Page 1

ORIGINAL INSTRUCTIONS

Winch Installation Guide

Every winching situation has the potential for personal injury. In order to minimize that risk, it is important to read this guide

and The Basic Guide to Winching Techniques carefully. Please familiarize yourself with the operation of your winch before

using it and be constantly safety oriented. In this guide we provide important safety information and instructions on how to

install your winch. Please read the Basic Guide to Winching Techniques for information on how to properly use your winch

and proper rigging techniques.

Please keep this manual and other product literature found in this kit for future reference. In this kit you will find the following

pieces of literature: Winch Installation Guide, Basic Guide to Winching Techniques, Specification and Performance Data,

Product Warranty, Replacement Parts List and other product literature specific to some products.

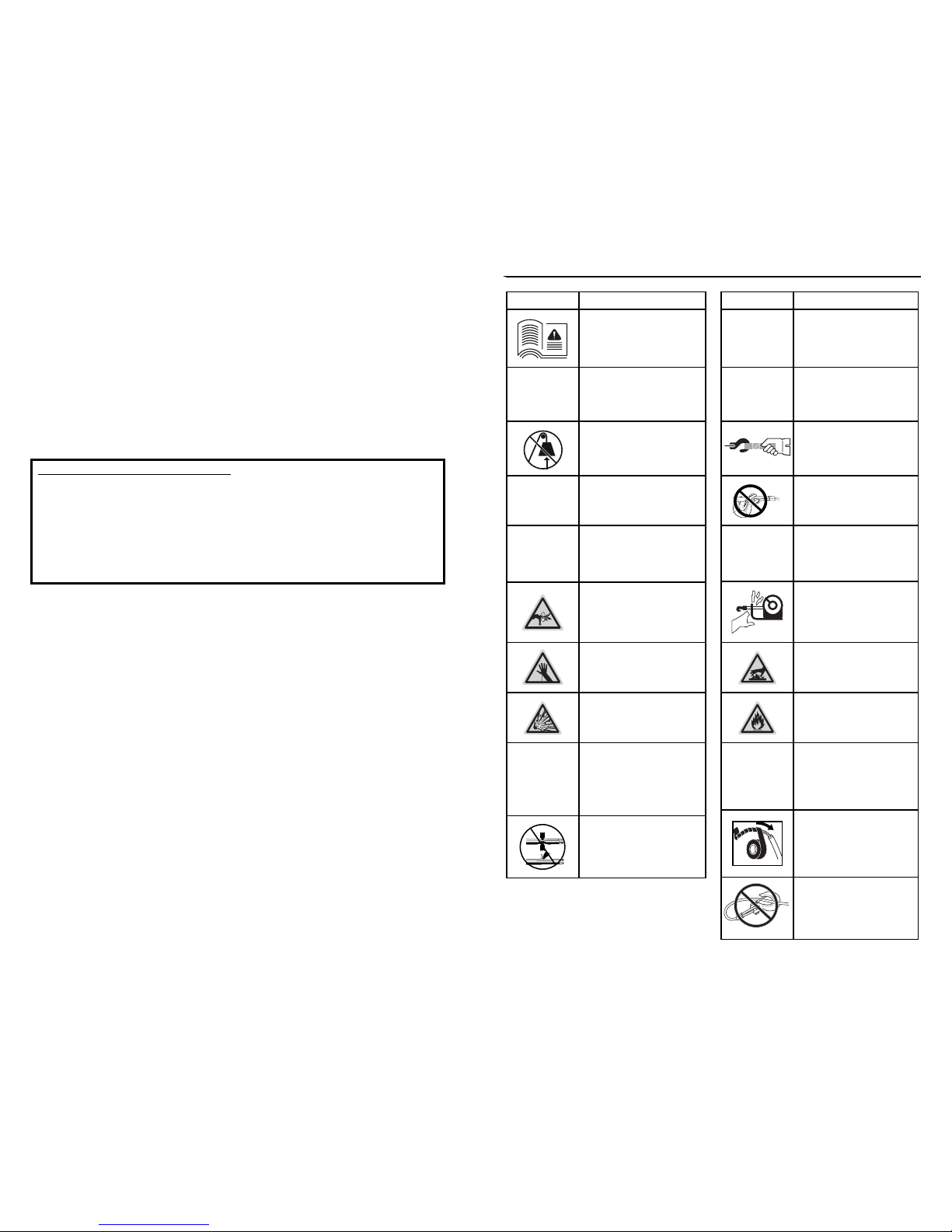

SYMBOL INDEX

SYMBOL EXPLANATION

Read All Product

Literature

Always Wear Hearing

and Eye Protection

Never Use Winch as a

Hoist

Properly Seat Load in

Throat of Hook

Wind Rope on Bottom

of Drum

Finger/Fairlead

Crushing Hazard

Hand Piercing/Cutting

Hazard

Explosion/Bursting

Hazard

Never Route Electrical

Cables through Sharp

Edges Hazard

Avoid Installing

Electrical Cables

around Pinch and Wear/

Abrasion Points

SYMBOL EXPLANATION

Always Wear Leather

Gloves

Do Not Move People

Always Use Supplied

Hook Strap

Never Apply Load to

Hook Tip or Latch

Never Wind Rope Over

Top of Drum

Fairlead Pinch Point

Hot Surface Hazard

