IPS 2

IPS650, IPS800, IPS950

Installation

1(1)

E

Content

Safety Information ......................................................................................

2

General Information .................................................................................... 5

Installation Tools and Documentation ...................................................... 8

Special Tools .......................................................................................... 10

System Information .................................................................................. 13

EVC .......................................................................................................... 13

Engine Characteristics ............................................................................. 14

Engine Application Ratings .................................................................. 14

Engine Performance .............................................................................. 15

Arrangement and Planning ...................................................................... 17

Engine Placement .................................................................................. 17

Engine Room .......................................................................................... 19

Sound Absorption .................................................................................. 30

Electrochemical Corrosion ................................................................... 33

Installation ................................................................................................. 51

Volvo Penta IPS ...................................................................................... 51

Fiberglass Hull Constructions ............................................................ 51

Aluminium Hull Constructions ........................................................... 81

Engine Foundation ............................................................................... 82

Propulsion Unit Installation ................................................................ 87

Engine Installation ............................................................................... 92

Extension Shaft .................................................................................... 96

Exhaust System ................................................................................... 98

Cooling System .................................................................................. 100

Fuel System .......................................................................................... 111

General ................................................................................................ 111

Fuel Tanks .......................................................................................... 112

Piping .................................................................................................. 116

Fuel pressure ...................................................................................... 118

Lubrication System .............................................................................. 119

Electrical System ................................................................................. 120

Batteries .............................................................................................. 121

Alternator ............................................................................................ 130

Voltage Supply ................................................................................... 131

Connection ......................................................................................... 132

Fire Extinguishing System .................................................................. 140

Calibration and Settings ......................................................................... 142

IPS Calibration ...................................................................................... 142

Launching and Sea Trial ........................................................................ 148

Alphabetical index .................................................................................. 155

47704162 10-2014 © AB VOLVO PENTA 1

Safety Information

This installation manual contains information required

for the correct installation of your Volvo Penta product. Check that you have the correct manual.

Carefully read the chapters Safety precautions

and General information in the manual before

servicing or running the engine.

The

following types of special warning messages can

be found in this manual and on the engine:

WARNING!

Indicates

a hazardous situation which, if not avoided,

could result in death or serious personal injury.

IMPORTANT!

Indicates a situation which, if not avoided, could result

in property damage.

NOTICE! Important information that facilitates the

work process or item.

Set out below is a list of risks that must always be

borne in mind and the safety precautions that must

always be taken.

Plan ahead so that there is always sufficient

space for safe installation and (future) disassembly.

Lay

out the engine compartment (and other compartments such as the battery compartment) so that all

service points are accessible. Make sure not to come

into contact with rotating components, hot surfaces or

sharp edges when checking and servicing the engine.

Make sure that all equipment (e.g. pump drives, compressors) has protective covers.

Make sure the engine cannot be started while

work is in progress by not connecting the electrical

system or by switching off electrical power to the

engine at the main switches and locking them in the

OFF

position. Erect a warning sign at the helm station.

Only start the engine in well-ventilated areas.

Remember

that exhaust fumes are toxic and dangerous to inhale. Use an exhaust extractor to lead

exhaust fumes away from the exhaust pipe and crankcase ventilator when the engine is run in a confined

space.

Always wear protective goggles if there is a risk

of splinters, sparks and splashes from acid or other

chemicals. Eyes are extremely sensitive and injury

may result in loss of sight!

Avoid getting oil on the skin! Prolonged or

repeated contact with oil may lead to the disappearance

of the skin's natural oils. This will cause irritation,

dry skin, eczema and other skin problems. Old oil is

more hazardous to health than new. Use protective

gloves and avoid oil-soaked clothes and rags. wash

regularly, especially before meals. Use special skin

creams that facilitate cleaning and prevent the skin

from drying out.

Most chemical used in the product (engine and

reverse

gear oil, glycol, gasoline and diesel) or chemicals intended for use in the workshop (degreasing

agents, paints and solvents) are health hazards. Read

the instructions on the product packaging carefully!

Always follow safety instructions (the use of protective

masks, protective goggles, gloves etc.). Make sure

that other personnel are not inadvertently exposed to

hazardous substances, e.g. in the air they breathe.

Ensure good ventilation. Hand in used and surplus

chemicals to a recycling station.

Take extreme care when searching for fuel sys-

tem leaks and testing injectors. Wear protective goggles. The spray from an injector is at very high pressure and fuel can force its way into tissue and cause

a serious risk of blood poisoning (septicemia).

Stop the engine and disconnect the power at the

main switches before working on the electrical system.

2 47704162 10-2014 © AB VOLVO PENTA

Coupling adjustments must be made with the

engine stopped.

Use the lifting eyes installed on the engine/

reverse gear when lifting off the drive. Always check

that

the lifting equipment is in good condition and has

the capacity to lift the engine (engine weight including

reverse gear and any auxiliary equipment installed).

If the engine has auxiliary equipment that has

altered

its center of gravity, special lifting devices may

be required to obtain the correct balance for safe handling.

Never work on an engine that is suspended in an

engine hoist.

It is mandatory that no work be carried out on a

running engine. There are however adjustments that

require the engine to be run. Approaching a running

engine is a safety risk. Loose clothes and long hair

can

catch in rotating parts and cause serious injury. A

careless movement or a dropped tool may result in

injury when working in the vicinity of a running engine.

Be careful to avoid hot surfaces (exhaust pipes, turbochargers, charge air manifolds, start elements etc.)

and hot liquids in pipes and hoses on engines that are

running or recently stopped. Re-install all protective

covers that were removed during maintenance work

before starting the engine.

Make sure that all warning and information decals

on

the product are always visible. Change decals that

are damaged or painted over

Turbocharged engines: never start the engine

without the air cleaner installed. The rotating compressor

turbine in the turbocharger can cause severe

injury. Foreign objects that enter the inlet ducts can

also cause mechanical damage.

Never use start spray in the air intake. The use

of such products may result in an explosion in the inlet

manifold. Risk of injury.

Do not open the engine coolant filler cap (fresh-

water

cooled engines) when the engine is hot. Steam

or hot coolant may be ejected when system pressure

is released. Open the filler cap slowly and release the

system pressure carefully (freshwater cooled

engines). Hot coolant may spray out if the filler cap or

drain tap is opened, or if a plug or coolant pipe is

removed from a hot engine.

Hot oil can cause burns. Avoid getting oil on the

skin. Be sure to release the pressure from the lubrication system before starting work on it. Never start

or run an engine without the oil filler cap attached.

There is a risk of oil being ejected.

If the boat is in the water – stop the engine and

close

the seawater tap before working on the system.

All fuels, and many chemicals, are flammable.

Make sure they are not exposed to open flames or

sparks.

Gasoline, certain solvents and hydrogen from

batteries are extremely flammable and explosive in

the right concentration in air. No Smoking! Make sure

the workplace is well ventilated and take the necessary safety precautions before welding or grinding in

the vicinity. Always have a fire extinguisher accessible

at the workplace.

Store oil, fuel-soaked rags and old fuel and oil

filters in the correct manner. Oil-soaked rags may

ignite spontaneously in certain conditions. Old fuel

and

oil filters are harmful to the environment and must

be handed to a recycling station for destruction.

Make sure the battery compartment is built

according to current safety standards. Never allow

open flames or electrical sparks in the vicinity of the

batteries.

Never smoke in the vicinity of the batteries.

Batteries give off hydrogen gas during charging,

which may combine with air to form an explosive mixture. The gas mixture is extremely volatile and easily

ignited. Incorrect battery connection may cause

sparks which in turn may cause an explosion. Do not

change the battery connections when attempting to

start the engine (risk for sparks) and do not lean over

the batteries.

Safety Information

47704162 10-2014 © AB VOLVO PENTA 3

Make sure that the positive (+) and negative (–)

battery cables are correctly connected to the corresponding battery terminals. Wrong connection may

cause severe damage to electrical equipment. Refer

to the wiring diagram.

Always wear protective goggles when charging

or handling batteries. Battery electrolyte contains

highly corrosive sulfuric acid. Wash immediately with

soap

and copious amounts of water if battery electrolyte comes into contact with the skin. Flush immediately with water and seek medical attention if battery

acid gets in the eyes.

Never work alone when installing heavy compo-

nents, even when using safe lifting equipment e.g.

lockable blocks. Most lifting devices require the two

people, one to take care of the hoist and the other to

make sure no components catch or are damaged.

The components in the electrical system, ignition

system (gasoline engines) and fuel system on Volvo

Penta products are designed and manufactured to

minimize the risk of fire and explosion. Do not run

engines

in areas where there are explosive materials.

Always use fuels recommended by Volvo Penta.

Refer

to the Operator's Manual. Poor quality fuel may

damage the engine. Poor fuel quality in a diesel

engine may cause the fuel control mechanism to bind

which will lead to engine overspeeding with the risk of

engine damage and personal injury. Low fuel quality

may also lead to higher service costs.

Use an adjustable lifting beam to provide a safe

lift and to avoid damage to components on the top of

the engine. All chains and cables must run parallel

and

be as square as possible to the top of the engine.

Safety Information

4 47704162 10-2014 © AB VOLVO PENTA

General Information

About this installation manual

This

publication is intended as an installation guide for

Volvo Penta marine diesel engines for IPS installations. The publication is not exhaustive and does not

cover all conceivable installations, but should be considered as a recommendation and guidance according to Volvo Penta norms. Detailed installation instructions accompany most accessory kits.

The recommendations are the result of many years of

practical experience from all over the world. If it is

necessary or desirable to depart from recommended

routines, Volvo Penta is happy to offer assistance in

finding a solution for the installation in question.

It is the responsibility of the installer to ensure that

installation is carried out in a satisfactory manner, that

the installation is in good operable condition, that

approved materials and accessories are used and

that the installation fulfills all current instructions and

regulations.

This installation manual is intended to be used by professionally qualified and skilled personnel. It is therefore assumed that those persons using the manual

have fundamental knowledge of marine propulsion

systems and are capable of carrying out the associated mechanical and electrical work.

Volvo Penta continually improves it products and

reserves the right to make changes. All the information in this manual is based on product specifications

available at the time of publication. After this date all

important product modifications that change installation methods will be communicated via service bulletins.

Removal of complete engine assembly

In the event of a requirement to remove the entire

engine assembly from the vessel, it is the responsibility

of the boat builder to arrange reasonable means

for removal and re-installation.

Reasonable means that the engine assembly can be

lifted in and out within a moderate amount of time

using normal resources and methods available to the

industry. In this way costs and operational down-time

are kept to a minimum. For the sake of high demands

at high season on yards, the vessel manufacturers

instruction should be followed.

It is Volvo Penta policy to avoid unreasonable installations that increase extra costs for boat owners during the lifetime of the boat.

Plan the installation carefully

Great care must be taken when installing engines and

their components if they are to function perfectly.

Make sure that the correct specifications, drawings

and other data are available before work is begun.

