Toshiba 2152 DB Service Manual

TOSHIBA 2152 DB |

1 |

General Information

Chassis: C5S

Safety Instructions

X-RAY RADIATION PRECAUTION

1.The E.H.T. must be checked every time the receiver is serviced to ensure that the C.R.T. does not emit X-ray radiation as result of excessive E.H.T. voltage. The nominal E.H.T. for this receiver is 27.8 kV at zero beam current (minimum brightness) operating at 240V a.c. The maximum E.H.T. voltage permissible in any operating circumstances must not exceed 29.0 kV. When checking the E.H.T., use the ‘High Voltage Check’ procedure in this manual using an accurate E.H.T. voltmeter.

2.The only source of X-RAY radiation in this receiver is the C.R.T. To prevent X-ray radiation, the replacement C.R.T. must be identical to the original fitted as specified in the Parts List.

3.Some components used in this receiver have safety related characteristics preventing the C.R.T. from emitting X-ray radiation. For continued safety, replacement component should only be made after referring the Product Safety Notice below.

SAFETY PRECAUTION

1.This receiver has a nominal working E.H.T. voltage of 24.5 kV. Extreme caution should be exercised when working on the receiver with the back removed. Do not attempt to service this receiver if you are not conversant with the precautions and procedures for working on high voltage equipment. When handling or working on the C.R.T., always discharge the anode to the receiver chassis before removing the anode cap. The C.R.T., if broken, will violently expel glass fragments. Use shatter proof goggles and take extreme care while handling. Do not hold the C.R.T. by the neck as this is a very dangerous practice.

2.It is essential that to maintain the safety of the customer all cable forms be replaced exactly as supplied from factory.

3.A small part of the chassis used in this receiver is, when operating, at approximately half mains potential at all times. It is therefore essential in the interest of safety that when serving or connecting any test equipment the receiver should be supplied via a suitable isolating transformer of adequate rating.

4.Replace blown fuses within the receiver with the fuse specified in the parts list.

5.When replacing wires or components to terminals or tags, wind the leads around the terminal before soldering. When replacing safety components identified by the international hazard symbols on the circuit diagram and parts list, it must be a Toshiba approved type and must be mounted as the original.

6.Keep wires away from high temperature components.

PRODUCT SAFETY NOTICE

Many electrical and mechanical components in this chassis have special safety-related characteristics. These characteristics are often passed unnoticed by a visual inspection and the

X-ray radiation protection afforded by them cannot necessarily be obtained by using replacements rated at higher voltages or wattage, etc. Components which have these special safety characteristics in this manual and its supplements are identified by the international hazard symbols on the schematic diagram and parts list. Before replacing any of these components read the parts list in this manual carefully. Substitute replacement components which do not have the same safety characteristics as specified in the parts list may create X- ray radiation

