Page 1

WARRANTY.....Top Flite Models guarantees this kit to be free of defects in both

material and workmanship at the date of purchase. This warranty does not cover any component parts

damaged by use or modification. In no case shall Top Flite’s liability exceed the original cost of the

purchased kit. Further, Top Flite reserves the right to change or modify this warranty without notice.

In that Top Flite has no control over the final assembly or material used for final assembly, no

liability shall be assumed nor accepted for any damage resulting from the use by the user of the final

user-assembled product. By the act of using the user-assembled product, the user accepts all

resulting liability.

If the buyer is not prepared to accept the liability associated with the use of this product, the

buyer is advised to immediately return this kit in new and unused condition to the place of purchase.

Top Flite Models

P.O. Box 788

Urbana, Il 61803

Technical Assistance - Call (217) 398-8970

www.top-flite.com

CRS6P03 V3.1

READ THROUGH THIS INSTRUCTION BOOK FIRST. IT CONTAINS IMPORTANT INSTRUCTIONS AND WARNINGS CONCERNING THE ASSEMBLY AND USE OF THIS MODEL.

Entire Contents © Copyright 2002

USA

MADE IN

™

Page 2

Introduction............................................3

Precautions............................................3

Die-Cut Patterns ...............................4-5

Decisions You Must Make Early in the

Building Process ...................................6

Engine & Mount Selection ....................6

Full Cockpit (optional)...........................6

Flaps.....................................................6

Retracts ...............................................6

Common Abbreviations........................6

Types of Wood .......................................6

Supplies & Tools Needed......................6

Other Items Required............................7

Get Ready to Build.................................7

Build the Stab ........................................7

Build the Fin ..........................................8

Build the Elevators................................8

Build the Rudder....................................9

Build the Wing .....................................10

Tip Panels.............................................12

Wing Joining........................................13

Wing Structure Completion................14

Wing Sheeting......................................15

Fuselage Top........................................19

Fuselage Bottom .................................22

Wing Mounting.....................................26

Stab & Fin Mounting............................27

Firewall & Engine Installation.............30

Flaps .....................................................31

Tips for Robart Hinge Points...............33

Wing Tips .............................................34

Ailerons ................................................34

Finishing...............................................35

Cowl Finishing ....................................35

Final Sanding .....................................35

Fuelproofing........................................35

Balance the Airplane Laterally ...........36

Covering...............................................36

Recommended Covering Sequence...36

Apply the Decals & Trim......................36

Hinging .................................................37

Final Control Hardware Hookups.......38

Cockpit Finishing.................................38

Retracts Notes .....................................39

Cooling Notes ......................................40

Control Surface Throws......................40

Install Receiver, Switch & Battery......40

Balance Your Model.............................40

Final Hookups and Checks.................41

Preflight................................................41

Charge the Batteries...........................41

Find a Safe Place to Fly......................41

Ground Check the Model....................41

Range Check Your Radio ...................41

Engine Safety Precautions .................41

AMA Safety code .................................42

Flying....................................................42

Takeoff ................................................42

Flight...................................................43

Landing...............................................43

Flap Operation....................................43

Three-view drawing..............Back cover

2

Page 3

PROTECT YOUR MODEL, YOURSELF &

OTHERS – FOLLOW THIS IMPORTANT

SAFETY PRECAUTION

Your Top Flite F4U Corsair is not a toy,

but rather a sophisticated, working model that

functions very much like an actual airplane.

Because of its performance, the Corsair, if not

assembled and operated correctly, could possibly

cause injury to yourself or spectators and

damage property.

To make your R/C modeling experience totally

enjoyable, we recommend that you get

experienced, knowledgeable help with

assembly and during your first flights. You’ll

learn faster and avoid risking your model before

you’re truly ready to solo. Your local hobby shop

has information about flying clubs in your area

whose membership includes qualified instructors.

You can also contact the national Academy of

Model Aeronautics (AMA), which has more than

2,500 chartered clubs across the country. Through

any one of them, instructor training programs and

insured newcomer training are available.

Contact the AMA at the address or toll-free phone

number below:

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, IN 47302-9252

Telephone: (800) 435-9262

Fax: (317) 741-0057

INTRODUCTION

Thank you for purchasing the Top Flite GOLD

EDITION Corsair.

The Top Flite F4U Corsair is a sport scale model of

the Chance Vought F4U Corsair. This kit may be

built as a sport model for sport flying or detailed out

for sport scale competition. Either way, the model

possesses a very good scale outline.

The decals in the kit (and shown on the box cover)

duplicate a Korean war vintage F4U-4 Corsair

which lends itself well to a MonoKote®covering.

Most other types of the Corsair line, such as

the F4U-1A, may be built from this kit with

minor modifications.

Several color photo sets and 3-view drawings

suitable for sport scale documentation are

available from:

Scale Model Research

3114 Yukon Ave.

Costa Mesa, CA 92626

(714) 979-8058

The Top Flite Corsair is designed to fly as good as

it looks. The outer wing panels have jig tabs that

automatically build in approx. 1-1/4 degrees of

washout to prevent tip stalling. The computerdesigned, interlocking structure allows you to build

a straight and true model that will fly great.

This model aircraft is not for beginners. The Top

Flite Corsair has excellent flight characteristics and

is very maneuverable, but it is quite fast and does

not have the required stability and self recovery

characteristics of a good R/C trainer. A pilot should

be confident flying a sport aircraft with ailerons

before attempting to fly the Corsair.

Please inspect all parts carefully before starting to

build! If any parts are missing, broken or defective,

or if you have any questions about building or

flying this model, please call us at (217) 398-8970

and we'll be glad to help. If you are calling for

replacement parts, please look up the part

numbers and the kit identification number

(stamped on the end of the carton) and have them

ready when calling.

PRECAUTIONS

1. You must build the plane according to the plan

and instructions. Do not alter or modify the model,

as doing so may result in an unsafe or unflyable

model. In a few cases the plan and instructions

may differ slightly from the photos. In those

instances you should assume the plan and written

instructions are correct.

2. You must take time to build straight, true and strong.

3. You must use a proper R/C radio that is in first

class condition, the correct sized engine and

correct components (fuel tank, wheels, etc.)

throughout your building process.

4. You must properly install all R/C and other

components so that the model operates properly

on the ground and in the air.

5. You must test the operation of the model before

the first and each successive flight to insure that all

equipment is operating, and you must make certain

that the model has remained structurally sound. Be

sure to check external nylon clevises often.

Replace any that show signs of wear.

6. You must fly the model only with the competent

help of a well experienced R/C pilot if you are not

already an experienced R/C pilot at this time.

Remember: Take your time and follow directions to

end up with a well-built model that is straight and true.

NOTE: We, as the kit manufacturer, can

provide you with a top quality kit and great

instructions, but ultimately the quality and

flyability of your finished model depends on

how you build it; therefore, we cannot in any

way guarantee the performance of your

completed model, and no representations are

expressed or implied as to the performance or

safety of your completed model.