This facilitates correct planning and installation right

from the start.

Plan the engine compartment so that it will be easy to

perform routine service that involves changing components. Compare the engine service manual to the

original drawings where dimensions are stated.

When installing engines, it is extremely important that

no dirt or foreign objects enter the fuel, cooling, inlet

or turbo systems, as this may cause faults or the

engine to seize. Because of this, systems must be

sealed. Clean supply lines and hoses before they are

connected to the engine. Remove the protective caps

from the engine when an external system is connected.

General Information

47704162 10-2014 © AB VOLVO PENTA 5

Certified engines

A certified engine means that the engine manufacturer guarantees that both new engines and those in

operation

fulfill legislation and regulations. The engine

must correspond to the unit used for certification. In

order for Volvo Penta to be able to declare that

engines fulfill environmental legislation, the following

must be observed during installation:

• Service on injection pumps, pump settings and

injectors must always be carried out by an

authorized Volvo Penta workshop.

• The engine may not be modified in any way

except with accessories and service kits developed for the purpose by Volvo Penta.

• The installation of exhaust pipes and air intakes

(ventilation ducts) in the engine compartment

must be carefully planned as their design may

influence exhaust emissions.

• Seals may only be broken by authorized personnel.

IMPORTANT!

Only use genuine Volvo Penta parts. If non-Volvo

Penta parts are used it will mean that Volvo Penta

is no longer able to take responsibility for the

engine fulfilling certification requirements. Volvo

Penta will not reimburse damages and costs arising

from the use of non-Volvo Penta spare parts.

Seaworthiness

It is the responsibility of the boat builder to meet all

safety requirements applicable in the market where

the boat is sold. For example, in the U.S.A. US Fed-

eral Regulations for pleasure boats specify requirements. Requirements applicable in the EU are described below. In other markets, contact the competent

national authority for information and detailed descriptions of safety requirements.

From June 16 1998, all leisure craft and certain associated

equipment that is marketed and used within the

EU must be provided with a CE label confirming fulfillment of safety requirements established by the

European Parliament and European commission in

the Recreational Craft Directive. These normative

standards are reflected in the standards established

in support of the directive's objective regarding uniform safety requirements for leisure craft within the

EU.

Lifeboats and boats used in commercial navigation

are approved by classification societies in the country

where the boat is registered.

Mutual responsibility

Every engine consists of a large number of components working in unison. If one component deviates

from technical specifications it may lead to the engine

having a significantly greater impact on the environment. It is therefore essential that adjustable systems

are set correctly and that genuine Volvo Penta parts

are used.

Certain systems (e.g. the fuel system) may require

special professional expertise and test equipment.

For environmental reasons, some components are

factory sealed. No work may be performed on sealed

parts by unauthorized personnel.

Remember that most chemical products can harm the

environment if they are used in the wrong manner.

Volvo Penta recommends the use of bio-degradable

de-greasing agents for cleaning engine components,

unless the service manual states otherwise. When

working onboard take especial care to ensure that oil

and spills are collected for handing to a re-cycling station and not unintentionally pumped into the environment with bilgewater.

General Information

6 47704162 10-2014 © AB VOLVO PENTA

Metric Conversion Chart

Metric to American or UK units: American or UK to metric units:

To convert Multiply To convert Multiply

From To with From To with

Length mm in. 0.03937 in. mm 25.40

cm in. 0.3937 in. cm 2.540

m ft. 3.2808 ft. m 0.3048

Area mm² sq. in. 0.00155 sq. in. mm² 645.3

m² sq.ft. 10.76 sq. ft. m² 0.093

Volume cm³ cu. in. 0.06102 cu. in. cm³ 16.388

l, dm³ cu. ft. 0.03531 cu. ft. l, dm³ 28.317

l, dm³ cu. in. 61.023 cu. in. l, dm³ 0.01639

l, dm³ imp. gallon 0.220 imp. gallon l, dm³ 4.545

l, dm³ U.S. gallon 0.2642 U.S. gallon l, dm³ 3.785

m³ cu. ft. 35.315 cu. ft. cm³ 0.0283

Power N lbf 0.2248 lbf N 4.448

Weight kg kg lb. 2.205 lb. kg 0.454

Output kW

hp (metric)

(1)

1.36

hp (metric)

(1)

kW 0.735

kW bhp 1.341 bhp kW 0.7457

kW BTU/min 56.87 BTU/min kW 0.0176

Tightening

torques

Nm lbf ft 0.738 lbf ft Nm 1.356

Pressures Bar psi 14.5038 psi Bar 0.06895

MPa psi 145.038 psi MPa 0.006895

Pa mm Wg 0.102 mm Wg Pa 9.807

Pa in Wg 0.004 in Wg Pa 249.098

kPa in Wg 4.0 in Wg kPa 0.24908

mWg in Wg 39.37 in Wg mWg 0.0254

Energy kJ/kWh BTU/hph 0.697 BTU/hph kJ/kWh 1.435

Labor kJ/kg BTU/lb 0.430 BTU/lb kJ/kg 2.326

MJ/kg BTU/lb 430 BTU/lb MJ/kg 0.00233

kJ/kg kcal/kg 0.239 kcal/kg kJ/kg 4.184

Fuel cons. g/kWh g/hph 0.736 g/hph g/kWh 1.36

g/kWh lb/hph 0.00162 lb/hph g/kWh 616.78

Moment of

inertia

kgm² lbft² 23.734 lbft² kgm² 0.042

Flow, gas m³/h cu.ft./min. 0.5886 cu.ft./min. m³/h 1.699

Flow, fluids m³/h US gal/min 4.403 US gal/min m³/h 0.2271

Speed m/s ft./s 3.281 ft./s m/s 0.3048

mph knots 0.869 knots mph 1.1508

Temperature Celsius Fahrenheit °F=9/5 x °C

+32

Fahrenheit Celsius °C=5/9 x (°F–

32)

1) All catalog output data specified in horsepower refers to metric horsepower.

General Information

47704162 10-2014 © AB VOLVO PENTA 7

Installation Tools and Documentation

Publications

Installation manuals

Manuals are available for the EVC system, for example.

Installation instructions

There are installation instructions included with most

kits.

Drawings

Drawings are included in kits and additional drawings

are available electronically from Volvo Penta.

B E

Installation

P0014255

Installation Tools and Documentation

8 47704162 10-2014 © AB VOLVO PENTA

Posters

Refer to posters for the design of hull inserts, laminations,

drive unit installation and the installation and cal-

ibration of the EVC system.

VODIA

The VODIA diagnostic tool is used for reading fault

codes in clear text during diagnosis work. It can also

be used for setting EVC parameters.

The tool is very practical for fault tracing as it is possible

to see the values the EVC nodes are reading and

sending.

Refer to VODIA information at Volvo Penta Partner

Network or contact Volvo Penta to order.

Chemicals

There is a large range of chemicals available from

Volvo Penta.

Some examples:

•

Oil and coolant

•

Sealing compound and grease

•

Touch-up paint

Refer to Volvo Penta Spare Parts & accessories.

EVC-C3

P00008985

VODIA

p0006256

A

n

t

if o

u

l

i

n

g

P0004585

Installation Tools and Documentation

47704162 10-2014 © AB VOLVO PENTA 9

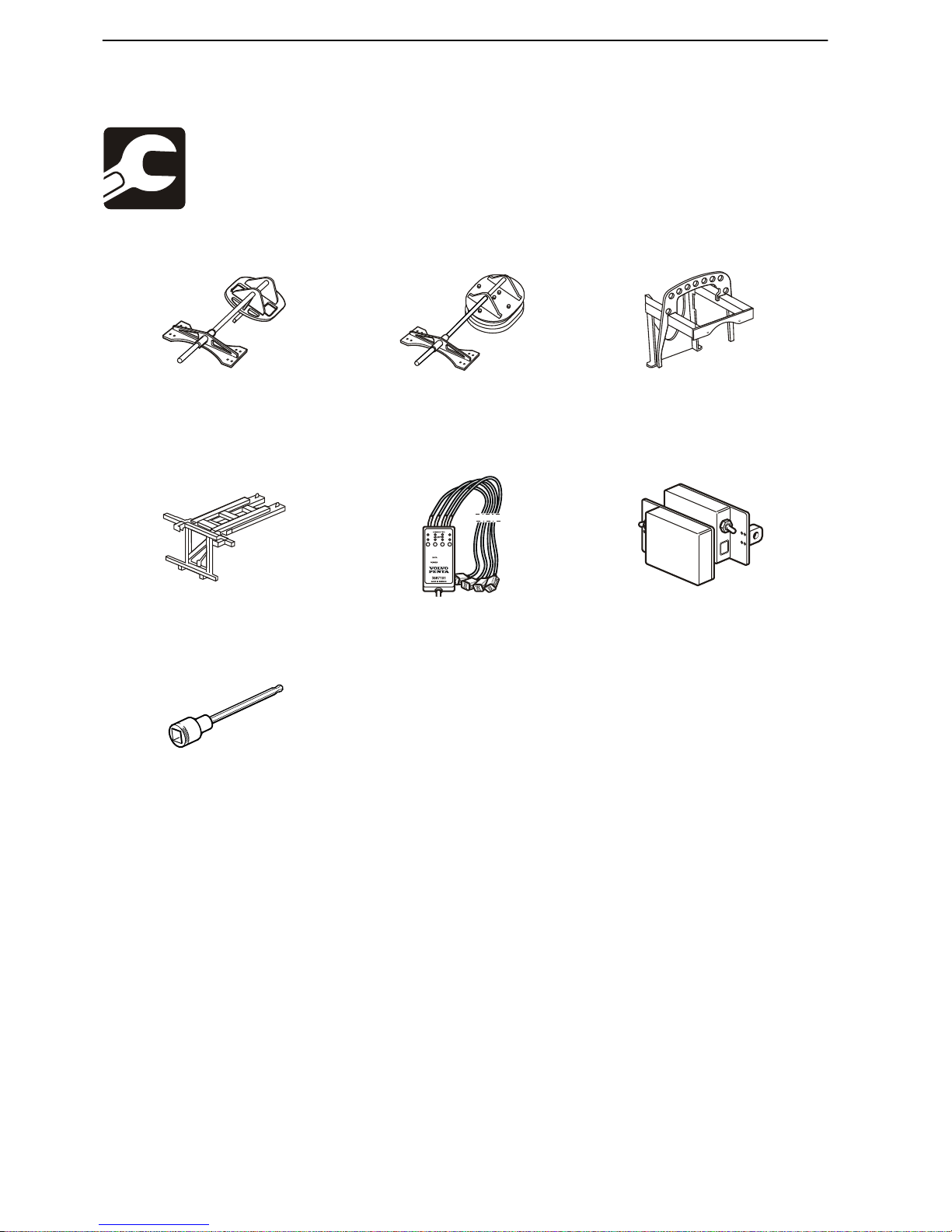

Special Tools

P0010517

P0010518

P0010505

3849633 Drill jig 3594503 Drill jig 21110860 Lifting tool

Location of engine bed and

engine mount positions (hull

inserts)

Lamination of hull inserts and

the location of engine beds

(complete with molding tools).

