Page 1

RC-32 INSTRUCTION MANUAL

INTRODUCTION

In this day and age of specialization, TOP FLITE MODELS felt

that it might be a refreshing

break from the "norm" to come

up with an airplane that was

specifically designed for FUN.

The Elder was not designed to

Pylon Race, fly Pattern, be

entered in Scale or be used in

Fun-Fly contests, which have

become anything but. Nope, the

Elder was designed for the FUN

of

it.

Relatively slow, realistic and

stately in flight, the Elder is easy

to fly and build. Furthermore, it's

a lightly-loaded design that does

not tend to build-up lots of inertia

with excess flight speed. This

means that fairly rough handling does not necessarily

mean destruction. Nothing is "crash-proof" but the

Elder is a rugged aircraft that will keep coming back for

more.

For the beginners, nothing fancy is needed; go out and

fly it. For those of you who are into detail ing, the design

lends itself extremely well to all kinds of "bells and

whistles"; flying wires, turnbuckles, detailed cockpits,

plastic machine guns, etc., etc., etc. We have flown our

prototypes both "stripped" and detailed to the nines.

Either way it still looks and flies great.

A word about power is in order. Fire-breathing,

Schneurle-ported engines are not needed and indeed

are not recommended for the Elder. Normal, everday

sport engines with mufflers are all that is needed to provide you with some delightful flying. Any discussion

about powering the Elder would be incomplete without

mentioning and highly recommending the use of the HP

.21 rotary-valved 4-cycle engine. This little jewel, when

installed in the Elder, makes probably the best possible

combination imaginable! With it's quiet, scale-like exhaust note, this engine flies the Elder beautifully! The 6

ounce fuel tank shown on the plans will keep this little

engine purring for almost an hour without coating your

airplane with oil! If you do decide on this engine, replace

the engine mount in your kit with a ".40-size" mount. It

all fits quite nicely; in fact, we've shown this installation

on the plans.

IMPORTANT NOTE:

TOP FLITE MODELS, INC. would certainly recommend

the Elder as a first R/C powered aircraft. However, if you

are a beginner to the sport of R/C aircraft, we would urge

you to seek and use experienced assistance in constructing and flying this airplane. Again, if you are new to this

hobby, consider this:

Flying this or any other radio-controlled model aircraft is

a PRIVILEGE and not a RIGHT and this privilege begins

with the utmost safety considerations to others and

yourself as well. An R/C model airplane in inexperienced

hands has the potential of doing serious personal or property damage. These safety considerations start at the

building board by following instructions, seeking competent help when you are confused and avoiding shortcuts. These considerations have to be carried over to the

flying field where safety must come first and limitations

Product Support

(Do Not Remove From Department)

TOP FLITE MODELS INC.

1901

NORTH NARRAGANSETT

AVENUE • CHICAGO,

ILLINOIS

60639

Page 2

cannot be exceeded. We urge you to:

1. Send for and obtain your AMA (Academy of Model

Aeronautics) membership which will provide insurance for your R/C activities — DO NOT RELY ON

HOMEOWNERS INSURANCE.

2. Join an AMA sanctioned R/C flying club in your area

where you can obtain competent, professional instruction in trimming and learning how to fly this

model.

Check with your favorite local hobby shop for the required AMA forms or the address where they can be ob-

tained.

WARNING!!!

A radio controlled model is not a "toy." Care and

caution must be taken in properly building the

model, as well as in the installation and use of the

radio control device. It is important to follow all

directions as to the construction of this kit as well

as installation and use of the engine and radio

gear. The advice and assistance of a well experienced builder and pilot is highly recommended. Don't take chances! Improper building, operation, or flying of this model could result in serious

property damage or in bodily injury to yourself or

others.

PRE-CONSTRUCTION NOTES

TheEIder, like otherTop Flite kits employs the use of diecut wood to ease the task of construction, parts fit and

identification. The dies used for this kit have been

rigorously checked for absolute accuracy and should

provide you with excellent fit. Die-cut parts should be

carefully removed from their sheets by first lightly sanding the back of each sheet of parts and then carefully

removing each part. Use a light garnet paper for the sanding and keep a sharp hobby knife with and X-acto #11

blade or equivalent handy for assistance in removing

any parts that might not have completely cut-through on

the dies. Parts which oppose one another and must be

precisely uniform—such as fuselage sides, ribs, etc...—

should be carefully "matched" after their removal from

the part sheets. Matching is the process of holding the

opposing pieces together with either pins, tape or spot

gluing and lightly sanding the edges of the parts until

they are identical. A sanding block with light garnet

paper is most useful for this and other phases of construction.

Your building surface should be at least large enough to

accommodate the wing panels. This surface should be

as absolutely flat as possible and yet be able to accept

pins easily. We have found that a product such as

Celotex fiber board works quite well for this purpose.

Another good surface can be found in most well-stocked

hardware stores, this is a 2'x 4'fiber board ceiling tile—these are quite inexpensive and can be used for several

airplanes before needing replacement.

As with most R/C kits that are constructed from wood, a

selection of tools—most of which can be found in the

average workshop—are a must to do the job correctly:

Hobby knife and sharp #11 blades

Single-edge razor blades

T-pins

Sanding blocks in assorted sizes

Sandpaper in various grits

Hand-held hobby saw, such as an X-acto

Dremel tool or power drill and assorted drill bits

Straight-edge, preferably metal, at least 36" long

90" triangle

Soldering iron, flux (silver) and solder

Carbide cut-off wheel for wire cutting

Small power jig-saw, such as a Moto-Saw

Razor plane

Tapes such as masking and cellophane

Our Elders were constructed using a variety of common

hobby adhesives including 5-minute epoxy, Cyanoacrylates, aliphatic resin (such as Titebond) and 1-hour

epoxy was used to secure the main wing wire tubes in

the wing roots. Since all of us have our own construction

techniques and favorite adhesives, stick with the ones

that you are familiarwith and prefer. However, in certain

areas there will be callouts for certain types of

adhesives and we urge you to try not to substitute since

doing so could possibly cause problems structurally

later on.

The last thing we should touch on before we begin actual construction is the sequence in which the Elder is

assembled. The sequence given to you in this booklet

has been proven to be the most straight-forward and provides the finished components in the orderthat you will

need them to progress to the next assembly phase. Try

to stick with the building order presented here to avoid

mistakes.

Spread the plans out on your work surface, cover them

with a clear plastic material, such as the backing from a

roll of Monokote or plastic wrap and commence construction.

WING ASSEMBLY

Wing construction for the Elder consists of building

three (3) separate pieces; the two wing panels and the

center section. These will be joined in the Final

Assembly section of this manual. You will need the

center section, with its top unsheeted during the

Fuselage Assembly section. In this sequence, be certain that you are working with a flat work surface. The

wing is built directly over the plans so cover them with

Monokote backing or food wrap.

