Page 1

BUILD

THE

BOTTOMOFTHE

FUSELAGE

1.

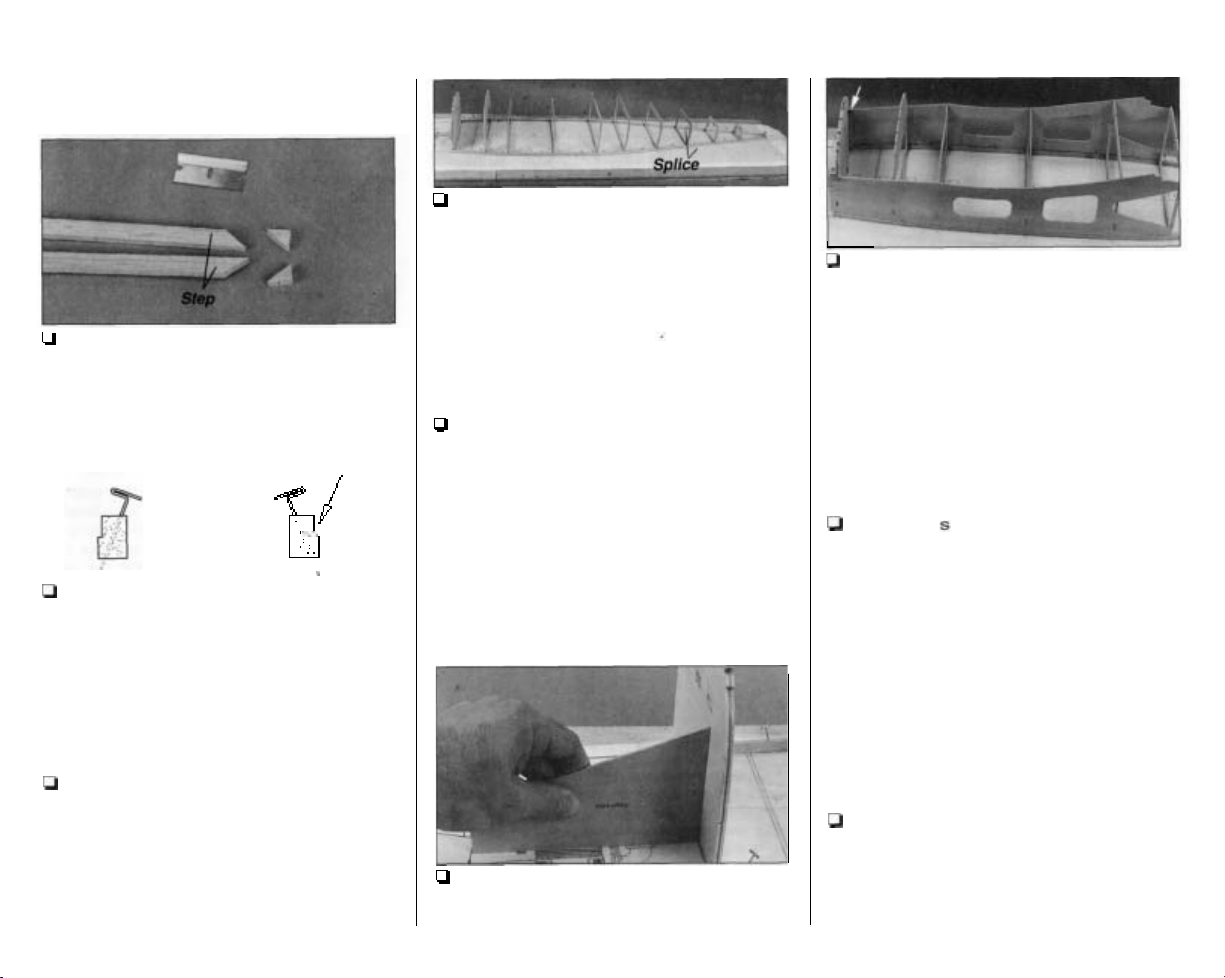

Cut a45degree angle at the aft end of two

1/4"x3/8"x36

you can

2.

Pin the stringers over their location on the

plan

so

outside of the fuselage. The front end of the

stringers should align with the

the front and extend past the firewall by

plenty of T

conform to the curvature of the plan.

"

splice

the

stepped balsa

them onto another stringer later.

step

is on the bottom and faces the

side stringers

"

S

TEP"

.

dashed lines

-

pins to hold the stringers down sothey

1/8".

so

near

Use

4.

Position but do not glue formers F1through

F11

on the side stringers sothe embossed names

on the formers face forward.

Are your

3/76

pushrod holes drilled?

5.

Glue formers F2through

stringers, holding them vertical with a

triangle. Don't be concerned about formers that are

slightly warped or twisted

be able to straighten these formers when you glue

3/16

"

the

stringers to them.

F11

to the side

90

degree

-

that is normal. You will

I

"

7.

Test fit, then glue the die-cut

fuse side doublers

and to the side stringers.

to the firewall until the next step. You may have to

reposition some of your T

interfere with the side doublers. Use your

triangle to hold the formers vertical while you glue

the doublers to them.

8.

Glue the fu e side doublers to the firewall with

30

-

minute epoxy using the firewall angle gauge to

make sure the firewall is set at the correct angle.

Use a large C

hold the doublers to the firewall until the epoxy fully

cures. Cut one 3

1/2"

x

36

"

so

on both the left and right sides behind the firewall.

Glue them in place with 30

balsa tri stock pieces. Shape the pieces

they fit between the firewall and the fuse sides

to formersF2throughF6only

Do

-

-

clamp or masking tape tosecurely

"

long piece from each of the

-

minute epoxy.

1/8"

not

glue the doublers

pinssothey do not

plywood

90

(2)

"

1/4"

x

3/8"

3. Cut another

side stringer in half. Bevel one end of both stringers

x 36"stepped balsa

to match the angles you cut on the stringers

already pinned to the plan.

the plan and glue them to the front stringers with

thin CA. Trim the ends

F11

by approximately

in

the following photo.

Pin the stringers to

so

they extend past former

1/8".

You can see the

splice

6.

Glue the firewall to the side stringers using

the die

-

cut

1/8"

hold the firewall at the correct angle.

plywood

firewall angle gauge

-37-

9.

Locate two of the

the outside of the tubes

them through the holes in formers

so

to

they extend forward of formerF6by Do not

glue the pushrod tubes in place until instructed to

so.

do

24

"

pushrod tubes. Sand

so

glue will stick. Slide

F6

through

F10

Page 2

-

..

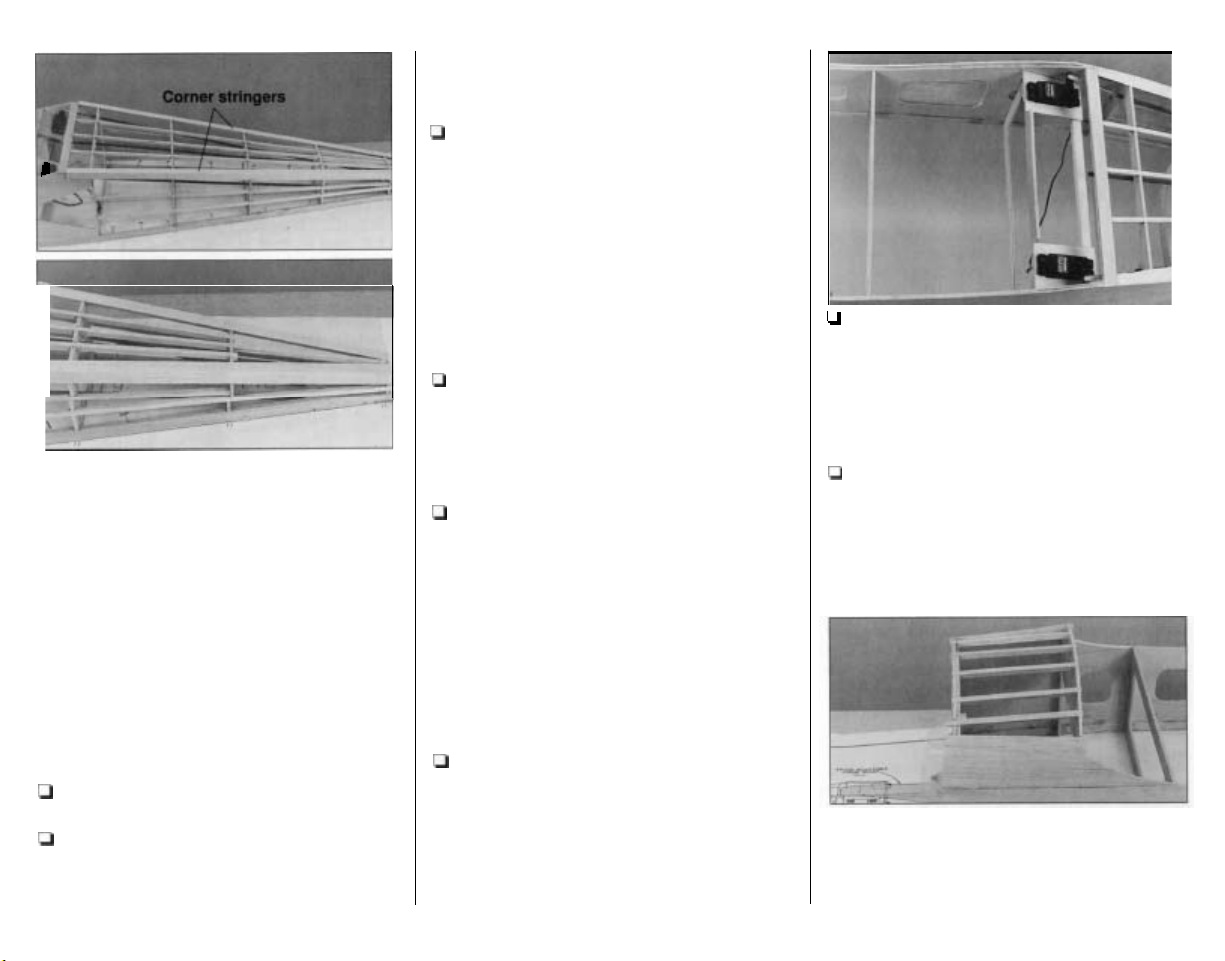

Refertothese photos for the next four steps.

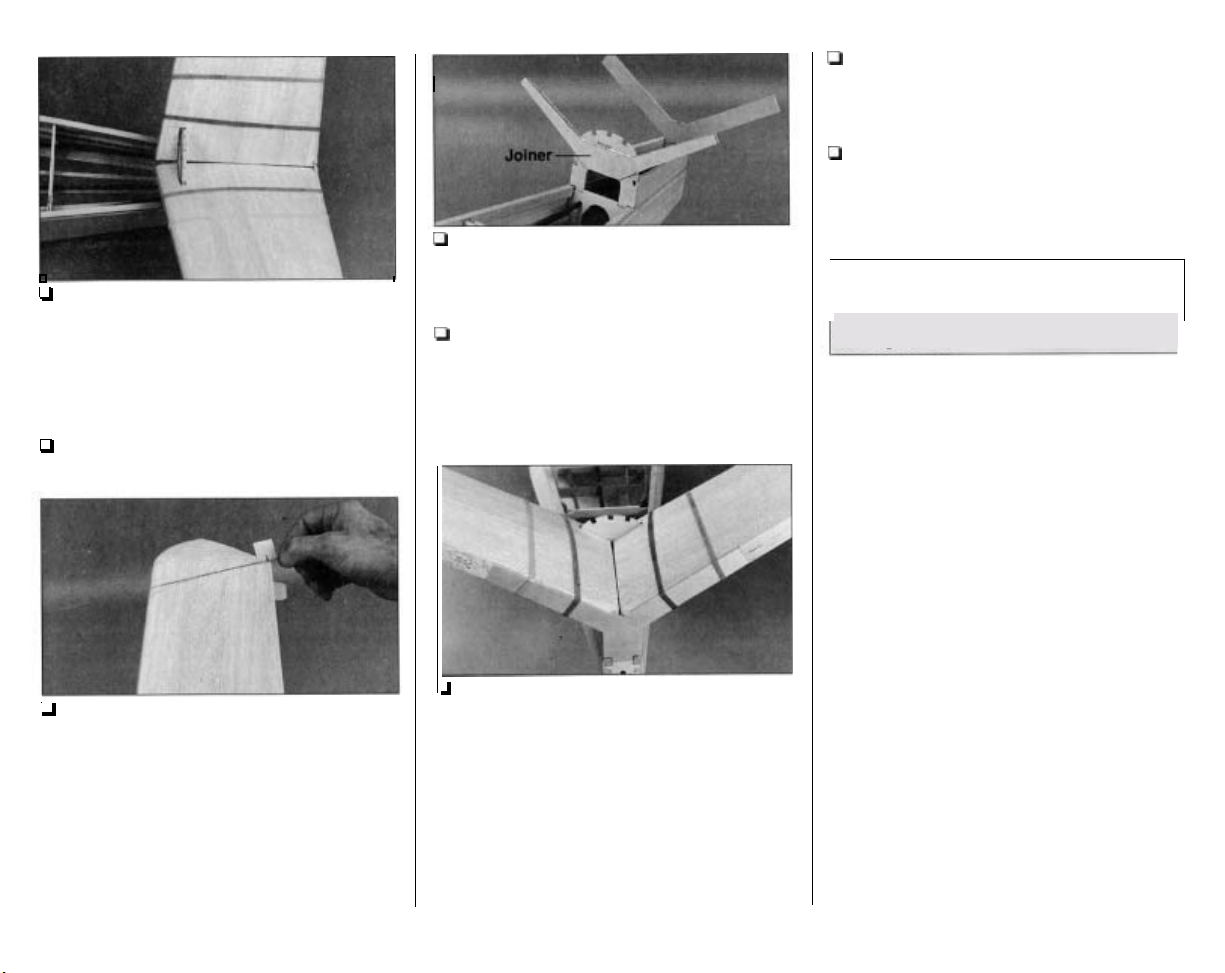

10. Glue the 3/16"x 1/2"x9-7/8" balsa bottom

fuse sheeting support

even with the fuse side doublers. Cut and fit, but

do not glue,

seven 3/16

notches of the formers as shown on the plan and in

the photo. Save the leftover pieces. The three

bottom stringers extend

You can see the stringers in the photo at step

page 38.

