope specified on the product

data sheet.

• Always install rope according to the

illustration below.

Anchoring wire rope on drum

Page 14

Safe Operating Guidelines

Avoid the following:

WARN Industrial Hoists

WARNING

NEVER:

• Never place any part of your body or clothing

near rotating or moving parts. Rotating drum

with rope under tension can create a pinch

point.

• Never handle ropes or operate hoist without

wearing eye protection and heavy gloves.

• Never stand close to hoist when operating. If

rope breaks it can fly back with tremendous

force.

• Never lift, pull, or otherwise transport people

with hoist.

• Never lift, pull, support or otherwise transport

loads over people.

• Never attempt to lift loads greater than rated

capacity of the hoist.

• Never raise a load until it jams and causes the

drum and motor to stall.

• Never allow a crane to “two block.”

NOTE: The three conditions above produce

excess loading on the hoist which may cause

hoist, rope or structural failure resulting in

a dropped load. Excess loads can create

undetectable damage, which may cause the

hoist to fail even when lifting loads within its

rated capacity.

• Never allow hydraulic system, electric motor or

mechanical brake to overheat.

• Never touch rope or rigging while lifting a load,

while anyone is at controls, or while operating

hoist.

• Never put rope around an object and hook it

back on itself. This will damage the rope.

• Never use hoist with less than five (5) wraps

of rope around hoist drum. The cable anchor is

not designed to hold the rated load. The rope

may pull free and drop the load with fewer than

Failure to observe these instructions could

lead to property damage, severe injury or

death.

Always watch for hazards from the cable,

drum pinch points, falling loads, and rope or

rigging under tension.

five wraps of rope on the hoist drum.

• Never let the rope slip through your hands.

• Never attempt to lift an off-center load of

any kind. This can cause the load to swing

dangerously. Make sure the load is directly

under the hoist.

• Never allow the load to swing or twist while

suspended.

• Never allow the load to bear against the

hook latch.

• Never leave a suspended load unattended.

• Never lift using the point of the hook. Make

sure the load is bearing on the saddle of the

hook.

• Never operate the hoist when flammable

materials or vapors are present. Electrical

devices produce arcs that can cause a fire or

explosion.

• Never operate the hoist when you are tired,

distracted, in a hurry, or under the influence

of drugs, alcohol, or medication that affects

alertness or judgement.

12 69

Page 15

WARN Industrial Hoists

Do the following:

ALWAYS:

• Always take your time to assess your

situation and plan your lift carefully.

• Always, prior to a lift, inspect mounting

structure, hoist, slings and/or other

accessories signs of damage. Replace

damaged components prior to a lift.

• Always know the weight of the load and

make sure the rigging, hoist, and mount will

carry the weight.

• Always verify that the load is directly under

the hoist, the rope is not tangled or kinked,

and that all people are standing clear of

the load.

• Always wear leather gloves.

• Always take up any slack in the rope slowly.

Begin the lift slowly. If there is any evidence

of overloading, immediately lower the load

and correct the situation.

• Always avoid shock loads to the hoist by

lifting rapidly or bouncing a load.

• Always make sure the hook latch is

functioning properly. Replace damaged

hook latch before operating hoist.

• Always make sure the rope spools in the

right direction. Hoists are equipped with

an automatic brake and will not function if

the rope spools off the drum in the wrong

direction. NOTE: The rope spooling

direction will accidentally be reversed if rope

is run all the way out and re-spooled in with

control switch in power out” direction.

• Always inspect and carefully rewind rope

after each use. Cuts, kinks, or frayed areas

reduce the tensile strength of rope. Replace

rope if damaged.

• Always keep the remote control away from

drum, rope, or rigging.

• Always inspect the remote control pendant

and cable for damage before using hoist.

• Always inspect hydraulic system or

electrical connections before using hoist.

• Always stand clear of the rope and load

during hoist operation.

• Always make sure that other hoist operators

understand the potential hazards and have

been trained in proper use of the hoist.

• Always make sure that the controller and

hoist assembly are installed, operated,

adjusted, and serviced by qualified

personnel familiar with its construction and

operation.

• Always verify that load limiting devices are

working properly.

Additional Guidelines:

• If the load must be immersed in any liquid

or dusty solid material, use a sling chain or

other rigging to allow the hook to remain

above the surface at all times.

• For additional information, refer to the

operation section of American National

Standard ANSI/ASME B30.16 and B30-9

(rigging) and the operation section of

Department of Energy Hoisting and Rigging

Standards DOE-STD-1090-99.

Page 16

Periodic Preventive Maintenance

WARN Industrial Hoists

• Keep hoist free of dirt, oil, grease, water and

other substances.

• Check all mounting bolts and make sure

they are tightened to the recommended

torque values on the product data sheet.

Replace any damaged fasteners.

• Periodically check all connections to be sure

they are tight and free of corrosion.

• Check rope for visible damage every time

hoist is operated. Examples of damage are:

cuts, knots, mashed or frayed portions, and

broken strands. Replace rope immediately

if damaged. Failure to replace a damaged

rope could result in breakage.

