Viessmann Vitola 200 Technical Manual

Technical Data Manual

Model Nos. and pricing: see Price List

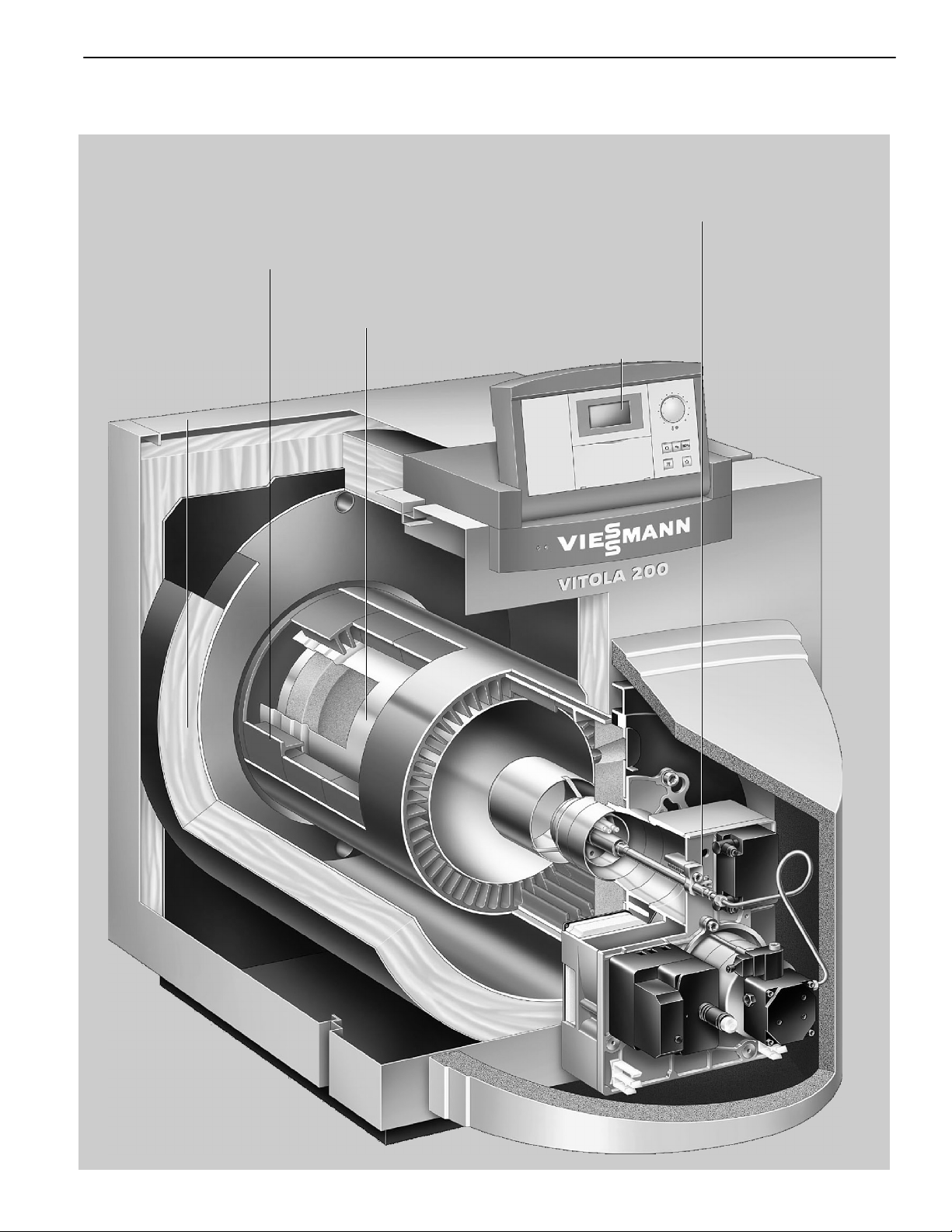

VITOLA 200

Hot water heating boiler without low limit

83 to 300 MBH / 24 to 88 kW

Vitola 200 with Vitoflame Burner and

Vitocell-H 300 domestic hot water tank

Vitola 200

VB2 Series

Oil-/Gas-Fired Boiler

for hydronic heating systems

with modulating boiler water temperatures

without low limit

with biferral heating surfaces of cast iron/steel

Heating input: 83 to 300 MBH

24 to 88 kW

5167 403 v1.6 04/2008

Vitola 200 with Vitoflame Burner, boiler stand

and Vitocell-V 300 domestic hot water tank

Oil-fired

Product Information

Vitola 200

High quality at an affordable price:

The double-wall sandwiched hea t exchanger

surface of the Vitola 200 is a milestone in the

history of heating technology. The Vitola 200

combines comfort with energy savings.

