Page 1

WARRANTY.....Top Flite Models guarantees this kit to be free of defects in both material and workmanship at the date of purchase. This

warranty does not cover any component parts damaged by use or modification. In no case shall Top Flite’s liability exceed the original cost of the purchased

kit. Further, Top Flite reserves the right to change or modify this warranty without notice. In that Top Flite has no control over the final assembly or material

used for final assembly, no liability shall be assumed nor accepted for any damage resulting from the use by the user of the final user-assembled product.

By the act of using the user-assembled product the user accepts all resulting liability. If the buyer is not prepared to accept the liability associated with the

use of this product, the buyer is advised to immediately return this kit in new and unused condition to the place of purchase.

Top Flite Models P.O. Box 788 Urbana, Il 61803 Technical Assistance Call (217)398-8970 www.top-flite.com

CTD6P03 V1.1

READ THROUGH THIS INSTRUCTION BOOK FIRST. IT CONTAINS IMPORTANT INSTRUCTIONS AND WARNINGS CONCERNING THE ASSEMBLY AND USE OF THIS MODEL.

Entire Contents © Copyright 2000

™

™

Wingspan:

53-1/4" [1353 mm]

Wing Area:

660 sq. in.

[42.6 sq.dm.]

Weight:

6 - 6-1/2 lbs

[2721 - 2948 grams]

Wing Loading:

21 - 23 oz./sq. ft.

[64 - 70 g/sq.dm.]

Fuselage Length:

49-5/8" [1261 mm]

Engine Required:

2-Stroke .40 - .61 or

4-Stroke .52 - .70

Page 2

TABLE OF CONTENTS

INTRODUCTION..................................................3

PRECAUTIONS ...................................................3

DECISIONS YOU MUST MAKE ..........................3

Engine selection .............................................3

Flaps...............................................................3

Power requirements and propellers...............3

FLIGHT CHARACTERISTICS.............................4

OTHER REQUIRED ITEMS ................................4

BUILDING SUPPLIES.........................................4

Glue & Fillers..................................................4

Tools...............................................................4

IMPORTANT BUILDING NOTES ........................5

DIE-CUT PATTERNS...........................................6

GET READY TO BUILD......................................7

BUILD THE TAIL SURFACES.............................7

Build the stab .................................................7

Build the rudder..............................................8

Build the fin ....................................................8

Install the hinges............................................9

Install the control horns ................................10

BUILD THE WING .............................................11

Build the bottom of the wing.........................11

Build the top of the wing ..............................14

Build the ailerons..........................................16

Install the aileron control horns....................16

Build the flap ................................................16

Build the wing tips........................................17

Standard wing tips........................................17

Optional wing tips.........................................18

Install the aileron and flap hinges................18

BUILD THE FUSELAGE ...................................18

Frame the fuselage......................................18

Make the cowl..............................................23

Mount the wing.............................................24

Install the landing gear .................................24

Mount the stab .............................................25

INSTALL THE SERVOS AND PUSHRODS ......26

Make the pushrods.......................................26

Install the servos in the fuselage .................26

Install the aileron servos..............................27

Install the flap servo (optional).....................27

Install the battery, receiver and switch.........27

Prepare the canopy......................................27

FINISHING .........................................................28

Prepare the model for covering....................28

Balance the airplane laterally ......................28

Cover your model with MonoKote®..............28

Covering sequence......................................28

Join the control surfaces..............................29

FINISHING TOUCHES.......................................29

Decals ..........................................................29

Panel lines....................................................29

GET YOUR MODEL READY TO FLY...............29

Balance your model .....................................29

Final hookups and checks ...........................30

Control surface throws.................................30

PREFLIGHT.......................................................30

Identify your model.......................................30

Charge the batteries.....................................30

Balance the propeller...................................31

Ground check your model ............................31

Range check your radio...............................31

ENGINE SAFETY PRECAUTIONS...................31

AMA SAFETY CODE ........................................31

FLYING...............................................Back Cover

Takeoff...........................................Back Cover

Flight ..............................................Back Cover

Landing ..........................................Back Cover

Your Top Flite Contender is not a toy, but a

sophisticated working model that functions very

much like an actual airplane. Because of its realistic

performance, if you do not assemble and operate

your Contender correctly, you could possibly injure

yourself or spectators and damage property.

To make your R/C modeling experience totally

enjoyable, get assistance with assembly and

your first flights from an experienced,

knowledgeable modeler. You’ll learn faster and

avoid risking your model before you’re truly ready to

solo. Your local hobby shop has information about

flying clubs in your area whose membership

includes qualified instructors.

You can also contact the Academy of Model

Aeronautics (AMA), which has more than 2,500

chartered clubs across the country. We recommend

you join the AMA which will insure you at AMA club

sites and events. AMA Membership is required at

chartered club fields where qualified flight instructors

are available.

Contact the AMA at the address or toll-free phone

number below.

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, IN 47302

(800) 435-9262

Fax (765) 741-0057

or via the Internet at: http://www.modelaircraft.org

Your Top Flite Gold Edition Contender is intended for

scale and general sport flying including mild aerobatics

such as loops, stall turns, rolls, etc. Its structure is

designed to withstand such stresses. If you intend to

use your Contender for more abusive types of flying

such as racing or aggressive aerobatics it is your

responsibility to reinforce areas of the model that will be

subjected to the resulting unusually high stresses.

PROTECT YOUR MODEL,

YOURSELF & OTHERS

FOLLOW THIS IMPORTANT

SAFETY PRECAUTION

2

Page 3

INTRODUCTION

Congratulations and thank you for purchasing the

Top Flite Gold Edition “Contender.” We are sure

you are eager to build and fly your Contender just as

we were eager to build and fly our prototypes. The

Contender was introduced thirty years ago and there

have been so many requests to bring it back that we

decided to remanufacture it to today’s high quality

standards for Top Flite Kits. You should find this kit

easy to build and a lot of fun to fly!

Get your other projects off your workbench, say

goodbye to your significant other for a while

and...keep reading!

Please inspect all parts carefully before you start to

build! If any parts are missing, broken or defective,

or if you have any questions about building or

flying this model, please call us at (217) 398-8970 or

e-mail us at productsupport@top-flite.com and

we’ll be glad to help. If you are calling for

replacement parts, please look up the part

numbers and the kit identification number

(stamped on the end of the carton) and have them

ready when you call.

PRECAUTIONS

1.You must build the plane according to the plan and

instructions. Do not alter or modify the model, as

doing so may result in an unsafe or unflyable model.

In a few cases the plan and instructions may differ

slightly from the photos. In those instances you

should assume the plan and written instructions

are correct.

2.You must take time to build straight, true

and strong.

3. You must use a proper R/C radio that is in first

class condition, the correct sized engine and correct

components (fuel tank, wheels, etc.) throughout your

building process.

4. You must properly install all R/C and other

components so that the model operates properly on

the ground and in the air.

5. You must test the operation of the model

before every flight to insure that all equipment is

operating and you must make certain that the model

has remained structurally sound.

6. If you are not already an experienced R/C pilot,

you must fly the model only with the help of a

competent, experienced R/C pilot.

Remember: Take your time and follow instructions to

end up with a well-built model that is straight and true.

DECISIONS YOU MUST MAKE

Recommended engine size:

.40 to .61 cu. in. [7.5cc to 10cc] 2-stroke

.52 to .70 cu. in. [8.5cc to 11.5cc] 4-stroke

Your Top Flite Gold Edition “Contender” will

perform well with any of the engines within the

recommended range. We flew our prototype with

the O.S.®40LA and the 60FP™and both engines

had more than ample power.

FLAPS

Your Contender is designed to incorporate a

center flap; however, the flap is optional and not

necessary for an excellent flying experience.

Without the flap, the takeoff roll is a bit longer and

the landing speed is slightly faster. If you do not

wish to build the flap, just disregard those parts of

the manual involving operational flap construction.

The flap is not difficult to build and it operates

well. The flap adds nicely to the model’s flight

characteristics. Very minor trim changes were

needed for our prototype when the flap was

lowered. You will find more information on the use

of the flap in the flying section.

The flap requires one additional standard servo.

POWER REQUIREMENTS AND PROPELLERS

We did our test flying using Top Flite®Power Point

®

Propellers and an OS .60FP engine. With the .60

2-stroke engine the model flew very well. A .61 will

provide more power than the model needs, but you

will appreciate the extra power when vertical

maneuvers are being performed. Initial test flights

were with the Power Point 11x7 propeller. As with

any model, you may experiment with different

propellers to find out what type works best for you.

NOTE: We, as the kit manufacturer, provide you with a

top quality kit and great instructions, but ultimately the

quality and flyability of your finished model depends on

how you build it; therefore, we cannot in any way

guarantee the performance of your completed model,

and no representations are expressed or implied as to

the performance or safety of your completed model.

3

Page 4

FLIGHT CHARACTERISTICS

During our flight testing we found no bad

characteristics in this airplane. Takeoffs were

straightforward with good ground handling. The

plane was airborne in approximately 100 feet [30m].

Once the plane is flying it goes exactly where you

point it. Depending on how you set up the model,

rolls can be very slow or very fast. Power-off stalls

were very soft and predictable with only the nose

dropping in the stall. There was no tendency for the

wing to tip stall. Landings were straightforward with

or without the flap. Without the flap you should

maintain a bit more airspeed on your approach. With

full flap deployment the plane slows very nicely and

allows for a very soft landing. If you have never flown

with flaps this an excellent model to learn with.

OTHER REQUIRED ITEMS

These are additional items you will need to complete

your Contender that are not included with your kit.

Order numbers are in parentheses (GPMQ4130).

Our exclusive brand is listed where possible: TOP is

the Top Flite®brand, GPM is the Great Planes

®

brand, and HCA is the Hobbico®brand.

❏ 4 to 5 Channel radio with 4 to 5 servos

❏ Engine

O.S. Engines Prop

.40 LA 10 x 6, 10 x 7

.61 FX 2-stroke 11 x 7, 12 x 6

FS .52 11 x 6, 11 x 7

FS .70 Surpass™4-stroke 13 x 8

Super Tigre

®

Prop

G-51 2-stroke 10 x 7, 11 x 6

G-61 2 stroke 11 x 7, 12 x 6

❏ Propellers appropriate for your engine

❏ (3) 2-1/2" [64mm] Wheels (GPMQ4223)

❏ (1) 8 - 10 oz. [240 - 300cc] Sullivan Flex Tank

(SULQ1739 or SULQ1740)

❏ (2) 12" [305mm] Servo Extensions (3 if optional

flap is used)

❏ (1) Y-connector

❏ (1) 3 feet [914mm] Medium Silicone Fuel Tubing

(GPMQ4131) (12" needed for the model)

❏ (1) 2-1/2" [64mm] Spinner (GPMQ4525)

❏ (1) 1/4" [6mm] (HCAQ1000) Foam Rubber Padding

❏ (2) rolls of Top Flite Super MonoKote

®

covering

❏ (1) 2" [50mm] 1/6th Scale Pilot

BUILDING SUPPLIES

Here’s a checklist of supplies you should have on

hand while you’re building. Some of these are

optional. Use your own experience to decide what

you need. We recommend Great Planes Pro™CA

and Epoxy.

