U-line U3024RINT00B User Manual

USER GUIDE & SERVICE MANUAL

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

RIGHT PRODUCT. RIGHT PLACE. RIGHT TEMPERATURE. SINCE 1962.

Modular 3000 Series • 3024R • 24" Solid Door Refrigerator

USER GUIDE

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

Contents

Intro |

|

|

Service |

Safety |

Troubleshooting |

Safety and Warning |

Warranty |

Disposal and Recycling |

|

|

Service Extended |

Installation |

Wire Diagram |

Environmental Requirements |

Product Liability |

Electrical |

Warranty Claims |

Cutout Dimensions |

Parts |

Product Dimensions |

Ordering Replacement Parts |

Side by Side Installation |

System Diagnosis Guide |

Anti-Tip Bracket |

Compressor Specifications |

General Installation |

Troubleshooting Extended |

Integrated Grille / Plinth Dimensions |

Control Quick Guide |

Grille / Plinth Installation |

Thermistor |

Door Swing |

Defrost |

Door Stop |

Remove Fan and Cover |

Door Adjust |

|

Operating Instructions |

|

First Use |

|

Control Operation |

|

Sabbath Mode |

|

Airflow and Product Loading |

|

Refrigerator Bins / Crisper |

|

Maintenance |

|

Cleaning |

|

Cleaning Condenser |

|

Extended Non-Use |

|

|

|

USER GUIDE

u-line.com

WELCOME TO U-LINE

Congratulations on your U-Line purchase. Your product comes from a company with over five decades of premium modular ice making, refrigeration, and wine preservation experience. U-Line continues to be the American leader, delivering versatility and flexibility for multiple applications including residential, light commercial, outdoor and marine use. U-Line’s complete product collection includes Wine Captain® Models, Beverage Centers, Clear Ice Machines, Crescent Ice Makers, Glass & Solid Door Refrigerators, Drawer Models, Freezers, Combo® Models, and more.

U-Line has captivated those with an appreciation for the finer things with exceptional functionality, style, inspired innovations and attention to even the smallest details. We are known and respected for our unwavering dedication to product design, quality and selection. U-Line is headquartered in Milwaukee, Wisconsin and has shipped product to five continents for over two decades and is proud to have the opportunity to ship to you.

PRODUCT INFORMATION

Looking for additional information on your product? User Guides, Spec Sheets, CAD Drawings, Compliance Documentation, and Product Warranty information are all available for reference and download at u-line.com.

PROPERTY DAMAGE / INJURY CONCERNS

In the unlikely event property damage or personal injury is suspected related to a U-Line product, please take the following steps:

1.U-Line Customer Care must be contacted immediately at +1.800.779.2547.

2.Service or repairs performed on the unit without prior written approval from U-Line is not permitted. If the unit has been altered or repaired in the field without prior written approval from U-Line, claims will not be eligible.

GENERAL INQUIRIES

U-Line Corporation

8900 N. 55th Street

Milwaukee, Wisconsin 53223 USA Monday - Friday 8:00 am to 4:30 pm CST T: +1.414.354.0300

F: +1.414.354.7905 Email: sales@u-line.com u-line.com

CONNECT WITH US

SERVICE & PARTS ASSISTANCE

Monday - Friday 8:00 am to 4:30 pm CST T: +1.800.779.2547

F: +1.414.354.5696

Service Email: onlineservice@u-line.com Parts Email: onlineparts@u-line.com

Designed, engineered and assembled in WI, USA

Introduction 1

USER GUIDE

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

Safety and Warning

NOTICE

Please read all instructions before installing, operating, or servicing the appliance.

Use this appliance for its intended purpose only and follow these general precautions with those listed throughout this guide:

SAFETY ALERT DEFINITIONS

Throughout this guide are safety items labeled with a Danger, Warning or Caution based on the risk type:

! DANGER

Danger means that failure to follow this safety statement will result in severe personal injury or death.

! DANGER

This unit contains R600a (Isobutane) which is a flammable hydrocarbon. It is safe for regular use. Do not use sharp objects to expedite defrosting. Do not service without consulting the “R600a specifications” section included in the User Guide. Do not damage the refrigerant circuit.

! WARNING

Service must be done by factory authorized service personnel. Any parts shall be replaced with like components. Failure to comply could increase the risk of possible ignition due to incorrect parts or improper service.

! WARNING

Warning means that failure to follow this safety statement could result in serious personal injury or death.

! CAUTION

Caution means that failure to follow this safety statement may result in minor or moderate personal injury, property or equipment damage.

Safety and Warning 1

USER GUIDE

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

Disposal and Recycling

! DANGER

RISK OF CHILD ENTRAPMENT. Before you throw away your old refrigerator or freezer, take off the doors and leave shelves in place so children may not easily climb inside.

If the unit is being removed from service for disposal, check and obey all federal, state and local regulations regarding the disposal and recycling of refrigeration appliances, and follow these steps completely:

1.Remove all consumable contents from the unit.

2.Unplug the electrical cord from its socket.

3.Remove the door(s)/drawer(s).

