Volkswagen Beetle 2012, Beetle 2017, Beetle Cabriolet 2012, Beetle Cabriolet 2017 Service Manual

Service

Repair Manual

Beetle 2012 ➤

The Beetle 2017 ➤

The Beetle Cabriolet 2012 ➤

The Beetle Cabriolet 2017 ➤

5-Cylinder Fuel Injection Engine (2.5L Engine, 4Valve)

Engine ID

CBTACBUACCC

A

Edition 12.2016

Service Department. Technical Information

List of Workshop Manual Repair Groups

Re pa ir G ro up

00 - General, Technical Data

10 - Engine Assembly

13 - Crankshaft, Cylinder Block

15 - Cylinder Head, Valvetrain

17 - Lubrication

19 - Cooling System

24 - Multiport Fuel Injection

26 - Exhaust System, Emission Controls

28 - Ignition/Glow Plug System

Service

Technical information should always be available to the foremen and mechanics, because their

careful and constant adherence to the instructions is essential to ensure vehicle road-worthiness

and safety. In addition, the normal basic safety precautions for working on motor vehicles must, as

a matter of course, be observed.

Beetle 2012 ➤, The Beetle 2017 ➤, The Beetle Cabriolet 2012 ➤, The Beetle Cabri ...

5-Cylinder Fuel Injection Engine (2.5L Engine, 4-Valve) - Edition 12.2016

Contents

00 - General, Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1 Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 Engine Number/Engine Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2 General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1 Cylinder Numbering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.1 Safety Precautions, Working on Fuel Supply System . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.2 Safety Precautions, Test and Measuring Instruments during Test Drive . . . . . . . . . . . . . . 5

3.3 Cooling System Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.4 Ignition System Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4 Repair Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.1 Guidelines for Clean Working Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.2 Foreign Objects in Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.3 Contact Corrosion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.4 Wire Routing and Securing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.5 Radiator and Condenser Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

10 - Engine Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1 Engine, Removing and Installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.1 Engine, Removing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.2 Engine and Transmission, Separating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1.3 Engine, Securing on Engine and Transmission Holder . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

1.4 Engine, Installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2 Subframe Mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2.1 Overview - Subframe Mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2.2 Engine Mount, Removing and Installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2.3 Engine, Supporting in Installation Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2.4 Subframe Mount, Adjusting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

2.5 Subframe Mount, Checking Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

3 Engine Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3.1 Engine Cover, Removing and Installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

4 Special Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

13 - Crankshaft, Cylinder Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

1 Cylinder Block, Belt Pulley Side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

1.1 Overview - Ribbed Belt Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

1.2 Ribbed Belt, Removing and Installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

1.3 Ribbed Belt Tensioner, Removing and Installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

1.4 Vibration Damper, Removing and Installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

1.5 Sub-Assembly Bracket, Removing and Installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

1.6 Engine Bracket, Removing and Installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

1.7 Sealing Flange, Removing and Installing, Belt Pulley Side . . . . . . . . . . . . . . . . . . . . . . . . 67

2 Cylinder Block, Transmission Side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

2.1 Overview - Cylinder Block, Transmission Side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

2.2 Overview - Drive Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

2.3 Overview - Flywheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

2.4 Drive Plate, Removing and Installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

2.5 Flywheel, Removing and Installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

2.6 Crankshaft Seal, Replacing, Transmission Side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

2.7 Sealing Flange, Removing and Installing, Transmission Side . . . . . . . . . . . . . . . . . . . . . . 78

3 Crankshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

3.1 Overview - Crankshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Contents i

Beetle 2012 ➤, The Beetle 2017 ➤, The Beetle Cabriolet 2012 ➤, The Beetle Cabri ...

5-Cylinder Fuel Injection Engine (2.5L Engine, 4-Valve) - Edition 12.2016

3.2 Crankshaft, Locking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

3.3 Crankshaft, Locking to Check/Adjust Valve Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

3.4 Crankshaft Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

3.5 Crankshaft, Measuring Axial Play . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

3.6 Crankshaft, Measuring Radial Clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

3.7 Main Bearing Shells Allocation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

4 Piston and Connecting Rod . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

4.1 Overview - Piston and Connecting Rod . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

4.2 Piston, Removing and Installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

4.3 Pistons and Cylinder Bore, Checking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

4.4 New Connecting Rod, Separating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

5 Special Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

15 - Cylinder Head, Valvetrain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

1 Cylinder Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

1.1 Overview - Cylinder Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

1.2 Overview - Cylinder Head Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

1.3 Cylinder Head, Removing and Installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

1.4 Cylinder Head Cover, Removing and Installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

1.5 Vacuum Pump, Removing and Installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

1.6 Compression, Checking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

2 Timing Chain Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

2.1 Timing Chain Cover, Removing and Installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

2.2 Timing Chain Cover Sealing Ring, Replacing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

3 Chain Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

3.1 Overview - Camshaft Timing Chains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

3.2 Overview - Timing Chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

3.3 Overview - Timing Mechanism Drive Chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

3.4 Valve Timing, Checking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

3.5 Valve Timing, Adjusting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

4 Valvetrain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

4.1 Overview - Valvetrain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

4.2 Camshaft, Removing and Installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

4.3 Valve Shaft Seal, Removing and Installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

5 Intake and Exhaust Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

5.1 Valve Guides, Checking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

5.2 Valve Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

6 Special Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

17 - Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

1 Oil Pan/Oil Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

1.1 Overview - Oil Pan/Oil Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

1.2 Oil Pan Lower Section, Removing and Installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

1.3 Oil Pan Upper Section, Removing and Installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

1.4 Oil Pump, Removing and Installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

1.5 Engine Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

2 Oil Filter/Oil Pressure Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

2.1 Overview - Oil Filter Housing/Oil Pressure Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

2.2 Oil Filter Housing, Draining . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

2.3 Oil Pressure and Oil Pressure Switch, Checking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

3 Special Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

19 - Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

1 Coolant System/Coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

ii Contents

Beetle 2012 ➤, The Beetle 2017 ➤, The Beetle Cabriolet 2012 ➤, The Beetle Cabri ...

5-Cylinder Fuel Injection Engine (2.5L Engine, 4-Valve) - Edition 12.2016

1.1 Connection Diagram - Coolant Hoses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

1.2 Overview - Engine Preheater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

1.3 Coolant System, Checking for Leaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

1.4 Coolant, Draining and Filling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

2 Coolant Pump/Thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

2.1 Overview - Coolant Pump/Thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

2.2 Coolant Pump, Removing and Installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

2.3 Coolant Thermostat, Removing and Installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

3 Radiator/Coolant Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

3.1 Overview - Radiator/Coolant Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

3.2 Radiator, Removing and Installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

3.3 Coolant Fan, Removing and Installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

4 Special Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

24 - Multiport Fuel Injection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

1 Injection System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

1.1 Component Locations - Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

1.2 Fuel System, Filling/Bleeding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

2 Fuel Injectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

2.1 Overview - Fuel Rail with Fuel Injectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

2.2 Fuel Injectors, Removing and Installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

2.3 Fuel Injectors, Checking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

3 Intake Manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

3.1 Overview - Intake Manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

3.2 Intake Manifold, Removing and Installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

3.3 Throttle Valve Control Module, Removing and Installing . . . . . . . . . . . . . . . . . . . . . . . . . . 237

4 Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

4.1 Overview - Air Filter Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

4.2 Air Filter Housing, Removing and Installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

5 Engine Control Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

5.1 Engine Control Module, Removing and Installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

6 Special Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

26 - Exhaust System, Emission Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

1 Exhaust Pipes/Mufflers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

1.1 Overview - Muffler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

1.2 Muffler, Removing and Installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

1.3 Exhaust System, Installing without Tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

2 Emissions Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

2.1 Overview - Emissions Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

2.2 Catalytic Converter, Removing and Installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

3 Secondary Air System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

3.1 Overview - Secondary Air Injection System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

3.2 Secondary Air Injection Pump Motor, Removing and Installing . . . . . . . . . . . . . . . . . . . . . . 263

3.3 Secondary Air Injection Solenoid Valve, Checking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

4 Exhaust Manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

4.1 Overview - Exhaust Manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

5 Special Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

28 - Ignition/Glow Plug System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

1 Ignition System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

1.1 Overview - Ignition System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

1.2 Ignition Coils with Power Output Stages, Removing and Installing . . . . . . . . . . . . . . . . . . 271

1.3 Knock Sensor, Removing and Installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

Contents iii

Beetle 2012 ➤, The Beetle 2017 ➤, The Beetle Cabriolet 2012 ➤, The Beetle Cabri ...

5-Cylinder Fuel Injection Engine (2.5L Engine, 4-Valve) - Edition 12.2016

1.4 Test Data and Spark Plugs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

2 Special Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 275

3 Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

iv Contents

Beetle 2012 ➤, The Beetle 2017 ➤, The Beetle Cabriolet 2012 ➤, The Beetle Cabri ...

5-Cylinder Fuel Injection Engine (2.5L Engine, 4-Valve) - Edition 12.2016

00 – General, Technical Data

1 Identification

(Edition 12.2016)

⇒ N1.1 umber/Engine Specifications”, page 1

1.1 Engine Number/Engine Specifications

Engine code -arrow A- and engine number -arrow B- (“serial

number”) are located on rear side of engine, above partition of

cylinder block/upper section of oil pan.

The engine code is also stamped in on the right side on cylinder

head and on cylinder block.

A label with the “engine code” and “serial number” is also af‐

fixed to the toothed belt guard.

The first three digits describe the mechanical structure of the

engine and are still stamped on the engine. The fourth position

describes the engine output and torque. It depends on the en‐

gine control module. Four-digit engine codes are found on the

type label and vehicle data label. It can also be read via the

engine control module.

Note

Vehicle data label locations. Refer to ⇒ Maintenance; Book‐

let 20.1; Vehicle Data Label.

