Page 1

RC-34 INSTRUCTION MANUAL

INTRODUCTION

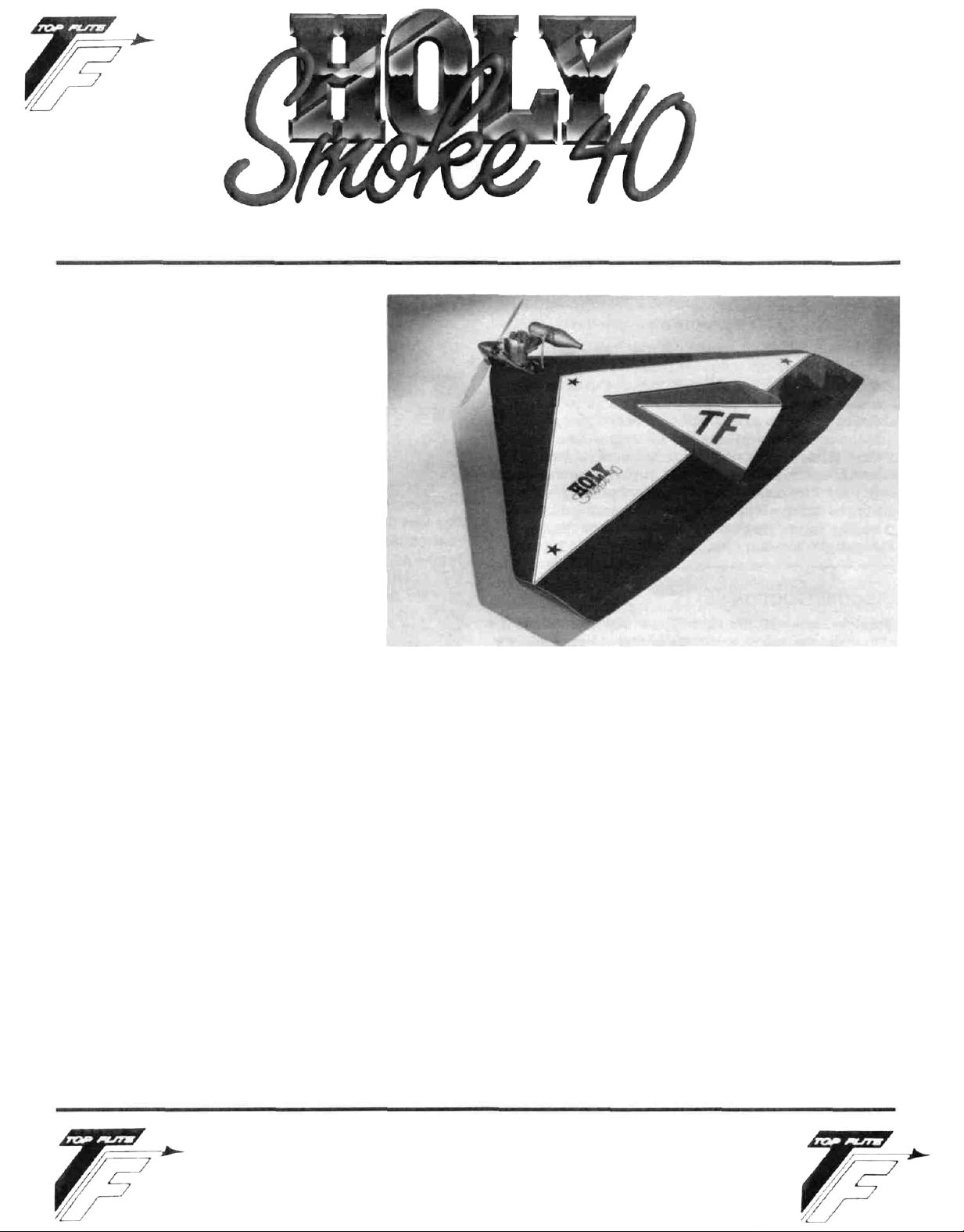

Holy smoke, what a name for an airplane!

The name was derived from comments

made by other modelers when they saw

this delta fly for the first time. From a

marketing standpoint, we're very happy

that the standard comment was not "Holy

Cow"!

The delta that we are presenting in this kit

was designed by Hal Parent! and it has a

long and successful history. The design is

exceptionally easy to fly due to its inherent stability and will accept a fairly

broad range of engine sizes (2-cycle) and

still remain flyable and fun. The design

itself is the essence of simplicity. We feel

that it is entirely possible to start construction on a Monday evening and have it

ready to fly by the following Saturday. It

may well be the perfect "other" airplane.

The "H.S. 40" has been test-flown off of grass fields as

well as asphalt with uniformly good results. When

powered with one of today's strong-running .40 engines

(Enya CX, O.S., etc.), the take-off is short and to the point.

We have test-flown the airplane with engines as small as

.25 (an 0.S. FSR) and it still flys quite nicely. Those of you

who may be considering the installation of a .60 engine

might first strongly consider one of the .40's or .45's

mentioned earlier. A .60 is going to give you some balan-

cing problems which might well result in a rather heavy

airplane.

