Page 1

USA

MADE IN

Wingspan: 65 in [1650mm]

Wing Area: 778 sq in [50.2 dm²]

Weight: 5.5 – 7.0 lbs [2500 - 3182g]

Wing Loading: 16 – 21 oz/sq ft

[50–64 g/dm²]

Length: 49.5 in [1257mm]

™

WARRANTY.....Top Flite Models guarantees this kit to be free of defects in both material and workmanship at the date of purchase. This warranty does

not cover any component parts damaged by use or modification. In no case shall Top Flite‘s liability exceed the original cost of the purchased kit. Further, Top Flite reserves

the right to change or modify this warranty without notice. In that Top Flite has no control over the final assembly or material used for final assembly, no liability shall be assumed

nor accepted for any damage resulting from the use by the user of the final user-assembled product. By the act of using the user-assembled product the user accepts all

resulting liability. If the buyer is not prepared to accept the liability associated with the use of this product, the buyer is advised to immediately return this kit in new

and unused condition to the place of purchase.

Top Flite Models 3002 N. Apollo Dr., Suite 1, Champaign, IL 61822 Technical Assistance Call (217)398-8970 productsupport@top-flite.com

READ THROUGH THIS INSTRUCTION BOOK FIRST. IT CONTAINS IMPORTANT INSTRUCTIONS AND WARNINGS CONCERNING THE ASSEMBLY AND USE OF THIS MODEL.

ELD4P03 for TOPA0215 V1.1Entire Contents © Hobbico, Inc 2012

Page 2

TABLE OF CONTENTS

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . .2

SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . .2

ADDITIONAL ITEMS REQUIRED . . . . . . . . . . . . .3

Hardware and Accessories . . . . . . . . . . . . . . . .3

Adhesives and Building Supplies . . . . . . . . . . . .3

Optional Supplies and Tools . . . . . . . . . . . . . . . .3

IMPORTANT BUILDING NOTES . . . . . . . . . . . . .4

GET READY TO BUILD. . . . . . . . . . . . . . . . . . . . .4

COMMON ABBREVIATIONS . . . . . . . . . . . . . . . .5

METRIC CONVERSIONS . . . . . . . . . . . . . . . . . . .5

DIE-CUT PATTERNS. . . . . . . . . . . . . . . . . . . . . . .6

BUILD THE TAIL SURFACES . . . . . . . . . . . . . . . .7

Build the Stab . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Build the Elevator . . . . . . . . . . . . . . . . . . . . . . . .7

Build the Fin and Rudder . . . . . . . . . . . . . . . . . .9

BUILD THE WING . . . . . . . . . . . . . . . . . . . . . . . . .9

Frame the Wing . . . . . . . . . . . . . . . . . . . . . . . . .9

Install the Wing Joiners . . . . . . . . . . . . . . . . . .11

Finish the Bottom of the Wing . . . . . . . . . . . . .12

Join the Wings . . . . . . . . . . . . . . . . . . . . . . . . .13

Build the Wingtip. . . . . . . . . . . . . . . . . . . . . . . .13

Build the Aileron . . . . . . . . . . . . . . . . . . . . . . . .14

Finish the Wing. . . . . . . . . . . . . . . . . . . . . . . . .15

Make the Cockpit (Optional) . . . . . . . . . . . . . . .15

BUILD THE FUSELAGE . . . . . . . . . . . . . . . . . . .16

Frame the Fuselage . . . . . . . . . . . . . . . . . . . . .16

Mount the Wing to the Fuselage . . . . . . . . . . .20

Finish the Fuselage . . . . . . . . . . . . . . . . . . . . .21

Adding the Wing Fairing . . . . . . . . . . . . . . . . . .23

Assemble and Install the Landing Gear. . . . .24

Tailskid Installation . . . . . . . . . . . . . . . . . . . . . .26

Tail Wheel Wire Installation . . . . . . . . . . . . . . .26

FINAL CONSTRUCTION. . . . . . . . . . . . . . . . . . .27

Mount the Engine . . . . . . . . . . . . . . . . . . . . . . .27

Install the Radio . . . . . . . . . . . . . . . . . . . . . . . .27

FINISHING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Fuelproofing . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Prepare the Model for Covering . . . . . . . . . . . .28

Balance the Model Laterally. . . . . . . . . . . . . . .28

Cover Your Model with MonoKote. . . . . . . . . . .28

Installing the Stab and Fin . . . . . . . . . . . . . . . .29

Join the Control Surfaces. . . . . . . . . . . . . . . . .30

Install the Elevator and Rudder Pushrods and

Control Horns . . . . . . . . . . . . . . . . . . . . . . . . . .31

Install the Aileron Pushrods & Control Horns. .32

Scale Details . . . . . . . . . . . . . . . . . . . . . . . . . .32

Final Hookups and Checks . . . . . . . . . . . . . . .33

Control Throws . . . . . . . . . . . . . . . . . . . . . . . . .34

GET YOUR MODEL READY TO FLY . . . . . . . . .34

Balance your Model . . . . . . . . . . . . . . . . . . . . .34

PREFLIGHT . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Identify Your Model . . . . . . . . . . . . . . . . . . . . . .35

Charge the Batteries . . . . . . . . . . . . . . . . . . . .35

Balance Propellers . . . . . . . . . . . . . . . . . . . . . .35

Find a Safe Place to Fly . . . . . . . . . . . . . . . . . .35

Ground Check Your Model . . . . . . . . . . . . . . . .35

Range Check Your Model . . . . . . . . . . . . . . . . .35

CHECK LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

ENGINE SAFETY PRECAUTIONS . . . . . . . . . . .36

AMA SAFETY CODE. . . . . . . . . . . . . . . . . . . . . .36

FLYING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Takeoff . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Flight. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Landing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

INTRODUCTION

Congratulation and thank you for purchasing the To p

Flite Elder. The Top Flite Elder is a classic design from

the early years of modeling, brought back by requests

from modelers just like you! This easy flying model will

provide you with many hours of relaxing flight. Though

it is simple to build and fly, it also has its own unique

character that seems to appeal to modelers of all ages

and is guaranteed to get the attention of everyone at

the field. We hope you enjoy building the Top Flite Elder

as much as we have enjoyed bringing it back to the

modeling world and introducing it to a whole new

generation of modelers.

- 2 -

PROTECT YOUR MODEL,

YOURSELF & OTHERS

FOLLOW THESE IMPORTANT

SAFETY PRECAUTIONS

1. Your Top Flite Elder should not be considered a

toy, but rather a sophisticated, working model that

functions very much like a full-size airplane. Because

of its performance capabilities, the Top Flite Elder, if

not assembled and operated correctly, could possibly

cause injury to yourself or spectators and damage to

property.

2. You must assemble the model according to the

instructions. Do not alter or modify the model, as

doing so may result in an unsafe or unflyable model.

In a few cases the instructions may differ slightly

from the photos. In those instances the written

instructions should be considered as correct.

3. You must take time to build straight, true

and strong.

4. You must use an R/C radio system that is in firstclass condition, and a correctly sized engine and

components (fuel tank, wheels, etc.) throughout the

building process.

5. You must correctly install all R/C and other

components so that the model operates correctly on

the ground and in the air.

6. You must check the operation of the model before

every flight to insure that all equipment is operating

and that the model has remained structurally sound.

Be sure to check clevises or other connectors often

and replace them if they show any signs of wear or

fatigue.

7. If you are not already an experienced R/C pilot,

you should fly the model only with the help of a

competent, experienced R/C pilot.

Page 3

NOTE: We, as the kit manufacturer, provide you

with a top quality kit and great instructions, but

ultimately the quality and flyability of your finished

model depends on how you build it; therefore, we

cannot in any way guarantee the performance of

your completed model, and no representations

are expressed or implied as to the performance or

safety of your completed model.

Remember: Take your time and follow the

instructions to end up with a well-built model

that is straight and true.

Before starting to build, compare the parts in this kit

with the Parts List, and note any missing parts. Also

inspect all parts to make sure they are of acceptable

quality. If any parts are missing, broken or defective,

or if you have any questions about building or flying

this airplane, please call us at (217) 398-8970, or

e-mail us at productsupport@top-flite.com. If you

are contacting us for replacement parts, please be

sure to provide the full kit name (Top Flite Elder)

and the part numbers as listed in the Parts List.

If you have not flown a model before, we recommend

that you get the assistance of an experienced pilot in

your R/C club for your first flights. If you’re not a

member of a club, your local hobby shop has

information about clubs in your area whose

membership includes experienced pilots.

In addition to joining an R/C club, we strongly

recommend you join the AMA (Academy of Model

Aeronautics). AMA membership is required to fly at

AMA sanctioned clubs. There are over 2,500 AMA

chartered clubs across the country. Among other

benefits, the AMA provides insurance to its members

who fly at sanctioned sites and events. Additionally,

training programs and instructors are available at

AMA club sites to help you get started the right way.

Contact the AMA at the following address or toll-free

phone number.

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, IN 47302-9252

Tele. (800) 435-9262

Fax (765) 741-0057

Or via the Internet at: http://www.modelaircraft.org

ADDITIONAL ITEMS REQUIRED

Hardware and Accessories

This is the list of hardware and accessories required

to finish the Top Flite Elder. Order numbers are

provided in parentheses.

❏ Engine - .40 - .46 [6.5 – 7.5cc ] 2-stroke

.52 [8.5cc ] 4-stroke

❏ Radio - Four channel radio with four,

40 oz.-in. servos.

❏ Wheels – Two 3-3/4" Wheels. Williams Brother

Vintage Wheels (WBRQ1306)

❏ Spinner Great Planes Brass Spinner Nut –

choose for your engine shaft size.

❏ Propellers - Choose prop appropriate for

your engine

❏ Fuel line - Standard 3' tubing (GPMQ4131)

❏ Fuel tank - 10 oz (SULQ1385)

❏ MonoKote - For color scheme on the box:

❏ 2 - Six foot rolls “Cream” (TOPQ0212)

❏ 1 – Six foot roll “Red” (TOPQ0201)

❏ 1 – Six foot roll “Insignia Blue”(TOPQ0207)

- 3 -

Adhesives and Building Supplies

In addition to common household tools (screw drivers,

drill, etc.), this is the “short list” of the most important

items required to build the Top Flite Elder. We

recommend Great Planes Pro™ CA and Epoxy glue.

❏ 1 oz. Thin Pro CA (GPMR6002)

❏ 1 oz. Medium Pro CA+ (GPMR6008)

❏ CA Accelerator (GPMR6034)

❏ 6-Minute Epoxy (GPMR6045)

❏ 30-Minute Epoxy (GPMR6047)

❏ R/C-56 Canopy Glue (JOZR5007)

❏ Hobby knife (RMXR6907)

❏ #11 blades (RMXR6930)

❏ Small T-pins (HCAR5100)

❏ Builder’s triangle (HCAR0480)

❏ Electric drill

❏ Small Phillips and flat blade screwdrivers.

❏ Pliers with wire cutter (HCAR0630)

❏ Great Planes Plan Protector (GPMR6167) or

wax paper

❏ Sanding tools and sandpaper assortment (see

Easy-Touch

❏ Sealing Iron (TOPR2100)

❏ Small torch or 40 watt soldering iron

™

Bar Sander section)

Optional Supplies and Tools

Here is a list of optional tools mentioned in the

manual that will help you build the Top Flite Elder.

❏ Great Planes CG Machine™ (GPMR2400)

❏ Top Flite Precision Magnetic Prop Balancer™

(TOPQ5700)

™

❏ Top Flite Hot Sock

❏ Straightedge with scale (HCAR0475)

❏ Cutting mat (HCAR0456)

❏ Masking Tape (GPMR1010)

❏ CA Debonder (GPMR6039)

iron cover (TOPR2175)

Page 4

❏ CA Applicator Tips (HCAR3780)

❏ Epoxy Brushes (GPMR8060)

❏ Mixing Sticks (GPMR8055)

❏ Threadlocker (GPMR6060)

❏ Denatured Alcohol (for epoxy clean up)

❏ Silver solder (GPMR8070)

❏ Felt-Tip Marker (TOPQ2510)

❏ Rotary tool such as Dremel

❏ Rotary tool reinforced cut-off wheel

(GPMR8200)

❏ 1/16" to 1/4" drill bit set

❏ Other drill bits used: 17/64" (or 1/4"), #48 (or

5/64"), #36 (or 7/64), 6-32 tap, 1/4" tap

-or-

❏ Great Planes tap and drill set (GPMR8108)

❏ Dead Center™ Engine Mount Hole Locator

(GPMR8130)

™

❏ Great Planes AccuThrow

(for measuring control throws, GPMR2405)

Deflection Gauge

EASY-TOUCH™ BAR SANDER

Here’s the complete list of Easy-Touch Bar Sanders

and Adhesive Backed Sandpaper:

5-1/2" Bar Sander (GPMR6169)

11" Bar Sander (GPMR6170)

22" Bar Sander (GPMR6172)

33" Bar Sander (GPMR6174)

44" Bar Sander (GPMR6176)

11" Contour Multi-Sander (GPMR6190)

12’ roll of Adhesive-backed:

80-grit sandpaper (GPMR6180)

150-grit sandpaper (GPMR6183)

180-grit sandpaper (GPMR6184)

220-grit sandpaper (GPMR6185)

Assortment pack of 5-1/2" strips (GPMR6189)

IMPORTANT BUILDING NOTES

There are two types of screws used in this kit:

Sheet metal screws are designated by a number

and a length.