Recommended Safety Parts

Item |

Part No. |

Description |

|

C440 |

24082476 |

PF, 6600pF, ± 3%, 1500V |

|

C463 |

24212152 |

CD, 1500pF, ± 10% |

|

C801 |

24082363 |

PF, 0.22uF, ± 20%, AC250V |

|

C813 |

24094656 |

CD,2200pF,± |

20%, AC400V |

C814 |

24094656 |

CD,2200pF,± |

20%, AC400V |

R327 |

24339569 |

MF, 5.6 ohm, 2W |

|

R448 |

24338338 |

MF, 0.33 ohm, 1W |

|

R801 |

24009954 |

Metal-Glazed Resistor, 2.2M ohm, 1/2W |

|

R808 |

24019340 |

PTC Thermistor, 290V, 18 ohm |

|

R890 |

24381333 |

OME, 33k ohm, 1/2W |

|

R899 |

24005007 |

Metal-Glazed Resistor, 8.2M ohm, 1W |

|

R920 |

24000940 |

FR, 2 ohm, 2W |

|

R920 |

24000568 |

FR, 4.7 ohm, 1W |

|

L462 |

------------- |

DY, Supplied with V901 |

|

L901 |

23200205 |

Coil, Degaussing, TSB-2333AR |

|

T401 |

23224983 |

Transformer, Horiz. Drive, TLN1039 |

|

T461 |

23236464 |

Transformer, Flyback, TFB41 23AR |

|

T801 |

23211858 |

Line Filter, TRF3139 |

|

T862 |

23217287 |

Transformer, Converter, TPW3331AR |

|

Q404 |

23314375 |

Transistor, ON4409(508D) |

|

Q862 |

A8643108 |

Photo Coupler, TLP621(GR-LF |

|

F470 |

23144875 |

Fuse, 0.63A |

|

F801 |

23144507 |

Fuse, 3.15A |

|

P801 |

23372012 |

Power Cord |

|

S801 |

23145434 |

Switch, Power, 2C2P |

|

V901A |

23902067 |

Socket, CRT, 10P |

|

V901 |

23312642 |

Picture Tube, A51EF543X69 |

|

V901 |

23312571 |

Picture Tube, A51EAL55X01 |

|

Service Adjustments

GENERAL INFORMATION

All adjustments are thoroughly checked and corrected when the receiver leaves the factory. Therefore the receiver should operate normally and produce proper colour and B/W pictures upon installation. However, several minor adjustments may be required depending on the particular location in which the receiver is operated.

This receiver is shipped completely in cardboard carton. Carefully draw out the receiver from the carton and remove all packing materials. Plug the power cord into a convenient 240 volts 50 Hz AC two pin power outlet. Turn the receiver ON. Check and adjust all the customer controls such as BRIGHTNESS, CONTRAST and COLOUR Controls to obtain natural colour or B/ W picture.

AUTOMATIC DEGAUSSING

A degaussing coil is mounted around the picture tube so that external degaussing after moving the receiver is normally unnecessary, providing the receiver is properly degaussed upon installation. The degaussing coil operates for about 1 second after the power to the receiver is switched ON. If the set is moved or faced in a different direction, the power switch must be switched off at least 30 minutes in order that the automatic degaussing circuit operates properly. Should the chassis or parts of the cabinet become magnetized to cause poor colour purity, use an external degaussing coil. Slowly move the degaussing coil around the faceplate of the picture tube, the sides and front of the receiver and slowly withdraw the coil to a distance of about 2 m before disconnecting it from AC source. If colour shading still persists, perform the COLOUR PURITY ADJUSTMENT and CONVERGENCE ADJUSTMENTS procedures.

HIGH VOLTAGE CHECK

CAUTION: There is no HIGH VOLTAGE ADJUSTMENT on this chassis.

1.Connect an accurate high voltage meter to the second anode of the picture tube.

2.Turn on the receiver. Set the BRIGHTNESS and CONTRAST Controls to minimum (zero beam current).

3.High voltage will be measured below 29.0 kV (2152DB), 32.0 kV (2857DB).

HEIGHT ADJUSTMENT

1.Receive the UK PHILIPS pattern, and set the contrast to max, colour and brightness to centre.

2.Adjust HEIGHT Control (R350) so that white blocks at top and bottom of the picture are just masked.

HORIZONTAL CENTRE ADJUSTMENT

1.Receive the UK PHILIPS pattern.

2.Adjust HPOS (Bus control) so the pattern centre can be located at the screen centre.

FOCUS ADJUSTMENT

Adjust FOCUS Control on FLYBACK TRANS. (T461) for well defined scanning lines in the centre area on the screen.

SET-UP ADJUSTMENT

The following adjustments should be made when a complete realignment is required or a new picture tube is installed.