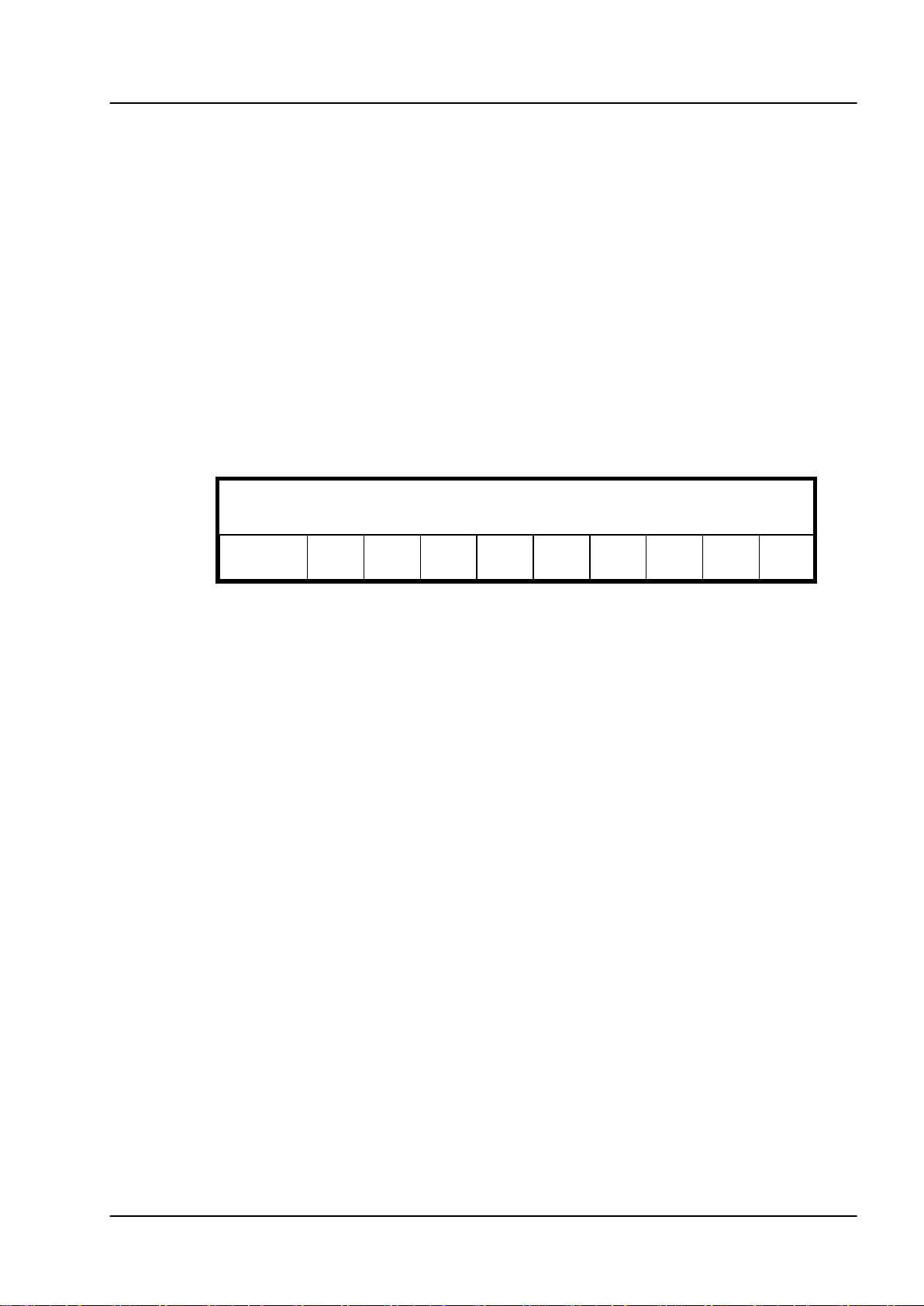

Engine Data

Edition 06/2011; Version 3.0

Engine Codes CBTA CBUA

Manufactured From 07/2007 From 07/2007

Emission values in accordance with TIER 2/BIN5 (US coa‐

lition)

Displacement cm³ 2480 2480

Output kW at RPM 125/5700 125/5700

Torque Nm at RPM 240/4250 240/4250

Engine idle speed

Engine speed limitation RPM approximately 6300 approximately 6300

Hole diameter in mm 82.5 82.5

Stroke mm 92.8 92.8

Compression ratio 9.5 9.5

5)

RPM 680 680

SULEV. Refer to 1).

Volkswagen Technical Site: https://vwts.ru

1. Identification 1

Beetle 2012 ➤, The Beetle 2017 ➤, The Beetle Cabriolet 2012 ➤, The Beetle Cabri ...

5-Cylinder Fuel Injection Engine (2.5L Engine, 4-Valve) - Edition 12.2016

Engine Codes CBTA CBUA

Valves per cylinder 4 4

RON minimum

95 unleaded

2)

95 unleaded

2)

Fuel injection, ignition Motronic ME 17.5 Motronic ME 17.5

Knock control 2 sensors 2 sensors

Camshaft adjustment yes yes

Intake manifold change-over no no

Oxygen sensor regulation 2 sensors 3 sensors

Catalytic Converter yes yes

Exhaust Gas Recirculation (EGR) no no

Charging no no

Secondary Air System no yes

1) SULEV: Super Ultra Low Emission Vehicles

2) Also 91 RON, but with reduced performance.

3) according to Mexico Exhaust Gas Standard NOM-042-SEMARNAT-2003

4) according to resolution No. 15, dated 12/13/1995 from Conama

5) Applies to manual and automatic transmission. If voltage supply of Engine Control Module (ECM) drops below 12 volts, idle speed is

raised in stages up to 780 RPM. Idle speed is not adjustable.

6) Engine Control Module, Replacing. Refer to ⇒ C5.1 ontrol Module,

Removing and Installing”, page 243 .

2 Rep. Gr.00 - General, Technical Data

Beetle 2012 ➤, The Beetle 2017 ➤, The Beetle Cabriolet 2012 ➤, The Beetle Cabri ...

5-Cylinder Fuel Injection Engine (2.5L Engine, 4-Valve) - Edition 12.2016

2 General Information

⇒ N2.1 umbering”, page 3

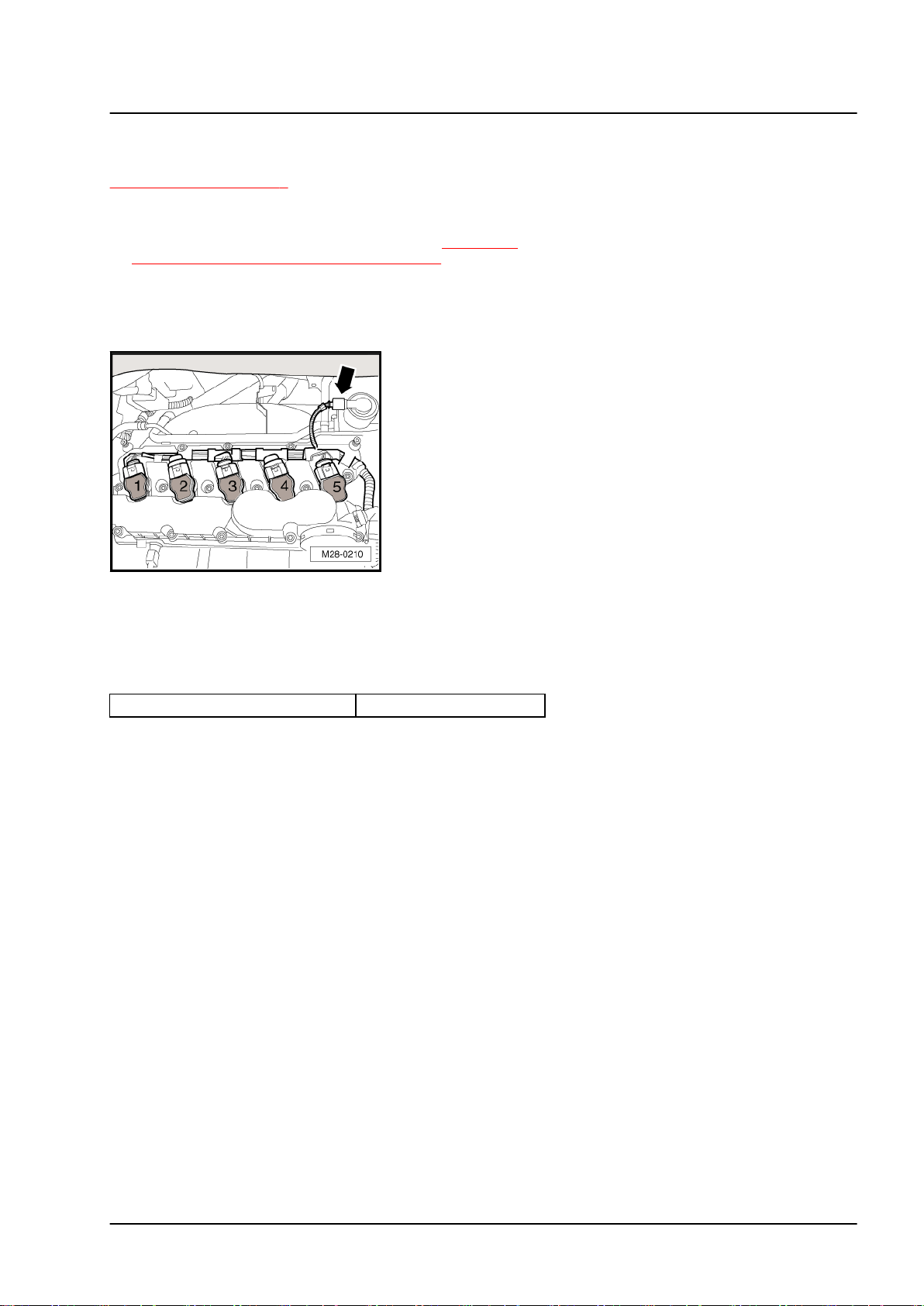

2.1 Cylinder Numbering

– Remove the air filter (engine cover). Refer to ⇒ F4.2 ilter

Housing, Removing and Installing”, page 241 .

Note

Ignore -arrow-.

Note

Cylinder 1 is located opposite the fuel supply side.

Ignition sequence 1 - 2 - 4 - 5 - 3

2. General Information 3

Beetle 2012 ➤, The Beetle 2017 ➤, The Beetle Cabriolet 2012 ➤, The Beetle Cabri ...

5-Cylinder Fuel Injection Engine (2.5L Engine, 4-Valve) - Edition 12.2016

3 Safety Precautions

⇒ P3.1 recautions, Working on Fuel Supply System”, page 4

⇒ P3.2 recautions, Test and Measuring Instruments during Test

Drive”, page 5

⇒ S3.3 ystem Safety Precautions”, page 5

⇒ S3.4 ystem Safety Precautions”, page 6

3.1 Safety Precautions, Working on Fuel Supply System

Note the Following Whenever Working on the Fuel Supply Sys‐

tem:

WARNING

The fuel system is under pressure!

♦ Always wear protective eyewear and protective clothing

to prevent injuries and contact with skin.

♦ Wrap a cloth around the wiring connections before loos‐

ening hose connections. Then release pressure by care‐

fully pulling off the line.

DANGER!

Leaking fuel is a fire hazard.

WARNING

Any type of fuel leak will result in an increased risk of fire.

Do not turn on the ignition, open the front doors, or attempt to

start the engine at any time while any part of the vehicle’s fuel

system is unassembled. Failing to heed this warning could

result in fire and personal injury

Caution

Risk of destroying electronic components when disconnect‐

ing the battery.