Fire and Burn Hazard

Never Route Electrical

Cables through or near

Moving Parts Hazard

Exposed Wiring

Hazard, Insulate

Exposed Wiring and

Terminals

Never Hook Back on

Rope

Page 2

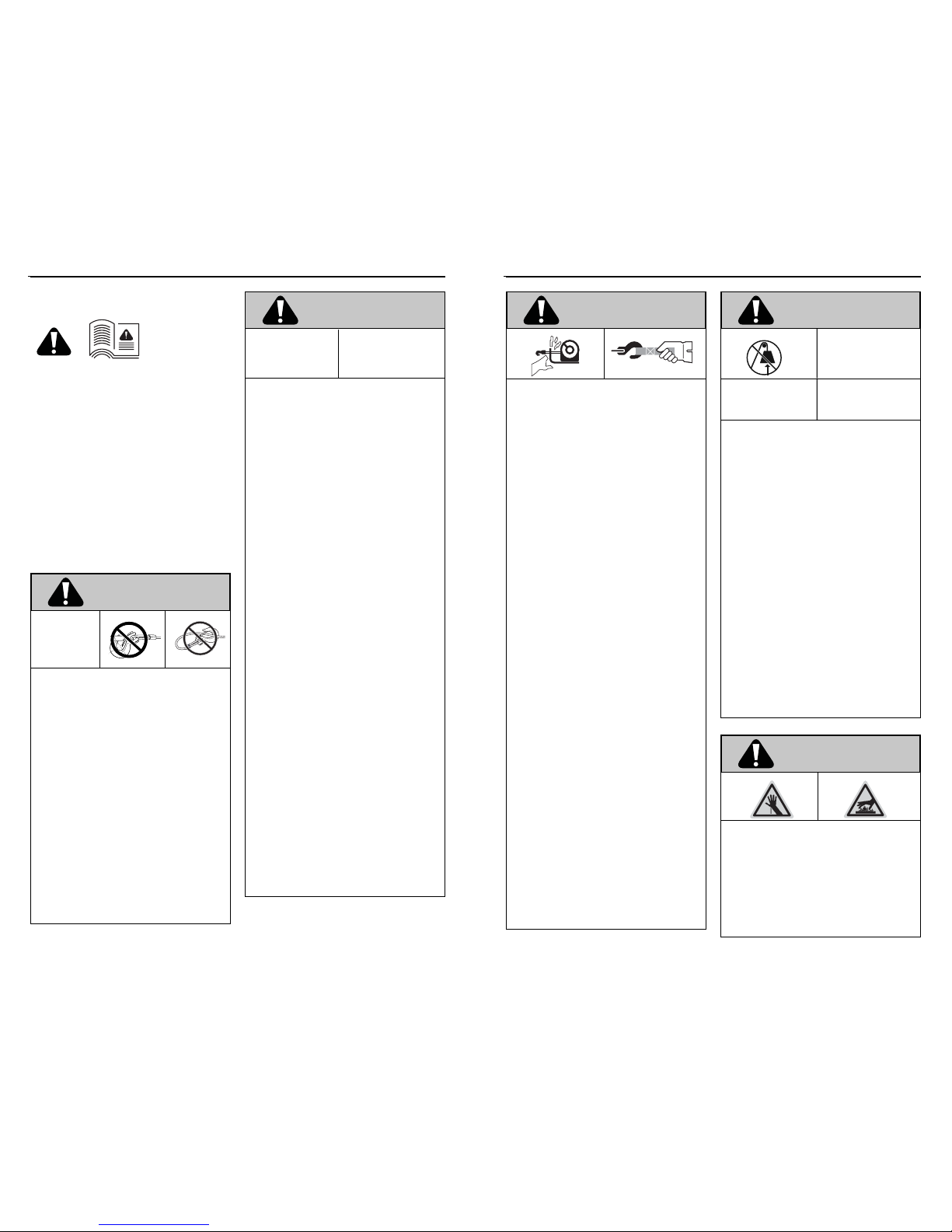

GENERAL SAFETY PRECAUTIONS

As you read these instructions, you will see

WARNINGS, CAUTIONS, NOTICES and NOTES.

Each message has a specifi c purpose. WARNINGS

are safety messages that indicate a potentially

hazardous situation, which, if not avoided could result

in serious injury or death. CAUTIONS are safety

messages that indicate a potentially hazardous

situation which, if not avoided, could result in minor

or moderate injury. A CAUTION may also be used

to alert against unsafe practice. CAUTIONS and

WARNINGS identify the hazard, indicate how to avoid

the hazard, and advise of the probable consequence

of not avoiding the hazard. NOTICES are messages

to avoid property damage. NOTES are additional

information to help you complete a procedure.

PLEASE WORK SAFELY!

Warnings and Cautions

MOVING PARTS ENTANGLEMENT

HAZARD

Failure to observe these instructions could

lead to serious injury or death.

• Always ensure hook latch is closed and not

supporting load.

• Never apply load to hook tip or latch. Apply load

only to the center of hook.

• Never use a hook whose throat opening has

increased, or whose tip is bent or twisted.

• Always use a hook with a latch.

• Always ensure the operator and bystanders are

aware of the stability of the vehicle and/or load.

• Always keep wired remote control lead and

power cord clear of the drum, rope, and rigging.

