Page 1

Supple

Mounting bosses and adapters

mentary instructions

Document ID:

32036

Page 2

1 Conte

nts

Conten

1 Product description

2 Welded socket - universal

3 Welded socket - VEGABAR

4 Welded socket - Level switch

5 Adapter

6 Welding instructions

ts

2.1 Thread. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Clamp according to DIN 32676, ISO 2852/316L . . . . .

2.3 Hygienic fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Bolting acc. to DIN 11851 . . . . . . . . . . . . . . . . . . . . .

2.5 Bolting acc. to DIN 11864-1 . . . . . . . . . . . . . . . . . . .

3.1 VEGABAR 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 VEGABAR 52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 VEGABAR 53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 VEGABAR 54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 VEGABAR 52, 54 - Paper industry . . . . . . . . . . . . . .

4.1 VEGASWING 51, 61, 63 . . . . . . . . . . . . . . . . . . . . . .

4.2 VEGAKON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 G¾ A on Clamp according to DIN 32676, ISO 2852 . .

5.2 G1½ A on Clamp according to DIN 32676, ISO 2852.

5.3 G1½ A on bolting acc. to DIN 11851 . . . . . . . . . . . . .

5.4 G1½ A on further hygienic fittings . . . . . . . . . . . . . . .

4

5

8

11

13

15

16

17

19

20

25

26

27

29

30

32

7 Supplement

7.1 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Mounting

36

32036-EN-110223

bosses and adapters

Page 3

1 Produc

t description

Welde

Adapter

d socket

1 Produc

Welded sockets are used for connection of level and presssure

sensors to the process. Depending on the version, the process fitting

is optional or belongs to the scope of delivery. Depending on the

version, accessory parts such as welding dummies and blind stoppers

are available.

Screwed adapters are used for adaptation of level and pressure

sensors with connection G¾ A or G1½ A to existing welded sockets.

Depending on the version, the seal is optional or belongs to the scope

of delivery.

t description

32036-EN-110223

Mounting

bosses and adapters 3

Page 4

2,5mm

(0.1")

16,5mm

(0.65")

G1/2

ø 32 mm

(1.26")

ø 28 mm

(1.1")

2,5mm

(0.1")

16,5mm

(0.65")

ø 38 mm

(1.5")

ø 33 mm

(1.3")