Perform the adjustments in order as follows:

1.Color Purity

2.Convergence

3.White Balance

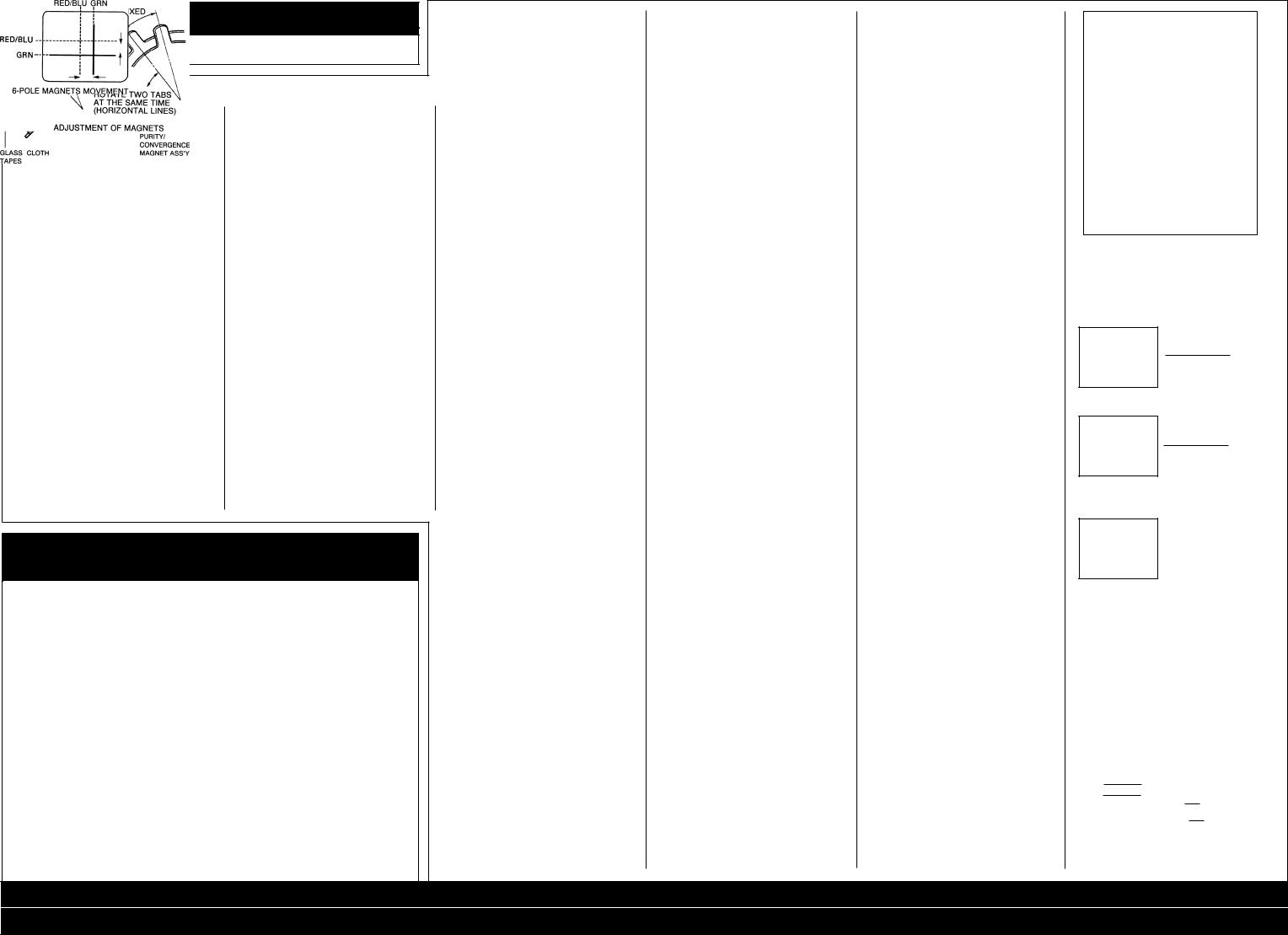

Note: The PURITY/CONVERGENCE MAGNET assembly and rubber wedges need mechanical positioning. Refer to figures

COLOR PURITY ADJUSTMENT

NOTE: Before attempting any purity adjustments, the receiver should be operated for at least fifteen minutes.

