Page 1

WARRANTY.....Top Flite Models guarantees this kit to be free of defects in both

material and workmanship at the date of purchase. This warranty does not cover any component parts

damaged by use or modification. In no case shall Top Flite's' liability exceed the original cost of the

purchased kit. Further, Top Flite reserves the right to change or modify this warranty without notice.

In that Top Flite has no control over the final assembly or material used for final assembly, no

liability shall be assumed nor accepted for any damage resulting from the use by the user of the final

user-assembled product. By the act of using the user-assembled product the user accepts all resulting

liability.

If the buyer is not prepared to accept the liability associated with the use of this product, he

is advised to immediately return this kit in new and unused condition to the place of purchase.

Top Flite Models

3002 N. Apollo Dr., Suite 1

Champaign, IL 61822

Technical Assistance - Call (217) 398-8970

P516P03 V1.1

READ THROUGH THIS INSTRUCTION BOOK FIRST. IT CONTAINS IMPORTANT INSTRUCTIONS AND WARNINGS CONCERNING THE ASSEMBLY AND USE OF THIS MODEL.

USA

MADE IN

TM

Page 2

METRIC CONVERSION CHART ............2

INTRODUCTION .....................................3

Precautions ..........................................3

DIE PATTERNS.....................................4,5

DECISIONS YOU MUST MAKE EARLY IN

THE BUILDING SEQUENCE..................6

Engine and Mount Selection .................6

Supplies and Tools Needed..................6

Other Items Required...........................7

Common Abbreviations........................7

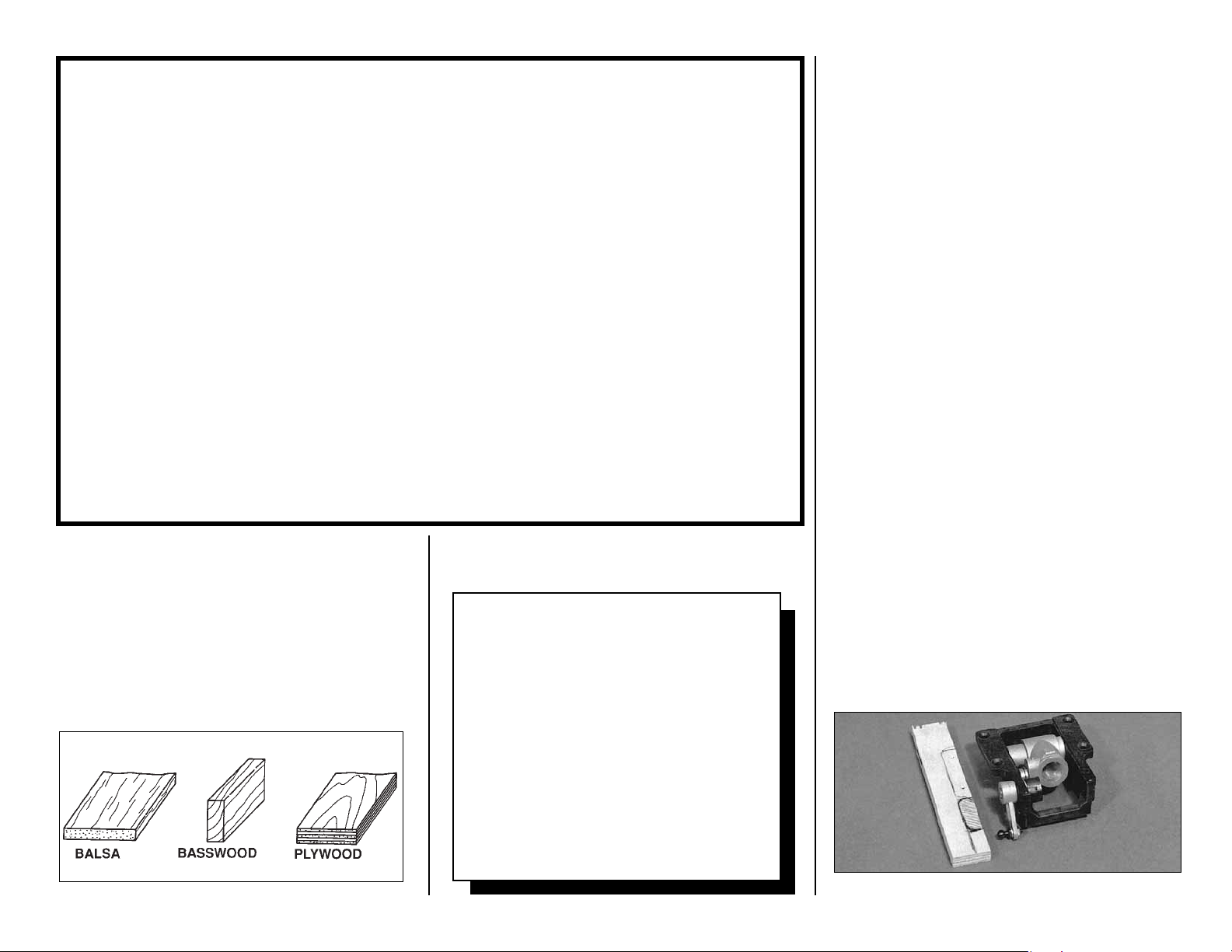

Types of Wood......................................7

Tips for Competition-Minded Modelers.7

GET READY TO BUILD..........................8

Build the Tail Surfaces..........................8

Build the Fin ........................................11

Build the Rudder..................................12

Build the Wing.....................................13

Join theWing Panels ............................18

Sheet the Wing....................................21

Build the Fuselage...............................25

Tips for Silver Soldering ......................28

Mount the Wing to the Fuselage..........32

Attach the Stab and Fin.......................34

Prepare the Elevators..........................36

Fuselage Completion...........................37

Install the Dorsal Fin............................40

Make the Top Cowling.........................41

Mount the Cowling ...............................43

Build the Wing Fillet.............................43

Install the Forward Wing Fair ing ..........45

Fit the Radiator....................................46

Operational Flaps................................46

FINISHING.............................................49

Final Sanding ......................................49

Fuelproofing ........................................49

Balancing the Plane Laterally..............49

Covering..............................................49

Apply Trim ...........................................50

Exhaust Stacks....................................51

Apply Decals .......................................51

Hinging................................................51

Final Control Hardware Hookup ..........52

Mount the Landing Gear......................53

Fixed Landing Gear.............................53

Retracts...............................................53

Cockpit Finishing.................................53

Install Receiver, Switch and Battery ....54

Balance Your Model.............................54

Final Hookups and Checks ..................55

Control Surface Throws.......................55

PRE-FLIGHT..........................................56

Charge the Batteries ...........................56

Find a Safe Place to Fly ......................56

Ground Check the Model.....................56

Range Check your Radio.....................56

Engine Safety Precautions..................56

AMA SAFETY CODE.............................56

General ...............................................56

Radio Control ......................................57

FLYING ..................................................57

2-VIEW DRAWINGS ..............................60

METRIC CONVERSIONS

1" = 25.4 mm (conversion factor)

1/64" = .4 mm

1/32" = .8 mm

1/16" = 1.6 mm

3/32" = 2.4 mm

1/8" = 3.2 mm

5/32" = 4 mm

3/16" = 4.8 mm

1/4" = 6.4 mm

3/8" = 9.5 mm

1/2" = 12.7 mm

5/8" = 15.9 mm

3/4" = 19 mm

1" = 25.4 mm

2" = 50.8 mm

3" = 76.2 mm

6" = 152.4 mm

12" = 304.8 mm

15" = 381 mm

18" = 457.2 mm

21" = 533.4 mm

24" = 609.6 mm

30" = 762 mm

36" = 914.4 mm

- 2 -

T

ABLE OF CONTENTS

Page 3

- 3 -

INTR

ODUCTION

Thank you for purchasing the Top Flite

GOLD EDITION

P-51D Mustang.

The Top Flite P-51D is an excellent sport

scale model that is just as “at home” with sport

flying as it is in competition. Its exact scale

outline allows you to add authentic details and

take it into serious competition if desired. Its

modern construction and refined aerodynamics,

incorporating features such as computerdesigned airfoils that progressively change from

root to tip with built-in washout, give you a plane

that will build straighter and fly better than warbird

kits of the past.

The Gold Edition Mustang is approximately

1/7th scale. The exact scale ratio is 1: 6.83. The

trim scheme allows you to finish a very

impressive model using Top Flite Super

MonoKote®. The MonoKote covered prototype,

shown on the box, was good enough to finish 2nd

in Expert at the very competitive 1992 Blue

Grass Scale Classic in Kentucky. It scored quite

well in static due to its excellent outline, and

posted the highest flight scores in the expert

category. This performance earned the Mustang

an invitation to the 1992 Scale Masters.

Please inspect all parts carefully before

starting to build! If any parts are missing,

broken or defective, or if you have any

questions about building or flying this model,

please call us at (217) 398-6300 and we’ll be

glad to help. If you are calling for replacement

parts, please look up the part numbers and

the kit identification number (stamped on the

end of the carton) and have them ready when

calling.

PRECAUTIONS

1. You must build the plane according to the

plans and instructions. Do not alter or modify

the model, as doing so may result in an unsafe or

unflyable model. In a few cases the plans and

instructions may differ slightly from the photos. In

those instances you should assume the plans and

written instructions are correct.

2. You must take time to build straight true and

strong.

3. You must use a proper R/C radio that is in

first class condition, the correct sized engine and

correct components (fuel tank, wheels, etc.)

throughout your building process.

4. You must properly install all R/C equipment

and other components so that the model operates

properly on the ground and in the air.

5. You must test the operation of the model

before the first and each successive flight to

insure that all equipment is operating, and you

must make certain that the model has remained

structurally sound. Be sure to check external

nylon clevises often, and replace any that show

signs of wear.

6. If you are not already an experienced R/C pilot

at this time, you must fly the model only with the

competent help of a well experienced R/C pilot .

NOTE: We, as the kit manufacturer,

can provide you with a top quality kit

and thorough instructions, but

ultimately the quality and flyability of

your finished model depends on how

you build it; therefore, we cannot in

any way guarantee the performance of

your completed model, and no

representations are expressed or

implied as to the performance or

safety of your completed model.

Remember: Take your time and follow

directions to complete a well-built

model that is straight and true.

WARNING! THIS IS NO

T A TOY!

The model you will build from this kit is not a toy! It is capable of serous bodily

harm and property damage. IT IS YOUR RESPONSIBILITY AND YOURS ALONE -

to build this kit correctly, properly install all R/C components to test fly the model, and

fly it ONLY with experienced, competent help in accordance with all safety standards

as set down in the Academy on Model Aeronautics Safety Code. It is suggested that

you join the AMA to become properly insured before you attempt to fly the model. IF

YOU ARE JUST STARTING R/C MODELING, CONSULT YOUR LOCAL HOBBY

SHOP OR WRITE TO THE ACADEMY OF MODEL AERONAUTICS TO FIND AN

EXPERIENCED INSTRUCTOR IN YOUR AREA.

