BACK TO ENGINE INDEX

RM710E-D

Pages From Manual

1KZ-TE

TO MODEL INDEX

FOREWORD

TOYOTA MOTOR CORPORATION

This REPAIR MANUAL has been prepared to provide information covering general service repairs

for the

Please note that the publications below have also been prepared as relevant service manuals for the components and system in this engine.

All information in this manualisbased on the latest productinformation atthe timeofpublication.However,

specifications and procedures are subject to change without notice.

A ll r ight s r es er v ed. This CD may not be repro-

duced or copied, in whole or in part, without the

written permission ofToyota Motor Corporation.

First Printing; Jun. 11, 1999 01--990611--00--2

1KZ-TE ENGINE equipped on the TOYOTA HILUX.

Applicable models:

S

HILUX Electrical Wiring Diagram

TOYOTA MOTOR CORPORATION

1999

KZN165 series

Manual Name Pub. No.

EWD307F

CAUTION

Thismanualdoesnotincludeallthe necessaryitemsaboutrepairand service.Thismanual ismade

for the purpose of the use for the persons who have special techniques and certifications. In the

casesthatnon--specializedoruncertifiedtechniciansperformrepairorserviceonlyusingthismanual or withoutproper equipment or tool, that may cause severe injury to you or other people around

and also cause damage to your customer’s vehicle.

In order to prevent dangerousoperation anddamages toyour customer’s vehicle, besure to follow

the instruction shown below.

S

Mustreadthis manual thoroughly.It is especiallyimportantto have good understandingallthe

contents written in the PRECAUTION of ”IN” section.

S

Theservice methodwritten inthismanualisveryeffectivetoperform repairandservice.When

performingtheoperationsfollowingtheproceduresusingthismanual,besureto usetoolsspecified and recommended. If using non--specified or recommended tools and service method,

be sure to confirm safety of the technicians and any possibility of causing personal injury or

damage to the customer’s vehicle before starting the operation.

S

Ifpartreplacementisnecessary,mustreplacethepartwiththe samepartnumberorequivalent

part. Do not replace it with inferior quality.

S

It is importantto note that this manual containsvarious ”Cautions” and ”Notices” that must be

carefullyobserved in order to reduce the risk of personal injury during service orrepair, or the

possibilityt hat impr oper serviceorrepairmaydamagethevehicleor render it unsafe. It isalso

important to understand that these ”Cautions” and ”Notices”are not exhaustive, because it is

important to warn of all the possiblehazardous consequences thatmight resultfrom failure to

follow these instructions.

BACK TO MAIN FOREWORD & To Engine Index

MAIN INDEX

ENGINE 1KZ-TE: HILUX

Pages From Manual1KZ-TE

TO MODEL INDEX

June 2000

INTRODUCTION

PREPARATION

SERVICE SPECIFICATIONS

DIAGNOSTICS

ENGINE MECHANICAL

TURBOCHARGER

EMISSION CONTROL

ELECTRONIC CONTROL DIESEL

ENGINE FUEL

COOLING

LUBRICATION

STARTING

CHARGING

ALPHABETICAL INDEX

BACK TO MAIN INDEX

I NTRO DUCTI O N

HOW TO USE THIS MANUAL IN--1.............

GENERAL INFORMATION IN--1..................

IDENTIFICATION INFORMATION IN--3..........

ENGINE SERIAL NUMBER IN--3.................

REPAIR INSTRUCTIONS IN--4.................

GENERAL INFORMATION IN--4..................

FOR ALL OF VEHICLES IN--8..................

PRECAUTION IN--8.............................

HOW TO TROUBLESHOOT

ECU CONTROLLED SYSTEMS IN--9.........

GENERAL INFORMATION IN--9..................

HOW TO PROCEED

WITH TROUBLESHOOTING IN--10..............

HOW TO USE THE DIAGNOSTIC CHART

AND INSPECTION PROCEDURE IN--20..........

TERMS IN--25.................................

ABBREVIATIONS USED IN THIS MANUAL IN--25....

1KZ-TE

Pages From Manual

TO MODEL INDEX

CLICK HERE TO VIEW CHAPTER INDEX

HOW TO USE THIS MANUAL

GENERAL INFORMATION

1 . I NDE X

An INDEX is provided on the first page of each section to guide you to the item to be repaired. To assist you

in finding your way through the manual, the section title and major heading aregiven at the top of everypage.

2 . P RE CAUTI O N

At the beginning of each section, a PRECAUTION is given that pertains to all repair operations contained

in that section.

Read these precautions before starting any repair task.

3. TROUBLESHOOTING

TROUBLESHOOTING tables are included for each system to help you diagnose the problem and find the

cause. The fundamentals of how to proceed with troubleshooting are described on page IN--9.

Be sure to read this before performing troubleshooting.

4. PREPARATION

Preparation lists the SST (Special Service Tools), recommended tools, equipment, lubricant and SSM (Special Service Materials) which should be prepared before beginning the operation and explains the purpose

of each one.