GLUE/FILLER

❏ 4 oz. [120g] Thin CA (GPMR6004)

❏ 4 oz. [120g] Medium CA+(GPMR6010)

❏ 2 oz. [60g] Thick CA- (GPMR6015)

❏ CA Accelerator (GPMR6035)

❏ CA Debonder (GMPR6039)

❏ CA Applicator Tips (HCAR3780)

❏ 6-minute epoxy (GPMR6045)

❏ 30-minute epoxy (GPMR6047)

❏ 4 oz. [120g] Pro Wood Glue (GPMR6161)

❏ Lightweight Hobby Filler (Balsa Color, HCAR3401)

TOOLS

❏ #11 Blades (HCAR0311, 100 qty.)

❏ Single Edge Razor Blades (HCAR0312, 100 qty.)

❏ Razor Plane (MASR1510)

❏ Hobbico Builder’s Triangle (HCAR0480)

❏ T-Pins (HCAR5100 (S), HCAR5150 (M),

HCAR5200 (L)

❏ 1/4-20 Tap and drill (GPMR8105)

❏ 6-32 Tap and drill (GPMR8102)

❏ Tap wrench (GPMR8120)

❏ Drill Bits:

1/16" [1.6mm] 5/64" [2mm]

3/32" [2.4mm] 1/8" [3.2m

5/32" [4.0mm] 11/64" [4.4mm]

3/16" [4.8mm] 13/64" [5.2mm]

7/32" [5.6mm] 1/4" [6.4mm]

17/64" [6.7mm]

❏ Curved Tip Scissors (HCAR0667)

❏ Great Planes Plan Protector (GPMR6167)

or wax paper

❏ Masking Tape

❏ Easy-Touch™Bar Sanders*

❏ Dremel®#178 cutting bit for countersinking

screws in the fuel tank hatch. (DRER1178)

RECOMMENDED COVERING

TOOLS AND ACCESSORIES

❏ Top Flite Heat Gun (TOPR2000)

❏ Top Flite Trim Seal Tool (TOPR2200)

-and-

❏ Top Flite Sealing Iron (TOPR2100)

❏ Top Flite Hot Sock™(TOPR2175)

-or-

❏ 21st Century®Sealing Iron (COVR2700)

❏ 21st Century Cover Sock (COVR2702)

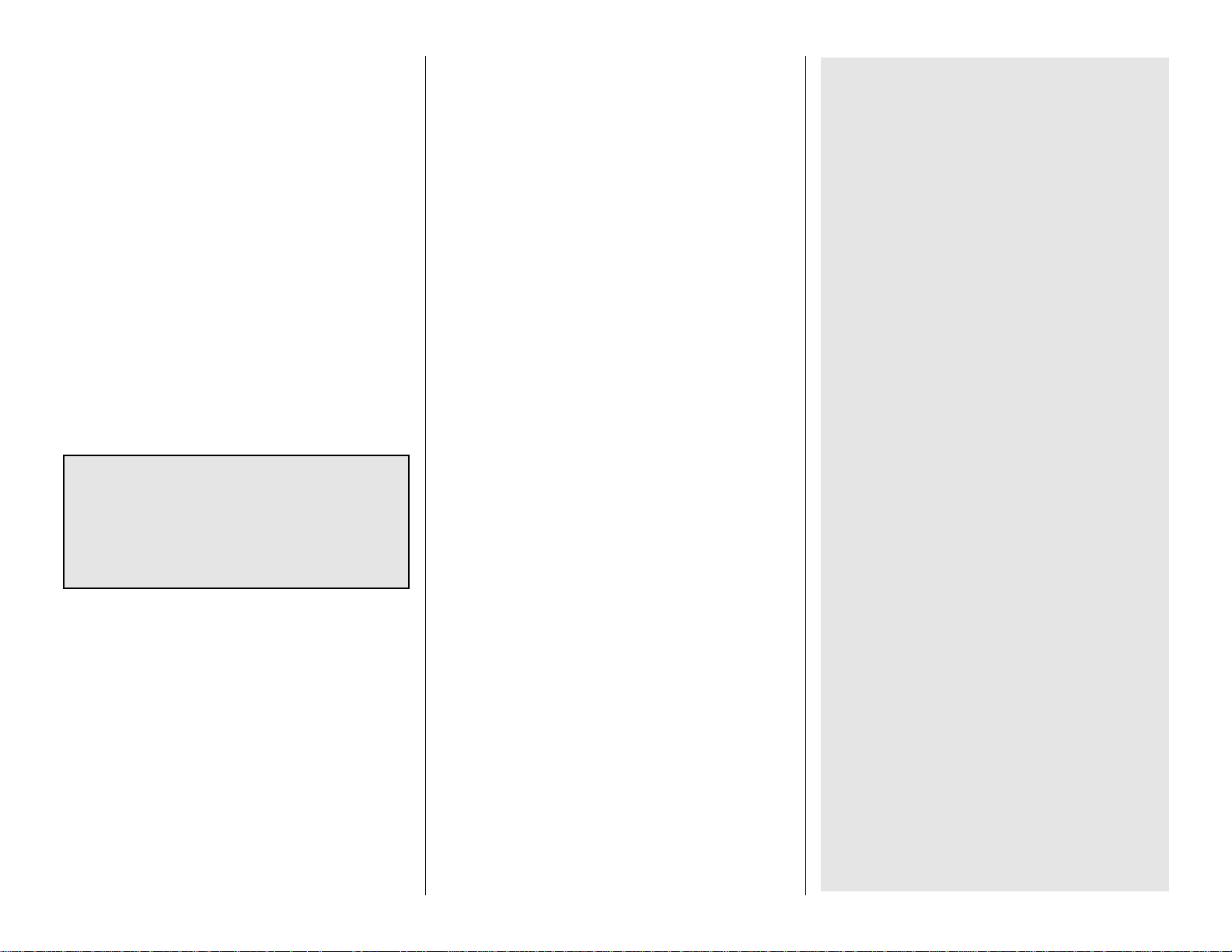

EASY-TOUCH™BAR SANDER

A flat, durable, easy to handle sanding tool is a

necessity for building a well finished model. Great

Planes makes a complete range of Easy-Touch Bar

Sanders (patented) and replaceable Easy-Touch

4

Page 5

Adhesive-backed Sandpaper. While building the

Contender we used two 5-1/2" [140mm] Bar Sanders

and two 1 1" [280mm] Bar Sanders equipped with 80grit and 150-grit Adhesive-backed Sandpaper.

Here's the complete list of Easy-Touch Bar Sanders

and Adhesive Backed Sandpaper.

5-1/2" [140mm] Bar Sander (GPMR6169)

11" [280mm] Bar Sander (GPMR6170)

22" [560mm] Bar Sander (GPMR6172)

33" [840mm] Bar Sander (GPMR6174)

44" [1120mm] Bar Sander (GPMR6176)

11" [280mm] Contour Multi-Sander (GPMR6190)

12' [300mm] roll of Adhesive-backed sandpaper:

80-grit (GPMR6180)

150-grit (GPMR6183)

180-grit (GPMR6184)

220-grit (GPMR6185)

Assortment pack of 5-1/2" [140mm] strips (GPMR6189)

We also use Top Flite 320-grit (TOPR8030, 4 sheets)

and 400-grit (TOPR8032, 4 sheets) wet-or-dry

sandpaper for finish sanding.

IMPORTANT BUILDING NOTES

There are two types of screws used in this kit:

Sheet metal screws are designated by a number

and a length.

For example #6 x 3/4" [19.1mm]

Machine screws are designated by a number,

threads per inch and a length.

For example 4-40 x 3/4" [19.1mm]

When you see the term test fit in the instructions, it

means that you should first position the part on the

assembly without using any glue, then slightly

modify or custom fit the part as necessary for the

best fit.

Whenever the term glue is used you should rely

upon your experience to decide what type of glue to

use. When a specific type of adhesive works best for

that step we will tell you what type of glue to use.

Whenever just epoxy is specified you may use either

30-minute epoxy or 6-minute epoxy. When 30-minute

epoxy is specified it is highly recommended that you

use only 30-minute (or 45-minute) epoxy because you

will need the working time and/or the additional strength.

Occasionally we refer to the top or bottom of the

model or up or down. To avoid confusion, the top or

bottom of the model is as it would be when the

airplane is right side up and will be referred to as the

top even if the model is upside down during that

step, i.e. the top main spar is always the top main

spar even if the wing is upside down when you are

working on it. Similarly, move the former up means

move the former toward the top of the fuselage even

if the fuselage is upside down when you are working

on it.

When you get to each step, read that step completely

through to the end before you begin. Frequently

there is important information or a note at the end of

the step that you need to know before you start.

Photos and sketches are placed ahead of the step

they refer to. Frequently you can study photos in

following steps to get another view of the same parts.

COMMON ABBREVIATIONS

Deg = degrees Elev = elevator

Fuse = fuselage " = inches

LE = leading edge Ply = plywood

Stab = stabilizer TE = trailing edge

LG = landing gear mm = millimeters

TYPES OF WOOD

BALSA BASSWOOD PLYWOOD

Metric Conversion Chart

1” = 25.4mm (conversion factor)

Note: An inch/mm scale is provided on the

fuselage plan.