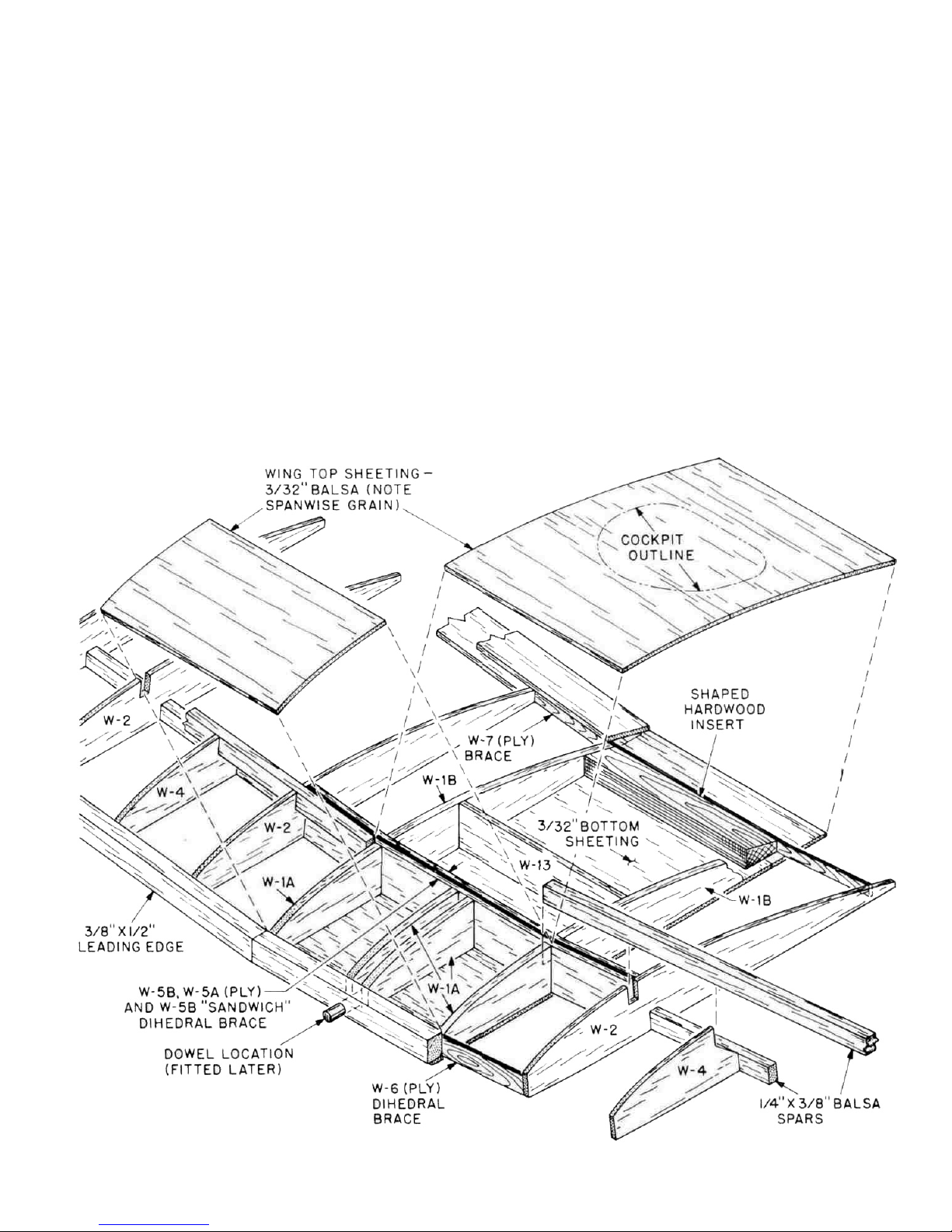

1. Start with the center section first. Locate the die-cut

sheets containing parts W-5A (ply), W-5B (2, balsa),

W-6 (ply), W-7 (ply), W-1 A (there are four but you need

two at this time, balsa) and W-1 B (2, balsa). Remove

these parts from their sheets and clean-up any rough

edges before assembly. Also, locate the shaped

hardwood insert for the wing bolts and W-13 as well.

2. Using the plans as a guide; measure, cut and buttglue the three required lengths of 3/32" balsa sheet

that makes-up the bottom center section sheeting.

Note desired cross-grain of this sheeting. Measure,

2

Page 3

cut and glue in place the

3/8" x 1/2" leading edge. Glue

the forward ply dihedral brace, W-6, in place against

the inside surface of the leading edge piece—be

sure it's centered. Glue the two forward W-1A half

ribs in place against the rear face of the dihedral

brace, lined-up with the edges of the bottom

sheeting at right angles to your work surface.

3. As shown on the plans, the center dihedral brace is a

composite made by laminating the two W-5B's to

each side of the ply W-5A, resulting in a 1/4" thick

part—do this now. Glue the completed center

dihedral brace in place to the bottom sheeting and

the two rear edges of the W-1A half ribs—again, be

sure it's centered.

4. Now glue the two rear W-1 B ribs in place to the bottom sheeting and rear face of the center dihedral

brace. As shown, these two half ribs also line-up

with the outside edges of the bottom sheeting, at

right angles to the work surface. Now glue the

shaped hardwood wing bolt insert in place between

the W-1B ribs, with its rear edge lined-up with the

rear edges of these ribs. Finally, glue remaining W-7

ply dihedral brace in place against the rear edge of

the shaped wing bolt insert and the two W-1B

ribs—be sure it too is centered. Locate and mark the

position of W-13 on the outside surfaces of the two

W-1B ribs, do this with light pencil marks (you will

need these marks for later locating and cutting-out

the cockpit opening). Glue W-13 in place.

NOTE: For the time-being, this completes the center

section construction. We will finish it after we have

used it in the construction of the fuselage. Set it

aside for now and build the two wing panels. The

wing panels are constructed directly over the plans

—build both at the same time.

3

Page 4

5. Locate and remove all of the required die-cut parts,

W-2's (12), W-3's (10), W-4's (10) and the W-8 wingtips

and the W-9, 10, 11 and 12 wingtip formers. These

should be removed carefully and their edges

cleaned-up with a sanding block as needed. Start

construction by accurately cutting and positioning

the bottom 3/32" x 1" leading edge sheeting strip in

place.

Dothesamethingfortherear 3/32"x

1 "trailing

edge sheeting as well. Now take one of the W-2 ribs

and test fit it in place between these two sheet

strips. The notches should fit accurately, allowing

the bottom of the rib to contact the work surface. If

any adjustment is needed due to gaps, move the rear

sheeting strip slightly forward or back as needed;

once satisfied, pin the sheeting in place.

