Page 1

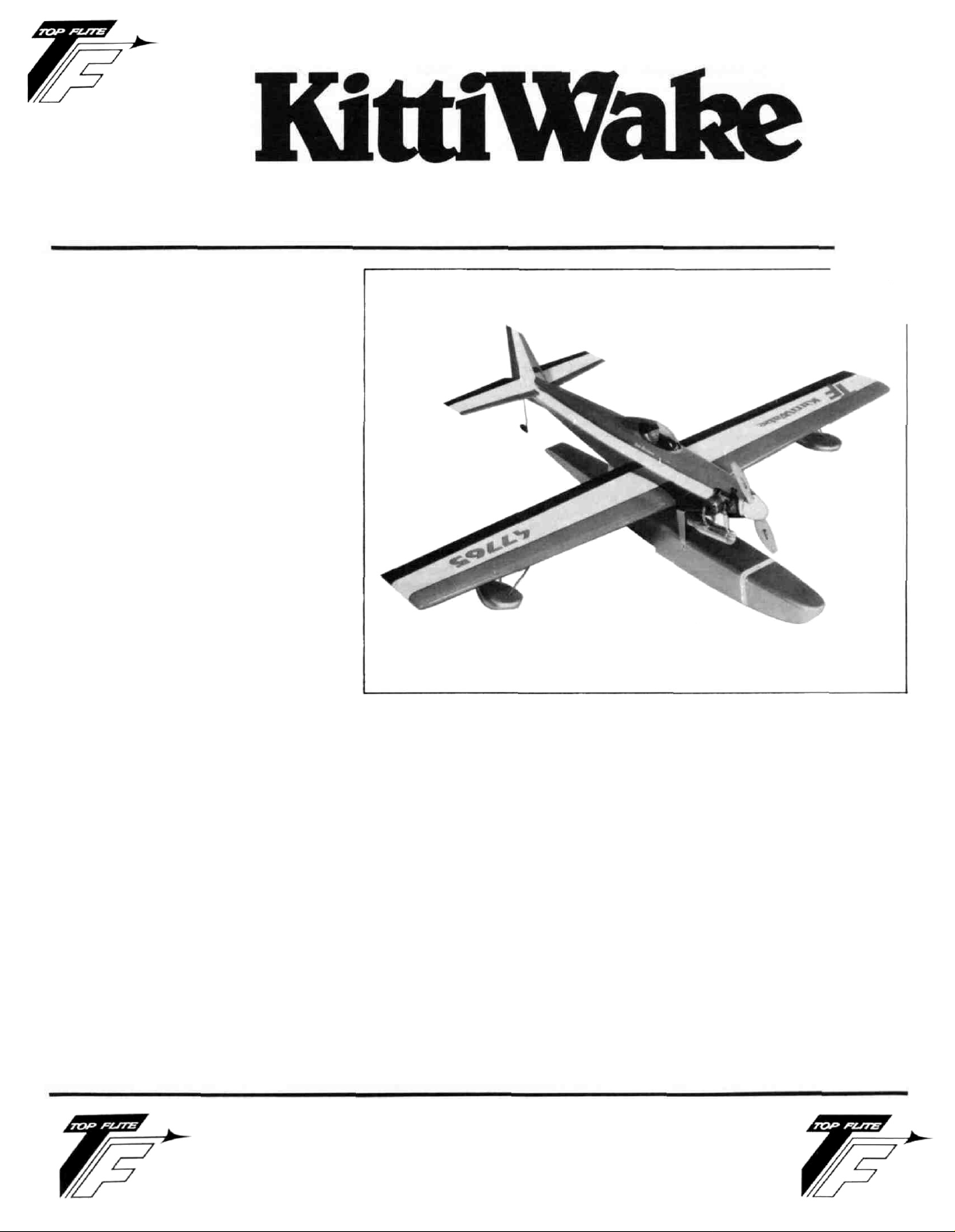

AEROBATIC R/C SEAPLANE

RC-36 KITTIWAKE INSTRUCTION MANUAL

INTRODUCTION

The KittiWake, proof-positive that there

can be more to R/C seaplane flying than

just take-offs and landings! Top Flite

Models is sure that your KittiWake will

provide you with hours of flying fun and

performance.

Realistic, finished flying weights of 3 to

3-1/2 pounds can be expected when the

model is built to the following instruc-

tions. Our prototypes were all covered

and flown with Monokote® coverings.

The covering instructions will give you

the details of how we accomplished the

few extra precautions that should be ex-

ercised when covering a seaplane.

Engine selection for your KittiWake is im-

portant. Our prototypes have been

powered with a variety of engines, rang-

ing from .19's through .28's. The KittiWake

that is shown in the ads and on the label

of your kit has a O.S. .25 FSR installed

with a Mac's muffler. This has been an

excellent combination, providing lots of power at the top

end while offering an excellent and reliable idle. A

reliable idle is an absolute must! Face it,yourKittiWake

will have to spend a portion of each flight taxiing on the

water and without a reliable idling engine, you better

have access to a boat to go out and get it when the

engine "flames out." Take extra time to work on the idle

of the engine you choose—it will pay off later.

While on the subject of engines, it is worthwhile to point

out that the physical mounting of your engine does not

necessarily have to be a side-mount, as shown. Your

engine can be mounted up-right, at a 45 degree angle,

even inverted (although we do not necessarily like an in-

verted engine in a seaplane due to potential flooding

problems). Generally speaking, the use of a muffler on

your engine is highly recommended as it greatly

enhances the idle characteristics as well as serving to

keep you on good terms with people who may also be at

your flying site! Therefore, mounting your engine in the

nose of your KittiWake should take into consideration

the positioning of the muffler. Mounting the engine up-

right or at a 45 degree angle allows the use of most

engine's stock muffler set-ups. Side mounting the

engine, as we did, most usually requires a replacement

muffler (one with a longer header) or a header extension.

Our prototypes all used fiber-filled motor mounts, sized

for whatever engine chosen for the airplane. Your local

retailer should be able to supply you with the correct

mount for your engine.

IMPORTANT NOTE:

TOP FLITE MODELS, INC. does not recommend the

KittiWake as a first R/C powered aircraft. However, if you

are a beginner to the sport of R/C flying, we would urge

you to seek and use experienced assistance in con-

structing and flying this airplane. Again, if you are new

to this hobby, consider this:

Flying this or any other radio-controlled model aircraft is

a PRIVILEGE and not a RIGHT and this privilege begins

with the utmost safety considerations to others and

yourself as well. An R/C model airplane in inexperienced

TOP FLITE MODELS INC.

2635 S. WABASH AVENUE • CHICAGO, ILLINOIS 60616

Page 2

hands has the potential of doing serious personal or property damage. These safety considerations start at the

building board by following instructions, seeking competent help when you are confused and avoiding shortcuts. These considerations have to be carried over to the

flying field where safety must come first and limitations

cannot be exceeded. We urge you to:

1. Send for and obtain your AMA (Academy of Model

Aeronautics) membership which will provide insurance for your R/C activities — DO NOT RELY ON

HOMEOWNERS INSURANCE.

2. Join an AMA sanctioned R/C flying club in your area

where you can obtain competent, professional instruction in trimming and learning how to fly this

model.

Check with your favorite local hobby shop for the required AMA forms or the address where they can be obtained.

WARNING!!!

A radio controlled model is not a "toy." Care and

caution must be taken in properly building the

model, as well as in the installation and use of the

radio control device. It is important to follow all

directions as to the construction of this kit as well

as installation and use of the engine and radio

gear. The advice and assistance of a well experienced builder and pilot is highly recommended. Don't take chances! Improper building, operation, or flying of this model could result in serious

bodily injury to others, yourself, or property

damage.

PRE-CONSTRUCTION NOTES

The KittiWake, like other Top Flite kits employs the use of

die-cut wood to ease the task of construction, parts fit

and identification. The dies used for this kit have been

rigorously checked for absolute accuracy and should

provide you with excellent fit. Die-cut parts should be

carefully removed from their sheets by first lightly sanding the back of each sheet of parts and then carefully

removing each part. Use a light garnet paper for the sanding and keep a sharp hobby knife with an X-acto #11

blade, or equivalent, handy for assistance in removing

any parts that might not have completely cut-through by

the dies. Parts which oppose one another and must be

precisely uniform—such as ribs, etc.—should be

carefully "matched" after their removal from the part

sheets. Matching is the process of holding the opposing

pieces together with either pins, tape or spot gluing and

lightly sanding the edges of the parts until they are identical. A sanding block with light garnet paper is most

useful for this and other phases of construction.