Inspect for cracks, pinches, frayed wires or loose

connections. Damaged components must be

replaced before operation.

• Always pass remote lead thru window when used

in vehicle.

• Never hook back on rope.

MOVING PARTS ENTANGLEMENT

HAZARD

Failure to observe these instructions could

lead to serious injury or death.

General Safety:

• Always Know Your Winch. Take time to fully read

the Instructions and/or Operations Guide, and/or

Basic Guide to Winching Techniques, in order to

understand your winch and its operations.

• Never exceed winch or winch rope rated capacity.

Double line using a snatch block to reduce winch

load.

• Always wear heavy leather gloves when handling

winch rope.

• Never use winch or winch rope for towing. Shock

loads can damage, overload and break rope.

• Never use a winch to secure a load.

• Never operate this winch when under the infl uence

of drugs, alcohol or medication.

• Never operate this winch if you are under 16 years

of age.

Installation Safety:

• Always choose a mounting location that is

suffi ciently strong to withstand the maximum pulling

capacity of your winch.

• Always use class 8.8 metric (grade 5) or better

hardware.

• Never weld mounting bolts.

• Always use factory approved mounting hardware,

components, and accessories.

• Never use bolts that are too long.

• Always complete the winch installation and hook

attachment before installing the wiring.

• Always keep hands clear of winch rope, hook

loop, hook and fairlead opening during installation,

operation, and when spooling in or out.

• Always position fairlead with warning readily visible

on top.

