Page 1

PAGE 1 99387 Rev. A0

WINCH USER GUIDE

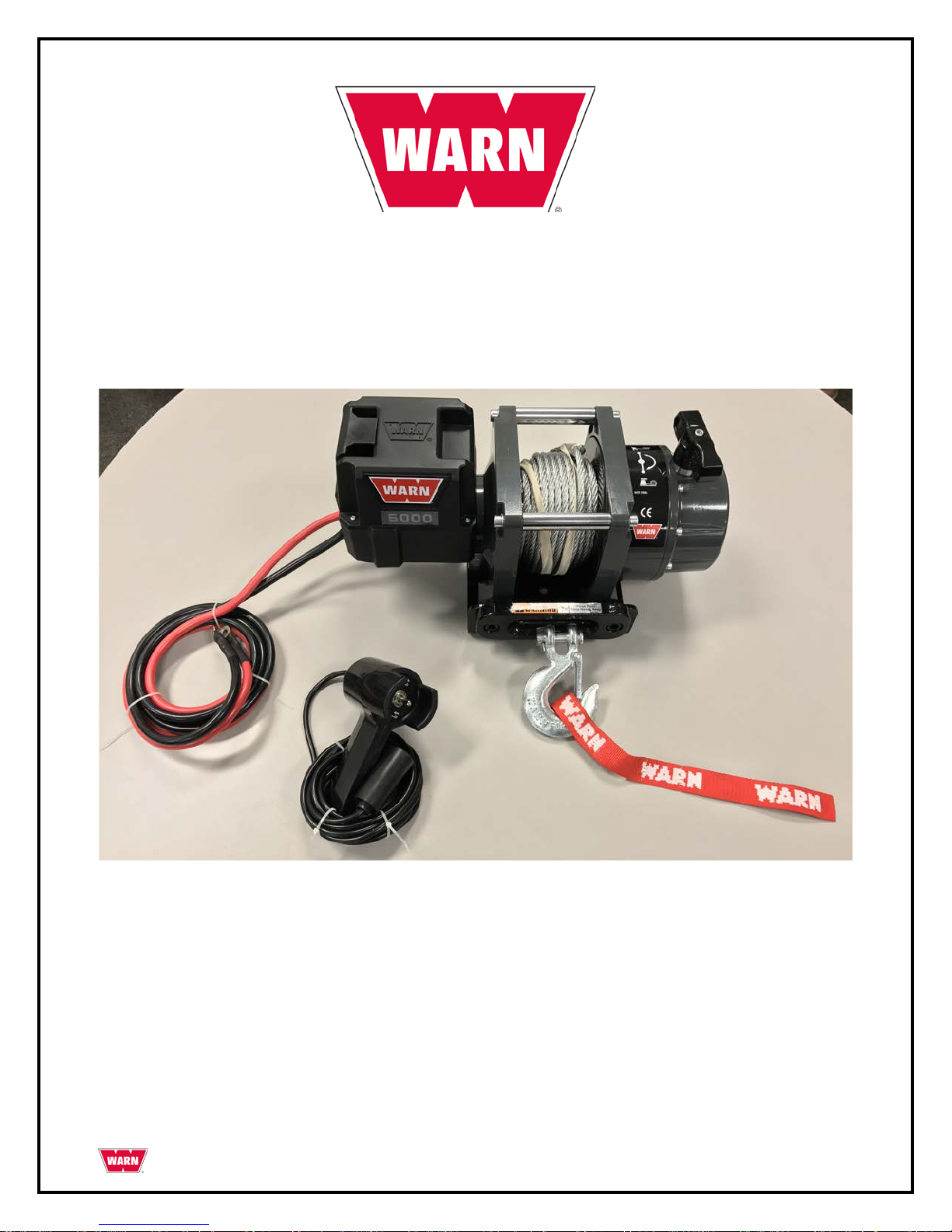

WARN® 5000 Utility Winch

Part Number: 99963, 99964

English ..................................................1

Spanish .............................................. 15

French ................................................ 29

Page 2

PAGE 2 99387 Rev. A0

Your safety, and the safety of others, is very important. To help you make informed decisions about safety, we have provided

installation and operating instructions and other information on labels and in this guide. This information alerts you to potential hazards

that could hurt you or others. It is not poss ible to warn you about all potential hazard s associated with this product, you must use your

own good judgment.

CARELESS WINCH INSTALLATION AND OPERATION CAN RESULT IN SERIOUS INJURY OR EQUIPMENT DAMAGE. READ

AND UNDERSTAND ALL SAFETY PRECAUTIONS AND OPERATING INSTRUCTIONS BEFORE INSTALLING AND OPERATING

THIS PRODUCT.

This guide identifies potential hazards and has important safety messages that help you and others avoid personal injury or death.

WARNING and CAUTION are signal words that identify the level of hazard. These signa l words mean:

WARNING signals a hazard that

could

cause serious injury or death, if you do not follow recommendations.

CAUTION signals a hazard that

may

cause minor to moderate injury, if you do not follow recommendations.

This guide uses

NOTICE

to call attention to important mechanical information, and Note: to emphasize general information worthy of

special attention

Product Description: WARN® 5000 Utility Winch

The WARN® 5000 Utility Winch is a powerful pulling tool. Powered by a 12 volt DC power source this

compact winch has a pulling capacity of 5000 pound / 2268 kilos.

The unit has a 12’ remote control for power in and power out operation, 60’ of 1/4” wire rope and clasp hook.

A freespooliong clutch is a standard option.

Introduction

Thank you for choosing WARN® for your utility winch needs. All WARN® products have been designed and

manufactured for many years of problem-free operation. For future reference please record the following

information:

Model/Part Number: Date of Purchase:

Before you begin

Read the instructions completely to familiarize yourself with the installation process.

Review all the notices, cautions and warnings to make sure the kit will be installed correctly and safely.

Page 3

PAGE 3 99387 Rev. A0

Safety Precautions

The following are general safety precautions that every winch operator should know. Taking precedence over

any specific rule listed here, however, is the most important rule of all—USE COMMON SENSE.

A few minutes spent reading these rules can make an operator aware of dangerous practices to avoid and

precautions to take for his own safety and the safety of others. Frequent examinations and periodic

inspections of the equipment as well as conscientious observance of safety rules may save lives as well as

time and money.

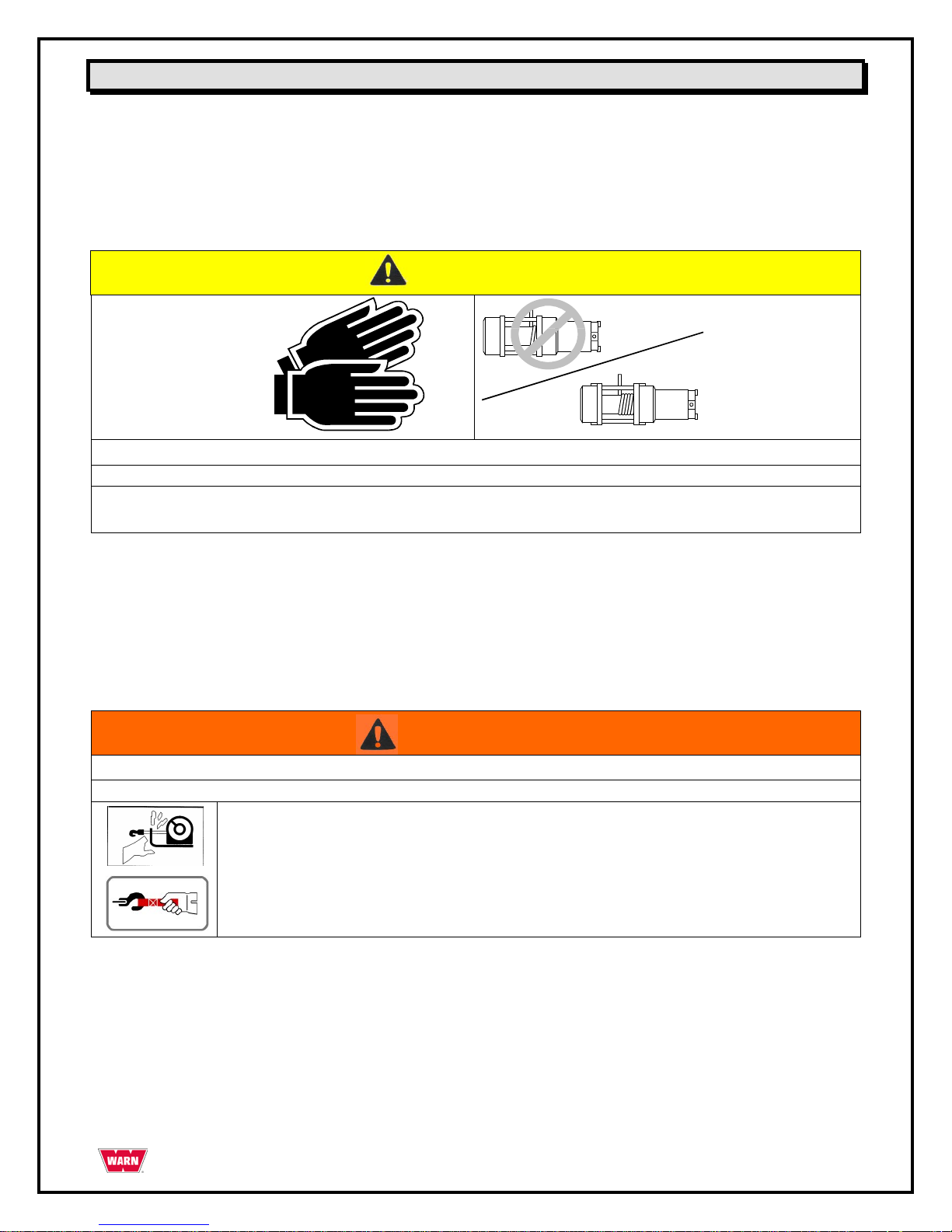

WARNING

MOVING PARTS ENTANGLEMENT HAZARD

Failure to observe these instructions could lead to severe injury or death.

To avoid injury to hands or fingers.

• Always keep hands clear of wire rope, hook loop, hook and fairlead opening during installation, operation and when

spooling in or out.

• Always use extreme caution when handling hook and wire rope during spooling operations.

• Always use supplied hook strap whenever spooling wire rope in or out, during installation or operation to avoid injury

to hands or fingers.

WARNING

FALLING OR CRUSHING HAZARD

Failure to observe these instructions could lead to severe injury or death.

• Never use as an overhead hoist, or to suspend a load.

• Never use to lift or move persons.

Page 4

PAGE 4 99387 Rev. A0

Safety Precautions - continued

CAUTION

MOVING PARTS ENTANGLEMENT HAZARD

Failure to observe these instructions could lead to minor to moderate injury.

General Safety:

• Always Know Your Winch: Take time to fully read and understand the included Installation and Operations guide,

and Basic Guide to Winching Techniques, in order to understand your winch and the winching op e r a ti on.

• Never operate this winch if you are under 16 years of age.

• Never operate this winch when unde r the influence of drugs, alcohol or med i ca ti on.

• Never exceed winch or wire rope rated capacity. Double line using a snatch block to reduce winch load.

