Service Training

Self-study programme 328

The 2004 Caddy

S328_001

The 2004 Caddy is built on the same platform as the 2004 Golf. Compared with the previous

model based on the Polo platform, we have improved the technology and comfort considerably.

The 2004 Caddy will thus take a leading position among its rivals.

Unlike its predecessor, the 2004 Caddy now comes in three different versions.

The Caddy Van, Caddy Shuttle and Caddy Life cover a wide range of needs.

In addition to, increased payload, more space and also improved functionality, the 2004 Caddy

has a boarder engine range that now also offers greater performance.

Furthermore no shortcuts have been taken in crash safety.

The self-study programme shows the design and

function of new developments.

The contents will not be updated.

2

NEW

For current testing, adjustment and repair instructions,

refer to the relevant service literature.

Important

Note

Contents

In brief . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Occupant protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Electrical system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Heating and air-conditioning . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Radio, telephone and navigation. . . . . . . . . . . . . . . . . . . . . . . . 66

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

3

In Brief

The 2004 Caddy

Where is the 2004 Caddy built?

In 1993, a joint venture was set-up between the

Polish car manufacturer FSR

(in Polish = Fabryka Samochodów

Rolniczych,

English = Factory for Agricultural

Automobiles)

and Volkswagen Group.

Volkswagen Poznan GmbH has been a

100-percent subsidiary of Volkswagen

Commercial Vehicles since 1997.

The original business concept behind Volkswagen Poznan GmbH was to assemble light commercial

vehicles from kits. Kits from the different Volkswagen Group brands were delivered to Poznan for

complete assembly. Operations were expanded constantly over the next years. Around 3,400 members

of staff currently work at the plant.

The plant in Poznan

S328_002

Major investments include the set-up of a new

paint shop, a new body plant and new assembly

lines for the 2004 Transporter and the 2004

Caddy.

The result is a complete automobile plant with its

own logistics services, quality assurance

department and all associated areas. Among

others, the latest laser welding and soldering

techniques are being used for the new models.

With the launch of the 2004 Transporter, the plant now has its very own product for the first time. All

2004 Transporters with open superstructures are produced in Poznan. The 2004 Transporter Kombi also

rolls off the assembly line in Poznan.

Now Poznan has another product of its own - the 2004 Caddy.

Paint shop

S328_004

4

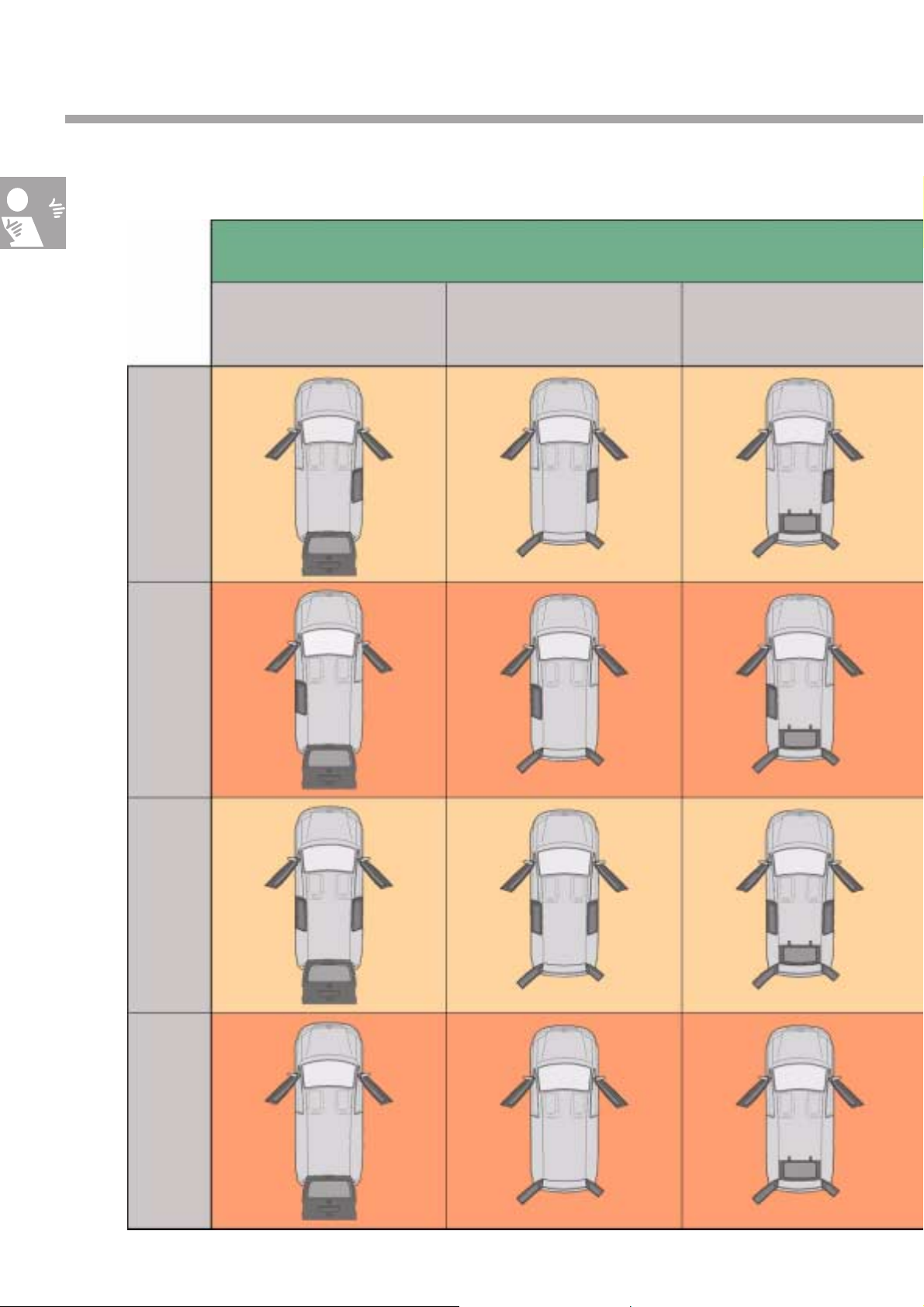

The Competitors

The diagram shows the field of competitors facing the 2004 Caddy. Only one version of each vehicle is

shown to represent the respective range.

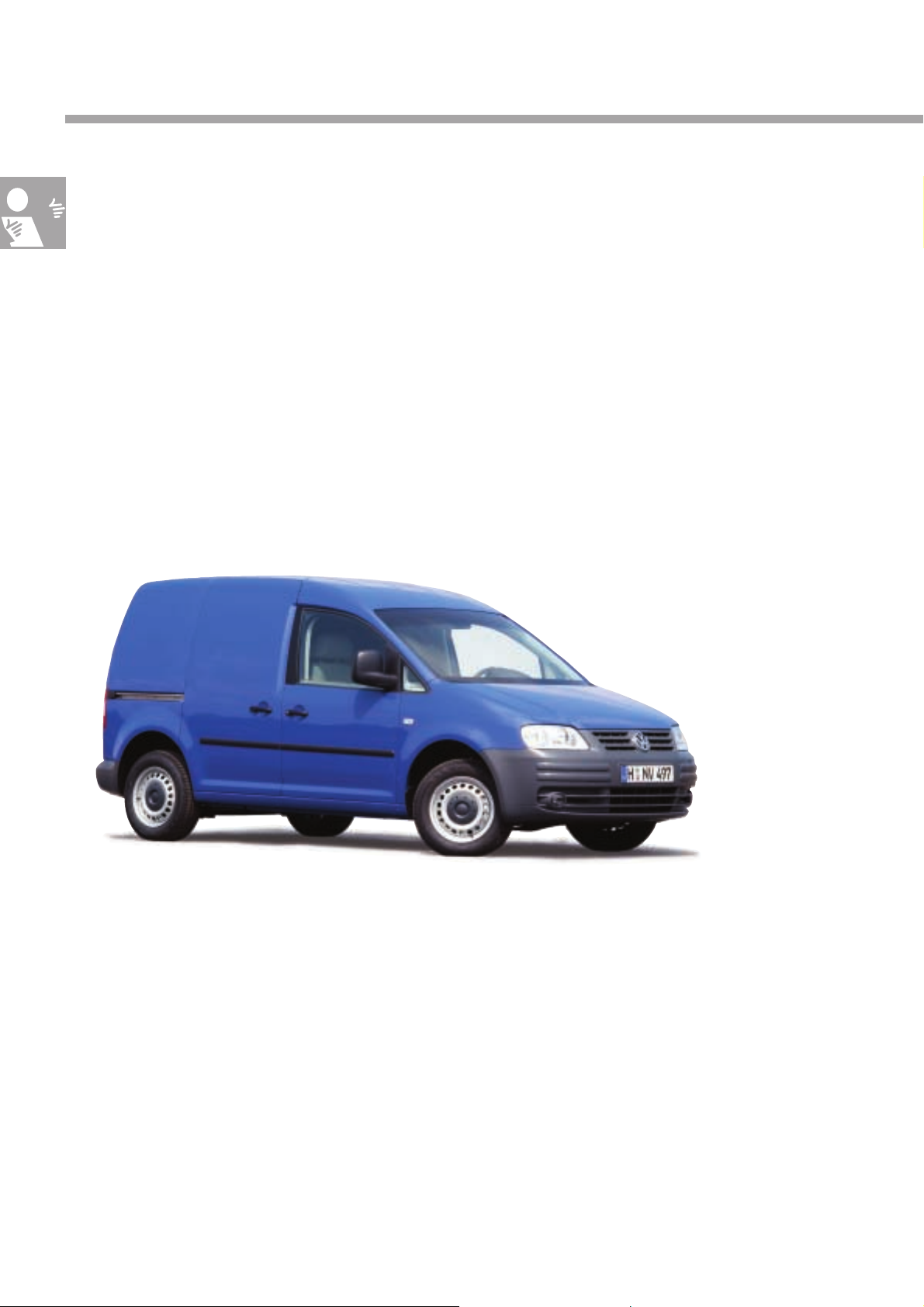

2004 Caddy Van

S328_096

Fiat Doblò

Opel Combo

Immediate rivals

Competition

Renault Kangoo

Ford Tourneo Connect

Citroën Berlingo

Mercedes Vaneo

2004 Caddy Shuttle/Life

S328_162

S328_097

5

In Brief

Technical highlights in the 2004 Caddy

The 2004 Caddy is setting new standards with the Caddy Van, Caddy Shuttle and Caddy Life versions.

It features a modern design with smooth outer surfaces all-round.

