Volkswagen T3 other 1987 User Manual

www.westfaliaT3.info - a useful site for enthusiasts and owners of VW Westfalia T25 / T3 / Vanagon campers

Diagnostic Service Manuals

DOMETIC

Dometic

MANUAL REFRIGERATOR

DIAGNOSTIC SERVICE

MANUAL

The

Corporate Office

Technical Services

Dometic

Warranty

Department

Department

Corporation

2320 Industrial Parkway

Elkhart, IN 46515

219-295-5228

205 E. Fenn St.

LaGrange, IN 46761

219-463-2191

509 S. Poplar St.

LaGrange, IN 46761

219-463-4858

OS1286

8/89

D-l

NOTES:

www.westfaliaT3.info - a useful site for enthusiasts and owners of VW Westfalia T25 / T3 / Vanagon campers

D-2

MANUAL REFRIGERATOR

www.westfaliaT3.info - a useful site for enthusiasts and owners of VW Westfalia T25 / T3 / Vanagon campers

DIAGNOSTIC SERVICE ‘MANUAL

Table of Contents

Diagnostic Flow Charts

Page

No Operation . . . . . . . . . . . . .

No

12OV

No Gas Operation (Piezo Igniter)

AC Operation . . . . . . . . .

. . . .

No Gas Operation (Automatic Reigniter)

Operation and Diagnosis

Dometic Manual Refrigerators.

Glossary of Terms

Service Bulletins

. . . . . . . . . . . .

. . . . . . . . . . . .

. . . . . .

D-4-l

D-4-2

D-4-3

. .

D-4-4

D-6-

1

D-8-l

D-9-l

D-3

MANUAL REFRIGERATOR

www.westfaliaT3.info - a useful site for enthusiasts and owners of VW Westfalia T25 / T3 / Vanagon campers