6. You are now going to provide the proper dihedral

angle to the leading edges and the spars to give you

an accurate, tight fit when the two panels are joined

to the center section later. Take the center section

structure that you just built and position it in place

against the inboard edges of the two sheeting strips

that are pinned in place. Tilt the center section structure down until the front and rear ply dihedral brace

arms contact the sheeting. The resulting angle of

the side of the center section is the angle that you

want to impart to the inboard ends of both spars and

the leading edge. Take one of the 3/8" x 1/2" x 30"

leading edges and lay it in place on the leading edge

sheet, against the now tilted center section—note

the gap at the bottom due to the tilt. Use a razor blade

to trim the end of the leading edge to fit flush and

square to the tilted center section's leading edge.

Once satisfied, mark and cut the other end of the

leading edge to end at the outboard edge of the

leading edge sheeting. You should now have a

perfect fitting leading edge—repeat the process for

the opposite panel and glue the leading edge in

place. Now do the same thing to the inboard ends of

the top and bottom spars. Position and pin the bottom spar in place over the plans. Glue the first, inboard W-2 rib in place to the rear face of the leading

edge, to the spar and the rear trailing edge sheeting

strip. Hold the tilted center section structure in

place to provide accurate placement of this first rib.

7. Glue all of the remaining W-2 ribs in place.

8. Glue the top spar in place into the W-2 rib slots—use

the center section once again to ensure proper inboard positioning of the spar end.

9. Glue all of the W-4 half ribs in place to the top and

bottom spars and the leading edge.

10. Glue all of the W-3 angled rear ribs in place. NOTE:

Where the forward ends of these ribs contact the W-2

ribs, they should be chamfered to fit flush, do this

with your sanding block.

11. As shown on the cross sections on the plans, the

bottom rear trailing edge sheeting strip needs to be

chamfered a little to receive the top rear trailing

edge strip. Do this now with your sanding block.

Once satisfied, glue the top rear trailing edge

sheeting

strip

(3/32" x 1")

in

place, again using

the

tilted center section structure for alignment and

positioning. Pin in place and allow to dry.

12. Glue

wingtip W-8 in place to the ends of the wing

panels. Note the positions of and glue wingtip

formers W-9, W-10,W-11 and W-12 in place.

13. Remove the wing panels from the work surface. Inspectthem for anydriedglobsof glue, remove these

with a #11 X-acto knife. While holding both panels

together, make sure they are identical by using a

sanding block to go around all of the edges to match

them as closely as possible. Take your time here and

do a neat job.

14. Use a razor plane and your sanding block to now

shape the leading edge down to the cross sections

shown. A strip of masking tape just behind the

leading edge and across all of the ribs will protect

them while you are forming the leading edge shape.

Finally, use a well-worn piece of light sandpaper to

go over all of the wing panel surfaces to totally

smooth it out for covering later.

15. You will notice on the plans that each wing panel is

shown with three lengths of 1/4" sq. spruce which is

meant to serve as wing wire anchor points. If it is

your intention to use these wires on your model, cut

and glue these anchor points in place.

TAIL GROUP

The tail group of your Elder, hopefully like the rest of the

airplane, is quite straight-forward and buildable directly

over the plans. Note there are a few options open to you

with these parts in terms of shape. The stab's gentle

curves which terminate in sharp points at the trailing

edge of the elevators give a certain "look." This look can

be changed by rounding the outboard trailing edges of

the elevators to get rid of the sharp point. This "softens"

the look of these shapes. The same thing can be done to

the fin and rudder, top and bottom—looks nice. As

shown, you can also seal lop the trail ing edges of the rudder and elevators to give yet another look.

1. Start with the stab, build it directly over the plans

which you have covered with the clear backing from

Monokote or food wrap. Position S-1 in place and

pin. Cut a length of 1/4"x 1/2" stock to glue to the forward edge of S-1—glue in place. Glue the two S-2

leading pieces to the two S-3 pieces to form the two

required leading edges. Glue these in place to each

side of S-1 and the 1/4" x 1/2" trailing edge of S-1.

2. Cut, fit and glue the two 1/4" sq. balsa ribs into each

side of the stab. Use short lengths of 1/4" x 1/2" stock

to make the fillets—note their grain direction.

3. From the 1/4 " x 1-1/2" x 24" balsa stock supplied,

measure and cut the two elevators. Notch them as

shown to accept the 1/4" dia. x 3-1/2" dowel elevator

joiner. With the stab still in position on the work

bench, position the elevator halves in place and pin.

Protect the trailing edge of the stab with a strip of

waxed paper and epoxy the dowel elevator connector in place in the notches made earlier—allow to dry

completely.

4

Page 5

4. Remove the stab and elevators from the plans. Build

the fin next in the same manner using the R-1 and R-2

die-cut pieces with a 1/4" sq. and 1/4" x 1/2" balsa

frames shown. Cut the rudder to shape from the remainder of the 1/4" x 1-1/2" balsa stock used for the

elevators. Position the rudder in place to the back of

the fin and glue R-3 in place to the leading edge of

the rudder. Remove the parts from your building

board.

5. The elevators, stab, fin and rudder are now finalsanded to shape. Start by using masking tape to

mount the elevators to the stab. Use a sanding block

to go over all of the outside surfaces, to carefully

match them. Lay the stab on a flat working surface,

masking tape down, and use the sanding block to

sand it flat. Use the sanding block to taper the

elevators as shown on one side; once satisfied, tape

the stab/elevator hinge line, turn the stab over,

remove the tape from this side, and repeat the process. The same method is used for the fin and rudder. Once complete, use sandpaper to round the

leading edges. Set these parts aside for covering

and assembly to the fuselage.

FUSELAGE ASSEMBLY

Before starting construction, study the plans and drawings to familiarize yourself with how the fuselage is

assembled. Note that it really is nothing more than a

basic "box" fuselage with semi-formers in the nose area

to create the rounded cowling effect. This simple and effective way of making a fuselage can only be ruined in

one way; building it crooked. This can be done by not

making the fuselage side frames identical and/or missizing the top and bottom cross braces. Another common error is to make improper joints. The Elder relys a

great deal on the strength of its frame—make those

joints fit correctly. Note also that the uprights and cross

braces are a mix of both spruce and balsa. These are

notated.

1. Locate and remove die-cut parts F-6 and F-10, two of

each. Securely pin F-6 in place directly over your

covered fuselage plan. Note that the bottom aft

spruce longeron terminates in the rear notch in part

F-6. Glue the forward end of the bottom spruce

longeron into F-6, disregard the curve of this

longeron for now.

2. Pin F-10 in place directly over the plans. Measure

and cut the top rear spruce longeron that fits in place

from the back of the "tab" on F-10 aft to the tail post.

(A tool such as an X-acto mitre box and razor saw is

quite good for cutting spruce.) Glue the top rear

longeron in place to F-10.