11. Glue the fronts of the three bottom stringers

to the sheeting support, then use your 90 degree

triangle

and glue the bottom stringers

12. Glue the 3/16"x 3/16"side stringers and

pushrod guide tubes

13. Cut the bottom

formers where shown on the plan from two 1/2"

36"balsa triangle sticks. Glue the corner stringers

in place.

Disregard the servos.

in position. Sand the ends

the aft bottom fuse stringers from

"

x 3/16

"x36"balsa sticks to fit in the

to

the sheeting support.

to

hold each former at the correct angle

to

to

the formers.

the formers.

corner stringers

to

fit on the

MOUNT THE SERVOS

1.

Optional:

out the back of the fuselage, cut a third 3/16

pushrod guide tube (not included)

"

. Roughen the outside of the tube with coarse

21

sandpaper

through the holes in the bottom of the formers until

the front extends past former F7 by approximately

1/2". Glue the tube to the formers (this tube is

visible in the photo at step

2. Test fit your servos in the

(or

ruddervator/elevator

they fit. Glue a servo tray

front

the

3. Cut an

36"basswood stick tofit between the fuse sides

approximately 1-7/8" aft of former F5 where shown

on the plan. It will be helpful if you cut the rail

length that will provide a

fuse side doublers

position without using glue. Position the aft servo

tray rail between the fuse sides.

5

4. Position your servos into the servo trays and

place the trays on the rail and former

Temporarily thread two nylon clevises just a few

turns onto two 36

Install the pushrods into the pushrod guide tubes

and connect the clevises

x

your servos.

For routing your receiver antenna

(so

glue will stick) and slide the tube

5).

aft servo trays

doubler

to

from a 1/4"x3/8"

friction fit

to

servo arms on

of both trays.

aft

servo tray rail

"

servo trays) to make sure

so

it will temporarily stay in

one-end threaded pushrods.

-

38

toalength of

the bottom of

"

outer

between the

to

F5.

5.

Position the rail and the servo trays sothe

servo arms align with the pushrods. Glue the rail

and servo trays

this position. Drill 1/16

mount the servos with the screws that came with

your radio.

to

former F5 and the fuse sides in

"

holes in the servo trays and

FINISH FRAMING THE FUSE

1. Refertothe photo in the following step and

test fit a die

on the right side of the fuse. The front edge of the

x

forward fuse doubler should align with the front

edge

surface of the doubler and glue it in place. Be sure

a

that former F2 remains square and flat.

2.

side of the fuselage. Use

leftover from the aft bottom stringers

forward bottom stringers

the firewall and

-

cut 1/8" balsa

of

the fuse side doubler. Wet the outer

Gluetheotherforwardfusedoublertotheleft

F2.

forward fuse doubler

3/16

"

x

3/16"balsa sticks

that fit in the notches of

Glue the stringers in place.

to

make the

1

Page 3

3.

Sand the stringers even with the formers.

Sand the fronts of the triangle corner stringers

so

they blend to the ply side doublers and the bottom

sheeting support.

"

STEP

"

....

....

.

4.

One at a time, remove the T-pins in the main

side stringers aft of former

angle from the outside

F6.

Replace them at an

so

they will not interfere with

the side sheeting.

late in

1950

military was evaluating the

at the age

as a trainer.

of

53.

During this time the

YT-34

prototypes for use

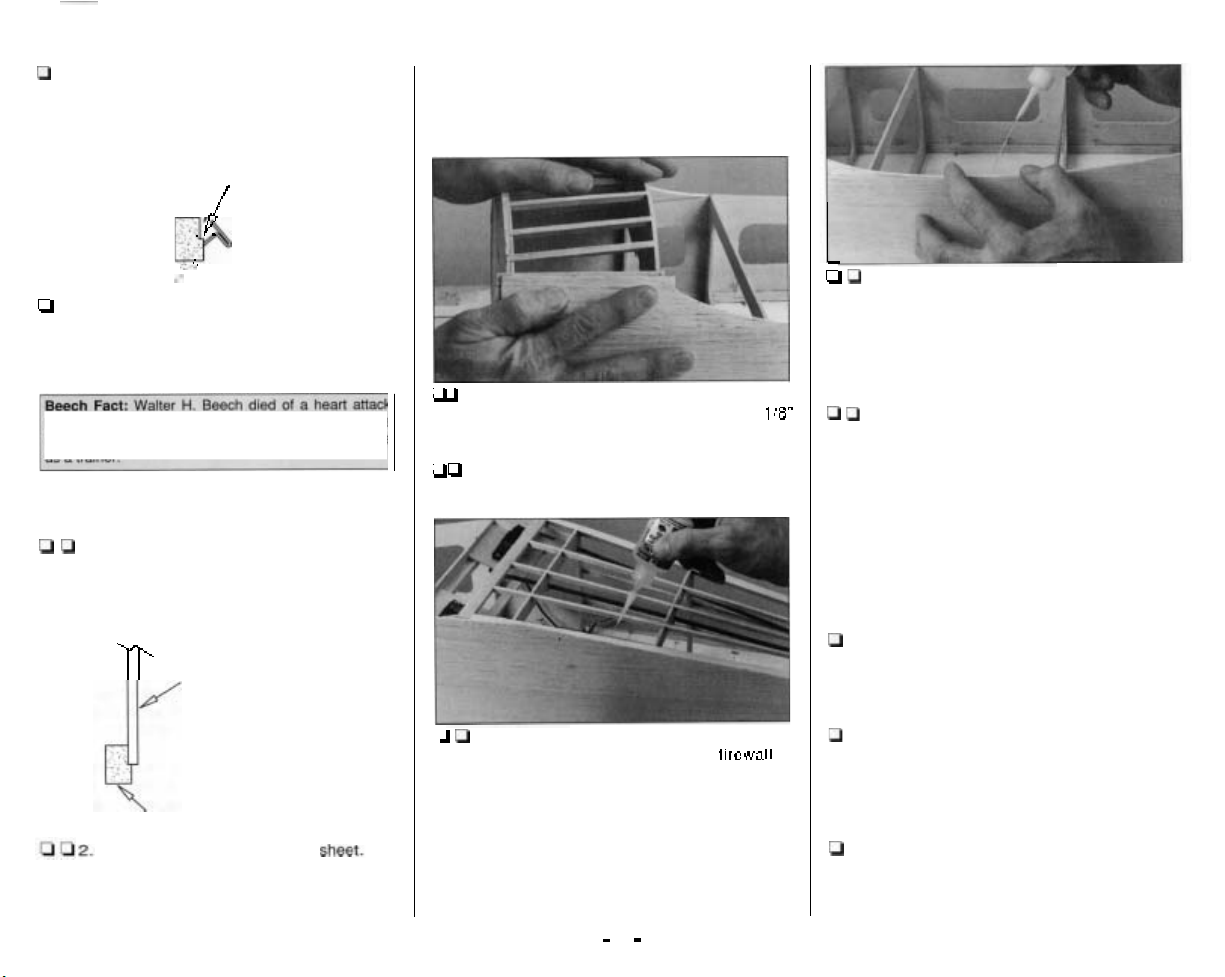

SHEET THE FUSELAGE SIDES

1.

Glue

two

3/32

"x3

"

x

48

"

together to make a

6"x

48"fuse

the glue is dry, sand the sheets

even and smooth.

3/32

"

SIDE

balsa sheets

side

sheet.

so

they are flat,

SHEET

After

Note:

The side sheet will not reach all the way

back to the end of the fuselage. We will instruct you

3/32

"

to add a piece of leftover

balsatothe

rear later.

3.

Reposition the side sheet on the fuse. Mark

and trim the front bottom of the side sheet

above the bottom of the balsa front fuse doubler.

4.

Test fit the side sheet and make any further

adjustments necessary for a good fit.

6.

A little section at a time, carefully pry the

fuse side from the fuse side doubler and apply thin

or medium CA between the two. Quickly press

them together.

thoroughly glued

7.

Glue the fuse side tothe side stringers with

Do

this until the fuse side is

to

the side doubler.

thin CA and hold them together until the CA cures.

You

can really see how the bottom half of the fuse

will remain straight, true and flat

(as

flat as your

building board) when you remove it from your

building board!

8.

Return to step 1and glue another side sheet

to

the left fuse side the same way.

'

MAIN

FUSE

STRINGER

True one edge of the fuse side Hold

the side sheet on the right fuse side and mark the

wing saddle and corner stringer on the sheet. Trim

3/16

"

the sheet about

outside of the lines.

5.

Apply a bead of medium CA to the

ledge

portion of the side stringer from the to

former

F6.

Working quickly, position the side sheet

onthe ledge oftheside stringer and press it into

position where you have applied the glue. After the

CA dries apply thin CA

sheet aft of former

CA applicator tip, such as the Pacer Z

to

the side stringer and side

F6

from inside the fuse. A long

-

Ends"with a

Teflon@ tube, helps you apply the CA just where

you need it.

39

9.

Add pieces of leftover

the side sheets

photo at step

10.

Remove the T-pins and lift the fuselage from

to

the end of the fuselage. See the

11.

3/32

"

balsatoextend

your building board. Reinforce glue joints you

couldn't reach earlier or those that don't

look strong.

Page 4

11. Trim, then sand the fuselage side sheeting

and stringers that extend aft of former F11

are flush.

so

they

2. True the edges of both tail cone halves with

coarse sandpaper and a bar sander. Thoroughly

sand the mating surfaces

Carefully glue the tail cone halves together with

thin CA. Use just a few drops at a time.

Note:

Do not use CA accelerator on any of the

ABS plastic. Accelerator may cause the plastic to

develop cracks over time and prevent some types

of paint from sticking.

so

glue will stick.

If

you are building the straight tail, Skip to

the Sfraight Tail Stab and Fin

on page

Mount

45.

MOUNT THE V-TAIL STAB

Note:

Build accurately during the next few steps.

The stab saddle and the aft formers align the stab

and set the incidence, which will greatly affect the

way your model flies.

GLUE THE TAIL CONE TOGETHER

1. Cut both formed ABS

the cutlines. The cutlines can be most easily seen

from the inside. We highly recommend a pair of

curved Kyosho Lexan Scissors because you can

cut straight lines or small tight curves easily and

accurately. You could also use a small pair of

regular scissors or score the plastic along the

cutlines with a hobby knife and flex the plastic until

the excess breaks free.

tail cone halves

along

3. Trim the clear plastic

of the tail cone. Do not glue the tail lens in place

until after you paint the tail cone.

4.

If you are installing a tail navigation light,

make an

leftover ABS plastic and glue it to the rear of the tail

cone. Drill a 5/32

for the tail light lens included with the lighting kit.

