Page 1

Warn Industries, Inc.

12900 S.E. Capps Road

Clackamas, OR USA 97015-8903

1-503-722-1200 FAX: 1-503-722-3000

www.warn.com

Customer Service / Service Clients: 1-800-543-9276

International Sales Support / Les Ventes internationales

Soutiennent: 1-503-722-3008

© 2011 Warn Industries, Inc.

WARN®, the WARN logo are registered trademarks of Warn Industries, Inc.

WARN® et le logo WARN sont des marques

déposées de Warn Industries, Inc.

79295A2

ENDURANCE / 12.0XE WINCH

INSTALLATION AND OPERATOR’S GUIDE

GUIDE D’INSTALLATION ET OPERATEUR

Page 2

English .................................................................... 1-12

Français ................................................................ 13-24

Español ................................................................. 25-36

Page 3

ORIGINAL INSTRUCTIONS

SYMBOL INDEX

Winch Installation and Operator’s

Guide

Every winching situation has the potential for personal injury. In order to minimize that

risk, it is important to read this guide and The Basic Guide to Winching Techniques

carefully. Please familiarize yourself with the operation of your winch before using it, and

be constantly safety oriented. In this guide, we will set forth many of the basic rules of

safe winch operation. Please read The Basic Guide to Winching Techniques for more

information on your winch and proper rigging techniques. Remember, because every

winching situation is different, your constant good judgment and consistent focus on

safety are of great importance.

TABLE OF CONTENTS:

SAFETY

Symbol Index ............................................................................................................... 2

General Safety Precautions .....................................................................................3-5

Safe Working Conditions .............................................................................................6

INSTRUCTIONS

Mounting Winch ........................................................................................................... 7

Mounting Cooling Fan .................................................................................................8

Electrical Connections ................................................................................................. 9

Operating Instructions ..........................................................................................10-11

Stretching Wire Rope ..........................................................................................11-12

Warn Industries Inc.

12900 SE Capps Road

Clackamas, OR 97015

USA

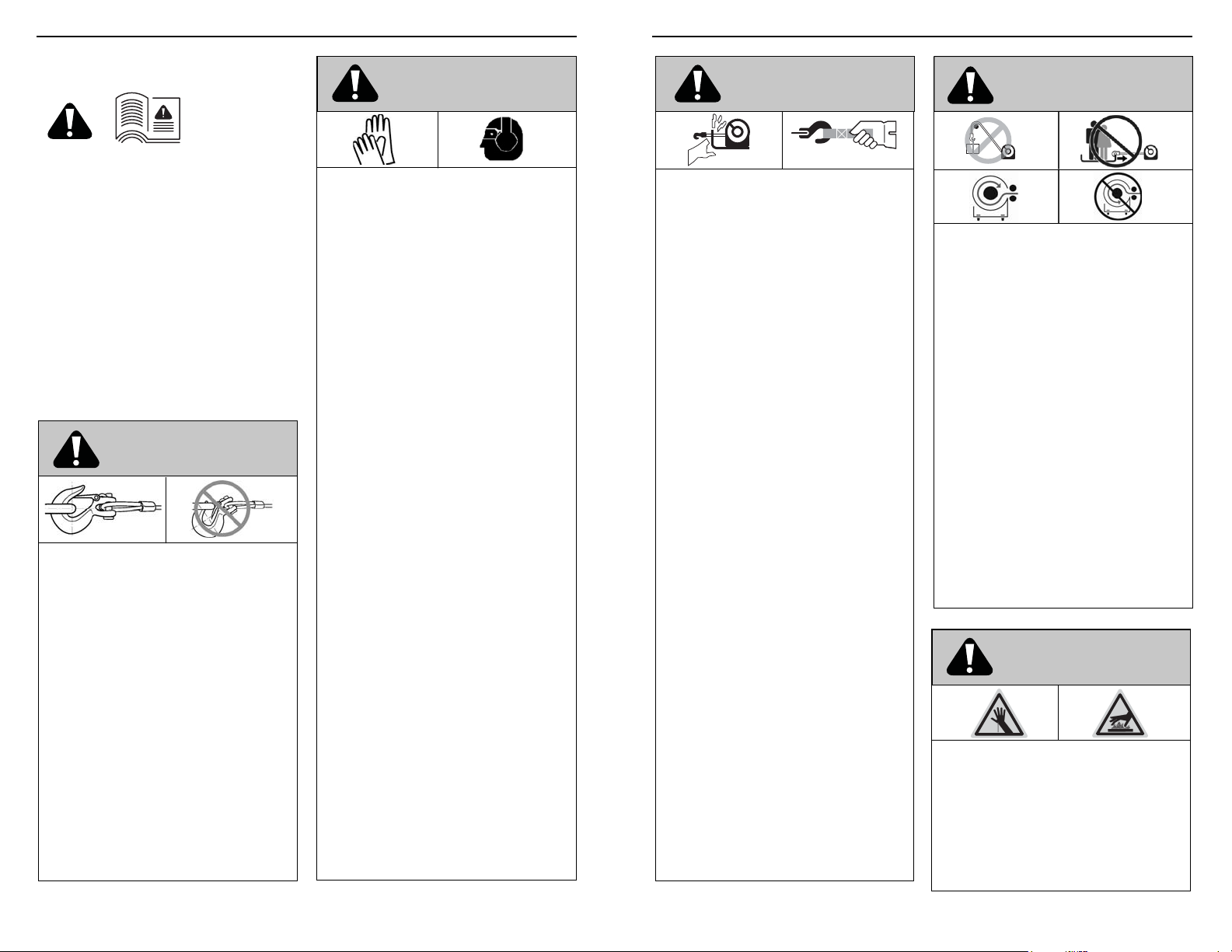

SYMBOL EXPLANATION

Read the Instruction

Manual

Always Wear Hearing

and Eye Protection

Never Use Winch as a

Hoist

Properly Seat Load in

Throat of Hook

Wind Rope on Bottom

of Drum

Finger/Fairlead Crushing

Hazard

Hand Piercing/Cutting

Hazard

Explosion/Bursting

Hazard

Sharp Edge Hazard

SYMBOL EXPLANATION

Always Wear Leather

Gloves

Do Not Move People

Always Use Supplied

Hook Strap

Never Apply Load to

Hook Tip or Latch

Never Wind Rope Over

Top of Drum

Fairlead Pinch Point

Hot Surface Hazard

Fire and Burn Hazard

Moving Parts Hazard

WARN® and the WARN logo are registered trademarks of Warn Industries, Inc.

© 2011 Warn Industries, Inc.

WARN INDUSTRIES * WINCH

1

Customer Service: (800) 543-WARN

(9276)

International: (503) 722-1200

Fax: (503) 722-3000

www.warn.com

WARN INDUSTRIES * WINCH

2

Page 4

GENERAL SAFETY PRECAUTIONS

GENERAL SAFETY PRECAUTIONS

Warnings and Cautions

As you read these instructions, you will see

WARNINGS, CAUTIONS, NOTICES and NOTES.

Each message has a specifi c purpose. WARNINGS

are safety messages that indicate a potentially

hazardous situation, which, if not avoided could result

in serious injury or death. CAUTIONS are safety

messages that indicate a potentially hazardous

situation which, if not avoided, could result in minor

or moderate injury. A CAUTION may also be used

to alert against unsafe practice. CAUTIONS and

WARNINGS identify the hazard, indicate how to avoid

the hazard, and advise of the probable consequence

of not avoiding the hazard. NOTICES are messages

to avoid property damage. NOTES are additional

information to help you complete a procedure.

PLEASE WORK SAFELY!

WARNING

MOVING PARTS ENTANGLEMENT

HAZARD

Failure to observe these instructions could

lead to serious injury or death.

• Always ensure hook latch is closed and not

supporting load.

• Never apply load to hook tip or latch. Apply load

only to the center of hook.

• Never use a hook whose throat opening has

increased, or whose tip is bent or twisted.

• Always use a hook with a latch.

• Always ensure the operator and bystandnders are

aware of the stability of the vehicle and/or load.

• Always keep wired remote control lead and

power cord clear of the drum, rope, and rigging.

Inspect for cracks, pinches, frayed wires or loose

connections. Damaged components must be

replaced before operation.

• Always pass remote lead thru window when used

in vehicle.

WARNING

MOVING PARTS ENTANGLEMENT

HAZARD

Failure to observe these instructions could

lead to serious injury or death.

General Safety:

• Always Know Your Winch. Take time to fully read

the Instructions and/or Operations Guide, and/or

Basic Guide to Winching Techniques, in order to

understand your winch and its operations.

• Never exceed winch or winch rope rated capacity.

Double line using a snatch block to reduce winch

load.

• Always wear heavy leather gloves when handling

winch rope.

• Never use winch or winch rope for towing. Shock

loads can damage, overload and break rope.

• Never use a winch to secure a load.

• Never operate this winch when under the infl uence

of drugs, alcohol or medication.

• Never operate this winch if you are under 16 years

of age.

Installation Safety:

• Always choose a mounting location that is

suffi ciently strong to withstand the maximum pulling

capacity of your winch.

• Always use grade 5 (grade 8.8 metric) or better

hardware.

• Never weld mounting bolts.

• Always use factory approved mounting hardware,

components, and accessories.

• Never use bolts that are too long.

• Always complete the winch installation and hook

attachment before installing the wiring.

• Always keep hands clear of winch rope, hook

loop, hook and fairlead opening during installation,

operation, and when spooling in or out.

• Always position fairlead with warning readily visible

on top.

• Always prestretch rope and respool under load

before use. Tightly wound rope reduces chances of

“binding”, which can damage the rope.

WARNING

MOVING PARTS ENTANGLEMENT

HAZARD

Failure to observe these instructions could

lead to serious injury or death.