Here is an overview of the highlights:

Caddy Van

• Payload up to 750 kg

• Towing up to 1,500 kg

• Loading capacity up to 3.2 m

• Sliding door on right and left (optional),

Sliding door opens wide to 700 mm

3

• Clear glass headlamps with H1/H7 bulbs

• Electromechanical power

steering

• Navigation/preparation

for telephone (optional)

S328_096

• Rear axle with leaf springs

• ABS - MK70 system (Conti Teves)

• Generous storage compartments in the

doors and cab roof ceiling of driver’s cab

6

• Crash-optimised pedals and

crash-optimised steering

column

• Airbag system with

front side airbags

• Glazed load compartment,

same as Shuttle (optional)

Caddy Shuttle/Caddy Life

The Shuttle version of the 2004 Caddy, offering further highlights compared with the Caddy Van, comes

in 2 versions:

– Caddy Shuttle is the “Basic” version and

– Caddy Life is the “Comfort” version

• Up to 7 seats in the

Caddy Shuttle/Caddy Life

• Rear vent wings (optional)

on Caddy Shuttle/Caddy Life

S328_097

• ESP (optional)

MK60 system (Conti Teves)

• Tipping 1st seat row in passenger

compartment on Caddy Shuttle/Caddy Life

• Generous storage facilities in

Caddy Life passenger compartment

• Removable and locking tow bar

on Caddy Shuttle/Caddy Life

• 2nd seat row in passenger compartment (optional) in form of folding and

removable double bench

• Sliding windows in

sliding doors

7

In Brief

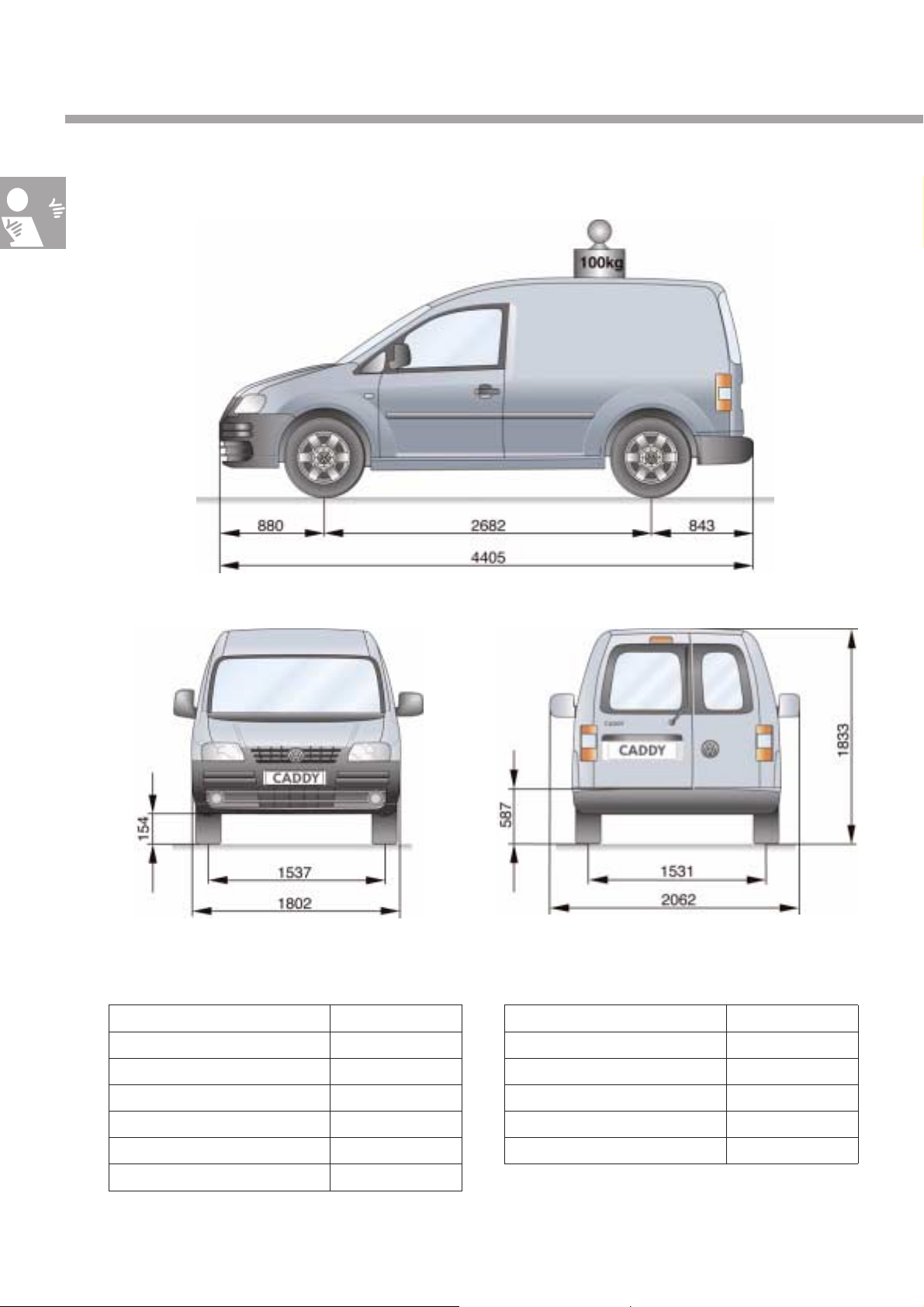

Technical data

Caddy Van

S328_005

S328_094S328_006

Dimensions

Length 4,405 mm

Length with tow bar 4,505 mm

Width 1,802 mm

Width with mirrors 2,062 mm

Height 1,833 mm

Overhang length at front 880 mm

Overhang length at rear 843 mm

Height of load sill 587 mm

Ground clearance 154 mm

Wheelbase 2,682 mm

Track width at front 1,537 mm

Track width at rear 1,531 mm

Tank capacity 60 l

8

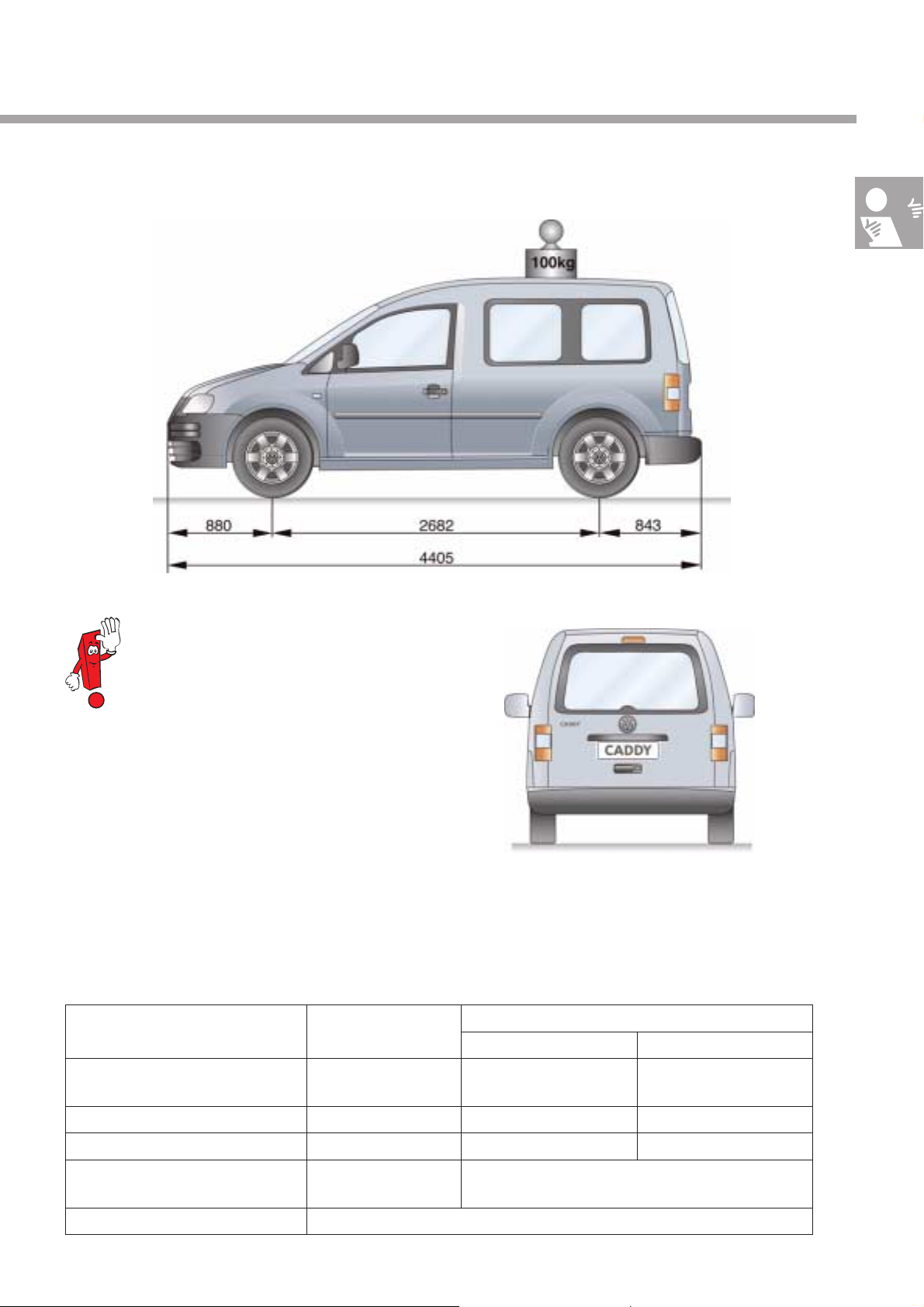

Caddy Shuttle/Caddy Life

The Caddy Van, Caddy Shuttle and

Caddy Life look the same from the

front. The outside dimensions of the

different Caddy versions are the same.

They only differ in equipment and

weight.

S328_095

S328_007

Weight

Caddy Van Caddy Shuttle/Caddy Life

5-seater 7-seater

Curb weight including driver* 1,400 – 1,481 kg 1,476–1,560 kg (Shuttle)

1,521 – 1,605 kg (Life)

Maximum weight* 2,150 – 2,235 kg 2,000 – 2,124 kg 2,165 – 2,250 kg

Braked towing capacity* 1,200 – 1,500 kg 1,200 – 1,500 kg 1,035 – 1,350 kg

Load without driver* up to 750 kg 503 - 653 kg (Shuttle)

479 - 608 kg (Life)

Roof load 100 kg

* Depending on engine and equipment

1,513-1,597 kg (Shuttle)

1,558 –1,642 kg (Life)

9

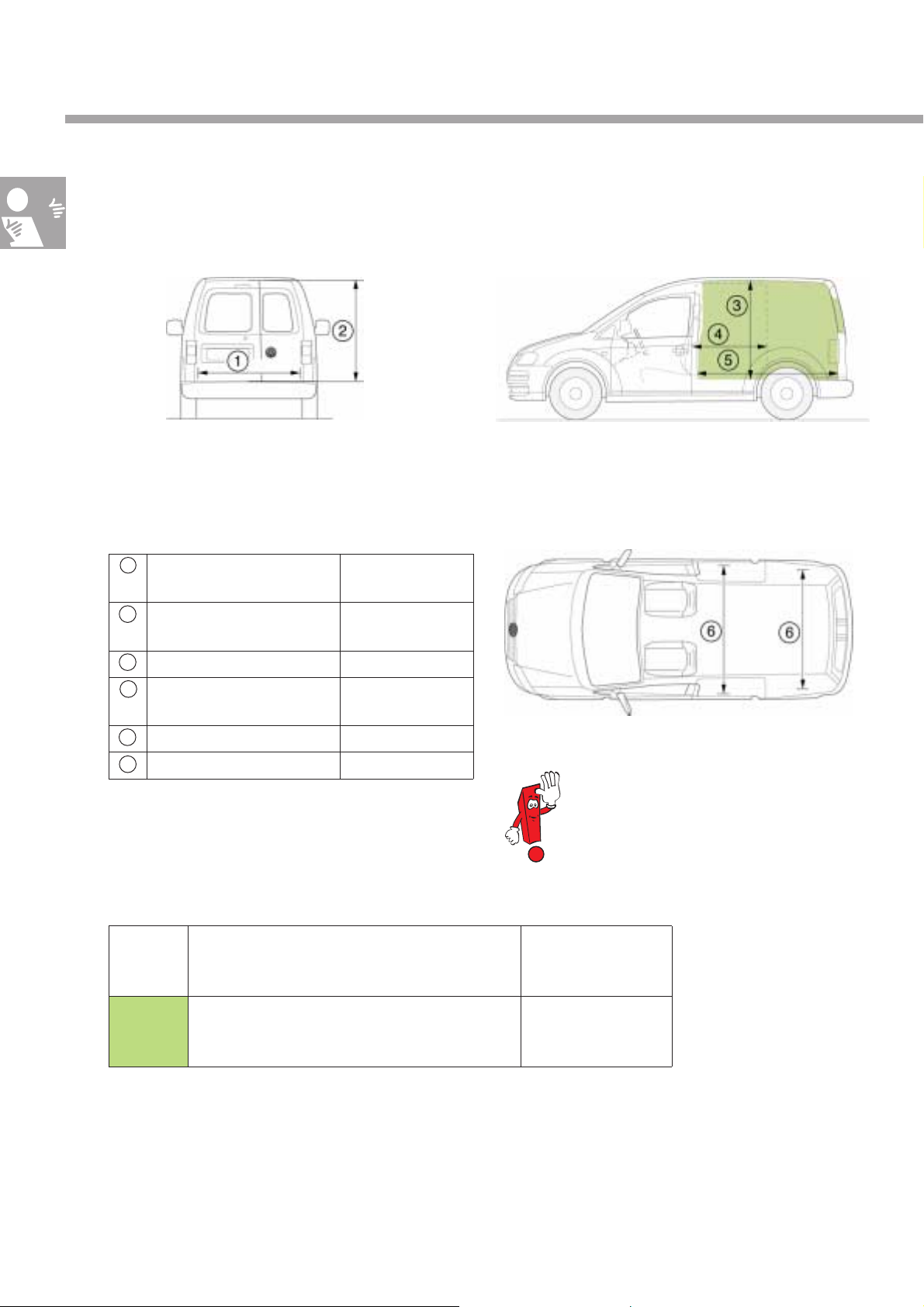

In Brief

Interior dimensions

Caddy Van

S328_008b

Load compartment dimensions

1 Opening width -

rear door/tailgate

2 Opening height -

rear door/tailgate

3 Loading height up to 1,257 mm

4 Opening width -

sliding door

5 Loading length up to 1,781 mm

6 Loading width 1,172 to 1,558 mm

1,181 mm

1,116 mm

700 mm

Load compartment – Volume

S328_008a

S328_009

The pictures show the Caddy Van with

wing doors. A tailgate is also available

as an option.

