Page 1

Product Support

(Do Not Remove From Department)

METRICK

RC-29 SAILPLANE INSTRUCTIONS

INTRODUCTION

There is no question, two-meter sailplanes have arrived

in the mainstream of the modeling community and show

every sign of remaining for a long time. The reasons why

are many and varied but the fact that they are easier to

build and still provide every bit the flyability of the larger

Standard Class and Open Class sailplanes should not be

overlooked. Until quite recently, the designs available,

either in kit or plan form, have generally reflected the

"floater" approach, with emphasis on very light con-

struction yielding exceedingly low wing-loadings. Airfoils on these aircraft have usually been variations on the

ever-present Clark-Y The models themselves have been

typified by a kind of back-to-basics look as opposed to the

considerable design work showing-up in the Standard

and Open classes. While these "first generation"-type

two-meter designs filled the initial need, competition has

begun to disclose the drawbacks to lightly loaded and

constructed models especially those using airfoils which

TOP FLITE MODELS INC:

1901 NORTH NARRAGANSETT AVENUE • CHICAGO, ILLINOIS 60639

do not provide penetration in anything less than no-wind

conditions. It was inevitable that designers would begin

to explore the sophistication of two-meter sailplanes and

their resultant designs are now beginning to show-up on

flying fields. These designs are now being referred to as

"second generation." Your Top Flite METRICK two-meter

sailplane definitely falls into this category.

The METRICK is the fulfillment of several important

design criteria that we felt a second-generation twometer sailplane should possess:

1. The ability to be flown in a wide variety of wind

conditions and yet remain competitive by virtue of

airfoil efficiency and relatively clean aerodynamics.

2. Airframe strength to survive and even take advantage

of high-velocity 12-volt winch launches.

3. Expandability to allow the use of spoilers, releasable

Page 2

and captive towhook systems and room for reasonable ballasting as desired by the pilot.

4. The ability to accept and use today's radio equipment

including the standard configuration 500 mah battery

pack.

5. An overall appearance that is as pleasant to look at as

it is efficient.

In our opinion, the METRICK not only has met these

criteria but in actual practice has exceeded them. In

contest situations the METRICK has been launched with a

12 volt winch into 15mph+ winds, penetrated forward

from launch about 1/4 mile and completed the 10-minute

task with a high 90's spot landing—all of this in a 31

ounce, unballasted condition! It is interesting to point out

that in this particular contest, all other 2-meter designs,

and many Standard class entries either folded their wings

on tow or were blown so far back off of launch that they

were forced to land well down-wind of the landing site.

Since very few of us have anything to say about the

weather conditions that a given contest is going to have,

the METRICK had to handle the worst and still come out

on top. What about light or no-wind conditions? Your

METRICK will really come into its' own on these types of

days! The design has a longer than usual tail-moment

which dampens the usual low-speed porpoising tendencies associated with newer second generation two-meter

sailplanes.Stalls, the nemesis of

up much hard gained altitude, are very shallow with the

METRICK. The glide in these light conditions is nothing

short of incredible. The airfoil used on the METRICK

allows you to cover so much sky with such a minimal loss

of altitude you will no longer have many excuses for

missing thermals! When the nose is trimmed slightly

down the design will accelerate rapidly with a very flat

glide rate, getting you from point A to B faster than you

can believe at virtually the same altitude you started at.

The METRICK can be launched using any one of the

commercially available hi-start systems as well as 6 or 12

volt winches. The design also slope soars beautifully and

has an .049 engine set-up shown on the plans. You will

find, no matter what configuration you set the airplane

up with—engine or unpowered—your METRICK has

hands-off performance, making it an excellent choice for

a first R/C ship and an equally smart choice if competition

is your goal.

sail

planes since they

eat

PRE-CONSTRUCTION NOTES

The METRICK, like other Top Flite kits employs the use of

die-cut wood to ease the task of construction, parts fit and

identification. The dies used for this kit have been rigorously checked for absolute accuracy and should provide

you with excellent fit. Die-cut parts should be carefully

removed from their sheets by first lightly sanding the

back of each sheet of parts and then carefully removing

each part. Use a light garnet paper for the sanding and

keep a sharp hobby knife with an X-acto #11 blade or

equivalent handy for assistance in removing any parts

that might not have been completely cut-through on the

dies. Parts which oppose one another and must be precisely uniform—such as fuselage sides, ribs, etc...—

should be carefully "matched" after their removal from

the parts sheets. Matching is the process of holding the

opposing pieces together with either pins, tape or spot

gluing and lightly sanding the edges of the parts until

they are identical. A sanding blockwith light garnet paper

is most useful for this and other phases of construction.

Your building surface should be at least large enough to

accommodate the wing panels. This surface should be as

absolutely flat as possible and yet be able to accept pins

easily. We have found that a product such as Celotex fiber

board works quite well for this purpose. Another good

surface can be found in most well-stocked hardware

stores, this is a 2' x 4' fiber board ceiling tile—these are

quite inexpensive and can be used for several airplanes

before needing replacement.

As with most R/C kits that are constructed from wood, a

selection of tools—most of which can be found in the

average workshop—are a must to do the job correctly:

Hobby knife and sharp #11 blades

Single-edge razor blades

T-pins

Sanding blocks in assorted sizes

Sandpaper—220, 320, 400 and light garnet paper

Hand-held hobby saw, such as an X-acto

Power drill and assorted drill bits

Straight-edge, preferably metal, at least 24" long

90° triangle

Small power jig-saw such as the Moto-Saw

Tapes such as masking and cellophane.

Our METRICK's were constructed using a variety of common hobby adhesives including 5-minute epoxy, Cyanoacrylates, aliphatic resin (such as Titebond) and 1-hour

epoxy was used to secure the main wing wire tubes in the

wing roots. Since all of us have our own construction

techniques and favorite adhesives, stick with the ones

that you are familiar with and prefer. However, in certain

areas there will be callouts for certain types of adhesives

and we urge you to try not to substitute since doing so

could possibly cause problems structurally later on.

The last thing we should touch on before we begin actual

construction is the sequence in which the METRICK is

assembled. The sequence given to you in this booklet has

been proven to be the most straight-forward and provides the finished components in the order that you will

need them to progress to the next assembly phase. Try to

stick with the building order presented here to avoid

mistakes.

Spread the plans out on your work surface, cover them

with a clear plastic material, such as the backing from a

roll of Monokote or plastic food wrap and commence

construction.