Your building surface should be at least large enough to

accommodate the wing. This surface should be as absolutely flat as possible and yet be able to accept pins

easily. We have found that a product such as Celotex

fiber board works quite well for this purpose. Another

good surface can be found in most well-stocked hardware stores—a 2' x 4' fiber board ceiling tile. These are

quite inexpensive and can be used for several airplanes

before needing replacement.

As with most R/C kits that are constructed from wood, a

selection of tools—most of which can be found in the

average workshop—are a must to do the job correctly:

• Hobby knife and sharp #11 blades

• Single-edge razor blades

• T-pins

• Sanding blocks in assorted sizes

• Sandpaper in various grits

• Hand-held hobby saw, such as an X-acto

• Dremel tool or power drill and assorted drill bits

• Straight-edge, preferably metal, at least 36" long

•90" triangle

• Soldering iron, flux (silver) and solder

• Carbide cut-off wheel for wire cutting

• Small power jig-saw, such as a Moto-Saw

• Razor plane

• Tapes, such as masking and cellophane

Our KtttiWakes were constructed using a variety of

common hobby adhesives including 5-minute epoxy,

cyano-acrylates, and 1-hour epoxy. Since all of us have

our own construction techniques and favorite

adhesives, stick with the ones you are familiar with and

prefer. However, in certain areas there will be cal louts for

certain types of adhesives, and we urge you to try not to

substitute since doing so could possibly cause problems structurally.

The last thing we should touch on before we begin actual construction is the sequence in which the KittiWake

is assembled. The sequence given to you in this booklet

has proven to be the most straight-forward and provides

the finished components in the order in which you will

need them to progress to the next assembly phase. Try

to stick with the building order presented here to avoid

mistakes.

Spread the plans out on your work surface, cover them

with a clear plastic material, such as the backing from a

roll of MonoKote® or plastic wrap and commence construction.

WING CONSTRUCTION

It is important that you study the plans and illustrations

to understand how this wing is constructed. It is also at

this point that you make up your mind about the possible

addition of the optional landing gear set-up that we've

shown on the plans. The grooved trunnion block

material is a stock item by Sig Mfg. Co. (their #SH-655)

and the V dia. landing gear wire is bent from the pattern

provided on the plan. This set-up has worked well in actual practice. The rib reinforcements for the trunnion

blocks, RR-1 through RR-3, have been accurately

depicted for you on the plans. The addition of the optional landing gear will permit you to use the model

either on the land or in the water. Additionally, Halico

2

Page 3

sells a pre-bent, tempered aluminum landing gear that

mounts directly to the fuselage, at the forward float leg

location. Ken Willard has used this variation quite successfully (see RCM Magizine, November, 1986). The

following instructions assume the float plane version

only.

1. From their die-cut sheets, carefully remove all

wing ribs, W-1 (A and B) through W-8. Where

necessary, use a #11 blade to free the parts, making very sure that bottom tabs remain attached.

(These have been partially cut through for later

removal, should one break off, reattach it with a

spot or two of glue). If needed, lightly sand the

edges of the ribs to remove any burring. Locate

and remove die-cut (ply) parts W-9 and W-10. Addi-

tionally, locate and have ready the four 1/ 4"x 3/8"x

24"wing spars, the two 3/8 x

edges and the two 1/8" x

balsa. Of course, as we proceed with these in-

structions, you will need wing sheeting

(1/16"balsa) from the stock provided in your kit.

Protect your plans with clear food wrap or

MonoKote® backing. We will build the center

section first, followed by the outer panels.

3/4"

x 24" leading

1/4"

x 36" sub spars—all

tween the W-1 B's, about 3/8" ahead of the trailing

edge. Sand the insert as needed to fit and when

satisfied, epoxy in place. The bottom of this structure is now sheeted with 1/16" balsa from the

leading edge back to the trailing edge. Do this accurately and neatly. Use a small sanding block to

now smooth the rib/sheeting joints, keeping the

outer

(Note: The following outer wing panel construction steps assume that both the left and right

panels are built simultaneously. Also, this is the

point at which your decision about installing the

landing gear option, shown on the plans, should

be

rib

be

should now be epoxied in place to the concerned

surfaces of W-1A and B flat.

made. The patterns provided on the plans for

reinforcement parts RR-1 through RR-3 should

used to make the 1/16" Ply parts and these

ribs.)

2. Cut two 2

portant: cut one of these lengths from one piece

of spar stock and the other piece from a different

length of spar stock). From one of the leading

edge pieces, cut a

of the spar pieces directly over the plans. Now

securely pin the two rear W-1 B's in place against

the spar, making sure that they are perfectly ver-

tical to your work surface (use a triangle or block

to be sure). Now set the W-9 dihedral brace in

place on the work surface, against the bottom

spar and the two W-1 B's. Like the W-1 B's, ac-

curately position and securely pin the forward

W-1A's in place against the W-9 brace. With the

above securely in place, glue the

leading edge stock to the front of each W-1A (do

not glue to the break-away tabs). Now carefully

glue the top length of spar stock in place to the

W-1 B's. Starting from the leading edge, cut, fit

and glue all of the center-section's 1/16" balsa

sheeting in place; allow to dry.

3. Carefully remove this assembly from your work

surface. Unpin the short length of spar stock from

your work surface. Turn the assembly over and

epoxy W-10 in place against the rear face of the

leading edge and up against the top sheeting.

Carefully glue W-9 in place against the W-1A's and

B's, the top spar and sheeting. Take care here to

wipe-off any excess adhesive on the outer surfaces of the ribs and W-9. Glue the remaining

length of spar stock in place against W-9 and to

the W-1 B's. Carefully remove the bottom rib tabs

from each rib section and use a sanding block to

smooth the bottom of this structure as well as

bevel the bottom rear edge of the top sheeting.

From the kit, locate the shaped basswood wing

bolt insert. As shown, this part fits in place be-

11/16"

lengths of 1/4" x 3/8" spar stock (Im-

2-11/16" piece.

Accurately

2-11/16"

pin one

piece

of

4. Use the full cross section of the wing, the view

directly beneath the wing plan, to now accurately

cut and bevel the top and bottom 1/4" x 3/8" spars

and the

inboard W-1 ribs are angled to provide the needed

7/8" dihedral for each wing panel. In order to provide this angle uniformly to each W-1 rib section,

we've provided you with a dihedral guage, shown

here. Use this as a pattern to now makethis guage

from either scrap ply or balsa. As you did for the

center section, now pin the bottom spars accurately in place over the plans. Take care here to

ensure that they are in place straight. These bottom spars are only in place for accurate rib alignment at this time.

3/8"x3/4"

leading edges.

You'll

note that the

FULL SIZE

DIHEDRAL GAUGE

FORW1-A&W1-B

3

Page 4

5. Starting with tip rib W-8 and working inboard to

W-2, securely pin each rib in place overthe bottom

spar, making sure each is perpendicular to your

bench at 90°. Using the dihedral guage that you

made in Step 4, now accurately and securely pin

both W-1A and B rib sections in place. Note that

W-1A is spaced 1/16" ahead of the spar to compensate for the thickness of W-9 (ply dihedral brace).

Now trial-fit the pre-cut and beveled 3/8"x3/4"

leading edges in place against each rib face and

on each rib's bottom tab. Use a soft pencil to now

mark each ribs location on the leading edge and

remove. Apply glue to the marks made and glue

the leading edge in place, securing with pins.

Glue the top spar in place, W-8 through W-1B

(remember that you need a 1/16" gap for W-9, use a

scrap spacer).

6. As shown on the plans, each wing panel has a

sub-spar system which allows for the cutting and

hinging of the inset ailerons. These sub-spars are

made from 1/8" x

1/4"

balsa and the effected ribs

(W-8 through W-3) are slotted for their installation.

Cut, fit and glue the forward sub-spar in place

from W-8 to W-3. Now cut and trial-fit the rear sub-

spar in place at the rear of the slots provided in

ribs W-8through W-5. Note that the inboard end of

this sub-spar extends to and contacts W-4 and

that when in place correctly, there is an approx-

imate 1/8" gap between the front and rear subspars (this allows for 1/16" cap sheeting after the

ailerons are removed from the wing). Glue the rear

sub-spar in place.