Winching Safety:

• Always inspect winch rope, hook, and slings

before operating winch. Frayed, kinked

or damaged winch rope must be replaced

immediately. Damaged components must be

replaced before operation. Protect parts from

damage.

• Always remove any element or obstacle that may

interfere with safe operation of the winch.

• Always be certain the anchor you select will

withstand the load and the strap or chain will not

slip.

• Always use supplied hook strap whenever

spooling winch rope in or out, during installation

and during operation.

• Always require operators and bystanders to be

aware of vehicle and or load.

• Always be aware of stability of vehicle and load

during winching, keep others away. Alert all

bystanders of an unstable condition.

• Always unspool as much wire rope as possible

when rigging. Double line or pick distant anchor

point.

• Always take time to use appropriate rigging

techniques for a winch pull.

• Never touch winch rope or hook while someone

else is at the control switch or during winching

operation.

• Never engage or disengage clutch if winch is

under load, winch rope is in tension or drum is

moving.

• Never touch winch rope or hook while under

tension or under load.

• Always stand clear of winch rope and load and

keep others away while winching.

• Never use vehicle to pull load on winch rope.

Combined load or shock load can damage,

overload and break rope.

• Never wrap winch rope back onto itself. Use a

choker chain or tree trunk protector on the anchor.

WARNING

FALLING OR CRUSHING HAZARD

Failure to observe these instructions could

lead to serious injury or death.

• Always stand clear, keep hands clear, keep others

away.

• Never operate winch with less than 5 wraps of rope

around the drum. Rope could come loose from the

drum, as the rope attachment to the drum is not

designed to hold a load.

• Never use winch as a hoist or to suspend a load.

• Always be certain anchor will withstand load, use

appropriate rigging and take time to rig correctly.

• Never use winch to lift or move persons.

• Never use excessive effort to freespool winch rope.

• Always use proper posture/lifting technique or

get lifting assistance while handling and installing

product.

• Always spool the rope onto the drum in the

direction specifi ed by the winch warning label on

the winch and/or documentation. This is required

for the automatic brake (if so equipped) to function

properly.

• Always spool the winch rope onto the drum as

indicated by the drum rotation label.

WARNING

CUT AND BURN HAZARD

Failure to observe these instructions could

lead to serious injury or death.

To avoid injury to hands and fi ngers:

• Always wear heavy leather gloves when handling

winch rope.

• Always be aware of possible hot surfaces at winch

motor, drum or rope during or after winch use.

WARN INDUSTRIES * WINCH

3

WARN INDUSTRIES * WINCH

4

Page 5

GENERAL SAFETY PRECAUTIONS

SAFE WORKING CONDITIONS

WARNING

CHEMICAL AND FIRE HAZARD

Failure to observe these instructions could

lead to serious injury or death.

• Always remove jewelry and wear eye protection.

• Never route electrical cables across sharp edges.

• Never route electrical cables near parts that get

hot.

• Never route electrical cables through or near

moving parts.

• Always place the supplied terminal boots on

wires and terminals as directed by the installation

instructions.

• Never lean over battery while making

connections.

• Never route electrical cables over battery

terminals.

• Never short battery terminals with metal objects.

• Always verify area is clear of fuel lines, fuel tank,

brake lines, electrical wires, etc., when drilling.

• Always consult operator’s manual for proper

wiring details.

• Always insulate and protect all exposed wiring

and electrical terminals.

CAUTION

CUT AND BURN HAZARD

Failure to observe these instructions could

lead to minor or moderate injury.

• Never let winch rope slip through your hands.

CAUTION

MOVING PARTS ENTANGLEMENT

HAZARD

Failure to observe these instructions could

lead to minor or moderate injury.

To avoid injury to hands or fi ngers:

• Never leave remote control where it can be

activated during free spooling, rigging, or when the

winch is not being used.

• Never leave the winch remote control plugged in

when installing, freespooling, rigging, servicing or

when the winch is not being used.

NOTICE

AVOID WINCH AND EQUIPMENT

DAMAGE

• Always avoid side pulls which can pile up wire

rope at one end of the drum. This can damage

wire rope or winch.

• Always ensure the clutch is fully engaged or

disengaged.

• Always use care to not damage the vehicle frame

when anchoring to a vehicle during a winching

operation.

• Never submerge winch in water.

• Always store the remote control in a protected,

clean, dry area.

WARNING

Always stand

clear, keep

hands clear,

keep others

away.

WARNING

Always require

operators and

bystanders to be

aware of vehicle

and or load.

CAUTION

Never leave

remote control

where it can be

activated during

free spooling,

rigging, or when

the winch is not

being used.

NOTICE

Never submerge

winch in water.

SAFE WORKING CONDITIONS

The operator should always

operate the winch from a safe

position when pulling a load. The

safe areas are: (1) Perpendicular

to the wire rope, (2) Inside the

vehicle with the hood up (if winch

is mounted on front of vehicle).

These safe positions will help

prevent the wire rope from striking

the operator if the wire rope fails

when under load.

Operate winch from the fully

extended remote control cord

length whenever possible. The

operator must always be at least

8 ft. (2.44 m) from the winch

while operating. This will prevent

entanglement with the fairlead and

keep the operator out of harms

way during winch load pulling.

Never work around the wire

rope while under load.

Sound Emissions

The winch is designed so

that the sound emissions do not

exceed 70 dBa from the operator’s

station. The operator must be

at least 8 ft. (2.44 m) from the

winch while operating. If the winch

is exceeding 70 dBa from the

operator’s station, have the winch

inspected at an authorized service

center.

Cleaning

Do not direct high pressure

water (pressure washers, car

washes, etc.) between the drum

support and drum fl ange or clutch

lever.

Use low pressure water and a

soapy rag or sponge to clean the

winch.

Avoid using chemicals that

may damage the fi nish.

Thoroughly clean salt residue

from the winch as soon as possible

to minimize corrosion.

Maintenance

No lubrication is required for

the life of the winch unless the

winch has been submerged in

water. If this occurs, a qualifi ed

service center must complete

service as soon as possible to

prevent corrosion damage. If the

control pack is submerged, it must

be replaced when the winch is

serviced.

Check battery cables and

electrical connections at 90 day

intervals to be certain they are

clean and tight at all connection

points.

Inspect the wire rope before

and after each winching operation.

When damaged, replace with the

size specifi ed in the Replacement

Parts List, or go to the Warn

website at www.warn.com.

The wire rope must always

spool onto the drum as indicated

by the drum rotation decal on the

winch.

WARN INDUSTRIES * WINCH

5

WARN INDUSTRIES * WINCH

6

Page 6

MOUNTING WINCH

MOUNTING COOLING FAN

MOUNTING WINCH

Choose a mounting location

that is suffi ciently strong enough

to withstand the loads you intend

to winch. Only the mounting

orientations shown are possible for

safe winching operation. All others

are improper and inappropriate.

The use of recommended bolt

and lock washer combinations

torqued to recommended levels will

Control Pack Installation

Mount the control pack

according to the instructions

included in the WARN mounting

system kit. Use the bracket

included in the kit.

The control pack mounting

fasteners may also be moved to

the unused holes in the control

pack base plate for additional

mounting fl exibility.

prevent vibration during operation.

The mounting details indicate the

proper torque levels.

Remember the winch rope

must always spool onto the drum

as indicated by the drum rotation

decal.

Refer to the following

diagrams for proper mounting

orientation.

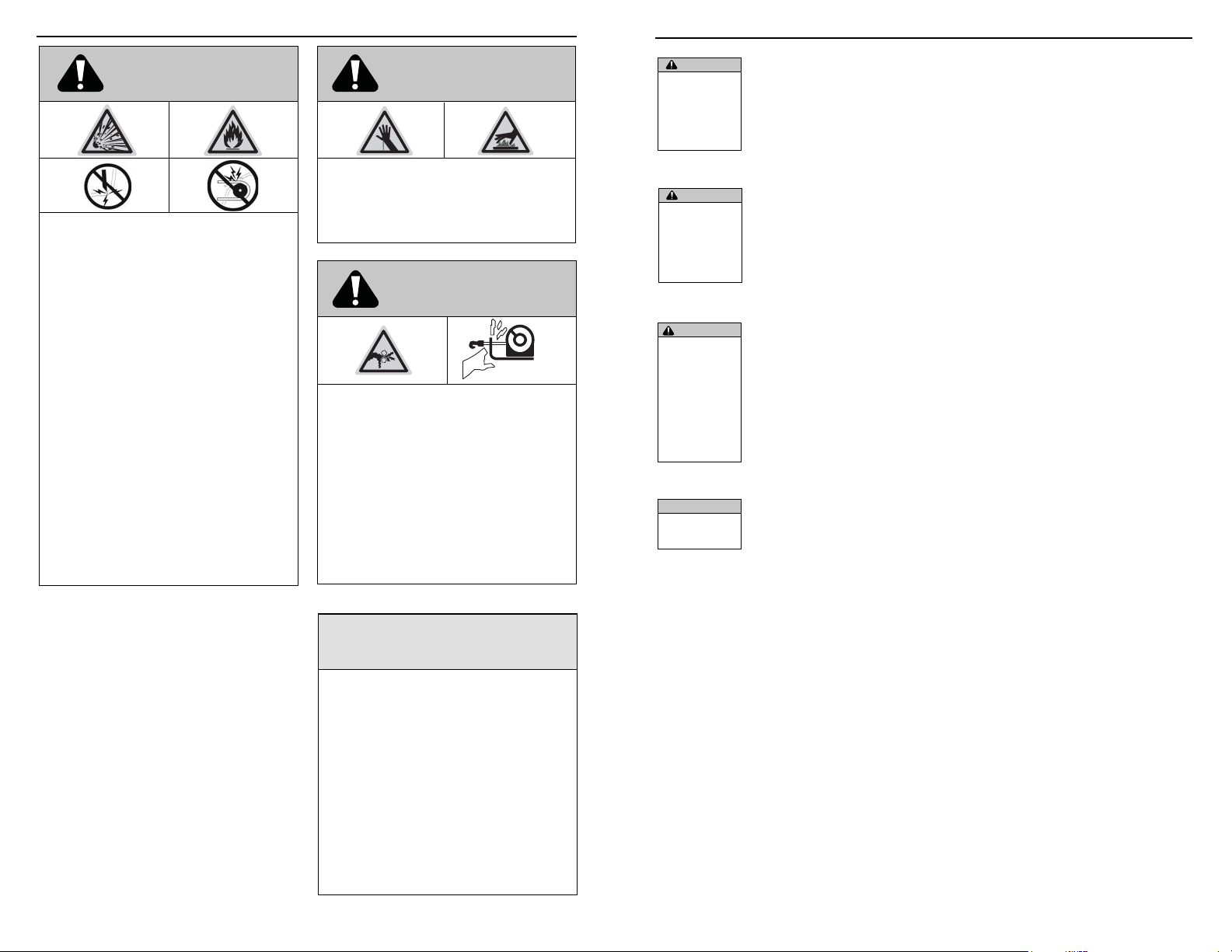

Mounting Bolt Pattern:

Standard: 10” x 4.5”, 254 mm x 114.3 mm

Plate Thickness Bolt Length

1/4” (7 mm) 1.25” (32 mm)

3/8” (10 mm) 1.5” (40 mm)

1/2” (13 mm) 1.5” (40 mm)

Mounting Details:

(1) Smooth and fl at, thickness = 1/4” (6.4 mm)

(2) 3/8” (9.525 mm) lockwasher X 4

(3) 3/8-16 X 1 1/4” long, grade 5 bolt X 4

Torque 30-35 ft. lbs. (41-47Nm)

WARNING

Always choose

a mounting

location that is

suffi ciently strong

to withstand the

maximum pulling

capacity of your

winch.

WARNING

Always complete

the winch

installation and

attach the hook

before installing

the wiring.

WARNING

Never use bolts

that are too long.

COOLING FAN MOUNTING

The fan must be correctly

installed to provide the best

performance. The fan should be

mounted in a location that is as

clean, dry, and cool as possible.

The mounting location must also

provide clearance for the fan’s

control cable as well as the outlet

hose. When mounting the fan,

insure that the inlet is unobstructed

and higher than the winch. Also

insure that the winch exhaust outlet

is not near the fan inlet.

Best locations for the fan will

vary depending on the vehicle.

Typical location include: near

air intake box and inner fender

inside engine compartment.

Avoid mounting fan near exhaust

manifold, turbocharger, or radiator.

Maximum operating temperature is

175°F (80°C). Avoid sharp edges

when routing fan control cable and

hose.

If your vehicle is used in

extremely dusty conditions you can

choose to equip the winch cooling

fan with a high performance

fi lter. Filter part number RC-0790

available from K&N Filters is

recommended for this application.

The fi lter can be installed directly to

the fan inlet.

Mounting Steps

1. Determine the fan mounting

location.

2. Mount fan on a fl at surface,

mark and drill mounting holes.

3. Loosely attach the fan using

WARN supplied 1/4-inch bolts,

lock nuts, and washers or sheet

metal screws.

4. Tighten fasteners.

5. Attach hose to fan outlet.

6. Route fan outlet hose to winch

and tie down with tie wraps. Cut

off excess hose.

7. Thread plastic fi ttings into winch

motor end cap. Tighten and align

fi tting with hose.

8. Connect the fan outlet hose to

the plastic fi tting positioned

above the “W” on the motor end

cap.

9. Route fan control cable along

fan outlet tubing and attach with

tie wraps.

10. Connect fan control cable to

plug behind and below winch

control pack.

11. Connect the remaining hose to

the plastic fi tting positioned

below the “W” on the motor end

cap.

12. Route winch exhaust hose and

tie down with tie wraps. Cut off

excess hose.

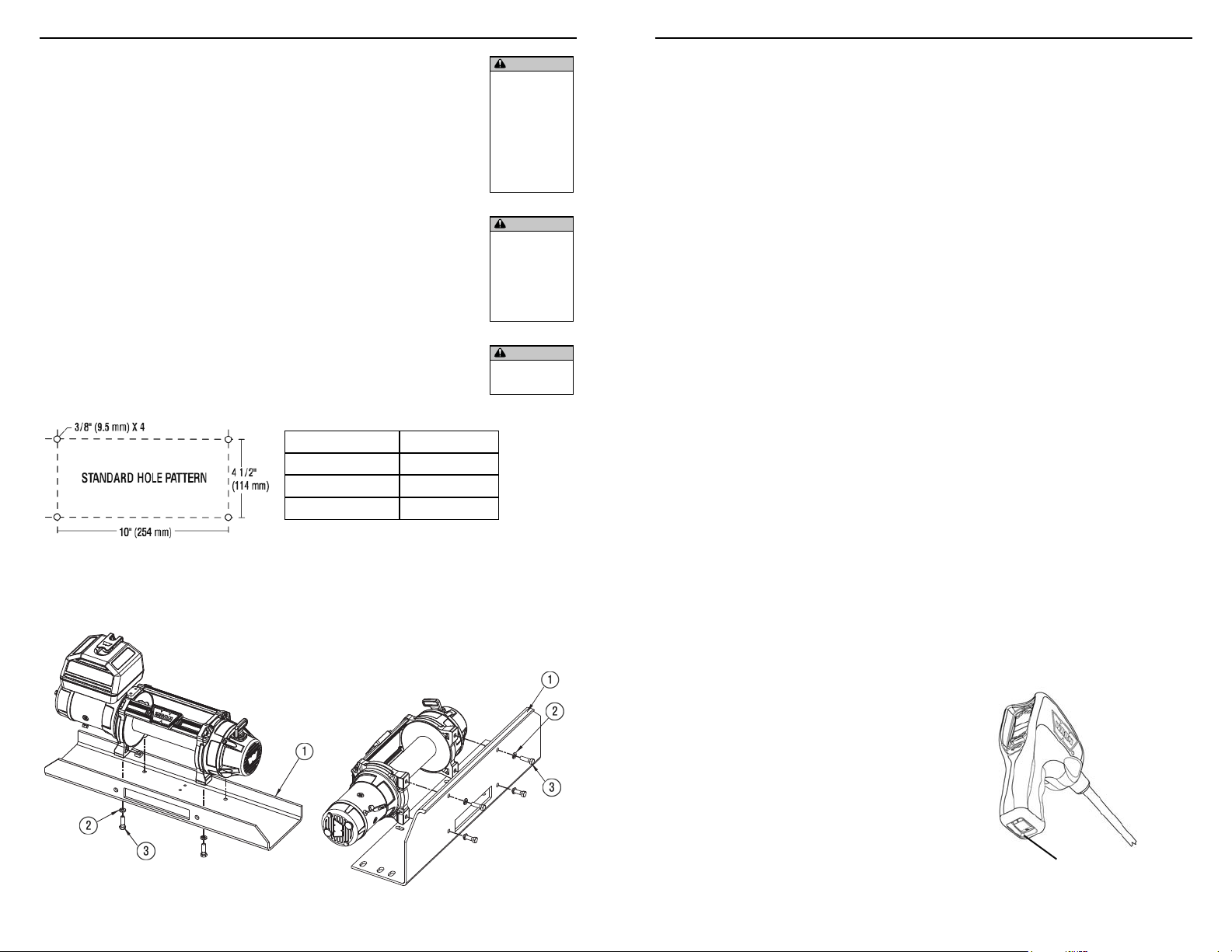

Cooling Fan

The cooling fan is used

to cool the winch motor. A

thermostat inside the winch motor

automatically controls the fan

and turns it on and off according

to the winch motor temperature.

The fan will not run until the winch

motor reaches a predetermined

temperature.

There is also a fan override

switch in the remote handle that

can be used to operate the fan.

When properly connected the

fan delivers cooling air that fl ows

through the inlet hose to the winch

motor. Hot air from the winch motor

is exhausted through the outlet

hose.

See the Cooling Fan Mounting

Instructions for proper fan, hose,

and control cable installation.

Fan Override Switch

WARN INDUSTRIES * WINCH

7

WARN INDUSTRIES * WINCH

8

Page 7

ELECTRICAL CONNECTIONS

OPERATING INSTRUCTIONS

ELECTRICAL CONNECTIONS

Use the included insulating

boots on exposed connections to

prevent electrical shorting. Route

battery connection cables in areas

which will not cause them to

chafe or cut through the insulation

causing a potential short circuit.

Upon completion of

installation, check winch for proper

operation.

Electrical Diagrams:

F1

A

F2

Blue

Black

Battery Recommendations

A fully charged battery and

good connections are essential

to the proper operation of your

winch. The minimum requirement

for a 12 volt DC battery is 650 Cold

Cranking Amps.

Pin # Color

1 Brown

2 White

3 Black

4 Green

5 Blue

6 Red

1

2

3

6

5

4

Black

Red

Green

Brown

White

WARN INDUSTRIES * WINCH

9

WARNING

Never route

electrical cables

across sharp

edges.

WARNING

Never route

electrical cables

near parts that

get hot.

WARNING

Never route

electrical cables

through or near

moving parts.

WARNING

Always place

the supplied

terminal boots

on wires and

terminals as

directed by

the installation

instructions.

WARNING

Always insulate

and protect all

exposed wiring

and electrical

terminals.

WARNING

Always

take time to

fully understand

your winch and

the winching

operation by

reviewing The

Basic Guide

to Winching

Techniques

included with

your winch.