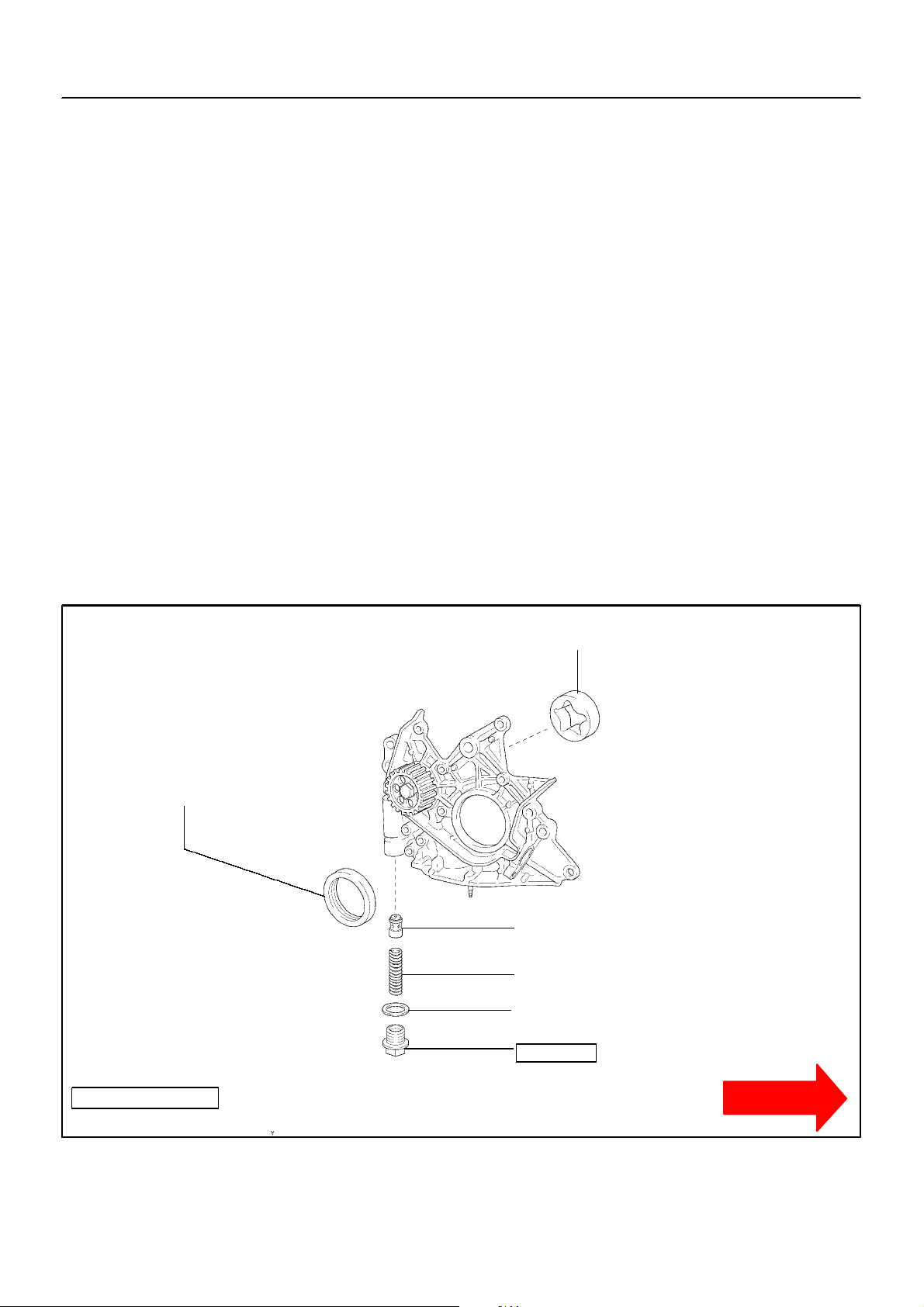

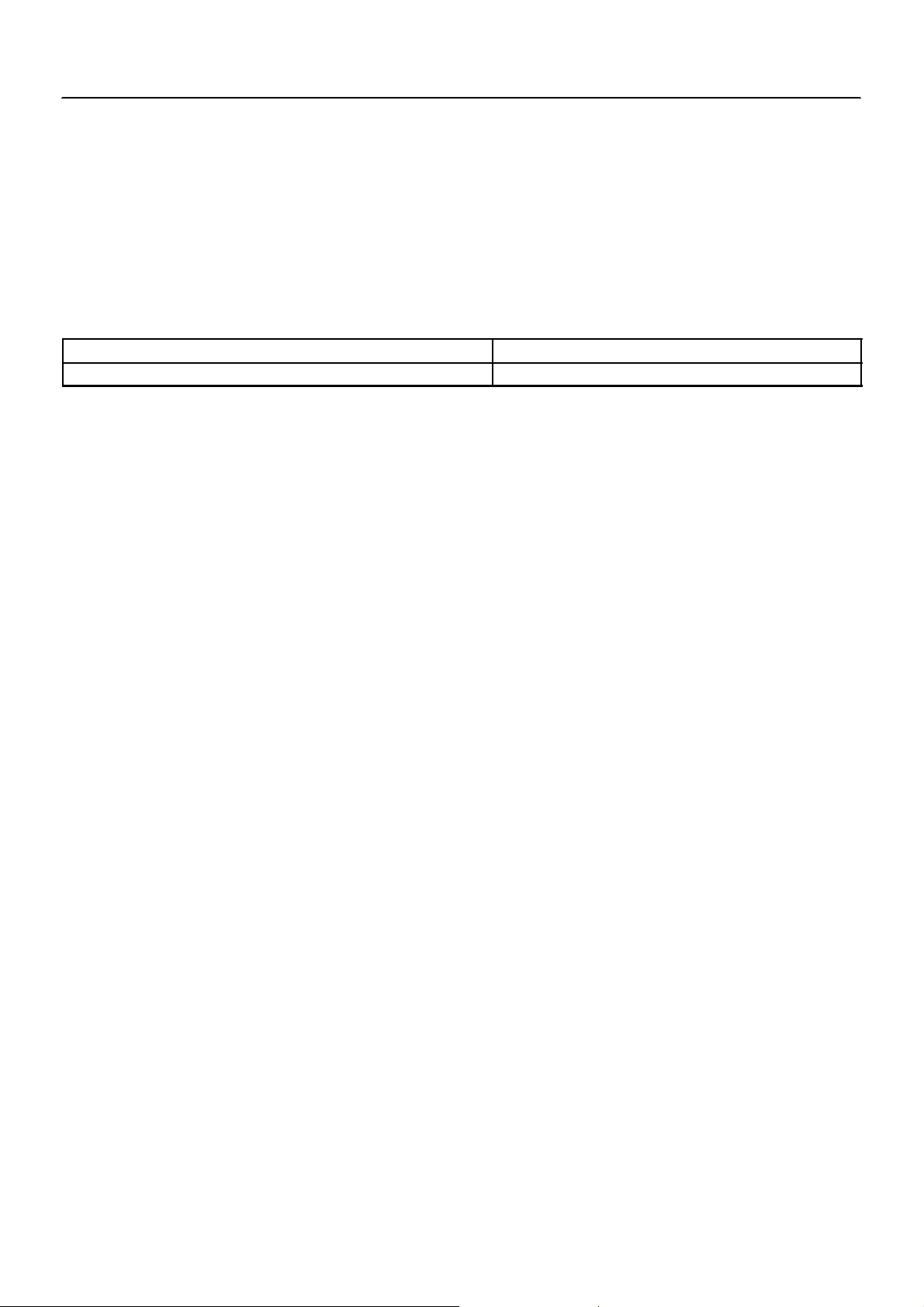

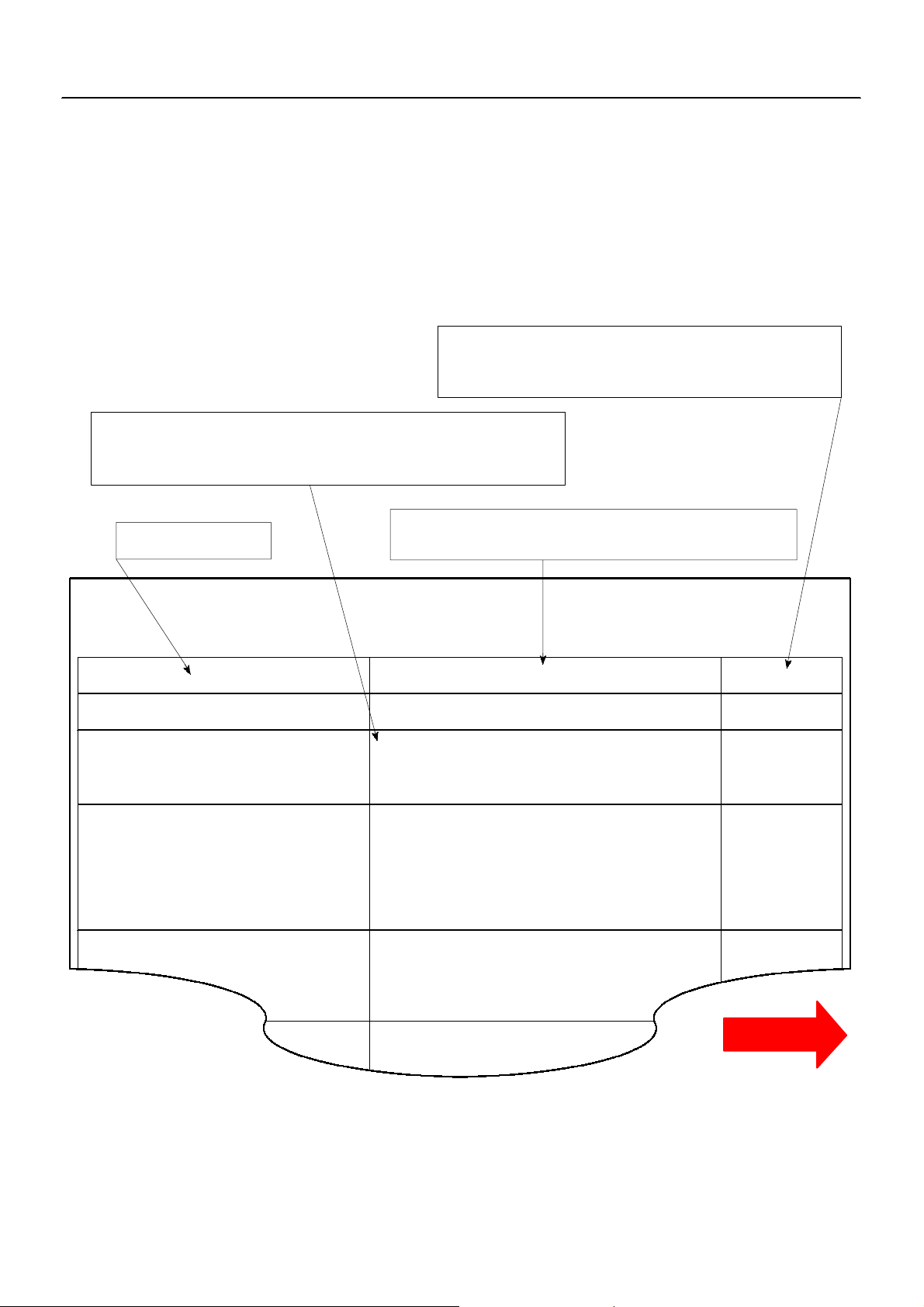

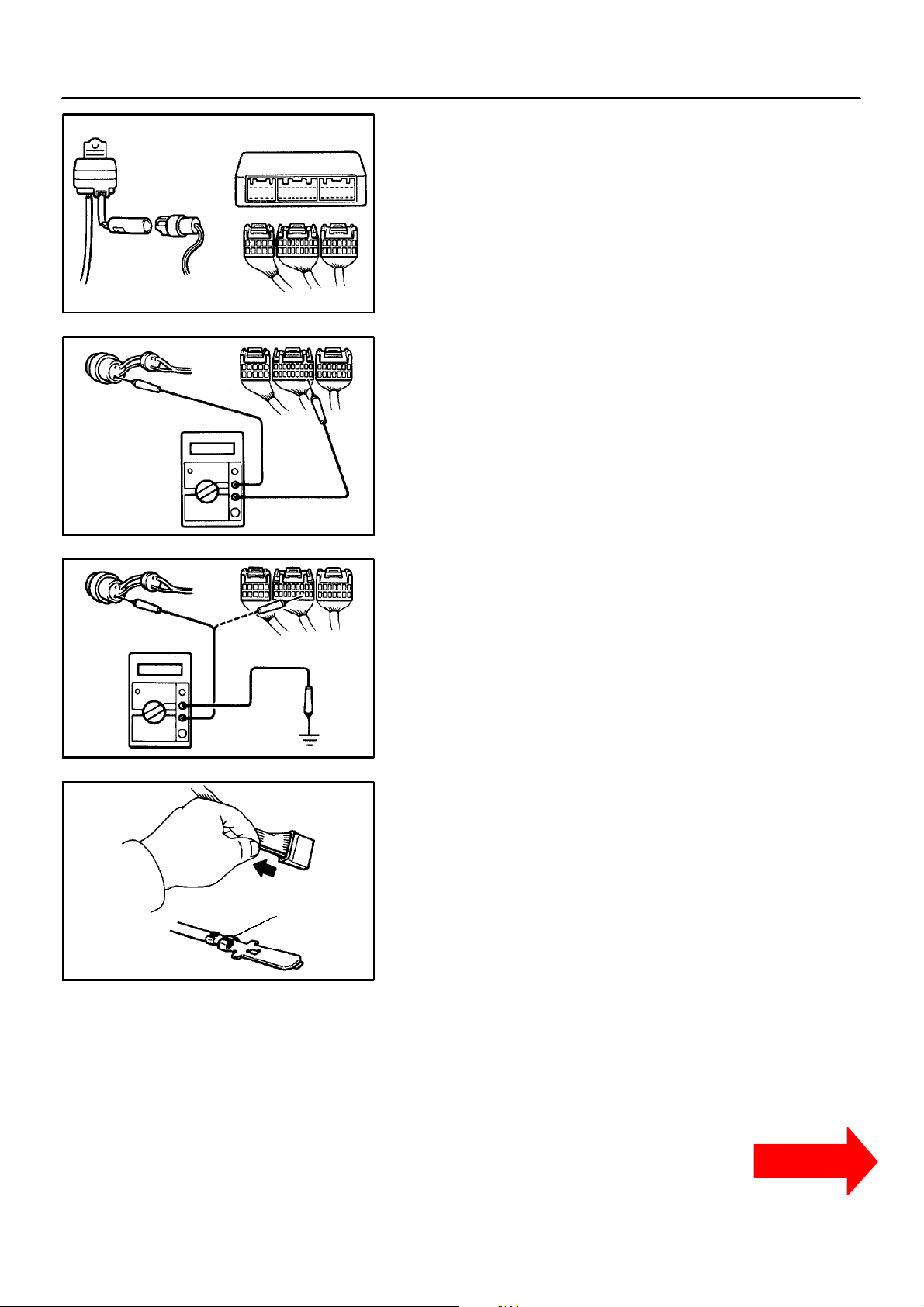

5 . RE PAI R P RO CE DURE S

Most repair operations begin with an overview illustration. It identifies the components and shows how the

parts fit together.

Example:

--INTRODUCTION HOW TO USE THIS MANUAL

1KZ-TE

Pages From Manual

TO MODEL INDEX

IN--1

IN04V--04

z Crankshaft Front Oil Seal

Driven Rotor

Relief Valve

Spring

z Gasket

Plug

49 (500, 36)

N∙m (kgf∙cm, ft∙lbf) : Specified torque

z Non--reusable part

B07996

CONTINUED

B08237

CLICK HERE TO VIEW CHAPTER INDEX

IN--2

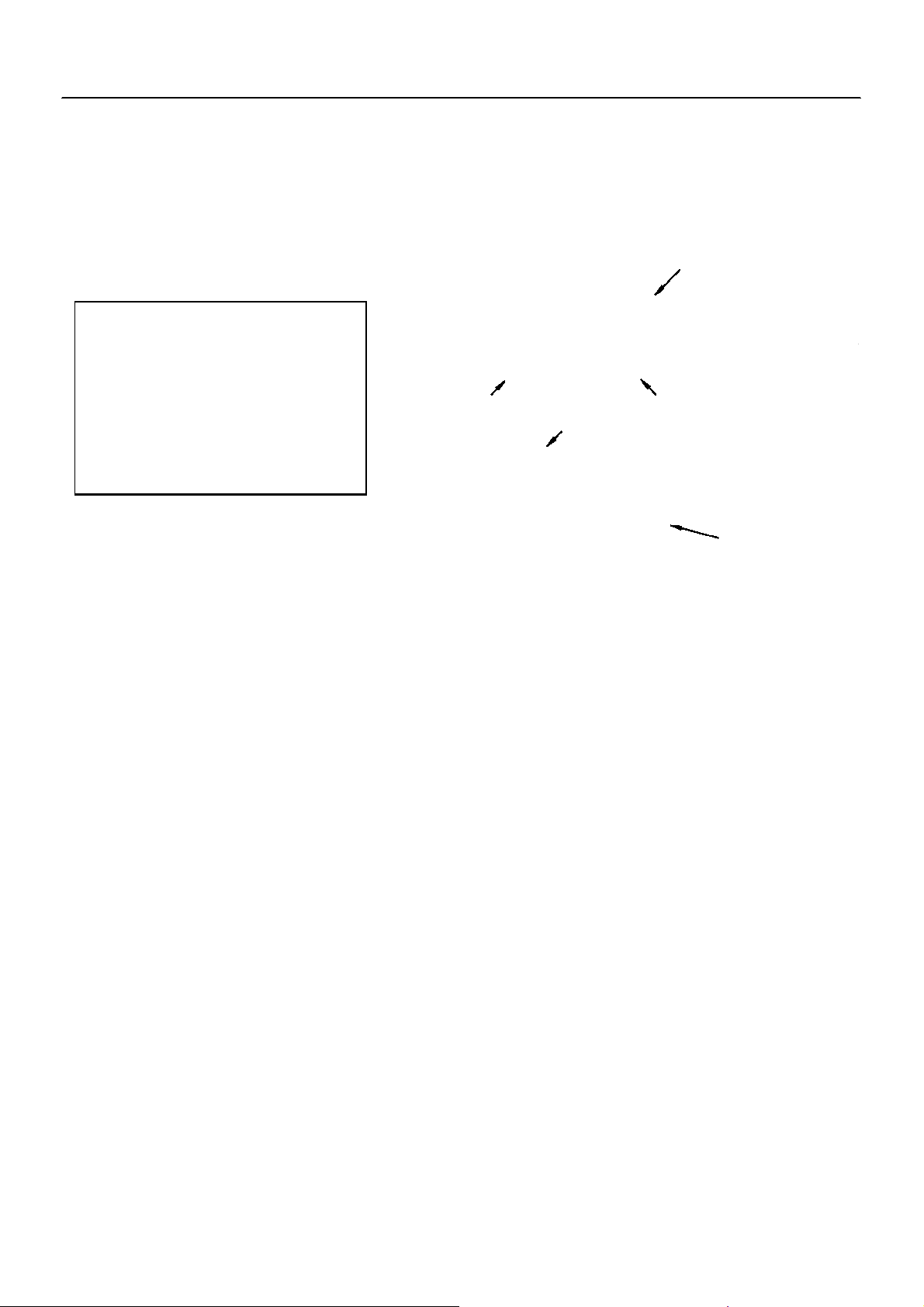

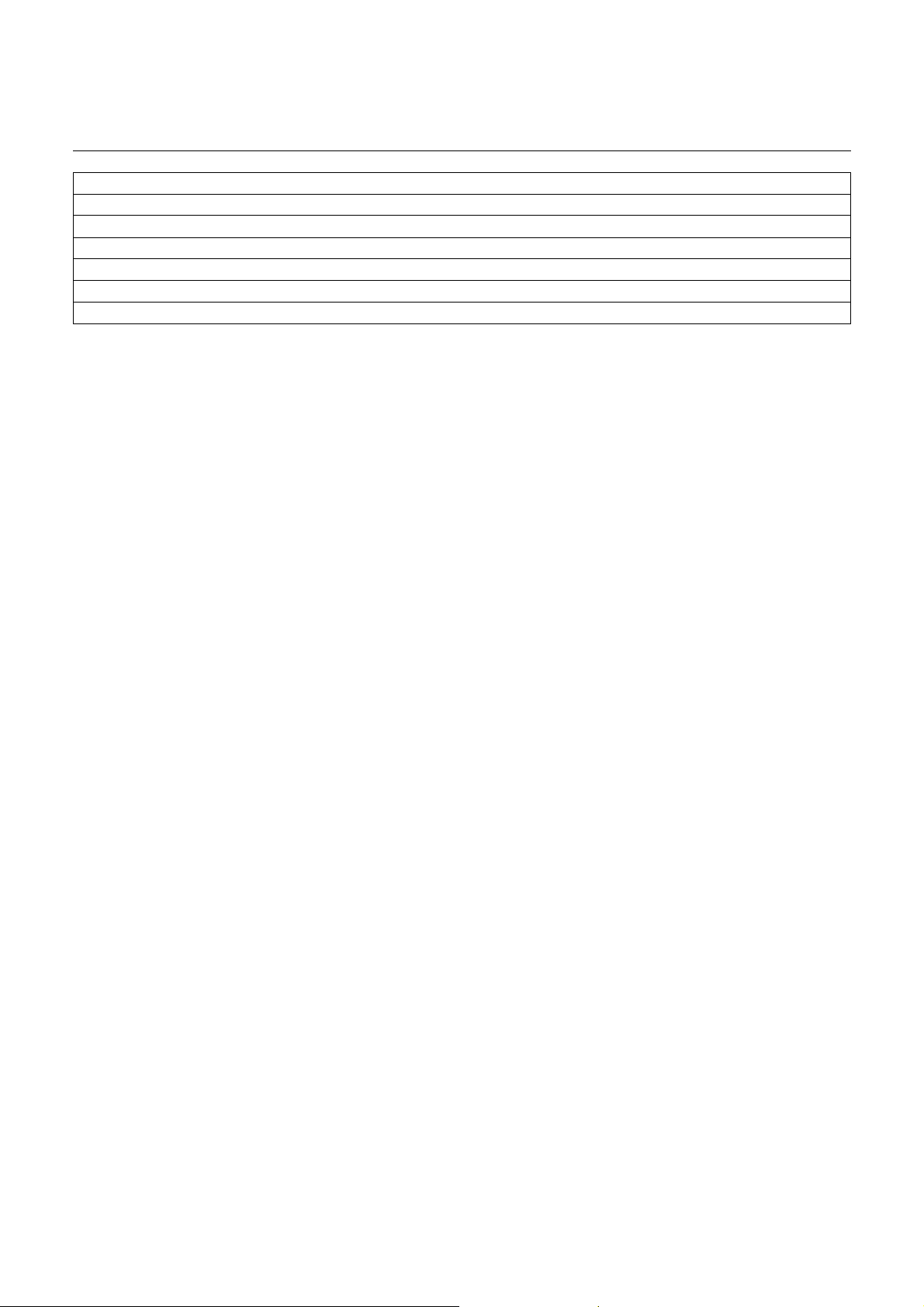

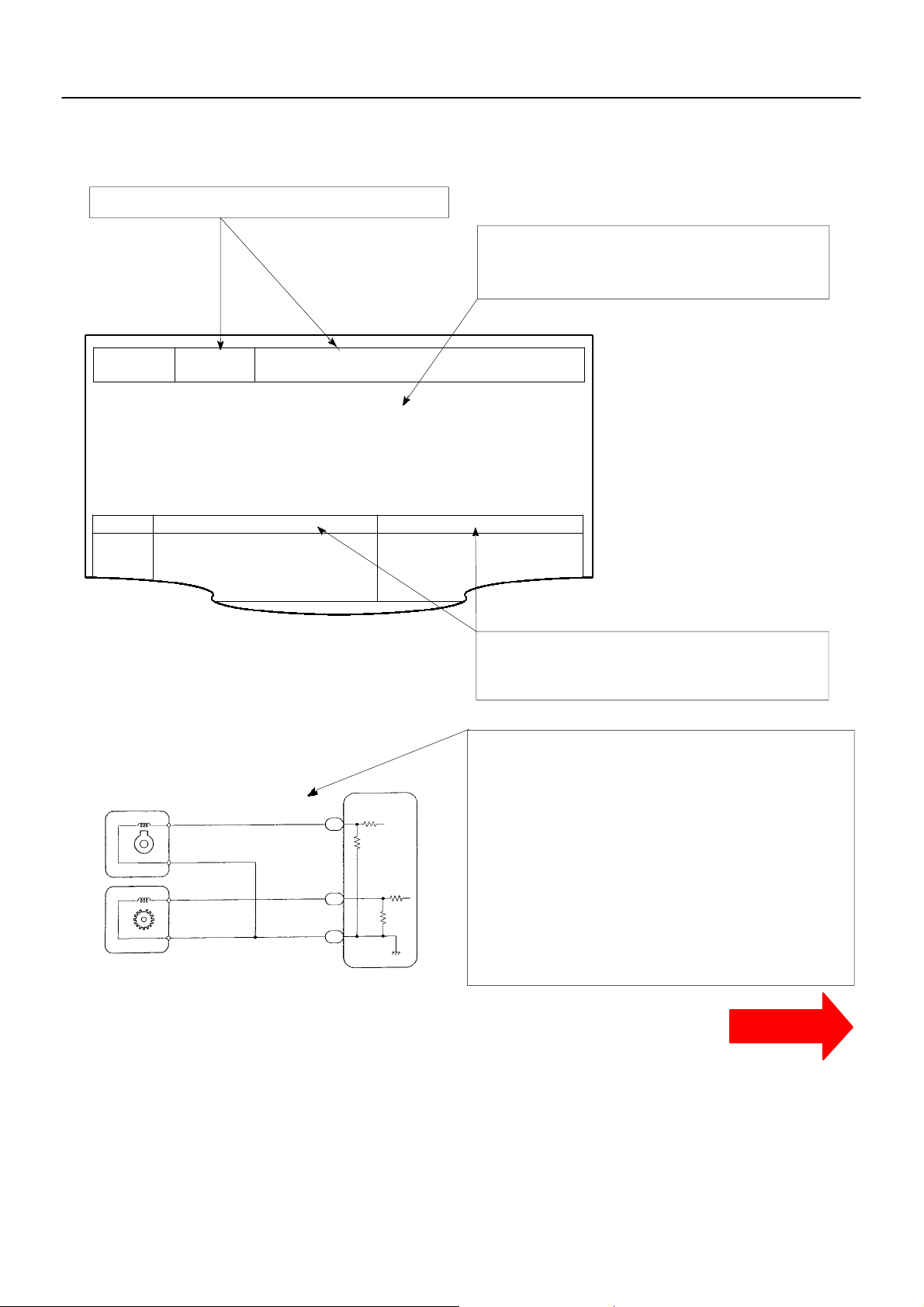

The procedures are presented in a step--by--step format:

The illustration shows what to do and where to do it.

S

S The task heading tells what to do.