2

Page 3

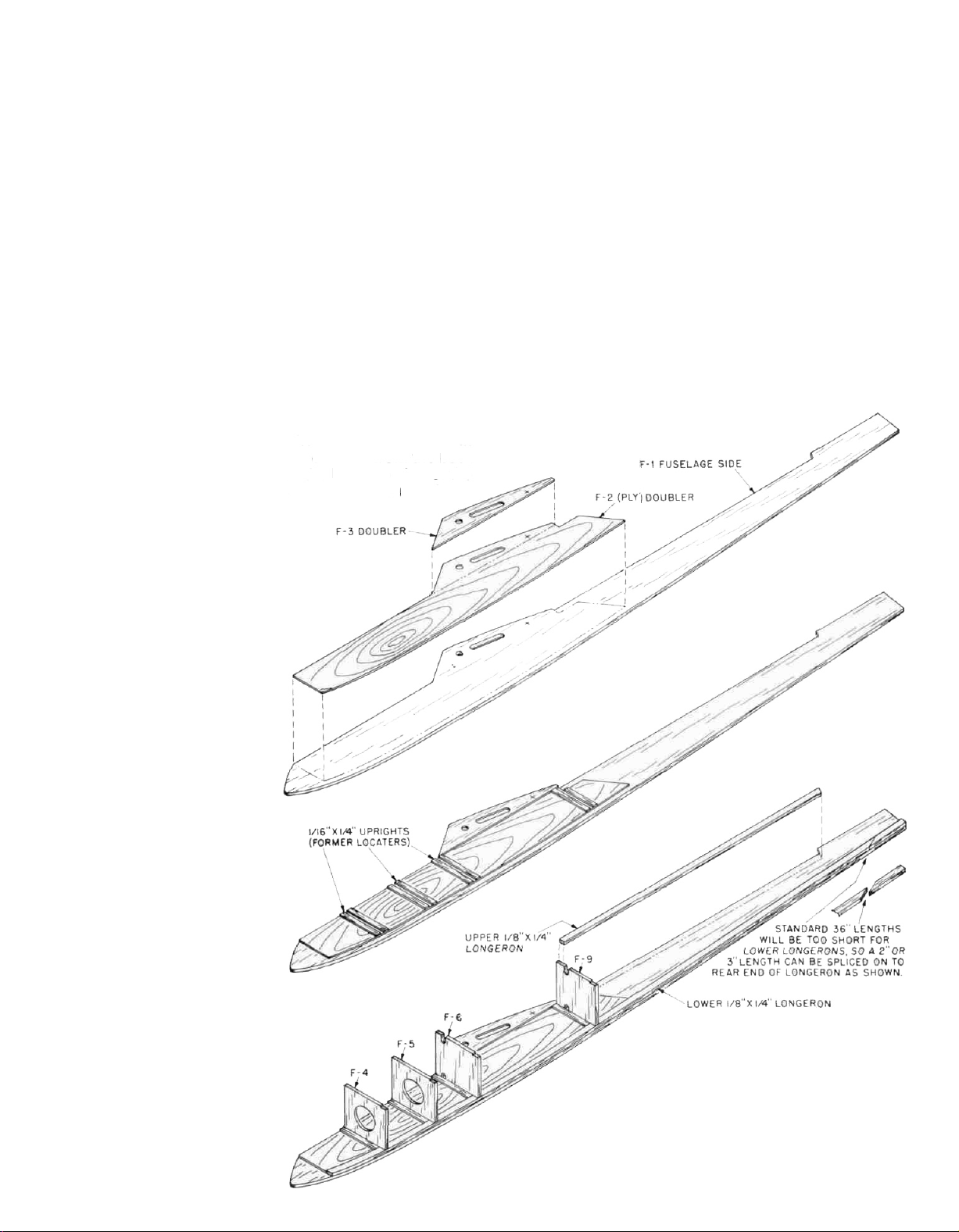

FUSELAGE ASSEMBLY

1. Remove die-cut fuselage parts; F-1, F-2 (ply) and

F-3—do this carefully and, as mentioned earlier, use

an X-acto knife to expedite this. Start construction,

by gluing (we used contact cement) the F-2 fuselage

doublers to the F-1 fuselage sides. Do this as accurately as possible, lining-up slots and holes for the

wing mating points and making sure these doublers

are flush with the top edges of the fuselage sides—

MAKE A LEFT AND RIGHT FUSELAGE SIDE.

2. Glue the 1/16" balsa F-3 doublers in place onto the

F-2's, again lining-up the slots and holes and making

sure the top fuselage side edges—allow to dry.

3. Using the 1/8" x 1/4" x 36" balsa stock supplied, glue the

bottom fuselage longerons in place, starting at the

front of the F-2 doubler, pinning and gluing as you

work aft. Note that you will need to add an additional

1-1/4"

full-length bottom longeron.

4. Cut and glue the top rear 1/8" x 1/4" balsa longerons in

place. Note that this longeron extends from the back

of the F-9 former position to the leading edge of the

fin location where it is cut on an angle to match the

fin.

of

this

longeron stock

at

the rear to complete

5. Using a sharp pencil and a straightedge, mark the

locations of all fuselage formers; F-4, F-5, F-6, F-7, F-8

and F-9, including the location of the rear 1/8" x 1/4"

fuselage uprights, behind former F-9—mark these

locations on the right fuselage side. Holding the left

fuselage side to the right, so that they are accurately

matched, transfer the former locations to the left

fuselage side.

6. Now accurately glue the 1/16" x 1/4" balsa "former

locators" in place on each side of the former F-4, F-5,

F-6 and F-9 locations. Use a scrap piece of 1/8" wood to

simulate the thickness of these formers, ensuring an

accurate slot and therefore a good fit.

7. Note the 1/8" x 1/4" balsa "nyrod spacer" at the rear of

the fuselage, directly below the leading edge of the

fin. Cut and glue one of these to each fuselage side.

to

3

Page 4

8. You will now need to drill an angled hole in the left

rear fuselage side for the red outer nyrod rudder

pushrod. Note the location of this on the plans. We

used a piece of sharpened brass tubing that was the

same diameter of the outer plastic tubing, in order to

get a good fit. Be sure to keep the location of this

pushrod as low in the fuselage as possible to avoid

any interference from the action of the stabilator

bellcrank.

9. Pin, tape or lightly spot glue the two fuselage sides

together, with their outer surfaces touching—align

them to each other very carefully. Using the sanding

block, sand their outer edges to match them identically. While the sides are still together, carefully

match the main wing tube holes and the access

slots—the main wing tube holes must line-up accurately.

10. Remove both W-1 ply wing root ribs and both F-11

fuselage root ribs carefully from their sheets.

Remove the main wing tube holes from each of the

ribs and the access slots from the F-11 ribs—use a

hobby knife to assist you. Take one of the F-11 ribs

and locate the indentation at the back, called out with

an arrow. Drill a 1/8" dia. hole in this rib, at 90° to its

surface—this rib is now your "drill guide" for the rest

of the ribs. Insert one of the main wing wire tubes

into the hole in the "drill guide" rib, letting one end of

it extend out from the rib about 1/16". Now drill the 1/8"

dia. hole needed in the remaining F-11 and W-1's, by

placing the rib onto the wing wire tube, lining up the

rib to be drilled with the "drill guide" rib and drilling

the hole—repeat this process until all four ribs have

accurately aligned and drilled holes. Use the same

procedure on the now matched fuselage sides; insert

one of the main wing wire tubes into the hole in the

fuselage side, slide an F-11 rib onto the tube and

down flat against the outside of the fuselage side,

position as shown on the plans and drill the 1/8" dia.

hole. Repeat this process with the other fuselage

side.

11. Remove ply tailskid F-12 from its sheet. Position F-12

in place on one of the fuselage sides, as shown on the

plans. Mark its forward edge location on the longeron

in pencil. With a single edge razor blade, remove

approximately 1/32" of the thickness of the longeron,

forward to the pencil mark—this becomes half of the

slot that F-12 will fit into. Do the same thing to the

other fuselage side.

12. Lay the right fuselage side on your work surface in

front of you with the inside facing you. Take one of the

servos that you plan to use and position it between

the F-5 and F-6 former locations. Note the position of

the output arm. With a pencil, mark this location on

the 1/16" x 1/4" upright former locator in front of F-6.

Remove former F-6 and F-9 from their sheets and

position them in place on the fuselage side. Mark the

location of the output arm on F-6 and mark the

location of the red outer pushrod housing, shown on

the plans, on F-9. Sand or file a 3/16" slot on each side of

these two formers so that the red outer pushrod can

fit with the formers in place.

13. Remove formers F-4, F-5, F-10 (ply), F-7 and F-8 from

their sheets. (Note that formers F-5, F-6 and F-9 are

the same width—stack them to be sure and use a

sanding block if needed to get them that way.) Glue

formers F-5, F-6 and F-9 in place on the right fuselage

side. Apply glue to the opposite edges of these formers and position the left fuselage side on them.

Tape and/or pin this structure so that it is absolutely

square and allow to dry completely.

14. With medium sandpaper, completely "rough-up"

both outer red pushrod tubes. Install the stabilator

pushrod on the

right fuselage

side by

sliding it,

from

the rear, through the slot in F-9 and then F-6, so that

about Vs" of it is exposed in front of F-6—see plans.

Slot the rear 1/8" x 1/4" upright, behind F-9, just below

the top rear longeron to accept this tube and press it

in place above the rear spacer, just below the fin. Cut

off the excess tubing exactly where shown on the

plans and use 5-minute epoxy to glue this tube in

place along the fuselage side and at F-6 and F-9.