10

Colour Volumes

Name Volumes

Load compartment volumes up to 3,200 l

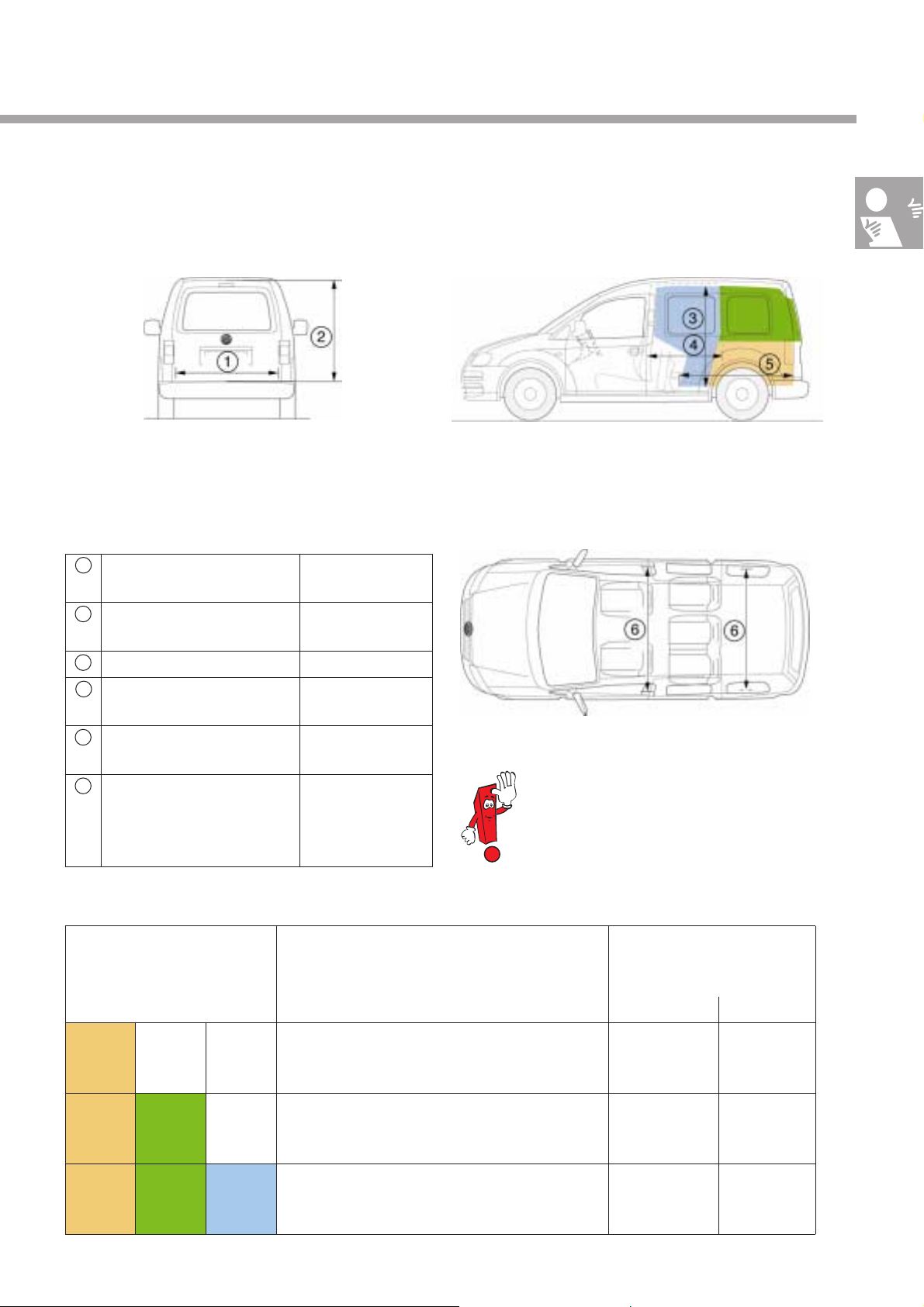

Caddy Shuttle/Caddy Life

S328_010b

Luggage compartment -dimensions

1 Opening width -

rear door/tailgate

2 Opening height -

rear door/tailgate

3 Loading height up to 1,238 mm

4 Opening width -

sliding door

5 Luggage compartment

length

6 Luggage compartment

width (Shuttle)

Luggage compartment

width (Life)

1,181 mm

1,116 mm

700 mm

up to 1,354 mm

1,170 to 1,340 mm

1,120 to 1,340 mm

S328_010a

S328_011

The pictures show the Caddy Shuttle

with tailgate. It can also be equipped

with optional wing doors.

Luggage compartment – volume

Colour partial volume

Name Volume

Volume, closed luggage compartment,

behind 1st seat row in passenger compartment

Volume, open luggage compartment,

behind 1st seat row in passenger compartment

Volume, open luggage compartment,

behind front seats with tipped 1st seat row

Sum of partial volume

Caddy Shuttle Caddy Life

up to 626 l up to 560 l

up to 1,266 l up to 1,200 l

up to 2,305 l up to 2,239 l

11

In Brief

Overview of doors

Caddy Van

… with tailgate … with rear

Right-hand sliding doorLeft-hand sliding doorSliding doors on both sidesWithout sliding door

wing doors

… with rear

wing doors and

“ladder flap”

12

S328_012

Caddy Shuttle/Caddy Life

… with tailgate … with rear

wing doors

… with rear

wing doors and

“ladder flap”

The 2004 Caddy comes in a wide range of

versions. The variable equipment with sliding

doors, rear wing doors, tailgates or a ladder

flap.

S328_013

The picture shows the complete Caddy

range.

The assignment of left-hand and righthand drive vehicles can be found in the

current sales literature.

The ladder flap will be available later

on.

13

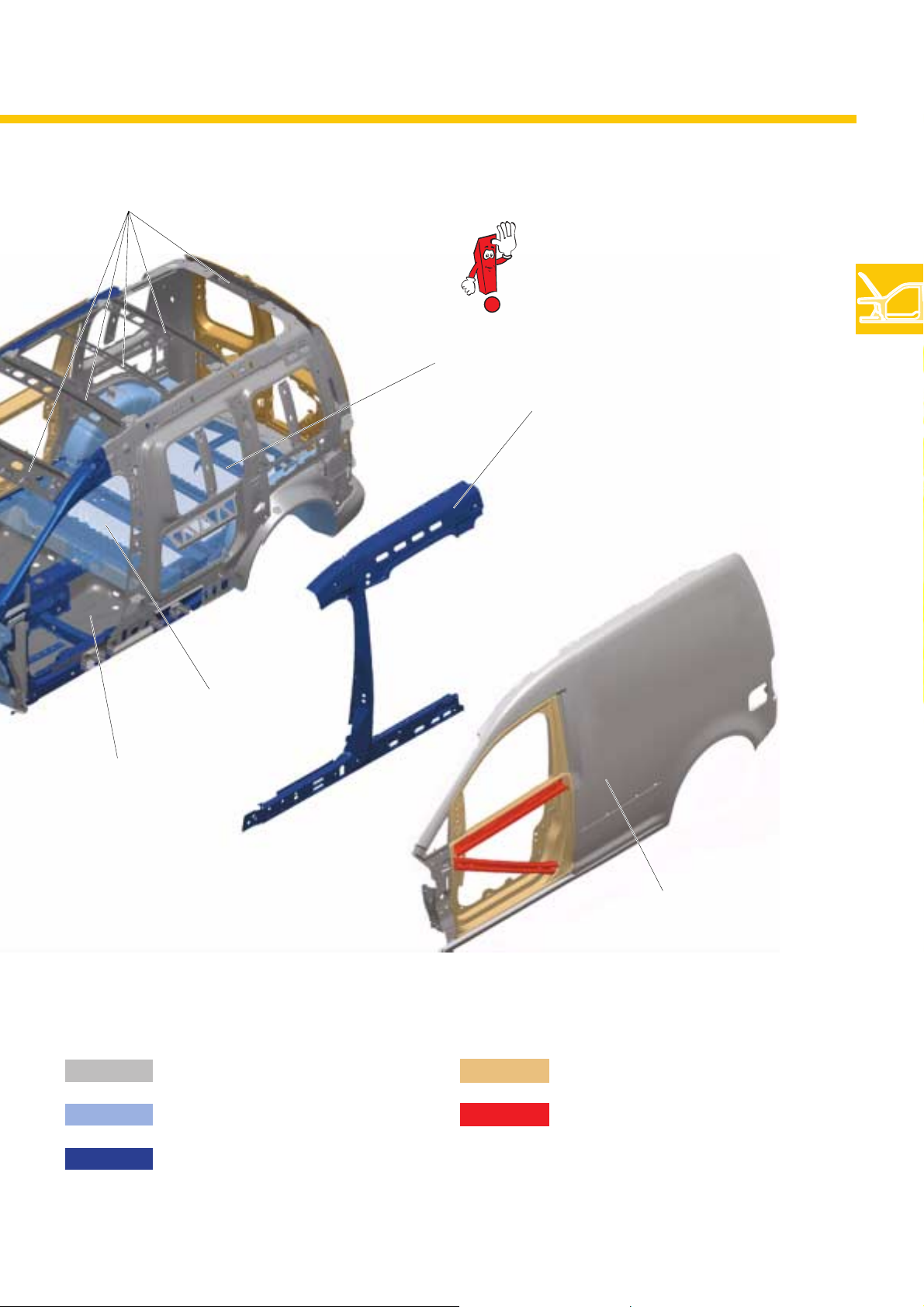

Body

Body in white

A sturdy body in white has a decisive influence on the stability and thus also on the driving safety of a

vehicle. This particularly important for vehicles that are mainly used as fast commercial vehicles.

The driving comfort also benefits from a good body design. That is a plus for the Caddy Shuttle and the

Caddy Life when used as a family and leisure vehicle.

The 2004 Caddy has a torsionally stiff and low

weight two-shell body structure (inside/outside

body shell). The following structural features can

be distinguished in terms of function:

– Floor pan with frame structure,

with tailored blanks at front (different sheet

thicknesses, welded before shaping)

– inner body shell,

with reinforcement elements,

– outer body shell,

single-piece side section

– Roof reinforcements

– Use of different sheet qualities depending on

the loading of the respective body areas

– Reinforcement and impact elements for

improved occupant protection in the front

doors

Floor pan - front

with tailored blanks

Longitudinal member - front

S328_168

14

Floor - front

increasing sheet thickness

Longitudinal member - front

Roof reinforcements

The pictures show the body

in white of the Caddy Van.

