Page 1

8888

Operating Instruction

VEGADIS 371 Ex

16.85

VEGADIS 371 Ex

Page 2

Contents

Safety information ........................................................................................ 2

1 Product description

1.1 Function and configuration ................................................................. 3

1.2 Types and versions ............................................................................. 3

1.4 Dimensions ......................................................................................... 3

1.3 Approvals ............................................................................................ 3

1.5 Technical data ..................................................................................... 4

2 Mounting

2.1 Mounting instructions .......................................................................... 5

3 Electrical connection

3.1 Sensor connection .............................................................................. 6

3.2 Sensor connection Ex-area ................................................................ 7

3.3 Terminal coordination .......................................................................... 8

3.4 Ex-separating chamber ....................................................................... 8

4 Set-up

4.1 Indicating and adjustment elements ................................................... 9

4.2 Adjustment ........................................................................................ 11

4.3 Mounting of the relay modules .......................................................... 14

4.4 Reset ................................................................................................. 15

Contents

5 Diagnosis

5.1 Simulation ......................................................................................... 16

5.2 Fault signals ...................................................................................... 16

Safety information

The described module must only be installed and

operated as described in this operating instruction.

Please note that other action can cause damage for which

VEGA does not take responsibility.

2 VEGADIS 371 Ex

Page 3

Product description

1 Product description

1.1 Function and configuration

VEGADIS 371 Ex is a digital indicating instrument with

integral level switches and current output for panel,

surface or rail mounting with LC-display for digital and

quasianalogue demonstration.

Max. 4 relays in pairs can be used as relay modules.

The modules can be retrofitted. VEGADIS 371 Ex is

an indicating instrument and can hence not be

adjusted.

The indication is individually scalable between -9999

and 9999. The decimal point can be shifted. The

indicated unit can be chosen individually. You can add

a lable with the units to the cover.

Configuration

Any sensor can be connected to the meas. circuit of

VEGADIS 371 Ex delivering a standardized

4 … 20 mA-signal or a 0 … 10 V-signal.

1.2 Types and versions

VEGADIS 371

Digital indicating instrument with integral level switches

for front panel mounting or surface mounting.

VEGADIS 371 Ex

Digital indicating instrument with integral level switches

for front panel mounting or surface mounting with Exapproval.

1.3 Approvals

VEGADIS 371 Ex (appropriate apparatus) is available

with the following approval:

Explosion protection

- Classification

II 1G [EEx ia] IIC EC-type approval

TÜV 97 ATEX 1174,

-

Conformity certificate

PTB no. Ex-97.D.2073 X.

For these applications note the appropriate legal

documents (EC-type approval and conformity

certificate). These are supplied with the instrument.

VEGADIS 371 EX

Ex-relevant technical data are stated in the following

attached documents:

EC-type approval TÜV 97 ATEX 1174

Conformity certificate PTB no. Ex-97.D.2073 X

CE-conformity

VEGADIS 371 Ex meets the protective regulations of

EMVG (89/336/EWG) and NSR (72/23/EWG). The

conformity has been judged acc. to the following

standards:

EMVG Emission EN 50 081 - 1:

1992

Susceptibility EN 50 082 - 2: 1995

NSR EN 60 010 - 1: 1993

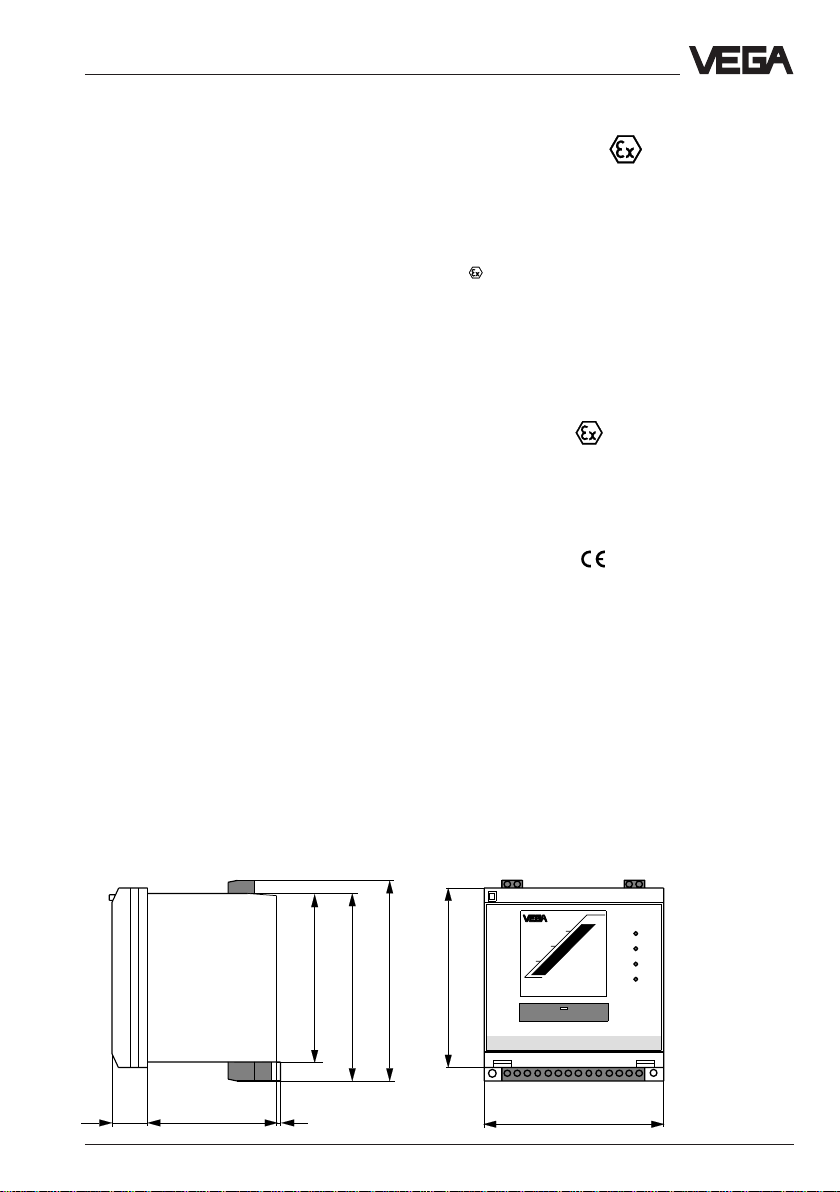

1.4 Dimensions

92

102

19

VEGADIS 371 Ex 3

69

2

109

96

16.85

VEGADIS 371 EX

96

Page 4

1.5 Technical data

General

Series instrument for front panel or wall mounting or

Dimensions W = 96 mm, H = 104 mm, D = 90 mm

Weight approx. 400 g

Housing material plastic ABS/POM

Cross section area of conductor max. 2,5 mm

Ambient conditions

Permissible ambient temperature -20°C … +60°C

Storage and transport temperature -40°C … +85°C

Temperature error 0,01 %/K

Electrical protective measures

Protection class II

Overvoltage category II

Protection

- wall or carrier rail mounting IP 20

- front panel mounting IP 40

V oltage supply

Supply voltage 20 … 250 V AC/DC

Power consumption 4 W, 12,5 VA

Sensor input (floating)

Transmission analogue

Connection line to the sensor 2-wire

I

active

- sensor supply 25 … 15 V (range 4 ... 20 mA)

- shortcircuit limitation approx. 30 mA

I

passive

- inner resistance < 250 Ω (range 4 ... 20 mA)

U

- inner resistance > 100 kΩ (range 0 ... 10 V)

Current output 0/4 … 20 mA (signal circuit, floating)

Resolution 0,1 % (range 0/4 ... 20 mA)

max. load 500 Ω

Fault signal approx. 22 mA

Linearity error 0,1 %

Relay output

Number of relays 4 (2 modules with 2 relays each)