The radio installation in your H.S. 40 is straight-forward

and the radio/tank compartment is roomy enough for all

but the largest of servos. As with most R/C models, the

radio installation should be made with achieving the

correct Center of Gravity as the goal. If your battery

pack, for instance, has to be located at the rear of the

radio compartment in order to achieve the correct C.G.,

that's fine and superior to having to add lead. The installation shown on the plans is typical of our prototypes; yours may be different due to varying radio components and engine weights.

Flying your H.S. 40 should prove to be a delight. There

just aren't many maneuvers that this design is not

capable of. The possible exception might be those

maneuvers which require some rudder.

IMPORTANT NOTE:

TOP FLITE MODELS, INC. does not recommend the

Holy Smoke 40 as a first R/C powered aircraft. However, if

you are a beginner to the sport of R/C flying, we would

urge you to seek and use experienced assistance in constructing and flying this airplane. Again, if you are new

to this hobby, consider this:

Flying this or any other radio-controlled model aircraft is

a PRIVILEGE and not a RIGHT and this privilege begins

with the utmost safety considerations to others and

yourself as well. An R/C model airplane in inexperienced

hands has the potential of doing serious personal or property damage. These safety considerations start at the

building board by following instructions, seeking competent help when you are confused and avoiding shortcuts. These considerations have to be carried over to the

flying field where safety must come first and limitations

TOP FLITE MODELS INC.

1901 NORTH NARRAGANSETT AVENUE • CHICAGO. ILLINOIS 60639

Page 2

cannot be exceeded. We urge you to:

1.Send for and obtain your AMA (Academy of Model

Aeronautics) membership which will provide insurance for your R/C activities — DO NOT RELY ON

HOMEOWNERS INSURANCE.

2. Join an AMA sanctioned R/C flying club in your area

where you can obtain competent, professional instruction in trimming and learning how to fly this

model.

Check with your favorite local hobby shop for the required AMA forms or the address where they can be obtained.

WARNING!!!

A radio controlled model is not a "toy." Care and

caution must be taken in properly building the

model, as well as in the installation and use of the

radio control device. It is important to follow all

directions as to the construction of this kit as well

as installation and use of the engine and radio

gear. The advice and assistance of a well experienced builder and pilot is highly recommended. Don't take chances! Improper building, operation, or flying of this model could result in serious

bodily injury to others, yourself, or property

damage.

PRO-CONSTRUCTION NOTES

The Holy Smoke 40, like other Top Flite kits employs the

use of die-cut wood to ease the task of construction,

parts fit and identification. The dies used for this kit

have been rigorously checked for absolute accuracy

and should provide you with excellent fit. Die-cut parts

should be carefully removed from their sheets by first

lightly sanding the back of each sheet of parts and then

carefully removing each part. Use a light garnet paper

for the sanding and keep a sharp hobby knife with an

X-acto #11 blade, or equivalent, handy for assistance in

removing any parts that might not have completely cutthrough by the dies. Parts which oppose one another

and must be precisely uniform—such as ribs,

etc.—should be carefully "matched" after their removal

from the part sheets. Matching is the process of holding

the opposing pieces together with either pins, tape or

spot gluing and lightly sanding the edges of the parts until they are identical. A sanding block with light garnet

paper is most useful for this and other phases of construction.

Your building surface should be at least large enough to

accommodate the wing. This surface should be as absolutely flat as possible and yet be able to accept pins

easily. We have found that a product such as Celotex

fiber board works quite well for this purpose. Another

good surface can be found in most well-stocked hardware stores—a 2' x 4' fiber board ceiling tile. These are

quite inexpensive and can be used for several airplanes

before needing replacement.

As with most R/C kits that are constructed from wood, a

selection of tools—most of which can be found in the

average workshop—are a must to do the job correctly:

• Hobby knife and sharp #11 blades

• Single-edge razor blades

• T-pins

• Sanding blocks in assorted sizes

• Sandpaper in various grits

• Hand-held hobby saw, such as an X-acto

• Dremel tool or power drill and assorted drill bits

• Straight-edge, preferably metal, at least 36" long

• 90" triangle

• Soldering iron, flux (silver) and solder

• Carbide cut-off wheel for wire cutting

• Small power jig-saw, such as a Moto-Saw

• Razor plane

• Tapes, such as masking and cellophane

Our Holy Smoke 40's were constructed using a variety of

common hobby adhesives including 5-minute epoxy,

cyano-acrylates, aliphatic resin (such as Titebond) and

1-hour epoxy. Since all of us have our own construction

techniques and favorite adhesives, stick with the ones

that you are familiar with and prefer. However, in certain

areas there will be callouts for certain types of

adhesives, and we urge you to try not to substitute since

doing so could possibly cause problems structurally.

The last thing we should touch on before we begin actual construction is the sequence in which the Holy

Smoke 40 is assembled. The sequence given to you in

this booklet has been proven to be the most straightforward and provides the finished components in the

order that you will need them to progress to the next

assembly phase. Try to stick with the building order

presented here to avoid mistakes.

Spread the plans out on your work surface, cover them

with a clear plastic material, such as the backing from a

roll of Monokote or plastic wrap and commence construction.

LEADING EDGE CRUTCH ASSEMBLY

The Leading Edge Crutch serves to "tie together" all ten

of the wing ribs and align them at the same time. This

assembly should be built flat over the plans. Be sure that

your plans are covered with either the clear backing from

a roll of Monokote or a clear food wrapping material.