Cross member

Reinforcing element

Floor panel - rear

Floor panel - front

Normal-strength sheet

Higher strength sheets

S328_014

Side section (one-piece)

Mounted partsSheet qualities

Doors

Side impact elements

High-strength sheets

15

Body

Wing doors

The Van version of the 2004 Caddy comes with glazed wing doors split in the ratio 2/3 to 1/3.

The windows in the wing doors can be covered with an optional dark opaque film. The Caddy Shuttle/

Caddy Life can be optionally fitted with the wing doors.

Inside handle

Outside handle

S328_087

Locking lever

S328_088

The left-hand wing door needs to be opened first. The outside handle on the left-hand door is integrated

in the number plate light fitting. The locking level built into the bottom of the right-hand door can then be

used to open the right-hand wing door. Wing doors lock at a 90° angle when opened. If the door

latches are detached, the wing doors will open to approx. 170° due to a stop in the hinge.

Tailgate

The Caddy Shuttle and Caddy Life come with a tailgate with rear window as standard. The Caddy Van

can also be fitted with a tailgate. The tailgate can be opened with an outside handle. A draw loop is

provided to help pull it down.

Draw loop

16

Outside

handle

S328_089

S328_090

Sliding door

The 2004 Caddy is equipped with a sliding door

reaching up to the roof on the passenger side.

The drivers side can also be fitted with an

optional sliding door.

The sliding door opens to a maximum width of

70 cm.

Only the Caddy Van with a glazed load

compartment can be equipped with a sliding

door.

The Caddy Shuttle and Caddy Life have sliding

doors a with windows.

S328_092

Protection of the tank filler flap

The tank filler flap is located on the driver’s side

just in front of the D-pillar. To ensure that it is not

damaged when the door is slid backwards, the

2004 Caddy has a locking unit when equipped

with a sliding door on the left-hand side.

Function

When the tank filler flap is open, a Bowden

cable attached to the tank filler flap activates a

rotating bolt in the locking unit. The blocking

latch connected to the rotating bolt is then

moved outwards so that the sliding door hits it

and cannot be pushed back any further.

Blocking latch

Blocking unit

Bowden cable

on tank filler flap

Bowden cable

S328_103

Rotating bolt

Blocking latch

S328_132

Connect to

tank filler flap

17

Body

Window

Sliding window

The version of the Caddy Van with glazed load

compartment can be optionally fitted with a

sliding window in the sliding door.

The Caddy Shuttle can also be equipped with an

optional sliding window in the sliding door.

The Caddy Life comes with the sliding window as

standard.

S328_129

Vent windows

Optional manual vent windows are also

available for the Caddy Shuttle and Caddy Life.

Both sides will be equipped with vent windows

when this option is chosen.

S328_130

18

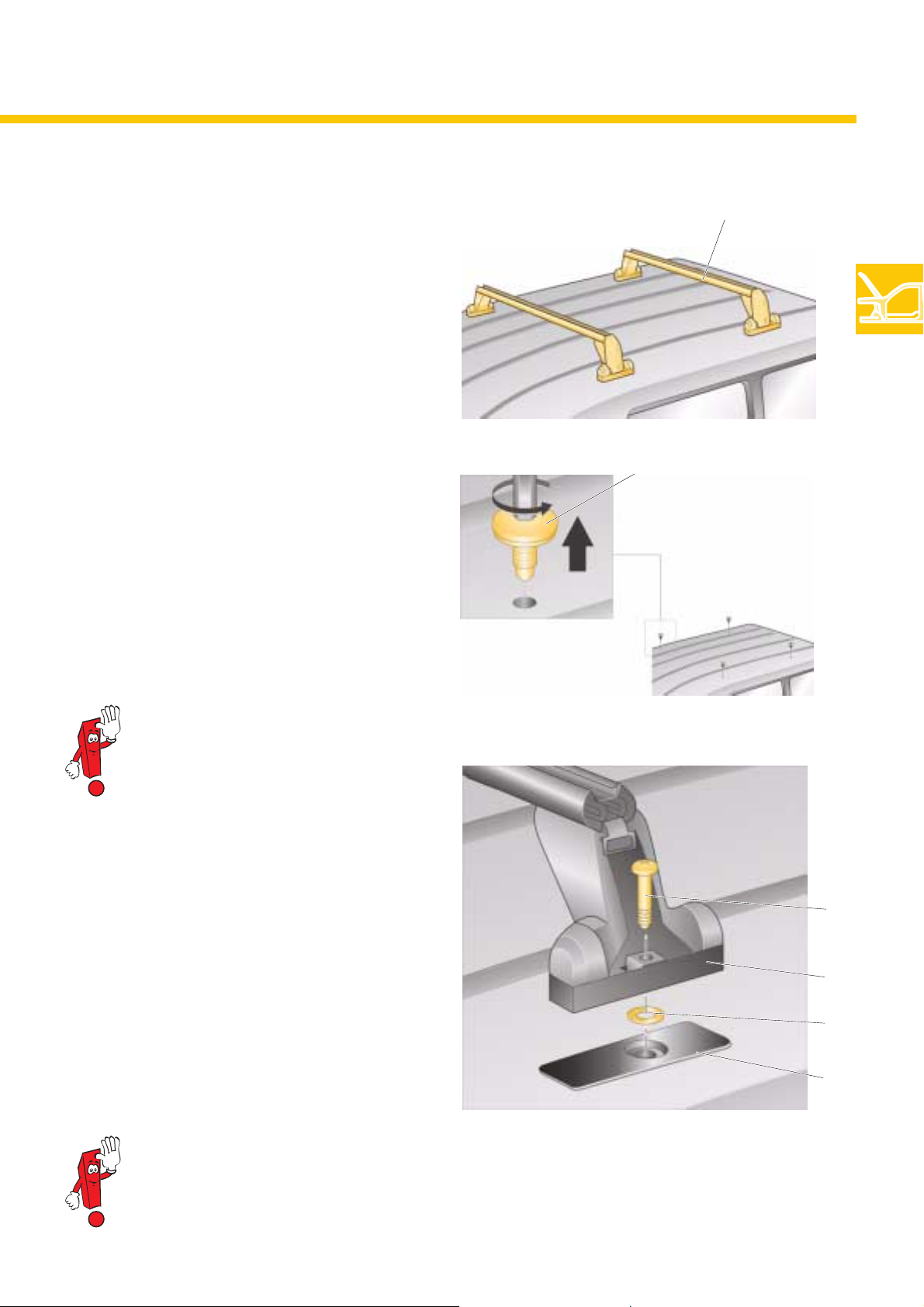

Roof rack

A system with a bolt-on base carrier is used for

the roof rack on the 2004 Caddy.

There are special accessories allowing you to

attach a roof box, bicycles, skis, surfboards or

boats on the base carrier.

The bolt-on base carrier guarantees a high level

of stability.

Base carrier

S328_017

4 screws with rubber seals are fitted on the

vehicle roof. These screws need to be removed

together with the seal to fit the base carrier.

The sealing screws should be kept and

fitted again when the base carrier is

removed to seal the roof.

The base carrier is secured with the supplied

screws and seals.

Screw with

seal

S328_104

Screw

The seals prevent water leaking into the

body.

Refer to the operating manual for information on fitting the base carrier.