The detailed text tells how to perform the task and gives other information such as specifications

S

and warnings.

Example:

Illustration:

what to do and where

1KZ-TE

Pages From Manual

TO MODEL INDEX

--INTRODUCTION HOW TO USE THIS MANUAL

Taskheading: whatto do

21. CHECK PISTON STROKE OF OVERDRIVE BRAKE

(a)

Place SST and a dial indicator onto the overdrive brake piston as shown in the illustration.

SST 09350--30020 (09350--06120)

Set part No. Component part No.

Detailed text : howto do task

Measure the stroke applying and releasing the compressed

(b)

air (392 —785kPa,4—8kgf/cm

in the illustration.

Piston stroke: 1.40 — 1.70 mm (0.0551 — 0.0669 in.)

2

or 57 —114 psi) as shown

Specification

This format p rovides the experienced technician with a FAST TRACK to the information needed. The upper

case task heading can be read at a glance when necessary, and the text below it provides detailed information. Important specifications and warnings always stand out in bold type.

6 . RE FE RE NCE S

References have been kept to a minimum. However, when they are required you are given the page to refer

to.

7. SPECIFICATIONS

Specifications are presented in bold type throughout the text where needed. You never have to leave the

procedure to look up your specifications. They are also found in Service Specifications section for quick reference.

8 . CAUTI O NS , NO TI CE S , HI NTS :

CAUTIONS are presented in bold type, and indicate there is a possibility of injury to you or other

S

people.

NOTICES are also presented in bold type, and indicate the possibility of damage to the components

S

being repaired.

HINTS are separated from the text but do not appear in bold. They provide additional information to

S

help you perform the repair efficiently.

9 . S I UNI T

The UNITS given in this manual are primarily expressed according to the SI UNIT (International System of

Unit), and alternately expressed in the metric system and in the English System.

Example:

Torque: 30 N∙m (310 kgf∙cm, 22 ft∙lbf)

CLICK HERE TO VIEW CHAPTER INDEX

--INTRODUCTION IDENTIFICATION INFORMATION

1KZ-TE

Pages From Manual

TO MODEL INDEX

IN--3

B09246

IDENTIFICATION INFORMATION

IN0E6--02

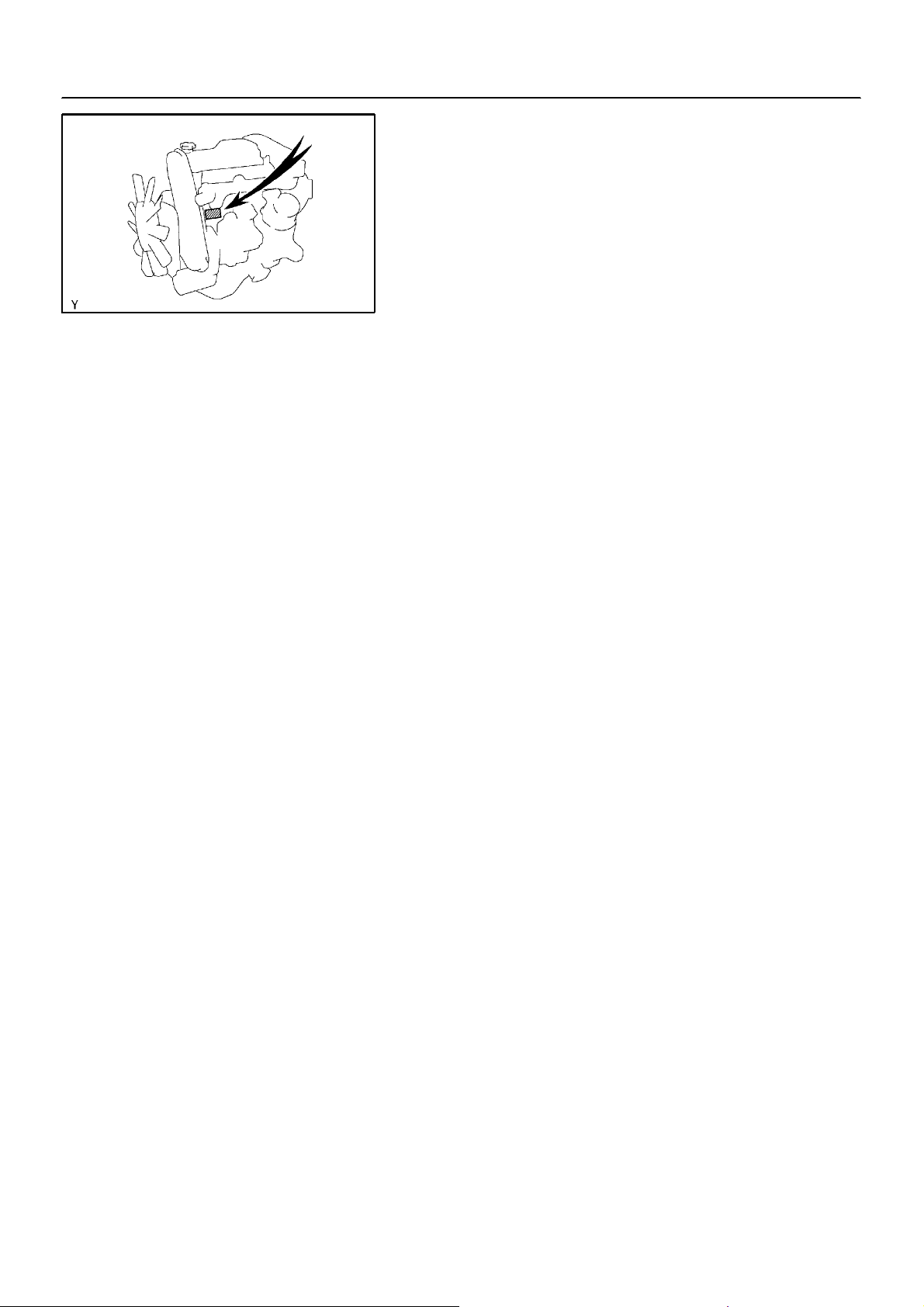

ENGINE SERIAL NUMBER

The engine serial number is stamped on the engine block, as

shown in the illustration.

CLICK HERE TO VIEW CHAPTER INDEX

IN--4

--INTRODUCTION REPAIR INSTRUCTIONS

1KZ-TE

Pages From Manual

TO MODEL INDEX

P23717

REPAIR INSTRUCTIONS

IN0E7--02

GENERAL INFORMATION

BAS I C RE PAI R HI NT

(a) Use fender, seat and floor covers to keep the vehicle

clean and prevent damage.

(b) During disassembly, keep parts in the appropriate order

to facilitate reassembly.

(c) Observe the following operations:

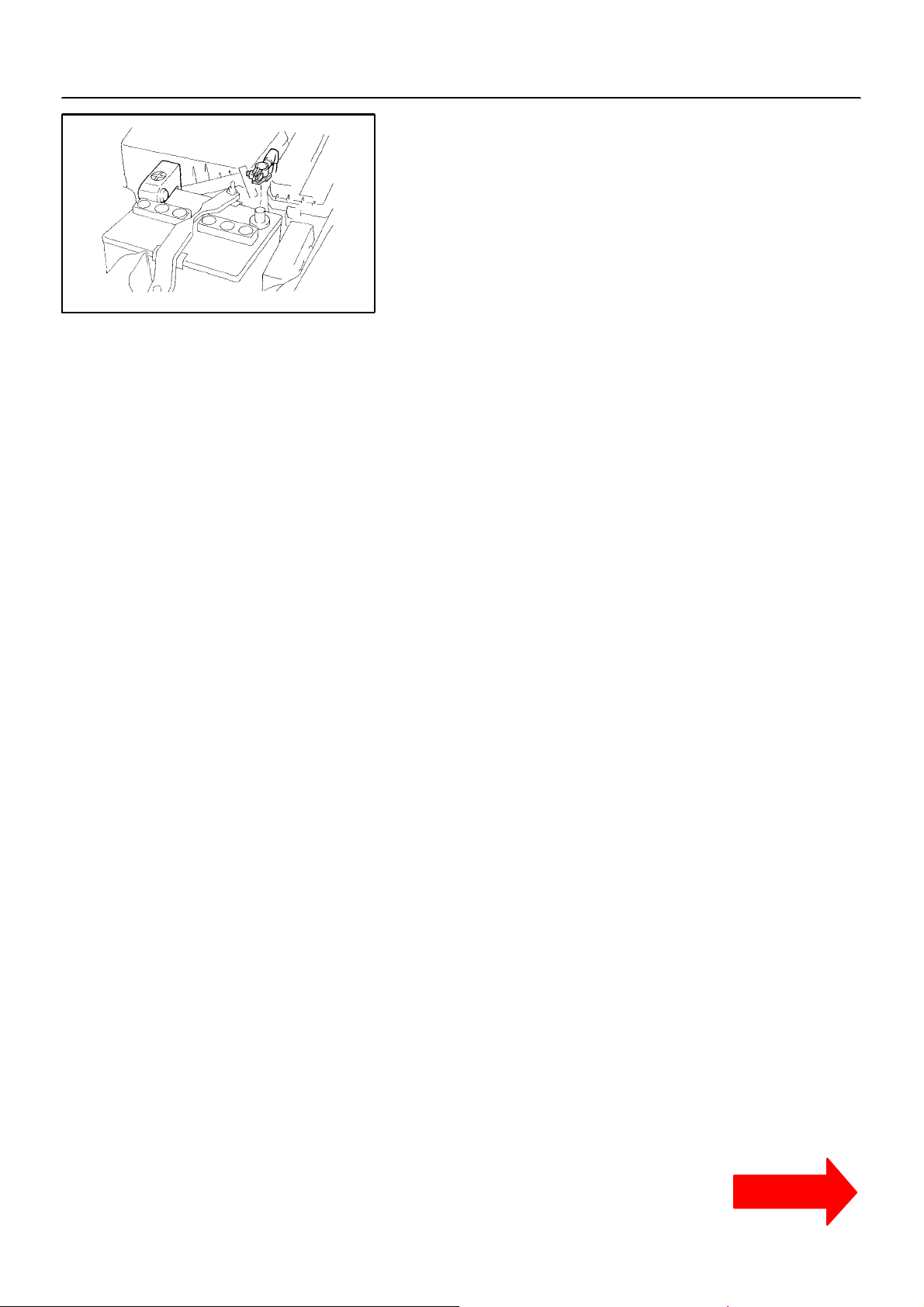

(1) Before performing electrical work, disconnect the

negative ( --) terminal cable from the battery.

(2) If it is necessary to disconnect the battery for in-

spection or repair, always disconnect the negative

(--) terminal cable which is grounded to the vehicle

body.

(3) To prevent damage to the battery terminal, loosen

the cable nut and raise the cable straight up without

twisting or prying it.

(4) Clean the battery terminals and cable ends with a

clean shoprag. Do not scrape them with a file orother abrasive objects.

(5) Install the cable ends to the battery terminals with

the nut loose, and tighten the nut after installation.

Do not use a hammer to tap the cable ends onto the

terminals.

(6) Be sure the cover for the positive (+) terminal is

properly in place.

(d) Check hose and wiring connectors to make sure that they

are secure and correct.

(e) Non--reusable parts

(1) Always replace cotter pins, gaskets, O--rings and oil

seals etc. with new ones.

(2) Non--reusable parts are indicated in the component

illustrations by the ”z” symbol.

(f) Precoated parts

Precoated parts are bolts and nuts, etc. that are coated

with a seal lock adhesive at the factory.

(1) If a precoated part is retightened, loosened or

caused to move in any way, it must be recoated with

the specified adhesive.

(2) When reusing precoated parts, clean off the old

adhesive and dry with compressed air. Then apply

the specified seal lock adhesive to the bolt, nut or

threads.

(3) Precoated parts are indicated in the component il-

lustrations by the ”L” symbol.

(g) When necessary, use a sealer on gaskets to prevent

leaks.

CONTINUED

CLICK HERE TO VIEW CHAPTER INDEX

1KZ-TE

Pages From Manual

TO MODEL INDEX

IN--5

--INTRODUCTION REPAIR INSTRUCTIONS

(h) Carefully observe all specifications for bolt tightening

torques. Always use a torque wrench.

(i) Use of special servicetools (SST) and special service ma-

terials (SSM) may be required, depending on the nature

of the repair. Be sure to use SST and SSM where specified and follow the proper work procedure. A list of SST

and SSM can be found in section PP (Preparation) in this

manual.

Medium Current Fuse and High Current Fuse

Equal Amperage Rating

BE1367

(j) When replacing fuses, be sure the new fuse has the cor-

rect amperage rating. DO NOT exceed the rating or use

one with a lower rating.

AbbreviationPart NameSymbolIllustration

FUSE

MEDIUM CURRENT FUSE

HIGH CURRENT FUSE

FUSE

M--FUSE

H--FUSE

FUSIBLE LINK

CIRCUIT BREAKER

FL

CB

V00076

(k) Care must be taken when jacking up and supporting the

vehicle. Be sure to lift and support the vehicle at the proper locations.

Cancel the parking brake on the level place and

S

shift the transmission in Neutral (or N position).

When jacking up the front wheels of the vehicle at

S

first place stoppers behind the rear wheels.

When jacking up the rear wheels of the vehicle at

S

first place stoppers behind the rear wheels.

CONTINUED

CLICK HERE TO VIEW CHAPTER INDEX

IN--6

1KZ-TE

Pages From Manual

TO MODEL INDEX

--INTRODUCTION REPAIR INSTRUCTIONS

When either the front or rear wheels only should be

S

jacked up, set rigid racksand place stoppers in front

and behind the other wheels on the ground.

After the vehicle is jacked up, be sure to support it

S

on rigid racks. It is extremely dangerous to do any

work on a vehicle raised on a jack alone, even for

a small job that can be finished quickly.

(l) Observe the following precautions to avoid damage to the

following parts:

(1) Do not open the cover or case of the ECU unless

absolutely necessary. (If the IC terminals are

touched, the IC may be destroyed by static electricity.)

WRONG CORRECT

WRONG CORRECT

IN0253

IN0252

(2) To disconnect vacuum hoses, pull off the end, not

the middle of the hose.

(3) To pull apart electrical connectors, pull on the con-

nector itself, not the wires.

(4) Be careful not to drop electrical components, such

as sensors or relays. If they are dropped on a hard

floor, they should be replaced and not reused.

(5) When steam cleaning an engine, protect the elec-

tronic components, air filter and emission--related

components from water.

(6) Never use an impact wrench to remove or install

temperature switches or temperature sensors.

(7) When checking continuity at the wire connector, in-

sert the tester probe carefully to prevent terminals

from bending.

(8) When using a vacuum gauge, never force the hose

onto a connector that is too large. Use a step--down

adapter for adjustment. Once the hose has been

stretched, it may leak.