1. From your kit box, locate the two pieces of 1/8" x

1-3/16" x 28" balsa sheets that will become the leading

edge crutches. Lay these directly over the plans and

carefully cut each end to fit as shown. The outer end

is cut to fit against the inside face of tip rib W-5 while

the inner end is cut at an angle corresponding with

the centerline of the airplane. Once satisfied with

the fit over the plans, glue the two crutch pieces

together at the center, pin parts accurately over the

plans.

2. From your die-cut sheet RC-34-2, carefully remove

parts W-6A and W-6B. Glue W-6A to W-6B to form a

triangle. Fit the finished W-6A/B part in place directly behind the leading edge crutch assembly at the

center. You might have to lightly sand this assembly

for a nice fit. Once satisfied, glue this part in place,

directly over the plans.

2

Page 3

3. Locate die-cut sheet RC-34-1 (2 req'd.) and remove

the two Motor Mount Fillers. These are now glued in

place against the leading edges of the two leading

edge crutches, at the nose, directly behind the spinner shown on the plans. Now use your sanding block

to lightly smooth off the glue joints. From the ply diecut sheet RC-34-6, remove the two W-7 parts. Use

your sanding block to clean up their edges. Glue one

of the W-7 parts directly on top of the leading edge

crutch assembly, aligning its rear edge with the rear

edge of W-6B and its forward edges with those of the

two motor mount fillers. Use weights to make sure

that W-7 stays flat against the leading edge crutch

assembly until it is dry.

4. Remove the leading edge crutch from the plans, turn

it over and use your sanding block to smooth out any

glue joints. Glue the remaining W-7 part in place to

the bottom surface of the crutch assembly, exactly

aligned with the W-7 previously glued to the top surface. Again, use weights to hold this part in place

and allow it to dry.

Remove this assembly from your building board as

we will now build the rest of the airplane.

GENERAL CONSTRUCTION

1. From the die-cut sheets provided, carefully remove

all of the required wing ribs W-1 through W-5, two of

each. Note that these ribs each have temporary

"tabs" attached to the front and rear ends (W-2 and

W-3 have them in the center as well). These are there

to provide stability during construction on a flat sur-

face—do not remove these until told to do so. Use

pins to now locate each rib in its appropriate posi-

tion over the plans and vertical to your work surface.

We would suggest using a 90° triangle to be sure

that the ribs are truly vertical.

2. Carefully slide the previously built leading edge

crutch assembly into the slots provided on the front

of each rib (except W-5). The ply W-7's should fit on

the inside faces of the two W-1 's at the nose and the

outer ends of the crutch assembly should be in contact with the inner surfaces of the two W-5's. It may

be necessary to trim a little here or there to achieve

the proper fit. If so, do it now.

With the crutch still in place but not yet glued, turn

your attention to the slots provided in the ends of

each rib. Locate the 3/32" x 7/8" x 36" bottom trailing

edge balsa piece provided in your kit and carefully

slide it into place in the rear rib slots.

Now take the time to inspect this structure for cor-

rect alignment and that each piece is indeed contacting the other in the previously described manner.

Once satisfied, glue the leading edge crutch and

trailing edge piece to each rib. A slow-setting CA is

just the ticket here. Don't worry about getting glue

onto the bottom of the crutch assembly, we'll do that

when we remove the structure from the building

board.

3. From die-cut sheet RC-34-2, carefully remove former

W-9. Lightly sand the edges of this part to fit in place

between the two W-1 ribs and against the rear edge

of the crutch assembly. Note that the "peaked" side

of W-9 is the top. Once satisfied, glue W-9 in place,

again being sure that it is vertical to your building

surface.

4.There are four(4) 3/16"x3/8"x24" wing spars provided

in your kit; locate two of them. Bevel the inboard

ends of these spars to fit against W-9 as shown on

the plans. Test fit the spars in place in the slots provided. Once satisfied, glue these spars in place. Trim

the outer ends flush with the outer faces of the two

W-5's.

5. Use light sandpaper and your sanding block to now

bevel the front edges of each rib flush with the

leading edge crutch. From your kit box remove the

two 1/2" x 1-1/8" x 36" balsa strips provided. These are

the leading edges and wingtip material. From each

piece cut a 24" length and place the balance back in

the kit box for later use. Bevel the inner and outer

ends of the two 24" pieces to fit in place as shown on

the plans. Note that each rib has been provided with

"lip" at the leading edge; these position the leading

edge accurately for gluing. Glue the leading edges in

place to each rib and the front edge of the crutch

assembly. Pin and/or weight as needed and allow to

dry.

6. Your kit has been provided with twelve pieces of 3/32"

x 3" x 36" balsa for planking purposes, locate and

have ready six of these at this time. Stress-relieved

balsa sheet can sometimes have curved edges and it

may be necessary for you to use a straight-edge and

X-acto knife to true them up. This is important

especially when the wood is used for butt-glued

planking purposes.

IMPORTANT

NOTE:

The plans

depict

the top view of

the airplane. The right side is shown with the top

planking removed and you can therefore see the

planking patterns used for the bottom of the wing.

The left side of the wing depicts the patterns used

for the top sheeting. In the next steps we are dealing

only with the top sheeting.