1/64" = .4mm

1/32" = .8mm

1/16" = 1.6mm

3/32" = 2.4mm

1/8" = 3.2mm

5/32" = 4mm

3/16" = 4.8mm

1/4" = 6.4mm

3/8" = 9.5mm

1/2" = 12.7mm

5/8" = 15.9mm

3/4" = 19mm

1" = 25.4mm

2" = 50.8mm

3" = 76.2mm

6" = 152.4mm

12" = 304.8mm

15" = 381mm

18" = 457.2mm

21" = 533.4mm

24" = 609.6mm

30" = 762mm

36" = 914.4mm

5

Page 6

6

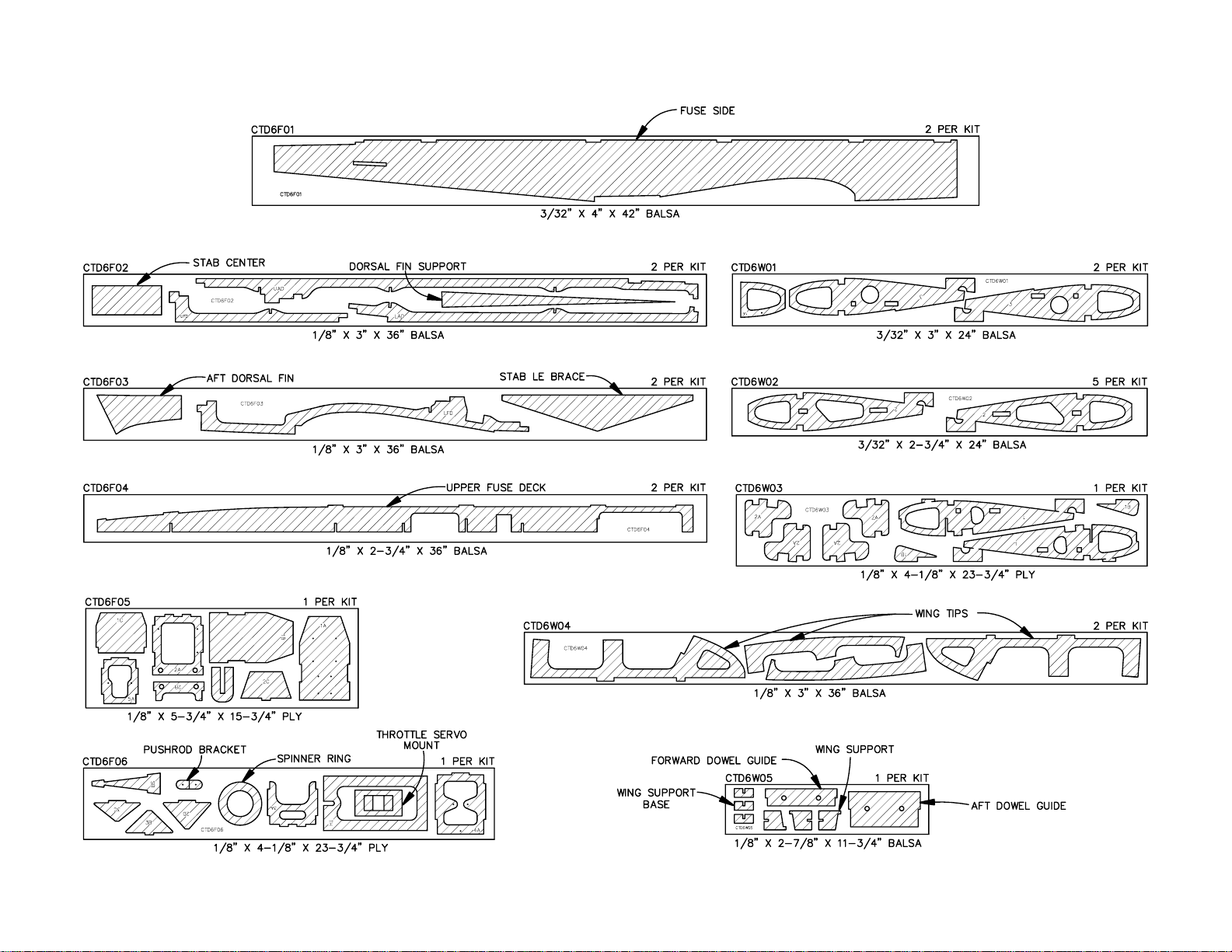

DIE-CUT PATTERNS

Page 7

GET READY TO BUILD

1. Unroll the plan sheets. Roll them inside out so

they lie flat.

2. Remove all the parts from the box. Use a ballpoint

pen (not a felt tip pen) to lightly write the name or

size on each piece so you can identify it later. Use

the die-cut patterns on page 6, to identify and mark

the die-cut parts before you remove them from their

die sheets. Many of the parts already have numbers

stamped on them, but in some cases the number is

located alongside the parts or only on the die

drawings. You may remove all the die-cut parts from

their die sheets now or wait until you need them. If a

part is difficult to remove, don't force it out but cut

around it with a #11 blade. After you remove the

parts from their die sheets, lightly sand the edges to

remove slivers or die-cutting irregularities. Save

some of the larger leftover pieces of wood.

3. Separate the parts into groups such as stab, fin,

wing, and fuse. Store smaller parts in zipper-top

food storage bags.

BUILD THE TAIL SURFACES

Build the stab

❏ 1.Work on a flat surface over the plan. Pin the stab

plan to the building board and cover the plan with

Plan Protector. Refer to the plan to identify the parts

and their location. The plan may be cut apart on the

dashed lines if space is a problem.

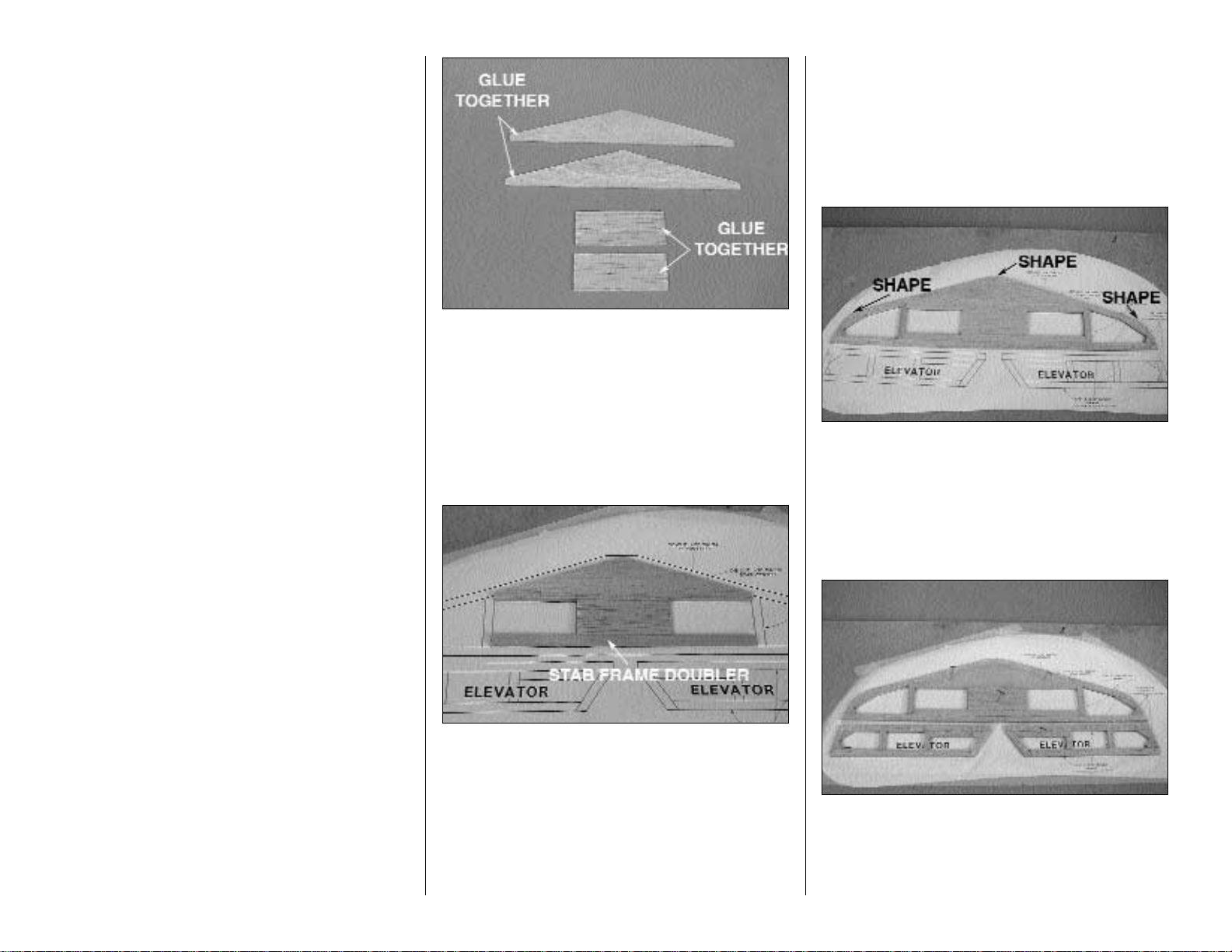

❏ 2. Locate and glue the two die-cut 1/8" [3.2mm]

balsa LE braces together to form one 1/4" LE brace.

Locate and glue the two die-cut 1/8" [3.2mm] balsa

stab centers together to form one 1/4" stab center.

❏ 3. Glue the die-cut 1/8" balsa stab center to the LE

brace as shown on the plan.

❏ 4. Pin the center section to the plan.

❏ 5. Locate the 1/4" x 3/8" x 12" [6.4 x 9.5 x 305mm]

basswood stab brace. Cut it to a length of 11" then

glue it to the aft edge of the stab center in the

location shown on the plan.

❏ 6. Use two 1/4" x 3/8" x 30" [6.4 x 9.5 x 762mm]

balsa sticks to make the frame for the stab. Cut the

sticks to the length shown on the plan and glue them

together to form the stab.

❏ 7. Use leftover pieces of the 1/4" x 3/8" x 30" [6.4

x 9.5 x 762mm] balsa sticks to make the 1/4"

[6.4mm] balsa gussets. Cut them as shown on the

plan and glue them in place.

❏ 8. Remove the stab from the plan. Shape the

corners and the center LE of the stab assembly as

shown on the plan. Pin the stab back to the building

board after you have shaped the stab.

❏❏9. Use two 1/4" x 3/8" x 30" [6.4 x 9.5 x 762mm]

balsa sticks to make the frames for the elevator. Cut

the sticks to the shape shown on the plan. Glue the

sticks together the same way the stab was

assembled. Make a left and right elevator.

7

Page 8

❏❏10. Insert a T-pin through the center of the

elevator LE near the tip and near the root. Place a

straightedge across the T-pins and draw a

centerline on the elevator LE with a ball point pen.

This line is used as a reference when we install the

hinges in a later step. Draw a centerline along the TE

of the stab the same way.

❏❏11. Shape the LE of the elevator to a “V” as

shown on the plan. Use the line you have drawn as

a reference when sanding the LE.

❏❏12. Final sand the stab and elevator. Shape the

LE of the stab and the TE of the elevator as shown

in the cross-section on the plan. Hint:The Great

Planes Easy Touch Multi-Sander works great for

shaping the round LE and TE.

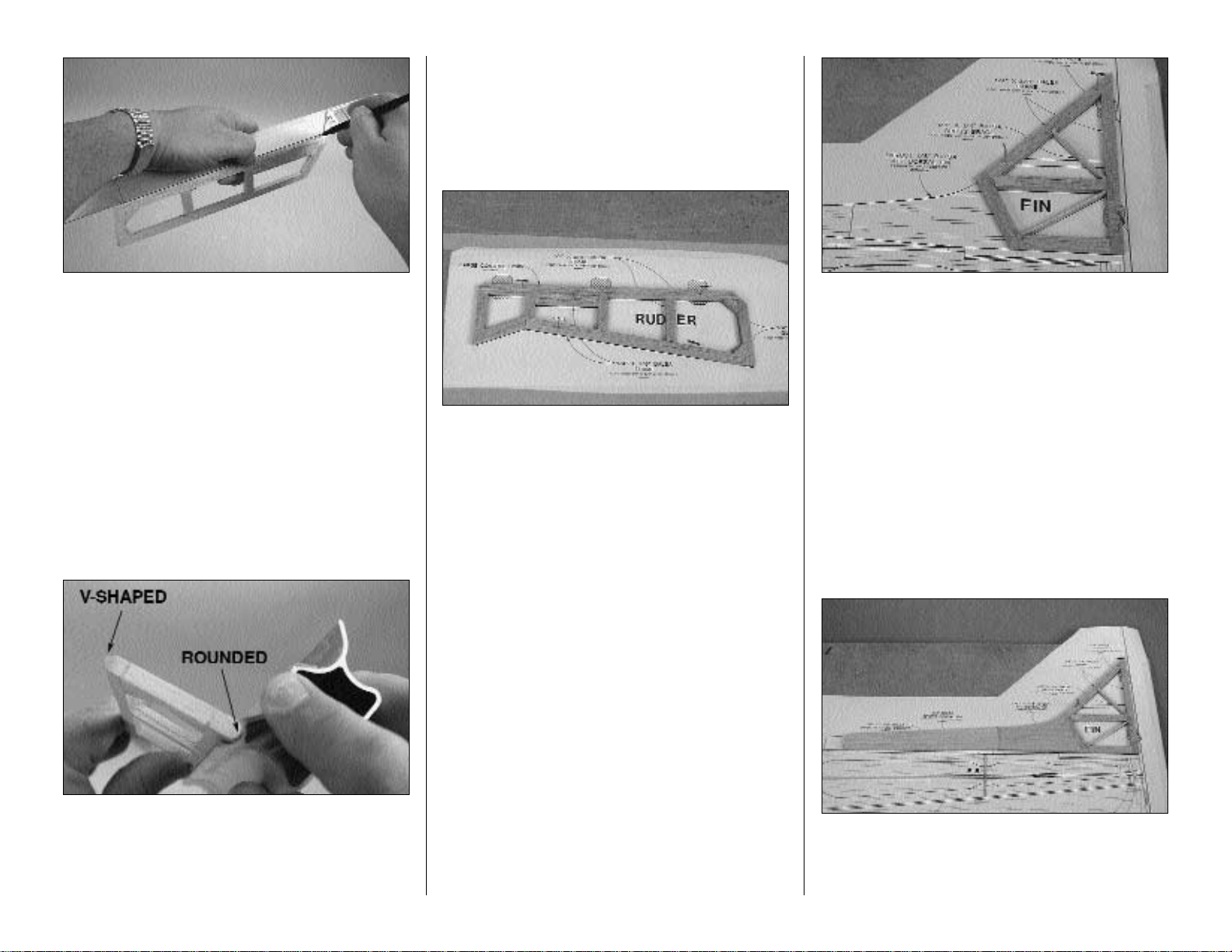

Build the rudder

❏ 1.Work on a flat surface over the plan. Pin the

rudder plan to the building board and cover the plan

with Plan Protector. The plan may be cut apart if

space is a problem.