G3/4

2 W elde

d socket - universal

ead G½ A

Thr

Thread G¾ A

2 Welded

socket - universal

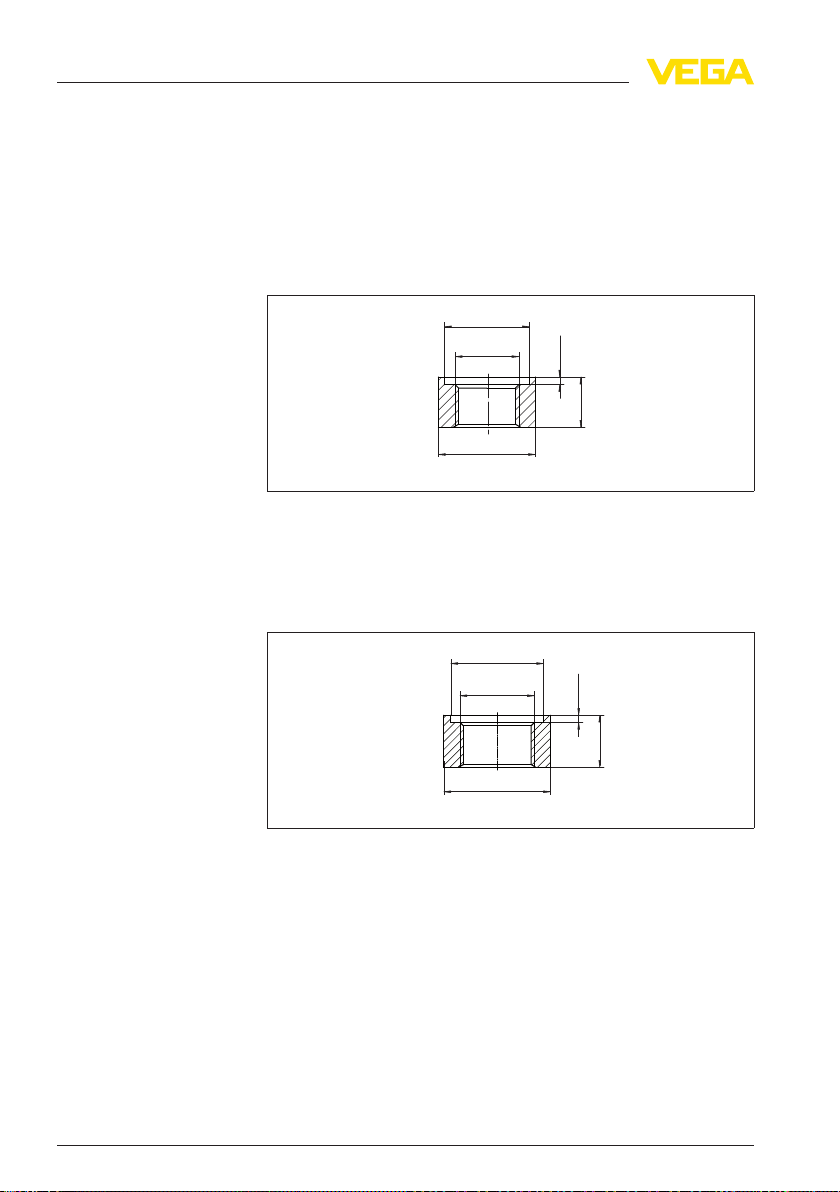

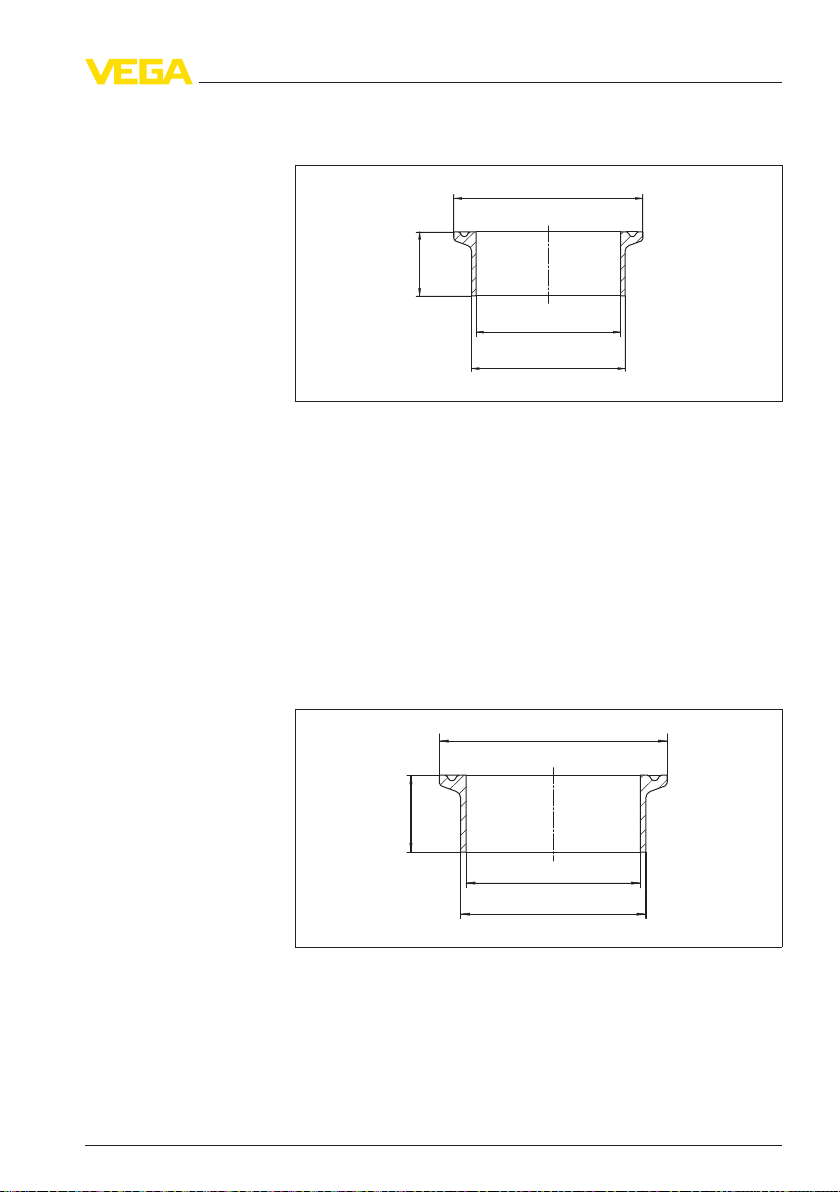

2.1 Thread

Welded socket G½ A acc. to DIN 3852-X

Art. no. 2.36839

Material 316L

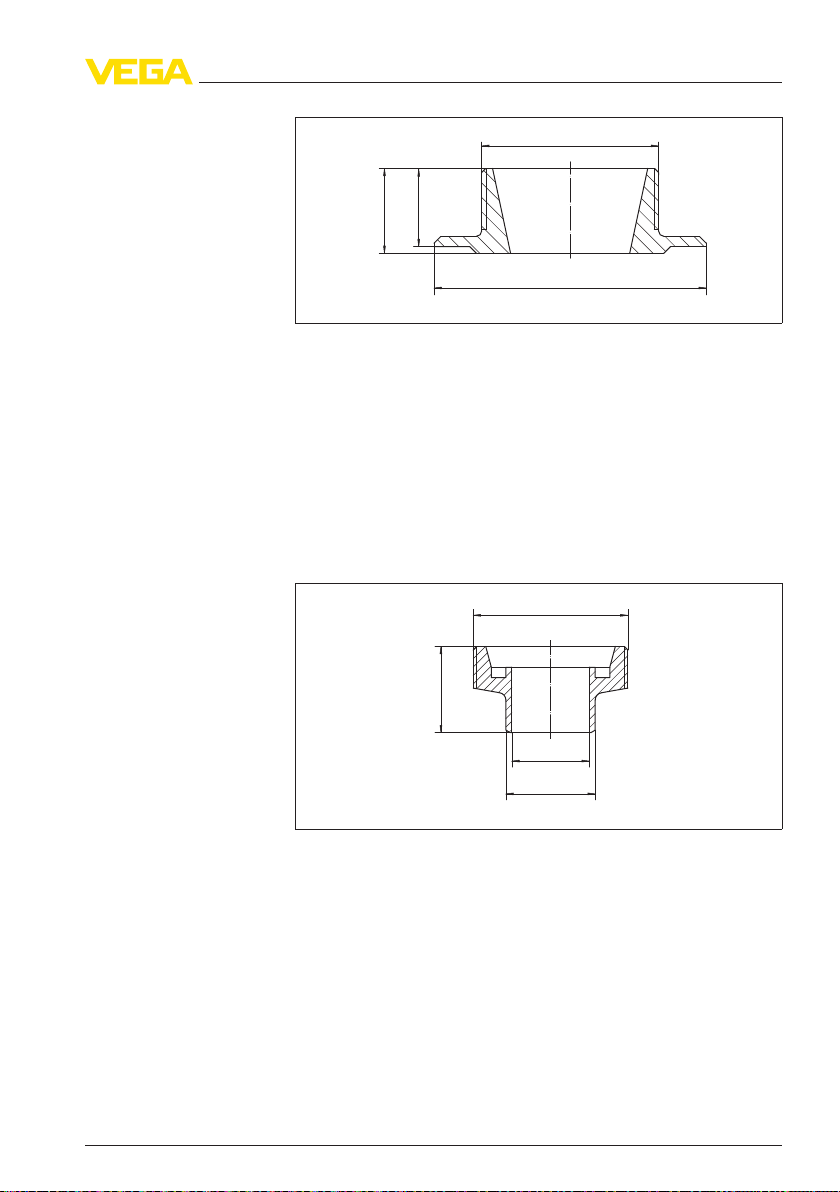

Fig. 1: Dimensions

Welded socket G¾ A acc. to DIN 3852-X

Art. no. 2.36840

Material 316L

welded socket G½ A acc. to DIN 3852-X

welded socket G¾ A acc. to DIN 3852-X