CONTINUED

CLICK HERE TO VIEW CHAPTER INDEX

--INTRODUCTION REPAIR INSTRUCTIONS

1KZ-TE

Pages From Manual

TO MODEL INDEX

IN-- 7

Example

IN0002

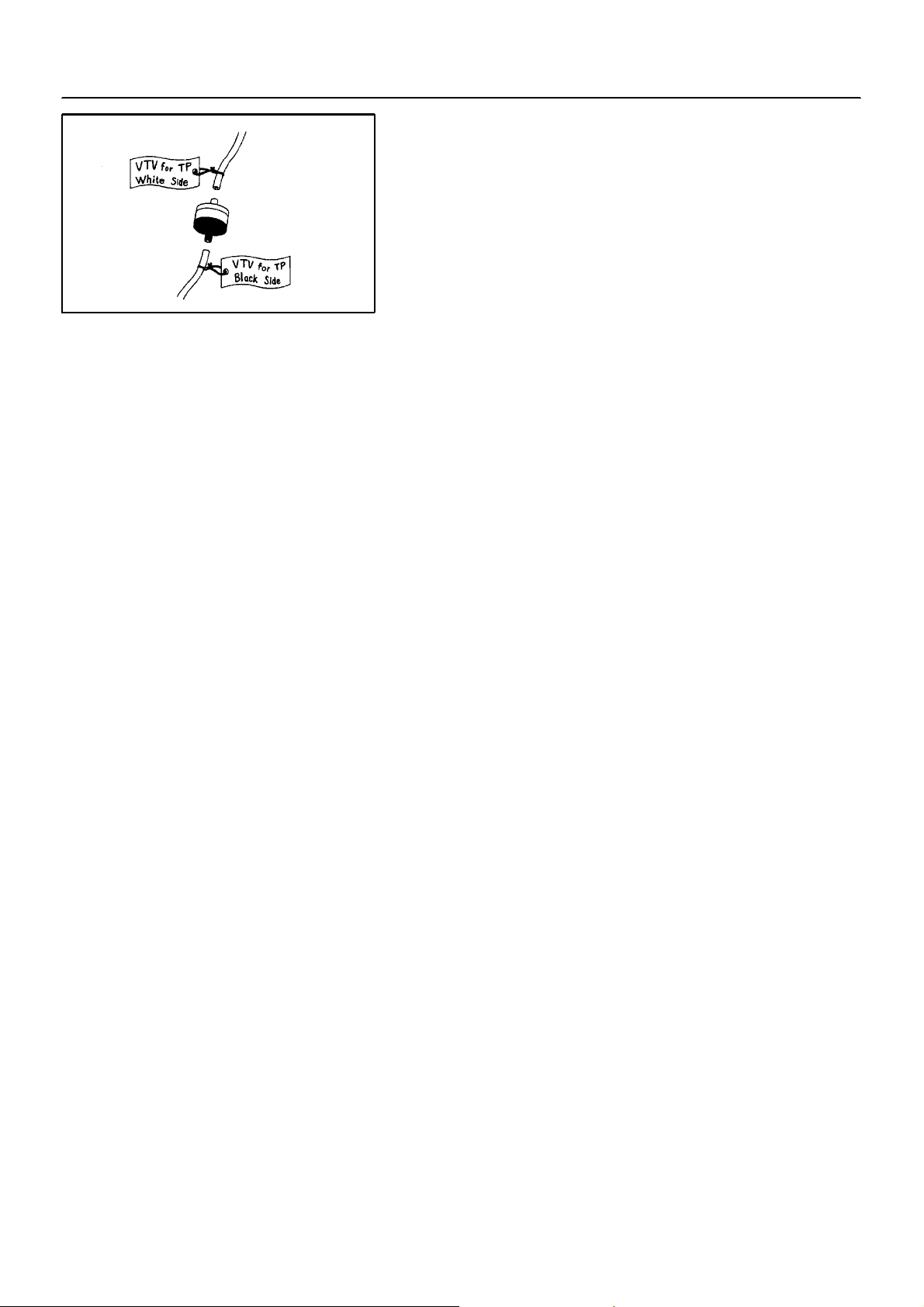

(m) Tag hoses before disconnecting them:

(1) When disconnecting vacuum hoses, use tags to

identify how they should b e reconnected.

(2) After completing a job, double check that the vacu-

um hoses are properly connected. A label under the

hood shows the proper layout.

(n) Unless otherwise stated, all resistance is measured at an

ambient temperature of 20˚C(68˚F). Because the resis-

tance may be outside specifications if measured at high

temperatures immediately after the vehicle has been running, measurementshould be made when the engine has

cooled down.

CLICK HERE TO VIEW CHAPTER INDEX

IN-- 8

FOR ALL OF VEHICLES

PRECAUTION

1. IF VEHICLE IS EQUIPPED WITH MOBILE COMMUNICATION SYSTEM

For vehicles with mobile communication systems such as two --way radios and cellular telephones, observe

the following precautions.

(1) Install the antenna as far as possible away from the ECU and sensors of the vehicle’s electronic

system.

(2) Install the antenna feeder at least 20 cm (7.87 in.) away from the ECU and sensors of the ve-

hicle’s electronic systems. For details about ECU and sensors locations, refer to the section on

the applicable component.

(3) Avoid winding the antenna feeder together with the other wiring as much as possible, and also

avoid running the antenna feeder parallel with other wire harnesses.

(4) Check that the antenna and feeder are correctly adjusted.

(5) Do not install powerful mobile communications system.

2 . FO R US I NG HAND -- HE LD TE S T E R

CAUTION:

Observe the following items for safety reasons:

Before using the hand--held tester, the hand--held tester’s operator manual should be read

SSSS

throughly.

Be sure to route all cables securely when driving with the hand--held tester connected to the

SSSS

vehicle. (i.e. Keep cables away from feet, pedals, steering wheel and shift lever.)

Two persons are required when test driving with the hand--held tester, one person to drive the

SSSS

vehicle and one person to operate the hand--held tester.

--INTRODUCTION FOR ALL OF VEHICLES

1KZ-TE

Pages From Manual

TO MODEL INDEX

IN0E8--02

CLICK HERE TO VIEW CHAPTER INDEX

HOW TO T ROUBLESHOOT ECU CONTROLLED SYSTEMS

GE NE RAL I NFORMATI ON

A large number of ECU controlled systems are used in the HILUX. In general, the ECU controlled system

is considered to be a very intricate system requiring a high level of technical knowledge and expert skill to

troubleshoot. However, the fact is that if you proceed to inspect the circuits one by one, troubleshooting of

these systems is not complex. If you have adequate understanding of the system and a basic knowledge

of electricity, accurate diagnosis and necessary repair can be performed to locate and fix the problem. This

manual is designed through emphasis of the above standpoint to help service technicians perform accurate

and effective troubleshooting, and is compiled for the following major ECU controlled systems:

System Page

Engine DI --1

The troubleshooting procedure and how to make use of it are described on the above pages.

FO R US I NG HAND -- HE LD TE S T E R

Before using the hand--held tester, the hand held --tester’s operator manual should be read throughly.

S

S If the hand--held tester cannot communicate with ECU controlled systems when you have connected

the cable of the hand--held tester to DLC3, turned the ignition switch ON and operated the scan tool,

there is a problem on the vehicle side or tool side.

(1) If communication is normal when the tool is connected to another vehicle, inspect the diagnosis

data link line (Busline) or ECU power circuit of the vehicle.

(2) If communication is still not possible when the tool is connected to another vehicle, the problem

is probably in the tool itself, so perform the Self Test procedures outlined in the Tester Operator’s

Manual.

1KZ-TE

--INTRODUCTION HOW TO TROUBLESHOOT ECU CONTROLLED

SYSTEMS

Pages From Manual

TO MODEL INDEX

IN-- 9

IN050--05

CLICK HERE TO VIEW CHAPTER INDEX

Pages From Manual

INTRODUCTION – HOW TO TROUBLESHO O T ECU CONTROLLED SYSTEMS

HOW TO PROCEED WITH TROUBLESHOOTING IN-10

1. CUSTOMER PROBLEM ANALYSIS IN-11

2. SY M PTOM CONFIRMATION AND DIAGNOSTIC TROUBLE CODE CHECK IN-12/13

3. SYMPTOM SIMULATION IN-14/15

4. DIAGNOSTIC TROUBLE CODE CHART IN-16

5. PROBLEM SYMPTOMS TABLE IN-17

6. CIRCUIT INSPECTION IN-18/19

1KZ-TE

TO MODEL INDEX

CLICK HERE TO VIEW CHAPTER INDEX

Pages From Manual

IN-- 10

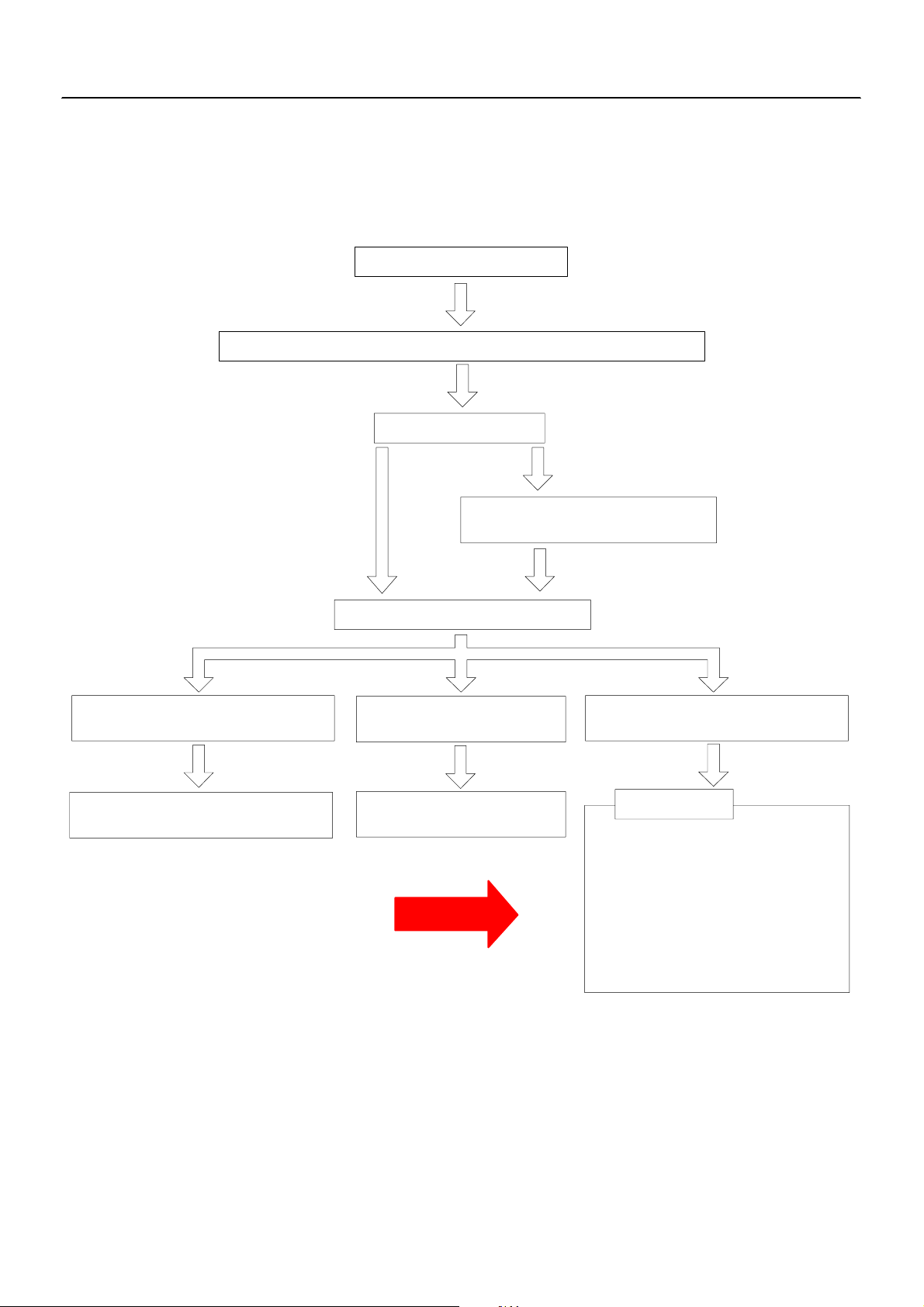

HOW TO P ROCE E D WI T H T ROUBL E S HOOT I NG

Carry out troubleshooting in accordance with the procedure on the following page. Here, only the basic procedure is shown. Details are provided in each section, showing the most effective methods for each circuit.

Confirm the troubleshooting procedures first for the relevant circuit before beginning troubleshooting of that

circuit.

Vehicle Brought to Workshop

1

Customer Problem

Analysis

1KZ-TE

TO MODEL INDEX

--INTRODUCTION HOW TO TROUBLESHOOT ECU CONTROLLED

SYSTEMS

1

Ask the customer about the conditions and the

environment when the problem occurred.

IN051--0 5

2

Symptom Confirmation

and Diagnostic Trouble

3

Symptom Simulation

Code Check

2, 3

Confirm the symptoms and the problem conditions,

and check the diagnostic trouble codes.

(When the problem symptoms do not appear

during confirmation, use the symptom simulation

method described later on.)

4

Diagnostic Trouble

Code Chart

5

Problem Symptoms Table

4, 5, 6

Check the results obtained in Step 2, then confirm

the inspection procedure for the system or the part

which should be checked using the diagnostic

6

Circuit Inspection or Parts

trouble code chart or the problem symptoms table.

Inspection

7

7

Repair

Check and repair the affected system or part in

accordance with the instructions in Step 6.

8

Confirmation Test

8

After completing repairs, confirm that the problem

has been eliminated.

(If the problem is not reproduced, perform the

End

confirmation test under the same conditions and

in the same environment as when it occurred for

the first time.)

CLICK HERE TO VIEW CHAPTER INDEX

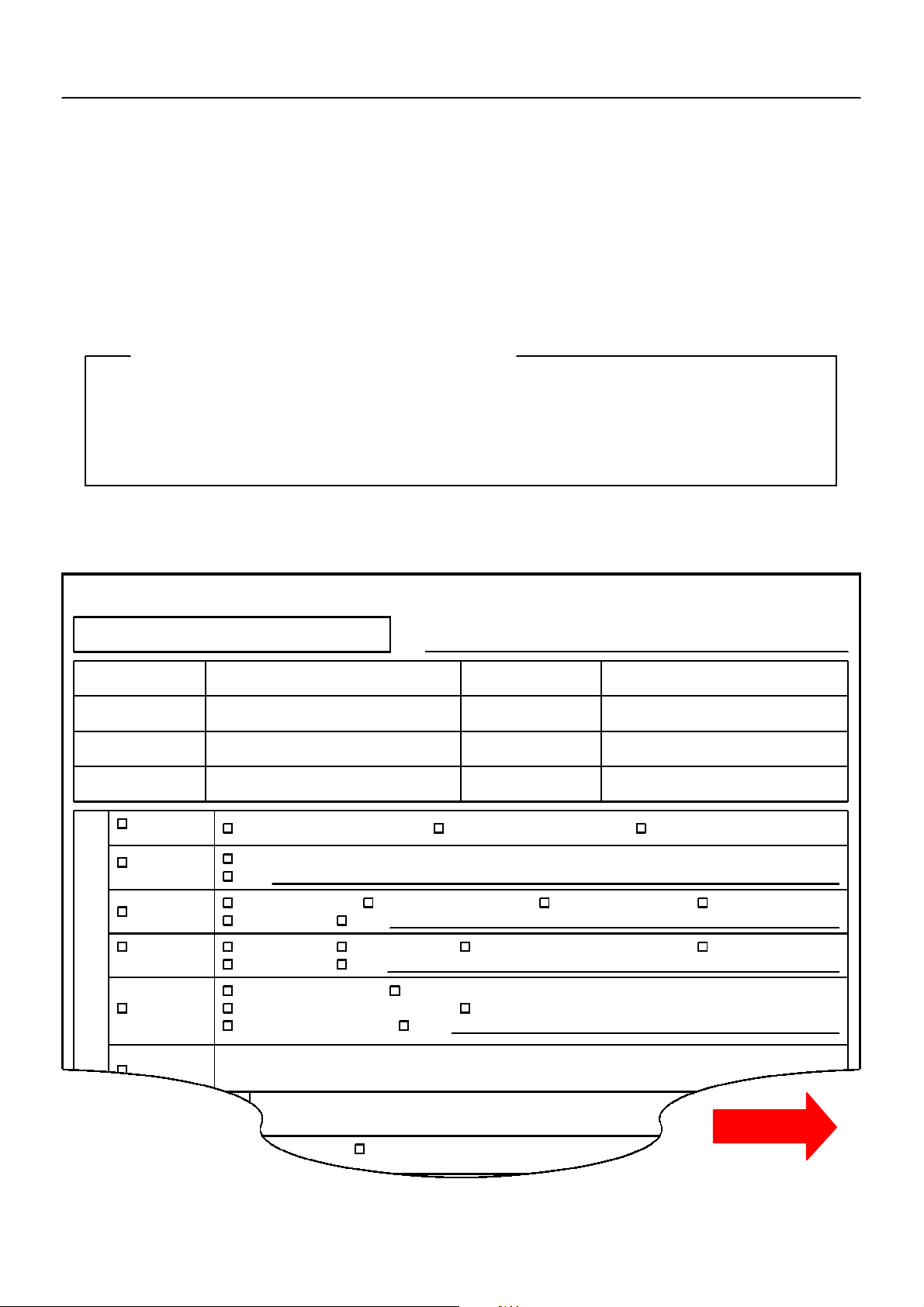

1 . CUS TO ME R P RO BLE M ANALY S I S

In troubleshooting, the problem symptoms must be confirmed accurately and all preconceptions must be

cleared away in order to give an accurate judgement. To ascertain just what the problem symptoms are, it

is extremely important to ask the customer about the problem and the conditions at the time it occurred.