3

Page 4

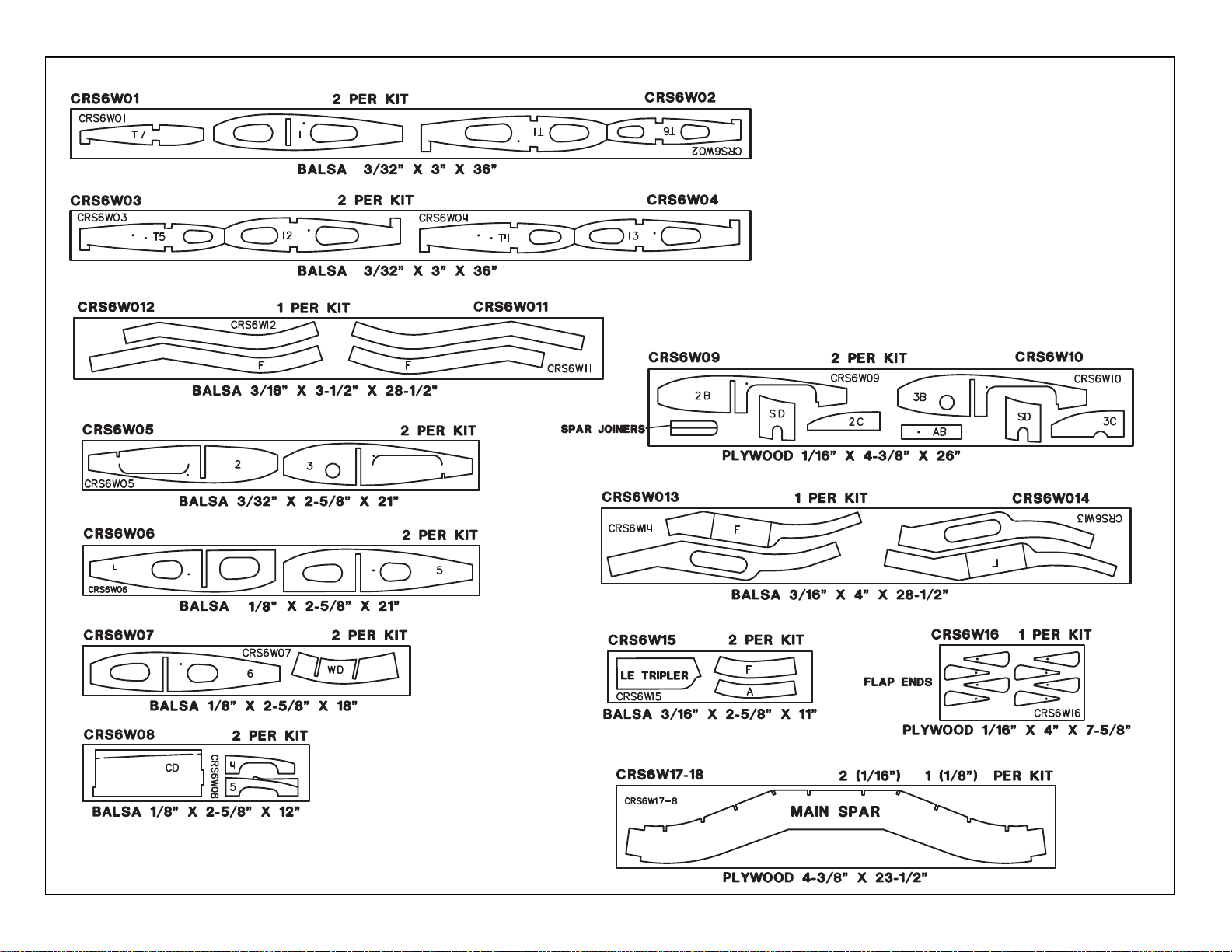

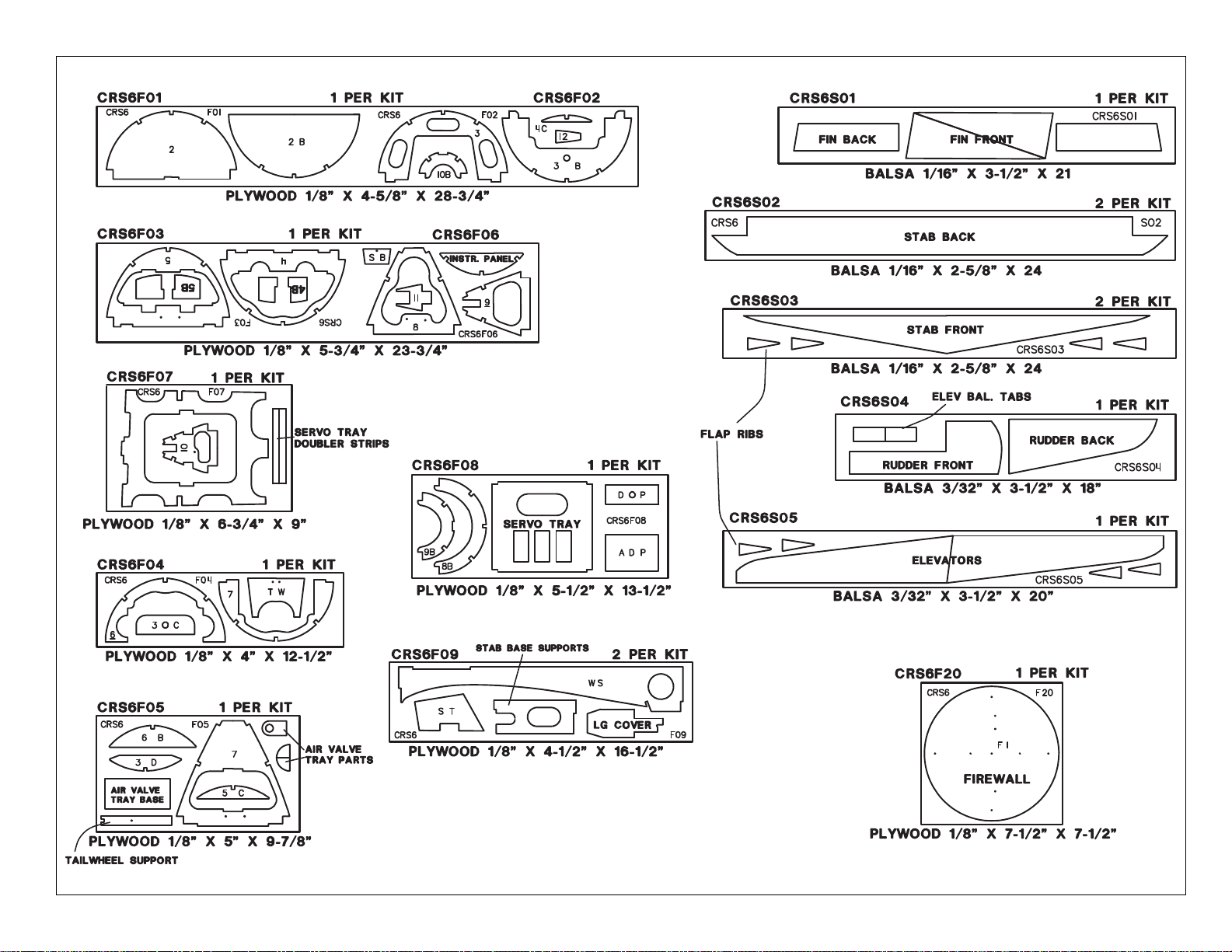

4

DIE-CUT PARTS

Page 5

5

DIE-CUT PARTS

Page 6

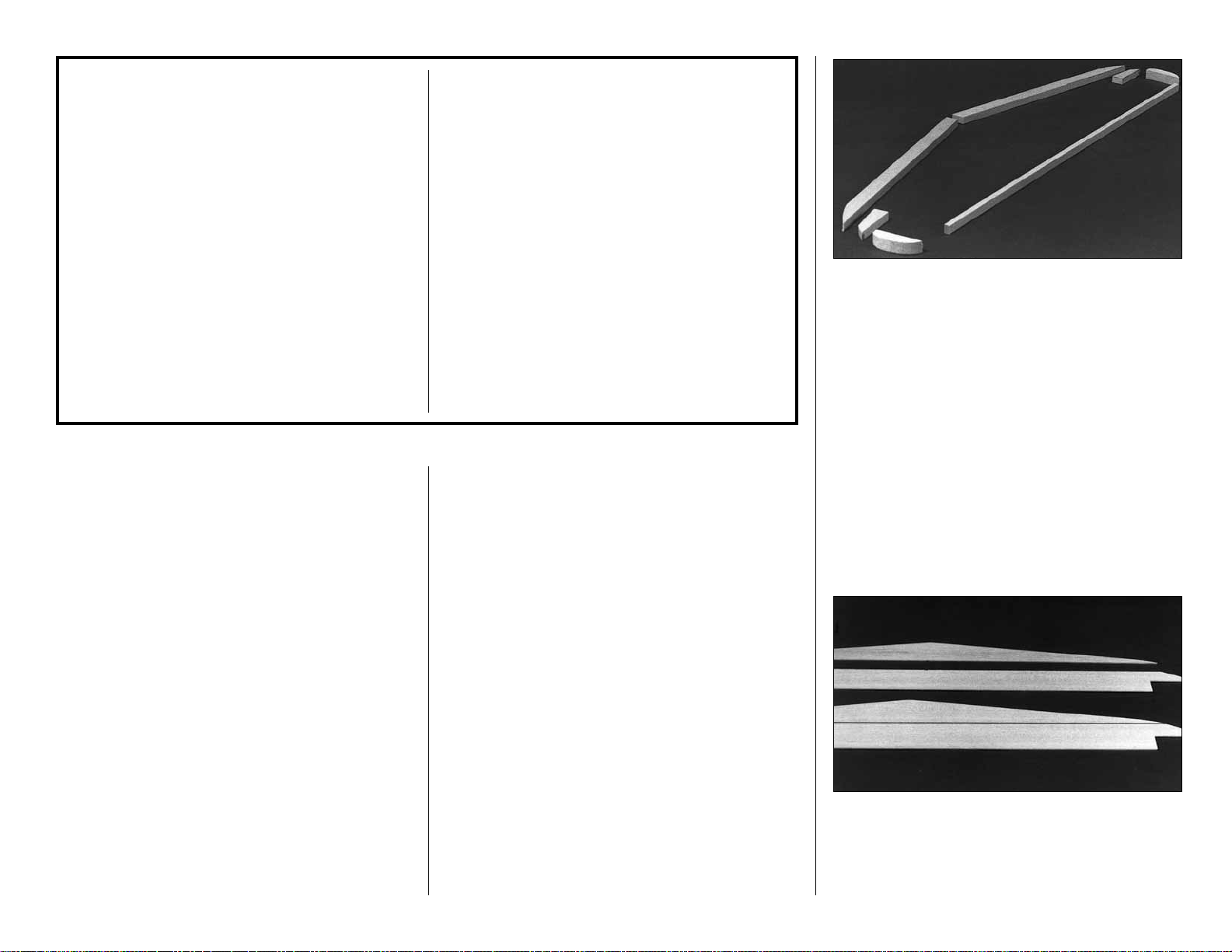

SUPPLIES AND TOOLS NEEDED

❏ 2 oz. Thin CA Adhesive (GPMR6003)

❏ 2 oz. Medium or Thick CA (GPMR6009)

❏ 6-Minute Epoxy (GPMR6045)

❏ 30-Minute Epoxy (GPMR6047)

❏ Hand or Electric Drill

❏ Drill Bits: 1/16", 3/32", 1/8", 5/32", 3/16",

13/64", 7/32", 1/4", and 5/16"

❏ Soldering Iron & Silver Solder

❏ Sealing Iron (TOPR2100)

❏ Heat Gun (TOPR2000)

❏ Hobby Saw (Razor Saw)

❏ Hobby Knife, #11 Blades

❏ Plier

❏ Screwdrivers (Phillips & Flat Head)

❏ T-Pins (HCAR5150)

❏ Straightedge

❏ Short Ruler

❏ Masking Tape (required for construction)

❏ Sandpaper (coarse, medium, fine grit)*

❏ Bar Sanders (see below)

❏ Waxed Paper

❏ Lightweight Balsa Filler (HCAR3401)

❏ 1/4-20 & 8-32 Tap, (GPMR8105) (GPMR8103)

❏ Tap Wrench

❏ Isopropyl Rubbing Alcohol (70%)

❏ Rotary tool (Dremel

®)

) or similar (optional)

On our workbench, we have four 11" Great

Planes®Easy-Touch™Bar Sanders, equipped

with #50, #80, #150 and #220-grit sandpaper.

This setup is all that is required for almost any

sanding task. Custom sanding blocks can be

made from balsa for sanding hard to reach spots.

We also keep some #320-grit wet-or-dry

sandpaper handy for finish sanding before

covering. Great Planes Easy-Touch Bar

6

DECISIONS YOU MUST MAKE

EARLY IN THE

BUILDING SEQUENCE

ENGINE AND MOUNT SELECTION

The recommended engine size range is as follows:

.60 to .90 cu. in. 2-stroke

.90 to 1.20 cu. in. 4-stroke

NOTE: The smaller engines in the range provide

more than enough power to fly the Corsair well. Do

not hesitate to use them.

The instructions show an OS®.61 2-stroke engine

side mounted at a 45 degree inverted position. It

also shows a Top Flite internal muffler

(TOPQ7915). This power package works very well.

Most .61 2-stroke engines will fit in the supplied

EM60120 engine mount.

The instructions also show the installation of an OS

1.20 4-stroke engine. Even though it is shown

