Page 1

WARRANTY.....Top Flite Models guarantees this kit to be free of defects in both

material and workmanship at the date of purchase. This warranty does not cover any component parts

damaged by use or modification. In no case shall Top Flite's liability exceed the original cost of the

purchased kit. Further, Top Flite reserves the right to change or modify this warranty without notice.

In that Top Flite has no control over the final assembly or material used for final assembly, no liability

shall be assumed nor accepted for any damage resulting from the use by the user of the final userassembled product. By the act of using the user-assembled product the user accepts all resulting liability.

If the buyer is not prepared to accept the liability associated with the use of this product, he is

advised to immediately return this kit in new and unused condition to the place of purchase.

Top Flite Models

P.O. Box 721

Urbana, IL 61801

Technical Assistance - Call (217)398-8970

ENTIRE CONTENTS ©COPYRIGHT 2001 P406P03 V2.0

READ THROUGH THIS INSTRUCTION BOOK FIRST. IT CONTAINS IMPORTANT INSTRUCTIONS AND WARNINGS CONCERNING THE ASSEMBLY AND USE OF THIS MODEL.

TM

Page 2

METRIC CONVERSION CHART..............2

INTRODUCTION.......................................3

Precautions ............................................3

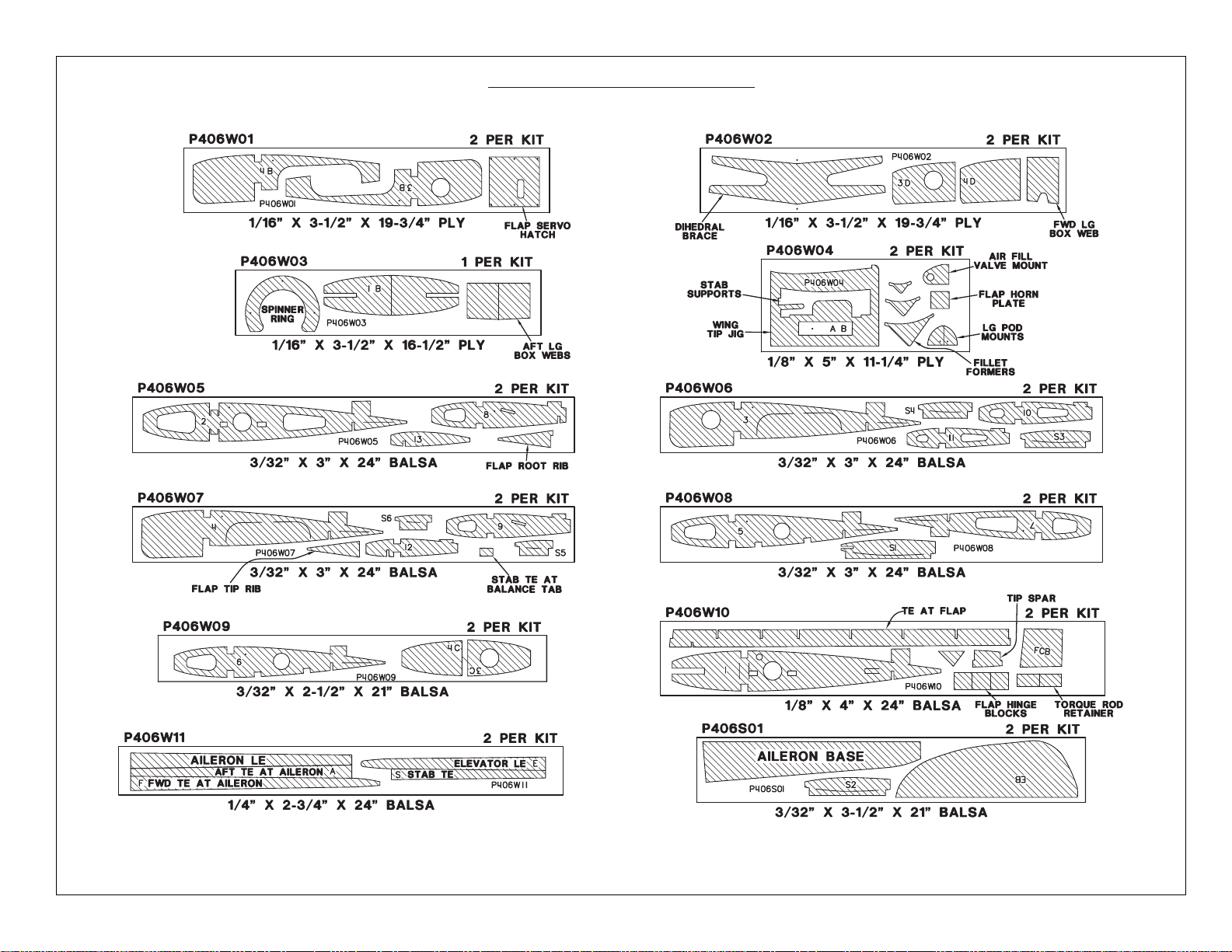

DIE PATTERNS.......................................4,5

DECISIONS YOU MUST MAKE...............6

Engine and Mount Selection ..................6

Retracts..................................................6

Wheel Selection .....................................6

Flaps.......................................................6

Drop Tank...............................................6

Static Display Propeller..........................6

Supplies and Tools .................................7

Other Items Required.............................7

Common Abbreviations..........................7

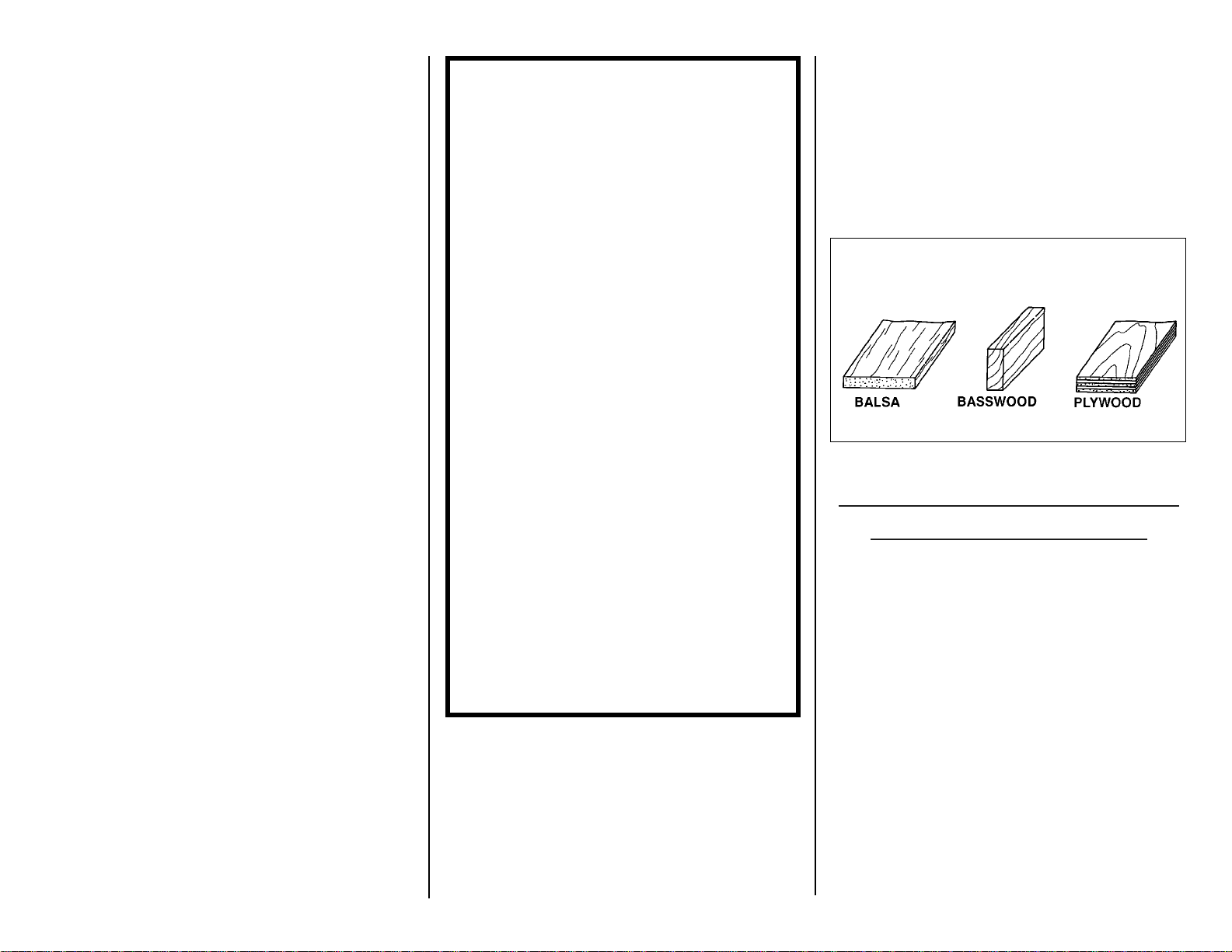

Types of Wood........................................7

TIPS FOR COMPETITION-

MINDED MODELERS ..............................7

Deviations from scale.............................7

Scale Documentation.............................8

Scale Retracts and Doors ......................8

GET READY TO BUILD............................8

Build the Horizontal Stabilizer ................8

Build the Fin ..........................................11

Build the Elevators.................................12

Build the Rudder....................................13

BUILD THE WING ...................................15

Install the Center Rib (W-1)...................18

Preparing for the Flaps..........................19

Join the Wing Panels.............................21

Fixed Landing Gear Assembly..............22

Mount the Landing Gear........................23

Sheet the Bottom of the Wing ...............24

Sheet the Top of the Wing.....................25

Wing Completion...................................26

Build the Flaps.......................................27

Build the Ailerons ..................................28

BUILD THE FUSELAGE..........................29

Build the Fuselage Top..........................32

Mount the Wing to the Fuselage ...........36

Attach the Stab and Fin.........................37

Build Fuselage Bottom..........................37

Build Top Cowling..................................38

Build the Wing Fillet...............................39

Build the Wing Belly Pan.......................41

Fit the Flaps...........................................41

Build the Cowl .......................................42

Build the Landing Gear Pods.................44

Fuel Proofing.........................................45

Balance the Airplane Laterally...............45

Retracts.................................................45

FINISHING...............................................45

Colors....................................................46

Finishing Techniques.............................46

Apply the Decals ...................................48

Draw on the Panel Lines .......................48

Final Clear Coat ....................................49

Exhaust Stacks......................................49

Hinging..................................................49

Final Engine Installation........................49

Final Control Hardware Hookup............50

Cockpit Finishing...................................51

Install Receiver, Switch, and Battery.....52

Balance Your Model...............................52

Final Hookups and Checks ...................53

PREFLIGHT.............................................53

AMA SAFETY CODE ..............................54

FLYING ....................................................54

2-VIEW DRAWING ..................................56

METRIC CONVERSIONS

In. x25.4 =mm (conversion factor)

1/64” = .4 mm

1/32” = .8 mm

1/16” = 1.6 mm

3/32” = 2.4 mm

1/8” = 3.2 mm

5/32” = 4 mm

3/16” = 4.8 mm

1/4” = 6.4 mm

3/8” = 9.5 mm

1/2” = 12.7 mm

5/8” = 15.9 mm

3/4” = 19 mm

1” = 25.4 mm

2” = 50.8 mm

3” = 76.2 mm

6” = 152.4 mm

12” = 304.8 mm

15” = 381 mm

18” = 457.2 mm

21” = 533.4 mm

24” = 609.6 mm

30” = 762 mm

36” = 914.4 mm

- 2 -

T

ABLE OF CONTENTS

Page 3

- 3 -

INTR

ODUCTION

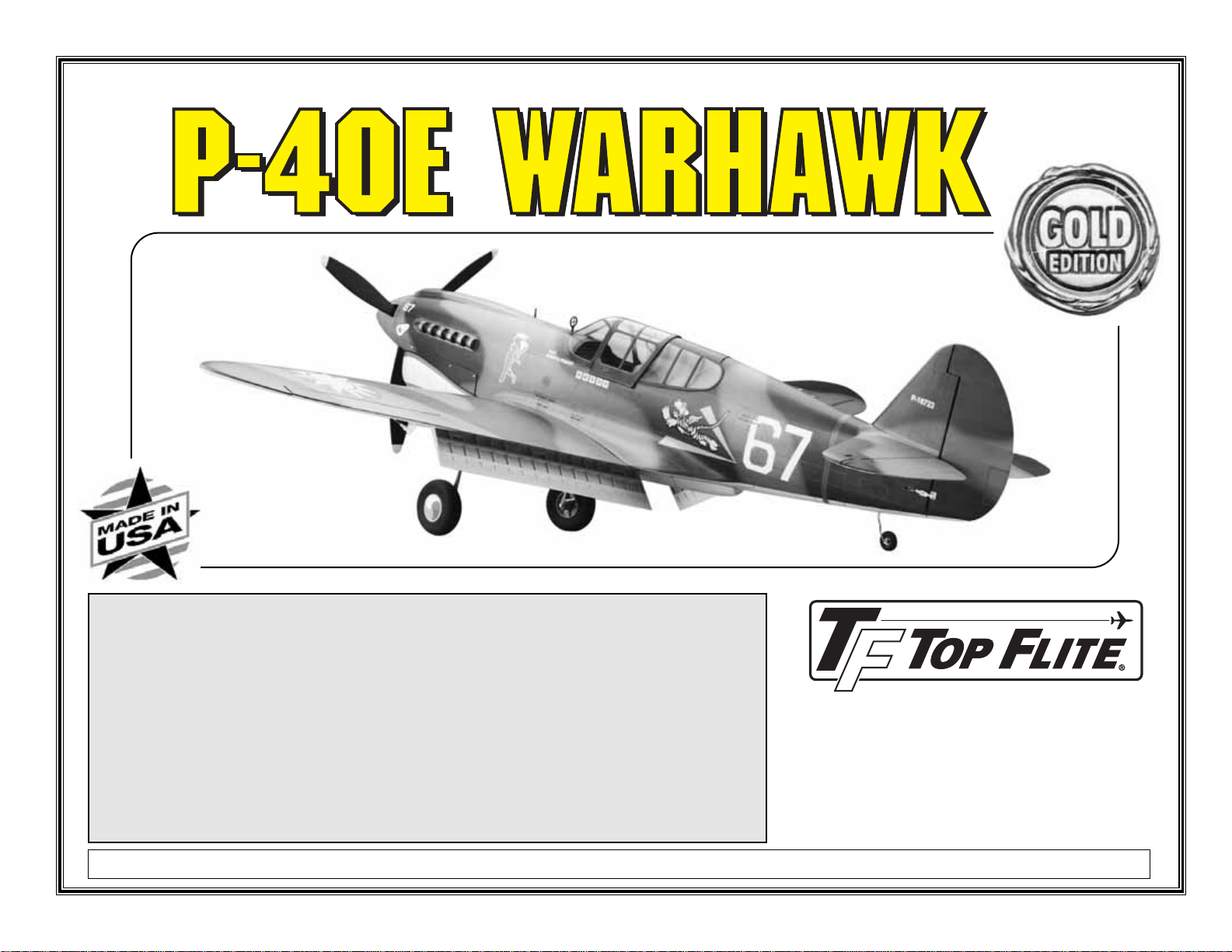

Thank you for purchasing the Top Flite

®

GOLD EDITION™

P-40E Warhawk.