♦ Follow the steps for disconnecting the battery.

Disconnect the battery only when the ignition is turned off. Refer

to ⇒ Electrical Equipment; Rep. Gr. 27; Battery; Battery, Discon‐

necting and Connecting.

Even Very Small Particles of Dirt Can Cause a Fault. When

Working on the Fuel Supply and on the Fuel Injection System,

Observe the Following Guidelines for a Clean Working Environ‐

ment:

♦ Always clean the connection locations and the area around

them with engine or brake cleaner before loosening.

♦ The always dry the cleaned locations.

4 Rep. Gr.00 - General, Technical Data

Beetle 2012 ➤, The Beetle 2017 ➤, The Beetle Cabriolet 2012 ➤, The Beetle Cabri ...

5-Cylinder Fuel Injection Engine (2.5L Engine, 4-Valve) - Edition 12.2016

♦ Seal any open lines and connections immediately with a

suitable caps.

♦ Place the removed parts on a clean surface and cover them.

Only use lint-free cloths.

♦ Install only clean parts: remove the replacement parts from

their packaging just before installing them. Do not use parts

that have been stored loose (for example, in tool boxes etc.).

♦ Do not work with compressed air when the system is open.

♦ Do not move the vehicle if possible.

♦ Protect any disconnected connectors from dirt and moisture

and connect them only when they are completely dry.

3.2 Safety Precautions, Test and Measur‐

ing Instruments during Test Drive

If Testing Equipment Must be Used During a Road Test, Ob‐

serve the Following:

WARNING

Distraction and testing equipment that is not secured proper‐

ly can cause accidents.

♦ Operating testing equipment while driving is a distrac‐

tion.

♦ Testing equipment that is not secure increases the risk

of injury.

♦ Always secure testing equipment on the rear seat.

♦ Have a second person operate the testing equipment.

♦ Operate the testing equipment from the rear seat.

♦ Do not operate the testing equipment from the front pas‐

senger seat.

♦ The deployment of the front passenger airbag during an

accident can cause injury to the person.

3.3 Cooling System Safety Precautions

WARNING

Hot steam may escape when opening the reservoir.

♦ Wear protective goggles and protective clothing to pre‐

vent damage to eyes and scalding.

♦ Cover the cap with a cloth and open very carefully.

3. Safety Precautions 5

Beetle 2012 ➤, The Beetle 2017 ➤, The Beetle Cabriolet 2012 ➤, The Beetle Cabri ...

5-Cylinder Fuel Injection Engine (2.5L Engine, 4-Valve) - Edition 12.2016

Caution

When doing any repair work, especially in the engine com‐

partment, pay attention to the following due to the tight work‐

ing conditions:

♦ Route all lines in their original locations.

♦ To prevent damage to the lines, make sure there is suffi‐

cient clearance to all moving or hot components.

Note

♦

When the engine is warm the cooling system is under pres‐

sure. If necessary release pressure before commencing re‐

pair work.

♦

Secure all hose connections with hose clamps. Refer to the

Parts Catalog for the allocation.

♦

The Spring Clip Pliers -VAS6499- are recommended for in‐

stalling spring clamps.

♦

Replace the gaskets and seals.

♦

Route the coolant hoses free of tension.

♦

Coolant hoses must not come into contact with other compo‐

nents.

♦

Pay attention to the markings on the coolant connection and

hoses.

3.4 Ignition System Safety Precautions

WARNING

To reduce the risk of personal injury and/or damage to the

fuel injection and ignition system, always observe the follow‐

ing:

Do not touch or remove ignition wires when engine is running

or turning at starter speed.

Only disconnect and reconnect wires for injection and ignition

system, including test leads, if ignition is turned off.

Fuel pump is activated with switching on the ignition and by

door contact switch on the driver door.

For this reason before opening fuel supply system, if the bat‐

tery was not disconnected, the voltage supply is interrupted..

6 Rep. Gr.00 - General, Technical Data

Beetle 2012 ➤, The Beetle 2017 ➤, The Beetle Cabriolet 2012 ➤, The Beetle Cabri ...

5-Cylinder Fuel Injection Engine (2.5L Engine, 4-Valve) - Edition 12.2016

4 Repair Information

⇒ f4.1 or Clean Working Conditions”, page 7

⇒ O4.2 bjects in Engine”, page 7

⇒ C4.3 orrosion”, page 7

⇒ R4.4 outing and Securing”, page 8

⇒ a4.5 nd Condenser Assembly”, page 8

4.1 Guidelines for Clean Working Condi‐

tions

When working on the fuel supply/injection system, pay careful

attention to the following “5 rules” of cleanliness:

♦ Thoroughly clean the connection points and the surrounding

area before loosening.

♦ Place the removed parts on a clean surface and cover them.

Only use lint-free cloths.

♦ Carefully cover or seal opened components if the repair is

not performed immediately.

♦ Install only clean parts: remove the replacement parts from

their packaging just before installing them. Do not use parts

that have been loosely stored or unpackaged (for example,

in tool boxes etc.).

♦ When the fuel system is open: avoid working with com‐

pressed air if possible. If possible do not move vehicle.

♦ Protect any disconnected connectors from dirt and moisture

and connect them only when they are completely dry.

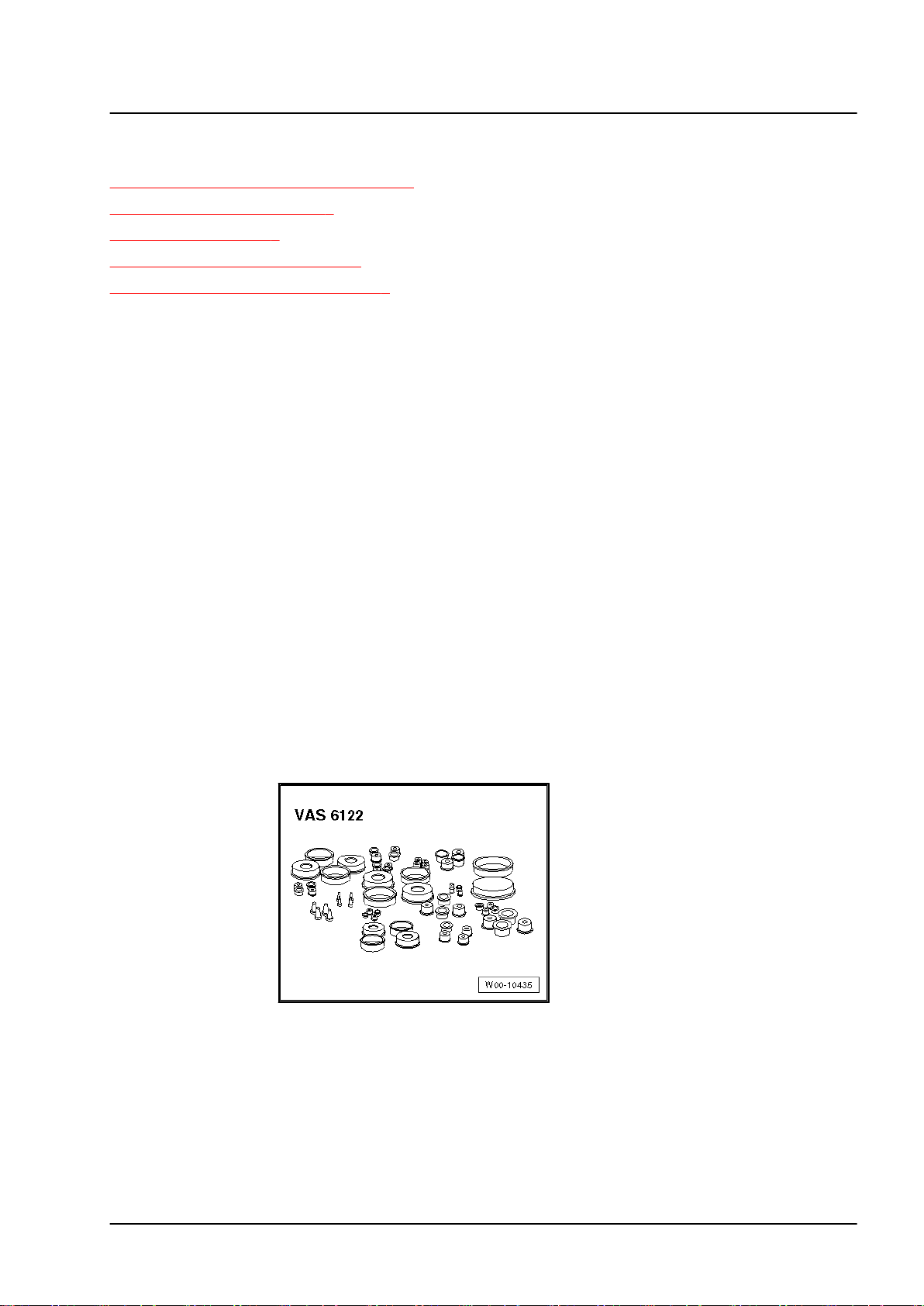

4.2 Foreign Objects in Engine

♦ To prevent foreign objects from entering when working on

the engine, seal open intake and exhaust channels with

suitable plugs, for example from the Engine Bung Set VAS6122-.

4.3 Contact Corrosion

Contact corrosion can occur if incorrect fasteners (bolts, nuts,

washers, etc.) are used.

For this reason, only fasteners with a special surface coating

are installed.

In addition, rubber or plastic parts and adhesive are made of

materials that do not conduct electricity.

If there are doubts about whether parts can be used or not, then

use new parts. Refer to the Parts Catalog.

4. Repair Information 7

Beetle 2012 ➤, The Beetle 2017 ➤, The Beetle Cabriolet 2012 ➤, The Beetle Cabri ...

5-Cylinder Fuel Injection Engine (2.5L Engine, 4-Valve) - Edition 12.2016

4.4 Wire Routing and Securing

♦ Mark the lines of all types before removal to avoid inter‐

changing them and to ensure the original installation posi‐

tion.

♦ If necessary, draw sketches or take pictures.

♦ Due to the limited space inside the engine compartment, be

especially careful when working near moving or hot parts to

avoid damaging the lines.

4.5 Radiator and Condenser Assembly

When assembled correctly, the radiator, condenser and turbo‐

charger may have slight impressions on their plates. This is not

damage. Do no replace the cooler, condenser or turbocharger

because of impressions like that.

8 Rep. Gr.00 - General, Technical Data

Beetle 2012 ➤, The Beetle 2017 ➤, The Beetle Cabriolet 2012 ➤, The Beetle Cabri ...