Disposal and Recycling 1

USER GUIDE

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

Environmental Requirements

This model is intended for indoor/interior applications only and is not to be used in installations that are open/ exposed to natural elements.

This unit is designed to operate between 50°F (10°C) and 100°F (38°C). Higher ambient temperatures may reduce the unit’s ability to reach low temperatures and/or reduce ice production on applicable models.

For best performance, keep the unit out of direct sunlight and away from heat generating equipment.

In climates where high humidity and dew points are present, condensation may appear on outside surfaces. This is considered normal. The condensation will evaporate when the humidity drops.

! CAUTION

Damages caused by ambient temperatures of 40°F (4°C) or below are not covered by the warranty.

Environmental Requirements 1

USER GUIDE

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

Electrical

! WARNING

SHOCK HAZARD — Electrical Grounding Required. Never attempt to repair or perform maintenance on the unit until the electricity has been disconnected.

Never remove the round grounding prong from the plug and never use a two-prong grounding adapter.

Altering, cutting or removing power cord, removing power plug, or direct wiring can cause serious injury, fire, loss of property and/or life, and will void the warranty.

Never use an extension cord to connect power to the unit.

Always keep your working area dry.

NOTICE

Electrical installation must observe all state and local codes. This unit requires connection to a grounded (three-prong), polarized receptacle that has been placed by a qualified electrician.

The unit requires a grounded and polarized 115 VAC,

60 Hz, 15A power supply (normal household current). An individual, properly grounded branch circuit or circuit breaker is recommended. A GFCI (ground fault circuit interrupter) is usually not required for fixed location appliances and is not recommended for your unit because it could be prone to nuisance tripping. However, be sure to consult your local codes.

See CUTOUT DIMENSIONS for recommended receptacle location.

Electrical 1

USER GUIDE

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

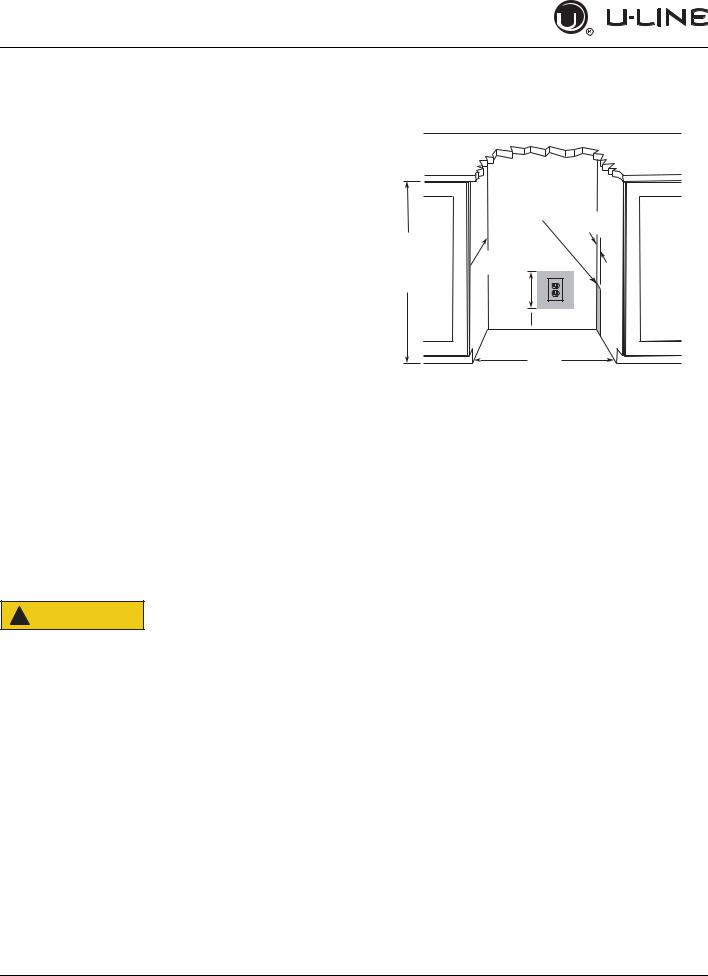

Cutout Dimensions |

CUTOUT DIMENSIONS |

PREPARE SITE |

|

Your U-Line product has been designed exclusively for a built-in installation. When built-in, your unit does not require additional air space for top, sides, or rear. However, the front grille must NOT be obstructed.

The product is designed and manufactured for seamless integration in the specified cutout opening shown, which requires precise measurements. The opening must be square and plumb front to back. Although not required, you may choose to increase the overall cutout width for ease of installation.

The Modular 3000 Series units are engineered with a variety of adjustment features to help ensure a seamless installation. Adjustable doors, leveling legs and grille will assist in fine tuning the installation.

All 3000 Series models fully integrate into overlay/face frame, inset or European/frameless cabinet styles and install seamlessly into standard 24" (610 mm) depth cabinet base.

33-7/8"

(860 mm) to 34-7/8" (886 mm)

Preferred location for electrical outlet

is in adjacent

cabinet. 5/8" (16 mm)

24"  (610 mm)

(610 mm)

7" (178 mm)

4"  (102 mm)

(102 mm)

23-3/4"

(605 mm)

Metric measurements rounded and optimized.