Attaching device for propulsion

unit when lifting by hoist

P0010506

p0010872

3849664 Lifting tool 3887101 Break-out box 21406897 Calibration tool

Position device when lifting by

fork lift

Used together with the VODIA

tool for calibrating IPS units

Drive unit alignment (complete

pair)

P0001856

3863070 Allen key socket

Torque tightening propeller

retainer rings

Installation Tools and Documentation, Special Tools

10 47704162 10-2014 © AB VOLVO PENTA

Other Special Equipment

p0005125

VODIAVODIA

p0008375

P0004580

88890074 Multimeter 88820047 VODIA, diagnostic

tool

9998493 Hose

Used in combination with

9998339 Manometer

.

PDA only

P0008329

P0004349

21244540 Measuring tool 9998339 Manometer

Measuring engine mount compression

Measuring fuel feed pressure

Installation Tools and Documentation, Special Tools

47704162 10-2014 © AB VOLVO PENTA 11

Chemical products

P0001874

P0001871

828250 Grease alt.

21347121 Grease

(400 gr)

1381065 Corrosion protection

3817243 Rubber lubricant

Installation Tools and Documentation, Special Tools

12 47704162 10-2014 © AB VOLVO PENTA

System Information

EVC

Refer to the Installation EVC installation manual for

EVC system installation instructions.

System Information, EVC

47704162 10-2014 © AB VOLVO PENTA 13

Engine Characteristics

Engine Application Ratings

The engines covered by this manual are used chiefly

in

two different operating conditions: Rating 4 and Rat-

ing 5, as described below.

Rating 4

Special light commercial traffic

For light, planing boats in commercial traffic. Operated

for fewer than 800 hours per year.

Typical boats: High-speed patrol boats for search and

rescue and the armed forces, and special high-speed

fishing boats. Recommended cruising speed: 25

knots.

Full power may be utilized for max 1 hour per 12 hour

period. Between full-throttle periods, engine revolutions must be reduced by at least 10% from full rpm.

Rating 5

Recreational use

Only for pleasure boats operated by owners for their

recreation. Operated for fewer than 300 hours per

year.

Full power may be utilized for max 1 hour per 12 hour

period.

Between full-throttle periods, engine revolutions must

be reduced by at least 10% from full rpm.

Engine Characteristics, Engine Application Ratings

14 47704162 10-2014 © AB VOLVO PENTA

Engine Performance

Marine engine power is specified, just like automobile

and truck engines, according to one or more power

norms. Power is specified in kW or hp, always at a

rated rpm.

Most engines provide the power specified on the condition that they have been tested in the conditions the

power

norms state, and have been broken in properly.

According to ISO standards, tolerances are normally

±5 %, which is a reality that must be accepted for series-produced engines.

Power measurement

Engine manufacturers normally measure engine

power at the flywheel, but before power reaches the

propeller, losses occur in the drive train and propeller

shaft bearings. These losses amount to 4–6 %.

All major marine engine manufacturers determine

engine power according to ISO 8665 (supplement to

ISO 3046 for pleasure boats). If an exhaust system is

not included, engine tests are performed with a back

pressure of 10 kPa (1.45 psi).

Engine performance

Engine power is affected by a number of different factors. Among the most important are air pressure, outdoor temperature, humidity, fuel calorific value and

exhaust back pressure. Deviations from normal values

affect diesel and gasoline engines in different ways.

Diesel engines use large amounts of air for combustion. If the mass of air is reduced, the first sign is an

increase in black exhaust smoke. The effects of this

are especially noticeable at the planing threshold when

the engine must produce maximum torque.

If the deviation differs significantly from normal air flow,

the diesel engine will lose power. In the worst case the

loss may be so great that torque is insufficient for the

boat to overcome the planing threshold.

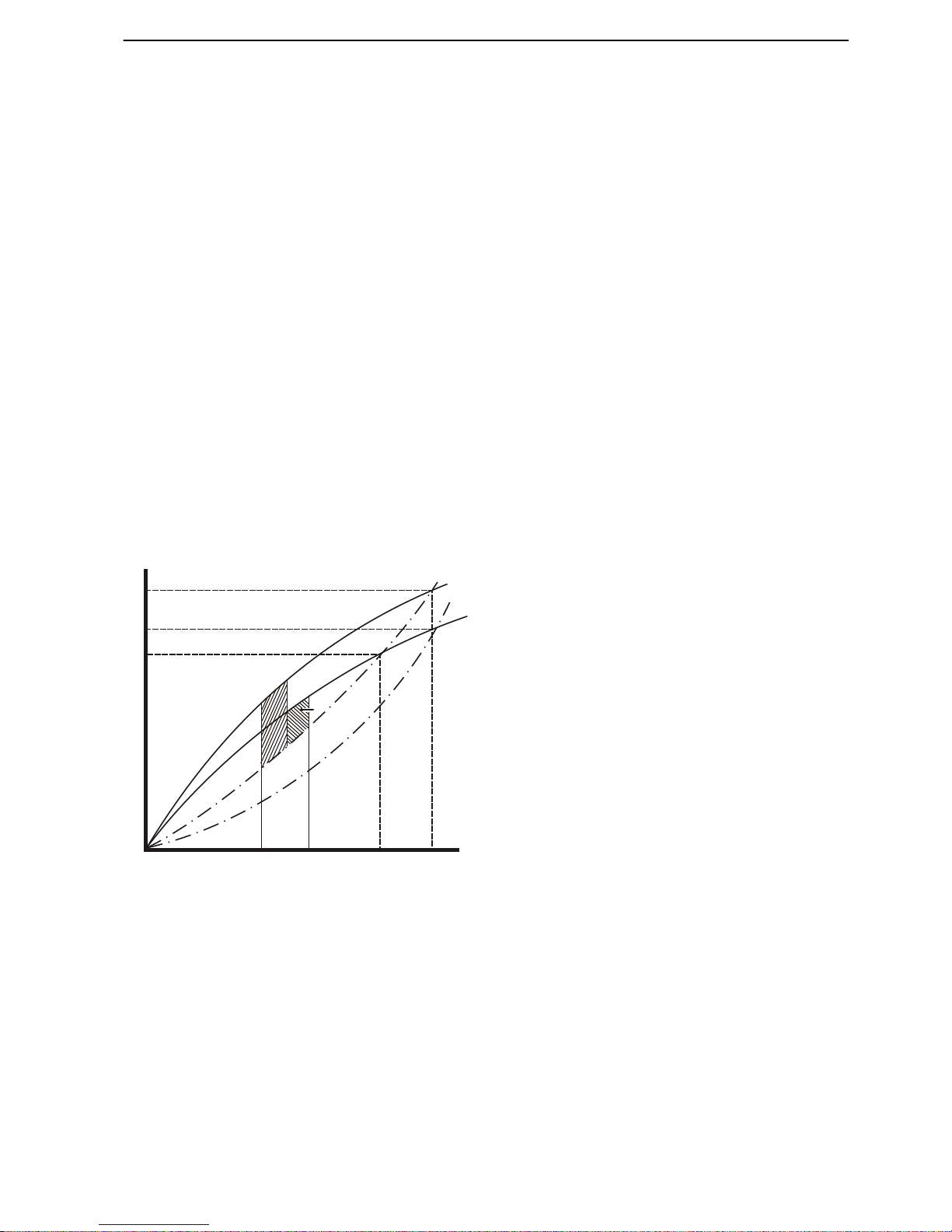

Point A is where the indicated engine power is equal

to the power acting on the propeller. Volvo Penta IPS

drive units have defined propeller sizes that are dimensioned for engine characteristics.

1

2

3

4

5

6

A

B

C

P0004571

Connection between performance-influencing factors in inboard

engines

1

Power

2 rpm

3 Power loss due to atmospheric conditions

4 Loss due to large propeller

5 Critical area

6 Indicated rpm

Engine Characteristics, Engine Performance

47704162 10-2014 © AB VOLVO PENTA 15

Other factors that influence performance

It is important to keep exhaust back pressure low.

Power losses caused by back pressure are directly

proportional to the increase in back pressure, which

also increases exhaust temperature.

Boat

weight is another important factor that influences

speed. Increased boat weight has a great influence on

speed, especially on planing or semi-planing hulls. A

new boat that is tested with half full fuel and water tanks

and without a load, may lose 2-3 knots when it is driven

fully loaded with fuel, water and equipment for the voyage.

Boats made from fiberglass reinforced plastic absorb

water when they are afloat which means they become

heavier over time. Marine fouling is an often-overlooked problem that greatly affects boat performance.