For example #6 x 3/4" long [19.1mm]

When you see the term test fit in the instructions,

•

it means that you should first position the part on

the assembly without using any glue, then

slightly modify or custom fit the part as necessary

for the best fit.

Whenever the term glue is written you should rely

•

upon your experience to decide what type of glue

to use. When a specific type of adhesive works

best for that step, the instructions will tell you what

glue is recommended.

• Whenever just epoxy is specified you may use

either 30-minute epoxy or 6-minute epoxy. When

30-minute epoxy is specified, it is highly

recommended that you use only 30-minute (or

45-minute) epoxy because you will need the

working time and/or the additional strength.

• Photos and sketches are placed before the step

they refer to. Frequently you can study photos in

following steps to get another view of the same parts.

• Not all die-cut parts have a name, or their complete

name stamped on them, so refer to the die

drawings on page 6 for identification. When it’s

time to remove the parts from their die sheets, if

they are difficult to remove, do not force them out.

Instead, use a sharp #11 blade to carefully cut the

part from the sheet, then lightly sand the edges to

remove any slivers or irregularities. Save some of

the larger, leftover pieces of wood.

A flat, durable, easy to handle sanding tool is a

necessity for building a well finished model. Great

Planes makes a complete range of Easy-Touch Bar

Sanders and replaceable Easy-Touch Adhesive-

backed Sandpaper. While building the Top Flite

Elder, we used two 5-1/2" Bar Sanders and two 11"

Bar Sanders equipped with 80-grit and 150-grit

Adhesive-backed Sandpaper.

This is a number six screw that is 3/4" long.

Machine screws are designated by a number,

threads per inch, and a length.

For example 4-40 x 3/4" long [19.1mm]

This is a number four screw that is 3/4" long with

forty threads per inch.

- 4 -

GET READY TO BUILD

1. Unroll the plan sheets. Roll them inside out so

they lie flat.

2. Remove all the parts from the box. Use a ballpoint

pen (not a felt tip pen) to lightly write the name or

size on each piece so you can identify it later. Use

the die-cut patterns on pages 6 and 7 to identify and

mark the die-cut parts before you remove them from

their die sheets. Many of the parts already have

Page 5

numbers stamped on them, but in some cases the

number is located alongside the parts or only on the

die drawings in the manual. Do not remove the die-cut

parts until instructed to do so. If a part is difficult to

remove, don’t force it out but cut around it with a hobby

knife and a #11 blade. After you remove the parts from

their die sheets, lightly sand the edges to remove

slivers or die-cutting irregularities. Save some of the

larger scraps of wood.

3. Separate the parts into groups such as stab, fin,

wing, and fuse. Store smaller parts in zipper-top

food storage bags.

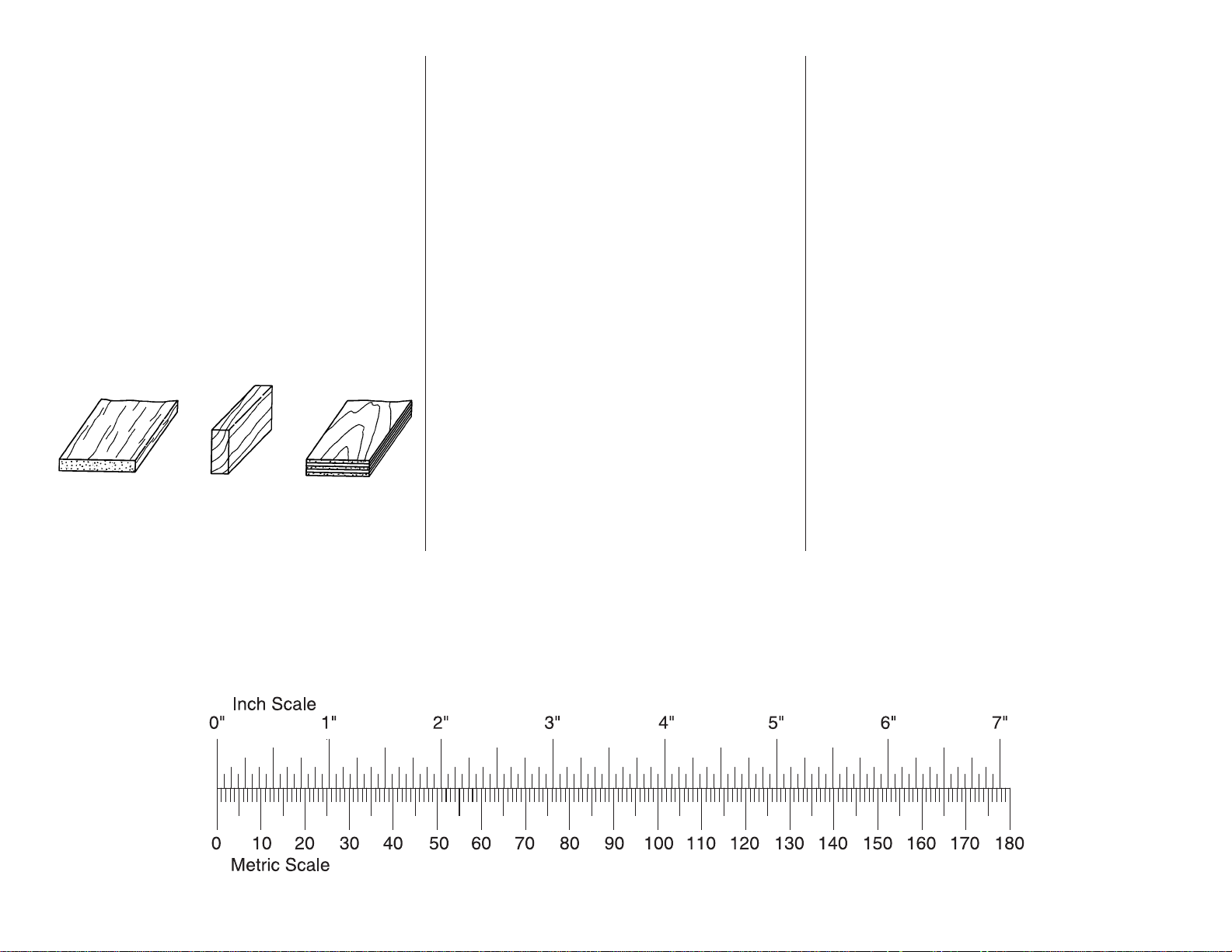

TYPES OF WOOD

BALSA BASSWOOD PLYWOOD

COMMON ABBREVIATIONS

deg. = Degrees

Elev = Elevator

Fuse = Fuselage

LE = Leading Edge (front)

LG = Landing Gear

Lt = Left

Ply = Plywood

Rt = Right

Stab = Stabilizer

TE = Trailing Edge (rear)

" = Inches

METRIC CONVERSIONS

1" = 25.4mm (conversion factor)