❏ 2. Use one 1/4" x 3/8" x 30" [6.4 x 9.5 x 762mm]

balsa stick and leftover pieces of 1/4" x 3/8" x 30"

[6.4 x 9.5 x 762mm] balsa stick from the stab and

elevator to make the frame for the rudder. Cut the

sticks to the shape shown on the plan. Glue the

sticks together the same way the stab and elevator

were assembled.

❏ 3. Draw a centerline on the rudder LE the same

way it was done to the elevator.

❏ 4. Final sand the rudder. Shape the LE to a “V” the

same way it was done for the elevator and as shown

on the plan.

❏ 5. Shape the TE, top and bottom of the rudder to

the rounded shape shown on the plan.

Build the fin

❏ 1. Pin the fuselage plan to the building board and

cover the plan with Plan Protector.

❏ 2. Use one 1/4" x 3/8" x 30" [6.4 x 9.5 x 762mm]

balsa stick to make the frame of the fin. Cut the stick

to the lengths shown on the plan. Pin the sticks in place

as needed. Glue the sticks together to form the fin.

❏ 3. From 1/8" x 1/4" x 30" [3.2 x 6.4 x 762mm] balsa

stick, cut the cross braces and glue them in place at

the location shown on the plan.

❏ 4. Glue the two die-cut 1/8" [3.2mm] balsa aft

dorsal fin halves together, laminating them to make

a 1/4" [6.4mm] dorsal fin.

❏ 5. From 1/4" x 3" x 24" [6.4 x 76 x 610mm] balsa

sheet, cut the center dorsal fin to the size and

shape shown on the plan.

❏ 6. Glue the aft dorsal fin to the fin. Glue the center

dorsal fin to the aft dorsal fin. All of these parts must

be lying on a flat surface while gluing, to ensure a

flat, straight assembly.

8

Page 9

❏ 7. Remove the assembly from the plan.

❏ 8. Final sand the fin assembly. Shape the LE of the

fin and the top of the dorsal fin to the shape shown

on the plan.

❏ 9. Draw a centerline on the TE of the fin in the

same manner as was done for the stab.

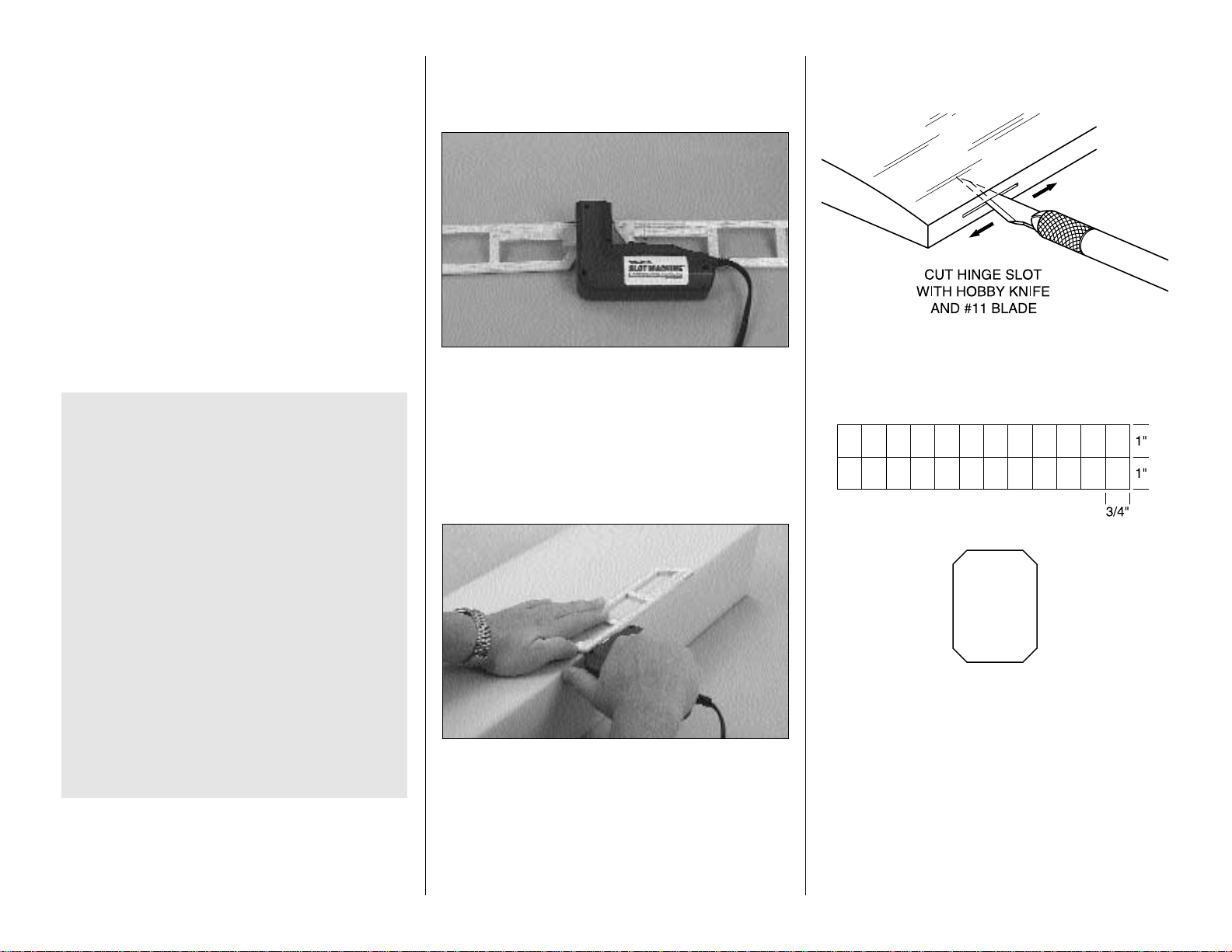

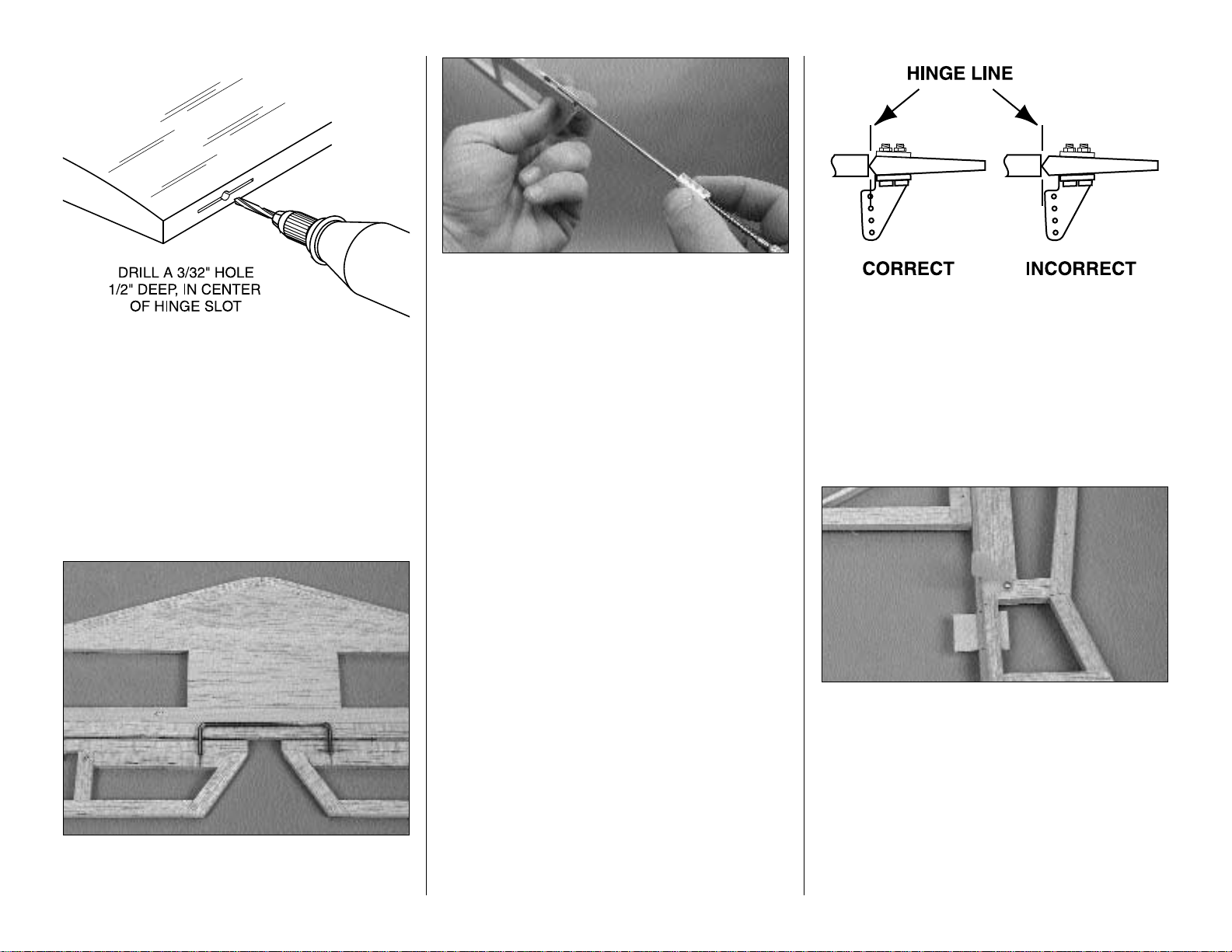

Install the hinges

❏ 1. Mark the location of the hinge slots on the

elevator halves, stab, fin and rudder where shown on

the plan.

We have simplified the task of cutting hinge slots

with the introduction of the Great Planes Slot

Machine™. This simple electric tool cuts a perfect

width slot for use with CA hinges.

To cut the hinge slot place the blades onto the wood

where you want the slot. Lightly press the teeth into

the wood. When you are satisfied with the location

press the button on the handle and the blades will

cut easily into the balsa wood.

If you choose not to purchase a Slot Machine you

can make the slots following these instructions.

❏ 2. Cut the hinge slots in the elevators, stab, fin and

rudder along the centerlines you marked earlier with

a #11 blade.

❏ 3. Using the sketch above, cut nine hinges from

the CA hinge strip supplied with the kit. Snip the

corners off so they go into the slots easier. You may

cut all nineteen hinges that will be used for the

airplane or just cut them as you need them.

❏ 4. Test fit the hinges into the slots. If the hinges do

not slide into the slots easily, work your knife blade

back and forth in the slot a few times to provide more

clearance (it is really the back edge of the blade that

does the work here in widening the slot).