3. Locate one of the three 1/4" x1" x 3 "ply formers that

are supplied with your kit. Hold this former in place

on top of F-10, in front of the "tab." With a pencil,

mark its forward location on the former. From your

1/4" sq. balsa stock, cut and fit the top forward

longeron which extends forward from the pencil

mark you just made to the back face of the firewall.

Note that you will have to make a slight cut in the top

of this longeron at the wing's leading edge location

to get It to bend back down to follow the drawing—

just "crack" It slightly at this point. Glue this

longeron in place.

4. Cut, fit and glue In place all of the uprights and

diagonal braces (1/4" sq. and 1/4" x 1/2" balsa) from

the nose back to and including the 1/4" sq. uprights

just ahead of the F-10 former (these connect the

front edge of the F-10 with the top rear edge of F-6).

5. Cut, fit and glue In place the rearmost 1/4" sq. spruce

tailpost upright—be sure that the correct angle is

also trimmed Into its bottom end for the bottom

longeron. With the frame firmly secured to the

building board, bend the bottom longeron up to meet

the rearmost upright that was Just Installed. Glue

and securely block this longeron in place.

6. With the exception of the 1/4" x 1/2" servo tray bearer,

cut, fit and glue all remaining balsa and spruce

uprights in place; thus completing the basic frame.

You will now want to make a second, identical frame.

We have found the easiest way to be sure that they

are identical is to build the second frame directly on

top of the first. Be sure to cover the first frame with

Monokote backing or food wrap first.

7. Hold or tape the two completed frames together and

use your sanding block to make sure they are iden-

tical. Separate them and sand their sides smooth

(both sides) with the sanding block.

8. Measure and cut the two required 1/4" x 1/2" x 2-1/2"

balsa cross braces that fit at the top and bottom of

the fuselage at the wing's trailing edge. Measure

and cut the 1/4" x 2-1/2" balsa bottom cross brace that

fits in the bottom of the radio compartment and the

1/4"x2-1/2" spruce cross brace that fits in place at the

top, front of the two frames. Locate all of the three

1/4" x 1" x 3" ply formers. Position the two frames up-

side down over the top view on the plans—accurately please! Pin them in place at right angles to the

work surface. (NOTE: Due to the slight incidence

angle in these frames, they will not fit flat to the surface. This is not important at this time.) Epoxy the

two forward 1/4" x 1" x 3" landing gear formers in

place in the notches provided in the F-6's. Glue the

two remaining balsa bottom cross braces in placepin and al low to dry. Remove the frame from the work

surface, turn it over and glue the forward 1/4" sq.

spruce and rear(wing'strailing edge) 1/4 "x 1/2 "cross

braces in place. Now epoxy the remaining 1/4"x1"x

3" ply former in the space left on top of F-10.

9. Locate the 1/4" x 2-5/8" x 3" ply firewall. You must now

use the plans to locate the position of your motor

mount on the firewall. This mount is installed inverted. Mark the location of the four mounting holes

onto the firewall. Use a drill and a 1/8" dia. drill bit to

drill the holes through the firewall. Use the four 4-40

blind mounting nuts provided and epoxy them in

place to the back of the firewall, into the holes just

drilled—keep adhesive out of the threads. Test

mount the motor mount with the 4-40 x 7/8" bolts provided. Remove the mount and epoxy the firewall to

5

Page 6

the front of the fuselage frame, align it carefully and

allow to cure.

10. Use your sanding block and medium sandpaper to

now go over the frame. Make sure the edges are all

square and clean.

11. Locate and assemble, if needed, the fuel tank that

you plan to use. This airplane can use either 4,6 or 8

oz. fuel tanks. Note that we are showing the Sullivan

slant-type tank that is mounted inverted in the nose.

This is because this position places the tube outlets

more inline with the engine's carb. Fit your tank into

the nose of the fuselage frame. Use short (3")

lengths of scrap balsa stock to make "support" for

it. With the fuselage open at this time, it's easy to

see if the tank will sit level—adjust as needed. In this

6

Page 7

way, when the fuselage is done, your tank can be inserted from the wing opening into the nose and

removed, if needed, with assurance that it is

mounted

correctly.

Now use

a 3/16

"drill

bit to

drill

the

two required holes for the fuel tank (one for fuel feed

and filling and the other for the pressure tap and

overflow). Remove the tank.

12. Drill and tap the holes necessary In the motor mount

to attach your engine (we like to use 4-40 Allen-head

bolts for this purpose). Attach the motor mount to

the firewall and the engine to the mount. By viewing

from the front, determine the location of the throttle

tube housing exit hole. This should be lined-up with

the carb's throttle arm. Drill a 3/16" dia. hole through

the firewall for this tube. Rough-up the outer surface

of the outer throttle tube housing and glue it in place

in the firewall—about 3/16" of it should protrude out

from the face of the firewall, the rest of it runs into

the radio compartment. Be sure your tank still fits

nicely.

13. The servos shown on the plans are of average configuration, however yours may be different; taller,

wider, etc... The Elder will accept almost any radio

system, there is plenty of room. Lay the fuselage

frame over the side view of the plans and take one of

the servos that you plan to use and lay it in place,

about where they are shown on the plans.

Remember that these servos will be mounted on the

1/8" ply servo tray. Observe if your servos will fit. Cut,

fit and glue the 1/4" x 1/2" balsa servo tray bearers in

place between the two uprights in the radio (servo)

compartment—note that their outer edges are flush

with the rest of the fuselage frame

14. You can now sheet the bottom of the fuselage from

the nose (between the two landing gear formers)

back to the last bottom 1/4" x 1/2" cross brace—don't

sheet any further back. Note this sheet is applied

cross grain. Use your sanding block to clean the

edges flush with the frame sides. Sand the landing

gear mounts and sheeting to a smooth curve when

viewed from the side.

15. Use the 3/32" x 4" x 24" balsa sheet provided to now

make the primary fuselage sides. Be economical

here, you will need the rest of this sheeting later. Lay

the fuselage frame on the sheet with the forward

edge of it lined-up with the leading edge of the wing.

Use a pencil to trace the fuselage side outline onto

the sheeting. Cut out the fuselage side and glue it in

place, repeat the process for the other side. Use your

sanding block to again true-up edges and generally

tidy the fuselage.

16. Stand the fuselage on its nose, firewall flat to the

work surface. Locate and glue in place the two side

F-4 formers to the firewall sides, flush with its front

face.

17.

Locate and glue in place the two side formers, F-5.

Glue balsa former F-7 to ply former F-8 (see plans).

Glue the F-7/F-8 former in place at the top of the

fuselage where the leading edge of the wing will be.

18. Locate and accurately pin in place the wing center

section to the top of the fuselage—take your time

and locate it as accurately as possible. Use a 1/4"

dia. drill to drill through F-7, F-8, the leading edge

and dihedral brace of the center section—back up

the dihedral brace with a piece of scrap wood to

avoid splintering as the drill bit passes through it.