Turn-on voltage min. 10 mV

Switching current min. 10 μA

Breaking capacity max. 54 W DC, 500 VA AC

Indication of switching condition LED lights - relay energized

Digital indication

Zero point (4 mA or 0 V) -9999 … 9999

Final point (20 mA or 10 V) -9999 … 9999

Decimal point individually selectable

mounting on rail 35 x 7,5

2

max. 250 V AC, 250 V DC

max. 3 A AC, 1 A DC

LED off - relay deenergized

Product description

4 VEGADIS 371 Ex

Page 5

Mounting

2 Mounting

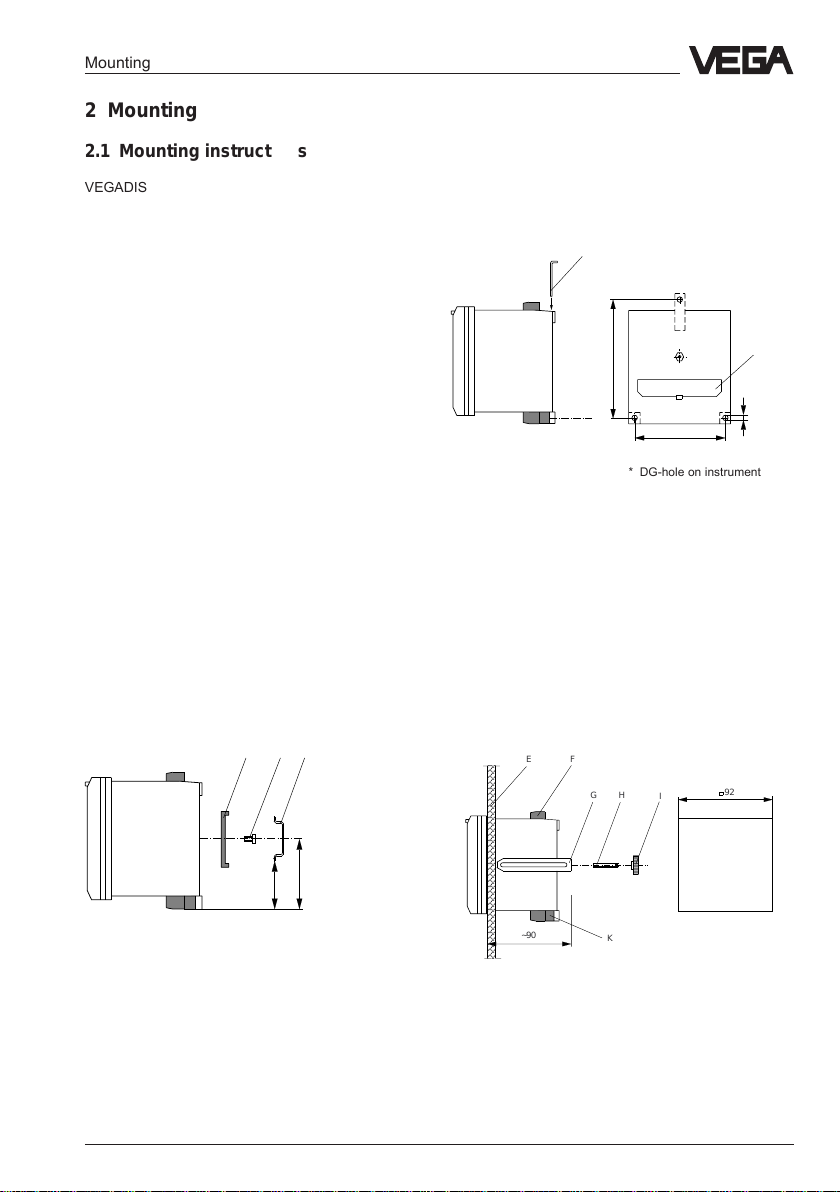

2.1 Mounting instructions

VEGADIS 371Ex indicating instrument can be either

mounted directly to the wall with three screws, plugged

on carrier rail 35 x 7,5 acc. to DIN EN 50 022 or

lowered into a front panel. VEGADIS 371Ex must be

generally mounted outside hazardous areas.

Before mounting VEGADIS 371 you should adjust the

requested sensor signal (Ia, Ip, U). The slide switch on

the rear of VEGADIS 371 under the cover is no more

accessible after mounting the instrument.

Dependent on the application and the sensor you can

choose between active current measurement (Ia),

passive current measurement (Ip) or voltage

measurement (U). Factory setting "Ia“ see also

"4.2 Adjustment“. The position of the switch also

modifies the application conditions for Ex-instruments

(VEGADIS 371Ex). Note the type approval or the

conformity certificate of VEGADIS 371Ex.

Carrier rail mounting

• Place the adapter plate (A) to the rear of VEGADIS

371 (spring of the adapter plate to the bottom) and

tighten the plate with screw B (M4 x 6).