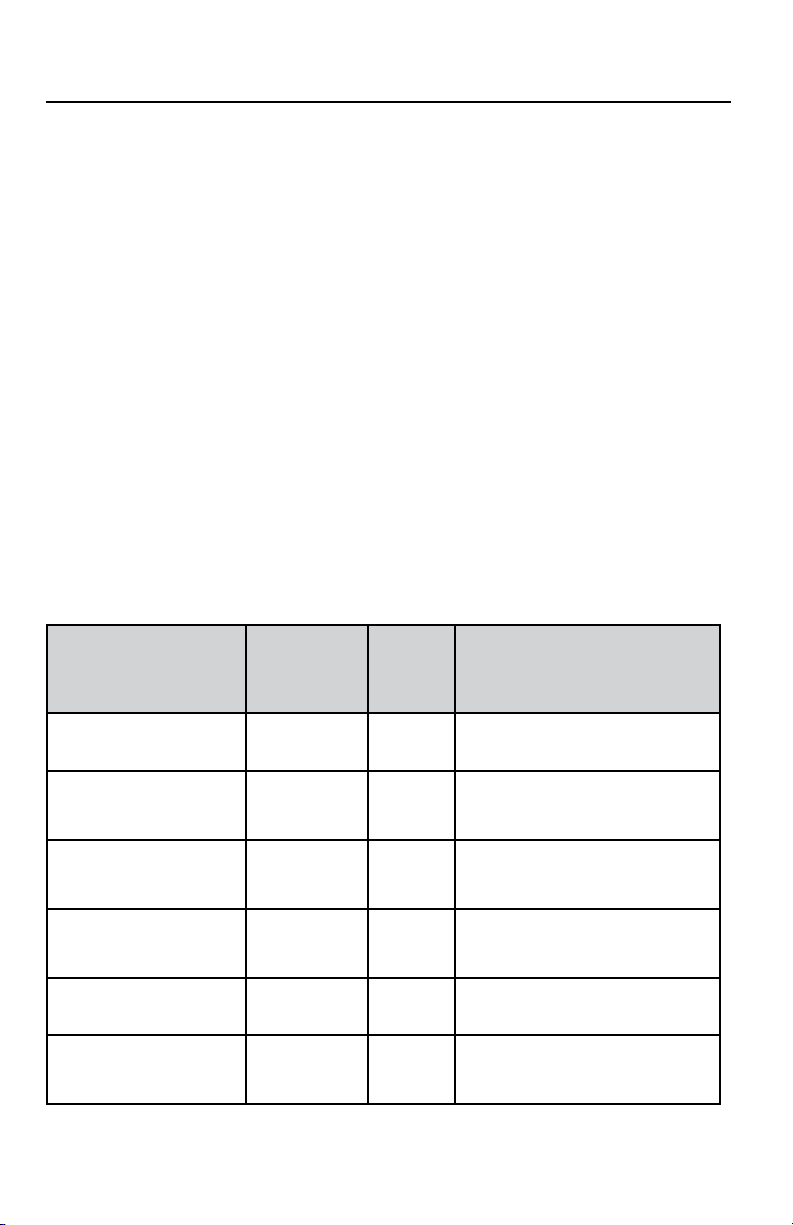

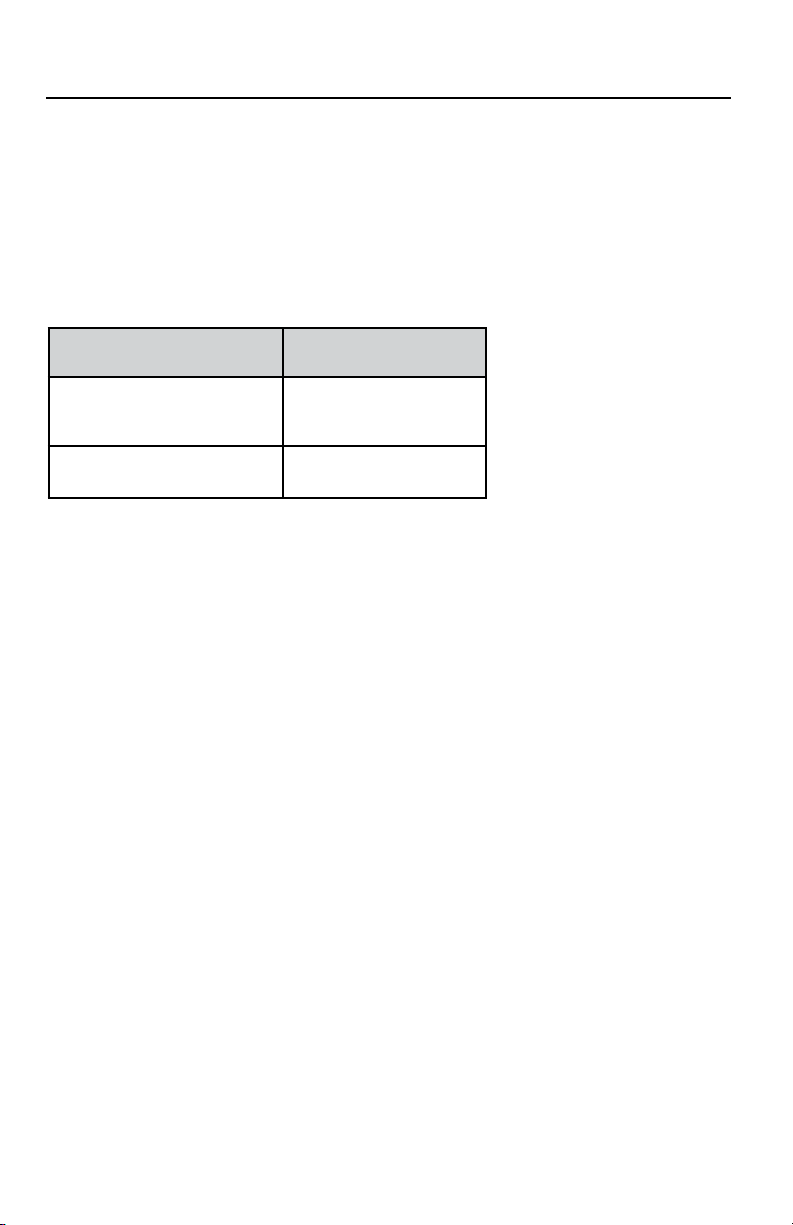

Preventive Maintenance Schedule

Maintenance activity

Check fasteners

After first

operation

X X

• Regularly check brake for slippage or drift.

This is detected visually when hoist is under

load. If hoist drum continues to turn after

controls are released, brake may need to

be replaced.

• Periodically clean and grease brake

assembly. This will ensure proper

performance and extend the life of the hoist.

If hoist seems to labor or get excessively hot

during the lowering of loads, the brake will

need to be serviced or replaced.

• Check motor brushes periodically and

replace when necessary.

NOTE: Only the motor bushes and brake

assembly require periodic replacement.

Before

each

use

Semi-annually or after each

25 hours of operation

Check electrical or

hydraulic connections

Spool out and check

rope

Clean and grease

brake assembly

Check motor brushes

Visual check of hoist

and control

X X

X

X

X

X X X

14 67

Page 17

WARN Industrial Hoists

Trouble Shooting: Electric Hoists

PERSONAL INJURY

Failure to observe these instructions could

lead to severe injury or death.

• Never lean over battery while making

connections.

• Always disconnect all wires from battery,

before beginning work.

• Always disconnect negative terminal first

and reconnect negative terminal last.

• Always remove jewelry and wear eye

protection.