Academy of Model Aeronautics

5151 East Memorial Dr.

Muncie, IN 47302-9252 (800) 435-9262

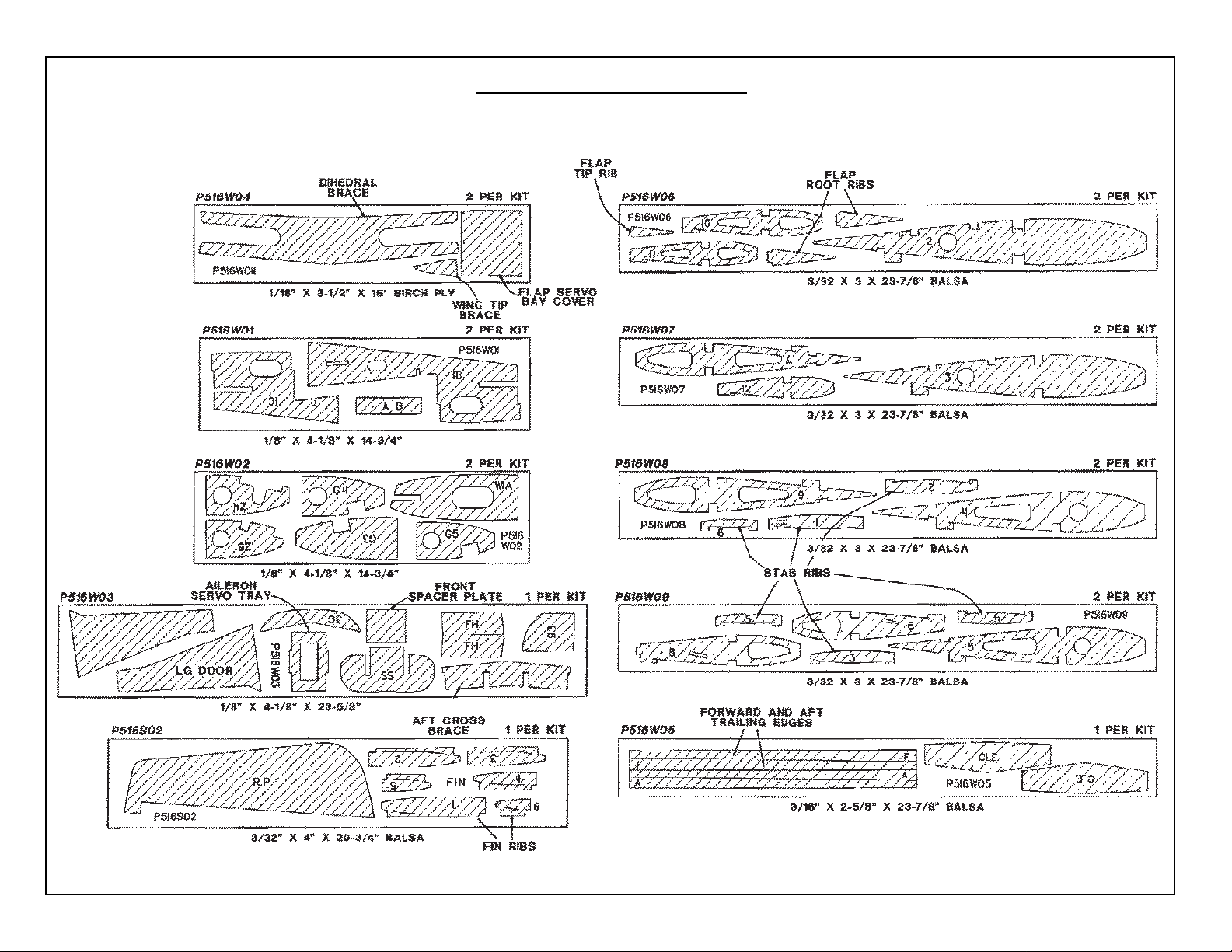

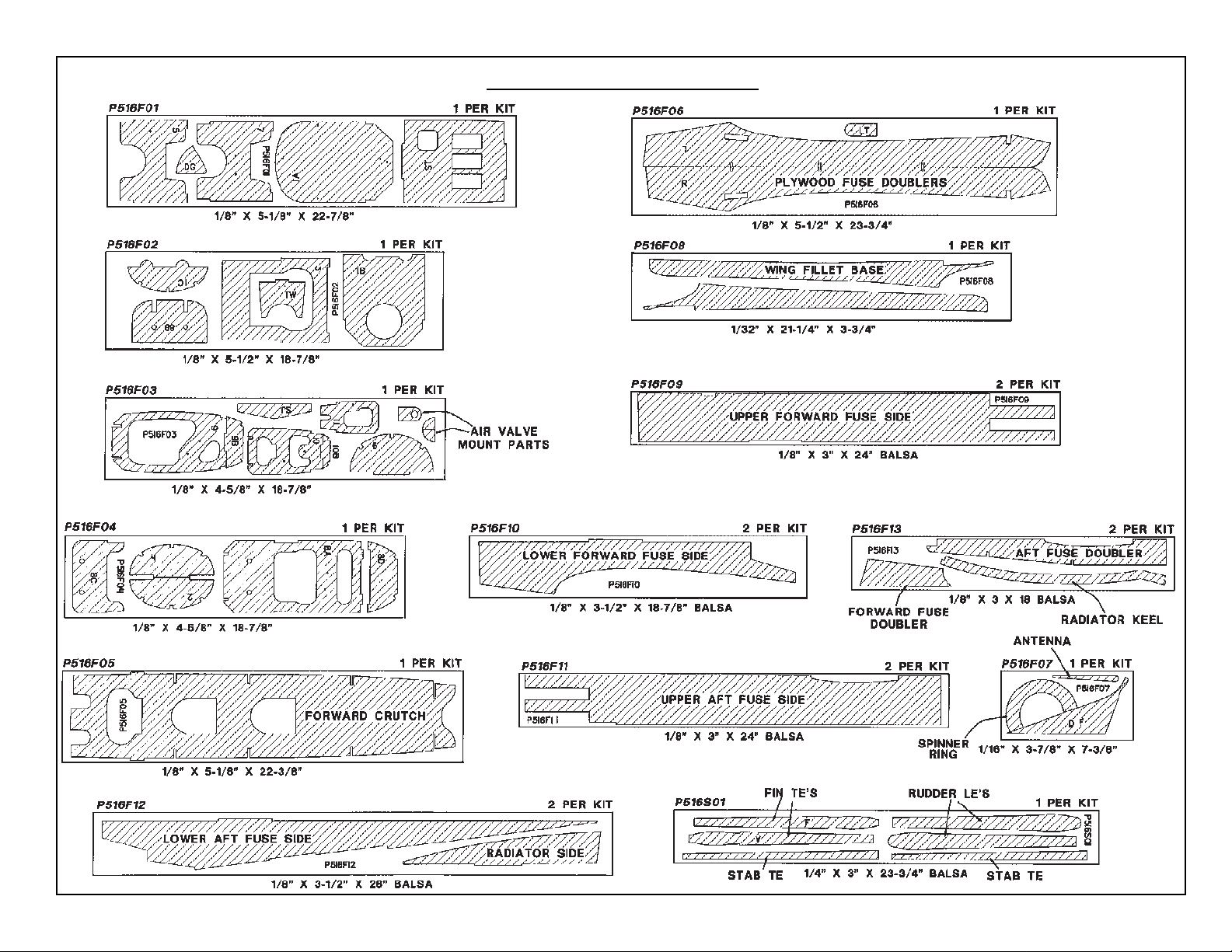

Page 4

- 4 -

DIE-CUT PATTERNS

PLY

PLY

PLY

Page 5

- 5 -

DIE-CUT PATTERNS

PLY

PLY

PLY

BIRCH PLY

BIRCH PLY

PLY

PLY

PLY

Page 6

SUGGESTED SUPPLIES AND TOOLS

❏ 2 oz. Thin CA

❏ 2 oz. Medium CA

❏ 2.5 oz. 5-Minute Epoxy

❏ 2.5 oz. 30-Minute Epoxy

❏ Hand or Electric Drill

❏ Drill Bits: 1/16”, 3/32”, 1/8”, 5/32”, 3/16”,

13/64”, 1/4”, 5/64" & 17/64”

❏ Sealing Iron (Top Flite)

❏ Heat Gun (Top Flite)

❏ Hobby Saw (X-Acto Razor Saw or Coping

Saw)

❏ X-Acto Knife, #11 Blades

❏ Pliers

❏ Screwdrivers

❏ T-Pins

❏ Straightedge with measuring scale

❏ Masking Tape (Required for construction)

❏ Sandpaper (coarse, medium, fine grit)*

❏ T-Bar Sanding Block (or similar)

❏ Waxed Paper

❏ Lightweight Balsa Filler (such as Hobbico

HobbyLite™)

❏ 1/4-20 Tap, Tap Wrench

❏ Isopropyl Rubbing Alcohol (70%)

❏ Dremel Moto Tool or similar (optional)

NOTE: On our workbench, we have

four 11” T-Bar sanders, equipped with

#50, #80, #150 and #220-grit

sandpaper. This setup is all that is

required for almost any sanding task.

Sanding blocks can be made from

balsa for sanding hard to reach spots.

We also keep some #320-grit wet-ordry sandpaper handy for finish

sanding before covering.

- 6 -

DECISIONS YOU MUST MAKE EARLY

IN THE BUILDING SEQUENCE

ENGINE AND MOUNT SELECTION

The recommended engine size range is as

follows:

.60 to .91 cu. in. (10cc to 15cc) 2-cycle

.90 to .120 cu. in. (15cc to 20cc) 4-cycle

The Mustang will fly well with any of the

recommended engines. The 4-cycle engines

and most .90 2-cycle engines will turn a larger

prop at lower RPM’s. This is often desirable for

scale realism. Many .60 2-cycle engines

produce about as much horsepower as the

popular .90 2-cycle engines and will fly the

Mustang fine. If you use a .60 2-cycle, a

Schnuerle ported engine is preferred.

If you will be side mounting your engine,

the 2-cycle engines will not stick out of the cowl

as much as 4-cycles will. If you mount your

engine inverted, you will need to provide ample

cooling air entry and exit areas.

This kit includes an EM60120 engine

mount that will hold most engines in the

recommended size range. The Top-Flite In-Cowl

exhaust system works very well in the Mustang

when the engine (2-Stroke) in mounted inverted.

RETRACTS

The choice whether or not to use fixed

gear or retracts is up to you. Retracts offer

good looks and great flight realism at the cost of

some expense and complication. For sport

flying and moderate competition work we

recommend you choose an air operated system

such as the Robart #605 90-degree retracts.

These offer the easiest installation and reliable

operation. Mechanical retracts could be fitted,

but the length and weight of the tire/strut

assembly would overload most servos. More

information on retracts is found in the “Tips for

Competition-Minded Modelers” section and in

the construction sequence. A Robart retractable

tail gear will work well and may be mounted to

F-10 (you must modify the lightening holes in F-

10). You must actuate the tail gear retract with

a servo or a 3/8” air cylinder and add a pull-pull

tail wheel steering system to your model.

Century Jet Models also offers a retract/strut

package that is specifially tailored for the P-51.

WHEEL SELECTION

The scale tire size is 4”. The

recommended range of tire sizes is 3-1/4” to 4”.

If you use fixed gear, you may choose to use

the smaller tires to reduce drag in the air. If you

use 3/8” offset Robostruts, they are only

available to fit up to 3-1/4” tires at the time of

this writing. Robart main wheels are very close

to scale for a P-51. A 1-1/4” tail wheel is scale

and recommended.

FLAPS

This model is designed with all the

provisions in place to include operating flaps

that are very scale. They require some

craftsmanship and time but are not very difficult

to install, if you follow the instructions. They

enhance the model’s flight characteristics and

scale appeal while causing no bad effects. No

trim correction of any kind is needed when they

are used with the recommended throws. The

flaps require one channel, a Y-harness, and two

standard or mini servos. They are highly

recommended for those who wish to install

them. More information on the use of the flaps

may be found in the flying section.

Page 7

COMMON ABBREVIATIONS USED IN

THIS BOOK AND ON THE PLANS:

deg.= Degrees Ply = Plywood

Elev= Elevator Stab = Stabilizer

Fuse= Fuselage " = Inches

LE= Leading Edge (front) Rt = Right

LG= Landing Gear Lt = Left

TYPES OF WOOD

TIPS FOR COMPETITION-MINDED

MODELERS

COUNTERBALANCES

The elevator and rudder counterbalances may

be added for scale appearance. They do not

affect the flight performance. Their locations and

sizes are dashed in on the plans.

SCALE RETRACTS AND DOORS

The retract landing gear pivot location shown

on the plans is basically correct. The stance of the

model (and strut length) shown with the gear down

is correct. Keep in mind that the Mustang's gear,

like that in most modern aircraft, compresses

under the weight of the aircraft and extends when

the aircraft takes off. This fact means that the rigid

struts commonly used on models will not fold into

the scale locations. The only reasonable way to

overcome this problem is to use oleo struts (such

as Robart Robostruts) that have springs light

enough to compress under the weight of the model

and thus function in a scale fashion.

If you should choose to modify your kit to

include very scale retracts and doors, most of the

work is up to you. Fully cycling gear doors

require much preplanning, excellent

craftsmanship, and are generally expensive. We

can, however, offer a few hints:

1. Bob Violett Models’ T-33 main landing gear

retracts may be a good place to start for the

following reasons.

- 7 -

OTHER ITEMS REQUIRED

Four to six channel radio with 4 to 7 servos.

Engine (see page 6 and the box side panel)

Engine Mount (see page 6)

Propellers (see engine instructions for recommended sizes). Note: The 4-blade prop shown on the

front of this manual is specially made for display purposes from two wooden props and is not usable

for actual flight.

Pilot figure (1/7 or 2” scale recommended)

4” (102mm) P-51 Spinner (CB #5103 (red), #5105 (black), #5106 (white) recommended)

Fuel Tank (Most 10 to 14 oz. (296cc to 415cc) tanks will fit)

3-1/4” (83mm) to 4” (102mm) Main Wheels (2) (see page 6)

1-1/4” (32mm) Tail wheel (see page 6)

3/16” (4.8mm) Wheel Collars (4 for fixed gear main wheels)

3/32” (2.4mm) Wheel Collars (2 for tail wheel)

Top Flite®Super MonoKote®(2 rolls) Aluminum plus Red, White, Black, and Olive Drab shown

Silicone Fuel Tubing

Latex Foam Rubber Padding (Hobbico® 1/4” thick foam)

Optional:

Retracts ..................Robart #605

Air Control Kit............Robart #188

Hinge Points (for flaps)...Robart #309

Robostruts................Robart #653 L&R

SCALE DOCUMENTATION

This model was designed using the KokoFan 3-view drawings as the reference for

outline. This fact makes it preferable to use

those drawing for scale documentation.

The drawings and many Mustang photo

packs are available from:

Scale Model Research

3114 Yukon Ave.

Costa Mesa, CA 92626

(714) 979-8058

Page 8

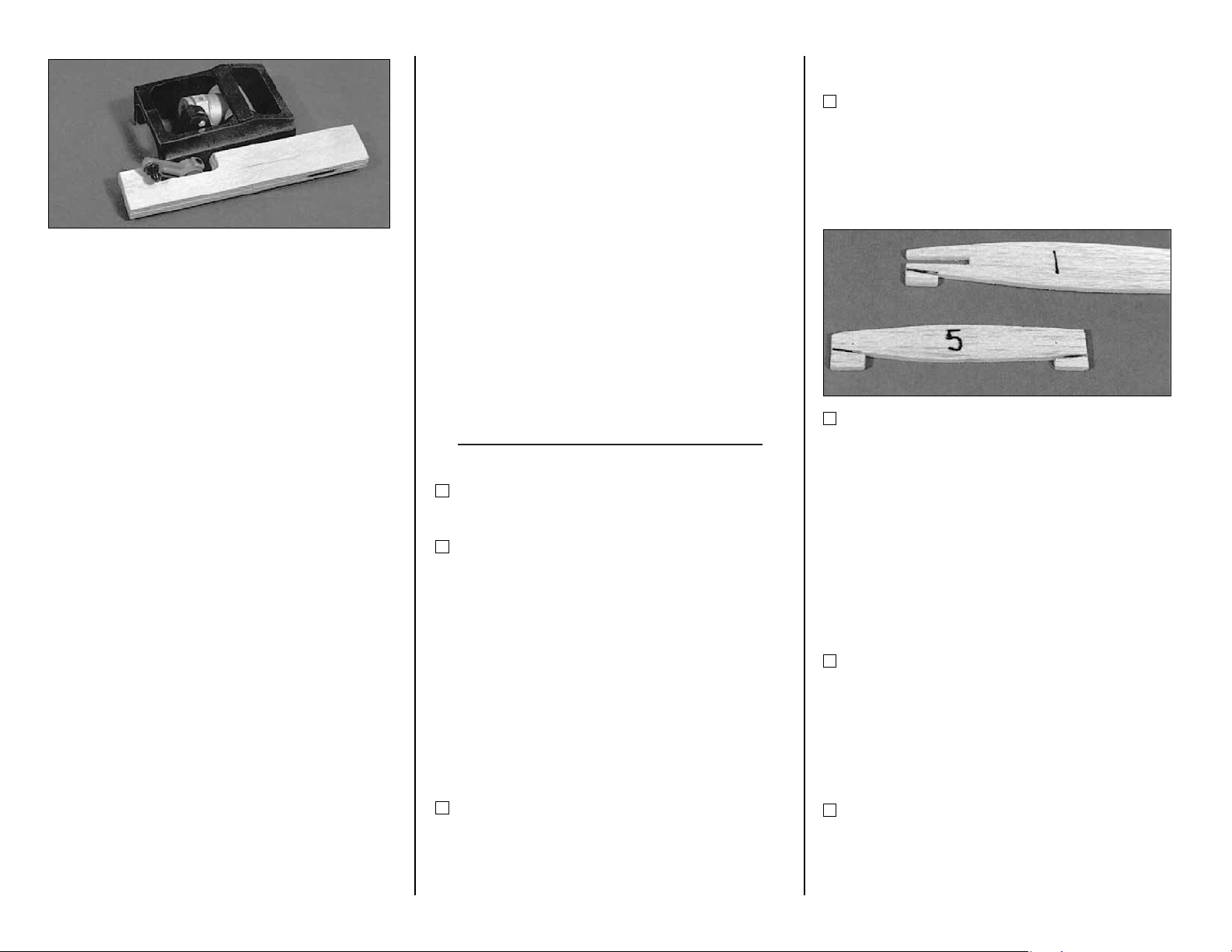

“Photos of Violett T-33 main landing gear and

suggested 1/4" plywood aft mounting rail.”

a. They are very low profile and can be

buried in the wing deeply enough to leave room

for outer doors.

b. They lock down in a position that is angled.