• Place VEGADIS 371 from the bottom to the carrier

rail (C) and push the instrument to the top until

snap-in.

Wall mounting

• Insert the metal sleeve (D) from top into the housing

cut-out.

• Fasten the instrument with three screws (ø max.

4 mm) directly to the wall.

D

105

80

* DG-hole on instrument

Cover

Ø4,5*

Front panel mounting

• Remove the two pluggable terminal boards (F) and

the terminal board (K) to the top.

• Screw the pin (H) to the rear of VEGADIS 371 and

tighten with a screwdriver.

• Insert VEGADIS 371 from the front into the front

panel (E).

• Push the terminal strap (G) from the back to the pin

(H) and pull with the knurled nut (I) against the front

panel (E).

BC

A

61

43,5

EF

~90

H

G

I

K

92

Front panel

cut-out

VEGADIS 371 Ex 5

Page 6

3 Electrical connection

3.1 Sensor connection

Note

Switch off the voltage supply before starting

connection work.

Electrical connection

Active operation (Ia)

+-

Voltage

supply

Passive operation (Ip)

+-

1)

4 ... 20 mA

Sensor

1)

4 ... 20 mA

+

output

-

Sensor

Signal conditioning

instrument

VEGAMET

Voltage

supply

1) Active or passive operation selectable with slide switch.

See “4.1 Indicating and adjustment elements“

6 VEGADIS 371 Ex

Page 7

Electrical connection

3.2 Sensor connection Ex-area

Note:

When using VEGADIS 371 the connection of an iasafety barrier type 145 is not possible. For the use on

sensors in hazardous areas, use VEGADIS 371 Ex.

VEGADIS 371 Ex must be generally mounted outside

hazardous areas.

Active operation (Ia)

Signal and supply circuit

(sensor is powered, 4 … 20

mA)

+-

Voltage

supply

Passive operation (Ip)

Active intrinsically safe signal circuit

4 ... 20 mA

+-

1)

Ex-area

4 ... 20 mA

Intrinsically safe,

passive sensor, e.g.

pressure transmitter

1)

Ex-area

VEGAPULS 81 E Ex

4 ... 20 mA

+

output

-

Voltage

supply

Voltage

supply

1) Active or passive operation selectable with slide switch.

See “4.1 Indicating and adjustment elements“

VEGADIS 371 Ex 7

Page 8

Electrical connection

3.3 Terminal coordination

Meas. data input

-

+

2

1

16.85

18171615 141312 11 10 9 876 5

Relay

Rel.

4

Relay

module 2

Relay

2

Relay

module 1

Relay

1

3

Current output

-

+

4

3

N- L1+

Voltage

supply

3.4 Ex-separating chamber

When several instruments are mounted in a row, the

blue Ex-separating chamber must be plugged to the

terminals of the sensor input (terminals 1 and 2) on

VEGADIS 371 Ex, to ensure the required distance

(50 mm).

• Place the Ex-separating chamber acc. to the figure

to the terminals of the sensor input (terminals 1 and

2) and loop the sensor line to the front out of the Exseparating chamber.

• Push the Ex-separating chamber to the front until

snap-in.

When switching on voltage supply, the software

version of VEGADIS 371 is displayed for approx.

4 seconds.

Tipp:

For parameter adjustment of connected HART

sensors, sockets are integrated in the terminals of the

meas. data input. A VEGACONNECT can be

connected directly to these sockets without an additional HART resistor being necessary.

8 VEGADIS 371 Ex

Page 9

Set-up

4 Set-up

4.1 Indicating and adjustment elements

8

7

1

6

5

1 Slide switch

2 Relay control lamps (1 … 4)

3 Plus key

4 Minus key

5 Cover

6 Shackle

7 Rotating switch

8 Digital indication

2

3

Fig. 4.1

4

The figures in brackets relate to the information in

figure 4.1.

To open the cover (5), insert a screwdriver into the two

slots marked with arrows.

Turn the screwdriver by a quarter turn and the cover

(5) opens.

To protect the instrument against unauthorized

adjustment, the cover (5) of VEGADIS 371 can be

sealed. Insert the seal wire with closed cover in the top

left corner through the hole of the lug.

Designation:

In practise it has proven to mark VEGADIS. Information on the appropriate measurement loop and the unit

of the indicated value help to avoid failures and

misunderstandings. On the housing a shackle (6) is

provided for designation. Here you can insert one of

the supplied labels.