Remove the center section and set aside for now.

Once again stand the fuselage on it's nose, flat on

the work surface and glue the top F-3 former in place

on top of the firewall and flush with it's front face.

19. Measure, cut and glue in place the top 1/4" sq. balsa

cowl longeron from F-7 through F-3 and out past the

firewall as shown on the plans to pick-up F-2. Cut, fit

and glue the two side 1/4" sq. balsa cowl longerons

to the slots in the F-4's. Now fit in place cowl former

F-2, don't glue yet. Observe how this former is fitting

in place, make sure that it is parallel with the firewall

and that when viewed from the side it is also parallel

with the firewall. Once satisfied, glue it to the three

1/4 " sq. balsa longeron ends. Now glue the two F-1

cowl pieces to the front face of F-2, leaving a 3/32"

"shelf" for mounting the cowling sheet.

20. You are now going to sheet the nose of the fuselage

as follows: Start by sheeting the top of the fuselage

from F-7 out to F-2. Do this in two pieces with the

seam on the centerline of the top 1/4" sq. balsa

longeron. Wetting the top of the sheet

(3/32"

balsa

through-out) will help conform it to the formers. Use

thick CA adhesive for this operation; in that way no

pins or tape will be needed. Next, cut and fit a piece

of sheeting that will fit against the edge of the top

sheet, extend down to the centerline of the side 1/4"

sq. balsa cowling longeron and fit between F-1 (on

the top of F-2) and half the thickness of F-4. The next

piece butts up against the edge of the last piece just

installed, down to the bottom of F-1, angling back to

the bottom of F-4. This then leaves only the sides of

the fuselage open at the tank compartment. This

area is done in two pieces also. One from the

7

Page 8

centerline of F-5 up to the top sheeting and the other

from the centerl ine of F-5 down to the bottom edge of

the fuselage. This completes the sheeting of the

front end of the airplane. If you have taken your time

and fitted these pieces with a minimum amount of

gaps, all that remains is sanding to shape.

21. Use a sanding block to bevel the inside ends of the

spruce fuselage framework at the tailpost—see

plans. Once satisfied, glue these ends accurately

together providing equal bends to each side of the

fuselage. Now accurately cut and glue in place all of

the remaining spruce and balsa cross braces as

shown.

22. Once again, accurately position the wing center section in place on the fuselage. Using the trailing edge

as your mark, finish sheeting the top of the fuselage,

cross grain, back to the point where the fuselage

sides end. Remove the center section from the

fuselage.

23. With the exception of final sanding and rounding as

shown on the plans, the fuselage is now complete.

LANDING GEAR AND TAILSKID ASSEMBLY

Note that the front and rear 1/8" dia. M.W. landing gear

forms are supplied to you pre-bent. Note on the plans

that they must be joined together at the bottom, towards

the wheels. We recommend soft copper wire for first

firmly wrapping the two pieces together followed by

soldering the legs together. We would highly recommend the use of HARRIS'S STAY-CLEAN FLUX and their

silver solder for this operation. Although a soldering iron

will work with patience, these joints can be quickly and

permanently made with the use of a small hobby-type

gas torch.

1. Locate the position of the rear "crossed-axle" wire

to the bottom rear ply L/G plate on the fuselage bottom. While holding the wire in place, slip the two

formed metal clips onto the wire. Using a pencil to

mark the hole locations of these clips onto the ply

base, remove the wire and clips. Drill shallow, small

diameter "guide holes" for the clip's screws. Now

attach the landing gear wire to the fuselage with the

clips and the #2 x 3/8" screws provided—there is no

need to overtighten them. Repeat this process with

the forward landing gear wire.

2. Pull the two components together until they touch.

The two short bent "arms" on the forward leg should

line-up with the legs of the rear L/G wire. If needed,

use pliers to adjust these arms until they neatly fit.

3. Use soft copper wire to now neatly wrap the forward

short arms to the rear L/G wire as shown on the

plans. Apply some STAY-CLEAN flux to the joint and

solder. Repeat the process on the other side. Be neat

and try and be sure that the joint is at once solid

without a lot of excess solder. Once satisfied, completely clean the solder joints of any flux.

4. As shown, the crossed-axle landing gear system

derives its ability to accept landing loads and shock

from the two (2) independent axle legs. These need

to be joined at two points, each 2-1/2" in from the

wheels. This distance has shown very good shockabsorbing ability for Elders weighing 3-3-1/2 lbs. Join

these axles by first measuring the 2-1/2" distance required, wrapping with soft wire (about 3/8") and

soldering. Again, clean the solder joints completely.

5. The same process is now used to make the rear

tailskid assembly. First bend the 1/16" dia. M.W. provided to the shape shown using pliers. Wrap the tip

of the skid with soft copper wire and solder. Now

tape the main skid wire in place to the bottom'rear of

the fuselage. Locate the pre-bent tailskid support

wire and wrap it in place to the tailskid with soft wire.

Solder it in place to the skid. Remove the assembly

from the fuselage and again, clean the solder joints

completely.

6. Remove the main landing gear from the fuselage.

The landing gear and tailskid are now complete and

can be used as is or painted flat black or aluminum

(we use K&B epoxy paints for this as well as other

painting needs on this airplane). As we did on some

of our prototypes, you may wish to add wood back-

ing to the wires, sand these to airfoil shape and paint

them a wood color—looks great! We used 1/8" x 1/4"

hard balsa with a 1/8" dia. "groove" sanded into one

edge, carefully fitting the piece in place. We glued

the wood to the metal with thick CA adhesive and

sanded the whole affair smooth. Then we used clear,

paintable Monokote to cover the "wooded" parts of

the landing gear to provide a one-piece look and airbrushed wood-colored epoxy paint on the whole

thing.

FINAL ASSEMBLY

1. Locate one of the 1/4" dia. by 3-1/2" dowels. Insert the

dowel into the hole previously drilled in the leading

edge of the wing center section. As shown on the

plans, it extends all the way back to the main wing

dihedral brace with about 1/4" - 3/8" of it extending

out to connect with the F-7/F-8 formers; trim the

length as needed. Now install the center section to

the wing with the forward dowel in place. Liberally

8

Page 9

apply epoxy around and beneath this dowel. Then

glue in place the two remaining W-1A half ribs into

position on each side of the dowel. Fill the resulting

cavity above the dowel with more epoxy and allow

the structure to cure.

2. The top of the wing center section can now be completely sheeted, cross grain. As with the wing

panels, slightly bevel or chamfer the trailing edge of

this part to allow proper seating of the top sheet.

When dry, use a small sanding block to clean the

edges of the top sheeting flush with the outer surfaces of the W-1A and W-1 B ribs.

3. Carve and sand the short leading edge of the center

section to shape, matching the two wing panels.