mounted inverted, it could also be mounted upright

or on its side; the decision is yours. Flexible exhaust

systems are available for most 4-stroke engines and

there is more than enough room inside the Corsair’s

cowl to route the exhaust out the bottom. You would

also have to change the cowl mounting. The engine

is shown on the plans mounted to a JT-122 SV

isolation mount which may no longer be available.

The supplied EM60120 mount will fit the O.S. 1.20.

FULL COCKPIT

(Optional)

You must decide before you build the fuselage if

you will be adding the optional full cockpit kit

(TOPQ8404) to your Corsair. If you are undecided,

you should build it as though you are going to

install it. That way you can add it at a later time

should you want to.

FLAPS

You must decide early in the building process if

you are going to use operating wing flaps. These

are not required but do add to the Corsair's

appearance and flyability. The flaps as described

in this manual work very well, giving super stable

slow flight with virtually no trim changes. Obviously

there is some extra work and craftsmanship

required to fit operating flaps to the model. If you

use operating flaps, you will need to have (2)

standard servos and small Robart hinge points

(ROBQ2508) available during construction.

RETRACTS

You will need to decide early whether you intend to

use retractable landing gear in your Corsair.

Robart 100 degree rotating retracts (ROBQ1815)

were used in the prototypes and the rib spacing

and mounts in the kit are designed to accept them.

Century Jet Models 90 degree rotating retracts

(CJMQ3055) will also work as well. Other retracts

have not been tested.

COMMON ABBREVIATIONS USED IN

THIS BOOK AND ON THE PLANS:

Deg. = Degrees Ply = Plywood

Elev = Elevator Rt = Right

Fuse = Fuselage Stab = Stabilizer

LE = Leading Edge TE = Trailing Edge

(front) (rear)

LG = Landing Gear " = Inches

Lt = Left Tri = Triangle

TYPES OF WOOD

Page 7

Sanders are made from lightweight extruded

aluminum and can be found at most hobby shops.