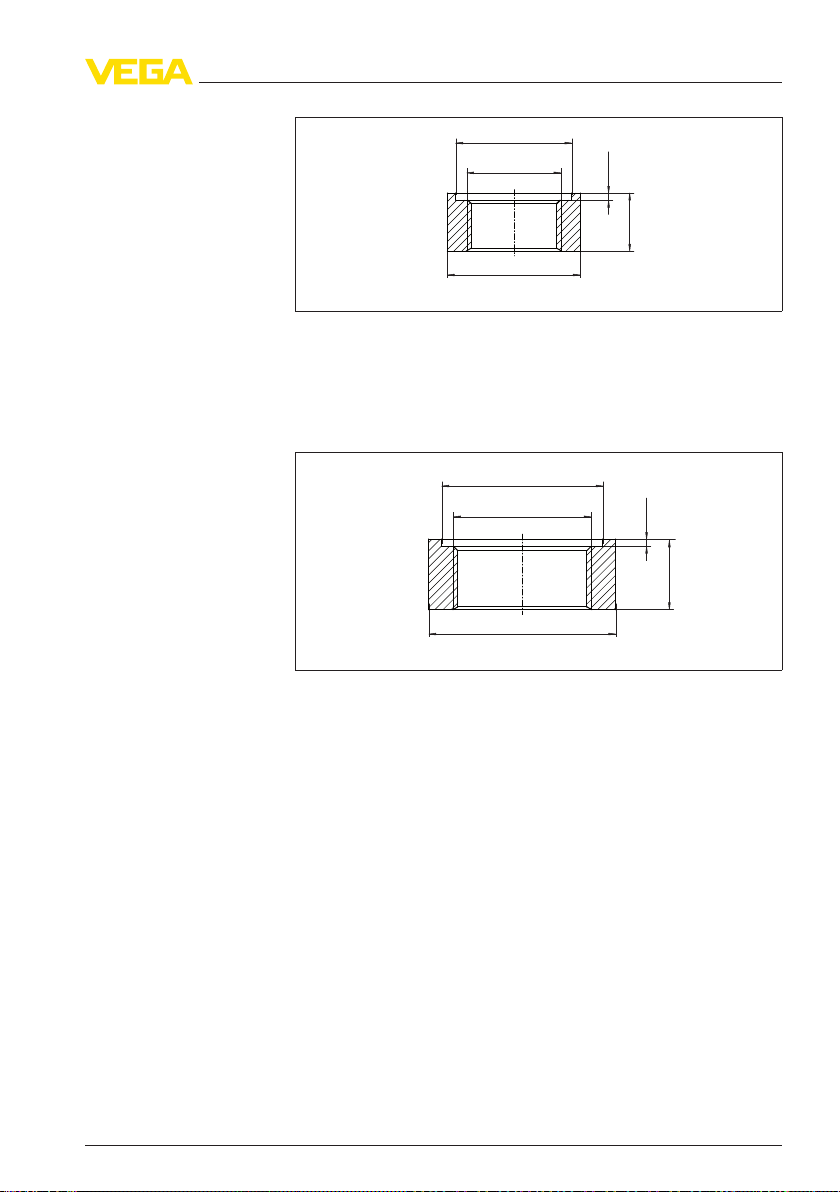

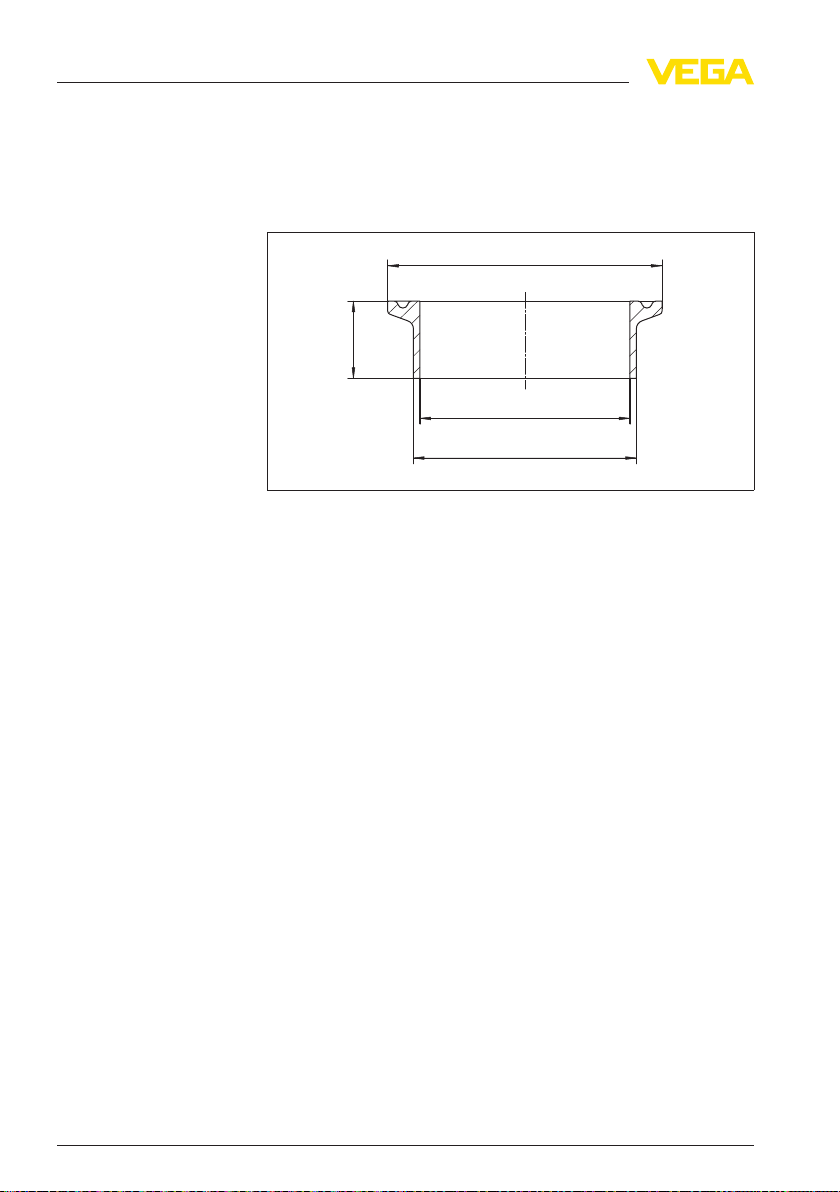

Thread G1 A

Fig. 2: Dimensions

Welded socket G1 A acc. to DIN 3852-X

Art. no. 2.36841

Material 316L

4 Mounting

32036-EN-110223

bosses and adapters

Page 5

2,5mm

(0.1")

20,5mm

(0.81")

ø 41 mm

(1.61")

ø 47 mm

(1.85")

G1

2,5mm

(0.1")

24,5mm

(0.97")

ø 56 mm

(2.21")

ø 65 mm

(2.56")

G1 1/2

2 W elde

d socket - universal

ead G1½ A

Thr

Clamp 1"