Installation Safety:

• Always choose a mounting location that is sufficiently str ong to wit hs t a nd t he ma x i mum pulling capacity of your

winch.

• Always use factory approved switches, remote controls, accessories and installation components.

• Always use grade 5 or better hardware, never weld bolts and never use longer bolts than those supplied from

factory.

• Always complete winch mounting and attachment of hook to hook loop before wiring winch during installation.

• Always position fairlead with WARNING label on top.

• Always spool the wire rope onto the drum as indicated by the drum rotation label on the winch.

Required for automatic brake to work (if winch is so equipped) and for correct installation orientation.

• Always prestretch wire rope and respool under load before use. Tightly wound wire rope reduces chances of

"binding", which is wire rope working its way down into a loosely wound wire rope layer, and catching or damaging

itself.

Winching Safety:

• Always inspect winch installation and wire rope and hook condition before operating winch. Frayed, kinked or

damaged wire rope must be replaced immediately. Loose or damaged winch installation must be corrected

immediately.

• Never hook wire rope back onto itself. This damages the wire rope. Always use a choker chain, wire choker rope or

tree trunk protector on the anchor.

• Always prior to winching, remove any element that may interfere with safe winch operation.

• Always take your time when rigging for a winch pull.

• Always be certain the anchor you select will withstand the load, and the strap or chain will not slip.

• Never engage or disengage clutch if winch is under load, wire rope is in tension or wire rope drum is moving

• Always unspool as much wire rope as possible when rigging. Double line or pick distant anchor point.

• Never winch with less than 5 wraps of wire rope around the drum, the wire rope could come loose from the drum.

• Always stand clear of wire rope and load during operation.

• Never touch wire rope or hook while in tension or under load.

• Never touch wire rope or hook while someone else is at the control switch or during winching operation.

• Never touch wire rope or hook while remote control is plugged into winch.

• Always stand clear of wire rope and load and keep others away while winching.

• Always require operator and bystanders to be aware of stability during winching of vehicle and/or load.

• Always keep remote control lead clear of the drum, wire rope and rigging. Inspect for cracks, pinches, frayed wires

or loose connections. Replace if damaged.

Page 5

PAGE 5 99387 Rev. A0

Safety Precautions - continued

CAUTION

CUT AND BURN HAZARD

Failure to observe these instructions could lead to minor to moderate injury.

To avoid injury to hands and fingers:

• Always wear heavy leather gloves when handling a wire rope.

• Never let wire rope slip through your hands.

• Always be aware of possible hot surface at winch motor, drum or wire rope during or after winch use.

CAUTION

Moving Parts Entanglement Hazard

Failure to observe these instructions could lead to minor to moderate injury.

•

Never apply load to hook tip or lat ch. A pply load only to t he center of hook.

• Never use a hook whose throat opening has increased, or whose tip is bent or twisted.

NOTICE

AVOID WINCH AND EQUIPMENT DAMAGE

• Always avoid continuous side pulls, which can pile up wire rope at one end of the drum. This can damage your wire

rope or winch.

• Always ensure the clutch is fully engaged or Disengaged.

• Never use winch to tow other vehicles. Shock loads can momentarily exceed capacity of wire rope & winch

• Always use care to not damage your frame when anchoring your vehicle during a winching operation.

• Never "jog" wire rope under load. Shock loads can momentarily exceed capacity of wire rope and winch.

• Never use winch to secure a load during transport.

• Never submerge winch in water.

• Always store the winch in a protected, clean, dry area.

Part number & Cord ends for the WARN® 5000

PART NUMBERS

99964

12v DC 5000# Utility Winch - US

99963

12v DC 5000# Utility Winch - International

Page 6

PAGE 6 99387 Rev. A0

Parts List

The WARN® 5000 Utility Winch consists of the follo wing main components.

1. WARN 5000 Winch Unit

2. Remote with 12’(3.7 m) Lead

3. Fairlead

4. 2 – 6’ (1.8 m) x 6 gauge cable

5. Latch Hook and Hook Strap

6. Mounting Hardware

1

2

3

4 5 6

Page 7

PAGE 7 99387 Rev. A0

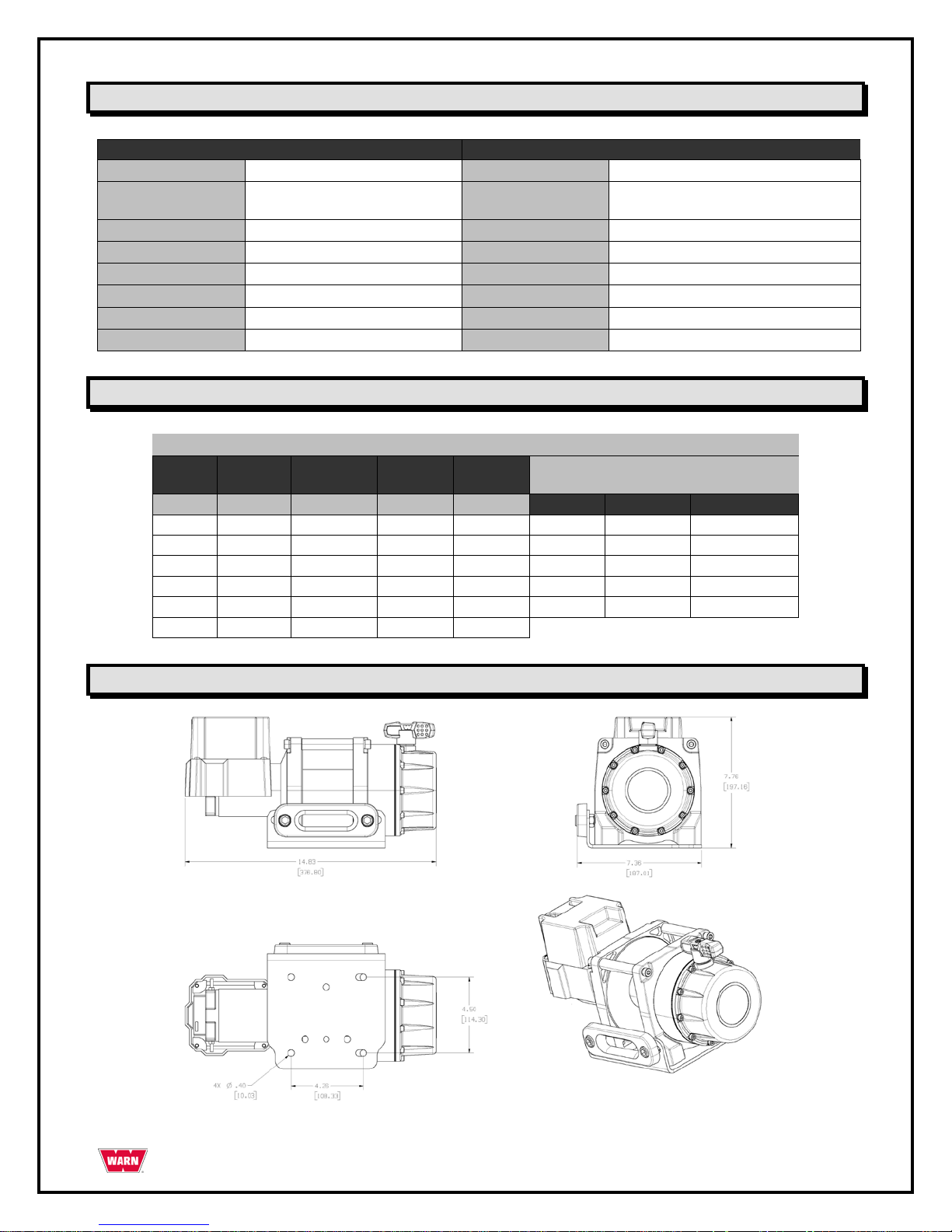

Specification Data for the WARN® 5000

FEATURES

Pulling Capacity

5000lbs. (2268 kg)

Brake

Dynamic and mechanical br aking

Switch Type

Remote with 12’ (3.7 m)

Lead

Warranty

1 year limited

Motor

Permanent Magnet

Wire Rope

1/4" (6.35 mm) X 60' (18.3 m)

HP

1.9 HP 3.0" Diameter

Drum Diameter

2.5" (6.35 cm)

Power

12 volt DC

Fairlead

Hawse

Gear Train

3-Stage planetary

Hole Pattern

4 holes

Gear Ratio

216:1

Electrical Leads

2 – 6’ (1.8 m) x 6 gauge cable

Clutch

Lever- Multi-directional

Weight

42 lbs. (19.1 kg.)

Performance Data for the WARN® 5000

PERFORMANCE DATA: 5000

Load

Current

Speed

Pulling Power by Wire Rope

Layer

Lbs.

Kg

Amps

Ft/min

M/min

Layer

lbs.