IMPORTANT NOTES ABOUT CA HINGES

This kit is supplied with a CA hinge material

consisting of a 3-layer lamination of Mylar and

polyester. It is specially made for hinging model

airplane control surfaces. When properly installed,

this type of CA hinge provides the best combination

of strength, durability and easy installation. We trust

all of our Gold Edition warbirds to these hinges, but

it is essential to install them correctly. Carefully

follow the hinging instructions in this manual for the

best result.

The most common mistake made by modelers when

installing CA hinges is making the hinge slots too

tight restricting the flow of CA to the back of the

hinges; or not using enough glue to fully secure the

hinge over its entire surface area. This results in

hinges that are only tack glued into the hinge slots.

The techniques for cutting the hinge slots and gluing

in CA hinges (near the end of the manual) have been

developed to ensure thorough and secure gluing.

9

Page 10

❏ 5. Drill a 3/32" [2.40mm] hole, 1/2" [13mm] deep in

the center of the hinge slots. Use a rotary tool with a

3/32" [2.40 mm] drill bit or a carbide cutter for the

best results. Re-insert your knife blade to clean out

the slot after you drill the hole.

❏ 6. Test fit the elevator halves to the stab with

the hinges.

❏ 7. Position the elevator joiner wire on the trailing

edge of the stab and center it between the elevators.

Mark the LE of both elevators where the joiner will enter.

❏ 8. Cut a slot in the leading edge of both elevator

halves to accommodate the joiner wire. This can be

done easily with the Great Planes “Groove

Tube”™ as shown in the photograph. Hint: If you do

not have a Groove Tube, use a 5/32" [4mm] brass

tube sharpened at one end to cut the slot.

❏ 9. Accurately drill holes in the elevators for the 1/8"

joiner wire. Begin by drilling a 1/16" [1.6mm] pilot

hole. Then drill the final hole to a depth of 7/8"

[22.2mm] with a 9/64" [3.6mm] drill bit. (The hole is

drilled slightly oversize to allow for positioning and to

create a hard epoxy “sleeve” around the wire).

❏ 10. Roughen the joiner wire with coarse sandpaper,

then clean the wire thoroughly with alcohol to remove

any oily residue.

❏ 11. Test fit the joiner wire into the elevators. Then,

glue it in using epoxy. When gluing, lay the elevators

on a flat surface with the LE along a straightedge to

insure perfect alignment. Cover the top of the joined

elevators with a sheet of wax paper. Then, lay a flat,

heavy object on top. A telephone book works well.

This will insure a true flat elevator assembly when

the epoxy cures.

Install the control horns

❏ 1. Place a large control horn at the location

indicated on the elevator plan and rudder plan. Use

a ballpoint pen to mark the location where the holes

need to be drilled.

❏ 2. Check for correct alignment. Drill two 3/32"

[2.4mm] holes for the control horn mounting bolts

through the rudder .

❏❏3. Repeat step 2 for the right half of the elevator.

❏ 4. Apply a small drop of thin CA in the holes to

harden the wood. Redrill the holes after the CA

has hardened.

❏ 5. Attach the control horn to the left side of the

rudder with two 2-56 x 1/2" [12.7mm] machine

screws.

❏ 6. Attach the control horn to the bottom right side

of the elevator with two 2-56 x 1/2" [12.7mm]

machine screws.

There, that went pretty quick. If your workbench is a

mess, clean it off and get ready to move on to the wing!

10

Page 11

BUILD THE WING

Build the bottom of the wing

❏ 1. Cut the wing plan on the dashed line. Tape the

two wing plan halves together to form the full plan for

the wing.

❏ 2. Work on a flat surface over the plan. Pin or tape

the wing plan to the building board and cover the

plan with Plan Protector.

❏ 3. When building the wing it is important to note that

the wing is being built upside-down over the plan.

❏ 4. Locate four die-cut 3/32" [2.4mm] balsa W-2

ribs and four die-cut 1/8" [3.2mm] ply W-2A

doublers. Glue a W-2A doubler to each W-2 rib with

6-minute epoxy. Make sure that you make two for

the left wing and two for the right wing.

❏ 5. After the epoxy has cured, remove the area on

W-2 that will hold the landing gear block. Do this on

all four of the assemblies that you just glued together.

❏ 6. Locate two die-cut ply W-1 ribs and two die-cut

ply W-1B doublers. Glue a W-1B doubler to each

W-1 rib with 6-minute epoxy. Make sure that you

make one left side and one right side when gluing

them together.

❏ 7. Cut the two 1/4" x 3/8" x 48" [6.4 x 9.5 x

1220mm] basswood wing spars to the length shown

on the plan. Pin one of the wing spars to the plan.

Make sure that the pins will not be in the way for

placing any of the ribs on the spar.

❏ 8. Position ribs W-1, W-2 and W-3 on the wing

spar at the locations indicated on the plan. Make

sure when you place the ribs that all of the ribs have

the jig tab in contact with the building board. Place

the remaining wing spar in position on the bottom of

the wing in the notches on the ribs W-1, W-2 and W-

3. When positioning the ribs be sure the ribs are

perpendicular to the building table. When you are

satisfied with the fit glue the ribs to the bottom wing

spar only. It is important to remember you are

building the wing upside down. Be sure to glue only

the bottom wing spar.

❏ 9. Locate two 9/16" x 7/8" x 24" [14.3 x 22.2 x

584mm] balsa TE sticks. Glue the two TE sticks

together where they will meet at the center of the

wing. Test fit the TE on the wing jig tabs. When you

are satisfied with the fit glue the TE to the end of the

ribs only! Do not glue the TE to the jig tabs.

❏ 10. Cut off the excess TE material outboard of the

tip rib.

11

Page 12

❏ 11. Locate the die-cut 1/8" [3.2mm] ply forward

dowel guide and the die-cut 1/8" [3.2mm] ply aft

dowel guide. Measure the distance between the

center of the holes in the forward dowel guide. Draw

a centerline on the forward dowel guide.

❏ 12. Use 6-minute epoxy to glue the die-cut 1/8"

[3.2mm] ply forward dowel guide and the die-cut 1/8"

[3.2mm] ply aft dowel guide in place between the two

W-1 ribs as shown on the plan. Be sure that the side

of the forward dowel guide with the centerline on it is

facing the front of the wing.

❏ 13. Locate the two die-cut balsa 3/32" [2.4mm] half

ribs W-1A. There is a pin punch mark on the top of

each rib. Glue the two W-1A ribs to each other

forming one 3/16" W-1A rib. Make sure that the

punch marks are aligned.

❏ 14. Glue the W-1A rib assembly in place between

the W-1 ribs in the location shown on the plan. W-1A

supports the wing sheeting you will be adding later

so make sure it is properly centered. Glue W-1A in

position with the side of the rib with the pin punch

nearest your building board.

❏❏15. Locate two 3/32" x 1-1/4 “ x 30" [2.4 x 32 x

762mm] balsa sub LE sticks. Test fit the sub LE

against the front of the ribs on the right side of the

wing making sure that each rib comes in contact with

the sub LE. Sand the front of the ribs as needed.

When you are satisfied with the fit, glue the sub LE

to the front of the ribs and the front of the forward

dowel guide. Be sure that the joining of the two sub

LE sticks is directly over the centerline that you

drew on the forward dowel guide.

❏❏16. Sand the sub LE stick so that it is flush with

the wing ribs.

❏17. Repeat step 15 and 16 for the left side of the wing.

❏❏18. Locate the two maple landing gear rails and

two maple torque blocks. Measure in from the end of

the landing gear rail 1/4" [6.4mm]. Mark a line with a

pen. Use 6-minute epoxy to glue a torque block to

one of the landing gear rails at the mark you just

made. Do the same for the remaining landing gear

rail and torque block. Set it aside and allow the

epoxy to cure.

❏❏19. From the 1/4" x 1/4" x 18" [6.4 x 6.4 x

457mm] basswood stick, cut four 2" [51mm] sticks to

be used for the servo rails. Glue two rails into the

slots in the two W-3 ribs in the left wing. The slot in

the aft of rib W-3 is longer than the forward slot. This

is to allow you to get exact spacing for your brand of

servo. Be sure to position the rear servo rail for your

servo. Glue them in place when you are satisfied

with the fit.

❏20. Repeat step 19 for the servo rails in the right wing.

❏ 21. If you plan to install the optional flap, (and if

you’re not, how come? It really is a lot of fun and

adds another dimension to flying the Contender!) cut

two additional 4-1/4" [108.4mm] servo rails from the

remainder of the 1/4" x 1/4" x 18" [6.4 x 6.4 x 457mm]

basswood stick. These will serve as the servo rails

for the flap servo. Install these in the slots between

the two W-1 ribs in the same way you did for the

aileron servos.

CCoonntteennddeerr FFuunn FFaacctt

The original Contender was designed by

renowned scale modeler Dave Platt in 1969!

12

Page 13

❏ 22. Glue the 1/4" x 1" x 3-29/32" [6.4 x 25.4 x

99mm] basswood wing bolt plate in place between

the W-1 ribs and onto the doublers W-1B with

6-minute epoxy.

❏❏23. By now your landing gear rail assembly

should have cured. Drill a 5/32" [4mm] hole through

both of the landing gear rails and the torque blocks.

Drill from the side of the landing gear rail that has the

groove. As you drill, make sure you hold the drill at a

90 degree angle to the landing gear rail and that the

hole is centered in the torque block.

❏❏24. Use 6-minute epoxy to glue the landing gear

rail assembly to the slots in W-1 and W-2. Be sure that

you glue the torque block securely to W-1 when gluing

the rail in place. Do this for both sides of the wing.

❏ 25. Locate one of the 3/32" x 3" x 24" [2.4 x 76 x

610mm] balsa wing sheets. Cut it into four pieces

3/32" x 3/4" x 24" [2.4 x 19.1 x 610mm].

❏26. See the Hot Tip that follows, then glue one of the

3/32" x 3" x 24" [2.4 x 76 x 610mm] balsa sheets to

one of the 3/32" x 3/4" x 24" [2.4 x 19.1 x 610mm]

balsa sheets to make one 3-3/4" [95mm] sheet. Make

four sheets for the top and bottom LE wing sheeting.

❏❏27. Test fit the wing skin sheeting. The sheeting

should join at the center of the rib W-1A and be

against the notch in the rib. Glue the wing skin

sheeting in place on top of the spar and against the

notch in the rib. When the glue has cured apply a bead

of glue to the top of each rib and along the sub LE. Pull

C. Turn the sheet over and apply weights on top of

the sheet to hold it flat. Apply thin CA sparingly to

the seam between the two pieces, quickly wiping

away excess CA with a paper towel as you proceed.

D. Turn the sheet over and remove the masking

tape, then apply thin CA to the seam the same

way you did for the other side.

E. Sand the sheet flat and smooth with your bar

sander and 150 grit sandpaper.

B. Use masking tape to tightly tape the two

sheets together joining the trimmed edges.

A. Use a metal straightedge as a guide to trim

one edge of both sheets.

WING SHEETING

13

Page 14

the sheeting down making sure it contacts the surface

of each rib and the sub LE. Hold it in place until the

glue has cured.

❏❏28. Trim the sheeting flush to the wing sub LE.

❏ 29. Repeat steps 27 and 28 for the other side of the

wing. Be sure that you glue the sheeting securely at the

center of the wing where the sheeting comes together.

❏ 30. From one 3/32" x 3" x 30 [2.4 x 76 x 762mm]

balsa sheet cut three pieces 3" x 4-5/16" [76 x

1 10mm]. Edge glue the three pieces in the same way

that was done for the LE sheeting.