Test fit the tail light.

aft tail cone former

"

tail lens

er

hole in the rear of the tail cone

-

40

-

to fit on the end

from a piece of

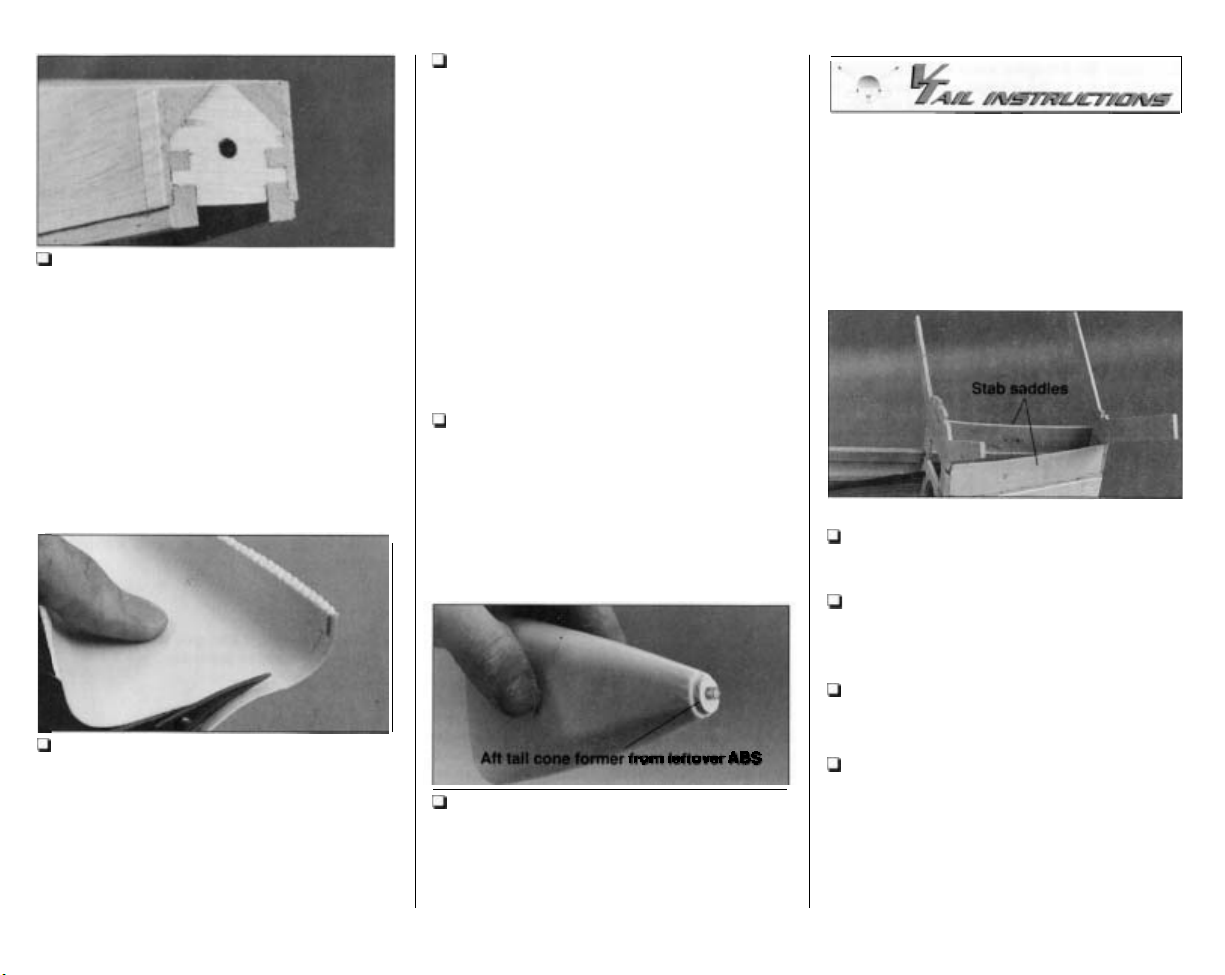

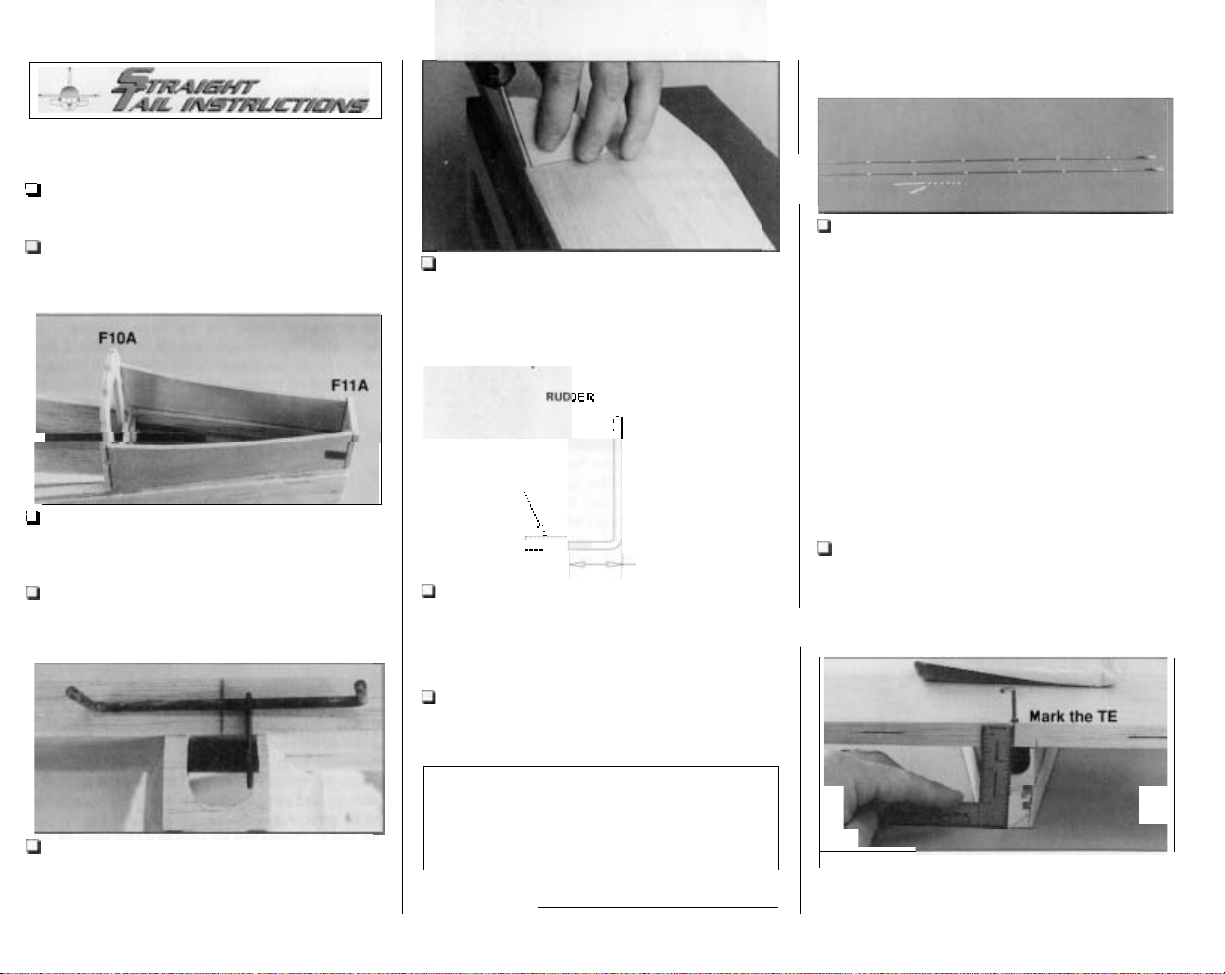

Refer to this photo for the following three steps.

V1. Glue the die-cut 1/8" plywood

former F11AV

sure F11AV

V2. Glue the die-cut 1/8" plywood

saddles

F11AV. The angle of the aft edge of the stab

saddle sets the angle of F11AV (which is 90').

V3. Glue the die-cut 1/8" plywood former

to the top of F10 and the front edge of the stab

saddles. F1OAV may be slightly aft of F10.

V4. Test fit the stab halves on the fuse by sliding

them onto the joiner portion of former FlOAV.

Bevel the ends of the stabs as necessary

all the way onto former F1OAV. Bevel the top, inner

edge of the stab saddles to match the angle of the

stabs but

The ends of former F11AV should contact the

inboard ends of the stab

to the aft bottom former F11. Make

accurately

to the top of the main side stringers and

do not change the incidence angle.

aligns with F11

aft upper

.

V-tail stab

FIOAV

so

they fit

Page 5

V5. Remove the stab halves. Temporarily

position the die

doubler

on the front of former FlOAV and test fit

the stab again. Make adjustments if necessary

-

cut 1/16"plywood

V-tail

LE

so

the stab aligns the same as it did in the previous

#64

step. Use

stabs to F11

V6. InsertaT-pin in the

rubber bands to temporarily hold the

AV.

center

of the top of the

firewall.

\

V8.

Glue the 1/16"plywood V-tailLEdoubler to

the front of former F1OAV with 30

-

minute epoxy.

Study the next three steps before you proceed.

Then work quickly and carefully.

V9. Mix enough 30-minute epoxy to thoroughly

joiners

coat both sides of the

on former F1OAV and

the insides of the stab halves where they contact

the

joiners.

Fiberglass to the epoxy

You may add some Great Planes Milled

to

thicken it and add

strength.

V11.Turn the fuselage over and inspect the glue

joints that hold the stab in place. If necessary, add

-

minute epoxy to joints that may not have

30

received enough.

V12. After the epoxy fully cures, sand the joiner

portion of flush with the top and bottom of

the stabs. Add balsa filler

so

it is smooth and matches the contour of the stab

if

needed. Sand the filler

sheeting.

Beech

Fact:

Magazine,

100

the

In the April, 1959 issue

the Beechcraft Bonanza was included in

best designs list.

The

only

other aircraft

of

Fortune

included in the list was another world famous airplane

the

Douglas DC-3.

V7.

Tie a loop on one endofa

string and connect it to the T

54

"

-

pin in the top of the

piece of

firewall. Put a piece of masking tape with an arrow

on it near the other end of the string. Slide the tape

along the string and align the arrow with the corner

of one of the stab halves. Swing the tape over to

other corner on the other stab half. Shift the stab

halves and slide the tape along the string until the

arrow aligns with the corners on both stab halves.

Once you have confirmed that the stabs will align,

remove them from the fuselage.

V10.

Coat both sides of the forward V-tail

LE

doublers, the front of the rear joiners, the tops of

the saddles, the insides of the stab halves where

they contact the joiners and the TE of the stabs

where they contact the joiners with epoxy. Slide the

stab halves into position and use rubber bands to

hold them in place. Use the pin and string to align

the stab halves and,

if

necessary, use T-pins or

masking tape to hold them in position. Apply a fillet

of epoxy where both stab halves meet. Wipe away

excess epoxy before it cures and do not disturb the

model until the epoxy is fully cured.

-41-

Page 6

BUILD THE TURTLE DECK

V1.

Glue formers

of their respective formers.

F7A, F8A

and

F9A

to the tops

V3.

Sand the stringers and formers sothat they

will blend.

V4.

balsa sheets-one sheet on the

of the turtle deck and one sheet on the

side of the turtle deck. Examine the four

x

aside to be used for the tops.

the skin for the bottom of the left turtle deck side

from one of the

the bottom. Use the bottom turtle deck sheet

pattern on the plan

approximate shape.

How to use the patterns to make the turtle

deck skins

Cut the pattern from the plan. Spray the back of

the pattern and one of the sheets with

Repositionable Spray Adhesive. Press the sheets

together and press the pattern onto one of the

sheets. Cut the skins along the lines with a sharp

#11

The turtle deck is sheeted with four

24

"

balsa sheets and set the

V5.

Follow the Hot Tip that follows and make

1/16

"

balsa sheets you selected for

blade.

bottom

two

to

cut the sheet tothe

softest sheets

1/16

of each side

fop

of each

1/16

x

3M

75

3

V7.

stringers, formers and stab.

Glue the bottom turtle deck sheet to the

"

"

V8.

bottom turtle deck sheet and the fuse side with a

leftover piece of

other side the same way.

side of the turtle deck with the top turtle deck

pattern on the plan and one of the soft

24

"

the turtle deck and trim where needed.

Fill in the small

1

/16"

V9.

Sheet the bottom of the turtle deck on the

V1O

.