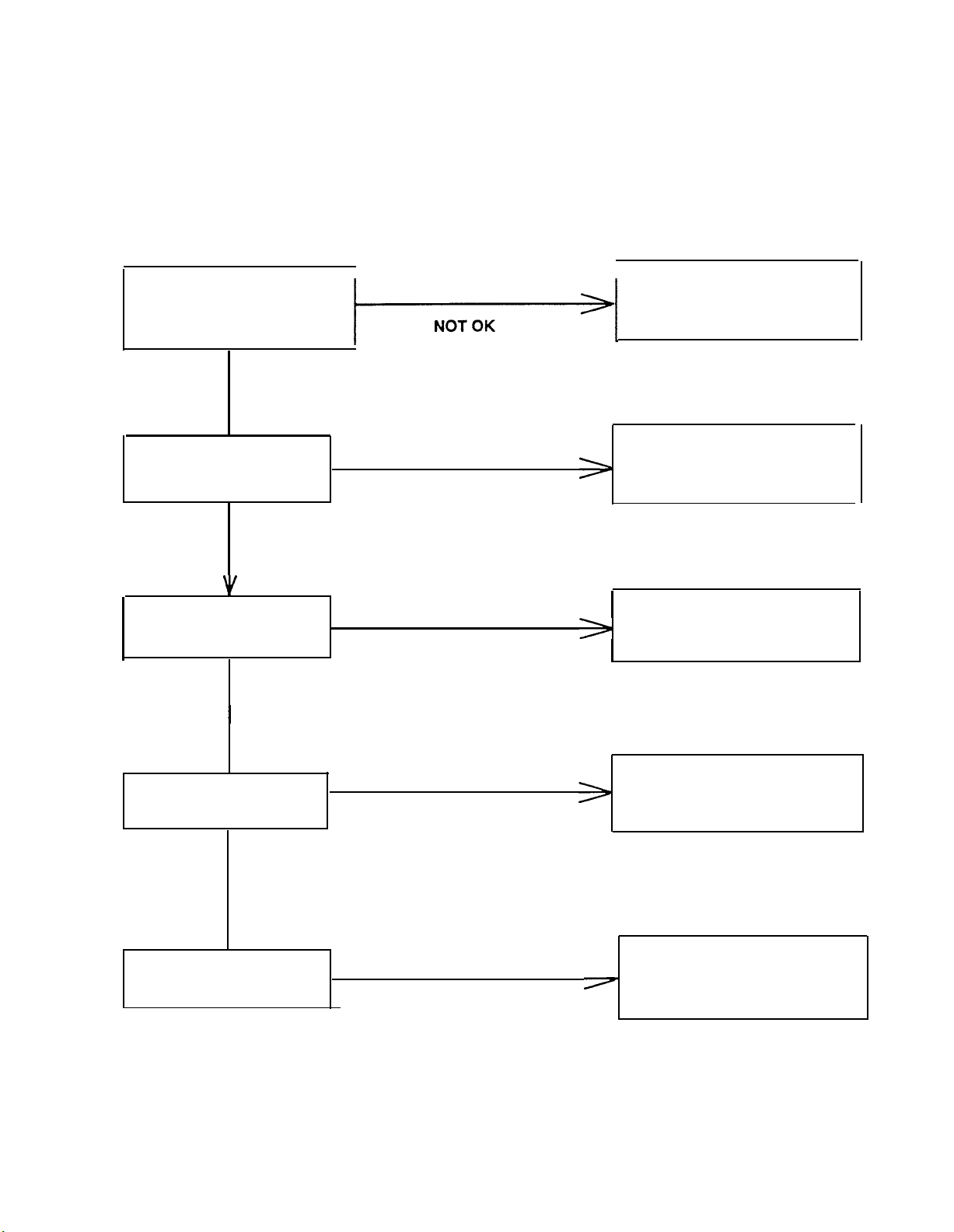

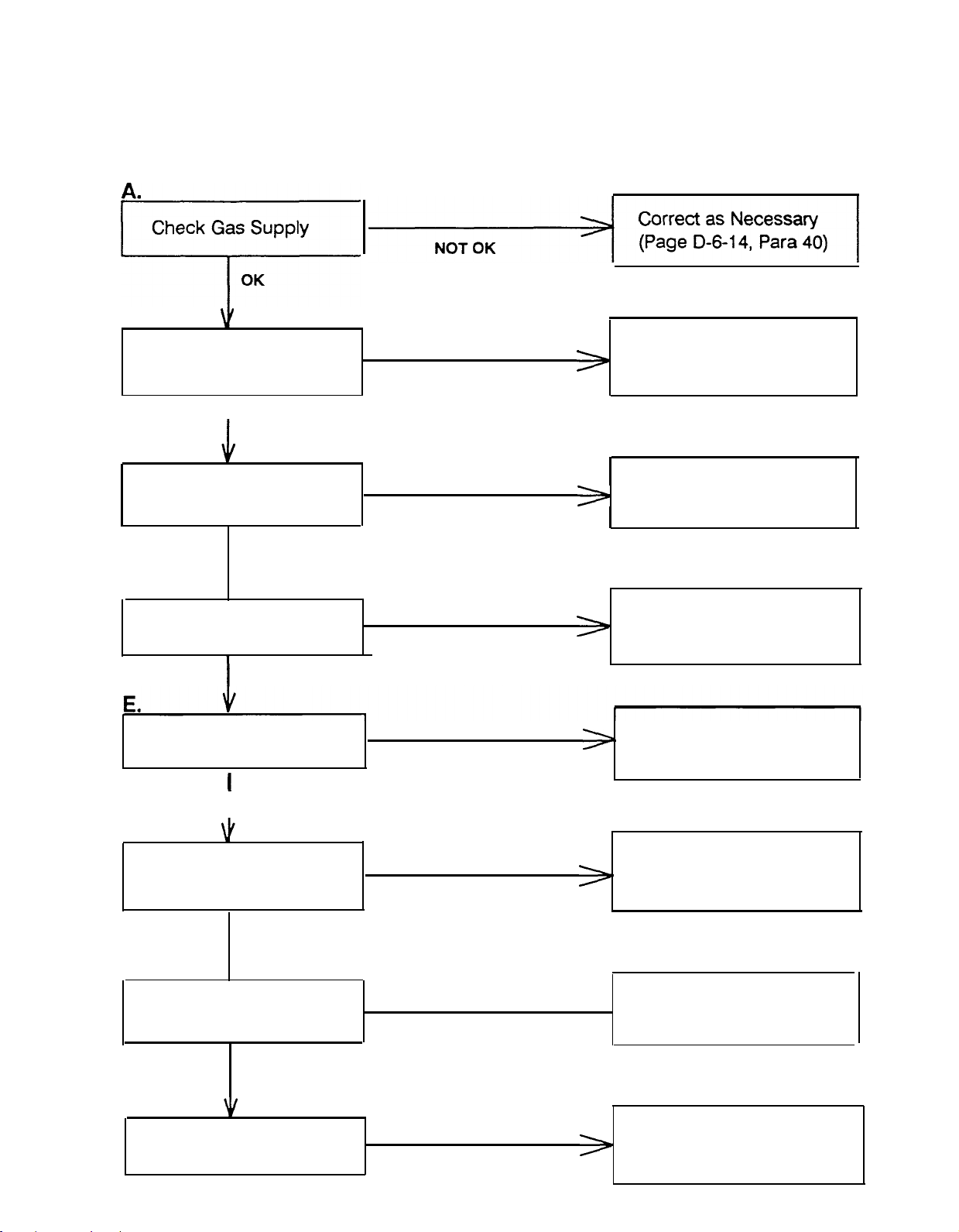

DIAGNOSTIC FLOW CHART

NO OPERATION

A.

Check Supply Voltage

1. 110 Volt Plug

2. Wire Size

OK

B.

Check Fuse

C.

Check wiring

V

OK

\/

1

I~>1

NOT OK

NOT OK

Correct as Necessary

Correct as Necessary

>

Replace if Defective

>

Correct as Necessary

1

OK

DD.

Check Switch

E.

Check Thermostat

V

OK

NOT OK

NOT OK

>

Correct as Necessary

(Page D-6-20,

, Correct as Necessary

’

Continuity Check

Para.

66)

D-4-l

MANUAL REFRIGERATOR

www.westfaliaT3.info - a useful site for enthusiasts and owners of VW Westfalia T25 / T3 / Vanagon campers

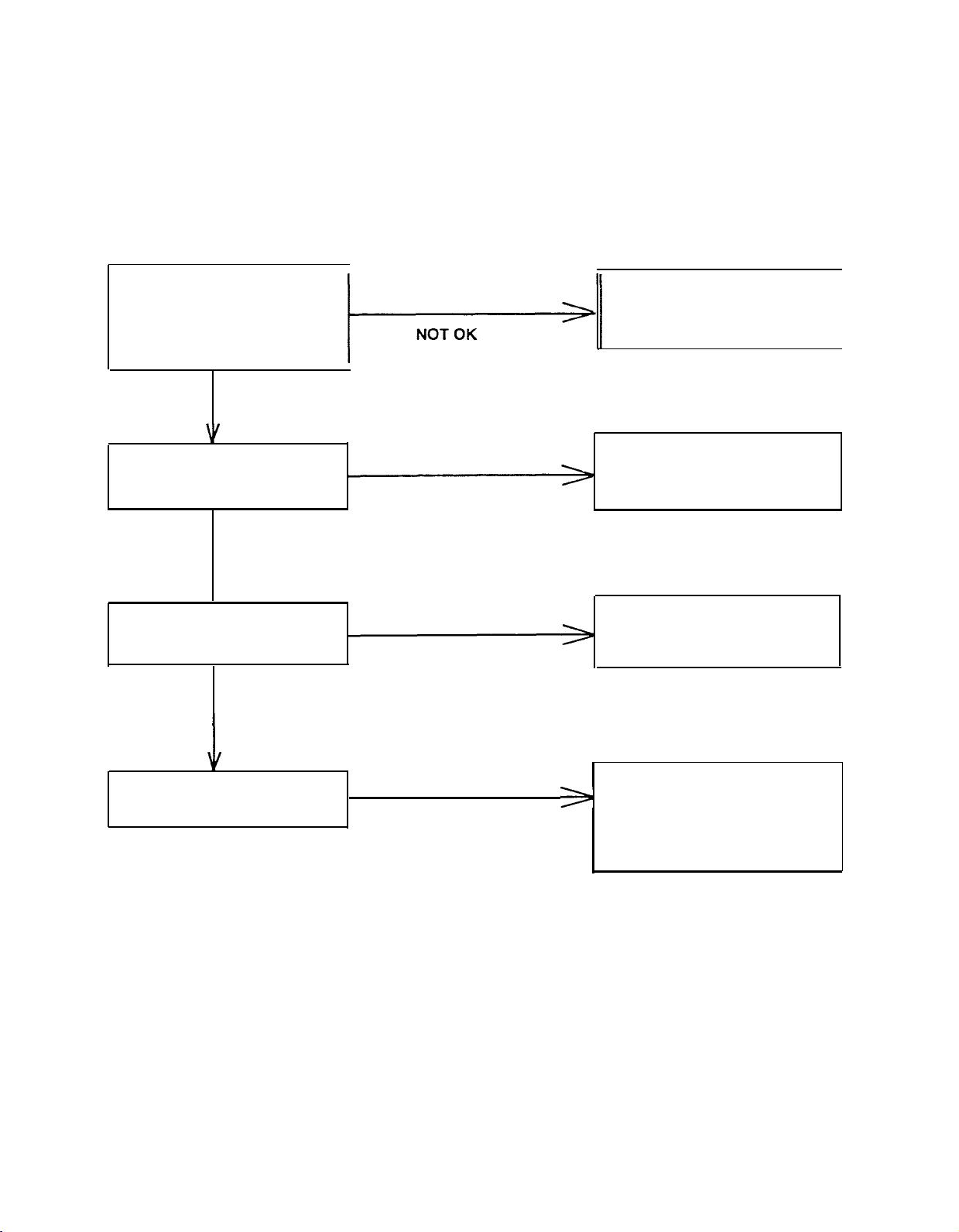

DIAGNOSTIC FLOW CHART

A.

1. Check AC Power

2. Refrigerator Plugged in

3. Breaker

4. Coach

Plug

OK

NO 120 VOLT AC OPERATION

~=I

Correct as Necessary

i

B.

Check Selector Switch

c.