Using the same method, install the rudder pushrod

tube along the left fuselage side. Note that this tube

gently bends downward once past F-9 so that it

arrives at the rear of the fuselage, laying along the

top of the bottom fuselage longeron and exits

through the slot we drilled earlier. Once the glue has

set, use a sharp single edge razor blade to trim off the

excess tubing on the outside rear of the left fuselage

side. Use a sanding block to sand this exit smooth

with the fuselage.

15. Glue ply former F-10 in place, directly above F-6. Note

that this former protrudes above the fuselage top by

a little more than 1/8".

16. Glue the 1/8" x 1/4" balsa cross brace in place at the

bottom of the fuselage, below F-7. This brace is the

gluing "shelf" for the 1/16" ply floor, forward to the

nose and the 1/16" cross-grain balsa floor, aft to the tail.

17. Temporarily install—do not epoxy yet—the 1/4" I.D.

main wing wire tube and the 3/32" I.D. rear fuselage

incidence tube in the appropriate holes on the fuselage sides. Install and glue in place former F-8—this

former sits immediately in front of the rear 3/32" I.D.

fuselage incidence tube. Now cut, fit and glue a

length of 1/8" x 1/4" balsa directly beneath this tube and

against the rear bottom of F-8. Temporarily install the

channeled maple "U" block in place over the main

wing wire tube, open end facing up. Install and glue

in place former F-7 so that it fits flush to the rear of the

"U" block as shown on the plans. Remove the "U"

block and both of the fuselage wing tubes.

18. Install former F-4, holding the two fuselage sides

together at the nose with tape. Check to be sure that

the structure is still "square".

19. Glue the hardwood noseblock in place. Note that this

block fits between the two balsa fuselage sides,

immediately in front of the F-2 ply fuselage doublers.

Tape the block and the fuselage sides firmly in position and allow to dry completely.

4

Page 5

20. Glue the shaped balsa forward "canopy fairing"

piece in place, on top of the fuselage directly behind

the noseblock. Use the sanding block to bring it flush

with the fuselage sides.

21. Using a piece of the 30", 1/16" balsa sheet supplied,

carefully cut and fit the canopy/hatch base. Use your

sanding block to bevel each end of this base to fit

accurately to the forward canopy fairing block and

the angled former F-10 at the rear. The base should

be sanded flush with the outside surfaces of the

fuselage sides. Remove the base and with a soft

pencil, mark the locations of formers F-4 and F-5 on

the outside top of each fuselage side. Lightly tackglue the base back in place as it will only be removed

after final fuselage sanding.

22. Bevel the bottom edges of canopy formers C-2 and

C-5 to match the required angles at the forward (C-2)

canopy fairing and the rear (C-5) angled former F-10.

Glue these two formers in place to the canopy base

also lightly tack-gluing them to their mating surfaces.

23. Glue the two remaining canopy formers, C-3 and C-2

in place on the base, using the pencil marks you

made earlier on the fuselage sides for location. Note

that these two formers are inset 1/8" from the edge of

the base on each side.

24. Using a flat work surface, glue and pin the 1/4" triangular balsa stock provided to the inside top edge of

canopy sides C-1—be sure to make a right and left

side! When dry, carefully fit the canopy sides in place,

trim as needed to get a good fit and glue and pin them

in place. When dry, sheet the top of the canopy with

cross-grain 1/8" balsa from the back face of C-2 to the

forward face of C-5. Pin and allow to dry completely.

Use your sanding block to sand the canopy/fuselage

sides flush and smooth.

25. Re-install the 1/4" I.D. main wing tube and the rear 3/32"

rear incidence tube, centering them so that equal

lengths

Apply epoxy (we used 1-hour type for this) to each

end of the maple "U" block and fill it about halfway

with epoxy also smearing some on the back face

where it will contact F-7—slide this block in place

over the tube. Make sure the tube is "buried" in glue.

Now apply epoxy to the incidence tube/F-8 joint liber-

ally, again, bury it—let these assemblies dry.

26. You must now decide whether to go with the fixed

towhook provided or with a radio-actuated captive

towhook system such as the FOURMOST RACING

PRODUCTS towhook shown on the plans as an

option. If you are opting for this captive set-up, the

installation shown on the plans works very nicely and

is quite simple. In fact, when we used this system, we

slotted the ply floor, installed the mounting rails and

secured the FOURMOST towhook in place on them

and then installed the ply floor to the fuselage.

If you are installing the stock towhook, position and

hold the 1/16" x 2" x 16" ply forward floor in place and

protrude

from each

fuselage

side (about

3/32").

mark fuselage outline in pencil. Trim-off the excess

with a hobby saw. Glue the ply floor in place, from the

center of the cross brace beneath F-7 forward and on

to the nose block—tape and allow to dry. Epoxy a

length of 1/16" x 1/2" ply—provided in an 8" length—to

the inside center of the ply floor, between the cross

brace and the back of F-6, this is the towhook plate

doubler. Determine the location of F-6 and mark its

rear edge location across the bottom of the fuselage

in light pencil. Then draw a light centerline of the

fuselage on the bottom from the F-6 line back. Measure

back

1-1/2"

and

drill a 3/32"

floor and the ply doubler. Epoxy the 2-56 blind

mounting nut provided into this hole from the inside

of the fuselage—use glue liberally around the nut's

base, without getting any into the threads.

27. Using 1/8" balsa sheet, cross grain, sheet the top of the

fuselage from the rear edge of F-7 forward to the

angled back face of F-10 and from the forward face of

F-8 to the rear edge of F-9. "Cap" the top of the two

fuselage sides between the two edges of the sheeting

with 1/8" x 1/4" balsa aligning the outer edges with the

fuselage sides. The resulting rectangular opening in

the fuselage top is for the access hatch.

28. As shown on the plans, the access hatch is a simple

frame made from 1/8" x 1/4" balsa, on edge. We used

scraps of bond paper front, back and on each side for

spacing while making this frame. As shown, install

two pieces of 1/8" x 1/4" balsa as shelves on the back

face of F-7 and the front face of F-8 to seat this hatch.

Sheet the hatch with 1/8" balsa, cross grain, lightly

sand the edges flush with the frame and lightly tack

glue the hatch in place for final sanding.

29. Glue the fuselage sides together at the rear, from the

leading edge fin position, back to the ends of the

fuselage sides at the bottom—keep glue out of the

slot you have cut in the rear longerons for F-12. Check

the fuselage carefully for equal bending and that the

top and bottom are aligned. Secure as necessary and

allow to dry.

30. Cut,

fit

and glue

bevel for fin fit. Turn the fuselage over and install

bottom 1/16" balsa cross grain sheeting from ply floor

back to point shown. Use a straight edge and a knife

to cut a 1/16" wide by 2" long slot in a piece of 1/16" balsa

sheet. This allows F-12 to slip in place. Glue this

remaining bottom sheet in place. Once everything is

dry, use a sanding block and medium grade paper to

sand the fuselage sides, top and bottom smooth. Pay

particular attention to the side-view contour at the

top of the fuselage where the 1/8" sheet meets the 1/4"

turtle deck. Sand the side and top view shapes into

the nose block but do not round any edges yet.

1/4"

balsa

turtle

dia.

hole through the ply

deck

in

place—note

5

Page 6

FIN AND BELLCRANK ASSEMBLY

1. Remove all required FIN parts from the die-cut

sheets; FIN #'s 1, 2 and 3 (two of each) and FIN #'s 4

and

5.

Also carefully remove the

ply) using an X-acto knife as needed. Sand all edges

of the bellcrank and the surface until it is completely

smooth. Note on the plans that the bottom edge of

F-1 butts to the top edge of F-2 and the top edge of F-3

butts to the bottom edge of F-2; lightly sand these

edges to create a flat, gapless fit. Remove the oblong

die-cut from FIN-2's.

2.