kg

0 0 40

13.8

4.2 1 5000

2268

1000

453.6

81

10.9

3.3 2 4280

1941

2000

907.2

118

9.3

2.8 3 3750

1701

3000

1360.8

152

8.1

2.5 4 3341

1515

4000

1814.4

188

6.8

2.1 5 3020

1369

5000

2268

220

5.4

1.6

Dimensional Data for the WARN® 5000

Page 8

PAGE 8 99387 Rev. A0

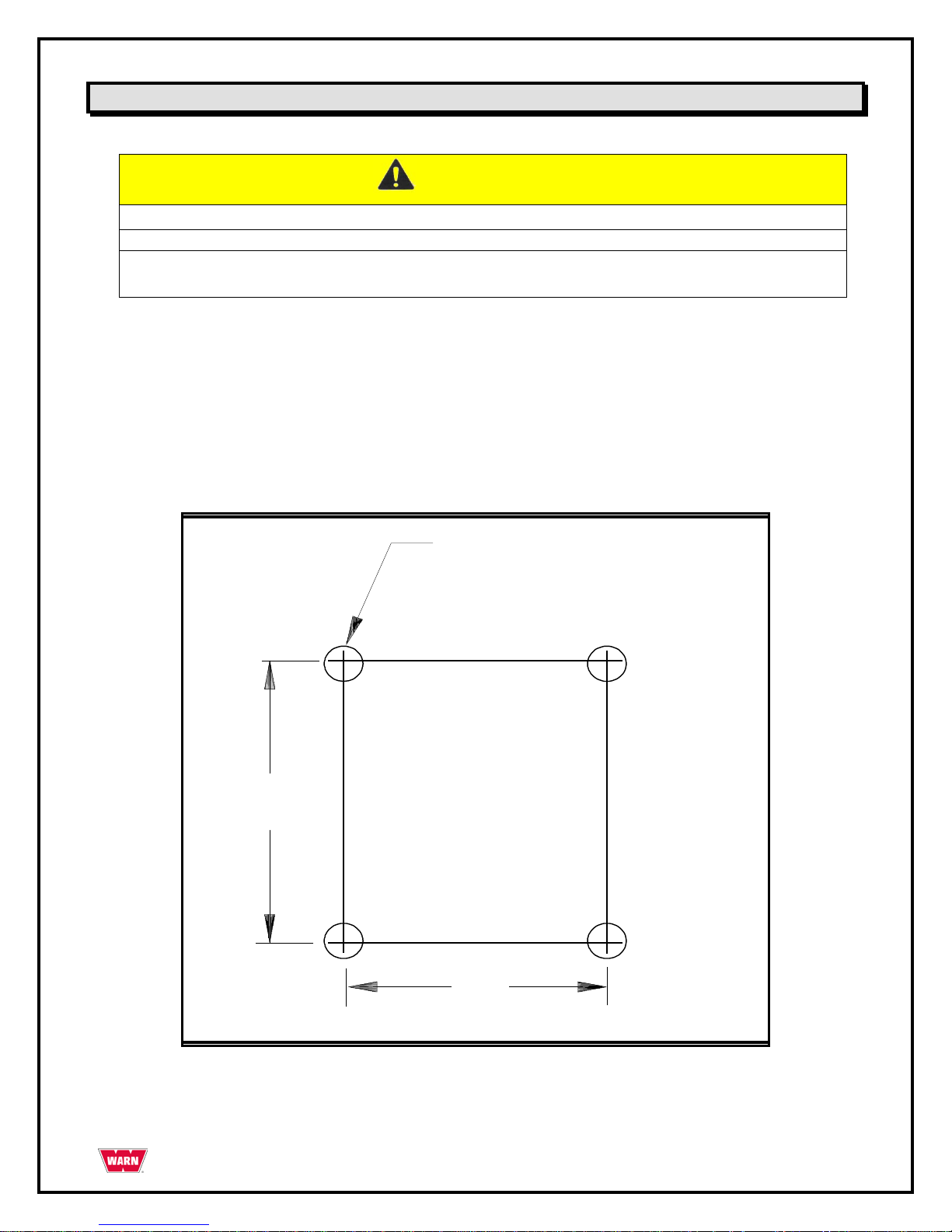

Winch Installation to fixed location

CAUTION

Winch Failure Hazard

Failure to observe these instructions could lead to minor or moderate injury.

Always choose a mounting location that is sufficiently strong to withstand the loads you

intend to winch

The 5000 can be mounted to a fixed location by utilizing the mounting hole pattern for the winch unit.

First, choose a mounting location that is sufficiently strong enough to withstand the loads you intend

to winch.

Next, drill four holes to the dimensions specified in the drawing below.

Mounting Plate Hole Pattern

3/8" [9.52 mm] DIA (4 plcs)

4.5"

[114mm]

4.25"

[107.95

mm]

Page 9

PAGE 9 99387 Rev. A0

Winch Installation to a fixed location- continued

To secure the winch, alwa ys use:

▫ A flat, secure mounting location at least 3/16 in. (4.8 mm) thick steel.

▫ 3/8 in. lockwasher x 4.

▫ 3/8-16 x 1in. long, hex head capscrew, Grade 5 or better x 4.

▫ Torque mounting bolts to 30-35 ft-lbs (41-47 Nm).

Bolt length may need to be longer than specified above depending upon the thickness of the material the

winch is mounted to.

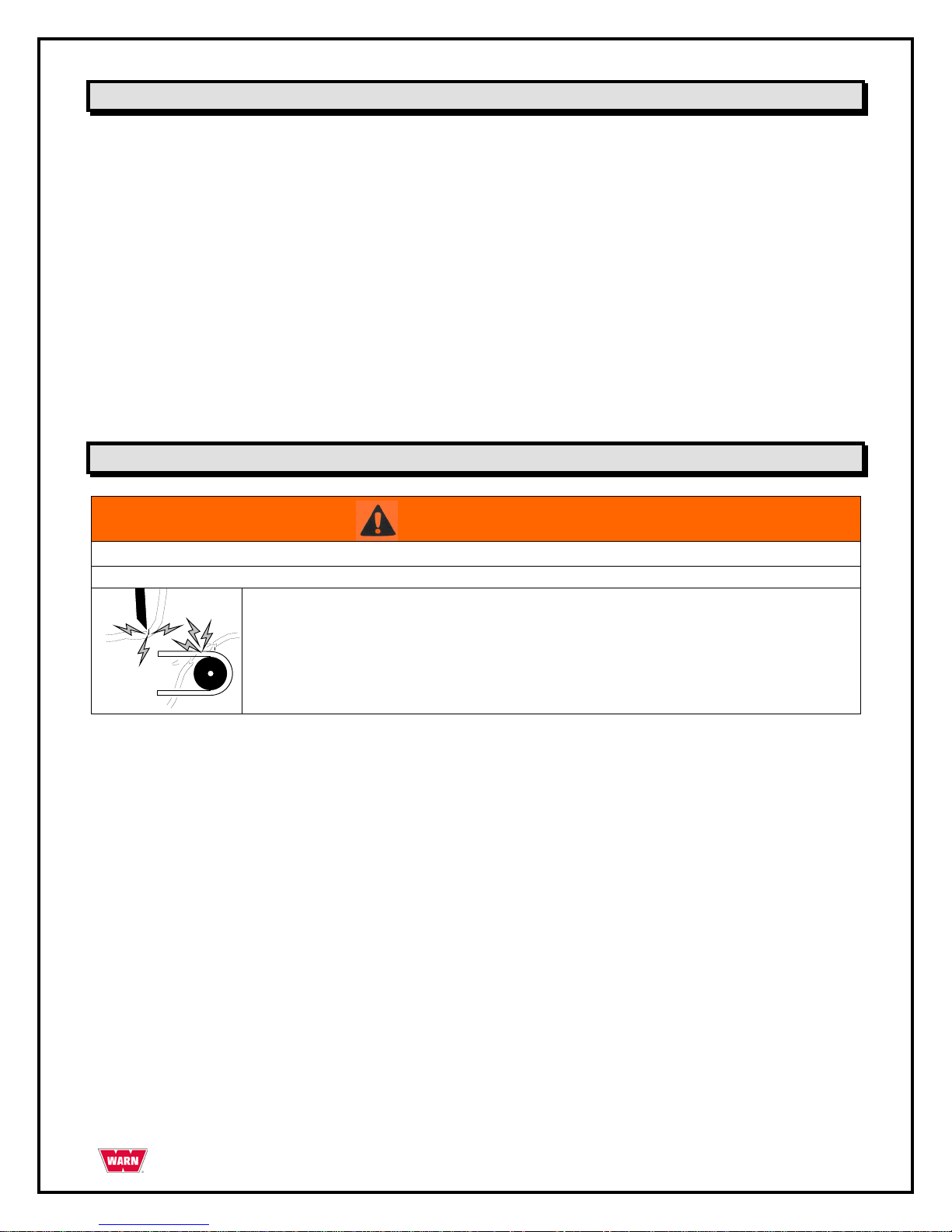

Wiring Instructions

WARNING

Shock & Fire Hazard

Failure to observe these instructions could lead to severe injury or death.

Never route electrical cables across sharp edges

Never route electrical cables through or near moving parts.

Always read and follow all wiring instructions included in operators guide.

Always insulate and protect all exposed wiring and electrical terminals

Install battery cables with red lead connected to the positive terminal of battery, and black lead to

the negative terminal of battery.

Verify that all wiring connections are clean and tight.

Before using the winch, verify the following:

Wiring to all components is correct.

There are no exposed wiring or terminals, cover any existing exposures with insulator plate,

terminal boots, heat shrink tubing or electrician’s tape.

Page 10

PAGE 10 99387 Rev. A0

Operating Instructions

USING THE REMOTE CONTROL

The remote pendant control is hard wired to the winch and can be operated in the remo te position away from

the winch unit or with the pendant docked in the carrier plate.

Press the black power-out button to spool wire rope off of the drum, or press the white power-in button to

spool wire rope onto the drum.