Makeatopturtledecksheetfortheleft

balsa sheets you set aside. Test fit the sheet to

balsa.

wedge

between

1

/16"

the

x

3

"

x

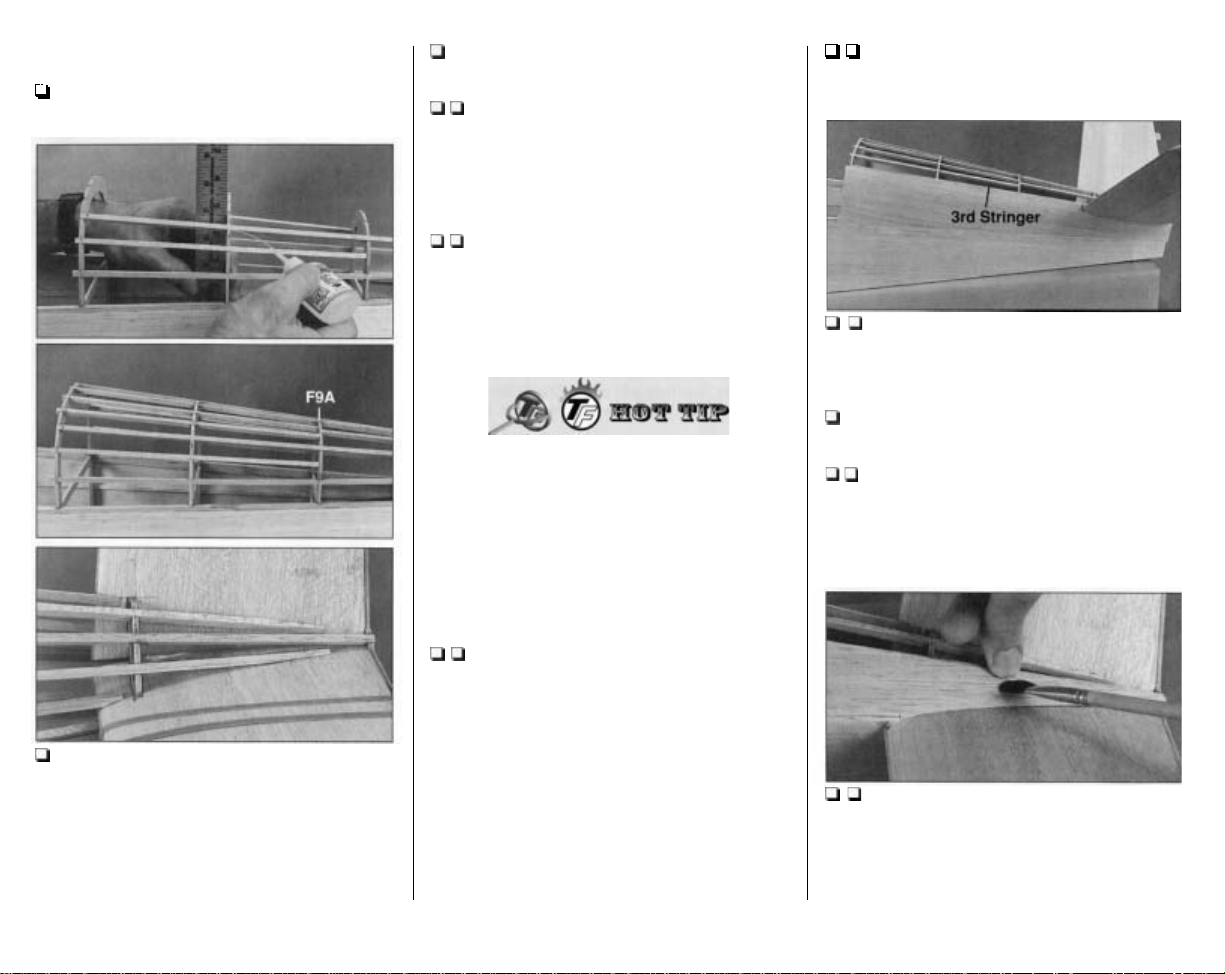

V2.

Cut the turtle deck stringers from six

3/16

"x3/16

"x36

"

of the stringers that contact the stab

sheeting. Glue the stringers into the notches of the

formers as shown on the fuselage plan and in the

photo. Note the arrangement of the stringers at

F9A. Important: Align the formers with a

straightedge as you glue them

balsa sticks. Trim the aft edge

so

to

the stringers.

they fit the

V6.

trim where needed. The top edge of the sheet

in the center of the third stringer. Ifnecessary, wet

the sheet with a

so

Hint: The best way to accurately cut the sheet

your model is with careful test fitting, close

observation, and removing only small amounts of

material at a time. When done this way, you will

be rewarded with a great looking model even

before

favorite part!

Test fit the bottom turtle deck sheet and

50/50

solutionofalcohol and water

it will bend easier.

you cover it. Then, sheeting will be your

-42-

ends

to

fit

V11

turtle deck. Use a paint brush

50/50

(especially from the leading edge of the stab to the

end of the sheet). Be patient, bend the sheet a little

at a time, and keep applying water and alcohol.

. Gluethe

mixture of alcohol and water tothe sheet

top

turtledecksheettothe

to

liberally apply a

Page 7

IMPORTANT NOTE:

sandasthey build

If

very end.

to

even the turtle deck sheeting with the fuse

sides, you may do

thin

ABS

fitted and must match the sheeting.

you prefertodo a little sanding now

the 1/16"turtle deck sheeting because the

tail cone

Some modelers prefer

instead of waiting until the

so

but

do not excessively

and ABS

cabin

have yettobe

to

V12. Sheet the other sideofthe turtle deck

the same way. Fill in the space between the two

turtle deck sheets on top near former F7A with a

leftover piece of 1/16 balsa.

V13. Apply hobby filler where needed. Use

masking tape

isn't needed.

soitis

sheeting at the front should be even with F7A

where it meets the

to

keep filler off the sheeting where it

Do

not build up a fillet.

V14. Trim, then sand the turtle deck sheeting

flush with former F7A and The

step

on the side stringer.

It's beginning to look like a Bonanza, isn't it !

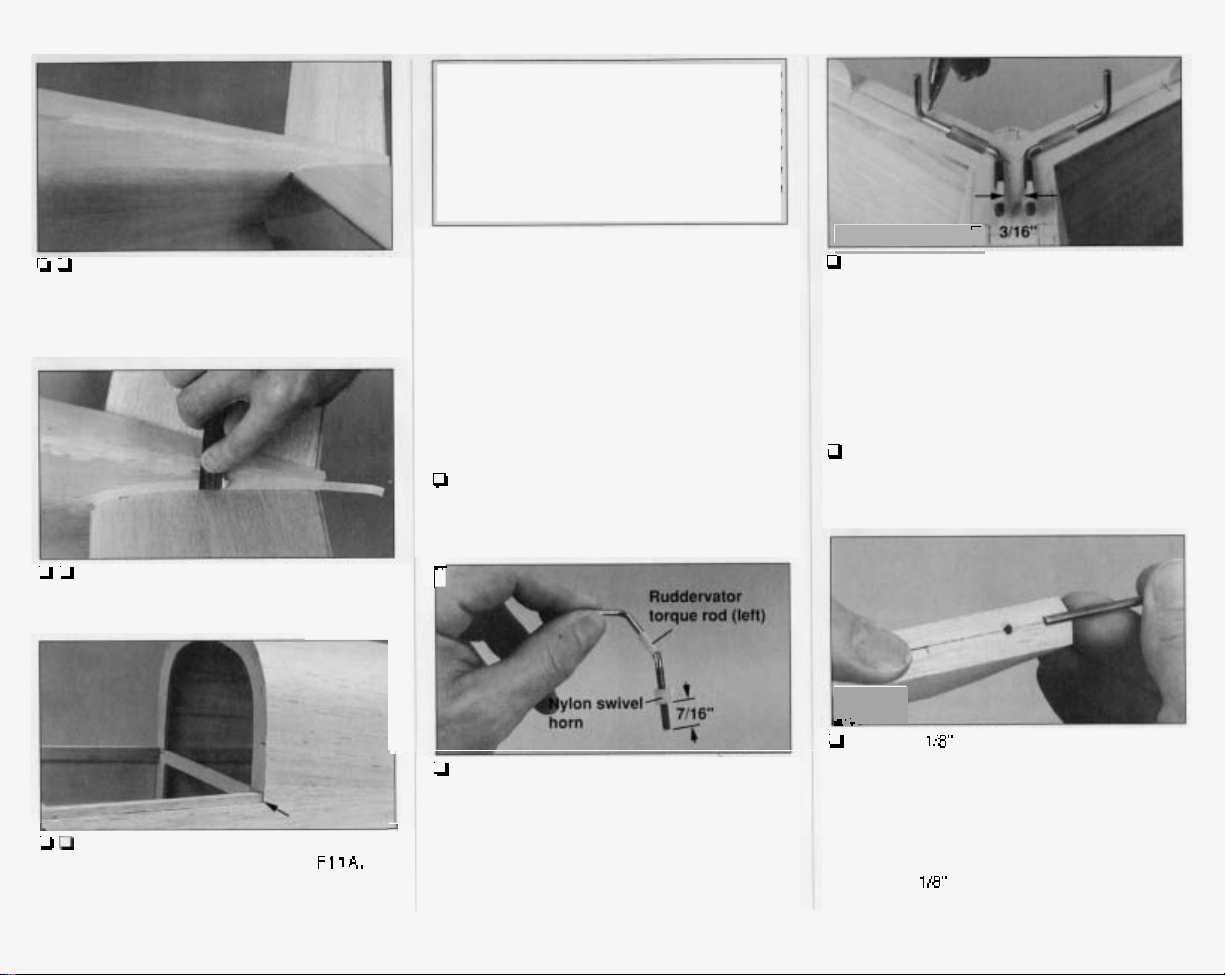

HOOKUPTHE RUDDERVATORS

V1.

Cut the remaining

of the stabilizers. Test fit the ruddervators

stab with the hinges.

V2. Tap threads into both nylon

-

with a 6

onto one of the

bottom of the swivel is 7/16

torque rod. Thread the other swivel horn onto the

other ruddervator torque rod the same amount.

Compare the

swivels are threaded on

32 tap. Thread one of the swivel horns

two

two

hinge

slots

on

the TE

to

swivel

horns

ruddervator torque rods

"

from the end of the

torque rods and make sure both

so

the same amount.

-43-

the

the

V3. Use a straightedge and aballpoint pen

extend

the centerlines on the stab TE until they

meet in the center of FIlA. Position the torque

rods on the centerlines

apart. Accurately mark the location of the

portion of the torque rods (that fit into the

ruddervators) on the TE of the stab.

V4.

ruddervators

the marks

Remove the torque rods and fit the

to

the stab with the hinges. Transfer

to

theLEof the ruddervators.

V5. Drill a hole in the

edge of the ruddervators at the marks you made.

Cut a groove in the

torque rods. Test fit the ruddervators

with the torque rods.

Hint:

Use a brass tube sharpened at one end

to

cut the grooves for the torque rods.

so

the swivels are 3/16

center

LE's

to

accommodate the

of the leading

to

to

arm

the stab

"

Page 8

V6.

Cut away former F1IAVsothe torque rods

can move back and forth. Reposition the

ruddervators with the torque rods and make sure

they do not interfere with former

look something like the photo when you're done.

V7.

Cut 7"frOm the non-threaded end of a

x

36

"

pushrod wire.

wire with a cloth dampened with alcohol or other

solvent. Cut six

inner pushrod tube, then slide the bushings evenly

spaced onto the wire. Make sure the bushings at

the ends of the wire will not protrude from the guide

tube or the control could become stuck during

If the bushings slide onto the wire easily, hold

flight.

them

in

place with a drop of thin CA. Make sure the

CA cures before you proceed

inadvertently glue the pushrods into the guide

tubes! Slide a silicone

and thread the clevis onto the wire about 15full

turns. Make a second pushrod the same way.

Clean residual oil from the

1/4"

long

retainer

F11

bushings

onto a nylon

AV.

It should

,074''

from the white

so

you do not

clevis

V8.

Install the pushrods in the guide tubes.

Temporarily connect the clevises to the torque rods

and fit the ruddervators to the stab. Place a servo

arm on your ruddervator servos.

1-1'4"

V9.

ruddervators neutral, use a felt tip pen to mark the

pushrods exactly

arms. Remove the pushrods from the fuselage. Cut

them at the marks you made.

wire pushrod. Reinsert the pushrods into the

fuselage and thread

Temporarily connect the pushrods to the servos and

ruddervators. Adjust the length

necessary by turning the clevises in or out.

(FllTC)

material as needed to clear the torque rods

and pushrods.

With the servos centered and the

1-1/4

from the holes in the servo

V10.

Silver solder a

FIT

V1.

Glue the die-cut balsa tail

on the end of the fuselage. Remove

threaded coupler

a

nylon clevis onto the couplers.

of

the pushrods

THE

TAIL

CONE

-44-

onto each

cone former

V2.

Glue the die-cut plywood tail

to

mounts

notches in the

torque rods. Fit the tail cone on the aft end of the

fuse and fasten it to the mounts with four

screws.

the tail cone former. Cut U-shaped

top

of the tail conetoclear the

Make

sure the screws donot interfere

with the ruddervator torque rods.

V3.

After you have fitted the tail cone, skip to

Sheet the

bottom

of the fuserage

on page

if

Beech

Fact:

confusing Bonanzas. This is because there were

versions built. The F33 produced in 1970 was the

short

long cabin (and is the subjectofour

Edition straight tail). The additional

cabin on the

formerly available

additional new

as six place seating and a larger cargo door, were

available. Price

The F33A, it turns out, is one of the most

cabin and the produced in 1971 was the

Top Flite Gold

33A

matched the baggage space

only

the

33A

on

was

-

found cabin space other options, such

of

19

the V-tail. With this

$41,600

cone

#2x3/8"

50.

two

inches of the

(back then).