Therefore, they compensate for some of the

dihedral in the P-51 wing.

c. They have a pivot block strut hole diameter

that directly accepts Robostruts when shimmed

with a piece of K&S brass 13/32" O.D. tubing.

d. They do not have an uplock and therefore

can pull the strut and tire farther than 90 degrees

and fully into the wheel wells.

e. Use 5/8" I.D. Robart air cylinders mounted

inboard of the retracts to actuate these units.

These cylinders have enough power to lift and

hold the long strut and heavy tire.

REMEMBER: A retract and strut like this is a

very rigid unit. This gives excellent ground

handling, but requires strong mounts.

2. 4-inch wheels are the closest to scale.

However, offset struts to hold 4" wheels may be

hard to find. Robart makes an offset strut to hold

their 3-1/4" wheel, which works well and looks

close to scale. Robart may offer struts for 4"

wheels at some time after this writing.

3. Bob Violett Models has offset door hinges

that are excellent for hinging inner main landing

gear doors. They also offer small scale-looking

air cylinders that are specifically designed for

actuating landing gear doors. The real Mustang’s

inner doors are closed during take off and

landing. When “gear-up” is selected, they open,

allow the wheels to come in, then close again.

Duplicating this action requires either 2-channels,

or a very tricky mechanism. The inner doors on

the real aircraft would often fall open when the

engine was off and hydraulic pressure was lost.

4. The holes for the forward wing mounts may be

drilled so the 1/4-20 nylon bolts are concealed

under the inner doors.

________________________________________

________________________________________

GET READY TO BUILD

1. Unroll the plan sheets. Re-roll the plans

inside out to make them lie flat.

2. Remove all parts from the box. As you do,

figure out the name of each part by comparing it

with the plans and the parts list. Using a felt tip or

ball point pen, write the part name or size on

each piece to avoid confusion later. Use the diecut patterns shown on pages 4 and 5 to identify

the die-cut parts and mark them before punching

out. Save all scraps. If any of the die-cut parts

are difficult to punch out, do not force them!

Instead, first cut around the parts with an X-acto

knife. After punching out the die-cut parts, use

your T-Bar or sanding block to lightly sand the

edges to remove any die-cutting irregularities.

3. As you identify and mark the parts,

separate them into groups, such as fuse

(fuselage), wing, fin and stab (stabilizer), and

hardware.

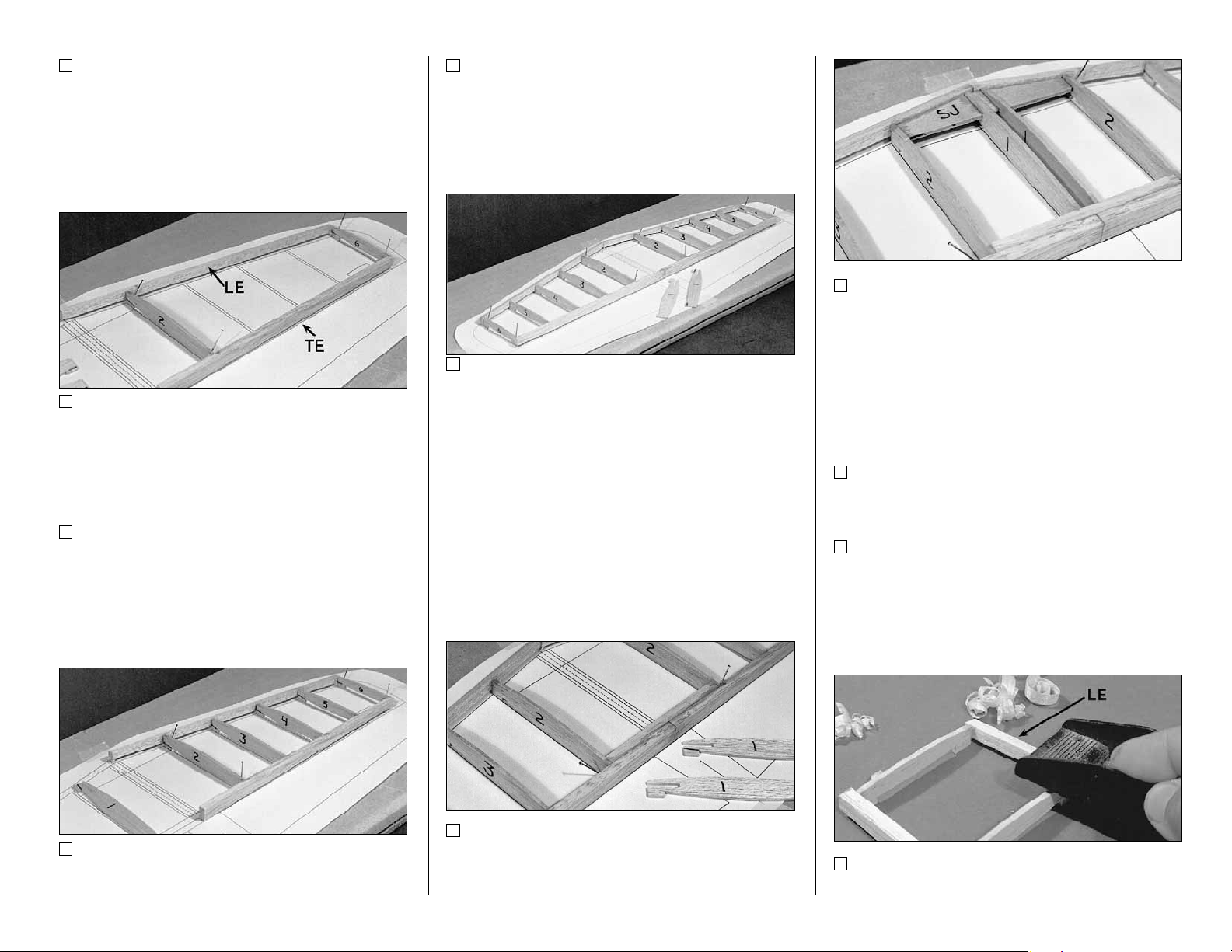

BUILD THE TAIL SURFACES

1. Work on a flat surface over the plans

covered with waxed paper. Refer to the plans to

identify the parts and their locations.

2. Punch out both sets of the die-cut 3/32"

balsa ribs S-1 to S-6. There are jig tabs on the

bottom edges of these ribs. If any of these break

off, carefully glue them back on with thin CA.

Lightly sand any imperfections. You may need to

finish cutting the notch in the forward portion of

S-1 for the Stab Joiner (SJ) with a knife. Using a

pen, mark the extensions of the bottom edge of

the ribs across the fore and aft jig tabs. These

will aid in centering the Leading and Trailing

Edges.

3. The Stab Trailing Edges (TE’s) are diecut from 1/4" balsa. Since some crushing may

happen when die-cutting wood of this thickness,

they are supplied slightly long and can be

trimmed. Smooth the edges of these pieces with

sandpaper.

4. The stab and fin Leading Edges (LE’s)

are made from the 1/4" x 30" tapered balsa stock.

Cut two pieces about 1/4" longer than the length

shown on the plans for the stab LE.

- 8 -

Page 9

5. Starting with the right half of the stab, pin

ribs S-2 and S-6 to the building board over their

locations on the plans.

6. Center the LE vertically on the front edge

of ribs S-2 and S-6. Glue it in place with CA.

7. Center the TE vertically on the back edge

of ribs S-2 and S-6. Glue it in place with CA.

8. Glue ribs S-3, S-4, and S-5 in their places.

All the jig tabs should rest on the work surface.

9. Trim the LE and TE so they end exactly

over the stab centerline.

10. Repeat steps 5 through 8 to build the left

half of the stab. The left half of the stab is built

next to the right half with the two halves butt

glued together for now.

11. Trim the 1/4" x 7/16" x 4-1/4" hard balsa

stab TE joiner, if necessary, to fit between the

S-2’s. Securely glue it to the TE’s and the S-2’s.

12. Trim the length of the die-cut 1/8"

plywood Stab Joiner (SJ), if required, for a good

fit between the S-2’s. Place the stab joiner into

the slots in the S-1’s and work the whole

assembly into position. Make sure all parts are

properly aligned and the S-1 jig tabs contact the

work surface. Glue in the stab joiner and the S-1’s.

13. Using medium CA, reinforce any glue

joints that do not look strong.

14. Carefully remove the stab from the

building board but try not to damage the jig tabs,

as they will be useful until after the top of the stab

is sheeted.

15. Use a razor plane and a sanding block to

- 9 -

Page 10

- 10 -

blend the top surface to the LE (particularly

toward the tip), even with the ribs. Sand the TE,

if required, to blend with the ribs.

TIPS FOR MAKING WING

AND STAB SKINS

A. Whenever possible, pre-join the balsa sheets

to make a “skin” before attaching them to the

structure.

B. Many modelers like to sort the wood to put the

best wood with the most even grain structure on

the top of the wing and stab.

C. Make your skin larger than needed to allow for

misalignment. On a large surface like the wing,

3/8" extra is suggested.

D. To make skins the following steps are

suggested:

1. True up the edges of the sheets with a

metal straight edge and a sharp knife or a “T-Bar”

sanding block.

2. Test fit the sheets together to make sure

they match well.

3. Glue the sheets together with thin CA over

a flat surface covered with waxed paper. I quickly

wipe the joint with a fresh paper towel to remove

excess glue and make sanding easier. Mark the

poorest surface that you think should be the

inside of the sheet with an “I”.

4. Working on a flat surface, sand the skin

with a large flat sanding block and fresh, sharp

220-grit sandpaper.

5. Trim the perimeter of the sheet to even up

the edges.

16. Make four stab skins from three 1/16" x 3"

x 30" balsa wing sheet pieces. See the sketch for

the proper layout on the wood. Refer to the plans

for the exact shapes and sizes, but remember to

make the skins slightly oversize.

17. Pin the stab structure onto the flat

building surface. Test fit the two skins over the

structure. Make sure the skins meet well at the

center. Adjust them if necessary.

18. Apply an even bead of medium or thick

CA to the top edges of the structure. Place the

skin in its proper position and press it firmly down

until the glue has set. Repeat this step for the

other top skin.

Hint: A small stack of magazines can

be used to hold the sheeting down.

19. Remove the stab from the building board.

Trim off the jig tabs with a sharp knife. Trim and

blend the LE and TE to the ribs as you did before.

Check all glue joints, adding glue as necessary.

20. If you want to modify the stab for the

scale balance tabs or a different hinging

technique, now is the time to add the appropriate

structure. Refer to the plans for the locations and

sizes of the balance tabs (parts not included).

Page 11

21. It is important to get a good glue bond

between the stab structure and the bottom stab

skins. Apply a heavy bead of medium or thick CA

to all of the bottom edges of the right side of the

stab structure. Place a skin on the structure and

hold it in place with your hands until the glue sets.

Repeat this for the left side. Be careful not to

bend or twist the stab during this step.

22. True up the ends of the stab with a

sanding block. Round the leading edge of the

stab to match the cross section on the plan.

23. Glue on the shaped 5/8" balsa Stab Tips.

Use a razor plane and a sanding block to shape

them to match the stab airfoil. You may contour

the tip to its final shape now, or wait until the

model is nearer completion.

BUILD THE FIN

1. Cut a 9-1/2" length of the tapered 1/4"

balsa stabilizer LE stock left over from the stab.

2. Glue the die-cut 1/4" balsa Fin Forward

and Aft TE’s (FF and FA) together with CA.

Since these pieces are thick and die-cut, they will

probably require a little touch up and blending

with a sanding block.

3. Punch out the die-cut 3/32" balsa ribs V-1

through V-6. Be sure to preserve their jig tabs.

4. Pin ribs V-1 and V-6 to the building board

over their proper locations. Center the LE on the

front of the ribs and glue it in place. Notice that

the fin LE protrudes through the stab into former

F-11.

5. Center the Fin TE on the aft edge of the

ribs and glue it in place.

6. Put ribs V-2 through V-5 into their places

and glue them. Remember, all jig tabs should

contact the work surface.

7. Apply extra medium CA glue to any joints

that do not appear to be well glued.

8. Blend the LE to match the ribs on the

upward facing (left) fin side. Sand the TE if

necessary to blend smoothly with the ribs.

9. Make a skin for each side of the fin using

the 1/16" balsa sheet left over from the stab

skins. See the sketch on page 10.

10. With the structure flat on the table, glue

on the left skin.

11. Trim off the jig tabs and blend the LE and

TE to the ribs on the right side of the fin.

- 11 -

Page 12

12. If you are adding scale balance tabs, add

the simple additional structure as shown in the

photo. (Parts not included).

13. Glue on the right skin.

14. True up the edges of the fin sheeting with

a sanding block. Shape the LE to match the

cross section on the plans.

15. Glue the shaped 3/4" balsa fin tip to the

top of the fin. Use a razor plane and a sanding

block to do the initial shaping of the tip. Final

shaping should be done later, with the fin taped to

the rudder.