The Top Flite P-40E is an excellent sport scale

model that is just as “at home” sport flying as it is in

competition. Its exact scale outline allows you to

detail it out and take it into serious competition. Its

modern construction and refined aerodynamics,

incorporating features such as built-in washout and

computer designed airfoils that progressively change

from root to tip, give you a plane that will build

straighter and fly better than warbirds of the past.

The Gold Edition Warhawk is approximately 1/7th

scale. The exact scale ratio is 1:6.9. The trim

scheme used on the model pictured on the box

duplicates that used by the legendary Flying

Tigers. Three large sheets of decals are included

to help you duplicate this scheme. You can cover

your P-40 with olive drab, tan, and grey

MonoKote®, but, to get truly authentic results, you

must paint the model. Helpful information on

painting can be found in the

Finishing Section

.

The Top Flite Warhawk makes an excellent

scale competition aircraft. The front end of this

model has been specially engineered to allow you

to completely hide most engines in the

recommended range. The large cowling will even

completely hide an O.S. 1.20 Surpass. The

cowling is designed to use the scale cooling air

entrance and exit to cool your model engine.

Engines such as the O.S. .61 SF (2c) and O.S.

1.20 Surpass (4c) have been flown in the Warhawk

and required no additional cooling. A special 2cycle muffler with headers to fit several of the

recommended engines has been specifically

designed for and tested in the P-40. This muffler

provides good sound reduction while fitting entirely

inside the cowling. More information on the

recommended engines and related items can be

found in the

Engine and Mount Selection

Section

.

Please inspect all parts carefully before

starting to build! If any parts are missing,

broken or defective, or if you have any

questions about building or flying this model,

please call us at (217) 398-8970 and we’ll be

glad to help. If you are calling for replacement

parts, please look up the part numbers and the

kit identification number (stamped on the end

of the carton) and have them ready when

calling.

PRECAUTIONS

1. You must build the plane according to the

plans and instructions. Do not alter or modify

the model, as doing so may result in an unsafe or

unflyable model. In a few cases the plans and

instructions may differ slightly from the photos. In

those instances you should assume the plans and

written instructions are correct.

2. You must take time to build straight, true, and

strong.

3. You must use a proper R/C radio that is in first

class condition, the correctly sized engine and

correct components (fuel tank, wheels, etc.)

throughout your building process.

4. You must properly install all R/C and other

components so that the model operates properly

on the ground and in the air.

5. You must test the operation of the model before

the first and each successive flight to insure that all

equipment is operating, and you must make certain

that the model has remained structurally sound.

Be sure to check external nylon clevises often and

replace if they show signs of wear.

6. You must fly the model only with the

competent help of a well experienced R/C pilot if

you are not already an experienced R/C pilot at

this time.

WARNING! THIS IS NO

T A TOY!

The model you will build from this kit is not a toy! It is capable of serious bodily

harm and property damage. IT IS YOUR RESPONSIBILITY AND YOURS ALONE -

to build this kit correctly, properly install all R/C components to test fly the model and

fly it ONLY with experienced, competent help in accordance with all safety standards

as set down in the Academy on Model Aeronautics Safety Code. It is suggested that

you join the AMA to become properly insured before you attempt to fly the model. IF

YOU ARE JUST STARTING R/C MODELING, CONSULT YOUR LOCAL HOBBY

SHOP OR WRITE TO THE ACADEMY OF MODEL AERONAUTICS TO FIND AN

EXPERIENCED INSTRUCTOR IN YOUR AREA.

Academy of Model Aeronautics

5151 E. Memorial Drive

Muncie, IN 47302 (800)435-9262

Page 4

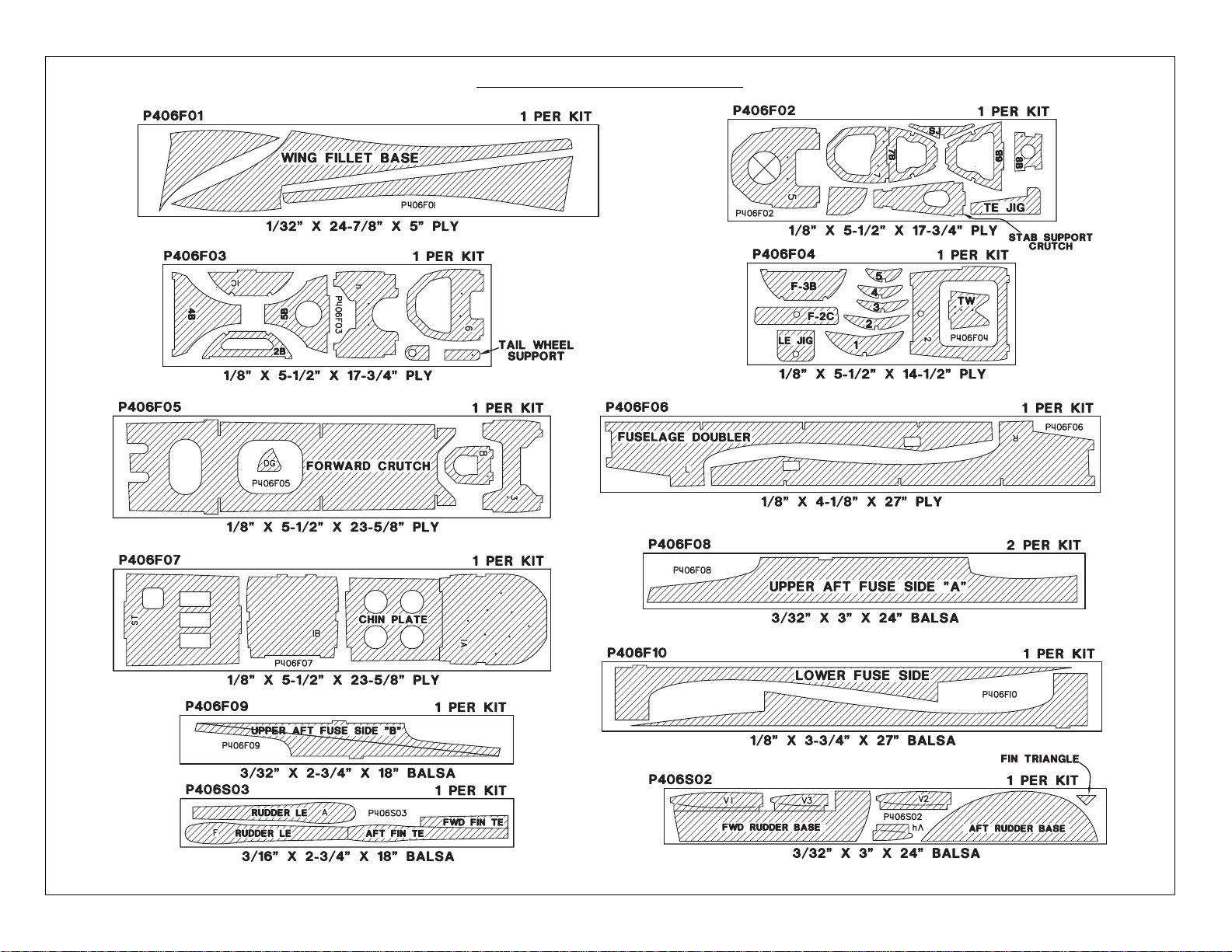

DIE-CUT PATTERNS

- 4 -

Page 5

DIE-CUT PATTERNS

- 5 -

Page 6

Remember: Take your time and follow

directions to end up with a well-built model that

is straight and true.

DECISIONS Y

OU MUST

MAKE EARL

Y IN THE

BUILDING SEQUENCE

ENGINE AND MOUNT SELECTION

The recommended engine size range is as

follows:

.60 to .91 cu. in. 2-cycle

.90 to .120 cu. in. 4-cycle

The Warhawk will fly well with any of the

recommended engines. The 4-Cycle engines and

most .90 2-Cycle engines will turn a larger prop at

lower RPM’s. This is often desirable for scale

realism. Many .60 2-Cycle engines produce about

as much horsepower as the popular .90 2-Cycle

engines and will fly the Warhawk fine. If you use a

.60 2-Cycle, a Schnuerle ported engine is

preferred. The prototype P-40 with all of the

options, including flaps, retracts, drop tank, paint

etc., has been flown with an O.S. .61 SF. This

combination works fine and gives very realistic

scale power. Most modelers are accustomed to a

larger power reserve and would probably prefer

more power if they load up their P-40 with all of the

extras.

Even though the P-40 is designed to house the

engine inverted, a modeler desiring a more

utilitarian setup can mount his engine with the

cylinder head sticking out the right side of the

model. The same engine centerline should be

used.

The mount selection is up to you. If you use an

O.S. 1.20 4-cycle, the plans show (and the firewall

is spaced for) a J-tec No. JT-122 SV (JTEG8450).

The included mount will hold many 2-Cycle

engines such as the O.S. .61 SF.

A special muffler and header is available that

will fit inside your cowling. It is primarily designed

for 2-cycle engines mounted inverted.

*Header for O.S. .61SF (TOPQ7920)

*Header for SuperTigre S61K & S75K

(TOPQ7925)

*Muffler for above (TOPQ7915)

RETRACTS

The choice whether or not to use fixed gear or

retracts is up to you. Retracts offer good looks and

great flight realism with the added expense and

complication. The model is designed to use the

Robart #615 (ROBQ1815) rotating retracts, as

these offer the easiest installation and most

reliable operation. More information on retracts is

found in the “Tips for Competition Minded

Modelers” section and in the construction

sequence. For item numbers, see "Other Items

Required", page 7.

WHEEL SELECTION

The true scale tire size is 4-5/8”. The

recommended range of tire sizes is 3-1/4” to 4”.

The 4” wheels fit comfortably into the wing when

retracted. If you use fixed gear, you may choose

to use the smaller tires to reduce drag in the air.

Robart 4" (ROBQ1537) main wheels are very close

to scale appearance for a P-40. A 1-1/4” tail wheel

is scale and recommended.

FLAPS

This model is designed to incorporate split

flaps that are very scale. They are not difficult to

assemble, but they do require good craftsmanship

if they are to fit well. They add a good deal to the

model’s flight characteristics and scale appeal

while causing no bad effects. No trim correction of

any kind is needed when they are used with the

recommended throws. The flaps add drag and lift

to the model on landing approaches, which gives

the plane a very steady, locked-in feel. The flaps

require one channel, a Y-harness, and two

standard or mini servos. They are highly

recommended for those who wish to install them.

More information on the use of the flaps may be

found in the

Flying Section

.

DROP TANK

P-40s in combat used drop tanks most of the

time. Top Flite has made a correctly sized,

vacuum-formed drop tank available for your

warbird. The tank comes with a release

mechanism and is easy to assemble and install.

The drop tank will add a great deal of realism to

your Warhawk. Part #TOPQ7900

STATIC DISPLAY PROPELLER

When displaying your model, nothing adds

more realism than a good looking scale propeller.

Top Flite has a 3-bladed scale propeller available

for your P-40. Remember, this propeller is for

static display only; do not attempt to run the engine

with it mounted. Part # TOPQ7907

- 6 -

NOTE: We, as the kit manufacturer, can

provide you with a top quality kit and great

instructions, but ultimately the quality and

flyability of your finished model depends on

how you build it. Therefore, we cannot in any

way guarantee the performance of your

completed model, and no representations are

expressed or implied as to the performance or

safety of your completed model.

Page 7

SUGGESTED SUPPLIES AND TOOLS

We recommend only Top Flite Supreme™

glues for the assembly of our models.

❑

2 oz. CA [thin] (TOPR1003)

❑

2 oz. CA+ [thick] (TOPR1008)

❑

6-Minute Epoxy (TOPR1040)

❑

30-Minute Epoxy (TOPR1043)

❑

Hand or Electric Drill

❑

Drill Bits: 1/16”, 3/32”, 1/8”, 5/32”, 3/16”, 13/64”,

1/4”, 17/64”

❑

Sealing Iron (Top Flite) (TOPR2100)

❑

Heat Gun (Top Flite) (TOPR2000)

❑

Hobby Saw (X-acto Razor Saw)

❑

X-acto Knife, #11 Blades

❑

Pliers

❑

Screw Drivers

❑

T-Pins

❑

String

❑

Straightedge with length graduations

❑

Masking Tape (Required for construction)

❑

Sandpaper (coarse, medium, fine grit)*

❑

T-Bar Sanding Block (or similar)

❑

Waxed Paper

❑

Lightweight Balsa Filler such as Hobbico

®

HobbyLite™ (HCAR3400)

❑

1/4-20 Tap, Tap Wrench

❑

Isopropyl Rubbing Alcohol (70%)

❑

Dremel Moto Tool or similar (optional)

❑

Razor Plane

*NOTE: On our workbench, we have

four 11” T-Bar sanders, equipped with

#50, #80, #150 and #220-grit sandpaper.

This setup is all that is required for

almost any sanding task. Sanding

blocks can be made from balsa for

sanding hard to reach spots. We also

keep some #320-grit wet-or-dry

sandpaper handy for finish sanding

before covering.

COMMON ABBREVIATIONS USED IN

THIS BOOK AND ON THE PLANS:

deg. = Degrees

Elev = Elevator

Fuse = Fuselage

LE = Leading Edge (front)

LG = Landing Gear

Lt = Left

Ply = Plywood

Rt = Right

Stab = Stabilizer

TE = Trailing Edge (rear)

" = Inches

TYPES OF WOOD

TIPS FOR COMPETITION-

MINDED MODELERS

DEVIATIONS FROM SCALE

The rudder hinge line has been simplified to

allow you to use conventional model hinging

techniques. The elevator hinge line near the tip of

the stab was changed slightly to simplify the

elevator shape.

If you plan to compete with the trim scheme

shown on the box, here are a few things to

consider:

The full size P-40 that was duplicated is a

P-40E which was restored and is still in existence.

It matches the Koku Fan 3-view very well, with a

few exceptions.

- 7 -

OTHER ITEMS REQUIRED

❑

Four to seven channel radio with 4 to 8

servos.

❑

Engine (see page 6)

❑

Propellers (see engine instructions for

recommended sizes).