1/64" = .4mm

1/32" = .8mm

1/16" = 1.6mm

3/32" = 2.4mm

1/8" = 3.2mm

5/32" = 4mm

3/16" = 4.8mm

1/4" = 6.4mm

3/8" = 9.5mm

1/2" = 12.7mm

5/8" = 15.9mm

3/4" = 19mm

1" = 25.4mm

2" = 50.8mm

3" = 76.2mm

6" = 152.4mm

12" = 304.8mm

15" = 381mm

18" = 457.2mm

21" = 533.4mm

24" = 609.6mm

30" = 762mm

36" = 914.4mm

- 5 -

Page 6

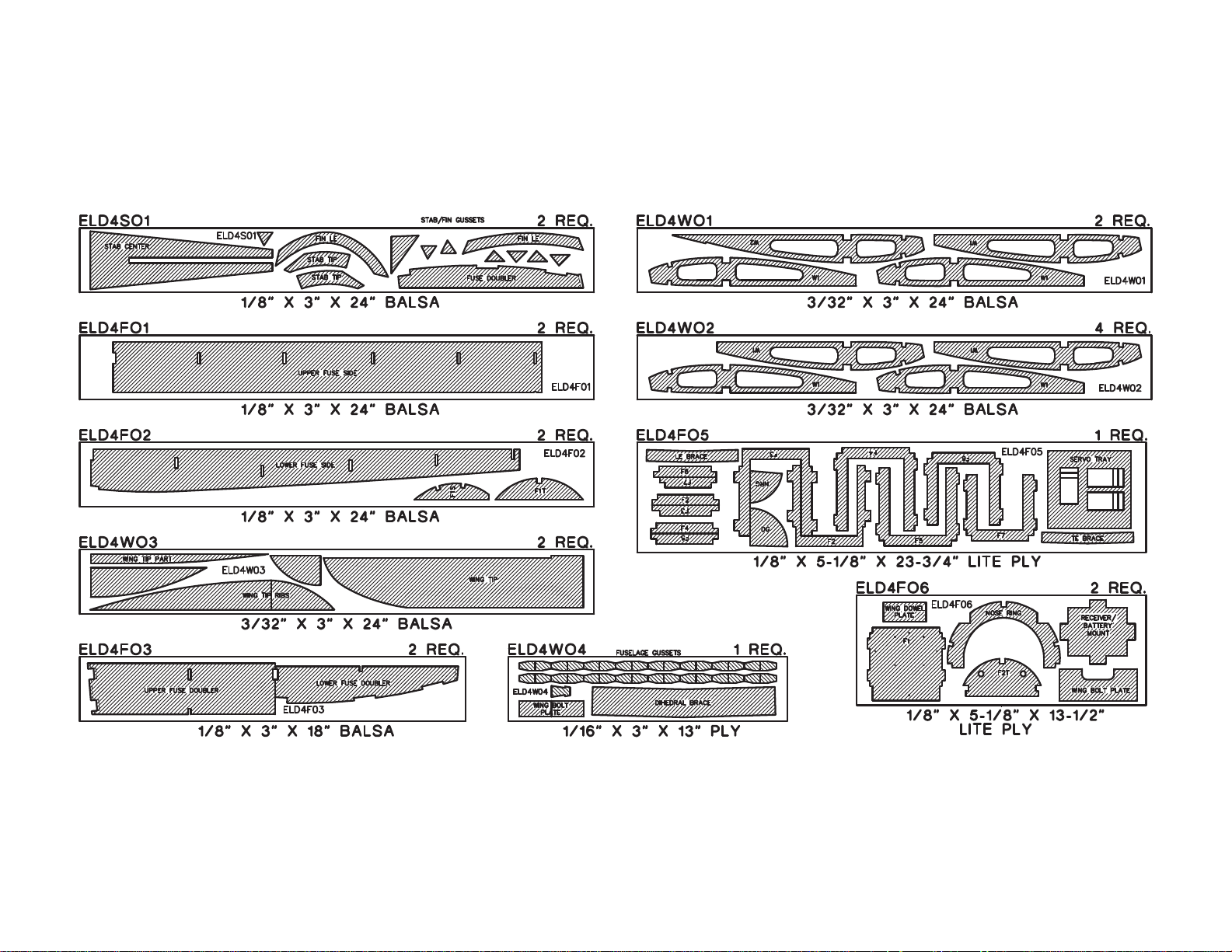

DIE-CUT PATTERNS

- 6 -

Page 7

BUILD THE TAIL SURFACES

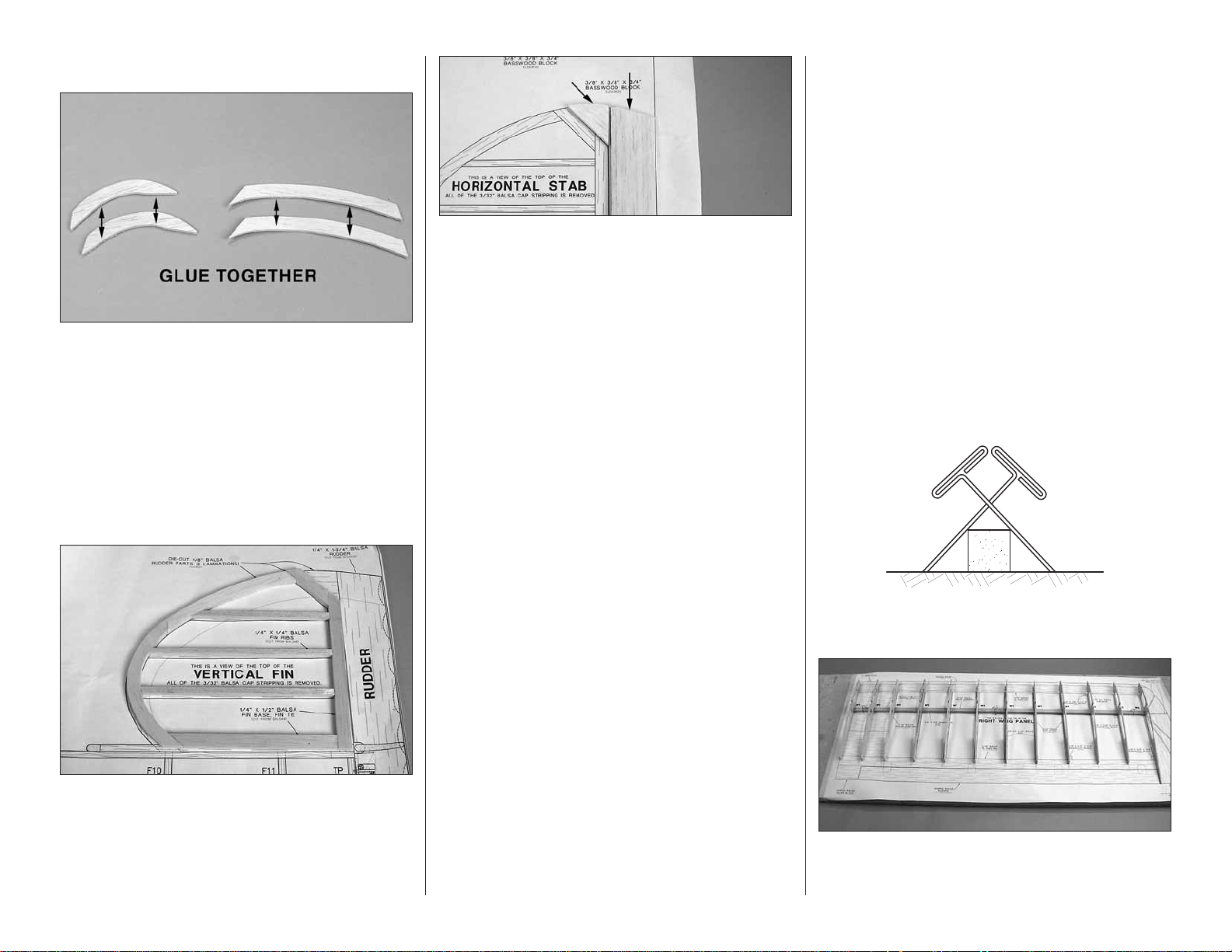

Build the Elevator

Build the Stab

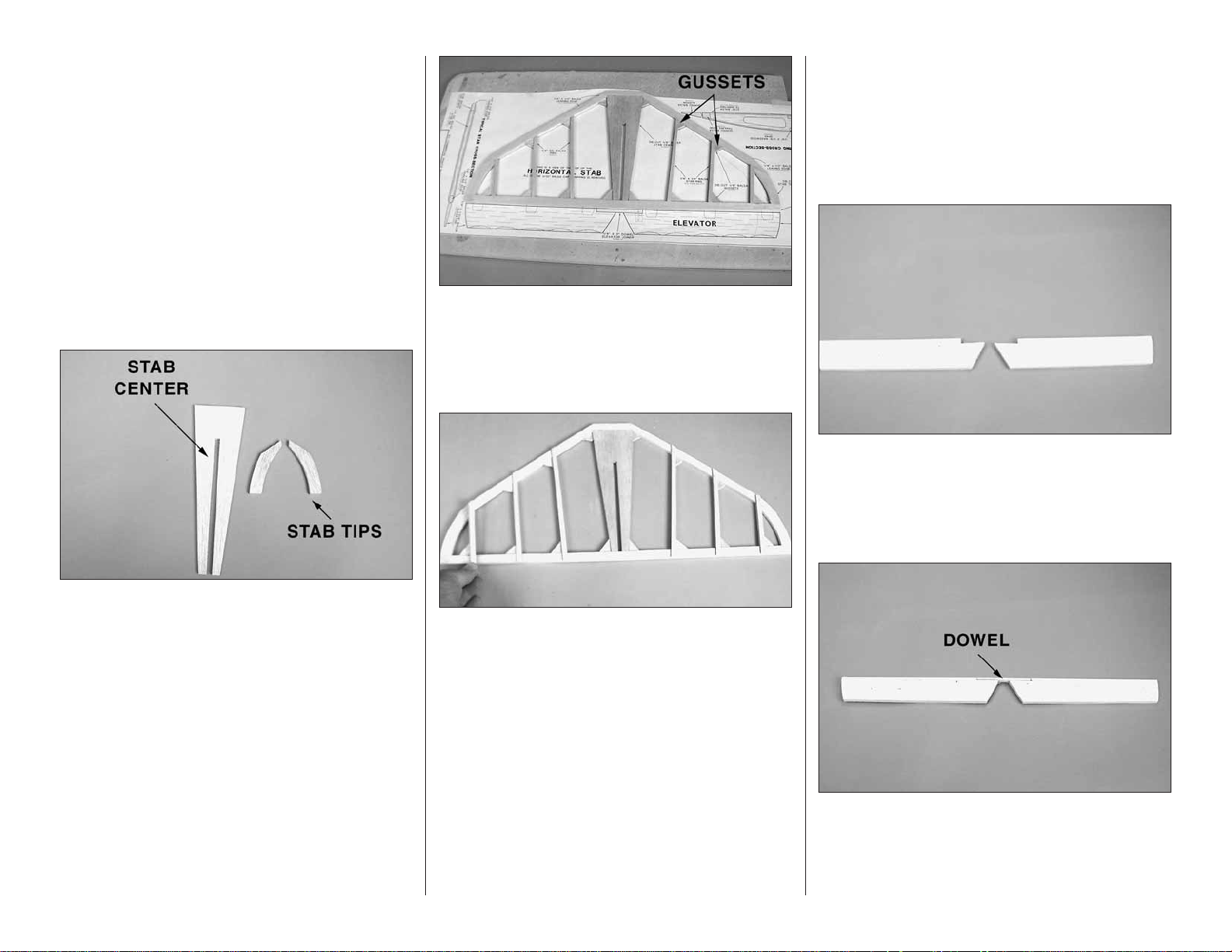

❏ 1. Tape the Wing/Stab Plan view to your building

board. Cover the plan with Plan Protector.

❏ 2. Locate the two die-cut 1/8" [3mm] balsa stab

center pieces. Glue them together with medium CA

to make one 1/4" [6mm] stab center.

❏ 1. From the 1/4" x 1-3/4" x 36" [6 x 32 x 914mm]

balsa sheet, cut two pieces 10-1/2" [267mm] in length.

❏ 6. Glue the remaining gussets in place as shown

on the plan.

❏ 2. Using the plan as your guide, cut and shape

each of them to match the shape of the elevator

shown on the plan.

❏ 3. Locate four die-cut 1/8" [3mm] balsa stab tips.

Glue them together to form two 1/4" [6mm] stab tips.

❏ 4. Pin the stab center over the plan. Using your

plan as a guide, build the leading edge and trailing

edge of the stab from 1/4" x 1/2" x 36" [6mm x 13 x

914mm] balsa sticks. Cut 1/4" x 1/4" [6mm x 6mm]

balsa sticks to the proper length for the stab ribs.

Glue them in place with medium CA.

❏ 5. Glue the die-cut 1/8" [3mm] balsa gussets in

place next to the stab tip on the left side of the stab.

Center them on the 1/4" [6mm] stab parts. Repeat

this for the right side of the stab.

❏ 7. From 3/32" x 1/4" x 36" [2.4mm x 6 x 914mm]

balsa stick, cut out cap strips and glue them in place

on the stab ribs. Do this on both the top and bottom

of the stab. Note: On the stab cross-section you will

see that the cap strips extend across the leading and

trailing edge.

❏ 8. Sand the cap strips to the shape shown on the

stab cross-section. This is also a good time to final

sand the leading edge of the stab. Use the crosssection as your guide for sanding the final shape.

- 7 -

❏ 3. Pin the elevator halves to the plan. Locate and

test fit the 1/4" x 3" [6 x 75mm] dowel in place in the

cut-outs on the LE of the elevator. When you are

satisfied with the fit of the dowel, glue it in place with

6-minute epoxy.

Page 8

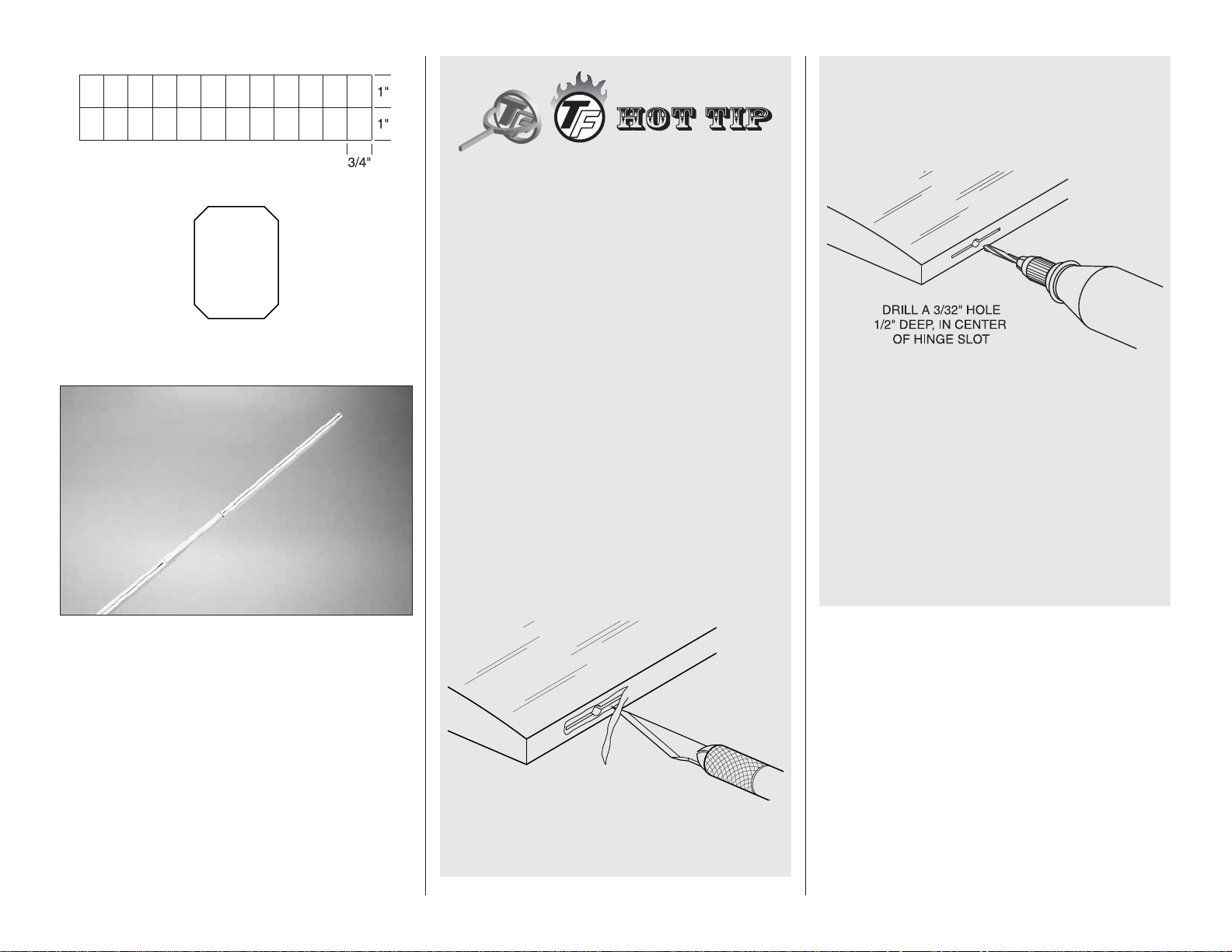

❏ 4. Locate the 2" x 9" [50 x 230mm] hinge material

and cut sixteen hinges as shown in the above sketch.

USING CA HINGES

The hinge material supplied in this kit consists of a

3 layer lamination of Mylar and polyester. It is

specially made for the purpose of hinging model

airplane control surfaces. Properly installed, this

type of hinge provides the best combination of

strength, durability and ease of installation. We trust

even our best show models to these hinges, but it

is essential to install them correctly. Please follow

the instructions carefully to obtain the best results.

These instructions may be used to effectively install

any of the various brands of CA hinges.

The most common mistake made by modelers

when permanently installing this type of hinge is

not applying a sufficient amount of glue to fully

secure the hinge over its entire surface area; or,

the hinge slots are very tight, restricting the flow

of CA to the back of the hinges. This results in

hinges that are only “tack glued” approximately

1/8” to 1/4” into the hinge slots. The following

technique has been developed to help insure

thorough and secure gluing.

Trial fit the hinge into the slot. If the hinge does

not slide in easily, work the knife back and forth in

the slot a few times to provide more clearance (it

is really the back edge of the blade that does the

work here in widening the slot).