They are available in three sizes – 5-1/2"

(GPMR6169) – 11" (GPMR6170) for most general

purpose sanding and 22" (GPMR6172) for long

surfaces such as wing leading edges. We

recommend using the 2" wide self-adhesive

sandpaper sold in 12' rolls by Great Planes.

Standard sandpaper can be attached by gluing it

to the sander with brush-on rubber cement. Apply

the rubber cement to both the bottom of the

sander and the back of the sandpaper. When both

surfaces are dry to the touch, press the sandpaper

firmly onto the sander. Spray adhesive can be

used for this purpose but it’s much harder to

remove the sandpaper when you need to replace

it. Use a knife blade for cutting sandpaper, not

your good scissors!

GET READY TO BUILD

❏

1. Unroll the plan sheets. Reroll the plan sheets

inside out to make them lie flat.

❏ 2. Remove all parts from the box. As you do,

determine the name of each part by comparing it

with the plan. Using a felt-tip pen, write the part

name or size on each piece to avoid confusion later.

Use the die-cut patterns shown on pages 4 and 5 to

identify the die-cut parts and mark them before

punching out. Save all scraps. If any of the die-cut

parts are difficult to punch out, do not force them!

Instead, first cut around the parts with a hobby knife.

After punching out the die-cut parts, use your bar

sander or sanding block to lightly sand the edges to

remove any die-cutting irregularities.

❏ 3. As you identify and mark the parts, separate

them into groups, such as fuse (fuselage), wing, fin

and stab (stabilizer), and hardware.

BUILD THE STAB

❏

1. Arrange the stab portion of the plan on a

flat building board (you may wish to cut out the

stab section). Cover the area over the stab with

waxed paper.

7

OTHER ITEMS REQUIRED

❏ Four-Channel Radio with 4 servos (additional

channels and servos required if retracts and/or

flaps are used).

❏ Top Flite Power Point

®

Propellers (see engine

instructions for recommended sizes)

❏ Prop Safety Nut (Great Planes has sizes and

styles that work nicely)

❏ 12 oz Fuel Tank (DUBQ0212)

❏ 5/32" Wheel Collars - 4 (GPMQ4306)

❏ 3/32" Wheel Collars - 2 (GPMQ4302)

❏ Top Flite MonoKote Covering Material (Insignia

Blue and Yellow)

❏ Fuelproof Paint* for Cowl, Canopy and Oil

Coolers (Top Flite LustreKote™recommended)

❏ Latex Foam Rubber Padding, 1/4" thick

(HCAQ1000)

❏ Silicone Fuel Tubing (GPMQ4131)

❏ Plastic Pilot: Williams Bros. Standard, 2" Scale

#17600 (WBRQ1050)

❏ Main Gear Retracts (optional)...Robart #615

(ROBQ1815) Century Jet 33325 - complete

kit (CJMQ3055)

❏ Air Control Kit (optional retracts)...Robart

#188VRX (ROBQ2307) (Not required with CJ

33325)

❏ Oleo Robo Struts (optional)...Robart #650

(ROBQ1700) (Not required with CJ 33325)

❏ Hinge Points (optional flaps)...Robart #308

(ROBQ2508)

❏ 3-1/4" Main Wheels...Robart #134 (ROBQ1534)

❏ 1-1/4 Tail Wheel (GPMQ4242)

❏ .60 to .80 2-stroke, .90 to 1.20 4-stroke

NOTE: Top Flite “LustreKote Paint” matches

MonoKote covering and is available in aerosol cans.

❏ 2. Cut the balsa 3/8" x 5/8" x 24" LE stock to fit

nicely at the center joint. Save excess material for

the fin LE. Trim the tip of the LE to the approximate

shape on the plan but leave about 1/16" excess for

final shaping later.

❏ 3. Cut the balsa 1/4" x 3/8" x 30" TE stock to

the correct length. Extra material is kept for the Fin.

❏ 4. Cut the two elevator tip blocks from the 1/2"

x 1/2" x 4" balsa stick provided. Shape the tips to

match the plan shape.

❏ 5. Make the stab tips from excess 3/8" x 5/8" LE

stock. Set the previously made parts aside for now.

❏ 6. Make a top and bottom stab skin by placing

the 1/16" die-cut balsa pieces, stab front and stab

back, together over waxed paper and glue them

together with thin CA. Block sand the skins lightly

with 220-grit sandpaper.

Page 8

❏ 7. Pin the bottom skin to the stab plan. Draw

tick marks for the rib spacing on the skin to match

the plan. Glue the LE and TE pieces on top of the

bottom skin.

❏ 8. Cut the “ribs” from two 3/32" x 3/8" x 24"

balsa sticks. Align them with the “tick” marks and

glue in place. Do not overlook the two angled

pieces in the center over the fuse stab base.

❏ 9. Check the fit of the stab tips. Sand if

necessary, then glue them in place.

❏ 10. Use a bar sander to flatten the top of the

exposed structure. No parts should be left high or

low. Check all glue joints and add glue to any that

appear weak.

❏ 11. Glue on the top stab skin with medium or

slow CA. Be sure to apply glue to all ribs as well

as the LE and TE.

❏ 12. True the stab tips to match the die-cut

stab skins.

❏ 13. Draw a centerline around the stab to help

you maintain symmetry during sanding. Rough

shape the LE and the tips to the approximate cross

section shown on the plan.

BUILD THE FIN

❏

1. Trim the 3/8" x 5/8" LE and the 1/4" x 3/8" TE

to match the plan. Notice that they extend down

into the formers.

❏ 2. Make a left and a right fin skin by placing the

die-cut 1/16" balsa fin front and fin back together

over waxed paper and applying thin CA to the joint.

Block sand lightly.

❏ 3. Pin the right skin to the plan. Glue the LE and

TE on top of the skin.

❏ 4. Cut to length and glue in the 3/32" x 3/8"

“ribs” where indicated on the plan.

❏ 5. Block sand the structure until it is flat.

❏ 6. Use medium CA to glue the left fin skin to all

the ribs, the LE and the TE.

❏ 7. Draw a centerline around the fin to assist you

in hinging and shaping. Shape the LE of the fin to

match the cross section on the plan.