With a 1/8"dia.

at the top of the bellcrank for the 1/8" O.D. brass drive

tubes to be inserted—drill these holes at right angles

to the bellcrank. With a 1/16" dia. drill bit, drill-out the

two holes at the bottom of the bellcrank that will be

used for connection to the elevator servo. Lightly

sand-off any burrs.

3. Insert the forward 1/8" O.D. x 1/4" "pivot tube" and the

rear 1/8" O.D. x 1/4" "drive tube" into the holes at the

top of the bellcrank, center them so that an equal

amount of tubing is showing on each side of the

bellcrank. Making sure that these tubes are roughly

at right angles to the bellcrank, place a small amount

of Cyanoacrylate to the tube/ply joints to hold them in

place.

4. Assemble the 1/8" thick fin "core" directly over the

plans using the 1/8" x 1/2" balsa stock provided for the

leading edge and FIN #4 and 5. Glue a length of 1/16" x

1/4" balsa stock on top of the leading edge, flush with

the front edge of it.

5. On a flat work surface, make-up two fin "cover

assemblies" by edge gluing FIN #'s 1, 2 and 3

together. Holding these two assemblies together so

that they match as closely as possible, lightly sand

the leading and trailing edges with a sanding block to

get them as straight as possible and matched to oneanother.

6. Set one of the fin cover assemblies aside and glue the

other one directly to the fin core assembly, the leading edge against the 1/16" x 1/4" strip that was glued in

place earlier. Make sure this assembly is flat by pinning it to the work surface. Glue another length of

1/16" x 1/4" balsa to the trailing edge of the exposed FIN

5 core and up against the cover assembly—allow to

dry.

7. Remove the fin assembly from the worksurface and

turn it over. Glue another 1/16" x 1/4" balsa strip to the

leading edge of the core as was done on the other

side. Fit in place, pin but do not glue, the remaining

fin cover assembly. Cut and fit the remaining 1/16" x 1/4"

balsa trailing edge strip that fits immediately behind

the fin cover—glue this in place and pin. Remember,

at this point the unglued fin cover is in place but

removeable.

drill

bit,

drill-out

BELLCRANK

the

two

required holes

(3/32"

8. Slip a scrap piece of 1/8" balsa inside the fin, from the

bottom, directly under the small indention on the

FIN-2 ply part (there is an arrow pointing to this).

Using a 1/8" dia. drill bit, drill a hole all the way through

the fin—NOTE, while a drill press is most useful here

it is not necessarily needed if reasonable care is taken

to drill this hole at as close to right angles as possible.

9. Remove the unglued fin cover assembly and the

scrap 1/8" balsa. Install the bellcrank into the fin by

pressing the forward "pivot" tube into the 1/8" dia.

hole you just drilled. You will note that the rear

"drive" tube is now free to move up and down in the

oblong hole. With the fin and bellcrank flat on the

work surface, you can now glue the remaining fin

cover assembly in place with the "pivot" tube

pressed through the hole in FIN-2—allow this

assembly to dry.

10. Using the sanding block, sand the sides of the completed fin as smooth as possible. Carefully cut-out

the 1/4" FIN-6 fairing. Lay the fin assembly over the

plans in the exact position shown and glue FIN-6 in

place on the leading edge of the fin. Set this assembly

aside for final sanding.

6

Page 7

RUDDER

1. Carefully cut-out rudder parts R-1, R-3, R-4 and R-5

from the printed 1/4" balsa sheet provided. Remove

plywood die-cut part R-2 from its sheet.

2. Position the completed fin and bellcrank assembly in

place on the plans and pin. Start rudder construction

by first cutting and pinning the 1/4" x 1/2" tailpost piece

in place about 1/32" away from the trailing edge of the

fin as shown. Next, fit R-1 in place with the bottom of

it about 1/32" away from the top of the fin—if necessary, trim R-1 to fit as shown. Once satisfied with the

fit, glue R-1 in place. Remove the fin from the plans

and build the rest of the rudder as shown, pin and

allow to dry.

STABILATOR ASSEMBLY

1. Carefully remove die-cut parts E-1 (1/8" balsa), E-2

(1/16""

balsa)

and cut-out parts

E-3

from

1/4"

balsa

sheet

which is printed. Note that the outside shapes of all of

the E-1's and E-2's should be identical—carefully and

accurately stack these parts together, pin and with a

sanding block, "match" all of their edges. This procedure should produce a precise fit.

2. The stabilator halves will be built directly over the

plans and both halves will be built at the same time.

Start construction by accurately pinning E-2 in place

followed by cutting, gluing and pinning the 1/4" sq.

leading edge in place. Complete the stab outline by

cutting and gluing in place the remaining pieces of

1/4" x 1/2" balsa stock shown. Glue the 1/4" E-3 rear

gussets in place and cut the forward gussets from the

1/4" x 1/2" balsa provided and glue in place. Next, cut

and glue the

1/16"" x 1/4"

diagonal

"ribs"

in place.

3. Now glue the slotted 1/8" balsa E-1 in place directly on

top of the bottom E-2. Pin in place and allow to dry.

4.

From the

3/32" x 1/4"

ply strip provided, cut

two

3-3/32"

lengths. These will be used for the stab "cap roots."

As shown on the plans,

use a sharp pencil, a ruler

a triangle to locate the two positions for drilling the

stab roots with the two required

1/8" dia. holes. Again, when you

are drilling these holes, do so

at right angles.

and

3. Using a single edge razor blade, relieve 1/16" of the

bottom tailpost area to accept ply part R-2 on the left

side only. R-2 should be fitted to rest flush with the

top surface of the rudder assembly. Once satisfied,

glue R-2 in place.

4.

Sand the outside of the rudder to the shape shown on

the plans, followed by using the sanding block and

light sandpaper to sand each side smooth. As shown

in the drawing, bevel the leading edge of the tailpost,

where it will be hinged to the rudder, to facilitate free

left and right movement. Set the rudder aside for

final airfoiling.

5. Remove the stab halves from the plan and place one

half over the other so that they match as closely as

possible—pin together in this position and using the

sanding block, match their outlines including the

radiusing of the leading edge tips as shown on the

plans. Carefully sand the root sections flat. Unpin the

two

stab halves. Glue the

3-3/32"

ply root caps to the

stab roots, carefully matching the 1/8" dia. holes with

the tube slots in E-1—allow to dry before proceeding

to Step 6.

6. From the hardware package, remove; one (1) 3/32" dia.

x

2-5/8" wire; two (2)33/32" I.D. x 133/16" brasstubes; one (1)

3/32" x 2" wire; two (2) 3/32" I.D. x 7/8" brass tubes.

You will need to use a slower drying epoxy, such as

15-minute to have the proper amount of time to do

the job right. You are now going to epoxy the forward

13/16"

long stab pivot tubes and the rear

7/8"

long stab

drive tubes in place through the holes drilled in the

3/32" ply stab roots and into the slots in E-1. Be very

careful to not get any adhesive in the tubes themselves. As soon as both forward tubes are in place, fill

the remaining area of the slots with epoxy and level it

with your finger. Repeat this process with the rear

tubes. Note that these tubes are flush with the 3/32" ply

stab roots. Insert the forward and rear wires into one

stab half and slip the other stab onto the wire ends

and lay this whole assembly directly over the

stabilator plan and pin accurately in place with the 1/4"

gap in the center, as shown. Now glue the remaining

E-2's in place directly over the E-1's and tubes—pin

and allow to dry completely.

7. Remove the stabs from the plan and trial-fit them to

the fin and bellcrank assembly. The fit we are looking

for is firm bordering on tight—not free or loose. The

firm fit retains the stab halves in place to the fin. On

one of our prototypes we made the components so

accurately that the fit was too free and we cured this

by smearing a thin film of 5-minute epoxy on the

wires and lightly sanding them until all fits were firm.

8. Using a sanding block and light sandpaper, sand the

top and bottom of the stabs until they are quite

smooth and set them aside for final airfoil sanding.