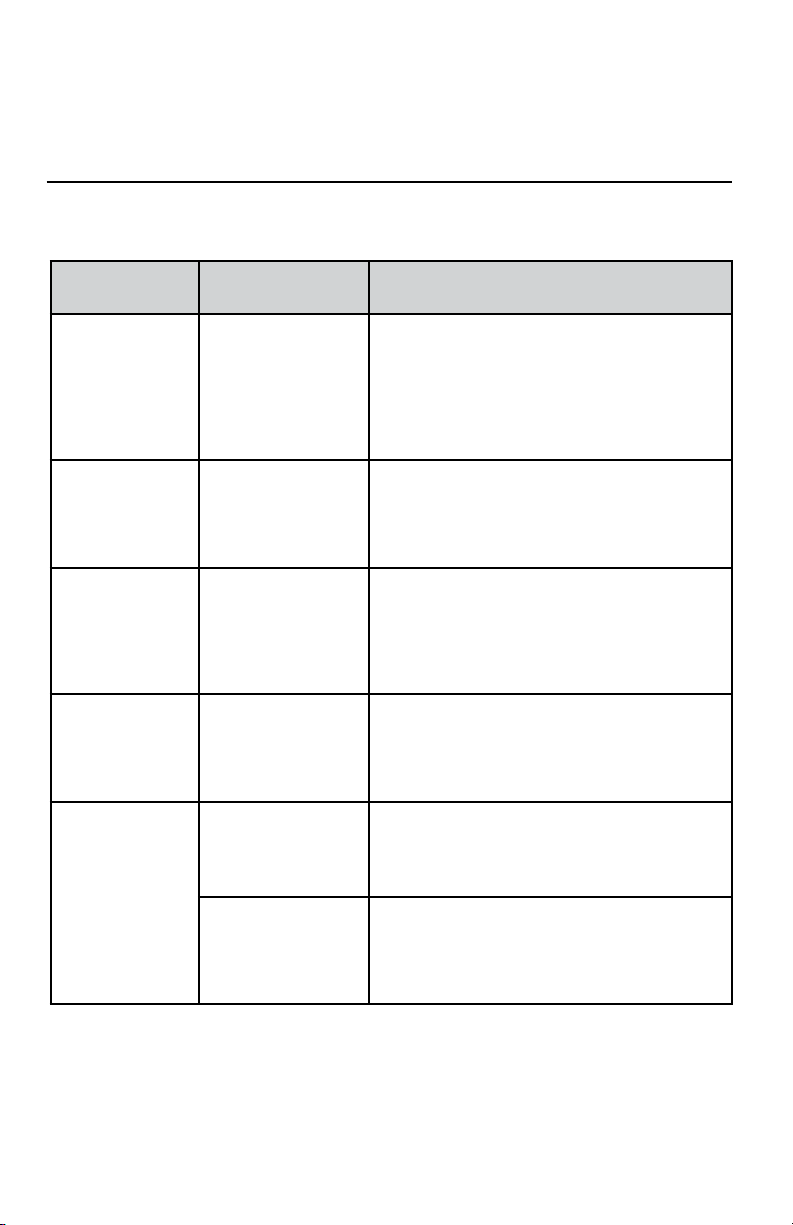

Problem Possible cause Corrective action

WARNING

Hoist won’t

operate in either

direction or

motor doesn’t

operate

Hoist will powerout but not

power-in

Power is not

connected -orEmergency on/off

switch (optional) is

in “off” position

Power to remote

pendant has been

interrupted

Failure in remote

control pendant

switch or wiring

Failure of components or wiring

inside controller

A) Check wiring connections. Check for 12v

(24v) at positive (+) terminal on controller.

Check for voltage at F1, F2 and A terminals

with remote switch in either direction. B)

Check position of emergency on/off switch.

Check for 12v (24v) at center pin of remote

socket on controller. Check continuity of remote lead connector from center pin to either

side pin with remote control pendant on/off

switch in both positions. Replace remote

control pendant if there is no continuity.

Check for 12v (24v) at center pin of remote

socket on controller. Check continuity of remote lead connector from center pin to either

side pin with remote control pendant on/off

switch in both positions. Replace remote

control pendant if there is no continuity.

Check for 12v (24v) at center pin of remote

socket on controller. Check continuity of remote lead connector from center pin to either

side pin with remote control pendant on/off

switch in both positions. Replace remote control pendant if there is no continuity. If none

of these corrective actions resolves problem,

return controller to Warn Industrial for service.

Page 18

WARN Industrial Hoists

Problem Possible cause Corrective action

Hoist will

power-in but

not power-out

Motor tries to

power-out but

hoist stalls or

locks-up

Hoist operates in both

directions but

will not lift rated

load

Hoist slows

down and stalls

during powerout

Hoist vibrates

badly or is

noisy during lifting or lowering

of load

Power to remote

control pendant

has been interrupted

Load brake failure Service or replace load brake.

Low voltage at

hoist

Brake needs

service

Brake needs

servicing

Mounting surface

is not flat. Tie rod

or tie bar is bent

Check for 12v (24v) at center pin of remote

socket on controller. Check continuity of remote lead connector from center pin to either

side pin with remote control pendant on/off

switch in both positions. Replace remote

control pendant if there is no continuity

A) Be sure wiring cable size guidelines have

been met. B) Check condition of battery. C)

Check all power wiring and connections for

corrosion. Clean and tighten connections.

Service or replace load brake.

Service or replace load brake.

Check to make sure mounting surface is flat

to within +/- 0.020 in. (0.50 mm). Replace tie

rod or tie bar if necessary. Check for bent or

cracked housings.

16 65

Page 19

WARN Industrial Hoists

Trouble Shooting: Hydraulic Hoists

NOTE: Hydraulic system failures typically follow

the same pattern: a gradual or sudden loss of

pressure or flow resulting in a loss of motor

power. Any one of the system components

may be at fault. Refer to the table for general

recommendations. If necessary, consult a

knowledgeable hydraulics representative.

NOTE: See product data sheet for hydraulic

specifications.

PERSONAL INJURY

Failure to observe these instructions could

lead to severe injury or death.

Never use a relief valve that exceeds the

hydraulic motor pressure rating. Use of this

valve can overload the hoist.

Problem Possible cause Corrective action

WARNING

Hoist won’t operate

in either direction

Hoist will power-out

but not power-in

Hoist will power-in

but not power-out

or stalls during

power-out

Hoist operates in

both directions but

will not lift rated

load

Hoist vibrates

badly or is noisy

during lifting or

lowering of load

No hydraulic pressure

Geartrain, brake, or motor

failure

Brake assembled incorrectly

Load brake failure Service or repair load brake

Low system pressure or

excessive system back

pressure

Brake needs servicing Service or replace load brake

Mounting surface is not

flat. Tie rod or tie bar is

bent.

Check hydraulic system schematic

and connections

Send hoist to authorized Warn Industrial service center for repair

Repair or replace brake assembly

Check system pressure at motor inlet

and outlet ports

Check to make sure mounting

surface is flat to within +/- 0.020 in.

(0.50 mm). Replace tie rod or tie

bar if necessary. Check for bent or

cracked housings.

Page 20

WARN Industrial Hoists

Customer Support

Should you have any questions about this product or these instructions, please call WARN’s customer

service through the numbers below, Monday thru Friday between 7:00 AM and 4:00 PM Pacific Time

for assistance. Or for e-mail support, visit our web site www.WARN.com and click on customer

service section.

NOTE: Only qualified persons should repair the hoist.

United States International

Phone: 503-722-1200 or

800-543-9276 (US only)

FAX: 503-722-3000 FAX: 503-722-3005

Phone 503-722-3008

18 63

Page 21

WARN Industrial Hoists

WARN® Commercial Products Limited One (1) Year Warranty Statement

Warn Industries, Inc. (WARN) warrants to the original purchaser that the mechanical components and electrical

components of the “WARN” Products specified below will be free of defects in material and workmanship for a

period of one (1) year from the original date of purchase. This Warranty applies only to the original purchaser

of the Products. To obtain any warranty service, you must provide WARN with proof of purchase and date of

purchase acceptable to WARN, such as a copy of your purchase receipt. This warranty does not cover the

removal or reinstallation of the Product. WARN will, at its option, repair, replace or refund the purchase price of

a defective Product or component, provided you return the defective Product or component during the warranty

period, transportation charges prepaid, to Warn Industries Service Department or a Factory Authorized Service

Center. Attach your name, address, telephone number, a description of the problem, and a copy of your

receipt and original bill of sale bearing the WARN serial number of the defective Product and date of purchase.

This warranty does not apply (i) to parts or components excluded below, or (ii) if the Product has been

damaged by accident, abuse, misuse, collision, overloading, modification, misapplication, improper installation,

or improper service. This warranty is void if any WARN serial number has been removed or defaced.

THE WARRANTY SET FORTH ABOVE IS THE ONLY WARRANTY. THERE ARE NO OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

ANY IMPLIED WARRANTY WHICH BY LAW MAY NOT BE EXCLUDED IS LIMITED IN DURATION TO ONE

(1) YEAR FROM THE DATE OF ORIGINAL RETAIL PURCHASE OF THE PRODUCT.

WARN SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES

(INCLUDING, BUT NOT LIMITED TO, LOST PROFITS, DOWN TIME OR LOSS OF USE) UNDER ANY

LEGAL THEORY, EVEN IF WARN WAS ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

Some states do not allow the exclusion of implied warranties or the exclusion or limitation of liability for

incidental or consequential damages, or limitations on how long an implied warranty lasts, so the above

limitation or exclusion may not apply to you. This warranty gives you specific legal rights. You may also have

other rights that vary from state to state.

