Page 1

INSTALLATION INSTRUCTIONS

UNIVERSAL PLOW MOUNT KIT

Part Number: 91810

GENERAL SAFETY PRECAUTIONS

Your safety, and the safety of others, is very important. To help you make informed decisions about safety, we have

provided installation and operating instructions and other information on labels and in this guide. This information

alerts you to potential hazards that could hurt you or others. It is not possible to warn you about all potential hazards

associated with this product, you must use your own good judgment.

CARELESS INSTALLATION AND OPERATION CAN RESULT IN SERIOUS INJURY OR EQUIPMENT DAMAGE. READ AND

UNDERSTAND ALL SAFETY PRECAUTIONS AND OPERATING INSTRUCTIONS BEFORE INSTALLING AND OPERATING THIS

PRODUCT.

This guide identies potential hazards and has important safety messages that help you and others avoid personal injury

or death. WARNING and CAUTION are signal words that identify the level of hazard. These signal words mean:

WARNING signals a hazard that could cause serious injury or death, if you do not follow recommendations. CAUTION

signals a hazard that may cause minor to moderate injury, if you do not follow recommendations.

This guide uses NOTICE to call attention to important mechanical information, and Note: to emphasize general

information worthy of special attention.

WARNING

IMPACT AND MOVING PARTS ENTANGLEMENT HAZARD

Failure to observe these instructions could lead to severe injury or death

• Always Read the Plow Operator’s Manual, the Winch Operator’s Manual and all warning labels before operating.

• Always use extreme caution when drilling on any vehicle. Make sure that all fuel lines, brake lines, electrical wires, and other objects are not punctured

or damaged when/if drilling on the vehicle. Thoroughly inspect the area to be drilled (on both sides of material) prior to drilling, and relocate any objects

that may be damaged. Failure to inspect the area to be drilled may result in vehicle damage, electrical shock, re or personal injury.

• Always wear safety glasses when installing this kit. A drilling operation will cause ying metal chips. Flying chips can cause eye injury.

• Always use extreme caution when cutting and trimming during tting.

• Always remove jewelry and wear eye protection.

• Always use appropriate and adequate care in lifting components into place.

• Always insure components will remain secure during installation and operation.

• Always tighten all nuts and bolts securely, per the installation instructions.

• Always operate the vehicle at a walking speed with the blade installed. Never exceed 5 mph (8 km/h), even with blade up.

• Always plow cautiously, impact with hidden or stationary object may cause the vehicle to stop suddenly or go out of control.

• Never operate the vehicle on slopes greater than 10 degrees with the plow installed.

• Never stand or ride on the plow.

• Always stay clear of moving parts and joints. Always keep others away when operating or adjusting plow.

• Always perform regular inspections and maintenance on the plow mechanism, fasteners, cable and related hardware.

• Always replace all worn or damaged parts before operating.

• Never operate this WARN product with damaged or missing parts.

• Always drive slowly over bumpy and rough terrain. Driving at speeds that cause the plow to bounce while in the up position can cause the winch to backdrive, causing the plow to work its way down. This may result in the plow impacting a stationary object and cause damage to the vehicle and operator

injury or death.

• Always drive at speeds such that the plow does not bounce and be aware of the plow position while driving at all times.

• Never raise the top of the plow above the headlights of the ATV, as it may damage the vehicle and plow.

Read installation and operating instructions thoroughly.

WARN INDUSTRIES, INC. 12900 S.E. Capps Road,

Clackamas, OR USA 97015-8903, 1-503-722-1200, FAX: 1-503-722-3000

Customer Service: 1-800-543-9276

Dealer Locator Service: 1-800-910-1122

International Sales/Customer Service: 1-503-722-3008

International Fax: 1-503-722-3005

©2013 Warn Industries, Inc. WARN® and the WARN logo are trademarks of Warn Industries Inc. 1 91853A0

Page 2

CAUTION

MOVING PARTS ENTANGLEMENT HAZARD

Failure to observe these instructions could lead to minor or moderate injury

• Always take time to fully read and understand the installation and Operations Guide included with this product.

• Never operate this product if you are under 16 years of age.

• Never operate this product when under the inuence of drugs, alcohol or medications.

Read installation and operating instructions thoroughly.

NOTICE

EQUIPMENT DAMAGE

• Use caution while mount is on vehicle without plow.

• Remove plow mount before recreational riding. Damage to plow mount parts may occur.

• Always store this product out of the weather between use to protect against corrosion and freezing, and keep product operating smoothly.

Read installation and operating instructions thoroughly.