! CAUTION

Unit can NOT be installed behind a closed cabinet door.

Cutout Dimensions 1

USER GUIDE

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

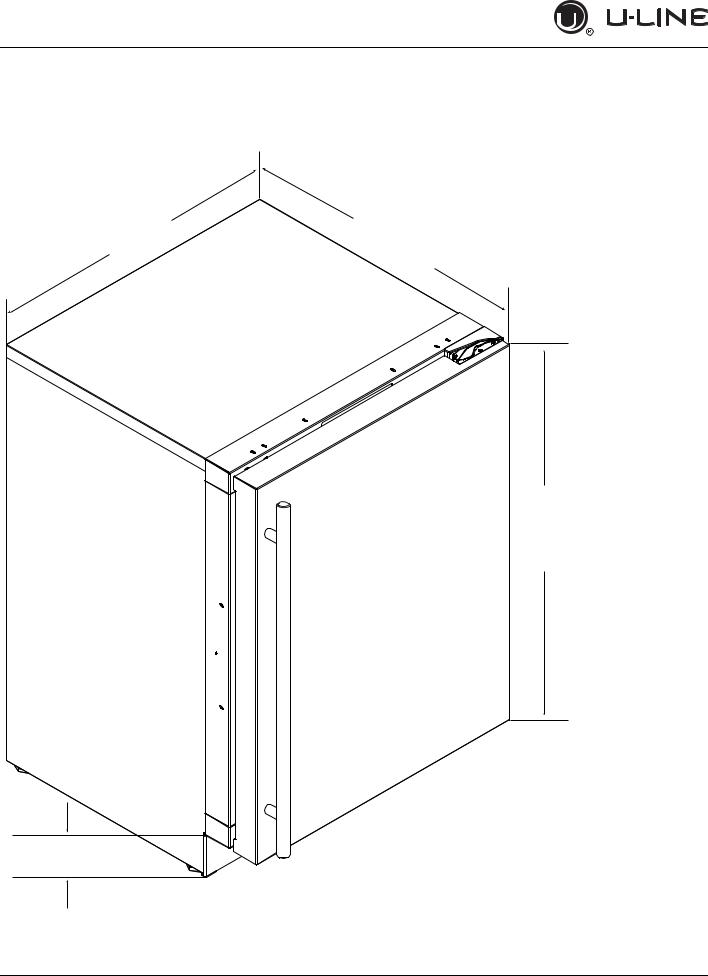

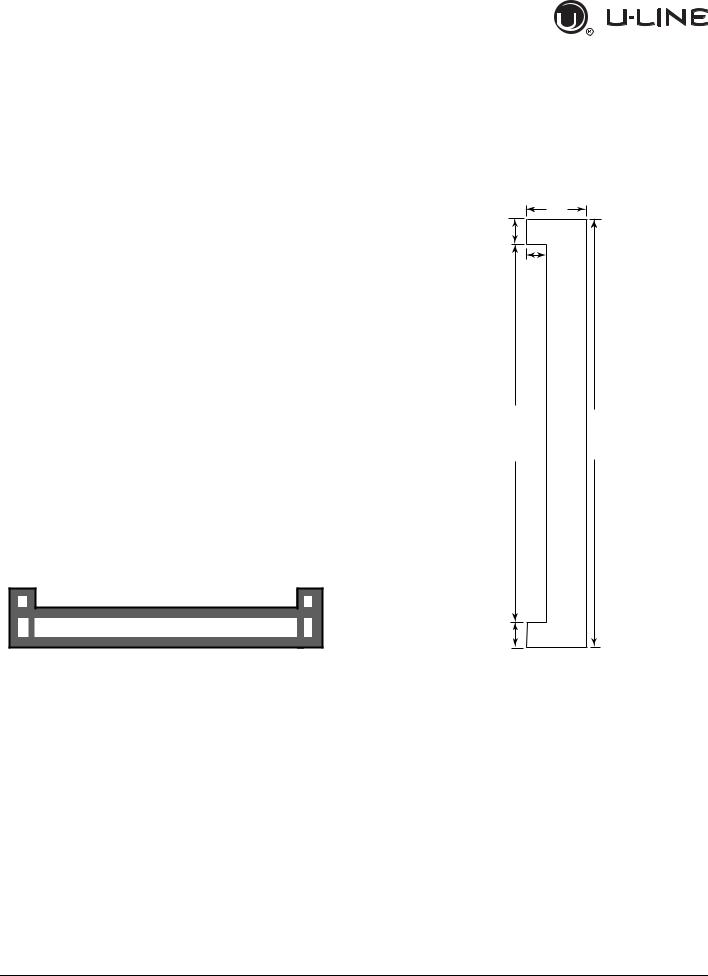

Product Dimensions

23-5/8"

(600 mm)

Not Including Handle

23-7/16" (590 mm)

33-11/16" to

34-11/16"

(856 mm to

881 mm)

3-5/8" to 4-5/8"

(92 mm to 118 mm)