7

Page 8

WING ASSEMBLY

Before starting this assembly sequence, you must make

the decision whether or not to build the spoiler option.

While the plans are sufficient in explaining the addition of

this option you should modify four (4) W-6 wing ribs by

relieving them to accept the 1/4" x 1" trailing edge stock,

which will be the spoilers. You will also note that the top

1/16" sheeting requirements are somewhat different and is

called out with —--— lines. Installation of the flexible

plastic dial chord housing tubes must be done before the

top, rear root section sheeting is installed. The spoiler

option shown on the plans has been used quite successfully on our prototypes and really makes the METRICK

quite "deadly" in the spot landing phase of your flights.

Note that the first phase of the wing construction is the

building of the two inboard wing sections, followed by

building and fitting the two outboard wing sections.

1. Start by removing all necessary die-cut parts from

their sheets—do this carefully, using an X-acto knife

as required. We have made a practice of stacking all

of the ribs together, in the order that they are used

and lightly sanding them to uniform shape with the

sanding block. Also be sure that the top and bottom

spar notches line-up, again using the X-acto knife if

needed. Next, prepare the 1/16" bottom leading edge

sheeting by cutting it exactly to size shown on plan—

note that unlike the top sheeting, the bottom sheet

extends from the rear of the bottom spar, forward to

the front of the 3/8" sq. leading edge. Use your metal

straight edge and knife to make the front and rear

edges straight and parallel. Pin the bottom leading

edge sheeting in place directly over the plans.

2. Cut, fit and pin the 1/16" bottom trailing edge sheet in

place over the plans. Use a pencil and a ruler to now

mark the locations of all the wing ribs—remember

that the bottom spar will cover up any marks that are

too close to the rear edge of the bottom leading edge

sheet, so make these marks further forward. Now

cut, carefully fit and glue the inboard bottom center

sheeting in place—again, use your straight edge to

achieve straight, gapless butt-joints.

3. Cut, fit and glue in place all of the bottom 1/16" x 1/4" cap

strips.

4. Cut, fit and glue the bottom 1/8" x 1/4" spruce spar in

place, lining it carefully up with the rear edge of the

bottom leading edge sheeting. Before pinning it in

place, use your straight edge to be sure it is straight

and accurately placed.

5. Use one of your W-6 "full chord" ribs as a spacer and

locate and glue the 3/8" sq. leading edge in place on

the bottom forward leading edge sheet. Be sure to

glue and pin the leading edge in place straight and

properly spaced.

6. When the leading edges have dried, remove all of the

pins from it and any you have in place back to the

spar. As shown on the plans, the bottom leading

edge sheeting, at the front has to be raised off of the

building surface by about 1/16" to conform to the

bottom forward shape of the wing ribs. As shown, we

did this by inserting some 1/16" sheet in place, deep

enough to achieve the proper curvature.

7. Glue W-7A and W-7B ribs in place at the outboard

end—note the 1/16" gap between these two ribs at the

spar to allow the installation of W-17 later on. Use a

triangle to be sure these ribs are at right angles to the

work surface. Moving inboard, glue all five W-6's in

place, again make sure they are at right angles with a

triangle.

8. Trial-fit ply brace W-14 in place—note the "to root"

arrow and the slight angle at that end. This means

that this part has to be oriented with the angled end

toward the fuselage. This part must fit onto the

bottom sheeting, against the forward face of the

bottom spar and terminate at the inboard edge of

W-2A, as shown. Glue W-14 in place making sure the

top edge of it will still accept the top spar to be

inserted later.

9. Glue the remaining forward partial ribs in place;

W-5A, W-4A, W-3A. Glue rear partial ribs W-5B and

W-4B (ply) in place.

10. Rear ply brace, W-15 is glued in place next. Like W-14,

this part has a "to root" arrow and an angle also and

must be oriented correctly. The installation of this

part is meant to create a "box" for the 1/4" I.D. brass

wing tubes. When gluing W-15 in place, use one of

these tubes as a "spacer" to ensure a good fit.

11. Glue rear partial rib W-3B in place.

12. Vs" balsa root ribs W-2A and W-2B are now glued in

place. Note that these ribs are slightly angled at the

top to match the two angles of W-14 and W-15 at the

root.

13. As shown on the plans, cut, fit and glue in place on

the rear face of the 3/8" sq. leading edge, the 1/16" x 1/4"

balsa "sheeting shelves", between each rib—see

cross-section.

8

Page 9

14. With the 1/8" balsa sheet provided, fit, cut and glue the

vertical grained "spar webs" in place between each

rib from W-4B out to W-7B. Note that these webs are

fitted flush with the forward edge of the spars and are

cut to fit between the top and bottom spars. Do this

step carefully to ensure good, positive fits.

15. Now cut, fit and glue the forward 1/16" balsa webs in

place between each rib from the inboard W-6 out to

the inboard position shown for dihedral brace W-17.

Note that the grain of these webs runs horizontal or

parallel with the span and that they are full depth

from the top of the bottom sheeting to the top of each

rib and full against the forward face of each of the 1/8"

balsa spar webs.

16. Use a small sanding block and light sandpaper to

bevel the bottom trailing edge sheeting as shown on

the plans.

17. Cut, fit and glue the top 1/16" x 7/8" trailing edge in place.

Pin and allow to dry completely.

18. Unpin and remove the two wing panels from the

work surface. Prop-up the outboard end of each

panel

1-1/8",

with

the inboard end flush

with

the edge

of your workbench. Using the sanding block, carefully sand the inboard face of wing panel so that it is

smooth and straight. This should be done accurately

to provide a flat gluing surface for ply cap ribs W-1.

Repin

wing

sections flat

to

the worksurface.

19. Glue W-1 directly to wing panel roots, carefully

lining-up the large wing tube hole in W-1 with the

space between W-14 and W-15. Be sure W-1 is also

flat against the worksurface—allow to dry.

20. Trial-fit one of the 1/4" I.D. brass wing tubes through

the large hole in W-1 and into the box between W-14

and W-15. As shown on the plans, the tube must fit

against W-4B (ply) and contact the bottom spar. This

fit imparts the correct dihedral angle when the panels

are aligned to the fuselage. Once satisfied, remove

the tube. Cap-off one end of the tube to keep epoxy

from entering it when it is permanently put in place.

We simply placed one end of the tube over a piece of

bond paper, applied Cyanoacrylate adhesive around

the joint and sanded off the excess paper, leaving a

bond paper" cap".

21. Measure, cut and fit—but do not glue—the top 1/8" x

1/4" spruce spar. Set these aside for immediate installation after the main wing tubes have been installed.

22. Mix a batch of 1-hour type epoxy and be sure to mix

enough since we are now going to fill the wing tube

box with epoxy and tubing. Pour epoxy directly into

the wing tube box to the level of the bottom of the

hole in W-1. Insert the 1/4" I.D. wing tube into the hole

and in place as described in Step 20 above. Pour

epoxy over the tube to a level at the bottom of the

wing rib spar notches. Make sure the wing tube is in

and will stay in the proper position and glue the top

spruce

wing

spar in place.

Pin

as

needed and

allow

to

dry completely.

23. Cut, fit and glue the top 1/16" balsa leading edge

sheeting in place—note that this sheeting, unlike the

bottom, extends from the back surface of the leading

edge to halfway across the top wing spar, leaving

about 1/8" of the top of the spar exposed. Pin and allow

to

dry.

24. From the 3/32" x 1/4" ply strip stock provided, make and

epoxy in place the wing eyehook screw bases, which

are epoxied to the back side of W-2B—refer to plans

for location.

25. Carefully and accurately cut and fit the two required

pieces of 1/16" balsa sheet needed for the inboard top

center section. Glue in place the forward piece of this

sheeting, leaving the remaining piece for installation

after the rear wing incidence tubes are installed. Cut,

fit and glue in place all of the top 1/16" x 1/4" cap strips.

26. Remove the panels from the worksurface. Press in

place, through the rear 1/8" dia. holes drilled earlier,

the

3/32"

I.D. x 1-3/16"

brass

incidence tubes.