POWER-OUT

POWER-IN

Page 11

PAGE 11 99387 Rev. A0

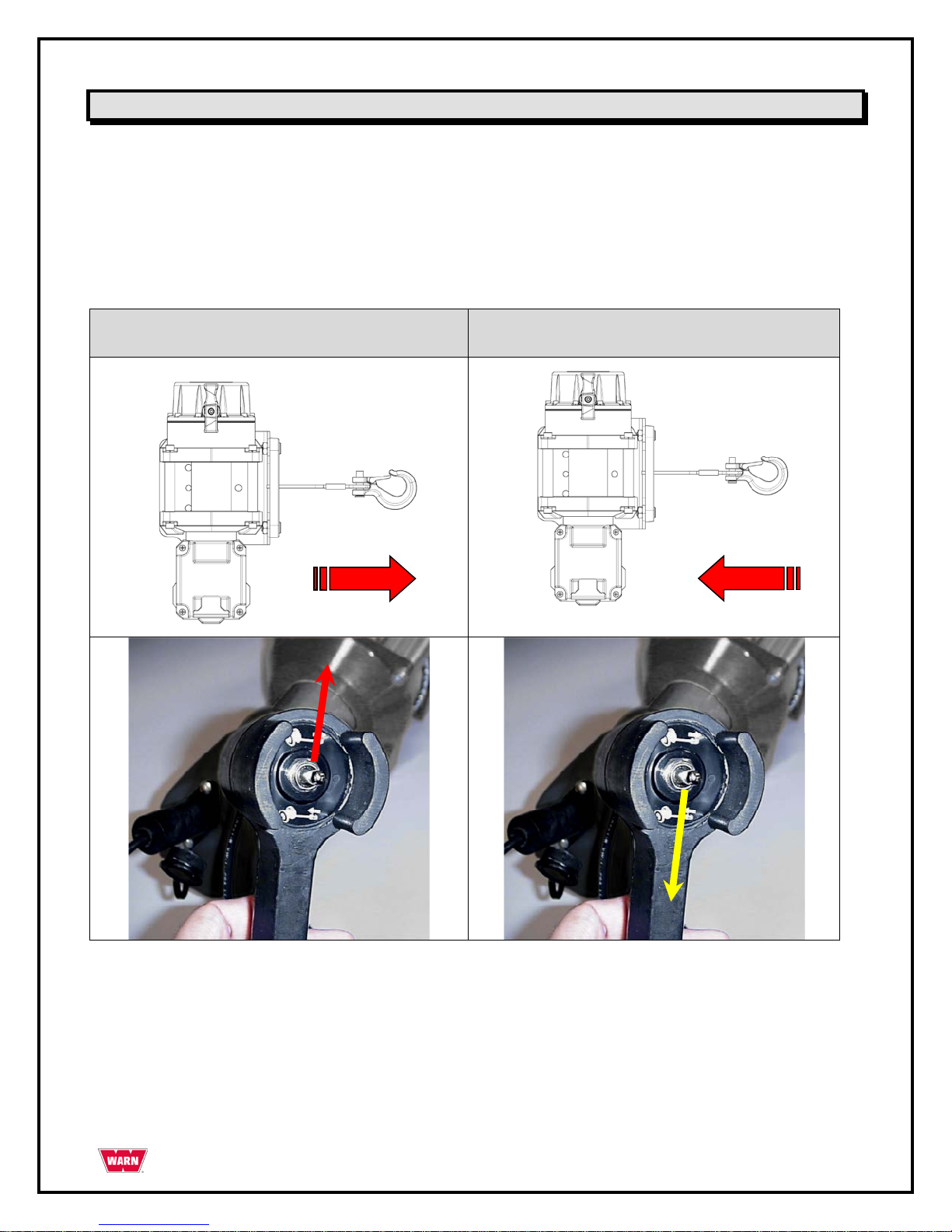

Operating Instructions - continued

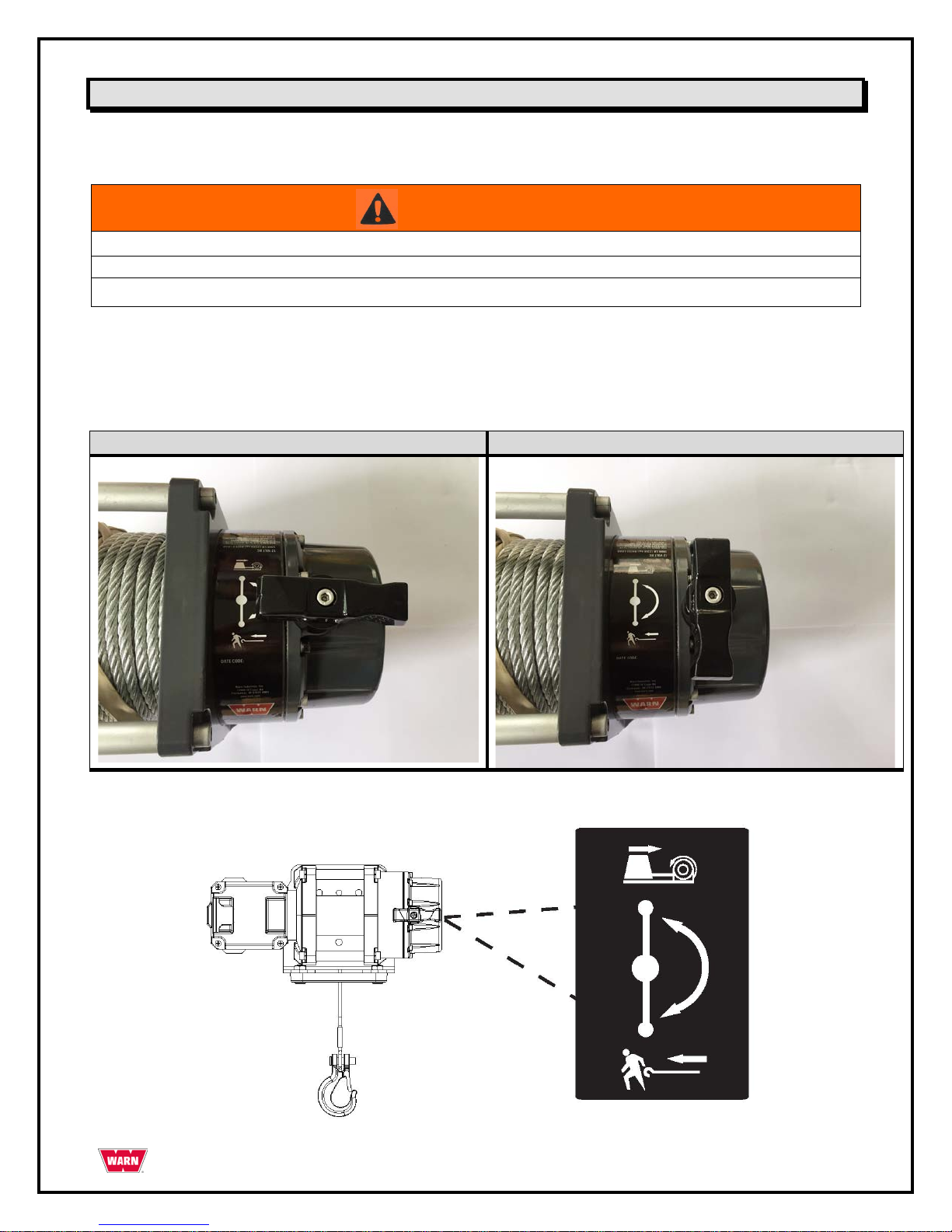

CLUTCH OPERATION

WARNING

Winch Function Hazard

Failure to observe these instructions could lead to injury or property damage

Never engage or disengage the clutch if the winch is underload or wire rope is under tension.

When the clutch is engaged the gear train is coupled to the wire rope drum and power may be transferred

from the winch motor. When the clutch is in freespool the gear train and wire rope drum a re uncoupled

allowing the drum to rotate freely. The clutch lever, located on top of the motor, controls the clutch position.

To prevent damage, always fully engage or fully disengage the clutch lever.

Engaged

Disengage - Freespool

Page 12

PAGE 12 99387 Rev. A0

Operating Instructions - continued

SPOOLING OUT

Freespooling is generally the quickest and easiest way to spool out wire rope. Before freespooling wire rope

out from the winch, power out enough rope to remove any tension the wire rope may be under before

disengaging the clutch. Now freespool by manually spooling out enough wire rope for the winching

operation.

CAUTION

Personal Injury Hazard

Failure to observe these instructions could lead to minor or moderate injury.

Always wear leather gloves when handling wire rope

Never winch with less than 5 wraps of wire rope around the drum.

STRETCHING THE WIRE ROPE

The life of a wire rope is directly related to the care and use it receives. During its first use, a new wire rope

must be spooled onto its drum under a load of at least 500 lb. (227kg). Spool out the entire wire rope length

leaving 5 wraps on the drum, then power in the wire rope under a load of 500 lb. (227kg) or more. This will

stretch new wire rope and create a good wire wrap around the drum. Failure to do so may result in the outer

wire wraps drawing into the inner wraps, binding, and damaging the wire rope.

WARNING

Moving Parts Entanglement Hazard

Failure to observe these instructions could lead to severe injury or death.

ALWAYS keep hands clear of the wire rope, hook loop, hook and fairlead ope ning

during installation, operation and when spooling in or out.

ALWAYS use supplied hook strap whenever spooling the wire rope in or out, during

installation, or operation to avoid injury to hands or fingers.

Page 13

PAGE 13 99387 Rev. A0

Operating Instructions - continued

SPOOLING IN UNDER LOAD

The wire rope must al ways spool onto the bottom of the drum as indicated by decal on the winch.

Power in the wire rope evenly and tightly on the drum. This prevents the outer wire wraps from

drawing into the inner wraps, binding and damaging the wire rope.

Avoid shock loads when spooling, by using the control switch intermittently to take up wire rope

slack. Shock loads can momentarily far exceed the winch and wire rope ratings.

SPOOLING IN UNDER NO LOAD

Assisted: Have your assistant hold the hoo k with the hook strap putting as much constant tension

on the wire rope as possible. While keeping tension, the assistant should walk toward the winch

while you operate the control switch spooling in the wire rope. Release the switch when the hook is

a minimum of 4 ft (1.2m) from the fairlead opening. Spool in the remainder for storage.

Unassisted: Arrange the wire rope to be spooled so it will not kink or tangle when spooled. Be sure

any wire rope on the drum is tightly and evenly layered. Spool enough wire rope to complete the next

full layer on the drum. Tighten and straighten the layer. Repeat process until the hook is a minimum

of 4ft (1.2m) from the fairlead. Spool in the remainder for storage.

SPOOLING REMAINDER FOR STORAGE

Keep hands clear of the wir e rope, hook and fairlead opening. Always use the hook strap to hold hook when

spooling under no load. Carefully power in the remaining wire rope, jogging the control switch to take up the

last of the slack. Secure t he hook to a suitable anchor point near the winch. Be careful not to overtighten or

damage may occur to the wire rope or a nchor point

.

RIGGING

Always spool out as much wire rope as possible when preparing rigging. Pick an anchor as far away

as is practical; this provides the winch with its greatest pulling power.

Rigging a double line with a snatch block will reduce the load on the winch to half without significant

loss of spooling speed.

Natural anchors such as trees, stumps and rocks are the handiest when available. Attach the choker

chain, wire choker rope or tree trunk protector on the anchor as low as possible to avoid pulling the

anchor down. If several possible anchors are available but they are not strong enough individually, it

may be practical to attach a wire or chain choker around several anchors to form a strong collective

anchor point.

Page 14

PAGE 14 99387 Rev. A0

Operating Instructions - continued

OVERLOADING/OVERHEATING

This winch is rated for intermittent duty. It should not be operated with the motor slowed down to a low

RPM. When the motor approaches stall speed, a very rapid heat build-up occurs which may cause motor

damage. Double line rigging will reduce the amperage draw from the motor allowing longer continual use

(see rigging section).

Maintenance & Warranty

MAINTENANCE

No lubrication is required for the life of the winch.

Inspect the wire rope before and after each winching operation. Replace when damaged.

WARRANTY

See separate sheet packed with wi nch

-Or-

If warranty sheet is lost or misplaced contact:

Warn Industries, Inc.

Customer Service Dept.

12900 SE Capps Rd

Clackamas, OR 97015-8903.

United States:

Phone: 503.722.1200 or (800) 543-9276 (US only)

Fax: 503.722-3000

International:

Phone: 503.722.3008

Fax: 503.722.3005

© 2017 Copyright Warn Industries, Inc. All r ights reserved.

Page 15

PAGE 15 99387 Rev. A0

GUÍA DEL CABRESTANTE PARA EL USUARIO

Cabrestante de uso genera l WARN® 5000

Nº DE REFERENCIA: 99964, 99963

Page 16

PAGE 16 99387 Rev. A0

Su seguridad y la seguridad de los demás es muy importante. Para ayudarle a tomar decisiones informadas sobre seguridad, se

proporcionan instrucciones de instalación y operación, y otra información en etiquetas Esta información le alerta sobre posibles peligr os

que puedan afectarle a usted y a otros. N o es posible advertirle s obre todos los posib les peligros que puedan estar relac ionados con el

uso de este producto, por lo que deberá utilizarlo usando el sentido común.

LA INSTALACIÓN Y OPERACIÓN INCORRECTAS DEL CABRESTANTE PUEDEN RESULTAR EN LESIONES GRAVES O DAÑOS

AL EQUIPO. LEA TODAS LAS PRECAUCIONES DE SEGURIDAD E INSTR U CC ION ES DE OPER AC IÓN AN TES D E INST ALAR Y

PONER EN FUNCIONAMIENTO ESTE PRODUCTO.

Esta guía identifica posibles peligros y b rinda importantes mensajes de seguridad que le ayudarán a usted y a otros a evitar daños

personales o la muerte. Las palabras ADVERTENCIA y PRECAUCIÓN indican el grado de peligro. He aquí su significado:

ADVERTENCIA indica un peligro que

puede

ocasionar daños personales de gravedad o la muerte si no se siguen las

recomendaciones.

PRECAUCIÓN indica un peligro que

puede

ocasionar daños personales leves o moderados si no se siguen las

recomendaciones.

Esta guía emplea la palabra

AVISO

para llamar la atención sobre importante información de carácter mecánico, y la palabra Nota: para

poner énfasis sobre información general digna de especial atención.

Descripción del producto: Cabrestante de uso general WARN® 5000

El cabrestante de uso general 5000 de WARN es una poderosa herramienta de arrastre. Accionado por una

fuente de energía de 12 voltios de CC, este compacto cabrestante tiene una capacidad de tiro de 2268 kilos

(5000 libras).