• Always prestretch rope and respool under load

before use. Tightly wound rope reduces chances of

“binding”, which can damage the rope.

WARNING

WARNING

GENERAL SAFETY PRECAUTIONS

MOVING PARTS ENTANGLEMENT

HAZARD

Failure to observe these instructions could

lead to serious injury or death.

Winching Safety:

• Always inspect winch rope, hook, and slings

before operating winch. Frayed, kinked

or damaged winch rope must be replaced

immediately. Damaged components must be

replaced before operation. Protect parts from

damage.

• Always remove any element or obstacle that may

interfere with safe operation of the winch.

• Always be certain the anchor you select will

withstand the load and the strap or chain will not

slip.

• Always use supplied hook strap whenever

spooling winch rope in or out, during installation

and during operation.

• Always require operators and bystanders to be

aware of vehicle and or load.

• Always be aware of stability of vehicle and load

during winching, keep others away. Alert all

bystanders of an unstable condition.

• Always unspool as much winch rope as possible

when rigging. Double line or pick distant anchor

point.

• Always take time to use appropriate rigging

techniques for a winch pull.

• Never touch winch rope or hook while someone

else is at the control switch or during winching

operation.

• Never engage or disengage clutch if winch is

under load, winch rope is in tension or drum is

moving.

• Never touch winch rope or hook while under

tension or under load.

• Always stand clear of winch rope and load and

keep others away while winching.

• Never use vehicle to pull load on winch rope.

Combined load or shock load can damage,

overload and break rope.

• Never wrap winch rope back onto itself. Use a

choker chain or tree trunk protector on the anchor.

FALLING OR CRUSHING HAZARD

Failure to observe these instructions could

lead to serious injury or death.

• Always stand clear, keep hands clear, keep others

away.

• Never operate winch with less than 5 wraps of rope

around the drum. Rope could come loose from the

drum, as the rope attachment to the drum is not

designed to hold a load.

• Never use winch as a hoist or to suspend a load.

• Always be certain anchor will withstand load, use

appropriate rigging and take time to rig correctly.

• Never use winch to lift or move persons.

• Never use excessive effort to freespool winch rope.

• Always use proper posture/lifting technique or

get lifting assistance while handling and installing

product.

• Always spool the rope onto the drum in the

direction specifi ed by the winch warning label on

the winch and/or documentation. This is required

for the automatic brake (if so equipped) to function

properly.

• Always spool the winch rope onto the drum as

indicated by the drum rotation label.

CUT AND BURN HAZARD

Failure to observe these instructions could

lead to serious injury or death.

To avoid injury to hands and fi ngers:

• Always wear heavy leather gloves when handling

winch rope.

• Always be aware of possible hot surfaces at winch

motor, drum or rope during or after winch use.

WARNING WARNING

WARNING

Page 3

GENERAL SAFETY PRECAUTIONS

AVOID WINCH AND EQUIPMENT

DAMAGE

• Always avoid side pulls which can pile up winch

rope at one end of the drum. This can damage

winch rope or winch.

• Always ensure the clutch is fully engaged or

disengaged.

• Always use care to not damage the vehicle frame

when anchoring to a vehicle during a winching

operation.

• Never submerge winch in water.

• Always store the remote control in a protected,

clean, dry area.

NOTICE

MOVING PARTS ENTANGLEMENT

HAZARD

Failure to observe these instructions could

lead to minor or moderate injury.

To avoid injury to hands or fi ngers:

• Never leave remote control where it can be

activated during free spooling, rigging, or when the

winch is not being used.

• Never leave the winch remote control plugged in

when installing, freespooling, rigging, servicing or

when the winch is not being used.

CHEMICAL AND FIRE HAZARD

Failure to observe these instructions could

lead to serious injury or death.

• Always remove jewelry and wear eye protection.

• Never route electrical cables across sharp edges.

• Never route electrical cables near parts that get

hot.

• Never route electrical cables through or near

moving parts.

• Always place the supplied terminal boots on

wires and terminals as directed by the installation

instructions.

• Never lean over battery while making

connections.

• Never route electrical cables over battery

terminals.