4. Once again, accurately pin and/or tape the wing

center section in place to the fuselage. Use the

plans for reference to now drill two 1/8" dia. wing bolt

holes through the top rear of the center section and

through the 1/4 "x1 "x 3" ply former directly beneath

it—note the angle that these two holes are drilled at

to take into account the slope of the top airfoil at that

point. Remove the center section from the fuselage.

Tap the two holes in the ply former with either an 8-32

tap or an 8-32 metal bolt. Once the threads have been

established use a little thin CA adhesive to "coat"

them and then run the tap into the holes once again;

this toughens-up the threads. It may be necessary to

run the tap or bolt through these threads several

times to allow the nylon 8-32 bolts to clear. Use a 3/16"

drill bit to now "clear-out" the two 1/8" holes in the

wing center section for clear passage of the wing

bolts. Now bolt the center section in place on the

fuselage.

5. Locate die cut former F-9 (balsa). As you can see

from the plans this former is trimmed at the bottom

(sanding block) to fit onto the top of the center section's leading edge where it becomes the "shelf" for

the 3/32" x 1/4" fuselage fairing strips. Apply glue to

the bottom of this part and position it accurately in

place on the center section, flat against the rear face

of F-8—don't get glue on F-8. Start making the

fuselage/wing fairing by first cutting to length the

top center 3/32 " x 1/4" balsa strip (the center one when

viewed from the top). Sand its rear bottom edge to

match the contour of the center section's sheeting.

Once satisfied, carefully glue in place to the top of

F-9 and the center section sheeting. Repeat this process to the left and right of this center strip until the

rough fairing is complete. With the center section

still in place, use your sanding block and sandpaper

to now smooth the fuselage/wing joint to a onepiece look. Any small gaps or rough edges can be filled with a filler such as DAP White Vinyl Spackling

compound and sanded smooth again. Remove the

center section from the fuselage.

6. You can now make the cockpit cut-out in the wing

center section. The pattern for this is provided on the

plans and it can either be traced or the pattern itself

cut-out of the plans to serve as a cutting guide. Use a

#11 X-acto knife for this purpose and try to be as neat

as possible.

7. Locate the four remaining 1/4" dia. by 3-1/2" dowels.

These will be used to now make the "king post" that

fits to the wing center section. This is most easily

made by first constructing two separate

"triangular" pieces and then joining the two pieces

at the top. Chamfer the top ends to fit as shown on

the plans and epoxy. The bottom ends of the "king

post" must also be chamfered to sit squarely on the

top surface of the center section, ahead of the

cockpit. Don't attach this structure yet, it will be

assembled to the wing after covering.

8. The two wing panels can now be permanently attached to the wing center section. We recommend

that you use epoxy for this operation. With the

center section flat on your building surface, slide the

two panels in position onto the exposed arms of the

front, center and rear dihedral braces. The fit should

be accurate; the front brace fits against the back

face of the panel's leading edge; the center brace is

in contact with both the top and bottom spars; and

the rear brace is inside of the top and bottom rear

trailing edge sheet strips. The panel's spars, leading

edges and trailing edges should also be cleanly contacting the outside surface of the center section's

sides. Take your time here to ensure that this is the

case before committing to actual attachment.

Locate or make a couple

of

1-3/4"

high supports for

the wingtips to provide the required dihedral angle.

Now epoxy the panels in place to the center sec-

tion— don't use so much glue that it runs or drips but

enough to provide a good glue joint. One-hour epoxy

is best for this step. Allow the structure to cure completely.

9. Remove the completed wing from the bench and

take some time to now go over it completely. Check

the joints for gaps, etc. Use more epoxy to now go

over the joints, making sure that every contact point

has adhesive. When you are satisfied, use light

sandpaper to smooth the wing panel/wing center

section joints to match.

10. Locate the two required rear fuselage pushrod exits

(die-cut, ply). Note on the plans where these fit

beneath the stab location—glue in place.

11. A 1/16" x 3/8" x 12 "ply strip is provided for the fuselage

frame "joint caps". These can be drawn with pencil

on the strip of ply and scissors or shears can then be

used to cut them out. These are glued in place to

each of the exposed fuselage upright and cross

brace joint, as shown. Once these are in place, use

sandpaper to lightly smooth their edges.

COVERING & FINISH

Now that al I of the various components of your Elder are

completely assembled and sanded to their final shapes,

you can turn your attention to covering. This is the point

that can separate your model from anyone else's. You

must decide what you want the finished airplane to look

like. We have finished our prototypes in a wide variety of

color schemes representing everything from an R.A.F.

WWI fighter (as shown on the label; in cream Monokote

9

Page 10

with red, white and blue Roundels and tail treatment) to

a German WWI fighter (all red Monokote with black Iron

Cross's on a white background) to civilian-type versions

(dove gray fuselages, transparent blue wings and tailgroup and chrome Monokote "cowls!") Interestingly, no

matter what color scheme we used, there was always a

group of people at the flying site who would stand there

looking at the Elder, arguing about what real, full-scale

aircraft it represented. Just remember that the Elder is

not a scale model, you're free to cover it in any configuration that strikes your fancy—it will look great!

Before covering, it is suggested that the final finish be

applied to the open spruce fuselage structure. This can

be done several ways. There is a very good product on

the market called Varathane that is sold through most

well-stocked hardware and lumber supply outlets. This

material is essentially clear and will leave the spruce

about its same color, maybe a little darker, and

somewhat shiney. It is resistant to spent fuel and quite

durable in actual use. Epoxy paint, mixed to achieve a

woodish brown color and brushed or sprayed also works

well. Take your time here, use light sandpaper to go over

the framework, smoothing it for the finish of your

choice. When applying the finish, be sure that all of the

exposed wood, except the top, rear stab glueing area,

receives paint. We then used flat black paint (again,

epoxy is great) to paint each of the ply "joint-caps", this

really makes the structure come to life!

Now for the covering itself. Use the directions that are

supplied with each roll of Monokote and cover each of

the various components separately; fuselage, wing,

stab, elevators, fin and rudder. Some of you might have a

problem with the wingtips of the Elder, if this is your first

venture into the use of Monokote or your first R/C

airplane. We tried a method on one of our prototypes that

worked quite well for these tips. First, cover the wing

panels totally, starting with the bottoms first, including

'the wingtips. Then cover the tops of the wing panels out

to and including the last outboard W-2 wing rib, but not

the wingtips themselves. Next, cut an elongated

triangular piece of Monokote to fit over the space between the forward W-2 rib and the forward W-9 wingtip

former—keep the edges straight, allow about 1/8"

overlap and iron this piece in place. Move now to the

next exposed triangular area between W-9 and W-10 and

repeat the process. This method will provide a much

easier covering situation for the newcomer and, if done

carefully, gives you a nice looking, wrinkle-free wingtip.