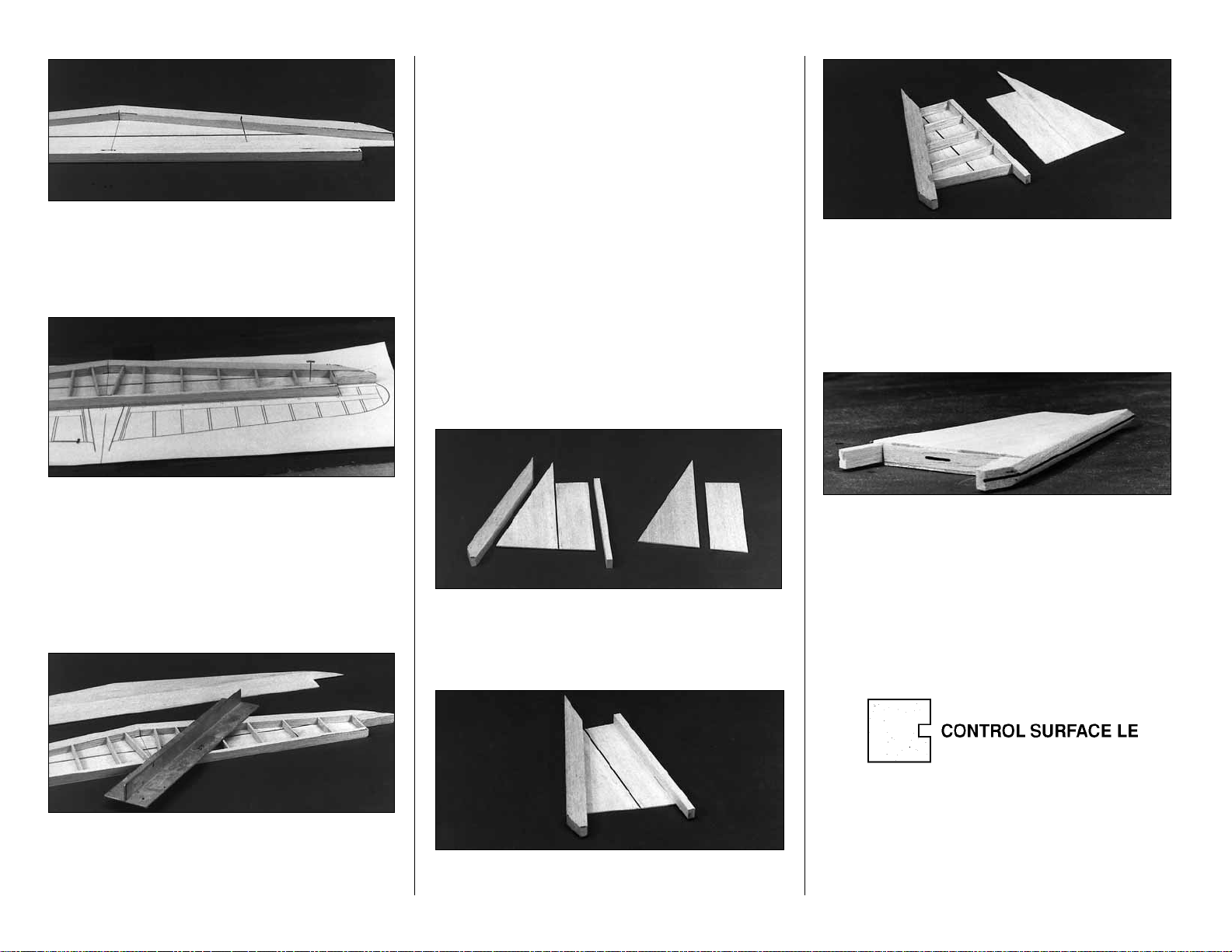

BUILD THE ELEVATORS

❏

1. Place the 3/32" balsa die-cut elevators over

the plan. Mark the locations of the “ribs” on both

sides of both elevators.

❏ 2. From the grooved 1/2" x 1/2" x 30" balsa

control surface LE, cut two pieces to the length

shown on the plan.

❏ 3. Slide the elevators into the slot in the control

surface LE’s. Glue with CA.

8

Page 9

❏ 4. Hang the LE’s over the edge of the table and

glue the 3/32" x 1/4" “ribs” (made from 3/32" x 1/4"

x 30" balsa) to the elevators at the locations

marked earlier.

❏ 5. Flip the elevators over onto their other side

and glue the “ribs” onto the second side.

❏ 6. Center the 3/32" die-cut balsa balance tabs

on the forward surfaces of the elevator LE’s. Glue

them in position as indicated by the plan.

❏ 7. Glue the elevator tip blocks (cut earlier) to the

end of the elevators.

❏ 8. Cut 2" balsa balance tab LE’s from 1/4" x

1/2" stock. Glue them to the front edge of the

elevator as shown on the plan.

❏ 9. Cut balance tab root cap strips from leftover

balsa 3/32" balsa. Glue them to the root end of the

balance tabs as shown on the plan. Glue a rib to

the balance tab (made from 3/32" x 1/4" x 30"

balsa) between the tip and the root cap strip.

❏ 10. Make doubler caps for the root end of each

elevator from leftover 1/8" balsa. Glue a cap to the

root end of each elevator. Make four torque rod

doublers (see plan for shape and location) from

leftover 3/32" balsa. Glue them to both sides of the

elevators in the locations shown on the plan.

❏ 11. Sand the tip of each elevator to match the

outline on the plan.

❏ 12. Use a bar sander to sand the ribs to match

the typical cross-section on the plan. Note that

there is some outward curvature to provide the

scale ribbed appearance.

❏ 13. Tape the elevators to the stab for blending

and shaping.

❏ 14. Remove the elevators and shape the LE to a

“V” as shown on the cross-section if you are using

the standard hinging technique. (See the Hinging

section and the plan sheets for alternatives.)

BUILD THE RUDDER

❏

1. Trim the grooved 1/2" x 1/2" balsa LE (left over

from the elevators) to the length shown on the plan.

Cut the balance tab LE from the 1/4" x 1/2" stock.

❏ 2. Join the 3/32" die-cut balsa rudder pieces,

rudder front and rudder back together with CA.

Mark the “rib” locations on both sides of the rudder.

❏ 3. Glue the rudder sheet into the slot in the

rudder LE.

❏ 4. Cut “ribs” from the 3/32" x 1/4" x 30" balsa

sticks and glue them to both sides of the rudder.

❏ 5. Glue the 1/4" x 1/2" balance tab LE to the

front edge of the rudder.

Photo for steps 1-6

❏ 6. Make doublers from leftover 3/32" sheet to

reinforce the area where the torque rod protrudes

into the rudder (see plan for location).

❏ 7. Shape the rudder to match the photos and

the typical cross-section on the plan. Tape the

rudder to the fin for shaping.

❏ 8. Shape the LE to a “V” as shown on the

cross-section if you are using the standard

hinging technique.