Product Dimensions 1

USER GUIDE

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

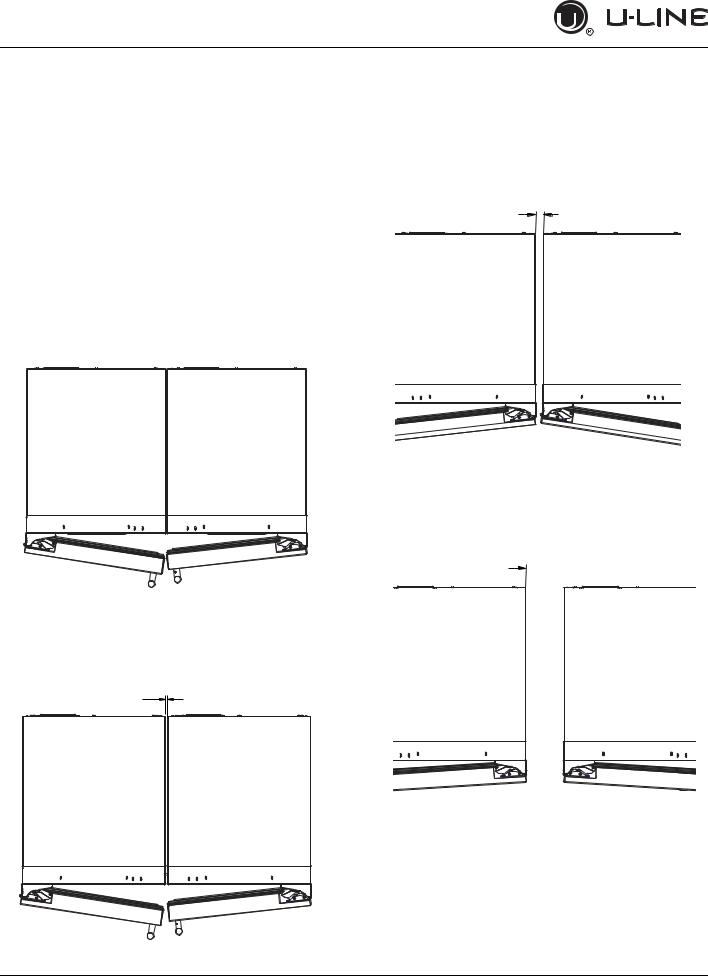

Side-by-Side Installation |

Hinge-by-Hinge Installation (Mullion) |

|

OTHER SITE REQUIREMENTS |

When installing two units hinge-by-hinge, 13/16" (22 mm) |

|

is required for integrated models. Additional space may be |

||

|

||

Side-by-Side Installation |

needed for any knobs, pulls or handles installed. |

Units must operate from separate, properly grounded electrical receptacles placed according to each unit’s

electrical specifications requirements. |

13/16" (22 mm) |

|

Cutout width for a side-by-side installation is the total of the widths listed under Cutout Dimensions in each unit’s Installation Guide. Each door can be opened individually (one at a time) without interference.

Stainless steel models which include the standard stainless handle will require 4-9/16" (116 mm) to allow both doors to open to 90° at the same time.

4-9/16" (116 mm)

4-9/16" (116 mm)

However, to ensure unobstructed door swing (opening both doors at the same time), 1/4" (6.4 mm) of space needs to be maintained between the units.

1/4" (6 mm)