When covering the fuselage be sure that the bottom

covering—the piece that you should apply

first—overlaps into and on the firewall by about 1/4 " at

least. Additional information on how to use Monokote is

now available on video tape. See your dealer or write to

Top Flite.

Assuming that the airplane is now covered, turn your at-

tention to fuel-proofing the engine compartment. We

like to use and highly recommend a liberal coat of

polyester resin. This material should be applied to all exposed wood in the inside of the cowl area and over all of

the Monokote seams that terminate in the cowl itself.

This seals the wood as well as the Monokote seams and

avoids "fuel creep" later on. Be sure to keep the resin out

of the bolt holes in the firewall.

Use your X-acto knife to now clear-out all of the hinge

slots in the tail group. Do the same thing for the wing

hold-down bolt holes, the cockpit, the landing gear

screw holes, etc.

Mount the wing to the fuselage with the nylon bolts.

Place the stab in position on the top rear of the fuselage

and sight down the front of the model to observe if the

stab is sitting flat in relationship to the wing, without any

tilt. Once satisfied, hold the stab firmly in place in the

position that it is meant to be; square with the fuselage

and aligned correctly with the wing when viewed from

the top—make sure that it is exactly where you want it.

Use a sharp pencil and, while holding the stab in place,

trace the outline of the framework that is in contact with

the bottom of the stab onto the stab itself. Remove the

stab from the fuselage. Use your X-acto knife to now

lightly cut-out the frame outline from the bottom of the

stab's Monokote to expose the wood—this will be your

glueing surface. The stab can now be mounted to the

fuselage; we used a "thick" CA adhesive for this.

Next, prepare the fin for mounting to the stab by making

sure that all covering is removed from the bottom of it,

leaving exposed wood. Hold the fin in place on the stab

in the position that it is supposed to be; dead-centerwith

the fuselage centerline. Use the same pencil and mark

the fin's location on the top of the stab. Remove the fin

and use your X-acto knife to remove the covering from

the previously marked location, exposing the wood.

Before glueing the fin to the stab, use a pin to make lots

of small holes in the exposed wood of both the stab and

fin bottom, these need not be deep. Use a slower drying

adhesive (Titebond, 1-hour epoxy, etc.) to now glue the

fin in place on the stab. Use a length of light tape over the

top of the fin and on each tip of the stab to hold the fin in

place, at right angles, and allow to dry. Check periodically while this structure is drying to be sure that the fin has

not shifted and is in place at right angles to the stab and

on the centerline of the fuselage; we want everything

"square." When this structure is dry, remove the tape.

Thread a length of 20# fishing line (used for rigging thruout, if desired) through the hole at the top of the fin and

glue each end of the line into the holes at each tip of the

stab—carefully applied "thick" CA adhesive will work

well. The fin should now be quite immobile on the stab.

Use 1-hour epoxy to now glue the four hinges required into the trailing edge of the stab and the two hinges required into the fin. Next, mount the elevators to their

hinges followed by the rudder, again using 1-hour epoxy.

A little acetone or CA debonder on a clean paper towel

can be used to clean-off any glue that has oozed out of

the hinge slots.

Mount the landing gear assembly to the fuselage with

the screws and clips provided. Mount the clips securely

but do not over-tighten.

Install the motor mount to the firewall and your engine to

the motor mount. We would suggest that you mount your

engine using 4-40 Alien-head bolts into pre-tapped holes

in the motor mount. Cut a couple of 10"-12" lengths of

10

Page 11

medium fuel tubing. Use a razor blade to cut a sharp

angle on one end of each of these lengths. Insert these

angled ends into the holes you drilled earlier in the

firewall. Use a pair of pliers, long-nosed, to reach in from

the wing opening and pull the tubing ends through the

tank compartment, out into open view, without pulling

them all the way through the firewall. Trim the ends

square and attach them to the correct tank tubes. Now

pull the tubes back out from the firewall while moving

the tank into the fuselage. Trim the tubing to length and

attach the ends to the engine and pressure tap.

The triangular-shaped "flying-wire post" that is shown

sitting in front of the cockpit can now be glued (epoxy) in

place by first positioning it on the top of the wing to

determine it's final position. Once satisfied, press on

the top of it, indenting the covering slightly. Remove the

covering material in these indentations, exposing wood

and glue the post in place. If you have decided to add the

optional flying wires (20#-test fishing line), drill small

holes

(1/32"

dia.)

into

the tops of the spruce upright posts

that you installed during wing construction. We used

very small cotter pins for the flying wire anchor points,

these can now be epoxied into the holes. Before adding

the flying wires, apply any decoration or markings to the

wings that you have decided upon, then add these wires.

As shown on plans, the exposed framework of the aft

fuselage is shown with bracing wires and tubes in each

joint corner for their attachment, if you have decided on

this as an option, now is the time to add them.

The 1" x 1-3/4" windscreen is now trimmed to shape using

the outline provided on your plans and glued in place

just ahead of the cockpit opening. Position the bottom

edge of the windscreen in place on the wing center sec-

tion and press down to leave an indention. Use an X-acto

knife to cut through the indention and wood beneath it.

The windscreen can now be inserted into this "slot" and

held in place with a small amount of adhesive. If you are

using a "pilot,"he should now be epoxied in place in the

cockpit (assuming that he's all painted and ready to fly).

At this point you might well be considering detailing

your Elder with a few "goodies." We have used a few

items that were "off-the-shelf" in most well-stocked

hobby shops. Williams Bros. makes some nice 2-1/2"

scale machine guns, WW I type, both German and

British. We used one of their Vicker's guns on the model

shown on your box label. Simply glue a couple of dowels

into the bottom of the gun and it can then be glued right

into the center section of the wing, beneath the "king

post." As shown on the plans, we also used a Williams

Bros. "vintage" pilot (the one with the leather flying cap

& goggles) as well as their wheels. On a couple of the

prototypes we detailed the cockpits with instruments

from Lou Proctor and a genuine hardwood, stained in-

strument panel (veneer). All kinds of neat looking flying

wire clips and little metal parts can be easily made from

light aluminum. Detailing the Elder is up to you; any way

you choose, it'll look great.

With the possible exception of additional final detailing

such as outlined above, your Elder is now essentially

finished, needing only the installation of the radio.

RADIO INSTALLATION

The method of installing your radio in the Elder is shown

on the plans. Note that we have provided you with a 1/8" x

2-7/8" x 4-7/8"

ply servo tray.

Use

a pencil and straight edge

to lay-out the positions of your servos on this tray. Note

that we are showing the rudder and elevator servos at

the rear, side-by-side with the throttle servo just ahead,

mounted sideways. Drill a 1/4" dia. hole into each of the

servo pencil marks and use a Dremel saw or a jig-saw to

remove the servo cut-out's (3) required. Test-fit the ser-

vos into the tray and the tray into the fuselage—it is

meant to rest atop the two 1/4" x 1/2" balsa bearers that

were built into the fuselage frame earlier. Note that the

tray can be slid fore and aft a little to provide some C.G.