• Never short battery terminals with metal objects.

• Always verify area is clear of fuel lines, fuel tank,

brake lines, electrical wires, etc., when drilling.

• Always consult operator’s manual for proper

wiring details.

• Always insulate and protect all exposed wiring

and electrical terminals.

CUT AND BURN HAZARD

Failure to observe these instructions could

lead to minor or moderate injury.

• Never let winch rope slip through your hands.

CAUTION

WARNING CAUTION

SAFE WORKING CONDITIONS

Safety

When installing your ATV/UTV winch

system, read and follow all mounting and

safety instructions.

Always use caution when working with

electricity and remember to verify that no

exposed electrical connections exist before

energizing your winch circuit.

For specifications and performance data,

refer to the specification sheet supplied with

your winch.

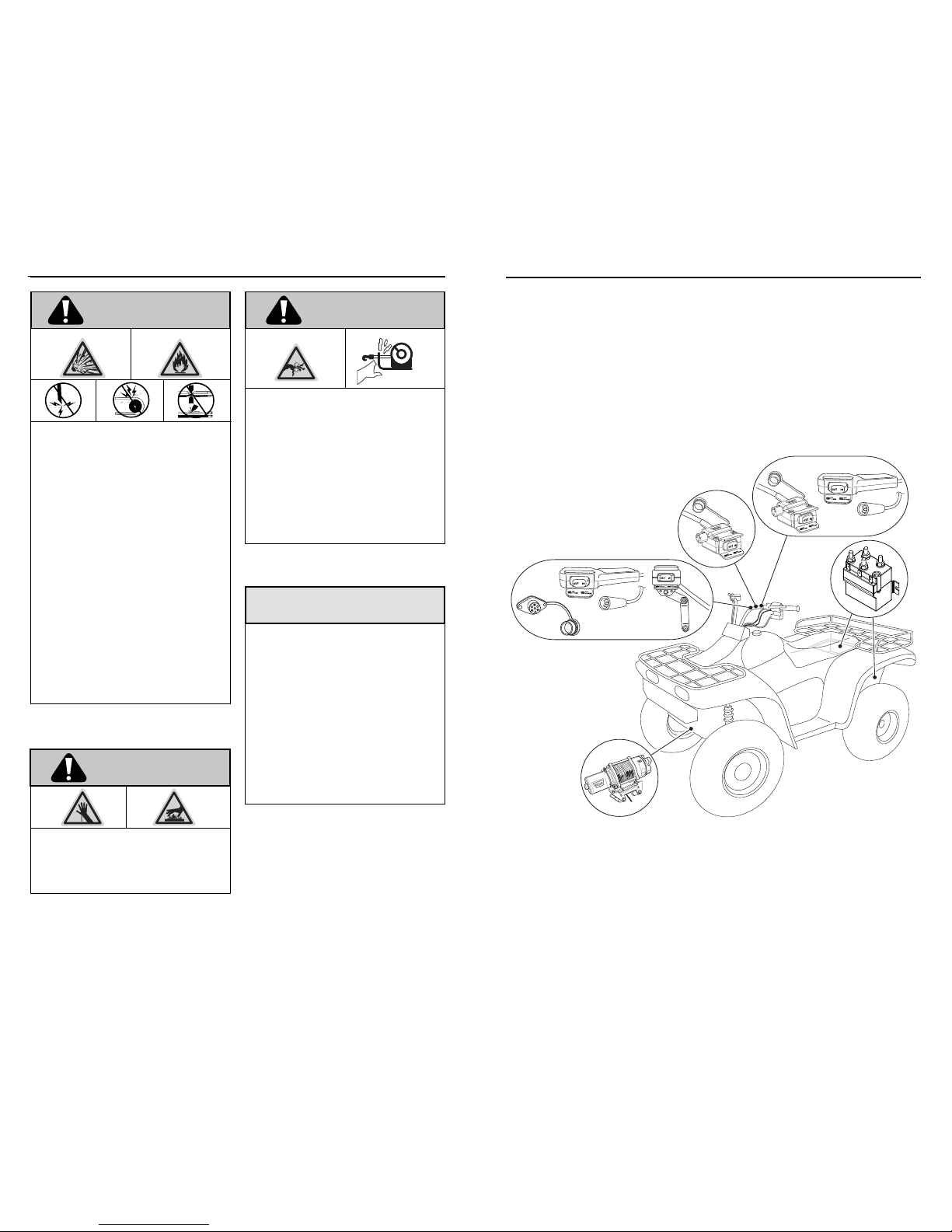

Figure 1: To install the complete kit, you will need to mount the winch, contactor