Engine Characteristics, Engine Performance

16 47704162 10-2014 © AB VOLVO PENTA

Arrangement and Planning

Engine Placement

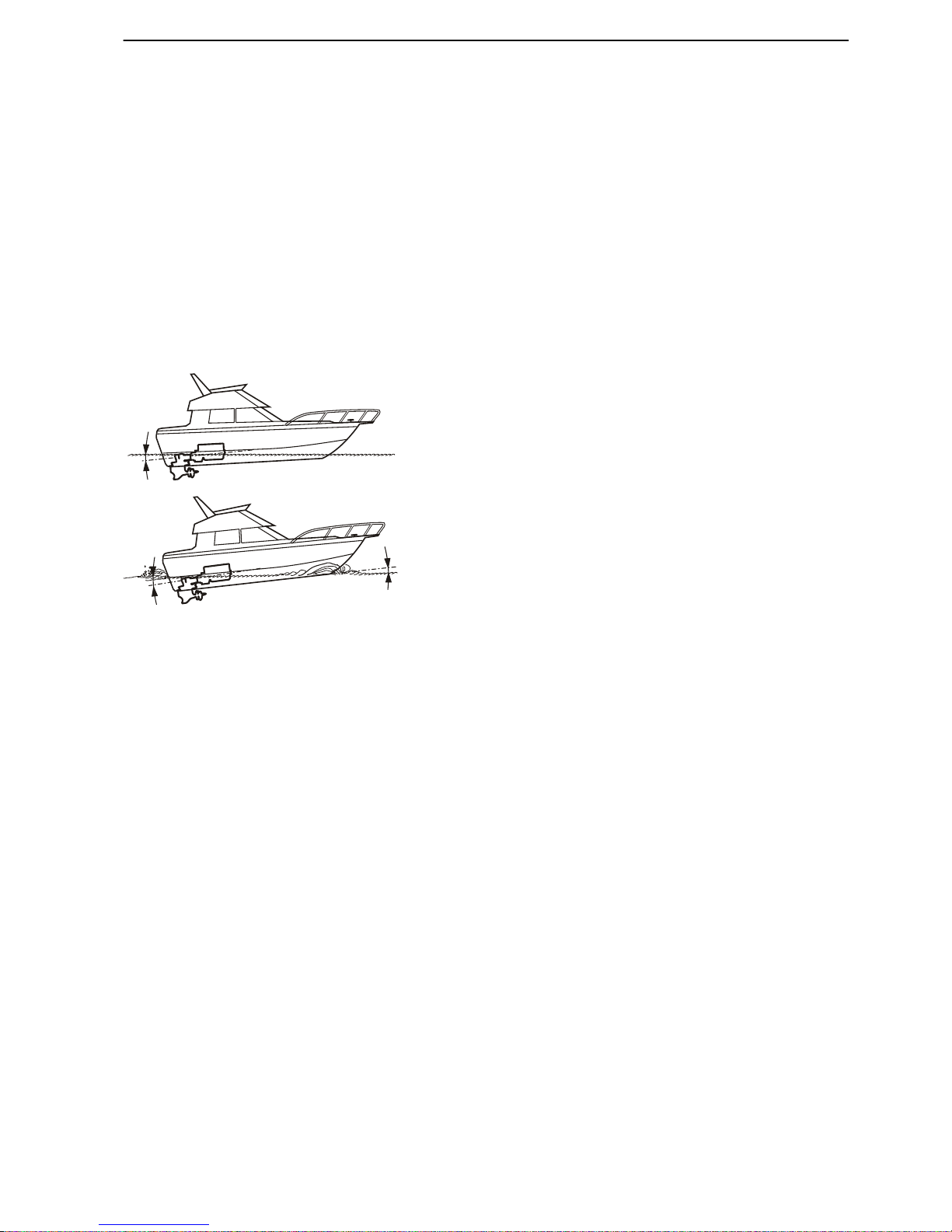

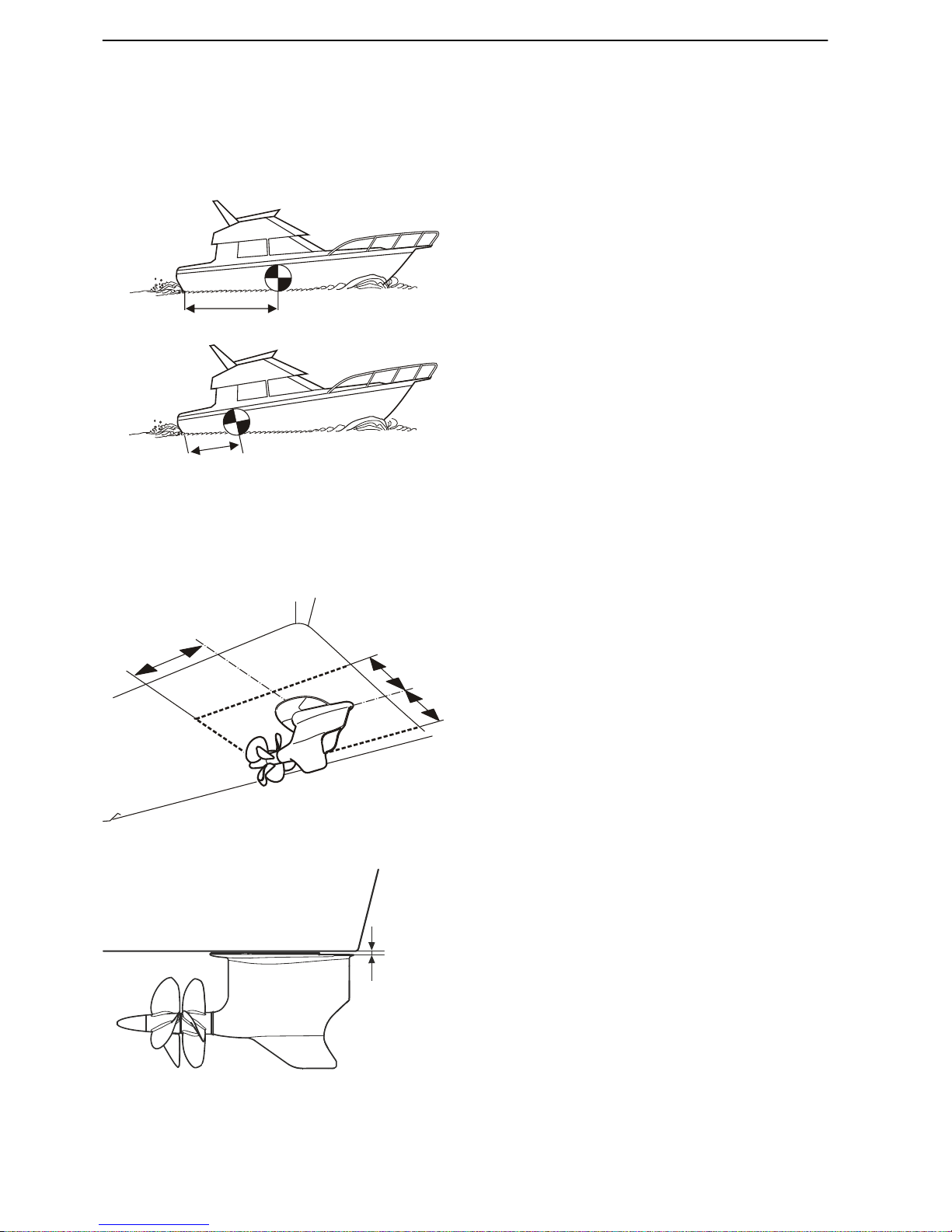

Engine Inclination

To ensure the engine receives lubrication and cooling

in a satisfactory manner, it is important that maximum

engine inclination is not exceeded. Engine inclination

must therefore be checked.

Be

careful to avoid the front of the engine's being lower

than the flywheel, i.e. an exaggerated negative inclination that may impair engine lubrication and cooling

system venting.

Each engine type has a maximum permissible engine

inclination while the boat is under way. This inclination

includes both the installation angle and the increase in

trim angle the boat attains when moving at speed

through the water.

A Engine inclination with the boat at rest.

B Boat trim angle under way.

C Total engine inclination under way, maximum per-

missible inclination (A+B).

A boat's weight distribution is affected by the choice of

driveshaft length.

See technical data for limit values.

P0010566

A

B

C

Arrangement and Planning, Engine Placement

47704162 10-2014 © AB VOLVO PENTA 17

Weight Distribution

The location of the longitudinal center of gravity is of

great

importance for trim angle at top speed etc. Generally speaking, a fast boat should have its center of

gravity further aft than a slower boat.

The center of gravity has great influence on a boat's

static and dynamic stability. It is therefore important to

consider CoG position both when the boat is loaded

and unloaded.

It is important that heavy components such as engines,

fuel and water tanks and batteries be located such that

the best possible trim is achieved when the boat is in

the water, and generally that as low a vertical CoG as

possible is attained.

Fuel and water tanks must be located longitudinally as

close to the center of gravity as possible in order that

the center of gravity is not moved when water and fuel

levels change.

It is an advantage not to locate the fuel tanks in the

vicinity of the hot engine compartment. If possible, the

batteries must be located in a separate, well-ventilated

section.

Clearance Around Propulsion Units

Objects that protrude from the hull bottom cause turbulence. If such are present in the vicinity of the drive

units, propeller propulsion ability will be impaired.

Place no objects inside the dashed lines.

A min. 3000 mm (118")

B min. 400 mm (16")

C min. 50 mm (2")

Clearance between hull and Ips drive unit is 9 mm

(+ 5 mm - 2 mm)

A

B

P0005314

Figure A

shows an installation with good weight distribution and trim

angle.

Figure B shows an incorrect installation with poor trim angle as the

result.

A

B

B

P0006153

P0019672

C

Arrangement and Planning, Engine Placement

18 47704162 10-2014 © AB VOLVO PENTA

Engine Room

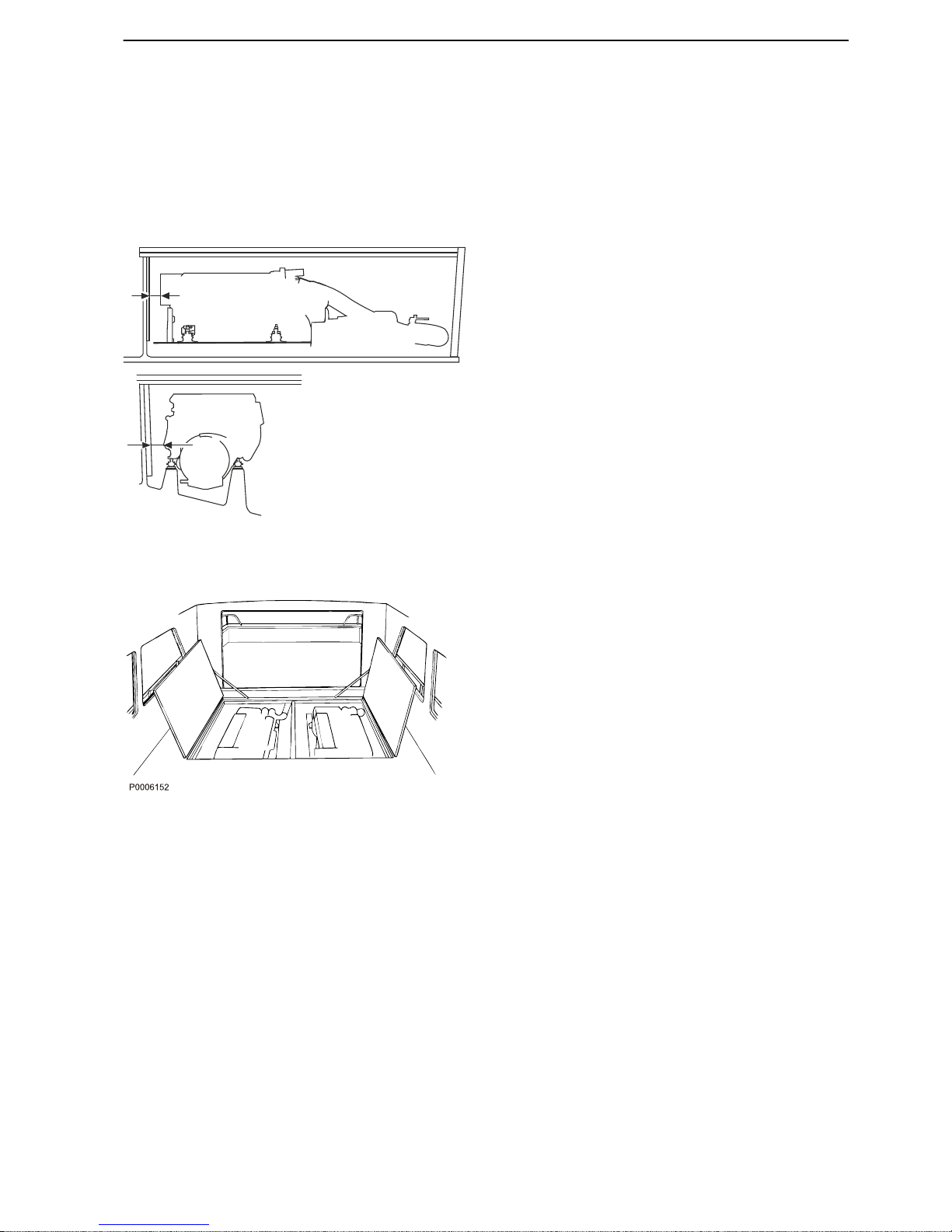

Accessibility for Maintenance

When the engine installation is designed, great

emphasis must be placed on engine service accessibility.