❑

Pilot figure (1/7thor 2” scale

recommended)

❑

4” P-40 Top Flite spinner

#TOPQ5401 red, #TOPQ5400 white

❑

Fuel Tank (Most 10 to 16 oz. tanks will fit)

❑

3-1/4” to 4” Main Wheels (2) (see page 6)

❑

1-1/4” Tail wheel

❑

3/16” Wheel Collars (4 for fixed gear main

wheels)

❑

3/32” Wheel Collars (2 for tail wheel)

❑

Top Flite Super MonoKote (2 rolls) Clear

(see

Finishing Section

)

❑

Paint (see

Finishing Section

)

❑

Silicone Fuel Tubing

❑

Latex Foam Rubber Padding (1/4” thick)

Optional:

❑

Drop Tank...............TOPQ7900

❑

Static Prop..............TOPQ7907

❑

Retracts ..................Robart #615

❑

Air Control Kit .........Robart #188

❑

Robostruts ..............Robart #650

❑

Engine Mount .........(see page 6)

Page 8

The most serious deviation is in the rear

portion of the canopy. The rear window recesses

(White ABS plastic in the model kit) were removed

from the full scale aircraft. This is presumably to

allow for a passenger. If you plan to enter serious

competition, you will probably want to modify your

kit to eliminate these panels. We chose to have

the kit build as a stock P-40E.

The P-40 was equipped with a variety of guns.

The guns in the photos differ from the ones on the

3-view. This is not a problem; just duplicate the

ones in the photos as we did on our prototypes

using 3/16” brass tubes.

Always work from the photos of the full size

aircraft and the proper 3-view drawing when

finishing your model because that is what you will

use for documentation.

SCALE RETRACTS AND DOORS

The retract landing gear pivot location shown

on the plans is correct. The stance of the model

(and strut length) shown with the gear down is

correct. Keep in mind that the Warhawk's gear,

like that in most modern aircraft, compresses

under the weight of the aircraft and extends when

the aircraft takes off. This fact means that the rigid

struts commonly used on models will not fold into

the scale locations. The normal way to deal with

this problem in models is to set up the model to

have the proper stance, and then have the wheel

retract into a position short of the scale location.

The only other reasonable way to overcome this

problem is to use oleo struts (such as Robart

Robostruts) that have springs light enough to

compress under the weight of the model and thus

function in a scale fashion.

The full scale P-40 uses landing gear doors on

the pods. We have not made these functional on

any of our models so we cannot offer any help on

implementing these.

GET READ

Y TO BUILD

NOTE: When you see "CA," use super

thin Supreme glue. When you see

"CA+," use thick Supreme glue.

❑

1. Unroll the plan sheets. Re-roll the plans

inside out to make them lie flat.

❑

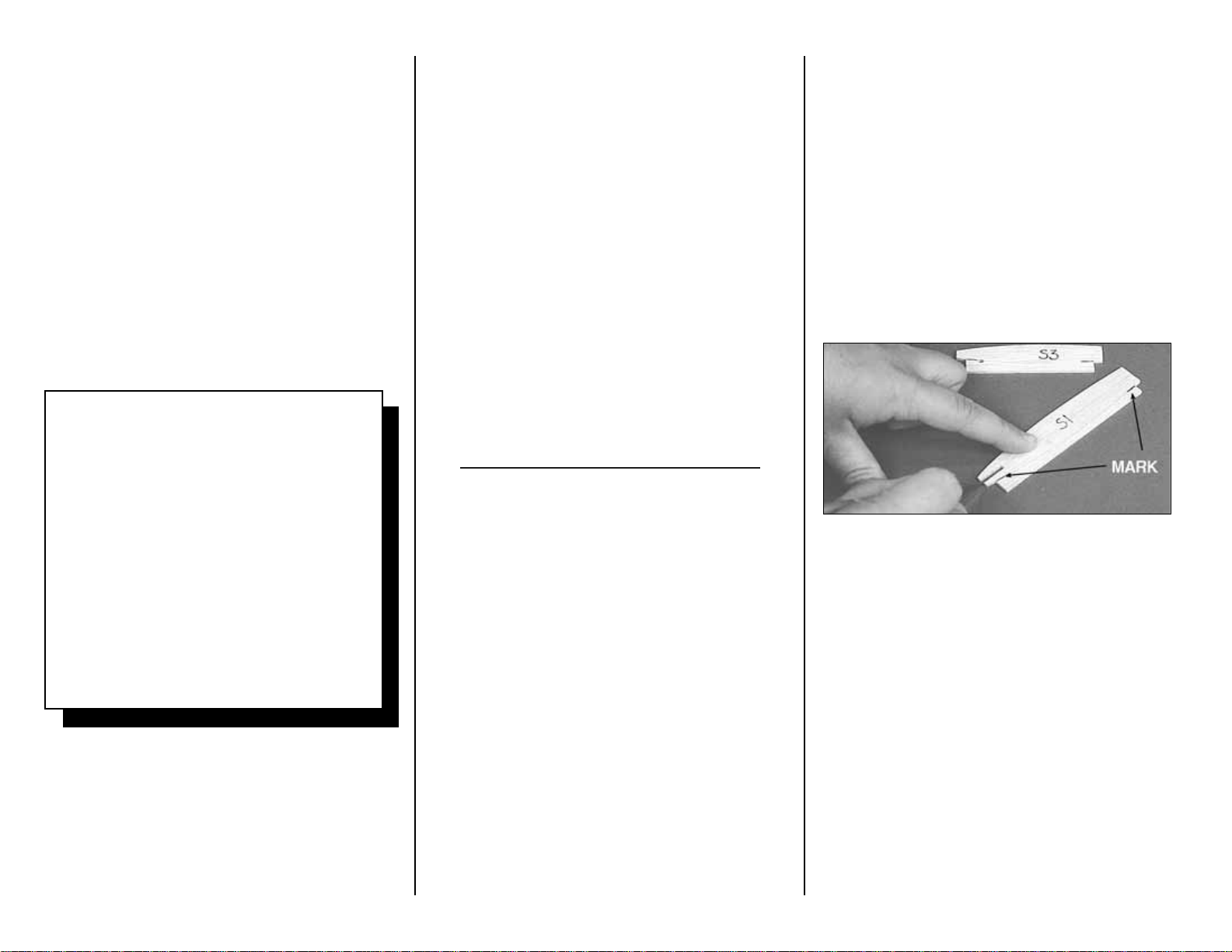

2. Remove all parts from the box. As you do,

identify the name of each part by comparing it with

the plans and the parts list at the back of this book.

Using a felt tip or ball point pen, write the part

name or size on each piece to avoid confusion

later. Use the die-cut patterns shown on pages 4

and 5 to identify the die-cut parts and mark them

before punching out. Save all scraps. If any of

the die-cut parts are difficult to punch out, do not

force them! Instead, first cut around the parts with

a sharp hobby knife. After punching out the die-cut

parts, use your T-Bar or sanding block to lightly

sand the edges to remove any die-cutting

irregularities.

❑

3. As you identify and mark the parts, separate

them into groups, such as fuse (fuselage), wing,

fin and stab (stabilizer), and hardware.

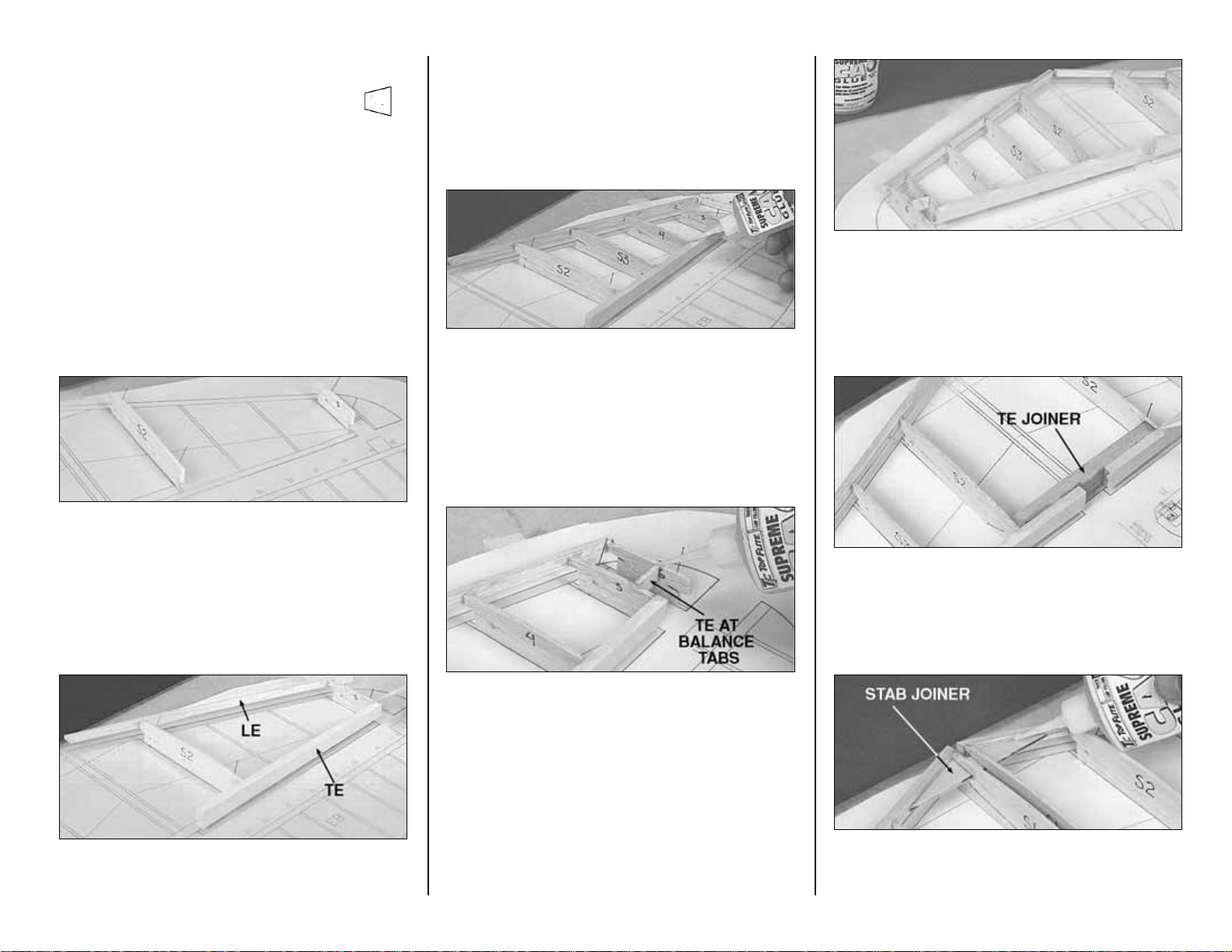

BUILD THE HORIZONTAL STABILIZER

❑

1. Work on a flat surface over the plans

covered with waxed paper. Refer to the plans to

identify the parts and their locations.

❑

2. Punch out both sets of the die-cut 3/32”

balsa ribs S-1 to S-6. There is a jig tab on the

bottom edge of each of these ribs. If any of these

break off, carefully glue them back on with CA.

Lightly sand any imperfections. You may need to

finish cutting the notch in the forward portion of S-1

for the Stab Joiner (SJ) with a knife. Use a pen to

mark the extensions of the bottom edge of the ribs

across the fore and aft ends of the jig tabs. These

will help you when you trim off the jig tabs later.

❑

3. The stab Trailing Edges (S) are die-cut

from 1/4” balsa. Since some crushing may happen

when die-cutting wood of this thickness, they are

supplied slightly long and can be trimmed. True up

the ends of these pieces with sandpaper. Also

true up the top and bottom edges of these pieces

with a T-bar.

- 8 -

SCALE DOCUMENTATION

This model was designed using the Koku-Fan

3-view drawings as the reference for outline.

This fact makes it preferable to use those

drawings for scale documentation. The

drawings and many Warhawk photo packs are

available from:

Scale Model Research

3114 Yukon Ave

Costa Mesa, CA 92626

(714) 979-8058

The trim scheme shown on the box is from

photo pack #588 (54 pictures $35) -or- #588a

(16 pictures $16) +$3 S&H

Page 9

❑

4. The stab and fin Leading Edges (LE’s) are

cut to length from the 1/4” x 30” tapered

balsa stock. Cut two pieces about 1/4”

longer than the length shown on the plans

for the stab LE.

HINT: Bevel the front edge of the stab

and fin ribs to match the sweep angle of

the LE stock. This will give you a better

fit and a stronger glue joint.

❑❑

5. Starting with the right half of the stab,

pin ribs S-2 and S-5 to the building board over their

locations on the plans.

❑❑

6. Center the LE vertically on the front

edge of ribs S-2 and S-5. Glue it in place with CA.

❑❑

7. Center the TE vertically on the back

edge of ribs S-2 and S-5. Glue it in place with CA.

❑❑

8. Glue ribs S-3 and S-4 in their places.

All of the jig tabs should rest on the work surface.

❑❑

9. Glue rib S-6 to the LE. Glue the die-cut

3/32” balsa TE at Balance Tab between ribs S-5

and S-6 at the location shown on the plans.

❑❑

10. Trim the LE and TE near the stab

center so they match the endpoints shown on the

plans.

❑

11. Repeat steps 5 through 10 to build the left

half of the stab. The left half of the stab is built

beside the right half and the two halves do not

touch for now.

❑

12. Trim the 3/8” x 9/16” x 4-1/2" hard balsa

stab TE Joiner, if necessary, to fit between the

S-2’s. Securely glue it to the stab TE’s and the

S-2’s using CA.

❑

13. Check the fit of the die-cut 1/8” plywood

Stab Joiner (SJ) and adjust if required for a good

- 9 -

Page 10

- 10 -

fit to the stab LE’s. Place the Stab Joiner into the

slots in the two S-1’s and work the whole assembly

into position. Make sure all parts are properly

aligned and the S-1 rib jig tabs contact the work

surface. Glue in the Stab Joiner and the S-1’s

using CA.

❑

14. Cut two 1/4” wide cross grain strips off the

end of a 1/16” x 3” x 30” wing sheet. Glue these

strips between the two S-1 ribs flush with their top

edges. These strips will reinforce the stab skins

where they join at the center and strengthen the

stab.

❑

15. Use CA+ to reinforce any glue joints that

do not look strong.

❑

16. Carefully remove the stab from the

building board but try not to damage the jig tabs,

as they will be useful until after the top of the stab

is sheeted.

❑

17. Use a razor plane and a sanding block to

cut down the top surface of the LE (particularly

toward the tip) until it is even with the ribs. Sand

the TE, if required, to have a smooth transition

from the ribs.