B. Drill a 3/32” [2.4mm] hole, 1/2” [13mm] deep,

in the center of the hinge slot. If you use a Dremel

Moto-Tool® for this task, it will result in a cleaner

hole than if you use a slower speed power or

hand drill. Drilling the hole will twist some of the

wood fibers into the slot, making it difficult to

insert the hinge, so you should reinsert the knife

blade, working it back and forth a few times to

clean out the slot.

C. Trial fit the hinges into the slots and, without

using any glue, temporarily attach the control

surface, to verify the fit.

❏ 5. Mark a centerline down the LE of the elevator.

Repeat this for the trailing edge of the stab. Using the

plan as your guide, mark the location for each of the

hinges on the stab and elevator, then cut matching slots

in the stab and elevator. The Great Planes Slot

Machine™ (GPMR4010) works very well and makes the

job of cutting hinge slots fast and easy! If you do not

have a Slot Machine use the Expert Tip that follows.

A. Cut the hinge slot using a #11 blade in a

standard #1 knife handle. The CA hinges provided

have a thickness that fits this type of slot very well.

- 8 -

STOP! DO NOT GLUE THE HINGES IN PLACE

UNTIL AFTER THE MODEL IS COVERED!

❏ 6. Sand the elevator to its final shape, matching

the contours you sanded on the stab and sanding the

leading edge to a “V” shape as shown on the plan.

You will notice on the plan that there is a dashed line

on the elevator trailing edge forming a scalloped

shape. This pattern is provided for you if you decide

that you would like to have a scalloped TE. We did

this on the model shown on the box cover. Use the

plan as your guide for cutting the scalloped edge

should you decide to do this option.

Page 9

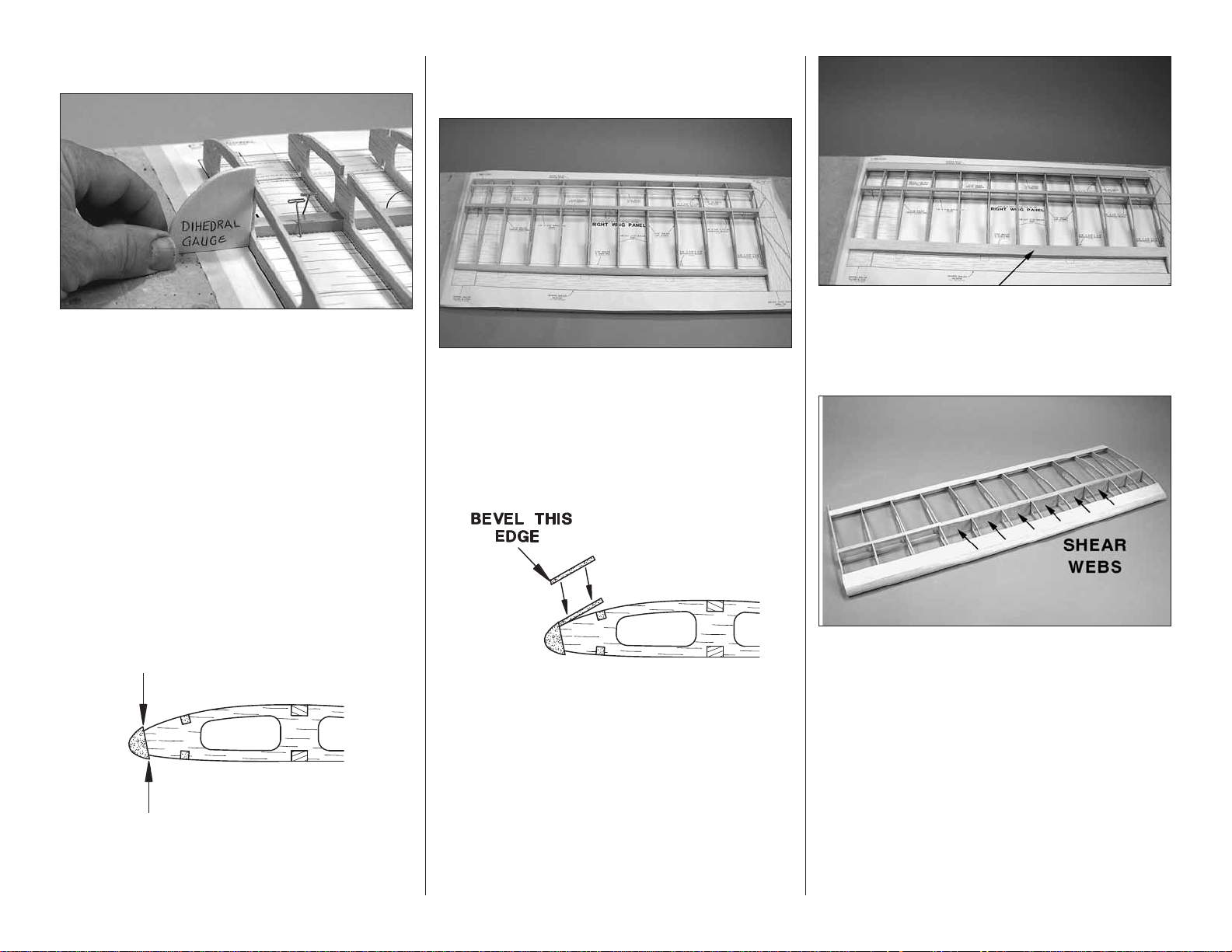

Build the Fin and Rudder

❏ 1. Tape the Fin and Rudder Plan view to your

building board. Cover the plan with Plan Protector.

❏ 2. Locate two sets of die-cut 1/8" [3mm] balsa fin

leading edge pieces. One set is short the other is

long. Glue the two long fin leading edge pieces

together to form one 1/4" [6mm] fin leading edge. Do

the same with the short set.

❏ 4. From the remaining piece of the 1/4" x 1-3/4" x

36" [6 x 32 x 914mm] balsa sheet, cut the rudder tip

and the 1-3/4" portion of the rudder. Using leftover

¼" x ½" stick, cut the stick to a length of 9". Glue the

stick to 1/4" x 1-3/4" x 36" [6 x 32 x 914mm] portion

of the rudder forming a 2-1/4" wide rudder.

❏ 5. Glue the two rudder parts together.

❏ 6. From 3/32" x 1/4" [2.4mm x 6mm] balsa stick,

cut out cap strips and glue them in place on the fin

ribs. Do this on both the left and right side of the fin

the same way as you did for the horizontal stab.

Note: On the fin cross-section you will see that the cap

strips extend across the leading and trailing edge.

❏ 7. Sand the cap strips to the shape shown on the

fin cross-section. This is also a good time to final

sand the leading edge of the fin. Use the crosssection as your guide for sanding the final shape.

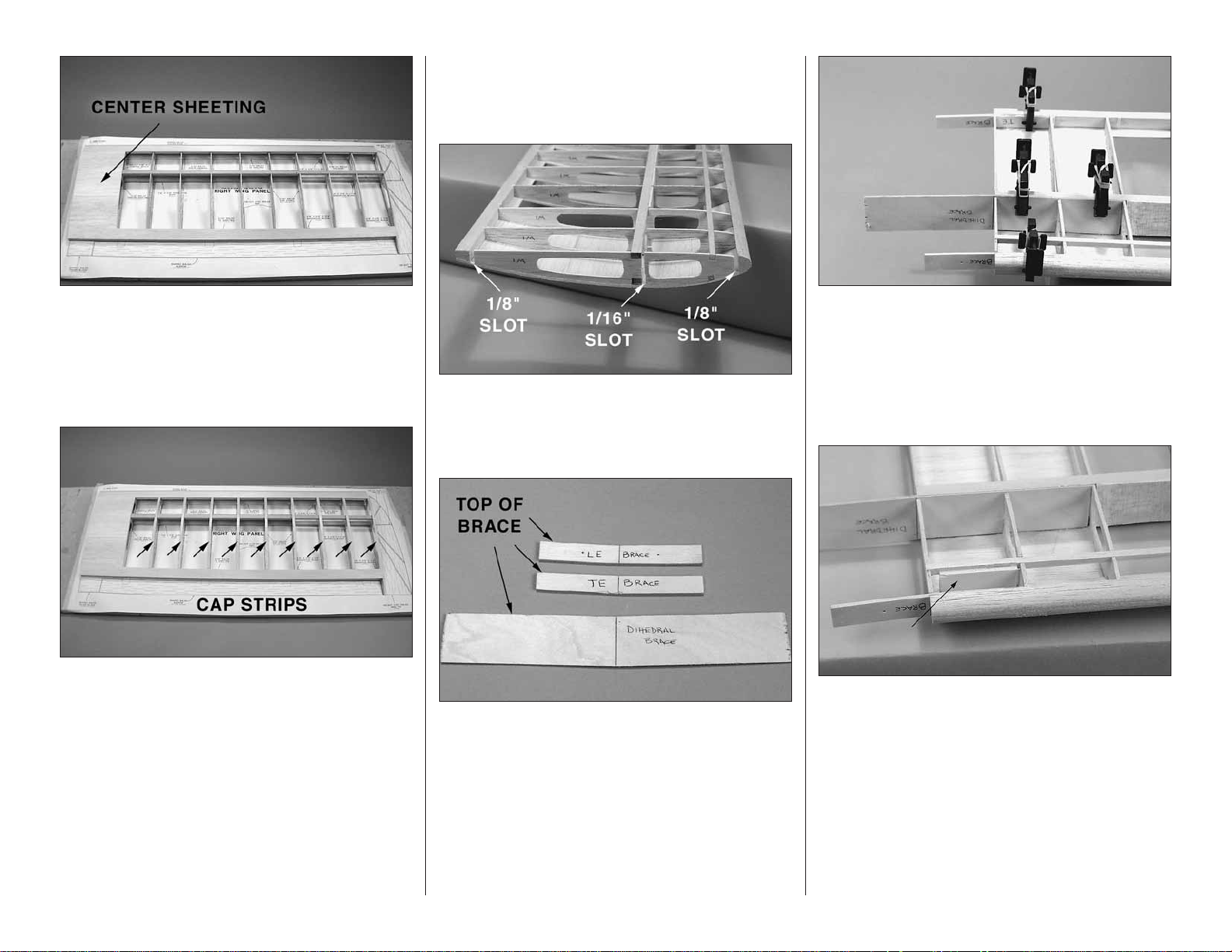

BUILD THE WING

Frame the Wing

❏ ❏ 1. Tape the Right Wing Plan view to your

building board. Cover the plan with Plan Protector.

❏ ❏ 2. Locate one of the shaped balsa leading

edges and one of the shaped balsa trailing edges.

Cut each of them to a length of 29-3/4" [759mm]. Be

sure to save the leftover pieces. They will be used as

filler blocks later in the building process.

❏ ❏ 3. Locate two 1/4" x 3/8"x 30" [6 x 9.5 x 760mm]

basswood spars. Cut each of them to a length of

29-3/4" [756mm].

❏ ❏ 4. Locate two 3/16" x 3/16" x 36" balsa [4.8 x

4.8 x 914mm] leading edge sub spars. Cut each of

them to a length of 29-3/4" [759mm].

❏ 3. Cut the 1/4" x 1/2" x 36" [6 x 12 x 914mm] balsa

stick to make the frame structure of the fin. Glue the

parts together to create the fin framework. Cut the

1/4" x 1/4" x 36" [6 x 6 x 914mm] balsa sticks to fit

between the fin frame as shown on the plan. Glue

them in place.

❏ 8. Mark a centerline down the LE of the rudder.

Repeat this for the trailing edge of the fin. Using the

plan as your guide, mark the location for each of the

hinges on the fin and rudder, then cut matching slots

in the fin and rudder using the same procedure you

used for the stab and elevator. Sand the rudder and

the fin to the shape shown on the cross-section. Be

sure to make the oval cut out in the rudder for the

elevator to pass through.

❏ 9. Trial fit the hinges into the slots and without

using any glue, temporarily attach the control surface

to verify the fit.

❏ 10. The plan shows the option of a scalloped

trailing edge on the rudder just as the elevator did. If

you chose to scallop the elevator you may want to

scallop the rudder as well.

- 9 -

❏ ❏ 5. Pin one of the basswood spars to the plan

with T-Pins.

❏ ❏ 6. Test fit the die-cut 3/32" {214mm] balsa W1

ribs over the basswood spar in the locations shown

on the plan.