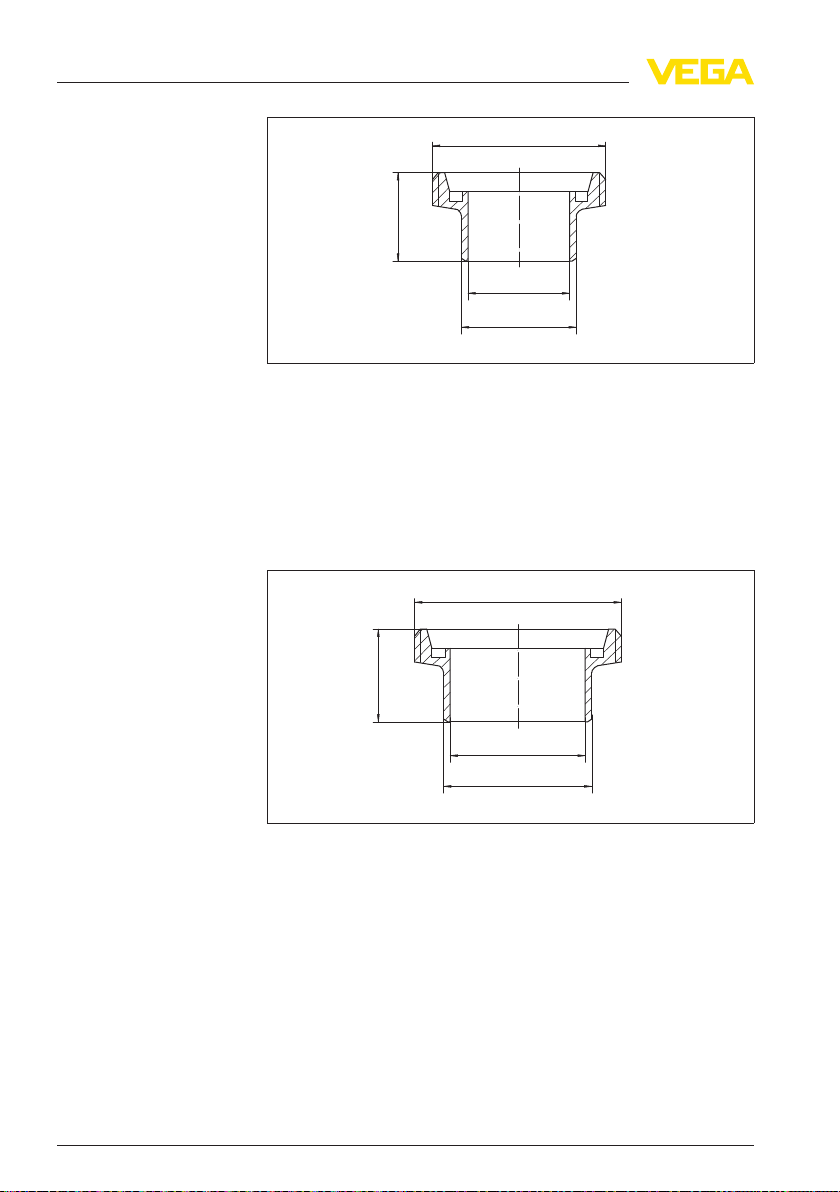

Fig. 3: Dimensions

welded socket G1 A acc. to DIN 3852-X

Welded socket G1½ A acc. to DIN 3852-X

Art. no. 36842

Material 316L

Fig. 4: Dimensions

welded socket G1½ A acc. to DIN 3852-X

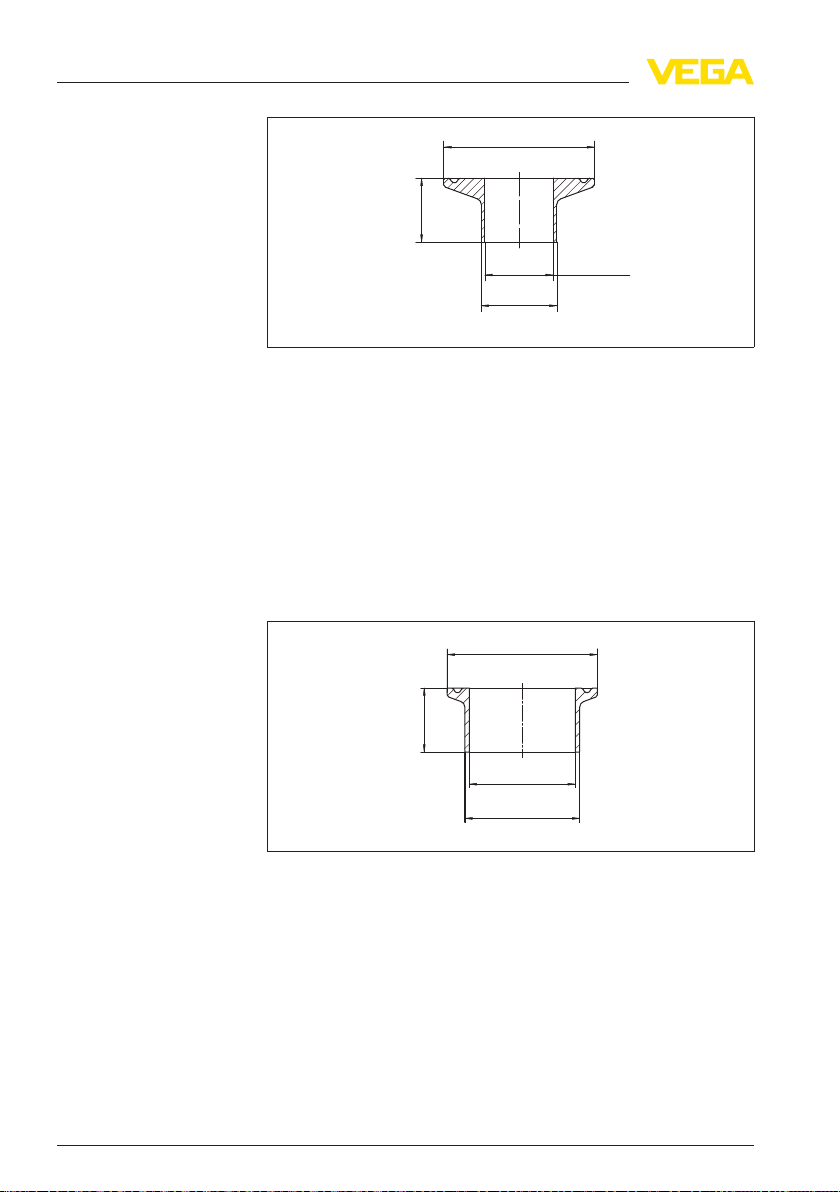

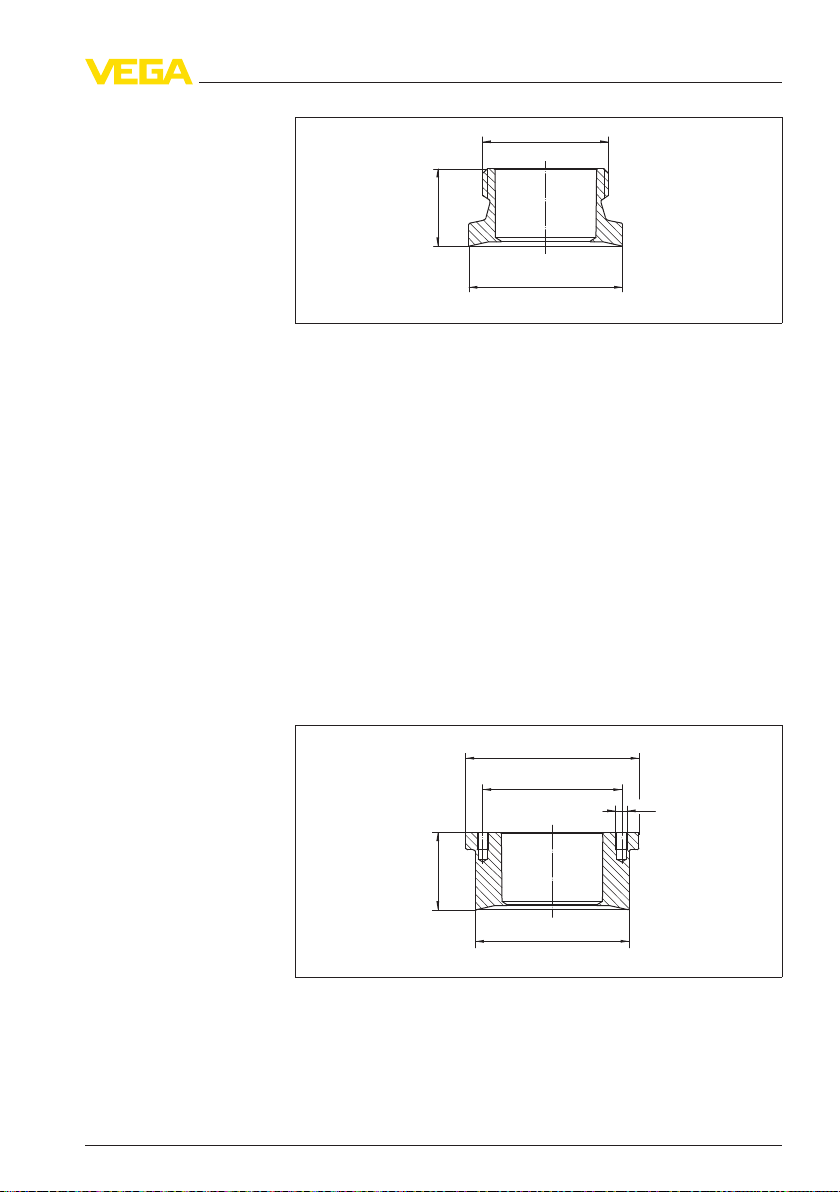

2.2 Clamp according to DIN 32676, ISO 2852/316L

Welded socket Clamp 1" PN16 DIN 32676, ISO 2852/316L

Product code ESTC.AXX

Material 316L

Seal (optional)

Material EPDM, FKM

32036-EN-110223

Mounting

Tension ring

Material 1.4301

bosses and adapters 5

Page 6

21,5 mm

(0.85")

ø 22,6 mm

(0.89")

ø 25,6 mm

(1.01")

ø 50,5 mm

(1.99")

21,5 mm

(0.85")

ø 35,6 mm

(1.4")

ø 38,6 mm

(1.52")

ø 50,5 mm

(1.99")

2 W elde

d socket - universal

Clamp 1½"

Clamp 2"

Fig. 5: Dimensions

welded socket Clamp 1" PN16 DIN 32676, ISO 2852/316L

Welded socket Clamp 1½" PN16 DIN 32676, ISO 2852/316L

Product code ESTC.BXX

Material 316L

Seal (optional)