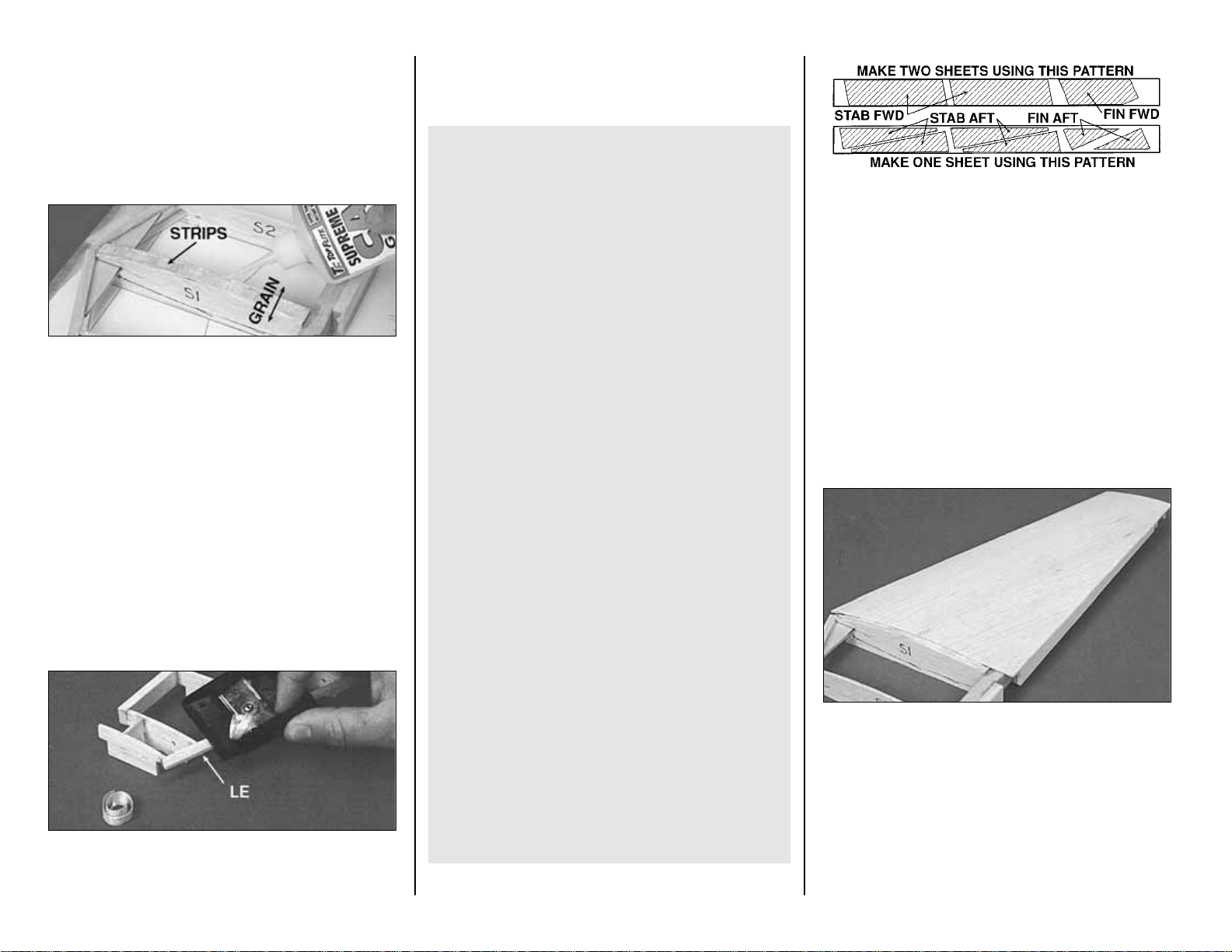

TIPS FOR MAKING WING AND STAB

SKINS

A. Wherever practical, pre-join the balsa sheets to

make a “skin” before attaching them to the

structure.

B. Many modelers like to sort the wood so they

can put the best wood with the most even grain

structure on the top of the wing and stab.

C. Make your skin larger than needed to allow for

misalignment. On a large surface like the wing,

3/8” extra is suggested.

D. To make skins the following steps are

recommended:

1. True up the edges of the sheets with a

metal straight edge and a sharp knife or a “T-Bar”

sanding block.

2. Test fit the sheets together to make sure

they match well.

3. Glue the sheets together with CA over a flat

surface covered with waxed paper. A quick wipe

of the joint with a fresh paper towel will remove

excess glue and make sanding easier. Mark the

poorest surface that you think should be the inside

of the sheet with an “I”.

4. Place the skin on a large flat surface and

sand it with a large flat sanding block and fresh,

sharp 220 paper.

5. Trim the perimeter of the sheet to even

things out.

❑

18. Make four stab skins from three 1/16” x 3”

x 30” balsa wing sheet pieces. See the sketch for

the proper layout on the wood. Refer to the plans

for the exact shapes and sizes, but remember to

make the skins slightly oversize.

❑

19. Pin the stab structure onto the flat building

surface. Test fit the skins over the structure. Make

sure the skins meet well at the center. Adjust them

if necessary.

❑

20. Apply an even bead of CA+to the upward

facing edges of the structure. Place the skin in its

proper position and press it firmly down until the

glue has set. Take your time here as a strong joint

is critical. Repeat this step for the other top skin.

❑

21. Remove the stab from the building board.

Trim off the jig tabs with a sharp knife. Trim and

Page 11

blend the LE and TE to the ribs as you did before

and sand the bottom edges of the ribs lightly with a

T-bar sander. Check all glue joints, adding glue as

necessary

❑

22. Cut two 1/4” wide strips off the end of a

1/16” x 3” x 30” wing sheet. Glue these strips

between the two S-1 ribs flush with their bottom

edges.

❑

23. It is important to get a good glue bond

between the stab structure and the bottom stab

skins. Apply a heavy bead of CA+to all of the

upward facing edges of one side of the stab

structure. Place a skin on the structure and hold it

in place with your hands until the glue sets.

Repeat this for the other bottom skin. Be careful

not to bend or twist the stab during this step.

❑

24. True up the ends of the stab with a

sanding block. Round the leading edge of the stab

to match the cross section on the plan.

❑

25. Glue on the 5/8” thick shaped balsa Stab

Tips. Use a razor plane and a sanding block to

airfoil them to match the stab. You may contour

the tip to its final shape now, or wait until the model

is nearer completion.

❑

26. Cut away the skin in the area of the

balance tabs. True up the skin with a T-bar.

❑

27. Cut away the skin at the center of the stab

at the LE and TE as shown in the photo

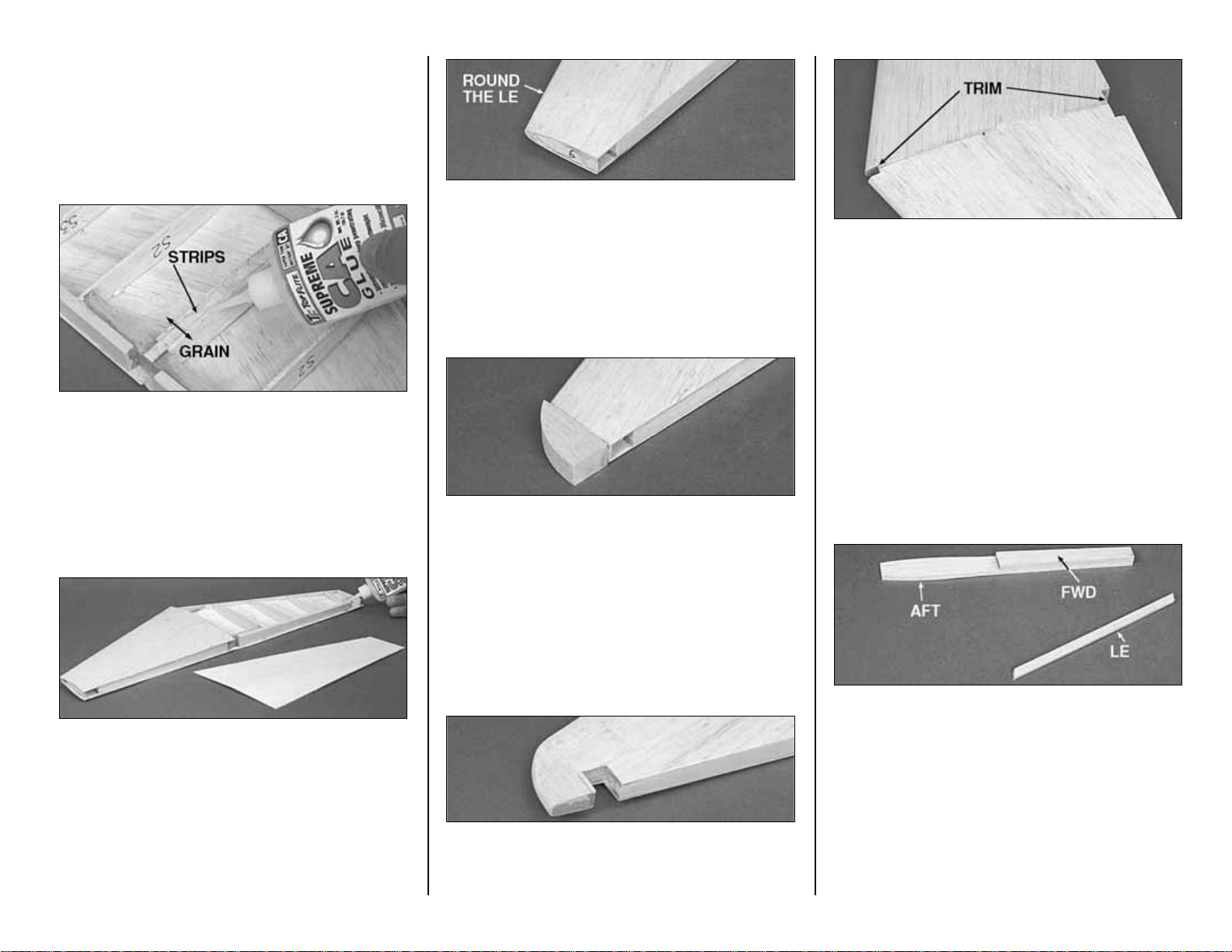

BUILD THE FIN

❑

1. Cut a 6-5/8” length of the tapered 1/4” balsa

stabilizer LE stock. Notice that the fin LE protrudes

through the stab.

❑

2. Glue the die-cut 3/16” balsa Fwd and Aft

Fin TE’s together with CA. Since these pieces are

thick and die-cut, they will probably require a little

touch up and blending with a sanding block.

❑

3. Punch out the die-cut 3/32” balsa ribs V-1

through V-4. Be sure to preserve their jig tabs.

- 11 -

Page 12

❑

4. Pin ribs V-1 and V-4 to the building board

over their proper locations. Center the LE

vertically on the front of the ribs and glue it in

place.

❑

5. Center the Fin TE vertically on the aft edge

of the ribs and glue it in place.

❑

6. Put ribs V-2 and V-3 into their places and

glue them. Remember, all jig tabs should contact

the work surface.

❑

7. Glue the die-cut 3/32” balsa Fin Triangle

into the corner of V-4 and the Trailing Edge.

❑

8. Apply extra CA+ glue to any joints that do

not appear to be well glued.

❑

9. Blend the LE to match the ribs on the

upward facing (left) fin side. Sand the TE, if

necessary, to blend smoothly with the ribs.

❑

10. Make a skin for each side of the fin using

the 1/16” balsa sheet left over from the stab skins.

Make the skin so it overhangs past V-1 about 1/2”;

this will allow fitting to the stab later. See the

sketch on page 11.

❑

11. With the structure flat on the table, glue on

the left skin.

❑

12. Trim off the jig tabs and blend the LE and

TE to the ribs on the right side of the fin.

❑

13. Glue on the right skin. Be sure to get a

good bond between the ribs and the skin.

❑

14. True up the edges of the fin sheeting with

a sanding block. Shape the LE to match the crosssection on the plans.

❑

15. Glue the shaped 3/4” balsa Fin Tip to the

top of the fin at the location shown on the plans.

Use a razor plane and a sanding block to do the

initial shaping of the tip. Final shaping should be

done later, with the fin taped to the rudder.

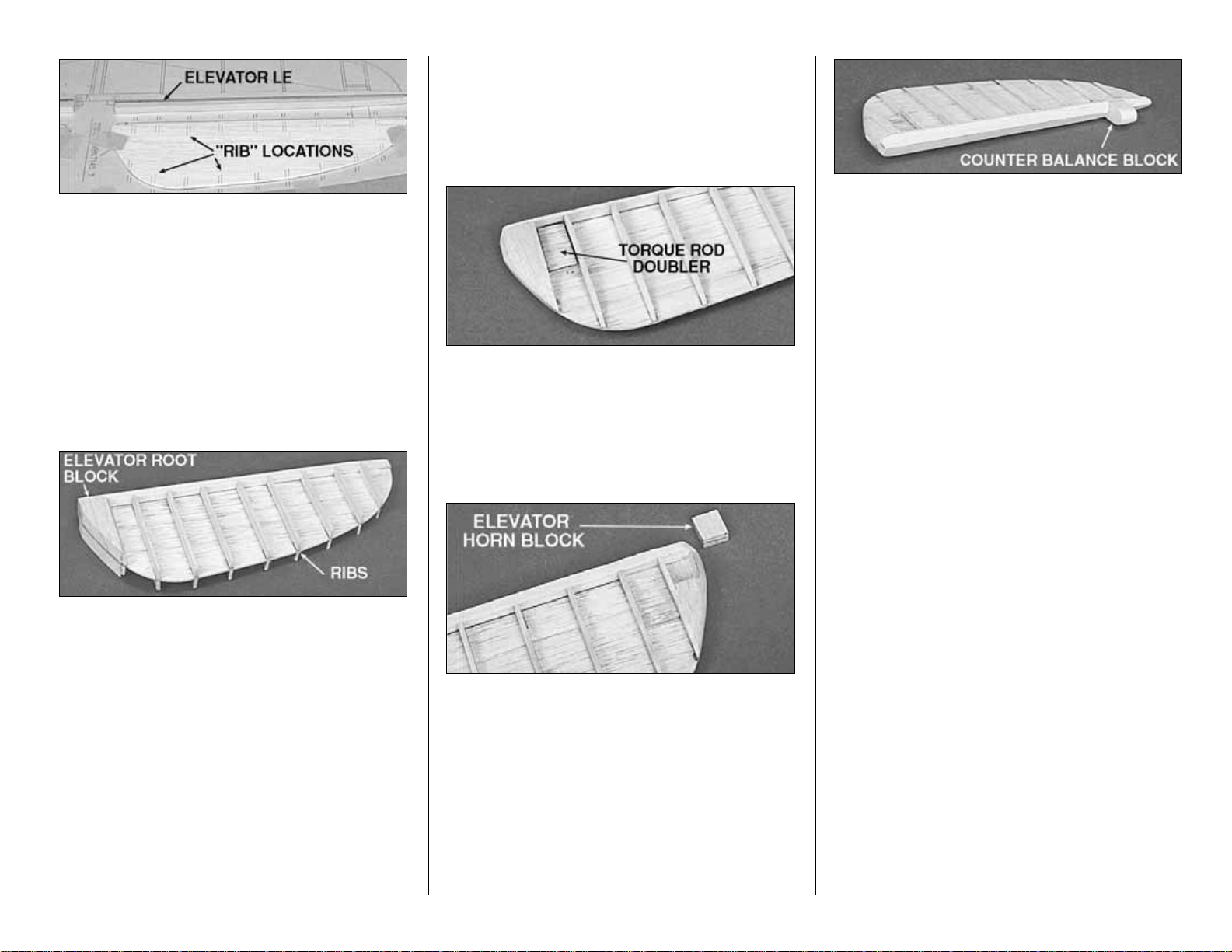

BUILD THE ELEVATORS

NOTE: Build both elevators using the

following steps:

❑❑

1. Place the die-cut 3/32” balsa Elevator

Bases (EB) on the plans and mark the “Rib”

locations on both sides using the “tick” marks on

the plans.