Press

the

F-11 fuselage ply wing ribs in place over the protruding ends of the fuselage wing tubes. Slip the forward

1/4" dia. wing rod and the rear 3/32" dia. incidence wire

in place through the fuselage and slip the wings in

place. Line-up the trailing edge tip of the W-1 root ribs

with the F-11 fuselage ribs and tape or pin accurately

in place. Make four 1/16" ply wing incidence tube

"formers", as shown on the plan, using ply leftover

from the die-cut sheets. Epoxy one on each side of

the wing incidence tubes as shown, fill with epoxy

and allow to cure. When dry, finish sheeting the top

rear center section of each panel.

27. Remove the F-11 fuselage ribs and accurately tackglue them to the W-1 root ribs—these will be

removed after final sanding of the wings and be

installed on to the fuselage during the FINALASSEMBLY stage of these instructions.

28. The outboard wing panels are now built directly over

the plans, using the same techniques described ear-

lier in this section. Note that in the outboard wing

panels the vertical 1/8" balsa shear webs are only

installed between W-7B and W-8. Note that the 1/16"

horizontal-grained full-depth webs are only fitted

between the outboard end of ply dihedral brace W-17

and rib W-8 and between W-8 and W-9. When the

panels are complete, lightly taper the trailing-edge

facing ends of triangular gussets G-1 and G-2 and

glue them in place as shown. When the outboard

panels are complete remove them from the worksurface, prop-up the tips

at

W-13

1-1/4"

and

use a sanding

block to bevel the inboard surface of the panels to

achieve the proper polyhedral angles shown on the

plan. Take your time here and do a careful job—each

completed wing panel must carry the same polyhedral angles.

29.

The

two

13/16" x 1" x 6" balsa

wingtip

blocks are

first

rough-cut to shape, using the plans for templates

and then glued in place. Use a hobby knife to first

bring the tips down to rough shape and then use a

sanding block and sandpaper to finish the job. Note

9

Page 10

the "typical wingtip cross sections" shown on the

plan.

30. The outboard panels are now joined to the inboard

panels by first epoxying W-17 in place in the inboard

panel and then epoxying the two panels together,

proping-up

dry completely.

FINAL ASSEMBLY

1. Use your sanding block and medium-to-light sandpaper to airfoil the fin, rudder and stab halves to

shape—note cross sections on plans.

2. Thread at least 1/4" of the 1" threaded stud provided

into one end of the inner yellow pushrod and then

thread a clevis in place on the stud. Since we don't

want this clevis to have any possibility of unscrewing

itself from the stud, add a drop or two of Cyanoacrylate to the threads. Install the wing rods and wings to

the fuselage. Attach the clevis which is now con-

nected to the pushrod, to the exposed 1/16" dia. hole in

the bottom of the fin and insert the opposite end of

the yellow inner pushrod into the end of the red outer

pushrod tube at the top rear of the fuselage. Apply a

slow drying glue to the bottom of the fin, where it

rests against the lower longerons and to the sides of

the fin, where it "nests" between the fuselage sides

and carefully slip the fin in place into the rear of the

fuselage. Now mount the stab halves to the fin and

view the assembled aircraft from the front. Make sure

the fin is 90° to the fuselage and that the stab halves

are flat and alinged at right angles to the fin—take

your time to ensure everything is properly aligned.

Use pins, tape, etc... to hold the fin in the proper

position and allow to dry completely.

3. With the wings in place on the fuselage, lightly pencil

the outline of the root F-11 ply ribs onto the portion

extending forward onto the canopy sides. Then mark

the top and bottom location of the front face of

angled former F-10. Remove the wings and remove

the previously tack glued F-11 ribs from the right and

left wing roots. With a saw, using the top and bottom

the

tips, at W-13, 1-1/4"

as

shown.

Allow

31. The wing panels should now be carefully and completely sanded to final shape. Note the progression

shown on the plans for bringing the leading edge

down to final shape and the template provided for

checking the leading edge entry. Also note that as the

to

inboard sections are sanded, the tack-glued F-11 ribs

will assume the exact shape of the W-1 wing root ribs.

location marks you just made, cut off the front of the

F-11 ribs. Glue the two small forward pieces of these

ribs in place on each side of the canopy hatch, using

the outline you drew for

parts of F-11 in place over the wing tubes and to the

fuselage sides. Use a sanding block to bring any

protruding ends of the wing tubes flush with the F-11

ribs.

4. Glue ply tailskid F-12 into the slot at the bottom rear

of the fuselage. The completed fuselage is now

sanded to final shape—refer to the plans for typical

radiusing.

5. Carefully remove the previously tack glued canopy/

hatch and the access hatch from the fuselage. Using

the 1/16" x 1/2" ply strip provided, cut a length to fit

accurately between the two inside fuselage sides at

the forward base of the canopy/hatch. Epoxy this to

the bottom of the canopy base so that approximately

1/16" of its forward edge will fit beneath the front balsa

canopy fairing. This becomes the forward canopy

"hold-down". Since the canopy is held in position at

the rear when the wings are in place, all that is

needed is a simple hook made from a straight pin,

one for the bottom rear of the canopy base and one

for the floor of the fuselage, and a rubber band.

6. Locate the positions for the two wing-joining eyehooks, drill small diameter guide holes into the W-1

ribs and screw the hooks in place. A pair of pliers are

used to slightly open these hooks so that #62 rubber

bands or a spring, if you wish, can be used to join the

panels to the fuselage.

placement.

Glue the two

rear

10

Page 11

COVERING

Earlier in the introduction, we spoke of design criteria and

in the #1 statement "airfoil efficiency" and "clean aerodynamics" were mentioned. The METRICK was designed

to be a clean, relatively fast two-meter sailplane and

while the basic shapes have been provided, what the

airplane is covered with is certainly an issue. Airframe

cleanliness and full flight potential is realized by using

Monokote for this airplane. You will need two rolls of

Monokote for the METRICK, leaving some left over.

Cover each of the separate components; wings, stab

halves, rudder, canopy/hatch, access hatch and fuselage,

also cover the spoilers separately if you have built this

option. Follow the instructions provided with each roll of

Monokote. Remember, to keep it simple, light and beauti-

ful, keep it Monokote!

After covering, your spoilers and access hatch are hinged

RADIO INSTALLATION

The radio installation in your METRICK is very straightforward and therefore should not present a great many

problems. As the plans show, the design is set-up for

standard configuration 500 mah battery packs with room

left over for any ballast required to arrive at the proper

C.G. (Center of Gravity). As shown on the plans, the

battery pack should be installed in the forward-most

compartment of the fuselage, with the connector harness

facing aft. Small, custom cut pieces of foam rubber are

used to securely nest the pack in place—pack firmly, not

tight, to avoid any shifting. Remember that this compart-

ment will in all likelihood have to receive a small amount

of ballast (lead) to achieve the C.G.

The compartment directly behind the battery pack is

used for the receiver. In our METRICK's, we mounted the

receiver in place on its' side, leaving quite a bit of room on

the other side of this compartment which was used for

the switch. If your antenna is not internally mounted,

simply drill a 1/16th hole in the side or bottom of the

fuselage, route the antenna through this hole and aft back

to the rudder post area where you can secure it with a

rubber band and a small hook made from a straight pin.

The servo compartment, as shown, is directly behind the

receiver. This

rudder and stab—servos. Note that the servos shown on

the plan are reversed to one another for optimum servo

output wheel clearance. In the case of radio systems that

have a servo reversing feature, this presents no problem.

If your radio does not have this feature, then you must

first determine the direction that your servos go to

achieve the proper surface directions upon radio command. The servos must then be mounted correctly into

the fuselage. As noted earlier, the leftover piece of 3/32" x

1/4" ply strip that was used for the stabilator roots should

be used for the two required servo mounting rails. These

should be carefully cut to fit accurately between the

area

is

used to house the flight

control-

using Monokote Trim sheets with the "wet" adhesive.