La unidad cuenta con un interruptor de control remoto para operaciones de enrollado y desenrollado, 18,3 m

(60 pies) de cable de 6,35 mm (1/4 pulg.) de diámetro y un gancho con seguro. El embrague para enrollado

manual es una opción estándar.

Introducción

Gracias por su adquisición del modelo de WARN para sus necesidades generales de arrastre e izado. Todos

los productos de WARN se han diseñado y manufacturado para una operación sin problemas durante muchos

años. Para refere ncia futura, guarde la siguiente información en un lugar seguro:

Modelo/Nº de referencia: Fecha de compra:

Antes de comenzar

Lea las instrucciones en su totalidad para familiarizarse con el proceso de instalación.

Revise todos los avisos, precauciones y advertencias para asegurarse de que el conjunto se instala

correcta y seguramente.

Page 17

PAGE 17 99387 Rev. A0

Precauciones de seguridad

A continuación se indican algunas precauciones generales de seguridad que toda persona que vaya a usar el

cabrestante debe conocer. La norma más importante, por encima de todas las demás: USE EL SENTIDO

COMÚN.

Unos pocos minutos empleados en leer estas normas pueden hacer que el operario tome conciencia de

acciones peligrosas que deben evitarse y de las precauciones a tomar para su propia seguridad y la seguridad

de los demás. Las revisiones frecuentes y las inspecciones periódicas del equipo, así como un seguimiento

consciente de las reglas de seguridad pueden salvar vidas, y también ahorrar tiempo y dinero.

ADVERTENCIA

PELIGRO DE ENREDO EN LAS PIEZAS MÓVILES

De no seguirse estas instrucciones podrían producirse lesiones graves o la muerte.

Para evitar daños en las manos.

--Mantenga siempre las manos alejadas del cable, del bucle del gancho, del gancho y de la abertura de la guía durante la

instalación, la operación, y en el enrollado y desenrollado.

• Use siempre precaución extrema en el manejo del gancho y el cable durante las operaciones de enrollado y

desenrollado.

• Use siempre la correa del gancho suministrada cuando vaya a enrollar o desenrollar el cable durante la instalación o la

operación para evitar lesiones en las manos.

ADVERTENCIA

PELIGRO DE CAÍDA O APLASTAMIENTO

De no seguirse estas instrucciones podrían producirse lesiones graves o la muerte.

• No utilice nunca el cabrestante como grúa vertical, ni para suspender una carga.

• No utilice nunca el cabrestante para levantar o desplazar personas.

Page 18

PAGE 18 99387 Rev. A0

Precauciones de seguridad – Continuación

PRECAUCIÓN

PELIGRO DE ENREDO EN LAS PIEZAS MÓ VILES

De no seguirse estas instrucciones podrían producirse lesiones menores o de poca gravedad.

Seguridad general:

• Sea siempre consciente del funcionamie nto del cabrestante: Tómese su tiempo para leer y comprender completamente la guía de

Instalación y operaciones, y la Guía básica de técnicas del cabrestante, que vienen con el mismo, para poder comprender el

funcionamiento del cabrestante.

• No haga funcionar nunca este cabrestante si usted es menor de 16 años de edad.

• No haga funcionar nunca el cabrestante si se encuentra bajo la

influencia de drogas, alcohol o medicamentos.

• No exceda nunca la capacidad nominal del cabrestante ni del ca ble de tiro. Emplee un cable doble utilizando una polea pasteca

para reducir la carga del cabrestante.

Seguridad para la instalación:

• Elija siempre una ubicación de montaje que sea lo suficientemente sólida para soportar la capacidad de carga máxima del

cabrestante.

• Utilice siempre interruptores, controles remotos, accesorios y componentes de instalación que estén aprobados de fábrica.

• Utilice siempre tornillería de grado 5 o superior, pernos que nunca hayan sido soldados y no utilice nunca pernos que sean más

largos que los suministrados por la fábrica.

• Complete siempre el montaje y acoplamiento del gancho del cabrestante al bucle del gancho antes de cablear el cabrestante

durante la instalación.

• Ponga siempre la guía del ca ble con la etiqueta de ADVERTENCIA en su parte superior.

• Enrolle y desenrolle el cable en el tambor siempre según lo

indicado por la etiqueta de rotación del tambor del cabrestante. Es necesario para que funcione el freno automático (si viene con el

cabrestante) y para una orientación correcta de la instalación.

• Realice siempre un estiramiento previo del cable y vuelva a enrollarlo c on carga antes de usarlo. Un cable bien enrollado reduce el

riesgo de “agarrotamiento”, que consiste en el cable enrollándose en una capa de cable que está enrollada flojamente, y

enganchándose o dañándose a sí mismo.

Seguridad en el enrollado y desenrollado:

• Revise siempre la instalación del cabrestante y el estado del cable antes de su uso. Si el cable está deshilachado, retorcido o

dañado, deberá reemplazarse de inmediato. Cualquier pieza instalada que esté suelta o dañada deberá corregirse de inmediato.

• No enganche nunca el cable sobre sí mismo. Esto deterioraría el cable. Utilice una cadena o un cable de estrangulación, o un

protector de tronco de árbol en el anclaje.

• Antes del enrollado, no olvide nunca retirar cualquier elemento que pueda interferir con una operación del cabrestante segura.

• Tómese su tiempo siempre cuando utilice un cabrestante.

• Verifique siempre que el anclaje seleccionado soportará la carga y que la correa o la cadena no se deslizará.

• Nunca embrague ni desembrague si el cabrestante está soportando una carga, si el cable está en tensión o si el tambor del cable

está en movimiento.

• Siempre desenrolle tanto cable como sea posible al prepararse para el maniobrado. Emplee un cable doble o elija un punto de

anclaje distante.

• No accione nunca el cabrestante si no hay al menos 5 vueltas de cable alrededor del

tambor. El cable podría soltarse del tambor ya que el dispositivo de sujeción del cable al tambor no es apto para soportar una carga.

• Manténgase siempre alejado del cable y de la carga durante el accionamiento del cabrestante.

• No toque nunca el cable ni el gancho mientras éstos estén en tensión o con carga.

• No toque nunca el cable ni el gancho si hay alguien cerca del interruptor de control, o si el cabrestante está en funcionamiento.

• No toque nunca el cable ni el gancho si el control remoto está enchufado al cab restante.

• Manténgase siempre alejado del cable y de la carga, y no deje que otros se acerquen mientras el cabrestante esté en

funcionamiento.

• Haga que el operario y otras personas presentes sean conscientes de la estabilidad durante la operación del cabrestante en el

manejo del vehículo o la carga.

• Mantenga siempre el cable del c ontr ol remoto alejado del tambor, del cable y del maniobrado. Inspeccione la posible existencia de

grietas, pellizcos, cables deshilachados o conexiones sueltas. Reemplácelo si está dañado.

Page 19

PAGE 19 99387 Rev. A0

Precauciones de seguridad - Continuación

PRECAUCIÓN

PELIGRO DE CORTES Y QUEMADURAS

De no seguirse estas instrucciones podrían producirse lesiones menores o de poca gravedad.

Para evitar daños en las manos:

• Lleve puestos siempre guantes gruesos de cuero para manejar el cable.

• Nunca deje que el cable se deslice por sus manos.

• Tenga siempre en cuenta que las superficies del motor, del tambor o del cable del cabrestante pueden estar

calientes durante o después del uso del mismo.

PRECAUCIÓN

Peligro de enredo en las piezas móviles

De no seguirse estas instrucciones podrían producirse lesiones menores o de poca gravedad.

• No aplique nunca la carga a la punta del gancho o al seguro del mismo. Aplique la carga únicamente en el centro

del gancho.

• No utilice nunca un gancho cuya abertura haya aumentado, o cuya punta esté doblada o retorcida

AVISO

EVITE DAÑOS AL EQUIPO Y AL CABRESTANTE

• Evite siempre los tirones laterales continuos ya que pueden apilar el cable en un extremo del tambor. Esto puede

dañar el cable o el cabrestante.

• Compruebe siempre que se ha embragado o desembragado completamente.

• No utilice nunca el cabrestante para remolcar otros vehículos. Las cargas repentinas pueden exceder

momentáneamente la capacidad del cable y el cabrestante.

• Sea precavido siempre para no dañar la estructura cuando vaya a anclar su vehículo en una operación con el

cabrestante.

• No desplace nunca el cable en pequeñas sacudidas cuando esté con carga. Las cargas repentinas pueden exceder

momentáneamente la capacidad del cable y el cabrestante.

• Nunca utilice el cabrestante para amarrar una carga durante el transporte.

• No sumerja nunca el cabrestante en agua.

• Guarde siempre el cabrestante en un área protegida, limpia y seca.

Número de referencia y terminales del cable para el modelo WARN 5000

NÚMEROS DE REFERENCIA

99964

Cabrestante de uso general 5000 12 V CC

99963

Cabrestante de uso general 5000 12 V CC - Internacional

Page 20

PAGE 20 99387 Rev. A0

Lista de piezas

El cabrestante de us o general 5000 de WARN consta de los s i guientes componentes princi pales.

1. Unidad de cabrestante WARN 5000

2 Remoto con guía de 3,7 m (12 pies)

3 Guía: Escoben

4. 2 cables de 1,8 m (6 pies) y calibre 6

5. Gancho de retenci ón, con corr ea

6. Accesorios de montaje

1

2 3 4 5 6

Page 21

PAGE 21 99387 Rev. A0

Especificaciones para el modelo WARN 5000

CARACTERÍSTICAS

Capacidad de tracción

2268 kg (5000 lb)

Freno

Frenado dinámico y mecánico

Tipo de interruptor

Remoto con guía de 3,7 m (12 pies)

Garantía

Limitada de 1 año

Motor

Imán permanente

Cable

6,35 mm (1/4 pulg) X 18,3 m (60

pies)

CV

1,9 CV 7,62 cm (3 pulg) de

diámetro

Diámetro del tambor

6,03 cm (2,375 pulg)

Potencia

12 voltios de CC

Guía

Escoben

Tren de engranajes

Planetario de 3 fases

Esquema de los

orificios

3 orificios

Relación de

transmisión

216:01

Conexiones eléctrica s

2 cables de 1,8 m (6 pies) y calibre 6

Embrague

Palanca - Multidireccional

Peso

19,1 kg (42 lb)

Especificaciones técnicas para el modelo WARN 5000

ESPECIFICACIONES TÉCNICAS: 5000

Carga

Corriente

Velocidad

Potencia de tiro por capa de cable

libras

Kg

Amperios

pies/min

m/min

Capa

libras.

kg

0 0 40

13.8

4.2

1

5000

2268

1000

453.6

81

10.9

3.3

2

4280

1941

2000

907.2

118

9.3

2.8

3

3750

1701

3000

1360.8

152

8.1

2.5

4

3341

1515

4000

1814.4

188

6.8

2.1

5

3020

1369

5000

2268

220

5.4

1.6

Dimensiones del modelo WARN 5000

Page 22

PAGE 22 99387 Rev. A0

Instalación del cabrestante en una ubicación fija

PRECAUCIÓN

Peligro del fallo del cabrestante

De no seguirse estas instrucciones podrían producirse lesiones menores o de poca

gravedad.

Elija un lugar de montaje que sea lo suficientemente resistente para soportar las cargas que

desee elevar con el cabrestante.