VEGADIS 371 Ex 9

Page 10

Set-up

Rotating switch (7)

Stage 1

In menu stage 1 you find all necessary functions which

are necessary for adjustment of the indicating

instrument. When you are in menu stage 1, the

"VEGA“-logo is shown non-flashing.

Note

When you want to activate the pump changeover

function, all relay outputs you want to coordinate to the

pump changeover function must have the same

function. When relay 1 e.g. switches on when the

adjusted max. value is reached, all following relays

must have the same adjustment.

0 - OPERATE = Indication measured value

1 - Relay 1 on = Relay 1 on

2 - Relay 1 off = Relay 1 off

3 - Relay 2 on = Relay 2 on

4 - Relay 2 off = Relay 2 off

5 - Relay 3 on = Relay 3 on

6 - Relay 3 off = Relay 3 off

7 - Relay 4 on = Relay 4 on

8 - Relay 4 off = Relay 4 off

9-t

i

A - Out 0 … 20 mA,

Out 4 … 20 mA = Current output

B - Display min = Scaled indication at 0 %

C - Display max = Scaled indication at 100 %

D - Decimal point = Decimal point

E - Offset correction = Offset correction

F - Simulation = Simulation

Stage 2

In menu stage 2 you find the functions which are

necessary for adjustment of the pump changeover

function.

In rotating switch position 0 (Operate) you have to

push the plus and minus key together for approx. 3

seconds to change to menu stage 2 (pump

changeover function). When you are in menu stage 2,

the "VEGA“-logo flashes on the display. Push again

both keys to return to menu stage 1. After approx. 10

minutes the indication changes automatically to menu

stage 1.

= Integration time

With the rotating switch (16 steps) you choose the

appropriate function.

0 - OPERATE = Indication of meas. value

1 = Pump changeover function Relay 1 on/off

2 = Operating time indication Rel 1

3 = Pump changeover function Relay 2 on/off

4 = Operating time indication Rel 2

5 = Pump changeover function Relay 3 on/off

6 = Operating time indication Rel 3

7 = Pump changeover function Relay 4 on/off

8 = Operating time indication Rel 4

9 = ---- (not coordinated)

A = ---- (not coordinated)

B = ---- (not coordinated)

C = ---- (not coordinated)

D = ---- (not coordinated)

E = ---- (not coordinated)

F = ---- (not coordinated)

Plus/Minus keys (3 and 4)

With these keys you modify the value of the digital

indication. When you keep the key pushed, the digital

indication changes its value with raising speed.

Slide switch (1)

With the slide switch on the rear of the instrument you

can changeover between voltage measurement, active

sensor input and passive sensor input.

Ia - Active operation: The sensor is powered by

VEGADIS 371. Sensors connected in this

configuration are called passive sensors.

VEGADIS 371 reacts like a current source.

Ip - Passive operation: VEGADIS 371 is connected to

the sensor line (current input 4 … 20 mA). Sensors connected in this configuration are called

active sensors. VEGADIS 371 reacts like a

current sink.

U - VEGADIS measures the voltage 0 … 10 V

Note

The position of the switch changes also the application

conditions for Ex-instruments (VEGADIS 371 Ex).

Also note the type approval or the conformity

certificate of VEGADIS 371 Ex.

10 VEGADIS 371 Ex

Page 11

Set-up

4.2 Adjustment

Stage 1

When switching on the voltage supply, the LED of the

relays shortterm light and the display indicates for

approx. 4 seconds the software version of VEGADIS

371.

The figures in brackets relate to the figure under 4.1

Indicating and adjustment elements.

Course

• Choose the requested mode with the rotating switch

(7).

• Push one of the two keys (3 or 4). The digital

indication (8) begins to flash.

• Push one of the two keys to change the value of the

digital indication appropriately. When the rotating

switch (7) is set to "OPERATE“, the keys (3 and 4)

are without function.

• You can save the adjusted value by changing the

position of the rotating switch (7).

Example

- an upright cylindrical (linear) tank with a content of

2700 l.

- the max. volume is 2650 l, the min. volume 50 l.

- the level sensor in the vessel is a pressure

transmitter (passive), providing a standardized

4 … 20 mA-signal.