Check Thermostat

w

NOT OK

OK

V

NOT OK

OK

I

D.

Check 120 Volt Heater

If

NOT OK

Correct as Necessary

(Page D-6-20,

Correct as Necessary

Continuity Check

Correct as Necessary

B

Ohm’s Reading

Bulletin

(Page D-9-l 4, D-9-l 5)

#28

Para.

66)

D-4-2

NO GAS OPERATION - Models Equipped with Piezo igniter

www.westfaliaT3.info - a useful site for enthusiasts and owners of VW Westfalia T25 / T3 / Vanagon campers

.

Check Gas Supply

9

B.

Check Switch

.C.

v

I

OK

OK

MANUAL REFRIGERATOR

DIAGNOSTIC FLOW CHART

Correct as Necessary

NOT OK

>

(Page D-6-20,

Para

66)

Check Thermostat

OK

D.

Check Gas Pressure

Check Flue & Burner

V

OK

I

OK

F.

Check Piezo Resistance

I

NOT OK

NOT OK

NOT OK

NOT OK

Correct as Necessary

=>

Continuity Check

Correct as Necessary

>

>

>

(Page D-6-13,

Correct as Necessary

No Obstructions

Correct as Necessary

(Page D-6-l 8,

Para.

Para.

37)

58)

OK

G.

Check Piezo Electrode

,H.

Check Spark Gap

of Electrode to Burner

V

V

r

Replace ElectrodPara

>

(Page D-6-18,

I

OK

NOT OK

NOT OK

D-4-3

Correct as Necessary

>

(Page D-6-19,

Para.

Para.

58)

62)

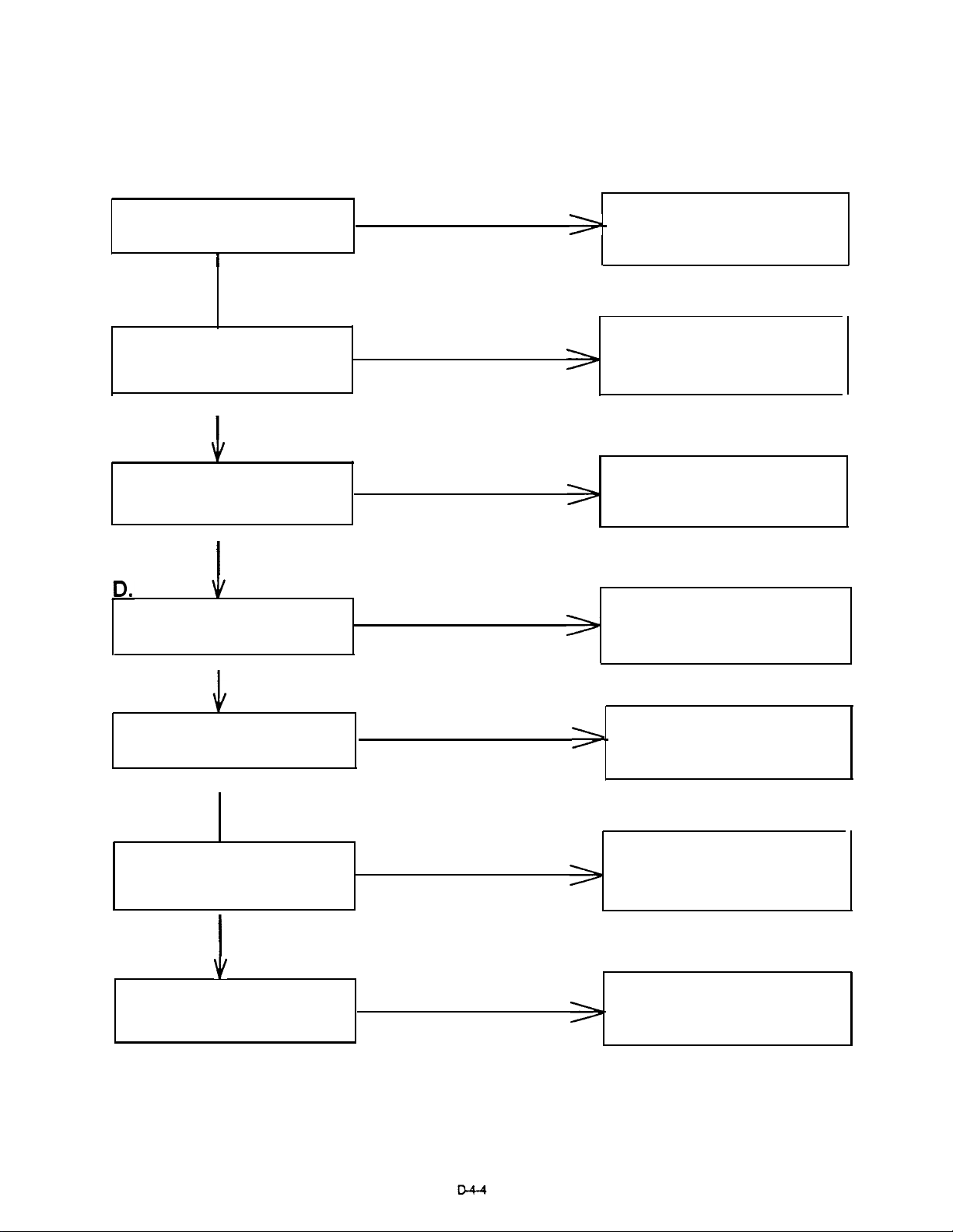

MANUAL REFRIGERATOR

www.westfaliaT3.info - a useful site for enthusiasts and owners of VW Westfalia T25 / T3 / Vanagon campers

DIAGNOSTIC FLOW CHART

NO GAS OPERATION - Models Equipped with Automatic Reigniter

A.

>

Check Gas Pressure

NOT OK

I

OK

Correct as Necessary

(Page D-6-13,

Para

37)

B.

Check Gas Supply

C.

Check 12 Volt D.C.

Supply

V

I

I

v

I

OK

OK

I

Check Switch

I

OK

_E.

Check Thermostat

NOT OK

NOT OK

NOT OK

NOT OK

Correct as Necessary

>

>

B

>

(Page D-6-14,

Correct as Necessary

Correct as Necessary

(Page D-6-20,

Correct as Necessary

Check for Continuity

Para.

Para.

40)

66)

OK

F.

Check Flue & Burner

,G.

Check Electrode

V

V

I

I

OK

NOT OK

NOT OK

Clean Assembly

>

Orifice as Necessary

Replace Electrode

>

(Page D-6-19,

&

Para.