handlebar mounted Mini-rocker switch and remote socket (optional on some models). Mounting locations may vary depending

on make and model of the ATV/UTV. Read and understand the following instructions to choose the appropriate mounting

locations.

Page 4

MOUNTING

Step 1 - Mount the Winch

ATV/UTV winch mounting kits are available from

your WARN Dealer to satisfy nearly all ATV/UTV

applications. For information on available kits,

contact your WARN product dealer.

NOTE: For optimal performance and the results

you expect, WARN mounting plates are strongly

recommended.

CAUTION

To prevent accidental activation

of the winch and serious injury, complete the winch

installation and attach the hook before installing the

wiring.

To secure the winch, always use:

• A flat, secure mounting location at least 4.8

mm (3/16 in.) thick.

• 8 mm (5/16 in.) Lock washers.

• M8-1.25 X 20 mm, class 8.8 hex head cap

screws when using a one-piece winch mount

plate.

Figure 2 and 3: Orientation of winch to mounting plate and bolt lengths.

20mm25mm20mm

NOTE: When using separate winch mount and

fairlead plates use M8-1.25 X 25 mm class 8.8

hex head cap screws on the motor side of the

base as shown in Figure 3.

1. Set winch in mounting location. Torque the

mounting bolts to 16 N-m (12 lb-ft).

2. Remove bottom tie bolt. This bolt should be

retained for winch service.

3. Remove elastic band retaining rope.

4. Put clutch in freespool position.

5. Manually feed cable loop through fairlead.

6. Attach hook to cable loop and re-engage

clutch.

WARNING

Always use supplied hook strap.

7. Install hook strap on hook.

MOUNTING

Step 2 - Mount the Contactor

•

1.

Your new WARN winch can do a lot of work!

This work is the conversion of electrical power

into mechanical power. The contactor is

the electromagnetic switch that controls the

electrical power to your winch. The contactor

must be correctly installed for it and the winch

to work properly. The following instructions

will assist you in the installation of your WARN

contactor.

Disconnect the vehicle battery cables,

negative terminal first. All work with

electrical wires and cables must be

completed with the battery completely

disconnected from the vehicle wiring.

WARNING

To prevent severe injury or death.

Never lean over battery while making connections.

WARNING

To prevent severe injury or death.

Never route electrical cables over battery terminals.

WARNING

To prevent severe injury or death.

Never short battery terminals with metal objects.

2. It is recommended that the contactor be

mounted close to the battery and in a

location that is as clean and dry as possible.

Figure 4. Contactor for

the WARN ATV/UTV winc

WARNING! Do not mount on or near a heat

source such as engine or exhaust. Ensure the

selected location does not collect or retain

water and the mounting of the contactor

does not block drain holes. Exact location

will vary depending on the ATV/UTV. Typical

locations include inside, on top or on the side

of rear storage box, under the seat or, on a

few models, in front near battery.

3. Ensure the contactor mounting location

selected provides sufficient clearance from

all metal structures such as frame tubes. Do

NOT place tools or other items in a position

that might come in contact with the contactor

posts.

WARNING

To prevent severe injury or death.

Always verify area is clear of fuel lines, fuel tank, brake

lines, electrical wires, etc., when drilling.

4. Drill the mounting holes for the contactor and

proceed to step three. Do NOT mount the

contactor at this time.