Important Point in the Problem Analysis:

The following 5 items are important points in the problem analysis. Past problems which are thought to be

unrelated and therepair history, etc. may also help in some cases, so as much information as possibleshould

be gathered and its relationship with the problem symptoms should be correctly ascertained for reference

in troubleshooting. A customer problem analysis table is provided in the troubleshooting section for each

system fo r your use.

Important Points in the Customer Problem Analysis

D What ---- ---- -- V ehicle model, system name

D When -- ---- ---- Date, time, occurrence frequency

D Where -- ------ -- Road conditions

D Under what conditions? -- ---- ---- Running conditions, driving conditions, weather conditions

D How did it happen? ---- ---- -- Problem symptoms

1KZ-TE

--INTRODUCTION HOW TO TROUBLESHOOT ECU CONTROLLED

SYSTEMS

Pages From Manual

TO MODEL INDEX

IN-- 11

(Sample) Engine control system check sheet.

CUSTOMER PROBLEM ANALYSIS CHECK

ENGINE CONTROL SYSTEM Check Sheet

Customer’s Name

Driver’s Name

Data Vehicle

Brought in

License No.

Problem Symptoms

Engine does

not Start

Difficult to

Start

Poor Idling

Poor

Drive ability

Engine Stall

Engine does not crank No initial combustion No complete combustion

Engine cranks slowly

Other

Incorrect first idle Idling rpm is abnormal High ( rpm) Low ( rpm)

Rough idling

Hesitation Back fire Muffler explosion (after --fire) Surging

Knocking

Soon after starting After accelerator pedal depressed

After accelerator pedal released

Shifting from N to D

Other

Other

Inspector’s

Name

Model and Model

Year

Frame No.

Engine Model

Odometer Reading

During A/C operation

Other

km

miles

Others

Datas Problem

CONTINUED

Constant Sometimes ( times per day/month)

CLICK HERE TO VIEW CHAPTER INDEX

IN-- 12

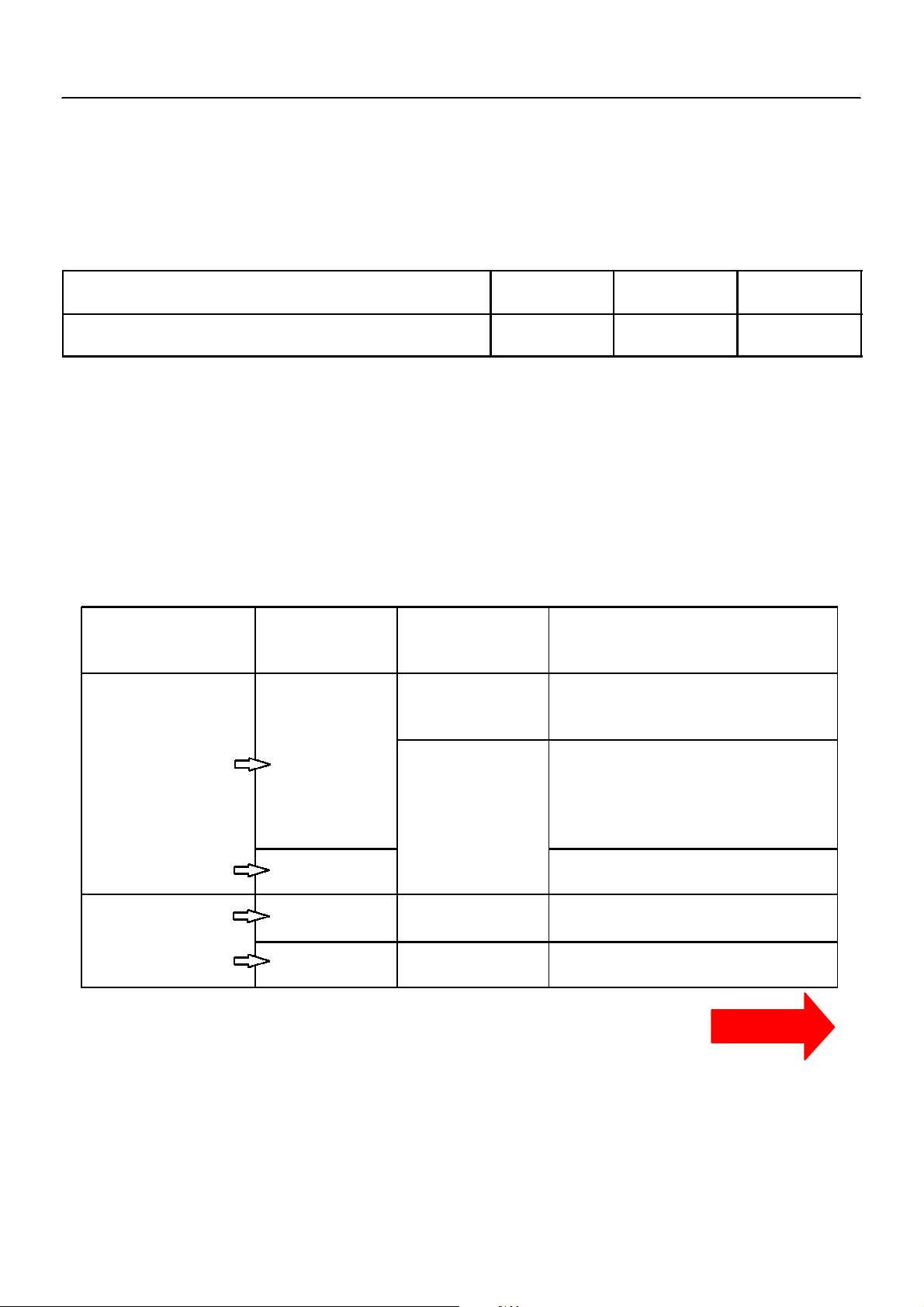

2 . S Y MP TO M CO NFI RMATI O N AND DI AG NO S T I C TRO UBLE CO DE CHE CK

The diagnostic system in the HILUX fulfills various functions. The first function is the Diagnostic Trouble

Code Check in which a malfunction in the signal circuits to the ECU is stored in code in the ECU memory

at the time of occurrence, to be output by the technician during troubleshooting. Another function is the Input

Signal Check which checks if the signals from various switches are sent to the ECU correctly.

By using these check functions, the problem areas can be narrowed down quickly and troubleshooting can

be performed effectively. Diagnostic functions are incorporated in the following systems in the HILUX.

1KZ-TE

--INTRODUCTION HOW TO TROUBLESHOOT ECU CONTROLLED

SYSTEMS

Pages From Manual

TO MODEL INDEX

Engine

System

Diagnostic Trouble

Code Check

f

(with Test Mode)

Input Signal Check

(Sensor Check)

f

Other Diagnosis

Function

Diagnostic Test

Mode

In diagnostic trouble code check, it is very important to determine whether the problem indicated by the diagnostic trouble code is still occurring or occurred in the past but returned to normal at present. In addition,

it must be checked in the problem symptom check whether the malfunction indicated by the diagnostic

trouble code is directly related to the problem symptom or not. For this reason, the diagnostic trouble codes

should be checked before and after the symptom confirmation to determine the current conditions,as shown

in the table below. If this is not done, it may, depending on the case, result in unnecessary troubleshooting

for normally operating systems, thus making it more difficult to locate the problem, or in repairs not pertinent

to the problem. Therefore, always follow the procedure in correct order and perform the diagnostic trouble

code check.

DIAGNOSTIC TROUBLE CODE CHECK PROCEDURE

Diagnostic Trouble

Code Check (Make a

note of and then clear)

Diagnostic Trouble

Code Display

Confirmation

of Symptoms

Problem symptoms

exist

Diagnostic Trouble

Code Check

Same diagnost ic

trouble code is

displayed

Problem Condition

Problem is still occurring in the diagnostic

circuit

Normal Code Display

No problem

symptoms exist

Problem symptoms

exist

No problem

symptoms exist

Normal code is

displayed

Normal code is

displayed

Normal code is

displayed

The problem is still occurring in a place

other than in the diagnostic circuit

(The diagnostic trouble code displayed

first is either for a past problem or it is a

secondary problem)

The problem occurred in the diagnostic

circuit in the past

The problem is still occurring in a place

other than in the diagnostic circuit

The problem occurred in a place other

than in the diagnostic circuit in the past

CONTINUED

CLICK HERE TO VIEW CHAPTER INDEX

Taking into account the above points, a flow chart showing how to proceed with troubleshooting using the

diagnostic trouble code check is shown below. This flow chart shows how to utilize the diagnostic trouble

code check effectively, then by carefully checking the results, indicates how to proceed either to diagnostic

trouble code troubleshooting or to troubleshooting of problem symptoms.

Making a note of and clearing of the diagnostic trouble codes displayed

--INTRODUCTION HOW TO TROUBLESHOOT ECU CONTROLLED

SYSTEMS

Diagnostic trouble code check

Symptom confirmation

Problem symptoms

exist

1KZ-TE

No problem symptoms

exist

Pages From Manual

TO MODEL INDEX

IN-- 13

D Diagnostic trouble code displayed

D Problem symptoms exist

Troubleshooting of problem indicated

by diagnostic trouble code

Simulation test using the symptom

simulation methods

Diagnostic trouble code check

D Normal code displayed

D Problem symptoms exist

Troubleshooting of each

problem symptom

CONTINUED

D Normal code displayed

D No problem symptoms exist

System Normal

If a diagnostic trouble code was

displayed in the initial diagnostic

trouble c ode check, it indicates

that the trouble may have occurred

in a wire harness or connector in

that circuit in the past. Therefore,

check the wire harness and connec t or s ( S ee page I N -- 20) .

CLICK HERE TO VIEW CHAPTER INDEX

IN-- 14

3. SYMPTOM SIMULATION

The most difficult case in troubleshooting is when there are no problem symptoms occurring. In such cases,

a thorough customer problem analysis must be carried out, then simulate the same or similar conditions and

environment in which the problem occurred in the customer’s vehicle. No matter how much experience a

technician has, or how skilled he may be, if he proceeds to troubleshoot without confirming the problem

symptoms he will tend to overlook something important in the repair operation and make a wrong guess

somewhere, which will only lead to a standstill. For example, for a problem which only occurs when the engine is cold, or for a problem which occurs due to vibration caused by the road during driving, etc., the problem can never be determined so long as the symptoms are confirmed with the engine hot condition or the

vehicle at a standstill. Since vibration, heat or water penetration (moisture) is likely cause for problem which

is difficult to reproduce, the symptom simulation tests introduced here are effective measures in that the external causes are applied to the vehicle in a stopped condition.

Important Points in the Symptom Simulation Test:

In the symptom simulation test, the problem symptoms should of course be confirmed, but the problem area

or parts must also be found out. To do this, narrow down the possible problem circuits according to the symptoms before starting this test and connect a tester beforehand. After that, carry out the symptom simulation

test, judging whether the circuit being tested is defective or normal and also confirming the problem symptoms at the same time. Refer to t he problem symptoms table for each system to n arrow down the possible

causes of the symptom.