1.Demagnetize the picture tube and cabinet using a degaussing coil.

2.Set the brightness and contrast to maximum.

3.Use a green raster from among the built-in test signals.

4.Loosen the clamp screw holding the yoke and slide the yoke backward or forward to provide vertical green belt (zone) in the picture screen.

5.Remove the Rubber Wedges.

6.Rotate and spread the tabs of the purity magnet around the neck of the picture tube until the green belt is in the center of the screen. At the same time, enter the raster vertically.

7.Slowly move the yoke forward or backward until a uniform green screen is obtained. Tighten the clamp screw of the yoke temporarily.

8.Check the purity of the red and blue raster.

CONVERGENCE ADJUSTMENTS

NOTE: Before attempting any convergence adjustments, the receiver should be operated for at least fifteen minutes.

CENTRE CONVERGENCE ADJUSTMENT

1.Use the cross-dot pattern from among the built-in test signals.

2.Set the brightness and contrast for well defined pattern.

3.Adjust two tabs of the 4-Pole Magnets to change the angle between them and superimpose red and blue vertical lines in the center area of the picture screen.

4.Turn the both tabs at the same time keeping the angle constant to superimpose red and blue horizontal lines at the center of the screen.

5.Adjust two tabs of 6-Pole Magnets to superimpose red/blue line and green one. Adjusting the angle affects the vertical lines and rotating both magnets affects the horizontal lines.

6.Repeat adjustments 3, 4, 5 keeping in mind red, green and blue movement, because 4- Pole Magnets and 6-Pole Magnets have

mutual interaction and make dot movement complex.

CIRCUMFERENCE CONVERGENCE ADJUSTMENT

1.Loosen the clamping screw of deflection yoke slightly to allow the yoke to tilt.

2.Temporarily put a wedge as shown. (Do not remove cover paper on adhesive part of the wedge.)

3.Tilt front of the deflection yoke up or down to obtain better convergence in circumference. Push the mounted wedge into the space between picture tube and the yoke to fix the yoke temporarily.

4.Put other wedge into bottom space and remove the cover paper to stick.

5.Tilt front of the yoke right or left to obtain better convergence in circumference.

6.Keep the yoke position and put another wedge in either upper space. Remove cover paper and stick the wedge on picture tube to fix the yoke.

7.Detach the temporarily mounted wedge and put it in another upper space. Stick it on picture tube to fix the yoke.

8.After fixing three wedges, recheck overall convergence. Tighten the screw firmly to fix the yoke and check the yoke is firm.

9.Stick three adhesive tapes on wedges.

Dot Movement Pattern

Service Mode General

Instructions

1. ENTERING TO SERVICE MODE

1) Press  button once on Remote Control.

button once on Remote Control.

2) Press  button again to keep pressing.

button again to keep pressing.

3) Keep pressing the  button, press MENU button on TV set.

button, press MENU button on TV set.

RCUT |

S |

32H |

|

(Service mode dIsplay)

2.SELECTING THE ADJUSTING ITEMS

Every pressing of CHANNEL ▲ button changes the adjustment items in the following order.

(▼ button for reverse order.)

3.ADJUSTING THE DATA

Pressing of VOLUME ▲ or ▼ button will change the value of data in the range from 00 to FF. The variable range depends on the adjusting item.

4. NORMAL OPERATION ON THE SERVICE MODE

Press MENU button on TV.

Adjustment mode |

|

|

|

Service mode |

|

|

|

|

|

|

|

RCUT |

|

Address |

|

|

S |

32H |

|

Data |

Press |

|

|

|

|

|

|

|

|

|

|

|

Press |

|

|

|

|

|

|

|

|

5. EXIT FROM SERVICE MODE

Press POWER button on the remote control to turn off the TV once.

Safety Instructions / Safety Parts / Service Adjustments / Service Mode General Instructions / Service Mode Cont’d / Test Signal Selection

Adjustment of Video Chroma System / CRT Diagram / Text Diagram / AV Diagram / Main Diagram / Main Diagram Cont’d

TOSHIBA 2152 DB |

2 |

Service Mode Cont’d

OTHER SERVICE FUNCTION

The following key entry during display of adjustment menu provides special functions.