7. From your kit, locate the 1/16" x 3" balsa sheet

stock. (Note that whenever you are applying balsa

sheet stock to a structure, it is almost always necessary to "true- up" edges by the use of a sharp

X-acto blade and a long metal straight edge.

These instructions assume that you will be doing

this as you progress.) Cut and fit the 2" wide

lengths of sheet required for the top, rear trailing

edge. Apply a moderate amount of glue to each

rib and glue this sheet in place; weight and/or pin

as needed to secure. Move forward to the top front

sheeting. Cut, fit and glue this piece in place (note

that the rear edge of this sheeting is cut to fit

halfway across the width of the spar). Now cut, fit

and glue the 1/16"x1/4" cap strips in place to the top

of each rib; W-8 through W-4.

8. Remove the wing panels from the work bench and

lay them back down, upside down. Glue the bottom spar in place. Now carefully remove all of the

tabs from the wing ribs. Use a long sanding block

to lightly smooth the bottom wing rib contours

and to bevel the trailing edge sheeting. Again,

with the panel's upside down on your bench,

locate and remove the two W-4A inboard aileron

"riblets". These are now glued in place, 1/16" outboard of W-4 (use scrap of balsa as a spacer), to

the sub-spar and top sheeting. Use a pencil to

now draw the aileron "cut-out" lines directly onto

the top sheeting. With this out of the way, cut, fit

and glue in place the bottom trailing edge

sheeting; pin and/or weight and allow to dry.

9. From your kit, locate the 10" length of slotted

hardwood tip float trunnion stock;

1/4" x 1/2"

. As

shown on the plans, you need to cut two 3-1/2"

lengths and six at 7/16"; do this now. Next,

drill

3/32" dia. hole through the 3-1/2" pieces, just outboard of the W-5 rib. This hole allows passage of

the 3/32" dia. formed main tip float wire. Trial-fit

these wires in place now. Some chamfering of the

slot and hole may be needed to allow the wire to

nest in the slot. Once satisfied, epoxy the two

3-1/2"

trunnion

blocks

in place to the front of the

bottom spar and ribs W-6 and W-5, carefully lining

up the hole just drilled with the outboard face of

W-5. Tape the formed tip float wires in place to

their trunnion blocks. Now carefully glue the 7/16"

lengths of trunnion blocks in place, over the wire

stub end, to W-5 and the top of the already-installed

3-1/2"

trunnion

block.

The resultant

positioning

of the formed wire, as shown on the plans, should

be vertical to the bottom surf ace of the wing. Note

that the remaining 7/16" lengths of trunnion stock

should first be trimmed to conform to the bottom

curvature of W-5 and epoxied in place per the

spacing shown in section C-C.

10. The bottom leading edge sheeting is now cut, fitted and glued in place, making sure that the glue

is kept out of the tip float trunnion slots and holes;

weight and/or pin as needed and allow to dry.Cut,

fit and glue the bottom 1/16" sheeting that fits over

W-5 and W-6, between the leading and trailing

edge sheets—bottom of wing only. The bottom

center section sheeting can now be cut, fitted and

glued in place. All of the bottom 1/16" x 1/4" rib cap

strips are now cut and glued in place. The last

thing to do in this step is to locate and clear-out

the

tip float trunnion slots and holes.

11. In this step you will be joining the outer panels to

the center section. If you've been careful to this

point, all that is needed is to lightly sand the inboard faces of the wing panels to render them truly flat and at the correct angle to achieve the required 7/8" dihedral. Now carefully trial-fit the

center section to each wing panel (one at a time)

to check fit. Some trimming of W-9 may be needed. Once you've achieved a good fit, prop up each

panel's wing tip 7/8" and check for the proper angle

in each panel, when in placetothecenter section;

sand and trim as needed to achieve this fit. For

joining the wing panels, we suggest an adhesive

like 30-minute epoxy as it gives you plenty of time

to work. Apply a moderate amount of glue to each

side of the center section and the rear face of W-9,

where it contacts the spars. Slide one of the wing

panels in place to the center section and gently

move it up and down a little to disperse the glue

evenly. Slip on the other panel and do the same

thing. Place the wing on your bench with the tips

supported at 7/8" each. Weight the center section

to

hold it flat. Use tape and/or pins to maintain the

a

4

Page 5

wing panel's alignment. Before leaving this structure to cure, carefully remove any oozing

adhesive from the tops of the wing panel's still exposed W-1B ribs.

12. Remove the now-assembled wing from your

bench and inspect yourwork.Useasanding block

to clean-up the joints. The leading edge of the

wing is now first razor-planed to rough shape

followed by the sanding block to achieve final

shape. Take your time here and bring these

shapes down to those shown on the plans.

13. The top of the fully sheeted center section,

behind the spar, is now opened up to accept your

aileron servo. As shown on the plans, the aileron

servo is to be installed on it's side. The opening

that you need to make should correspond with the

dimensions of your system's servo. Under no circumstances should the width of this opening exceed the inside dimensions of the fuselage interior

(2-1/8"

between the

F-2

doublers). Most radio

system manufacturers provide what is called an

Aileron Servo Tray for their servos. This is what

we've used on our prototypes and recommend to

you. The servo is mounted to the tray and the tray

can then be mounted into the opening in the

center section and to the floor. The tray can be

held in place with servo mounting tape or you can

do as we did and install a couple of scrap spruce

rails (1/4" thick) and screw the tray to the rails. You

should now make-up the aileron servo mounting

system that you're going to use. As shown, the

aileron servo's output arm is fitted with the DuBro

EZ Connector (supplied) which is used to drive

the aileron drive cable. Install this connector to

the output arm that you plan to use. (IMPORTANT

You will not need a great deal of "throw" from

your servo to the output arm and we suggest that

this connector be mounted on the output arm's

innermost hole.) Place the servo, in place to the

servo tray and with the EZ connector attached, into the opening. Now observe where the cable

housing tube (one in each panel) needs to enter

the compartment, through the W-1B ribs and

carefully mark these locations on the ribs.

Remove the servo and use a 1/8" drill bit (handheld) to drill these first two holes. Use the plans to

now drill the remaining 1/8" holes through ribs W-2

through W-5. Angle drill the tube exit holes, as

shown on the plans, just inboard of W-6 (also see

Section C-C)

14. From your kit, locate the 36" length of aileron

drive cable and drive cable tubing. Lightly sand

the surface of the tubing and cut it into two 18"

lengths. Now install the tubing into the holes

you've drilled, as shown on the plans—don't glue

yet, just get it into place with the excess protruding out of the aileron end. Working from one

side, slide the cable into the tube, working it as

needed to negotiate the corners—be patient, it'll

go. Run the cable all the way through and out the

other side, centering it in the servo compartment.

Try moving the cable back and forth a few times, it

should be fairly smooth and free. Adjust the asyet unglued tubing to achieve free movement of

the cable (a little heat from your heat gun at the

curves, really helps). Once satisfied, use slowsetting CA glue to permanently secure the tubes

at each rib station and the angled exit points—do

thiswiththecablestill in place. When dry, remove

the cable and trim the outboard angled ends of

the tubing flush with the sheeting.

15. Cut, fit and glue the top center section sheeting to

each wing panel followed by the last cap strip

pieces over the two W-3 ribs. Lightly sand the

outer faces of the W-8 ribs smooth and flat. You

can now glue the 1" x

1-1/4" x 6-1/8"

balsa wingtip

blocks in place to the W-8 ribs but NOT to the

outer ends of the ailerons. These blocks can now

be shaped and final-sanded, as shown on the

plans. The entire wing should be sanded and

smoothed to final shape.

16. Using the marks made earlier, the ailerons can

now be cut from the wing. Use a sharp #11 knife

and a straight edge. Once the ailerons are free;

sand the aileron bays smooth and straight. Cut, fit

and glue 1/16" balsa sheet over the open rib ends

and against the top and bottom sheeting, thus

closing uptheaileron bay.As shownonthe plans,

the ailerons now need to be beveled, to facilitate

free movement. Do this now with your sanding

block. Also sand the face of W-4A flat and smooth.