WARNING

Never engage or

disengage clutch

if winch is under

load, winch rope

is in tension or

drum is moving.

WARNING

Never operate

winch with less

than 5 wraps

of rope around

the drum. Rope

could come

loose from the

drum, as the

rope attachment

to the drum is

not designed to

hold a load.

NOTICE

Do Not powerout rope more

than 30 ft.

without allowing

the winch to cool

for 20 minutes

before powering

rope back in.

Instead, place

the clutch in

freespool and

pull the rope off

by hand.

Remote Control Switch

Do not leave the remote

plugged into the winch when not in

use. Leaving the remote plugged

in, may result in a dangerous

condition and/or battery drain.

Vertical/Horizontal Remote:

Clutch Operation

When the clutch is engaged,

the gear train is coupled to the

wire rope drum and power can be

transferred from the winch motor.

When the clutch is disengaged it

is in the freespool position and the

gear train and wire rope drum are

uncoupled allowing the drum to

rotate freely.

The clutch lever, located on

the winch housing opposite the

motor, controls the clutch position.

To prevent damage, always fully

engage or fully disengage the clutch

lever.

Disengaged:

Engaged:

WARN INDUSTRIES * WINCH

10

Spooling Out

Freespooling is generally the

quickest and easiest way to spool

out wire rope. Before freespooling

wire rope out from the winch,

power out enough rope to remove

any tension the wire rope might be

under. Disengage the clutch. Then

freespool by manually spooling out

enough wire rope for the winching

operation. See The Basic Guide

to Winching Techniques for more

information.

Always leave at least 5 wraps

of rope on the drum.

Spooling In Under Load

Never exceed winch’s rated

line pull.

Power-in the wire rope evenly

and tightly on the drum. This

prevents the outer wire wraps

from sinking into the inner wraps,

binding, and damaging the wire

rope.

Avoid shock loads when

spooling, by pulsing the control

switch to take up wire rope slack.

Shock loads can momentarily far

exceed the winch and rope ratings.

Spooling In Under No Load

Spooling with an Assistant: Have

the assistant hold the hook strap

putting as much constant tension

on the wire rope as possible. While

keeping tension, the assistant

should walk toward the winch while

you operate the control switch

spooling in the wire rope. Release

the switch when the hook is a

minimum of 6 ft. (2 m) from the

fairlead opening.

Spool in the remainder for

storage as directed below.

Spooling Alone: Arrange the wire

rope to be spooled so it will not

kink or tangle when spooled. Be

sure any wire rope on the drum is

tightly and evenly layered. Spool

enough wire rope to complete the

next full layer on the drum.

Tighten and straighten the layer.

Page 8

OPERATING INSTRUCTIONS & STRETCHING WIRE ROPE

STRETCHING WIRE ROPE

OPERATING INSTRUCTIONS

Cont.

Repeat process until the hook is a

minimum of 6 ft. (2 m) from the

fairlead opening.

Spool in the remainder for

storage as directed below.

Spooling Remainder for Storage

When the hook is within 6 ft. (2 m)

of the fairlead, disconnect the hook

from the anchor or load. Hold onto

the supplied hook strap and hold

tension on the winch rope. Slowly

power-in the winch by “pulsing”

the power-in switch on the remote

control until the hook is within

3 ft. (1 m) of the fairlead. Stop

winching in and attach the hook

to a suitable anchor point on the

vehicle.

DO NOT POWER THE

HOOK INTO THE FAIRLEAD.

This could cause damage to the

fairlead. Once the hook is suitably

attached to the vehicle, power-in

the remaining slack in the winch

rope by “pulsing” the power-in

switch on the remote control until

there is minimal slack in the winch

wire rope.

Overloading/Overheating

This winch is rated for

intermittent duty. When the motor

approaches stall speed, very rapid

heat buildup occurs which may

cause motor damage.

Double-line rigging (see

The Basic Guide to Winching

Techniques) will reduce the

amperage draw, and reduce heat

buildup in the motor. This allows

longer continual use.

STRETCHING WIRE ROPE

The life of a wire rope is

directly related to the use and care

it receives. During its fi rst use, a

new wire rope must be spooled

onto its drum under a load of at

least 1000 lbs. (454 kgs). Use the

following instructions to properly

stretch the wire rope onto the

winch drum.

1) Choose a FLAT AND LEVEL

location that is large enough to run

out the entire length of wire rope.

2) Turn the clutch lever on the

winch to the “Free Spool” position.

Spool out the wire rope to the last

5 wraps on the drum. Once the

wire rope is spooled out, turn the

clutch lever on the winch to the

“Engaged” position.

3) Attach the hook end of the rope

to a suitable anchor point and back

the vehicle away from the anchor

point until there is very little slack in

the wire rope. Before getting out of

the vehicle, set the parking brake,

place the vehicle in gear or park

and turn the vehicle off.

4) Connect the remote control to

the winch. Standing approximately

8 ft. (2.44 m) away from the

winch, power-in the winch until

all of the slack is wound onto

the winch drum. Disconnect the

remote control from the winch.

Hold tension on the wire rope with

one hand; carefully push the wire

rope to the side of the drum the

wire rope is attached to so there

are no gaps between each coil

on the drum. Be sure to check

that the wire rope is winding off

of the bottom of the drum, not the

top, or the automatic load holding

brake will not function properly.

(If the wire rope is winding off the

top you have powered the winch

“out” instead of “in” on the remote

control).

WARNING

Always keep

hands clear

of winch rope,

hook loop, hook

and fairlead

opening during

installation,

operation, and

when spooling in

or out.

WARNING

Never touch

winch rope

or hook while

someone else

is at the control

switch or

during winching

operation.

WARNING

Always wear

heavy leather

gloves when

handling winch

rope.

WARNING

Always use

supplied hook

strap whenever

spooling winch

rope in or

out, during

installation or

operation to

avoid injury

to hands and

fi ngers.

WARNING

Always

prestretch rope

and respool

under load

before use.

Tightly wound

rope reduces

chances of

“binding”, which

can damage the

rope.

WARNING

Never touch

rope or hook

while someone

else is at the

control switch or

during winching

operation.

WARNING

Never operate

winch with less

than 5 wraps

of rope around

the drum. Rope

could come

loose from the

drum, as the

rope attachment

to the drum is

not designed to

hold a load.

STRETCHING WIRE ROPE Cont.

5) The following steps should be

done using two people for proper

safety. If you attempt to tension

your wire rope alone be sure to

always engage the parking brake,

place the transmission in gear

and turn the vehicle off every time

you exit the vehicle to inspect the

winch wire rope. Never exit the

vehicle with a load on the winch

wire rope. Tensioning the wire rope

is critical to ensure a long product

life. Tensioning the wire rope will

prevent outer layers of wire rope

from pinching and deforming the

inner layers.

6) Use care to evenly wrap each

layer to prevent damage to the

rope.

7) Pass the remote control through

the driver’s window for the driver

of the vehicle to operate. Instruct

your assistant to stand to the side

of the vehicle and away from the

winch wire rope. Your assistant

should signal you if the wire rope

is winding correctly by watching

it move across the fairlead as

the wire rope is powered in.

Start the vehicle and place the

transmission in neutral. Release

the parking brake while applying

moderate brake pedal pressure.

Press power-in on the remote

control switch. After winching in

for approximately 6 ft. (2 m), stop

winching. Slowly let up off of the

brake pedal and then apply the

parking brake. This will ensure that

there is no load on the winch rope.

Then place the transmission in

park or in gear and turn the vehicle

off. Exit the vehicle and inspect the

winch to make sure that the wire

rope is being evenly wound onto

the winch drum and not sinking

into the lower layer. If the wire rope

is sinking, power the wire rope

out and repeat this step from the

beginning with more brake pedal

pressure.

8) When you are convinced the

wire rope is winding onto the winch

drum properly, repeat step 6 until

the vehicle is within 6 ft. (2 m) of

the winch anchor. Once within 6 ft.

(2 m), slowly let up off of the brake

pedal and then apply the parking

brake. This will ensure that there

is no load on the winch wire rope.

Then place the transmission in

park or in gear and turn the vehicle

off. Exit the vehicle. Disconnect

the hook from the anchor. While

holding onto the supplied hook

strap, hold tension on the winch

rope and slowly power-in the winch

by “pulsing” the power-in switch on

the remote control until the hook

is within 3 ft. (1 m) of the fairlead.

Stop winching in and attach the

hook to a suitable anchor point on

the vehicle.

DO NOT POWER THE

HOOK INTO THE FAIRLEAD.

This could cause damage to the

fairlead. Once the hook is suitably

attached to the vehicle, power-in

the remaining slack in the winch

rope by “pulsing” the power-in

switch on the remote control until

there is minimal slack in the winch

wire rope.

WARN INDUSTRIES * WINCH

11

WARN INDUSTRIES * WINCH

12

Page 9

TRADUCTION DE LA NOTICE ORIGINALE

INDEX DES SYMBOLES

Treuil

Guide d'installation et manuel de

l'utilisateur

Chaque situation de treuillage peut potentiellement occasionner des blessures. Afi n

de minimiser ce risque, il est important de lire attentivement le présent guide ainsi que

le manuel de base des techniques de treuillage. Veillez à vous familiariser avec le

maniement du treuil avant de l'utiliser et à vous préoccuper avant tout de la sécurité.

Nous exposons dans ce guide de nombreuses règles de sécurité fondamentales pour

le maniement du treuil. Veuillez lire le manuel de base des techniques de treuillage

pour de plus amples informations concernant votre treuil et les techniques adéquates de

câblage. Ne pas oublier, comme chaque situation de treuillage est différente, le bon sens

et l'attachement constant aux principes de sécurité sont d'une importance primordiale.