WARN reserves the right to change Product design without notice. In situations in which WARN has changed

a Product design, WARN shall have no obligation to upgrade or otherwise modify previously manufactured

Products.

No WARN dealer, agent or employee is authorized to make any modification, extension or addition to this

warranty.

Warranty inquires and Products returned for warranty service should be sent to:

WARN INDUSTRIES, INC.

Customer Service Department

12900 SE Capps Road

Clackamas, OR 97015

1-800-543-WARN (1-800-543-9276)

Products covered by this warranty Products not covered by this warranty

Commercial winch products Finish and wire rope for commercial winches

Commercial hoist products Finish and wire rope for commercial hoist products

Commercial accessory products Finish and wire rope

Page 22

20 61

Page 23

Précautions de sécurité générales

Avertissements et Mises en Garde

AVERTISSEMENT

Les directives suivantes comprennent des indications intitulées AVERTISSEMENT, ATTENTION,

AVIS et REMARQUE. Chacune a un objectif bien

précis : AVERTISSEMENT présente des consignes

de sécurité décrivant un danger potentiel qui peut

entraîner des blessures graves. ATTENTION comprend des consignes de sécurité signalant un danger

potentiel qui peut entraîner des blessures légères

ou modérées. ATTENTION sert aussi à décrire une

utilisation dangereuse. ATTENTION et AVERTISSEMENT identifient un danger, indiquent comment

l’éviter et montrent ses conséquences possibles si on

l’ignore. AVIS présente des consignes concernant les

dommages matériels potentiels. REMARQUE donne

des renseignements additionnels qui permettent

d’accomplir une procédure. PRIÈRE DE TRA-

VAILLER PRUDEMMENT !

AVERTISSEMENT

DANGER DE HAPPEMENT PAR DES

PIÈCES MOBILES

Le non-respect des consignes peut entraîner

des blessures graves ou la mort.

RISQUES ASSOCIÉS AUX PRODUITS

CHIMIQUES ET RISQUE D’INCENDIE

Le non-respect des consignes peut

entraîner des blessures graves ou la mort.

• Ne jamais faire fonctionner le palan dans

un environnement contenant des matériaux

explosifs ou combustibles.

• Toujours retirer les bijoux et porter des

lunettes de sécurité.

• Ne jamais se pencher au-dessus de la

batterie en procédant aux connexions.

• Avant de percer, toujours s’assurer que

la zone ne contient pas de conduites de

carburant, de réservoir de carburant, de

conduites de frein, de câblage électrique, etc.

• Ne jamais installer les câbles électriques :

- sur des bords tranchants,

- par ou à proximité de pièces mobiles;

- à proximité de pièces pouvant devenir

chaudes.

• Toujours isoler et protéger tous les fils et

bornes électriques exposés.

• Toujours installer les capuchons de borne

de la manière indiquée dans les instructions

d’installation.

Pour éviter de se blesser les mains ou les doigts

:

• Toujours garder les mains éloignées du câble,

de la boucle du crochet et du crochet durant

l’installation et l’utilisation du palan.

• Toujours faire très attention en manipulant le

crochet et le câble pendant les manœuvres de

déroulement.

• Toujours utiliser un cordon du crochet pour

enrouler ou dérouler le câble.

• Toujours débrancher tous les fils de la batterie

avant de commencer le travail.

• Toujours débrancher la borne négative en

premier et rebrancher la borne négative en

dernier.

AVERTISSEMENT

DANGER DE CHUTE OU D’ÉCRASEMENT

Le non-respect des consignes peut entraîner

des blessures graves ou la mort.

• Ne jamais utiliser le palan pour soulever ou

transporter des personnes.

• Toujours utiliser un câble de la taille spécifiée

sur la fiche de données de produit.

Page 24

Précautions de sécurité générales

ATTENTION ATTENTION

DANGER DE HAPPEMENT PAR DES

PIÈCES MOBILES

Le non-respect des instructions peut

entraîner des blessures mineures ou

modérées.

Consignes de sécurité générales :

• Toujours se familiariser avec le palan. Prendre

le temps de bien lire le manuel d’installation

et d’utilisation afin de comprendre l’appareil et

son fonctionnement.

• Les personnes âgées de moins de 16 ans ne

doivent jamais faire fonctionner cet appareil.

• Ne jamais faire fonctionner l’appareil

sous l’effet de drogues, de l’alcool ou de

médicaments.

• Ne jamais dépasser la capacité du palan

ou du câble indiqué sur la fiche technique

du produit. Un câblage double avec poulie

ouvrante permet de réduire la charge subie

par le treuil.

Consignes de sécurité se rapportant à

l’installation :

• Toujours choisir une surface de montage

suffisamment résistante pour supporter la

capacité de levage maximale du palan.

• Toujours utiliser un matériel de montage, des

composants et des accessoires homologués

par le fabricant.

• Toujours utiliser un matériel de montage de

catégorie 8 ou supérieure.

• Ne jamais souder les boulons de montage.

• Toujours faire attention quand on utilise des

boulons plus longs que ceux fournis par le

fabricant. Des boulons trop longs peuvent

endommager la base ou empêcher le palan

d’être monté de manière sûre.

• Toujours monter le palan et fixer le crochet

à la boucle d’extrémité du câble avant de

raccorder le câblage électrique.

• Toujours enrouler le câble sur le tambour

dans le sens spécifié par l’autocollant de

rotation ou la documentation du palan. Cela

est nécessaire pour que le frein automatique

fonctionne correctement.

• Toujours étirer au préalable le câble et

l’enrouler sous charge avant de l’utiliser. Un

câble enroulé de manière serrée réduit le

risque qu’il coince et soit endommagé.

DANGER DE HAPPEMENT PAR DES

PIÈCES MOBILES

Le non-respect des instructions peut

entraîner des blessures mineures ou

modérées.

• Toujours inspecter le câble, le crochet et

les élingues avant de faire fonctionner le

palan. Tout composant endommagé doit

être remplacé avant l’utilisation. Protéger les

pièces de dommages potentiels.

• Toujours signaler toute défectuosité, tout

fonctionnement inhabituel ou dommage subi

par le palan.

• Ne jamais laisser la télécommande branchée

sur le palan durant le câblage ou quand le

palan n’est pas utilisé.

• Ne jamais accrocher le câble à lui-même.

Cela l’endommagerait.

• Toujours s’assurer que tout objet ou obstacle

pouvant gêner la bonne utilisation du palan

est écarté.

• Toujours prendre le temps d’utiliser des

techniques de câblage adaptées avant

d’utiliser le palan pour soulever.

• Ne jamais utiliser le palan avec moins de 5

spires de câble enroulées autour du tambour.

Le câble pourrait se dérouler du tambour.

• Ne jamais toucher le câble ou le crochet

lorsque le câble est tendu ou sous charge.

• Ne jamais toucher le câble ou le crochet

lorsqu’une autre personne est à l’interrupteur

de commande ou durant le fonctionnement

du palan.

• Ne jamais toucher le câble ou le crochet

lorsque la télécommande est branchée sur le

palan.

• Toujours se tenir à l’écart du câble et de

la charge et ne jamais laisser personne

s’approcher durant l’utilisation.

• Toujours être conscient de la stabilité du

véhicule et de la charge durant le levage.