Also make sure that the complete engine can be

lifted out without damage to the boat.

NOTICE! There must also be sufficient space for

sound-dampening materials. The recommended minimum distance for sound-dampening materials is 180

mm (7") (A) and 200 mm (8") (B); see illustration.

Removal of complete engine assembly

If the complete engine assembly must be lifted out of

the boat it is the boatbuilder's responsibility to do so

using reasonable methods for removal and re-installation. This means: within reasonable time using normal resources and methods available to the industry

to limit costs and operational downtime. It is Volvo

Penta policy to avoid installations that involve extra

costs for boat owners during the lifetime of the boat.

A

B

P 1162600

Arrangement and Planning, Engine Room

47704162 10-2014 © AB VOLVO PENTA 19

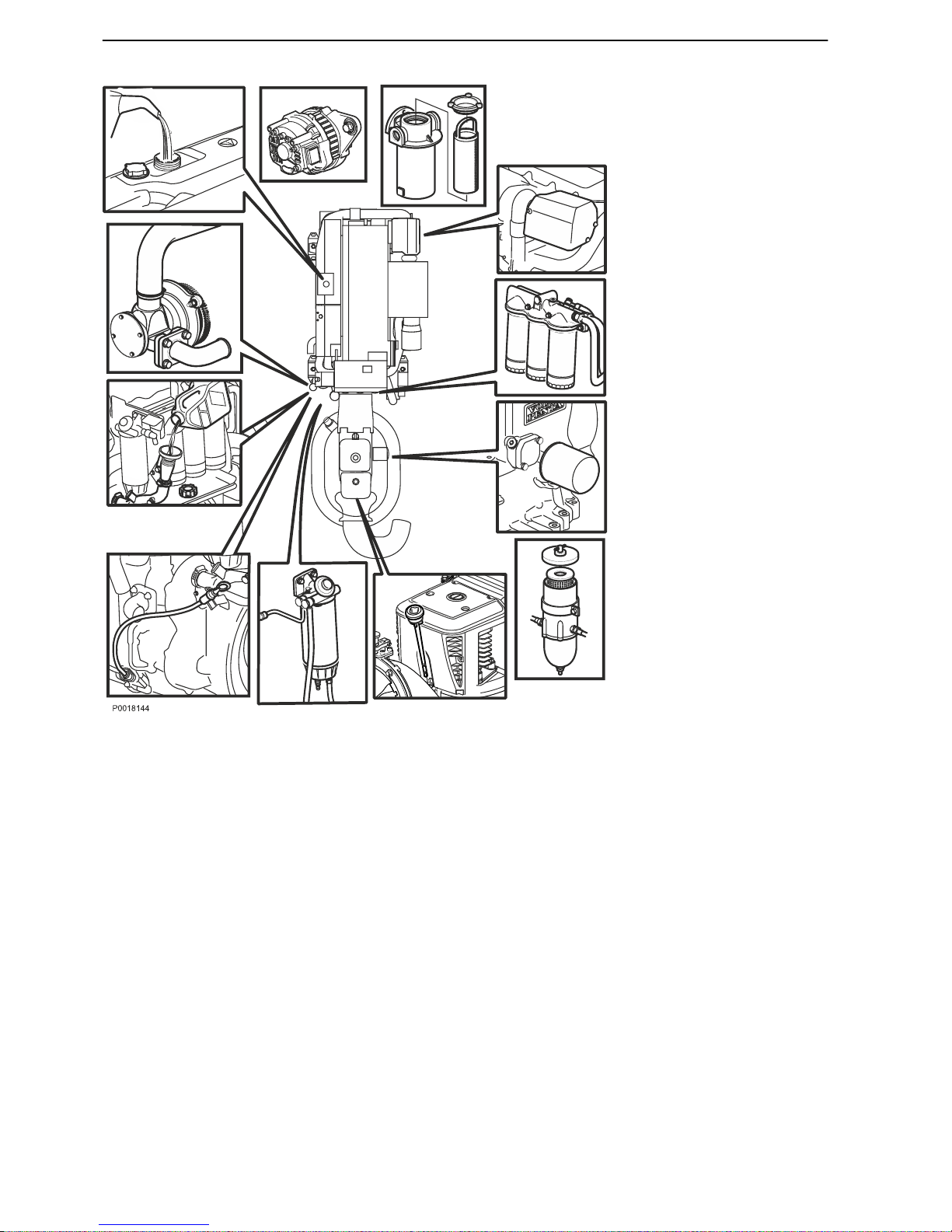

General maintenance

Items that usually require maintenance accessibility:

•

Coolant

• Oil change and filling (engine, drive)

• Filter changes (oil, fuel, air and crankcase

breather)

• Drivebelt change and adjustment/tensioning

• Removal of valve cover

• Changing impeller, seawater pump

• Water filter, cleaning

Repairs

Items that may require maintenance accessibility:

• Removal of injectors, cylinder head, radiator etc.

• Removal or exchange of electrical components

• Removal of flywheel and vibration damper

• Measurement at diagnostic points

Arrangement and Planning, Engine Room

20 47704162 10-2014 © AB VOLVO PENTA

Engine Room Ventilation

Engine performance

Diesel

engines require a surplus of air. Deviations from

normal values first present themselves as more black

smoke than usual. This may be especially noticeable

at the planing threshold when the engine must deliver

the highest possible torque.

If deviations from normal values are great, the diesel

engine will lose power. The power loss may be so great

that a planing boat is unable to overcome the planing

threshold.

In order for the engine to function properly and provide

full power, it is absolutely essential that both inlet and

outlet air ducts are dimensioned and installed correctly.

Two principle conditions must be met:

A The engine must receive sufficient air (oxygen) for

fuel combustion.

B The engine compartment must be ventilated such

that the temperature can be kept at an acceptably

low level.

Ventilation is also important to keep the temperature

of engine electrical and fuel systems low, and to guarantee normal engine cooling.

Ventilation must also be suitably adapted if crew members will be present in the engine compartment.

NOTICE! Current national safety regulations and legislation must be followed. Each classification society

has its own rules that must be followed as required.

Engine power at high altitudes above sea level

In most cases marine engines are used at, or close to,

sea level. However, there are lakes at high altitudes

above sea level.

Operations at high altitudes involve a power loss owing

to a drop in air density (and thereby oxygen levels) as

altitude increases. This will result in the development

of smoke and the turbocharger running at abnormally

high rpm with increased wear.

However, power loss is not significant below approx.

500 m (1640 ft) above sea level. At altitudes in excess

of 500 m (1640 ft) above sea level, power loss is

around 0.1% per 100 m (328 ft).

Volvo Penta IPS 650, 800 and 950 engines are not

suitable for operations above 1,500 m (5,000 ft).

Arrangement and Planning, Engine Room

47704162 10-2014 © AB VOLVO PENTA 21

Dimensioning of air intake and ducts

The following basic facts must be considered in

calculations when planning an installation.

•

All combustion engines, regardless of manufacture

or type, require a certain amount of oxygen (or air)

for the combustion process. However, diesel

engines work with a somewhat larger air surplus

than gasoline engines.

•

Furthermore, all engines emit a certain amount of

heat to the surroundings, i.e. engine compartment.

•

Heat radiation is smaller on modern, compact

engines

than on older, less compact engines. Mod-

ern engines enjoy a great advantage in this.

Ducts and pipes for inlet and outlet air

It is an advantage if ducts and pipes for inlet and outlet

air can be planned as early as the design stage, as they

can then be built into the hull or superstructure. This

eliminates the requirement for separate ducts.

It is relatively simple to design a system for providing

the engine with a sufficient quantity of combustion air,

but significantly more difficult to ventilate heat radiation

away.

The engine draws in air efficiently and naturally takes

it from whatever direction it can. If inlet and outlet ducts

are too small, the engine will draw in air from both ducts

and no ventilation air will be expelled through the outlet

duct. This will create dangerously high temperatures in

the engine compartment.

Most of the engine heat radiation must be carried away

from the engine compartment. It is a mandatory

requirement to keep engine compartment temperature

below the maximum permissible limit.

Fans

Normally an extraction (suction) fan must be installed

in the outlet duct to ventilate the engine compartment

more efficiently and thus keep engine compartment

temperature low.

Conversely, fans may never be installed in the inlet

duct as this may lead to engine compartment overpressure, with the risk of gases or air leaking into other

parts of the boat.

For diesel engines the fan may very well be thermostat

controlled; it must start at an engine compartment temperature of around +60 °C (+140 °F), measured in the

engine compartment.

NOTICE! Fan hose connections for diesel engines

must be located as high in the engine compartment as

possible to carry away hot air, while for gasoline

engines as low as possible to carry away fumes.

Arrangement and Planning, Engine Room

22 47704162 10-2014 © AB VOLVO PENTA

Engine temperature

It

is important that inlet temperature be kept as low as

possible bearing in mind that engine performance figures apply at a test temperature of +25 °C (+77 °F).

Temperature

≤ 25 °C (77 °F) Full power

> 25 °C (77 °F) Power loss approx. 1% per 10

°C

Inlet air temperature at the air filter may not be higher

than 25

°C (77 °F) for full power to be achieved. During

sea trials the temperature in the air filter must not be

higher than 20 °C (68 °F) above the outside temperature.

Engine surface temperature is rather high at certain

points. Certain individual engine components such as

charge regulators and relays must therefore be installed on bulkheads or at other locations where the temperature is relatively low.

Maximum temperature at electrical component

installation locations is 70 °C (158 °F). However, the

starter motor and alternator have their given locations.

Engine compartment pressure

Volvo Penta recommends that negative pressure in the

engine compartment not fall below 0.5 kPa (0.07 psi)

at full speed. A slight negative pressure in the engine

compartment is not harmful and it prevents gases from

being forced out of the engine compartment into other

boat spaces.

Arrangement and Planning, Engine Room

47704162 10-2014 © AB VOLVO PENTA 23

Engine air consumption

The engine consumes a certain amount of air during

the

combustion process. This requires the inlet duct to

have a certain internal cross-sectional area.

This area can be calculated using the formula:

A = 1.9 × engine power

A = Area in cm

2

Engine power in kW

The value applies to inlets, without obstacles, that are

up to 1 m (3.3 ft) with only one 90-degree bend. The

bend radius must be at least twice the duct diameter.

If longer ducts or more bends are used, the area must

be corrected by multiplying by the coefficient in the

Coefficient of bends table.

Coefficient of bends

Duct length, m (ft.)