3

Page 4

7. The first piece of planking that you are going to attach will be the rear one which is one-piece from tip

to tip and flush with the bottom 3/32" x 7/8" balsa strip

installed in the rib slots earlier—see cross-sections

on plans. Glue and pin this rear piece of planking in

place to the tops of the ribs and along the trailing

edge of the bottom sheet.

8. The next two pieces of planking to be installed are

those that fit from the the centerline of the spars, forward to the rear face of the landing edges. Trim the

inboard ends to fit flush with the inside faces of the

W-1 ribs and on top of W-9, as shown. Once the planking pieces are trimmed to fit, use a little ammonia on

their top surfaces to get them to bend easier to fit the

tops of the ribs. Glue these two pieces of planking in

place, pin or weight as needed and allow to dry.

9. Remove W-10 from its die-cut sheet and lightly sand

its edges to fit between the W-1 's at the rear position

shown on the plans. Use a triangle to accurately

locate this former and glue it in place, aligning the

top edge with the tops of the W-1's.

10. Using the left-hand view of the wing (remember,

that's the top planking patterns shown), finish planking the left and right-hand side of the top of the wing.

Trim the centerline ends of each piece of planking to

provide a true centerline for accurately locating the

fin. Note that the entire left and right center planking

pieces can also be made separately, on a flat surface and then fitted in place on each side of the

centerline. Just be sure that, if you do it this way, you

leave just a little extra material at the rear to trim and

therefore achieve a nice, gapless fit.

SCRAP 3/32" BALSA STRIPS IN

PLACE BETWEEN RIBS AS "SHELVES"

RIB (TYPICAL) FOR BUTT-SHEETING

SHEETING JOINT

11. Using the

1/4"x3"x36"

piece of balsa provided and

the pattern shown on the plans, carefully cut and

glue the four required pieces together to form the

rough shape of the fin. Use a sanding block to finish

the fin into the side-view configuration shown.

Follow this by sanding the fin assembly smooth on

each side and then rounding the leading, trailing and

top edges to a "half-round", as shown. Streamlining

or airfoiling this surface is not needed or desirable.

12. The fin's support tab requires a slot that is 1/4" wide

and

3-1/16"

long.

This is located on the exact

centerline of the wing. As shown on the plans, the

rear

end of this slot is measured

at

3-1/16"

from the

trailing edge. Cut this slot with a fresh #11 X-acto

blade. The forward end of the slot should be at the

rear face of W-10. Trial fit the fin in place and dress

the bottom edge of it as required to achieve a

uniform fit to the top surface of the wing's planking.

Once satisfied, set aside the fin for later installation.

13. From your parts bag, locate the

four 4-40 blind

mounting nuts and their corresponding 1-1/4" motor mount

bolts. Also locate the two 3/16" x 3/4" x 5-1/2" maple

motor mounts and the two top

7/8" x 1-3/4" x 5-1/2"

balsa cowl blocks. Before assemblying the motor

mounts and cowl blocks in place as shown on the

plans, let's first trial fit the whole thing on the nose

with your engine sitting in place between the maple

mounts. Is the fit a comfortable one or is it too tight

or too loose? Engines vary somewhat in case width

and if yours happens to be a little too wide, then you

will find that the engine will either not fit at all or a little too tight. If this is the case then you must use a

sanding block to remove a little of the width from the

two balsa cowl blocks. Try to do this evenly and a little at a time while continually trial-fitting the engine.

Once satisfied, you can move on to the next step. If

your engine fits too loosely between the mounts

then you must add material to the sides of the cowl

blocks to space them out a little. 1/16" sheet balsa on

each block would move the mounts inward 1/8", etc.

14. Glue the balsa cowl blocks in place in the nose

against the inside faces of the W-1's, against the

front face of W-9 and against the W-7 ply floor. Use a

scrap of balsa to scrape out any oozing glue

because we want the maple motor mounts to fit in

place squarely to the floor and the cowl blocks.

Lightly tack glue the two maple motor mounts to the

ply floor only, exactly in the position they will eventually be. Set your engine in place on the mounts

with the thrust washer just clearing the front of the

nose (see top view and engine cross-section on

plans). Now carefully mark the lug hole positions on

the motor mounts with a pencil or sharpened object

of some kind. Remove the engine and break the two

motor mounts free from the ply floor. Use a drill

press and a 1/8" dia. drill bit to drill the two required

holes in each motor mount (a hand drill can be used

if you are careful). In order to get the motor mounts to

sit flush against the W-7 ply floor, you must now use

a Moto-Tool and grinder bit to counter-sink the 4-40

blind nuts. Epoxy these nuts in place to the bottom

of each motor mount, being careful to keep glue out

of the nut's threads. Using medium to slow curing

epoxy, glue the mounts permanently in place. When

the glue has cured remove the pins holding the structure in place to your building board and remove the

wing.

15. Turn the wing over exposing the unplanked bottom

and block-up the nose until the trailing edge lays flat

to your work surface. Use an X-acto knife to carefully

remove the rear building tabs on all of the ribs. This

exposes the forward edge of the bottom trailing

edge strip installed at the beginning. Take one of the

3/32" x 3 " x 36" planking pieces, true-up its edges with

a straight-edge and razor and glue it in place against

the forward edge of the trailing edge piece and

against each rib. (We found that a truer butt-joint

could be made by first gluing scrap pieces of balsa

underneath the piece of balsa planking that was

already in place thus creating a sort of "shelf". The

excess material left over from the die-cut sheets provides plenty of these shelf pieces.) Pin or weight this

4

Page 5

planking in place and allow to dry.