TABLE DES MATIÈRES :

SÉCURITÉ

Index des symboles ................................................................................................... 14

Mesures générales de sécurité ............................................................................15-17

Conditions de travail sures ........................................................................................ 18

INSTRUCTIONS

Montage du treuil ....................................................................................................... 19

Montage du ventilateur de refroidissement ...............................................................20

Raccordements électriques ....................................................................................... 22

Instructions d'utilisation ........................................................................................22-23

Étirement initial du câble .....................................................................................23-24

Warn Industries Inc.

12900 SE Capps Road

Clackamas, OR 97015

États-Unis

SYMBOLE EXPLICATION

Lire le manuel

d'utilisation

Toujours porter un

dispositif de protection

auditive et oculaire

Ne jamais utiliser le treuil

comme palan.

Positionner correctement

la charge dans la gorge

du crochet

Enrouler le câble sur le

dessous du tambour

Danger d'écrasement

des doigts dans le guidecâble

Risque de percement/

coupure des mains

Risque d'explosion/

rupture

Danger en raison d'une

arête tranchante

SYMBOLE EXPLICATION

Toujours porter des

gants de cuir

Ne pas déplacer des

personnes

Toujours utiliser la

sangle de crochet

fournie

Ne jamais appliquer la

charge sur l'extrémité ou

le loquet du crochet

Ne jamais enrouler le

câble sur le dessus du

tambour

Point de pincement du

guide-câble

Risque de surface

chaude

Risque d'incendie et de

brûlure

Danger lié à des pièces

mobiles

Service à la clientèle : (800) 543-WARN

WARN® et le logo WARN sont des marques déposées de Warn Industries Inc.

© 2011 Warn Industries Inc.

WARN INDUSTRIES * TREUIL

13

International : (503) 722-1200

(9276)

Télécopie : (503) 722-3000

www.warn.com

WARN INDUSTRIES * TREUIL

14

Page 10

MESURES GÉNÉRALES DE SÉCURITÉ

Avertissements et mises

en garde

AVERTISSEMENT

MESURES GÉNÉRALES DE SÉCURITÉ

AVERTISSEMENT

AVERTISSEMENT

Les directives suivantes comprennent des

indications intitulées AVERTISSEMENT, ATTENTION,

AVIS et REMARQUE. Chacune a un objectif bien

précis : AVERTISSEMENT présente des consignes de

sécurité soulignant un danger potentiel qui, s’il n'est

pas évité, peut entraîner des blessures graves ou la

mort. ATTENTION comprend des consignes de sécurité

signalant un danger potentiel qui, s'il n'est pas évité,

peut entraîner des blessures légères ou modérées.

ATTENTION sert aussi à signaler une utilisation

dangereuse. ATTENTION et AVER TISSEMENT

identifi ent un danger, indiquent comment l'éviter et

montrent ses conséquences possibles si on l'ignore.

AVIS présente des consignes visant à éviter les

dommages matériels. REMARQUE donne des

renseignements additionnels qui aident à accomplir une

procédure. TRAVAILLEZ PRUDEMMENT !

AVERTISSEMENT

DANGER DE HAPPEMENT PAR DES

PIÈCES MOBILES

Le non-respect des consignes peut entraîner

des blessures graves ou la mort.

• Toujours s'assurer que le loquet du crochet est

fermé et qu'il ne soutient aucune charge.

• Ne jamais appliquer la charge sur l'extrémité ou le

loquet du crochet. Appliquer la charge uniquement

au centre du crochet.

• Ne jamais utiliser un crochet dont l'ouverture de la

gorge a augmenté ou dont l'extrémité est courbée

ou tordue.

• Toujours utiliser un crochet muni d'un loquet.

• Toujours s'assurer que l'opérateur et les personnes

présentes sont conscients de la stabilité du véhicule

et/ou de la charge.

• Toujours garder le fi l de la télécommande et le

cordon d'alimentation à l'écart du tambour, du

câble et du câblage. S'assurer qu’il n’y a pas de

fi ssures, de points de pincement, de fi ls effi lochés

ou de connexions desserrées. Tous les composants

endommagés doivent être remplacés avant d'utiliser

le produit.

• Toujours faire passer la télécommande par la

fenêtre, si on l'utilise de l’intérieur d’un véhicule.

WARN INDUSTRIES * TREUIL

DANGER DE HAPPEMENT PAR DES

PIÈCES MOBILES

Le non-respect des consignes peut entraîner

des blessures graves ou la mort.

Consignes de sécurité générales :

• Il faut toujours avoir une bonne connaissance

du treuil. Prendre le temps de bien lire le manuel

d’utilisation, et/ou le manuel de base des techniques

de treuillage, afi n de comprendre le treuil et son

fonctionnement.

• Ne jamais excéder la capacité nominale du treuil

ou du câble d'acier. Un câblage double avec poulie

ouvrante permet de réduire la charge subie par le

treuil.

• Toujours porter des gants de cuir épais durant la

manipulation du câble du treuil.

• Ne jamais utiliser le treuil ou le câble du treuil

pour faire du remorquage. Cela peut endommager,

surcharger et casser le câble.

• Ne jamais se servir du treuil pour maintenir une

charge.

• Ne jamais faire fonctionner l'appareil sous l'effet de

drogues, de l'alcool ou de médicaments.

• Ne jamais laisser des personnes âgées de moins de

16 ans utiliser ce treuil.

Consignes de sécurité se rapportant à

l’installation :

• Toujours choisir une surface de montage

suffi samment résistante pour supporter la capacité

de traction maximale du treuil.

• Toujours utiliser un matériel de montage de

catégorie 8,8 ou supérieure.

• Ne jamais souder les boulons de montage.

• Toujours utiliser un matériel de montage, des

composants et des accessoires homologués par le

fabricant.

• Ne jamais utiliser des boulons trop longs.

• Toujours achever le montage du treuil et la fi xation

du crochet avant d'effectuer le câblage.

• Toujours garder les mains éloignées du câble

du treuil, de la boucle du crochet, du crochet et

de l'ouverture du guide-câble durant l'installation

et l’utilisation de l'appareil et l'enroulement ou le

déroulement du câble.

• Toujours positionner le guide-câble avec

l'avertissement visible sur le dessus.

• Toujours étirer au préalable le câble et l’enrouler

sous charge avant de l’utiliser. Un câble enroulé de

manière serrée réduit le risque qu'il coince et soit

endommagé.

15

DANGER DE HAPPEMENT PAR DES

PIÈCES MOBILES

Le non-respect des consignes peut entraîner

des blessures graves ou la mort.

Consignes de sécurité concernant le

treuillage :

• Toujours inspecter le câble du treuil, le crochet

et les élingues avant de faire fonctionner le treuil.

Tout câble de treuil effi loché, tordu ou endommagé

doit être remplacé immédiatement. Tous les

composants endommagés doivent être remplacés

avant d'utiliser le produit. Protéger toutes les

pièces contre le risque de dommages.

• Toujours s'assurer que tout objet ou obstacle

pouvant gêner la bonne utilisation du treuil est

écarté.

• Toujours s'assurer que le point d'ancrage choisi

peut supporter la charge et que la sangle ou la

chaîne ne glisse pas.

• Toujours utiliser la sangle de crochet fournie pour

enrouler ou dérouler le câble du treuil, durant

l'installation ou l'utilisation.

• Toujours exiger de l'opérateur et des personnes

présentes d’être attentifs au véhicule et à la charge.

• Toujours être conscient de la stabilité du véhicule

et de la charge durant le treuillage. Veiller à ce

que personne ne s'approche. Alerter toutes les

personnes alentour en cas d'instabilité.

• Toujours dérouler autant de câble que possible

avant de procéder au câblage. Utiliser une ligne

double ou choisir un point d’ancrage distant.

• Toujours prendre le temps d'utiliser des techniques

de câblage adaptées avant d'utiliser le treuil pour

tirer.

• Ne jamais toucher le câble du treuil ou le crochet

lorsqu'une autre personne est à l'interrupteur de

commande ou durant le fonctionnement du treuil.

• Ne jamais essayer d'embrayer ou de débrayer si

le treuil est sous charge, si le câble du treuil est en

tension ou si le tambour est en train de tourner.

• Ne jamais toucher le câble ou le crochet lorsque le

câble est tendu ou sous charge.

• Toujours se tenir à l'écart du câble du treuil et de

la charge durant l'utilisation et ne jamais laisser

personne s'approcher.

• Ne jamais se servir d'un véhicule pour tirer une

charge sur le câble du treuil. La charge combinée

ou un choc peut endommager, surcharger et casser

le câble.

• Ne jamais replier le câble du treuil sur lui-même.

Utiliser toujours une chaîne ou une protection de

tronc d'arbre sur le point d'ancrage.

WARN INDUSTRIES * TREUIL

DANGER DE CHUTE OU

D'ÉCRASEMENT

Le non-respect des consignes peut entraîner

des blessures graves ou la mort.

• Toujours rester à l'écart, en gardant les mains et les

autres personnes à l'écart également.

• Ne jamais utiliser le treuil avec moins de 5 spires de

câble enroulées autour du tambour. Le câble pourrait

se dérouler du tambour, étant donné que l'ancrage du

câble n'est pas conçu pour retenir une charge.

• Ne jamais utiliser le treuil comme palan ou pour

suspendre une charge.

• Toujours s'assurer que le point d'ancrage peut

supporter la charge, et prendre le temps d'employer

des techniques de câblage appropriées.

• Ne jamais utiliser le treuil pour soulever ou

transporter des personnes.

• Ne jamais forcer trop fort pour dérouler le câble du

treuil.

• Toujours utiliser une posture/technique de

levage adéquate ou demander de l'aide lors de la

manipulation ou de l'installation du produit.