Alerter les personnes alentour en cas de

situation instable.

• Toujours garder le fil de la télécommande à

l’écart du tambour, du câble et du câblage.

S’assurer qu’il n’y a pas de fissures, de

points de pincement, de fils effilochés ou

de connexions desserrées. Remplacer la

télécommande en cas de dommages.

22 59

Page 25

Palans WARN Industries

ATTENTION ATTENTION

RISQUE DE COUPURE ET DE

BRÛLURE

Le non-respect des instructions peut

entraîner des blessures mineures ou

modérées.

Pour éviter de se blesser les mains et les

doigts :

• Toujours porter des gants de cuir épais

durant la manipulation du câble d’acier.

• Ne jamais laisser le câble glisser dans les

mains.

• Toujours penser aux surfaces chaudes au

niveau du moteur du palan, du tambour

ou du câble durant ou après l’utilisation du

palan.

• Ne jamais monter le contrôleur dans un

endroit où il risque de servir de marchepied

ou pour poser ou suspendre des outils.

• Toujours éviter d’endommager les bornes

situées sur la surface supérieure de

l’enceinte.

• Toujours maintenir les outils et autres

matériels conducteurs d’électricité à l’écart

des bornes en permanence.

DANGER DE HAPPEMENT PAR DES

PIÈCES MOBILES

Le non-respect des instructions peut

entraîner des blessures mineures ou

modérées.

• Ne jamais appliquer la charge sur l’extrémité

ou le loquet du crochet. Appliquer la charge

uniquement au centre du crochet.

• Ne jamais utiliser un crochet dont l’ouverture

de la gorge a augmenté ou dont l’extrémité

est courbée ou tordue.

• Toujours utiliser un crochet muni d’un loquet

• Toujours s’assurer que le loquet du crochet

est fermé et qu’il ne soutient aucune charge.

• Si l’on manie la télécommande de l’intérieur

d’un véhicule, toujours faire passer la

télécommande par une fenêtre pour éviter de

pincer le fil.

• Ne jamais laisser la charge se balancer

ou tourner sur elle-même quand elle est

suspendue.

• Ne jamais laisser une charge suspendue sans

surveillance.

AVERTISSEMENT

AVIS

ÉVITER D’ENDOMMAGER LE PALAN ET

L’ÉQUIPEMENT

• Ne jamais « secouer » le câble sous

charge. Les charges de choc peuvent

momentanément dépasser de loin la capacité

du câble et du palan.

• Ne jamais se servir du palan pour maintenir

une charge pendant le transport.

• Ne jamais submerger le palan dans l’eau.

• Toujours ranger la télécommande dans un

endroit sûr, propre et sec.

Le non-respect des consignes peut entraîner

des dommages matériels, des blessures

graves ou la mort.

• Ne jamais dépasser la pression hydraulique

ou le débit maximal recommandé pour l’un

quelconque des composants utilisés.

• Toujours connecter le treuil au système

hydraulique tel qu’indiqué sur le schéma

hydraulique.

• Toujours utiliser le bon type de distributeur

tel qu’indiqué sur le schéma hydraulique.

• Toujours se tenir à l’écart des conduites

hydrauliques lorsque le treuil est en marche.

• Toujours installer les composants

hydrauliques conformément aux

recommandations du fabricant.

Page 26

Palans WARN Industries

Qu’est-ce qu’un Palan ?

WARN Industries produit de nombreux types de

palans et de treuils. Quelle est la différence entre

un palan et un treuil ?

Les palans et les treuils se ressemblent. Tous

deux ont un moteur, un tambour rotatif avec un

câble, des réducteurs, une base et généralement

un circuit de commande électrique. Toutefois,

les palans et les treuils sont utilisés à des fins

différentes.

Les palans servent à soulever une charge en

l’air alors que les treuils sont utilisés pour tirer

une charge horizontalement sur le sol. Étant

donné qu’une charge suspendue en l’air crée des

dangers uniques, les palans sont construits selon

des normes de sécurité plus élevées. En outre, à

la différence des treuils, l’opérateur d’un palan ne

peut pas dérouler le câble « en roue libre » ou en

désengageant le moteur du train d’engrenages.

Frein Mécanique

Le frein mécanique génère de la chaleur quand

les charges sont abaissées et le câble déroulé.

Prendre soin d’éviter la surchauffe du frein

mécanique.

Avec les charges plus lourdes, laisser plus de

temps au frein pour refroidir entre les utilisations.

Le sifflement ou broutement associé à un

frein mécanique neuf est normal et disparaît

généralement à l’usage.

LA SURCHAUFFE DU FREIN MÉCANIQUE

PEUT ENTRAÎNER DES DOMMAGES

PERMANENTS OU LA DÉFAILLANCE DU

FREIN. REMPLACER TOUT COMPOSANT DE

FREIN ENDOMMAGÉ AVANT DE REPRENDRE

L’UTILISATION DU PALAN.

Télécommande

Utilisation de l’interrupteur

Ne pas laisser la télécommande branchée dans

le palan lorsque celui-ci n’est pas en usage. Une

télécommande qui reste branchée risque de

provoquer l’activation imprévue du palan et/ou de

vider la batterie.

enrouler le câble

(lever la charge)

dérouler le câble

(baisser la charge)

Télécommande résistant à

l’eau à usage intensif

Télécommande

standard

24 57

La télécommande CE

comprend un bouton

d’arrêt d’urgence

verrouillable.

Page 27

Palans WARN Industries

Liste de Contrôle Avant

l’installation

1 Vérifier que les composants suivants ont bien

été reçus :

• Le palan

• Le contrôleur

• La télécommande

• Le matériel de montage du palan

2 Lors du déballage du palan, contrôler s’il y a

eu des dommages, notamment des barres

d’accouplement, tirants, logements ou boîtiers

faussés ou fissurés. Corriger tout dommage

avant d’installer le palan.

3 S’assurer que l’environnement du palan et du

contrôleur est exempt de :

• Vapeurs combustibles

• Fumées chimiques

• Vapeurs d’huile

• Matières corrosives

4 S’assurer que la température de l’air ambiant

entourant le palan et le contrôleur reste entre

-29° C et 49° C.

5 S’assurer que la structure de montage peut

supporter la pleine traction nominale du palan.

6 S’assurer que la flèche ou la structure de

levage du palan ne se déformera pas sous

deux fois la pleine charge nominale du palan.

Montage du Palan

Utiliser autant que possible les fixations qui sont

fournies ou des boulons classe 8.8 métrique

de même taille de filetage. Les deux barres

d’accouplement ou tirants doivent être en place.

Utiliser des rondelles plates et des rondelles de

blocage entre les têtes de boulon et la surface de

montage.

Pour les supports de tambour à boulons

traversants :

De 1 à 4 filets doivent dépasser de l’écrou carré.

Des boulons trop longs risquent d’endommager

les supports de tambour et des boulons trop

courts ne seront pas assez solides. Utiliser des

rondelles plates et des rondelles de blocage entre

les têtes de boulon et la surface de montage.

Pour les supports de tambour filetés :

Des boulons trop longs risquent d’endommager

les supports de tambour ou de ne pas bien ancrer

le palan. Des boulons trop courts ne seront pas

assez solides. La longueur des boulons doit les

faire pénétrer de 24 à 35 mm dans la base du

palan.

1 S’assurer que la surface de montage est plane

à +/-0,50 mm. Si la surface n’est pas plane,

utiliser un dispositif de calage au besoin pour

éviter de déformer le palan.