Page 9

MOUNT THE STAB AND FIN

CENTER THE STAB

ST1. Glue the die-cut 118" balsa

F11A

former

to former F11

.

aft upper

ST2. Securely glue the die-cut 1/8" plywood

straight tail stab saddles

to

the top of the main

fuse side stringer and F11A.

ST3. Glue the die-c ut 118" plywood upper former

FlOA

to the top of former F10. Glue the front of the

stab saddles

ST4. Use a bar sander with 80

to

F 1OA.

-

grit sandpaper

to

sand the front of the stab sothe TE will align with

F11A.

ST6.

TE. Use the die

Mark the

rod drill guide

center

-

cut 1/8" plywood

of the stab 1 / 8 from the

rudder torque

to drill a 3/16"hole through the

center of the stab at the mark. Make sure you drill

from the

top

of the stab.

Hint:

A6"piece of 3/16

brass tube sharDened at one end cuts a clean hole.

TOROUE

ROD

CUT

OFF

...

. .

.

ST7. Cut the threaded end of the

rod

so

the threads extend 5/8" as in the sketch.

Tap threads in the ,nylon

5/8"

rudder torque

swivel horn

with a 6-32

tap. Thread it onto the rudder torque rod until it is

even with the end.

ST8. Insert the rudder torque rod through the

You'll

hole from the bottom of the stab.

have to

force it a little because of the bend in the wire.

ST1.

Cut

7

"

,074"

x36"

from the non-threaded end of a

pushrod wire.

Clean residual oil from

the wire with a cloth dampened with alcohol or

other solvent. Cut six 1/4" long

bushings

from the

white inner pushrod tube, then slide the bushings

evenly spaced onto the wire. Make sure the

bushings at the ends of the wire will not protrude

from the guide tube or the control could become

If

stuck during flight.

the bushings slide onto the

wire easily, hold them in place with a drop of thin

CA. Make sure the CA cures before you proceed

so

you do not inadvertently glue the pushrods into

the guide tubes! Slide a silicone

nylon

clevis

and thread the clevis onto the wire

retainer

onto a

about 15 full turns. Make a second pushrod the

same way.

ST2. Connect one of the pushrods tothe nylon

swivel horn on the rudder torque rod and slide the

pushrod into the rudder pushrod guide tube in the

fuselage. Position the stab on the stab saddle.

Place a weight on top of the stab to hold it in place.

ST5.

sanding drum

Use a hobby knife or a Multi-Pro with a

to

cut F11Atoclear the horn on the

elevator joiner wire and the rudder torque rod.

Beech

Quote:

"

The

Beechcraft Bonanza is a

masterpiece of engineering; it's an airplane that

of

constitutes a modern miracle

aeronautical design;

and in our opinion, marks a new milestone in the

progress

of

aviation.

"

-45-

-

WalterH.Beech

August

1,

1946

I

ST3.

former

saddles.

Align the TE of the stab with the center of

F1

1. Mark the TE of the stab above the stab

Page 10

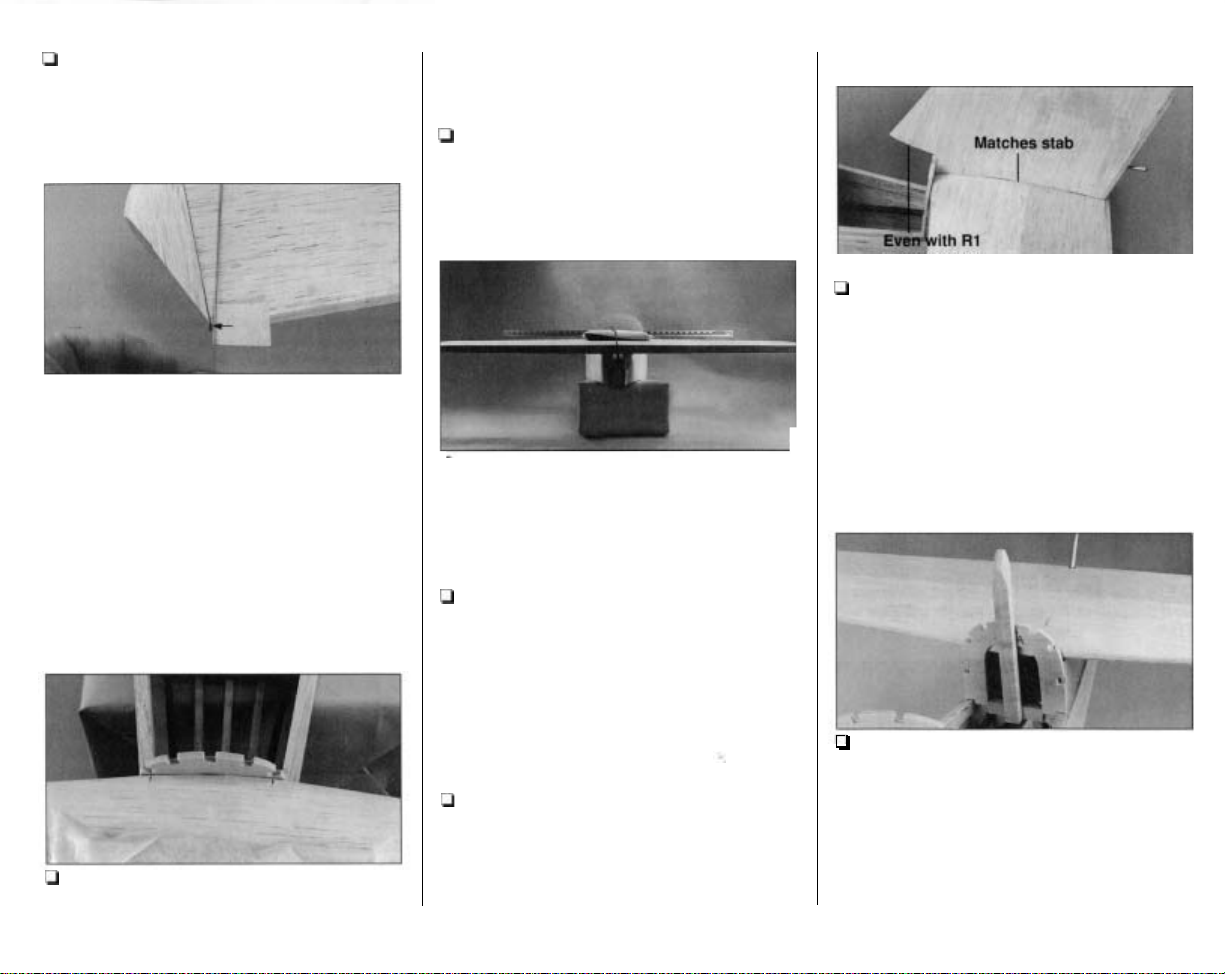

ST4. Insert a T-pin in the center of the top of the

firewall.

I

ST5. Tiealoop on one end of a54"

string and connect it

firewall. Put a piece of masking tape with an arrow

on it near the other end of the string. Slide the tape

along the string and align the arrow with the corner

of one of the stab halves. Swing the tape over

the other corner on the other side of the stab. Shift

the stab and slide the tape along the string until the

arrow aligns with both corners of the stab.

ST6. Mark the

former F1

OA.

to

the T-pin in the top of the

LE

of the stab where it aligns with

piece of

to

ALIGN THE STAB HORIZONTALLY

STl. Place two clothespins on the top offormer

F4 and rest a straightedge on the top

sides, propped up against the clothespins. See the

following photo.

I

ST2. Stand behind the fuselage and view the

stab and the straightedge

necessary, carefully sand one side of the stab

saddle

so

the stab will align with the straightedge.

ST3. Move the rudder pushrod wire back and

forth

to

interfere with the. fuse sides and the rudder torque

rod can move freely.

pushrod wire or the

saddle.

binding here.

the saddle. Place the stab on the saddle sothe

marks you made earlier align. Before the epoxy

cures, confirm alignment once more using the

and

epoxy has fully cured.

make sure the clevis and horn do

There must not be any possibility of

ST4.

Use 30-minute epoxy toglue the stab

string

technique.Donot proceed until the

to

seeifthey align.

If

necessary, adjust the

clearance

of

slot

in the stab

the fuse

not

pin

-46-

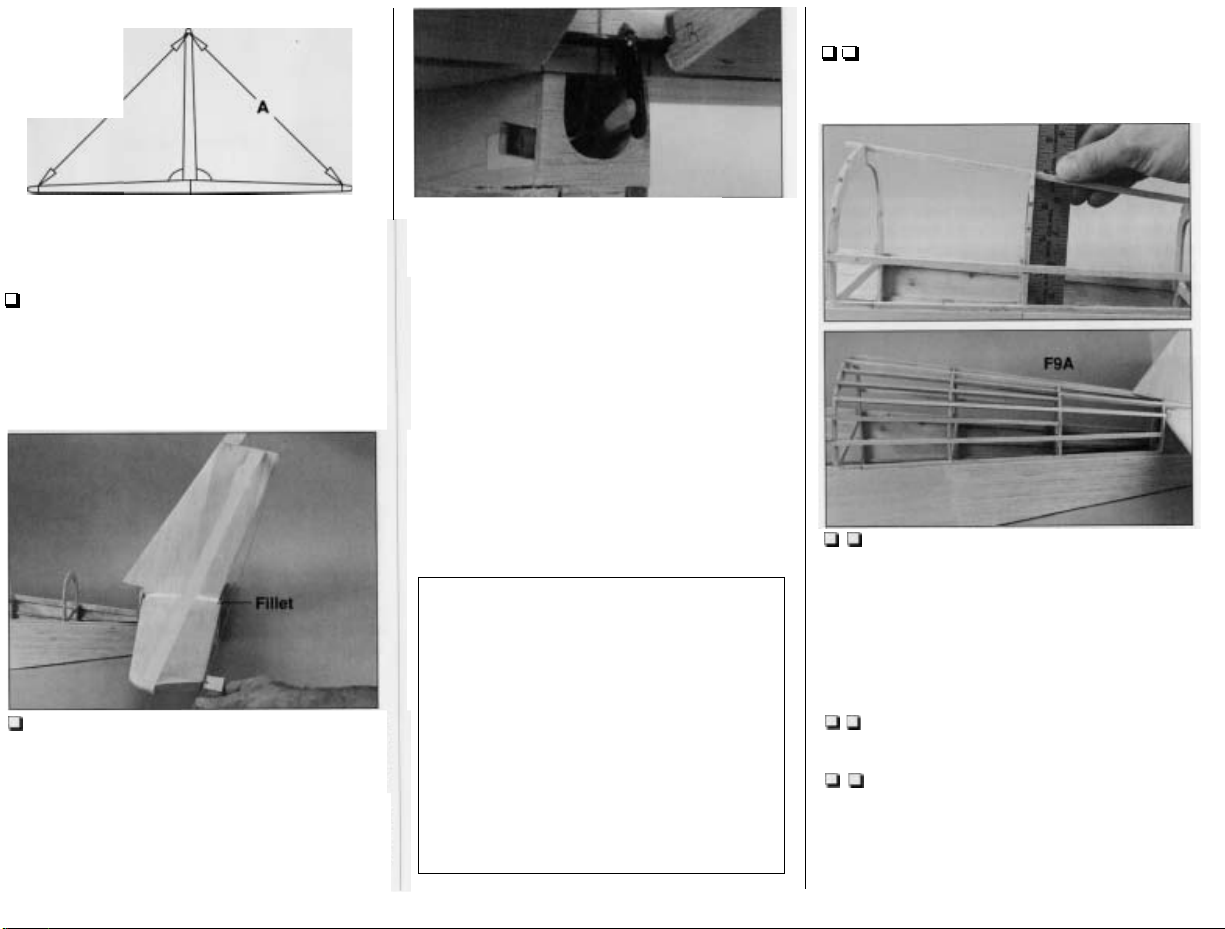

MOUNT THE FIN

STI. Trim the sheeting on the bottom of the fin

until it matches the top of the stab. Make sure you

trim both sides evenly

the fin sheeting in front of former F1OA

with fin rib R1 as shown in the photo. R1 of the fin

should rest on former F10 and the rear of the stab.

so

the fin sits vertical. Trim

1

If

ST2.

basswood fin post on the front of F1

up into the fin until it hits the

position and remove the fin. Mark the location of

to

the fin post. Apply 30

and FlOA. Clamp the fin post to FlOA aligned with

the marks you made.

vertical and is centered on former

post aligns the front of the fin with the fuselage.

With the fin on the stab, place the

LE.