9

Page 10

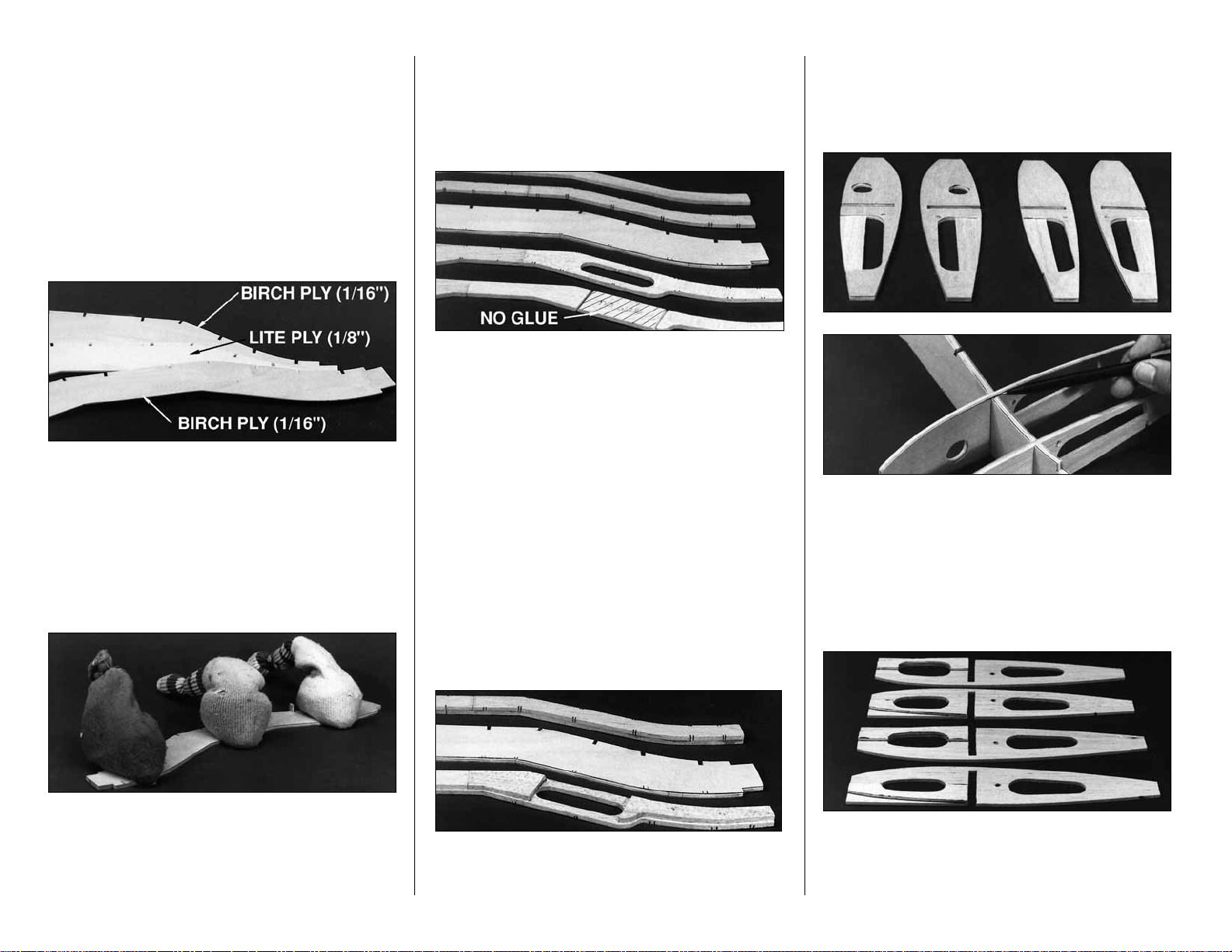

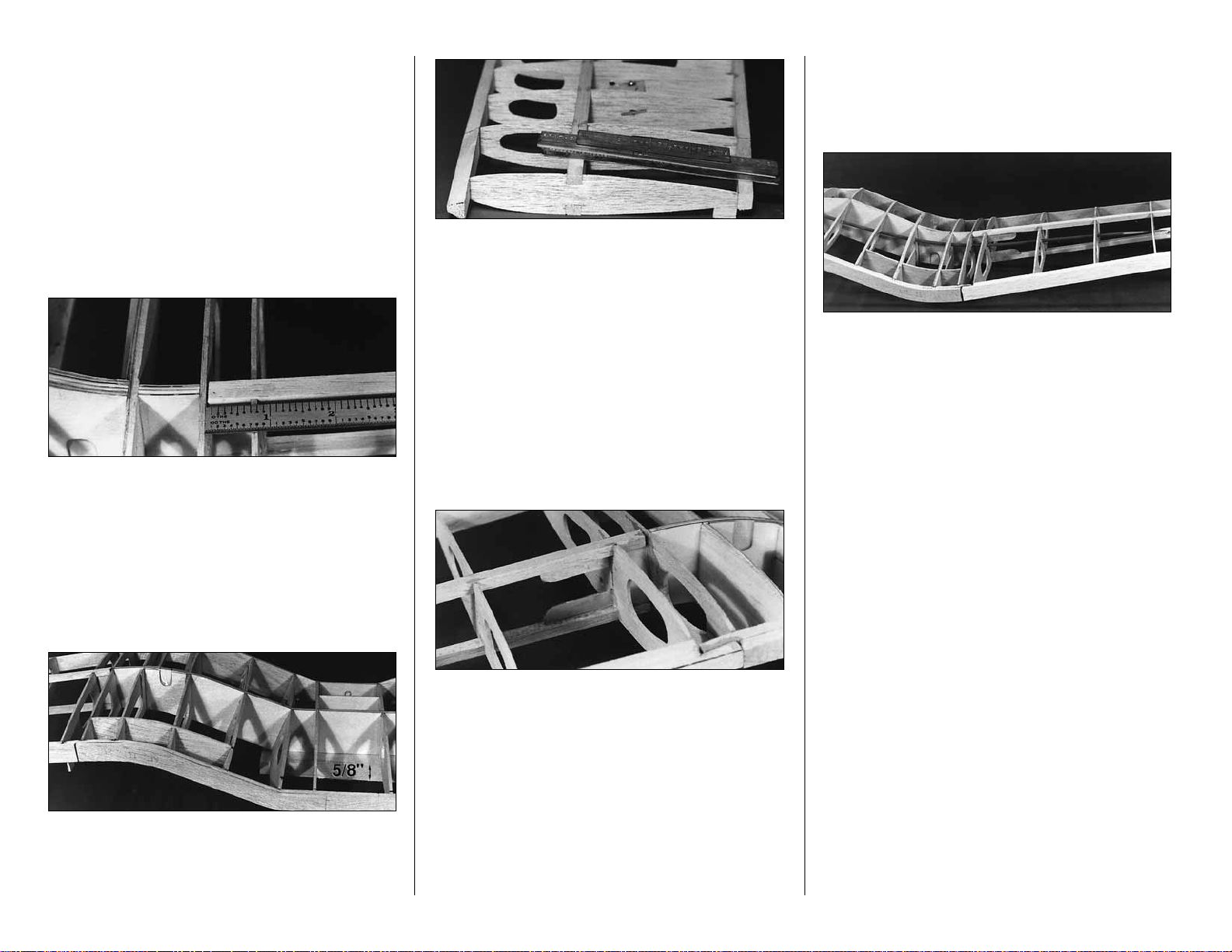

BUILD THE WING

WING CENTER SECTION

NOTE: The center section main spar is made of one

die-cut 1/8" plywood piece sandwiched between two

die-cut 1/16" birch plywood pieces.

NOTE: The wing root ribs are stamped only with a

number (2 is R-2), the wing tip ribs are stamped

with T and a number (T 4 is T-4).

❏ 1. Lightly sand the surfaces of the three pieces

that make up the main spar to make sure they will

lie flat together for a good glue joint.

❏ 2. Make some short sticks from leftover 1/8"

balsa to key the rib slots together and assure

proper alignment during gluing. Test fit pieces.

❏ 3. Use 30-minute epoxy to glue the spar pieces

together. Use weights to hold them flat on the

table while the glue cures. Apply thin CA on the

edges of the spar, especially to areas that do not

appear to be well glued.

❏ 4. Clean up the edges of the spar with

sandpaper. If you will be installing retracts, you

may want to cut any holes required for your

retracts in the spar at this time. See the

instructions that came with your retracts.

❏ 5. Join the die-cut 3/16" balsa aft leading edge

pieces at the center over the template provided on

the plan. Use the plan to mark the rib locations on

the aft LE. Glue the die-cut 3/16" balsa fwd

leading edge pieces to the aft leading edge.

(Center the fwd leading edge on the aft leading

edge as shown on the cross-sectional view.) Refer

to the photo - do not put glue where indicated.

❏ 6. Join the die-cut 3/16" balsa fwd trailing edge

pieces at the center over the template provided on

the plan. Use the plan to mark the rib locations on

the fwd TE. Glue the die-cut 3/16" balsa aft trailing

edge pieces to the fwd trailing edge. (Center the aft

trailing edge on the fwd trailing edge as shown on

the cross-sectional view.)