Number

bends

1 (3.3) 2 (6.6) 3 (9.8) 4 (13.1) 5 (16.4)

1 1 1.04 1.09 1.13 1.20

2 1.39 1.41 1.43 1.45 1.49

3 – 1.70 1.72 1.74 1.78

Engine compartment ventilation

In addition to its air consumption, the engine radiates

heat. Heat radiation must be carried away from the

engine compartment in order to keep the temperature

down to permissible values.

The same dimensions must be chosen for the outlet

and

inlet channels in order to achieve low flow speeds

and low noise levels.

Ventilation inlet/outlet area is calculated according

to the following formula:

Area (cm2) = 1.65 × engine power (kW)

These values must be corrected in accordance with the

Coefficient of bends table in regard to bends and duct

length.

Outdoor temperature is assumed to be +30 °C (86 °F).

Correction factors according to the Correction factor

table must be used where applicable.

Correction factor

Outside temperature °C

(°F)

Correction factor

+20 (68) 0.7

+30 (86) 1.0

+40 (104) 1.4

Arrangement and Planning, Engine Room

24 47704162 10-2014 © AB VOLVO PENTA

Choice of fan

The fan must be dimensioned for airflow according to

the following:

Outlet air (m3/min) = 0.07 × engine power (kW)

The

total pressure increase at the fan must be 10 mm

(0.39") water gauge (100 Pa).

These two values, flow and total pressure increase, are

sufficient for selecting a fan. If the fan is installed

directly on the bulkhead, i.e. without a connecting duct,

the total pressure increase value may be reduced by 7

mm (0.28") water gauge (70 Pa). This means that a

somewhat smaller fan may be used.

Arrangement and Planning, Engine Room

47704162 10-2014 © AB VOLVO PENTA 25

Calculation of air ducts

Example 1: IPS650, 375kW (510 hp)

Calculation of areas for one 375kW engine with an

unlimited

airflow and an outside temperature of +30 °C

(+86°F).

Air consumption:

The following is obtained for each engine:

Area for engine air consumption: 1.9 × 375 = 713

cm2 (110.5 sq.in)

No corrections according to the Coefficient of bends

and Correction factor tables The area 713 cm² (110.5

sq.in) gives a duct diameter of 267 mm (10.5") for each

engine (2√(area/π).

Multiply by the number of engines to calculate the area

of the engine compartment inlet duct.

Ventilation:

1

Air intake: Area = 1.65 × 375 = 619 cm2 (95.4

sq.in). This gives a diameter of 304 mm (12.0") for

a single engine.

2

Air outlet: Area = 1.65 × 375 = 619 cm2 (95.4

sq.in). This gives a diameter of 304 mm (12.0") for

a single engine.

3 Extraction fan capacities: 0.07 × 375 = 26.2

m3/min (1091 ft3/min).

4 Multiply each sum by the number of engines to cal-

culate the area and fan capacity for a common

engine compartment.

Arrangement and Planning, Engine Room

26 47704162 10-2014 © AB VOLVO PENTA

Calculation of air ducts

Example 2: IPS800, 459 kW (625 hp)

Calculation of areas for one 459 kW engine with an

unlimited

airflow and an outside temperature of +30 °C

(+86°F).

Air consumption:

The following is obtained for each engine:

Area for engine air consumption: 1.9 × 459 = 872

cm2 (135.5 sq.in)

No corrections according to the Coefficient of bends

and Correction factor tables The area 874 cm² (135.5

sq.in) gives a duct diameter of 267 mm (10.5") for each

engine (2√(area/π)).

Multiply by the number of engines to calculate the area

of the engine compartment inlet duct.

Ventilation:

1

Air intake: Area = 1.65 × 459 = 757 cm2 (117.6

sq.in). This gives a diameter of 304 mm (12.0") for

a single engine.

2

Air outlet: Area = 1.65 × 459 = 757 cm2 (117.6

sq.in). This gives a diameter of 304 mm (12.0") for

a single engine.

3 Extraction fan capacities: 0.07 × 459 = 32.1

m3/min (1091 ft3/min).

4 Multiply each sum by the number of engines to cal-

culate the area and fan capacity for a common

engine compartment.

Arrangement and Planning, Engine Room

47704162 10-2014 © AB VOLVO PENTA 27

Calculation of air ducts

Example 3: IPS950, 533 kW (725 hp)

Area

calculations for one engine with a 2 m (6.6 ft) long

duct, 2 bends and an outside temperature of +20 °C

(+68 °F).

Air consumption:

Area for engine air consumption: 1.9 × 533 = 1012.7

cm2 (156.9 sq.in)

Correction for duct length and bends = 1.41 from the

Coefficient of bends table.

This gives 1012.7 × 1.41 = 1428 cm2 (221.3 sq.in). The

area 1428 cm2 (213.9 sq.in) corresponds to a duct

diameter of 419 mm (16.5").

Multiply by the number of engines to calculate the area

of the engine compartment inlet duct.

Ventilation:

1 Inlet, engine compartment: Area = 1.65 × 533 =

880 cm2 (136.4 sq.in). This corresponds to a duct

diameter of 329 mm (13").

2 Outlet, engine compartment: Area = 1.65 × 533

= 880 cm2 (136.4 sq.in). This corresponds to a duct

diameter of 329 mm (13").

3 Correction, inlet and outlet: Air temperature = 0.7

from the Correction factor table, plus a correction

for duct length and bends = 1.41 from th Coefficient

of bends table.

This gives 880 × 0.7 × 1.41 = 868.6 cm2 (134.6

sq.in). This corresponds to a duct diameter of 327

mm (12.9") for each inlet and outlet.

4 Extraction fan capacities: 0.07 × 533 (kW) = 36

m3/min (1271 ft3/min).

5 Multiply each sum by the number of engines to cal-

culate the area and fan capacity for a common

engine compartment.

Arrangement and Planning, Engine Room

28 47704162 10-2014 © AB VOLVO PENTA

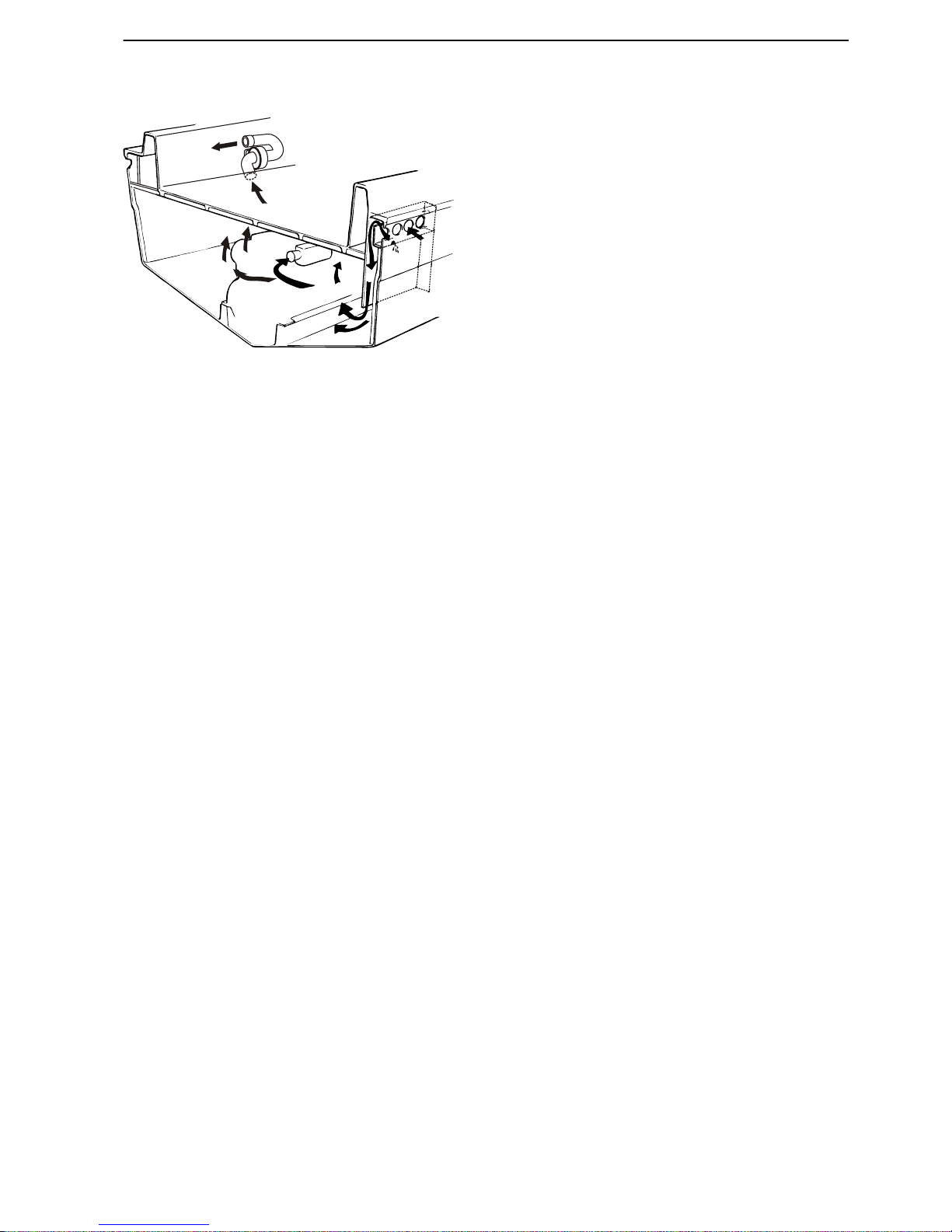

Location of ventilators and air inlets

NOTICE! Air inlets and outlets may never be located

on the transom. Air in this area mixes with water and

exhaust fumes, and must never be allowed into the

boat.

Air inlet function

Air inlets and outlets must function well even in bad

weather

and must therefore have efficient water traps.

For the most part noise insulation must be built in.

Air inlets and outlets must be located as far away from

each other as possible so that an effective through flow

is achieved.

If inlets and outlets are too close to each other air is

able to recirculate, which will provide inadequate ventilation.

Location of air ducts

Ducts or pipes for engine air supply must be run to a

place as close to the air filter as possible, but with a

minimum distance of 20–30 cm (8–12") in order to definitely prevent water from entering the engine; refer to

the adjacent figure.

The inlet ventilation duct for diesel engines must be led

in far down into the engine compartment, but not so far

down that any bilge water is able to block air supply.

The outlet duct must be located diametrically opposite

on the other side of the engine.

All ducts and pipes must be run such that there is the

least possible flow resistance. Bends may not be

sharp, but must be moderately rounded. The minimum

radius is double the diameter. Obstacles or constric-

tions must always be avoided.

The ducts must be cut obliquely at the ends to provide

best flow.

Always take any llocal regulations into consideration.

If it is not possible to arrange drainage, ventilation

hoses must be bent upwards somewhat in order to

form a gooseneck that prevents seawater forcing its

way into the engine compartment. Remember to build

the engine compartment as spaciously as possible to

facilitate engine service.