Hold the fin post in

-

minute epoxy to the fin post

Be certain the fin post i s

so

OA

and slide it

FlOA.

it is even

The fin

Page 11

BUILD

THE

TURTLE

DECK

A=A

ST3. After the epoxy cures, position the fin on

the fin post and confirm that the fin remains

vertical. Make adjustments if necessary. Use the

pin and

distance between the tip of the fin and the stab tips.

the fin with 30

or microballoons

to

and fin sheeting to the stab with 30

Make sure the

former F11

the stab and the fin sheeting. Use masking tape

string

technique or a ruler tomeasure the

ST4. Glue the top of the fin post to the inside of

the bottom of the fin). Glue the base of the fin

-

minute epoxy and milled fiberglass

(so

all the epoxy won't run down

-

TE

of the fin is

minute epoxy.

centered

. Apply a small fillet of epoxy between

hold the fin until the epoxy is fully cured.

over

to

Test

fit

temporarily hook up the pushrods. Make sure you

can move the controls without any interference or

binding. Make adjustments if necessary.

engine Model 18was being produced for the military

in a variety of configurations. But as unpatriotic as it

may have seemed at the time,

to

postwar years. The twin would certainly continue

but the Model

mark

-

the biplane was on its way out. The trend was

continuing toward all metal, light planes (started by

Luscombe as early as

workona

overtime basis. After much careful study

to

find

out

of

design, wind tunnel and static testing,onDecember

22,

1945, the first Bonanza was on its maiden voyage

by

test pilot Vern Carstens.

ilown

the rudder and eleva

one

hadtothink ahead

17

Staggerwing was a question

1934).

At

new

model wastobe done on a voluntary,

what typeofplanetobuild, and after hours

Beechcraft, design

itor and

The

of

the market

twin

-47-

ST1. Glue formers

of

their respective formers.

tops

ST2.

Cut

the

seven 3/16

stringers into the notches of the formers as shown

on the fuselage plan and in the photo. Note the

arrangement of the stringers at F9A.

Important:

you glue the stringers

blend together.

1/16

each side of the turtle deck and one sheet on the

top of each side of the turtle deck. Examine the

four 1/16

softest sheets aside

"x3/16

Align the formers with a straightedge as

ST3. Sand the stringers and formers sothey

ST4. The turtle deck is sheeted with four

"

balsa sheets-one sheet on the bottom of

"

x3x24balsa sheets and set the two

F7A, F8A

turtle deck stringers

"x30"balsa sticks. Glue the

to

them.

to

be used for the top.

and

F9A

to

the

from

Page 12

ST5.

to a length of 21-1/2". Position the sheet

side of the turtle deck

bottom of the stab and is parallel

stringer from the bottom as shown in the photo.

Cut one of the bottom turtle deck sheets

so

the top edge contacts the

on

the left

to

the third

ST7. Reposition the sheet. Mark and cut it

along the line.

matches the bottom of the stab.

ST8.

deck side sheet and the fuse side with

piece of 1/16

Do

this until the sheet accurately

Fill in the small

"

balsa. See the following photo.

wedge

between the turtle

stab

a

leftover

STI

and the stab with a leftover piece of 1/16"balsa.

same way. Add the

the stab.

1. Fill most of the space between the fin

ST12. Sheet the right side of the turtle deck the

partial fillet

between the fin and

ST6. Use a ballpoint pen tomark the bottom

of

the stab onto the sheet. Remove the sheet and

cut along the line you marked.

ST9. Trim the top of the sheet so it

the center of the third stringer. Trim the bottom of

the sheet

Glue the sheet in position.

I

sheet

and the top,

sheet

Glue the sheet in position. Make

1/16 leftover piece of balsa to fit between the

turtle deck sheets in the front.

so

it matches the topofthe fuse side.

ST10.

Trim another 1/16

to fit between the bottom turtle deck sheet

center

stringer. Trim the aft end of the

"x3

so it fits the fin and ends at former FlOA.

a

-48-

"

x

24

wedge

ends

"

balsa

from a

two

in

ST13. Trim, then sand the turtle deck sheeting

so

it is flush with former F7A and

sheeting at the front should be even with F7A

where it meets the

ledge

on the side stringer.

IMPORTANT NOTE: Some modelers prefer to

sand as

very end.

to

sides, you may do

1/16 turtle deck sheeting because the ABS

cone

must match the sheeting.

they

build

insteadofwaiting until the

If you prefer to do a little sanding now

even the turtle deck sheeting with the fuse

and ABS

so

but

do

not over-thin

cabin

have yet to be fitted and

A. The

the

tail

Page 13

HOOK

UP

THE

RUDDER AND

ELEVATO

Note: As on the full size Beechcraft, the elevators

and rudder can touch,

set

so

that this does not happen during flight.

R

but

the rudder throw

will

be

BUILD

ST1. Use the pattern on the plantomake the

dorsal fin base from leftover 1/16

dorsal fin base

sure the front of the base is centered on the fuse

centerline.

THE

DORSAL FIN

"

to

the top of the turtle deck. Make

balsa. Glue the

ST1. Install the pushrods in the guide tubes.

Temporarily connect the clevises to the rudder

control horn

place.

ST2. Place a servo arm on your rudder and

elevator servos. With the servos centered and the

rudder and elevators neutral, use a felt

mark the pushrods exactly 1

the servo arms. Remove the pushrods from the

fuselage. Cut them at the marks you made.

ST3. Silver solder a threaded coupler onto

each wire pushrod. Reinsert the pushrods into the

fuselage and thread a nylon clevis onto the

couplers. Temporarily connect the pushrods

servos and rudder and elevator. Adjust the length

of the pushrods

in or out.

and

fit the rudder and elevator

-

-1/4"

if

necessary by turning the clevises

tip pen to

from the holes in

in

to

the

1/16

"

...

ST2.

Cut the 15" tapered balsa dorsal tin

the shape shown on the plan. Glue the dorsal fin

LE

to the fin LE and the dorsal fin brace.

ST3.

Make

two

1/16

"

balsa sheeting and pattern on the plan. Test

fit and glue one of the sheets

dorsal fin base. Wet the sheet and glue it

dorsal

fin

LE.

LE

off

fin

Glue the other dorsal fin sheet in position.

to one side when you glue the sheet to it.

dorsal fin sheets from leftover

Make sure you do not pull the dorsal

-49-

1/2"

to

the turtle deck and

to

LE

the

ST4.

the dorsal fin and fin.

to

Glue the

ST5.

fin filler to blend them

front of the dorsal fin to complete the taper and

each layer to fully dry before you apply the next.

Apply Hobbylite filler to the dorsal fin and

blend it to the turtle deck.

in one application but build up thin layers, allowing

1/16

"

die-cut plywood fin filler

to

the fin. Apply fillertothe

Do

not apply all the filler

,

ST6. Sand the fillet, blending the dorsal fin, fin

filler and fin into one smooth contour.

to

Page 14

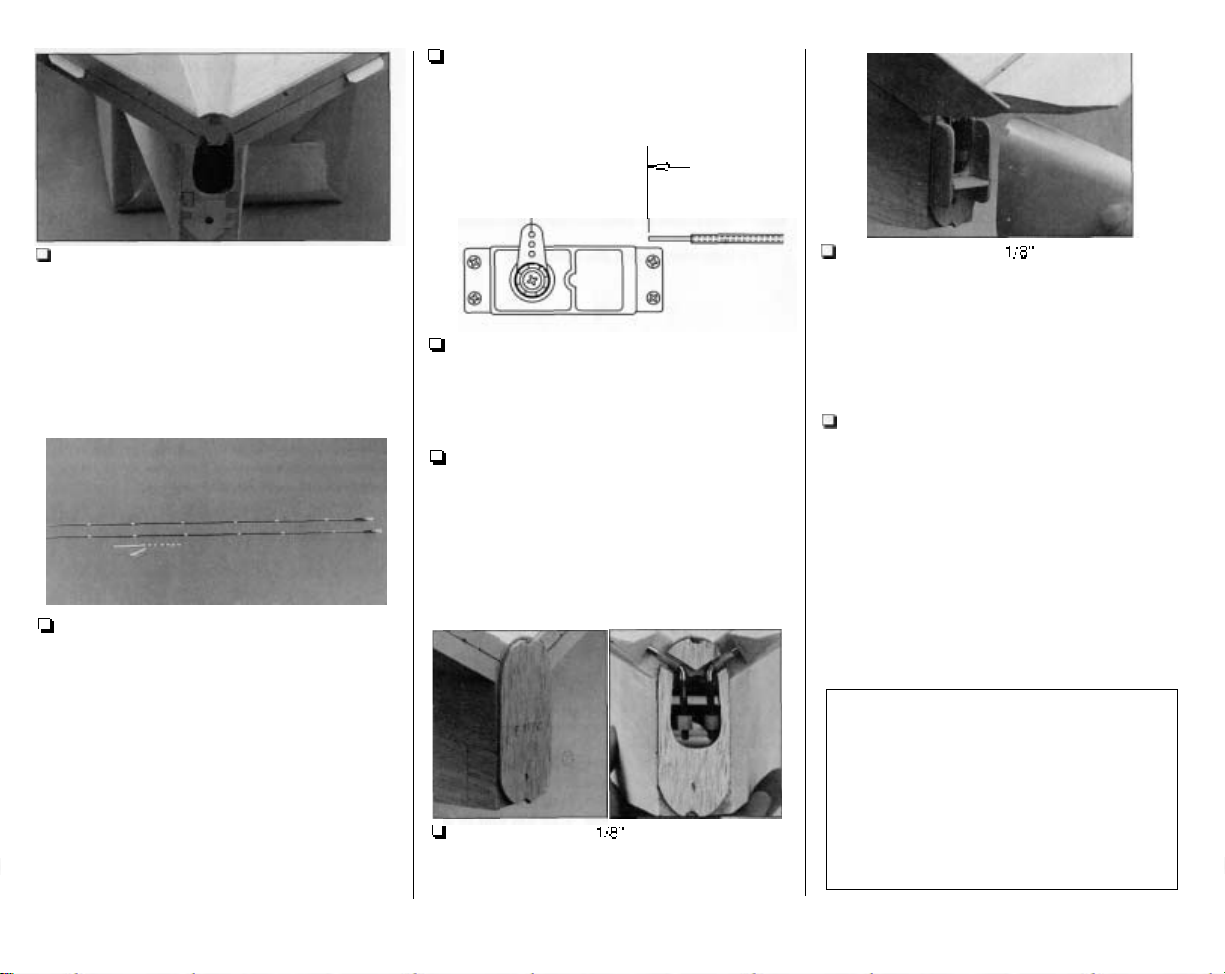

FIT THE TAIL CONE

SHEET THE BOTTOMOFTHE

FUSELAGE

1.Ifyou are going tohook up working lights,

now is a convenient time to route the wire for the

light in the tail. Route the wire through the formers.

Glue the wire to the formers with rubber cement or

a drop of CA

enough wire to extend past former F11

extend about 2

so

they don't rattle around. Allow

so

"

past the back of the tail cone.

it will

MOUNT THE ENGINE

ST1. Glue the die-cut 1/8" balsa tail cone

former (F11TC) on the end of the fuselage.

Remove material as needed to clear the torque

rods and pushrods. There must be

of

binding

ST2. Refer to the photo at stepV2on page

shows the V

Glue the die

the tail cone former. Cut round notches in the tail

cone to clear the joiner wire. Fit the tail cone on the

aft end of the fuse and fasten it to the mounts with

four

not

Mount the tail cone to the fuselage.

tail cone and the TE of the rudder with leftover

balsa. Use lightweight hobby filler to blend the fin to

the stab and the tail cone to the fin.

here.

-

tail but the straight tail is the same.

-

cut

1/8"

plywood tail cone mounts to

#2

x

3/8" screws. Make sure the screws

interfere with the elevator torque

ST3. Remove the elevators and joiner wire.

ST4.

Fill

the small space between the top of the

no

possibility

rod.

44.

do

2. Cut a

of 28. True both edges of the sheet with a hobby

knife and a straightedge. Pin the sheet to the

bottom of the fuselage in the 'center

butts against the front edge of the tail cone.

It

3. True both edges ofanother 3/32"x 3

balsa sheet. Position the sheet on the bottom of the

fuselage next to the center sheet. Use a ballpoint

pen

Cut the sheet along the line you drew.

with the remainder of the sheet on the other side of

the fuselage.

4.

the glue dries, sand the fuselage bottom sheet

is flat and the edges are even. Sand the bottom at

the formers and stringers

flat. Glue the fuselage bottom sheet to the bottom

of the fuselage.

5. Shape the bottom

shown in the cross sections on the plan

blend with the tail cone at the rear.

3/32

"

x 3

"x30"balsa sheet to a length

to

mark the side of the fuselage onto the sheet.

Glue the three bottom sheets together. After

so

that they are even and

corners

of the fuselage as

-50-

so

the end

Do

the same

"x30

so

so

they

1.

Glue the die-cut 1/8"plywood servo tray

doublers to the bottom of both die

plywood forward servo trays. Mount your throttle

servo to one tray and your nose wheel steering

servo to the other tray.

2.