Page 10

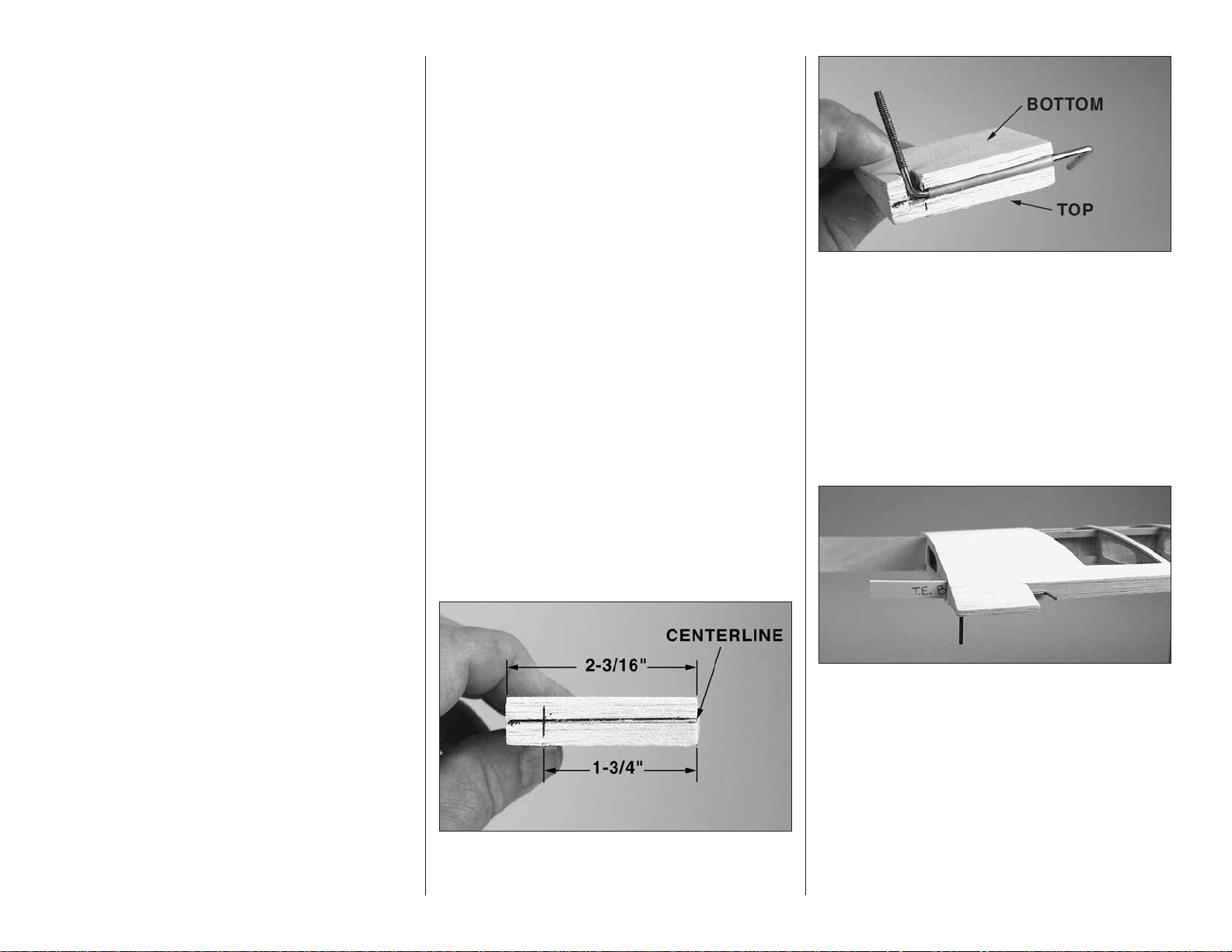

❏ ❏ 7.

Test fit the W2 rib at the end of the basswood spar.

❏ ❏ 8. Locate the die-cut 1/8" [3mm] plywood

dihedral gauge. Place the gauge flat on the building

board at the root of the wing and against the side of

the W1 rib. Once you are satisfied with the rib

placement, use CA to glue the rib to the basswood

spar. Important! Be sure you use the gauge to set

the angle of the rib. Failure to do so will not provide

the wing with the required amount of dihedral.

❏ ❏ 9. Use CA to glue each of the ribs onto the

basswood spar. Make sure that each of the ribs is

perpendicular to the building board.

❏ ❏ 12. Glue each of the remaining ribs to the

shaped balsa leading edge, centering them as you go.

❏ ❏ 13. Place the shaped balsa trailing edge in

position as shown on the plan. The trailing edge should

be placed flat on the building board and against each of

the ribs. When satisfied with the fit, glue the trailing

edge in place to the eleven W1 ribs and the W2 rib.

❏ ❏ 16. Locate one of the 3/32" x 1" x 30" [2.4 x 25 x

760mm] balsa trailing edge sheets. Cut it to a length

of 29-3/4" [756mm]. Glue it in place on the trailing edge

of the wing.

❏ ❏ 10. Glue the 3/16" x 3/16" x 29-3/4" [4.8 x 4.8

x756mm] balsa leading edge sub spar into the

notches in the top of the wing. Glue the 1/4" x 3/8" x

29-3/4" [6 x 9.5 x 756mm] basswood top spar into the

notches in the top of the wing.

❏ ❏ 11. Beginning at one end of the wing, center the

shaped balsa leading edge on the front of the rib.

Glue it to the rib. Center the leading edge on the rib

at the opposite end of the wing and glue it in place.

❏ ❏ 14. Locate one of the 3/32" x 1-1/8" x 30" [2.4 x

28 x 760mm] balsa leading edge sheets. Cut it to a

length of 29-3/4" [756mm]. Using a sanding block,

bevel one edge of the sheet to get a good fit between

the sheeting and the leading edge of the wing.

❏ ❏ 15. Glue the leading edge sheeting in place

between the leading edge and the balsa leading edge

sub spar.

- 10 -

❏ ❏ 17. From the 3/32" x 3" x 24" [2.4 x 75 x 610mm]

balsa sheet, cut out six shear webs. When cutting the

shear web be sure the grain is perpendicular to the

wing spars. Position the shear webs on the wing

spars as shown on the plan. When satisfied with the

fit, glue them in place.

❏ ❏ 18. From a sheet of 3/32" x 3" x 30" [2.4 x 75 x

760mm] balsa sheet, cut three pieces 4-3/8" [111mm]

in length. Edge glue the three sheets together to form

a sheet 4-3/8" x 9" [11 x 229mm]. Once the glue has

dried, cut the sheeting to fit between the leading

edge sheet and the trailing edge sheet as shown on

the plan.

Page 11

Install the Wing Joiners

Important!

The following steps are for the right wing panel.

❏ ❏ 19. Place the sheeting flat on the bench and

sand the joints of the sheeting smooth on the side

that will be the top of the wing. When you have

completed the sanding and are satisfied with the fit,

glue the sheeting in place between the leading edge

and trailing edge sheeting.

❏ ❏ 20. From 3/32" x 1/4" x 36" [214 x 614 x

914mm] balsa stick, cut and glue nine cap strips into

place. Cut each one to fit between the leading edge

sheeting and the trailing edge sheeting on each rib.

❏ ❏ 21. Remove the wing from the building board

and turn it over. Glue the 3/16" x 3/16" x 29-3/4"

balsa [4.8 x 4.8 x 756mm] leading edge sub spar in

the notches in the bottom of the wing.

❏ 22. Repeat steps 1-21 for the left wing.

❏ 1. At the root rib, cut a 1/8" [3mm] slot in W1 as

shown for the leading edge and trailing edge brace.

Cut a 1/16" [1.6mm] slot through two W1 ribs for the

dihedral brace.

❏ 2. Locate the die-cut 1/8" [3mm] plywood leading

edge and trailing edge brace as well as the laser-cut

1/16" [1.6mm] plywood dihedral brace. Mark a

centerline on each of them.

❏ 3. Test fit each of the braces in the slots you just

cut. When fitting the braces it is important that they

are installed properly. Important! The top of the

brace must be glued so that it is in contact with the

top sheeting of the wing.

- 11 -

❏ 4. When you are satisfied with the fit of each

brace, glue them in place with 30-minute epoxy. Use

the center line you made on each brace as a guide

to position the brace. It is important that exactly half

of each brace goes into each wing panel. Set the

wing panel aside until the epoxy has fully cured.

❏ 5. Glue the die-cut 1/8" [3mm] ply sub spar dowel

brace to the balsa sub spars as shown on the plan.

Page 12

Finish the Bottom of the Wing

❏ ❏ 1. For the right wing panel, locate a 3/32" x

1-1/8" x 30" [2.4 x 28 x 760mm] balsa bottom leading

edge sheet. Cut it to a length of 29-3/4" [756mm].

Bevel one edge of the sheet as you did with the

sheeting on the top of the wing. When you are

satisfied with the fit, glue the sheeting in place on the

bottom of the wing.

❏ ❏ 2. Locate a 3/32" x 1" x 30" [2.4 x 25 x 760mm]

balsa bottom trailing edge sheet. Cut it to a length of

29-3/4" [756mm]. Glue it in place on the trailing edge

of the bottom of the wing.

❏ ❏ 3. Sheet the center section of the bottom wing

following the same procedure you used for sheeting

the center section on the top of the wing.

❏ ❏ 4. From 3/32" x 1/4" x 36" [2.4 x 6.4 x 914mm]

balsa sticks, cut nine cap strips. Cut each one to fit

between the leading edge sheeting and the trailing

edge sheeting on each rib.

❏ ❏ 5. On the wing plan there are four locations

shown for 3/8” x 3/8” [9.5 x9.5mm] basswood blocks.

The blocks are provided in the kit and are cut to the

lengths shown on the plan. If you plan to install wire

and turnbuckles on your model, proceed with

installing the basswood blocks as shown on the plan.

If you choose to use the elastic cord as we did on our

model then you can substitute balsa blocks for the

basswood. The balsa is a little easier to work with

than the basswood and will retain the elastic cord

better than the basswood. Locate the 3/8” x 3/8” x 18”

[9.5 x 9.5 x 457mm] balsa stick and cut it to the

length specified on the plan for each of the four

blocks. Glue the blocks on the positions shown on

the plan.

❏ ❏ 6. Whether you have installed the balsa or

basswood blocks, drill a 1/16" [1.6mm] hole through

the center of the entire length of the block.

❏ ❏ 7. Locate the 30" [762mm] shaped balsa

aileron. From one end of the aileron cut a piece

2-3/16" [55.8mm] in length.

❏ ❏ 9. Cut a slot as shown in the photo along the

centerline starting at the end. The slot needs to be

1/8" [ 3mm] wide to accommodate the torque rod.

The slot can be cut easily with the Great Planes®

Groove Tube™ (GPMR8140) or the slot can be cut

with your hobby knife. Notice that these blocks are

not symmetrical so make the one for the left wing the

mirror image of this one.

❏ ❏ 10. Cut another slot perpendicular to the slot you

just cut to accommodate the arm of the torque rod.

You now need to make a decision. When the Elder

was originally introduced it had flying and landing

wires on it. Though these wires are not a structural

part of this model, they do add a great “Vintage” look

to the model. If you have ever installed wires and

turnbuckles you know there is some additional work

and cost to do this. For our model we used elastic

cord to simulate the flying wires. This was much

easier and less expensive than using actual wire. We

will give complete instructions for installing wire or

elastic flying wires as we get further into the building

process. If you choose not to install any of the wires

skip steps 5 & 6.

❏ ❏ 8. Mark a centerline on this piece of aileron

stock. Make another mark 1-3/4" [44mm] from the

end of the block.

- 12 -

❏ ❏ 11. Glue the block with the torque rod in place

in the slot, being careful not to get any glue onto the

metal wire. Tip – Apply a small amount of petroleum

jelly to the end of the plastic bearing. This will prevent

glue from getting onto the wire. Important! Before

gluing the block in place be sure that you have the

correct torque rod in place in the block. The

un-threaded arm of the torque rod should protrude

into the area where the aileron will be attached. The

threaded end of the arm will protrude towards the

bottom of the wing. Make sure that you install the

correct rod for each wing half.

Page 13

Join the Wings

❏

1. Glue the die-cut 1/8" [3mm] ply sub spar dowel

brace to the balsa sub spars on the left wing panel

as done on the right wing panel.

❏ 2. At the root rib of the left wing panel, cut two 1/8"

[3mm] slots in W1 at the leading edge and trailing

edge for the leading edge and trailing edge braces.

Cut a 1/16" [1.6mm] slot through the two W1 ribs for

the Dihedral Brace.

❏ 3. Test fit the two wing panels together, inserting

the wing joiners from the right wing panel into the

slots you just cut in the left wing panel.

Now that both of the wing panels are joined, go back

to the section, “Finish the Bottom of the Wing”.

Follow the instructions to finish the bottom of the left

wing the same way you did the right wing.