16. Again using the X-acto knife, remove all remaining

building tabs from the bottoms of all of the ribs. Accurately bevel cut the ends of the two remaining bot-

tom spars and glue in place.

17. From your parts bag locate two 5-1/4 " long slotted

hardwood landing skid mounts and two slotted lan-

ding gear uprights. Epoxy the two 5-1/4" long skid

mounts in place in the cutouts provided in ribs W-2

and W-3 as shown on the plans. Be sure the slotted

side is exposed! Use a 3/32" dia. drill bit to drill a hole

through each block, in the slot, at the outboard face

of W-2. Temporarily install the two formed 3/32" dia.

M.W. skids in place in the slotted blocks. Apply

epoxy to the two short slotted blocks—on the slotted side and bottom edge—and glue these in place

over the stub ends of the wire skids and against W-2.

Carefully remove the wire skids and allow these

assemblies to cure.

18. While the bottom of the leading edge crutch

assembly and the ribs are still exposed, finish gluing

these pieces together as you did on the top. A bead

of slow set CA on each side of each rib will do nicely.

19. Cut, fit and glue the bottom leading edge planking

pieces in place. Note that like the top planking, the

rear edges are cut to fit halfway across the width of

the spar and that the inboard ends are cut to fit flush

with the inside faces of the W-1 ribs and the W-9

former (the exposed cavity described by the shape of

W-7 will be filled-in with balsa blocks and the hardwood nosegear mount). When dry, use your sanding

block to sand the outer faces of W-5 tip ribs flat. Using the two remaining pieces of the 1/2" x 1-1/8"

leading edge stock, glue these in place to the W-5's

as wingtips. Sand the leading and trailing edges of

these tips flush with those of the wing when viewed

from the top. Sand the tops and bottoms to match

the airfoil contours except for the leading edge; this

will be shaped later.

20. If so desired, now is a good time to lay in a strip of

light fiberglass along the inside centerline of the top

planking from W-9 back to W-10. Although there is no

real stress in this area, fiberglass does serve to stiffen and strengthen the wood. This is also a good

time to give the entire tank/radio compartment a

coat or two of polyester resin. While the resin is cur-

ing, take the time to make your fuel tank. An 8 ounce

DuBro tank is shown on the plans. We've also used a

Pylon SS-8 Slant tank which fits nicely in place on its

side thus giving you a bit more room in the nose, if

you need it. Set the tank aside; it will be installed in a

little while.

21. You now must install the servos on their respective

hardwood mounts (four pieces of 1/4" x 3/8" x 5"

basswood are supplied for this purpose). First cut

the length of these rails to fit snuggly between the

W-1 sides as shown. Start with the rearmost mount

and epoxy it in place at the lowest possible point

that still allows your servos to fit without contacting

the top planking. Using your servos as spacers, install and glue the next rail in place—remove the ser-

vos. The next rail to be installed is the rear aileron

servo mount. Note that in the cross-section we show

that the aileron servo is mounted lower than the two

rear elevator and throttle servos. This is done to

allow clearances of the various drive cables. Again

using your servo as a spacer, install and glue the forward aileron servo rail in place and remove the servo.

Allow the epoxy to cure. Cut about 19" of white tubing (two piece @ 36" supplied) and install it in the

left wing panel from just inside W-1 through all of the

wing ribs, exiting at the wing tip; this is the receiver

antenna tube. CA adhesive works well to secure this

tube, and the others, to each rib if you first lightly

sand the tube's surface. Using wood screws (not

supplied), position and install the three required servos.

22. The throttle pushrod, unlike the others is made up of

a plastic inner and outertubing (one

piece of each

@

12" supplied). Install and glue in place the outer

throttle pushrod tubing as shown on the plans. Next,

drill a small dia. hole, about 1/8", through W-10 where

the elevator pushrod (one piece @ 12", threaded

one-end, supplied) exits the elevator servo toward

the rear—see cross-section of radio compartment

on plans. Use an X-acto knife to now make a small exit slot in the bottom planking to allow the free fore

and aft movement of the elevator pushrod. Note that

we are showing a "Z-bend" at the servo output arm.

Once you're satisfied you can remove and set aside

the elevator servo, its pushrod and the throttle servo,

they have served their purpose for now and will be installed after the airplane is finished.

23. From you parts bag, locate the small metal "balllink" (threaded), the small nut for it, the nylon dual

take-off aileron ball connector and three brass

threaded couplers. As shown on the plans, the balllink is mounted on your aileron servo's output arm

and secured with the nut. Now snap the nylon dual

take-off connector on the ball-link, positioned as

shown on the plans. Drill two 1/8" dia. holes, one

through each W-1 rib side at the exit points of the

aileron drive cables. From your kit box, locate the re-

maining 36" length of braided cable. Cut each of

these in two equal 18" lengths (a carbide cut-off

wheel will cut the cable nicely). Use a soldering iron

to solder a threaded brass coupler on one end of

each cable. Slip the white tubing over the cable.