Foot

Seal

Protective

film

S328_105

19

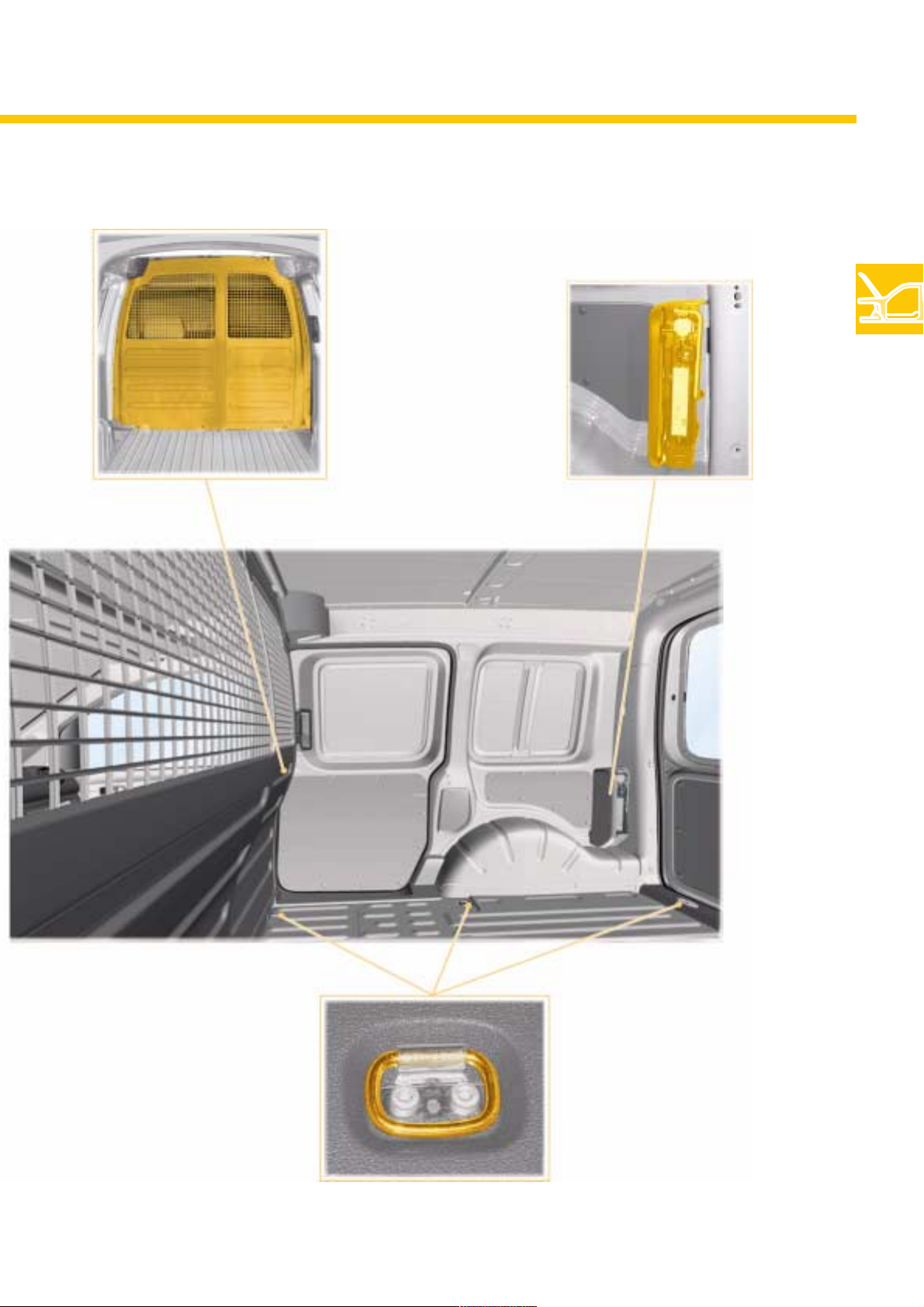

Body

Interior concept

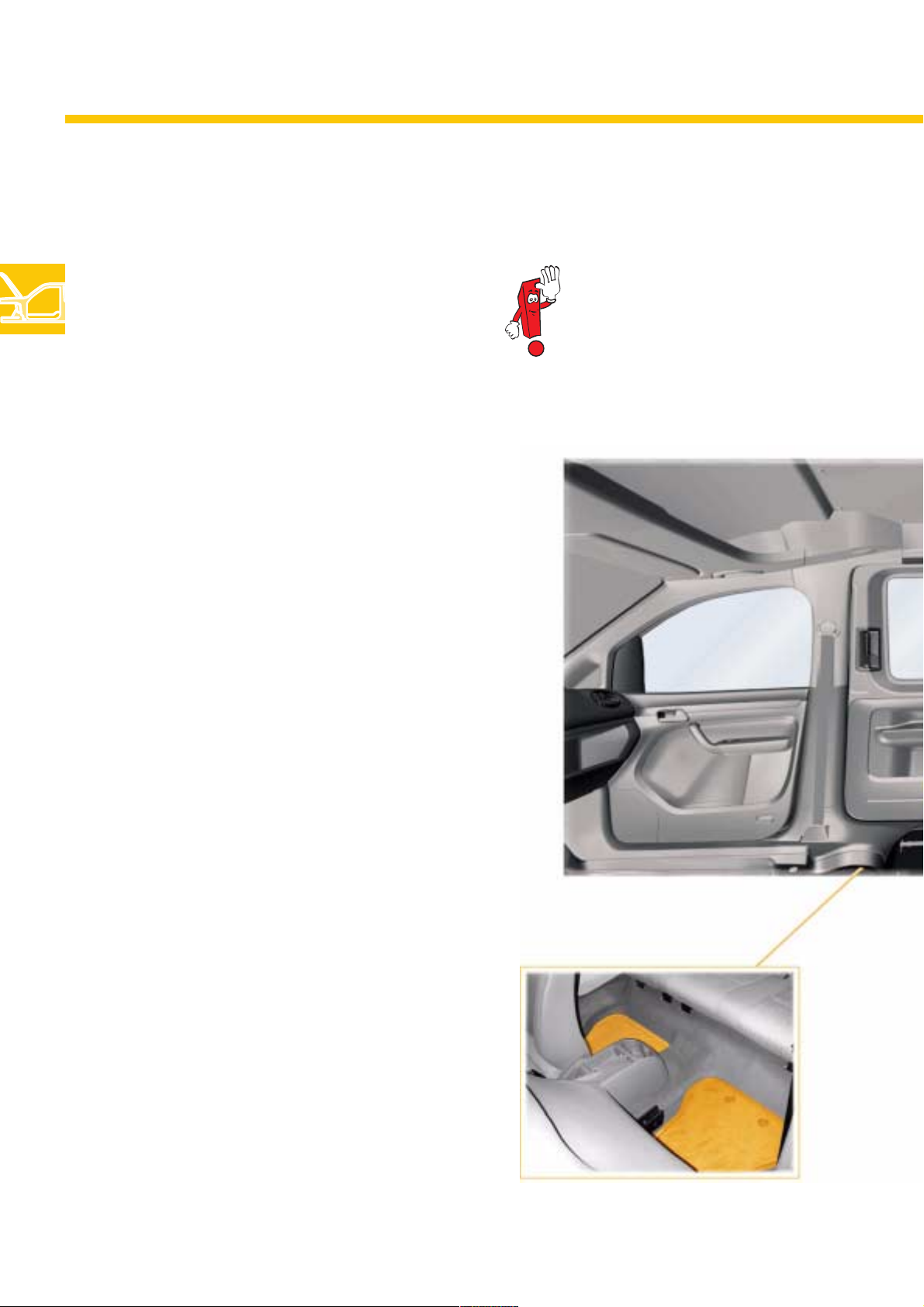

Caddy Van

The equipment provided in the Caddy Van is

mainly directed at commercial vehicle

applications.

Storage compartments in the side doors and an

overhead compartment have been provided for

the driver and front passenger

– in addition to the storage bins in the

– dash panel and centre console.

The generous overhead storage is particularly

useful. It can even hold A4 binders thanks to the

width of 1000 mm, depth of 400 mm and height

of up to 250 mm.

Overhead storage

The cargo is safely secured by the lashing rings

and the bulkhead between the cab and the load

compartment. The bottom half of the bulkhead is

made from a plastic surface and the top from a

plastic grille.

The floor of the load compartment can also be

covered with an optional rubber mat.

The side panels underneath the windows in the

load compartment are protected with noncoated hardboard. There are no additional

storage compartments here.

20

Storage in driver’s door

Bulkhead

Jack and tool set,

mounted without cover

Lashing rings on floor

S328_151

21

Body

Caddy Shuttle/Caddy Life

The Shuttle version of the 2004 Caddy comes in

the equipment derivatives

– Caddy Shuttle as the “Basic” version and

– Caddy Life as the “Comfort” version.

In the Caddy Shuttle, the floor of the passenger

compartment is fitted with carpet (Dilours) as

standard. Four lashing rings on the floor allow

safe anchoring of loads.

The side panels of the passenger compartment

are made from varnished hardboard. They do

not have storage compartments. The ceiling is

is also lined with varnished hardboard.

There are two storage compartments with

removable lids in the footwell in front of the first

row of seats in the passenger compartment.

The jack and tool set are mounted on the side

wall without a cover.

The picture shows a Caddy Life.

The Caddy Life has additional features

compared with the Caddy Shuttle. The side

panels are moulded sections with integrated

storage bins.

Attachment rings are mounted above the

windows for an optional net partition.

A further option is storage nets with hooks for

hanging items. The Caddy Life comes with a

luggage area cover as standard (not shown

here).

The jack and tool set are stowed away behind a

cover in the side panelling.

22

Compartment in floor

Hooks for net partition and storage net

Jack and tool set

behind panel

Sliding door storage

S328_152

Storage between C and D-pillar

23

Body

Dash panel

The 2004 Caddy has an all-new dash panel. There are two versions that mainly differ in the centre

console equipment.

Centre console type with

– open storage

– cup holders

– ashtray in passenger compartment

Fitted as standard in the Caddy Van and

Caddy Shuttle.

Centre console

(Caddy Shuttle/Life)

Centre console type with

– Compartment for a CD changer under the

armrest lid

– Air-conditioning vents

– fold-out cup holder

– 12 V socket

This centre console is longer and comes as

standard in the Caddy Life and is an option in

the Caddy Shuttle.

Cup holder

Armrest

with storage

compartment

Socket 12 V

24

Storage

Centre console

(Caddy Van/Shuttle)

Further differences between the console

types are the materials used and the

resulting material feel.

Cup holder

Storage

Ashtray

2 x 2 cup holders

Left-hand storage compartment on

top of dash panel

(Caddy Van and Caddy Shuttle)

Right-hand storage compartment on

top of dash panel -without lid

Left-hand storage compartment on

top of dash panel - with lid and

document holder (Caddy Life)

Ashtray and cigarette

lighter

S328_153

Storage compartment on

passenger side

containing key switch for front

passenger airbag

Key switch

for front passenger airbag

25

Body

Seats

The driver and front passenger seats in the

2004 Caddy are individual seats. The first row of

seats in the Caddy Shuttle/Life is a 3-seat bench

split 1/3-2/3. An optional double bench can be

fitted in the second row.

Head restraints

Handle for

folding seat

Side airbag

Adjustment of

backrest tilt

Height adjustment

S328_030

Seats (example Caddy - 7-seater)

Individual seats

driver/front

passenger

1st seat row

in passenger

compartment

The adjustment of the seats is described

in detail in the operating manual.

The picture shows a vehicle fitted with

all available seats (Shuttle/Life version

with drawer).

The drawer is always combined with the

height adjuster in the Caddy Shuttle/

Life and vice versa.

2nd seat row

in passenger

compartment

S328_093

Longitudinal

adjustment

Features on driver’s seat and front passenger seat Caddy

Longitudinal adjustment

Adjustable backrest tilt

Head restraint height adjustable

Side airbag (optional)

Individually adjusted heated seats (optional)

Storage under seat (optional)

Head restraint height and tilt adjustable

Drawer under seat (optional)

Seat height adjustable

Backrest folds forward (when there is only one sliding door, always

on the opposite side of the vehicle)

Drawer/storage

Va n

Caddy

Shuttle

Caddy

Life

26

Seats in passenger compartment

The three-seat bench in the first seat row of the

passenger compartment is split into a 1/3 seat

and a 2/3 seat. The bench is permanently

screwed to the floor and cannot be removed.

The backrests of each seat section can be folded

forward separately and lock into a horizontal

position. If the seat section fastenings on the

vehicle floor are unlocked, you can fold the

folded seats forwards again, i.e. tip them.

This can be done without removing the head

restraints. Gas-filled springs make tipping the

seats easy.

The seat sections can be secured in position with

folding struts so that they do not move on the

road.

1st row of seats in passenger compartment individual seat tipped

Loop

for releasing

backrest

Floor latch

S328_148

1st row of seats in passenger compartment tipped completely

2nd row of seats in passenger compartment folded

Loop for

folding

Loop for unlocking

on vehicle floor

Strut

S328_150

Screw fastening

Gas-filled

struts

The double seat bench for the second row of

seats is fixed to the floor with 4 bolts.

The top left loop is used to unlock the backrest,

which can then be folded forward.

Pulling the two bottom loops releases the

fastening of the seat bench to the vehicle floor so

you can take the seat out from the rear of the

vehicle.

Strut

S328_032

27

Occupant protection

Occupant protection

The 2004 Caddy is equipped with the proven occupant protection systems, the airbag system,

the belt system and a child restraint system (Isofix) depending on the vehicle version.

The complete airbag system includes:

– Driver airbag

– Front passenger airbag – single-stage*

– Front side airbags*

* Optional for Caddy Van

The belt system includes:

– Three-point safety belts with belt tensioners

and belt pressure limits on the driver’s and

front passenger seat

– Three-point safety belts without belt

tensioners for the rear seat rows. The centre

seat on the first row of seats has a retractor

built into the top of the backrest to roll up the

belt.

The Isofix child restraint system is integrated on

the two outside seats of the first seat row.

Side airbag for

front passenger

Front airbag for

front passenger

Front passenger

airbag

module

28

S328_036

A key switch in the glove compartment allows

you to disable the front passenger airbag in the

2004 Caddy.

Airbag control unit

with crash sensor for

front airbags

Driver

airbag

module

The picture shows the Caddy Life.

Front passenger

side airbag

module

Three-point seat belt,

integrated in seat

Front airbag

for driver

Side airbag crash sensor,

in cab under driver’s/front

passenger’s seat

Side airbag

for driver

S328_037

Three-point seat belt with

rack and pinion belt

tensioner, fixed to body

Driver

side airbag

module

29

Engines

1.4l/55 kW petrol engine

The 1.4l/55 kW petrol engine has already proven

itself in the Golf and now features in the

2004 Caddy.

Technical features

– 4-valve technology

– 2 hollow overhead camshafts

– Reduced-weight crankshaft

– Lightweight piston

– ME 7.5.10 engine management

– Aluminium sump with oil level sensor

– Electronic power control with contact-free

sensors

– Exhaust gas recirculation with electrical valve

– Single-spark ignition coils

– Non-return fuel system

– Air filter integrated in the engine cover

S328_038

Engine code BCA

Type 4-cylinder in-line engine

Displacement 1,390 cm

Bore 76.5 mm

Stroke 75.6 mm

Valves per cylinder 4

Compression ratio 10.5 : 1

Maximum output 55 kW at

5,000 rpm

Maximum torque 126 Nm at

3,800 rpm

Engine management ME 7.5.10

Fuel Super unleaded RON 95

(normal unleaded at

RON 91 with reduction in

performance)

Exhaust gas

treatment

Exhaust gas recirculation,

starter/main catalytic

converter, Lambda

control

3

Torque and power diagramTechnical data

Torque (Nm)

Power (kW)

S328_039

Engine speed (rpm)

30

Emissions standard EU4/EOBD

1.6l/75 kW petrol engine

The 1.6l/75 kW petrol engine has already been

used in the Golf and Touran and is now being

mounted in the 2004 Caddy.