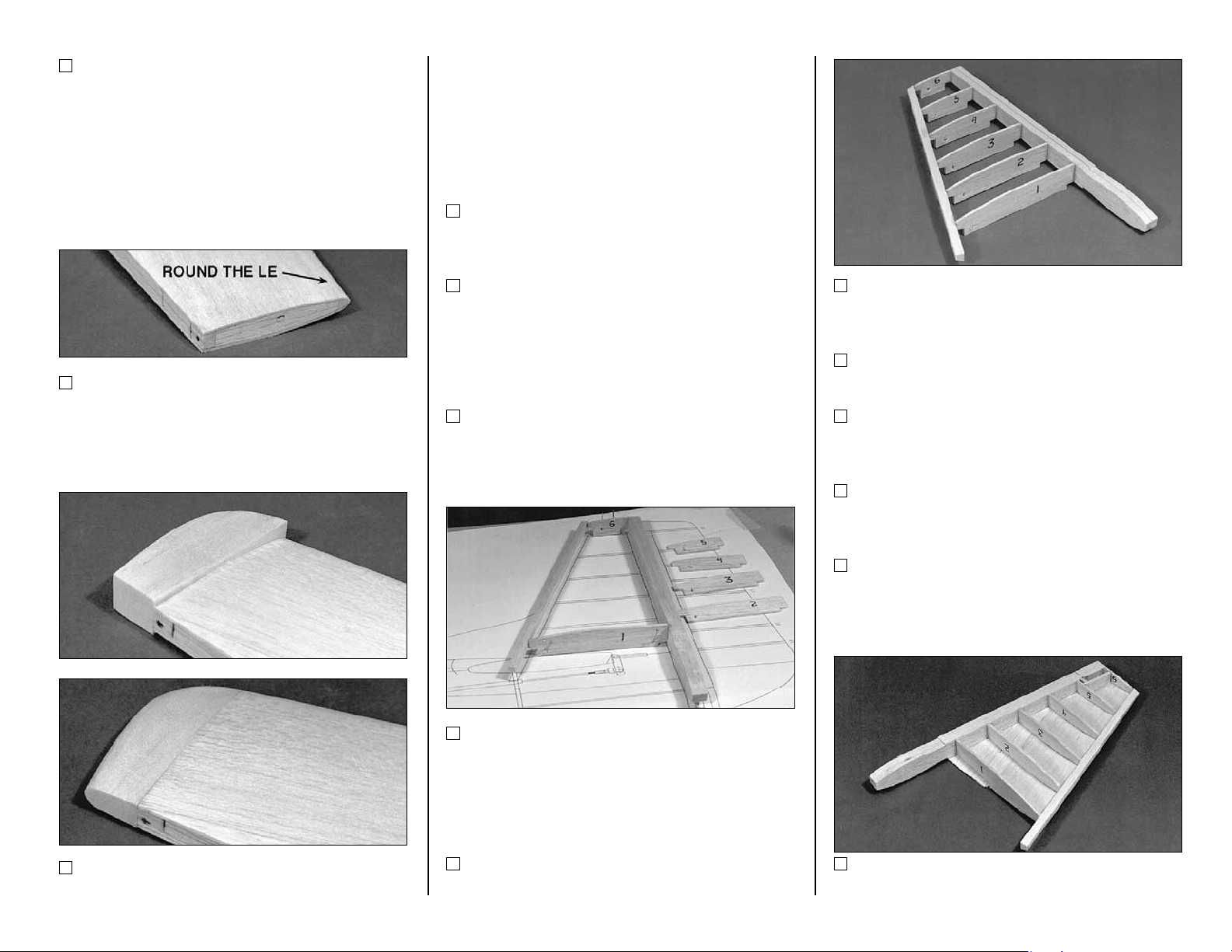

BUILD THE RUDDER

1. Glue the two die-cut 1/4" balsa Rudder

LE’s together with medium CA. Even up the

edges with a sanding block, but save any tapering

for later.

2. Draw a centerline on the aft surface of the

LE. Draw two parallel lines 1/16" away from both

sides of the centerline.

3. Align the die-cut 3/32" balsa Rudder Plate

(RP) over the plans and mark the “Rib” locations

on both sides of the rudder plate. (See the photo

below.)

4. Hold the Rudder Plate centered on the

rudder LE. Apply thin CA to the joint.

5. Glue the two 1/2" thick shaped balsa

Rudder Tips to both sides of the top of the

rudder plate.

6. Glue the two 1/2" thick shaped balsa

Rudder Bases to both sides of the bottom of the

rudder plate.

7. Cut “ribs” from the 3/32" x 1/2" x 30"

balsa sticks and glue them onto both sides of the

rudder at the locations you previously marked.

8. Refer to the photos and the cross sections

- 12 -

Page 13

on the plans to obtain the shape of the rudder.

Use a razor plane and sanding block to “rough in”

the shape of the rudder. Final shaping and fitting

should be done after the fin is glued onto the

fuselage, but you may wish to tape the rudder to

the fin at this point to blend the tips of both.

BUILD THE WING

NOTE: The wings are built “UPSIDEDOWN” on the plans. The jig tabs are

attached to what is, in the end, the

TOP surface of the wing.

VERY IMPORTANT! Since it is the

standard convention to show the Top

View of the wing, and the wing panels

are built upside-down, the LEFT wing

panel is built over the RIGHT Wing Top

View and vice-versa. This does not

present any problems. Just be sure to

build a left and a right wing.

1. Place the wing plan on your building board

and cover it with waxed paper (you may wish to

cut the wing panel sections of the plan apart to

make handling easier.)

2. Hold the 1/4" x 3/8" x 36" balsa Spars over

the wing plans. Mark the Spars about 1/4" longer

than they need to be. Cut off the spars at the

marks and save the excess for the Flap Servo

Mounts.

3. Punch out all the die-cut 3/32" balsa wing

Ribs. Smooth out any imperfections with

sandpaper. Be sure to keep the jig tabs attached

to the ribs.

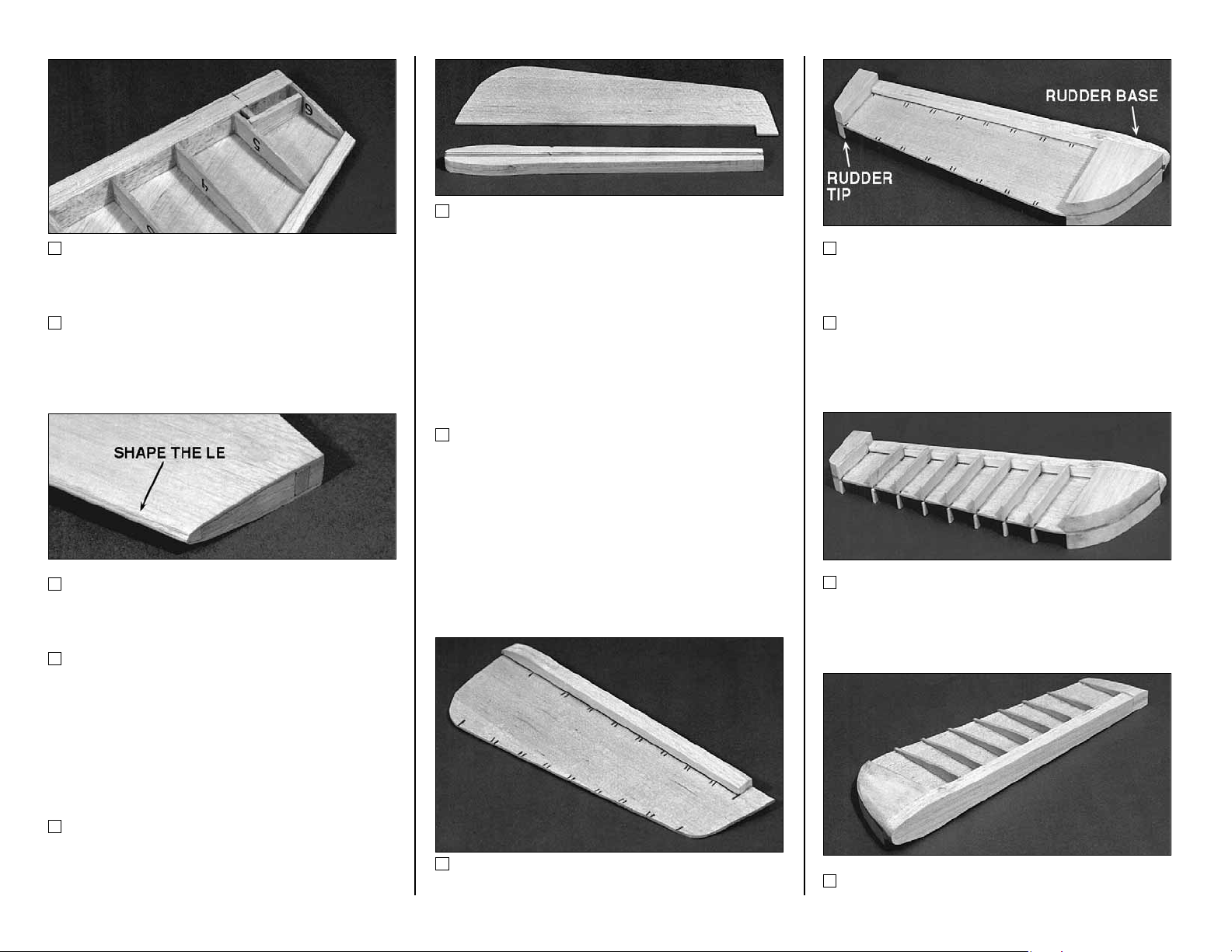

4. Ribs W-1 through W-8 have punch marks

just aft of the spar that locate the aileron

pushrods for you. Drill a 3/16” hole at each of

these marks.

5. Drill 1/8" holes through the punch marks in

the two die-cut 1/8" plywood Aileron Bellcrank

Plates (AB). Assemble the bellcrank parts as

shown in the sketch, making a left and a right

plate. Be sure to put a drop of 5-minute epoxy

on the 4-40 nut and threads to prevent the

bellcrank from vibrating loose.

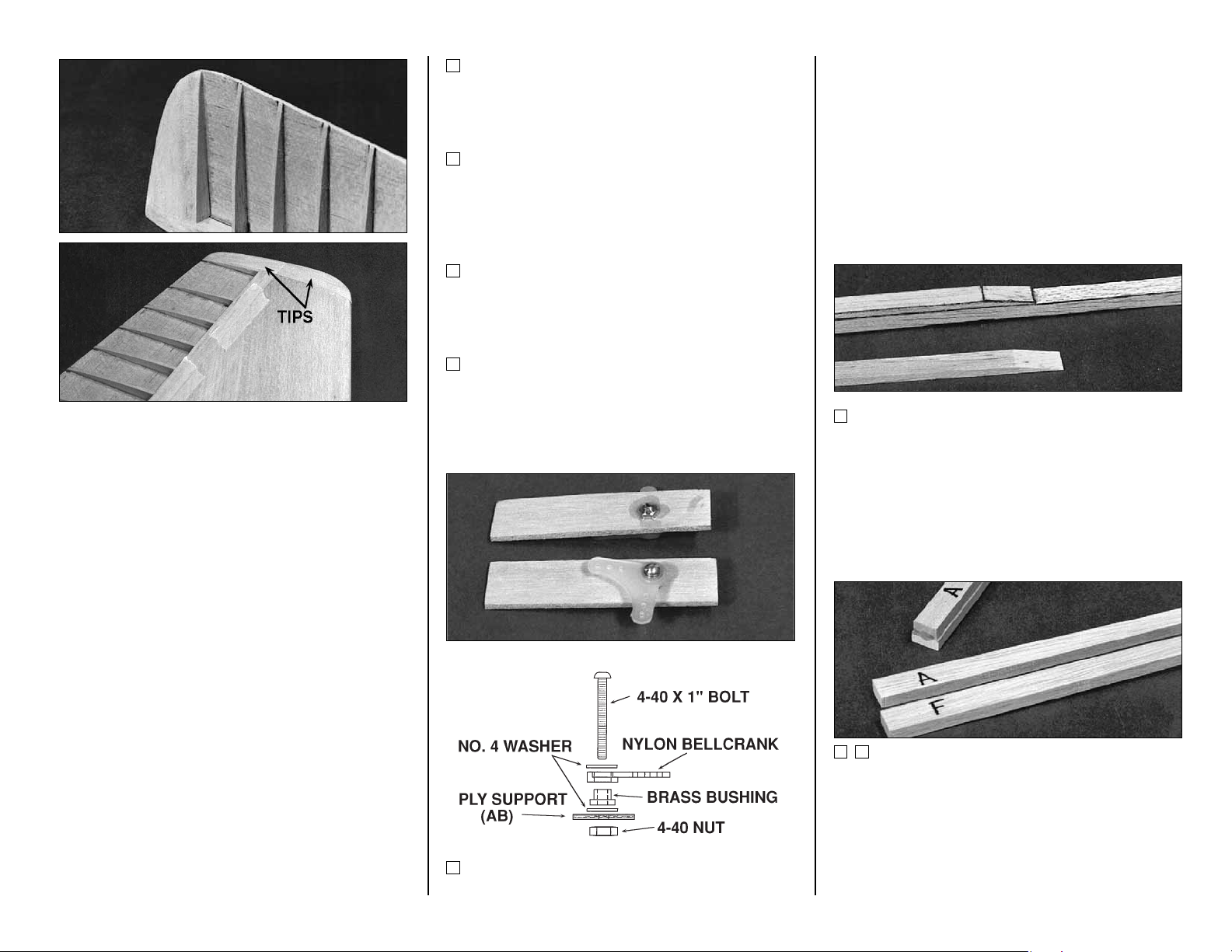

6. Taper one end of each of the four 1/8" x

3/8" x 18" balsa Spar Doublers to match the spar

detail drawing on the plans. Glue a Spar Doubler

to each Spar with the root (non-tapered) end of

the doubler aligned with the root end of the Spar.

7. Center the die-cut 3/16" balsa Aft

Aileron Trailing Edge (A) on the die-cut 3/16"

balsa Forward Aileron Trailing Edge (F) and

glue them together with thin CA. Use a sanding

block to taper the two pieces slightly as shown in

the cross sectional drawing on the plan. These

pieces are die-cut slightly long to allow you to trim

off any imperfections.