2 Serrer tous les boulons de montage aux

couples recommandés sur la fiche de données

de produit.

3 Utiliser les emplacements de trous de montage

indiqués sur la fiche de données de produit.

Page 28

Palans WARN Industries

Montage du Contrôleur (Palans Électriques)

1 Enlever les vis fixant le couvercle au support

du contrôleur.

2 Monter le contrôleur verticalement de façon

à ce que l’eau ne s’accumule pas dans le

couvercle.

3 Monter le contrôleur dans un endroit qui n’est

pas soumis à des vibrations intenses. Utiliser

des rondelles de blocage pour empêcher les

écrous de montage de se desserrer.

4 Monter le contrôleur de façon à ce qu’il soit

protégé contre les outils ou autres objets

lourds.

5 Le contrôleur peut être monté dans un endroit

exposé aux intempéries, mais il doit être

protégé contre les risques de dommages

causés par les outils ou autres objets lourds.

6 Utiliser les dimensions de montage indiquées.

AVERTISSEMENT

RISQUE D’INCENDIE

Le non-respect des consignes peut

entraîner des blessures graves ou la mort.

• Ne jamais monter le contrôleur dans un

endroit où il risque de servir de marchepied

ou pour poser ou suspendre des outils.

• Toujours éviter d’endommager les bornes

situées sur la surface supérieure de

l’enceinte.

• Toujours maintenir les outils et autres

matériels conducteurs d’électricité à l’écart

des bornes en permanence.

Dimensions de montage d’un contrôleur type

26 55

Page 29

Palans WARN Industries

Connexions des fils Électriques

Voir les illustrations à la page suivante.

Consignes relatives aux connexions :

• Utiliser du fil de batterie de Ø 32 pour toutes

les connexions d’alimentation. Une longueur

de fil excessive peut résulter en une chute

de tension et entraîner des performances

médiocres.

• Minimiser la longueur des fils autant que

possible. Quand des fils de plus de 3 m de

long sont nécessaires, utiliser du fil de Ø 52.

• Poser les fils le long d’endroits protégés pour

éviter qu’ils soient usés ou endommagés.

• Utiliser des capuchons d’isolation sur

toutes les connexions de bornes exposées

pour éviter les courts-circuits. Glisser les

capuchons de bornes sur les fils avant de

les brancher aux bornes.

• Utiliser des connecteurs épissés pour

raccorder les fils du thermorupteur du

moteur.

• Raccorder les fils F1, F2, A et de masse

comme illustré pour les modèles à droite.

Pour les modèles à gauche, la borne F1 du

contrôleur doit être raccordée à la borne F2

du moteur et la borne F2 du contrôleur à la

borne F1 du moteur.

• S’assurer que toutes les connexions

électriques sont propres et bien serrées.

• Il est recommandé d’installer un sectionneur

de puissance dans un endroit d’accès

facile. Cela fournit un sectionneur durant

l’utilisation et sert de dispositif de sécurité

supplémentaire. Utiliser un interrupteur de

300 A.

• Il est recommandé d’installer un coupecircuit de 300 A dans le fil positif (+) près de

la batterie pour protéger contre les courtscircuits.

AVERTISSEMENT

RISQUES ASSOCIÉS AUX PRODUITS

CHIMIQUES ET RISQUE D’INCENDIE

Le non-respect des consignes peut entraîner

des blessures graves ou la mort.

• Ne jamais installer les câbles électriques :

- sur des bords tranchants;

- par ou à proximité des pièces mobiles;

- à proximité de pièces pouvant devenir

chaudes.

Page 30

Palans WARN Industries

noir

2

3

1

brun

Connexions pour les moteurs c.c. à enroulements série (3 bornes)

Rotation du tambour: Vu dans le sens horaire de fin de moteur

noir

1

2

3

brun

Connexions pour les moteurs c.c. à enroulements série (3 bornes)

Rotation du tambour: Compteur affiché dans le sens horaire de fin

de moteur

28 53

Page 31

Palans WARN Industries

#2

#1

Moteur

à

aimant permanent

+

_

Batterie

Couvercle de

Contr leur

2 1

3

+

#2

noir

_

#1

Contr leur

Connexions pour les moteurs c.c. à aimant permanent (2 bornes)

Rotation du tambour: Vu dans le sens horaire de fin de moteur

#2

#1

Moteur

à

aimant permanent

Couvercle de

Contr leur

noir

2

1

3

+

Batterie

_

#2

_

+

#1

Contr leur

Connexions pour les moteurs c.c. à aimant permanent (2 bornes)

Rotation du tambour: Compteur affiché dans le sens horaire de fin

de moteur

Page 32

Palans WARN Industries

COMPOSANTS FOURNIS PAR LE CLIENT

MOTEUR

DISTRIBUTEUR

À 3 POSITIONS ET 4 VOIES

RAPPEL PAR RESSORT

(TIROIR CYLINDRIQUE)

POMPE

Palans Hydrauliques: Généralités

REMARQUE : le schéma du circuit hydraulique

et la description des composants sont donnés

à titre de référence générale. Consulter un

représentant qualifié en hydraulique pour obtenir

des recommandations spécifiques en matière de

sélection des composants, d’interconnexion, de

disposition et de meilleures pratiques.

La pression nominale du moteur du treuil est

déterminée par a) la pression maximale admissible à

l’orifice d’entrée du moteur et b) la chute de pression

maximale admissible dans le moteur. On définit la

chute de pression comme étant la différence entre

la pression à l’orifice d’entrée et la pression à l’orifice

de sortie du moteur du treuil. Le fait de dépasser la

pression d’entrée maximale peut endommager le

moteur du treuil. Le dépassement de la chute de

pression maximale peut causer la défaillance des

composants du treuil.

La plage de température de fonctionnement

recommandée pour le moteur hydraulique est de

38 à 66 ºC. La plage maximale est de -21 à 82 ºC.

NE PAS dépasser le débit nominal du moteur

hydraulique. Consulter la fiche technique du produit

pour les spécifications hydrauliques précises.

Vérification Finale

de l’installation:

• Revérifier le matériel de montage

au cas où il y aurait des boulons

desserrés, etc…

• S’assurer que tous les composants

et raccords du système hydraulique

sont en bon état.

• S’assurer que tous les raccords

hydrauliques sont bien serrés.

• Vérifier la rotation du moteur : Le

tambour doit tourner dans le sens

indiqué par l’étiquette de rotation

du tambour collée sur le haut du

support de tambour. Si le tambour

tourne dans le sens opposé,

revérifier les raccords hydrauliques

et électriques.

Le non-respect des consignes peut entraîner

des dommages matériels, des blessures

graves ou la mort.

• Ne jamais dépasser la pression hydraulique

• Toujours connecter le treuil au système

• Toujours utiliser le bon type de distributeur

• Toujours se tenir à l’écart des conduites

• Toujours installer les composants

FLUIDE HYDRAULIQUE : le fluide hydraulique

utilisé avec le treuil doit être une huile hydraulique

antiusure pour pressions extrêmes contenant

des inhibiteurs d’oxydation et de corrosion. Il doit

contenir un agent antimousse et posséder une

viscosité de 100 à 300 SUS pour une température

de 15 à 46 ºC. On recommande un niveau de

filtration nominal de 10 microns ou moins.