(Center of Gravity) change, if needed. Later, it will be permanently glued in place.

The receiver and battery pack are meant to be installed

forward of the servo tray, as shown. These components

should be installed using foam rubber. The receiver

antenna on our prototypes was simply routed out

through the fuselage, internally, and tied-off at the tail

post of the rear fuselage framework. The switch harness

may be attached directly to the fuselage side, away from

engine exhaust.

Next make the rudder and elevator pushrods. You have

been provided with a 36" length of 1/4" dia. dowel. Cut

this in half to make two 18" pushrods. As shown on the

plans, attach the non-threaded end of the 6" (threaded

one-end) control wires to the ends of each dowel with

epoxy and tightly wrapped thread. From the inside of the

fuselage, slip the pushrods in place through the

fuselage and out the ply pushrod guides at the rear of the

fuselage. Some small amount of bending of the control

wires will be needed to provide free, unbinding movement. Make sure while doing this that the bends you put

into the wires are as minimal as possible—avoid any

hard bends.

Locate the two nylon horns provided for the elevator and

rudder. Mark the locations and drill the two holes in each

of these surfaces for their mounting. Mount the horns in

place. Thread the clevises onto the threaded end of each

of the pushrods and attach the clevises to the horns.

Now test the movement and action of the rudder and

elevator while moving the pushrods by hand. It is essen-

tial that the movement be smooth, non-binding and easy

—not sloppy. Use 1/16" dia. M.W., epoxied and wrapped

as before at the other end of each pushrod to make the

connection to the servos. A simple "Z "-bend is all that is

needed for the servo connection.

Adjust the whole system for neutral and test the move-

ment of the surfaces when actuated by your radio. The

plans show the recommended movement of the rudder

and elevator and this can be adjusted by moving the

clevises in or out on the horns. In would be more movement or throw and out would be less.

Make the connection from the throttle servo to the

engine by screwing at least 1/4" of the 1" threaded stud

into one end of the inner plastic tube provided. Thread a

clevis onto the stud and connect to the throttle servo.

Again, test the operation of this connection to be sure

11

Page 12

that is is free and non-binding.

Since the pushrods are exposed, you may wish to give

them a coat of the same material that you used for the

fuselage framework to protect them from spent fuel.

PRE-FLIGHT INSTRUCTIONS

This section assumes that your Elder is completely

done, covered, painted as needed, etc. We are now going

to establish the correct C.G. (Center of Gravity). Start by

completely assembling the airplane. Note on the plans

that the mark shown for the C.G. point is directly over the

spars and directly beneath the top mating point of the

"king-post". Slip a length of string under the kingpost

and lift the airplane off your bench. The airplane, ideally,

should hang suspended either level or slightly nosedown. This would mean that the C.G. is where it should

be to provide you with a stable flying airplane.

If the tail hangs low, some of the equipment has to be

moved forward. Remember, this balance is always

achieved without fuel in the tank—that's burn-off

weight and cannot be counted. The easiest component

to move is the battery pack. Depending on the pack's

configuration, it can be installed beneath the fuel tank. If

you still need more weight forward, slide the servo tray

all the way forward as far as it will go. If more weight is

needed (highly unlikely) then you will have to add lead

weight in the nose, beneath the tank. If you have to add

lead, don't worry, the Elder will still fly quite well.

If the airplane is nose-heavy, then try moving the servo

tray back as far as it will go, etc... Once the airplane

hangs suspended as it should, you will have to now glue

the servo tray permanently in place against the 1/4"x1/2"

balsa bearers that it rests on.

Prior to flying, get in the habit of making a complete

check of the airframe. Is the prop tight?. Batteries in

both the airplane and transmitter fully charged? Engine

bolts tight? All components firmly attached to each

other? Fuel lines clear? Wheels roll easily? Make a radio

system check as well—up is up, down is down and the

throttle moves in the right direction. You're ready to fly!

FLYING INSTRUCTIONS

Once again, if this is your first R/C aircraft DO NOT AT-

TEMPT TO FLY IT YOURSELF. Go to your local hobby

shop and get information about any local flying clubs in

your area. It is within such groups that knowledgeable,

experienced individuals can be found to assist you.

Assuming that the radio system (airborne and transmitter) are fully charged and that your engine is completely

broken-in and reliable, let's fly! Fill the tank and turn the

radio system on. With the engine running at idle, point

the Elder directly into the wind and advance the throttle

slowly. With most "tail-draggers" a small amount of

right rudder will be needed to keep the airplane on a

straight heading. With a little experience you will be able

to keep the take-off roll quite straight. As the speed

picks-up, the tail will lift and in a short time the airplane

will lift-off. Keep the plane headed straight with the nose

in a shallow climb—do not "horse" it up with excess up

elevator, that is the beginning of a "snap roll" and at low

altitude this can quickly become a crash!

Once sufficient altitude is reached (75'-100'), try some

turns to get used to the handling characteristics. Nonaileron equipped models react a little slower in theturns

and these turns tend to the "skidding" type. If all of the

homework was correctly done on the ground, your Elder

should be flying quite nicely. While at altitude, try the

throttle and get used to the slow-speed characteristics

of the airplane before setting-up your landing. Use the

transmitter trims to correct for any unwanted climbing,

diving or turning tendencies from straight and level

flight at cruise speeds. Like most aircraft that have flatbottom airfoils, the Elder will naturally want to climb at

full power and settle at low throttle. A point somewhere

in between these two throttle settings will provide the

"cruise" speed. This setting will vary according to a.) the

engine size and b.) the finished weight of your model.

With some flying time experience you will find that the

Elder is quite aerobatic; loops from level flight, left and

right snap rolls, left and right spins with almost instant

recovery. Inverted flight is possible with practice.

Landings can be as slow and predictable as you'd like,

just maintain your heading into the wind all the way

through touch-down and roll-out to a stop. We have

found that the Elder steers quite well on the ground with

deflected rudder and short bursts of power—be sure

you're holding full-up elevator while you are doing this.

We sincerely hope that this has been a good project for

you and that the hours on the building board will be

rewarded with many, many enjoyable flights.

INDEX

INTRODUCTION

............................

1

PRE-CONSTRUCTION

NOTES

.................

2

WING

ASSEMBLY

...........................

2

TAILGROUP................................ 4

FUSELAGEASSEMBLY.

......................

5

LANDINGGEARANDTAILSKIDASSEMBLY ..... 8

FINALASSEMBLY

...........................

8

COVERINGANDFINISH

......................

9

RADIO INSTALLATION .......................

11

PRE-FLIGHT................................

12

FLYING ....................................

12

12

150083

Loading...

Loading...