- for further processing you need an additional

4 … 20 mA-output signal.

- the full and empty adjustment had been carried out

correctly. The sensor delivers the following values:

Max. volume (display max.)

20 mA = 2650 l

Min. volume (display min.)

4 mA = 50 l

- relay 1 should switch on an emptying pump at a

volume of 90 % and switch off the pump at a volume

of 10 %.

First choose the parameters of your application:

Slide switch

• loosen the cover on the rear of VEGADIS 371 with a

screwdriver. Under this cover there is a slide switch

(1) by which you can adjust the kind of input:

I

= active current input (Ia)

active

I

= passive current input (Ip)

passive

U = voltage measurement (U)

For the given example choose Ia (active current

input).

Current output

• Set the rotating switch (7) to position A. With the

keys (3 and 4) you can choose between measured

value output 4 … 20 mA or 0 … 20 mA.

For the given example choose 4 - 20.

The display indications have the following meaning:

0 - 20 = 0 … 20 mA; 4 - 20 = 4 … 20 mA

VEGADIS 371 requires for the scaling of the indication

the adjustment of the volumes for 4 mA and 20 mA.

The vessel must not be filled or emptied. Proceed as

follows to adjust the two values:

Decimal point

VEGADIS 371 requires for this example the

adjustment of the values for 4 mA and 20 mA (0 % and

100 %). As the range of the example tank is from 50 l

to 2650 l, you require all four positions of the digital

indication.

• Set the rotating switch (7) to position D (Decimal

Point).

• By pushing the keys (3 and 4) you move the

decimal point.

Scaled indication at 0 %

• Set the rotating switch (7) to position B (Display

min.).

• Push the plus key (3) to increase the indicating

value or the min. key (4) to reduce the indicating

value (0,1 %-steps).

• When you keep the key pushed, the digital

indication (8) changes the indicating value quicker.

For the given example adjust the digital indication

(8) to the value 50.

Scaled indication at 100 %

• Set the rotating switch (7) to position C (Display

max.).

• Push the plus key (3) to increase the indicating

value or the minus key (4) to reduce the indicating

value (0,1 %-steps).

• For the given example set the digital indication (8) to

the value 2650.

Relay

• Set the rotating switch (7) to position 1 (relay 1 on).

When the selected relay is not mounted, four

dashes appear on the digital indication. With the

keys (3 and 4) you can modify the value of the

indication. For the given example set the digital

indication (8) to the value 90,0 (90,0 %). Hence the

internal relay 1 switches on when this value is

reached.

VEGADIS 371 Ex 11

Page 12

• Set the rotating switch (7) to position 2 (relay 1 off).

With the keys (3 and 4) you can change the value of

the indication. For the given example you set the

digital indication (8) to the value 10,0 (10,0 %).

Hence the internal relay 1 switches off when this

value is decreased. The appropriate relay control

lamp (2) lights when the relay is energized. When

the switch points are too close together (< 0,1 %),

the appropriate LED flashes. The relay takes the

safe condition. In mode "Operate“ a fault signal is

displayed.

• When you want to control further relays, proceed in

the same way than for relay 1.

The positions for adjustment of the appropriate

relays are stated in the list of the rotating switch (7)

under 4.1 Indicating and adjustment elements.

Mode A

Set-up

Level

Mode A (B)

off (on)

on (off)

t

LED

Relay on

Relay off

Note

When you want to change the mode (i.e. the switching

function of the relays) you have to exchange the on

and off-values (see fig. 4.2)

• Mode A (overfill protection)

switch on point < switch off point

To adjust e.g. for relay 1 mode A (overfill protection)

you have to enter with position 1 (relay 1 on) of the

rotating switch (7) the lower value and with position

2 (relay 1 off) the higher value. Hence relay 1 is

switched off when the max. level is reached

(deenergized condition) and switched on when min.

level is reached.

• Mode B (dry run protection)

switch on point > switch off point

When you want to adjust mode B (dry run

protection) for relay 1, you have to enter with

position 1 (relay 1 on) of the rotating switch (7) the

higher value and with position 2 (relay 1 off) the

lower value. Hence relay 1 is switched on when

Mode B

Relay on

Relay off

Fig. 4.2

max. level is reached and switch off (deenergized

condition) when min. level is reached.