❏ 7. The hatched area of the forward LE which was

not glued may be cut loose with a razor saw and

removed after the glue has set on the rest of the part.

❏ 8. Drill 3/16" holes through all ribs and doublers

that require them for aileron linkage routing. These

holes are located by punch marks in the ribs just

aft of the spar.

❏ 9. Glue the die-cut 1/16" plywood R-2B rib

doublers to the die-cut 3/32" balsa R-2 ribs. Glue

the plywood R-3B rib doublers to the balsa R-3

ribs. Be sure to make a left and a right of each

assembly. Trial fit the R-3 assembly into the spar

slot – you may find it necessary to bevel the

plywood doubler along the top side a little for a

smooth transition.

❏ 10. Glue the die-cut 1/8" balsa R-4B sub ribs to

the die-cut 1/8" balsa R-4 ribs. Glue the R-5B sub

ribs to the R-5 ribs. Be sure to make a left and a

right of each assembly.

10

Page 11

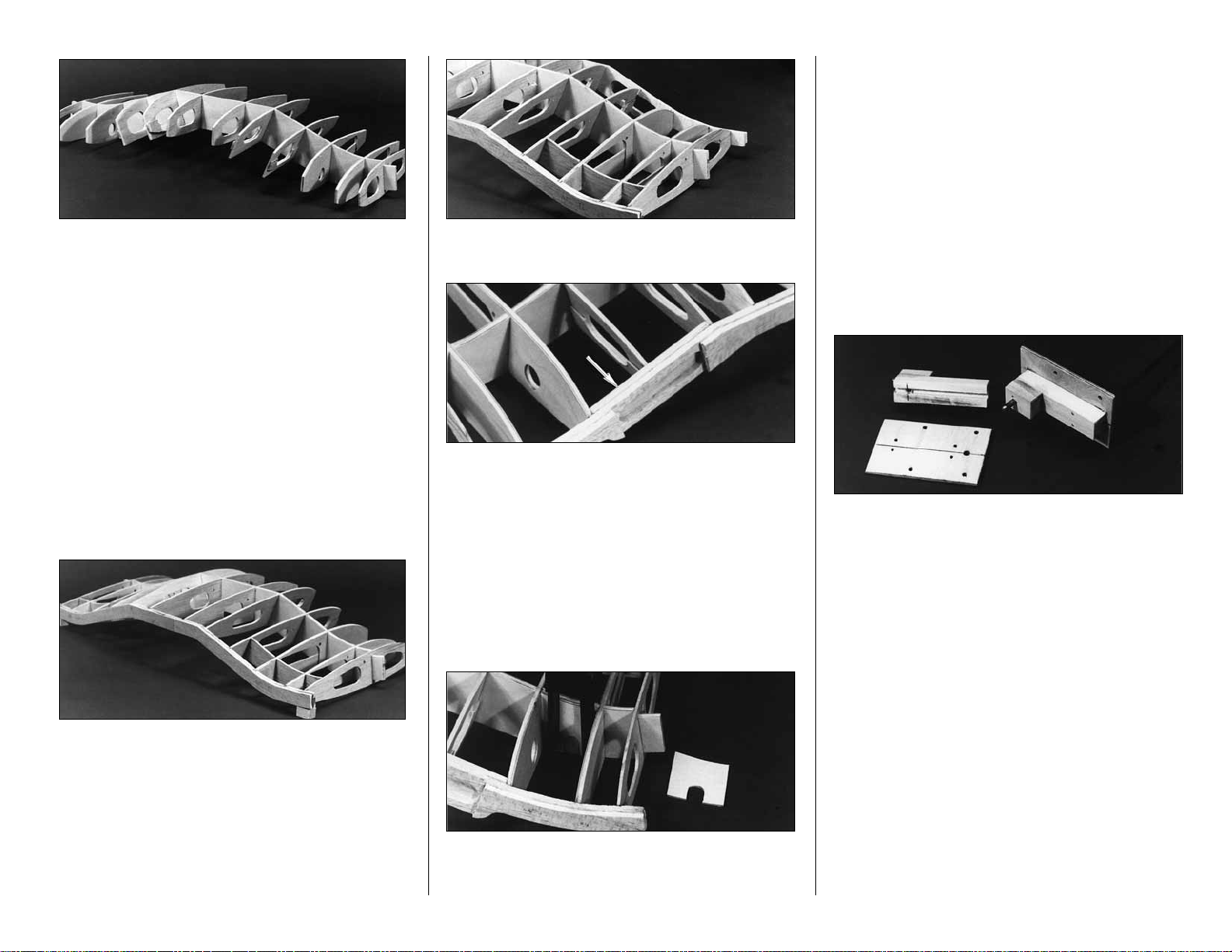

❏ 11. Plug the die-cut ribs R-1 to R-6 into the

spar. Hold this assembly over the plan to make

sure the ribs are perpendicular to the spar and not

skewed. When you are satisfied that all ribs are

fitting properly, lightly glue them in place with a

drop of CA. You will glue all these joints thoroughly

after the LE, TE and a few other parts are installed.

❏ 12. Make a couple of 1/2" tall balsa blocks to

support the ends of the R-1’s and prevent the center

section from twisting. Tack glue these to the R-1’s.

❏ 13. Slide the die-cut balsa well doublers (WD)

into place - do not glue yet.

❏ 14. Glue the TE assembly in place. Check the

center section on a flat table to be sure it is not

twisted. Flex and reglue joints to take out any warps.

❏ 15. Align the LE assembly onto the front edge

of the wing. Glue only to ribs R-1, R-2 and R-3.

❏ 16. Glue the die-cut 3/16" balsa LE triplers in

place between R-3 and R-5. Glue ribs R-4 and R-5

to the LE.

❏ 17. Glue both 1/8" die-cut plywood dowel

plates (DP and ADP) in place as shown on plan.

Glue the R-6’s to the LE. Drill a hole through the

LE of the wing through the hole in the forward

dowel plate (DP). Start with a small drill and

gradually increase the size to 5/16".

❏ 18. If you are using retracts, glue in the die-cut

1/16" plywood spar doublers (SD) on both sides

of the spar using 30-minute epoxy. Cut a notch in

the main spar to match the strut cutout in (SD).

The notch will probably need to be deepened

slightly during final retract fitting. Keep this cut

smoothly radiused to prevent the creation of a

weak spot in the wing. A small Dremel

®

drum

sander is helpful here. See Page 42 for details on

retract installation.

19. If you are using fixed landing gear, assemble

both sets of fixed gear parts with 30-minute epoxy

as follows:

❏ A. Drill the holes in the 1/8" x 1-13/16" x 3"

5-ply plates using the pattern on the wing plan.

❏ B. Glue each basswood 7/16" x 5/8" x 7/8"

landing gear retainer block to a grooved bass

landing gear mount.

❏ C. Refering to the drawing on the wing plan, drill

a 5/32" hole where shown into each Grooved LG

mount and through each LG retainer block.

❏ D. Slide a 1/8" plywood plate onto each main

landing gear wire. Trial fit the LG block assemblies,

relieve any parts if necessary to allow the 1/8" plates

and the block assemblies to almost come together

(a little pressure during final assembly is good).

NOTE: The wire Landing Gear in the kit differs in

appearance from the wire LG in the photos.

❏ E. Drill the four 5/64" holes shown in each

basswood block assembly for the #4 x 1/2" sheet

metal screws, using the 1/8" plate as a pattern.