62)

NOTES:

www.westfaliaT3.info - a useful site for enthusiasts and owners of VW Westfalia T25 / T3 / Vanagon campers

D-5

OPERATION

www.westfaliaT3.info - a useful site for enthusiasts and owners of VW Westfalia T25 / T3 / Vanagon campers

&

DIAGNOSIS

OF

DOMETIC

MANUAL REFRIGERATORS

D-6-1

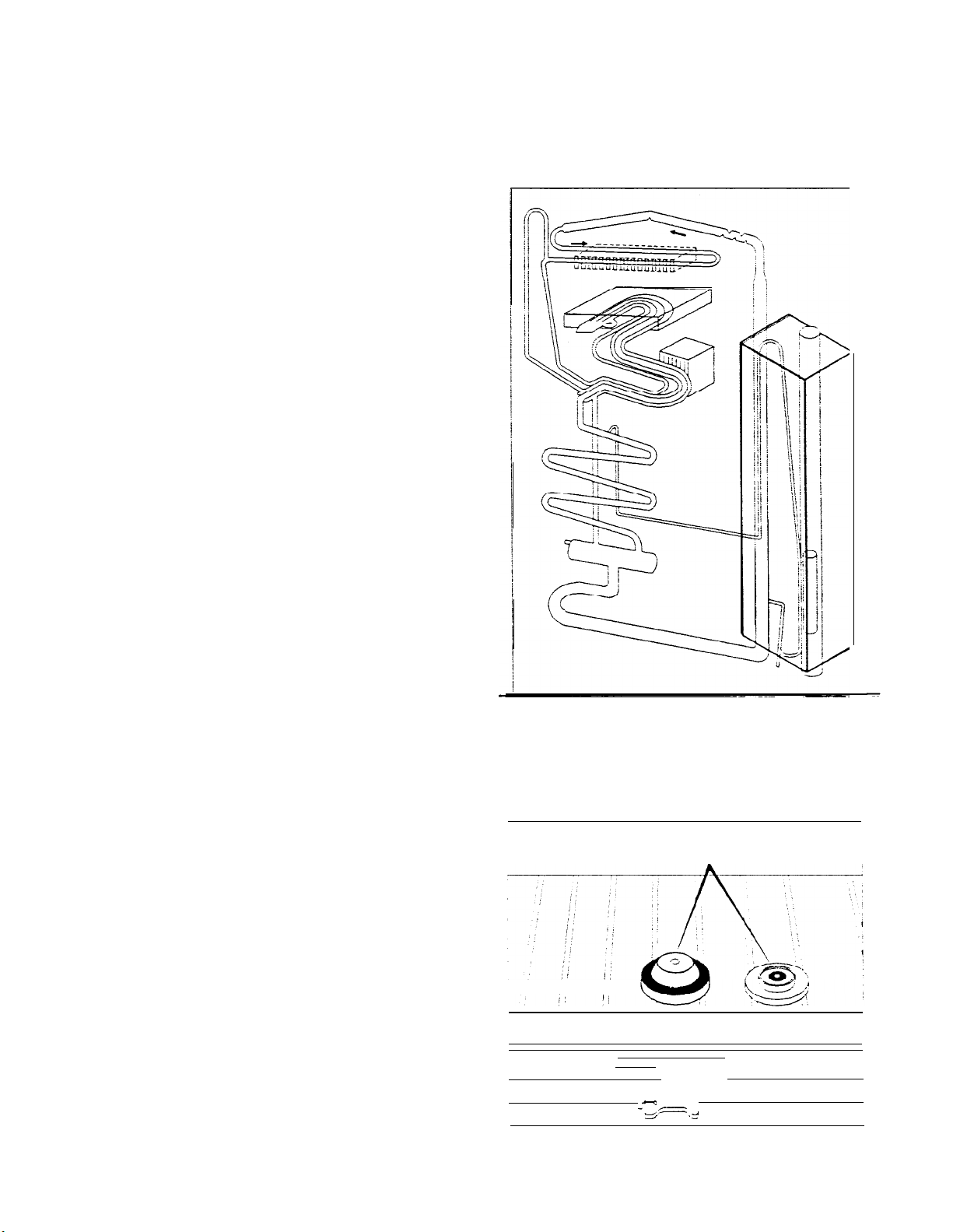

This is Dometic’s Manual Refrigeration Diagnosis and Troubleshooting program. In this program

www.westfaliaT3.info - a useful site for enthusiasts and owners of VW Westfalia T25 / T3 / Vanagon campers

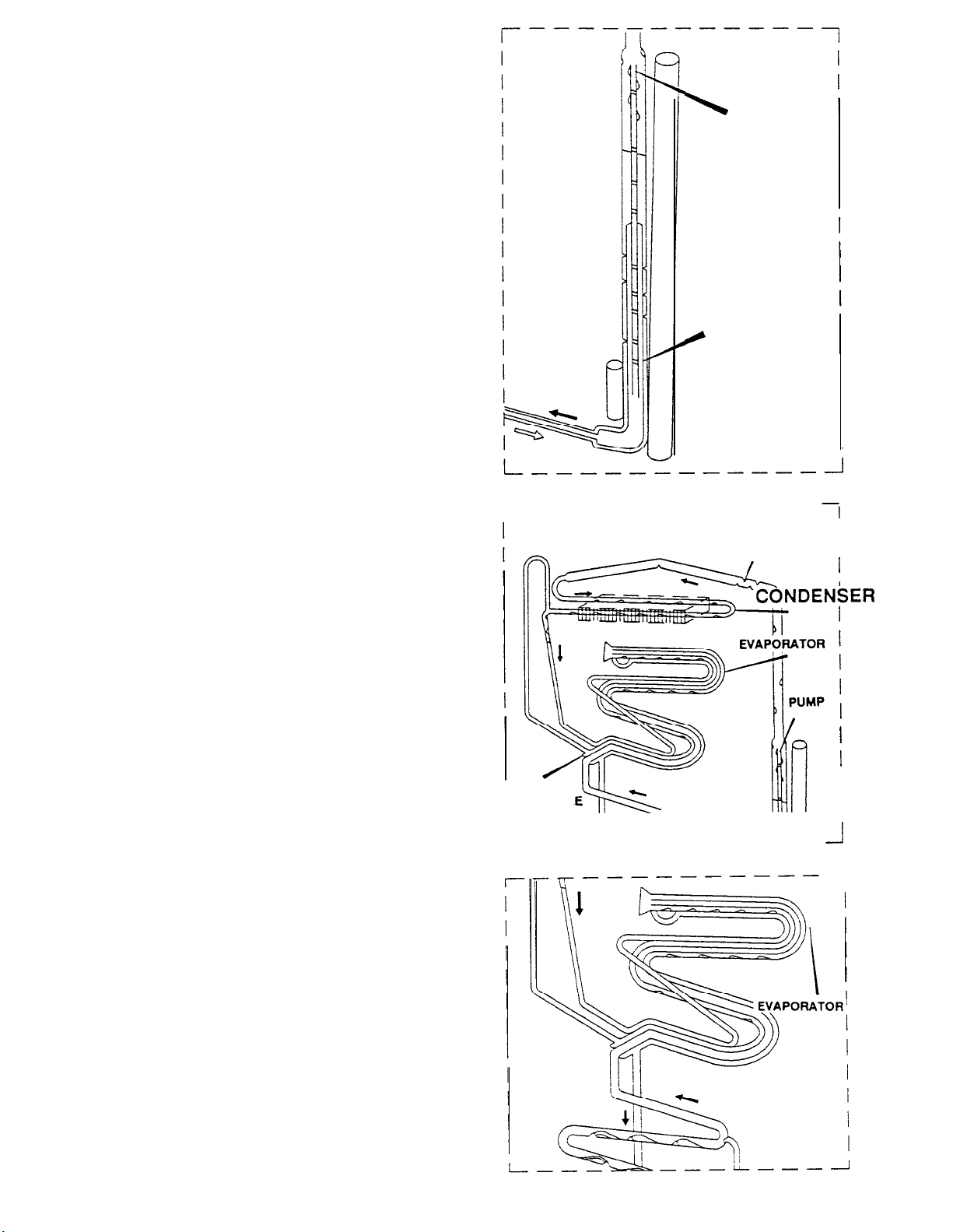

(1)

we will discuss the way an absorption cooling unit operates, and the diagnostic procedures

used to troubleshoot the complete refrigerator system.