Cut a 8-3/4"

x

36"basswood stick to fit between the

3/8"

fuselage sides behind former F2. Test fit, then glue

the servo rail to the fuse sides and former F2 1-7/8"

below the top edge

"

3. Cut a 8-13/16

the fuselage side doublers

servo rail. Place the throttle and nose wheel

it

steering servo and tray between the rails. Adjust

the position of the aft rail to fit your servos. Glue

the aft servo rail in place. Do not glue the servo

trays in place until instructed to do

4.

Glue the FlT/FlDT assembly to the top of the

firewall. Use a straightedge to make sure

they align.

forward

servo

rail from a

of

F2.

"

aft

servo rail tofit between

7/8

"

aft of the forward

so.

-

cut 118

1/4"

"

x

Page 15

5.

Glue the die-cut 1/8" plywood

doubler

to the back of the firewall, centered on the

firewall

engine mount punch marks, 1/8" below the notch in

the center of F1DT as shown on the plan.

FIXED LANDING GEAR RETRACT LANDING GEAR

(VIEWED

FROM THE FRONT)

7/32

"

IVIEWED FROM THE FRONT)

7/32

"

6. Drill the correct size holes through the punch

marks on the front of the firewall as shown in the

sketches above. Tightly hold a

on the back

so

the drill does not split the wood

thick

block of wood

when it comes through.

7.

Press four 8-32 blind nuts into the holes on

the back of the firewall. Use an 8

-

32x1-1/2"

socket head cap screw with some large washers to

draw

the blind nuts into the wood. Wick thin CA

around the back of the blind nuts to permanently

hold them in place.

8.

Temporarily clamp the die-cut

tank

floor

to the forward servo rail so it is centered

1/8"

plywood

on the back of the firewall doubler. Turn the

fuselage over and push the tank floor up until it

contacts the edge of the bottom blind nuts. Glue a

"x3/16

3/16

firewall under the tank floor to serve as a

tank floor

"x3"balsa stick to the back of the

forward

ledge.Donot glue the tank floor to the

ledge until instructed to do so.

9.Ifyou have not already done

fuselage side doublers and fuselage sides

so,

sand the

so

they

are flush with the front of the firewall.

10. Cut the

halves and trim off any

spacer bar

off both

engine mount

flashingsothey easily fit

together. Loosely bolt your engine mount to the

x

firewall with four 8/32

screws,

#8

lock washers and flat washers. Adjust

1-1/4" socket head cap

the mount so your engine will fit. Tighten the

screws to securely hold the mount to the firewall.

Use small clamps

to

hold your engine to the mount

so the front of the drive washer (or the back plate

-

of your spinner) is 6

1/4 from the firewall. Mount a

flat wood stick or the back plate of your spinner to

the engine so you can measure the distance.

Beech Fact: Inaddition to the aforementioned

benefits the V

manufacturing costs through fewer parts, fewer parts

for

Beech dealers to stock, reduced damage from

debris thrown from the prop and wheels, and spin

recovery superior to that of an airplane with a

conventional tail.

-

tail offers, others include lower

-

51

-

11. Mark the engine mounting bolt holes on the

Hint:

mount.

Mark the holes with a wire rod

sharpened at one end. Heat the tip of the rod with a

center

torch to dimple the engine mount in the

of

the holes.

12. Remove the engine from the mount and the

if

mount from the firewall. Use a drill press,

you

have access to one, or use a hand drill to drill the

holes with a #29 or 9/64 drill bit for 8

Tap 8

-

32 threads into the mount. Screw the mount

-

32 screws.

back onto the firewall. Screw the engine to the

-

mount with 8

32x1"screws to see how it fits.

Page 16

MOUNT THE NOSE LANDING GEAR

Continue with these instructions ifyou are

If

installing fixed landing gear.

installing retracts, skip to

53.

page

Fixed

gear

I

F1.

Draw a line connecting the punch marks on

both die

braces.

die

plan. Mark the location of the

gear rails onto the braces.

-

cut

1/8"

Cut the braces off at the line. Glue the two

-

cut

1

/8"

F2.

Place the braces over their locationonthe

F3. Remove the engine mount from the firewall.

plywood nose

plywood

Retractable

nose gear plates

1/4"

you are

gear

on

landing gear

together.

plywood landing

F4.

Cut a bevel on the end of the

9

"

plywood

on the end

right side of the firewall and in the notch in former

F2. Position the right brace and align the front of

the rail with the front of the brace. Mark the rail

aftofformer F2.

the mark. Mark the other rail in the same manner.

F5.

the rails to the firewall and former

braces

front of the rails are even with the front of

the braces.

F6.

nose gear plate. Press four

holes in the plate, and secure them with thin CA.

landing gear

of

the braces. Test fit a rail through the

Use 30-minute epoxy to simultaneously glue

to

the rails and the firewall. Make sure the

Drill

1/8"

holes through the punch marks in the

rails

Remove the rail and cut it at

4-40

1/4"x9/16

to match the angle

1/8"

F2,

and the rail

blind nuts into the

-52-

F7.

"

x

Position the nose gear plate on the front of

the braces. Trim the rails

interfere. Use 30

gear plate to the rails and rail braces. Hold the

plate in position with masking tape until the epoxy

is fully cured. Add balsa triangle

on the plan cut from leftover fuse corner stringers.

See the photo at step

F8. Mount the nylon

nose plate with four

the holes in the nose gear bearing for the nose

gear strut with a

numbered drill set, an

F9. Enlarge the outer hole in the black, nylon

steering arm

Mount the heavy duty

the steering arm with the

Mount the 3/16

bearing with a

and the steering arm and a 6-32

cap screws as shown on the plan. Notice that the

steering arm is slightly off center when the nose

gear is centered.

FIO. Temporarily fit your nose steering servo

and tray on the forward servo rails. Fit a servo arm

to

your servo.

-

#10

with a

nose gear wire

3/16

so

minute epoxytoglue the nose

the blind nuts do not

braces

11.

nose gear bearing

4-40

x

1/2"

screws. Enlarge

drill bit

(if

11/64

#

41

you don't have a

"

drill bit will work too).

drill bit or a hobby knife.

Screw-Lock connector

one-way star washer.

"

wheel collar

to the nose gear

x

1/4"

as shown

and

set screw

socket head

to the

to

Page 17

Beech Fact:

been manufactured and over

cousins have been manufactured.

percentage are still flying today. Experts

factors contributing to the Bonanza's success

including Walter Beeches' reputation,

built to last forever

Class-A

production^

Nearly

10,000

V-tail Bonanzas have

1,800

of

its

straight tailed

A

very

tooling ordered before the Bonanza

design and appearance, new

and its all-around performance.

the

large

cite

many

Bonanza's

went

into

MARK

1/8"

SPACER

NOSE GEAR RAIL

F11.

Thread a 4-40

metal

clevis

pushrod.

the other end of the pushrod to the Screw

connector in the steering arm. Cut the pushrod

about 1/4" past the connector. Make a slight bend

in the pushrod near the Screw

aligns with the hole in the connector. Temporarily

secure the pushrod to the connector with a

set screw.

F12. Securely glue the nose steering servo tray

to

the servo rails. Make sure your servo is

centered, and tighten up the 4

clevis with a drop of thread lock for extra security.

small

File

securely hold the set screws.

That was easy wasn't it? Now hook up the throttle.

It's just

55.

page

onto a

Connect the clevis to the servo. Connect

flat spots in the nose gear strut to

as

easy! Skip to

hex nu

.095

followed by a 4-40

x

12

"

nose steering

-

Lock connector soit

-

40 jam nut on the

Hook

Up

The

-

Lock

Throttle

on

Retractable nose gear

Note:

While there are other retractable nose gear

units that may work in the Top Flite Gold Edition

Beechcraft, the Robart 631isshowninthis manual

because it rotates 105

forthismodel.

mounting position would have to be raised and the

rails would have to be slanted upward toward the

frontofthe model in ordertoachieve the scale

appearance of the full size Beechcraft. These

modifications are up

RI.Ifyou're using the Robart 631 nose gear

retract, mark a line 7-7/8" from one end of both 1/4"

x

9/16"x

9

"

position the pivot point of the 631 nose gear 7-7/8"

from the aft edge of F2.

plywood

andisdesigned specifically

A 90 unit would work but the

to

you.

landing gear rails.

-

53

-

This will

R2. Glue one 114x9/16x2-1/ 4 plywood

and one 1/8"x9/16

spacer

on the end of both rails that you made the

spacer

mark on, but on the other side of the rail.

"x2-1/4" plywood

Bottom

\

R3. Temporarily place the landing gear rails

R4. Use 30-minute epoxy to glue the rails to the

firewall and former F2 and the die

landing gear braces

to the rails and the firewall.

-

cut 1/8" plywood

rail

rail

Page 18

R5.

Use small clamps to hold the nose gear to

the rails

aligns with the marks you made on the top of the

rails. Mark the locations of the mounting holes on

the landing gear rails.

holes at the marks you made. Temporarily mount

your landing gear with

nuts (not included).

interfere with the wheel and strut. Use a Dremel

Tool or a razor saw

accommodate the strut. Retract the nose gear and

make sure it does not interferewith the firewall.

Note:

so

nose wheel is centered on the strut. On the Robart

631

wheel and the strut to center the wheel. The nose

wheel

between the rails when retracted.

so

the pivot point (on the Robart

R6.

Remove the landing gear and drill

6-32

x 3/4

screws and blind

R7.

Remove the two

Adjust the

the nose wheel is neutral and make sure the

strut we inserted two#8washers between the

centering spring

mustbeneutral

3/16"stringers that

to

cut the firewall to

on your retracts

and

centered

631's)

5/32

to fit

Hint:

File or sand a slight bevel to the bottom

edges of the rails to guide the nose wheel, in case

"

R8. If

disconnects handy, temporarily connect them to

your nose gear air cylinder and actuate the nose

gear with the air pump. This will give you a good

indication of any problem areas that you can

you have your air pump and some quick

correct now.

U

R9.

Cut

plywood

nose steering servo to the servo tray

shaft is on the

on the plan. See the photo at step

the servo is

u

valve in the same location as in our prototype, drill

a

1/2"

steering servo tray mount

3/16"off the aft edge of the die-cut

nose steering servo tray.

left

side of the servo tray as shown

offset

toward the aft edge of the servo

R10.

If

you would like to mount your air control

hole in the die-cut

118"

plywood

at the punch mark.

so

R11.

-54-

1/8"

Mount your

the output

Note that

right nose

R11.

Test fit the servo tray (with the servo) in the

die

-

cut

1/8"

assembly in the servo rails. Position the mounts

and the tray

centered between the

the servo tray and the mounts in this position.

R12.

steering cable inner pushrod guide tube and slide

the pieces through the holes in the firewall and

former

plywood

Cut

F2.

Glue the tubes to the firewall and

servo tray mounts

so

the output shaft of the servo is

1/8"

holes in former

two

4-5/8"

pieces from the white nose

and fit the

F2.

Glue

F2.

CONNECT THE NOSE

STEERING

Several pull-pull steering cable systems are

available that will work in your Bonanza. We

selected the Sonictronics

System.

R1.

Enlarge the hole in two Screw-Lock pushrod

connectors with a

-

lock connectors to a large servo arm and

screw

fasten each with a nylon retainer. Connect one end

of

a14"

included with the pull

long pull-pull cable to a threaded rod

PULL-PULL

#121

Pro-Control

#46or5/64"drill bit. Mount the

-

pull steering set using the

Cable

Page 19

swage

to secure the cable. Fit the threaded rod into

one of the Screw

lock it down with a

Connect another piece of cable to the other

Screw

-

Lock connector the same way, then thread

the cable through the guide tubes toward the nose

gear strut.

R2.

Install a 0-80 threaded ball link ball (not

included) onto the arm on both sides of the nose

wheel strut with a 0

of both cables to the threaded ball links with the

swages. Tighten the loop in the cable just enough

so

it

will not come

Temporarily hook up the steering servo to your

radio system and test the movement. Adjust the

tension on the cables or make other adjustments

needed.

Note:

If your nose gear steering arms did not come

bent

90"

-

Lock connectors and temporarily

4-40

x

118" socket head screw.

-

80 nut. Connect the other end

off

the ball. Crimp the swages.

as shown, dosonow.

FINISH CONSTRUCTION

HOOKUPTHE THROTTLE

1. Mount your engine mount and engine to the

firewall. Mount your muffler

throttle pushrod will not interfere.

to make sure your

iteeringservo

This is the throttle servo location for fixed gear,

if

This is the throttle servo location for retractable gear.

2.

Place your throttle servo tray with the servo in

the rails. Connect the

to your servo with a small, brass

connector.

pushrod

-

a 0

thread lock on the nut. Glue the throttle servo tray

to the rails.

Connect the other end of the throttle

to the engine with a nylon

80

threaded ball

,074"

x 12"

and 0-80

-

55

-

throttle pushrod

ball socket

nut.