El modelo 5000 puede montarse en una ubicación fija usando el patrón de agujeros de montaje para la

unidad del cabrestante. Elija un lugar de montaje que sea lo suficientemente resistente como para

soportar las cargas que desee desplazar.

A continuación, haga 4 taladros según las dimensiones especificadas en la ilustración siguiente.

Esquema de los orificios de la placa para el montaje

3/8" [9.52 mm] DIA (4 plcs)

4.5"

[114mm]

4.25"

[107.95mm]

Page 23

PAGE 23 99387 Rev. A0

Instalación del cabrestante en una ubicación fija - Continuación

Para asegurar el cabrestante utilice siempre:

▫ Un lug ar plano y seguro para el montaje de por lo menos 4,8 mm (3/16 pulg) de grosor.

▫ Una arandela de bloqueo de 1/4 pulg. x 4.

▫ Un t ornillo de cabeza hexagonal de 3/8-16 x 1 pulg. de largo, de grado 5 ó mejor x 4.

▫ Apriete los pernos de montaje con un par de torsión de 41-47 Nm (30-35 pies-lbs).

Es posible que la longitud del perno deba ser más larga que la espe cificada anteriormente, dependiendo del

grosor del material en el que esté montado el cabrestante.

Instrucciones de cableado

ADVERTENCIA

Peligro de electrocución

De no seguirse estas instrucciones podrían producirse lesiones de gravedad o la muerte.

No pase los cables eléctricos por bordes agudos.

No pase los cables eléctricos por partes móviles o cerca de ellas.

Lea y siga todas las instrucciones de cableado que se incluyen en el manual de

operaciones.

Ponga aislamiento y proteja los cables y terminales eléctricos que estén expuestos.

Instale los cables de la batería, con el rojo conectado al terminal positivo de la misma y el negro al

terminal negativo.

Compruebe que las conexiones de los cables estén limpias y apretadas

Antes de utilizar el cabrestante, compruebe lo siguiente:

Que el cableado de todos los componentes sea correcto.

Que no haya cables o terminales expue stos. Cubra aquellos que estén expuestos con hoja

aislante, funda de terminal, entubación por contracción al calor o cinta adhesiva de electricista.

Page 24

PAGE 24 99387 Rev. A0

Instrucciones de op eración

CÓMO USAR EL CONTROL REMOTO COLGANTE

El control remoto colgante está conectado al cabrestante por cable y puede operarse alejado de la unidad del

cabrestante o con el control acoplado a la placa transportadora.

Pulse el botón negro para desenrollar el cable del tambor, o pulse el botón blanco para enrollar el cable en el

tambor.

DESENROLLADO

ENROLLADO

Page 25

PAGE 25 99387 Rev. A0

Instrucciones de op eración - Continuación

ACCIONAMIENTO DEL EMBRAGUE

ADVERTENCIA

Peligro durante el funcionamient o d el c a br es t a nte

De no seguirse estas instrucciones podrían producirse lesiones de gravedad o la

muerte.

No embrague ni desembrague nunca si el cabrestante se encuentra con carga o si el cable tiene

tensión.

Cuando el embrague está activado, el sistema de engranajes se acopla al tambor del cable y, en estas

condiciones, puede transferirse movimiento desde el motor del cabrestante. Cuando el embrague está en el

modo de enrollado libre, el sistema de engranajes y el tambor del cable están desengranados, lo que permite

que el tambor gire libremente. La palanca del embrague, situada en la parte superior del motor, controla la

posición del mismo. Para evitar daños, engrane y desengrane siempre completamente la palanca del

embrague.

Activado

Desactivado – Enrollado libre

Page 26

PAGE 26 99387 Rev. A0

Instrucciones de op eración - Continuación

DESENROLLADO

Generalmente, el desenrollado manual es la forma más rápida y sencilla de sacar el cable ha cia afuera. Antes

de proceder al desenrollado manual, saque suficiente cable a fin de eliminar cualquier tensión en la que

pueda estar sometido el mismo antes de desembragar. A continuación, proceda al desenrollado manual,

sacando manualmente suficiente cable para la operación.

PRECAUCIÓN

Peligro de lesiones

De no seguirse estas instrucciones podrían producirse lesiones menores o de poca

gravedad.

Lleve puestos siempre guantes gruesos de cuero para manipular el cable.

No accione el cabrestante si no hay al menos 5 vueltas de cable alrededor del tambor.

TENSIÓN DEL CABLE

La vida útil del cable está directamente relacionada con la forma en que se utiliza y se cuida el mismo.

Durante su primer uso, un cable nuevo debe enrollarse en su tambor bajo una carga de por lo menos 227 kg

(500 libras). Desenrolle todo el cable dejando 5 vueltas en el tambor y a continuación, enrolle el cable bajo

una carga de 227 kg (500libras) o más. Esto tensará el cable nuevo y creará un correcto enrolla do del mismo

alrededor del tambor. De no hacerse así, las vueltas exteriores se podr ían trabar con las vueltas interiores

produciendo atascamientos y daños en el cable.

ADVERTENCIA

Peligro de enredo en las piezas móviles

De no seguirse estas instrucciones podrían producirse lesiones de gravedad o la muerte.

Mantenga siempre las manos alejadas del cable, del bucle del gancho, del gancho y

de la abertura de la guía durante la instalación, la operación, y en el enrollado y

desenrollado.

Utilice siempre la correa del gancho suministrada cuando vaya a enrollar o

desenrollar el cable, o durante la instalación o la operación, para evitar daños en las

manos.

Page 27

PAGE 27 99387 Rev. A0

Instrucciones de op eración - Continuación

ENROLLADO CON CARGA

El cable debe enrollarse alrededor del tambor en el sentido indicado por la marca de rotación que hay

en el cabrestante.

Enrolle el cable uniformemente y bien tensado alrededor del tambor. Esto evita que las vueltas más

externas del cable se traben con las vueltas internas, lo cual puede ocasionar atascamientos y daños

al cable.

Evite las sacudidas de la carga cuando esté enrollando; para ello, utilice el interruptor de control de

forma intermitente a fin de tensar y hacer entrar las porciones del cable que puedan quedar flojas.

Las sacudidas de la carga pueden sobrepasar momentáneamente la capacidad nominal del

cabrestante y del cable.

ENROLLADO SIN CARGA

Con asistencia: Pida a su ayudante que sujete el gancho y la correa del mismo, tensando el cable

de forma constante y tanto como sea posible. Manteniendo tenso el cable, el ayudante debe caminar

hacia el cabrestante mientras usted acciona el interruptor de control para enrollar el cable. Suelte el

interruptor cuando el gancho esté a una distancia mínima de 1,2 m (4 pies) de la abertura de la guía.

Luego, enrolle la parte final del cable para su almacenamiento.

Sin asistencia: Disponga el cable de forma que no se doble ni se trabe al enrollarlo. Aseg úre se de

que el cable ya enrollado alrededor del tambor esté bien tenso y dispuesto en capas uniformes.

Enrolle el cable lo suficiente para formar la siguiente capa completa alred edor del tambor. Tense y

enderece la capa. Repita este proceso hasta que el gancho quede a una distancia mínima de 1,2 m (4

pies) de la guía para el cable. Luego, enrolle la parte final del cable para su almacenamiento.

ENROLLADO DE LA PARTE FINAL PARA EL ALMACENAMIE NTO

No toque el cable, el gancho ni la abertura de la guía. Siempre utilice la correa del gancho para sujetar el

mismo al enrollar el cable cuando no haya carga. Con mucho cuidado, vaya enrollando la parte final del cable

activando y desactivando repetidamente el interruptor de control a fin de enrollar la parte floja final. Fije el

gancho en un punto de anclaje a decuado cercano al cabrestante. Asegúrese de no tensar en exceso ya que

ello podría dañar el cable o el punto de anclaje.

MANIOBRADO

Siempre desenrolle cuanto más cable sea posible al prepararse para el maniobrado. Elija el punto

más alejado posible de fijación; esto proporciona al cabrestante mayor capacidad de tracción.

El uso de línea de doble cable y una polea reduce la carga del cabrestante a la mitad sin pérdida

significativa de la velocidad de enrollado.

Los puntos de anclaje naturales como, por ejemplo, árboles , tocones y rocas, son los más cómodos

cuando están disponible s. Acople una cadena o un cable de estrangulación, o un protector de tronco

de árbol al punto de anclaje, a la menor altura posible, para evitar derribarlo. Si hay varios puntos de

anclaje disponibles pero no son lo suficientemente resistentes por separado, puede acoplar un cable

o una cadena de estrangulación alrededor de var ios puntos a fin de formar un punto de ancl aje

“colectivo” lo suficientemente resistente.

Page 28

PAGE 28 99387 Rev. A0

Instrucciones de op eración - Continuación

SOBRECARGA/SOBRECALENTAMIENTO

El cabrestante está indicado para un servicio intermitente. No se debe poner en funcionamiento con el motor

reducido a bajas RPM. Cuando el motor se aproxima a la velocidad crítica, se genera calor muy

rápidamente, lo que puede ocasionar daños al motor. El uso de línea de doble cable reducirá los

amperios del motor, permitiendo un uso continuo mayor (vea la sección del maniobrado).

Mantenimiento y garantía

MANTENIMIENTO

No se requiere lubricación durante la vida útil del cabrestante.

Inspeccione el cable de tiro antes y después de cada operación efectuada con el cabrestante. Si presenta

daños, sustitúyalo.

GARANTÍA

Vea la hoja adicional incluida con el cabrestante

-o-

Si la hoja de la garantía se ha perdido, póngase en contacto con

Warn Industries, Inc.

Customer Service Dept.

12900 SE Capps Rd

Clackamas, OR 97015-8903.

Estados Unidos:

Teléfono: 503.722.1200 ó (800) 543-9276 (EE.UU. solamente)

Fax: 503.722-3000

Internacional:

Teléfono: 503.722.3008

Fax: 503.722.3005

© 2017 Copyright Warn Industries, Inc. All ri g hts reserved.

Page 29

PAGE 29 99387 Rev. A0

GUIDE DE L'UTILISATEUR DU TREUIL

Treuil utilitaire WARN® 5000

Numéro de pièce : 99964, 99963

Page 30

PAGE 30 99387 Rev. A0

Votre sécurité et celle des autres est très importante. Pour vous permettre de prendre des décisions éc lairées dans le domaine de la

sécurité, nous vous avons fourni des instructions relatives à l'installation et à l'utilisation du produit ainsi que d'autres informations

figurant sur des étiquettes apposées sur le prod uit. Ces informations attirent l'attention sur les dang ers potentiels pouvant vous affecter

ainsi qu'autrui. Nous ne sommes pas en mesure de vous mettre en gar de contre tous les dangers potentiels associés à ce produit. Il vous

incombe par conséquent de faire preuve de jugement.

TOUTE INSTALLATION OU UTILISATION IMPRUDENTE DU TREUIL PEUT ENTRAÎNER DES BLESSURES GRAVES OU

ENDOMMAGER L'ÉQUIPEMENT. PRENDRE SOIN DE LIRE ET DE BIEN ASSIMILER LES CONSIGNES DE SÉCURITÉ ET

D'UTILISATION DU PRODUIT AVANT D E L 'IN ST ALLER ET DE L'UTILISER.