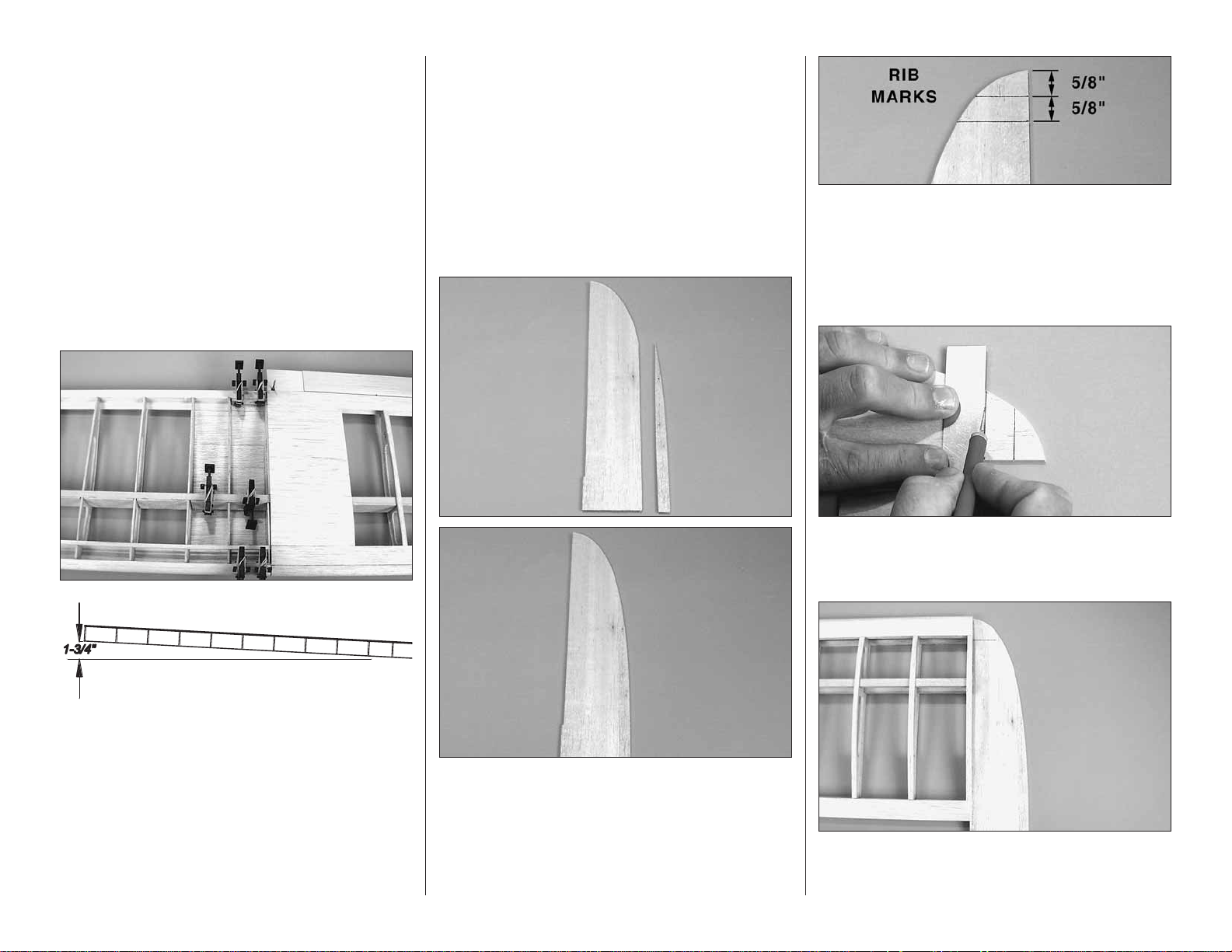

Build the Wingtip

❏ ❏ 3.

and make two marks on the bottom of the tip. From the

tip, measure down 5/8" [15.9mm] and draw a line

perpendicular from the edge of the wing tip. Measure

down from that line another 5/8" [15.9mm] and draw

another line perpendicular from the edge of the wing tip.

When satisfied with the fit, turn the wingtip over

❏ 4. When you are satisfied with the fit, mix 1 oz. of

30-minute epoxy. Glue the joiners and the wing

together with 30-minute epoxy, making sure you

apply liberal amounts to the joiner and the spars.

Before the glue dries, place one wing flat on the

building surface and measure the distance from the

table to the bottom of the wing. The distance should

be 1-3/4". Block the wing to maintain this distance

while the glue dries.

❏ ❏ 1. Locate the die-cut 3/32" [2.4mm] balsa

wingtip parts. Glue the two pieces together to form

the completed wingtip.

❏ ❏ 2. On the right wing test fit the wing tip in place,

making sure you have a good fit between the tip and

the end of the wing.

- 13 -

❏ ❏ 4. With your hobby knife, score the lines half

way through the balsa. The scores will allow you to

bend the end slightly when installing the wing tip.

❏ ❏ 5. Using medium CA, glue the wingtip in place

to the end of the wing. Be sure that the wingtip and

the wing are flat on the building board before gluing

Page 14

it in place. Do Not Glue the front 1-1/4" [32mm] of

the tip to the wing. Proceed to the next step after the

glue has completely cured.

❏ ❏ 6. Carefully bend the tip of the wingtip on the

score until the tip takes on the contour of the wing.

When the proper bend has been achieved, use thin

CA to glue the tip to the wing.

Build the Aileron

❏ ❏ 1. Cut the ailerons to length as shown on the

plans. Mark a centerline on the LE of the aileron.

❏ ❏ 8. When satisfied with the fit, glue the wing tip

ribs in place.

❏ ❏ 2. Fit the aileron onto the wing panel and mark

the location of the torque rod. Drill a 7/64" [2.8mm]

1/2" [13mm] hole on the mark.

❏ ❏ 7. Locate the four die-cut 3/32" [2.4mm] balsa

wing tip ribs. In the sketch, you can see how each

of the wing tip ribs needs to be beveled where they

contact the wing. Bevel each of them to the angles

shown on the plan.

❏ ❏ 9. From the leftover balsa leading edge, fit a

piece to fill in the front of the wing tip.

❏ 10. Repeat steps 1–9 for the left wingtip.

- 14 -

❏ ❏ 3. Using your Great Planes® Groove Tube or a

hobby knife, cut a 1/8" [3mm] slot from the end of the

aileron to the hole you just drilled.

❏ ❏ 4. Mark a centerline down the trailing edge of

the wing. Using the plan as your guide, mark the

location for each of the hinges on the aileron and

wing trailing edge, then cut matching slots in the

aileron leading edge and wing trailing edge. Be sure

to follow the same technique described earlier in the

“Expert tip for using CA hinges”.

❏ ❏ 5. Trial fit the hinges into the slots and, without

using any glue, temporarily attach the aileron to

verify the fit.

STOP! DO NOT GLUE THE HINGES IN PLACE

UNTIL AFTER THE MODEL IS COVERED!

Page 15

❏ ❏ 6. Sand the aileron to its final shape as shown

on the cross section of the wing. Sand a “V” in the

leading edge.

❏ 7. Repeat steps 1-6 for building the aileron for the

left wing.

Finish the Wing

❏ 1. Locate two laser-cut 1/16 x 3/4" x 1-1/2" [1.6 x 19

x 38mm] plywood wing bolt plates. Glue them in place

on the top of the wing. The plates should be positioned

1-1/2" [38mm] from the trailing edge of the wing.

❏ 3. Using a 1/4" x 3/8" x 30" [6 x 9.5 x 762mm]

basswood stick, cut two pieces 1" [25mm] long for

the servo mounting rails. Glue them in place on the

wing skin with 6- minute epoxy.

Make the Cockpit (Optional)

When the Elder was originally introduced we found

that modelers chose to finish the plane in different

ways. The original plan had a cockpit in the top of the

wing. Some modelers chose not to do this. Just as

you had to make a choice to scallop the elevator and

rudder, you need to decide if you would like to make

the cockpit. If not, skip this section.

❏ 2. Cut out the cockpit from the sheeting. When you

remove the sheeting the W1 wing rib will be in the

middle of the cockpit. Remove the rib in this area to

create the open cockpit. This will not compromise the

strength of the wing.

❏ 3. When you finish your model you will find that

either Fourmost Cockpit Coaming (FORQ2014) or

18" of black neoprene fuel tubing makes a nice finish

to the cockpit opening. Installation instructions are at

the end of the construction process.

❏ 2. On the bottom of the wing, cut an opening for

the aileron servo. Begin by drawing a line that is just

behind the basswood main spar. With that line as a

reference, make an opening large enough for your

particular brand of servo.

❏ 1. Locate the cockpit pattern on the plan and cut it

out. Place the pattern on the top of the wing so that

the back edge of the cockpit pattern is 2-1/2" [64mm]

from the trailing edge of the wing. Trace the pattern

onto the wing.

- 15 -

Page 16

BUILD THE FUSELAGE

Frame the Fuselage

Notice that you are building the right side first.

❏ 1. Tape the Fuselage Plan side view to your

building board. Cover the plan with Plan Protector.

Build the right fuselage side first.

❏ ❏ 2. Locate the die-cut 1/8" [3mm] balsa fuse

sides. Edge glue the two halves together.

❏ ❏ 6. Glue the fuse doubler to the fuse side on the

lines you have drawn.

Note: The left side will be glued to the other side.

❏ 7. Locate six 1/4" x 1/4" x 36" [6 x 6 x 914mm]

basswood sticks. These will be the longerons and

the longeron braces. Because these will be part of

the open tail structure it is recommended that you

take some time to sand them now. Later in the

construction process you will be applying a finish and

you will find it much easier if you sand the sticks now

before they become part of the model. Sand them

being careful not to round the edges.

❏ 8. From one 1/4" x 1/4" x 36" [6 x 6 x 914mm]

basswood stick cut two pieces 13" [330mm] long.

❏ ❏ 3. Locate the die-cut 1/8" [3mm] balsa fuse

side doublers. Edge glue the two halves together.

❏ ❏ 4. Locate the die-cut 1/8" [3mm] balsa landing

gear doubler. Glue this to the fuse side doubler.

Note: The left fuse side will have the doubler glued

on the other side.

❏ ❏ 5. Draw a line parallel to the top of the fuse side

1/4" [6mm] from the top. Draw another line

perpendicular to this line, aligned with the back of the

first set of slots in the fuse side.

- 16 -

❏ 9. Locate two 1/4" x 1/4" x 36" [6 x 6 x 914mm]

basswood sticks. On one end of each stick cut a 45

degree angle.

❏ 10. On one end of each of the 13" [279mm] sticks

cut a 45 degree angle. Using 6-minute epoxy glue a

13" [330mm] stick to the 36" [914mm] stick, gluing

them together on the 45 degree cut. Do this for the

remaining two sticks. This will give you two longerons

48-3/4" [1239mm] long. Use a long straightedge to

keep the sticks straight.

Page 17

❏ ❏ 11. Glue one of the 48-3/4" [1239mm] basswood

longerons to the top of the right fuse side as shown

on the plan. Glue the end of the stick where you

made the splice to the fuse side. Do not have the

splice at the rear of the fuselage. The 48-3/4"

[1239mm] longeron is longer than shown on the plan.

Place the longeron on the plan at the back of the

fuselage and allow the excess longeron length to

extend beyond the front of the fuselage. Set the

remaining 48-3/4" [1239mm] basswood longeron

aside until you do the left side of the fuselage.

❏ ❏ 12. Glue a 36" [914mm] basswood longeron in

place on the bottom of the fuse side. After the glue

has cured, cut the longeron to length as shown on

the plan.

❏ 14. This completes the right side of the fuselage.

Now is a good time to sand the side of the fuselage

while you can lay it flat on the bench. Repeat steps

2-13 for the left side of the fuselage. It is very

important that you make a left and right side

fuselage! This is easily done if you build the left side

of the fuselage on top of the right side you have

already made. On the right fuselage side, insert

some 1/8” balsa under the longerons to keep them

straight. Place Plan Protector or a sheet of wax

paper on top of the completed right side and proceed

building the left side on top of it.

❏ 16. Pin the right fuselage over the plan. Glue die-

cut 1/8" [3mm] plywood formers F2 through F7 in

place in the notches on the right fuselage side. Be

sure to glue them perpendicular to the fuselage.

❏ ❏ 13. From the remaining basswood stick, cut the

longeron braces to fit in the locations shown on the

plan. Glue them in place once you are satisfied with

the fit. For maximum strength we recommend that

they be glued in place with 6-minute epoxy because

CA does not bond as well to basswood. You can use

CA if you prefer, just be careful in handling the

fuselage until you glue the gussets in place later in

the building process.

❏ 15. Locate the right fuselage side. On the front of

the fuselage you will see an embossed line that is

approximately 1/8" [3mm] inside the edge of the front

of the fuselage. Cut the fuselage on the embossed

line. This will provide you with the proper amount of

right thrust when you assemble the fuse. Do this on

the right fuselage side only and be sure you only cut

the sheeting. Do not cut the longerons!

- 17 -

❏ 17. Locate two die-cut 1/8" [3mm] plywood F1

formers. Glue these together to form the 1/4" [6mm]

firewall. Make sure the punch marks are visible on

one side.

Page 18

FOR STEPS 22-27 USE THE TOP VIEW OF THE

FUSELAGE PLAN AS AN AID IN KEEPING THE

FUSELAGE STRAIGHT.