- 12 -

Page 13

❑❑

2. Draw a centerline on both surfaces of

the die-cut 1/4” balsa Elevator LE (E). Draw two

parallel lines 1/16” away from center line on the aft

side.

❑❑

3. Hold the Elevator Base centered

between the lines on the Elevator LE. Use CA to

glue the Elevator Base to the LE.

❑❑

4. Cut “ribs” from the 3/32” x 3/8” x 36”

balsa sticks and glue them onto both sides of the

elevator base at the locations you previously

marked.

❑❑

5. Glue a 3/8” thick shaped balsa

Elevator Root block to each side of the Elevator

Base.

❑❑

6. Refer to the photos on this page and the

cross-sections on the plans to obtain the shape of

the elevators. Use a razor plane and sanding

block to “rough in” the shape of the elevators. Trial

fit the elevators to the stab for final shaping.

❑❑

7. Glue a die-cut 1/8” balsa elevator

Torque Rod Doubler to both sides of the Elevator

Base as shown on the plans.

❑❑

8. Cut a pocket in the bottom of the right

elevator to match the 1/4” x 1/2” x 5/8” Elevator

Horn Block. Check the plans for the proper

location.

❑❑

9. Glue, using 6-minute epoxy, the birch

plywood Elevator Horn Block in the pocket on the

bottom side of the right elevator. Shape the

Elevator Horn Block edge to match the elevator.

❑❑

10. Place the elevator over the plans and

mark position of the 5/8” x 5/8” x 11/16” balsa

Counter Balance Block on the elevator LE. Glue

the Counter Balance Block in place. Shape the

front of the block to a full radius. Allow

approximately 1/16” clearance on both sides of the

counter balance block in the stab opening.

❑❑

11. Shape the Elevator LE to a “V”

shape to allow elevator travel. See the crosssection on the plans for the correct shape.

❑❑

12. Tape the elevators to the stabilizer.

Hold the bent 1/8” Elevator Joiner Wire up to the

elevator and mark the location of the holes (see

the plans for the joiner location).

❑❑

13. Remove the elevators from the

stabilizer. Drill 1/8” holes in the elevators for the

Joiner wire. Make slots inboard of the holes to

allow the wire to be inset into the elevators.

❑❑

14. Test fit the joiner wire into the

elevators. Check to see if the elevators align with

each other properly. Make adjustments if required.

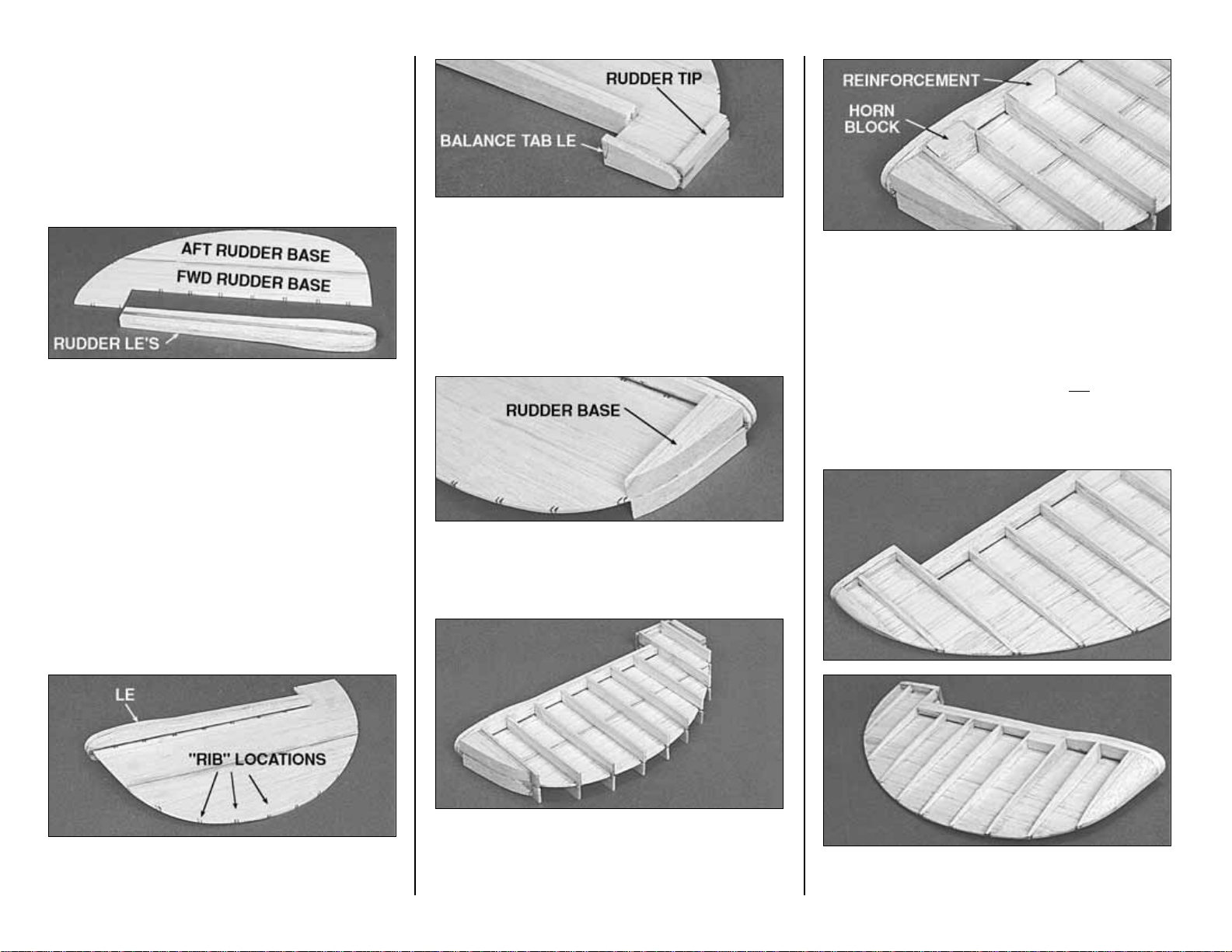

BUILD THE RUDDER

❑

1. Glue the two die-cut 3/16” balsa Rudder

LE’s together with CA+. Even up the edges with a

sanding block, but save any tapering for later.

- 13 -

Page 14

❑

2. Draw a centerline on the aft surface of the

LE. Draw two parallel lines 1/16” away on both

sides of the centerline.

❑

3. Glue the die-cut 3/32” balsa FWD Rudder

Base to the die-cut 3/32” balsa AFT Rudder Base.

❑

4. Align the Rudder Base over the plans and

mark the “Rib” locations on both sides of the

Rudder Base.

❑

5. Hold the Rudder Base centered on the

rudder LE. Apply CA to the joint.

❑❑

6. Center the 1/4” x 3/4” x 2” balsa rudder

Balance Tab LE on the top of the rudder plate.

Glue it with CA.

❑❑

7. Glue a 1/4” x 1/4” x 1-3/4 stick balsa

Rudder Tip to each side of the top of the rudder

plate.

❑❑

8. Glue a 1/2” thick shaped balsa Rudder

Base to each side of the bottom of the rudder

plate.

❑❑

9. Cut “ribs” from the 3/32” x 1/2” x 36”

balsa sticks and glue them onto both sides of the

rudder at the locations you previously marked.

❑❑

10. Glue the a 3/8” x 1/2” x 1-1/16” balsa

Rudder Reinforcement Stick to each side of the

rudder at the location shown on the plans. These

will strengthen the rudder when the slot to clear the

elevator joiner wire is cut out.

❑❑

11. Glue the 1/2 x 5/8” x 15/16” hard

balsa Rudder Horn Block to the left side of the

rudder where it is shown on the plans.

❑❑

12. Refer to the photos and the cross-

- 14 -

Page 15

sections on the plans to obtain the shape of the

rudder. Use a razor plane and sanding block to

“rough in” the shape of the rudder. Final shaping

and fitting should be done after the fin is glued

onto the fuselage, but you may wish to tape the

rudder to the fin at this point to blend the upper

ends of both.

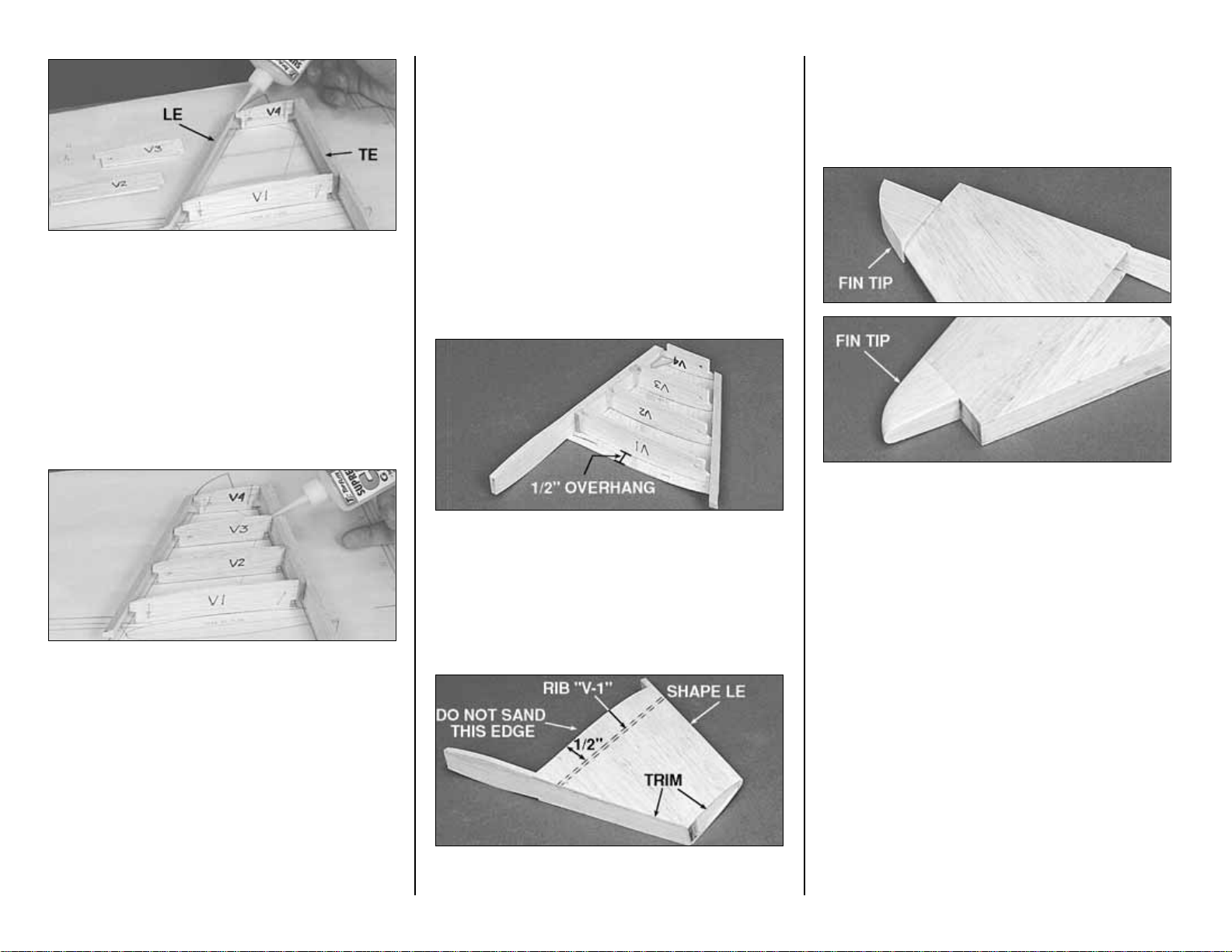

BUILD THE WING

NOTE: The wing halves are built

“UPSIDE-DOWN” on the plans. The jig

tabs are attached to what is, in the end,

the TOP surface of the wing.

NOTE: Since it is the standard

convention to show the Top View of the

wing, and the wing panels are built

upside-down, the LEFT wing panel is

built over the RIGHT Wing Top View

and vice-versa. This does not present

any problems; just be sure to build a

left and a right wing panel.

❑

1. Place the wing plan on your building board

and cover it with waxed paper (you may wish to cut

apart the wing panel sections of the plan to make

handling easier.)

❑

2. Hold the four 1/4” x 3/8” x 36” hard balsa

Spars over the wing plans. Mark the spars about

1/4” longer than they need to be. Cut off the spars

at the marks and save the scraps for the flap and

aileron servo mounts.

❑

3. Punch out all the die-cut 3/32” balsa wing

Ribs. Smooth out any imperfections with

sandpaper. Be sure to keep the jig tabs attached

to the ribs.