Material EPDM, FKM

Tension ring

Material 1.4301

Fig. 6: Dimensions

welded socket Clamp 1½" PN16 DIN 32676, ISO 2852/316L

Welded socket Clamp 2" PN16 (ø 64 mm) DIN 32676, ISO 2852/

316L

Product code ESTC.CXX

Material 316L

Seal (optional)

Material EPDM, FKM

32036-EN-110223

6 Mounting

bosses and adapters

Page 7

sion ring

21,5 mm

(0.85")

ø 47,6 mm

(1.87")

ø 51,6 mm

(2.03")

ø 64 mm

(2.52")

28 mm

(1.1")

ø 60,3 mm

(2.37")

ø 64,1 mm

(2.52")

ø 77,5 mm

(3.05")

Ten

Material 1.4301

2 W elde

d socket - universal

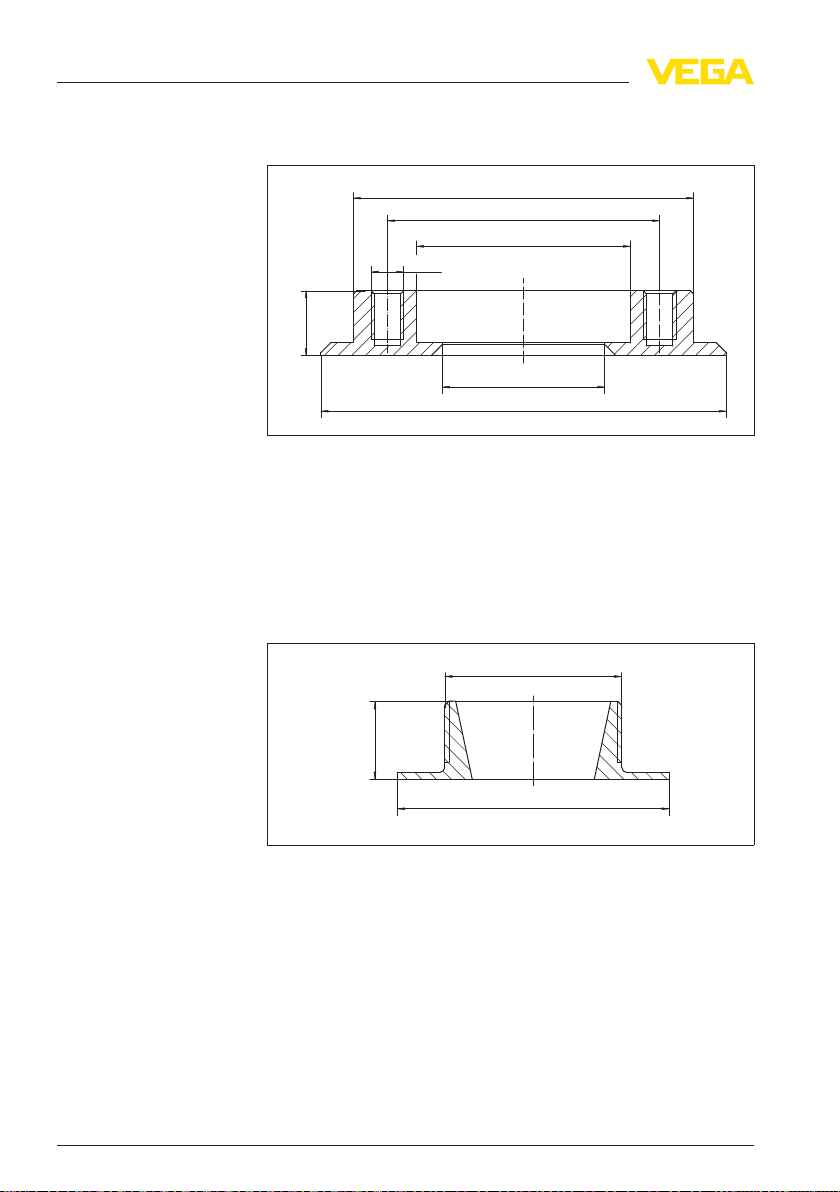

Clamp 2½"

Clamp 3"

Fig. 7: Dimensions

ISO 2852/316L

welded socket Clamp 2" PN16 (ø 64 mm) DIN 32676,

Welded socket Clamp 2½" PN16 (ø 77.5 mm) DIN 32676,

ISO 2852/316L

Product code ESTC.DXX

Material 316L

Seal (optional)

Material EPDM, FKM

Tension ring

Material 1.4301

Fig. 8: Dimensions

316L

welded socket 2½" PN16 (ø 77.5 mm) DIN 32676, ISO 2852/

Welded socket 3" PN16 (ø 91 mm) DIN 32676, ISO 2852/316L

Product code ESTC.EXX

Material 316L

32036-EN-110223

Mounting

bosses and adapters 7

Page 8

28 mm

(1.1")

ø 72,9 mm

(2.87")

ø 76,7 mm

(3,02")

ø 91 mm

(3,58")

2 W elde

d socket - universal

l (optional)

Sea

Material EPDM or FKM

Tension ring

Material 1.4301

Hygienic fi

tting LA

Fig. 9: Dimensions

316L

welded socket 3" PN16 (ø 91 mm) DIN 32676, ISO 2852/

2.3 Hygienic fittings

Welded socket LA for compression nut

Product code ESTA.LAXXX

Material 316L

Seal (optional)

Material EPDM

Welding dummy

Product code DMONT.A

Material 1.4305

Blind stopper

Product code DMONT.B1

Material 316Ti

32036-EN-110223

8 Mounting

bosses and adapters

Page 9

40 mm

(1.58")

ø 79,6 mm

(3.13")

Rd 65 x 1/6

40 mm

(1.58")

ø 79,6 mm

(3.13")

ø 72 mm

(2.84")

ø 90 mm

(1.54")

M6

2 W elde

d socket - universal

Hygieni

c fi

tting LB

Fig. 10: Dimensions

welded socket LA for compression nut

Welded socket LB for tension flange

Product code ESTA.LBXXX

Material 316L

Seal (optional)

Material EPDM

Welding dummy

Product code DMONT.C

Material 1.4305

Blind stopper

Product code DMONT.D

Material 316Ti

DRD connection

32036-EN-110223

Mounting

Fig. 11: Dimensions

Welded socket DRD

welded socket LB for tension flange

Product code ESTD.AAXX

Material 316L

bosses and adapters 9

Page 10

20 mm

(0.79")

ø 84 mm (3.31")

ø 66 mm (2.6")

ø 105 mm (4.13")

M10

ø 125 mm (4.92")

ø 50 mm (1.97")

Rd 52 x 1/6

25 mm

(0.98")

ø 75 mm

(2.95")

2 W elde

d socket - universal

l (optional)

Sea

Material PTFE

Cone connection DN 25

Cone connection M52 x 2

Fig. 12: Dimensions

welded socket DRD

Welded socket conus DN 25

Product code ESTK.KAXX

Material 316L

Seal (optional)

Material EPDM

Fig. 13: Dimensions

welded socket conus connection DN 25

Welded socket conus M52 x 2

Product code ESTK.KBXX

Material 316L

Seal (optional)

Material EPDM

32036-EN-110223

10 Mounting

bosses and adapters

Page 11

M52 x 2

25 mm

(0.98")

23 mm

(0.91")

ø 80 mm

(3.15")

29 mm

(1.14")

ø 26 mm

(1.02")

ø 31 mm

(1.22")