TEST SIGNAL SELECTION

Every pressing of button changes the test patterns on screen as described below in SERVICE MODE.

Signal off NTSC signals (14 patterns)

|

|

PAL signals |

(14 patterns) |

About inside signal: The inside signal is output at video input terminal from QA01, and is not output with the pin inserted into terminal. (Single color signal can be output.)

Signals

Red single colour

Green single colour

Blue single colour

Black single colour

White single colour

Picture

Using method

Purity and White uniformity of CRT Red single colour.

Stopping G and B output of Q501 Green single colour.

Stopping R and B output of Q501 Blue single colour.

Stopping R and G output of Q501 Black single colour.

Making black signal of approx. 1Vp-p in QA01 White single colour.

Making white signal of approx. 1Vp-p in QA01

Signals

W/B adjustment

Picture

Using method

White balance adjustment White part.

White balance adjustment/check in light area. Black part.

White balance adjustment/check in dark area. Making. approx. 1Vp-p signal in QA01.

Signals

Black cross-bar

White cross-bar

Picture

Using method

Picture position (horizontal, vertical and slant) in CRT adjustment.

Making approx. 1 Vp-p signal in QA01.

Signals

Black cross-hatch

White cross-hatch

Picture

Using method

Convergence and vertical amplitude adjustment Making approx. 1 Vp-p signal in QA01.

Signals

Black cross-dot

White cross-dot

Picture

Using method

Convergence adjustment

Making approx. 1Vp-p signal in QA01.

Signals

H signal (Left, right, white)

H signal (Left, right, black)

Picture

Using method

For checking (of purity drift) of white uniformity of CRT H signal (Left, right, white).

Check in light area.

H signal (Left, right, black). Check in dark area.

The adjustment will be the best, if the time when unevenness of colour in light area occurs, is a little longer than that in dark area.

Making approx. 1Vp-p signal in QA01.

ITEM:

Initialisation of QA02 (Memory)

ADJUSTMENT PROCEDURE:

After replacing QA02, the following initialisation is required.

1.Call up the adjustment mode display following the steps 1 and 2.

2.Press the CALL button on the Remote Control and CHANNEL ▲ buttons on the TV set simultaneously. The initialisation of QA02 has been completed.

3.Check the picture carefully. If necessary, adjust any adjustment item.

Perform “AUTOMATIC SEARCH MEMORY”

ITEM: SUB-BRIGHTNESS (Address: BRTC)

ADJUSTMENT PROCEDURE:

1.Set CONTRAST to “00,, and BRIGHTNESS to “50” by adjusting user controls.

2.Set the TV in service mode to get white crossbar of inside pattern.

3.Select BRTC (brightness correction), and adjust the  - / + button to reduce the value so that white portion of inside pattern slightly light.

- / + button to reduce the value so that white portion of inside pattern slightly light.

4.Rotate R350 to show the belt of vertical retrace. See next figure.

5.Adjust  - / + button to increase the data value of BRTC, and set it just before the difference between the belt of vertical retrace and the border of black portion of inside pattern is visible. After that, return vertical height and contrast.

- / + button to increase the data value of BRTC, and set it just before the difference between the belt of vertical retrace and the border of black portion of inside pattern is visible. After that, return vertical height and contrast.

ITEMS:

HORIZONTAL POSITION ADJUSTMENT (HPOS)

VERTICAL POSITION ADJUSTMENT (VPOS)

ADJUSTMENT PROCEDURE:

1.Set the TV in service mode, and get black or white cross-bar signal with VIDEO button on remote hand unit.

2.Select either HPOS (Horizontal picture phase) or VPOS (Vertical picture phase) with CHANNEL ▲, ▼ buttons, and adjust horizontal or vertical picture position in the center of screen with VOLUME  - / + buttons.