The benefits at a glance:

H Biferral heat exchanger of cast iron and steel

for high operational reliability and a long

service life.

H Reduced emissions with the Viessmann

Chassis or Vitoflame Burner.

H Saves energy and preserves the

environment via low boiler water

temperatures; cold start ability; A.F.U.E.

of up to 87.4% (oil-fired version).

H Optimal temperature modulation due to

wide water passageways and a large

water content.

H Straight-forward installation and start-up –

Burners supplied by Viessmann are tested

with a combustion analyzer at operating

temperature and matched to the boiler

input in the factory.

H Short installation times due to the

Viessmann Fastfix Installation System.

Save up to 50% of the installation time

when installing boiler panelling and

control. Simple assembly is achieved with

components which merely snap together ,

making special tools unnecessary.

The biferral sandwiched heat exchanger of

cast iron and steel offers high operational

reliability and a long service life

5167 403 v1.6

2

Biferral sandwiched heat exchanger s urface Viessmann Vitoflame 100 Burner

of cast iron and steel offers high

operational reliability and a long

service life

3” / 75 mm boiler shell

insulation

Product Information

Cut-Away Section

Removable stainless steel Vitotronic 200 –

combustion chamber indoor/outdoor

digital boiler and heating

system control

5167 403 v1.6

3

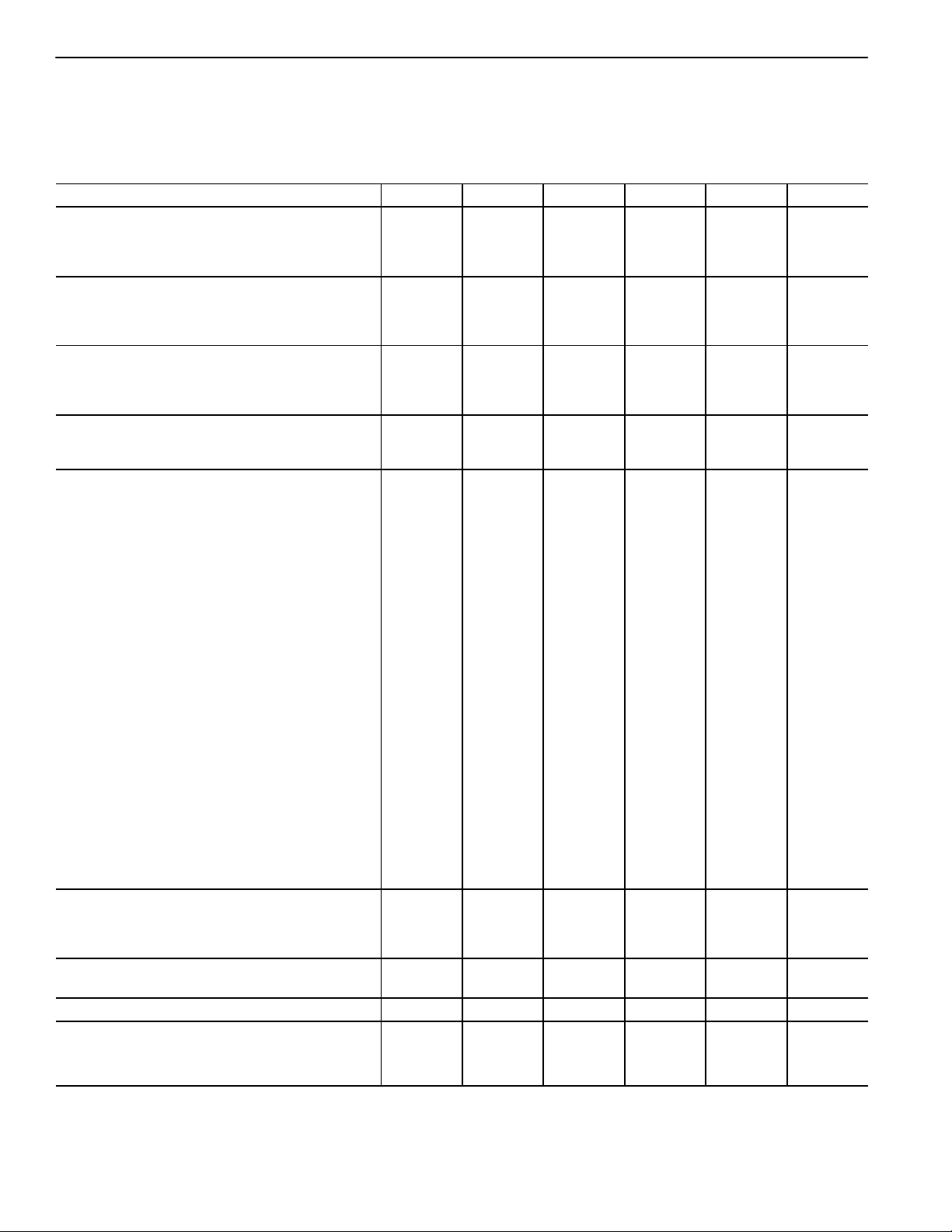

Technical Data

Technical data

Boiler Model Model No. VB2-18 VB2-22 VB2-33 VB2-40 VB2-50 VB2-63

CSA gas rating

CSA oil rating input

Net I=B=R rating

A.F.U.E.

Dimensions

Length

Width

Height

Overall dimensions

Total length

Total width

Total height (operation)

- Height 1

position for operation)

- Height 2

position for servicing)

Height of boiler stand

Height of Vitoce ll-H under boiler

- 42 to 53 USG / 160 to 200 ltr

-92USG/350ltr

- 120 USG / 450 ltr

Weight boiler shell

Total weight (boiler with insulation,

burner and boiler control)

Boiler water content USG

Max. operating pressure psig 30 30 30 30 30 30

Boiler water connections

Supply and return

Safety supply (Safety Header)

Safety return, drain valve

*1

Propane burners have same input/output as natural gas burners.

*2

Net I=B=R rating based on piping and pick-up allowance of 1.15.

*3

Annual Fuel U tilization Efficiency with optional stack damper.

*4

Overall dimensions with Viessmann Vitoflame 100 Burner installed.

*5

Seepage6.