❏ 18. The firewall has eight punch marks. Draw two

reference lines for mounting the engine to the firewall

as shown. If you are using the O.S. FS 52 or O.S. 46

FX, the remaining four punch marks are exactly

where you need to drill the engine mounting holes. If

you are using a different engine you may find that

you have to adjust the location of the mounting holes

for your particular engine and muffler combination.

Drill four 5/32" [4mm] holes on the engine mount

punch marks for the 6-32 blind nuts.

❏ 20. Locate the firewall mounting gauge. This

gauge will set the proper amount of right thrust

required for the engine. Glue the F1 firewall to the

fuselage side with 6-minute epoxy. Be sure to use the

gauge when gluing it in place. Do not glue the gauge

to the firewall or fuse.

❏ 22. Glue the left side of the fuselage to the formers.

Be careful to maintain the proper angle for the firewall.

Use the firewall mounting gauge to verify the firewall is

correct as you glue the fuselage side in place.

❏ 23. Lay the fuselage upside down on the bench.

Locate the two 1/4" x 1" x 3-7/8" [6 x 25 x 98mm]

plywood landing gear mounting plates and glue

them in place in the bottom of the fuselage with

6-minute epoxy.

❏ 19. Use a small hammer and tap the four 6/32

blind nuts into the holes you just drilled. After they

are in place, put a few drops of thin CA on the blind

nut being careful not to get any glue onto the threads.

Note: The blind nuts are installed on the rear of F1.

Pay special attention to the orientation of the firewall

as shown above.

❏ 21. Locate die-cut 1/8" [3mm] parts F2T through

F7T. Glue them in place on top of the formers. F3T

and F4T only need to be tack glued in place as they

will be removed later in the building process. The

others are a permanent part of the structure.

- 18 -

Important! The kit contains two of 1/8" x 3" x 30"

[3 x 76 x 762mm] soft balsa sheets. These two

sheets are soft balsa and should be set aside.

They will be used later for the cowl construction.

There are two sheets of 1/8" x 3" x 24" [3 x 76 x

610mm] medium balsa. The medium balsa

sheets are to be used in the following steps.

Page 19

❏ 28. Glue the 1/16" [1.6mm] tail gusset in place at

the rear, bottom of the fuselage with 6-minute epoxy.

❏ 24. From the 1/8" x 3" x 24" [3 x 76 x 610mm]

balsa, sheet the bottom of the fuselage. The grain of

the balsa needs to run across the width of the

fuselage. Once you have the fuselage bottom

completed, take the time to sand the bottom of the

fuselage. It will be much easier to do while the

fuselage is placed flat on the bench.

❏ 26. Cut and glue the remaining cross braces in

place on the top and bottom of the fuselage.

❏ 29. From 1/8" x 3" x 24" [3 x 76 x 610mm] balsa,

sheet the top of the fuselage from former F5 to the

rear of the fuselage. The grain of the balsa needs to

run across the width of the fuselage.

❏ 30. Locate two die-cut 1/8" [3mm] plywood F2T

formers. Glue them together to form one 1/4"

[6mm] former.

❏ 25. Cut the aft end of the longerons to the angle

shown on the plan. Once the angle has been cut,

glue the longerons together with 6-minute epoxy. Use

small clamps to hold the tail together while the glue

is curing. Be sure that you do not twist the longerons

when you clamp and glue them together. The

fuselage and longerons should remain completely

flat to the building board during the gluing process.

❏ 27. Locate the sheet of 32 laser-cut 1/16 [1.6mm]

plywood fuse gussets. Use 6-minute epoxy to glue

them in place over each of the cross brace joints.

Refer to the plans for exact positioning. You will find

it helpful to use small clamps to hold them in place

while the epoxy cures.

- 19 -

❏ 31. Trial fit the F2T former in place in front of

fuselage former F2. When you are satisfied with the

fit, glue it in place with 6-minute epoxy.

Page 20

❏ 32. Earlier you temporarily glued F3T and F4T in

place. Remove and discard them.

❏ 33. Locate the two die-cut 1/8" x 1-1/2" x 3-5/8" [3

x 38 x 92mm] plywood wing bolt mounting plates.

Glue them together to form one 1/4" [6mm] thick

wing bolt mounting plate.

Mount the Wing to the Fuselage

❏ 1. Position the wing onto the fuselage with the

leading edge of the wing against former F2T.

❏ 3. Measure from the tip of the left wingtip to the tail

of the fuselage and from the right wingtip to the tail of

the fuselage. Adjust the wing until the distance is equal.

❏ 4. When you are satisfied with the placement of

the wing, mark the location for the wood dowels onto

the leading edge of the wing with a pencil. Make the

marks through the center of both of the holes in F2T

onto the wing leading edge.

❏ 34. From former F5 measure forward 1-1/2"

[38mm]. Make a mark on both sides of the fuselage.

❏ 35. Glue the wing bolt mounting plate in position

with 6-minute epoxy. The rear of the mounting plate

is the side with the cut-out. This should be towards

the rear of the fuselage and aligned on the marks

you made on the fuselage.

❏ 2. Measure from the side of the fuselage to the

wing tip. Adjust the wing as needed until the distance

on the left side and right side are equal.

- 20 -

❏ 5. Drill a 1/4" [6mm] hole through each of the

marks you made on the wing leading edge. Be sure

to drill through the wing leading edge and the

plywood sub-spar dowel brace inside of the wing.

❏ 6. Locate the 1/4" x 4" [6 x 102mm] wood dowel.

Cut it into two 2" [51mm] pieces.

❏ 7. Apply a liberal amount of epoxy into the holes

you drilled in the wing. Apply a thin layer of epoxy to

the portion of the dowel that you will insert into the

wing. Insert the two wooden dowels into the holes,

twisting them as you insert them. Leave the dowel

Page 21

extending 3/8" [9.5mm] out of the wing leading edge.

Wipe any excess glue from the exposed dowel. Allow

the glue to cure then round the ends of the dowels as

shown on the plan. This will make it easier to insert

the dowels through the holes in F2T when installing

the wing on the fuselage.

❏ 8. On the top center of the wing at the aft end of

the wing is the plywood wing bolt plate. Measure

from the center of the wing 1-1/8" [28mm] to the left

and right. Make a mark on the center of each

plywood wing bolt plate.

drilling be sure that the drill remains perpendicular to

the top of the wing. If the drill does not remain

perpendicular to the wing you may not hit the center of

the wing bolt mounting plate in the fuselage.

❏ 10. Remove the wing from the fuselage. Drill a

17/64" [6.7mm] clearance hole through the wing bolt

holes you drilled in the wing. Do not drill through the

holes in the wing bolt plate in the fuselage.

❏ 11. Using a 1/4-20 tap, tap each of the holes in the

wing bolt mounting plate. After they have been tapped

apply a couple of drops of thin CA onto the threads in

the wing bolt mounting plate. After the CA has

completely cured, run the tap through the threads again

to clear out any excess glue on the threads.

❏ 12. Install the wing onto the fuselage and screw

the nylon wing bolts through the wing into the

threaded block in the fuselage to be sure that

everything fits properly. When you are satisfied

things fit well, remove the wing.

Finish the Fuselage

❏ 2. Turn the fuselage upright on the bench. Using the

triangle or square, mark a line across the top of the

fuselage perpendicular from the end of the line on the

right side of the fuselage. Turn the fuselage and

continue the line down the left side of the fuselage.

❏ 9. Double check all your measurements to be sure

the wing is still properly positioned. When you are

satisfied with the positioning of the wing drill a 13/64"

[5.2mm] hole through the wing on the marks you made

on the wing bolt plates. Drill through the wing and the

wing bolt mounting plate inside of the fuselage. When

❏ 1. Place the fuselage on your bench with the right

side of the fuselage facing up. Using a builders

triangle or a small square, mark a line across the

side of the fuselage from the bottom corner of the

fuselage to the top of the fuselage, perpendicular to

the top fuselage.

- 21 -

❏ 3. Prepare the engine mount by cutting off the tabs

and slide the two halves together as shown.

❏ 4. Install the engine mount to the firewall with four

6-32 x 3/4" [19mm] socket head cap screws, four #6 flat

Page 22

washers and four #6 lock washers. Temporarily place

your engine in the mount to set the width of the

mounting rails to fit your engine. Remove the engine

and tighten all the engine mount mounting bolts. For

our model we will be installing the engine inverted so

we have installed the engine mount inverted. Be sure to

properly install your engine mount for the position you

choose to install your motor. Drill two 3/16" [4.8mm]

holes in the firewall to accommodate the fuel line and

the engine pressure line from the fuel tank.

❏ 5. Locate the two die-cut 1/8" [3mm] balsa F1S

formers. Glue them in position on both the left and

right side of the fuselage. Use the lines you have

drawn on the sides of the fuselage as reference for

gluing them in place.

❏ 7. Locate the two die-cut 1/8" [3mm] plywood nose

rings. Glue them together to form one 1/4" [6mm]

plywood nose ring.

❏ 8. You are now going to install the nose ring to the

fuselage. The positioning of the nose ring is

determined by the length of your engine. Temporarily

position your engine onto the engine mount. (Do not

permanently mount your engine to the mount).

Determine where the nose ring will be positioned so

when the engine is installed the front of the engine

thrust washer is approximately 1/4" - 3/8" [6mm –

9mm] further forward than the nose ring. Mark the

location of the nose ring on the basswood rails.

❏ 10. From the remainder of the 3/16" x 3/16" x 36"

[4.8 x4.8 x 914mm] balsa stick, cut, fit and glue the

remaining side stringers from F1S to the nose ring.

Do this for both sides of the fuselage.

❏ 6. From a 3/16" x 3/16" x 36" [4.8 x4.8 x 914mm]

balsa stick cut the balsa side stringers. Sand a bevel

on the end of the sticks that are glued flush to the

fuselage side. Cut the sticks to length so they fit to

the middle of former F1S and glue them in place.

❏ 9. Insert the nose ring onto the basswood rails.

Locate the die-cut 1/8" [3mm] nose ring gauge

(NRG). Use it to set the angle of the nose ring as

shown. Glue the nose ring to the rails. If there is any

of the basswood rail extending beyond the nose ring,

cut it off flush with the nose ring.

- 22 -

❏ 11. From a leftover 1/4" x 1/4" [6 x 6mm] basswood

stick, cut a stick for the center fuselage stringer to fit

from former F2T to the front of the nose ring. Glue it

in position. Glue the die-cut 1/8" [3mm] plywood

former F1T to the top of F1. Slide it forward or aft

slightly to fit under the basswood stick.

❏ 12. You are now going to sheet the front of the

fuselage. This is going to require compound bends to

the sheeting. To accomplish this you must wet the

wood before gluing it into place. Rubbing alcohol

misted onto the wood with a spray bottle works best

but you can also accomplish the task with water.

Page 23

Bevel the sheeting

where it contacts the

fuselage side.

❏ ❏ 13. All of the sheeting is going to be cut from

the 1/8" x 3" x 30" [3 x 76 x 762mm] soft balsa

sheeting that you previously set aside when building

the fuselage. Cut a piece of sheeting to fit from the

sheeted fuselage side, forward to the nose ring.

When glued in place the top edge of the sheeting

should be aligned on the center of the middle

stringer. Bevel the end of the balsa sheeting where it

will contact the fuselage side. This will provide a

better transition from the cowl to the fuselage. Wet

the wood and allow it to soften before gluing.

❏ ❏ 15. Cut two more pieces of sheeting long enough

to fit from the fuselage side to the front of the nose ring.

Cut one of the sheets to a width of 1-1/2" [38mm] (save

the remaining half of the sheeting to be used when

sheeting the opposite side of the fuselage). Edge glue

the full sheet to the 1-1/2" [38mm] wide sheet. This will

form a piece of sheeting wide enough to wrap around to

the center fuselage stringer.

❏ 16. Wet the wood and allow it to soften. When it is

sufficiently soft, glue the sheeting in place to the

previously installed sheet and work the sheeting

towards the top of the fuselage. When the sheeting is

fully glued into place to all of the stringers trim the

sheeting down to the middle of the center stringer on

the top of the fuselage.

❏ 18. Blend the sheeting from the cowl to the

fuselage with a balsa filler as well as filling in any

gaps in the seams where the sheeting meets. Allow

it to dry and then sand the front portion of the cowl

and fuselage.

Adding the Wing Fairing

❏ 1. Install the wing back onto the fuselage and

secure it in place with the nylon wing bolts.

❏ ❏ 14. When sufficiently softened to bend and fit the

fuselage, glue it in place with CA glue. Some CA

accelerator will be helpful in gluing the sheeting in place.

❏ 17. Repeat steps 13-16 for the opposite side of

the fuselage.

- 23 -

❏ 2. Locate a leftover piece of 1/8" thick sheeting.

Slide it in place at the wing leading edge just behind

former F2T. Use a pen or pencil to trace the shape of

the top of the fuselage onto the sheeting. Remove

the sheeting. Then cut the sheeting 3/32" [2.4mm]

inside the line you have just traced onto the sheeting.