- / + buttons.

ITEM:

VERTICAL AMPLITUDE ADJUSTMENT (HIT)

ADJUSTMENT PROCEDURE:

1.Set the TV in service mode, and get black or white cross-hatch signal with VIDEO button on remote hand unit.

2.Select HIT (Vertical amplitude) with CHANNEL ▲ , ▼ buttons, and adjust vertical amplitude with VOLUME  - / + buttons so that vertical amplitude lacks a little.

- / + buttons so that vertical amplitude lacks a little.

3.Adjust vertical amplitude with VOLUME  - / + buttons so that the first bar on cross-hatch signal touches edge of screen.

- / + buttons so that the first bar on cross-hatch signal touches edge of screen.

WHITE BALANCE ADJUSTMENT

CUTOFF ADJUSTMENT

(RCUT)

(GCUT)

(BCUT)

DRIVE ADJUSTMENT

(GDRV)

(BDRV)

1. Set Contrast to 40, and brightness to +20 by

picture control.

2.Set the TV in service mode, and get the inside W/B adjusting signal with VIDEO button.

3.Select RCUT, GCUT and BCUT with CHANNEL ▲, ▼ buttons, to set individual values to 32, and to set GDRV and BDRV to 20 with

VOLUME  - / + buttons.

- / + buttons.

4.Press  button on the remote control and rotate Screen VR to get one slight horizontal line on screen.

button on the remote control and rotate Screen VR to get one slight horizontal line on screen.

Note:Every pressing of  button provides Horizontal line picture and Normal picture alternately.

button provides Horizontal line picture and Normal picture alternately.

5.Press  button to release horizontal line picture, and select the two other colours which did not light in the above step with CHANNEL ▲,▼ buttons. Then tap VOLUME

button to release horizontal line picture, and select the two other colours which did not light in the above step with CHANNEL ▲,▼ buttons. Then tap VOLUME

- / + buttons so that three colours slightly light in the same level.

- / + buttons so that three colours slightly light in the same level.

To correct white balance in light area, select GDRV and BDRV with CHANNEL ▲,▼ buttons to adjust.

To correct white balance in dark area, perform fine adjustment of RCUT, GCUT and BCUT.

Light area check (to show white)

Dark area check (to show black)

SELF DIAGNOSTIC FUNCTION

1)Press “9” button on Remote Control during display of adjustment menu. The diagnosis will begin to check if interface among IC’s are executed properly.

2)During diagnosis, the following displays are

shown.

|

(SELF CHECK) |

|

|

(1) |

23904981 |

|

|

(2) |

POWER |

: |

00 |

(3) |

BUS LINE |

: |

OK |

(4) |

Bus CONT |

: |

OK |

(5) |

BLOCK |

: |

UV V1 V2 |

|

|

|

QV01 |

|

|

|

|

1)Part number of microcomputer (QA01)

2)Operation number of protecting circuit ----“00” is normal. When indication is other than “00”, overcurrent apts to flow, and circuit parts may possibly be damaged.

3)BUS LINE CHECK ---- “OK” is normal. “SDA1-GND” means that SDA line is shorted to ground.

“SCL1-GND” means that SCL line is shorted to ground.

“SCL1-SDA1” means that SDA line is shorted to SCL line.

4)BUS CONT----“OK” is normal.

When indication shows “Q OOO NG”, the device with the number may possibly be

damaged. |

|

5) BLOCK |

|

UV : TV reception mode |

|

V1: VIDEO 1 input mode ( |

1) |

V2 :VIDEO 2 input mode ( |

2) |

Indicated color of mode now selected: Green and Red

Indicated color of other modes: White Green: Normal

Red: The microcomputer operates to provide judgement of no video signal. The red color is still indicated though the signal is input, failure may exist in input signal line including QV01.

QV01: In case of indication green --- Normal In case of indication red with input signal ----

Failure may exist in output line including QV01.