- 13 -

Page 14

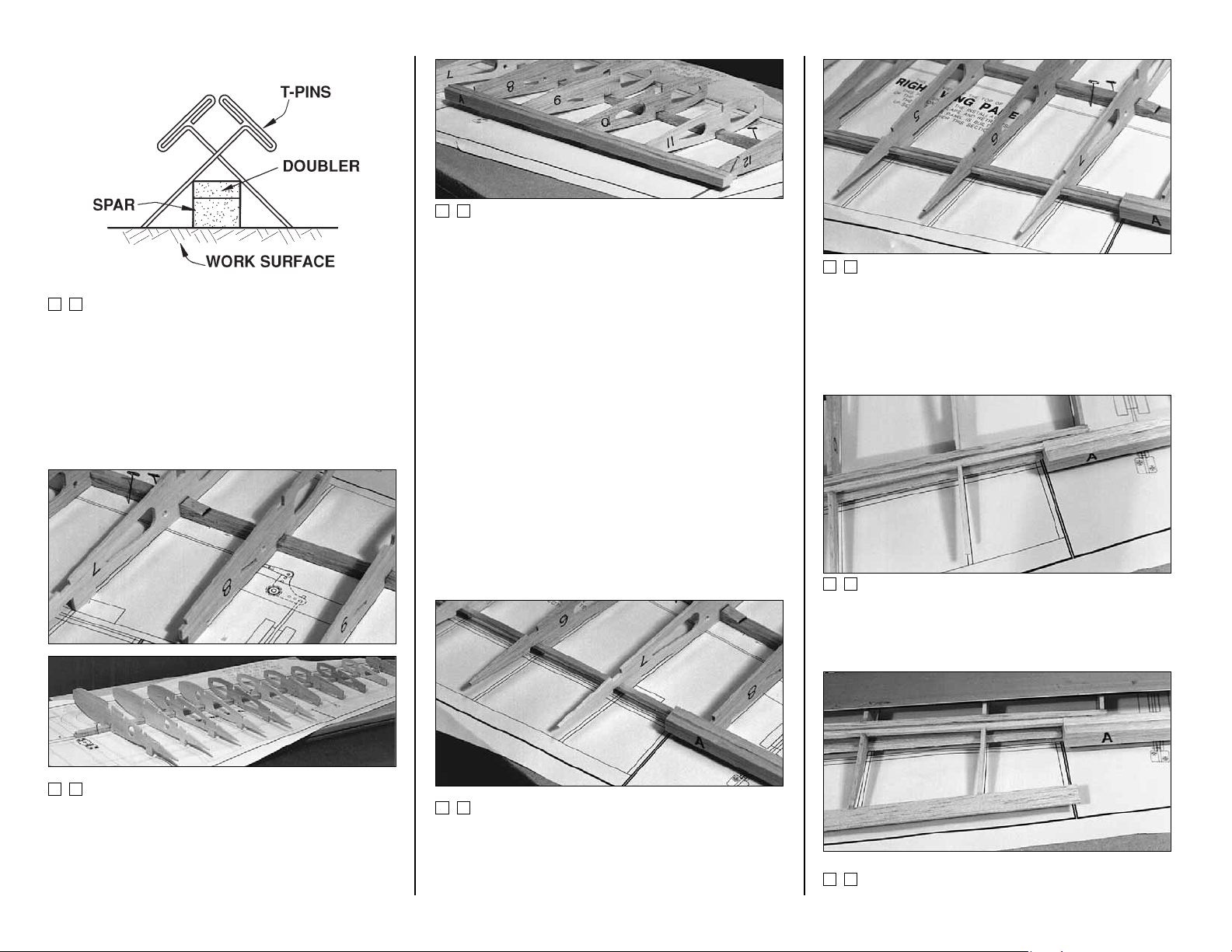

8. Pin a Spar assembly to the building

board at three or four locations using the crosspinning technique shown in the sketch with the

Doublers up.

9. Glue the die-cut 3/32" balsa ribs W-2

through W-12 to the Spar. These should be

vertical and aligned over their appropriate

locations as indicated on the plans. The jig tabs

located near the aft end of the ribs should all

contact the work surface.

10. Glue the aileron Trailing Edge

assembly to the aft edge of ribs W-8 through

W-12. The upward facing edges of the ribs and

the Trailing Edges should be even and the jig

tabs should all be touching the work surface

during this step.

NOTE: The inboard end of the aileron

TE extends approximately 15/16"

inboard of rib W-8, as shown on the

plan.

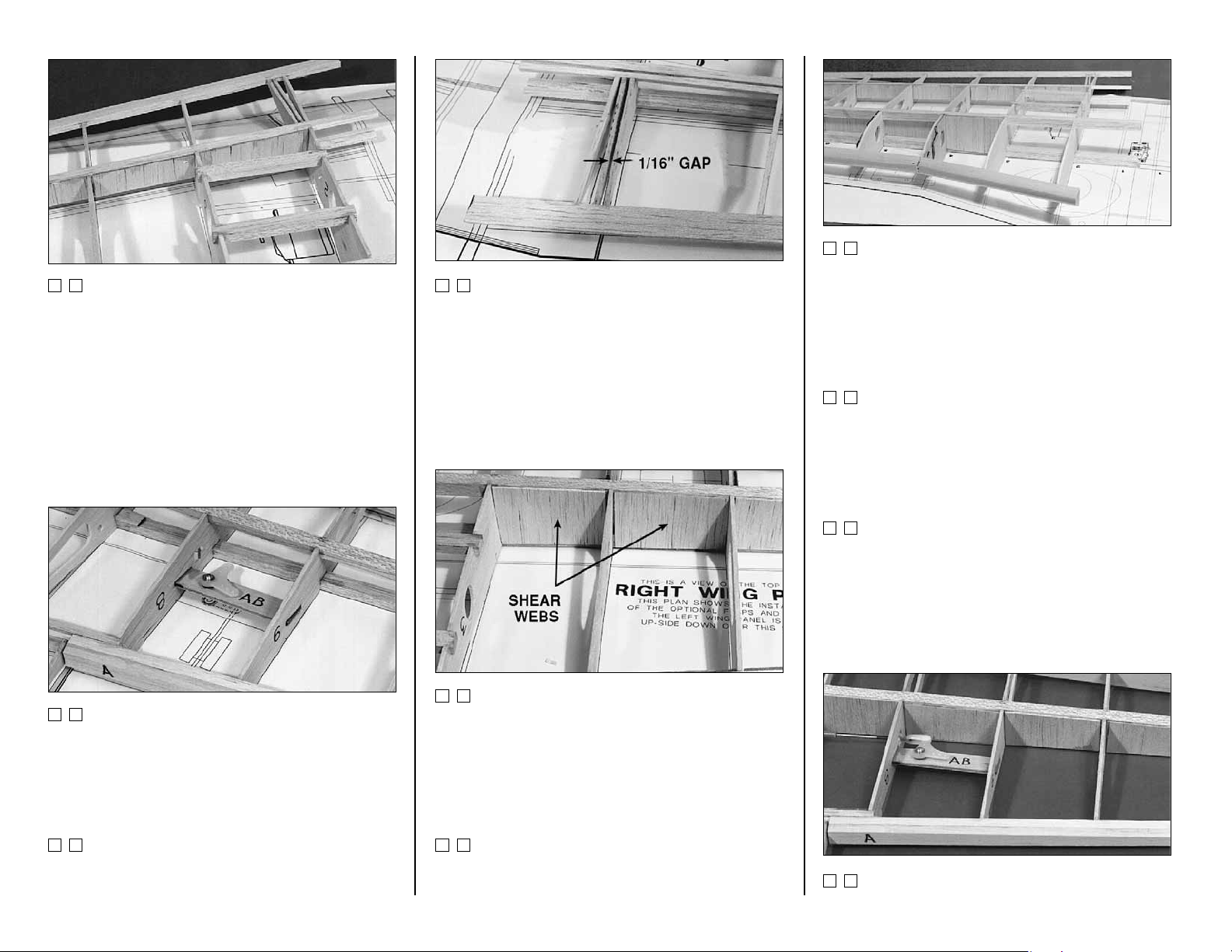

11. Glue the lower 1/8" x 3/16" x 21" balsa

TE Spar as far forward as possible in the slots in

ribs W-2 through W-8.

12. Glue the lower 1/8" x 1/8" x 21" balsa

Flap LE into the aft portion of the slots in ribs

W-2 to W-7. There should be a 1/16" gap

between the TE spar and the flap LE.

13. Repeat steps 11 and 12 for the slot in

the upper side of the ribs.

14. Glue the 1/2" x 21" tapered balsa

- 14 -

Page 15

Flap TE to ribs W-2 and W-7. The flap TE

should be centered on the aft edges of the ribs

and should protrude straight back (see the crosssections on the wing plan). Make sure all the jig

tabs are contacting the table. A metal straight

edge can be placed on the structure over the jig

tabs to hold them all down.

15. Sight down the TE of the wing from

the root end, making sure all the ribs are aligned

at the same height. Use paper to shim under any

low jig tabs. Glue the Flap TE to the remainder of

the ribs.

16. Work the upper spar assembly into

place. Make sure it fits well. Put some weights

on top of the structure to make sure it is firmly on

the work surface. Use CA to glue in the top spar.

17. Use a razor saw to put a V-notch in the

shaped balsa Leading Edge to allow it to “bend”

(break) at R-4. Use the LE detail drawing on the

wing plan for reference.

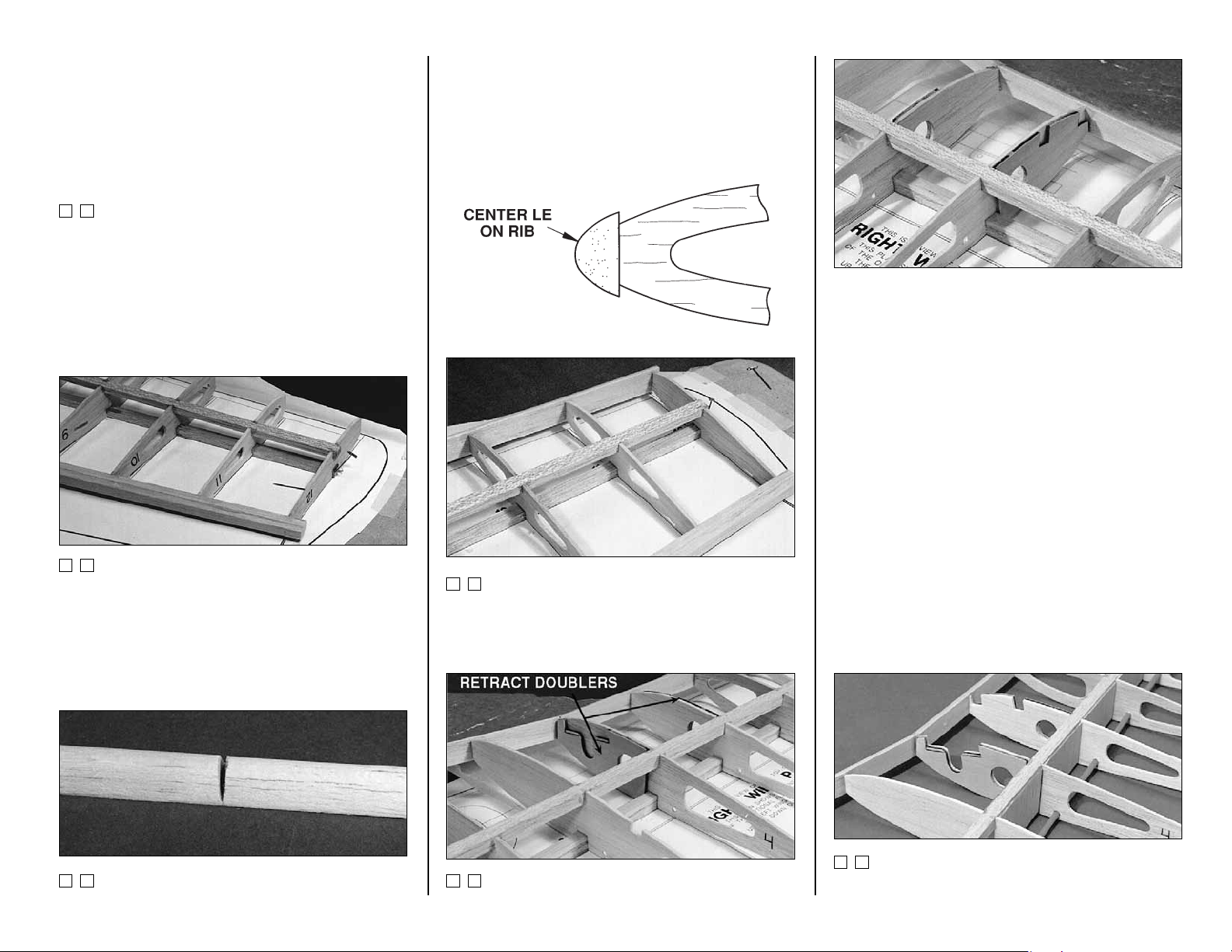

18. Hold the LE centered vertically on the

front edge of the ribs. Use CA to glue it in place.

19. Use thick CA to glue in the die-cut 1/8"

plywood Landing Gear Doublers. Since the

wing panels are built upside-down, the “openings”

in the doublers should face upwards as shown in

the photos. The right side wing plan shows the

placement of the two doublers for retract gear

(Z-4 and Z-5). The left side wing plan shows the

placement of the three fixed gear doublers (G-3,

G-4, and G-5).

Retract Doublers shown

20. Use a sharp knife to trim the balsa ribs

to match the cut-outs in the doublers.

- 15 -

Page 16

21. If you are going to use flaps, trim the

1/4" x 3/8" balsa stock left over from the wing

Spars to the length shown on the plans for the

flap servo bay rails. Glue the rails into the

notches in W-2 and W-3 with CA. If you do not

plan to use flaps, you may fill the notches with

scrap wood or put the rails in anyway.

22. Glue the aileron bellcrank assembly

into the slots in ribs W-8 and W-9. The bellcrank

should face upwards as shown in the photo.

23. Fit, then glue, in the die-cut 3/32" balsa

Flap Tip Rib at the location shown on the plans.

24. If you plan to use flaps, fit and glue in

the two die-cut 3/32" balsa Flap Root Ribs. Use

a scrap piece of 1/16" balsa to space the root ribs

apart. If you are not using flaps, these parts may

be glued in anyway, or discarded.