❏ 31. Cut the bottom center sheeting template from

the plan. Trace the pattern onto the balsa sheets that

were just glued together. Cut the balsa sheet to match.

❏ 32. Test fit the balsa sheeting to the center of the

bottom of the wing between the W-1 ribs. When you

are satisfied with the fit, glue it in place.

❏ 33. From the leftover 3/32" x 3" x 30" [2.4 x 76 x

762mm] balsa sheet, cut two 3" x 1-3/4" [76 x 44mm]

sheets to be used as the sheeting around the aileron

servos. Fit the sheets and glue them in place.

❏ 34. Cut an opening in the aileron sheeting to

accommodate the size of your particular brand

of servo.

❏ 35. Use a razor plane to shape the 9/16" x 7/8"

[14.3 x 22.2mm] TE that you glued in place in step 9.

Shape the TE to match the airfoil of the ribs.

❏ 36. Sand the entire bottom of the wing.

Build the top of the wing

❏ 1. Remove the wing from the building board. Turn

the wing over and place it over the plan and we’ll

finish the wing construction.

❏ 2. Locate the die-cut 1/8" [3.2mm] ply wing

support and base. Slide the base into the wing

support and glue them together. Make three

assemblies

❏ 3. Place a wing support under the center rib, the

left tip rib and the right tip rib. These will support the

wing on the workbench while sheeting and sanding

the top of the wing. Apply a couple of weighted bags

on the wing to hold it firmly on the workbench.

14

Page 15

❏ 4. Fully seat the top wing spar in the rib notches and

glue in place. The jig tabs on ribs W-1 must be sanded

off prior to sheeting.

❏ 5. Sheet the LE of the wing in the same way you

did the sheeting on the bottom of the wing. Sheet

both the left and right side of the wing.

❏ 6. Trim the sheeting flush to the wing sub LE.

❏ 7. Cut the jig tabs from the ribs. Lightly sand the ribs

even with the trailing edge. Make sure when you cut

them off that you maintain the airfoil of the rib.

❏ 8. Cut fourteen 3" x 2-1/8" [76 x 54.2mm] balsa

shear webs from leftover 3/32" x 3" x 30" [2.4 x 76 x

762mm] balsa sheet. Cut two 2-1/8" x 1-1/2" [54.2 x

38mm] balsa shear webs.

❏ 9. Glue one of the 1-1/2" x 2-1/8" [38 x 54.2mm]

balsa shear webs in place between the W-3 ribs for

both wing halves. Glue the 2-1/8" x 3" [54.2 x 76mm]

balsa shear webs between each of the remaining

ribs. The shear webs will need to be trimmed slightly

on the W-2 ribs that have the ply doublers. At the

center of the wing use two shear webs and trim them

to fit the center section.

❏ 10. From the leftover 3/32" x 3" x 30" [2.4 x 76 x

762mm] balsa, sheet the center section of the wing.

If you will be installing the optional flap, mark the

servo location and cut the opening for it.

❏ 11. Sand the entire top of the wing.

❏ 12. Locate the two 1/2" x 1-1/4" x 24" [12.7 x 32 x

610mm] balsa LE sticks. Glue them to the front of

the balsa sub LE. Be sure the LE sticks are joined

directly over the joint of the sub LE stick. Trim the

end of the LE flush with the tip rib.

❏ 13. Use a razor plane to shape the wing LE to the

shape shown on the plan. Sand the wing LE to its

final shape.

❏ 14. Measure over 1" from each side of the leading

edge joint and mark it with a pen. Be sure the mark

is centered on the LE.

❏ 15. On the marks that you have made, push a

T-pin through the balsa LE, sub LE and the forward

dowel guide. The pin should be centered in the hole

in the forward dowel guide.

❏ 16. Using the pin holes in the LE as a reference,

drill a 1/8" pilot hole through the LE. Check to make

sure the hole is centered in the hole of the forward

dowel guide. Then drill a 1/4" [6.4mm] hole through

the LE. It will line up perfectly with the holes in the

forward dowel guide.

❏ 17. Locate two 1/4" x 4" [6.4 x 25.4mm] hardwood

wing dowels. Round one end of each dowel as

shown on the plan. Slightly round the other end for

ease of insertion.

❏ 18. Apply 30-minute epoxy to the holes in the

forward and aft dowel guide. Slide one dowel into

each hole, making sure that the rounded end

protrudes through the LE and that the other goes all

the way through both dowel guides.

15

Page 16

Build the ailerons

❏❏1. Locate a 1/4" x 3/8" x 30 [6.4 x 9.5 x 762mm]

balsa stick. Using the plan as a guide, cut the stick

as shown on the plan and glue the pieces together to

make the aileron.

❏❏2. Remove the aileron from the plan. Make a

mark at the center of the aileron at each end and

place a T-pin at each mark. Place a straightedge

along the aileron LE at the pins and draw a

centerline on the aileron LE.

❏❏3. Mark the location of the hinges and cut the

hinge slots using the same technique used for the

elevator and the rudder.

❏❏4. Shape the LE to a “V” and round the TE as

shown on the plan.

❏ 5. Repeat steps 1 - 4 for the other aileron.

Install the aileron control horns

❏❏1. Place a large control horn on the bottom of

the right aileron as indicated on the aileron plan. Use

a ballpoint pen to mark the location where the holes

need to be drilled.

❏❏2. Drill two 3/32" [2.4mm] holes for the control

horn mounting bolts through the right aileron.

❏❏3. Apply a small drop of thin CA in the hole to

harden the wood. Redrill the hole after the glue cures.

❏❏4. Attach the control horn to the right aileron with

two 2-56 x 1/2" [12.7mm] machine screws.

❏ 5. Repeat steps 1 through 4 for the left aileron.

Build the flap

❏ 1. You must build the flap regardless of whether

you are going to have it operational or fixed. The

construction steps are the same.

❏ 2. From 1/4" x 3" x 30" [6.4 x 76 x 762mm] balsa

sheet, cut the 1/4" [6.4mm] balsa flap TE doubler as

shown on the plan. Pin it in place on the plan.

❏ 3. Build the flap frame from 1/4" x 3/8" x 30" [6.4

x 9.5 x 762mm] balsa sticks. Cut the sticks and glue

them in place as shown on the plan.

❏ 4. Cut the 1/8" x 1/4" [3.2 x 6.4mm] balsa flap

diagonal braces as shown on the plan. When

satisfied with the fit glue them in place.

❏ 5. Sand both sides of the flap.

❏ 6. Round the flap TE as shown on the flap

cross section.

CCoonntteennddeerr FFuunn FFaacctt

In the 1970’s the Contender was one of the

“must have” models. It was extremely popular

as a sport plane and was particularly well

suited as a fun fly contest airplane.

16

Page 17

Perform step 7 only if you are NOT going to have

a functional flap.

❏ 7. Glue the flap in position in the center of the wing

at the location shown on the plan.

Steps 8 - 12 are for building the functional flap.

❏ 8. Draw a centerline on the leading edge of the

flap the same way it was done for the aileron.

❏ 9. Mark the location for the hinges and cut the

hinge slots.

❏ 10. Using the centerline as a reference taper the

LE to a “V” as shown on the flap cross-section.

❏ 11. Mark the location for the flap hinges on the

wing TE and cut the hinge slots.

❏ 12. Install the control horn on the top of the flap as

shown on the plan. Use the same installation method

used on the aileron.

Build the wing tips

❏ 1. Locate the 1/8" [3.2mm] die-cut balsa wing tip

parts. Each wing tip consists of two halves. Glue the

left and right halves together. Do this to make four

wing tips.

❏ 2. Glue two wing tip assemblies together to make

one 1/4" [6.4mm] wing tip. Do the same for the other

wing tip.

❏ 3. Sand the wing tip edges round just as you did

for the TE of the aileron.

Before we can continue, you’ll need to decide which

wing tip shape you wish to use on your Contender.

The standard tip is the original “nostalgia” tip shape

and the model performs quite nicely with this tip. The

optional tip shape was evolved onto the original

Contender design to make its handling even better,

particularly eliminating a “roll coupling from rudder”.

With the optional wing tips, your model will just yaw

upon rudder application, without the need to use

opposite aileron to correct a roll couple. Additionally,

your Contender will have even better slow speed

handling, without any loss of aerobatic performance.

Note that the model flew excellently in both

configurations and the decision to install or not to

install the optional tips is not a crucial one for basic

flight handling.

Standard wing tip

❏❏1. Glue the wing tip into the slots in the tip ribs

of the wing. Make sure the wing tip is aligned at the

center of the wing LE and TE.

❏❏2. Locate the 1/8" x 1-3/8" x 30" [3.2 x 34.9 x

762mm] balsa sheet and cut four wing tip braces for

each wing tip. Use the above sketch and photos as

a guide when cutting the braces. Position the braces

as shown on the plan then glue them in place when

you are satisfied with the fit.

CCoonntteennddeerr FFuunn FFaacctt

When the Contender was originally introduced

it was advertised as “Buildable in 8 hours”

and the instructions consisted of 12 sketches.

We are not so sure about the 8 hours but

we are sure you will like this expanded

construction manual.

17

Page 18

❏❏3. From the 1/2" x 1/2" x 6" [12.7 x 12.7 x

152mm] balsa stick, cut two wing tip blocks and

glue them in position as shown on the plan. One

block is glued on each side of the wing tip.

❏❏4. Sand the wing tip blocks to shape.

❏ 5. Repeat steps 1 - 4 for the other wing tip.

Optional wing tip

❏❏1. Test fit the wing tip into the slots in the tip rib.

Make sure there is enough room in the slots for the wing

tip to be slanted upward approximately 40 degrees.

❏❏2. On the wing plan, locate the templates for the

four optional wing tip braces. Cut one of each

brace from the 1/8" x 1-3/8" x 30" [3.2 x 34.9 x

762mm] balsa sheet.

❏❏3. Use the braces as a gauge to set the wing tip

angle and glue the wing tip in position.

❏❏4. Glue the braces in position as shown on the

plan and in the above photographs. Two braces are

located on each side of the wing tip.

❏❏5. From the 1/2" x 1/2" x 6" [12.7 x 12.7 x

152mm] balsa stick cut two wing tip blocks and

glue them in position as shown on the plan. One

block is glued on each side of the wing tip.

❏❏6. Sand the wing tip blocks to shape.

❏ 7. Repeat steps 1 - 6 for the other wing tip.

Install the aileron and flap hinges

❏ 1. If you have been following the instructions you

should already have the hinge slots located in the

leading edge of the ailerons and flap. Hold the

aileron in place on the wing and mark the location

where the hinge slots need to be cut into the wing

TE. Do this for both aileron locations.

❏ 2. If you are making the functional flap, hold the

flap in place and mark the location where the hinge

slots need to be cut into the wing TE.

❏ 3. Cut all of the aileron and flap slots into the TE

of the wing.

❏ 4. Place all of the control surfaces in place with the

hinges to make sure that everything is properly

positioned. When you are satisfied that everything

fits, remove the control surfaces from the wing. Final

hinge installation will be done after the covering has

been completed.

BUILD THE FUSELAGE

Frame the fuselage

As we go through the next few steps it is important

to note that we are building the fuse

upside-down over the plan.

❏ 1.Work on a flat surface over the plan. Pin or tape

the fuselage plan to the building board and cover

the plan with Plan Protector.

18

Page 19

❏ 2. Locate the two die-cut 1/8" [3.2mm] balsa upper

fuse deck halves. Glue them together and then pin

them over the fuselage bottom view.