4

*1

*3

*5

(control unit in

*5

(control unit in

input

output

output

*2

for gas

for oil

for NG

for LP

for oil

*4

MBH

kW

MBH

kW

MBH

kW

MBH

kW

MBH

kW

MBH

kW

%

%

%

inches

mm

inches

mm

inches

mm

inches

mm

inches

mm

inches

mm

inches

mm

inches

mm

inches

mm

inches

mm

inches

mm

inches

mm

lbs

kg

lbs

kg

ltr

inches

inches

inches

90

26

75

22

83

24

72

21

65

19

63

18

84.5

86.0

87.1

23¼

589

21¼

537

27¾

706

43¾

1112

25¼

639

32¾

830

37

940

45¾

1160

9¾

250

26

658

287

130

381

173

18.5

70

1½

116

34

97

28

107

31

92

27

84

25

80

23

84.0

85.8

87.2

25¾

655

22¼

565

28½

726

46¼

1178

26¼

667

33½

850

37¾

960

46½

1180

9¾

250

26

658

–

–

–

–

335

152

434

197

23.2

88

1½

1

1

1

1

146

42

122

35

135

39

116

34

106

31

101

30

84.0

85.8

87.2

32¼

817

23½

599

29¼

743

52¾

1340

27½

701

34

865

38¼

975

47

1195

9¾

250

26

658

31

790

430

195

542

246

31.2

118

1½

185

54

154

45

170

50

146

43

134

39

127

37

84.0

85.8

87.3

32¼

817

26½

674

32¼

819

53¼

1350

30½

776

37

940

41¼

1050

50

1270

9¾

250

26

238

69

198

57

219

64

189

55

172

50

164

48

83.9

85.7

87.4

37¾

956

27¾

702

33½

853

58½

1489

30½

776

38½

975

42¾

1085

51½

1305

9¾

250

300

88

249

73

300

88

258

76

217

64

224

66

83.9

85.7

87.1

42

1070

27¾

702

33½

853

63

1603

30½

776

38½

975

42¾

1085

51½

1305

9¾

250

–

658

31

790

–

37¼

947

573

260

697

316

37.0