UNDERSIDE OF

WING

1/8" DIAMETER SHARPENED

BRASS TUBING

AILERON TUBING

EXIT LOCATION

Working on top of the exposed ribs, visually line-up

the coupler end of the cable/tubing assembly with

the previously drilled hole in W-1 and either pin it in

position so that it does not move or have a friend

hold it for you. As shown on the plans, gently bend

5

Page 6

the cable/tube assembly around to the exit point

shown at the aileron horn location. Use a marking

pen to note the location of the tube on each rib.

Repeat this operation for the opposite wing panel.

Again, use the 1/8" drill bit to drill holes through the

W-2's and W-3's that will allow the tubing to pass.

Now use a piece of sharpened 1/8" dia. tubing to

make the tubing exits, at the angles shown, through

the bottom, rear planking. With the cables still inside the tubes, feed the tubes through the various

holes until they exit. Test the action of the cables;

movement should be free and easy. Once satisfied,

use slow setting CA to anchor the tubes in place to

the ribs and planking. Trim the aileron exit tube ends

flush with the planking—remove the cables and set

aside for installation when the airplane is finished.

24.

You

should

have

about

15"-16" of white tubing left

over from the antenna tube; this will be used for the

nosegear steering cable. As shown, this cable is

driven by the opposite end of your servo's output

arm. Locate the remaining 12" length of braided

cable and solder the brass coupler in place. Thread

one of the black nylon mini-links in place on the

coupler. This will be the servo end of the steering

cable. From your planking stock

2-7/16" x 3-7/8" rectangle and glue

(3/32"

balsa), cut a

this

in place on the

W-1 ribs and flush with the front face of W-9. You

should wind-up with a little of the W-1's thicknes still

exposed on each side to allow seating for the rest of

the bottom planking—fit this piece carefully. As

before with the aileron tubes, drill a 1/8" dia. hole

through the right-side W-1 at the correct position for

the servo's output arm to drive the steering cable.

Slip the cable into the tubing and hold it in position

over this hole, again, you might have a friend hold it

there for you. Now gently bend the cable/tubing as

shown on the plans around towards the nose to the

exit point shown. Use a marker to note the passage

point through W-1 at the front. Use a drill bit to drill

the hole through W-1 and a sharpened piece of tubing to make the exit hole through the planking just installed. Install the tubing through all three holes and

test the action of the cable, as before, it should be a

free fit. Adjust the tubing to obtain the optimum

movement and glue it in place. Remove the cable

and the aileron servo. Trim the tubing flush with the

planking.

25. The balance of the bottom planking can now be installed. In order to find and clear out the landing gear

skid slots later, use a straight edge and pencil to

make horizontal and vertical reference marks on the

sheeting already in place. Note that the hatch area is

left open with the inboard ends of the planking trimmed flush with the inboard faces of the W-1's. All

that should remain after planking is the open hatch

area and the nose bottom.

26. From the kit, locate the four blocks required to fill-in

the bottom nose area; 2 @ 1" x 1-1/2" x 5-1/2" balsa; 1

@

3/4" x 1" x 3-1/2 " balsa and 1 @

3/4" x 1-7/8" x 2"

bssswood. The hardwood block is used to mount the

5/32" dia. coiled nose gear. The two 1-1/2" wide balsa

blocks fit on the outside edges of the W-1 's, against

the W-7 ply floor and against the face of W-9. The re-

maining 3/4" wide block fills in the remaining slot.

Use your sanding block as needed to achieve a good,

flush fit of these four blocks. Use a drill press to drill

a vertical 5/32" dia. hole through the hardwood block

at the position shown on the plans for the nose gear.

Glue all four blocks in place. After the glue has set,

chuck-up the 5/32" dia. drill bit in a hand drill and complete the hole in the hardwood block all the way

through the floor, into the engine compartment.

27. The radio compartment hatch supplied in your kit

measures 1/4" x 3-3/4" x 9" and is balsa. It is mounted

to the four 1/2" sq. hardwood blocks supplied. Glue

these blocks in place in the four corners of the hatch

opening at a depth which will leave the hatch flush

with the planking. Install the four die-cut ply

triangles that were left from die-cut sheet RC-34-6,

on each corner of the hatch. Use a razor blade to

remove 1/16" of depth of the hatch corners, in the

shape of the ply triangles and epoxy these in place.

Now locate the hatch in position on the four hardwood mounts—use tape to hold it there if need be.

With a 3/32" drill bit, drill a guide hole through each of

the four corners of the hatch and in contact with the

hardwood mounts, just enough to leave a mark on

each of the mounts. Remove the hatch and use a 1/16"

drill bit to drill a guide hole through each of the

mounts. Locate four of the #2 x 3/8" wood screws supplied and screw the hatch in place to the mounts.

Once satisfied with the fit, remove the screws and

lightly tack glue the hatch in place to the

mounts—you want to be able to remove it after sanding. Using the cross-reference marks made earlier,

use an X-acto knife to clear-out the two rear landing

skid slots.

28. Use a razor blade to first rough shape the upper and

lower nose blocks. Follow this with a sanding block

and coarse sandpaper to bring these blocks down

further.

Use the razor plane again to rough shape the

leading edges—refer to cross-sections on the plans.