AVERTISSEMENT

ou le débit maximal recommandé pour l’un

quelconque des composants utilisés.

hydraulique tel qu’indiqué sur le schéma

hydraulique.

tel qu’indiqué sur le schéma hydraulique.

hydrauliques lorsque le treuil est en marche.

hydrauliques conformément aux

recommandations du fabricant.

Schéma Hydraulique

30 51

Page 33

Installation du Câble d’acier

1 Insérer le câble dans la fente du tambour tel

qu’indiqué.

2 Faire une boucle et insérer de nouveau

l’extrémité dans la fente. La portion de câble

active ou portant la charge doit être la plus

proche de l’embase du tambour.

3 Insérer la cale ou l’écrou hexagonal (7/16 po.)

fourni avec le palan dans la boucle et tirer

l’extrémité active du câble afin d’enchâsser

la cale ou l’écrou hexagonal dans la fente.

L’extrémité du câble doit rester visible dans la

fente tel qu’indiqué. La cale verrouille le câble

dans la fente.

4 L’extrémité du câble étant bien fixée, enrouler

soigneusement le câble sur le tambour de

façon uniforme. Maintenir le câble sous

tension en permanence.

5 Toujours laisser 5 spires de câble sur le

tambour au minimum. A défaut, l’extrémité

du câble pourrait se détacher du tambour et

entraîner la chute de la charge.

Palans WARN Industries

ATTENTION

Le non-respect de ces instructions peut

entraîner des blessures modérées et des

dommages matériels.

• Toujours installer le câble dans le sens indiqué

par l’autocollant de rotation apposé sur le

tambour, sinon le frein ne fonctionnera pas.

• Toujours utiliser un câble de la taille spécifiée

sur la fiche de données de produit.

• Toujours installer le câble conformément à

l’installation ci-dessous.

Ancrage du câble sur le tambour

Page 34

Palans WARN Industries

Consignes de Sécurité de l’utilisation

NE JAMAIS :

• Ne jamais placer une partie du corps ou

d’un vêtement près des pièces rotatives

ou mobiles. Le tambour en rotation avec le

câble sous tension peut créer un point de

pincement.

• Ne jamais manipuler des câbles ou

faire fonctionner le palan sans porter de

protection oculaire et des gants épais.

• Ne jamais se tenir près du palan pendant le

fonctionnement. Si le câble se rompt, il peut

revenir en arrière avec grande force.

• Ne jamais utiliser le palan pour soulever,

tirer ou transporter des personnes.

• Ne jamais soulever, tirer ou transporter des

charges au-dessus de personnes.

• Ne jamais tenter de soulever des charges

supérieures à la capacité nominale du palan.

• Ne jamais soulever une charge jusqu’à ce

qu’elle se bloque ou que le tambour et le

moteur calent.

• Ne jamais laisser une grue atteindre une

position de double blocage.

Remarque : les trois conditions ci-dessus

produisent une charge excessive sur le

palan qui peut entraîner une défaillance du

palan, du câble ou de nature structurelle,

entraînant la chute de la charge. Les

charges excessives peuvent produire des

dommages indécelables pouvant entraîner

la défaillance du palan même s’il lève

des charges dans la limite de sa capacité

nominale.

• Ne jamais laisser surchauffer le circuit

hydraulique, le moteur électrique ou le frein

mécanique.

• Ne jamais toucher le câble ou le câblage

pendant le levage d’une charge, pendant

que quelqu’un est aux commandes ou

pendant le fonctionnement du palan.

AVERTISSEMENT

Le non-respect de ces consignes peut

entraîner des dommages matériels, des

blessures graves ou la mort.

Toujours faire attention aux dangers posés par

le câble, les points de pincement, les chutes de

charge et le câble ou le câblage sous tension.

• Ne jamais enrouler le câble autour d’un

objet ou l’accrocher à lui-même. Cela

l’endommagerait.

• Ne jamais utiliser le palan avec moins de

5 spires de câble enroulées autour du

tambour. L’ancrage du câble n’est pas conçu

pour retenir la charge nominale. Le câble

peut se détacher et entraîner la chute de

la charge avec moins de 5 spires de câble

enroulées autour du tambour.

• Ne jamais laisser le câble glisser dans les

mains.

• Ne jamais tenter de soulever une charge

quelconque si elle est décalée. Cela peut

provoquer le balancement dangereux de

la charge. S’assurer que la charge est

directement sous le palan.

• Ne jamais laisser la charge se balancer

ou tourner sur elle-même quand elle est

suspendue.

• Ne jamais laisser la charge peser sur le

loquet du crochet.

• Ne jamais laisser une charge suspendue

sans surveillance.

• Ne jamais soulever une charge en utilisant

la pointe du crochet. S’assurer que la charge

pèse sur le talon du crochet.

• Ne jamais utiliser le palan en présence de

matériaux ou de vapeurs inflammables.

Les appareils électriques produisent des

arcs pouvant causer un incendie ou une

explosion.

32 49

Page 35

Palans WARN Industries

• Ne pas utiliser le palan si l’on est fatigué,

distrait, pressé ou après avoir consommé de

la drogue, de l’alcool ou des médicaments

affectant les facultés ou le jugement.

TOUJOURS :

• Toujours prendre le temps d’évaluer la

situation et préparer le levage avec soin.

• Avant un levage, toujours vérifier l’état de

la structure de montage, du palan, des

élingues et autres accessoires. Remplacer

les composants endommagés avant un

levage.

• Toujours connaître le poids de la charge

et vérifier que le câblage, le palan et la

monture supportent le poids.

• Toujours vérifier que la charge se trouve

directement sous le palan, que le câble n’est

pas entortillé ou tordu et que personne ne se

trouve à proximité de la charge.

• Toujours porter des gants de cuir.

• Toujours éliminer le mou du câble lentement.

Commencer le levage lentement. S’il semble

y avoir surcharge, abaisser immédiatement

la charge et corriger le problème.

• Toujours éviter les charges de choc

exercées sur le palan quand on soulève

rapidement la charge ou fait rebondir la

charge.

• Toujours s’assurer que le loquet de crochet

fonctionne correctement. Remplacer un

loquet de crochet endommagé avant

d’utiliser le palan.

• Toujours s’assurer que le câble s’enroule

dans le bon sens. Les palans sont équipés

d’un frein automatique et ne fonctionneront

pas si le câble se déroule du tambour dans

le mauvais sens.

REMARQUE : le sens d’enroulement du

câble s’inverse accidentellement si le câble

est complètement déroulé puis enroulé de

nouveau avec l’interrupteur de commande

en position de déroulement.

• Toujours inspecter et rembobiner

minutieusement le câble après chaque

utilisation. Les endroits coupés, tordus ou

effilochés réduisent la solidité du câble.

Remplacer le câble s’il est endommagé.

• Toujours garder la télécommande à l’écart

du tambour, du câble et du câblage.

• Toujours vérifier l’état de la télécommande et

de son fil avant d’utiliser le palan.

• Toujours inspecter les connexions

hydrauliques ou électriques avant d’utiliser

le palan.

• Toujours se tenir à l’écart du câble et de la

charge durant l’utilisation du palan.

• Toujours s’assurer que les autres opérateurs

du palan comprennent les dangers potentiels

et ont été formés à l’utilisation correcte

du palan.

• Toujours s’assurer que l’ensemble

contrôleur et palan est installé, utilisé,

réglé et entretenu par du personnel qualifié

familiarisé avec sa construction et son

fonctionnement.