• Toujours enrouler le câble sur le tambour dans le

sens spécifi é par l’étiquette d'avertissement apposée

sur le treuil ou la documentation du treuil. Cela est

nécessaire pour que le frein automatique (le cas

échéant) fonctionne correctement.

• Toujours enrouler le câble du treuil sur le tambour

comme indiqué par l’autocollant de rotation du

tambour.

AVERTISSEMENT

RISQUE DE COUPURE ET DE BRÛLURE

Le non-respect des consignes peut entraîner

des blessures graves ou la mort.

Pour éviter de se blesser les mains et les doigts :

• Toujours porter des gants de cuir épais durant la

manipulation du câble du treuil.

• Toujours penser aux surfaces chaudes au niveau

du moteur du treuil, du tambour ou du câble durant

ou après l'utilisation du treuil.

16

Page 11

MESURES GÉNÉRALES DE SÉCURITÉ

CONDITIONS DE TRAVAIL SURES

AVERTISSEMENT

RISQUES ASSOCIÉS AUX

PRODUITS CHIMIQUES ET RISQUE

D'INCENDIE

Le non-respect des consignes peut

entraîner des blessures graves ou la mort.

• Toujours retirer les bijoux et porter des lunettes

de sécurité.

• Ne jamais faire passer les câbles électriques pardessus des bords tranchants.

• Ne jamais faire passer les câbles électriques à

proximité de pièces qui s'échauffent.

• Ne jamais faire passer les câbles électriques à

travers des pièces mobiles ou à proximité.

• Toujours placer les capuchons fournis sur les

fi ls et les bornes, conformément aux instructions

d'installation.

• Ne jamais se pencher au-dessus de la batterie en

procédant aux connexions.

• Ne jamais faire passer les câbles électriques pardessus les bornes de la batterie.

• Ne jamais court-circuiter les bornes de la batterie

avec des objets métalliques.

• Toujours s'assurer que la zone ne contient pas de

conduites de carburant, de réservoir de carburant,

de conduites de frein, de câblage électrique, etc.,

avant tout perçage.

• Toujours consulter le manuel de l'utilisateur pour

les informations correctes de câblage.

• Toujours isoler et protéger tous les fi ls et bornes

électriques exposés.

WARN INDUSTRIES * TREUIL

ATTENTION

RISQUE DE COUPURE ET DE

BRÛLURE

Le non-respect des instructions peut entraîner

des blessures mineures ou modérées.

• Ne jamais laisser le câble du treuil glisser dans les

mains.

ATTENTION

DANGER DE HAPPEMENT PAR DES

PIÈCES MOBILES

Le non-respect des instructions peut entraîner

des blessures mineures ou modérées.

Pour éviter de se blesser les mains ou les doigts :

• Ne jamais laisser la télécommande dans un

emplacement où elle peut être activée durant la mise

en roue libre, le câblage ou quand le treuil n'est pas

utilisé.

• Ne jamais laisser la télécommande du treuil

branchée durant l'installation, le déroulement en

roue libre, le câblage, l'entretien ou quand le treuil

n'est pas utilisé.

AVIS

Éviter d'endommager le TREUIL et

l'équipement

• Toujours éviter de tirer sur le côté, ce qui a pour

effet d'empiler le câble du treuil sur l'une des

extrémités du tambour. Cela peut endommager le

câble ou le treuil.

• Toujours s'assurer d'avoir complètement embrayé

ou complètement débrayé.

• Toujours faire attention à ne pas endommager le

cadre du véhicule si l'on décide de s'arrimer à un

véhicule pour pouvoir travailler avec le treuil.

• Ne jamais submerger le treuil dans l'eau.

• Toujours ranger la télécommande dans un endroit

sûr, propre et sec.

17

AVERTISSEMENT

Toujours rester

à l'écart, en

gardant les

mains et les

autres personnes

à l'écart

également.

AVERTISSEMENT

Toujours exiger

de l'opérateur et

des personnes

présentes d’être

attentifs au

véhicule et à la

charge.

ATTENTION

Ne jamais

laisser la

télécommande

dans un

emplacement

où elle peut être

activée durant

la mise en roue

libre, le câblage

ou quand le treuil

n'est pas utilisé.

AVIS

Ne jamais

submerger le

treuil dans l'eau.

CONDITIONS DE TRAVAIL

SURES

Pendant la traction d'une

charge, l'opérateur doit toujours

faire fonctionner le treuil en se

tenant en position sûre. Les

emplacements sûrs sont : (1)

perpendiculaires au câble, (2) à

l'intérieur du véhicule avec le capot

relevé (si le treuil est monté à

l'avant du véhicule). Ces endroits

sûrs permettront d'empêcher que

le câble ne frappe l'opérateur en

cas de rupture sous charge.

Autant que possible, utiliser

le treuil avec le câble de la

télécommande complètement

déployé. Celui-ci doit toujours

demeurer à une distance minimale

de 2,44 m du treuil pendant

son fonctionnement. Cela évite

d'être happé par le guide-câble

et maintient l'opérateur dans une

zone de sécurité durant la traction

de la charge.

Ne jamais travailler à

proximité d'un câble sous charge.

Niveau de bruit

Ce treuil est conçu de

manière à ce que le niveau

de bruit émis ne dépasse pas

70 dBa à l’endroit où se trouve

le manipulateur. Celui-ci doit

demeurer à une distance minimale

de 2,44 m du treuil pendant son

fonctionnement. Faire inspecter

le treuil dans un centre de service

agréé si le bruit dépasse 70 dBa

au niveau de l’opérateur.

WARN INDUSTRIES * WINCH

18

Nettoyage

Ne pas diriger un jet d’eau

haute pression (laveuses haute

pression, lave-auto, etc.) entre le

support et le rebord du tambour ou

le levier d’embrayage.

Nettoyer le treuil à l’aide

d’eau sous faible pression et d’une

éponge ou d’un chiffon savonneux.

Ne pas utiliser de produits

chimiques qui pourraient

endommager la fi nition.

Nettoyer soigneusement les

résidus de sel du treuil le plus vite

possible afi n de minimiser l'effet de

corrosion.

Maintenance

Le treuil ne nécessite aucune

lubrifi cation pendant sa durée de

vie, sauf s’il a été immergé dans

l’eau. Si cela se produit, faire

réaliser une inspection complète

par un centre de service dès que

possible pour éviter tout dommage

dû à la corrosion. Si le coffret de

commande est immergé, il doit

être remplacé au moment de

l’intervention de service sur le

treuil.

Vérifi er les câbles de batterie

et les connexions électriques tous

les 90 jours pour s’assurer qu’ils

sont propres et correctement

serrés à tous les points de

connexion.

Inspecter le câble avant et

après chaque utilisation du treuil.

S’il est endommagé, le remplacer

par un câble de calibre conforme à

la liste des pièces de rechange, ou

se rendre sur le site Internet Warn

à l'adresse www.warn.com.

Le câble doit toujours

s’enrouler sur le tambour dans

le sens indiqué par l’étiquette de

rotation du tambour apposée sur

le treuil.

Page 12

MONTAGE DU TREUIL

MONTAGE DU VENTILATEUR DE REFROIDISSEMENT

MONTAGE DU TREUIL

Choisir une surface de

montage suffi samment résistante

Se reporter aux schémas

suivants pour l’orientation de

montage correcte.

pour supporter les charges

qui seront halées. Seules les

orientations de montage indiquées

sont recommandées pour utiliser le

treuil en toute sécurité. Toute autre

orientation du treuil est inadaptée

et ne doit pas être utilisée. Utiliser

les boulons et les rondelles d’arrêt

recommandés, ainsi que les

couples de serrage recommandés

pour éviter les vibrations du treuil

pendant son fonctionnement. Les

détails de montage indiquent les

Installation du coffret de

commande

Monter le coffret de

commande suivant les instructions

jointes au kit de système de

montage Warn. Utiliser la console

comprise dans le kit.

Pour plus de fl exibilité dans

le montage, on peut aussi déplacer

les fi xations de montage du coffret

de commande aux trous inutilisés

de la plaque de base du coffret.

valeurs de couple adéquates.

N'oubliez pas que le câble du

treuil doit toujours s’enrouler sur le

tambour dans le sens indiqué par

l’étiquette de rotation du tambour.

Entraxe de fi xation :

Standard : 254 mm x 114,3 mm

9,5 mm (quantité = 4)

TROUS STANDARD

114 mm

(4 ½ inch)

Épaisseur de

plaque

1/4” (7 mm) 1,25” (32 mm)

3/8” (10 mm) 1,5” (40 mm)

10” (254 mm)

1/2” (13 mm) 1,5” (40 mm)

Détails de montage :

(1) Lisse et plat, épaisseur = 1/4” (6,4 mm)

(2) Rondelle d'arrêt 3/8” (9,525 mm) X 4

(3) Boulon catégorie 5 3/8-16 X 1 1/4” de long X 4

Couple de serrage 41 à 47 Nm)

WARN INDUSTRIES * TREUIL

19

Longueur de

boulon

AVERTISSEMENT

Toujours choisir

une surface

de montage

suffi samment

résistante pour

supporter la

capacité de

traction maximale

du treuil.

AVERTISSEMENT

Toujours achever

le montage du

treuil et fi xer le

crochet avant

d'effectuer le

câblage.

AVERTISSEMENT

Ne jamais utiliser

des boulons trop

longs.

MONTAGE DU VENTILATEUR DE

REFROIDISSEMENT

Le ventilateur doit être

correctement installé pour

fonctionner de façon optimale. Le

ventilateur doit être monté dans un

emplacement aussi propre, sec et

frais que possible. L’emplacement

de montage doit assurer un

dégagement suffi sant pour le câble

de commande du ventilateur ainsi

que le tuyau de sortie. Lors du

montage du ventilateur, s’assurer que

l’arrivée n’est pas obstruée et qu’elle

est située plus haut que le treuil.