Technical features

– An assembled camshaft

– Roller rocker arm

– SIMOS 7.1 engine management

– Aluminium sump with oil level sensor

– Electronic power control

– Exhaust gas recirculation with electrical valve

– Electronic distributorless ignition

– Non-return fuel system

– Secondary air system

S328_040

Engine code BGU

Type 4-cylinder in-line engine

Displacement 1,595 cm

Bore 81.0 mm

Stroke 77.4 mm

Valves per cylinder 2

Compression ratio 10.3 : 1

Maximum output 75 kW at

5,600 rpm

Maximum torque 148 Nm at

3,800 rpm

Engine management Simos 7.1

Fuel Super unleaded RON 95

(normal unleaded at

RON 91 with reduction in

performance)

Exhaust gas

treatment

Exhaust gas recirculation,

catalytic converter,

Lambda control

3

Torque and power diagramTechnical data

Torque (Nm)

Engine speed (rpm)

Power (kW)

S328_041

Emissions standard EU4/EOBD

31

Engines

1.9l/77 kW TDI engine

The 1.9l/77 kW TDI engine has already proven

itself in the Golf and now features in the

2004 Caddy.

Technical features

– Diesel engine with exhaust-gas turbocharger

– Unit injector system

– Overhead camshaft

– EDC 16 engine management

– Electronic power control with contact-free

sensors

– Exhaust gas recirculation

– Electrical intake manifold flap

S328_044

Technical data Torque and power diagram

Engine code BJB

Type 4-cylinder in-line engine

Displacement 1,896 cm

Bore 79.5 mm

Stroke 95.5 mm

Valves per cylinder 2

Compression ratio 19 : 1

Maximum output 77 kW at

4,000 rpm

Maximum torque 250 Nm at

1,900 rpm

Engine management EDC 16

Fuel Diesel min. 51 CN

Exhaust gas treatment Exhaust gas recirculation

and oxidation catalytic

converter

3

Torque (Nm)

Engine speed (rpm)

Power (kW)

S328_045

32

Emissions standard EU3

2.0l/51 kW SDI engine

The 2.0l/51 kW SDI engine with unit injector

technology is a further development of the 1.9l/

74 kW TDI engine used in the Touran.

Technical features

– Naturally aspirated diesel engine

– Unit injector system

– Overhead camshaft

– EDC 16 engine management

– Electronic power control with contact-free

sensors

– Exhaust gas recirculation

– Electrical intake manifold flap

S328_042

Engine code BDJ

Type 4-cylinder in-line engine

Displacement 1,968 cm

Bore 81.0 mm

Stroke 95.5 mm

Valves per cylinder 2

Compression ratio 19 : 1

Maximum output 51 kW at

4,200 rpm

Maximum torque 140 Nm at

2,200 – 2,400 rpm

Engine management EDC 16

Fuel Diesel min. 51 CN

Exhaust gas treatment Exhaust gas recirculation

and oxidation catalytic

converter

3

Torque and power diagramTechnical data

Torque (Nm)

Engine speed (rpm)

Power (kW)

S328_043

Emissions standard EU3

33

Transmission

Gearbox

Two mechanical manual gearboxes conceived for transverse installation feature in the 2004 Caddy.

The gearboxes are based on the proven group manual gearboxes. They have been further developed

with the following changes.

Changes:

– Shaft spacing increased

– Axle drive reinforced

– Gearbox and clutch housing adapted

– Without sender for driving speed

5-speed gearbox 0AH

The gearbox is a further development of the 02T

manual gearbox, as already used in the Polo, for

example.

The gearbox has 5 gears and can transmit

torques of up to 200 Nm.

It is used with the petrol engines and the SDI

engine.

5-speed gearbox 0A4

S328_047S328_133

The gearbox is a further development of the 02J

manual gearbox. The construction has been

specially reinforced for the greater torque to be

transferred and is already used in the 2004

Golf.

The gearbox has 5 gears and can transmit

torques of up to 250 Nm. It is used with the

TDI engine.

34

Both gearboxes do not have a sender wheel for the speed.

The speed signal is transmitted by the ABS system.

Engine-gearbox combinations

Engine 5-speed

manual gearbox

0AH

1.4l/55 kW

petrol engine

BCA

1.6l/75 kW

petrol engine

BGU

5-speed

manual gearbox

0A4

1.9l/77 kW

TDI engine

BJB

2.0l/51 kW

SDI engine

BDJ

35

Chassis

Front axle

The 2004 Caddy has an optimised McPherson front axle with lower wishbones and MacPherson struts.

The axle is basically the same as the front axle on the 2004 Golf and provides optimum comfort with

good driving dynamics. The standing height has been increased especially for use in the 2004 Caddy.

Technical features are:

– Aluminium assembly carrier

– Wishbones

– Decoupled spring and damper connection by

rubber/metal bearings for the struts

– 3rd generation wheel bearings

– Active speed sensor, the sender wheel is

integrated in the wheel bearing seal.

Assembly carrier

Coupling rod

(console)

– Anti-roll bar with 1 : 1 connection. The anti-roll

bar is connected directly to the strut via a

coupling rod and thus ensures good stability.

– Opening at front in subframe for gearbox

pendulum support

Anti-roll bar

Strut bearing

36

Wishbone

Assembly carrier

(subframe)

Gearbox pendulum

support

Strut

Wheel bearing housing

Wheel bearing

S328_048

Assembly carrier

The assembly carrier holds the traverse link, antiroll bar and steering rack.

It is made up of three parts and has a central

subframe to which consoles are connected on

the left and right. The components of the assembly carrier are made from aluminium.

The assembly carrier is bolted rigidly to the body

at six points. This stiffens the front section of the

body.

This connection and the optimum configuration

of the rubber/metal bearings in the traverse link

and the strut bearing allow good driving dynamics and body acoustics.

Left console

Subframe

Connection to body

Right console

S328_102

Bolt for fastening

to body

Right console

Subframe

Left console

S328_098

37

Chassis

Strut bearing

The strut bearing is a rubber/metal bearing. The

connection of the springs and the damper to the

body are uncoupled from each other. The spring

force is thus channelled separately into the body

and tensioning of the damper bearing is

avoided. This improves the ride comfort and

reduces the noise transmission from the road to

the body.

The bearing has a smooth characteristic curve in

the direction of travel. This improves the driving

comfort and vehicle acoustics.

The bearing is stiff in the transverse direction.

This has a positive effect on the driving dynamics

and the steering response.

Spring connection

Metal

Damper connection

Rubber element

S328_099

3rd generation wheel bearings

A compact third-generation wheel bearing unit

is used. The wheel bearing, wheel hub and

mounting form a unit that is screwed to the wheel

bearing housing.

The pretensioning forces for setting the bearing

play are no longer applied via the wheel

bearing bolts. This simplifies fitting and removal

procedures when the parts are service and the

life of the unit is increased.

S328_100

38

Rear axle

The 2004 Caddy has a rigid axle with leaf-spring suspension. It is a new design and is

characterised by both its simplicity and robustness.

Technical features are:

– Single-layer leaf spring for Caddy Van and

Caddy Shuttle

– Two-layer leaf spring for the Caddy Life

(increased comfort)

– Bump stop

(“additional spring” made of polyurethane)

Installation position of

active speed sensor

– Dampers position at an angle towards the

front to guarantee the through-loading width

under the load platform.

– Anti-roll bar connected to body via coupling

rods.

– Wheel bearings form a compact unit

consisting of the wheel bearing and wheel

hub.

– The magnetic track for the active speed

sensor is on the front side of the wheel

bearing (no sender wheel in wheel bearing

seal).

Bump stop

Leaf spring

Axle tube

(bolted to body)

Damper

Wheel hub with magnetic track

for active speed sensor

Magnetic track

Coupling rod

Anti-roll bar

Active speed sensor

Magnetic track

S328_167

S328_166

Wheel bearing

39

Chassis

Electromechanical power steering

The 2004 Caddy is equipped with a

electromechanical power steering system

(manufacturer ZF), which is made up of the

following main components

– the steering wheel and

– the electric motor with integrated control unit.

The steering system is mounted on the subframe.

The control unit is flanged to the electric motor.

Data for managing the steering is exchanged via

the drive CAN data bus.

Advantages of this steering system are:

– Simpler packaging (no need for traditional

components like a power steering fluid pump,

hoses, fluid reservoir and hydraulic fluid).

– Lower fuel consumption (~0.15 l/100 km)

– Speed-related steering assist (Servotronic)

– No risk of pollution as no oil is required.

– Good straight-line stability due to “active

return” and the resulting precise centre-return

of steering.

Electromechanical power steering

Assembly carrier

(subframe)

S328_170

Electric motor with

control unit

S328_050

40

Function

The electromechanical power steering is an

active system. It operates in relation to

– the driving speed,

– steering moment and steering speed,

– steering angle and

– return forces.

It therefore provides optimum steering assistance

for the driver.

Sender for

steering moment

Steering pinion

The assist power of the electric motor flanged on

parallel to the rack and pinion is transferred to

the rack via a second pinion (input pinion). This

pinion meshes in the steering rack and transfers

the assist power.

Control unit

Electric motor

Steering

column

Input pinion

Sender for

steering angle

Rack

S328_085

You will find detailed information in the self-study program 317 “The Electromechanical Power

Steering with Dual Pinion”.

41

Chassis

Steering column

The steering column is mechanically height and length adjusted. For optimum adaptation to the needs of

the driver, the height can be adjusted by 40 mm and the length by 50 mm. Moving the adjustment lever,

releases and locks the plate clamp for height and reach adjustment of the steering column.

The steering column is connected to the dash

panel module carrier with a mounting made

from diecast aluminium. The mounting is screwed

to the steering column console.

Console

Steering column

Adjusting lever

S328_169

Universal joint

shaft

Universal joint

S328_051

Mounting

Adjusting lever

Universal joint

S328_110

Multi-plate package for

height/reach adjustment

42

As part of occupant protection, the steering column and universal joint shaft are designed to slide inside

each other. This means the steering column and steering wheel cannot be pushed towards the driver

when the front section of the car is deformed in a collision.

Brakes

ABS system

The MK70 ABS system from Conti Teves is used

as standard in the 2004 Caddy.

It has the following technical features:

– Anti-lock brake system (ABS) with

– electronic brake pressure distribution (EBD).

ABS or ESP unit

Brake servo

The traction control system (TCS) and engine

braking control (EBC) are controlled by the

engine management.

ESP system

The MK60 system from Conti Teves with

integrated pressure sensor is optionally available

as an ESP system for the Caddy Shuttle/Caddy

Life from 75 kW.

Compared with the MK70 system, it has the

following additional technical features:

– Electronic Stabilisation Program (ESP) with

ESP button and ESP warning lamp

– Hydraulic brake assist (BA)

– Traction control system (TCS)

S328_052

MK70 system

Hydraulic unit

Control unit

S328_054

Please refer to self-study program 204 “ESP”

for further information on the electronic

stability program. Self-study program 264

“The Brake Assist System” has details on the

brake assist.

MK60 system

Hydraulic unit

Control unit

S328_053

43

Chassis

Brake servo

The 2004 Caddy uses a 10" brake servo from

Conti-Teves.

This brake servo has one essential new feature

called the “dual rate characteristic curve”. This

means that the brake assist works according to

a two-step curve.

A modified inside structure of the brake servo

leads to a progressive curve following a socalled “dual-rate characteristic curve”. A higher

brake pressure than is possible with conventional

brake servos can be reached even with low

pedal forces. This also guarantees good dosing.

S328_055

“Dual-rate characteristic curve”

When the brake pedal is pressed, the brake

pressure in the brake servo does not rise linearly

over the whole range.

From a specific pedal force threshold value, the

brake pressure rises more than the pedal force

and thus boosts the braking effect.

Crash-optimised pressure rods are built in the

brake servo.

Boost range

44

Brake pressure

Pedal force

Brake pressure

Threshold value

Pedal force

S328_101

Front brakes

Two different disc brake systems are used in the

2004 Caddy depending on the version or

engine.

They use ventilated brake discs.

Up to an engine output of 55 kW, disc brakes

with brake discs measuring Ø 280 mm x 22 mm

are fitted.