5-Cylinder Fuel Injection Engine (2.5L Engine, 4-Valve) - Edition 12.2016

10 – Engine Assembly

1 Engine, Removing and Installing

⇒ R1.1 emoving”, page 9

⇒ a1.2 nd Transmission, Separating”, page 18

⇒ S1.3 ecuring on Engine and Transmission Holder”, page 22

⇒ I1.4 nstalling”, page 24

1.1 Engine, Removing

Special tools and workshop equipment required

♦ Torque Wrench 1331 5-50Nm -VAG1331-

♦ Torque Wrench 1332 40-200Nm -VAG1332-

♦ Engine and Gearbox Jack -VAS6931-

♦ Spring Clip Pliers

♦ Step Ladder -VAS5085-

♦ Engine Holder Bracket -T03000-

♦ Cable Tie

♦ Foam Mat

♦ Tensioning Strap -T10038-

♦ Guide Pins -T10093-

♦ Adapters For Service Position -T10467-

Removing

– Observe the safety precautions. Refer to ⇒ P3 recautions”,

page 4 .

– Follow repair instructions. Refer to ⇒ I4 nformation”, page 7 .

Note

♦

The engine is removed downward together with the trans‐

mission.

♦

All cable ties which are opened or cut open when removing

engine, must be replaced in the same position when instal‐

ling engine.

♦

Seal the disconnected fuel and ventilation lines to prevent

dirt from getting into the system.

♦

Leave the key in the ignition lock to prevent the steering

wheel from locking.

♦

If engine oil must be drained because of work performed on

the removed engine, it should be performed with the engine

installed. If engine hangs on the -T03001-, the engine is not

in installation position and less engine oil flows out.

– Check the DTC memories for all control modules. Refer to

Vehicle Diagnostic Tester.

– Remove the air filter (engine cover). Refer to ⇒ F4.2 ilter

Housing, Removing and Installing”, page 241 .

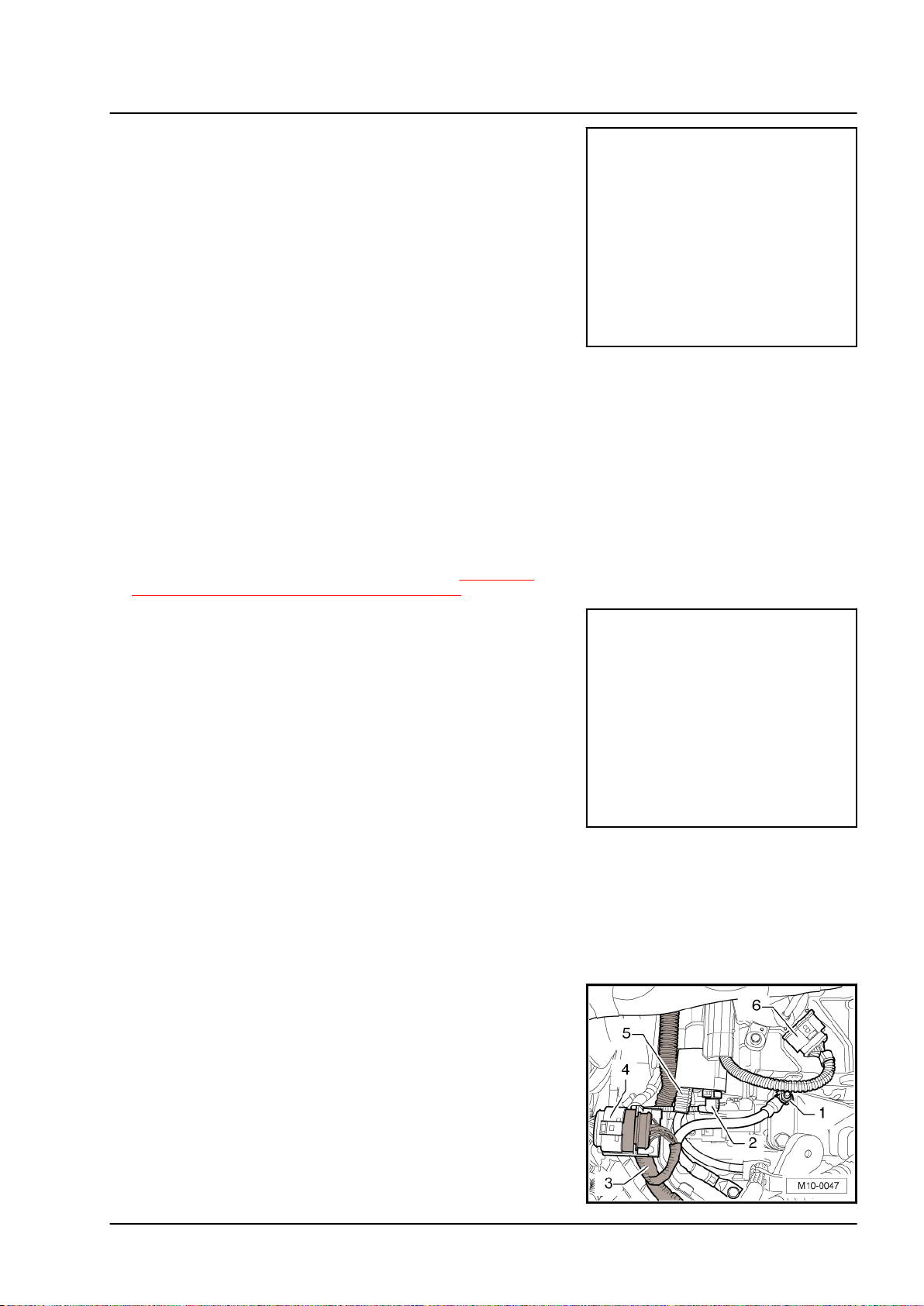

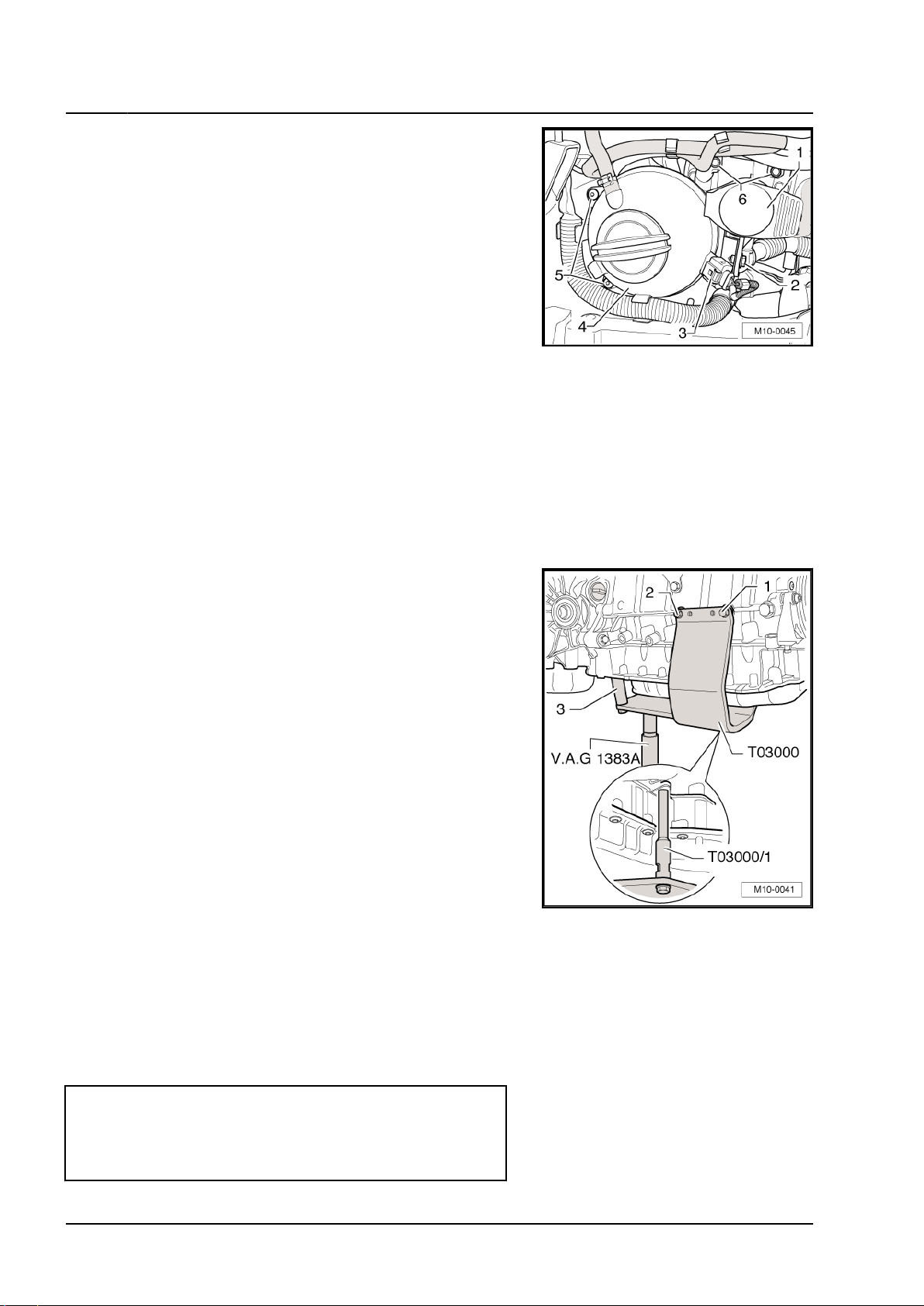

– Remove the intake hose -4- between the Throttle Valve Con‐

trol Module -J338- and the air filter. To do so, disconnect

1. Engine, Removing and Installing 9

Beetle 2012 ➤, The Beetle 2017 ➤, The Beetle Cabriolet 2012 ➤, The Beetle Cabri ...

5-Cylinder Fuel Injection Engine (2.5L Engine, 4-Valve) - Edition 12.2016

air hose -1-, if present, and air hose -2- (compress securing

ring) and remove spring clamp -3-.