1

2

3

4

5

P0004733

1 Engine air filter

2

Inlet duct, engine compartment

3 Outlet

4 Water trap

5 Extraction fan

P0004734

Arrangement and Planning, Engine Room

47704162 10-2014 © AB VOLVO PENTA 29

Sound Absorption

The

drive assembly must be installed so that noise and

vibrations are minimized. The noise that occurs is party

airborne noise and partly structural noise (vibrations).

Structural noise

Engine vibrations are transferred to the hull via the

engine mounts and engine bed. Other transfer routes

are through the transmission and propeller system,

exhaust pipes, coolant pipes, fuel pipes and electrical

and control cables.

Propeller pressure waves are transmitted through the

water to the hull. Propeller drive pulses are transferred

to the hull via support brackets, bearings and seals.

Airborne noise

This section concerns airborne noise from the engine

compartment. The most important method of reducing

airborne noise from the engine compartment is to seal

it properly. Further noise reductions can be achieved

by laying sound insulation material and by designing

noise baffles in the air inlets.

The engine installation must be noise insulated to provide as low a noise level as possible. Build noise baffles into the engine compartment. There are different

types of noise baffles to choose from. The illustration

shows a type that also provides drainage.

It is important to ensure that the insulation material is

sufficiently thick.

The greatest possible care must be taken to screen the

noise source as much as possible. Screen off the entire

bulkhead down to the hull, but leave a little gap so that

bilge water does not force its way into the insulation

material.

Cracks and openings etc. must be carefully sealed with

insulation material. In cases where the engine is installed beneath the deck, all bulkheads and decks must be

insulated.

1

P0004735

Engine compartment noise baffles

Arrangement and Planning, Sound Absorption

30 47704162 10-2014 © AB VOLVO PENTA

Make sure that there is sufficient space for inspections,

service and repairs and for engine movement during

operations before the insulation material is installed.

Also make sure that all covers are properly insulated.

Examples of insulation material design are shown

below. This type of insulation material is glued to the

frame.

1

2

3

P0004739

Insulation material installed on wood (plywood):

1 Wood (plywood)

2 Flameproof absorbent layer

3 Flameproof, reflective and noise insulating foil

1

2

3

4

P0004740

Insulation material installed on GRP:

1

GRP

2 Iron/PVC, thickness 2.5 mm (0.1”)

3 Flameproof absorbent layer

4 Flameproof, reflective and noise insulating foil

NOTICE! The insulation materials look different

depending

on the material the frame is made of - GRP

or wood.

P0006333

Arrangement and Planning, Sound Absorption

47704162 10-2014 © AB VOLVO PENTA 31

When electrical cables are run through a bulkhead, it

is advantageous to run them through a conduit or

grommet that can be sealed properly. This also protects the cable against wear.

Fuel hoses that are run through bulkheads must be

protected by grommets. The grommet seals and protects the hose against sharp edges that may cause

leaks.

Other lines such as electrical and battery cables can

be run through a rubber hose or a special PVC pipe

(installation pipe) built into the hull. Any gaps between

the pipes and the cables can be sealed with insulating

material or sealing compound.

P0004741

Bulkhead bushings

P0006334

Fuel hose protected by a grommet

Arrangement and Planning, Sound Absorption

32 47704162 10-2014 © AB VOLVO PENTA

Electrochemical Corrosion

General

NOTICE! Refer to the Service handbook Corrosion

measurement,

DPH/DPR & IPS for further information.

Corrosion theory

Corrosion in water is always electrochemical in nature.

This means that a weak electric current occurs at the

same time as chemical reactions takes place. Two

chemical reactions are required to make a metal corrode, an oxidation reaction (metal dissolving) and a

reduction reaction (generally oxygen consuming). Oxidation is referred to as an anode reaction and reduction is referred to as a cathodic reaction. In an oxidation

reaction, electrons are freed which are transported in

the metal to another point, where they are consumed

in a cathodic reaction.

Electrons are thus transported in the metal from the

anode to the cathode. This causes a weak DC current

in the opposite direction. An electric circuit must be

closed. This is achieved by the transport of ions in the

water.

Anodic and cathodic reactions must always balance

each other, which means that the electrons released

at the anode must be consumed at the cathode. If the

anodic and cathodic reactions occur evenly distributed

across the entire surface, general corrosion occurs.

The depth of attack then becomes basically equal

across the entire surface. This commonly occurs on

steel and bronze.

Fe Fe2+ +2 e-

O2 + H2O + 2 e 2 OH-

ANODE

CATHODE

P0011416

I

P0011417

Arrangement and Planning, Electrochemical Corrosion

47704162 10-2014 © AB VOLVO PENTA 33

If the anodic and cathodic reactions occur at different

points,

local corrosion occurs, i.e. deeper attack at certain points. The attacks on materials which can be passivated, such as stainless steel and aluminum are generally localized. There are different types of local corrosion. The most common types of attack on stainless

steels and aluminum are pitting corrosion and crevice

corrosion.

In addition to these local attacks, attack can be caused

by galvanic corrosion or stray currents. In areas where

rapid water flow occurs, damage cause by cavitation

can also occur.

If we ignore attacks related to material defects, the following types of corrosion can occur:

- General corrosion.

- Pitting.

- Crevice corrosion.

- Galvanic corrosion.

- Stray current corrosion.

- Cavitation.

A brief description of each type of corrosion is given

below.

General corrosion

General corrosion is the most common type of corrosion. This results in even attack across all or large parts

of the surface.

In seawater, mild steel and bronze are subject to general corrosion, but not stainless steel. In stationary

seawater, the corrosion rate of mild steel is about 0.1

mm/year (0.3 mm/year at the waterline) unless the

steel is protected by cathodic protection. Bronze is initially attacked at a rate of 0.05 mm/year, but after some

time the corrosion rate falls to a low level, since the

corrosion products (black, brown) have a protective

effect. Green/blue corrosion products are a sign of

higher corrosion rates and that the protective layer has

not been developed.

Aluminum can be subject to a certain amount of general corrosion in rapidly flowing water, but not in stationary water.

p0011418

Arrangement and Planning, Electrochemical Corrosion

34 47704162 10-2014 © AB VOLVO PENTA

Pitting corrosion

Pitting corrosion can occur on stainless steel and aluminum. The attack is caused by localized breakdown

of the passive oxide film on the metal surface. In natural water, it is generally chloride ions that initiate the

attack. The risk increases with rising water temperatures. There is a number of aluminum alloys with very

good

resistance to corrosion by seawater. If these are

connected together with more noble metals, they will

be attacked due to galvanic corrosion, however.

Very high levels of chromium and molybdenum are

required, above all, to make stainless steel fully resistant to the risk of pitting corrosion. If there is weak

cathodic protection (sacrificial anodes), excellent protection against pitting corrosion can be obtained on

simpler steels. Alloys of lower grades than 316 should

be avoided, however.

Crevice corrosion

An attack in the gap between two metal surfaces, or

between one metal surface and another materials is

called crevice corrosion. A so-called oxygen depletion

cell is formed when oxygen transport into the crevice

is lower than oxygen transport out to the cell opening.

Separate anodic and cathodic surfaces are formed.

The cathodic process, which requires access to oxygen, is formed in the gap opening and the anodic process, metal dissolving, takes place inside the gap. Crevice corrosion can occur on most metals, but the risk is

greatest on metals that can be passivated, such as

aluminum and stainless steel.

Deposit corrosion is closely related to crevice corrosion. It takes place under deposits and marine fouling

such as barnacles.

p0011419

p0011420

Arrangement and Planning, Electrochemical Corrosion

47704162 10-2014 © AB VOLVO PENTA 35

Galvanic corrosion

Metals From To

Galvanic corrosion is probably the most common

type of corrosion. It occurs when two metals of different nobility are in electric contact and are submerged

in the same body of water at the same time.

The least noble metal is corroded.

Information about the nobility of different metals is

obtained from galvanic potential tables which have

been prepared in various fluids, such as seawater.

See table to the left:

There are four factors which influence the seriousness of galvanic corrosion in each individual case.

These are:

- Area relationship between the anode (less

noble metal) and the cathode (more noble

metal). If the anode is small in relation to the

cathode, the depth of attack will be greater than

if the situation was reversed.

- Conductivity of the water. Seawater conducts

electricity better than fresh water, and corrosion

takes place at a greater rate.

- Potential difference between the two metals. A

large potential difference increases the power

behind the process.

- Lower corrosion rate can be obtained if the

more noble metal can be passivated. This

means that stainless steel is more noble than

copper, but the galvanic corrosion will be more

severe on aluminum when connected to copper

than when connected to stainless steel.

In seawater, total galvanic corrosion counted in

grammes of metal, will be greater than in water which

is not so salt. The greatest depth of corrosion on a

metal can be equally large in brackish or fresh water.

The better conductivity of seawater means that the

attack will be distributed evenly across the entire surface. In fresh water, there will be more local attack

close to the point of contact.

Graphite +0,19 +0.25V

Stainless steel 18‑8, Mo,

in passive state *

±0,00 -0.10 V

Stainless steel 18‑8 in

passive state *

‑0,05 -0.10 V

Nickel ‑0,10 -0.20 V

Nickel-aluminum-bronze -0,13 -0.22 V

Lead ‑0,19 -0.25 V

Silicon bronze (Cu, Zn, Si,

Mn, Sn)

‑0,26 -0.29 V

Manganese bronze (Cu,

Zn, Si, Mn, Sn)

‑0,27 -0.34 V

Aluminum brass (Cu, Zn,

Al)

‑0,28 -0.36 V

Solder (Pb, Sn) ‑0,28 -0.37 V

Copper ‑0,30 -0.57 V

Tin ‑0,31 -0.33 V

Red brass (Cu, Zn) ‑0,30 -0.40 V

Yellow brass (Cu, Zn) ‑0,30 -0.40 V

Aluminum bronze ‑0,31 -0.42 V

Stainless steel 18‑8, Mo,

in active state **

‑0,43 -0.54 V

Stainless steel 18‑8 in

active state **

‑0,46 -0.58 V

Cast iron ‑0,60 -0.71 V

Steel ‑0,60 -0.71 V

Aluminum alloy ‑0,76 -1.00 V

Galvanized iron and steel ‑0,98 -1.03 V

Zinc ‑0,98 -1.03 V

Magnesium and magne-

sium alloy consumed

‑1,60 -1.63 V

* Metals are in a passive state when they have a thin,

corrosion inhibiting coating. This coating is not

present in the active state.

** Still water.

Arrangement and Planning, Electrochemical Corrosion

36 47704162 10-2014 © AB VOLVO PENTA

cathode

anode

anode

cathode

1

2

P0011421

1 Seawater

2

Fresh water

The following should be considered, to counteract

galvanic corrosion:

-

Do not connect metals which are far away from

each other in the galvanic potential table.