Ce guide identifie les dangers potentiels et comporte des consignes de sécurité importantes qui permettent, à vous et à autrui, d'éviter

les risques de blessures graves ou de mort. Les termes AVERTISSEMENT et ATTENTION sont des indicateurs du niveau de danger.

Signification des indicateurs :

Le terme AVERTISSEMENT souligne un danger potentiel qui

peut

entraîner des blessures graves ou la mort si vous ne

suivez pas les consign es.

Le terme ATTENTION souligne un danger potentiel

susceptible

d'entraîner des blessures mineures ou modérées si

vous ne suivez pas l es consignes.

Ce guide utilise le terme

AVIS

pour attirer votre attention s ur des informations mécaniques importantes, et le terme Remarque : pour

souligner des informations générales qui méritent une attention particulière.

Description du produit : Treuil utilitaire WARN ® 5000

Le treuil utilitaire WARN® 5000 est un puissant outil de traction. Alime nté par une source de 12 volts c.c., ce

treuil compact possède une capacité de traction de 2268 kilos.

L'appareil est doté d'une télécommande permettant d'enrouler et dérouler le câble, d'un câble de 18,3 m de

long et 6,35 mm de diamètre et d'un crochet avec fermoir de sécurité. L'embrayage à déroulement en roue

libre fait partie de l'équipement standard.

Introduction

Merci d'avoir choisi le treuil utilitaire WARN®. Tous les produits WARN® ont été conçus et fabriqués de

manière à assurer un fonctionnement sans problèmes pendant des années. Prière de noter les informations

suivantes à titre de référence :

Numéro de modèle/pièce : Date d'achat :

Avant de commencer

Lire les instructions intégralement afin de se familiariser avec la procédure d'installation.

Prière de relire tous les avis, mises en garde et avertissements pour s'assurer que le kit est installé

correctement et en toute sécurité.

Page 31

PAGE 31 99387 Rev. A0

Mesures de sécurité

Voici quelques mesures générales de sécurité que tout utilisateur du treuil se doit de connaître. Cependant,

au-delà de toute consigne, la règle la plus importante à suivre est celle-ci : FAIRE PREUVE DE BON SENS.

Les quelques minutes consacrées à la lecture de ces consignes permettront à tout opérateur d'être conscient

des pratiques dangereuses à éviter et des précautions qu'il pourra prendre pour assurer sa sécurité et celle

d'autrui. Une vérification fréquente ainsi que des inspections périodiques de l'équipement et l'application

consciencieuse des consignes de sécurité pourront permettre de sauver des vies et d'économiser temps et

argent.

AVERTISSEMENT

DANGER DE HAPPEMENT PAR DES PIÈCES MOBILES

Le non-respect des instructions peut entraîner des blessures graves, voire mortelles.

Pour éviter de se blesser les mains ou les doigts :

• Toujours garder les mains éloignées du câble, de la boucle du crochet, du crochet et de l'ouverture du guide-câble

durant l'installation et l’utilisation du treuil et l'enroulement ou le déroulement du câble.

• Toujours faire très attention durant la manipulation du crochet et du câble pendant les manœuvres de déroulement.

• Toujours utiliser le cordon du crochet fourni pour enroule r ou d é r oule r le câble, durant l'insta l la t i on ou l'uti l isation, pour

éviter de se blesser les mains ou les doigts.

AVERTISSEMENT

DANGER DE CHUTE OU D'ÉCRASEMENT

Le non-respect des instructions peut entraîner des blessures graves, voire mortelles.

• Ne jamais utiliser l'appareil comme palan aérien ou pour suspendre une charge.

• Ne jamais utiliser l'appareil pour soulever ou transporter des personnes.

Page 32

PAGE 32 99387 Rev. A0

Mesures de sécurité - Suite

ATTENTION

DANGER DE HAPPEMENT PAR DES PIÈCES MOBILES

Le non-respect des instructions peut entraîner des blessures mineures ou modérées.

Consignes de sécurité générales :

• Toujours se familiariser avec le treuil : Prendre le temps de bien lire et comprendre le manuel d’installation et

d’utilisation ainsi que le manuel de base des techniques de treuillage inclus avec le treuil afin de se familiariser avec

l’appareil et son fonctionnement.

• Les personnes âgées de moins de 16 ans ne doivent jamais faire fonctionner cet appareil.

• Ne jamais faire fonctionner l'appareil sous l'effet de drogues, de l'alcool ou de médicaments.

• Ne jamais excéder la capacité nominale du treuil ou du câble d'acier. Un câblage double avec poulie ouvrante

permet de réduire la charge subie par le treuil.

Consignes de sécurité se rapportant à l’installation :

• Toujours choisir une surface de montage suffisamment résistante pour supporter la capacité de traction maximale

du treuil.

• Toujours utiliser des interrupteurs, télécommandes, accessoires et composants d'installation homologués par le

fabricant.

• Toujours utiliser un matériel de catégorie 5 ou supérieur, ne jamais souder les boulons ni utiliser des boulons plus

longs que ceux fournis par le fabricant.

• Toujours achever le montage du treuil et la fixation du crochet à sa boucle avant d'effectuer le câblage du treuil

durant l'installation.

• Toujours positionner le guide-câble avec l'étiquette d'AVERTISSEMENT sur le dessus.

• Toujours enrouler le câble sur le tambour tel qu'indiqué par l'autocollant de rotation apposé sur le treuil.

Nécessaire pour que le frein automatique puisse fonctionner (le cas échéant) et pour assurer une installation dans le

bon sens.

• Toujours étirer au préalable le câble d'acier et l'enrouler sous charge avant de l'utiliser. Un câble enroulé de manière

serrée permet de réduire le risque qu’il coince, c’est-à-dire que si le câble s’enroule de façon lâche, il peut s’enchevêtrer

et s’endommager lui-même.

Consignes de sécurité concernant le treuillage :

• Toujours inspecter l'installation du treuil et l'état du câble métallique avant de faire fonctionner le treuil. Tout câble

effiloché, tordu ou endommagé doit être remplacé immédiatement. Toute installation de treuil desserrée ou

endommagée doit être corrigée immédiatement.

• Ne jamais accrocher le câble à lui-même. Cela l’endommagerait. Toujours util i s e r une cha îne ou un câble à nœud

coulant, ou bien une protection de tronc d'arbre sur le point d'ancrage.

• Toujours s'assurer que tous les obstacles potentiels sont écartés, avant de commencer le treuillage.

• Toujours prendre le temps de bien procéder au câblage avant d'utiliser le treuil.

• Toujours s'assurer que le point d'ancrage choisi peut supporter la charge et que la sangle ou la chaîne ne glisse pas.

• Ne jamais essayer d'embrayer ou de débrayer si le treuil est sous charge, si le câble est en tension ou si le tambour

est en train de tourner.

• Toujours dérouler autant de câble que possible avant de procéder au câblage. Utiliser une ligne double ou choisir un

point d’ancrage distant.

• Ne jamais utiliser le treuil avec moins de 5 spires de câble enroulées autour du tambour, car le câble pourrait se

dérouler du tambour, étant donné que l'ancrage du câble n'est pas conçu pour retenir une charge.

• Toujours se tenir à l'écart du câble et de la charge durant l'utilisation.

• Ne jamais toucher le câble ou le crochet lorsque le câble est tendu ou sous charge.

• Ne jamais toucher le câble ou le crochet lorsqu'une autre personne est à l'interrupteur de commande ou durant le

fonctionnement du treuil.

• Ne jamais toucher le câble ou le crochet lorsque la télécommande est branchée sur le treuil.

• Toujours se tenir à l'écart du câble et de la charge durant l'utilisation et ne jamais laisser personne s'approcher.

• Toujours exiger de l'opérateur et des personnes présentes d'être conscients de la stabilité du véhicule ou de la

charge.

• Toujours garder la télécommande à l'écart du tambour, du câble et du câblage. S'assurer qu’il n’y a pas de fissures,

de points de pincement, de fils effilochés ou de connexions desserrées. Remplacer en cas de dommages.

Page 33

PAGE 33 99387 Rev. A0

Mesures de sécurité - Suite

ATTENTION

RISQUE DE COUPURE ET DE BRÛLURE

Le non-respect des instructions peut entraîner des blessures mineures ou modérées.

Pour éviter de se blesser les mains ou les doigts :

• Toujours porter des gants de cuir résistants durant la manipulation du câble d’acier.

• Ne jamais laisser le câble glisser dans les mains.

• Toujours penser aux surfaces chaudes au niveau du moteur du treuil, du tambour ou du câble durant ou après

l’utilisation du treuil.

ATTENTION

Danger de happement par des pièces mobiles

Le non-respect des instructions peut entraîner des blessures mineures ou modérées.

• Ne jamais appliquer la charge sur l'extrémité du crochet ou le loquet. Appliquer la charge au centre du crochet

seulement.

• Ne jamais utiliser un crochet dont la gorge s'est élargie ou dont l'extrémité est courbée ou tordue

AVIS

ÉVITER D'ENDOMMAGER LE TREUIL ET L'ÉQUIPEMENT

• Toujours éviter de tirer continuellement sur le côté, ce qui a pour effet d'empiler le câble sur l'une des extrémités du

tambour. Cela peut endommager le câble ou le treuil.

• Toujours s'assurer d'avoir complètement embrayé ou complètement débrayé.

• Ne jamais se servir du treuil pour remorquer d'autres véhicules. Les charges de choc peuvent momentanément

dépasser de loin la capacité du treuil du câble.

• Toujours faire attention à ne pas endommager le cadre si l'on décide d'arrimer le véhicule pour pouvoir travailler

avec le treuil.

• Ne jamais « secouer » le câble sous charge. Les charges de choc peuvent momentanément dépasser de loin la

capacité du treuil et du câble.

• Ne jamais se servir du treuil pour maintenir une charge pendant le transport.

• Ne jamais submerger le treuil dans l'eau.

• Toujours ranger le treuil dans un endroit sûr, propre et sec.

Numéros de pièce et extrémités de cordon du WARN 5000

NUMÉROS DE PIÈCE

99964

Treuil utilitaire 12 V c.c. nº 5000

99963

Treuil utilitaire (international) 12 V c.c nº 5000

Page 34

PAGE 34 99387 Rev. A0

Liste des pièces

Le treuil utilitaire WARN® 5000 comprend les composants principaux suiv ants.

1. Treuil WARN 5000

2. Télécommande à fil de 3,7 m (12 pi)

3 Guide-câble

4. Câble de 1,8 m (6 pi), calibre 6 (2)

5. Crochet avec loquet et sangle de crochet

6. Matériel de montage

1 2 3

4 5 6

Page 35

PAGE 35 99387 Rev. A0

Spécifications techniques du WARN 5000

CARACTÉRISTIQUES

Capacité de traction

2268 kg (5000 lb)

Frein

Système de freinage mécanique

dynamique

Type d'interrupteur

Télécommande à fil de 3,7 m (12 pi)

Garantie

Limitée d'un an

Moteur

Aimant permanent

Câble

18,3 m X 6,35mm (1/4 po x 60 pi)

Puissance

0,45 kW (1,9 CV), 7,62 cm de

diamètre

Diamètre du

tambour

6,35 cm (2,5 po)

Alimentation

12 V c.c.

Guide-câble

Ecubier

Train d’engrenages

Planétaire à 3 étages

Disposition des

trous

4 trous

Rapport de

démultiplication

216/01

Fils électriques

Câble de 1,8 m (6 pi), calibre 6 (2)

Embrayage

Levier multidirectionnel

Poids

19,1 kg (42 lb)

Données de performance du WARN 5000

DONNÉES DE PERFORMANCE : 5000

Charge

Courant

Vitesse

Puissance de traction, couche de câble

Lbs.