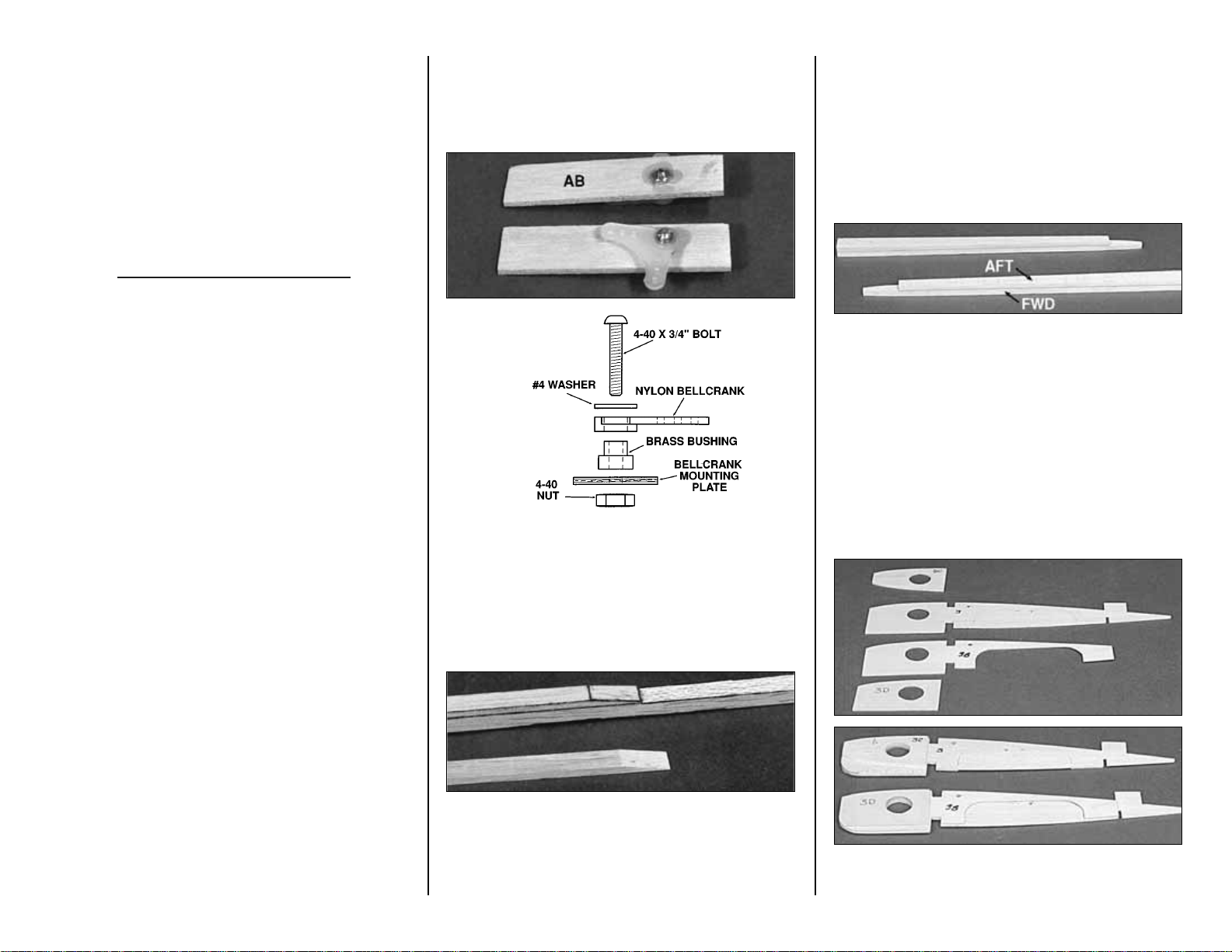

❑

4. Ribs W-1 through W-8 have punch marks

just aft of the spar that locate the aileron pushrods

for you. Drill a 3/16” hole at each of these marks.

❑

5. Drill 1/8” holes through the punch marks in

the two die-cut 1/8” plywood Aileron Bellcrank

Plates (AB). Assemble the bellcrank parts as

shown in the sketch. Be sure to put a drop of

6-minute epoxy on the 4-40 nut and threads to

prevent the bellcrank from vibrating loose.

❑

6. Taper one end of each of the four 1/8” x 3/8”

x 17-1/2” balsa Spar Doublers to match the spar

detail drawing on the plans. Glue a Spar Doubler

to each Spar with the root (non-tapered) end of the

doubler aligned with the root end of the spar.

NOTE: The top edge of the FWD

TRAILING EDGE AT AILERON curves

more than the bottom edge at the tip.

Since the wing is being built upside

down, the more curved edge faces

down next to the plans.

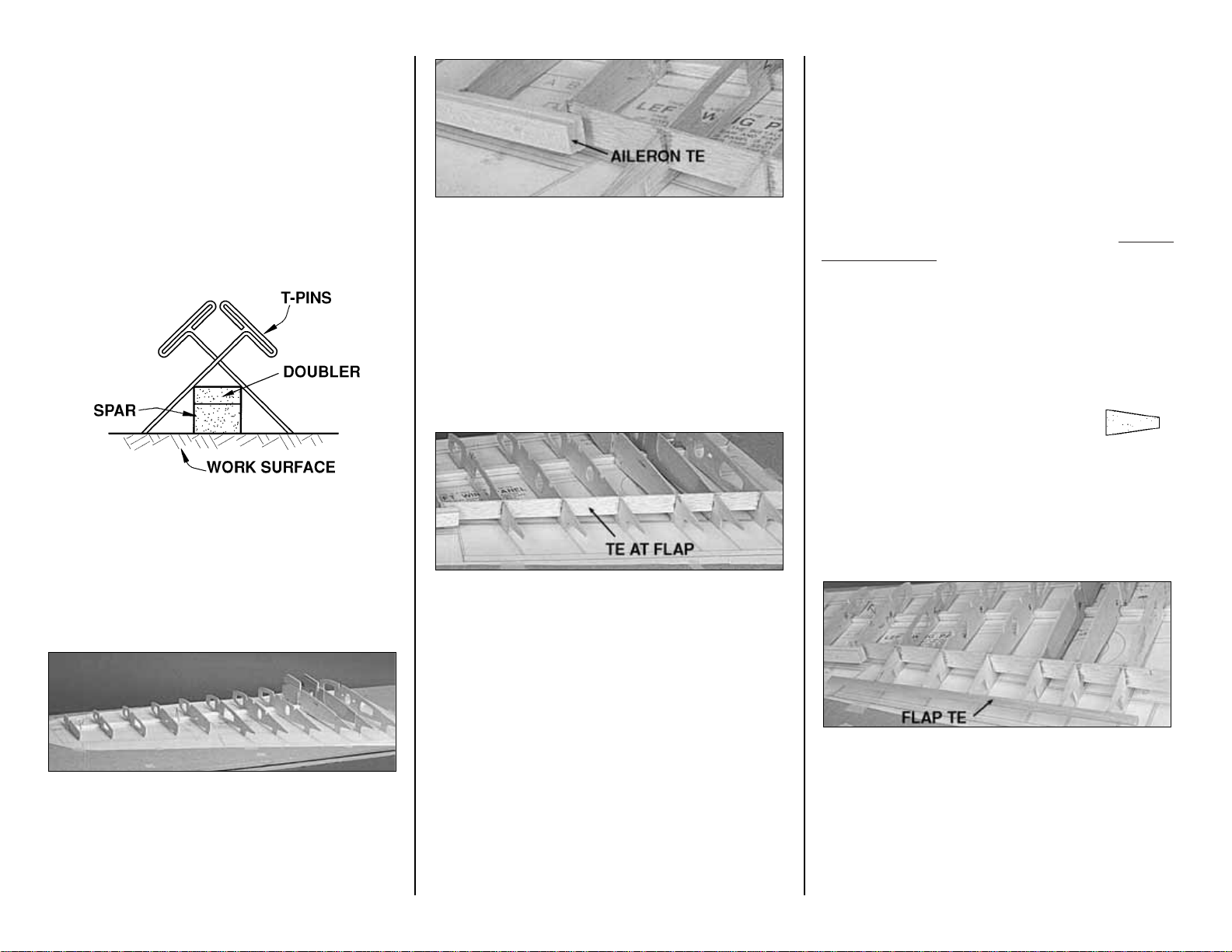

❑

7. Center the die-cut 1/4” balsa Aft Trailing

Edge at Aileron (A) on the die-cut 1/4” balsa

Forward Trailing Edge at Aileron (F) and glue

them together with CA. Be sure to make a left

and a right trailing edge. Use a sanding block to

taper the two pieces slightly as shown in the crosssectional drawing on the plan. These pieces are

die-cut slightly long to allow you to trim off any

imperfections.

❑

8. Each of the W-4 and W-3 ribs is made up of

four laminations. Refer to the plans for the proper

- 15 -

Page 16

order of the parts (e.g. 4C, 4, 4B, 4D.) Use CA+ to

glue the parts together. Be sure to make a left

and a right of each rib assembly.

❑

9. Enlarge the pushrod hole in each W-8 until

it is a 5/16” x 5/16” square hole. This will provide

clearance for the clevis.

❑❑

10. Pin a Spar assembly to the building

board at three or four locations using the crosspinning technique shown in the sketch.

❑❑

11. Glue the die-cut 3/32” balsa ribs W-2

through W-12 to the spar. These should be

vertical and aligned over their appropriate locations

as indicated on the plans. The jig tabs located

near the aft end of the ribs should all contact the

work surface.

❑❑

12. Glue the aileron trailing edge

assembly to the aft edge of ribs W-8 through W-12.

The upward facing edges of the ribs and the top

surface of the trailing edge should be even, and all

of the jig tabs should touch the work surface.

NOTE: The inboard end of the aileron TE extends

approximately 5/8” inboard of rib W-8, as shown on

the plan.

❑❑

13. Test fit the die-cut 1/8” balsa TE At

Flap to the wing ribs. You will probably have to

angle the notches with your hobby knife to match

the forward sweep of the trailing edge. Place the

TE At Flap back into the wing rib structure but do

not glue yet.

❑❑

14. Sight down the TE of the wing from

the root end; make sure all the ribs are aligned at

the same height. Use paper to shim under the jig

tabs of any ribs that are low. This will put the TE’s

of the ribs in line.

❑❑

15. When the TE At Flap is fitting in place

well, with all of the rib TE’s aligned, glue it in with

CA+.

NOTE: Do steps 16 and 17 for a plane without

operating flaps. Skip these steps for a plane

with operational flaps.

❑❑

16. Cut the ends of the tapered 1/2" x 19”

balsa Flap TE about 1/8” longer than it

is shown on the plan. Note: This Flap

TE is not used if you build operating

flaps.

❑❑

17. Glue the Flap TE to ribs W-2 and W-7.

The Flap TE should be centered vertically on the

aft edges of the ribs and should be symmetrically

aligned with the top and bottom of the ribs. Make

sure all the jig tabs are contacting the work

surface. A metal straightedge can be placed on

the structure over the jig tabs to hold them down

evenly.

- 16 -

Page 17

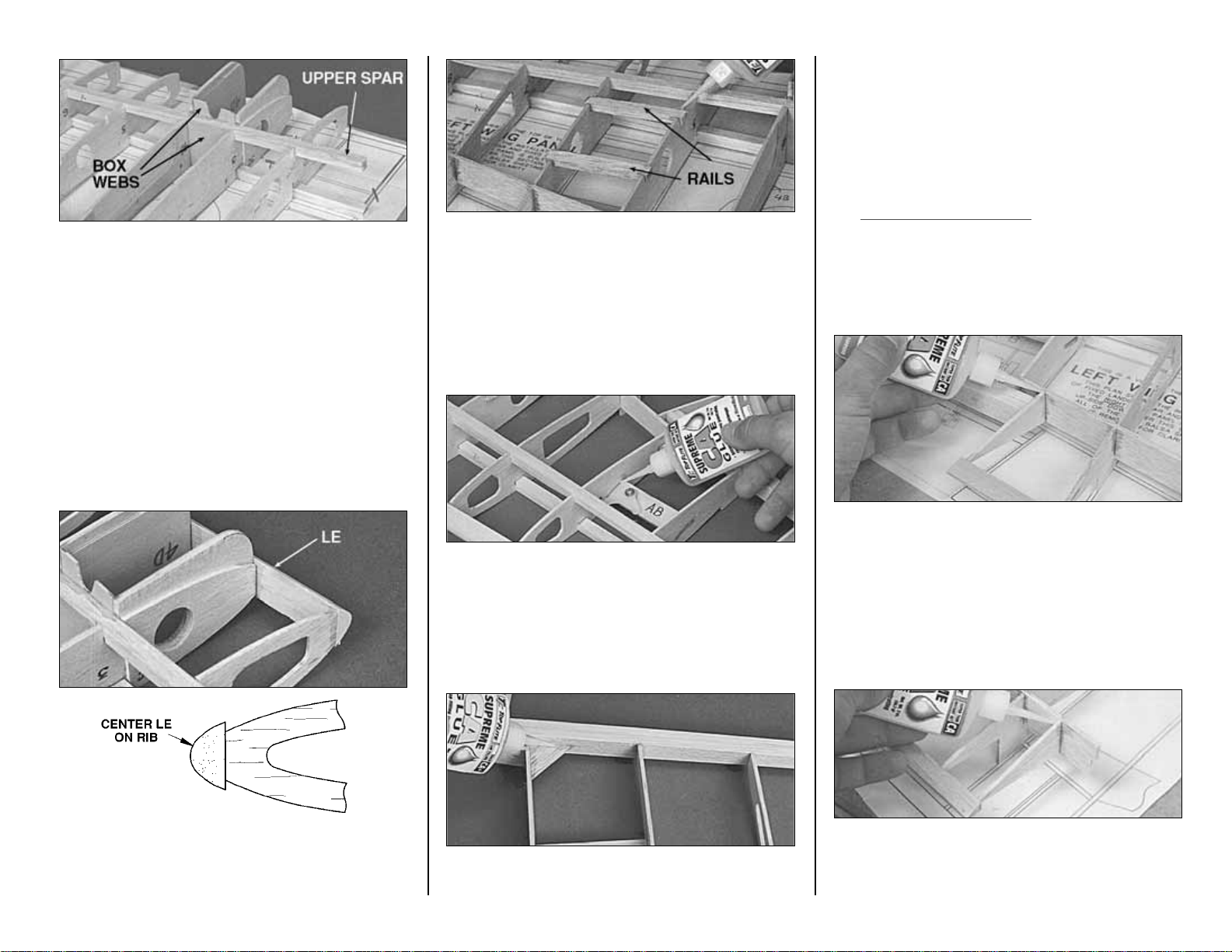

❑❑

18. Work the Upper Spar assembly into

place, making sure it fits well. Put some weights

on top of the structure to make sure it is held onto

the work surface. Fit the die-cut 1/16” plywood

Fwd and Aft LG Box Webs between W-3 and W-4

to confirm the angle of these ribs. Use CA to glue

in the top spar. Thoroughly glue the Fwd and Aft

LG Box Webs to the spars as well as W-3 and

W-4.

❑❑

19. Hold the shaped balsa Leading Edge

centered vertically on the front edge of the ribs.

Use CA to glue it in place.

❑❑

20. If you are going to use flaps, trim the

1/4” x 3/8” balsa stock left over from the wing spars

to the length shown on the plans for the Flap Bay

Rails. Glue the rails into the notches in W-5 and

W-6 with CA. If you do not plan to use flaps, you

should fill the notches with scrap wood.

❑❑

21. Glue the aileron bellcrank assembly

into the slots in ribs W-8 and W-9. The bellcrank

should face away from the building board as

shown in the photo.

❑❑

22. Glue the die-cut 1/8” balsa Corner

Brace into the corner of W-8 and the Trailing

Edge.

Note: Do steps 23 and 24 for a plane

without operating flaps. Skip them for a

plane with operating flaps.

❑❑

23. Test fit, then glue in the die-cut 3/32”

balsa Flap Tip Rib at the location shown on the

plans.

❑❑

24. Glue in the die-cut 3/32” balsa Flap

Root Rib.

- 17 -

Page 18

❑❑

25. Trim the 1/16” balsa Shear Webs to fit

behind the spar between ribs W-4 through W-12.

Glue them in place with CA+. Wick CA- into all the

joints of the Shear Webs and the Spars to make

sure they are well bonded. It is not important to

glue the shear webs to the ribs.