- Insulate different metals from each other by

using plastic or rubber (must not contain graphite).

- Paint the structure. The surface of both metals

should be painted. If painting is restricted to only

the less noble metal, heavy galvanic corrosion

could occur on surfaces where there is paint

damage. The reason for this is that the cathode/

anode relationship will be unfavorable.

- Install cathodic protection.

Stray current corrosion

As we learned in the corrosion theory chapter, corrosion occurs when a DC current flows into the water

from a metal surface. Similar stray currents from the

drive

can occur if there is a fault in the boat’s electrical

system, such as if couplings are exposed to dirt and

moisture, components are incorrectly installed or damaged. Stray currents can come from shore current

installations or adjacent boats. All metals, except a few

noble metals, are corroded by stray currents. Corrosion rates can be very high.

The sacrificial anodes on the drive are not dimensioned to counteract any stray currents. If stray currents occur, the anodes will be consumed very quickly

and the drive will be attacked.

Aluminum is particularly vulnerable to stray currents. If

the current density on the surface is high, corrosion can

also occur when there is a stray inwards current. AC

currents can also cause damage. The AC corrosion

rate for aluminum is 30% of the rate for DC. The corresponding rates for steel, copper and zinc are much

lower, at 1 %. Please refer to the figure to the left.

1200

1000

800

600

400

200

0

AL DC

AL AC

CU DC

CU AC

FE DC

FE AC

cm3/Ampere

P0011422

Arrangement and Planning, Electrochemical Corrosion

47704162 10-2014 © AB VOLVO PENTA 37

Corrosion protection

Drives are protected from corrosion by a number of

measures.

-

Alloys which are resistant to salt water.

- Avoidance of unsuitable combinations of metals.

Where appropriate, a favorable relationship

between anode and cathode is established.

- High quality surface treatment.

- Cathodic protection.

- Carefully designed electrical system.

- Recommendations to minimize external interference.

Recommendations from Volvo Penta and anti fouling

manufacturers must be followed. In addition, the material must be resistant to the alkali that is formed on

cathodically protected surfaces.

Cathodic protection is arranged by supplying a weak

DC current from an anode to the protected object. The

current which leaks in counteracts the corrosion current. The higher the protection current, the lower is the

rate of corrosion.

The current required for protection can be generated

in two ways. These are either with sacrificial anodes or

by applying a current. If sacrificial anodes are used, the

current is generated by connecting the protected

object with a less noble metal (anode). The difference

in electric potential creates a protective galvanic current. It can be said that corrosion is transferred to the

anode, which is why they are referred to as sacrificial

anodes.

Zn

P0011424

Zn

P0011425

Arrangement and Planning, Electrochemical Corrosion

38 47704162 10-2014 © AB VOLVO PENTA

If a current is applied, this is supplied from an external

source (rectifier, battery).

The materials used in sacrificial anodes are zinc, aluminum,

magnesium and iron. Please note that special

alloys are used, to meet the following requirements:

- No passivation, i.e. they do not stop supplying current.

- Even consumption.

- Low polarization tendency, i.e. they retain a sufficient potential difference to the object.

- Low self-corrosion.

Only use original anodes. Never paint over the anodes.

Iron anodes can be used to protect stainless steel and

bronze objects. Magnesium anodes can be used in

fresh water where the current supplied by zinc anodes

may not be enough in some cases. Please note that

magnesium anodes give overprotection to aluminum

in seawater. There is no risk of overprotection of aluminium if zinc or aluminum anodes are used for protection.

P0011426

Arrangement and Planning, Electrochemical Corrosion

47704162 10-2014 © AB VOLVO PENTA 39

Definitions

Single-pole system

In a single-pole system the actual engine block is

used

as the negative ground return for all components

on the engine block.

Two-pole system

In a two-pole system each electrical component on

the engine has an insulated direct current ground

return. The alternator, starter motor and all sensors/

senders are electrically insulated from the engine

block and are supplied without a braided ground strap

installed between the starter motor and engine block.

The engine block is not connected to the battery negative terminal (-).

All IPS engines are two pole.

Isolation transformer

A transformer with galvanically separated input and

output windings.

The isolation transformer separates galvanic shore

power from the boat and reduces the risk for galvanic

corrosion and stray current corrosion as described in

ABYC circuit diagram 8 and text E-11.7.2.2.1.4 thru

5. Corrosion damage caused by stray currents will not

be compensated for under warranty.

Ground fault circuit interrupter (GFCI)

A health and safety protection device, the GFCI cuts

the current to a circuit when current to ground

exceeds a predetermined value.

Spark generation between live conductors and

ground may occur at relatively low currents and will

not trip circuit breakers. Moreover, very low currents

may also constitute a danger for personnel. A GFCI

must be installed on the other side of the isolation

transformer as ground fault protection in the boat.

GFCI tripping sensitivity and tripping times must meet

local standards.

A GFCI located on the other side of the isolation transformer safeguards ground fault protection in the boat.

This is supplement to ABYC E-11 that ensures a

higher level of protection against electric shock.

Protection against electrochemical

corrosion

In order to avoid galvanic corrosion to underwater

components

such as hull fittings, swim ladders etc., it

is important that they be protected. Volvo Penta recommends connecting all components to a protection

anode (normally made of zinc) installed on the

transom. Trim tabs may have their own protection.

NOTICE! Normally, the system connecting individual

components must not have any contact with the negative circuit in the boat electrical system.

Local recommendations, e.g. ABYC, may state that

the battery negative terminal be connected to the galvanic circuit. If the galvanic circuit is connected to the

battery negative terminal (-), the engine block must

also be connected by a cable of a capacity sufficient

to conduct current at engine start; refer to the description in ABYC chapter E-11.

IMPORTANT!

If there is a risk for galvanic corrosion and stray current corrosion, an isolation transformer must be installed.

Volvo Penta IPS drive units are manufactured in a

nickel aluminum bronze alloy and are protected

against corrosion by two anodes. One is installed in

the exhaust system (iron) and the other on the

transom (aluminum). The drive unit has an underwa-

ter surface area that exceeds 1 m2 (10.8 ft2).

IMPORTANT!

The anodes must not be painted over.

IMPORTANT!

Do not connect Volvo Penta IPS units to each other.

IMPORTANT!

Do not connect the Volvo Penta IPS units to the

engine or any other components on board.

IMPORTANT!

Do not connect any other equipment to the Volvo

Penta IPS transom-mounted anode.

NOTICE! The above recommendations do not conflict

with ABYC E-11, in particular paragraphs 11.18.1 and

11.17.2.3.

IMPORTANT!

In steel and aluminum installations it is important to

ensure good insulation between the Volvo Penta IPS

unit and the hull. Volvo Penta disclaims responsibility

for any hull corrosion.

Arrangement and Planning, Electrochemical Corrosion

40 47704162 10-2014 © AB VOLVO PENTA

Protection against electrostatic

discharges and lightning strikes

For advice regarding the prevention of dangerous situations as a result of electrostatic discharges or lightning, refer to the applicable literature published by

national and international standards organizations

such as the International Electrotechnical Commis-

sion and American Boat and Yacht Council.

Special publications IEC 60092-507:2000 Electrical

installation

in ships Part 507: Pleasure craft, and ABYC

Standards and guidelines H-33 and E-4 may provide

guidance.

Painting a Volvo Penta IPS drive unit

Volvo Penta recommends that drive units be painted

in cases where the boat is used in waters where anode

consumption is higher than acceptable. This will

reduce anode consumption as the bronze surface

exposed to water is reduced significantly by external

painting. In order for the paint to adhere to the drive

unit a suitable base coat is recommended before antifouling paint is applied. Painting drive units is also useful in areas with much marine fouling.

IMPORTANT!

Do not use copper-based paints on the drive unit.

IMPORTANT!

Do not paint the groove (A) between the drive unit and

hull (does not apply to metal boats, where the inside of

the IPS hole is painted with anti-foulding paint).

IMPORTANT!

Do not paint the white plastic part (B).

A

B

P0006329

Arrangement and Planning, Electrochemical Corrosion

47704162 10-2014 © AB VOLVO PENTA 41

Shore supply and alternator installation

Example of an installation with isolation

transformer

For installation, refer to local regulations.

Single phase, 240 VAC system

1 2

3

24

23

22

4

5

6

7

21

20

8

9

10

111213

19

18

17

16

15

14

P0004769

1 Phase

2

Zero

3 Protective ground

4 2-pole, 3-wire grounded contact and female socket

5 Shore side

6 Boatside

7 Transformer shield

8 Alternator circuit breaker

9 Alternator (accessory)

10 To DC negative buss and ground plate, boat

11 Phase

12 Zero

13 Protective ground

14 240 VAC ground, female socket

15 240 V AC apparatus

16 Separate circuit breaker (typical)

17 GFCI

18 Changeover switch, land / alternator

19 Encapsulated single-phase 1:1 isolated transformer with metal shield

20 Main switch, shore power, with overvoltage protection

21 Power supply (isolated electrically from boat)

22 Connector, shore power cable

23 Shore supply cable

24 Shore connection

Arrangement and Planning, Electrochemical Corrosion

42 47704162 10-2014 © AB VOLVO PENTA

Two-phase, 120/240 VAC primary, 120/240 VAC secondary

1

2

3

27

25

4

8

9

10

11

12

13

14

15

16

17

18

7

6

5

P0004770

24

26

23

22

21

20

19

1 Phase

2

Zero

3 Phase

4 Protective ground

5 3-pole, grounded pin-type connector and 4-conductor socket

6 Shore side

7 Boatside

8 Transformer shield

9 Circuit breaker, alternator

10 Alternator (accessory)

11 To DC negative buss and ground plate, boat

12 Phase

13 Zero

14 Phase

15 Protective ground

16 240 VAC apparatus

17 120 VAC ground, female socket

18 120 VAC apparatus

19 Separate circuit breaker (typical)

20 GFCI

21 Changeover switch, land / alternator

22 Encapsulated single-phase 1:1 isolated transformer with metal shield

23 Main switch, shore power, with overvoltage protection

24 Power supply (isolated electrically from boat)

25 Connector, shore power cable

26 Shore power cable

27 Shore connection

Arrangement and Planning, Electrochemical Corrosion

47704162 10-2014 © AB VOLVO PENTA 43

Recommendations

In regard to personal safety and equipment care,

Volvo

Penta provides the following recommendations

for the installation of AC shore power:

Installations should be carried out according to figures

above.

Single phase, shows a single-phase installation for

240 VAC or 120 VAC.

Two-phase, shows an installation with a 240 VAC

input, 120/240 VAC output.

The figures are based on ABYC E-11 diagrams 8 and

11 but require a GFCI and an isolation transformer.

The figures are considered to be best practice and

follow recommendations from ABYC and ISO, and

offer protection against electrochemical corrosion and

electric shock.

The safety-related components are important for the

following reasons:

Isolation transformer

Refer to Arrangement and Planning page 40 for further information.

GFCI