TABLE OF CONTENTS

Tools Required .............................................................................................................................page 2

Parts List.........................................................................................................................................page 3

Installation ................................................................................................................................ page 4-7

Torque Specications ................................................................................................................page 6

Pre-Operation System Check .................................................................................................page 7

Maintenance/Care ......................................................................................................................page 8

Service ............................................................................................................................................ page 8

NOTES

• Your WARN® Universal Plow Mount Kit ts most, but not all ATVs. For any installation questions, contact your WARN

product dealer where you purchased your Universal Plow Mount Kit. If you are still unable to resolve the problem

please call Warn Industries Customer Service at: 1-800-543-9276.

• You will need to purchase a Plow Base, Plow Blade and a Plow blade-raising mechanism separately to complete your

plow system. For information on available kits, contact your authorized WARN product dealer or call Warn Industries

Customer Service at: 1-800-543-9276 for parts assistance. You may also visit our website: www.warn.com.

• These instructions assume that the factory skid plates are removed. Permanent factory skid plates will require drilling.

TOOLS REQUIRED

1/2” and 9/16” 23/64” drill bit Grease Pencil or Center

Punch

Tape Measure

©2013 Warn Industries, Inc. WARN® and the WARN logo are trademarks of Warn Industries Inc. 2 91853A0