❏ 3. Drill a 3/16" [4.8mm] hole in the punch marks on

formers F-2A, F-2B, F-4A and F-5A. These will

accommodate the pushrod installation as we build

the fuse.

❏ 4. Locate the 1/8" [3.2mm] die-cut ply former F-2A

and F-2B. Use 6-minute epoxy to glue F-2B to F-2A,

aligning the 1/4 holes in the formers.

❏ 5. Test fit formers F-2A, F-3A, F-4A and F-5A into

the slots in the upper fuse deck with the lettering

facing forward. Use a small triangle to make sure the

formers are perpendicular to the upper fuse deck,

then glue the formers in place.

❏❏6. Locate the die-cut 1/8" [3.2mm] balsa lower

aft fuse doubler (LAD), upper aft fuse doubler

(UAD), lower fuse doubler (LFD) and the upper

forward fuse doubler (UFD). Glue them in place on

the die-cut 3/32" [2.4mm] balsa fuselage side. The

doublers should be positioned so the tabs on the

front of the doublers are flush with the fuse front. Be

sure when you glue the doublers to the fuselage side

that you make a left and right fuselage side.

❏ 7. Repeat step 6 for the other fuselage side.

❏ 8. Glue the left fuselage side in place on the upper

fuse deck and to each of the fuselage formers. Do

the same for the right side of the fuselage.

❏ 9. Use some 120-grit sandpaper to roughen the

plastic outer pushrod tubes where they will come in

contact with the fuselage formers and the slot in the

side of the fuselage. Working from the open fuse

bottom, route the tubes though the F-4A, F5A and the

fuse sides. Make sure both pushrod guides extend

1/2" as shown. The tubes should also protrude at least

1" from the fuse side exits. Glue both pushrod guides

to each former and the fuse side.

❏ 10. Fill any gaps around the outer pushrod guide

tubes with a lightweight filler such as Hobbico

19

Page 20

HobbyLite™. Allow the filler to completely harden.

Trim the protruding pushrod guide tube to within 1/8"

from the fuse side. Then with a sanding block and

150-grit sandpaper, sand the pushrod guide tube

and filler material flush with the fuse side.

❏ 11. Locate the 2" [51mm] long balsa tapered tail

post and glue it in place at the end of the fuselage.

Sand it flush with the top and bottom of the fuse.

Sand the edges of the fuse bottom to be flush with

the fuse sides.

❏ 12. Remove the pins holding the fuselage to the

building board.

❏ 13. Sand the bottom of the fuse smooth. Using

3/32" x 3" x 30" [2.4 x 76 x 762mm] balsa, cut and

glue the sheets to the bottom of the fuselage. Cut the

balsa so that the grain of the sheeting is running

across the fuselage as shown on the plan crosssections. When you have finished gluing the

sheeting in place, sand it flush with the fuse sides.

❏ 14. Edge glue two pieces of 3/32" [2.4mm] balsa

and cut it to fit the area where the flap rests on the

fuselage bottom. Do this even if you are not installing

the functional flap.

❏ 15. If you are installing the functional flap, cut a

3/4" x 1" [19.1 x 25.4mm] slot in the center of the

sheeting. This will allow proper clearance for the flap

control horn to pass through the sheeting when the

flap is deployed.

❏ 16. Locate the die-cut 1/8" [3.2mm] ply formers

F-1A, F-1B and F-1C. Use 6-minute epoxy to glue

F-1A and F1-B together. Glue F-1C to the back of

F1-B, locating the top of F1-C 3/4" from the top of

F1-A/F1-B assembly . Set the assembly aside to cure.

❏ 17. Locate the die-cut 1/8" [3.2mm] ply stabilizer

base. Use 6-minute epoxy to glue it in place at the

rear of the fuselage. Use masking tape to hold it in

place while the epoxy cures.

❏ 18. Drill four 11/64" [4.4mm] diameter holes at the

punch marks on the upper half of the firewall assembly

to accommodate the engine mount blind nuts.

❏ 19. Drill four 3/32" [2.4mm] holes at the punch

marks on the lower half of the firewall assembly to

attach the nose gear mount.

❏ 20. On the back side of the firewall, install four

6-32 blind nuts in the 11/64" [4.4mm] diameter holes

you drilled. Wick some thin CA under the blind nuts

to help secure them to the firewall.

❏ 21. Use #4 x 1/2" [12.7mm] sheet metal screws to

secure the nose gear mount to the back of the firewall.

20

Page 21

❏ 22. Use 30-minute epoxy to glue the firewall in

position on the front of the fuselage.

❏ 23. Locate a 1/4" x 1/4" x 18" [6.4 x 6.4 x 457mm]

basswood stick. Cut the sticks to fit along the firewall

and fuselage side as shown on the plan. Epoxy them

in place.

❏ 24. Locate the engine mount and secure it to the

firewall with 6-32 bolts and #6 washers. Be sure that

the mount is centered on the firewall. Adjust the

mount to fit your engine.

❏ 25. Position the engine on the engine mount at

the location shown on the plan. Mark the mounting

hole locations.

Hint: The Great Planes Dead Center™tool works

great for doing this.

❏ 26. Based on the engine you have chosen to put

in the airplane, decide on a location for your fuel line,

vent line and throttle pushrod to pass through the

firewall. Mark the locations, then remove the engine

from the mount. Drill a 7/32" hole in the firewall

for the fuel and vent line and a 3/16" hole for the

throttle pushrod. This would be a good time to install

the outer pushrod tube for the throttle.

❏ 27. Drill 1/8" [ 3.2mm] pilot holes through the marks

you made on the rails of the engine mount. Secure the

engine to the mount with four #8 x 1" [25.4mm] sheet

metal screws.

❏ 28. Install the fuel tank and foam rubber as shown

on the plan. Cut some of the leftover 1/4" [6.4mm]

balsa sheet into two 1/4" x 1/4" x 3" [6.4 x 6.4 x

76mm] balsa sticks. After positioning the two sticks

to secure the tank, glue the sticks in place.

❏ 29. Position the die-cut 1/8" [3.2mm] ply fuel tank

hatch on the bottom of the fuselage. Drill a 1/16"

[1.6mm] hole in each corner of the hatch making

sure that the holes go into the firewall and F-2.

Remove the hatch, then place a drop of thin CA in

each of the holes in the firewall and F-2 to make the

holes more durable.

❏ 30. Drill 3/32" [2.4mm] clearance holes in the

hatch only. Use a Dremel #178 bit to countersink

the clearance holes. Attach the hatch with four #2 flat

head wood screws.

❏ 31. Glue formers F-2C, F-2D, F-3B and F-3C in

the slots in the top of the fuselage.

21

Page 22

❏ 32. Sheet the area between F-2D and F-3C with

3/32" x 3" x 30 [2.4 x 76 x 762mm] balsa sheet.

Sheet both sides first and sand them flush with the

top of the former, then sheet the top of the former.

❏ 33. Cut the forward deck sheeting template from

the plan. Cut two forward deck sheets from 3/32" x 3"

x 30 [2.4 x 76 x 762mm] balsa sheet. Place the sheet

in position from the firewall up to F-2D. When you

are satisfied with the fit, glue the forward deck

sheeting in place on both sides of the fuselage. Sand

the sheeting flush with the top of the formers, then

sheet the top with 3/32" [2.4mm] balsa.

❏ 34. From 1/4" x 3" x 24" [6.4 x 76 x 610mm] balsa

sheet, cut the forward dorsal fin using the template

on the plan as a pattern. Place the forward dorsal fin

in position behind F-3C. Place the fin assembly in

place on top of the fuselage. Make any adjustments

needed to the forward dorsal fin to get a good fit to

the fin. When you are satisfied with the fit glue the

forward dorsal fin in place.

❏ 35. Locate the two 1/8" [3.2mm] die-cut balsa

dorsal fin supports. The fin supports are die-cut

except at the very end of the support. Use a hobby

knife to finish the cut. These parts support the fin

assembly. It is important that when they are in place

the supports are exactly 1/4" [6.4mm] apart. Use

either the fin assembly or leftover 1/4" [6.4mm] balsa

to align and mark the exact position for the fin

supports. Glue the fin supports in position. Do not

glue the fin in position. (The fin is not glued in place

until after it has been covered) Note: Refer to the

photo at step 2 of “Mount the stab.”

❏ 36. After the supports are glued in place, slide the

fin assembly between the fin supports. Sand the fin

support to match the dorsal fin, as shown in the

above photo. Sand the fin supports to the shape as

shown in the cross-section at former F-5.

❏ 37. Locate the die-cut 1/8" [3.2mm] ply lower fin

guide. This tool will be used to hold the lower fin

perpendicular to the fuselage in the next step.

❏ 38. Center the lower fin on the bottom of the

fuselage. Use the lower fin guide to assure that the

lower fin is perpendicular to the bottom of the

fuselage. When you are satisfied with the fit, glue the

lower fin to the fuselage.

22

Page 23

Make the cowl

❏ 1. Screw the engine to the engine mount before

you perform the next few steps.

❏ 2. Cut the 1-1/4" x 3-1/4" x 4-1/2" [32 x 83 x

114.7mm] balsa cowl bottom to the shape shown

on the plan. Test fit it to the firewall at the location

shown on the plan. When you are satisfied with the

fit, tack glue the block onto the firewall. You will

remove this block later.

❏ 3. Place the 1/8" [3.2mm] ply die-cut spinner ring

over the engine. Mount the spinner (not included with

the kit) onto the prop shaft.

❏ 4. Use leftover 3/32" [2.4mm] balsa to make

spacers. Tack glue the spacers on the back of the

spinner and the front of the spinner ring. This will

assure proper placement of the spinner when the

cowl assembly is finished.

❏ 5. From the 1/2" x 3" x 15" [12.7 x 76 x 381mm]

balsa block cut two balsa cowl sides. Fit them

between the firewall and the spinner ring. The cowl

sides should make contact with the inside of the

spinner ring. Note: Depending on the engine you

chose for the model, you may find that you are going

to have to remove some balsa from the inside of the

cowl sides. When we installed the .46 engine the

cowl sides required no removal of balsa. With the .61

FX we found we removed a substantial amount of

balsa from the inside of the cowl sides. Remove

balsa from the inside of the cowl sides as needed for

your engine. When you are satisfied with the fit, glue

the cowl sides to the firewall and the spinner ring. Do

not glue the sides to the cowl bottom.

❏ 6. After you have glued the cowl sides in position,

remove the cowl bottom that was tack glued in

position in step 2. Glue a filler block made from

leftover 1/2" [12.7mm] balsa on the bottom of the

cowl sides as shown on the plan.

❏ 7. Glue a filler block made from leftover 1/2"

[12.7mm] balsa between the top of the cowl sides as

shown on the plan.

❏ 8. Use a razor plane to shape the cowl. Sand the

cowl to achieve the final shape.

❏ 9. Shape the balsa cowl bottom as shown in the

photograph. The cross-section of former F-1 also

shows the shape of the front of the cowl bottom.

23

Page 24

❏ 10. After you have finished the final shaping and

sanding, glue the cowl bottom in place.

Mount the wing

❏ 1. Locate the 1/2" x 3/4" x 1" [12.7 x 19.1 x

25.4mm] maple wing mounting blocks. Test fit

them into the notches in the fuse doubler. Glue them

in place with 6-minute epoxy . Spread a fillet of epoxy

around the blocks for a secure bond.

(While you’re waiting for the epoxy to cure, jump

ahead to page 27, “Prepare the canopy .” By the time

you are finished cutting and fitting the canopy the

glue should be cured well enough to move on to the

next step.)