Continuation for All Vehicles

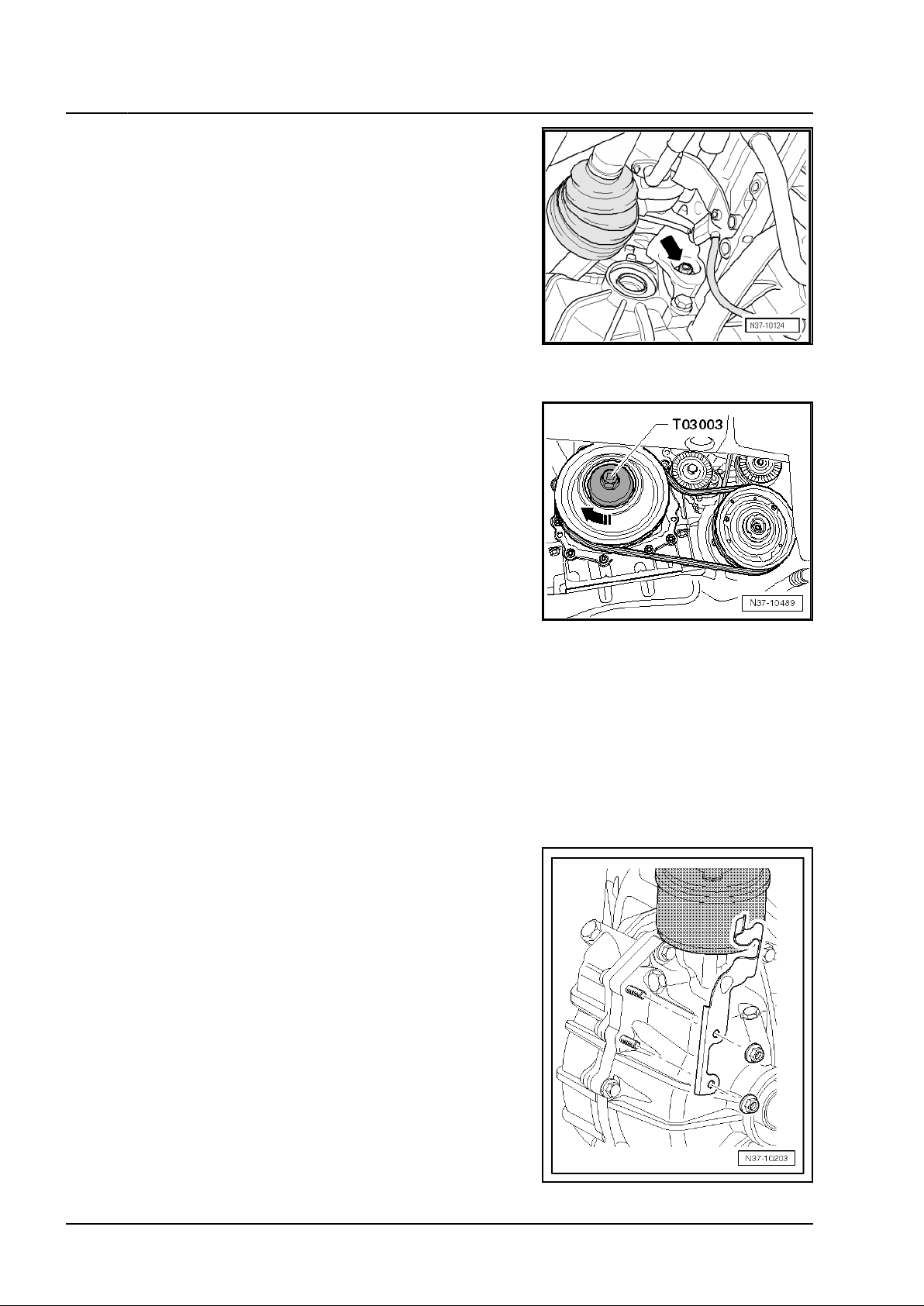

– Remove the intake air scoop from the lock carrier -arrows-.

– Remove the E-box cover inside the engine compartment

-arrows-.

Vehicles with Automatic Transmission

– Unclip the transmission control module -3- from the bracket

-7- and remove it upward.

10 Rep. Gr.10 - Engine Assembly

Beetle 2012 ➤, The Beetle 2017 ➤, The Beetle Cabriolet 2012 ➤, The Beetle Cabri ...

5-Cylinder Fuel Injection Engine (2.5L Engine, 4-Valve) - Edition 12.2016

– Disconnect the connector -2- from the transmission control

module.

Continuation for All Vehicles

– Remove the bolts -1 and 6-.

– Move the bracket -7- with the power steering fluid reservoir

to the side.

The hoses remain connected.

– Disconnect the line -5- and free it up.

– Disconnect the connector -4- from the engine control module

and free up the engine wiring harness. Refer to ⇒ C5.1 on‐

trol Module, Removing and Installing”, page 243 .

– Remove the battery and the battery tray. Refer to ⇒ Electri‐

cal Equipment; Rep. Gr. 27; Battery; Battery Tray, Removing

and Installing.

– Disconnect the connector -4-, open the locking mechanism

and lay the engine wiring harness -3- on the engine.

– Disconnect the ground cable -1- and the starter connections

-2 and 5-.

1. Engine, Removing and Installing 11

Beetle 2012 ➤, The Beetle 2017 ➤, The Beetle Cabriolet 2012 ➤, The Beetle Cabri ...

5-Cylinder Fuel Injection Engine (2.5L Engine, 4-Valve) - Edition 12.2016

Vehicles with Automatic Transmission

– Disconnect the connector -6- from the multifunction switch.

– Remove the selector lever cable from the transmission. Re‐

fer to ⇒ Rep. Gr. 34; Selector Mechanism; Selector Mecha‐

nism, Removing and Installing.

Vehicles with Manual Transmission

– Remove the selector mechanism from the transmission. Re‐

fer to ⇒ Rep. Gr. 34; Selector Mechanism; Selector Mecha‐

nism Assembly Overview.

– Remove the brace -1-.

– Remove the clutch slave cylinder -arrows- and move it to the

side. Do not open the line system.

Caution

Do not operate the clutch pedal anymore after slave cylinder

has been removed. Slave cylinder may be damaged by doing

this.

– Disconnect connector for back-up light switch from transmis‐

sion.

Continuation for All Vehicles

– Disconnect vacuum hose from brake booster.

– Disconnect the connector from the Heated Oxygen Sensor

-G39- on the bulkhead. Move the wiring harness to the side.

– Open the cap on the reservoir and then close it again to

release the pressure in the coolant system.

– Drain the coolant. Refer to ⇒ D1.4 raining and Filling”, page

187 .

Note

The vehicle has a manual hood support that is attached to the

lock carrier.

– Perform a service position. Refer to ⇒ Body Exterior; Rep.

Gr. 50; Lock Carrier; Service Position, Performing and Re‐

setting.

– Remove the radiator fan air shroud. Refer to ⇒ F3.3 an,

Removing and Installing”, page 212 .

12 Rep. Gr.10 - Engine Assembly

Beetle 2012 ➤, The Beetle 2017 ➤, The Beetle Cabriolet 2012 ➤, The Beetle Cabri ...

5-Cylinder Fuel Injection Engine (2.5L Engine, 4-Valve) - Edition 12.2016

To facilitate removal and installation of the engine without hav‐

ing to open the refrigerant circuit:

– Remove the ribbed belt. Refer to ⇒ B1.2 elt, Removing and

Installing”, page 51 .

WARNING

Refrigerant can cause serious injury.

♦ Do not open the A/C system refrigerant circuit.

– Remove the A/C compressor from the auxiliary components

bracket. Refer to ⇒ Heating, Ventilation and Air Conditioning;

Rep. Gr. 87; A/C Compressor; A/C Compressor, Removing

and Installing on Bracket.

Caution

Danger of causing damage to the refrigerant lines and hoses.

♦ Do not bend, twist or stretch the refrigerant lines and

hoses.

– Secure the A/C compressor with the -T10038- and a backing

onto the right longitudinal member.

– Remove the clamps for the power steering pressure line on

the transmission. Refer to ⇒ Suspension, Wheels, Steering;

Rep. Gr. 48; Hydraulic Power Steering; Overview - Hydraulic

Pipes and Reservoir.

– Remove the nuts -1- and the power steering pump line.

– If the vehicle has an engine preheater, remove the cable -2-.

1. Engine, Removing and Installing 13

Beetle 2012 ➤, The Beetle 2017 ➤, The Beetle Cabriolet 2012 ➤, The Beetle Cabri ...

5-Cylinder Fuel Injection Engine (2.5L Engine, 4-Valve) - Edition 12.2016

– Remove the power steering pump from the auxiliary compo‐

nents bracket and move it forward. Refer to ⇒ Suspension,

Wheels, Steering; Rep. Gr. 48; Hydraulic Power Steering;

Power Steering Pump, Removing and Installing.

• The power steering lines remain connected to the power

steering pump.

– Remove the four nuts -2- and the bolts -3-.

– Remove the front exhaust pipe -1- from the exhaust manifold

and tie it to the side. Refer to ⇒ C2.2 onverter, Removing

and Installing”, page 258 .

Caution

♦ Do not bend the decoupling element more than 10°.

♦ Do not stretch the decoupling element.

♦ Do not damage the wire mesh on the decoupling ele‐

ment.

– Remove the right drive axle. Refer to ⇒ Suspension,

Wheels, Steering; Rep. Gr. 40; Drive Axle; Drive Axle, Re‐

moving and Installing.

– Remove the left drive axle from the transmission. Refer to

⇒ Suspension, Wheels, Steering; Rep. Gr. 40; Drive Axle;

Drive Axle, Removing and Installing.

14 Rep. Gr.10 - Engine Assembly

Beetle 2012 ➤, The Beetle 2017 ➤, The Beetle Cabriolet 2012 ➤, The Beetle Cabri ...

5-Cylinder Fuel Injection Engine (2.5L Engine, 4-Valve) - Edition 12.2016

– Disconnect the fuel supply line -1- and the bleeder line -2-.

Refer to ⇒ Rep. Gr. 20; Couplings, Disconnecting Couplings.

– Seal the lines so that the fuel system is not contaminated by

dirt etc.

– Remove the coolant hoses from the heat exchanger

-arrows-.

– Open the spring clamps -arrows- and remove the coolant

hoses from the radiator.

– Remove the bolt -2- and move the windshield washer filler

tube forward -1-.

1. Engine, Removing and Installing 15

Beetle 2012 ➤, The Beetle 2017 ➤, The Beetle Cabriolet 2012 ➤, The Beetle Cabri ...

5-Cylinder Fuel Injection Engine (2.5L Engine, 4-Valve) - Edition 12.2016

– Remove the connector -3-.

– Remove the bolts -5- and place the coolant expansion tank

-4- on top of the engine with the hoses connected.

Note

Loosen the bolts on the engine mount and transmission mount

one turn.