Before we begin extensive troubleshooting

procedures on the cooling unit, let’s take a few

minutes to see how it operates.

(3)

The sealed combustion unit contains a

(2)

mixture of ammonia, water and

inhibiting agent. After this solution is

introduced into the coils, this unit is

pressurized with hydrogen gas. When

this system is in operation, the ammonia vaporizes in the hydrogen atmosphere and absorbs heat from inside

the refrigerator.

a rust

THE ABSORPTION SYSTEM

GAS

TEMPERATURE

EXCHANGER

ABSORBER

EVAPORATOR

Lil I

VESSEL

D-6-2

BOILER

.

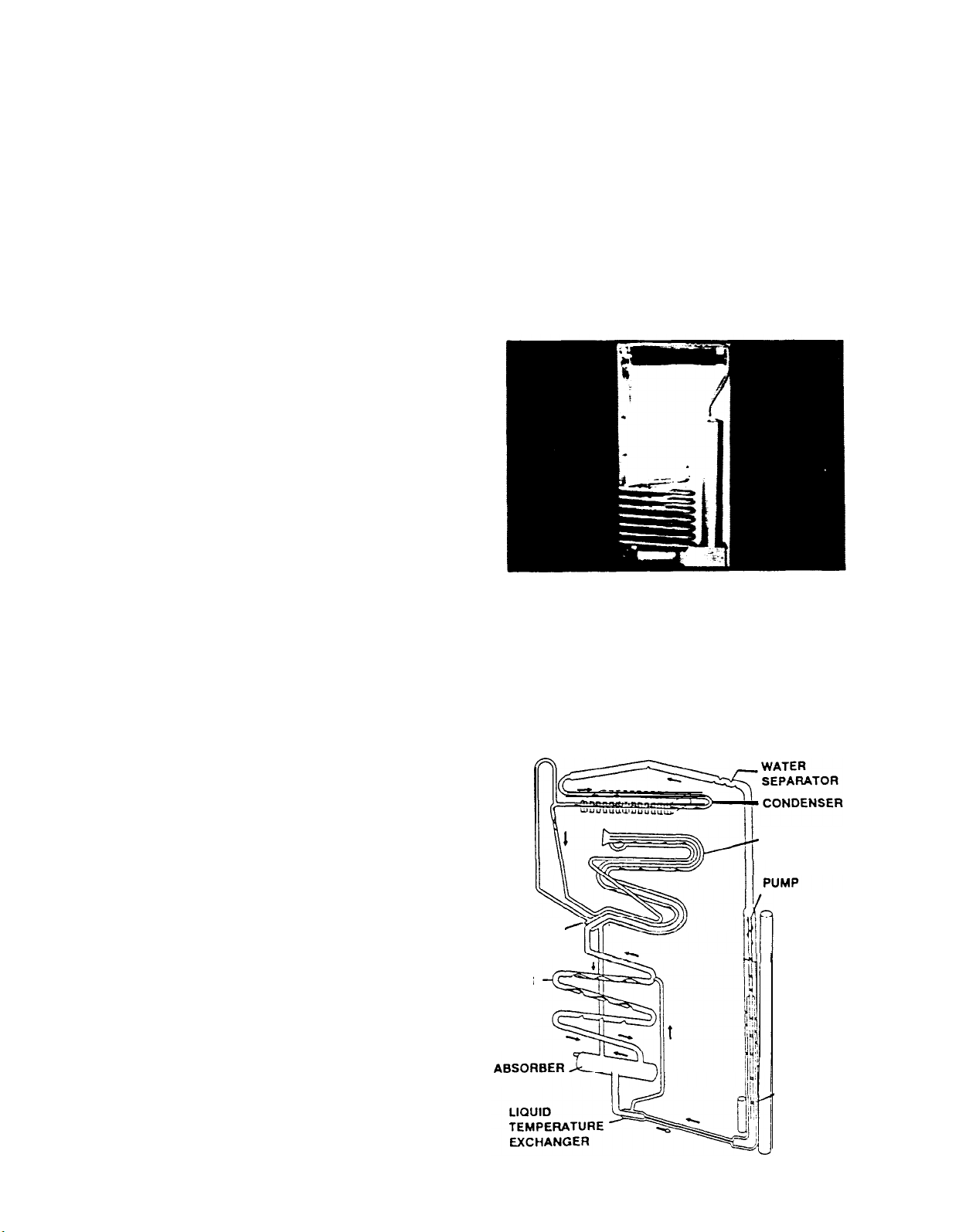

The cooling unit parts that accomplish this

www.westfaliaT3.info - a useful site for enthusiasts and owners of VW Westfalia T25 / T3 / Vanagon campers

(4)

‘cooling’ or heat extraction process, include the:

Boiler or Generator

\

/

BOILER

PUMP

(5)

Condenser

l-------------

GAS

TEMPERATUR

EXCHANGER

------------

WATER

SEPARATOR

-l

I

I

I

I

I

_-.I

1

(6)

Evaporator

D-6-3

(7)

www.westfaliaT3.info - a useful site for enthusiasts and owners of VW Westfalia T25 / T3 / Vanagon campers

Absorber

ABSORBER

Because the self-contained cooling unit

does not utilize an electric compressor

or pump, the cooling coils can be operated from a variety of heat sources. LP

gas, 120 volts AC and 12 volts DC

heating elements are the most commonly used heat sources for recreational vehicle applications.

THE ABSORPTION

TEMPERATURE

EXCHANGER

TEMPERATURE

EXCHANGER

SYSTEM

CONDENSER

EVAPORATOR

_

Before this cooling system can properly

(9)

extract heat from the cabinet of the

THREE REQUIREMENTS

FOR PROPER OPERATION

refrigerator, three requirements for proper refrigerator operation must be met.

These are precise heat, specified ventilation and proper leveling.