MULTI BUS E2PROM ADDRESS, ADJUSTING ADDRESS TABLE

Adjusting |

QAO2 |

Name |

Value of initializing |

|

|

method |

memory |

of |

QAO2 |

Adjustments |

|

|

address |

item |

(Hexa-decimal) |

|

|

|

|

|

|

|

|

S |

06B |

OSD |

60 |

OSD POSITION |

|

|

06C |

OPT |

07 |

OPTION |

|

F |

06D |

RCUT |

32 |

R |

CUT OFF |

|

06E |

GCUT |

32 |

G |

CUT OFF |

|

06F |

BCUT |

32 |

B |

CUT OFF |

|

070 |

GDRV |

20 |

G |

DRIVE |

F |

071 |

BDRV |

20 |

B |

DRIVE |

S |

072 |

CNTX |

39 |

SUB CONTRAST MAX |

|

F |

073 |

BRTC |

40 |

SUB BRIGHT CEN |

|

|

076 |

COLP |

32 |

SUB COLOUR CEN PAL |

|

F |

077 |

COLS |

32 |

SUB COLOUR CEN SECAM |

|

S |

078 |

CNTC |

2D |

SUB CONTRAST CEN |

|

|

079 |

CNTN |

20 |

SUB CONTRAST MIN |

|

|

07A |

BRTX |

12 |

SUB BRIGHT MAX (DIFFERENCE) |

|

|

07B |

BRTN |

10 |

SUB BRIGHT MIN (DIFFERENCE) |

|

|

070 |

COLX |

40 |

SUB COLOUR MAX |

|

|

07D |

COLN |

10 |

SUB COLOUR MIN |

|

|

082 |

5T4 |

19 |

SUB SHARP CEN OTHER (TV) |

|

|

083 |

5V4 |

19 |

SUB SHARP CEN OTHER (VIDEO) |

|

|

084 |

TXCL |

4A |

TEXT CONTRAST LEVEL |

|

|

086 |

VM0 |

05 |

VCD MODE DATA |

|

|

087 |

WCTL |

00 |

APRO MODE DATA |

|

|

08E |

WON |

2D |

WOOFER AUTO LOUDNESS |

|

|

097 |

EMX |

FC |

NICAM ON LEVEL |

|

|

098 |

EMN |

64 |

NICAM OFF LEVEL |

|

|

099 |

FMA |

00 |

FM ATTENUATOR LEVEL |

|

S |

09A |

STS |

00 |

STEREO SEPARATION |

|

F |

09B |

HPOS |

08 |

50Hz H-POSITION |

|

S |

09E |

HPS |

04 |

60Hz/50Hz H-POSITION (DIFFERENCE) |

|

F |

0AF |

PID |

11 |

PAL IDENT LEVEL |

|

|

0B0 |

TRP |

01 |

CROMA TRAP f0 |

|

S |

0B1 |

DLY0 |

07 |

Y DELAY TV SECAM (BG) |

|

|

0B2 |

DLY1 |

07 |

Y DELAY TV SECAM (OTHER) |

|

|

0B3 |

DLY2 |

07 |

Y DELAY VIDEO SECAM |

|

|

0B4 |

DLY3 |

04 |

Y DELAY TV OTHER (BG) |

|

|

0B5 |

DLY4 |

04 |

Y DELAY TV OTHER (DK, I) |

|

|

0B6 |

DLY5 |

05 |

Y DELAY TV OTHER (M,N) |

|

|

0B7 |

DLY6 |

05 |

Y DELAY TV OTHER (VIDEO) |

|

|

|

|

|

|

|

S ... semi-fixed data area which is fixed by model. (Do not adjust in field service.) F ... This item may require adjustments by models after initialization, when QAO2 is replaced.

Safety Instructions / Safety Parts / Service Adjustments / Service Mode General Instructions / Service Mode Cont’d / Test Signal Selection

Adjustment of Video Chroma System / CRT Diagram / Text Diagram / AV Diagram / Main Diagram / Main Diagram Cont’d

Loading...

Loading...