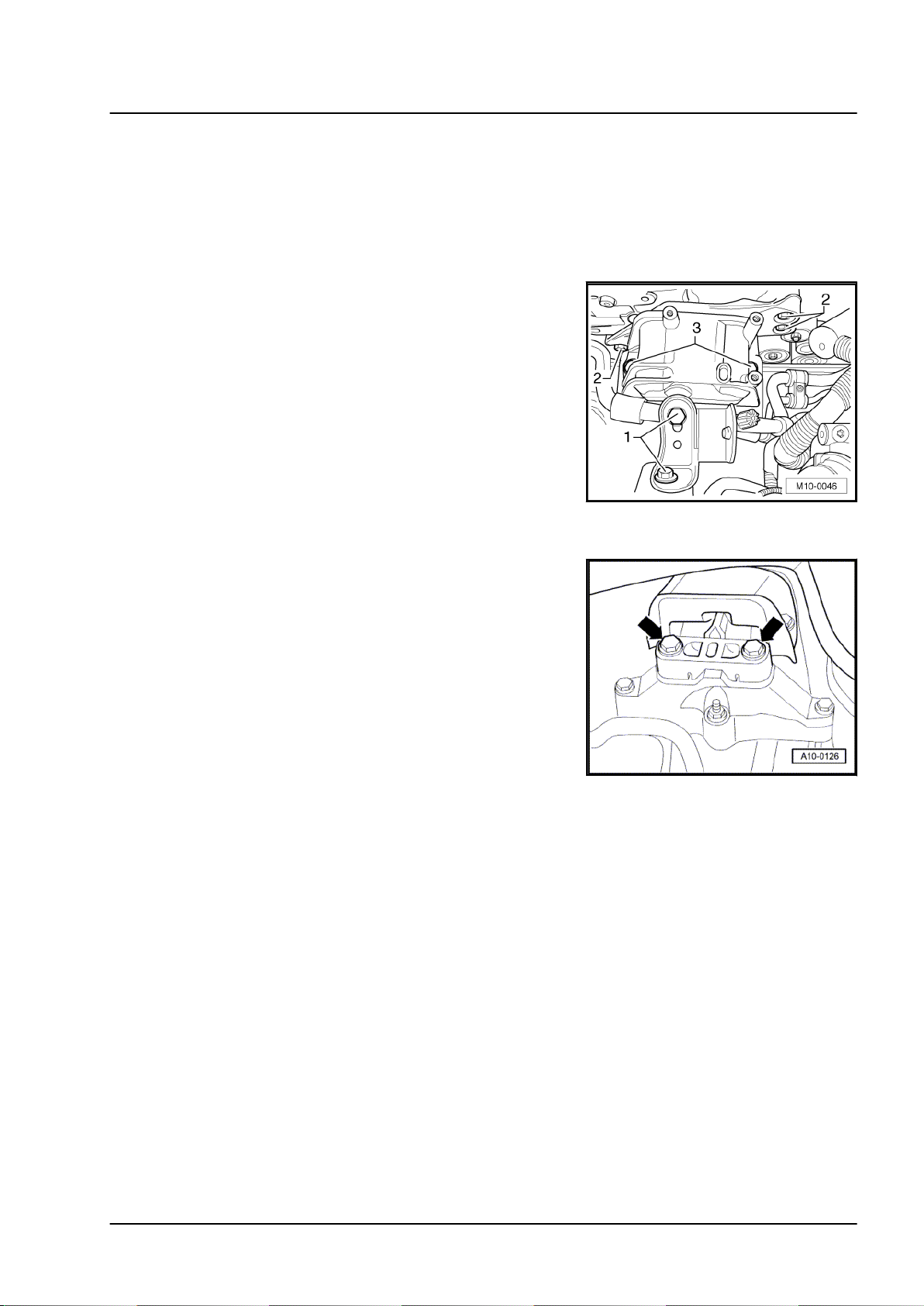

– Install the -T03000- as follows:

♦ Remove the -T03000/1- from the -T03000-.

♦ Attach the -T03000- to cylinder block with pin -3- and tighten

bolts -1 and 2- hand-tight.

♦ Then install in the -T03000/1- and tighten to 20 Nm.

♦ Then tighten bolts -1 and 2- to 25 Nm.

– Install the -VAS6931- on the -T03000- and slightly lift the

engine/transmission assembly.

WARNING

Use a step ladder such as -VAS5085- to remove the bolts for

the engine/transmission mount.

16 Rep. Gr.10 - Engine Assembly

Beetle 2012 ➤, The Beetle 2017 ➤, The Beetle Cabriolet 2012 ➤, The Beetle Cabri ...

5-Cylinder Fuel Injection Engine (2.5L Engine, 4-Valve) - Edition 12.2016

Note

The rear bolt -2- is accessible through a hole in the wheel

housing.

– Remove engine mount from above. To do this, remove the

bolts -1 through 3-.

– Remove the transmission mount from the transmission hold‐

er -arrows-.

Note

♦

Check that all hoses and lines between engine/transmission

assembly and body have been disconnected.

♦

A second technician is needed to lower the engine/transmis‐

sion assembly.

♦

The engine/transmission assembly must be guided with care

to prevent damage while lowering.

– Carefully lower the engine/transmission assembly. When do‐

ing this, rotate or push the engine/transmission assembly.

1. Engine, Removing and Installing 17

Beetle 2012 ➤, The Beetle 2017 ➤, The Beetle Cabriolet 2012 ➤, The Beetle Cabri ...

5-Cylinder Fuel Injection Engine (2.5L Engine, 4-Valve) - Edition 12.2016

1.2 Engine and Transmission, Separating

⇒ a1.2.1 nd Transmission, Separating, Vehicles with Automatic

Transmission”, page 18

⇒ a1.2.2 nd Transmission, Separating, Vehicles with Manual

Transmission”, page 21

1.2.1 Engine and Transmission, Separating,

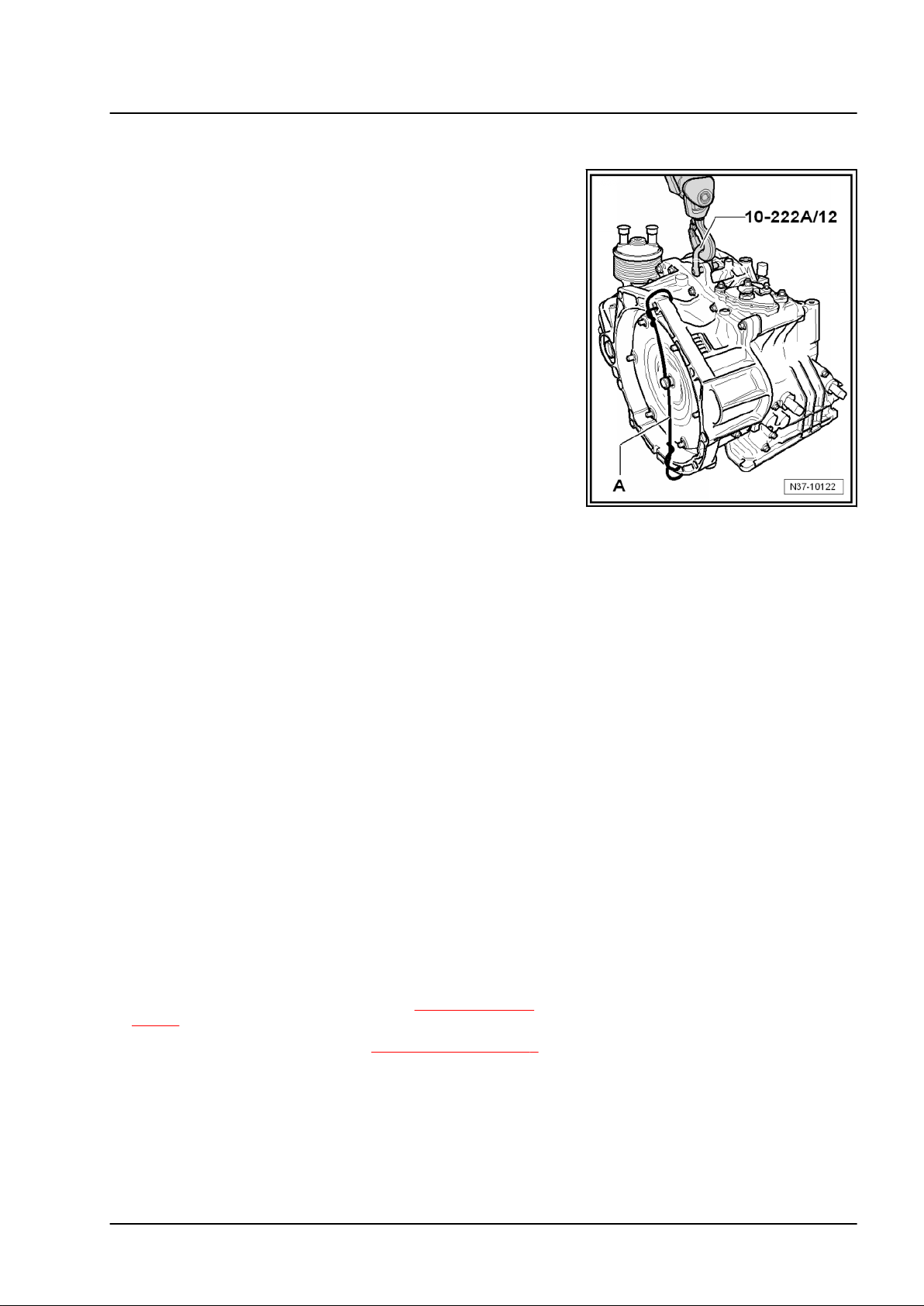

Vehicles with Automatic Transmission

Special tools and workshop equipment required

♦ Shop Crane -VAS6100-

♦ Torque Wrench 1332 40-200Nm -VAG1332-

♦ Engine/Gearbox Support Shackle (2 pc.) -10-222A/12-

♦ Crankshaft Adapter -T03003-

♦ Socket - Sw15 -V/175-

♦ Hose Clamps - Up To 25mm -3094- and Hose Clamps - Up

To 40mm -3093-

Procedure

– Observe the safety precautions. Refer to ⇒ P3 recautions”,

page 4 .

– Follow repair instructions. Refer to ⇒ I4 nformation”, page 7 .

• Engine with the transmission is removed and secured to the

-T10359A-.

– Remove the starter. Refer to ⇒ Electrical Equipment; Rep.

Gr. 27; Starter; Starter, Removing and Installing.

– Remove the bracket -1- from the upper starter bolt -arrow-.

– Remove the bolt from the top of the starter.

Note

Mark the coolant hoses on the ATF cooler to prevent mixing

them up when installing them again later.

– Clamp off the coolant hoses to the ATF cooler using -3094-

and -3093-.

18 Rep. Gr.10 - Engine Assembly

Beetle 2012 ➤, The Beetle 2017 ➤, The Beetle Cabriolet 2012 ➤, The Beetle Cabri ...

5-Cylinder Fuel Injection Engine (2.5L Engine, 4-Valve) - Edition 12.2016

– Open the spring clamps -A- and pull the coolant hoses

-B and C- off the ATF cooler.