Before capping the face of the ailerons, you'll

need to install the two die-cut W-11 aileron horn

mounting plates (1/16" ply)

in place

as

shown. Glue

these in now. Take one of the nylon control horns

from your kit, hold it in place on the bottom of the

aileron and use a pencil to mark the hole locations for later mounting. The front face of the nowprepared aileron can now be sheeted with 1/16"

balsa. Lightly sand the ailerons, top, bottom and

ends, with your sanding block. Use the sanding

block to slightly bevel the top, front edges of each

aileron, down to the hinge line (see Sections A-A

and

C-C).

17. Using the plans, mark the hinge locations for

each aileron on both the wing and aileron. Use a

#11 blade to carefully cut the hinge slots. Temporarily install the ailerons to the wing with the

nylon hinges. Check for fit and movement and

trim as needed for a perfect fit.

Your wing is now complete with the exception of installing the 1/4"dia. dowel in the forward center section. This

will take place during fuselage construction.

TIP FLOAT ASSEMBLY

From your kit, locate the four ABS plastic tip float

halves. You should have two right and two left halves. As

you can see from the diagram and the views on the

plans, these molded tip floats are mounted over a central light-ply "core" (TF-1). These cores are slotted at the

top to accept three

3/32"

I.D. x 3/8" brass tubes. These

5

Page 6

tubes provide mounting capability to the wing. The

secret to success here is the accurate cutting of the tip

float halves from their bases, thus providing a nice,

straight edge at the center.

1. As shown in the cross-section diagram, the tip

float has to be cut from it's base. The easiest way

to do this with absolute accuracy is to make a simple cutti ng tool. We use a 4 "-5" length of 1/8" x 3/8"

spruce or hard balsa to which we glue a #11 X-acto

blade, flat, to one end of this stick with about one

half of the blade's length protruding past the end

of the stick. When this tool is laid flat on the

bench, it can provide a consistently accurate cut

1/8" above the work surface. Use a flat formica

table top for this operation. Select one of the tip

float halves and place flat on the table and hold it

firmly to the table with one hand. With your other

hand, slide the X-acto tool all around the tip float,

scoring it lightly as you go. Repeat this operation

several times until you have a definite score line

all around the piece. You should now be able to

flex the plastic at the score line until it breaks

free. Repeat this procedure with the remaining

float halves.

halfway into the center—take your time to

achieve a good fit. Once satisfied, locate the six

required lengths of brass tubing from the parts

bag in your kit. Lay the TF-1's flat on a protected

work surface and epoxy one of the tubes into each

of the slots provided. Be sure the tubes are laying

flat and that glue does not get into them and allow

to cure completely. When dry, lightly sand the

tops of these tubes flush with the top edges of the

TF-1 cores.

2. As shown, the edges of each tip float should now

be sanded lightly to absolute flatness. A piece of

#320 sand paper taped to a piece of glass or a formica table top will work great for this purpose.

Simply hold the tip float half on the sandpaper

and move it lightly in a circular motion. Just a few

passes will be needed.

3. Locate and remove the two required TF-1 light-ply

cores from their die-cut sheet. These cores now

need to be final sanded to fit exactly into the

center of the tip float halves. They only need to fit

4. In this step you are going to glue the TF-1 cores

halfway into one of the tip float halves. We suggest using a slow-setting CA adhesive for this

operation. Use your finger to apply a liberal

amount of glue around the inside center edge of

the tip float half. Now carefully insert the TF-1

core halfway into the float half and lay the

assembly down on your protected work surface

(core side down) and allow to cure. Once the glue

has set, pick up the assembly and inspect it for

any glue runs, etc. These can be quickly removed

with a single edge razor blade. Once satisfied,

trial fit the other float half in place—it should fit

accurately, even if a little pressure is required to

do so. Remove the remaining unglued half.

5. Use a 3/32" dia. drill bit to carefully open up the

ends of each of the brass tubes. The remain ing tip

float half can now be glued in place. Again apply

glue all around the inside center edge of the part

and press it in place. Tape or hold the assembly

until cured.

6. Once again use the 3/32" drill bit to clear-out the

holes in the brass tubes. The now-assembled tip

floats should be lightly sanded along the center

joint with #320 paper to true them. Some filling

may be required along this joint and for this we

would suggest something like lacquer putty (probably the best choice), available at most

automotive paint supply outlets. On our pro-

totypes, we used both PIC's "Pie N' Patch" filler

and Model Magic Filler with great results. Finally,

we suggest wet-sanding the floats with #600

paper prior to painting. These floats can be

6

Page 7

painted with a variety of available paints,

preferably sprayed. Our choice is K&B epoxy.

MAIN FLOAT CONSTRUCTION

1. Locate and remove the two FL-1 main float sides

from their die-cut sheets. Tape or pin these ac-

curately together and use a sanding block to light-

ly sand their edges smooth. Now lay one of the

FL-1 parts directly over the side view of the main

float on the plans. Use a soft pencil to accurately

mark the position of each float former—top and

bottom. Use a straight edge to draw the former

locations directly onto the FL-1 part. Do the same

thing to the remaining FL-1 part.

2. Using the

glue the top and bottom longerons in place to

each FL-1 float side—REMEMBER, you want a

LEFT and a RIGHT float side!

3. Locate and carefully remove the seven required

float formers (FL-2 through FL-8) from their diecut sheets. Now trial-fit each former in place

against each of the FL-1 float sides. Use a single

edge razor blade to make any adjustments required to achieve a good fit to the float sides and

the 1/4" sq. longerons.

4. As shown, the main float is built upside down,

directly over the plans. Start by accurately positioning and pinning in place the

"former locator" directly over the centerline on

the top view of the main float. We'd suggest using

along straight edge to be certain that this piece is

straight. Starting with the forward FL-2 former, accurately glue each former in place to the 1/4" sq.

former locator making sure that each former is 90°

upright from your work surface; a triangle is

helpful here. Securely pin each former in place.

1/4"

sq. balsa stock provided in your kit,

1/4 "

sq. balsa

5. In this step you are going to glue the float sides in

place to the formers (still pinned and positioned

overthe plans). You will need to use a slow-drying

adhesive to allow you time to work. We suggest

the slowest setting CA-type adhesive you can find

or something like 15-30 minute epoxy. Before

glueing, trial-fit the sides to the former assembly

to be sure that everything fits as it should. While

doing this, experiment with bending the float

sides to fit the formers at both ends to get some

idea of the amount of pressure required. If there

seems to be too much pressure needed to do this,

a little common household ammonia, wiped or

sprayed on the float sides, helps the wood to

bend. Assuming that you are satisfied with the fit,

you can start to glue the FL-1 sides in place. We

suggest starting by applying glue to the inside of

each FL-1 (using the pencil marks made earlier)at

the FL-5 through FL-8 former locations. Working

quickly, position each FL-1 side in place to each

former; securely pin and/or weight as needed.

Now apply glue to the FL-4 through FL-2 former

locations drawn on the FL-1 sides and bend the

sides around these three forward formers. Again,

securely pin and/or weight as needed. Allow this

assembly to dry completely.

6. Carefully unpin and remove the float assembly

from your work surface. Use a sanding block to

now smooth the top and bottom. You can also

make a few passes with the sanding block on

each of the sides. Now carefully sand the front of

former FL-2 to render it flush with the sides. Do

the same thing to the rear FL-8 former. Once

satisfied, the front and rear balsa blocks can be

glued in place. These two blocks are now shaped

to conform to the top and side views, shown on

the plans, with the exception of the tops of each

block, leave these flush with the float sides for

now.

7

Page 8

7. Cut, fit and glue the

against the rear face of former FL-5, between the

bottom longerons of the float sides (see plans).

Locate and remove the two FL-9 "discs" from

their die-cut sheet. As diagramed, these discs

break down to four pieces each. Glue these

quarter-round pieces to each other to make four

1/4"

thick parts. Sand to 90° at the corners. As

shown on the plans, these four parts are glued in

place to form the "hard points" for attaching the

aluminum float legs. Do this now.

1/4"

balsa cross piece that fits

float. Start by laying one end of this piece on the

bottom, rear of the main float, from FL-5 back to

the tail block. Use a pencil to draw the outline of

the float on the ply. Use a jigsaw to now carefully

cut-out this rear sheeting. Use the remaining

plywood for the forward, bottom float sheeting.

Use the same process to mark and cut-out this

piece of sheeting. Once again, lay the float

assembly upside down on your flat work surface.