The brake carrier is integrated in the wheel

bearing housing.

From an engine output of 75 kW and in

the Caddy Shuttle/Life with 7 seats, a disc

brake system with brake discs measuring

Ø 288 mm x 25 mm is used.

The brake carrier is bolted to the wheel bearing

housing.

S328_056

Rear brakes

The 2004 Caddy has disc brakes with solid

brake discs measuring Ø 260 mm x 12 mm on

the rear axle.

So-called combi callipers are used for the brake

callipers. The brake pedal operates the brake

piston hydraulically and the handbrake

mechanically via a ratchet.

S328_057

S328_058

45

Chassis

Pedal cluster

The crash-optimised pedal cluster has a modular

structure and consists of

– clutch pedal,

– brake pedal and

– accelerator pedal.

The clutch pedal and the accelerator pedal have

contact-free position sensors that recognise the

pedal position.

Both pedals are made of plastic.

The brake pedal mounting is made from

aluminium and the brake pedal from steel sheet.

Clutch pedal

Brake pedal

Accelerator

pedal

S328_059

G476 clutch position sender

The clutch position sender is a Hall sender. When

the clutch is operated, it recognises the pedal

position and signals it to the engine control unit

by means of a permanent magnet attached to

the push rod. The engine control unit switches off

the speed control system.

On the diesel engines, the injection amount is

reduced briefly to avoid engine jolts upon gear

changes.

Permanent

magnet

Sender for

clutch position G476

Push rod

Clutch pedal

S328_112

Pedal travel

46

Senders for accelerator pedal position G79

and G185

The senders for the accelerator position work

according to the induction principle.

When the accelerator pedal is pressed, the

angle movement is converted into straight-line

movement to move a small metal plate back and

forth.

Accelerator pedal

Evaluation electronics evaluate this movement

and send a corresponding signal to the engine

control unit depending on the accelerator pedal

position.

The engine control unit then calculates the

injection amount from this data.

Metal plate

Cover for circuit board

Evaluation electronics

S328_111

You will find detailed information on the design and function of the contact-free senders in

the self-study programmes 316 “The 2.0l TDI Engine” or 321 “The Golf 2004 Running Gear”.

47

Electrical system

Locations of onboard supply

components

Battery

The battery is located at the front left of the

engine compartment.

E-box

The fuses and relays for the electrical

components in the engine compartment are

accommodated in the E-box.

Relay carrier

The relay carrier holds additional relays.

The configuration depends on the vehicle

equipment.

Relay carrier on onboard supply control unit

Battery

on left of engine compartment

The following relays are located in the relay

carrier on the onboard supply control unit:

– Relay 2 for voltage supply

terminal 30 - J689

– Relay for heated rear window J9

– Horn relay J413

– Relay 1 for double washer pump J729

– Relay 2 for double washer pump J730

– X contact relief relay J59

Fuse box

The fuses for the electrical components in the

vehicle are in the fuse box.

Pre-fuse box

The pre-fuse box is on the front side of the E-box.

It is part of the E-box and holds the fuses for the

alternator and the electromechanical power

steering.

48

Fuse and relay box

on left of engine compartment

Relay carrier

on left under dash panel

Pre-fuse box

on left of engine compartment

S328_060

Relay carrier on control unit for onboard

supply, on left under dash panel

Fuse box on left under

dash panel

49

Electrical system

Networking concept

Overview of network

To enable data exchange between the control

units, they are networked via different data bus

systems.

The diagnostic interface for data bus J533 (Gateway) forms the interface for the following data

buses:

– Drivetrain CAN data bus

– Convenience CAN data bus

– Infotainment CAN data bus

– Combi-instrument CAN data bus

(dash panel insert)

– Diagnostics CAN data bus

Control units connected to:

Drivetrain CAN data bus

Convenience CAN data bus

Infotainment CAN data bus

Combi-instrument CAN data bus

Diagnostics CAN data bus

LIN data bus

CAN data bus line

Communications line

LIN

LIN data bus line

In addition to the CAN data bus,

some electrical components are

networked via the LIN data bus.

50

Legend

G85 Steering angle sender

G273 Interior monitoring sensor

G384 Vehicle inclination sender

H12 Horn for anti-theft alarm

J65 Heater control unit

J104 ABS with EDL control unit

J220 Motronic control unit

J234 Airbag control unit

J285 Control unit with display in dash panel

insert

J301 Air conditioning system control unit

J345 Trailer detector control unit

J362 Immobilizer control unit

J386 Driver door control unit

J387 Front passenger door control unit

J393 Convenience system central control unit

J400 Wiper motor control unit

J412 Mobile telephone operating electronics

control unit

J500 Power steering control unit

J503 Control unit with display for radio and

navigation

J519 Onboard supply control unit

J527 Steering column electronics control unit

J533 Data bus diagnostic interface

S328_061

R Radio

T16 Diagnosis connector

51

Electrical system

J519 onboard supply control unit

Location

The onboard supply control unit has been placed

underneath the dash panel and forms a

module with the relay carrier.

Variants

The control unit for the onboard supply is

available in the Basic and Highline variants.

The Highline variant is built into vehicles with fog

lights.

Fog lights can only be added if the Basic version

of the control unit is replaced with the control

unit for the Highline variant.

Onboard supply

control unit

S328_171

S328_172

Relay carrier on

onboard supply

control unit

52

Tasks:

The onboard supply control unit activates and controls the following functions:

• Electrical load management

• Outside light control

• Turn signal control

• Wipers, front windscreen

Forwarding of data bus signals to the

wiper motor control unit

• Wipers, rear windscreen

• Heated rear windscreen

The heated rear windscreen is controlled

via the onboard supply control unit when

the button for a heated rear windscreen is

pressed and the alternator generates

enough voltage.

• Interior light control

Terminal 30 via which the interior lights are

supplied with power is controlled by the

control unit for the onboard supply.

• Terminal control, the onboard supply

control unit controls the following

functions:

– Terminal 75x via the relief relay for the

X contact

– Terminal 15 via the relay for voltage

supply terminal 15 in the E-box and on

the relay carrier on the control unit for

the onboard supply.

– Terminal 50 via the relay for voltage

supply terminal 50 in the E-box.

• Dimming, instrument illumination

The dimmable output terminal 58d

supplies the dimmable switches and

instruments with voltage.

• Fuel pump supply

When the driver’s door is opened, the

electrical fuel pump is supplied with

voltage by the onboard supply control

unit.

Once the engine has been started, it is

supplied via the engine control unit.

• Alternator exciter

The alternator is excited via the onboard

supply control unit.

53

Electrical system

Electrical load management

The electrical load management ensures that the

battery has sufficient electrical energy to start the

engine.

Electrical convenience consumers are switched

off for this purpose.

The technical safety is maintained.

The onboard supply control unit evaluates the

engine speed,

the battery voltage and

the alternator load via the DF signal

(Dynamo Field) when switching off.

U

Battery

Management not active Load management

13.8 V

The onboard supply control unit evaluates the

onboard supply load using this information and

the information on active high-power consumers

with a short active period.

The onboard supply control unit can request a

higher engine speed from the engine control unit

on the basis of this information.

Furthermore convenience consumers can be

switched off.

Three different operating modes are recognised

for load management:

– uncritical

– critical

– very critical

Cancel idle speed

increase

uncriticalcriticalvery critical

12.7 V

12.2 V

If the battery voltage is

below 12.7 V for longer

than 10 s

Charge time (30 s) fulfilled

(DF < 70 % …)

Request idle speed

increase …

If the battery voltage is

below 12.2 V for longer

than 30 s

Idle speed increase

Management active

Switch on consumers acc.

to priority list

Waiting time (120 s) met

(or DF < 70 %)

Switch off consumers acc.

to priority list

Consumer switch-off

54

S328_173

Outside light control

The onboard supply control unit evaluates the signals from the light switch directly. The information on

switching on the turn signal, the main beam lights and use of the flasher lights is sent via the steering

column electronics control unit J527 and the CAN convenience data bus.

Functional diagram

F

F4

J519

Terminal 15

Terminal RFL

Terminal FL

Terminal DDL

Terminal 56

Terminal 58

E1

Terminal 30

D

E4

E19

Terminal 15

J527

CAN data bus convenience

Legend

D Ignition switch terminal 15

E1 Light switch

E4 Switch for headlight dipper and

flasher

E19 Parking light switch

F Brake light switch

F4 Reversing light switch

J519 Onboard supply control unit

J527 Steering column electronics control unit

X

M25

S328_174

Term. 56 Driving lights

Term. 58 Side lights

Term. RFL Rear fog light

Term. FL Fog light

Term. DDL Day driving light

Function needs to be coded in the

onboard supply control unit.

The codes differ from country to

country

M25 High level brake light bulb

X Number plate light

55

Electrical system

Bulb monitoring

The functioning of the bulbs is monitored constantly. They are monitored while switched off

(cold monitoring) and switched on (hot monitoring).

Cold monitoring

The individual bulbs are switched on four times

in short intervals of 500 ms when the ignition is

turned on. The current value allows the onboard

supply control unit to detect a faulty bulb.

Hot monitoring

The individual bulbs are controlled by

semiconductor modules located in the onboard

supply control unit. They recognise whether there

is overloading, a short circuit or an open circuit.

Fault detection

In both monitoring types, an entry is made in the

fault memory and there is an indication in the

dash panel insert when a fault is recognised.

S328_175

S328_176

56

A new bulb is recognised by the monitoring

system, the fault is deleted and the displayed

indication cancelled.

S328_177

Turn signal control

When you tap turn light E2 briefly once, the turn lights will flash three times. If you tap again, the turn

lights will flash a further three times. This function is called lane-change flash.

Functional diagram

First request Renewed request

Request of the “Flash” function by tapping the turn

E2

signal switch

M5 or M7

M6 or M8

Legend

E2 Turn signal switch

M5 Front left turn signal bulb

M6 Rear right turn signal bulb

M7 Front right turn signal bulb

M8 Rear right turn signal bulb

Triggering of the turn signals by the onboard supply

control unit

S328_178

57

Electrical system

Front windscreen wiper system

Wiper control

The wiper system uses one motor with a mechanical connection between the wipers.

The operating rods for windscreen wiper switch E are transferred directly to the steering column

electronics control unit J527 and then to the onboard supply control unit J519 via the CAN data bus

convenience.

The onboard supply control unit directs the information on the selected wiper setting via the LIN data

bus to the wiper motor control unit J400 that regulates the wiping cycles.

In intermittent mode, the wiper cycles are speed-related.

Overview of wiper system

J104

F266

D

J400

E

J519

58

J533

J527

Legend

D Ignition/start switch

E Windscreen wiper switch

F266 Bonnet contact switch

J104 ABS with EDL control unit

S328_179

J400 Wiper motor control unit

J519 Onboard supply control unit

J527 Steering column electronics control unit

J533 Data bus diagnostic interface

Service and winter position

If you move the windscreen wiper switch to the

flick wiper position within 10 seconds after

parking and turning off the ignition, the wipers

will move to the top position.

This function will not work when the bonnet is

open.

S328_180

Anti-block function

The wiper system can detect from the current

consumption if the wipers jam.

If there is an obstacle in the wiper path, the

wiper system will attempt five times to push the

obstacle away. If it cannot remove the obstacle,

the wiper will stop in this position.

The obstacle then needs to be removed by hand.

The anti-block function covers the whole wiper

path just up to the top position.

If the wiper blade has frozen onto the bottom

edge of the windscreen, this is also recognised as

an obstacle and the wiper will attempt to free

itself five times. After the fifth attempt it will stop.

Alternating rest position

Rest position after the

first switch off

Blockage

S328_181

Rest position after the

second switch off

To avoid long-term deformation of the wiper

blades, the wipers move up slightly every other

time they are switched off.

This changes the position of the wiper blade.

In addition, the rest position can be changed

again if you switch off the ignition again several

times.