Side-by-Side Installation 1

USER GUIDE

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

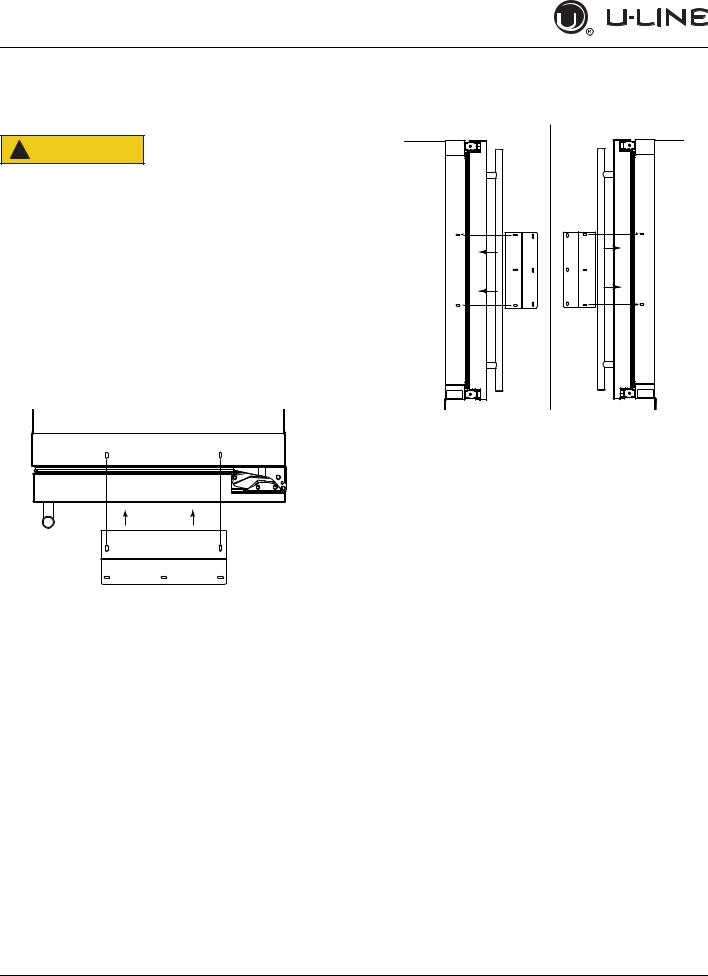

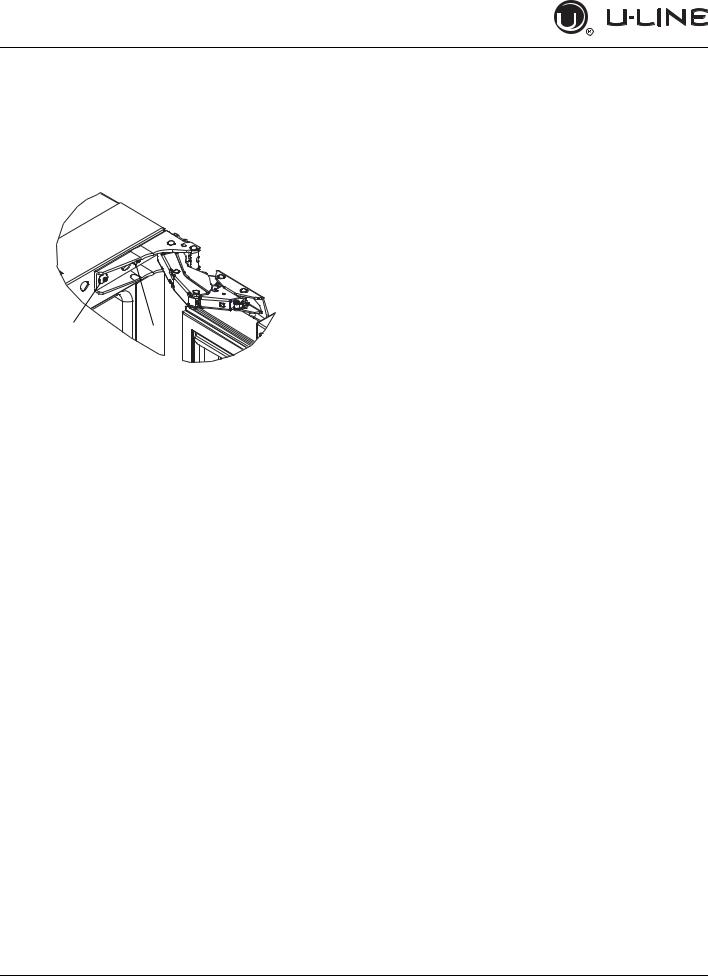

Anti-Tip Bracket

! CAUTION

The anti-tip bracket must be installed to prevent the unit from tipping when doors are fully opened or excess weight is placed on the front of the unit.

The anti-tip bracket has multiple mounting options. Mounting will depend on your particular cabinet configuration. Locate 3 #8x5/8" screws included with your unit.

SIDE MOUNT

Left Hinged Cabinet |

Right Hinged Cabinet |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TOP MOUNT

For ease of installation, the anti-tip bracket is pre-installed in the top mount position.

1.Completely slide the unit into its position in the cabinet. Be certain unit height is properly adjusted. (See GENERAL INSTALLATION).

2.Open door completely. Make certain door clears surrounding cabinetry.

3.Using a 3/32" (2.50 mm) drill bit, drill 3 pilot holes 5/8" (16 mm) deep into bottom of counter top. Use the anti-tip bracket as a template.

4.Install 3 #8x5/8" screws into the plate using a #2 Phillips head screwdriver.

Side mount position is used when you are unable to mount the bracket to the underside of your countertop.

1.Remove the pre-installed anti-tip bracket from the top mount position and align the bracket to the hinge side of the unit as shown above.

2.Reinstall the 2 #8x5/8" screws into the plate using a #2 Phillips head screwdriver.

3.Completely slide the unit into its position in the cabinet. Be certain unit height is properly adjusted. (See GENERAL INSTALLATION).

4.Open door completely. Make certain door clears surrounding cabinetry.

5.Using a 3/32" (2.50 mm) drill bit, drill 3 pilot holes 5/8" (16 mm) deep into cabinetry frame using the anti-tip bracket as a template.

6.Install 3 #8x5/8" screws into the plate using a #2 Phillips head screwdriver.

Anti-Tip Bracket 1

USER GUIDE

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

General Installation |

INSTALLATION |

LEVELING INFORMATION |

1. Plug in the power/electrical cord. |

|

1. Use a level to confirm |

|

the unit is level. Level |

|

should be placed along |

|

top edge and side |

|

edge as shown. |

1 |

|

2. If the unit is not level, remove grille and

adjust legs as

2

necessary. Use included tool to adjust

the height of the rear legs.

Rotate Front Legs to Adjust

Rotate Clockwise to raise rear leg.

Rotate Counter-Clockwise to lower leg.

3.Confirm the unit is level after each adjustment and repeat the previous steps until the unit is level.