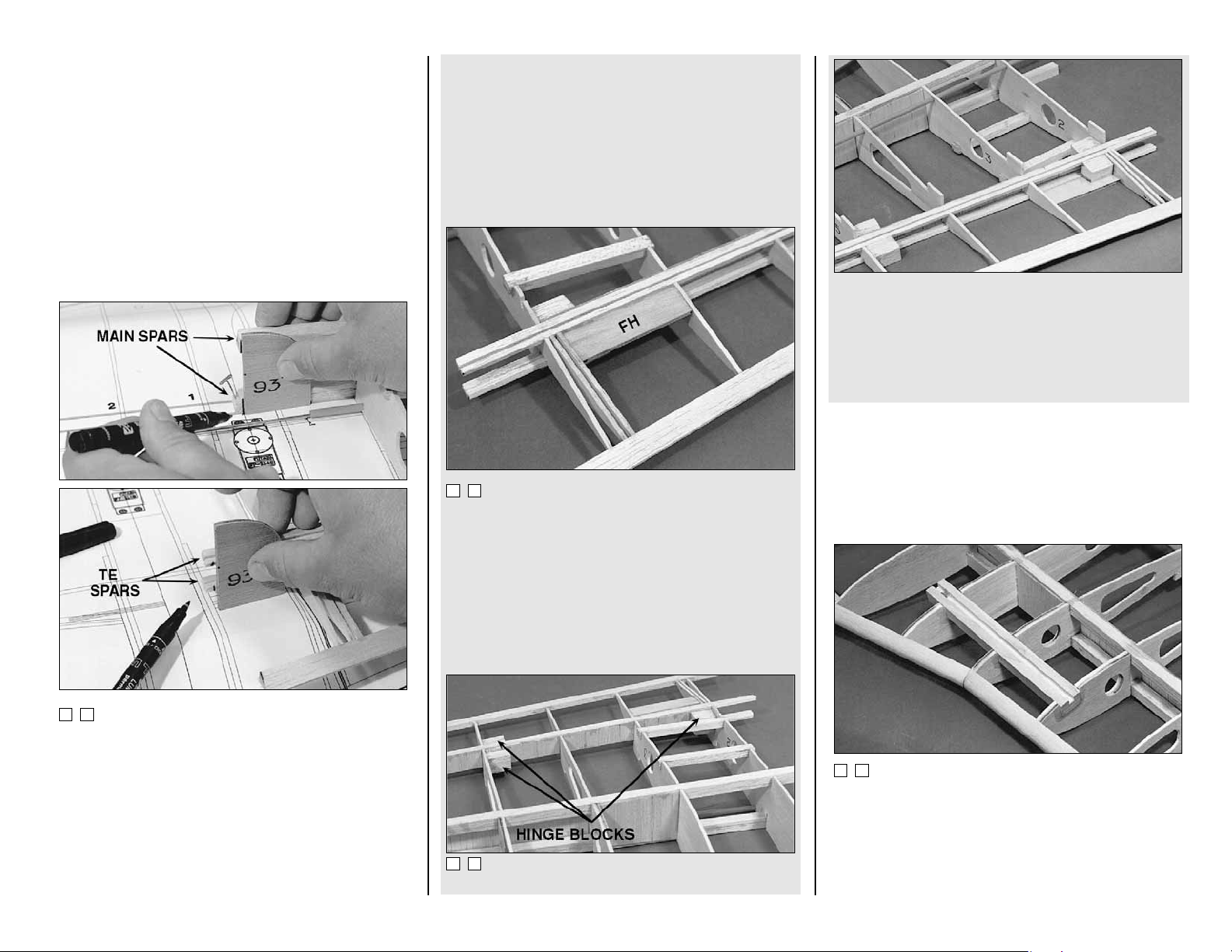

25. Custom fit 1/16" balsa Shear Webs to

fit behind the spar between ribs W-3 to W-12.

Glue them to the spars with medium CA. Wick

thin CA into all the joints of the shear webs and

the spars to make sure they are well bonded. It is

not important to glue the shear webs to the ribs.

26. Fit and glue a shear web to the front

of the spars between ribs W-3 and W-4 for extra

strength.

27. Sight down the wing trailing edge to

make sure it is still straight. Shim any low jig tabs

if required. Trim each of the 1/16" x 3" x 3/4"

balsa Aft Shear Webs to fit between ribs W-2

through W-8 in front of the TE Spar. Glue them in

place with the structure held firmly on your flat

work surface.

28. Cut a 16-1/2" long piece of Outer

Pushrod Tube. Roughen the outside of the tube

with 220-grit sandpaper. Feed the tube through

the holes in the ribs as shown on the plans. Use

CA to glue the tube to the ribs.

29. Cut five lengths of Inner Pushrod

Tube about 5/16" long. Slide them onto an .074"

x 34" Threaded End Pushrod Wire at the

intervals shown on the plans. Carefully apply a

small drop of CA to the short tubes if they are not

very snug on the wire.

30. Enlarge the pushrod hole in W-8 to

- 16 -

Page 17

allow for free movement of the pushrod and

clevis. Securely snap a nylon clevis onto the

bellcrank. Feed the wire assembly into the wing

and screw the threaded end well into the clevis.

Hint: The wire is extra long. After the threaded

end starts threading into the clevis, you may bend

over the excess wire and use it as a handle to

turn the wire the rest of the way into the clevis.

Be sure to hold the clevis securely with pliers

while threading the wire into it to keep from

stressing the clevis pin. Cut off the excess wire

flush with the root end of the spar.

31. Use the die-cut plywood 93 deg. tool

(93) as shown to mark the ends of the spars and

TE’s.

NOTE: When marking the spars, the

corner of the tool is on the wing

centerline. When marking the TE

spars and flap LE’s, the corner of the

tool is positioned where the TE spars

end on the plan.

DO STEPS 32 AND 33 IF YOU ARE BUILDING

OPERATING FLAPS.

32. Glue the die-cut 1/8" plywood Flap

Horn Base (FH) in its place between W-2 and

W-3. Note how it is flush with the upward facing

edge of the ribs.

33. Cut pieces approximately 1" long from

the 1/2" x 3/4" x 12" balsa stick provided to act as

flap hinge blocks. These are shown on the right

wing panel plan. Some custom fitting of these,

such as tapering, is required. Skip to step 36.

DO STEPS 34 AND 35 FOR FIXED GEAR.

34. Glue the 1/2" x 3/4" x 6-3/4" slotted

hardwood Landing Gear Rail and the 1/2" x 3/4"

x 1-1/2" maple LG Block with a generous amount

of epoxy. Their locations are shown on the left

wing panel drawing. Drill a 3/16" hole through the

rail and block at the location shown on the plan,

to allow the landing gear wire to be inserted.

- 17 -

Page 18

- 18 -

35. Make any adjustments necessary to

allow the bent wire main landing gear to slide

properly into place.

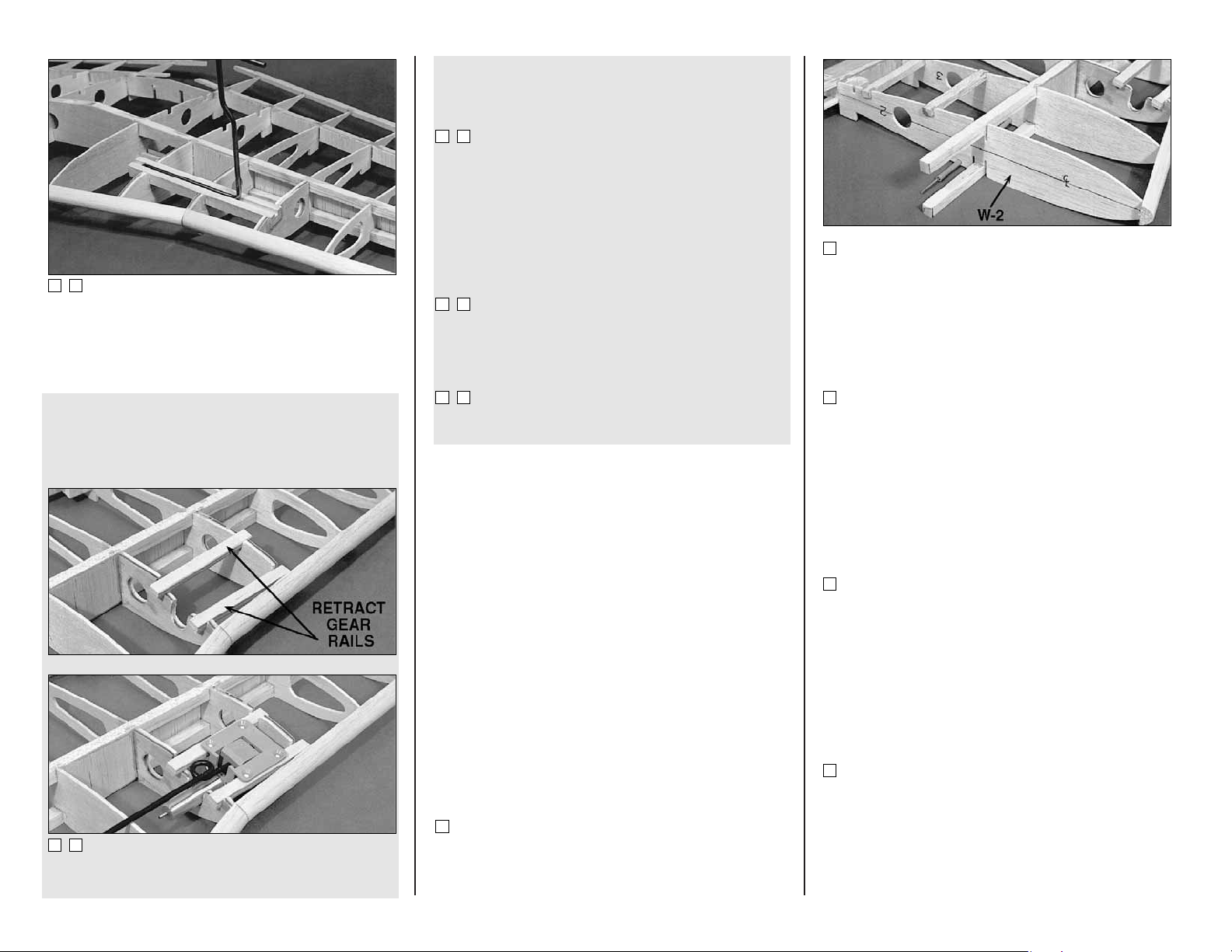

DO STEPS 36 - 39 FOR RETRACT GEAR.

36. Slide the 1/4" x 3/8" x 3-3/4" plywood

Retract Gear Rails into the slots in W-4 and W-5.

Test fit your retracts between the rails. If the rail

spacing is not correct (it should be for most

retracts) adjust the aft slots.

37. Manually extend and retract the gear,

noting the strut angle. Adjust the depth of the

slots if necessary to give a satisfactory angle

when the gear is retracted and extended. It will

be necessary to cut a slot in R-3 for the strut to

pass through.

38. Use generous amounts of 30-minute

epoxy to glue in the rails.

39. Mark and drill the retract mounting

holes in the retract rails.

Repeat steps 7 to 39 to build the other wing

panel.

NOTE: At this point you may remove

the wing panels from the building

board if you have not already done so.

Try to store your panels on a flat

surface with some weights on top of

them until they are joined and sheeted,

to prevent warping.

JOIN THE WING PANELS

1. Trim the ends of the spars, LE’s, and TE’s

of both panels very close to the tip rib W-12.

Excess overhang will affect the dihedral angle.

2. Draw a centerline on both W-2’s as shown

in the photos.

3. Trim all the spars at the root end of the

wing as they were previously marked with the 93

degree tool.

4. When you are totally ready to join the

wings, trim off all the jig tabs except those on

W-2 and W-12. Use a small sanding block to

“clean up” the area around the tabs.

5. Place the two 3/8" x 1-1/2" x 7-1/2"

Dihedral Jig Blocks under the two W-2 ribs.

Place the wing halves together upside-down.

The spars at W-2 and the W-2 jig tabs on both

panels should rest on the Jig Blocks. The tip

ends of the spars and the W-12 jig tabs rest on

the table (see photo on the next page).

Page 19

6. Test fit the wing panels on the Jig Blocks

with the two die-cut 1/16" plywood Dihedral

Braces in place. Adjust any parts until the panels

join up nicely at the spars. The die-cut 1/8"

plywood Aft Cross Brace (CB) should be

included in these test fittings. If it requires

trimming, take equal amounts off the right and left

ends.

7. Make two equal length sticks from scrap to

act as spacers between the two W-2’s. These

should be positioned on the W-2 centerline. The

length of these sticks will vary slightly depending

on how your spars are trimmed, but 5-1/2" is a

good starting point (see photo below). These two

sticks will make sure the W-2 ribs are parallel.

8. Test fit the Aft Cross Brace and the sticks

between the two W-2’s and adjust both sticks

equally if adjustment is required. You may notice

that the spars sweep forward slightly. This is

normal.

9. When the wing fits on the Jig Blocks with

the Aft Cross Brace (CB) and the two equal

length sticks in place, it is time to glue it together.

The best method is to use 30-minute epoxy. Coat

the mating surfaces of the spars and dihedral

braces. Then assemble the parts onto the Jig

Blocks. Use CA to tack glue the two equal length

sticks into place as shown in the photos. Use CA

to glue the Aft Cross Brace (CB) into place. Use

masking tape to clamp the dihedral braces to the

spars.

10. Make four 1/16" balsa shear webs to cap

the dihedral braces between W-2 and W-3.

11. Align and glue the die-cut 1/8" plywood

W-1C’s to the die-cut 1/8" plywood W-1B’s, being

sure to make a left and a right.

12. Plug the die-cut 1/8" plywood Aileron

Servo Tray between the two W-1B/C’s. Make

sure all the front edges are aligned. Use a 90

deg. triangle to hold each W-1B/C vertical while

you glue it to the servo tray.

13. Plug the die-cut 1/8" plywood F-8B into

the aft end of the assembly. Check to see that all

edges are square and properly aligned. Use a

hobby knife to make small adjustments to the

notches if required. Use a 90 deg. triangle to

hold the W-1B/C’s vertical while you glue them to

F-8B.