Glue the rear ply sheet accurately in place and

use weights to hold it firmly to the float until dry.

The forward ply piece is glued in place next. This

piece requires bending to match the bottom curve

of the float, so use all necessary weight to hold

this piece in place until dry.

9. Remove the float from your bench and take the

time to inspect your work. We've made it a habit to

go back at this time and re-glue all of the joints.

Once satisfied, use your sanding block to now

sand the ply bottom flush with the float sides and

front and rear blocks.

The main float assembly is now as complete as it

needs to be. Top sheeting and final sanding will

be done in the Final Assembly phase of these instructions.

GLUE TOGETHER

IN PAIRS

8. From your

plywood. This is the bottom sheeting for the main

kit,

locate the

1/16" x 3-1/2"

x36" piece of

STABILIZER AND FIN

1. Both the fin and stabilizer are cut from the two

3/16" x

These two pieces of wood should now be edgeglued together on your flat work surface to obtain

a single 4" wide piece.

2. Using the dimensional diagram provided,

measure, mark and cut-out the stabilizer and fin.

2"

x 21" balsa sheets provided in your kit.

8

Page 9

3. Use

4. Remove the now joined elevators from your

5. Locate and remove the two R-2 parts from their

6. As shown on the plans, the leading edges of the

a sanding block to smooth each side of these

surfaces. Remove the two elevator halves and

rudder from their die-cut sheets. Lay the stabilizer

on your flat work surface and pin or weight in

place. Use a strip of clear protective material

(food wrap) to line the trailing edge of the stab.

Position the two elevator halves firmly against

the trailing edge of the stab and pin or weight in

place. From your parts bag, locate the

of 3/16"dia. dowel, this is the elevator joiner. Epoxy

this dowel in place in the slot provided in each

elevator half and allow to cure.

bench. Lightly sand the leading edge of the

elevators smooth and flat. Now use masking tape

to accurately attach the elevators to the stab, on

one side only. Turn this assembly over and use a

sanding block to sand the leading edges, tips and

trailing edges to about halfway to the cross-

sections shown on the plans. Now tape the

elevators to the stab on the sanded side, turn the

assembly over, remove the tape and repeat the

sanding procedure just described. The fin and

rudder are match-sanded in the same manner.

die-cut sheet. As shown on the plans, these are

meant to provide a hard-point at the bottom,

leading edge of the rudder for mounting the water

rudder or tail wheel. Lightly sand the edges of

these parts smooth. Lay one of the R-2 parts in

place on the rudder and trace it's outline on the

rudder with a pencil. Use a single-edge razor

blade to now cut out a 1/16" deep inset location for

the R-2 part. Repeat this operation on the other

side of the rudder. Once satisfied with the fit,

epoxy the two R-2 parts in place. Weight or clamp

this assembly and allow to cure.

elevators and rudder are beveled to facilitate

movement. Use a sanding block to now bevel

these two parts. Now use the plans to locate and

mark the hinge locations on the elevators, stab,

fin and rudder. Carefully cut the hinge slots in

each of these surfaces and trial fit them

together—do not glue hinges in place yet. Once

satisfied with the fit of these parts to each other,

use a sanding block to match them to each other

while hinged in place.

2-1/2"

length

FUSELAGE CONSTRUCTION

A review of the plans and cross-sections reveals that the

fuselage construction is basically the typical box-type

which, when completed, lends itself to rounding. Before

starting, you should have available to you the radio

system that you plan to use and the engine, tank and

motor-mount.

1. From your kit, locate and remove from their diecut sheets, the following parts; F-1 (fuselage

sides, 2), F-3 (nose doublers,2), F-2 (fuselage

doublers, 2) and the light-ply fuselage formers,

F-5 and F-6. Tape or hold the two fuselage sides

together and use your sanding block to match

edges. Lay one of the fuselage sides directly over

the side view on the plans and carefuly mark the

locations (top and bottom) of the firewall, F-5, F-6

and the 1/4" sq. balsa bracing (@D-D). Use a

straight edge to now draw these locations directly on the fuselage side. Repeat this operation on

the other fuselage side (remember, you need a

RIGHT and LEFT side).

2. With the fuselage sides laying flat on your bench,

glue the F-3 nose doublers in place. Now lay the

F-2 fuselage doublers in place, being careful to

match the wing saddle area. Observe the fit in

relationship to the lines you drew earlier. If

necessary, trim the doublers to fit precisely. Once

satisfied, glue the F-2 part in place, weight or pin

and allow to dry. From your kit, locate the four required lengths of 1/4" triangle balsa stock. Cut, fit

and glue the triangular fuselage longerons in

place, top and bottom. Cut, fit and glue the four required lengths of triangular stock to the top and

bottom of the F-3 doublers and finally, glue

triangular stock in place, directly beneath the

stabilizer slots. With the fuselage sides still down

flat on the bench, cut, fit, and glue the 1/4 " sq.

balsa uprights in place (see D-D).

3. At this point, you may wish to start planning your

radio installation by placing one of the servos on

the fuselage side, marking its location on the

wood for later placement of servo rails or servo

rail braces.You may alsowishtoplotouttheeven-

tual location of the throttle pushrod. Next, make

sure that you can pass the fuel tank you're planning to use through the opening in former

F-5—route out as needed to accomplish this. The

last thing to do before joining the fuselage sides

is to bevel each side, at the tailpost, to provide a

nice fit when the sides are pulled together (see

top view of plans).

4. Trial-fit F-5 and F-6 in place on each of the

fuselage sides; dress them with the sanding

block if needed to achieve a nice fit. Lay the right

fuselage side down flat on the bench and glue F-5

in

place using a triangle to make sure that it is

perpendicular. Repeat this process with F-6. Apply glue to the other side of these two formers and

position the left fuselage side to them. Turn the

structure upside down on your bench and pin or

weight in place—allow to dry.

9

Page 10

5. Pull the fuselage sides together at the rear to

make sure that the two sides bend equally. Once

satisfied, apply glue to the inside rear of the

fuselage sides and glue them together. Use

clamps to hold the sides together until dry. Cut, fit

and glue the top and bottom

1/4"

sq. balsa cross

braces in place at D-D.

6. From your kit contents, locate the

1/4" x 1" x 7-1/4 "

plywood piece which will be used for the main

float and wing mounting blocks. Measure, cut

and fit the rear main float mounting block which

fits directly behind F-6 and between the fuselage

sides at the bottom. It will be necessary to bevel

each end of this block to fit snuggly between the

1/4"

triangle longerons and flush with the

fuselage sides. Epoxy this block in place. The

wing bolt mounting block is now cut to fit between the F-2 doublers and against the forward,

bottom face of F-6, flush with the wing saddle.

Save the remaining length of 1/4" x 1" ply, you'll

need it shortly.

7. Remove one of the two die-cut F-7 parts from its

die-cut sheet. This part is epoxied directly over

the rear main float block just installed. Measure,

cut and glue in place the bottom rear 1/16" balsa

sheet, applied cross-grain, from the rear edge of

F-7 back to the tailpost. Use a sanding block to

sand the edges flush with the fuselage sides.

8. In this step you are going to make the necessary

provisions for mounting the completed wing to

the fuselage. Cut a 3" length of 1/4" dowel from

the stock provided. Locate

the

two

#8-32 x 1-1/2"

nylon bolts from your kit contents. Placethewing

into the fuselage wing saddle, making sure it is

square and that the fit is good. Now is the time to

make any adjustments needed. Once satisfied,

place the fuselage/wing structure upside down

on your bench. Use weights to hold the wing firm-

ly to the fuselage. The first step is to drill the required 1/4" dia. hole through F-5 (at the mark pro-

vided), the wing's leading edge, W-10 and W-9.

Remove the wing, fit the 3" length of 1/4 "dowel in-

to the hole you've just drilled (DON'T glue yet) and

re-install the wing to the fuselage, using the end

of the dowel protruding from the wing's leading

edge (about 1/4") to key into the hole in F-5. Again,

use weights to hold the wing firmly to the

fuselage. Using the plans for reference, you now

must drill the two required guide holes for the rear

wing bolts. Use a 1/8 "dia. bit, at right angles to the

bottom wing surface, to drill these two holes

through the wing and wing bolt ply plate in the

fuselage. Remove the wing. Change drill bits to

3/16" dia. and redrill the two holes in the wing, thus

allowing bolt clearance. The two holes in the wing

bolt plate must now be tapped for #8-32 threads.