D-6-4

1. Level

2. Air Flow (Ventilation)

3. Heat

(10)

www.westfaliaT3.info - a useful site for enthusiasts and owners of VW Westfalia T25 / T3 / Vanagon campers

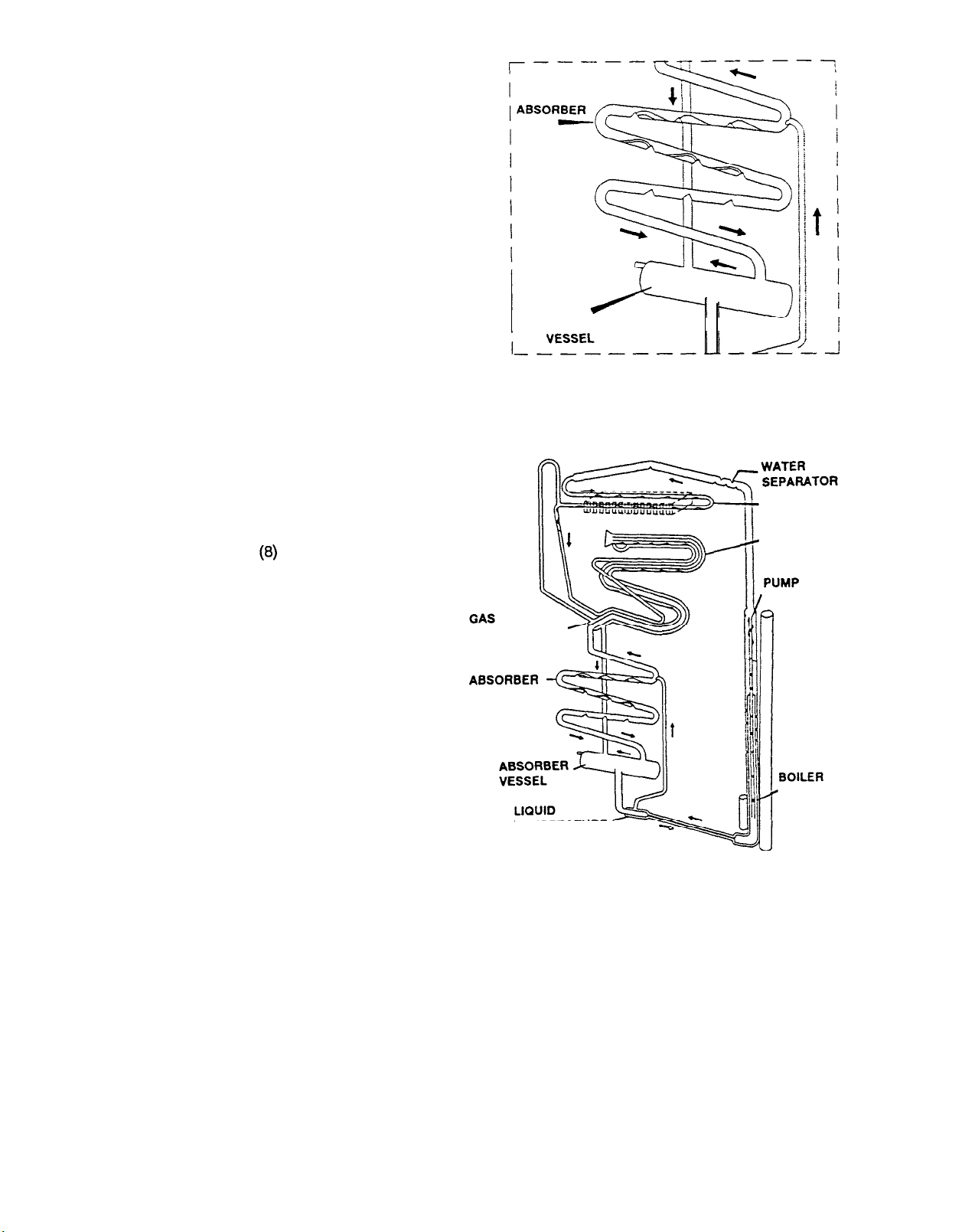

We will now take a closer look at how the

cooling unit functions in normal operation.

When proper heat is supplied to the boiler,

ammonia vapor is produced and rises in the

siphon pump, carrying with it a weak liquid

ammonia solution. As seen from this drawing,

the siphon pump, or pump tube, is an internal

arrangement within the boiler section. The boiler

section utilizes the ammonia-water liquid solution in the absorber and as it is heated, turns

the solution into a strong ammonia vapor, which

is needed to operate the system. This strong

ammonia vapor rises from the pump tube to the

condenser coil.

Any deviation from the listed amount of

heat to the absorption system will alter the

ammonia to water ratio, which, in turn, will

decrease the cooling unit’s overall efficiency.

The weak ammonia solution which remains

behind is diverted to the top of the absorber

coils to perform a function that we will discuss

in further detail later in the program.

c---_-------____---------__----_-__-7

I

I

i

I------------------------~

WATER

ENSER

PUMP

/

P

I

1

I

(11)

The air that passes through the condenser fins,

from the venting system, removes heat from the

ammonia vapor, causing it to condense into a

strong liquid ammonia solution. As a liquid, it

then flows to the low temperature evaporator, or

freezer companment, where it comes into

contact with a hydrogen atmosphere. When this

occurs, the ammonia begins to evaporate which

draws heat from inside the freezer section, to

the rear of the cooling unit.

(12)

This heat is then dissipated out through the

upper vent, which allows the refrigerators

interior temperature to properly maintain food

storage requirements. Not all of the liquid

ammonia evaporates in the freezer. What is left

continues to evaporate as it flows to the high

temperature evaporator, or food storage com-

partment.

COLD INTERIOR

D-6-5

U

www.westfaliaT3.info - a useful site for enthusiasts and owners of VW Westfalia T25 / T3 / Vanagon campers

As this process continues, the ammonia and

hydrogen vapors become intermixed and flow

downward into the absorber vessel. As the

ammonia vapor comes in close contact to the

liquid ammonia solution in the absorber vessel,

the ammonia is absorbed into the liquid

solution, allowing the hydrogen vapor to rise up

through the absorber coils. After this absorption

process, the vapor consists of mostly hydrogen

with some traces of ammonia.

3)

I--

I

1

I

I

I

I

I

I

To remove the remaining amounts of ammonia

vapor still present in the hydrogen, a

continuous flow of weak ammonia solution is

fed, by gravity, to the top of the absorber coil

from the boiler. As this weak ammonia solution

flows downward through the absorber, it

absorbs the ammonia vapor from the mixture,

allowing the hydrogen vapor to rise through the

absorber coil and return to the evaporator. With

the hydrogen returned to the evaporator and

the ammonia remixed into solution in the

absorber vessel, the cooling process can

continue.

Now that we have a basic understanding of

proper cooling unit flow and operation, let’s

take a step-by-step look at the three requirements for proper cooling unit operation. Please

note it is essential that these three requirements

be diagnosed before attempting to diagnose

the cooling unit. A problem with leveling, heat

input or ventilation may lead you to think that

the cooling unit is faulty, when actually it is not.

This

causes an

customer, and valuable shop time is wasted

because of incorrect diagnosis, By following

and checking the three unit requirements, costly

diagnostic errors can be eliminated.

increased expense to you, the

(14)

(15)

-------

I

---

__------

Ll_____i

THREE REQUIREMENTS

FOR PROPER OPERATION

1. Level

2.