1KZ-TE

--INTRODUCTION HOW TO TROUBLESHOOT ECU CONTROLLED

SYSTEMS

Pages From Manual

TO MODEL INDEX

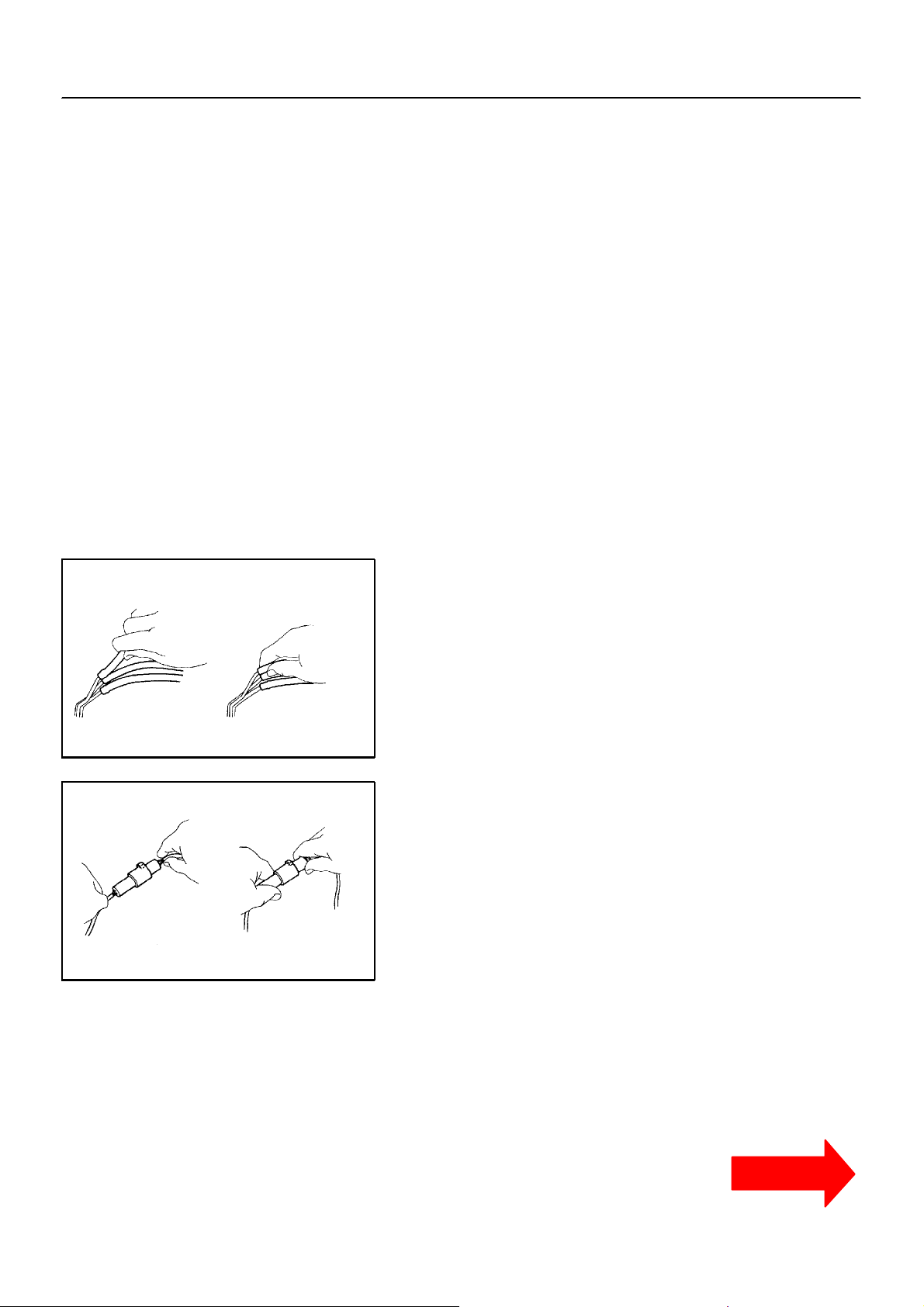

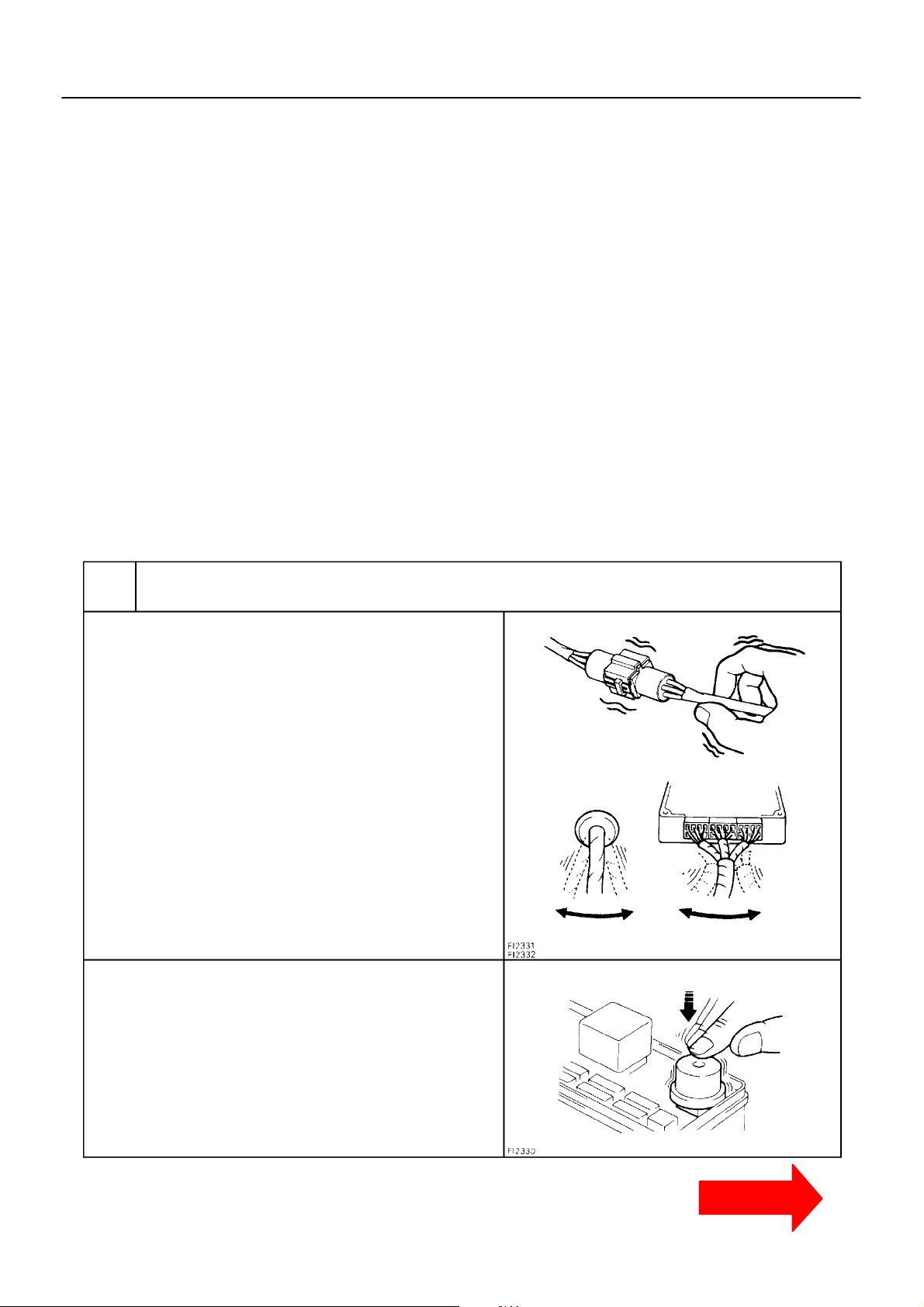

V I BRAT I O N M E T HO D: W h en vi b rat i o n seems t o b e t h e maj o r cau se.

1

CONNECTORS

Slightly shake the connector vertically and horizontally.

WIRE HARNESS

Slightly shake the wire harness vertically and horizontally.

The connector joint, f ulc r um of t he vibr at ion, and body

through portion are the major areas to be checked thoroughly.

PARTS AND SENSOR

Apply slight vibration with a finger to the part of the sensor

considered to be the problem cause and check that the

malfunction occurs.

Shake Slightly

Swing Slightly

Vibrate Slightly

HINT: Applying strong vibration to relays may result in open

relays.

V07268

CONTINUED

CLICK HERE TO VIEW CHAPTER INDEX

HE AT M E T HO D: W h en t h e p ro b l em seems t o o ccu r w h en t h e su sp ect area i s h eat ed .2

Heat the component that is the likely cause of the malfunction

with a hair dryer or similar object. Check to see if the malfunction

occurs.

NOTICE:

(1) Do not heat to more than 60˚C (140˚F). (Temperature

is limited not to damage the components.)

(2) Do not apply heat directly to parts in the ECU.

1KZ-TE

--INTRODUCTION HOW TO TROUBLESHOOT ECU CONTROLLED

SYSTEMS

Malfunction

Pages From Manual

TO MODEL INDEX

IN-- 15

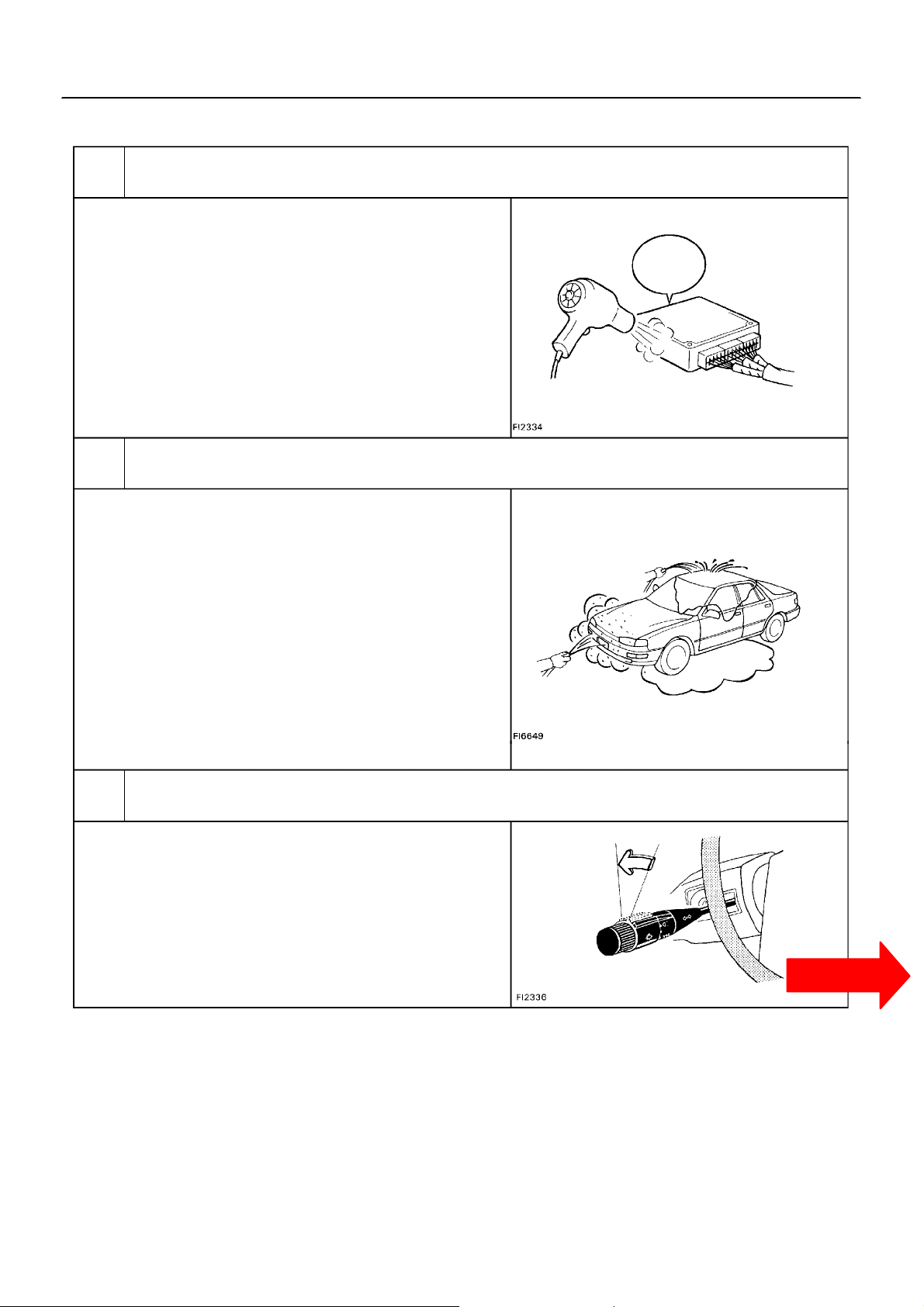

3 WAT ER SPRI NKL I NG MET HO D:

W h en t h e mal f u n ct i o n seems t o o ccu r o n a rai n y d ay o r i n a

high -- humidity condition.

Sprinkle water onto the vehicle and check to see if the malfunction occurs.

NOTICE:

(1) Never sprinkle water directly into the engine

compartment, but indirectly change the temperature and

humidity by applying water spray onto the radiator front

surface.

(2) Never apply water directly onto the electronic

components.

HINT:

I f a v ehic le is s ubjec t t o wat er leak age, t he leak ed wat er m ay

contaminate the ECU. When testing a vehicle with a water leakage problem, special caution must be taken.

4 O T HE R: W h en a mal f u n ct i o n seems t o o ccu r w h en el ect ri cal l o ad i s excessi ve.

Turn on all electrical loads including the heater blower, head

ON

lights, rear window defogger, etc. and check to see if the malfunction occurs.

CONTINUED

V07469

CLICK HERE TO VIEW CHAPTER INDEX

IN-- 16

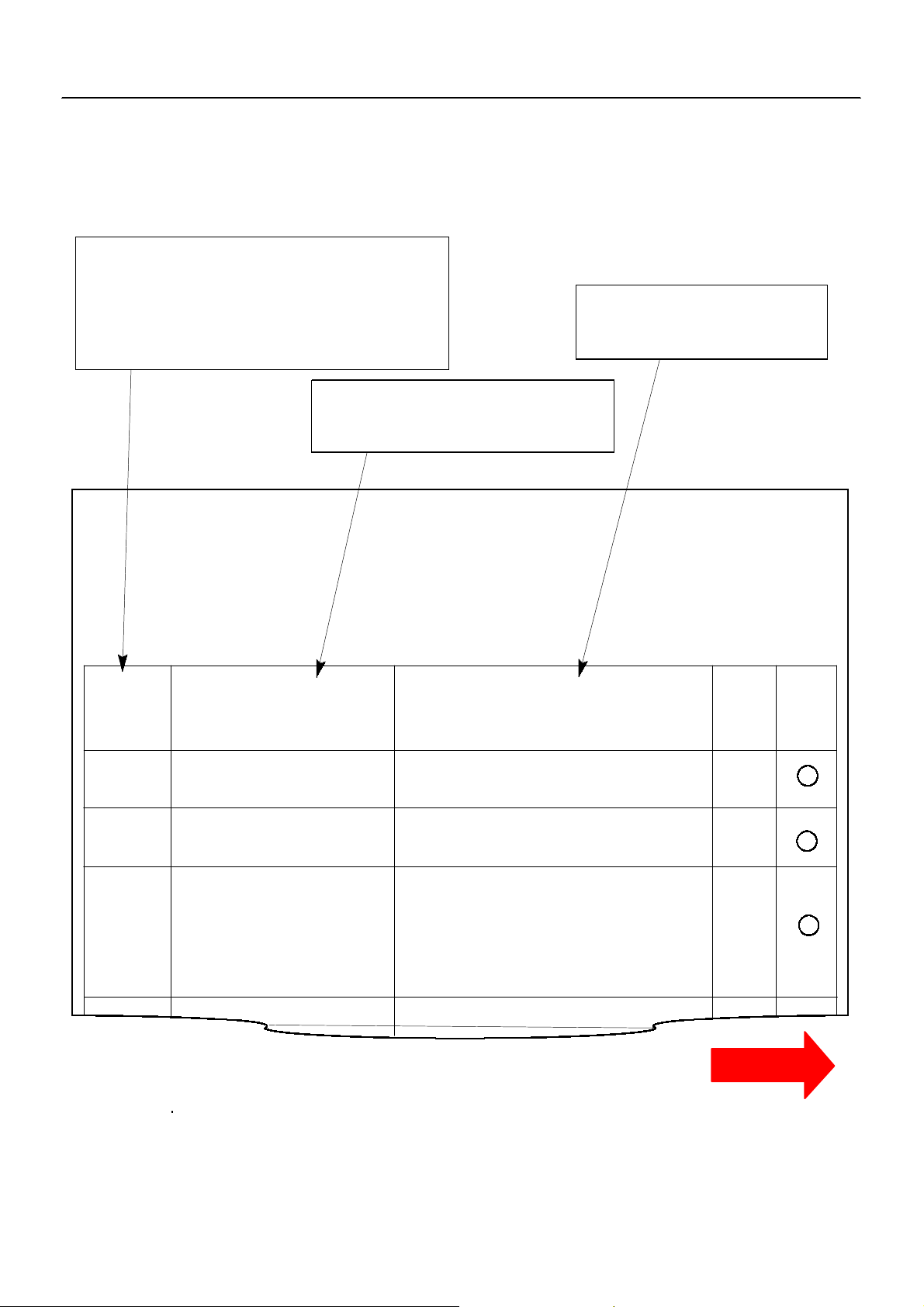

4 . DI AG NO S T I C TRO UBLE CO DE CHART

The inspection procedure is shown in the table below. This table permits efficient and accurate troubleshooting using the diagnostic trouble codes displayed in the diagnostic trouble code check. Proceed with troubleshooting in accordance with the inspection procedure given in the diagnostic chart corresponding to the

diagnostictrouble codes displayed. The engine diagnostic trouble code chartis shown below as an example.

D DTC No.

Indicates the diagnostic trouble code.

D Page or Instructions

Indicates the page where the inspection procedure

for each circuit is to be found, or gives instructions

for checking and repairs.

D Detection Item

Indicates the system of the problem or

contents of the problem.

1KZ-TE

--INTRODUCTION HOW TO TROUBLESHOOT ECU CONTROLLED

SYSTEMS

D Trouble Area

Indicates the suspect area of the

problem.

Pages From Manual

TO MODEL INDEX

DIAGNOSTIC TROUBLE CODE CHART

HINT:

Parameters listed in the chart may not be exactly the same as your reading due to the type of instrument or other

factors.

If a malfunction code is displayed during the DTC check in check (test) mode, check the circuit for that code

listed in the table below. For details of each code, turn to the page referred to under the ”See page” for the

respective ”DTC No.” in the DTC chart.

*1

DTC No.

(See page)

12

(DI -- 12)

13

(DI -- 28)

15

(DI -- 32)

Detection Item

Crankshaft Position Sensor Circuit

Malfunction

Engine Speed Sensor Circuit

Malfunction

Diesel Throttle Control Circuit

Malfunction

Trouble Area

D Open or short in crankshaft position sensor circuit

D Crankshaft position sensor

D Engine ECU

D Open or short in engine speed sensor circuit

D Engine speed sensor

D Engine ECU

D Open or short in E--VRV for main actuator circuit

D E--VRV for main actuator

D Diesel throttle position sensor circuit

D Diesel throttle position sensor

D Main actuator

D Vacuum hose disconnected or blocked

D Engine ECU

Check Engine

Warming Light

Normal Mode/

Test Node

ON / N.A

ON / N.A

ON / N.A

*2

Memory

Interior IC Malfunction

D Engine ECU

CONTINUED

CLICK HERE TO VIEW CHAPTER INDEX

5. PROBLEM SYMPTOMS TABLE

The suspect circuits or parts for each problem symptom are shown in the table below. Use this table to troubleshoot the problem when a ”Normal” code is displayed in the diagnostic trouble code check but the problem is still occurring. Numbers in the table indicate the inspection order in which the circuits or parts should

be checked.

HINT:

When the p roblem is not detected by the diagnostic system even though the problem symptom is present,

it is considered that the problem is occurring outside the detection range of the diagnostic system, or that

the problem is occurring in a system other than the diagnostic system.

D Circuit Inspection, Inspection Order

Indicates the circuit which needs to be checked for each problem

symptom. Check in the order indicated by the numbers.

1KZ-TE

Pages From Manual

TO MODEL INDEX

--INTRODUCTION HOW TO TROUBLESHOOT ECU CONTROLLED

SYSTEMS

D Page

Indicates the page where the flow chart for each circuit

is located.