Kg

Intensité

(A)

pi/min

M/min

Couche

lbs.

kg

0 0 40

13.8

4.2

1

5000

2268

1000

453.6

81

10.9

3.3

2

4280

1941

2000

907.2

118

9.3

2.8

3

3750

1701

3000

1360.8

152

8.1

2.5

4

3341

1515

4000

1814.4

188

6.8

2.1

5

3020

1369

5000

2268

220

5.4

1.6

Données dimensionnelles du WARN 5000

Page 36

PAGE 36 99387 Rev. A0

Installation du treuil sur un emplacement fixe

ATTENTION

Danger de défaillance du treuil

Le non-respect des instructions peut entraîner des blessures mineures ou

modérées.

Toujours choisir une surface de montage suffisamment résistante pour supporter les charges

qui seront halées.

Le 5000 peut être installé sur un emplacement fixe au moyen des trous de montage du treuil. Choisir tout

d'abord une surface de montage suffisamment résistante pour supporter les charges qui seront halées.

Percer ensuite 4 trous selon les dimensions spécifiées sur le dessin ci-dessous.

Disposition des trous de la plaque de montage

3/8" [9.52 mm] DIA (4 plcs)

4.5"

[114mm]

4.25

"

[107.95mm]

Page 37

PAGE 37 99387 Rev. A0

Installation du treuil sur un emplacement fixe-suite

Pour fixer le treuil, toujours se servir des éléments suivants :

▫ Une surface de montage plate et sûre en acier d'une épaisseur d'au moins 4,8 mm.

▫ 4 rondelles d'arrêt de 3/8 po.

▫ 4 vis à tête hexagonale de 3/8-16 x 1 po de long, catégorie 5 ou supérieure.

▫ Visser les boulons de fixation à un couple de 41 à 47 Nm.

Il se peut que les boulons doivent être plus longs que spécifiés ci-dessus selon l'épaisseur du matériau auquel

est fixé le treuil.

Installation du Câblage

AVERTISSEMENT

Risque de choc électrique

Le non-respect des consignes peut entraîner des blessures graves ou la mort.

Ne faites pas passer les câbles électriques sur des bords tranchants.

Ne faites pas passer les câbles électriques à travers des pièces mobiles ou à proximité.

Lisez et suivez toutes les instructions de câblage indiquées dans le manuel de

l'utilisateur.

Isolez et protégez tous les fils et bornes électriques exposés.

Raccordements electrique : câble rouge connecté à la borne positive, câble noir connecté à la borne

négative.

Assurez-vous que toutes les connexions sont propres et bien serrées.

Avant d’utiliser le treuil, veuillez vérifier les points suivants :

Le câblage de tous les composants est correct.

Aucun câble ni aucune borne n'est exposé. Couvrez-les sinon à l’aide de plaques isolantes, capuchons,

gaines thermorétrécissables ou ruban isolant.

Page 38

PAGE 38 99387 Rev. A0

Mode d'emploi

UTILISATION DE LA TÉLÉCOMMANDE CÂBLÉE

La télécommande est câblée au treuil et peut être actionnée à distance du treuil ou en la rangeant dans la

plaque de support.

Appuyer sur le bouton noir pour dérouler le câble ou sur le bouton blanc pour enrouler le câble sur le tambour

DÉROULER

ENROULER

Page 39

PAGE 39 99387 Rev. A0

Mode d'emploi - suite

FONCTIONNEMENT DE L'EMBRAYAGE

AVERTISSEMENT

Danger lié au fonctionnement du treuil

Le non-respect des instructions peut entraîner des blessures ou des dommages

matériels.

Ne jamais essayer d'embrayer ou de débrayer si le treuil est sous charge ou si le câble est sous

tension.

Lorsque l’embrayage est en prise, le train d'engrenages est couplé au tambour du câble et l’entraînement

peut alors être transféré du moteur du treuil. Lorsque l'embrayage est en mode de déroulement en roue libre,

le train d'engrenages et le tambour se découplent, ce qui permet au tambour de tourner librement. Le levier

d'embrayage, situé en haut du moteur, contrôle la position de l'embrayage. Pour éviter tout dommage,

tourner complètement le levier d'embrayage dans l'une ou l'autre position.

Embrayage

Désembrayage - Roue libre

Page 40

PAGE 40 99387 Rev. A0

Mode d'emploi - suite

DÉROULEMENT DU CÂBLE

Le déroulement en roue libre constitue généralement la façon la plus rapide et la plus facile de dérouler le

câble. Avant de mettre le treuil en roue libre pour dérouler le câble, dérouler au moteur une quantité

suffisante de câble avant de débrayer pour soulager le câble de toute tension. On peut alors dérouler

manuellement une qua ntité suffisante de câble pour pouvoir travailler avec le treuil.

ATTENTION

Risque de blessures

Le non-respect des instructions peut entraîner des blessures mineures ou modérées.

Toujours porter des gants de cuir durant la manipulation du câble d'acier.

Ne jamais utiliser le treuil avec moins de 5 spires de câble enroulées autour du tambour.

ÉTIREMENT DU CÂBLE

La durée de vie d’un câble est liée directement à son entretien et à son utilisation. Lors de sa première

utilisation, un câble neuf doit être enroulé sur so n tambour sous une charge d’au moins 227 kg. Dérouler

entièrement le câble de façon à ne laisser que 5 spires sur le tambour, puis enrouler le câble sous une charge

de 227 kg ou plus. Ceci permet d’étirer un câble neuf et de bien l’enrouler sur le tambour. Sinon, les spires

extérieures risquent de s'enfoncer dans les spires intérieures, ce qui peut coincer et endommager le câble.

AVERTISSEMENT

Danger de happement par des pièces mo bi les

Le non-respect des consignes peut entraîner des blessures graves ou la mort.

TOUJOURS garder les mains éloignées du câble, de la boucle du crochet, du crochet

et de l'ouverture d u guide-câble durant l'installation et l’utilisation du treuil et

l'enroulement ou le déroulement du câble.

TOUJOURS utiliser le cordon du crochet fourni pour enrouler ou dérouler le câble,

durant l'installation ou l'utilisation, pour éviter de se blesser les mains ou les doigts.

Page 41

PAGE 41 99387 Rev. A0

Mode d'emploi - suite

ENROULEMENT SOUS CHARGE

Le câble d'acier doit toujours être enroulé sur la partie inférieure du t ambour tel qu'indiqué par

l'autocollant apposé sur le treuil.

Enrouler mécaniquement le câble sur le tambour de manière uniforme et serrée. Cela empêche les

spires extérieures de s’enfoncer dans les spires intérieures, ce qui peut coincer et endommager le

câble.

Pour éviter les charges de choc durant l’enroulement du câble, actionner l’interrupteur de commande

de manière intermittente afin d'éliminer le mou du câble. Les charges de choc peuvent

momentanément dépasser de loin la capacité du treuil et du câble.

ENROULEMENT À VIDE

Enroulement assisté : Demander à un assi stant de tenir le crochet avec une corde ou un chiffon en

appliquant une tension aussi constante que possible sur le câble. Tout en maintenant la tension, il

devra se déplacer en direction du treuil pendant l'actionnement de l'interrupteur de commande pour

enrouler le câble. Relâcher l’interrupteur lorsque le crochet parvient à une distance minimum de

1,2 m de l’ouverture du gui de-câble. Enrouler le reste du câble.

Enroulement non assisté : Arranger le câble à enrouler de manière à ce qu’il ne s’entortille ni ne

s’emmêle pendant le rembobinage. S'assurer que le câble est enroulé sur le tambour de manière

uniforme et serrée. Enrouler une quantité suffisante de câble pour compléter une couche entière sur

le tambour. Serrer et étaler de manière égale la couche de câble. Refaire de même jusqu’à ce que le

crochet soit à au moins 1,2 m du guide-câble. Enrouler le reste du câble.

ENROULEMENT DU RESTE DU CÂBLE POUR LE RANGER

Éloigner les mains du câble, du crochet et de l'ouverture du guide-câble. Toujours utiliser un chiffon ou un

cordon pour tenir le crochet lorsque le câble est enroulé à vide. Enrouler mécaniquement le reste du câble

avec soin, en actionnant l’interrupteur de commande par petits coups afin d’éliminer le mou restant. Fixer le

crochet à un point d'ancrage approprié près du treuil. Éviter de trop tendre pour ne pas endommager le câble

ou le point d'ancrage

.

CÂBLAGE

Toujours dérouler autant de câble que possible avant de procéder au câblage. Choisir un point

d'ancrage approprié aussi distant que possible. Cela assure au treuil une puissance de traction

maximum.

Un câblage double avec poulie ouvrante permet de réduire de moitié la charge subie par le treuil sans

perte sensible de vitesse de rembobinage.

Des ancrages naturels tel qu’arbres, souches et rochers sont très utiles lorsqu’ils sont disponibles.

Attacher une chaîne ou câble à nœud coulant ou une protection de tronc d'arbre sur le point

d’ancrage aussi bas que possible pour éviter de tirer le point d’ancrage ver s le bas. Si plusieurs

ancrages sont disponibles mais qu’ils ne sont pas assez solides individuellement, il peut être prat iq ue

de les réunir en faisant un nœud coulant avec un câble ou une chaîne afin de constituer un puissant

point d’ancrage collectif.

Page 42

PAGE 42 99387 Rev. A0

Mode d'emploi - suite

SURCHARGE/SURCHAUFFE

Ce treuil est conçu pour un service intermittent. Ne pas le faire fonctionner avec le moteur tournant à bas

régime. Lorsque le moteur du treuil atteint une vitesse si faible qu’il peut caler, il se met à

surchauffer très rapidement, ce qui peut l’endommager. Un câblage double permet de réduire la

consommation de courant du moteur, ce qui permet une utilisation continue prolongée (voir la

section Câblage).

Entretien et garantie

ENTRETIEN

Aucune lubrification n’est nécessaire pendant la durée de service du treuil.

Inspecter le câble avant et après chaque utilisation du treuil. Le remplacer s’il est endommagé.

GARANTIE

Voir la feuille emballée avec l e tr eui l

-ou-

Si la feuille de garantie est per due ou introuvable, contacter :

Warn Industries, Inc.

Customer Service Dept.

12900 SE Capps Rd

Clackamas, OR 97015-8903.

États-Unis :

Tél : 503.722.1200 ou (800) 543-9276 (États-Unis seulement)

Télécopie : 503.722.3000

International :

Tél : 503.722.3008

Télécopie : 503.722.3005

© 2017 Copyright Warn Industries, Inc. All ri g hts reserved.

Loading...

Loading...