Page 3

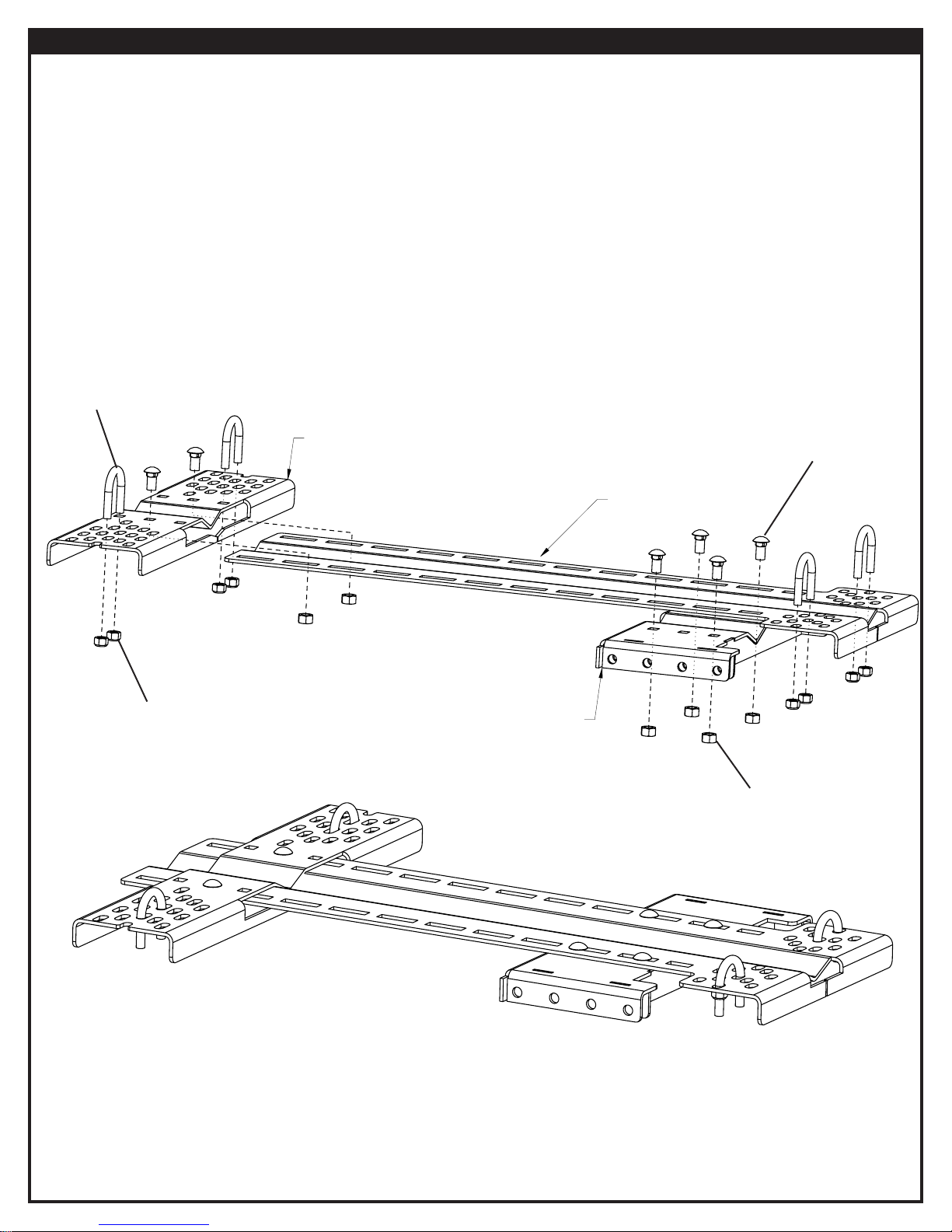

PARTS LIST

Part Number Qty Description

91811 1 PUSH TUBE ATTACH BRACKET

91809 1 ADJUSTABLE REAR CONTACT PLATE

91814 1 SPINE PLATE

63267 6 3/8 16 X 3/4 CARRIAGE HEAD BOLT

6779 6 3/8 16 LOCKING HEX NUT

2002 8 5/16 18 LOCKING HEX NUT

60869 4 5/16 18 X 13/8 X 2” UBOLT

60870 4 5/16 18 X 1 1/4 X 1 3/4” UBOLT (not shown)

61461 4 5/16 18 X 1 1/4 X 2” UBOLT (not shown)

5/16 - 18 X 1-3/8 X 2” U-bolt

5/16 - 18 Locking Hex Nut

Adjustable Rear Contact Plate

Push Tube Attach Bracket

3/8 - 16 x 3/4- Carriage Head Bolt

Spine Plate

3/8 - 16 Locking Hex Nut

Front of Vehicle

Final Assembly Reference

©2013 Warn Industries, Inc. WARN® and the WARN logo are trademarks of Warn Industries Inc. 3 91853A0

Page 4

INSTALLATION INSTRUCTIONS

WARNING

Always use extreme caution when drilling on any vehicle. Make sure that all fuel lines, brake lines, electrical wires, and other objects are not

punctured or damaged when/if drilling on the vehicle. Thoroughly inspect the area to be drilled (on both sides of material) prior to drilling, and relocate any

objects that may be damaged. Failure to inspect the area to be drilled may result in vehicle damage, electrical shock, re or personal injury.

WARNING

WARNING

Always wear safety glasses when installing this kit. A drilling operation will cause ying metal chips. Flying chips can cause eye injury.

Always take time to fully read and understand the installation and Operations Guide included with this product.

1. INSTALLATION 2. INSTALLATION

Factory Skid Plate

Figure 1: Locate skid plate and remove if possible.

Figure 2: Determine proper u-bolt size. U-bolt type must match frame tube cross

section.

3. INSTALLATION

(4) U-bolts

Place two u-bolts near the front end of frame (near or between front a-arms) and two u-bolts in the rear of frame (near or between foot

pegs). The front and rear sets of u-bolts should be no less than 10 inches and no more than 25 inches apart.

Front of vehicle

Front of vehicle

U-bolts 10” - 25” apart

Figure 3: Correct Placement (u-bolts parallel and between 10” - 25” apart).

©2013 Warn Industries, Inc. WARN® and the WARN logo are trademarks of Warn Industries Inc. 4 91853A0

Figure 4: Incorrect Placement - (u-bolts not parallel and over 25” apart)

Page 5

4. INSTALLATION

NOTE: If skid plate is NOT present, skip to step 7.

(1) Spine Plate

(1) Grease pencil or center punch

Front of spine plate less than

19 inches from the front of

the forward facing tires.

<19”

5. INSTALLATION

(1) Adjustable Rear Contact Plate

(1) Grease pencil or center punch

Figure 5: While centering spine plate, align with front u-bolts and mark skid plate

for clearance hole drilling.

6. INSTALLATION

WARNING

that all fuel lines, brake lines, electrical wires, and other objects are not punctured or

damaged when/if drilling on the vehicle. Failure to inspect the area to be drilled may

result in vehicle damage, electrical shock, re or personal injury.

NOTICE

and relocate any objects that may be damaged and then drill clearance holes for u-bolts.

NOTE: During operation, vibration may occur between skid plate and mount. Before installing

Always use extreme caution when drilling on any vehicle. Make sure

Thoroughly inspect the area to be drilled (on both sides of material) prior to drilling,

your plow mount, you may choose to add a sheet rubber isolator between skid plate and

mount, to eliminate excess vibration.

Figure 6: While centering rear contact plate, align with rear u-bolts and mark skid

plate for clearance hole drilling.

7. INSTALLATION

(2) U-bolts

(4) 5/16 - 18 Locking Hex Nut

Figure 8: Insert front pair of u-bolts through skid plate clearance holes and spine

Figure 7: Drill skid plate for u-bolt clearance holes.