S328_182

59

Electrical system

Control unit with display in dash panel insert J285

The control unit with display manages all display elements, the analogue gauges and the warning

lamps.

LED warning lamps

Dash panel insert

Revolution counter

Coolant temperature

The display comes in the following different

versions:

Digital

display

S328_143

Speedometer

Fuel gauge

60

Lowline has the displays:

– Clock

– Odometer

– Trip recorder

The Lowline version also

comes as a simplified basic

version without a coolant

temperature gauge. A red LED

illuminates when the coolant is

too hot.

Midline has the following

extras compared with the

Lowline version:

– Outside temperature

– Multi-function display or

– Warning texts instead of

multi-function display and

outside temperature

Highline has the following

extras compared with the

Midline version:

– Warning symbols/warning

texts instead of the multifunction display and

outside temperature

Lights

Side light

Turn signal

Headlights

The headlight unit has a clear glass lens plus one

reflector for dipped beam and one for main

beam lights. The turn signal light is also

integrated in the headlight unit.

The dipped beam light uses H7 bulbs, the main

beam light H1 bulbs. The side light is integrated

in the reflector for the main beam light.

The bulb for the turn signal is coloured yellow.

Fog lights

The fog lights are integrated in the bumper.

They are equipped with H1 bulbs.

Main beam

(H1 bulb)

Dipped beam

(H7 bulb)

Rear lights

The rear lights are split into three main areas.

The brake light is at the top.

The upper part of the centre area with the clear

lens contains the reversing light.

The lower part of this area holds the turn signal

light with a yellow-coloured bulb.

A twin filament bulb is fitted in the bottom section

of the light for the tail light and rear fog light.

S328_063

Fog light

(H1 bulb)

Brake light

Reversing light

Turn signal

Tail light/rear

fog light

S328_064

61

Heating and air conditioning

Climate control

Two different systems are used in the

2004 Caddy:

– Manual heating and ventilation system

– Semi-automatic Climatic air conditioning

Both systems use an air-conditioning unit with

the same design that has been adapted for the

respective requirements. The controls are

different, however.

Air outlet for

windscreen

Heating/air-conditioning unit

In the Caddy Van, there are only air vents for the

driver and front passenger in the dash panel.

The Caddy Life has additional vents at rear end

of the centre console for the rear passengers,

these are optional in the Caddy Shuttle.

Furthermore vents are also fitted in the footwell

of the Caddy Shuttle/Life for the passenger

compartment.

The heating units are equipped with dust filters

and the air-conditioning units with activated

charcoal filters.

The 2004 Caddy can be optionally equipped

with an auxiliary coolant heater.

Air distribution with activated

charcoal filter

Activated charcoal filter

Vent for driver’s

footwell

Left-hand vent for

passenger compartment

footwell

The picture shows a Caddy Life. Dummy

covers are fitted on the heating/air

conditioning unit in vehicles without

rear vents.

Vent for passenger

compartment

in centre console

S328_065

Vent for front

passenger’s

footwell

Right-hand vent for

passenger compartment

footwell

S328_163

Please refer to the repair guide for

information on how to exchange the

dust and activated charcoal filter.

62

Manual heating

Operating unit for manual heating

The temperature and air distribution is set

manually on the operating unit in the dash panel

for the vehicle interior as a single climate zone.

The temperature is not regulated. The rotary

knob for the temperature and air distribution

are connected the air-conditioning unit only

mechanically via a flexible shaft and a Bowden

cable.

Rear window heating

Seat heating,

left (optional)

Feedback LED

Mechanical

temperature rotary knob

Immediate heat button

auxiliary coolant heating

(optional)

Recirculation

Seat heating,

right (optional)

S328_066

Rotary knob for

fan speed

Mechanical rotary knob

for air distribution

Climatic

Climatic allows you to set the temperature with

the left-hand rotary knob.

The selected temperature is forwarded to the

Climatic system via a potentiometer. The Climatic

system controls the temperature flap in the airconditioning unit to automatically regulate the

interior temperature.

The air distribution is set only mechanically with

the right-hand rotary knob.

The ECON button switches the air conditioning

on and off. In ECON mode, the preheater in

vehicles with diesel engines is also switched off.

The Climatic air-conditioning unit has a

combined fresh air/recirculation flap.

Climatic operating unit

ECON button

Electronic

temperature rotary knob

Interior temperature sensor

S328_067

63

Heating and air conditioning

Thermo Top V auxiliary coolant heating

The 2004 Caddy can be optionally equipped with the Thermo Top V auxiliary coolant heating system.

It has the following technical features:

– The control unit for the auxiliary coolant heating is integrated in the heating unit.

The electrical contacts for the combustion air fan are mounted directly on the control unit.

– Furthermore the auxiliary coolant heating has a second NTC temperature sensor in the heating unit.

This improves the monitoring and control of the coolant temperature.

– The fuel is injected via a Venturi injector and mixed with the combustion air.

Combustion air fan

Control unit

Electrical

connection

Venturi injector

Water outlet

Temperature sensor

S328_114

Heat exchanger

64

Combustion air

intake

Fuel intake

Exhaust gas

outlet

Venturi injector

Combustion air intake

The intake air is guided via a ceramic housing in

the shape of a Venturi injector.

This leads to a knock-on effect that supports the

Fuel intake

fuel injection.

Glow pencil

fitting

Activating the Thermo Top V

There are three possibilities for activating the Thermo Top V auxiliary coolant heating.

The “Heating” or “Ventilation” functions can be set in the dash panel display.

S328_115

1. The auxiliary coolant heating can be activated using the immediate heat button on the operating unit.

2. The auxiliary coolant heating can be programmed using the multi-function display (MFD).

Programming is carried out via the dash panel display in the “Auxiliary heating” sub-item

(customisation).

3. Using the separate remote start control for the auxiliary coolant heating:

Switching on and off with the remote control (from distance of up to 600 m).

The immediate heat button in the operating unit shows the status of the auxiliary coolant heating:

The feedback LED is yellow while it is active.

When a switch-on time has been programmed for the auxiliary coolant heating,

the feedback LED is illuminated for approx. 10 seconds after the ignition is switched off.

For further information on auxiliary coolant heating systems, see

self-study program 280 “The Phaeton auxiliary heater Thermo TOP C and supplementary

heater Thermo TOP Z”.

65

Radio, telephone and navigation

Radio systems

Two different radios are available for the

2004 Caddy.

Radio R 100

Technical features

– 2 loudspeaker channels (only at front, each

20 Watt)

– RDS FM/AM Europa radio

– Control for an external 6-CD changer

– Telephone control (hands free)

– GALA speed-dependent volume control

– Self-diagnosis incl. loudspeaker diagnosis

– Transport mode (reduction of the current

requirement during transport and rest times)

Radio RCD 300

Technical features

– 2 or 4 loudspeaker channels (each 20 Watt),

the fader function is available when there are

4 channels

– RDS FM/AM Europa radio

– 2-tuner FM Diversity

– Integrated single CD drive

– Control for an external 6-CD changer

– Telephone control (hands free)

– GALA

– Self-diagnosis incl. loudspeaker diagnosis

– Transport mode (reduction of the current

requirement during transport and rest times)

S328_068

S328_069

66

RNS MFD-2 radio navigation system

The 2004 Caddy can also be equipped with a

radio featuring an integrated navigation system.

Technical features

– Multi-colour display (MFD)

– Dynamic traffic guidance

(avoiding jams)

– 2 or 4 loudspeaker channels (each 20 Watt)

– RDS FM/AM Europa radio

– Display of the stored stations with

RDS names

– Control unit for aerial selection

(external change-over box)

– Control for an external 6-CD changer

– Telephone control (hands free)

– GALA

– Traffic Information Memory (TIM)

– Self-diagnosis incl. loudspeaker diagnosis

– Display of navigation arrows and navigation

information in dash panel insert (Highline)

S328_071

Diversity refers to the different aerial signals.

The Diversity systems are used in the radio and radio-navigation systems to improve reception.

At least two separate aerials are required for a Diversity system.

67

Radio, telephone and navigation

Radio aerials

The 2004 Caddy has different aerials fitted in the front windscreen depending on the equipment.

Depending on the type of radio system, single aerials and Diversity aerials are used.

Single aerial

Aerial amplifier

Housing

Single aerial

The R 100 radio has a single aerial in the front

windscreen and an aerial amplifier.

R 100 radio

S328_155

Diversity aerials

Two independent aerials (Diversity aerials) can reduce reception interference like noise and crackling,

for example, in conjunction with the 2-tuner FM Diversity or the control unit for aerial selection (external

change-over box). This interference occurs frequently in residential areas or mountainous regions due to

reflection from houses and mountains. The reflection causes the signals to be delayed and leads to

interference.

2-tuner FM Diversity system

Aerial amplifier

Diversity aerial

The RCD 300 radio has an integrated

2-tuner FM Diversity system with two internal

receivers that process the incoming aerial signals

Housing

separately and combine them to make a single

signal.

S328_156

68

Control unit for aerial selection

The J515 aerial selection control unit (external

switch-over box) allows connection of the

Diversity aerials to the RNS MFD-2 radio

navigation unit. This monitors the incoming

aerial signals on the external switch-over box

and automatically switches to the aerial with the

stronger signal.

Radio RCD 300

Aerial amplifier

Housing

Control signal

Control unit for aerial selection

Aerial signal

RNS MFD-2 radio navigation system

Diversity aerial

S328_164

Telephone/navigation aerial

The 2004 Caddy can also be optionally equipped with an additional telephone/navigation aerial.

The aerial is used in conjunction with the following optional components:

– RNS MFD-2 radio navigation system

– Telephone/preparation for telephone*

– Remote control for auxiliary coolant heating*

* When the vehicle is equipped with a telephone/preparation for telephone and auxiliary coolant

heating with remote control, the reception signals are split by a frequency divider. If only one of the

two components are installed, the respective signal runs straight to the receiver and a divider is not

needed.

Roof aerial with:

– Aerial for GPS R50 navigation

– Aerial for R65 telephone

– Aerial for R182 auxiliary heater

GPS satellite

Remote control for

auxiliary coolant

heater

Auxiliary coolant heater

R87 aerial filter

Auxiliary coolant

heater

radio receiver R149

Mobile

telecommunications

RNS MFD-2 radio navigation

system

S328_159

Telephone

69

Service

Diagnosis

The VAS 5051 vehicle diagnosis, measuring and information system and the VAS 5052 vehicle diagnosis

and service information system are available for the 2004 Caddy.

The VAS 5051 vehicle diagnosis, measuring and

information system has the familiar operating

modes:

– Guided fault finding

– Vehicle self-diagnosis

– OBD (on-board diagnosis)

– Measuring technology

The ”Guided Fault Finding” operating mode

checks all control units installed in the vehicle for

fault entries and automatically compiles a system

test plan from the results.

In conjunction with ELSA information, for

example, the circuit diagrams or repair guides,

this mode guides you directly to the cause of the

fault.

VAS 5051

S328_072

In addition, you also have the option of compiling your own test plan.

The function and component selection records

the tests you select in the test plan. You can then

work through the tests in any order during the

diagnosis procedure.

The ”Vehicle self-diagnosis” mode can still be

used, but there is no further ELSA information

available.

For more detailed information on the procedure and guided fault finding, please refer to

chapter 7 of the VAS 5051 operating manual.

The “Guided Functions” mode is new. In this

way, without a complete vehicle system test, you

can quickly access general service functions, for

example, adapting vehicle keys.

It is used from the basis CD V06.00.00 and the

Volkswagen brand CD V06.42.00.

The VAS 5052 also has the

”Guided Fault Finding” and

“Guided Functions” operating

modes.

70

Notes

71

328

© VOLKSWAGEN AG, Wolfsburg, VK-21 Service Training

All rights and rights to make technical alterations reserved

000.2811.44.20 Technical status 04/04

❀ This paper was manufacturer from pulp that

was bleached without the use of chlorine.

Loading...

Loading...