140

1½

1

1

1

1

31

790

37¼

947

739

335

866

393

52.6

199

1½

1½

31

790

37¼

947

809

367

941

427

59

223

1½

1

1½

–

1

5167 403 v1.6

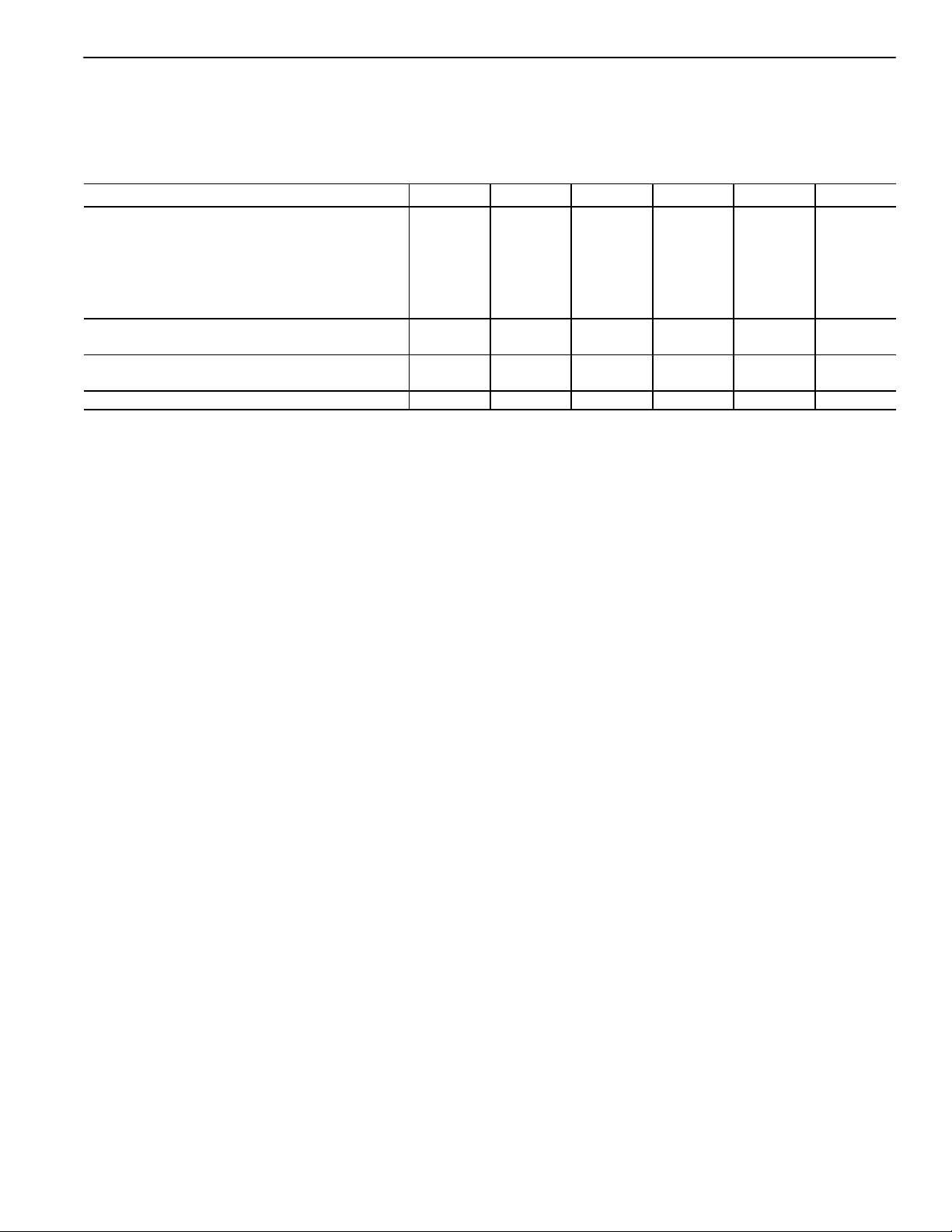

Technical Data

Technical data

Boiler Model Model No. VB2-18 VB2-22 VB2-33 VB2-40 VB2-50 VB2-63

Flue gas*6, temperature (gross)*7at

H 104°F / 40°C boiler water temp.

H 167°F / 75°C boiler water temp.

Flue gas mass flow

Vent pipe

Boiler vent

Flue gas volume, boiler USG

Required flue draft

*6

Combustion results are based on 11.0% to 13.0% CO2with fuel oil #2, 9.5% to 10.2% with natural gas,

or 10.0% to 11.5% CO

*7

Measured flue gas temperature with combustion air temperature of 68°F / 20°C.

*8

Ensure compatibility during burner selection.

*9

Ensure compatibility with chimney system. The chimney vent system must be suitable for the application (low flue gas temperature w ith

*8 *9

2

possible condensation), see page 10.

*9

°F

°C

°F

°C

lbs/h

kg/h

293

145

329

165

68

31

293

145

329

165

84

38

293

145

329

165

123

56

293

145

329

165

150

68

293

145

329

165

187

85

outer ∅ inches 5 5 6 6 7 7

ltr

39

10.3

14.0

53

20.6

78

29.1

110

41.5

157

“w.c. -0.02 -0.02 -0.02 -0.02 -0.02 -0.02

with pr opane, and a hot water heating system supply temperature of 167°F / 75°C, r eturn 140°F / 60°C.

293

145

329

165

236

107

45.7

173

"

For information regarding other Viessmann System Technology componentry, please reference doc umentation of the respective product.

5167 403 v1.6

5

Loading...

Loading...