IN-- 17

D Problem Symptom

PROBLEM SYMPTOMS TABLE

Symptom

Engine does not crank (Does not start)

No initial combustion (Does not start)

Cold engine (Difficult to start)

Hot engine

D Circuit or Part Name

Indicates the circuit or part which needs to be checked.

Suspect Area

1.Starter

2. Starter relay

1. ECU power source circuit

2. Pre--heating system

3. Compression

4. Engine ECU

1. Pre--heating system

2. Starter signal circuit

3. Water temperature sensor

4. Injector

5. Fuel filter

6. Diesel throttle body

7. Engine ECU

1. Starter signal circuit

2. Injector

3. Fuel filter

4. Diesel throttle body

5. Engine ECU

1. Fuel filter

2. Diesel throttle body

3 Engine ECU

See page

ST--3

ST--14

DI-- 93

ST--1

EM--2

IN--20

ST--1

DI-- 11 5

ED--10

FU--1

DI-- 26

IN--20

DI-- 11 5

CONTINUED

CLICK HERE TO VIEW CHAPTER INDEX

IN-- 18

6 . CI RCUI T I NSPECTION

How to read and use each page is shown below.

D Diagnostic Trouble Code No. and Detection Item

1KZ-TE

--INTRODUCTION HOW TO TROUBLESHOOT ECU CONTROLLED

SYSTEMS

D Circuit Description

The major role and operation, etc. of the circuit

and its component parts are explained.

Pages From Manual

TO MODEL INDEX

DTC 12

Crankshaft Position Sensor Circuit Malfunction

CIRCUIT DESCRIPTION

The crankshaft position sensor in the Engine Control System contains signal plate and a pickup coil for TDC signal.

The TDC signal plate has 1 tooth on its outer circumference. The TDC s ignal sensor generates 1 signal for every engine

revolution. The engine ECU detects the top dead center by the TDC signal s. The NE signal plate has 52 teeth and is

mounted in thes uppl y pump. The NE signal sensor generates 52 signals of engine 2 revolutions. The engine ECU detects

the engine speed and cam lift posi ti on of the s uppl y pump. The engine ECU uses TDC signal and NE signals for injection

control. And NE signal is used for injection volume control, also.

DTC No. DTC Detecting Condition Trouble Area

D Open or short in crankshaft position sensor

12

No TDC signal to engine ECU at 500 rpm or more

circuit

D Crankshaft position sensor

D Engine ECU

D Indicates the diagnostic trouble code, diagnostic

trouble code set parameter and suspect area of

the problem.

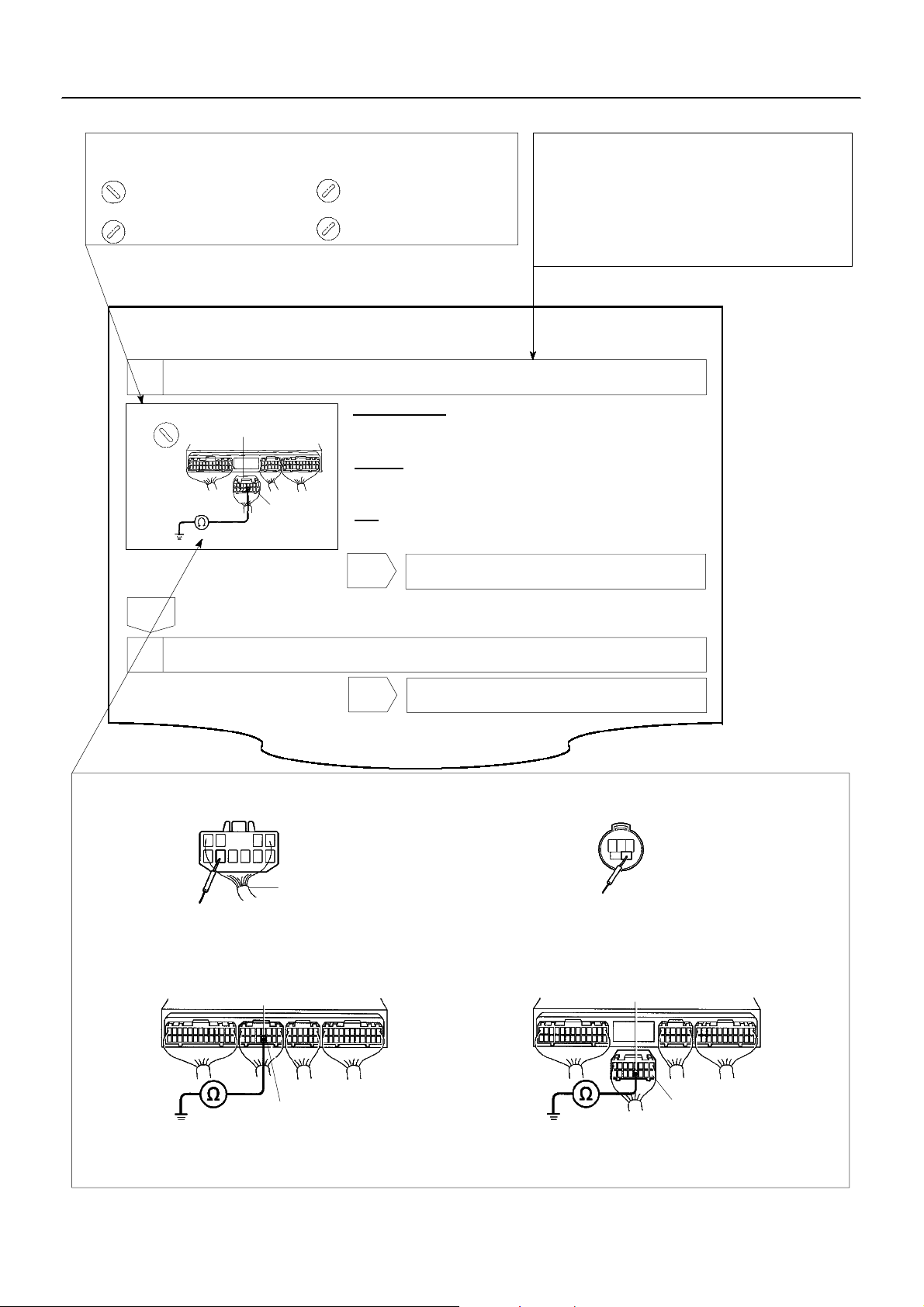

WIRING DIAGRAM

D Wiring Diagram

This shows a wiring diagram of the circuit.

Use this diagram together with ELECTRICAL

WIRING DIAGRAM to thoroughly understand the

circuit.

Wire colors are indicated by an alphabetical code.

B = Black, L = Blue, R = Red, BR = Brown,

Crankshaft Pos ition Sens or

1

2

Engine ECU

6

B-- W

L

G22+

E7

LG = Light Green, V = Violet, G = Green,

Engine Speed Sensor

(inside the Suppy Pump)

1

2

B-- R

BR L

B-- R

5

E7

6

E7

NE--

NE+

E2

O = Orange, W = White, GR = Gray, P = Pink,

Y = Yellow

The first letter indicates the basic wire color and the

second letter indicates the color of the stripe.

CONTINUED

B02134

CLICK HERE TO VIEW CHAPTER INDEX

1KZ-TE

--INTRODUCTION HOW TO TROUBLESHOOT ECU CONTROLLED

SYSTEMS

Pages From Manual

TO MODEL INDEX

IN-- 19

D Indicates the position of the ignition switch during the check.

LOCK

Ignition Switch LOCK (OFF)

START

Ignition Switch START

ON

Ignition Switch ON

ACC

Ignition Switch ACC

INSPECTION PROCEDURE

1 Check continuity between terminal THW of ECU connector and body ground.

LOCK

AB0117

A00265

THW

E6 Connector

PR EPA R ATIO N :

( a) R emov e t he glov e c ompar t ment .

(b) Disconnect the E6 connector of ECU.

CHECK:

Measure resistance between terminal THW of ECU connector

and body ground.

OK:

A00255

Resistance: 1 MΩ or higher

OK

G o t o st ep 3.

D Inspection Procedure

Use the inspection procedure to determine

if the circuit is normal or abnormal, and if

it is abnormal, use it to determine whether

the problem is located in the sensors,

actuators, wire harness or ECU.

NG

2

C h eck w at er t emp . sen so r ( S ee p ag e E D -- 15) .

OK

Replace water temp. sensor.

D Indicates the place to check the voltage or resistance.

D Indicates the connector position to be checked, from the front or back side.

Wire Harness

Check from the connector back side.

(with harness)

Check from the connector front side. (without harness)

In this case, care must be taken not to bend the terminals.

D Indicates the condition of the connector of ECU during the check.

TWH

THW

E6 Connector

Connector being checked is connected.

E6 Connector

Connector being checked is disconnected.

V08425

CLICK HERE TO VIEW CHAPTER INDEX

IN-- 20

FI0046

FI0047

FI0048

1KZ-TE

Pages From Manual

TO MODEL INDEX

--INTRODUCTION HOW TO TROUBLESHOOT ECU CONTROLLED

SYSTEMS

IN052--05

HOW TO US E THE DI AGNOS TI C

CHART AND I NS P E CT I ON

PROCEDURE

1. CO NNE CTO R CO NNE CTI O N AND TE RMI NAL I NSPECTION

S For troubleshooting, diagnostic trouble code charts or

problem symptomcharts are provided for each circuit with

detailed inspection procedures on the following pages.

S When all the component parts, wire harnesses and con-

nectors of each circuit except the ECU are found to be

normal in troubleshooting, then it is determined that the

problem is in the ECU. Accordingly, if diagnosis is performed without the problem symptoms occurring, refer to

step 8 to replace the ECU, even if the problem is not in the

ECU. So always confirm that the problem symptoms are

occurring, or proceed with inspection while using the

symptom simulation method.

S The instructions ”Check wire harness and connector” and

”Check and replace ECU” which appear in the inspection

procedure, are common and applicable to all diagnostic

trouble codes. Follow the procedure outlined below

whenever these instructions appear.

OPEN CIRCUIT:

This could be due to a disconnected wire harness, faulty contact in the connector, and a connector terminal pulled out, etc.

HINT:

It is rarely the case that a wire is broken in the middle of

S

it. Most cases occur at the connector. In particular, carefully check the connectors of sensors and actuators.

Faulty contact could be due to rusting of the connector

S

terminals, to foreign materials entering terminals or a deformation of connector terminals. Simply disconnecting

and reconnecting the connectors once changes the

condition of the connection and may result in a return to

normal operation. Therefore, in troubleshooting, if no abnormality is found in the wire harness and connector

check, but the problem disappears a fter the check, then

the cause is considered to be in the wire harness or connectors.

SHORT CIRCUIT:

This could be due to a contact between wire harness and the

body ground or to a short circuit occurred inside the switch, etc.

HINT:

When there isa short circuit between the wireharness and body

ground, check thoroughly whether the wire harness is caught

in the body or is clamped properly.