Integration time

• When you want to adjust an integration time

(reaction delay), set the rotating switch (7) to

position 9.

• With the keys (3 and 4) you can change the value of

the indication (0 up to 250 seconds).

Offset correction

As a factory setting, pressure transmitters are adjusted

in a certain position. When the transmitter is

mounted in another position, the measuring range is

shifted.

• Ensure that the sensor is unpressurized.

• To carry out an offset correction, set the rotating

switch (7) to position E (Offset correction). The

display now indicates the actual sensor current in

mA or the voltage in V.

• Push the plus and minus key (3 and 4) together.

The measuring range is not modified, but

completely shifted.

• Set the rotating switch (7) to position 0 (OPERATE).

All adjusted values are transferred to an EEPROMmemory and saved. They remain there even in case

of a probable voltage loss.

12 VEGADIS 371 Ex

Page 13

Set-up

Stage 2

Activation of the pump changeover function

It is the task of a pump changeover function, in case of

several pumps with the same function, to switch on the

pump with the shortest working time and to switch off

the pump with the longest working time.

This avoids overstress of the pumps and the lifetime of

the pumps is increased considerably. This increases

the reliability of the complete system and avoids

failures.

This means that all relays where a pump changeover

function is activated, are no more fixed coordinated to

a certain switch point but are switched on or off

dependent on the working time. VEGADIS 371 Ex

selects for switch on the relay with the shortest

working time and for switch off the relay with the

longest working time.

Example (see fig. 4.3)

Two emptying pumps should empty a vessel when a

certain level is reached. The first pump should switch

on at 80 % filling.

When the level increases, a second pump should be

switched on at 90 %.

Both pumps should be switched off again at 10 %

filling.

€ Enter the values of the concerned relays in stage 1

as follows:

1 Relay 1 on = 80,0

2 Relay 1 off = 10,0

3 Relay 2 on = 90,0

4 Relay 2 off = 10,0

€ Set the rotating switch to position 0

(Operate).

€ Change to the menu stage 2, where you push the

plus and the minus key together for approx. 3

seconds. The "VEGA“-logo flashes on the display.

€ Set the rotating switch to position 1 (pump

changeover function relay 1)

€ Set the indication with one of the two keys to "on“.

€ Set the rotating switch to position 3 (pump

changeover function relay 2)

€ Set the indication with one of the two keys to "on“.

€ Set the rotating switch to position 0

(Operate) and push the plus and minus key together

for approx. 3 seconds. The "VEGA“-logo no more

flashes. The pump changeover function is now

Level

Füllhöhe

On2

90%

On1

80%

Off1

0%

Off2

On

Relay 1

Off

On

Relay 2

Off

10 30 20 20 5 15

t [h]

Fig. 4.3

VEGADIS 371 Ex 13

Page 14

Set-up

Indication of the working times

When the pump changeover function of a relay is

activated, the working times can be enquired (positions

of the rotating switch 2, 4, 6, 8)

The working times of the relays which are coordinated

to the pump changeover function are saved every 8

hours in the EEPROM, i.e. the data saved last remain

even in case of power failure.

The working time is indicated in hours. The max.

indication is 9999 hours (over 1 year). If this value is

exceeded, the working time indication starts again at

0.

When you deactivate the pump changeover function of

a relay, the working time indication is set to 0 and

switched off.

When you carry out a reset, the pump changeover

function for all relays is deactivated and the working

time indication of all relays is reset to 0.

You can add or remove each relay individually to/from

the pump changeover function. Any combination is

possible.

The coordinated relays must all be operated in the

same mode (A/B):

Mode A (overfill protection)

Switch on point < Switch off point

Switch on relay:

The relay with the shortest working time

switches on.

Switch off relay :

The relay with the longest working time

switches off.

Mode B (dry run protection)

Switch on point > Switch off point

Switch on relay:

The relay with the shortest working time

switches on.

Switch off relay:

The relay with the longest working time

switches off.

realised for both pumps (relay 1 and 2).

4.3 Mounting of the relay modules

Up to 2 relay modules with 2 output relays each can be

mounted in VEGADIS 371. The mounting should be

made by skilled staff. Ex-approved instruments must

not be modified afterwards. When you want to retrofit

VEGADIS 371 Ex, send the instrument to VEGA. With

two relay modules totally 4 output relays are available.