Black Terminal

(negative -)

Blue Terminal

(negative -)

Mounting Bracket

Black Spade

Connector

Brown Spade

Connector

Yellow Terminal

(positive +)

Green Spade

Connector

Red Terminal

(positive +)

Page 5

MOUNTING

Step 3- Mount the Handlebar

Switch

WARNING

To prevent serious injury or death from

electrical fi re:

Never route electrical cables across sharp

edges.

Never route electrical cables near parts that

get hot.

Never route electrical cables through or near

moving parts.

Avoid pinch and wear/abrasion points when

installing all electrical cables.

WARNING

To avoid injury and property damage:

Use caution if moving or repositioning the ATV/UTV

controls so as to not compromise the safe operation

of the ATV/UTV. Select a mounting position that will

provide clearance for all vehicle controls.

Before securing the switch cable with tie wraps, make

sure that the handlebars have full range of motion.

1. Switch should be installed on the left

handlebar. A piece of electrical tape around

the handlebar will help prevent rotation of

mount on the handle bar.

2. Do NOT tighten over any hoses or cables.

3. Once the handlebar switch is mounted, route

the wire harness to where the contactor will

be mounted.

4. Using the provided wire splice, splice the

end of the red 20ga wire to a key controlled,

fused, accessory circuit (power-point) of the

ATV/UTV. The wire should only have power

when the key is in the “ON” position.

Figure 5: Handlebar Mount. Exact positioning may vary

depending on the ATV/UTV make and model.

Figure 6: Mini-rocker switch assembly.

Splice and tape

wire together

MOUNTING

Step 4 - Mount the Remote

Socket

(optional on some models)

WARNING

To prevent severe injury or death.

Always verify area is clear of fuel lines, fuel tank, brake

lines, electrical wires, etc., when drilling.

WARNING

To prevent serious injury or death from

electrical fi re:

Never route electrical cables across sharp

edges.

Never route electrical cables near parts that

get hot.

Never route electrical cables through or near

moving parts.

Avoid pinch and wear/abrasion points when

installing all electrical cables.

1. Determine the mounting location for the

remote socket, drill three holes and install

(see Figures 7 and 8).

2. Route the wire harness to where the

contactor will be mounted.

3. Using the provided wire splice, splice the

end of the red 20ga wire to a key controlled,

fused, accessory circuit (power-point) of the

ATV/UTV. The wire should only have power

when the key is in the “ON” position.

NOTE: If installing both switches, both 20 gage

red wires MUST be spliced to a key controlled

accessory circuit of the ATV/UTV as described in

step 4, page 9.

Figure 7 and 8. Remote socket installation

10-24 hex nut &

lockwasher

10-24 hex nut & hex

head capscrew

Keyway must point

down

6.4mm (1/4 in.) diameter, 2 places

22.2mm (7/8in.)

22.2mm (7/8in.) diameter

44.5mm (1-3/4in.)

Not to scale. Do NOT use as a template!

Page 6

MOUNTING

Step 5 - Mount the Dash Switch

(optional on UTV models)

WARNING

To prevent severe injury or death.

Always verify area is clear of fuel lines, fuel tank, brake

lines, electrical wires, etc., when drilling.

WARNING

To prevent serious injury or death from

electrical fi re:

Never route electrical cables across sharp

edges.

Never route electrical cables near parts that

get hot.

Never route electrical cables through or near

moving parts.

Avoid pinch and wear/abrasion points when

installing all electrical cables.

1. Determine the dash mounting location for

the dash switch (location is pre-determined

on some specific models). Mount switch

using bracket and supplied fasteners or cut

rectangle slot as shown in Figure 10.

2. Route the wire harness to where the

contactor will be mounted.

3. See wiring diagram provide, with contactor,

for switch wiring detail.

NOTE: If installing both switches, both 20 gage

red wires MUST be spliced to a key controlled

accessory circuit of the ATV/UTV as described in

step 4, page 9.

Figure 9 and 10 Dash Mount Installation

Not to scale. Do NOT use as a template!

21.1mm

(.83in.)

36.8mm

(1.45in.)

#10x5/8 in. sheet metal screw OR

M5x0.8 hexhead capscrew, M5-0.8

nut, washers.