This can either be done with a #8-32 tap or by us-

ing a #8-32 metal bolt. Be sure the cut threads are

clean and that the nylon bolts fit smoothly. Once

satisfied, apply a couple of drops of instant CA

glue to these threads to harden them. You can

now epoxy the

1/4"

dia. dowel permanently into

the wing's center section. Test fit the wing to the

fuselage and bolt in place. Once satisfied,

remove the wing from the fuselage.

9. In this step you must decide on what position you

want your engine; upright, side-mount, etc. Using

the plans, mark the center lines directly on the forward face of the

1/4

" ply firewall. Take care to be

accurate here. Assuming that you now know

which position you want your engine, carefully

mark the four holes required to install your mount

to the firewall. We suggest that you use #4-40 x

3/4" socket head bolts and blind nuts to attach

your mount. Drill the required holes, epoxy the

blind nuts in place and removethemountfromthe

firewall. The firewall can now be epoxied in place

between the two fuselage sides, Clamp in place

until cured.

10.

From the remaining length of 1/4" x 1" plywood,

measure, cut and fit the forward main float mounting block in place to the forward face of F-5, flush

with the bottom fuselage sides. Note that this

block must be slightly routed out at the center to

allow clearance for the wing's mounting dowel;

dothisnow. Epoxy this block in place and allow to

cure. Epoxy the remaining F-7 plywood part

directly over the main float mounting block just

installed.

11. Remove spinner ring former F-4 from its die-cut

sheet. As shown, this part fits directly to the front

of the two fuselage sides. Trial-fit F-4 in place by

bending the fuselage sides together, at the nose,

until the outer diameter of F-4 matches the outer

edges of the fuselage sides. This necessary bending can be made easier by wiping some ammonia on the fuselage sides in the area of the bending stress. F-4 must be accurately located.

Epoxy F-4 in place and clamp securely until

cured.

12. Sheet the bottom of the forward fuselage, from

the leading edge of the firewall back to the forward edge of the F-7 part, use your sanding block

to smooth the sheeting to the fuselage sides.

From your

kit,

locate

the two 3/8"x3"x3-1/2"

balsa

nose blocks. As shown on the plans, these are

now trimmed and fitted into place from the rear of

F-4 back to the front face of the firewall, top and

bottom. Usethe sanding blockto sand them flush

with the fuselage sides after gluing in place.

13. While we still have access to the inside of the

fuselage through the top, there are a couple of

things we can take care of at this time. First,

locate four (4) #4-40 blind mounting nuts from

your hardware package along with one #4-40 bolt.

Using the plans as a guide, you now need to mark

the positions of the four required holes to mount

the aluminum float legs to the fuselage. As

shown, these holes are positioned 7/8" on each

side of the fuselage/float leg centerline (see

cross-section). From your kit box, locate the two

10

Page 11

aluminum float legs. Use a ruler, triangle and a

sharpened nail (or scribe) to accurately mark the

vertical centerline on both float legs. Now use a

soft pencil and a ruler to mark the fuselage's

centerline of both of the F-7 ply plates, on the bottom of the fuselage. Use a small amount of CA

glue to now tack glue the as-yet unbent float legs

accurately in place on the bottom of the fuselage,

carefully lining up the centerlines. Now mark the

hole locations directly on the float legs and with a

7/64"

dia. drill bit, drill these holes through the

aluminum, F-7 and

at a time, apply epoxy to the edges of the blind

mounting nuts and, using a screwdriver and the

#4-40 bolt, cinch the glued nut down into the hole,

from the inside. Once all four nuts have been installed in this manner, carefully remove the tack

glued float legs from the fuselage.

The next thing to do at this time is to make all the

necessary provisions for mounting the rudder,

elevator and throttle servos. As shown, we have

mounted the servos as far back in the radio compartment as possible and close to the bottom of

the top sheeting. We used the radio

manufacturer's stock servo mount (plastic),

which allowed for all three servos to be mounted

side-by-side. However, there's plenty of room for

the throttle servo to sit ahead of the other two, as

shown on the plans. Doing this now makes servo

installation later a simple matter of a few screws.

1/4

" ply mounting blocks. One

viewed from the top, is squarely in position

relative to the wing. Use a piece of string or a ruler

to be sure that the distance from one wingtip to

the tip of the stabilizer is the same measurement

on each side. Glue the stabilizer in place and

allow to dry. Next, the fin is glued in place. Again

make sure that the fin is absolutely vertical to the

stabilizer and wing. Tape and/or pin in place and

allow to dry.

14. From your kit, locate the 3/8" x 3" x 30" balsa sheet

used for the top fuselage sheeting. Sand the front

edge to match the rear edge of the noseblock,

already in place. Cut and sand the rear edge to

match the tailpost angle.

should now be cut in the rearto provide for moun-

ting the fin. Hold the sheet accurately in place to

the fuselage and use a soft pencil to mark the

fuselage outline on it. Use a jigsaw to remove the

excess material. Glue the top sheet in place to the

top of the fuselage and rear of the top noseblock.

Lay the assembly upside down on the bench and

weight in place until dry. Once dry, use a sanding

block to smooth the edges flush with the fuselage

sides.

15. The fuselage can now be shaped and sanded to

final configuration, using the plans and cross

sections for reference. We'd suggest first using a

sharp razor plane to rough shape the fuselage,

followed by progressively lighter grades of sand-

paper to achieve final shape and surface

smoothness. Take your time here to get those

sexy lines that you admired so much in both the

ads and the box art!

16. With the wing bolted in placetothe fuselage,trialfit the stabilizer in place in the slot provided. Set

the assembly flat on atable and step back to sight

down the front of the model—everything should

look straight. If it isn't, some sanding and adjustment of one of the slot sides may be needed. If so,

do this now. Next, be sure that the stabilizer, when

As

shown, a

3/16"x

2"

slot

17. Locate and remove die-cut sub-fin R-3. This part

has a "lobe" on it's forward end which should

now be sanded-off to match the plans. Tape the

rudder in place to the fin. Trial-fit R-3 in place to

the bottom rear of the fuselage. It's rear edge

should match the rudder's angle and depth at this

point. Once satisfied, glue R-3 in place (leave the

rudder taped to the fin). Once the glue has dried,

use a sanding block to match the R-3 sub fin to the

rudder shape. Use sandpaper to round R-3 to

shape (see E-E).

18. The engine compartment opening is now made.

We suggest starting with a small hole over what

would be the top of the engine's head and working

outward from there. The idea here is that you want

the opening to be large enough to fit the engine in

place (at this point; without the muffler mounted

yet) by hand, but not overly large. Once you can fit

the engine in and out of the opening, try the motor

mount. With access through the spinner ring

(F-4), bolt the motor mount firmly in place to the

firewall. Now fit the engine in place to the motor

mount. Slide the engine forward and attach the

spinner (we use the stub of an old 9x6 prop for a

spacer). Now slide the engine back until the back

of the spinner contacts the F-4 spinner ring. With

a few scraps of 1/32" material (balsa or ply), space

11

Page 12

the back of the spinner 1/32" from the front of F-4.

This is the position that your engine should be for

drilling the holes in the motor mount. Mark these

engine lug holes now, on the motor mount with a

pencil or scribe. Remove the engine, spinner and

motor mount. Accurately drill the four required

holes in your motor mount (Note: For .25-sized

engines, we suggest using #4-40 socket head

bolts and tapping the motor mount for #4-40

threads.). Reassemble the mount, engine and

spinner to check for accuracy of fit. With

everything still in place, positioning of the two

fuel line holes (fuel feed and muffler

pressure/overflow venting) and the throttle

linkage should be noted on the firewall for drilling. The last thing to make provision for is the fitting of your engine's muffler with sufficient

clearance. Do this now.

Remove all of the above components from the

front of your fuselage. Using a longer drill bit of

the correct (never oversize) diameter to the fuel

tubing and throttle linkage housing, drill the

holes marked earlier through the firewall. It is at

this point that we suggest a coat of polyester

resin be given to the inside of the engine compartment and firewall (don't get any in the holes for

the motor mount). We also like to use resin inside

of the tank compartment and on the rear face of

F-5.

19.