14. Remove the rear stick. Work the

assembly into position in the center of the wing.

Trim the aft spars and flap LE, if necessary, to fit

the assembly. Trim the flap TE as shown on the

plans and in the photos to allow clearance for F-8B.

The photos with steps 17 and 18 show you the

finished assembly.

- 19 -

Page 20

15. Notice that the W-1 ribs in the assembly

are undersized 1/16" (except the area around the

top of the aileron servo) to allow for a center

doubler of 1/16" balsa center sheeting. Put

marks on the dihedral braces 3/4" both ways from

the center of the wing to aid in the alignment of

the center assembly.

16. The front of the assembly is positioned by

aligning the top edge of the assembly with the top

of the dihedral brace. Tack glue the assembly at

the front edge. NOTE: The word “top” refers to

the top surface of the wing.

17. The back end of the assembly is aligned

by centering the flap TE on the top edge of F-8B

at W-1. The Aft Cross Brace (CB) should

protrude about 1/16" on both sides of the W-1 ribs

to allow for the double sheeting.

18. Thoroughly glue all the joints in the area

of the center assembly with medium CA.

19. Make shear webs for the aft spar

between W-1 and W-2. Glue them to the front of

the aft spar with medium CA.

20. Trim the length of the 1/4" plywood

beveled edge Wing Bolt Plate until it fits between

the two W-2’s near their centerline.

21. Mark a centerline on the Wing Bolt Plate.

Mark two lines offset 3/4" on both sides of the

centerline as shown.

22. Mark the wing bolt hole locations as

shown in the sketch above. Drill 13/64" pilot

holes at the locations marked.

- 20 -

Page 21

23. Assemble the two die-cut 1/8" plywood

W-1A’s, the die-cut 1/8" plywood Front Spacer

Plate, and the Wing Bolt Plate as shown. Use a

90 deg. triangle to check the alignment. Then

glue the assembly together.

24. See the cross section at W-1 on the

fuselage plan for the proper orientation of the

angle on the front of the W-1A’s. Fit this forward

assembly between the two W-2’s. The aft edges

are centered on the front face of the dihedral

brace (you also may look ahead to the wing

sheeting section to see why the W-1 ribs are

undersized). The front is located by placing the

center of the 1/4" wing bolt plate 1/16" below the

centerline on the W-2’s (toward the bottom

surface of the wing).

25. Glue the two die-cut 3/16" balsa Center

Leading Edges (CLE’s) together with CA. Sand

their length, if necessary, until they fit between

the two wing leading edges in front of the Wing

Bolt Plate. Glue in the CLE’s. You may rough

contour them now, but do the final sanding after

the wing has been sheeted.

SHEET THE WING

1. Sort through the remaining 1/16" x 3" x 36"

wing sheeting. Pick out the best 8 sheets and set

them aside for the top of the wing.

2. Notice that the center wing rib W-1 is 1/16"

undersized everywhere but on top of the aileron

servo. This is to allow you to put 1/16" center

sheeting over the W-1 ribs to reinforce the centersection.

3. Cut 2" long pieces of sheeting from the

1/16" wing sheeting. Glue the sheeting to the top

and bottom of the two W-1 ribs (except on top of

the aileron servo tray) as shown in the photos.

- 21 -

Page 22

NOTE: This is a somewhat unique way

of joining the sheeting in the center of

the wing that eliminates the need for

glassing the center section. Do not try

to sand the center sheeting so the

wing skin will have 100% contact with

it. If the skin is left a little high on the

top surface of the wing, it is fine, since

this part of the wing is hidden under

the saddle.

4. Block sand the center sheeting slightly,

particularly on the bottom, to blend it with the

shape of the other wing ribs.

NOTE: The wing sheeting process

described here involves making a skin

that covers most of the wing first, then

gluing it to the structure. This

skinning process requires fairly quick

and accurate work when you apply the

skin to the wing. An alternative is

sheeting the wing with individual

sheets, which requires less

preparation and does not require you

to work as fast. It does not allow you

to pre-sand the seams. We

recommend you read through the

entire sheeting section before

proceeding. Then use whichever

process you are comfortable with.

NOTE: All balsa sheeting will usually

bend when it is cut from the log

because stresses are relieved. For

best results, trim the edges of the wing

sheeting with a long metal straight

edge and a sharp knife before joining

them.

5. Lay waxed paper over a flat smooth work

surface. You will join the wing skins on this

surface.

6. Edge glue four 1/16" x 3" x 36" balsa wing

sheets together with thin CA for each of the four

wing surfaces. Hint: A quick wipe of a paper

towel while gluing the sheets will soak up most of

the excess CA and make sanding the seams

easier.

7. LIGHTLY sand both sides of the skin over

the work surface with a sanding block and sharp

220-sandpaper.

NOTE: The steps below show sheeting the flap

with a separate piece of wood. This orients the

grain more parallel with the flap span and makes

it easier to fit.

NOTE: If you are building functioning

flaps, you may choose to cut the flaps

loose from the structure before

sheeting them. If there are any slight

warps in your flap trailing edges, this

will allow you to straighten them

during sheeting. If your structure

appears straight, we think you will find

it best to sheet the flaps while they are

still attached as shown in the

construction sequence.

8. Tape a skin to the bottom of the wing

structure, aligning it with the leading edge. Mark

the outer extents of the wing from the other side

of the structure. We usually leave about 3/8"

overhang where possible.

9. Cut the skin to the shape you marked.

Check the fit of the skin to the structure and make

adjustments until it fits well (see photo at step

15).

10. Trace the shape of the skin onto the other

bottom skin. Trace the shape of the skin onto the

two top wing skins. It is not an exact match, but

this will offer an excellent starting point.

11. Make the outer aileron pushrods by

putting a Z-bend in two of the .074 x 12"

Threaded End Pushrod Wires to match the

length shown on the wing plan.

12. Enlarge the outer hole in the aileron

bellcrank with a 5/64" drill bit. Hook the pushrod

up to the bellcrank. Make certain the Z-bend

can’t bind against the bellcrank plates.

13. Make cut-outs to allow the aileron

- 22 -

Page 23

pushrods to exit the bottom wing skins. The

plans show the proper size and location of these

holes. Reinforce the inside edges of the slots as

shown with strips of scrap balsa.

14. Put the wing upside-down on its “jig.”

You may want to tack glue the wing to the table

and jig to keep it from moving around.

15. Apply a generous bead of slow CA glue

to all the structure the skin will contact. Apply the

skin to the wing, starting with the leading edge.

Use thin CA and kicker to anchor the Leading

Edge. Roll the rest of the skin back over the

structure and press it in place until the glue sets.

16. Apply the other bottom wing skin.

17. If you are using functioning flaps, put light

marks on the skins where the hinges will go, so

you can find the blocks later.

NOTE: If you are building operating

flaps, you may leave a small gap in the

sheeting along the flap cut line to

make it easier to cut the flaps loose

later.

18. Sheet in the areas of the bottom of the

wing that are not covered by the main skin.

NOTE: Leave the wing on the jig until

you are ready to sheet the top of the

wing. This allows less time for

moisture and stress to twist the wing.

19. Trim any remaining jig tabs off the ribs

and blend any high spots away with a sanding

block.

20. Pass a 13/64" drill through the Wing Bolt

Plate. Then drill through the bottom skin to

eliminate any problems finding the holes later.

21. Fit the top wing skin to the wing.

NOTE: The top skin may be glued on

in one of three ways: You may glue

the skin to the wing structure all at

once as you did when sheeting the

bottom, you may glue on the individual

sheets separately, or you may follow

the procedure below.

22. Tape the wing skin to the LE in a few

places. Use thin CA to glue the skin to the

leading edge.

23. Set the wing horizontally on the table and

lift the trailing edge so the wing tilts forward at

about 40 deg.

- 23 -

Page 24

24. Working rapidly, put a stream of medium

CA on each rib at the spar and allow it to run

forward down the rib to the leading edge. Put a

bead of medium CA on the spar.

25. Hold the wing vertically on one wing tip

and, starting at the middle, roll the skin back onto

the wing. By holding the wing on its tip, and

putting equal pressure on both sides of the wing,

the wing will retain its proper shape and washout.

26. Now run glue down the aft portion of the

ribs and put glue on the trailing edges. Hold the

wing vertically on its tip again and press the aft

portion of the wing skin onto the structure.

27. Sheet the areas of the top of the wing

that are not covered by the main skins.

28. Cut out and enlarge the holes where the

wing bolts pass through the skins to about 1/2".

29. Locate the12-1/2" long double tapered

balsa Ailerons. The ailerons are very similar to

the elevators, but they are longer. Check the

taper of the ailerons over the plans to make sure

you have the correct parts.

30. Test fit the aileron to your wing. Trim the

aileron front edge and root end for a good fit. The

tip end of the aileron should be fitted after the

wing tip has been installed.

31. Die-cut 1/16" plywood Wing Tip Braces

are supplied to strengthen the aft end of the wing

tip. Saw a 1/16" slot along the centerline of each

shaped 1-1/4" balsa Wing Tip and glue the

braces in with CA as shown.

- 24 -

Page 25

32. Glue the Wing Tips onto the wing,

carefully centering the tip brace at the TE. Use a

knife, razor plane, and sanding block to shape the

wing tips.

33. Trim the tip of the aileron so it fits

properly between the flap and the wing tip.

Shape the LE of the aileron to the “V” shape as

shown in the photo and on the cross section on

the wing plan.

BUILD THE FUSELAGE

1. Test fit the die-cut 1/8" balsa Upper

Forward Fuse Side, Upper Aft Fuse Side,

Lower Forward Fuse Side, and Lower Aft Fuse

Side together. These should be aligned over the

Fuselage Side View on the plans, or by placing a

long straightedge along the top edge of the upper

parts. Adjust any joints that do not fit well.

2. Place waxed paper over your work

surface. Reassemble the parts and check their

alignment. For a straight fuselage, it is important

to have the fuse sides straight, and both the

same. Use thin and medium CA to glue the parts

together. Use a quick wipe with a paper towel to

remove excess glue, as this will make sanding

easier. Keep in mind that you are making a left

and a right fuselage side.

3. Glue the die-cut 1/8" balsa Radiator Side

to the bottom edge of each fuselage side. Sand

the joint with a sanding block and 220-grit

sandpaper.

4. Inspect the two fuselage sides. Choose

the Right and Left sides so the best surfaces will

face outward. Mark the inside of the appropriate

part RI and LI (for Right Inside and Left Inside.)

Sand the outside (and to a lesser extent the

inside) of each side with a sanding block and

sharp 220-grit sandpaper to smooth out the joints

and the surface.

5. Glue a die-cut 1/8" balsa Aft Fuse

Doubler to the inside of each fuselage side (be

sure to make a left and a right). Align the stab

saddle and the top edge of the doubler with the

fuse side when gluing.

6. Compare the two die-cut 1/8" Plywood

Fuse Doublers. Label the shorter one “R” (right)

and the longer one “L” (left). This will set the right

thrust in the firewall.

- 25 -

Page 26

7. Line up the fuselage doublers using the

notch at their back (for F-8) and the wing saddle

as the primary references. Be sure to put them

on the inside of the fuselage sides and make a

left and a right. Glue the doublers in place with

CA.

8. Glue the die-cut 1/8" balsa Forward Fuse

Doublers in place. They should touch the

Plywood Fuselage Doublers.

9. Glue a 1/8" x 3/8" x 9" balsa Doubler

Stick along the top edge of each fuselage side

beginning at the notch in the aft fuse doubler.

Tape the Fuselage Bottom View over your flat

building board (we recommend cutting that

part of your plan loose to make it easier to

handle). Cover the bottom view with waxed

paper.

Important Note: You are building the

fuselage upside-down over the Bottom

View. This aircraft has right thrust

built in. Since the fuse is built upsidedown, this will appear to be left thrust

until it is flipped over. Just follow the

instruction sequence and everything

will be fine.

10. Pin the die-cut 1/8" plywood Forward

Crutch over its location on the plans. Make sure

the front edge of the crutch matches the plans for

the correct thrust angle.

NOTE: Some formers are not

symmetrical and must be glued in with

the proper orientation. Glue in all the

formers with the I.D. numbers toward

the FRONT of the model and they will

all be correct.

11. Drill 3/16" holes through the punch marks

in formers F-5, F-7, F-8, F-9, F-10, and F-11.

These holes are for the pushrod mounting, and

you may confirm these locations using the crosssections on the fuselage plans.

12. Glue the die-cut 1/8" plywood former F-5

to the forward crutch at its location on the plans.

It should be perpendicular to the crutch with its

number facing forward.

13. Glue in the die-cut 1/8" plywood former

F-7 and the die-cut 1/8" plywood Servo Tray

(ST). F-7 must also be perpendicular to the

crutch.

- 26 -

Page 27

14. Place the die-cut 1/8" plywood former F-3

in its slot but do not glue it yet since its forward

slant is set by the fuselage sides.

NOTE: It is helpful to keep some

weights on the crutch while building

the fuselage to keep it flat on the table.

15. Place the left fuselage side in position.

Make sure its edge is down on the building board

and tack glue it at the following places: at the lock

notch near the front of the crutch; at the “bottom”

edge of F-3 near the front edge of the wing

saddle; at the top and bottom of F-7; and at the

top and bottom of F-5. Also glue F-3 to the

Crutch.

16. Glue the die-cut 1/8" plywood sub-former

F-8C to the Aft face of the former F-8A. The 1/4"

holes should line up. This assembly is now called

F-8.

17. Glue former F-8 to the Crutch. Tack glue

F-8 to the plywood doubler near the notch.

18. Test fit the 1/4" Fuselage Bolt Plate into

the fuselage structure. It may be necessary to

bevel the forward outboard edges slightly for an

interference-free fit. When it fits well, tack glue it

into the structure with CA.

19. Work the right fuselage side into place.

Check to see that all the notches are properly

engaged and if need be, make adjustments.

Apply thin and/or medium CA to all the joints

between F-3 and F-7.

20. Glue F-8 to both fuselage sides from the

wing saddle area to the middle of F-8, but do not

worry about gluing it near the crutch yet.

- 27 -

Page 28

- 28 -

21. Drill 5/64" holes through the two punch

marks in the die-cut 1/8" plywood Tail Wheel

Plate (TW).