Air Flow (Ventilation)

3. Heat

__A

I

D-6-6

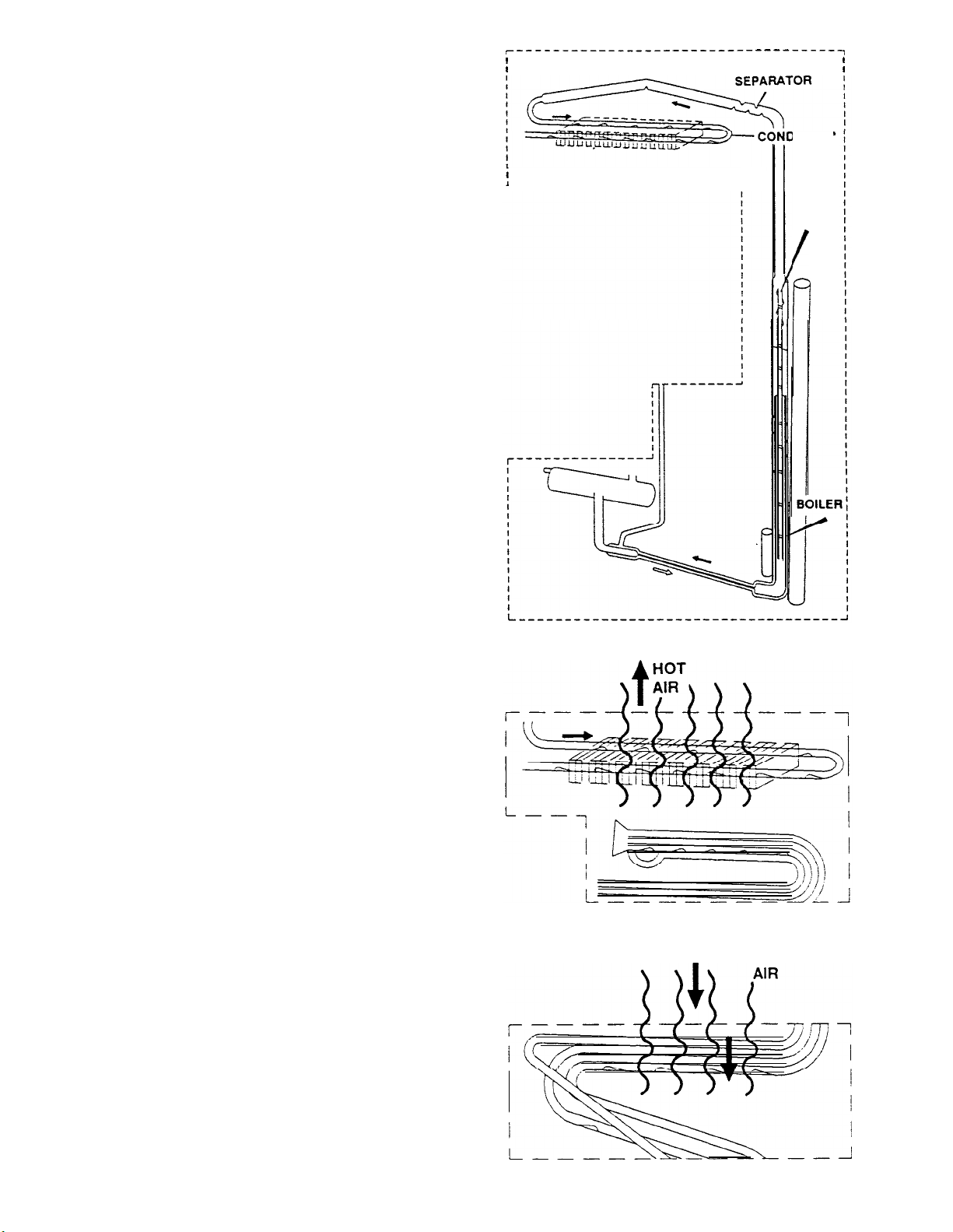

Since the absorption system utilizes no

www.westfaliaT3.info - a useful site for enthusiasts and owners of VW Westfalia T25 / T3 / Vanagon campers

(16)

mechanical pumps or compressors to circulate

the refrigerant within the system, proper leveling

is required to provide correct refrigerant flow in

the gravity-feed system. Without proper leveling,

refrigerant within the cooling coils will collect

and stagnate at certain areas. When this

happens the cooling process will stop.

(17)

On the older style cooling units equipped with

square boiler box covers, this condition can

cause permanent cooling unit failure. As we can

see from this drawing, square boiler box

cooling units utilize an exposed siphon pump

tube which will become excessively super-

heated in an out-of-level condition. This can

allow the rust inhibiting agent to chemically

break down and permanently block or restrict

the normal refrigerant flow through the pump.

Shaking, tipping or so called ‘burping the

refrigerator will not loosen or dislodge the

blockage. The only recommended service

procedure is to replace the cooling unit. To

prevent this occurrence, proper leveling is of

utmost importance when the RV is parked for

any length of time.

THREE REQUIREMENTS

FOR PROPER OPERATION

1.

Level

(18)

To level these units, the spirit or bubble level

should be placed in the approximate front and

center of the floor of the freezer compartment.

The coach should then be positioned so that at

least 3/4 of the bubble is within the required

mark while the refrigerator is in operation.

REMEMBER: Failure to property

boiler box can result in a lack of cooling or

permanent

the vehicle is moving, leveling is not critical as

the rolling and pitching movement of the RV will

keep the solution in motion, preventing the

solution from accumulating in the piping.