❑❑

26. Cut a 13” length of Outer Pushrod

Tube. Rough up the outside of the tube with 220

grit sandpaper. Feed the tube through the holes in

the ribs as shown on the plans. Use CA to glue

the tube in place.

❑❑

27. Cut three lengths of Inner Pushrod

Tube about 5/16” long and slide them onto a .074"

x 36" threaded one end wire, at the intervals

shown on the plans. Carefully apply a small drop

of CA to secure each short tube if they are not very

snug on the wire.

❑❑

28. Snap a Nylon Clevis with Clevis

Retainer securely onto the

bellcrank. Feed the wire

assembly into the wing and

screw the threaded end

well into the clevis. Hint: The

wire is extra long. After the

threaded end starts threading

into the clevis, you may bend over the excess wire

and use it as a handle to turn the wire the rest of

the way into the clevis. Be sure to hold the clevis

securely with pliers while threading the wire into it

to keep from stressing the clevis pin. Cut off the

excess wire about 1-1/4” beyond the root end of

the spar.

INSTALL THE CENTER RIB (W-1)

❑❑

29. Finish cutting the slot in the aft part of

the two W-1 ribs for the Wing Bolt Plate.

❑❑

30. Glue the die-cut 1/16” ply W-1B

doubler ribs to the W-1’s. Be sure to make a left

and a right.

❑❑

31. Glue the die-cut 1/8” balsa Fwd

Center Brace (FCB) to rib W-2 over its location on

the plans.

❑❑

32. Place rib W-1 into position. Glue it in

place with CA+. NOTE: FCB sets W-1 at the

correct angle.

- 18 -

Page 19

❑❑

33. Glue the 3/8” x 1-3/16” x 2-1/2” balsa

Center LE Block to the front of W-1 and the LE.

Cut a V-notch in the Center LE Block centered on

the dowel notch in W-1. This notch will assist you

in drilling for the dowel later.

❑❑

34. Insert the 1/4” x 3/8” balsa Servo

Mount Rails (left over from the wing spars) into

the slots in W-1 and W-2. Adjust the aft rail's

position to allow the servo you will use to fit

comfortably. Glue the rails in place.

❑❑

35. Trim the spars, the servo mounts, and

the LE Block flush with W-1.

INSTALL THE CENTER TE BLOCK

Do steps 1 and 2 if you are NOT building

operating flaps.

❑❑

1. Glue the 3/8” x 1/2” x 1-1/4” Center TE

Block to the TE of rib W-1 and the Flap TE.

❑❑

2. Trim off the end of the Center TE Block

flush with W-1. The block should be shaped after

the wing is joined and sheeted.

PREPARE THE WING PANELS

FOR THE FLAPS

Do steps 1 through 14 if you are building

operating flaps.

❑❑

1. Remove the wing panel from the

building board. Use a T-bar with fresh 220 grit

sandpaper to blend away any unevenness from

the structure. Pay special attention to the trailing

edge of the wing. It is important to make the

trailing edge as straight as possible so the split

flaps will fit well.

❑❑

2. Draw a centerline down the 1/16” x 1” x

19” plywood TE Strip.

❑❑

3. Use a T-bar with sharp 150 or 220 grit

paper to bevel the aft 3/8” of the TE Strip. This will

allow the TE to be only 3/32” thick when the flaps

are shut. See the cross-section on the plans for

the correct thickness and angle.

❑❑

4. Locate the two 3/32” x 5/8” x 18” balsa

TE Jig Strips. Check the straightness of these

jigs by holding them up on edge on a flat table.

True them up with a knife and a metal straight

edge if required.

- 19 -

Page 20

❑❑

5. Place the TE Strip with the beveled

and centerline-marked side down on a very flat

table. Glue a TE Jig Strip to the TE Strip. The jig

strip will keep the TE straight until the wing is

complete. Do not use excessive glue because it

will have to be sanded off later.

❑❑

6. Glue the TE assembly to the wing

structure. The aft end of ribs W-2 through W-7

should align with the centerline you drew on the TE

Strip. Do not force the ribs to touch the TE Strip.

This will cause the TE to warp when you remove

the Jig later; just fill any slight gaps with glue.

❑❑

7. Cut the die-cut 3/32” balsa Flap Tip

Rib in half along its centerline. Align half of the rib

over the plans and glue it in as shown in the photo.

❑❑

8. Align the die-cut 3/32” balsa Flap Root

Rib over its location on the plan and glue it in with

CA+.

❑❑

9. Trim off the ends of the TE Strip flush

with the W-1 rib and the Flap Tip Rib.

❑❑

10. Use a razor saw and a single edge

razor blade to trim off the bottom half of ribs W-2

to W-7 (behind the TE at Flap). The bottom side

is the side opposite the jig tabs.

❑❑

11. Use a T-bar sander to even up the ribs

inside the flap bay.

- 20 -

Page 21

❑❑

12. Cut the 5/8" X 5/8" X 6" balsa stick

into six equal blocks. Fit and glue these Flap

Hinge Blocks in place where shown on the wing

plan.

❑❑

13 Mark the locations of the hinge blocks

on the TE to help you find them later.

❑❑

14. Decide how you want to route the flap

servo extension wires. You will need to go through

or around the wheel well. Add passageways for

the extension in W-3 and W-4 if needed.

NOTE: Actual flap construction will

begin on page 27.

Repeat the previous wing sections (starting on

page 16) to build the other wing panel. Use the

other half of the wing plan, and remember to

build a right and a left wing panel.

JOIN THE WING PANELS

❑

1. Trim the ends of the spars and LE’s of both

panels even with rib W-12. Excess overhang will

affect the dihedral angle.

❑

2. Cut away the portion of rib W-1 around the

spars as shown in the photo. This will allow the

dihedral braces to pass through.

❑

3. Test fit the die-cut 1/16” plywood Dihedral

Braces into each wing half. Make sure the Brace

centerline can go all the way to the wing centerline.

Trim the ends of the Braces slightly, if required.

❑

4. Trim the jig tabs off all of the wing ribs

except W-1 and W-12. Use a T-bar to blend the

airfoil where the jig tabs were removed.

❑

5. Drill two 1/4” holes in the shaped 1/4”

plywood Wing Bolt Plate at the locations shown

on the wing plan.

❑

6. Test fit the 1/4” plywood Wing Bolt Plate

into each wing panel. Make adjustments, if

necessary, until the Wing Bolt Plate fits well.

❑

7. Assemble the two wing halves, the two

Dihedral Braces, and the Wing Bolt Plate together.

- 21 -

Page 22

Place the 3/8” x 2-5/8” x 10” balsa Wing Jig Block

under W-1. The W-1 jig tabs and the spar at W-1

should contact the Wing Jig Block. The W-12 jig

tabs and the spar at W-12 should contact your flat

work table.

❑

8. When you have confirmed that all of the

parts fit well, disassemble the wing parts. Coat the

inside of the Dihedral braces and the area of the

Spars that they contact with a thin film of 30-minute

epoxy. Reassemble the wing parts onto the jig

block. Align the two W-1 ribs with each other and

glue them together with CA. Make sure the wing is

properly jigged. Clamp the Dihedral braces to the

Spars with clamps or masking tape.

❑

9. Apply a fillet of 30-minute epoxy around the

Wing Bolt Plate.

❑

10. Use 30-minute epoxy to fill any gaps

where the Spars join in the middle.

❑

11. Drill a 3/16” pilot hole through the wing LE

for the 5/16" Wing Dowel. Gradually enlarge the

hole to 5/16” keeping the drill centered on the two

W-1 ribs.

❑

12. Make a 1/16” balsa shear web to fit

between W-2 and W-3. Glue it to the Dihedral

Brace on the aft side of the spar.

❑

13. Make the aileron pushrods from the 4”

threaded end rod. Use a Nylon

Clevis with a Clevis Retainer on

the horn end and a Z-bend on

the Bellcrank end. Make them

the length shown on the wing

plan top view.

❑

14. Drill out the outer hole in the bellcranks

with a 5/64” drill bit. Test fit the pushrod into the

bellcrank.

FIXED LANDING GEAR ASSEMBLY

Do the following six steps to make a left and a

right fixed gear assembly.

NOTE: The fixed gear is slightly shorter

than scale to improve ground handling.

❑❑

1. Use 30-minute epoxy to glue the 3/4” x

5/8” x 1” hardwood Landing Gear Block to one

end of the slotted 1/2” x 3/4” x 2-3/4” hardwood

Landing Gear Rail as shown on the plan and in

the photo.

❑❑

2. Locate the 1/8” x 1-11/16” x 2-3/4” birch

plywood Landing Gear Plate. Use the template

provided on the wing plan to mark the hole

locations. Drill the holes to the sizes indicated on

the template.

- 22 -

Page 23

❑❑

3. Test fit the bent Landing Gear wire

through the Landing Gear Plate. Chamfer the hole

in the plate for the wire, if required, until the wire

will lie fairly flat on the plate.

❑❑

4. Hold the Landing Gear Rail assembly

up to the Landing Gear Plate and wire. Mark the

location where the wire will insert into the Landing

Gear Rail.

❑❑

5. Drill the Landing Gear Rail assembly

with a 3/16” drill. Test fit the parts together and

chamfer the hole entries as required for a good fit.

Note: Small gaps will be pulled together when the

parts are screwed together.

❑❑

6. Mark the locations for the #4 screws.

Drill 3/32” pilot holes at the locations you marked.

Screw the parts together with #4 x 1/2” Sheet

Metal Screws.

MOUNT THE LANDING GEAR

Do the following eight steps for Retract and

Fixed Gear.

If you are using fixed gear, just substitute the fixed

gear assemblies for the retracts. They mount the

same way.

NOTE: By mounting the retracts to the rails first,

then gluing the rails into the structure, the retract

frames will be relaxed. If you glue the rails in by

themselves, the frame is likely to be bent when you

tighten the mounting screws; this will cause the

retracts to bind.

❑❑

1. Fit the 1/4 x 5/16” x 3-1/8” Landing

Gear Rails and the retracts between ribs W-3 and

W-4 as shown in the picture. Mark the locations of

the retract (or fixed gear) mounting screws.

❑❑

2. Remove the Rails and drill the locations

you marked with a 7/64” bit.

❑❑

3. Mark the locations of any notches you

need to make in the rails to facilitate retract

removal. Make these notches with a Dremel

®

Moto-Tool®.

NOTICE how the front corners of the

retract mounting lugs have been cut off

at an angle. This provides more

clearance for the landing gear pods.

The corners may be cut off using a

cutoff wheel. Be sure to use safety

glasses when using a cutoff wheel.

❑

4. Mount the retracts (or fixed gear

assemblies) to the rails with #6 x 1/2” sheet metal

screws.

❑

5. Test fit both retracts with rails into the wing

structure. View the struts from all angles to check

- 23 -

Page 24

their alignment. View the struts from the front of

the wing. The two struts should be parallel and

therefore perpendicular to the ground. Make slight

adjustments to the rails or structure until the

landing gear fits well.

❑

6. Glue in the retract rails with a generous

amount of 30-minute epoxy. Be careful not to glue

in the retracts (or fixed gear).

❑

7. After the glue has cured, remove the

landing gear and apply a fillet of 30-minute epoxy

to all of the plywood joints in the landing gear box

area.

❑

8. Round the front edges of the Landing Gear

Rails as shown in the photo. This will provide

clearance for the Landing Gear Pods.

SHEET THE BOTTOM OF WING

❑

1. Sort through the remaining 1/16” x 3” x 30”

wing sheeting. Pick out the best 8 sheets and set

them aside for the top of the wing.

NOTE: The wing sheeting process

described here has you sheet the wing

from the spar forward with one skin (2

skins for the bottom because of the

landing gear bay). You will then sheet

the wing from the spar back with

another skin. This technique is a good

compromise between sheeting the wing

with individual sheets, and making one

complete skin for the entire wing panel.

It allows you to presand all of the

seams that are over open structure and

it is easier to align and glue than a

complete one-piece skin.

NOTE: All balsa sheeting will usually

bend when it is cut from the log since

stresses are relieved. For best results,

trim the edges of the wing sheeting with

a long metal straight edge and a sharp

knife before joining them.

❑

2. Lay waxed paper over a flat smooth work

surface. You will join the wing skins on this

surface.

NOTE: Do the following steps for both

the right and left wing halves.

❑

3. Edge glue two 1/16” x 3” x 30” balsa wing

sheets together with CA for both the top and

bottom wing surfaces. Hint: A quick wipe of a

paper towel while gluing the sheets will soak up

most of the excess CA and make sanding the

seams easier.

NOTE: The steps below show the

sheeting of a wing with functioning

flaps. The wing without functioning

flaps is done the same way, but it will

look slightly different. When sheeting a

wing without functioning flaps, make

the skin aft of the spar so it covers the

structure all the way back to the Flap

TE.

❑

4. LIGHTLY sand both sides of the skin over

the work surface with a sanding block and sharp

220 sandpaper.

❑

5. Mark the skin as shown in the sketch

above. Cut the sheet in half diagonally and use

the pieces for the bottom forward portions of the

wing.

❑

6. Cut off a piece of the sheet you made in the

above step large enough to sheet the area inboard

of W-3. Glue the sheet in place. The aft edge of

the sheeting should extend back to the

approximate centerline of the spar.

NOTE: The bottom of the wing must

be sheeted with the wing on the jig

tabs and the Wing Jig Block to avoid

twists.

- 24 -

Page 25

❑

7. Use the leftover sheet from the previous

step to sheet the forward portion of the wing

outboard of W-4.

❑

8. Edge glue three (or four for fixed flaps)

1/16” x 3” x 30” balsa wing sheets together and

sand the seams. Tape the sheet to the bottom

surface of the wing along the edge created by the

forward sheeting. Mark the perimeter of the sheet

from the inside with a pen. Cut the sheet down

close to the correct size.

❑

9. Use the plans to help you locate the aileron

pushrod exit. Cut out an opening and reinforce the

skin from the inside with two small strips of 1/16”

scrap balsa.

❑

10. Tape the skin to the bottom of the wing

structure so it is aligned along the spar. Make sure

it fits well, especially at the root rib (W-1). Remove

the skin from the structure.

❑

11. Apply a bead of CA+ to all of the structure

the skin will touch.

❑

12. Attach the aileron pushrod to the bellcrank

and position the skin onto the structure. Gently

press the wing skin down onto the wing structure.

❑

13. Sheet any remaining openings in the

bottom wing skin such as the Trailing Edge

between the flaps (for the operating flap option).

❑

14. Use a punch to mark the hole locations in

the bottom wing skin for the wing bolts. Start these

holes so you can find the location later, after the

top wing skin is applied.

SHEET THE TOP OF THE WING

NOTE: This kit includes a special wing

jig to hold the wing at the proper

washout angle while you apply the final

wing skin. Twisted wings are a major

cause of bad flight characteristics.