CONTINUED

CLICK HERE TO VIEW CHAPTER INDEX

1KZ-TE

--INTRODUCTION HOW TO TROUBLESHOOT ECU CONTROLLED

SYSTEMS

Pages From Manual

TO MODEL INDEX

IN-- 21

Sensor Side

Sensor Side

Sensor Side

ECU Side

ECU Side

ECU Side

IN0379

IN0378

IN0380

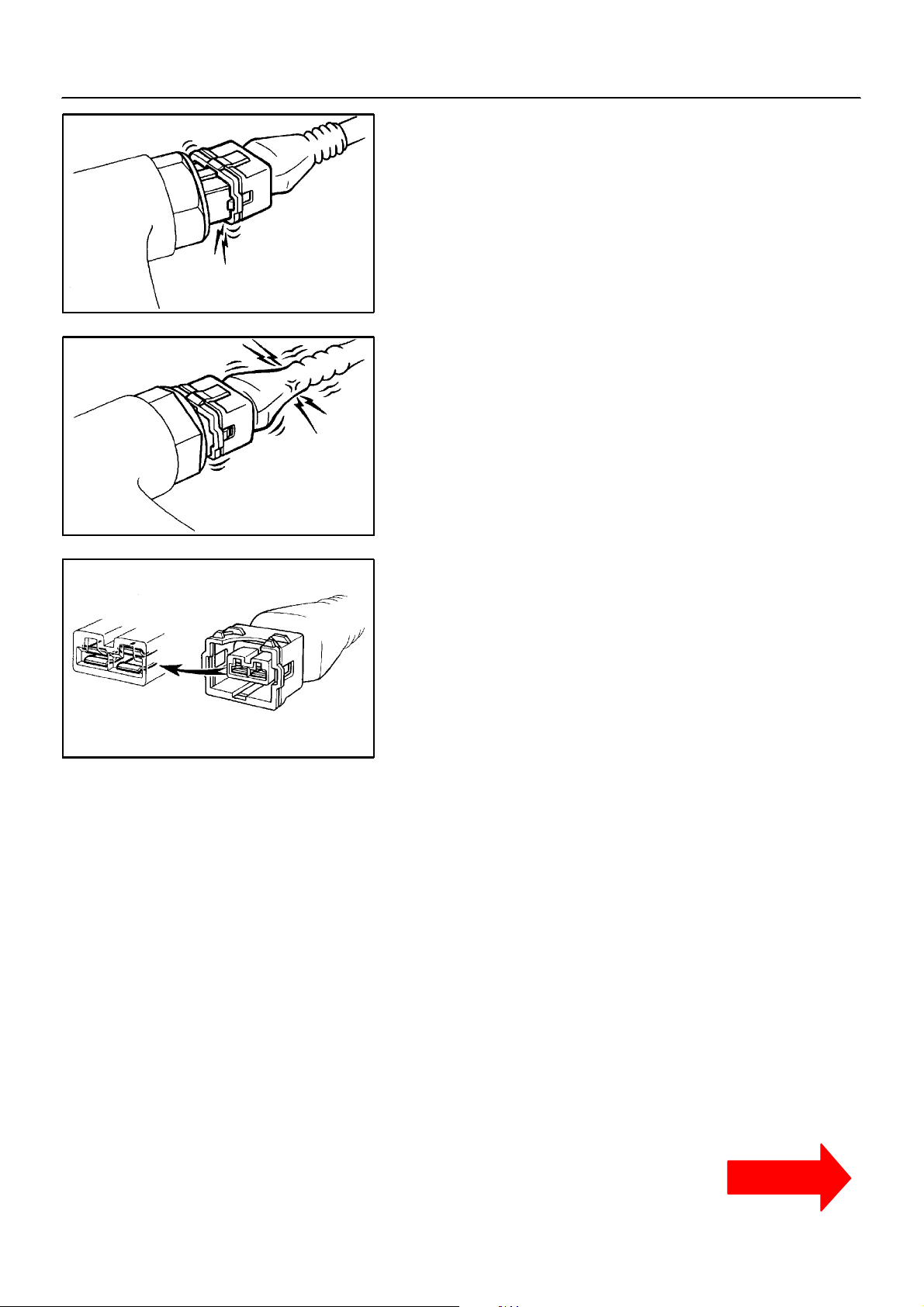

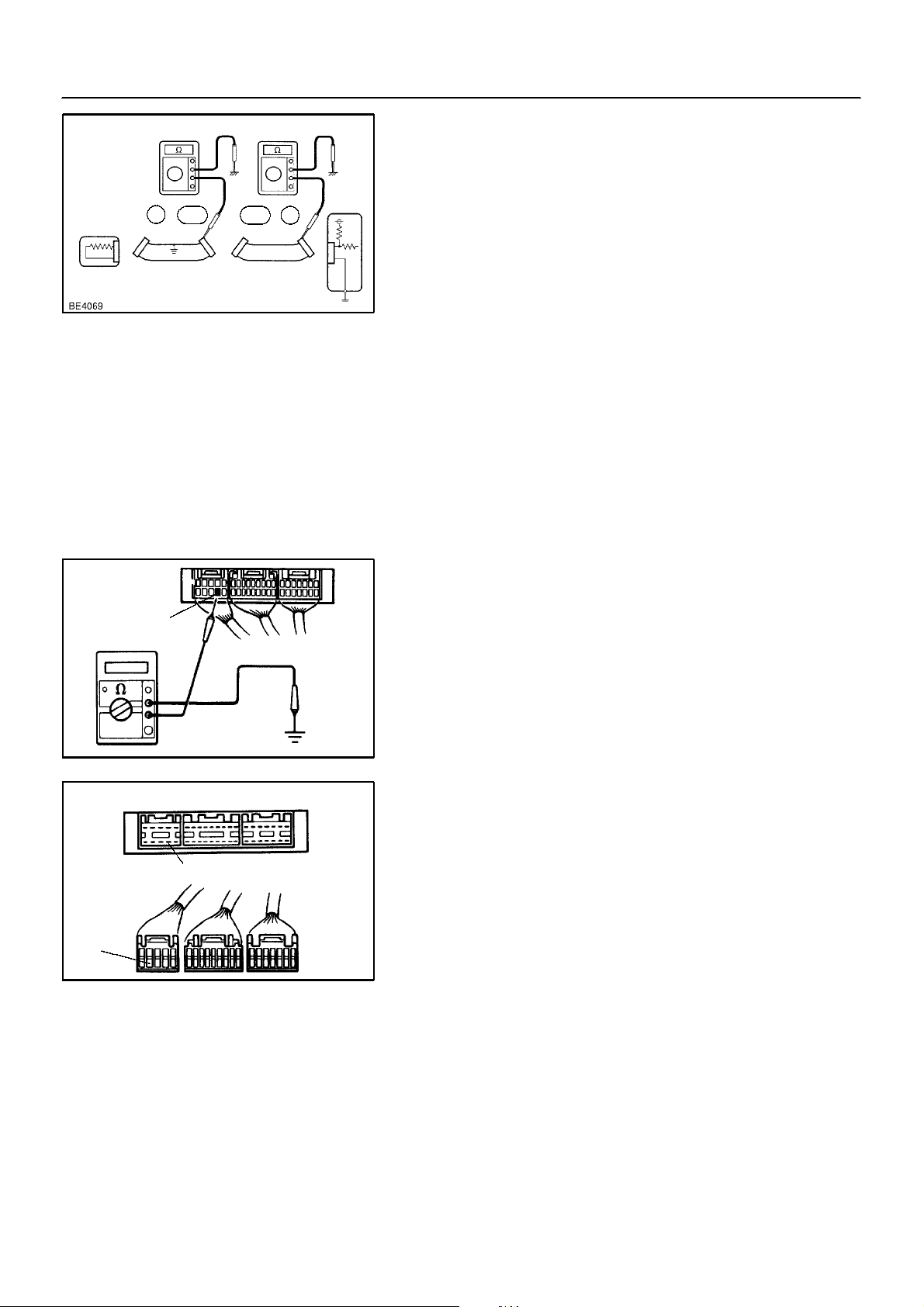

2 . CO NTI NUI TY CHE CK (O P E N CI RCUI T CHE CK)

(a) Disconnect the connectors at both ECU and sensor

sides.

(b) Measure the resistance between the applicable terminals

of the connectors.

Resistance: 1Ω or less

HINT:

Measure the resistance while lightly shaking the wire har-

S

ness vertically and horizontally.

S When tester probes are inserted into a connector, insert

the probes from the back. For waterproof connectors in

which the probes cannot be inserted from the back, be

careful not to bend the terminals when inserting the tester

probes.

3 . RE S I S TANCE CHE CK (S HO RT CI RCUI T CHE CK)

(a) Disconnect the connectors on both ends.

(b) Measure the resistance between the applicable terminals

of the connectors and body ground. Be sure to carry out

this check on the connectors on both ends.

Resistance: 1 MΩ or higher

HINT:

Measure the resistance while lightly shaking the wire harness

vertically and horizontally.

Pull Lightly

Looseness of Crimping

IN0381

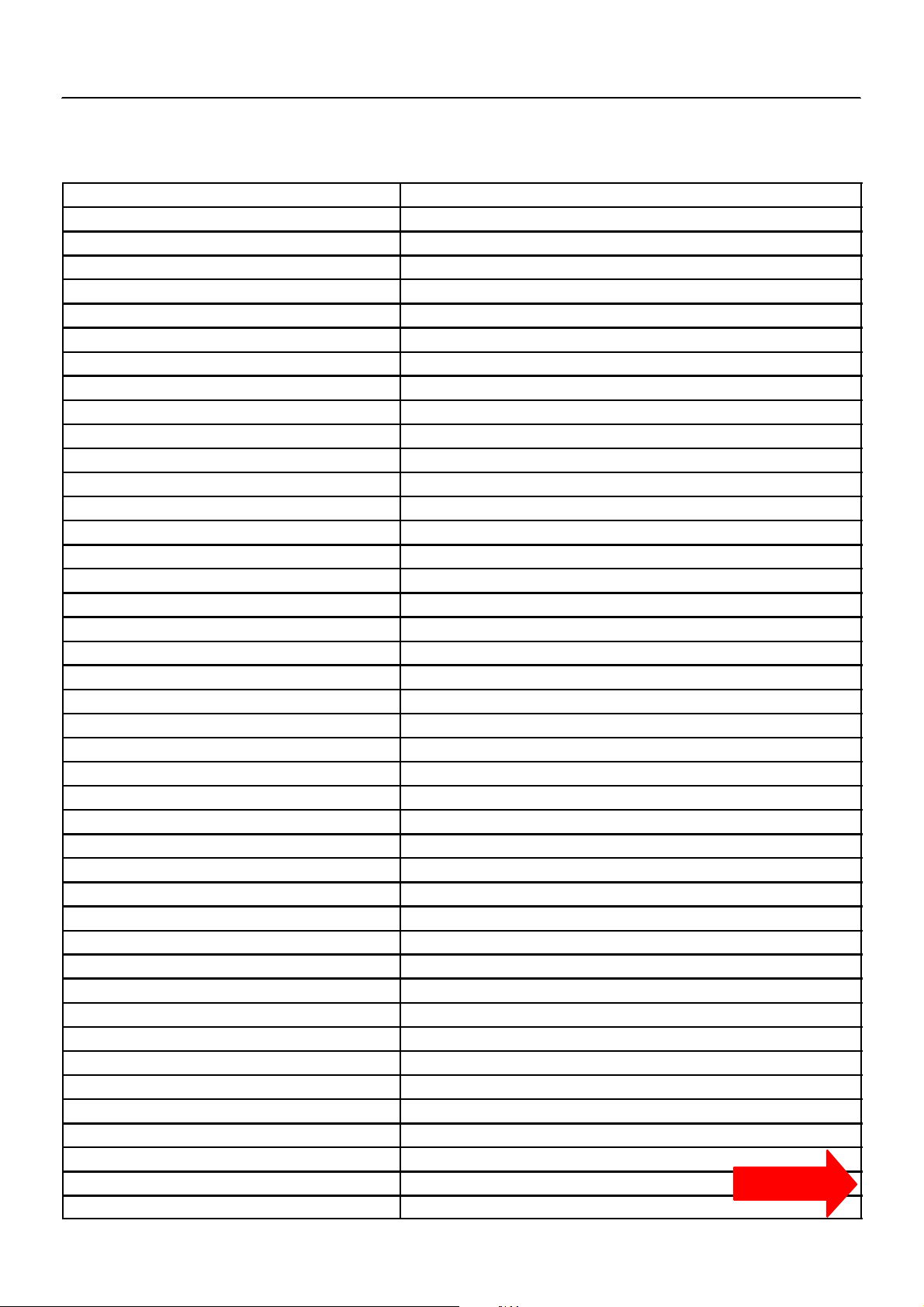

4 . V I S UAL CHE CK AND CO NTACT P RE S S URE CHE CK

(a) Disconnect the connectors at both ends.

(b) Check for rust or foreign material, etc. in the terminals of

the connectors.

(c) Check crimped portions for looseness or damage and

check that the terminals are secured in lock portion.

HINT:

The terminals should not come out when pulled lightly.

(d) Prepare a test male terminaland insert it in the female ter-

minal, then pull it out.

NOTICE:

When testing a gold--plated female terminal, always use a

gold--plated male terminal.

HINT:

When the test terminal is pulled out more easily than others,

there may be poor contact in that section.

CONTINUED

CLICK HERE TO VIEW CHAPTER INDEX

IN-- 22

FI7187

Fig. 1 ECU

Sensor

C

OPEN

1

2

B

121

22

A

1

1KZ-TE

Pages From Manual

TO MODEL INDEX

--INTRODUCTION HOW TO TROUBLESHOOT ECU CONTROLLED

SYSTEMS

5 . CO NNE CTO R HANDLI NG

When inserting tester probes into a connector, insert them from

the rear of the connector. When necessary, use mini test leads.

For water resistant connectors which cannot be accessed from

behind, take good care not to deform the connector terminals.

6 . CHE CK O P E N CI RCUI T

For the open circuit in the wire harness in Fig. 1, perform ”(a)

Continuity Check” or ”(b) Voltage Check” to locate the section.

Fig. 2

Sensor

Fig. 3

Sensor

Z17004

(a) Check the continuity.

(1) Disconnect connectors ”A” and ”C” and measure

the resistance between them.

ECU

C

1

2

B

A

1

1

2

2

In the case of Fig. 2,

Between terminal 1 of connector ”A” and terminal 1

of connector ”C” → No continuity (open)

Between terminal 2 of connector ”A” and terminal 2

of connector ”C” → Continuity

Z17005

Therefore, it is found out that there is an open circuit

between terminal 1 of connector ”A” and terminal 1

of connector ”C”.

(2) Disconnect connector ”B” and measure the resis-

ECU

tance between the connectors.

In the case of Fig. 3,

Between terminal 1 of connector ”A” and terminal 1

B2

1

1

2

2

22

AB1C

1

1

of connector ”B1” → Continuity

Between terminal 1 of connector ”B2” and terminal

1 of connector ”C” → No continuity (open)

B04722

Therefore, it is found out that there is an open circuit

between terminal 1 of connector ”B2” and terminal

1 of connector ”C”.

CONTINUED

CLICK HERE TO VIEW CHAPTER INDEX

1KZ-TE

--INTRODUCTION HOW TO TROUBLESHOOT ECU CONTROLLED

SYSTEMS

Pages From Manual

TO MODEL INDEX

IN-- 23

Fig. 4

Sensor

Fig. 5

Sensor

ECU

0V

CBA

C

2

SHORT

1

2

5V

B

1

5V

A

5V

1

1

2

2

Z17007

ECU

1

2

1

2

(b) Check the voltage.

In a circuit in which voltage is applied (to the ECU connector terminal), an open circuit can be checked for by conducting a voltage check.

As shown in Fig. 4, with each connector still connected,

measure the voltage between body ground and terminal

1 of connector ”A” at the ECU 5V output terminal, terminal

1 of connector ”B”, and terminal 1 of connector ”C”, in that

order.

If the results are:

5V: Between Terminal 1 of connector ”A” and Body Ground

5V: Between Terminal 1 of connector ”B” and Body Ground

0V: Between Terminal 1 of connector ”C” and Body Ground

Then it is found out that there is an open circuit in the wire harness between terminal 1 of ”B” and terminal 1 of ”C”.

7 . CHE CK S HO RT CI RCUI T

If the wire harness is ground shorted as in Fig. 5, locate the section by conducting a ”continuity check with ground”.

Fig. 6

Sensor

Z17008

Check the continuity with ground.

(1) Disconnect connectors ”A” and ”C” and measure

the resistance between terminal 1 and 2 of connec-

ECU

C

1

2

B

A

1

1

2

2

tor ”A” and body ground.

In the case of Fig. 6

Between terminal 1 of connector ”A” and body

ground → Continuity (short)

Between terminal 2 of connector ”A” and body

Z17009

ground → No continuity

Therefore, it is found out that there is a short circuit

between terminal 1 of connector ”A” and terminal 1

of connector ”C”.

CONTINUED

CLICK HERE TO VIEW CHAPTER INDEX

IN-- 24

1KZ-TE

--INTRODUCTION HOW TO TROUBLESHOOT ECU CONTROLLED

SYSTEMS

Pages From Manual

TO MODEL INDEX

Fig. 7

Sensor

Example

Ground

B2 B1

C

121

(2) Disconnect connector ”B” and measure the resis-

tance between terminal 1 of connector ”A” and body

ground, and terminal 1 of connector ”B2” and body

ground.

ECU

A

1

2

1

22

Between terminal 1 of connector ”A” and body

ground → No continuity

Between terminal 1 of connector ”B2” and body

ground → Continuity (short)

Z17808

Therefore, it is found out that there is a short circuit

between terminal 1 of connector ”B2” and terminal

1 of connector ”C”.

8 . CHE CK AND RE P L ACE E CU

First check the ECU ground circuit. If it is faulty, repair it. If it is

normal, the ECU could be faulty, so replace the ECU with a normal functioning one and check that the symptoms appear.

(1) Measure the resistance between the ECU ground

terminal and the body ground.

Resistance: 1 Ω or less

ECU Side

W/H Side

Ground

IN0383

(2) Disconnect the ECU connector, check the ground

terminals on the ECU side and the wire harness

side for bend and check the contact pressure.

Ground

IN0384

CLICK HERE TO VIEW CHAPTER INDEX

TERMS

ABBRE V I AT I O NS US E D I N T HI S M ANUAL

Abbreviations Meaning

A/C Air Conditioning

AC Alternating Current

ACC Accessory

ACIS Acoustic Control Induction System

ACSD Automatic Cold Start Device

ALT Alternator

AMP Amplifier

APROX. Approximately

A/T Automatic Transmission (Transaxle)

BACS Boost Altitude Compensation System

BAT Battery

BTDC Before Top Dead Center

BVSV Bimetallic Vacuum Switching Valve

CB Circuit Breaker

CCO Catalytic Converter for Oxidation

DC Direct Current

DLC Data Link Connector

DTC Diagnostic Trouble Code

ECD Electronic Control Diesel

ECT Electronic Control Transmission

ECU Electronic Control Unit

EDU Electronic Driving Unit

EFI Electronic Fuel Injection

E/G Engine

EGR Exhaust Gas Recirculation

EVAP Evaporative Emission Control

E--VRV Electronic Vacuum Regulating Valve

EX Exhaust

FIPG Formed In Place Gasket

FL Fusible Link

Fr Front

GND Ground

HAC High Altitude Compensator

IG Ignition

IIA Integrated Ignition Assembly

IN Intake

ISC Idle Speed Control

J/B Junction Block

J/C Junction Connector

LCD Liquid Crystal Display

LED Light Emitting Diode

LH Left--Hand

--INTRODUCTION TERMS

1KZ-TE

Pages From Manual

TO MODEL INDEX

CONTINUED

IN-- 25

IN00S--13

CLICK HERE TO VIEW CHAPTER INDEX

IN-- 26

--INTRODUCTION TERMS

1KZ-TE

Pages From Manual

TO MODEL INDEX

LHD

LO Low

MAP Manifold Absolute Pressure

MAX. Maximum

MIL Malfunction Indicator Lamp

MIN. Minimum

MP Multipurpose

M/T Manual Transmission

N Neutral

O2S Oxygen Sensor

O/D Overdrive

O/S Ov ersize

PKB Parking Brake

PS Power Steering

RAM Random Access Memory

R/B Relay Block

RH Right-- Hand

RHD Right--Hand Drive

ROM Read Only Memory

Rr Rear

SICS Starting Injection Control System

SPEC Specification

SSM Special Service Materials

SST Special Service T ools

STD Standard

SW Switch

TAC H Tachometer

TDC Top Dead Center

TEMP. Temperature

TM Transmission

TMC TOYOTA Motor Corporation

TWC Three-- Way Catalyst

U/D Underdrive

VCV Vacuum Control Valve

VIN Vehicle Identification Number

VSV Vacuum Switching Valve

w/ With

W/H Wire Harness

w/o Without

WU--TWC Warm Up Three-- Way Catalytic Converter

2WD Two Wheel Drive Vehicle (4x2)

4WD For Wheel Drive Vehicle (4x4)

Left--Hand Drive

Loading...

Loading...