– Seal the coolant hoses and connections with plugs taken

from -VAS6122-.

– Remove the upper transmission/engine bolts -arrows- using

a 12-point socket -A-.

– Turn the cap -1- in direction of -arrow- and remove it.

– Remove the six -converter nuts- using the -V/175-.

1. Engine, Removing and Installing 19

Beetle 2012 ➤, The Beetle 2017 ➤, The Beetle Cabriolet 2012 ➤, The Beetle Cabri ...

5-Cylinder Fuel Injection Engine (2.5L Engine, 4-Valve) - Edition 12.2016

– Turn the engine in the direction of engine rotation -arrow-

60° additional turn using the -T03003-.

Note

♦

The torque converter will be pulled out when the transmis‐

sion is separated from the engine if all 6 nuts are not re‐

moved!

♦

Counterhold the belt pulley/vibration damper using the T03003- when loosening the nuts on the torque converter.

– Remove the selector lever cable bracket from the transmis‐

sion.

20 Rep. Gr.10 - Engine Assembly

Beetle 2012 ➤, The Beetle 2017 ➤, The Beetle Cabriolet 2012 ➤, The Beetle Cabri ...

5-Cylinder Fuel Injection Engine (2.5L Engine, 4-Valve) - Edition 12.2016

– Secure the transmission with -10-222A/12- on the -

VAS6100- but do not lift.

– Remove the last transmission/engine bolt.

– While pressing the torque converter off the drive plate, sepa‐

rate the transmission from the engine.

Note

Secure the torque converter from falling out.

Assembling

Assembly is performed in reverse order of removal.

Tightening Specifications

♦ Transmission Removing and installing. Refer to ⇒ Rep.

Gr. 37; Transmission Removing and Installing.

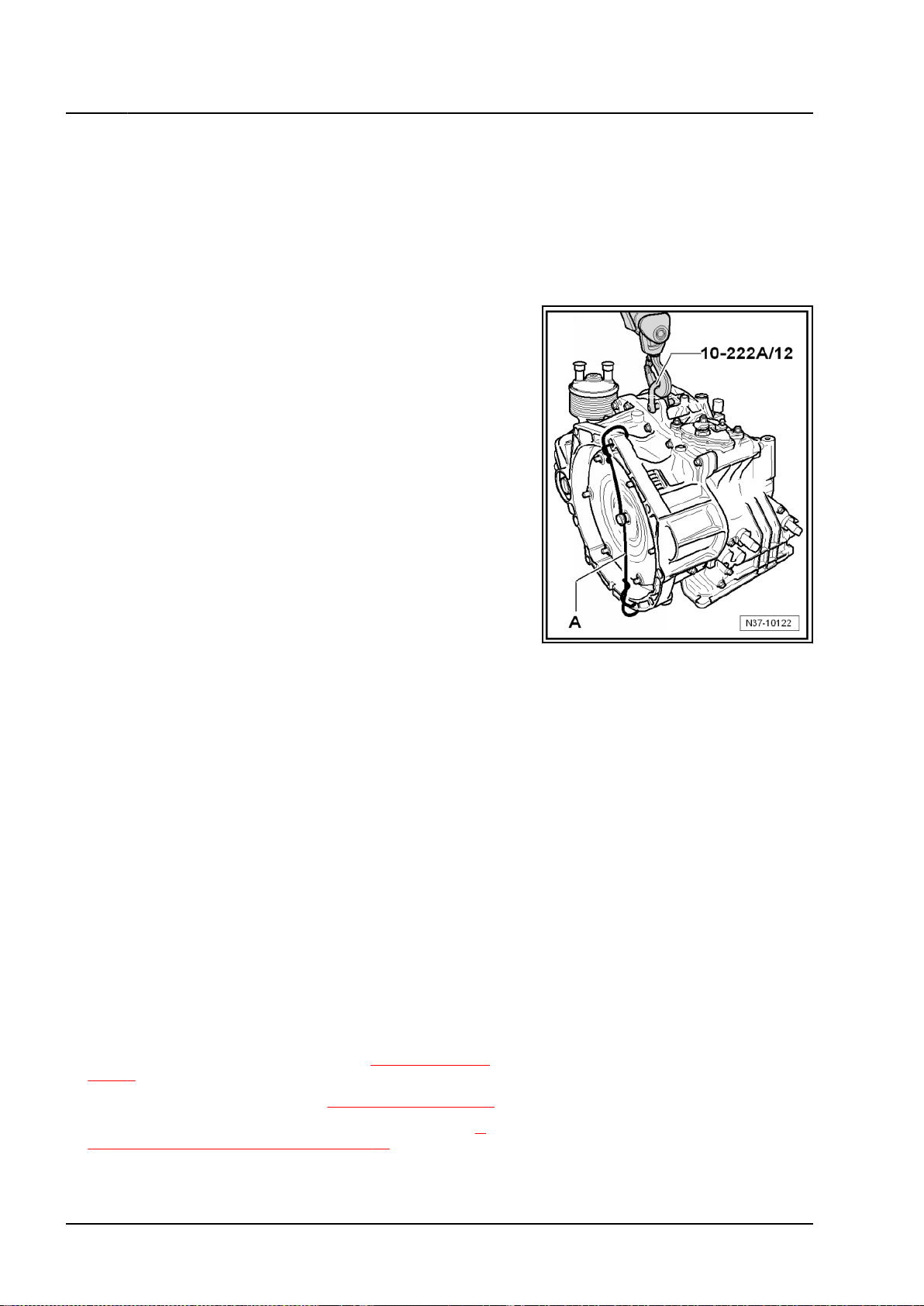

1.2.2 Engine and Transmission, Separating, Vehicles with Manual Transmission

Special tools and workshop equipment required

♦ Engine/Gearbox Support Shackle (2 pc.) -10-222A/12-

♦ Shop Crane -VAS6100-

♦ Torque Wrench 1332 40-200Nm -VAG1332-

Procedure

– Observe the safety precautions. Refer to ⇒ P3 recautions”,

page 4 .

– Follow repair instructions. Refer to ⇒ I4 nformation”, page 7 .

• Engine with the transmission is removed and secured to the

-T10359A-.

– Remove the starter. Refer to ⇒ Electrical Equipment; Rep.

Gr. 27; Starter; Starter, Removing and Installing.

– Disconnect all electrical connections from the transmission

to the engine and free them up.

1. Engine, Removing and Installing 21

Beetle 2012 ➤, The Beetle 2017 ➤, The Beetle Cabriolet 2012 ➤, The Beetle Cabri ...

5-Cylinder Fuel Injection Engine (2.5L Engine, 4-Valve) - Edition 12.2016

– Secure the transmission with -10-222A/12- on the -

VAS6100- but do not lift.

– Remove the upper engine/transmission connecting bolts.

– Support the transmission using a -VAS6100- and remove

the last bolts.

– Remove the lower engine/transmission connecting bolts.

– Separate the transmission from the engine; when doing this,

guide the transmission.

Assembling

Assembly is performed in reverse order of removal.

Tightening Specifications

♦ Transmission Removing and installing. Refer to ⇒ Rep.

Gr. 34; Transmission Removing and Installing; Tightening

Specifications for Transmission.

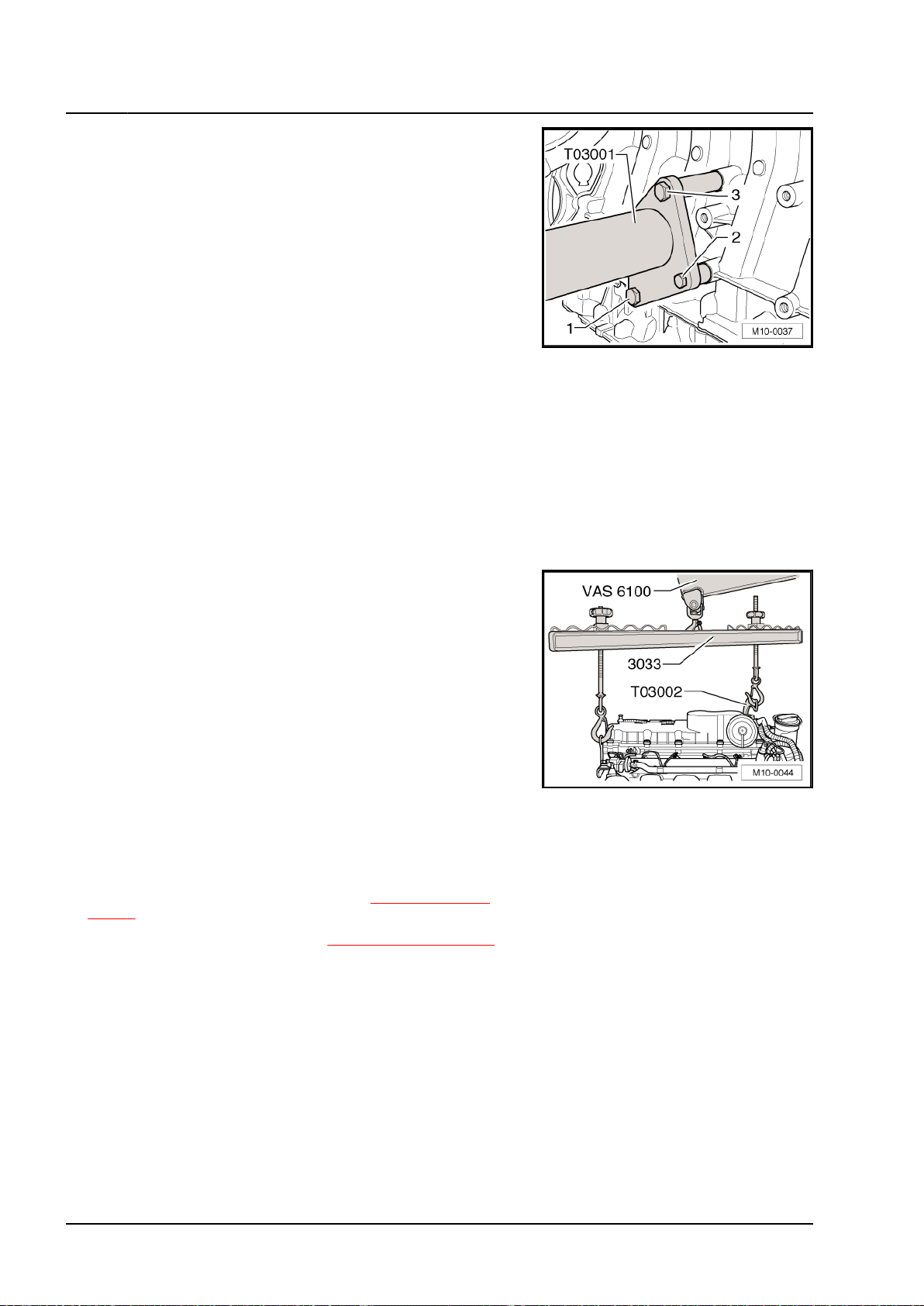

1.3 Engine, Securing on Engine and Transmission Holder

Special tools and workshop equipment required

♦ Lifting Tackle -3033-

♦ Shop Crane -VAS6100-

♦ Engine and Gearbox Bracket VAS6095A -VAS6095A-

♦ Engine And Transmission Holder - Engine Lateral Bracket

-T03001-

♦ Transport Arm -T03002-

Procedure

– Observe the safety precautions. Refer to ⇒ P3 recautions”,

page 4 .