Finally, the entire wing can be sanded with pro-

gressively lighter sandpaper until ready for covering. Take your time and get it right. Remove the tack

glued hatch and set it aside for covering.

6

Page 7

29. Locate and remove the W-8 ailerons from their diecut sheet. Glue lengths of 1/8" x 1/4 "balsa on each of

their ends as shown for stiffening. Tape these in

place to the trailing edge of the wing. Locate the 1/8"

x 1-3/4 " x 20" elevator piece and likewise, reinforce

each end with lengths of 1/8" x 1/4" balsa. Trim the

elevator as needed to fit snuggly between the

ailerons; we recommend about 1/16" spacing.

Remove these surfaces, sand them smooth and set

them aside for covering.

30. Use a slow cure epoxy to now glue the fin in place on

top of the wing. Apply adhesive liberally to those

areas of the tab that will contact W-10 and the bot-

tom sheeting as well as the bottom surface which

contacts the top sheeting. Squeegee off any excess

glue when the piece is in place. Use a 90° triangle

and tape to make absolutely sure that the fin is positioned squarely in place when viewed from the top

and that it is truly at 90 degrees vertical to the wing

itself. Allow this structure to cure completely.

Although not shown, we have included a length of

1/4" triangular stock which some of you may wish to

use to further strengthen the fin/wing joint. While we

have found this to be unnecessary, we understand

that some of you might like a fillet in this area.

FINAL ASSEMBLY

1. We have provided your kit with eight nylon hinges. If

you wish to hinge the flight surfaces with these now

is the time to carefully slot the surfaces themselves

and the trailing edge. An alternate method of hinging these surfaces is the use of Monokote. These

hinges are incredibly strong, color co-ordinated and

exceedingly effective aerodynamically. They are so

effective that the surface movements must be cut

down about 25%.

2. Locate the four metal landing gear straps and the

eight #2 x 3/8" wood screws used to retain them. As

shown on the plans, position the straps across the

landing skid slots and use an X-acto knife to clearout the balsa down to the hardwood, two straps for

each skid. Use a 1/16" drill bit to drill guide holes

through the hardwood blocks and secure the straps

with the #2 wood screws. Remove the screws and

straps for assembly when the airplane is covered.

3. As shown on the plans, assemble the nose gear with

the steering arm and the top and bottom retaining

wheel collars in place on the nose of the wing. File or

grind small "flats" in the nose gear wire to accept

the wheel collar's set screws, once you are satisfied

with the fit and movement. Remove these parts and

set them aside for assembly after covering.

4. Drill the appropriate holes through W-9 for your fuel

lines. A typical no-nonsense system is the two-line

set-up. This is where the fuel line from the tank's

clunk pick-up goes to the engine's carb and also is

used for filling the tank. The second line goes to the

engine's muffler nipple to provide tank pressure and

is also used for overflow when the tank is being fill-

ed. You might want to use some of those pieces of

triangular stock supplied to position the tank in

place. We have also found it helpful to wrap a little

strapping tape around the tank, lengthwise, leaving

a little "pull-tab" at the end to facilitate removing it

whenever needed.

COVERING

The Holy Smoke 40 really lends itself to the use of

Monokote for covering. Besides being light, colorful and

strong, Monokote is totally fuel-proof and easily

repairable.

Why not try a really wild trim or color scheme on your

H.S.40? On our prototypes we have done one color

scheme on the top and a totally different one on the bottom. Think about it! At the speeds this airplane flies, it is

comforting to know which end is up!

Once your color scheme has been decided, cover each

component separately; the wing/fin itself, the ailerons,

elevator and hatch cover. Once the covering is all in

place, clear-out the exit locations for the antenna tube,

the ailerons, the slot for the elevator pushrod, the landing skid slots and the nose gear steering cable. Apply a

couple of coats of polyester resin to the engine compartment area, carefully covering any area where Monokote

has been overlapped—this will permanently seal those

edges. You can then paint the engine compartment area.

We recommend the use of two-part epoxy paints but

there are several one-part paints that are on the market

which will match Monokote.

Clear-out the slots made earlier for the ailerons and

elevator and hinge these surfaces to the trailing edge of

the wing. A few small holes drilled in the hinges

themselves will let the epoxy use to glue them in place,

act as nails.

RADIO INSTALLATION & PRE-FLIGHT

1. Install all three servos. Using the cables with the

connectors soldered in place for the ailerons, screw

the couplers into the nylon dual take-off ball fitting.

There should be plenty of excess cable protruding

from the aileron ends of the tubes Center your servo. Slip a piece of card stock underneath the protruding cable and cut-off the excess cable with a car-

bide cut-off wheel. Now solder the brass coupler in

place to the cable and thread one of the black nylon

clevises in place on the coupler Repeat this procedure on the other aileron As shown, mount the

nylon horns on each aileron and connect the

clevises to the outer-most holes.

2. Use the above method to now connect the steering

cable to the steering arm on the nose gear. First

mount the nose gear to the nose; then make the

clevis connection to the opposite output arm of the

aileron servo. Cut-off the excess cable, solder the

brass connector in place and complete the connec-

tion with a black nylon clevis.