Use the same method described in the TIP FLOAT

ASSEMBLY section to accurately cut the molding

base off of the canopy. Next, securely tape a

sheet of #220 sandpaper over the area that the

canopy is to be mounted on the fuselage. Careful-

ly sand the base of the canopy to conform to the

top of the fuselage (it won't take much since the

fuselage, at this point, is only slightly rounded).

Once the canopy fits, hold it in place exactly

where you want it to be, and use a soft pencil to

draw its outline on the fuselage. If you wish, as we

did, to add cockpit detail, now is the time. We used a Wm. Brothers pilot head, suitably cut-down

to fit, scraps of black construction paper and a

few instrument decals we had laying around to

make a reasonable-looking cockpit. Once

satisfied, the canopy can be glued in place to the

fuselage with a slow-setting CA glue—tape or

hold and allow to set.

20.

There are some good fillet materials currently on

the market which we have used and recommend;

Penn's "Pie N' Patch" and Model Magic Filler.

Use the one that you're most comfortable with to

now apply a small fillet around the canopy (tape it

off with electrical tape) and around the

fin/fuselage, stabilizer/fuselage and subfin/fuselage joints. You should also lookoveryour

fuselage carefully for any nicks, dings or voids

and fill these at this time. Once the filler has set,

use a light grade of sandpaper to smooth these

out. You should now cut the last required hinge

slot in the rear edge of R-3 for rudder attachment.

FINAL ASSEMBLY

I. MAIN FLOAT ASSEMBLY

Back in the construction of the fuselage (Step 13), you

drilled the two required mounting holes in each of the

two unbent aluminum float legs. The float legs must

now be accurately bent to provide fit and attachment to

the main float and the plywood "hardpoints" built into it.

Take a look at the cross section shown on the plans of

this fuselage/float leg/main float relationship. You can

see that the float legs must be bent equally on each side

and that, at the bottom, they are bent slightly once again

to pick-up the vertical float sides. In all of this, the

fuselage/float relationship must provide for a.) proper

propeller clearance (9" dia. max prop size) and b.) the

correct angle of attack for the wing/fuselage/engine

combination.

1. Hold the float leg, straight edge down, vertically

in place on your flat bench. With a triangle and

scribe (sharpened nail will do) mark two vertical

lines on the float leg, each 1

-1/4"

on either side of

the centerline that you marked earlier. This provides you with an accurate

2-1/2"

inside bending

location. Place the float leg into a vice with a

piece of hardwood on each side of it (see

diagram) and make the first bend directly along

the line just marked on the part. This bend is made

by "eyeballing" the drawing provided. Turn the

part over and make the second bend. Remove the

part, lay it over the drawing to check for how close

you came. Continue this process until the part

matches the drawing. Repeat this procedure for

the other float leg.

12

Page 13

2. The method we suggest for locating the fuselage

to the main float istomakeapairoffrontand rear

scrap balsa stand-offs. These stand-offs are then

tack glued to the top of the main float and provide

a place for the fuselage, with the float legs attached, to accurately rest. The dimensions we used

are those directly behind the front float leg location,

beneath

rear float leg, beneath

F-5

(2-1/16")

and directly ahead

F-6

(2-1/4").

These two

dimensions take into consideration that the top

of the float has not yet been sheeted.

3. With the fuselage, float legs attached, now sitting

accurately over the main float, you can view the

assembly from the side and use a pencil to mark

the float leg ends for the second bend needed to

fit the vertical main float sides. These bends can

easily be done with a pair of pliers. Take a little

time to "tweek" these bends to achieve a good fit.

4. The bolt hole marks on each float leg end should

now be made. Remove the fuselage from the main

float and the stand-off fixtures (leave the stand-

offs in place) and remove the legs from the

fuselage. Drill the bolt holes accurately through

each leg end with a 7/64"dia. drill bit. Re-assemble

the legs to the fuselage and place the fuselage

back on the main float. Use the same drill bit to

now drill holes through the main float sides and

the plywood hard points. Install the four #4-40

blind nuts into the ply hard points with epoxy and

allow to cure.

5. Remove the fuselage from the main float and

remove the stand-off jigs from the main float top.

The top of the float can now be sheeted with the

1/16" balsa provided and shaped and sanded to

final form (see plans and cross sections). PLEASE

note that the bottom edges of the float are NOT

rounded, they are sanded to sharp, precise corners.

II. TIP FLOAT WIRE BRACES

1. Locate the 18" length of 3/32"dia. wire from your

kit. This wire is purposely untempered to allow

easy bending with common pliers. A carbide cutoff wheel in your Dremel Tool should be used to

cut this wire as needed. Accurate bending pat-

terns for these braces (2 per float, front and rear)

are shown on the right side cross section view of

the wing. Use the patterns to now bend and cut

the braces.

2. Now trial-fit the tip float and the supporting wire

braces in place to the wing. Use your pliers to ad-

just as needed for an accurate fit. Section C-C on

the plans demonstrates the correct relationship

of the tip floats to the wing. Once satisfied, set

these parts aside for later assembly after cover-

ing.

of

the

III. WATER RUDDER

1. Locate

the

two solder

clips,

the

1/16"

dia.

x 5-1/4"

wire arm and the 3/4 "x 1-1/4" piece of tin from your

kit parts. These are used to make the water rudder

system shown on the plans. We suggest using

Harris "Stay-Clean" solder flux for the required

soldering operations. Once the water rudder

assembly is made, carefully clean it off and round

the tin rudder as shown. On our prototypes, we

sprayed this part flat black with K&B epoxy. This

is not necessary but it looks very "finished".

IV. GENERAL

1. Bolt the wing to the fuselage. How does the wing

saddle fit look? It should be an excellent fit

because if it isn't water will find its way inside.

Now is the time to correct any gaps and achieve a

good fit. We suggest mixing up a thick mixture of

30-minute epoxy and white micro-balloons and

spreading this mixture directly onto the fuselage

wing saddle area. Cover the center section of the

wing with clear MonoKote backing to protect it

and then mount and bolt the wing in place. Allow

the micro-balloon filler to cure, remove the wing

and sand the fuselage sides smooth. The result

will be a perfect wing/fuselage fit that will not require any additional sealing.

2. On our prototype KittiWakes we used no fiberglass

for strengthening parts. However, you may wish

to do so. We suggest using only 3/4 oz. fiberglass

and only using this material in certain, small

areas such as the bottom, leading edge of the rudder, a square inch or so over each of the four bolt

holes in the main float, etc. Fiberglassing the en-

tire float is not needed and doing so could cause a

major weight gain.

COVERING

As mentioned right from the beginning, our prototypes

have all been covered and flown with MonoKote® covering. The airplane depicted on the label of your kit is totally covered with MonoKote, including the aluminum pinstriping and the tip floats (which were initially handcarved, shaped and hollowed from light balsa)! This

airplane has been flown a great deal as well as displayed at the various trade-shows and still, to this day,

looks fabulous. This demonstrates the viability of

MonoKote® as a covering for seaplanes and we highly

recommend it's use.

The tip floats, being plastic, lend themselves best to

paint. We have used and highly recommend sprayed

2-part epoxies, such as K&B or HobbyPoxy. These paints

were also used on our prototypes for areas such as the

water rudder assembly, inside the engine compartment

(flat black), the control horns (dark blue), the top of the

canopy (red) and the aluminum float legs (aluminum).

We suggest that all of the various components that are

going to be covered with MonoKote should first be

wiped with a tack rag or blown off with high pressure air

to remove any dust particles. Each component should

13

Page 14

be covered separately (elevators, rudder, ailerons, wing,

fuselage, etc.). After covering, locate and open up all required access points; hinge slots, bolt holes, etc. For

seaplane operations there really isn't much difference

in covering methodology other than being careful of

each required opening in the airframe. A structure such

as the main float, for instance, has requirements for four

holes (the float leg attach points). Common sense dictates that when the float legs are bolted in place to the

main float, the bolt threads should first be lightly coated

with a silicone sealer (best) or at least a coat of Vaseline.

While still on the subject of the main float, this particular

structure should be very carefully covered with the

overlapped seams measuring about 3/16" - 1/4". Additionally, these seams should be carefully worked over

with your MonoKote iron to be very sure they're in place

for good. It's taking the time to do these kinds of things

that has made MonoKote work so well for us on our prototypes.