S’assurer également que la sortie

d’échappement du treuil ne se trouve

pas près de l’entrée du ventilateur.

L’emplacement idéal pour le

ventilateur varie selon le véhicule.

L’installation se fait généralement

aux emplacements suivants :

près de la boîte de prise d’air et

de l’aile intérieure à l’intérieur du

compartiment du moteur. Éviter

de monter le ventilateur près du

collecteur d’échappement, du

turbocompresseur ou du radiateur.

La température maximale de

fonctionnement est de 80 ºC.

Éviter les bords coupants lors

de l’acheminement du câble de

commande du ventilateur et du tuyau.

Si le véhicule est utilisé

dans des conditions extrêmement

poussiéreuses, on peut équiper le

ventilateur de refroidissement du

treuil d’un fi ltre haute performance.

Le fi ltre numéro RC-0790 disponible

auprès de K&N Filters est

recommandé pour cette application.

Le fi ltre peut être installé directement

à l’entrée du ventilateur.

Étapes de montage

1. Déterminer l’emplacement de

montage du ventilateur.

2. Installer le ventilateur sur une

surface plane, puis marquer et percer

les trous de montage.

3. Fixer sans serrer le ventilateur à

l’aide de boulons 1/4 po, d’écrous de

blocage, de rondelles ou de vis à tôle

fournis par WARN.

4. Serrer les fi xations.

5. Fixer le tuyau à la sortie du

ventilateur.

6. Acheminer le tuyau de sortie du

ventilateur au treuil et le fi xer au

moyen d’attaches autobloquantes.

Couper la partie excédentaire du

tuyau.

7. Enfi ler les raccords en plastique

WARN INDUSTRIES * WINCH

20

dans le couvercle d’extrémité du

moteur du treuil. Serrer et aligner le

raccord avec le tuyau.

8. Connecter le tuyau de sortie du

ventilateur au raccord en plastique

positionné au-dessus du « W » sur le

couvercle d’extrémité du moteur.

9. Acheminer le câble de commande

du ventilateur le long du tube de

sortie du ventilateur et le fi xer à l’aide

d’attaches autobloquantes.

10. Connecter le câble de commande

du ventilateur à la prise située

derrière et en dessous du coffret de

commande du treuil.

11. Connecter le tuyau restant au

raccord en plastique positionné en

dessous du « W » sur le couvercle

d’extrémité du moteur.

12. Acheminer le tuyau

d’échappement du treuil et le fi xer au

moyen d’attaches autobloquantes.

Couper la partie excédentaire du

tuyau.

Ventilateur de refroidissement

Le ventilateur de

refroidissement sert à refroidir le

moteur du treuil. Un thermostat à

l’intérieur du moteur du treuil contrôle

automatiquement le ventilateur et

l’allume et l’éteint en fonction de la

température du moteur du treuil.

Tant que la température du moteur

du treuil n’atteint pas un niveau

prédéterminé, le ventilateur ne se

met pas en marche.

La télécommande comporte

aussi un interrupteur prioritaire

qui permet de faire fonctionner le

ventilateur. Lorsqu’il est correctement

connecté, le ventilateur envoie de

l’air de refroidissement à travers

le tuyau d’arrivée vers le moteur

du treuil. L’air chaud provenant du

moteur du treuil est évacué par le

tuyau de sortie.

Consulter les Instructions

de montage du ventilateur de

refroidissement pour savoir comment

installer correctement le ventilateur,

les tuyaux et le câble de commande.

ÉVENTER TERMINÉ

INTERVERTIR

Page 13

RACCORDEMENTS ÉLECTRIQUES

INSTRUCTIONS D’UTILISATION

RACCORDEMENTS

ELECTRIQUES

Utiliser des capuchons

d’isolation inclus sur les

connexions exposées pour éviter

les courts-circuits. Les fi ls de

batterie doivent passer par des

endroits qui ne risquent pas

d'endommager ou de percer

l’isolation et de créer des risques

de court-circuit.

Une fois l’installation

terminée, vérifi er que le treuil

fonctionne correctement.

Schémas électriques :

F1

A

F2

Black

Noir

Recommandations concernant

la batterie

La charge de la batterie et

la qualité des connexions sont

essentielles pour que le treuil

fonctionne correctement. La

capacité de démarrage à froid

minimum requise pour une batterie

de 12 V c.c. est de 650 A.

Broche n° Couleur

1 Marron

2 Blanc

3 Noir

4 Vert

5 Bleu

6 Rouge

Bleu

Blue

2

3

Noir

Black

Red

Rouge

Green

Vert

Brown

Marrion

White

Blanc

WARN INDUSTRIES * TREUIL

21

AVERTISSEMENT

Ne jamais faire

passer les câbles

électriques pardessus des bords

tranchants.

AVERTISSEMENT

Ne jamais faire

passer les câbles

électriques

à proximité

de pièces qui

s'échauffent.

AVERTISSEMENT

Ne jamais faire

passer les câbles

électriques à

travers des

pièces mobiles

ou à proximité.

AVERTISSEMENT

Toujours placer

1

6

5

4

les capuchons

fournis sur les

fi ls et les bornes,

conformément

aux instructions

d'installation.

AVERTISSEMENT

Toujours isoler

et protéger tous

les fi ls et bornes

électriques

exposés.

AVERTISSEMENT

Toujours

prendre le temps

de bien se

familiariser avec

le treuil et son

fonctionnement

en examinant le

Manuel de base

des techniques

de treuillage

inclus avec le

treuil.

AVERTISSEMENT

Ne jamais

essayer

d'embrayer ou

de débrayer si

le treuil est sous

charge, si le câble

du treuil est en

tension ou si le

tambour est en

train de tourner.

AVERTISSEMENT

Ne jamais

utiliser le treuil

avec moins de 5

spires de câble

enroulées autour

du tambour Le

câble pourrait

se dérouler

du tambour,

étant donné

que l'ancrage

du câble n'est

pas conçu pour

retenir une

charge.

AVIS

Ne pas dérouler

le câble de plus

de 9 m sans

laisser refroidir

le treuil pendant

20 minutes avant

de recommencer

l'enroulement.

Utiliser plutôt

l'embrayage en

déroulement libre

en tirant le câble

à la main.

Télécommande

Ne pas laisser la télécommande

branchée dans le treuil lorsque

celui-ci n’est pas en usage. Une

télécommande qui reste branchée

risque de créer des conditions

dangereuses et de vider la batterie.

Télécommande verticale/

horizontale :

Fonctionnement de l'embrayage

Lorsque l’embrayage est

en prise, le train d'engrenages

est couplé au tambour du câble

et l’entraînement peut alors être

transféré du moteur du treuil.

Lorsque l’embrayage est débrayé

et en position de déroulement en

roue libre, le train d’engrenages et

le tambour se désaccouplent, ce

qui permet au tambour de tourner

librement.

Le levier d’embrayage, situé sur

le carter du treuil en face du moteur,

permet de commander la position

de l’embrayage. Pour éviter tout

dommage, tourner complètement

le levier d'embrayage dans l'une ou

l'autre position.

Libéré :

En prise :

Déroulement du câble

Le déroulement en roue libre

constitue généralement la façon

WARN INDUSTRIES * TREUIL

22

la plus rapide et la plus facile de

dérouler le câble. Avant de mettre

le treuil en roue libre pour dérouler

le câble, dérouler au moteur une

quantité suffi sante de câble pour

soulager le câble de toute tension

éventuelle. Débrayer. On peut

maintenant dérouler manuellement

une quantité suffi sante de câble pour

pouvoir travailler avec le treuil. Voir

le manuel de base des techniques

de treuillage pour de plus amples

informations.

Toujours laisser au moins 5

spires de câble sur le tambour.

Enroulement sous charge

Ne jamais dépasser l’effort en

1ère couche du treuil.

Enrouler mécaniquement le

câble sur le tambour de manière

uniforme et serrée. Cela empêche les

spires extérieures de s’enfoncer dans

les spires intérieures, ce qui peut

coincer et endommager le câble.

Pour éviter les charges de

choc durant l’enroulement du

câble, actionner l’interrupteur de

commande de manière intermittente

afi n d'éliminer le mou du câble.

Les charges de choc peuvent

momentanément dépasser de loin la

capacité du treuil et du câble du treuil.

Enroulement à vide

Déroulement avec un assistant :

Demander à un assistant de tenir la

sangle de crochet en appliquant une

tension aussi constante que possible

sur le câble. Tout en maintenant

la tension, il devra se déplacer

en direction du treuil pendant

l'actionnement de l'interrupteur de

commande pour enrouler le câble.

Relâcher l’interrupteur lorsque le

crochet parvient à une distance

minimum de 2 m de l’ouverture du

guide-câble.

Enrouler le reste du câble pour

le ranger, de la manière indiquée

ci-dessous.

Déroulement tout seul : Arranger le

câble à enrouler de manière à ce qu’il

ne s’entortille ni ne s’emmêle pendant

le rembobinage. S’assurer que le

câble est enroulé sur le tambour de

manière uniforme et serrée. Enrouler

une quantité suffi sante de câble pour

compléter une couche entière sur le

tambour.

Serrer et étaler de manière égale la

couche de câble.

Page 14

INSTRUCTIONS D'UTILISATION ET ÉTIREMENT INITIAL DU CÂBLE

ÉTIREMENT INITIAL DU CÂBLE

INSTRUCTIONS D’UTILISATION

Suite

Refaire de même jusqu’à ce

que le crochet soit à une distance

minimum de 2 m de l’ouverture du

guide-câble.

Enrouler le reste du câble

pour le ranger, de la manière

indiquée ci-dessous.