INSTALLATION TIP

If the room floor is higher than the floor in the cutout opening, adjust the rear legs to achieve a total unit rear height of 1/8" (3 mm) less than the opening’s rear height. Shorten the unit height in the front by adjusting the front legs. This allows the unit to be gently tipped into the opening. Adjust the front legs to level the unit after it is correctly positioned in the opening.

2.Gently push the unit into position. Be careful not to entangle the cord.

3.Re-check the leveling, from front to back and side to side. Make any necessary adjustments. The unit’s top surface should be approximately 1/8" (3 mm) below the countertop.

4.Install the anti-tip bracket.

5.Remove the interior packing material and wipe out the inside of the unit with a clean, water-dampened cloth.

General Installation 1

USER GUIDE

|

u-line.com |

|

|

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE |

|

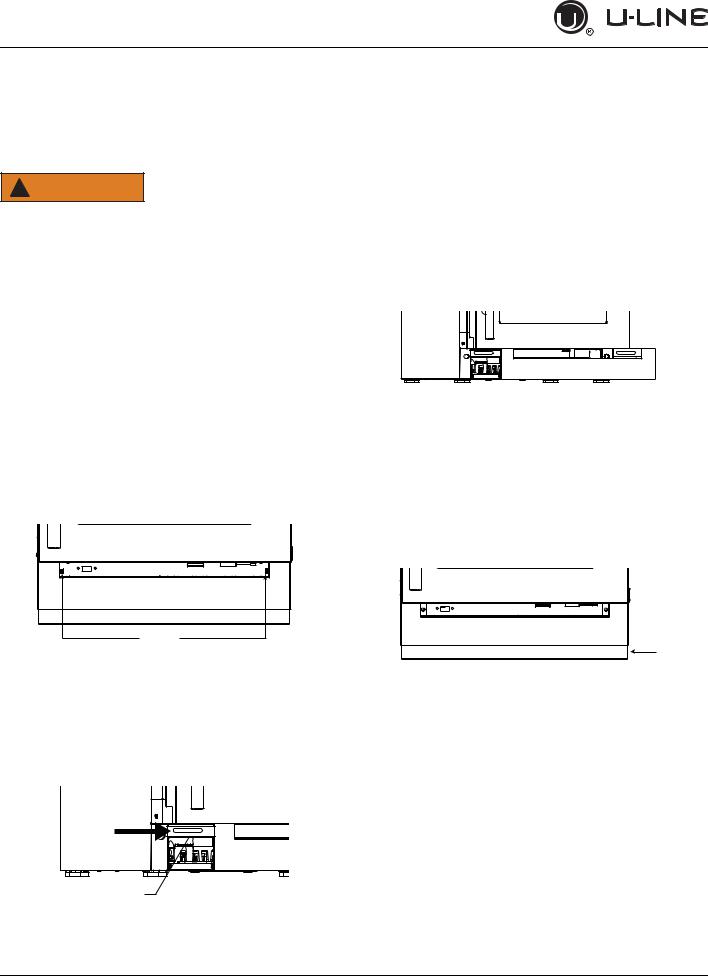

Integrated Grille - Plinth |

INTEGRATED GRILLE (PLINTH STRIP/BASE |

Dimensions |

FASCIA) DIMENSIONS |

|

|

PREPARE AND INSTALL INTEGRATED GRILLE (PLINTH STRIP/BASE FASCIA)

1.Use the dimensions provided in the diagram to cut and shape your integrated grille (plinth strip/base fascia) panel. Recommended panel thickness is between 1/4" (6 mm) and 3/8" (9 mm). Height will vary from 3-5/16" (84 mm) to 4-5/16" (110 mm) based on your grille (plinth strip/base fascia) height.

2.Finish or stain your grille (plinth strip/base fascia) panel to match your surrounding furniture. Finish front, back and edges to prevent warping. Carefully follow the manufacturer’s recommendations for finish application and cure times.

3.Apply double sided tape to the backside of the integrated grill (plinth strip/base fascia). Use the diagram below for reference. U-Line recommends 3M™ VHB™ tape, a high strength bonding tape.

4-5/16" |

110 mm) |

3-5/16" to |

(84 mm to |

1-9/16" (40 mm)

1" (25 mm)

20-5/8" (525 mm) |

23-3/4" (605 mm) |

Apply Tape To Shaded Area

1-9/16" (40 mm)

4.Remove backing paper from double sided tape.

5.Carefully align grille (plinth strip/base fascia) over integrated panel and press into position.

Integrated Grille - Plinth Dimensions 1

USER GUIDE

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

Grille - Plinth Installation |

Installing the grille |

|

(plinth strip/base fascia) |

REMOVING AND INSTALLING GRILLE (PLINTH STRIP/BASE FASCIA)

! WARNING

Disconnect electrical current to the unit before removing the grille (plinth strip/base fascia).

When using the unit, the grille (plinth strip/base fascia) must be installed.

Edges of sheet metal may be sharp.

Removing the grille (plinth strip/base fascia)

1.Disconnect electrical current to unit.

2.Using the included 7/64" Allen wrench, loosen (but do not remove) both grille (plinth strip/base fascia) lock screws. See below.