Dihedral angles can vary slightly; so if

your tip jigs require adjustment, just be

sure that both tip jigs are modified the

same, and are therefore identical. Be

careful not to change the washout

angle (the angle of attack of the tip ribs)

if you adjust the jigs.

❑

1. Make the skins for the top of the wing

forward of the spar using the same method that

you used on the bottom of the wing (Page 24,

Step 6.)

❑

2. Trim the remaining jig tabs of W-1 and W-

12. Blend any inconsistencies in the top wing

surface away with a T-bar and 220 grit paper.

❑

3. Temporarily place the 5/16 x 3-1/8” Wing

Dowel into the hole you drilled into the LE (do not

glue it yet).

- 25 -

Page 26

❑

4. Slide the die-cut 1/8” Plywood LE Jig over

the dowel.

❑

5. Tack glue the die-cut 1/8” Plywood TE Jig

to the bottom of the wing at the center as shown in

the photo.

❑

6. Place a die-cut 1/8” plywood Tip Jig under

each W-12 rib. You may tape or tack glue the wing

to the jig if you wish.

❑

7. Check the fit of the forward skin to the wing

structure. Make adjustments if required.

❑

8. Apply a bead of CA+ to the wing structure

and glue the forward wing skin in position.

❑

9. Make a skin for the aft portion of the wing

from four 1/16” x 3” x 30” balsa sheets. Trim it to fit

over the remaining open structure. Make a skin for

the other panel and trace the first wing skin shape

onto it.

HINT: You may find it easier to start

cutting out the opening for the Aileron

and Drop tank (optional) servos at the

center of the wing when only one top

aft skin is glued on.

❑

10. Apply a bead of CA+to the wing structure

and glue the aft wing skin in position. Glue both

right and left sheets in place.

❑

11. At this point, you should have the main

wing structure fully sheeted. You may now remove

the wing from the jig.

❑

12. Add a bead of CA+to the center joint to

add more strength at this critical area.

❑

13. Cut adequate clearance holes for the wing

bolts in the top wing skin.

WING COMPLETION

❑

1. Trim the sheeting where it protrudes past

the edge of the structure. It is preferred that you

trim the tip of the wing sheeting to the center of rib

W-12. This will allow you to sheet the section

between W-12 and W-13 more easily.

❑

2. Razor plane and sand the wing Leading

Edge until it blends into the airfoil well. Final

sanding near the tip should be done later, after the

tip is installed.

❑

3. Glue the die-cut 1/8” balsa Tip Spar and

the die-cut 3/32” balsa rib W-13 to the tip of the

wing as shown in the photo.

❑

4. Glue the shaped 3/4” balsa Tip LE Block to

the front of the wing.

- 26 -

Page 27

❑

5. Apply 1/16” balsa sheeting to the tip

section.

❑

6. Glue the shaped 5/8” balsa Tip TE Block to

the aft part of the wing tip.

❑

7. Square off the tip of the wing with a T-bar.

❑

8. Glue the shaped 1” balsa Wing Tip to the

tip of the wing as shown on the plans.

❑

9. Shape the tip of the wing with a razor plane

and a sanding block. Do not final shape the aft

portion of the tip until after the ailerons are built.

This will allow you to properly blend them together.

BUILD THE FLAPS

❑

1. Place the Flap section of the plans on a flat

work surface and cover it with waxed paper.

❑

2. Position a 1/16” x 3” x 30” balsa sheet over

the proper location on the plan. Mark the length

and width on the balsa sheet.

❑

3. Cut the Aft Flap Section from 1/16” x 1” x

18-1/2" plywood. Match the Aft section edge to the

balsa forward section edge. Sand the edges for a

clean match.

❑

4. Glue the sections together and mark the

final size from the plans. Cut the flap sheet down

to the proper size.

❑

5. Mark the “Rib and Spar Locations” on the

sheeting from the plans. NOTE: The ribs do not

extend to the aft edge of the plywood.

❑

6. Cut the Flap LE from the 3/16” x 5/16” x 36”

balsa stick. Place the LE and sheeting over the

plans to check proper length and angles. Glue the

LE on top of the sheeting aligned with the forward

edge.

❑

7. Cut 2-3/4" flap ribs from the 3/32” x 3/8” x

30” balsa sticks. Glue the Ribs to the sheeting at

the locations you marked earlier. NOTE: The Ribs

may be angle cut before gluing or sanded to shape

after gluing.

❑

8. Fit and glue the Fwd Flap Stringers. They

are pre-cut 3/16” x 3/16” x 15/16” balsa sticks.

❑

9. Fit and glue the Aft Flap Stringers. They

are pre-cut 1/8” x 3/16” x 15/16” balsa sticks.

❑

10. Use a sanding block to shape the ribs. The

sanded surface of the ribs and all stringer surfaces

will be flat when shaping is complete.

- 27 -

Page 28

❑

11. Place the TE on the edge of the work

surface. Use a sanding block to feather the edge

of the birch TE to approximately 1/32” thick. HINT:

The TE will change color from light to dark to light

when properly sanded.

❑

12. Lay the flap on a flat surface and glue a

1/32” x 3/16” x 18” Plywood Cap Strip to the top

of each of the two stringers and to the LE (refer to

the rib W-5 cross-section on the wing plan).

NOTE: Hold the cap strips flat with a straightedge

until glue cures. The Cap Strips make the flaps

resistant to warping.

❑

13. Glue the die-cut 1/8” balsa Flap Hinge

Doublers to the flaps at the locations shown on

plans.

❑

14. Glue the die-cut 1/8” plywood Flap Horn

Plates to the flaps at the locations shown on plans.

Note: These are located in different bays on the

right and left flaps.

BUILD THE AILERONS

❑

1. Draw a center line on the die-cut 1/4” balsa

Aileron LE and a line on each side 1/16” from the

center line. Also draw a center line on the other

side of the Aileron LE; this will help you “V” the

leading edge later.

❑❑

2. Place the die-cut 3/32” balsa Aileron

Base on the plans and mark the “Rib Locations."

❑❑

3. Place the Aileron Base between the

lines you drew on the LE center line and glue with

CA. NOTE: The Aileron LE is die-cut longer than

the Aileron Base to allow final trimming on both

ends.

❑❑

4. Cut “Ribs” from the 3/32” x 3/8” x 36”

balsa sticks. Glue the Ribs to both sides of the

Aileron Base between the marks.

❑❑

5. Refer to the plans for aileron crosssection shape. Use a razor plane and a sanding

block to shape the ailerons. Test fit the Aileron to

the wing for final shaping.

❑❑

6. Refer to the plans for the Aileron

Control Horn Block locations on the bottom of

the ailerons. Glue the 3/8” x 1/2” x 7/8” hard balsa

Aileron Control Horn Blocks in place.

❑❑

7. Shape the Aileron Control Horn Blocks

to match the aileron contour.

❑❑

8. Shape the Aileron LE in a “V” shape to

- 28 -

Page 29

allow proper aileron travel (refer to the crosssection at rib W-10 on the wing plan for the correct

shape).

❑❑

9. Tape the aileron to the wing and blend

the aft portion of the wing tip and the aileron to

create a smooth transition.

BUILD THE FUSELAGE

❑

1. Test fit the shaped 1/8” balsa Main

Fuselage Side to the die-cut 1/8” balsa Lower

Fuselage Side. For a straight fuselage it is

important to have the fuselage sides straight and

both sides the same. Reassemble the parts and

check them against the fuselage side view on the

fuselage plan for proper alignment. Use CA and

CA+ to glue the parts together. Use a quick wipe

with a paper towel to remove any excess glue, as

this will make sanding easier. Keep in mind that

you are making a left and a right fuselage side.

❑

2. Inspect the two fuselage sides. Choose the

Right and Left sides so the best surfaces will face

outward. Mark the inside of the appropriate part RI

and LI (for Right Inside and Left Inside.)

IMPORTANT NOTICE: Compare the two

die-cut 1/8” Plywood Fuse Doublers.

Label the shorter one “R” (right) and

the longer one “L” (left). This will set

the right thrust in the firewall.

❑

3. Glue the Fuselage Doublers to the

fuselage sides. Use the wing saddle curve and the

forward tab (see arrows) for proper positioning.

Tape the Fuselage Bottom View over

your flat building board (we recommend

cutting that part of your plan loose to

make it easier to handle). Cover the

bottom view with waxed paper.

Important Note: You are building the

fuselage upside-down over the Bottom

View. This aircraft has right thrust built

in. Since the fuse is built upside-down,

this will appear as left thrust until it is

flipped over. Just follow the instruction

sequence and everything will be fine.

❑

4. Pin the die-cut 1/8” plywood Forward

Crutch over its location on the plans. Make sure

the front edge of the crutch matches the plans for

the correct thrust angle.

NOTE: Some formers are not

symmetrical and must be glued in with

the proper orientation. Glue in all the

formers with the identification numbers

toward the FRONT of the model and

they will all be correct.

❑

5. Drill 3/16” holes through the punch marks in

formers F-3, F-4, F-5, F-6, F-7, and F-8. These

holes are for the pushrod routing and anchoring.

You may confirm these locations using the crosssections on the fuselage plans.

❑

6. Glue the 1/8” plywood Former F-3 to the

forward crutch at its location on the plans. It

should be perpendicular to the crutch with its

number facing forward.

- 29 -

Page 30

NOTE: It is helpful to keep some weight

on the crutch while building the

fuselage to keep it flat on the building

board.

❑

7. Glue in the die-cut 1/8” plywood Former F-4

and the die-cut 1/8” plywood Servo Tray (ST). F-4

must also be perpendicular to the crutch.

❑

8. Glue the die-cut 1/8” plywood sub-former F2C to the forward side of Former F-2. Make sure

the dowel hole is aligned. Glue F-2 in place. F-2

must also be perpendicular to the crutch.

❑

9. Place the die-cut 1/8” plywood Former F-1B

in its location, but do not glue it since its slant is set

by the fuselage sides. Test fit the die-cut 1/8”

plywood Chin Plate on top of formers F-1 and

F-2.

❑

10. Place the Left Fuselage side in position.

Make sure its edge is down on the building board

and tack glue it at the following places: the lock

notch near the front of the crutch; the edge at the

front of the wing saddle; the top of F-2, F-3,

and F-4.

❑

11. Work the Right Fuselage side into place.

Check to see that all the notches are properly

engaged and, if need be, make adjustments. Glue

the Right Fuselage side at the same places you

glued the Left Fuselage side in the previous step.

❑

12. Locate two 3/16” x 3/16” x 18” balsa

Stringers. They run from F-4 to F-8. Insert the

stringers into the slots between the crutch and the

fuselage sides. Glue the stringers along the edge

of the fuselage sides next to the plans.

❑

13. Place the die-cut 1/8” plywood Former F1B between the fuselage sides. Check fit of the

Chin Plate. Glue in Former F-1B, making sure it is

seated flush with the tabs on the forward crutch

and is positioned against the fuselage side

doublers.

❑

14. CA the Chin Plate to F-1B and F-2.

NOTE: Check the angle on the forward edge of

the Chin Plate, and make sure it matches the plans

and the angle on the front of the crutch.

❑

15. Epoxy the 1/2” x 3/4” x 7/8” hardwood

- 30 -

Page 31

Fuselage Bolt Blocks into the notches in the

fuselage side doublers at Former F-4. Use epoxy

to make a small fillet around the sides of the bolt

blocks. Also make an epoxy fillet between the bolt

block and Former F-4.

❑

16. Use CA+to finish gluing the fuselage sides

to Formers F-1B, F-2, F-3 and F-4.

❑

17. Drill 5/64” holes through the forward two

punch marks in the die-cut 1/8” plywood Tail

Wheel Plate (TW). Drill 1/8” holes through the two

AFT punch marks for nylon tail wheel support pegs

(see below).

❑

18. Glue the die-cut 1/8” plywood Tail Wheel

Plate (TW) to former F-8, making sure they are

perpendicular. Make sure the number on F-8

faces down.

❑

19. Place the 5/8” long piece of 1/8” O.D.

brass tubing over the top end of the wire. Squeeze

the exposed end of the tube firmly with pliers to

flatten it. Check the parts over the fuselage top

view to make sure they match up well. Silver

solder the brass tube to the wire (see below).

TIPS FOR SILVER SOLDERING

Use this process when soldering metal to metal

such as brass tube to wire, or pushrod ends to

wire.

A. Thoroughly clean the items to be soldered with

alcohol or degreasing solvent.

B. Roughen the area to be soldered with fine

sandpaper, then clean again.

C. Assemble the items to be soldered.

D. Apply a small amount of soldering flux. Acid

based flux works best when one or more of the

items is steel.

E. Heat the metal with a soldering gun or iron, and

apply solder to the metal. The metal must get

hot enough to melt the solder and the solder

must flow freely into the joint.

F. Do not move the parts until the solder has

cooled.

G. Clean off the excess flux with alcohol or

solvent. Coat the parts with a very fine film of

oil.

H. Test the joint by pulling hard.

❑

20. Mark the location for mounting the Metal

Ball on the flat of the Brass Tube. Drill a 1/16"

hole at the mark.

❑

21. Attach the ball permanently on the tail gear

with the Small Nut provided. Put a drop of

6-minute epoxy on the threads to prevent it from

vibrating loose.

❑

22. Use the 4-40 Set Screw to set the collar at

the height shown on the fuselage side view, but

orient the set screw so small adjustments can be

made later if required.

❑

23. Roughen the tubular Nylon Bearing on

the tail wheel wire with sandpaper so glue will stick

to it.

❑

24. Put a small drop of 6-minute epoxy on the

Nylon Bracket where the bolt holes are. Screw the

Nylon Bracket to TW with two #4 x 3/8” Sheet

Metal Screws. Then put a drop of epoxy on the

threads of the Sheet Metal Screws to prevent them

from vibrating loose.

❑

25. Pin the die-cut 1/8” plywood Stab Support

Crutch to the plans at its location. The fuselage

sides will protrude aft of the Stab Support Crutch

by approximately 3/8”. Glue F-8 to the front edge

of the Stab Support Crutch; it should be

perpendicular to the building board.

- 31 -

Page 32

❑

26. Glue in Formers F-5, F-6, and F-7 at the

locations marked on the plans. Make sure the

formers are perpendicular to the building board.

Pull the fuselage sides together at the aft end, and

glue them to F-8 and the Stab Support Crutch.

❑

27. Cut 3” off one end of the .074 x 35”

Threaded Both End Rod. Place a brass

Threaded Coupler over the unthreaded end of the

3” piece. Measure the length of the assembly. Cut

off the wire until the total assembled length is

3-1/2”. Silver solder the brass coupler to the wire.

❑

28. Screw the threaded end of the remaining

32” rod well into the end of the Nylon Two-Ended

Ball Link Socket.

❑

29. Cut outer Pushrod Tube for rudder to the

length shown on the plans and slide it through

formers F-8, F-7, F-6, F-5 and F-4. The Rudder