Enroulement du reste du câble

pour le ranger

Lorsque le crochet se trouve

à moins de 2 m du guide-câble,

détacher le crochet du point

d'ancrage ou de la charge. En

tenant la sangle de crochet fournie,

maintenir la tension sur câble

du treuil. Enrouler lentement le

treuil en appliquant de petites

pressions sur la touche « Power

in » (enrouler) de la télécommande

jusqu'à ce que le crochet soit à

moins de 1 m du guide-câble.

Arrêter le treuillage et fi xer le

crochet sur un point d'ancrage

approprié sur le véhicule.

NE PAS LAISSER PAS

LE CROCHET ATTEINDRE LE

GUIDE-CÂBLE. Cela pourrait

endommager le guide-câble. Une

fois le crochet fi xé correctement

au véhicule, enrouler le câble de

façon à éliminer le mou restant en

appliquant de petites pressions sur

la touche « Power in » (enrouler)

de la télécommande jusqu'à ce que

le mou soit minime sur le câble du

treuil.

Surcharge/surchauffe

Ce treuil est conçu pour

un service intermittent. Lorsque

le moteur est sur le point de

caler, une accumulation rapide

de chaleur se produit et peut

endommager le moteur.

Le câblage double (voir le

manuel de base des techniques

de treuillage) permet de réduire

le débit en ampères et de réduire

ainsi l’accumulation de chaleur

dans le moteur. Cela permet une

utilisation continue prolongée.

enroulé sur son tambour sous

une charge d’au moins 454 kg .

ÉTIREMENT DU CÂBLE

La durée de vie d’un câble est

liée directement à son entretien

et à son utilisation. Lors de sa

première utilisation, un câble neuf

doit être

enroulé sur son tambour

sous une charge d’au moins 454 kg

.

Suivre simplement les directives

suivantes pour étirer correctement

le câble sur le tambour.

1) Choisir un emplacement PLAT

ET DE NIVEAU suffi samment

grand pour pouvoir dérouler le

câble sur toute sa longueur.

2) Mettre le levier d'embrayage du

treuil en position « Free Spool »

(déroulement en roue libre).

Dérouler le câble de façon à ne

laisser que 5 spires sur le tambour.

Une fois le câble déroulé, mettre

le levier d'embrayage du treuil en

position « Engaged » (en prise).

3) Fixer le crochet du câble à

un point d'ancrage approprié

et éloigner le véhicule du point

d'ancrage jusqu'à ce qu’il n’y ait

presque plus de mou dans le

câble. Avant de descendre du

véhicule, serrer le frein à main et

mettre le véhicule en prise ou en

position de stationnement, puis

couper le moteur.

4) Brancher la télécommande au

treuil. Se tenir à environ 2,44 m

du treuil et enrouler le câble sur le

tambour du treuil jusqu'à éliminer

complètement le mou du câble.

Déconnecter la télécommande

du treuil. Maintenir le câble

tendu d'une main ; pousser avec

précaution le câble d'acier vers le

côté du tambour auquel le câble

est fi xé de façon à ce qu'il n'y ait

pas d'espace entre les spires sur

le tambour. S'assurer que le câble

d'acier s'enroule sur le bas du

tambour et non sur le haut, sinon

le frein de retenue automatique

de la charge ne fonctionnera pas

correctement. (Si le câble d'acier

WARN INDUSTRIES * TREUIL

23

AVERTISSEMENT

Toujours garder

les mains

éloignées du

câble du treuil,

de la boucle

du crochet,

du crochet et

de l'ouverture

du guidecâble durant

l'installation et

l’utilisation de

l'appareil et

l'enroulement ou

le déroulement

du câble.

AVERTISSEMENT

Ne jamais

toucher le

câble du treuil

ou le crochet

lorsqu'une autre

personne est

à l'interrupteur

de commande

ou durant le

fonctionnement

du treuil.

AVERTISSEMENT

Toujours porter

des gants de cuir

épais durant la

manipulation du

câble du treuil.

AVERTISSEMENT

Toujours utiliser

le cordon du

crochet fourni

pour enrouler

ou dérouler le

câble, durant

l'installation ou

l’utilisation pour

éviter de se

blesser les mains

ou les doigts.

AVERTISSEMENT

Toujours étirer

au préalable

le câble et

l’enrouler sous

charge avant

de l’utiliser. Un

câble enroulé de

manière serrée

réduit le risque

qu'il coince et soit

endommagé.

AVERTISSEMENT

Ne jamais

toucher le câble

ou le crochet

lorsqu'une

autre personne

manipule

l'interrupteur

de commande

ou durant le

fonctionnement

du treuil.

AVERTISSEMENT

Ne jamais

utiliser le treuil

avec moins de 5

spires de câble

enroulées autour

du tambour Le

câble pourrait

se dérouler

du tambour,

étant donné

que l'ancrage

du câble n'est

pas conçu pour

retenir une

charge.

ÉTIREMENT DU CÂBLE (suite)

s'enroule sur le haut, cela signifi e

que l'on a actionné le treuil en

mode de déroulement et non

d'enroulement au moyen de la

télécommande).

5) Par mesure de sécurité, les

étapes suivantes devraient être

effectuées par deux personnes. Si

l'on tente de tendre le câble tout

seul, s'assurer de toujours mettre

le frein à main, la transmission

en prise et d'éteindre le moteur

du véhicule chaque fois que

l'on descend du véhicule pour

inspecter le câble du treuil. Ne

jamais quitter le véhicule alors

que le câble du treuil porte une

charge. Le tensionnement du

câble est essentiel pour assurer

une longue durée de vie au

produit. Le tensionnement du

câble empêchera les couches

extérieures du câble de pincer et

déformer les couches intérieures.

6) Prendre soin d'enrouler chaque

couche de manière uniforme afi n

d'éviter d'endommager le câble.

7) Faire passer la télécommande

par la fenêtre du conducteur

afi n de l’utiliser. Demander

à l’assistant de s'éloigner du

véhicule et du câble. L’assistant

doit indiquer si le câble s'enroule

correctement à mesure qu'il défi le

sur le guide-câble et s'enroule.

Démarrer le véhicule et mettre

la transmission au point mort.

Desserrer le frein à main tout

en appuyant modérément sur la

pédale de frein. Appuyer sur la

touche « Power in » (enrouler)

de la télécommande. Effectuer le

treuillage sur environ 2 m, puis

arrêter. Relâcher lentement la

pédale de frein, puis serrer le frein

à main. Cela permet d'assurer

qu'il n'y a aucune charge sur le

câble. Mettre le levier de vitesse

en position de stationnement ou

WARN INDUSTRIES * TREUIL

24

en prise, puis couper le moteur.

Descendre du véhicule et inspecter

le treuil pour s'assurer que le câble

est enroulé uniformément sur le

tambour du treuil et qu'il ne creuse

pas la couche inférieure. Si c'est

le cas, dérouler le câble et répéter

cette étape à partir du début en

appliquant davantage de pression

sur la pédale de frein.

8) Après s'être assuré que le

câble s'enroule correctement

sur le tambour, répéter l'étape

six jusqu'à ce que le véhicule

soit à moins de 2 m du point

d'ancrage. Une fois la distance

atteinte, relâcher lentement la

pédale de frein puis serrer le frein

à main. Cela permet d'assurer

qu'il n'y a aucune charge sur le

câble. Mettre le levier de vitesse

en position de stationnement ou

en prise, puis couper le moteur.

Descendre du véhicule. Décrocher

le crochet du point d'ancrage. Tout

en retenant le cordon du crochet

fourni, maintenir la tension sur

câble et enrouler lentement le

treuil par de petites pressions sur

l'interrupteur de commande jusqu'à

ce que le crochet soit à moins

de 1 m du guide-câble. Arrêter le

treuillage et fi xer le crochet sur un

point d'ancrage approprié sur le

véhicule.

NE PAS LAISSER PAS

LE CROCHET ATTEINDRE LE

GUIDE-CÂBLE. Cela pourrait

endommager le guide-câble. Une

fois le crochet fi xé correctement

au véhicule, enrouler le câble de

façon à éliminer le mou restant en

appliquant de petites pressions sur

la touche « Power in » (enrouler)

de la télécommande jusqu'à ce que

le mou soit minime sur le câble du

treuil.

Page 15

INSTRUCCIONES ORIGINALES

ÍNDICE DE SÍMBOLOS

Cabrestante

Guía de instalación y del usuario

En cada situación donde se utiliza un cabrestante existe la posibilidad de ocasionar

daños personales. Para reducir al mínimo ese riesgo, es importante que lea esta

guía y la Guía básica de técnicas para el uso del cabrestante atentamente. Por favor,

familiarícese con la operación del cabrestante antes de usarlo y tenga siempre presente

la seguridad. En esta guía se establecen muchas de las reglas de seguridad para el

uso del cabrestante. Lea la Guía básica de técnicas para el uso del cabrestante para

obtener más información sobre su cabrestante y técnicas de maniobrado adecuadas.

Recuerde que debido a que cada situación en la que se utiliza el cabrestante es

diferente, es muy importante el buen juicio y un enfoque constante en la seguridad.

ÍNDICE:

SEGURIDAD

Índice de símbolos .................................................................................................... 26

Precauciones generales de seguridad .................................................................27-29

Condiciones de trabajo seguras ................................................................................ 30

INSTRUCCIONES

Montaje de cabrestante ............................................................................................. 31

Montaje del ventilador ...............................................................................................32

Conexiones eléctricas ...............................................................................................33

Instrucciones de operación ..................................................................................34-35

Estiramiento del cable .........................................................................................35-36

SÍMBOLO EXPLICACIÓN

Lea el manual de

instrucciones

Lleve puesta siempre

protección ocular y

auditiva