1.Align slots in grille (plinth strip/base fascia) rail with screw heads in base of unit

2.Push grille (plinth strip/base fascia) rails towards the center of the unit and set rails over screw head.

3.Slide grille (plinth strip/base fascia) into position. Using included 7/64" Allen wrench tighten grille (plinth strip/ base fascia) lock screws.

ADJUSTING GRILLE

(PLINTH STRIP/BASE FASCIA)

The grille (plinth strip/base fascia) has an automatic vertical plane adjustment and can also be adjusted on its horizontal plane as well. To adjust your grille (plinth strip/ base fascia) to match your surrounding furniture, follow the instructions below.

Grille Mounting

Screws

3.Gently pull grille (plinth strip/base fascia) away from unit until it stops.

4.Push grille (plinth strip/base fascia) rails towards the center of the unit to lift rails off lock screws.

Grille Rail

5. Pull grille (plinth strip/base fascia) free from unit.

Grille

Skirt

1.Loosen, but do not remove, the lock screws on the inside of the grille (plinth strip/base fascia) rails. Lock screws are located on the inside of each grille (plinth strip/base fascia) rail.

2.The grille (plinth strip/base fascia) can be extended horizontally by pulling out a maximum of 1-1/2"

(38 mm). Do not exceed 1-1/2" (38 mm). Secure the lock screws after adjusting.

3.The grille (plinth strip/base fascia) skirt may be manually adjusted to the height of your floor. Simply raise or lower the skirt as needed.

Grille - Plinth Installation 1

USER GUIDE

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

Door Swing

Stainless Steel models that are installed adjacent to a wall require 2-1/4” (57 mm) door clearance on hinge side to allow for door handle.

Units have a zero clearance when installed adjacent to cabinets.

|

2-1/4" MIN |

Wall |

||

|

(57 mm MIN) |

|||

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

90° Door Swing

Stainless

Door Swing 1

USER GUIDE

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

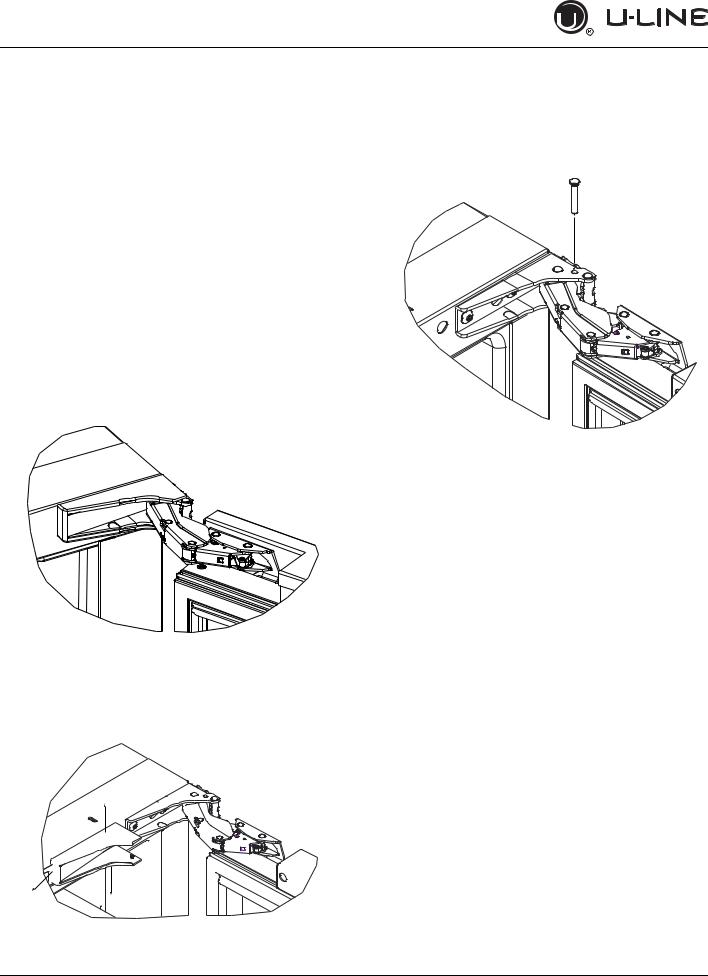

Door Stop

Your U-Line unit was shipped to you with the optional 90° pin.

Your unit’s door(s) will open 115° straight from the factory. If you would like the door stop at 90° follow these instructions.

3.Once cover is removed, slide hinge pin into hole as shown. Pin should slide into place, stopping the door at 90°; if the pin does not go into the hole shown, hold the door less than 90° open and try again.

NOTICE

If your unit is already undercounter, it will need to be moved out to access the hinge. With the 90° stop pin in place, you will not be able to replace the hinge cover.

1. Open door approximately 90°.

4. To fully seat the pin, tap it lightly with a hammer.

5. Carefully slide your unit back in place.

2.Remove hinge cover by lifting top and bottom of hinge cover and sliding the cover inwards to remove from hinge.

NOTICE

The pin can be removed to return the door swing back to its original 115° swing by tapping the pin out from the bottom of the hinge.