Carefully slot the fin and rudder and epoxy these hinges

in place ("flex" them a few times first to free them up) on

first the rudder and then the fin—wipe off any excess glue

with acetone. Locate and install the nylon rudder horn

using the two #2 wood screws provided. Install the

towhook and secure as shown on the plans.

If your flying site isn't grass you may wish to protect the

bottom of the fuselage from "gravel rash" by the addition

of a rubber-type skid strip. A length of this material

extending from in front of the towhook forward to the

nose works quite well. This self-adhesive material can be

found in most automotive supply stores. There are also

commercially available skid strips sold in hobby shops,

Airtronics is one of the manufacturer's who make it

available.

inside fuselage sides and on top of the 1/16" x 1/4" balsa

servo rail locators that were glued in place during fuselage construction. Locate and epoxy the forward rail in

place first, as close to former F-5 as possible. Trial-fit one

of your servos in place with the forward mounting lugs

resting on the forward servo rail. Slip the rear servo rail in

place with the rear mounting lugs of the servo resting on

it. This will locate the position of the rear servo rail—mark

its location in pencil on the inside of the fuselage, on each

side, remove the servo and epoxy the remaining servo

rail in place.

While the METRICK's radio compartment was specifically designed to accept most radio systems currently

available, the servo output arms for some systems may

require some trimming or modification in order to clear

the fuselage sides during their movement cycle. Once

you are satisfied that the servos move in the proper

11

Page 12

directions for the desired control response and can sit

side-by-side with the movement of the output arms not

coming in contact with each other or the fuselage sides,

the servos can be mounted in place using small #2 x 1/2"

wood screws (not supplied). At this point, servo con-

nection with the pushrods is the next stop. First, center

the servos, using the trims on the transmitter. The servo

output arms should fit approximately 90° to the fuselage

sides to deliver equal movement. You will probably have

to drill-out the holes in the servo output arms to about

.076 dia. to accept the 3" threaded one-end studs provided for servo connection. With a razor blade, cut-off all

but 1/2" of the inner yellow nyrod pushrod that is protrud-

ing into the servo compartment. Thread at least V4" of the

threaded end of the 3" threaded stud into the inner nyrod.

We would suggest "nuetrilizing" the rudder and

stabilator first, with tape. As shown on the plans, make a

"Z"-bend at the servo-end of the stud and cut off the

remainder of the stud. The "Z"-bend can now be pushed

in place through the drilled-out hole in the servo output

arm and the output arm screwed in place on the servo.

Note that the servo plug wires are routed forward,

through the hole in former F-5 to the receiver

compartment.

With our METRICK's we chose not to mount the switch in

the typically external manner, but rather left them loose

in the receiver compartment, packed with foam rubber in

the upright position. This requires that the canopy/hatch

be lifted up, the switch activated before and after each

flight. In practice, this proved to be perfectly acceptable

and the fuselage side was spared the need for the cutting

of holes for the switch—use the method that most agrees

with you.

If you are planning on flying your METRICK with 2 channels, your radio installation is now complete and you can

move on to the PRE-FLIGHT and FLYING sections of these

instructions.

As mentioned earlier in the instructions, if you have

planned to run a third spoiler channel you should now

install this servo. The third, optional, servo installation

shown on the plans for spoiler activation is the system we

used in our prototypes and works quite well. You will

need

to

fabricate

(material not supplied) for mounting this servo beneath

the access hatch, as shown. Use Dubro #181 "Ball-Links"

(not supplied) on each side of the servo output arm for

the loops in the ends of the spoiler chords to slip over. You

two

3/32" x 1/4" x 1-5/8"

ply servo rails

can see that as the servo is actuated, by moving the

"throttle" stick or lever on the transmitter, the arm

rotates, thus pulling the individual spoiler chords,

causing the spoilers to be pulled up. As the servo is

returned to its' original setting, the rubber bands in the

spoiler bays pull the spoilers back down flush with the

wing's upper surface. It is most important that the

tension relationships are the same for both spoilers and

that they deploy at the same angles and that they return

flush with the wing panels. Valuable wing efficiency can

be lost with improperly seated and/or deployed spoilers.

Note that the travel of a standard servo is sufficient to

deploy to spoilers to about 50°-70° at full movement. This

amount of travel is more than sufficent to achieve radical

loss of lift. 90° movement of the spoilers in relationship to

the surface of the wing is not needed. Once the servo is

mounted in place to your satisfaction, route the plug

harness wire forward, through former F-6 (you will have

to cut a small, appropriate-sized hole), through the servo

compartment and through former F-5 to the receiver.

Install the wing panels to the fuselage and secure with

two #62 rubber bands between the two eyehooks, as if in

preparation for flight. The two loose, unlooped ends of

the spoiler chords should now be inside of the fuselage,

roughly lined-up with the "Ball-links" on the servo output

arm—the servo should be set at the "low spoiler setting",

in other words spoilers down. At this point, we taped the

spoilers down, flush with the wing, using making tape.

Slip a short length (about 1/4") of 3/32" I.D. brass tubing (not

supplied) over one end of the spoiler chord, wrap the

chord around the "Ball-Link" and slip the end back

through the tubing, creating a loop about 5/16" long. Pull

on the chord until the slightest resistance is felt and crimp

the tubing with a pair of pliers. We applied a small drop of

instant glue to the tubing/chord joint to complete the

connection. Repeat this process with the opposite chord,

remove the tape holding the spoilers in place and test the

action of the spoilers, using the transmitter. Remember

that in order of priority, #1 is to have the spoilers sit flush

with the upper surface of the wing when fully at rest.

Test the action of the entire radio installation to make sure

that it is bind-free and that radio commands from the

transmitter provide the correct surface movement. This

cannot be stressed enough since backward servo installations are one of the number one reasons for initial

crashes—check it and then check it again!

12

Page 13

PRE-FLIGHT

1. CENTER OF GRAVITY: Although the METRICK has a

fairly wide C.G. range intital flights should be made

with a balance point located directly at the wing spar

location, or

wing. This is the time to add any ballast required to

achieve this balance point. Ballast should be lead

sheet or lead shot and should be placed forward

and/or beneath the battery pack. The ballast should

be securely but not permanently installed in order to

make changes for personal preference in glide later

on. If you have built the engine powered option it

may be necessary to switch the locations of the

receiver and battery pack to achieve the correct C.G.

2. RADIO AND AIRFRAME INSPECTION: Once again,

check the radio system to be sure that the surfaces

move in the desired direction by radio command and

FLYING

Whether your METRICK has been set-up powered or

unpowered, you will need to perform a series of handglides to develop a basic neutral trim. Assuming that the

C.G. is right and that the radio is on and functioning, run

into the wind until the airplane begins to feel "light" at

which time throw it straight, slightly nose-down with the

wings level. The airplane should glide straight forward at

a very flat angle. Try to remember what commands you

had to give the transmitter to achieve straight and level

flight. Repeat these hand-glides until you are certain

what is required. We used our transmitter trims to

achieve the flat glide that we were looking for and then

made the required adjustments on the servos, followed

by returning the trims to neutral and repeating the process until the plane flew flat and straight with no stick

movement on the transmitter necessary. This then is

dead-neutral trim. As your flight time and familiarity with

the METRICK build-up, you can experiment with moving

the C.G. progressively aft—we caution you to do this in

very small increments—until the point is reached that

you can literally vary the cruise speed of the airplane with

transmitter trim, without stalling. This is done by removing small amounts of lead ballast from the nose until you

are satisfied.