• Switch off voltage supply.

• Loosen the front of the housing of VEGADIS 371

with a coin or a screwdriver. On the lower side of

the housing there is a slot.

• Remove the front of the housing. You do not have to

loosen the connection cable of the digital indication

to mount the relay modules.

• Plug the first relay module carefully to module 1.

Note that the pins are not bent (see fig. 4.4).

• Fasten the relay module with a small screwdriver.

• A sticker is attached to the relay where the terminal

coordination is visible. Place this sticker to the

instrument housing in front of the appropriate

terminals.

• Connect the terminals of the relays.

• Switch the supply voltage on.

• Adjust the switch points so that you can use the

Note

The cover is lockable to protect the instrument against

unauthorized adjustment.

Fig. 4.4

14 VEGADIS 371 Ex

Page 15

Set-up

relay module (see "4.2 Adjustment“).

4.4 Reset

You can carry out a reset on VEGADIS 371. Hence all

adjusted values are reset to the original factory setting.

• Interrupt the supply voltage of VEGADIS 371.

• Push the plus and minus key (3 and 4) together and

hold the two keys pushed. Switch on the supply

voltage. The display indicates "-RES-“. The

instrument carries out a reset.

VEGADIS 371 has the following fatory setting (ResetDefault values).

Factory setting

Menu stage 1

- Relay switch on points (10,0 %)

- Relay switch off points (100,0 %)

- Display min. (0)

- Display max. (100)

- Decimal point (1. position)

- Integration time (0 s)

- Offset correction (0 μA)

- Current output (4 … 20 mA)

Menu stage 2

- Pump changeover function (OFF)

- Working time indication (0 hours)

VEGADIS 371 Ex 15

Page 16

Diagnosis

5 Diagnosis

5.1 Simulation

The figures in brackets relate to the figures under "4.1 Indicating and adjustment elements“.

• Set the rotating switch (7) to position F "Simulation“. The actual measured value is taken over and flashes. The

simulation is immediately active. Level changes are not indicated during simulation.

• With the keys (3 and 4) you can modify the value of the indication. You can adjust any requested value within

the scaled range and hence test also the function of the current output and the mounted output relays.

• After the simulation is finished, you have to set the rotating switch (7) again to position 0 “OPERATE“. Hence

the simulation is interrupted and the actual measured value is indicated again.

5.2 Fault signals

The following fault signals can be indicated on the display:

Fault signal/Failure Removal/Measure

E003 Failure during selfcheck Relays deenergize (safe condition), current output 22 mA.

E014 Shortcircuit Relays deenergize (safe condition), current output: 22 mA.

E015 Line break Relays deenergize (safe condition), current output: 22 mA.

E017 Relay switch points The LED of the concerned relay flash.

Difference too small The concerned relay deenergizes (safe condition).

E021 Indication scaling Repeat the adjustment "4.2 Adjustment“.

Difference too small Increase the difference between the two indication values.

E116 Pumps in different The LED of the concerned relay flashes.

mode The concerned relay deenergizes (safe condition).

Carry out a reset (see 4.4 Reset). Hence all adjusted values are reset to

factory setting.

When the failure occurs again, send the instrument to our repair

department.

Sensor current > 21 mA.

Check the terminals and the connection line to the sensor.

Sensor current < 3,6 mA.

Check the terminals and the connection line to the sensor.

Probably no sensor connected.

Repeat the adjustment "4.2 Adjustment“.

Increase the difference between the two relay switch points.

Change to menu stage 1.

Check the switching function of relay 1.

Set all relays which are used for pump changeover function to the same

switching function like relay 1 or deactivate the pump changeover

function for these relays.

16 VEGADIS 371 Ex

Page 17

Notes

VEGADIS 371 Ex 17

Page 18

Notes

18 VEGADIS 371 Ex

Page 19

Notes

VEGADIS 371 Ex 19

Page 20

VEGA Grieshaber KG

Am Hohenstein 113

D-77761 Schiltach

Phone (0 78 36) 50 - 0

Fax (0 78 36) 50 - 201

e-mail info@de.vega.com

ISO 9001

The statements on types, application, use and operating conditions of the

sensors and processing systems correspond to the actual knowledge at the

date of printing.

Technical data subject to alteration

19893-EN-060426

Loading...

Loading...