CLOSER

The door hinge has a self-closing feature that engages when the door is open approximately 6" (150 mm) (about 25°).

1

3 |

2 |

|

Door Stop 1

USER GUIDE

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

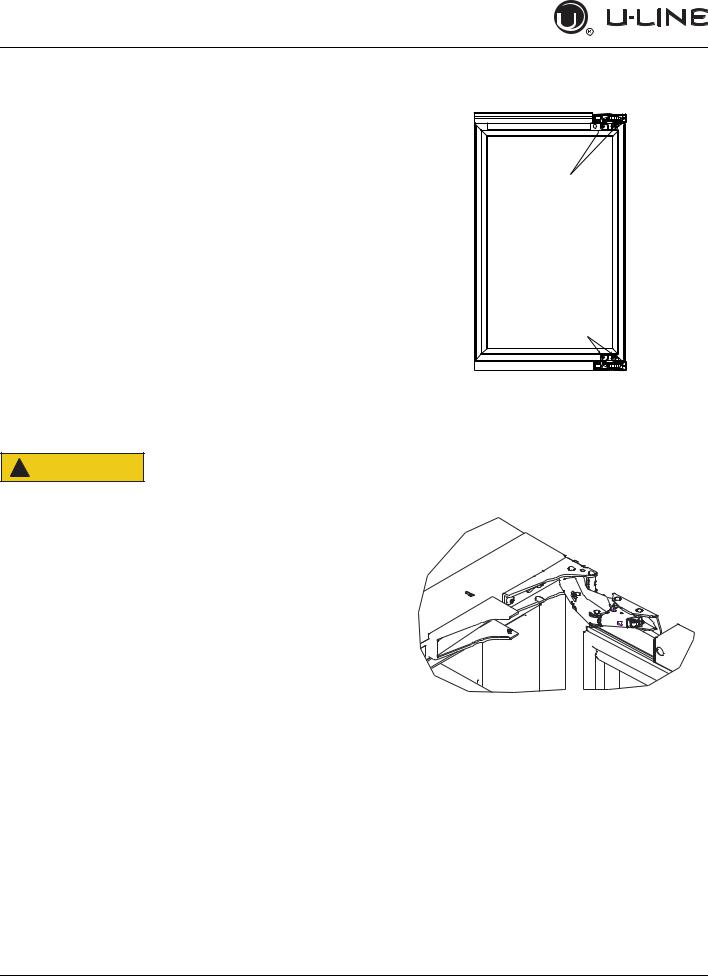

Door Adjustments

DOOR ALIGNMENT AND ADJUSTMENT

Align and adjust the door if it is not level or is not sealing properly. If the door is not sealed, the unit may not cool properly, or excessive frost or condensation may form in the interior.

NOTICE

Properly aligned, the door’s gasket should be firmly in contact with the cabinet all the way around the door (no gaps). Carefully examine the door’s gasket to ensure that it is firmly in contact with the cabinet. Also make sure the door gasket is not pinched on the hinge side of the door.

! CAUTION

Do not attempt to use the door to raise or pivot your unit. This would put excessive stress on the hinge system.

Alignment and Adjustment Procedure

1.Open door and remove gasket near the hinges.

2.Using a T-25 Torx Bit, loosen each pair of Torx head screws on both the upper and lower hinge plates.

T-25 Torx Screw |

T-25 Torx Screw |

REVERSING THE DOOR

1.Open door.

2.Remove top hinge cover by lifting top and bottom flaps and slide inwards. Repeat on bottom hinge.

3.Square and align door as necessary.

4.Tighten Torx head screws on hinge.

5.Reinstall gasket into the channel starting at the corner.

Door Adjustments 1

USER GUIDE

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

3.Using T-25 Torx bit loosen screw #1 and remove screw #2 on top and bottom hinge. Slide and remove the door from unit. Completely remove screw #1 on top and bottom.

2

1

4.Remove caps from screw heads on opposite side (2 on top and 2 on bottom). Using #2 Phillips bit remove the 4 underlying screws. Reinstall the screws and caps on the opposite side.

5.Partially install screw #1 in the outer most holes on top and bottom. Rotate door 180°, align hinge over screw #1 and slide/seat into position. Reinstall screw #2 on top and bottom. Tighten both screws and install hinge cover.

Align and adjust the door:

Align and adjust the door (see DOOR ALIGNMENT AND

ADJUSTMENT).

Door Adjustments 2

USER GUIDE

u-line.com

SAFETY • INSTALLATION & INTEGRATION • OPERATING INSTRUCTIONS • MAINTENANCE • SERVICE

First Use

All U-Line controls are preset at the factory. Initial startup requires no adjustments.

NOTICE

U-Line recommends allowing the unit to run overnight before loading with product.

When plugged in, the unit will begin operating under the factory default setting. Follow the on screen prompt for language selection and temperature units.

To turn the unit off, press  and hold for 5 seconds and release. The display will show a countdown to switching the unit off.

and hold for 5 seconds and release. The display will show a countdown to switching the unit off.

To power your unit on, simply press  and the unit will immediately switch on.

and the unit will immediately switch on.

First Use 1

Loading...

Loading...