damage to the coding unit. When

level

a square

REFRIGERATOR IS TO BE LEVEL

--

-

m

-_C==Z

_

LEVELS

-5

D-6-7

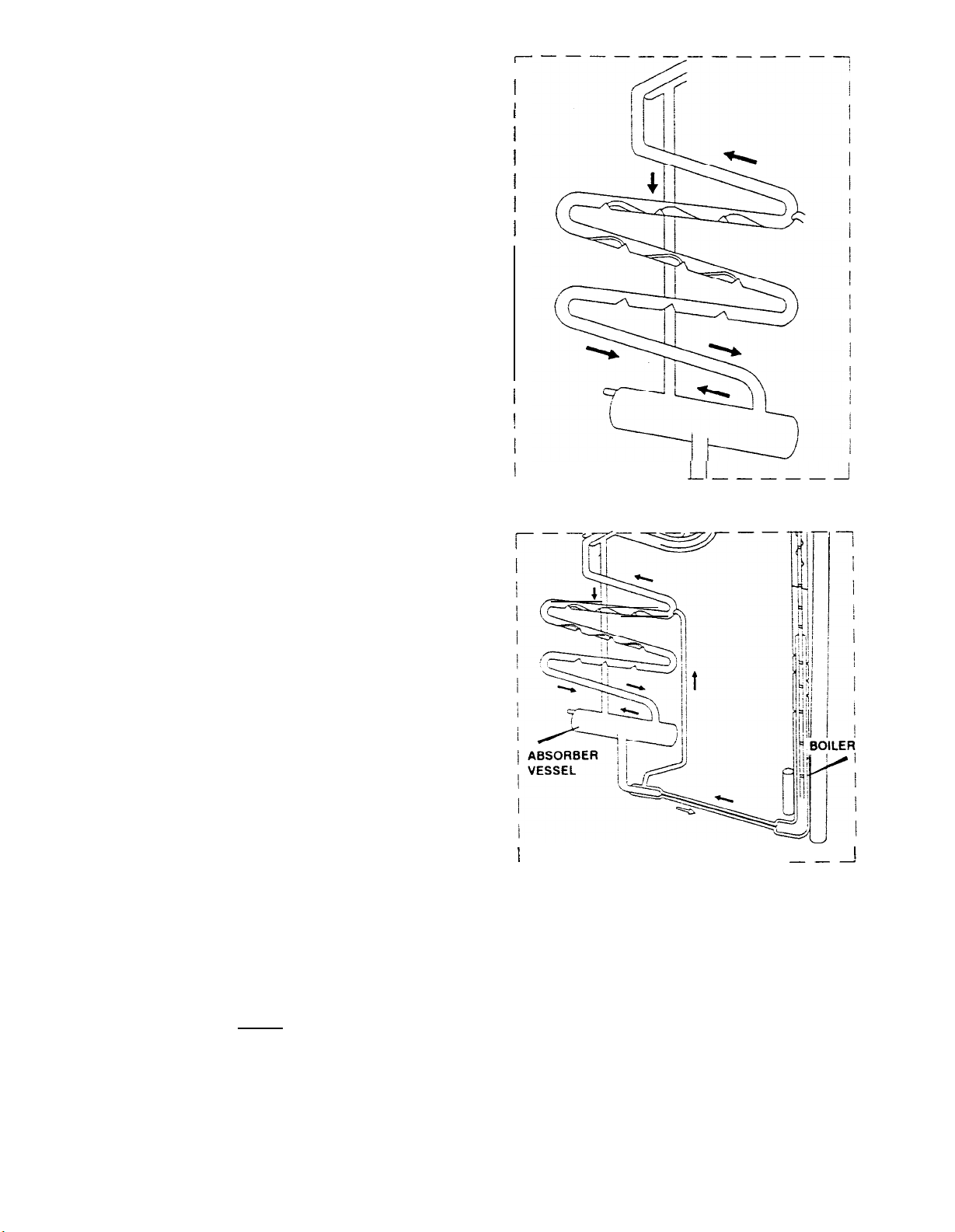

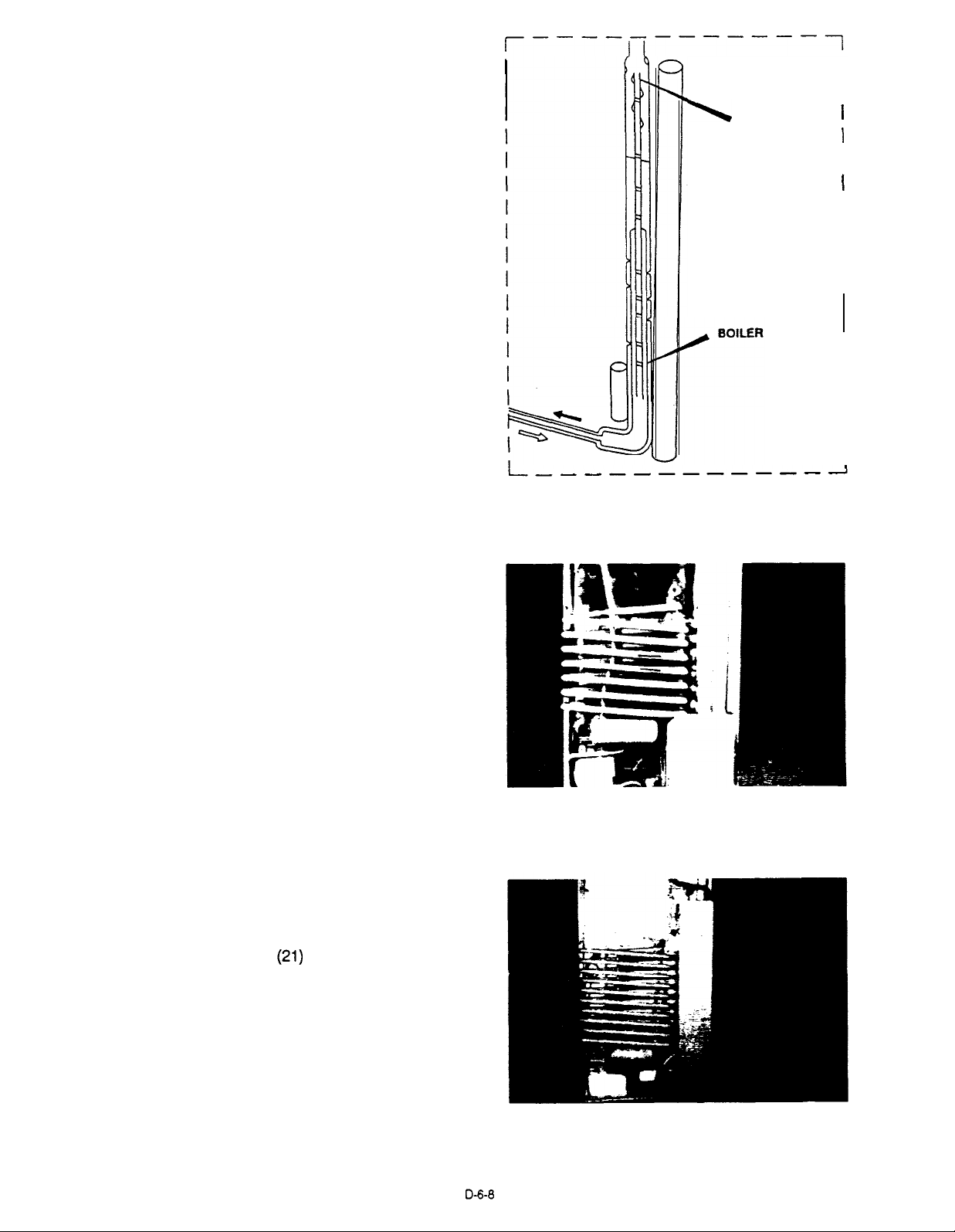

In recent years

www.westfaliaT3.info - a useful site for enthusiasts and owners of VW Westfalia T25 / T3 / Vanagon campers

type of cooling unit that utilizes an improved

siphon pump tube design which drastically

reduces the possibility of permanent damage to

the coils if operated in an out-of-level condition,

or too much heat is generated at the boiler

section. As we can see from this drawing, the

siphon pump tube is enclosed in the design

and is surrounded by a weak ammonia solution,

which will protect the pump tube from abnormally over-heating. This type of unit; however,

does not eliminate the need for proper leveling.

The unit still requires gravitational flow to

provide the proper cooling process, and if

leveling is outside the necessary limits, cooling

will dramatically slow down or stop completely.

The cooling coils are not normally damaged in

this fashion and once proper leveling is maintained, the cooling process will resume.

Dometic

has engineered a new

(19)

I

I

\

PUMP

I

I

I

I

I

I

I

I

I

I

I

I

I

I

Spirit or bubble levels are no longer being

(20)

supplied with the new style refrigerators as the

RV or vehicle only needs to be leveled so it is

comfortable to live in, with no noticeable sloping

of the floor or walls. For diagnosis, the new

style

protection boiler system, can be differentiated

from the older style coils by the shape and

design of the outer boiler box cover on the rear

of the cooling unit. These units will incorporate

a circular metal cover,

cooling

while the older style utilizes a square

. . .

shaped enclosure.

and troubleshooting of these units in more

detail later in the program.

units that incorporate the

We will discuss diagnosis

Loading...

Loading...