Rd 52 x 1/6

2 W elde

d socket - universal

Bolting DN 25

Bolting DN 40

Fig. 14: Dimensions

welded socket conus connection M52x2

2.4 Bolting acc. to DIN 11851

Welded socket, bolting DN 25 according to DIN 11851

Product code ESTR.DA1X

Material 316L

Seal (optional)

Material FKM, EPDM, NBR

Fig. 15: Dimensions

Welded socket, bolting DN 40 according to DIN 11851

Product code ESTR.FA1X

Material 316L

welded socket, bolting DN 25 according to DIN 11851

32036-EN-110223

Mounting

bosses and adapters 11

Seal (optional)

Material FKM, EPDM, NBR

Page 12

33 mm

(1.3")

ø 43 mm

(1.69")

ø 38 mm

(1.5")

Rd 65 x 1/6

Rd 78 x 1/6

35 mm

(1.38")

ø 50 mm

(1.97")

ø 55 mm

(2.17")

2 W elde

d socket - universal

Bolting DN 50

Bolting DN 80

Fig. 16: Dimensions

welded socket, bolting DN 40 according to DIN 11851

Welded socket, bolting DN 50 according to DIN 11851

Product code ESTR.GA1X

Material 316L

Seal (optional)

Material FKM, EPDM, NBR

Fig. 17: Dimensions

welded socket, bolting DN 50 according to DIN 11851

Welded socket, bolting DN 80 according to DIN 11851

Product code ESTR.IA1X

Material 316L

Seal (optional)

Material EPDM, NBR

12 Mounting

32036-EN-110223

bosses and adapters

Page 13

32 mm

(1.38")

ø 81 mm

(3.19")

ø 87 mm

(3.43")

RD 110 x 1/4

54 mm

(2.13")

ø 100 mm

(3.94")

ø 106 mm

(4.17")

Rd 130 x 1/4

2 W elde

d socket - universal

Bolting DN 100

Bolting DN 40

Fig. 18: Dimensions

welded socket, bolting DN 80 according to DIN 11851

Welded socket, bolting DN 100 according to DIN 11851

Product code ESTR.JA1X

Material 316L

Seal (optional)

Material EPDM

Fig. 19: Dimensions

welded socket, bolting DN 100 according to DIN 11851

2.5 Bolting acc. to DIN 11864-1

Welded socket DN 40 acc. to DIN 11864-1

Product code ESTR.FBXX

Material 316L

32036-EN-110223

Mounting

Seal (optional)

Material FKM, EPDM or NBR

bosses and adapters 13

Page 14

ø 38mm

(1

1

/

2

")

31mm

(1

7

/

32

")

ø 41mm

(1

39

/

64

")

Rd 65 x

1

/

6

ø 38 mm

(1.5")

26 mm

(1.02")

ø 43 mm

(1.69")

Rd 65 x 1/6

2 W elde

d socket - universal

Bolting DN 50

Fig. 20: Dimensions

welded socket DN 40 acc. to DIN 11864-1

Welded socket DN 50 acc. to DIN 11864-1

Product code ESTR.GBXX

Material 316L

Seal (optional)

Material FKM, EPDM or NBR

Fig. 21: Dimensions

welded socket DN 50 acc. to DIN 11864-1

32036-EN-110223

14 Mounting

bosses and adapters

Page 15

21 mm

(0.83")

G1/2

ø 50 mm

(1.97")

G1/2

21 mm

(0.83")

ø 30 mm

(1.18")

3 Welde

d socket - VEGABAR

ead G½ B

Thr

3 Welded

socket - VEGABAR

3.1 VEGABAR 17

Welded socket G½ B acc. to ISO 228-1 - vessel

Product code ESMBR17.86*IXTX

Material 316Ti

Fig. 22: Dimensions

Welded socket G½ B acc. to ISO 228-1 - pipeline

Product code ESMBR17.86*AXVX

Material 316Ti

welded socket G½ B acc. to ISO 228-1 - vessel

Thr

32036-EN-110223

Mounting

welded socket thread G½ B acc. to ISO 228-1 - pipeline

ead G1 B

Fig. 23: Dimensions

Welded socket G1 B acc. to ISO 228-1

Product code ESMBR17.85*IXTX

Material 316Ti

bosses and adapters 15

Page 16

21 mm

(0.83")

G 1

ø 30,1 mm

(1.19")

ø 50 mm

(1.97")

10,5 mm

(0.41")

25,5mm

(

1

")

12,5mm

(0.49")

G 1

ø 50mm

(1.97")

ø 29,3mm

(1.15")

3 W elde

d socket - VEGABAR

ead G1 hyg

Thr

Thr

ead G½ A

ienic

Fig. 24: Dimensions

welded socket G1 B acc. to ISO 228-1

Welded socket G1 aseptic

Product code ESMBR17.84*JXVX

Material 316L

Fig. 25: Dimensions

welded socket G1 aseptic

3.2 VEGABAR 52

Welded socket thread G½ A acc. to EN 837

Product code ESMBR52.GVBKVX

Material 316L

16 Mounting

32036-EN-110223

bosses and adapters

Page 17

21 mm

(0.83")

G 1 1/2

ø 50 mm

(1.97")

40 mm

(1.58")

G1

ø 50 mm

(1.97")

3 Welde

d socket - VEGABAR

ead G1 A

Thr

Thr

ead G½ B

Fig. 26: Dimensions

welded socket thread G½ A acc. to EN 837

Welded socket thread G1 A according to DIN ISO 228-1

Product code ESMBR52.GCBKVX

Material 316Ti

Fig. 27: Dimensions

welded socket thread G1 A according to DIN ISO 228-1

3.3 VEGABAR 53

Welded socket G½ B acc. to ISO 228-1 - vessel

Product code ESMBR53.GFIXTX

Material 316Ti

32036-EN-110223

Mounting

bosses and adapters 17

Page 18

21 mm

(0.83")

G1/2

ø 50 mm

(1.97")

G1/2

21 mm

(0.83")

ø 30 mm

(1.18")

21 mm

(0.83")

G 1

ø 30,1 mm

(1.19")

ø 50 mm

(1.97")

10,5 mm

(0.41")

3 W elde

d socket - VEGABAR

ead G1 B

Thr

Fig. 28: Dimensions

welded socket G½ B acc. to ISO 228-1 - vessel

Welded socket G½ B acc. to ISO 228-1 - pipeline

Product code ESMBR53.GFAXVX

Material 316Ti

Fig. 29: Dimensions

welded socket G½ B acc. to ISO 228-1 - pipeline

Welded socket G1 B acc. to ISO 228-1

Product code ESMBR53.GCIXTX

Material 316Ti

18 Mounting

Fig. 30: Dimensions

welded socket G1 B acc. to ISO 228-1

32036-EN-110223

bosses and adapters

Page 19

25,5mm

(

1

")

12,5mm

(0.49")

G 1

ø 50mm

(1.97")

ø 29,3mm

(1.15")

G1/2

ø 18,5mm

(

47

/

64

")

21mm

(

53

/

64

")

10,5mm

(

13

/

32

")

ø 30mm

(1

3

/

16

")

3 Welde

d socket - VEGABAR

ead G1 B hygienic

Thr

Thr

ead G½ A

d socket G1 B aseptic

Welde

Product code ESMBR53.GEJXVX

Material 316L

Fig. 31: Dimensions

welded socket G1 B aseptic

3.4 VEGABAR 54

Welded socket G½ A acc. to ISO 228-1

Product code ESMBR54.GBAXVX

Material 316L

Seal (optional)