– Follow repair instructions. Refer to ⇒ I4 nformation”, page 7 .

• The transmission is separated from the engine. Refer to ⇒

a1.2 nd Transmission, Separating”, page 18 .

For performing work, secure engine using -T03001- to VAS6095A-.

22 Rep. Gr.10 - Engine Assembly

Beetle 2012 ➤, The Beetle 2017 ➤, The Beetle Cabriolet 2012 ➤, The Beetle Cabri ...

5-Cylinder Fuel Injection Engine (2.5L Engine, 4-Valve) - Edition 12.2016

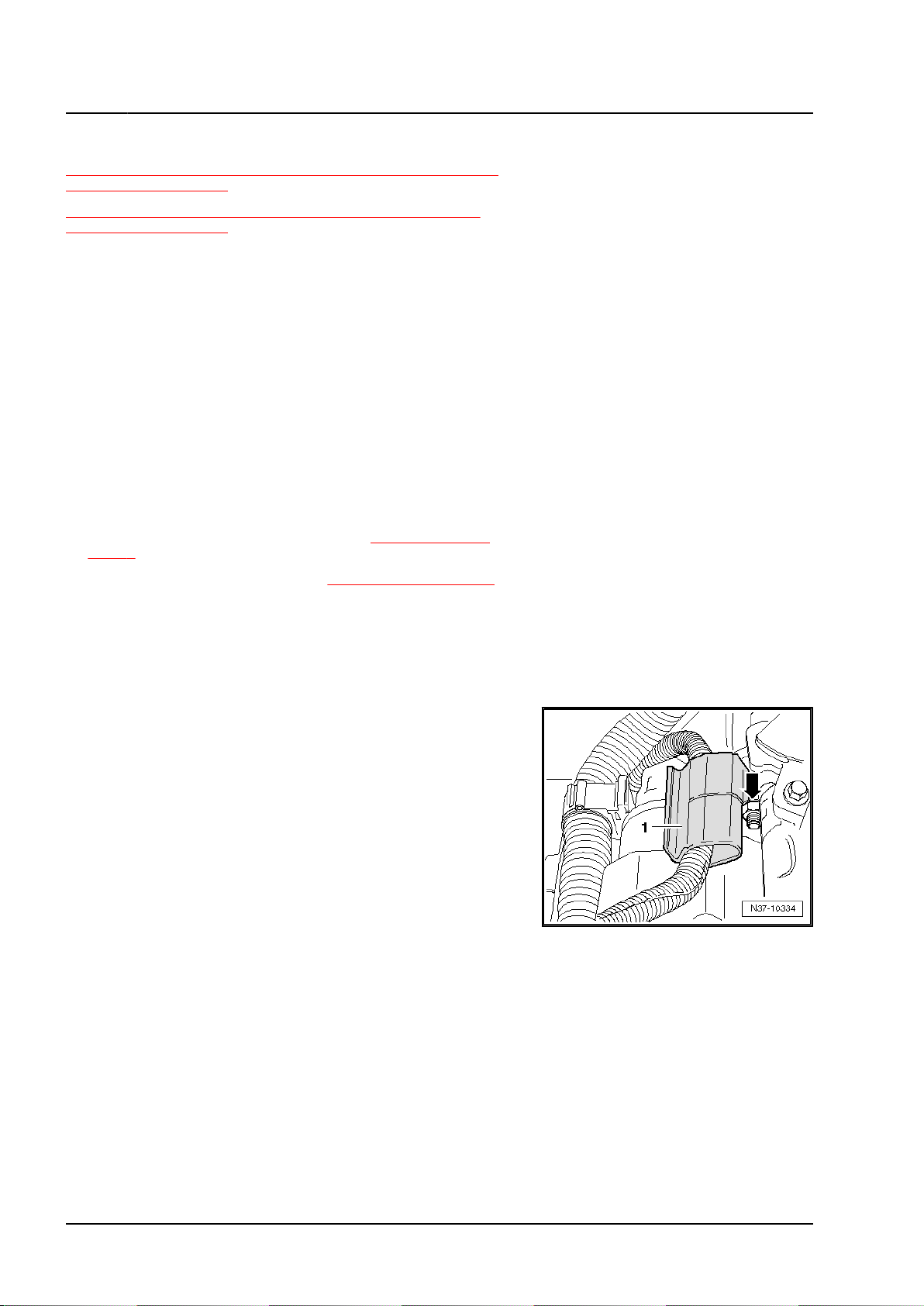

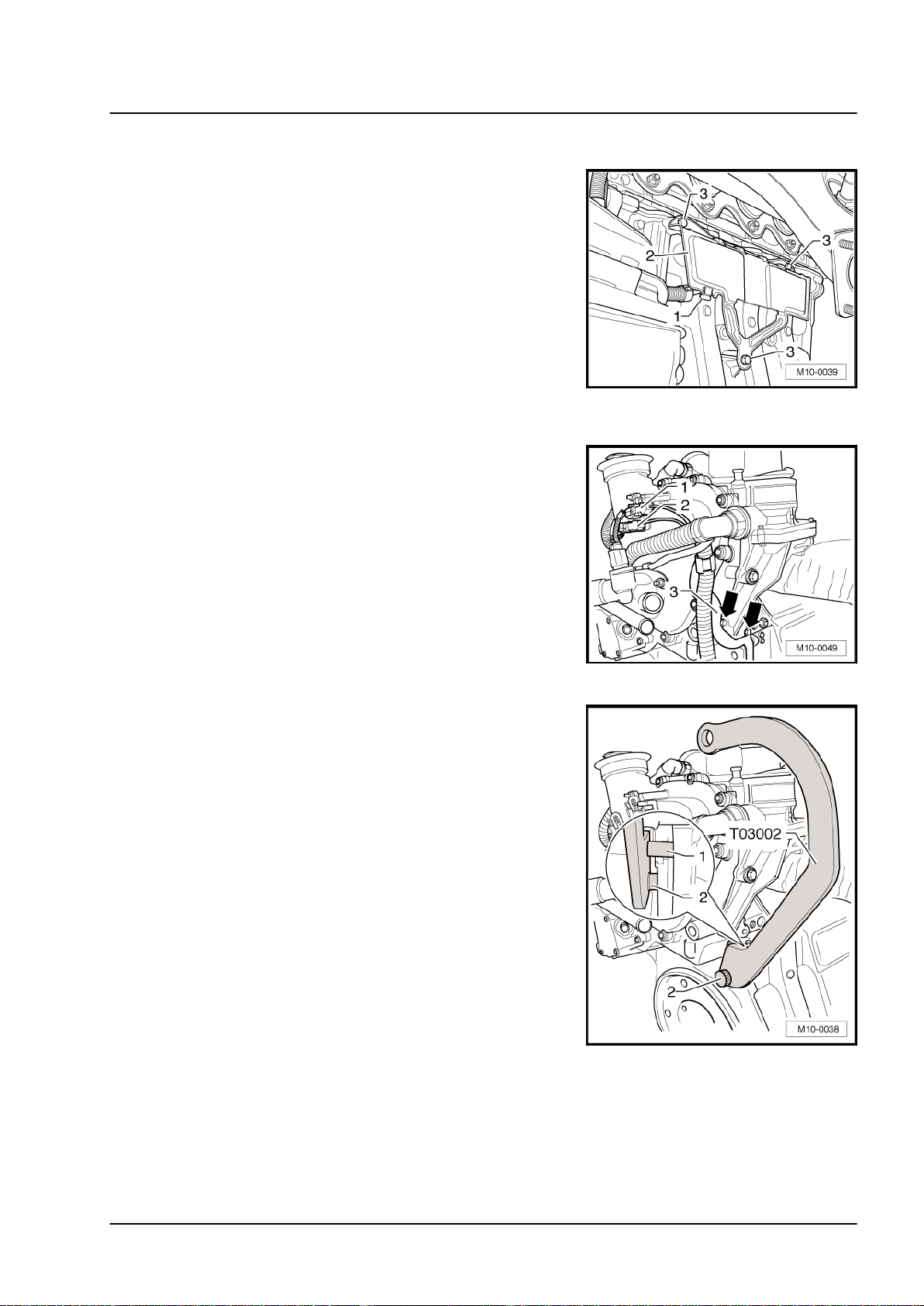

– Pull off clamp -1- for the wiring harness, remove the bolts -3-

and the cover plate -2-.

– Disconnect the connectors -1 and 2- and remove the bracket

-3- -arrows-.

– Install the -T03002-, as illustrated.

Pin -1- engages in cylinder block. Tighten knurled bolt -2hand-tight.

– Install the -T03001-.

1. Engine, Removing and Installing 23

Beetle 2012 ➤, The Beetle 2017 ➤, The Beetle Cabriolet 2012 ➤, The Beetle Cabri ...

5-Cylinder Fuel Injection Engine (2.5L Engine, 4-Valve) - Edition 12.2016

Tighten bolts -1 and 3- to 40 Nm, bolt -2- to 25 Nm.

Note

♦

Bolts are designed so that they cannot be lost.

♦

When removing, the -T03001- must be held tense in direc‐

tion of removal, otherwise the bolt -1- cannot be removed.

– Engage the -3033- as shown and lift out of the engine using

-VAS6100- from -VAG1383A-.

– Secure the engine to the -VAS6095A-.

1.4 Engine, Installing

Procedure

– Observe the safety precautions. Refer to ⇒ P3 recautions”,

page 4 .

– Follow repair instructions. Refer to ⇒ I4 nformation”, page 7 .

Install in reverse order of removal. Note the following:

Note

♦

Replace the bolts that were tightened with an additional turn.

♦

Replace the self-locking nuts and bolts, sealing rings, seals

and O-rings.

♦

Secure hose connections with standard production clamps.

Refer to the Parts Catalog.

♦

When installing, bring all cable ties back to same positions.

24 Rep. Gr.10 - Engine Assembly

Loading...

Loading...