©2013 Warn Industries, Inc. WARN® and the WARN logo are trademarks of Warn Industries Inc. 5 91853A0

plate. Loosely attach front end of the spine plate to u-bolts.

Page 6

8. INSTALLATION 9. INSTALLATION

(4) 3/8 - 16 x 3/4- Carriage Head Bolt

(1) Push Tube Attach Bracket

<24”

(4) 3/8 - 16 Locking Hex Nut

Pin Holes

Figure 8: Place push tube bracket against the spine bracket and adjust until a set

Pin Holes

Figure 9: Loosely fasten push tube bracket to spine bracket with carriage bolts and

of pin holes are less than 24 inches from the front of the forward facing tires.

10. INSTALLATION 11. INSTALLATION

(2) 3/8 - 16 x 3/4- Carriage Head Bolt

(1) Adjustable rear contact plate

(2) 3/8 - 16 Locking Hex Nut

locking nuts.

Figure 10: Slide adjustable rear contact plate onto spine plate to align with rear

Figure 11: Loosely secure rear contact plate to spine with carriage bolts.

u-bolts. Do not fasten at this time.

©2013 Warn Industries, Inc. WARN® and the WARN logo are trademarks of Warn Industries Inc. 6 91853A0

Page 7

12. INSTALLATION 13. INSTALLATION

(2) U-bolt

(4) 5/16 - 18 Locking Hex Nut

(4) U-bolt

(8) 5/16 - 18 Locking Hex Nut

(6) 3/8 - 16 x 3/4- Carriage Head Bolt

(6) 3/8 - 16 Locking Hex Nut

Figure 13: Tighten all hardware to torque specications in chart below.Figure 12: Loosely fasten rear contact plate to rear u-bolts with locking nuts.

TORQUE SPECIFICATIONS

Please use the recommended torque specications when assembling this product unless otherwise specied.

FASTENER SIZE FASTENER TORQUE Socket /Wrench Size

lb-ft (N.m)

5/16" U-bolt 17 (23) 1/2” socket

3/8" Carriage Bolt 30 (40) 9/16” socket

PRE-OPERATION SYSTEM CHECK

Perform system check:

1. Verify mount orientation is correct (see nal assembly image on page 3 for reference).

2. Check fasteners and make sure they are tight and to proper torque.

3. Verify that plow blade can rotate freely without interfering with tires or vehicle body. If interference is found, it may be necessary

to adjust the location of the plow mount towards the front of the vehicle.

4. Verify maximum plow lift height to avoid damage to plow mount, push tubes and frame.

Once system check has been performed, you are ready to operate your plow system.

©2013 Warn Industries, Inc. WARN® and the WARN logo are trademarks of Warn Industries Inc. 7 91853A0

Page 8

Figure 14: *Complete mount assembly shown with push tube and plow blade installed.

* Plow Base, Plow Blade and Plow blade-raising mechanism sold separately. For complete plow system options, go

to www.warn.com for the complete line of plow accessories available.

MAINTENANCE / CARE

• Inspect all metal parts on the plow, plow mount, and related hardware. Replace all parts that appear rusted or deformed prior to

use.

• Inspect all nuts and bolts on the plow, plow mount, and related hardware prior to each use. Tighten all nuts and bolts that appear

to be loose. Stripped, fractured, or bent bolts or nuts need to be replaced immediately.

• Check all moving and rotating parts. Remove debris that may inhibit the part from moving freely. Store out of the weather between use to protect against corrosion, freezing and to keep operating smoothly.

SERVICE

1. Refer to these installation instructions for illustrations and detailed information on the installation, safe and proper operation and

assembly diagrams of your Universal Plow Mount. If you are unable to resolve the problem, then go to step 2.

2. Contact your dealer where you purchased your Universal Plow Mount Kit. If, after discussing the problem with their parts and

service sta, you are still unable to resolve the problem then go to step 3.

3. If you are unable to resolve the problem to your satisfaction, please call Warn Industries Customer Service at: 1-800-543-9276. You

may also contact Warn Industries by visiting our website: www.warn.com.

CARELESS INSTALLATION AND OPERATION CAN RESULT IN SERIOUS INJURY OR EQUIPMENT DAMAGE. READ AND UNDERSTAND ALL

SAFETY PRECAUTIONS AND OPERATING INSTRUCTIONS BEFORE INSTALLING AND OPERATING THIS PRODUCT.

©2013 Warn Industries, Inc. WARN® and the WARN logo are trademarks of Warn Industries Inc. 8 91853A0

Loading...

Loading...