Assuming that your METRICK is an unpowered sailplane,

the next phase is a tow-launch. Although this method of

launching a sailplane can be intimidating to the beginner,

the METRICK's stability on tow is of great help. If you are

using a "Hi-Start" system—surgical chord and monofiliment line—pull the line back until you have about 20 lbs.

of tension. Hook the tow-ring onto the towhook on the

bottom of your model. With the transmitter on and of

course the receiver, hold the airplane in your right hand,

transmitter in your left, with the wings level and the nose

at about 15° to 20° up. Launch the airplane briskly and

level. The airplane should quickly assume about a 50° to

60° climb attitude and be moving in a straight line up and

away from you. Any corrections to maintain the straight

launch should be done with small movements of the

transmitter stick—avoid quick, full-throw movements

2-5/8"

back

from the leading edge of the

that the action of the servos is bind-free. If you have

installed a captive tow-hook system, test it's opera-

tion to be absolutely sure of release on command.

Inspect the airframe and it's various components.

Check for warps in all of the surfaces. If any are found,

now is

METRICK's employed the use of about 1/4" of wingtip

wash-out (wash-out is the raising of the trailing edge

wingtip). This was used to avoid any tip-stalling tendencies that might have shown up on our prototypes.

Subsequently, our METRICK's have been flown with

and without wash-out with equally good results—

pick the set-up that works best for you. Once everything has been checked to your satisfaction, make

sure the battery pack is charged and head for the

flying site.

because at launch speeds the flight surfaces are very

effective! As the airplane comes over the top of the Hi-

Start, it will begin to slow down and the nose will be

about level with the ground. At this point, apply some

down-elevator to let the tow ring come free from the tow

hook. The airplane should now be free from the tow ring

and flying on it's own. If you followed the hand-gliding

instructions, your METRICK will very likely be very close

to trimmed for flat and level flight.

First try a series of both left and right turns to get the feel

of the rudder, be sure to trim the rudder for straight flight

on the transmitter, if necessary. Next, while at altitude,

slowly feed in up elevator until you observe the airplace

beginning to "mush", this is the beginning of a stall and

knowing where it begins and how drastic it is can save

your airplane later on. Continue to hold up elevator until

the airplace fully stalls—it will literally stop flying.

Observe carefully what it does at this point. Does it lose

all airspeed, drop the nose and continue flying or does it

fall-off on one wingtip or the other? If it falls off on a

wingtip, some washout in the wingtips could help—not

cure—this phenomenon. Practically speaking, it is best to

know the stall characteristics of your particular airplane

and to avoid those flight circumstances which will lead to

them. While we are still at some altitude, try dropping the

nose a little with a touch of down elevator to get some

idea of the speed range that your METRICK provides. As

the model's speed picks up, the airfoil becomes quite

efficient and tends to resist the nose-down condition—

the result is a very flat, fast glide rate that allows you to

cover a lot of territory with a minimal loss of altitude.

Landings, especially some of the first ones, until you are

used to the airplane, should be set-up in the normal

fashion, except for the final up-wind leg which might

have to be longer than you are used to since the

METRICK, with the nose slightly down, as in a landing

approach, tends to want to stay airborne. If you have

equipped your plane with spoilers, the landing task

becomes very easy with incremental amounts of spoiler

the

time

to

correct them. Initial flights

with

our

13

Page 14

applied at the right times. If the METRICK is your first

sailplane or your 21st, there are three rules that always

apply in soaring:

1. Practice

2. Practice

3. Practice

We are going to assume that you are now fairly comfort-

able with the airplane and would like to attempt some

thermal soaring. As the METRICK comes off of tow, we

have made it a practice to penetrate out upwind in a fairly

straight line, watching the airplane carefully for lift (or

sink) information. If the airplane flies directly into a thermal, you will notice some decrease in forward speed and

a flattening of the glide together with a flat elevator-type

climb. When you see this, make a broad turn, searching

for the "core" of the thermal, avoiding the outer edges.

Once into the center of the lift, hold the rudder and

elevator combination that provides the highest rate of

ascent and at all costs, avoid stalling. You will find that the

METRICK will outclimb most anything at the field in the

same lift conditions—its rate of climb is awesome.

If you encounter a thermal during cruise that is either to

the left or right of the airplane, you will know because the

wing encountering the lift will kick up. When this hap-

pens, turn into the direction of the wing panel that went

up—right wing up; turn right, left... same procedure

except turn left. Again, search out the core of lift and

enjoy.

If you have chosen to power your METRICK with the

optional .049 engine set-up shown on the plans, all of the

above applies to you except, of course, for the launching

technique. Your engine should be started and the needle

valve set to provide maximum RPM's. Making sure that

your receiver and transmitter are on, the airplane should

be hand-launched with the wings level and the nose

slightly down, with a brisk throw—do not heave the

model, it is not necessary and could cause a stall. Let the

model climb-out and up at a shallow angle at first to

build-up airspeed and allow the wings to become efficient. With a standard reed-valve engine and three minutes of fuel, you should have little trouble reaching 300 to

400 feet of altitude. When the engine quits you are flying a

sailplane and the information mentioned earlier applies

concerning thermal activity.

No matter how you have chosen to fly your METRICK we

sincerely hope that it has been a rewarding project for

you and thatthe hours spent on the building board will be

nothing compared to the hours of soaring enjoyment to

come.

Speaking of soaring enjoyment, TOP FLITE MODELS,

INC. is very proud to be the first model aircraft company

to provide you with information and a membership dec-

laration for the world's largest R/C sailplane organization,

the LEAGUE OF SILENT FLIGHT. Your R/C soaring activ-

ities can take on a whole new meaning and importance

by participating in the L.S.F.'s Soaring Accomplishments

Program.

INDEX

Application for LSF Membership ......................................................................... 1

Covering ............................................................................................... 11

Fin and Bellcrank Assembly ............................................................................. 6

Final Assembly ......................................................................................... 10

Flying .................................................................................................. 13

Fuselage Assembly ..................................................................................... 3

Introduction ............................................................................................ 1

Pre-construction Notes .................................................................................. 2

Pre-flight............................................................................................... 13

Radio Installation ....................................................................................... 11

Rudder................................................................................................. 7

Stabilator Assembly..................................................................................... 7

Wing Assembly......................................................................................... 8

14

Page 15

LEAGUE OF SILENT FLIGHT

P.O. Box 39068

Chicago, Illinois 60639 USA

Hello...

You're in good company if you're curious about the LSF. Many are these days. The LSF is attracting the

attention and interest of R/C sailplane enthusiasts throughout the world.

The League of Silent Flight is an association of and for the individual sportsman. It is not a club... it is a

program ... and participation neither conflicts with nor requires club membership. However, many clubs

find that group participation in the LSF can excite new interest and bring new growth.

Membership can only be earned. Membership cannot be bought... there are no membership dues or

fees. To become a member, an R/C sportsman must fulfill the requirements of Level I of the LSF Soaring

Accomplishments Program: a 5 minute thermal flight; a 15 minute slope flight or a second 5 minute

thermal flight; and five spot landings within 3 meters (9.84 feet) of a target point.

Advanced levels in the program are progressively more challenging. Level V, for example, requires a 2

hour thermal flight, an 8 hour slope flight, a 10 km (6.21 mile) goal and return flight, as well as

considerable success in soaring competition.

Members (sportsmen who have achieved Level I or higher) are privileged to display the distinctive LSF

insignia. The LSF emblem on a jacket or sailplane is a symbol of proven performance. It is displayed with

pride... and recognized... anywhere in the world.

The LSF is a personal challenge, and serious sportsmen are invited to associate with the League. The first

step? Declare your intent.

To: LSF Executive Board

PO Box 39068

Chicago, Illinois 60639

I,

_______________________________,

concepts and criteria set forth in the Bylaws of the League of Silent Flight and give notice herewith of

intention to attain Level I of the LSF Soaring Accomplishments Program, and by so doing, earn full

recognition and privilege of membership.

Mailing Address:

AMA

(or

other

FCC

(or

other)

NOTE: ALL CORRESPONDENCE TO THE LSF MUST INCLUDE AT LEAST $1.00

IN STAMPS OR COIN FOR RETURN POSTAGE.

__________________________________________________

FAI

Affiliate)

Radio

Operator's

License

License

or Membership No.

No.

______________________________

(please

__________________________

print)

will

support the philosophies,

(Signature)

15

Loading...

Loading...