❏ 2. Position the wing in the saddle. If any minor

sanding needs to be done to get a good fit between

the fuselage and the wing do it now.

❏ 3. Insert a T-pin in the center of the fuse at the back

of the airplane. Place a Hobbico Retractable Fabric

Tape Measure (HCAR0478) (or any suitable

measuring device) over the T-pin and measure the

distance from the pin to the left tip rib of the wing and

then to the right tip rib of the wing. Adjust the wing until

the distance from the pin is the same on both sides.

❏ 4. With the plan as your guide, mark the drilling

location for the wing bolts on the wing bolt plate.

❏ 5. When the wing is properly positioned, drill a 1/8"

[3.2mm] pilot hole through the locations where the

wing bolts will go. Be sure you drill through the wing

bolt plate and the two maple blocks. Try to drill

straight in, perpendicular to the wing bolt plate.

❏ 6. Remove the wing and drill a 17/64"[6.7mm]

clearance hole through each of the pilot holes you

have drilled in the wing.

❏ 7. Use a #10 drill bit (or 13/64") [5.2mm] to drill

through each of the pilot holes in the two maple blocks.

❏ 8. Use a 1/4-20 tap to tap the threads in the maple

wing blocks. After you have the holes tapped, put a

couple of drops of thin CA on the threads to

strengthen them. Once the glue has cured, retap the

holes to clean out any excess glue.

Install the landing gear

❏ 1. Install the 5/32" [4mm] main landing gear in the

holes in the landing gear rail. Secure them in place

with the nylon landing gear straps. Place the straps

in position as shown on the plan then drill a 1/16"

[1.6mm] hole in the landing gear rails where the

straps will be located. Screw the straps in place with

#2 x 1/2" [12.7mm] sheet metal screws.

❏ 2. Locate the nylon steering arm. Shorten the

steering arm as shown in the sketch.

❏ 3. Insert the 5-32" [4mm] wheel collar into the

steering arm. Screw the 6-32 x 1/4" [6.4mm] socket

head cap screw into the steering arm assembly.

24

Page 25

❏ 4. Remove the fuel tank hatch, then place the

steering arm assembly between the nose gear mounts

on the firewall. Insert the 5/32" [4mm] wire nose gear

through the nose gear mount and the steering arm

assembly . Measure the length of the nose gear from the

bottom edge of the firewall to the center of the axle as

shown. This measurement should be 4-1/2" [114mm].

Tighten the screw on the steering arm tight enough to

leave a mark on the nose gear wire. Remove the nose

gear from the mount.

❏ 5. The reason for marking the nose gear wire in

the previous step is so you can locate the spot for a

flat on the wire. With the mark facing up, clamp the

nose gear in a vise and use the side of a flat file to

make a flat spot at the mark.

❏ 6. Reassemble the nose gear and install it into the

mount. Make sure the steering arm screw is directly

over the flat and tighten.

Mount the stab

❏ 1. Position the stab on the stab saddle. Measure

the distance from the stab tips to the center of the

fuse at F-4A as shown in the sketch. This will assure

proper alignment in relation to the wing.

❏ 2. When the stab is in proper position insert a

couple of T-pins through the stab and the stab base.

This will make it easy to place the stab back in the

proper location when the applying the glue.

❏ 3. Check to make sure that the stab is parallel with

the wing (see sketch at step 5). Make any adjustments

to the stab saddle to assure the stab is parallel with

the wing.

❏ 4. Remove the stab from the saddle but leave the

T-pins in place in the stab. Apply epoxy to the stab

saddle, then put the stab back in position using the

pins as guides.

❏ 5. Before the glue cures make sure that you align

the stab to be parallel with the wing as shown in

the sketch.

❏ 6. Hold the stab in position with masking tape

while the glue cures.

❏ 7. After the glue has cured install the elevator, fin

and rudder. Mark the location where the rudder

touches the elevator joiner wire. Cut a clearance

notch on the LE of the rudder for the joiner wire.

❏ 8. Mark the location on the fuselage for the lower

rudder hinge and cut the hinge slot.

25

Page 26

INSTALL THE SERVOS AND

PUSHRODS

Make the pushrods

❏ 1. Locate the die-cut 1/8" [3.2mm] ply pushrod

brackets. Drill a 3/16" [4.8mm] hole through each

punch mark.

❏ 2. Glue the pushrod brackets to the fuselage sides

at the locations shown on the plan.

❏ 3. Install the plastic outer pushrod tube in the front

half of the fuselage for the steering pushrod as shown

on the plan. You may need to remove the fuel tank to

get the tube in place.

❏ 4. Locate three 2-56 x 36" [914mm] threaded rods.

These will be used for the nose gear steering, the

rudder and the elevator.

Install the servos in the fuselage

NOTE: Before marking any of the pushrods, connect

the servos to the receiver and electronically center

each servo.

❏ 1. Glue the die-cut 1/8" [3.2mm] ply throttle

servo mount in place in the fuselage as indicated

on the plan.

❏ 2. Glue two 1/4" x 1/4" [6.4 x 6.4mm] basswood

servo rails in place as shown on the plan. The rear

rail is glued to the notches in the fuselage doubler.

The forward rail is glued to former F-3A.

❏ 3. Mount the servos to the rails and the plywood

mount as shown on the plan.

❏ 4. Slide a silicone retainer onto the rear end of a

nylon clevis. Thread the clevis 14 turns onto a 36"

wire pushrod (threaded on one end). Slide the

pushrod into the elevator pushrod tube until the

clevis pin is even with the holes in the elevator

control horn. Connect the clevis to the control horn.

❏ 5. Assemble a second wire pushrod for the rudder

pushrod tube.

❏ 6. With the elevator and rudder pushrods connected

to the control horns and the elevator and rudder

centered, mark the pushrod wires where they align

with the servo arms. Remove the pushrods, then trim

them about 1" forward of the marks.

❏ 7. Cut ten 1/8" [3.2mm] long pieces from the 12"

[305mm] plastic inner pushrod. Slide five bushings

onto each pushrod, spreading them out about 2-1/2"

apart, from the servo and the end of the pushrod. If the

bushings are tight and difficult to slide on, cut them to

a shorter length. Check the fit of both pushrods. When

you are satisfied with the fit, apply a small drop of thin

CA to each bushing to keep them in place on the

pushrod. Do not reinstall the pushrods into the tubes

until the CA has completely cured.

❏ 8. Enlarge one outside hole in the elevator and

rudder servo arms with a 5/64" bit. Make a 90 degree

bend in each of the pushrods at the point that you

marked. Cut off the excess wire, leaving about 3/8"

after the bend. Remove the clevises, then insert the

pushrods all the way into the tubes from the servo

end. Reattach the clevises and silicone retainers.

Poke the upturned wires through the servo horns

and secure them in position with nylon FasLinks

™

.

❏ 9. Locate the .074" x 1" [1.8 x 25.4mm] threaded

wire. Screw it into one end of the remaining inner

plastic pushrod. Slide a silicone retainer onto the end

of a nylon clevis. Screw the nylon clevis onto the

threaded wire.

❏ 10. Slide the inner plastic pushrod into the throttle

pushrod tube. Insert it from the firewall back into the

fuselage. Attach the clevis to the throttle arm and fully

close the throttle. Position the throttle servo so that it

would be in the position that will fully close the throttle.

❏ 11. Cut the inner plastic pushrod tube 2" from the

throttle servo. Remove the throttle pushrod from the

plastic pushrod tube.

❏ 12. Screw the .074" x 4" [1.8 x 102mm] wire

(threaded one end) onto the end of the plastic inner

pushrod tube. Reinsert the pushrod into the throttle

pushrod tube.

❏ 13. With the throttle pushrod connected to the

throttle arm and the servo positioned to close the

throttle, mark the pushrod wire where it aligns with

the servo arm. Remove the pushrods, then trim them

about 1" past the mark.

❏ 14. Enlarge one outside hole in the throttle servo

arm with a 5/64" bit. Make a 90 degree bend in the

pushrod at the point that you marked. Cut off the

excess wire, leaving about 3/8" after the bend.

Remove the clevis, then insert the pushrods all the

way into the tubes from the servo end. Reattach the

clevis and silicone retainer. Insert the upturned wire

through the servo horn and secure it in position with

nylon FasLinks.

❏ 15. Repeat step 14 for the steering pushrod.

26

Page 27

Install the aileron servos

❏ 1. Install both aileron servos in the servo bays with

four servo screws (included with your radio system).

Note that we routed the the servo wires out beside

the flap servo bay.

❏❏2. Locate a 2-56 x 12" [305mm] threaded rod.

Attach a clevis and a silicone clevis keeper to the

threaded end of the rod. Center the ailerons, then

mark the pushrods at the point where they meet the

holes in the servo arm. Make a 90 degree bend in the

wires. Enlarge the servo horn holes with a 5/64" drill

bit. Insert the bent wire pushrods onto the servo horn,

then secure them with Faslink pushrod keepers.

❏ 3. Repeat step 2 for the other aileron servo.

Install the flap servo (optional)

❏ 1. If you have chosen to have the functional flap,

mount the servo in the servo bay in the center of the

wing with four servo screws. Use the transmitter to

set the servo arm in the “up” position.

❏ 2. Locate a 2-56 x 12" [305mm] threaded rod.

Attach a clevis and a silicone clevis retainer to the

threaded end of the rod. Put the flap in the up position,

then mark the pushrod at the point where it meets the

hole in the servo arm. Make a 90 degree bend in the

wire. Enlarge the servo horn hole with a 5/64" drill bit.

Insert the bent wire pushrod onto the servo horn, then

secure it with Faslink pushrod keepers.

Install the battery, receiver and switch

❏ 1. Installing the receiver and the battery as shown

on the plan should work for most applications. We

found in the case of the airplane with a .61 engine

that it was nose heavy. With the .46 engine it

balanced close to the C.G. We recommend that you

check the balance of your airplane before locating

the battery and receiver.

❏ 2. The battery switch harness is easily installed

through the side of the fuselage with the Great

Planes Switch and Charge Jack Mounting Set

(GPMM1000). Follow the mounting instructions

included with the set. (The mounting set is not

included in this kit)

Prepare the canopy

❏ 1. Use a sharp scissor to cut out the canopy.

❏ 2. Test fit the canopy to the fuselage.

❏ 3. Mask the canopy for painting with Great Planes

Flexible masking tape. Mask it along the canopy

frame lines. An alternative to masking tape is to use

Hobbico Master Mask™(HCAR3410). Simply brush

it on, wait for it to dry then cut away the film from the

area you want to paint.

❏ 4. Spray paint the canopy frame using the

instructions that follow.

Painting Butyrate Canopies

with Top Flite LustreKote®.

Top Flite LustreKote is a high quality, fuel proof paint

that perfectly matches Top Flite MonoKote. The

paint is well suited to putting a high quality finish on

ABS but does have a tendency to curl materials

such as styrene and butyrate.

The following procedure allows you to airbrush

LustreKote with good results. The recommended

procedure requires that the paint be sprayed into a

jar or plastic mixing cup.

This is best done by spraying the paint through a

small brass tube or straw into the jar. For best results

spray no more than ½ oz. of paint into the jar at a

time. As the propellant “boils off” it will cause the

paint to foam slightly. Leave the paint in the open

container, stirring every 15 minutes until no more

foam appears on the surface of the paint and the

paint has warmed to room temperature. This allows

the propellant and some of the thinner to evaporate

out of the paint. Depending on the amount of paint in