22. Glue the die-cut 1/8" plywood Tail Wheel

Plate (TW) to former F-10, making sure they are

perpendicular. Make sure the number on F-10

faces down.

23. If there is an additional vertical web on

the nylon tail wheel bracket, trim it off so the part

resembles the one in the photos.

24. If there is excess length at the top of the

tail wire, trim it off with a cut-off wheel so there is

only about 3/8" remaining after the bend.

25. Place the 5/8" long piece of 1/8" O.D.

brass tubing over the top end of the wire.

Squeeze the exposed end of the tube firmly with

pliers to flatten it. Check the parts over the

fuselage top view to make sure they match up

well. Silver solder the brass tube to the top of the

tail wheel wire (see below).

TIPS FOR SILVER SOLDERING

Use this process when soldering metal to metal

such as brass tube to wire, or pushrod ends to

wire.

A. Thoroughly clean the items to be soldered

with alcohol or degreasing solvent.

B. Roughen the area to be soldered with fine

sandpaper. Then clean again.

C. Assemble the items to be soldered.

D. Apply a small amount of soldering flux. Acid

based flux works best when one or more of the

items is steel.

E. Heat the metal with a soldering gun or iron,

and apply solder to the metal. The metal must

get hot enough to melt the solder and the solder

must freely flow into the joint.

F. Do not move the parts until the solder has

cooled.

G. Clean off the excess flux with alcohol or

solvent. Coat the parts with a very fine film of oil.

H. Test the joint by pulling hard.

26. Mark the location of the Metal Ball on the

flat spot. Drill a 1/16" hole at the mark.

27. Attach the ball permanently to the tail

gear with the Small Nut provided. Put a drop of

5-minute epoxy on the threads to prevent it from

vibrating loose.

28. Use the 4-40 Set Screw to set the collar

at the height shown on the fuselage side view, but

orient the set screw so small adjustments can be

made later if required.

Page 29

29. Roughen the tubular Nylon Bearing on

the tail wheel wire with sandpaper so glue will

stick to it.

30. Put a small drop of 5-minute epoxy on the

Nylon Bracket where the two bolt holes are.

Screw the Nylon Bracket to TW with two #4 x 3/8"

Sheet Metal Screws. Then put a drop of epoxy

on the threads of the Sheet Metal Screws to

prevent them from loosening.

31. Cut 8" off one end of the .074 x 35"

Threaded Both

End Rod. Place a brass

Threaded Coupler over the unthreaded end of

the 8" piece. Measure the length of the

assembly. Cut length off the wire until the total

assembled length is 8-1/2". Slide a 5/16" length

of inner pushrod tube over this piece of wire as

shown on the plans. Silver solder the Brass

Coupler to the wire.

32. Screw the Brass Threaded Coupler of the

wire well into one end of the Nylon Two-Ended

Ball Link. Screw the remainder of the 35" rod

that you cut in the previous step into the other

end of the Ball Link.

33. Test fit the pushrod linkage onto the

tailgear assembly. Oblong the rudder pushrod

hole in F-10 sideways to allow for movement (see

next photo).

Adjust the wheel collar height for best alignment

of the pushrod. Apply some threadlocker to the

4-40 set screw and tighten it snugly. Remove the

pushrod.

34. Slide five 5/16" lengths of inner pushrod

over the rudder pushrod and space them as

shown on the plans.

35. Place the F-10/TW assembly in position

between the fuselage sides. It should be located

using the notches in the aft fuse doublers. Work

a piece of masking tape beneath the fuselage and

use it to pull the sides to the formers. Use a 90

deg. triangle to make sure the former is vertical.

Pull the upward facing edges of the fuselage

sides together with another piece of masking

tape.

- 29 -

Page 30

36. Make sure the fuse is centered over the

plans and use a couple of pins to hold it there.

When it is aligned, apply a generous bead of

medium CA to the joints of the fuselage sides,

F-10, and TW.

37. Fit F-9 into position over its location on

the plans and hold it with tape using the same

technique you used with F-10. Make sure it is

vertical with its number facing forward. Glue it in

with medium CA.

38. Glue the unglued portion of F-8 and the

aft end of the crutch to the fuselage sides.

39. Mark and cut-out the rudder pushrod exit

where shown on the fuselage plans. Bevel the

exit with a sharp knife at its front from the inside

and at its back from the outside to allow the outer

pushrod tube to exit at the angle shown on the

plans.

40. Work the wire portion of the rudder

pushrod through the exit, then through the rudder

pushrod holes in all the formers forward through

F-7. Hook up the ball link to the tailgear ball.

You may need to make a slight outward bend in

the pushrod wire just aft of the ball link to allow it

to exit without binding.

41. Work a lightly sanded 17-1/4" long Outer

Pushrod Tube through the formers around the

wire, starting at F-7 and ending at F-10. Glue the

outer pushrod tube to formers F-7, F-8, and F-9,

but not F-10.

42. Cut a 5" long piece of outer pushrod tube

and lightly sand the outside. For best results,

taper one end as shown.

43. Test fit the tube into the pushrod exit and

make sure the balsa wood is adequately cleared.

Glue in the tube.

44. Cut into the pushrod hole in the die-cut

- 30 -

Page 31

1/8" plywood former F-11, making it a notch. Test

fit F-11 into the fuselage. Make adjustments to

the notch if necessary. Glue in F-11.

45. Lightly sand a 22" length of outer pushrod

tube and feed it through the elevator pushrod

holes in the formers. Glue it to formers F-7

through F-10. NOTE: Refer to the plans for the

location of the aft end of the tube. It protrudes

past F-11 about 1/4".

46. Cut two 2" lengths of 1/4" balsa triangle

stock and use them to reinforce the joints of TW

and the fuselage sides (see photo below).

47. Cut two 11-1/4" lengths from the supplied

1/4" x 36" triangle stock. Test fit these in the aft

fuselage as shown. Notice on the plans

(sideview) that they stop 1/2" short of the aft end

of the fuselage sides. Glue them in place.

48. Test fit the die-cut 1/8" balsa Radiator

Keels into the slots in F-8, F-9, and F-10. You

may be required to shorten them slightly. Glue

them in place (see the photos at steps 50 and

51).

49. Cut an 11-3/4" length from the 3/16" x 3"

x 24" soft balsa Aft Fuse Bottom Sheet. Cut it

down until it is just wider than the two Keels.

50. Wet the sheet with water. Apply medium

CA glue to the keels, F-8, and F-9. Pull the sheet

into place with multiple pieces of masking tape.

Allow the wet wood to dry thoroughly.

51. Use a knife, a razor plane, and a coarse

sanding block to bevel the radiator sides and

bottom as shown. Look at the cross-sections on

the fuselage plans for reference.

52. Use the pattern provided on the plan to

cut two Radiator Corners from the 1/4" x 2" x 24"

soft balsa sheet.

53. Glue the Radiator Corners to the

fuselage. Wetting these parts may be required,

depending on the wood. You may wish to use

tape to hold these parts down while the glue sets.

NOTE: At this point, you should

remove the fuselage from the building

board and reinforce difficult to reach

glue joints from the inside.

- 31 -

Page 32

54. Roughly shape the Radiator Corners with

a knife and a razor plane. Save the final shaping

until after the aft bottom sheeting has been

applied.

55. A pattern for the gauge to set the firewall

angle is provided on the plan, since the Plywood

Fuse Doublers alone cannot be counted on to set

the correct 1.75 deg. of down thrust. Glue the

pattern to a piece of plywood or cardboard and

cut it out.

56. Test fit the die-cut 1/8" plywood Aft

Firewall (F-1B) into the front of the fuselage and

check the angle with the firewall gauge.

Remember, the Crutch and Doublers also set

right thrust. Make any necessary adjustments.

57. Glue in F-1B starting at the crutch. Use

the firewall jig to make sure the angle is correct.

58. Bevel the aft edges of the two 5" long

balsa 1" triangle pieces so they match up to F-3.

Glue in the triangles.

59. Apply a fillet of 30-minute epoxy to the

inside corner of the firewall and the fuse sides.

You also may want to use epoxy to fuelproof the

corners that will be difficult to get to after the Chin

Block is put on. Also apply a fillet of epoxy

around the Fuselage Bolt Plate.

60. Glue the two 3/4" x 2-5/8" x 4-3/8"

shaped balsa Chin Block pieces together as

shown. The angled end of the block aligns as a

projection of F-3. Glue the block to the fuselage.

61. Roughly shape the Chin Block. Final

shaping of the block will be done later.

MOUNT THE WING TO THE

FUSELAGE

1. Run a 1/4" drill bit through F-8 and F-8D to

clean out the holes so the dowels will fit through.

- 32 -

Page 33

2. Round the ends of the 2-1/2" long 1/4"

Dowels. Insert the Dowels into the wing (do not

glue yet).

3. Test fit the wing onto the fuselage. The

fuse dowel holes may have to be loosened up a

little more to allow the wing to go on smoothly.

4. Adjust the parts until the wing fits well on

the saddle. The CLE (Center Leading Edge) and

the wing saddle may require slight adjustments.

5. Tape some scrap 1/32" plywood (from the

wing fillet base die-cut sheet) to the wing skin

near the trailing edge and over the spar to

simulate the die-cut plywood Fillet Base being in

place. Again test fit the wing to the fuselage. If

there is much interference preventing the wing

from comfortably fitting down on the saddle,

shape the wing dowel holes oblong and adjust the

dowel slot in the wing structure until the

interference is gone.

6. Draw a centerline on the CLE to give you a

reference when aligning the wing.

7. Tape a piece of scrap balsa between the

fuselage sides at the aft end of the fuselage.

Stick a T-pin in the scrap balsa on the fuselage

centerline. Tie a five foot length of string to the

pin, which will aid in checking the wing alignment.

8. Put the wing in position on the fuselage.

Hold the string (with one end attached to the pin

at the tail) up to a wing tip. Put a piece of tape on

the string to mark the intersection of the string

and the wing tip. Swing the string over to the

other wing tip and check to see if the distances

are the same (see diagram). Adjust the position

of the leading edge of the wing until the wing is

properly aligned.

NOTE: Make sure the wing is held

securely and cannot shift while you

are drilling the mounting holes.

- 33 -

Page 34

9. Drill through the two holes in the Wing Bolt

Plate and through the Fuselage Bolt Plate with a

#10 drill (or 13/64"). Remove the wing and tap

the holes in the Fuselage Bolt Plate with a

1/4-20 tap. Wick some thin CA into the threads to

harden them. Allow the CA to cure fully. Run the

tap through the threads again to clean up the

threads. Drill out the holes in the Wing Bolt

Plate with a 17/64" bit.

10. Bolt the wing to the fuselage. Check to

be sure the dowels at the TE of the wing are

centered in the slots. Apply medium CA to the

dowels at the slots and allow to cure. Remove

the wing and make sure the dowels are

thoroughly glued in.

ATTACH THE STAB AND FIN

1. For scale accuracy, the fuselage sides in

the area of the stab saddle need to be contoured.

Study the cross sections on the plans as well as

the photos. Razor plane and block sand the

fuselage to obtain the proper shape.

2. Mark one side of the stab to be the top (it

doesn’t really matter which). Put a mark 1-1/4"

behind the leading edge at the center of the stab.

Put another mark 3/4" behind that one.

3. Use a sharp knife to cut a slot in the stab

skin between the two S-1 stab ribs and between

the marks. Cut the same slot in the bottom skin.

4. Make a notch favoring the bottom of the

stab to allow the horn on the bent wire elevator

joiner to protrude into the stab and rotate for up

and down elevator control (see the photo and

fuse side view plan).

5. Make sure the fin LE will fit through the slot

- 34 -

Page 35

in the stab. Shave the sides of the LE slightly as

needed.

6. Cut a notch at the aft edge of the stab

saddle to give the Elevator Torque Rod room to

rotate.

7. Test fit the stab into the stab saddle. Make

small adjustments to the saddle if necessary for a

good fit.

8. Make an elevator pushrod by sliding six

5/16" long pieces of Inner Pushrod Tube over a

.074 x 34" Pushrod Wire. Distribute them as

shown on the plans and cut the wire a little longer

than shown on the plan. Put a 3/16" long piece of

medium fuel tubing over a Nylon Clevis to

assure it will not open. Screw the Nylon Clevis

well onto the end of the pushrod wire. Attach the

Clevis to the Elevator Torque Rod.

9. Insert the pushrod assembly into the outer

tube that was previously installed in the fuselage.

10. Stick a short piece of 1/4" scrap balsa

into the slot in F-11 to simulate the rudder post.

Bolt the wing onto the fuselage for reference.

11. Set the stab in the stab saddle. Check

the alignment of the stab with the wing from the

front and rear of the model. Check from the top

view of the model to see if the stab is square to

the fuselage centerline.

12. Tack glue the stab on with medium CA

and again check its alignment. Glue the stab to

the saddle from the inside and outside of the

fuselage with 30-minute epoxy. Be sure to glue it

to F-11.

13. Work the fin into position. Trim any fin

sheeting away that prevents the fin TE from

standing vertical when you view it from the side

(the fin LE may also need to be shortened

slightly).

- 35 -

Page 36

14. Check the alignment of the fin from the

front and rear of the model to see if it is vertical.

Glue it in with thin and medium CA. Apply some

epoxy to the intersection of the fin LE and F-11,

being careful to avoid getting glue in the elevator

pushrod. Glue the fin trailing edge to the aft

fuselage sides with thin and medium CA.

PREPARE THE ELEVATORS

1. Locate the 11-1/4" long double tapered

balsa Elevators. Check the taper of the

elevators over the plan to make sure you have

the correct parts.

2. Place the elevators on the plan and draw

angled lines on the root and tip ends of each

elevator where shown.

3. Using a razor saw, cut off the ends of the

elevators at the previously drawn lines.

4. Hold the elevators up to the stab. With the

tips of the elevators aligned with the tips of the

stab, mark the locations where the elevator

torque rod will be inserted into the elevators.

5. Drill a 5/64" hole into the elevator for the

torque rod. Make a slot from the hole to the root

end of the elevator for the body of the rod to rest

in.

6. Tape both elevators to the stab. Carve

and sand the tips so they conform nicely to the

stab tips.

7. Tack glue a 1/4" x 3/4" x 2-3/8" Fillet

Block to the root end of each elevator. Cut a

notch so the torque rod can pass through it.

8. Sand the surfaces of the blocks so they