ELECTRICAL CONNECTIONS

Step 6 - Install the Wiring

WARNING

To prevent serious injury or death.

Always place the supplied terminal boots on wires and

terminals as directed by the installation instructions.

All wires must be attached to the contactor before

mounting the contactor to the ATV/UTV.

WARNING

To prevent serious injury or death from

electrical fi re:

Never route electrical cables across sharp

edges.

Never route electrical cables near parts that

get hot.

Never route electrical cables through or near

moving parts.

Avoid pinch and wear/abrasion points when

installing all electrical cables.

WARNING

Always insulate and protect all

exposed wiring and electrical terminals.

1. Slip terminal boots on yellow and blue cable

ends. See Figure 11 on following page.

2. Attach the yellow and blue electrical cables

to the motor terminals on the winch. Yellow

is marked #1 and blue is marked #2 on the

motor. Torque the terminal nuts on the

motor to 5.7 N-m (50 lb-in). Seat boots over

terminal.

3. Route the yellow and blue electrical cables

back to the contactor. Place boots over

ring terminals. Place ring terminals on color

coded contactor posts (yellow cable to yellow

post, blue cable to blue post). Install and

finger tighten nuts to retain ring terminals

on contactor posts. Do NOT tighten nuts or

seat boots at this time.

6. Install boots on ring terminal ends of red

and black cables. Place ring terminals on

color coded contactor posts (red cable to red

post, black cable to black post). Install and

finger tighten nuts to retain ring terminals

on contactor posts. Do NOT tighten nuts or

seat boots at this time. Route red and black

cables to battery. Do NOT connect cables to

battery at this time.

7. Mount the contactor to the location planned

in Step 3. Tighten contactor mounting

fasteners to 5.7 N-m or 50 lb-in.

8. Adjust cables to facilitate orderly and straight

routing of the cables from the contactor.

Avoid kinks or sharp bends in cables. Avoid

crossing cables over each other for at least

the first 6” (152mm) of cable starting from

the contactor post. Torque the contactor

terminal nuts to 4.5 N-m or 45 lb-in. Seat

boots over ring terminals and posts.

9. Carefully inspect battery and winch

electrical cable routing. Is it neat and tidy?

WARNING! Always route and secure

electrical cables away from sharp edges,

away from moving parts and away

from sources of heat. Zip tie and secure

electrical cables and wiring harness. Zip

ties should be snug, but not cutting into wire

insulation. Use electrical tape, pieces of

rubber hose or electrical conduit to protect

electrical cables and wire harness where

needed to avoid electrical cable insulation

wear or abrasion.

10. Attach battery cables, red (positive) cables

FIRST, black (negative) second. Install

boots as appropriate to protect connection.

Torque battery terminal fastener as directed

by vehicle service manual.

Page 7

ELECTRICAL CONNECTIONS

Figure 11. Wiring Installation diagram

Blue

Black

Red

Yellow

Black

Red

Green

Splice and tape

wire together

Remote optional

SYSTEM CHECK

WARNING

To prevent serious injury or death:

Always spool the winch rope onto the drum

as indicated by the drum rotation label.

Always Wind Rope on Bottom of Drum.

Never Wind Rope Over Top of Drum.

Once you have performed system check.

Turn key switch to ON position and check

winch for proper operation. The rope should

spool in and out in the direction indicated on

the switch.

Check

Before fi rst

operation

After each

use

Every 90 days

Take time to fully read the Instructions

and/or Operations Guide, and/or Basic

Guide to Winching Techniques, in order to

understand your winch and its operations

X

Check fasteners and make sure they are

tight and to proper torque.

Replace damaged fasteners.

XXX

Verify wiring to all components is correct

and be certain that all connections are

tight.

XX

Verify there is no exposed/bare wiring or

terminals.

Cover any exposures with terminal

boots, heat shrink tubing or electricians

tape.

XX

Inspect rope for damage.

Replace rope immediately if damaged.

XXX

Keep winch, rope and switch control

free from contaminants.

Use a clean rag or towel to remove

any dirt and debris.

X

INOUT

Loading...

Loading...