3. The elevator connection is made next. Slide the

elevator pushrod through the hole in W-10 and out

the slot on the bottom. Install the large nylon

elevator horn to the elevator at a position corresponding to the slot. Thread the large nylon clevis on the

7

Page 8

threaded end of the pushrod. With the elevator servo

centered, mark the location for the required

"Z-bend" in the pushrod. Make the "Z-bend", attach

the output arm to the pushrod and then to the servo.

4. As shown on the plans, the throttle pushrod is

plastic tubing with a 6" threaded wire and "Z-bend"

at the throttle servo end and a 1" threaded stud and

kwik-link at the carb end.

5. There is a gauge fixture provided on die-cut sheet

RC-34-2. This gauge, as shown on the plans, is used

to set the flight surfaces for neutral trim. DO NOT ATTEMPT TO SET NEUTRAL TRIM ON THIS AIRPLANE

USING ANY OTHER METHOD. With your radio on,

use this gauge and the adjustments available to you

through the clevises to set the ailerons and elevator

to neutral. Adjustments should be made either

mechanically or electronically (through your radio)

for the following flight surface movements:

Ailerons.. .... 3/8" up

3/8"down

Elevators. .....

3/4"

3/4"

up

down

Remember what was said earlier about the use of

Monokote hinges—they will make the flight surfaces about 25% more effective.

6. Note on the cross-section of the landing skid that

the skid itself is bent back at an angle. You should do

this now. The angle should be about 20 to 25

degrees. You should also bend the ends of these to a

"half-round". You might consider adding small

wheels to these skids by bending out an axle at the

ends, slipping on the wheel (1/2" to 3/4 "dia. would do)

and soldering a washer in place as a retainer. If you

fly off of a hard surface, wheels might be easier on

your ears. Mount the skids in place on the bottom of

the wing.

7. Adjust the nose gear steering arm and/or clevises for

neutral.

8. Install the fuel tank, fuel tubing, engine and muffler.

Make all necessary fuel connections and throttle

hook-ups.

9. We have found it convenient to install both the

receiver's switch harness and charging receptacle

directly to the radio hatch cover. Wrap the reciever

and battery pack in foam and install in the radio compartment. Button-up the hatch cover and, assuming

that you have already mounted your 2-1/4" dia. nose

wheel, you should be ready to balance the airplane.

10. Balancing this airplane at the point shown on the

plans is very important and should not be.

underestimated. The design is very pitch stable

when balanced at this point. Much can be done to

move the Center of Gravity fore or aft; a plastic spinner is lighter than a metal one and no spinner is

lighter than both, battery packs can be moved as far

back as W-10 and the throttle servo could be reposi-

tioned next to the aileron servo, etc., etc. Once the

balance has been achieved and your engine completely broken-in and reliable, you can head for the

flying field.

FLYING

This is the part all of us love and fear at the same time.

The Holy Smoke 40 is not too much different than most

aircraft in that all of the homework must be done before

lift-off. Since it isn't reasonable to ask you to test-glide

this airplane over tall grass, we're going to assume that

you did indeed follow the fore-going instructions.

Because if you did, then the test flights should be almost

routine.

We say "almost" because unless you are told ahead of

time, like right now, you could be in for a surprise or two.

First of all, the take-off. The take-off will be quick; be

ready for it. There is some tendency for the airplane to

torque a bit to the left due to its high power-to-size ratio;

be ready for it. For first flights we would suggest that you

have a helper hold the airplane on the ground, pointed into the wind while you apply full power. Have the helper

release the airplane at your command. In this situation,

the airplane is "flying" in less than a few feet. Now that

you're up there and have things pretty well under control

you might be interested in observing the airplanes rollrate. Next you might want to observe the roll-rate while

climbing vertically—neat, huh? Our Enya CX powered

H.S. 40's will climb and roll out of sight, a maneuver

guaranteed to make you an instant "club pro"!

All good things must come to an end, even eight ounces

of fuel—time to land. Delta's can fly slowly with their

noses up just so long. At some point all of the up elevator

available will peter-out and at that point a stall is achieved. As mentioned earlier, deltas tend to stall straight

ahead and gently. Gently, however, is a relative term. At

200 feet, gentle is one thing, but at 10 feet gentle can be

something else. All of this is telling you to keep the

speed up on your approach to a landing. Our best lan-

dings have been done by maintaining about 1/3rd throttle throughout the entire approach while steadily decending to the field. As soon as field threshold has been

reached, lower the throttle to full idle and flair to touchdown. Don't worry that your first few attempts are a bit

bouncy; you'll get the hang of it soon enough.

The stunt repertoire of the Holy Smoke 40 is just about

endless. Even without rudder input, we've been able to

knife-edge from one end of the field to the other on sheer

speed.

We sincerely hope that you've enjoyed this project and

that your Holy

Smoke

40 will indeed become your perfect

"other airplane".

INDEX

INTRODUCTION

PRE-CONSTRUCTION

............................

NOTES

.................

LEADING EDGECRUTCH ASSEMBLY........... 2

GENERAL CONSTRUCTION .............

FINAL ASSEMBLY ........................

7

COVERING. ................................ 7

RADIO

INSTALLATION & PRE-FLIGHT

..........

FLYING........................................................................ 8

Product Support

(Do Not Remove From Department)

8

1

2

3

7

150104

Loading...

Loading...