Doing this will allow for the sheeting that will be

applied in the next couple of steps. This piece

becomes the former for the wing fairing.

Page 24

❏ 3. From left over 3/32" x 3" [2.4 x 76mm] balsa

sheeting cut two pieces to a length of 3-1/2".

Assemble and Install the Landing Gear

❏ 1. Locate the two prebent wire landing gear wires

and one of the coils of wrapping wire. Make a wire

wrapped joint at each end and the middle of the main

landing gear wire where shown on the plan. If you

are new to making and soldering this type of a joint,

refer to the Soldering Hot Tip below.

B. Bend the soft wire around the two landing gear

wires being joined together. Continue to wrap the

soft wire around the landing gear wires until you

have approximately 20 turns of the soft wire

around the landing gear wire.

❏ 4. Set the former in place against former F2T. Do

not glue it in place! Fit one of the 3/32" x 3" x 3-1/2"

[2.4 x 76 x 89mm] balsa sheets to the former and the

wing. Do this for the left and right side. When you are

satisfied with the fit, glue the former to the wing and

the balsa sheets to the former and the wing. After

they have been glued in place, feather the wing

fairing sheeting and wing together with balsa filler.

❏ 5. Fill the small open area under the leading edge

of the wing with leftover balsa. Do this on both sides

of the fuselage.

HOW TO MAKE A WRAP AND SOLDER JOINT

A. Bring the two pieces of landing gear wire together.

Clean the wire where they make contact with each

other using 300-grit sandpaper. After cleaning the

wire, bring the two pieces of landing gear wire

together where you want them joined. With a 6"

[152 mm] piece of soft wire begin by laying the wire

parallel to the landing gear wires that you will be

joining. Then make a 90º bend in the end of the wire.

- 24 -

C. Bend the portion of the wire that was lying

perpendicular to the landing gear wires being

joined forward towards the wraps of soft wire. This

will prevent them from unraveling.

D. Cut the excess wire but leave enough folded

over the wraps of soft wire to keep the wire

in place.

Page 25

E. To get a good bond between the soft wrap wire

and the wire landing gear it is important to use a

good solder and flux. The Great Planes® Silver

Solder Kit (GPMR8070) works very well and

includes all the needed items for a good, strong

solder joint.

F.

Begin by applying a couple of drops of the liquid

flux onto the wire joint. With a small torch begin

heating the landing gear wire above and below the

joint. (The best bond will be achieved if the landing

gear wire gets hot enough for the solder to flow into

it as well as the wire wrapped joint). Heat the wire

hot enough to melt the solder but not so hot that the

wires turn glowing red. Apply a small amount of

solder to the wire wrapped joint and when it is hot

enough you will be able to see the solder flow

around the wire joint. There is no need to over apply

the solder. Use just enough to flow between all of

the gaps in the wire. After completing the soldering

wipe away excess flux with a little water. Then, dry

the joint. Washing away the flux will allow the paint

to adhere better when you paint the landing gear.

With a little practice you will find soldering a very

simple task.

❏ 2. After completing the three solder joints on the

main landing gear wire, lay the main landing gear

wire onto the fuselage so that the wire is laying

across the forward landing gear mounting plate.

Install two nylon humped landing gear straps over

the wire landing gear. Drill a 1/16" [1.6mm] hole

through the holes in the landing gear straps and into

the landing gear mounting plate. Screw the straps

into the mounting plate with #2 x 1/2" [13mm] sheet

metal screws.

❏ 3. Position the rear landing gear wire in place over

the rear landing gear mounting plate and secure it

with two nylon landing gear straps the same as you

did for the forward landing gear wire.

❏ 4. Bring the two landing gear wires together so the

rear landing gear wire makes contact with the forward

landing gear wire just below the solder joints you made

at each corner of the forward landing gear wire.

- 25 -

❏ 5. Wrap the two wires together with a 5" [127mm]

piece of soft wire, using the same technique used for

joining the forward landing gear wire. Solder the joint

together. Do this for both sides of the landing gear.

You need to decide if you are going to install a tail

skid wire or if you are going to install a steerable

tailwheel. Both are included in this kit. Steps 6 - 9 are

for the tail skid construction and installation. Skip to

the Tail Wheel Wire Installation after step 9 if you are

using a tailwheel.

Page 26

Tailskid Installation

❏ 6. Locate the pre-bent wire tail skid. Wrap and

solder it together in the three locations shown on the

plan. Once the solder has cooled, bend the end of

the wire to a slight angle as shown on the plan.

❏ 7. Lay the wire tail skid in position on the bottom

of the fuselage, making sure the bend you made in

the wire is pointed toward the top of the fuselage.

Tape the skid in place by wrapping some masking

tape around the wire and the wood cross brace.

❏ 9. You may wish to paint your tailskid before installing

it onto the fuselage. If so, do it now. This would also be

a good time to paint the main landing gear. When the

paint has dried place the tailskid in position on the

bottom of the fuselage. Secure it to the fuselage with

cotton cord or string (not included) by wrapping the

cord around the wire and the cross braces on the

fuselage. Once you have it secured with the cord, apply

thin CA to the cord and the cross brace. When the glue

has dried you may want to paint the cord the same

color as the landing gear skid.

Tail Wheel Wire Installation

DRILL

3/32"

HOLE

Cut a groove

the width of

the hole,

1/16" into the

leading edge

of the rudder

❏

2. Cut a groove into the leading edge of the rudder

the width of the hole you drilled. The groove needs to be

cut 1/16" [1.6mm] into the leading edge of the rudder.

Cut slot

❏ 8. Wrap and solder the wire tail skid support in

place as shown on the plan. When you are finished

remove the tailskid from the fuselage.

1-1/4"

1"

❏ 1. Drill a 3/32" [2.4mm] hole at the location shown

in the center of the rudder leading edge.

- 26 -

❏ 3. Cut a 1/16" x 15/16 [1.6 x 23.8mm] slot into the

center of the tail brace as shown.

Set the assembly aside until instructed to permanently

install it in the “Join the Control Surfaces” section of

the manual.

Page 27

FINAL CONSTRUCTION

Mount the Engine

❏ 1. Set your engine onto the engine mount. Position

it so that there is approximately 1/4" [6mm] clearance

between the front of the cowl and the front of the

thrust washer on the motor. If you have a small

C-clamp use it to hold the engine to the mount.

❏ 5. Cut the 11-3/4" [298mm] gray outer plastic

pushrod guide to a length of 9". Use sandpaper to

roughen one end of the 9" plastic tube. Insert the

smooth end of the tube through the firewall back into

the radio compartment. Apply a couple of drops of

CA to the roughened end of the tube. Then finish

inserting the rest of the tube flush with the firewall.

❏ 6. Before permanently installing the engine,

assemble the fuel tank following the manufacturer's

instructions. Then mount the fuel tank inside the

fuselage. Run the carburetor and vent lines through

the holes in the firewall.

❏ 7. Permanently mount the engine to the mount

and connect the fuel and vent lines.

Install the Radio

❏ 1. Locate the 1/8" [3mm] die-cut plywood servo

tray and the six 1/8" [3mm] die-cut plywood servo

tray reinforcements.

❏ 2. Mark the location of the engine bolt holes on the

engine mount. This can easily be done with a Great

Planes® Dead Center™ tool. If you do not have this

you can also heat the end of a pointed wire with a

torch and dimple the engine mount in the center of

each hole.

❏ 3. Remove the engine from the mount and drill four

#36 (or 7/64) [2.8mm] holes in the engine mount on the

marks. Tap 6-32 threads into the holes and mount your

engine with four 6-32 x 3/4" [19mm] socket head cap

screws, #6 flat washers and #6 lock washers.

❏ 4. Make a mark on the firewall to locate the

position that the throttle pushrod comes through.

Remove the engine and drill a 3/16" [4.8mm] hole

through the firewall.

❏ 8. Install the brass screw lock connector onto the

carburetor. You will complete the throttle installation

when you install the radio system.

- 27 -

❏ 2. Glue the plywood reinforcements to the bottom

of the servo tray.

❏ 3. From left over 1/4" x 1/4" [6 x 6mm] basswood

stringer material, cut two servo mounting rails 3-7/8"

[98mm] long. Glue them in position inside of the

fuselage at the location shown on the plan.

❏ 4. Glue the servo tray on top of the rails.

Page 28

❏ ❏ 5. Install the servos as shown following the

radio manufacturer's mounting instructions. Before

screwing the servos in place, drill a 1/16" [1.6mm]

hole through each of the servo mounting holes,

drilling into the plywood servo tray and the

reinforcement strips on the underside of the servo

tray. Skipping this step may cause the servo tray to

split when you screw the servos into position. Apply

a couple of drops of thin CA to harden the holes and

then screw the servos in place.

❏ 6. Permanently secure the receiver and battery in

place where shown on the plan. Be sure that you

wrap each of them in 1/4" [6mm] foam and secure

them so they are not able to move around inside the

fuselage. Connect your servos to the receiver

following the manufacturer's instructions. Route your

receiver antenna through the fuselage, attaching it to

the fuselage longerons at the rear of the model.

❏ 7. Mount your on / off receiver switch in a location

that does not interfere with the rest of the radio

system. It is good practice to mount your switch on

the side of the model opposite the exhaust.

❏ 8. Locate the .072 x 17-1/2" [445mm] pushrod wire

threaded on one end. This is the throttle pushrod

wire. Insert the unthreaded end of it through the

screw lock connector on the carburetor and into the

tube in the firewall. Feed the wire into the tube until

the end of the wire is over the throttle servo control

horn. Once the throttle pushrod wire is over the

throttle servo arm continue feeding the pushrod wire

into the tube an additional 1" [25mm]. At the screw

lock connector on the carburetor, cut the excess

throttle pushrod wire. When you cut the wire you will

be cutting off the threaded portion of the wire. This is

correct. Tighten the 4-40 set screw on the screw lock

connector to hold the throttle pushrod wire in place.

Connect the other end of the throttle pushrod to the

servo with a screw lock pushrod connector and the

4-40 set screw.

FINISHING

Fuelproofing

Remove the engine, engine mount and the throttle

pushrod. Fuelproof the entire engine compartment

including the firewall. Use epoxy, epoxy paint,

finishing resin or other fuelproof model paint.

Prepare the Model for Covering

❏ 1. Inspect all surfaces for uneven glue joints and

seams that require filler. Apply filler where needed.

Many small dents or scratches in balsa can be

repaired by applying a few drops of water or

moistening the area with a wet tissue. This will swell

the wood so you can sand it when it dries.

❏ 2. Final sand the entire model with progressively

finer grits of sandpaper, finishing with 320 or

400-grit sandpaper.

❏ 3. Use a large brush, air pressure or a Top Flite Tack

Cloth (TOPR2185) to remove dust from the model.

- 28 -

Balance the Model Laterally

Laterally balancing the model now will allow you to

install weight on the wingtip before covering the wing,

hiding the weight inside the wing. Other components of

the aircraft like the pushrods and landing gear should

not have any effect on the lateral balance when they

are installed in future steps.

❏ 1. Mount your wing and the engine.

❏ 2. With the wing level, carefully lift the model by

the engine propeller shaft and the aft end of the

fuselage at the bottom of the wire tail skid (this may

require two people). Do this several times.

❏ 3. If one wing always drops when you lift the model,

that side is heavy. Balance the airplane by gluing weight

inside the other wing tip. Glue the weight in place with

epoxy. An airplane that has been laterally balanced will

track better in loops and other maneuvers.

Cover your Model with MonoKote

It is assumed that you are an intermediate to

advanced modeler, so we won’t go into many details

on covering techniques, but here are some tips you

should consider:

A. Most importantly, NEVER CUT THE COVERING

DIRECTLY ON THE SHEETING. The Elder depends

upon the wood sheeting for some of its strength.

Modelers who cut through the covering tend to cut

into the sheeting and this will weaken the structure.

B. Use a Top Flite® Hot Sock™ to minimize dents in

the wood from your covering iron.

C. Some modelers have three irons going at once:

one on high heat without a Hot Sock for stretching

the covering around curves like wingtips; one on

medium heat with a Hot Sock for bonding the

covering to large sheeted areas like the wing and

stab; and a Trim Iron for small areas.

Page 29

D. When you cover large sheeted surfaces such as

the wing, bond the covering in the middle and work

outward, pushing out air as you proceed. Do not

move the iron in a circular motion, but move it lengthwise with the grain of the wood.

E. When you cover smaller parts with square edges

such as the elevators and ailerons, cover the ends

first with separate pieces of covering. Then, all you

have to do is wrap the covering around the top and

bottom and iron it down.

F. When you cover sharp junctions like where the

stab meets the fuse, cut narrow strips of covering

(3/8 to 1/2" [10 to 13mm] wide) and apply them in the

corners before you cover the major surfaces. The

larger pieces of covering will overlap the smaller

pieces. This technique also eliminates the need to

cut the covering after it has been applied.

Installing the Stab and Fin