Use a drop of

-

Screw-Lock

and

MOUNT THE WING TO THE FUSE

Remember the wing? Goget it

to

the fuse.

Bevel the end ofboth

wingboltblocks

-

cut

1/8"

die

2.

Use 30-minute epoxy to glue the wing bolt

blocks and holders in the fuse where shown on the

plan. See the photo at step

3. Place the wing in the wing saddle on the fuse.

Observe

sides that prevent the wing from fitting. Remove the

wing and sand the high spots

the fuse as accurately as possible.

ply fuse side doublers.

used to align the stab? Get your string out and stick

a T

just ahead of the tail cone.

with the fuse the same way you did the stab.

weights over the center section

shifting during the next few steps. Keep your string

handy

you proceed.

high spots

4.

Remember the

-

pin in the center of the bottom, middle stringer

5.

Use the arrow on the tape to align the wing

6.

Once you have the wing aligned, place

so

so

plywood

you can recheck alignment as

theymatchtheangleofthe

wing bolt block holder.

in the saddle of the

1/2"

8.

pin and

so

you

can mount it

x

1"

x

2-1/4"

balsa

so

the wing matches

Do

not sand the

string

method

to

keep it from

maple

fuse

you

Page 20

12. Spread a thin film of 30-minute epoxy on one

side of both wing dowel plates and fit them over the

dowels protruding through former F2D inside the

fuse. Accurately mark the location of the plates

on F2D.

crutch. Glue F1A

Remove the crutch.

3.

Cut the stringers from pieces of leftover 3/16

x

3/16"balsatofit from F1Atothe firewall. Glue

the stringers in position while using

triangle

to

stringers.

hold F IA perpendiculartothe top of the

to the side stringers only.

a

90

degree

"

7. Drill through

top sheeting

the wing with

perpendicular to the wing bolt plate as you drill

the head of the wing bolt will rest flat.

wing

in the wing bolt plate and the top sheeting with

round file or a 17/64 drill. Replace the wing on the

fuselage and bolt it down with the one 1/4" nylon

wing bolt.

9.

steps

10. Bolt the wing to your fuselage and leave the

wing bolts barely snug. Realign the wing.

11. Drill 1/4" holes through the 1/8" x 1"x2

plywood

holes with a round file or a piece of sandpaper

wrapped around something round such as

a

piece of brass tube. This will allow you toplug the

wing into the fuselage without too much resistance.

and

8.

Remove the wing and tap threads into the

bolt

block witha1/4-20 tap. Enlarge the hole

Replace the #7

5,

6, 7 and 8.

wing dowel plates. Slightly

only one

the wing bolt block on one side of

a

#7 drill. Keep the drill bit

drill

wing bolt plate, the

bit in your drill.

enlarge the

Repeat

a

pen or

so

13. Remove the wing. Clamp the wing dowel

to

plates

from the holes

F2D with C-clamps. Wipe excess epoxy

if

any is present.

SHEET THE FORWARD DECK AND

BOTTOM

1. Assemble your fuel tank. Position the tank

floor and the tank in the fuselage and determine

to

where

holes with

a

drill the holes for the fuel lines. Drill the

a

1 / 4 drill (or 15/64"drill for abetter fit).

6

"

2. Remove the tank and tank floor. Position the

die

-

cut 1/8" plywood

main side stringers

F7A. Position the die

on the fuse main side stringer soit contacts the

cabin crutch

so

the aft edge contacts former

-

cut

1/8"

plywood former

-56-

on

the fuse

1

FIA

4. Place 1/4" foam rubber on the tank floor. Test

fit your fuel tank with

with this kit.

time,

year.

5. Sheet the forward

3/32

"

sand the front even with the firewall. Sand the back

even with FlA, but do not sand the rest of the

sheeting until you fit the cabin.

Note:

so

you should replace them at least once

balsa. After you glue the sheeting in position,

#32

rubber bands

Rubber bands deteriorate over

fuse

deck with leftover

included

a

Page 21

-

El

6.Ifyou're installing retracts, turn the fuselage

over and build a small

balsa to support the sheeting around the nose

wheel cutout.

7. Use leftover 1/16"balsa sheeting to seal the

area around the nose gear between

This will prevent fuel and exhaust residue from

entering the fuselage.

-

framework

from leftover

and F2.

FIT

THE

1. Bevel one end offour 1/2"x1/2"

basswood blocks sothey fit between the fuse main

side stringers and formers F3 and F6 where shown

on the plan. Glue the blocks in position.

2.Ifyour fuel tank is in the fuse, remove it for now.

TOP

x

5/8"

the edges, and screw it back onto the fuse. A little

at a time, mark, then trim the crutch until it

accurately fits the fuse main side stringers.

6.

Use scissors to cut the molded ABS

along the cutlines (which are most visible from

top

inside the cabin top). The cabin top will be slightly

oversize to allow you to trim it for an exact fit to

your model. Use a felt tip pen to mark the moldedin center marks at the front and aft edges of the

cabin top

Do

instructed to do

sheeting over former F2A (over the center stringer).

Mark the center of the turtle deck sheeting over

former F7A (over the center stringer).

so

not trim the cabin top to fit your fuse until

7. Lightly mark the center ofthe front fuse

they will be easier to see while fitting.

so.

cabin

U

8.

Use leftover 3/32"balsa to sheet the bottom

forward fuse, aft of the cowl.

the nose wheel and strut

retracts.

9.

Remove the tank and foam rubber. Coat the

inside of the fuselage between the firewall and

former F2 including the back of the firewall with fuel

proof paint, epoxy or finishing resin.

Cut

the wheel well for

if

you are installing

3. Place the die-cut

on the fuselagesoit is centered and the edges

slightly extend past the side stringers. Use masking

tape to hold the cabin crutch to the fuselage.

1/8

plywood

cabin crutch

I

4.

Drill four 1/16"holes through the crutch into

the center

you drill each hole, temporarily hold the crutch to

the fuse with a #2

crutch that need to be sanded for a perfect fit to the

fuse main side stringers. Remove the crutch, sand

of

the blocks you glued to the fuse. After

x

1/2" screw.

5.

Use a ballpoint pen to mark areas of the

-57-

8.

Position the die-cut

former

former F7A. Lightly sand the edges of F7B

is approximately a

and F7A to accommodate the cabin top.

forward cabin former

same way.

crutch. Place a piece

F7B

on top of the crutchsoit contacts

9.

Test fit and shape the die-cut

10. Reposition the aft cabin former on top of the

1/8"

plywood

1

/16" difference between F7B

F2B

to former F2A the

of

thin cardboard between the

aft cabin

so

1/8"

plywood

there

Page 22

aft cabin former and F7A. The thickness of the

cardboard should be approximately 1/64

This is toprovide a little clearance for painting and

covering. Trace the outline of F7A onto the piece of

cardboard. Cut approximately 1/4" outside of the

line you drew. Reposition the cardboard shim and

glue the aft cabin former

in place.

11.

Make a shim and glue the front cabin former

to the crutch the same way.

12.

Temporarily position some balsa sticks

between the front and aft cabin formers to make

sure they and the shims tightly contact the fuse.

You are going

the more accurately they fit the fuse, the more

accurately your cabin top will fit the fuse.

to

to

the crutch with the shim

fit the cabin top tothe shims

"or.015".

so

centerline on the cabin top aligns with the

centerline on the fuse. Use a lead pencil

areas of the front of the cabin top that need to be

sanded for a perfect fit.

the areas you marked, erase the pencil marks, and

reposition the cabin top. Continue to mark, sand

and fit the cabin top until the front fits well.

14. Perform the same procedure to the aft edge

of the rear of the cabin top until it fits the rear

cardboard shim and the cabin top drops into place.

15.

With the cabin top on the fuse, make your

pencil marks where the bottom needs to be

trimmed. Sand the bottom edges of the cabin top

until it fits.

16.

Thoroughly roughen the entire inside of the

cabin top with 220

will stick.

Carefully

-

grit sandpaper soglue and paint

and

to

lightly

mark

sand

This will allow you to accurately fit the windows

later, but do not enlarge the openings yet

roughlycut them along the cutlines for now.

-

just

MOUNT THE CABIN TOP

1.

Remove the screws that temporarily hold the

crutch

3/4"

the holes. Using the holes in the crutch as a guide,

drill 1/16

just

fuse with the screws.

the hole through the crutch and the blocks in the

fuse with a

temporarily insert a 4

to hold the crutch in alignment as you drill the rest

of the holes.

to

the fuse. Glue four pieces of

x

3/4" leftover

"

holes up through the

glued on. Temporarily screw the crutch to the

2.

One at a time, remove a screw, and enlarge

1/8"

plywood to the crutch over

1/8"

ply pieces you

1/8"

drill. After you drill each hole

-

40x3/4" Phillips head screw

13.

Position the cabin

front contacts the cardboard shim and the

top

on the fuse sothe

17.

Use a Dremel tool with a carbide cutter or a

similar type of rotary tool, or small scissors to cut

the window openings along the cutlines inside the

cabin top. The window outlines in the cabin top are

about

1

/1

6

smaller than the windows themselves.

58-

3. Remove the crutch from the fuse and press

4

-

40 blind nuts into the holes in the top of the

crutch. Glue them with a little thin CA.

4.

Lightly

crutch formers

Place the crutch on the fuse with the cardboard

shims. Slip a piece of wax paper between the shim

and crutch formers at the back and front of the

crutch. Fasten the crutch to the fuse sides with four

spray the edges of the crutch and

F7B

and

F2B

with CA accelerator.

Page 23

4-40

x

3/4"

from inside the bottom of the fuse (we use a long

Great Planes

GPMR8002). Position the cabin top on the crutch.

Tape the cabin top to the fuse sides.

5.

medium CA bottle.

simultaneously press the side of the cabin top

down and to the side and glue the cabin top to the

crutch with a small fillet of medium CA.

small section at a time, making sure the crutch is

pressed down to the fuse main side stringer as you

glue. You should be able to reach all areas of the

crutch through the window cutouts. Since you pre-

primed the crutch with CA accelerator, you should

have to hold the parts together for only a few

seconds. Glue both sides

the crutch.

Note:

the top

not to glue the cabin sides or the crutch to the fuse

main side stringer. This should not be a problem

you do not use too much CA.

cap screws and washers accessible

3/32"Hexdriver Ball Wrench,

Make sure you have aCAapplicator on your

Do

not build up a large fillet of CA between

of

the crutch and the cabin sides. Be careful

A

little section at a time,

Do

of

the cabin top to

only a

6.

Glue the cabin top to the front and aft cabin

formers. Hint: It will be easier to glue the cabin

formers to the cabin top

fuselage on its nose and on its tail cone.

7.

Remove the cabin top and add medium CA

areas you couldn't reach before. Fasten the cabin

top to the fuse and lightly sand the fuse to match

the cabin top.

8.

Cut

if

accommodate the fuel tank.

the front cabin former and the crutch

if

you carefully place the

-59-

FIT

THE

WIND0

Note: The windows are individually cut and glued

to the inside of the cabin top.

1.

Cut each of the molded clear plastic windows

along the cutlines which are approximately 1/8"

outside of the raised edges. Sand the edges

smooth and even with 220

care not to scratch the windows.

2.

to

to

Fit the bottomofoneofthe windows in the

bottom of the matching window opening in the

cabin top. Observe how much the top, front and

aft edges of the window openings must be

trimmed

Remove the window and use a rotary tool with a

sanding drum

dowel to enlarge only the top, front and aft edges

of

fits.

cutouts

so

the window will fit the rest of the way in.

or

sandpaper wrapped around a

the window opening until the window accurately

Do

not trim the bottom edge of the window

so

the windows remain in line.

3.

Fit the rest of the windows the same way.

Beech

Fact:

first met at the Kansas based Travel Air

1920's.

was the office manager. They married in

1932,

Olive formed the Beech Aircraft

into production was the Model

wing biplane which later became known as the Beech

Staggerwing.

WalterH.Beech and Olive Ann Mellor

Thete, Walter served as president and Olive

with

two

other business associates, Walter and

WS

-

grit sandpaper. Use

Co.,

whose first plane

17R

negative-stagger

Co.inthe

1930.

late

In

Page 24

SHEET THE BOTTOM

OF

THE WING CENTER SECTION

1. Install your servo extension cords,

connectors and air linesifyou are installing

retracts. The servo extension cords don't have to

be connected

have to be connected to the retracts but they

should be installed

Plan this carefully. Be certain you have connected

both aileron extension cords into the same "Y"

connector and both flap extension cords into the

same "Y" connector. Give yourself plenty of slack

on the wires and air lines

connect everything after you cover your model.

to

the servos and the air lines don't

so

you can finish the sheeting.

so

you will be able

"

Y"

MAKE THE BELLY PAN

1. Bolt the wing tothe fuselage. Place the diecut 1/8" plywood

front of the wing

F2. Trim the bottom of F2W