Material Kalrez

Thread G¾ A

32036-EN-110223

Mounting

Fig. 32: Dimensions

welded socket G½ A acc. to ISO 228-1

Welded socket G¾ A acc. to DIN 3852-X

Product code ESMBR54.GAEXVX

Material 316L

bosses and adapters 19

Page 20

22,5 mm

(0.89")

ø 40 mm

(1.58")

G3/4

21mm

(

53

/

64

")

ø 47mm

(1

27

/

32

")

G

1

ø 40mm

(1

37

/

64

")

3 W elde

d socket - VEGABAR

l (optional)

Sea

Material Viton, EPDM, Kalrez

Thr

ead G1 A

M30 x 1.5

Fig. 33: Dimensions

welded socket G¾ A acc. to DIN 3852-X

Welded socket G1 A acc. to ISO 228-1

Product code ESMBR54.GCIXTX

Material 316Ti

Fig. 34: Dimensions

welded socket G1 A acc. to ISO 228-1

3.5 VEGABAR 52, 54 - Paper industry

Welded socket M30 x 1.5

Product code ESMBR54.BFGXVX

Material 316L

Seal (optional, mounting on pressure transmitter)

Material Viton

Welding dummy

20 Mounting

Product code DMONT.G

Material brass

32036-EN-110223

bosses and adapters

Page 21

stopper

M30x1,5

15mm

(0.59")

23mm

(0.91")

ø 40mm

(1.58")

ø 25mm

(0.98")

M30x1,5

15mm

(0.59")

23mm

(0.91")

ø 40mm

(1.58")

ø 25mm

(0.98")

Blind

Material 316Ti

3 Welde

d socket - VEGABAR

M30 x 1.5 for

headbox

Fig. 35: Dimensions

welded socket M30 x 1.5

Welded socket M30 x 1.5

Product code ESMBR54.BSGXVX

Material 316L

Seal (optional)

Material Viton

Welding dummy

Product code DMONT.G

Material brass

Blind stopper

Material 316Ti

32036-EN-110223

Mounting

Fig. 36: Dimensions

bosses and adapters 21

welded socket M30 x 1.5 for headbox

Page 22

21mm

(0.83")

ø 60mm

(2.36")

M44x1,25

3 W elde

M44 x 1.25

d socket - VEGABAR

d socket M44 x 1.25

Welde

Product code ESMBR**.B*MXVX

Material 316L

Welding dummy

Product code DMON T.F

Material brass

Blind stopper

Product code DMONT.H

Material 316Ti

M48 x 1.5

Fig. 37: Dimensions

Welded socket M48 x 1.5

welded socket M30 x 1.25

Product code ESMBR52.DGSXVX

Material 316L

22 Mounting

32036-EN-110223

bosses and adapters

Page 23

M 48 x 1,5

97 mm (3.82")

79 mm (3.11")

102 mm (4.02")

3 Welde

d socket - VEGABAR

G1" suitab

le for PASVE

Fig. 38: Dimensions

welded socket M48 x 1.5

Welded socket G1" suitable for PASVE

Product code ESMBR54.VPHXVX

Material 316L

Dummy

Product code DMONT.S

Material brass

Blind stopper

Product code DMONT.P

Material 316Ti

32036-EN-110223

Mounting

bosses and adapters 23

Page 24

ø 45 mm

(1.77")

G1

70 mm

(2.76")

38,5 mm

(1.52")

25 mm

(0.98")

ø 8 mm

(0.32")

17,6 mm

(0.69")

33,4 mm

(1.32")

26,7 mm

(1.05")

3 W elde

d socket - VEGABAR

PMC 1"

Fig. 39: Dimensions

welded socket G1" suitable for PASVE

Welded socket PMC 1"

Product code ESMBR54.PCDXVX

Material 316L

Fig. 40: Dimensions

welded socket PMC 1"

32036-EN-110223

24 Mounting

bosses and adapters

Page 25

26mm (1.02")

ø 53 mm

(2.09")

ø 32 mm

(1.26")

G 3

/4

29 mm

(1.14")

G 1

ø 60 mm

(2.36")

ø 39 mm

(1.54 ")

ded socket - Level switch

4 Wel

ead G¾ A

Thr

Thr

ead G1 A

4 Welded

socket - Level switch

4.1 VEGASWING 51, 61, 63

Welded socket G¾ A acc. to DIN 3852-X

Product code ESTSG.1GBX1

Material 316L

Seal

Material FKM, EPDM

Fig. 41: Dimensions

Welded socket G1 A acc. to DIN 3852-X

Product code ESTSG.1GAX1

Material 316L

welded socket G¾ A acc. to DIN 3852-X

32036-EN-110223

Mounting

Seal

Material FKM, EPDM

Fig. 42: Dimensions

bosses and adapters 25

welded socket G1 A acc. to DIN 3852-X

Page 26

21 mm

(0.83")

ø 47 mm

(1.85")

G 1

ø 40 mm

(1.58")

4 W elde

d socket - Level switch

4.2 VEGAKON

Thread G1 A

Welded socket G1 A acc. to DIN 3852-X

Product code ESTKN.1GA

Material 316Ti

Fig. 43: Dimensions

welded socket G1 A acc. to DIN 3852-X

26 Mounting

32036-EN-110223

bosses and adapters

Page 27

22,5 mm

(0.89 ")

G 3/4

ø 50,5 mm

(1.99")

ø 32 mm

(1.26")

5 A dapte

r

Clamp 1½"

5 Adapte

r

5.1 G¾ A on Clamp according to DIN 32676, ISO 2852

Adapter G¾ A according to DIN 3852-X on Clamp 1½" PN16

DIN 32676, ISO 2852/316L

Product code GEWADA-A.CG1

Material 316L

Seal (optional)

Material FKM, EPDM

Fig. 44: Dimensions

PN16 DIN 32676, ISO 2852/316L

adapter G¾ A according to DIN 3852-X on Clamp 1½"

Clamp 2"

32036-EN-110223

Mounting

Adapter G¾ A according to DIN 3852-X on Clamp 2" PN16 (ø

64 mm) DIN 32676, ISO 2852/316L

Product code GEWADA-A.CA1

Material 316L

Seal (optional)

Material FKM, EPDM

bosses and adapters 27

Page 28

22,5 mm

(0.89")

G 3/4

ø 64 mm

(2.52")

ø 32 mm

(1.26")

22,5 mm

(0.89")

G 3/4

ø 77,5 mm

(3.05")

ø 32 mm

(1.26")

5 A dapte

r

Clamp 2½"

Clamp 3"

Fig. 45: Dimensions

(ø 64 mm) DIN 32676, ISO 2852/316L

adapter G¾ A according to DIN 3852-X on Clamp 2" PN16

Adapter G¾ A according to DIN 3852-X on Clamp 2½" PN16 (ø

77.5 mm) DIN 32676, ISO 2852/316L

Product code GEWADA-A.CD1

Material 316L

Seal

Material FKM, EPDM

Fig. 46: Dimensions

PN16 (ø 77.5 mm) DIN 32676, ISO 2852/316L

adapter G¾ A according to DIN 3852-X on Clamp 2½"

Adapter G¾ A according to DIN 3852-X on Clamp 3" PN16 (ø

77.5 mm) DIN 32676, ISO 2852/316L

Product code GEWADA-A.CE1

Material 316L

Seal

Material FKM, EPDM

32036-EN-110223

28 Mounting

bosses and adapters

Page 29

22,5 mm

(0.89")

G 3/4

ø 91 mm

(3.58")

ø 32 mm

(1.26")

22,5 mm

(0.89")