After covering, the elevators, rudder and ailerons can be

hinged in place. We've made it a practice to drill a few

3/32" dia. holes on each side of the hinges, before installation, to allow the epoxy to flow and act as "pins"

when cured. As you proceed, keep a small amount of

acetone handy to wipe-off any excess epoxy.

The tip floats and tip float braces can now be installed

on the bottom of each wing panel. The method that

we've used to do this is simple and fast. First, install the

formed main tip float wire into it's hole and slot and

secure with the wood screws and washers. The front and

rear tip float brace wire-forms have already been bent

and pre-fitted earlier. Apply a slow-setting CA adhesive

to the ends of the braces and main tip float wire that fit

into the tip float itself and insert the front and rear wire

ends into the tip float, in approximately the correct positions. Now apply just a little CA adhesive to the opposite

ends of the wire braces and press this assembly into

place in the holes. If you need to remove the tip floats

from the wing, all you need to do is to remove the screws

and washers, flex the brace wires a couple times and the

assembly will come out.

The nylon control horns can now be permanently

mounted to the rudder, elevators and ailerons. Again,

we'd suggest silicone adhesive on the threads.

As mentioned earlier, we suggest a coat or two (brushed

is fine) of epoxy paint (K&B or Hobby Poxy) for the engine

compartment. Flat or satin black is our favorite because

it's neutral and easy to see when brushing. Once this is

done, the motor-mount, engine, muffler, fuel tank and all

necessary plumbing can be installed. The water rudder

won't be attached until after the radio is installed and

the airplane is assembled.

RADIO INSTALLATION

If

you have followed these instructions to this point, the

physical mounting of the four required servos should only be a matter of a few screws. This should be done now.

As

mentioned earlier in the Wing Construction steps,

the

aileron drive mechanism consists of the single

length of braided steel cable, driven at the center by the

aileron servo. Solder one of the threaded brass couplers

ononeendofthiscableand inserttheotherend intoone

of the openings at the aileron location on the bottom of

the wing. Feed the cable through and into the servo compartment, through the EZ connector on the servo's output arm and then into the tubing opening for the other

wing panel. Continue feeding the cable through this

panel until it exits on the other side. Attach one of the

nylon clevises to the threaded coupler and attach the

clevis to the aileron control horn. Use scraps of tape to

hold the ailerons in neutral. Now measure how much

cable needs to be cut-off in order to solder the remaining

coupler in place with a clevis attached. Mark and cut-off

this length of cable with a carbide cut-off wheel, lightly

tin the cable end, and solder the coupler to it. Attach the

clevis to the coupler and make the connection to the

aileron control horn. The clevises can now be adjusted

to center the ailerons and once satisfied, the set screw

in the EZ connector can be tightened. Test the action of

this mechanism with your radio system and make any

adjustments required.

1/4" dowel stock has been provided for the rudder and el-

evator pushrods, make and install these now. We sug-

gest you use 3/32 "dia. wire at the servo end of these push-

rods with either DuBro EZ connectors or "Z"-bends.

Don't use threaded clevises.

Assuming the throttle linkage of your choice has been

installed and works, make that connection to the throttle servo. The switch on our prototype was mounted internally (almost a "must" with seaplanes), against the

bottom of the fuselage top sheeting, just ahead of the

servo tray. A short length of wire through the fuselage

(use a close-fitting grommet of some sort; plastic tub-

ing, etc.) is then i nstal led to activate the switch external-

ly. If you look closely at the KittiWake on the box label, you

can see this on/off wire, just below the name on the

fuselage.

You should now make an exit for your receiver's anten-

na. We suggest that, like the switch, this exit be as high

up on the fuselage side as possible and that this exit

also be grommeted. Attach the other end of it to the top

of the fin with a wire hook and rubber band.

The only real water-proof ing measure that we took, other

than building the airplane tight to begin with, was wrapping the battery pack in clear plastic. The receiver and

battery pack should now be installed, remembering that

their positions may have to be changed for Center

of

Gravity needs.

Assemble your model completely and turn on the

switch. First make very sure that the ailerons, rudder and

elevators move in the correct directions by transmitter

command. Now you need to set-up your surface movements for initial test flights. The following is what we

suggest for first flights:

ELEVATORS.......... .5/16" from neutral 5/8" total

RUDDER................All available movement

AILERONS............

1/4"

from neutral 1/2" total

The above movements provide crisp control of the

model. If you have dual rate capability on your transmit-

ter, you may wish to decrease these movements slightly.

14

Page 15

The last thing to do is balance the model. The C.G.

shown on the plans is exactly where we have been flying

our prototypes. We've gone as far as 1/2" fore and aft of

this location and still had a managable airplane but not

necessarily a "happy" airplane. Therefore, do whatever

is needed to achieve the C.G. location shown and recommended.

After fully charging your radio system, you can head

the pond!

FLYING

Assuming that you have followed the instructions and

made sure that the engine is performing well, let's head

for the lake! The flying site that you choose is very important. It should offer you clear, unobstructed take-off and

landing room and it should also have access to the

water; a bank, stretch of sand, low pier, etc. Never, at any

time, should you operate your KittiWake when the water

is being used by swimmers or boaters. The last precaution we'll throw in here is that it is extremely unwise to

operate your KittiWake out of salt water. Salt water can

and will attack almost all metals, including battery

packs, receiver P.C. boards and servos. And it does so in

a matter of seconds. Fresh water on the other hand really does not hurt the electronics of a radio system, as long

as the system is given the opportunity to dry out between "dunkings". Our prototypes have not shown a

tendency to take on water and the fact that the radio

system is "suspended" in the upper part of the fuselage

does a great deal in protecting the system from sitting in

any pooled water that may get in.

It

does pay to create the best possible fit between the

wing and fuselage to minimize leakage.

Fill your tank and start the engine. From the work you've

done at home, the radio system should have already

been checked for any problems with vibration. After

making sure that all of the controls are moving in the correct directions, launch the airplane onto the water.

First try the action of the water rudder. This rudder

system works best at low speeds. You will find that the

faster the aircraft is moving, the less effective the water

rudder is. Do you have enough movement? In other

words, can you steerthe model comfortably in any direction? Remember that wind will effect the steering of the

model and that some additional time turning into the

wind may be required. What we are trying to find out in

these taxi tests is if we have enough steerage to easily

handle the model but not so much as to render it

"touchy".

If you find you need more steerage, return the model

shore and induce more movement into the flying rudder

by moving the clevis in, to the next hole. Try taxiing

again.

Once you're comfortable with the water handling characteristics, turn the airplane into the wind and advance

the throttle smoothly to about 1/3 rd. You'll find, as you do

this, it may be necessary to hold a small amount of right

rudder to compensate for intitial torque. The idea is to

hold the aircraft in as straight a line as possible while

proceeding upwind. Watch your airplane carefully. At

to

1/3 rd throttle you should be able to notice that it wants

come up on the step and, depending on your engine, it

may already be on the step. This is the point that a

seaplane must reach in order to take-off. It is possible

that your model is now planing on the step. Try this a

couple of times to get used to this transition phase of

your model. You should now be ready to try a take-off.

to

Again head the KittiWake into the wind, advance the throttle smoothly and look for the transition of the model onto

the step. After a few yards on the step to build-up speed,

the model will essentially by flying. A little back

pressure on the elevator stick should lift the model off

the water. Do Not lift the model off before reasonable flying speed has been reached.

Once airborne, grab some altitude and start the process

of checking out the effectiveness of the flight controls—remember that, if you have dual rate capability

with your radio system, you can increase or decrease

flight surface throws. Once you have the model settled

down and trimmed for straight and level flight, take the

time to idle back the engine and find out what a stall is

like while still at altitude. Our prototypes, balanced as

shown, stall rather cleanly with recovery almost instan-

taneous. The further back your C.G. is, the more the ten-

dancy will be to tip stall. Once you've seen some of the

low-speed characteristics of your KittiWake, you should be

a bit more comfortable with the landing.

Landing a seaplane is not too different from landing any

other type of model with the exception that it is important to keep the wings level. You want to land your airplane on the main float, not the tip floats. A couple of

feet off the water, start a gentle flare, to allow the main

float to just skim across the water—don't pancake the

float onto the water, you'll just ricochete back into the

air again. With the float skimming across the surface of

the water, chop the throttle and allow the model to settle

into the taxiing speed and return to shore.

Now is the time to relax a bit and think back about what

trim changes, if any, are needed. Make these now. Get