• Toujours vérifier que les dispositifs limiteurs

de charge fonctionnent correctement.

Consignes complémentaires :

• Si la charge doit être immergée dans un

liquide ou une matière solide poudreuse,

utiliser une chaîne d’élinguage ou un autre

dispositif approprié pour que le crochet reste

au-dessus de la surface en permanence.

• Pour tout renseignement complémentaire, se

reporter à la section d’utilisation des normes

ANSI/ASME B30.16 et B30-9 (câblage) de

l’American National Standard et à la section

d’utilisation DOE-STD-1090-99 des normes

de treuillage et de câblage du Department

of Energy.

Page 36

Palans WARN Industries

Maintenance Préventive Périodique

• Garder le palan exempt de saleté, de

graisse, d’eau et autres substances,

• Vérifier tous les boulons de montage et

s’assurer qu’ils sont serrés aux couples

recommandés sur la fiche de données

de produit. Remplacer toute fixation

endommagée.

• Contrôler périodiquement toutes les

connexions pour s’assurer qu’elles sont bien

serrées et non corrodées.

• Vérifier visuellement l’intégrité du câble

chaque fois que le palan est utilisé.

Exemples de dommages : coupures,

nœuds, portions écrasées ou effilochées et

torons cassés. Remplacer le câble d’acier

immédiatement s’il est endommagé. Toute

négligence à cet égard peut entraîner une

rupture du câble.

Programme de maintenance préventive

• Vérifier régulièrement que le frein ne

glisse pas. Si le tambour continue à

tourner après que les commandes ont été

lâchées, il se peut que le frein ait besoin

d’être remplacé.

• Nettoyer et graisser périodiquement

le frein pour s’assurer qu’il fonctionne

correctement et prolonger la vie utile

du palan. Si le palan semble peiner ou

devenir excessivement chaud lorsque les

charges sont abaissées, le frein a besoin

d’entretien ou d’être remplacé.

• Vérifier périodiquement les balais du

moteur et les remplacer si nécessaire.

REMARQUE : seuls les balais de

moteur et le frein doivent être remplacés

périodiquement

Activité de

maintenance

Après

la première

utilisa-

Avant

chaque

utilisation

Tous les semestres ou

toutes les 25 heures

de fonctionnement

tion

Vérifier les fixations X X

Vérifier les connexions

électriques ou

hydrauliques

Dérouler et vérifier le

câble

Nettoyer et graisser

le frein

Vérifier les balais du

moteur

Vérifier à l’oeil nu le

palan et la commande

X

X

X X X

34 47

X

X

X

Page 37

Palans WARN Industries

Dépannage : Palans Électriques

AVERTISSEMENT

BLESSURES

Le non-respect des consignes peut entraîner des blessures graves ou la mort.

• Ne jamais se pencher au-dessus de la batterie en procédant aux connexions

• Toujours débrancher tous les fils de la batterie avant de commencer le travail.

• Toujours débrancher la borne négative en premier et rebrancher la borne négative en dernier.

• Toujours retirer les bijoux et porter des lunettes de sécurité.

Problème Cause possible Mesure corrective

Le palan ne

fonctionne dans

aucun sens ou

le moteur ne

fonctionne pas

Le palan

déroule mais

n’enroule pas

L’alimentation

n’est pas connectée -oul’interrupteur

marche/arrêt

d’urgence (en

option) est en

position d’arrêt

L’alimentation

de l’interrupteur

à distance a été

coupée.

Défaillance de

l’interrupteur de la

télécommande ou

de son câblage

Défaillance des

composants ou

du câblage à

l’intérieur du con-

trôleur

A) Vérifier les connexions des fils. Vérifier

qu’il y a 12 V (24 V) à la borne positive (+) du

contrôleur. Vérifier la tension aux bornes F1,

F2 et A avec l’interrupteur à distance dans

un sens ou l’autre. B) Vérifier la position de

l’interrupteur marche/arrêt d’urgence.

Vérifier qu’il y a 12 V (24 V) à la broche

centrale de la prise de télécommande du

contrôleur. Vérifier la continuité du connecteur

du fil de télécommande entre la broche

centrale et l’une des broches latérales avec

l’interrupteur de la télécommande dans les

deux positions. Remplacer l’interrupteur de la

télécommande s’il n’y a pas continuité.

Vérifier qu’il y a 12 V (24 V) à la broche

centrale de la prise de télécommande du

contrôleur. Vérifier la continuité du connecteur

du fil de télécommande entre la broche

centrale et l’une des broches latérales avec

l’interrupteur de la télécommande dans les

deux positions. Remplacer la télécommande

s’il n’y a pas continuité.

Vérifier qu’il y a 12 V (24 V) à la broche

centrale de la prise de télécommande du

contrôleur. Vérifier la continuité du connecteur

du fil de télécommande entre la broche

centrale et l’une des broches latérales avec

l’interrupteur de la télécommande dans les

deux positions. Remplacer la télécommande

s’il n’y a pas continuité. Si aucune de ces

actions ne résout le problème, renvoyer le

contrôleur à Warn Industries pour service.

Page 38

Palans WARN Industries

Problème Cause possible Mesure corrective

Vérifier qu’il y a 12 V (24 V) à la broche

Le palan

enroule mais

ne déroule pas

Le moteur

essaie de

dérouler mais

le palan cale ou

se bloque

L’alimentation de

l’interrupteur de la

télécommande a

été coupée

Défaillance du

frein

centrale de la prise de télécommande du

contrôleur. Vérifier la continuité du connecteur

du fil de télécommande entre la broche

centrale et l’une des broches latérales avec

l’interrupteur de la télécommande dans les

deux positions. Remplacer la télécommande

s’il n’y a pas continuité.

Effectuer l’entretien du frein ou le remplacer.

Le palan fonctionne dans

les deux sens

mais refuse

de soulever

une charge

nominale

Le palan

ralentit et

cale durant le

déroulement

Le palan vibre

violemment

ou fait du

bruit lorsqu’il

soulève ou

abaisse les

charges

Tension insuf-

fisante au palan

Le frein a besoin

d’entretien

Le frein a besoin

d’entretien

La surface de

montage n’est

pas plane. Barre

d’accouplement

ou tirant faussé

A) S’assurer que les consignes concernant

la taille du câble électrique ont été suivies. B)

Vérifier l’état de la batterie. C) Vérifier que le

câble électrique et les connexions ne sont pas

corrodés. Nettoyer et serrer les connexions.

Effectuer l’entretien du frein ou le remplacer.

Effectuer l’entretien du frein ou le remplacer.

S’assurer que la surface de montage est

plane à 0,50 mm près. Remplacer la barre

d’accouplement ou le tirant si nécessaire.

Vérifier que les boîtiers ne sont ni faussés ni

fissurés.

36 45

Page 39

Palans WARN Industries

Dépannage : Palans Hydrauliques

REMARQUE : Les défaillances du circuit

hydraulique se passent généralement de

la même manière : une perte graduelle ou

soudaine de pression ou de débit résultant en

une perte de puissance du moteur. N’importe

lequel des composants du circuit peut en être

la cause. Se reporter au tableau pour connaître

les recommandations générales. Si nécessaire,

consulter un représentant expert en circuits

hydrauliques.

REMARQUE : voir la fiche de données de produit

pour les caractéristiques hydrauliques.

Problème Cause possible Mesure corrective

AVERTISSEMENT

BLESSURES