G 3/4

ø 119 mm

(4.69")

ø 32 mm

(1.26")

5 A dapte

r

Clamp 4"

Fig. 47: Dimensions

(ø 91 mm) DIN 32676, ISO 2852/316L

adapter G ¾ A according to DIN 3852-X on Clamp 32" PN16

Adapter G¾ A according to DIN 3852-X on Clamp 4" PN16 (ø

119 mm) DIN 32676, ISO 2852/316L

Product code GEWADA-A.CC1

Material 316L

Seal

Material FKM, EPDM

Fig. 48: Dimensions

(ø 119 mm) DIN 32676, ISO 2852/316L

adapter G¾ A according to DIN 3852-X on Clamp 4" PN16

5.2 G1½ A on Clamp according to DIN 32676, ISO 2852

Clamp 3"

32036-EN-110223

Mounting

Adapter G1½ A according to DIN 3852-X on Clamp 3" PN16 (ø

77.5 mm) DIN 32676, ISO 2852/316L

Product code GEWADA-B.CE1

Material 316L

Seal

Material FKM, EPDM

bosses and adapters 29

Page 30

30 mm

(1

3

/

16

")

G 1 1/2

ø 55 mm

(2

11

/

64

")

ø 91 mm

(3

37

/

64

")

22,5 mm

(0.89")

G 3/4

ø 56 mm

(2.21")

ø 32 mm

(1.26")

5 A dapte

r

Bolting DN 40

Bolting DN 50

Fig. 49: Dimensions

adapter G 1½ A according to DIN 3852-X on Clamp 3" PN16

(ø 77.5 mm) DIN 32676, ISO 2852/316L

5.3 G1½ A on bolting acc. to DIN 11851

Adapter G1½ A acc. to DIN 3852-X on bolting DN 40 acc. to

DIN 11851

Product code GEWADA-A.RA1

Material 316L

Seal

Material FKM, EPDM

Fig. 50: Dimensions

DIN 11851

Adapter G1½ A acc. to DIN 3852-X on bolting DN 50 acc. to

DIN 11851

Product code GEWADA-A.RB1

Material 316L

adapter G1½ A acc. to DIN 3852-X on bolting DN 40 acc. to

32036-EN-110223

30 Mounting

bosses and adapters

Page 31

l

22,5 mm

(0.89 ")

G 3/4

ø 68,5 mm

(2.70")

ø 32 mm

(1.26")

22,5 mm

(0.89")

G 3/4

ø 86 mm

(3.39")

ø 32 mm

(1.26")

Sea

Material FKM, EPDM

5 A dapte

r

Bolting DN 65

Bolting DN 100

Fig. 51: Dimensions

DIN 11851

adapter G1½A acc. to DIN 3852-X on bolting DN 50 acc. to

Adapter G1½ A acc. to DIN 3852-X on bolting DN 65 acc. to

DIN 11851

Product code GEWADA-A.RC1

Material 316L

Seal

Material FKM, EPDM

Fig. 52: Dimensions

DIN 11851

adapter G1½ A acc. to DIN 3852-X on bolting DN 65 acc. to

Adapter G1½ A acc. to DIN 3852-X on bolting DN 100 acc. to

DIN 11851

Product code GEWADA-A.RD1

Material 316L

32036-EN-110223

Mounting

bosses and adapters 31

Page 32

22,5 mm

(0.89")

G 3/4

ø 121 mm

(4.76")

ø 32 mm

(1.26")

22,5 mm

(0.89")

G 3/4

ø 65,8 mm

(2.59")

ø 54 mm

(2.13")

5 A dapte

r

l

Sea

Material FKM, EPDM

Fig. 53: Dimensions

to DIN 11851

adapter G1½ A acc. to DIN 3852-X on bolting DN 100 acc.

5.4 G1½ A on further hygienic fittings

DRD connection

Tuc

henhagen DN 32

32 Mounting

Adapter G1½ A acc. to DIN 3852-X on DRD connection

Product code GEWADA-A.AA1

Material 316L

Seal

Material FKM, EPDM

Fig. 54: Dimensions

adapter G1½ A acc. to DIN 3852-X to DRD

Adapter G1½ A acc. to DIN 3852-X on Tuchenhagen DN 32

Product code GEWADA-A.TA3

Material 316L

Seal

Material EPDM

32036-EN-110223

bosses and adapters

Page 33

22,5 mm

(0.89")

G 3/4

ø 71 mm (2.8")

ø 84 mm (3.31")

ø 32 mm (1.26")

5 A dapte

r

Fig. 55: Dimensions

adapter G1½ A acc. to DIN 3852-X on Tuchenhagen DN 32

32036-EN-110223

Mounting

bosses and adapters 33

Page 34

1

3

2

6 W elding

instructions

rations

Prepa

Welding dummy

6 Welding

Information:

The following welding instructions are for information only. In general,

the relevant welding regulations must be noted. The AD leaflets must

also be noted when welding on pressure vessels.

When welding stainless steel, utmost cleanness is necessary. E.g. it is

not allowed to use rusty tools or screwed parts. Also make sure that no

mild steel is processed in the closer environment.

Use enought inert gase for tack-welding. Make sure that you use tackwelding and not spot-welding. For tack-welding and welding, the

protective gas pure argon must be used.

The suitable welding dummy must be used to avoid the distortion of

the welded socket.

instructions

Weldin

g procedure

34 Mounting

Fig. 56: Welding

1 Welded socket

2 Dummy

3 Pipeline or vessel wall

It is generally recommended to divide the weld joint into several

segments.

dummy

32036-EN-110223

bosses and adapters

Page 35

8

1

5

3

7

2

6

4

6 Wel

ding instructions

Pressure bearing

Fig. 57: Segmental

welding

After welding a segment, weld immediately the segment that lies

exactly opposite. Interrupt the welding process after welding two

segments until the weld joint cools or carefully cool the weld joint

yourself before you start welding again.

The pressure loading capacity depends on the quality of the welding

as well as the material of the welded socket. With threaded sockets,

the thread length must be used completely bearing.

32036-EN-110223

Mounting

bosses and adapters 35

Page 36

7 Suppl

ement

7 Supp

lement

7.1 Technical data

General data

Material 316L corresponds to 1.4404 or 1.4435, 316Ti corresponds to 1.4571.

Max. process temperature on the welded socket, depending on the seal

- FKM -20 … +120 °C (-4 … +248 °F)

- FFKM -20 … +120 °C (-4 … +248 °F)

- EPDM -40 … +120 °C (-40 … +248 °F)

- EPDM cleaning temperature max.

1 h

- NBR -20 … +105 °C (-4 … +221 °F)

-40 … +140 °C (-40 … +284 °F)

36 Mounting

32036-EN-110223

bosses and adapters

Page 37

7 Sup

plement

32036-EN-110223

Mounting

bosses and adapters 37

Page 38

7 Suppl

ement

38 Mounting

32036-EN-110223

bosses and adapters

Page 39

7 Sup

plement

32036-EN-110223

Mounting

bosses and adapters 39

Page 40

VEGA Grieshaber KG

ISO 9001

Am Hohenstein 113

77761 Schiltach

Germany

Phone +49 7836 50-0

Fax +49 7836 50-201

E-mail: info@de.vega.com

www.vega.com

Printing date:

statements concerning scope of delivery, application,

All

practical use and operating conditions of the sensors and

processing systems correspond to the information avail-

able at the time of printing.

© VEGA Grieshaber KG, Schiltach/Germany 2011

Subject to change without prior notice 32036-EN-110223

Loading...

Loading...