11

Page 12

❏ F. Disassemble the parts and enlarge the hole

drilled in the previous step in the 1/8" plate to 1/8"

for clearance.

❏ G. Reassemble the fixed gear parts.

❏ 20. Measure and drill the gear mounting holes in

the 1/4" x 5/16" x 3" plywood mounting rails.

Mount the fixed gear plates or retracts – test fit

between R-2B and R-3B while holding the 1/16"

die-cut plywood R-3C gear reinforcement tripler in

place (if you are using retracts, make sure the

retract will clear the wing skins). Adjust the height of

R-3C if necessary. Do this for both wing panels.

❏ 21. Glue the R-3C’s in position.

❏ 22. Tilt the LG assemblies (fixed or retract) until

the struts protrude straight down (the left and right

struts should be parallel to each other and

perpendicular to the ground). Check the fit of the

R-2C’s, adjust their height if necessary, then glue

them in place. Glue in the mounting rails.

❏ 23. Remove the LG assemblies and apply a

small fillet of 30-minute epoxy to all joints involving

plywood in the landing gear mounting areas. Apply

some epoxy to the dowel plate joints also.

❏ 24. Glue all ribs to the spar. Glue both WD’s to

ribs R-1, R-2, R-3 and R-4. Reinforce any glue

joints that appear weak.

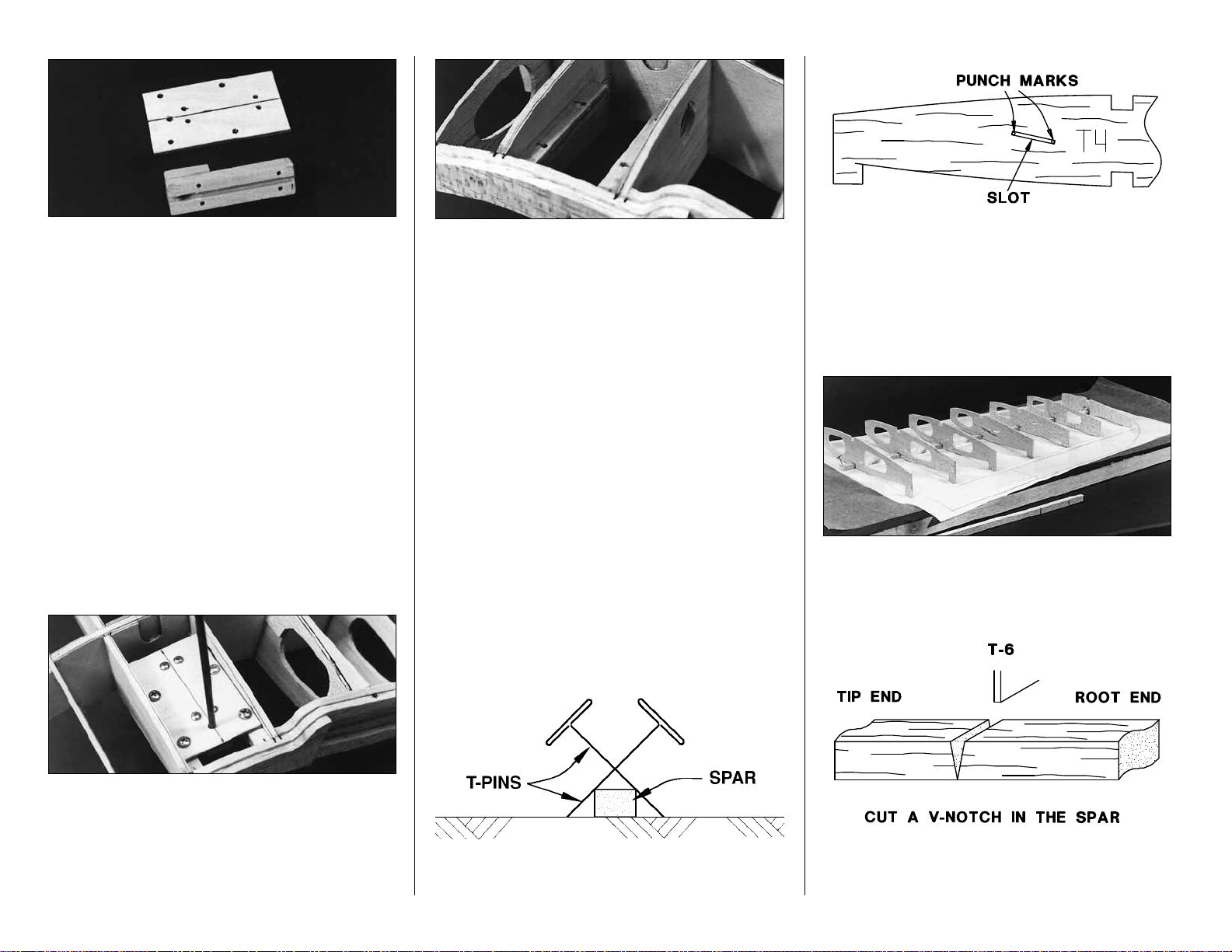

TIP PANELS

NOTE: The tip panels are built “UPSIDE-DOWN”

on the plan (the jig tabs are attached to what is,

in the end, the TOP surface of the wing.)

❏❏1. Place the tip panel plan over a flat building

board (you may wish to cut out these sections of the

plan sheet). Cover with waxed paper.

❏❏2. Cut the top 1/4" x 3/8" x 20" hard balsa

spar to length. Pin it in place over the plan.

❏❏3. Cut a 1/16" slot in the 3/32" balsa die-cut

ribs T-4 and T-5 between the punch marks

provided to allow the bellcrank platform to slide in

place later.

❏❏4. Glue die-cut 3/32" balsa ribs T-1 through

T-7 to the spar with the jig tabs at the TE flat

against the work surface.

❏❏5. Cut a V-notch in the bottom 1/4" x 3/8" x 20"

balsa spar so it can bend at T-6. Slide the bottom

spar into place. It will be glued in step 8.

12

Page 13

❏❏6. Notch the inner end of the shaped LE and

TE stock to match the plan.

❏❏7. Glue the TE to the ribs. Notice that T-7 is

glued flush with the top (toward plan) edge of the TE.

❏❏8. With the wing slightly weighted down so

the entire top spar and all the jig tabs rest on the

building board, apply glue to all joints involving the

bottom spar. Make sure the bottom spar is

securely glued at T-6 where it is notched.

❏❏9. Glue the LE to the ribs, centering it on all

ribs except T-7. T-7 is glued flush with top edge

(toward plan) of the LE.

❏❏10. Draw lines with a pen and a straight

edge as shown in the photos to mark the tapering

of the bottom of the LE and TE. Use a knife and a

sanding block to carefully taper the LE and TE.

❏❏11. Assemble the bellcrank parts onto the

die-cut 1/16" ply support – make a left and a right.

Be sure to put a drop of 6-minute epoxy on the

thread and nut of the 4-40 bolt to prevent it from

vibrating loose.

❏❏12. Glue the bellcrank assembly securely in

place through the slots in ribs T-4 and T-5.

❏❏13. Cut a 1/16" x 3/8" slot in the top and

bottom of T-1 so the 1/16" plywood spar joiners

can pass through the rib and overlap the main spar

when the panels are joined.

REPEAT THE WING TIP PANEL STEPS 1-13 TO

BUILD THE OPPOSITE PANEL. BE SURE TO

MAKE A LEFT AND A RIGHT TIP PANEL.

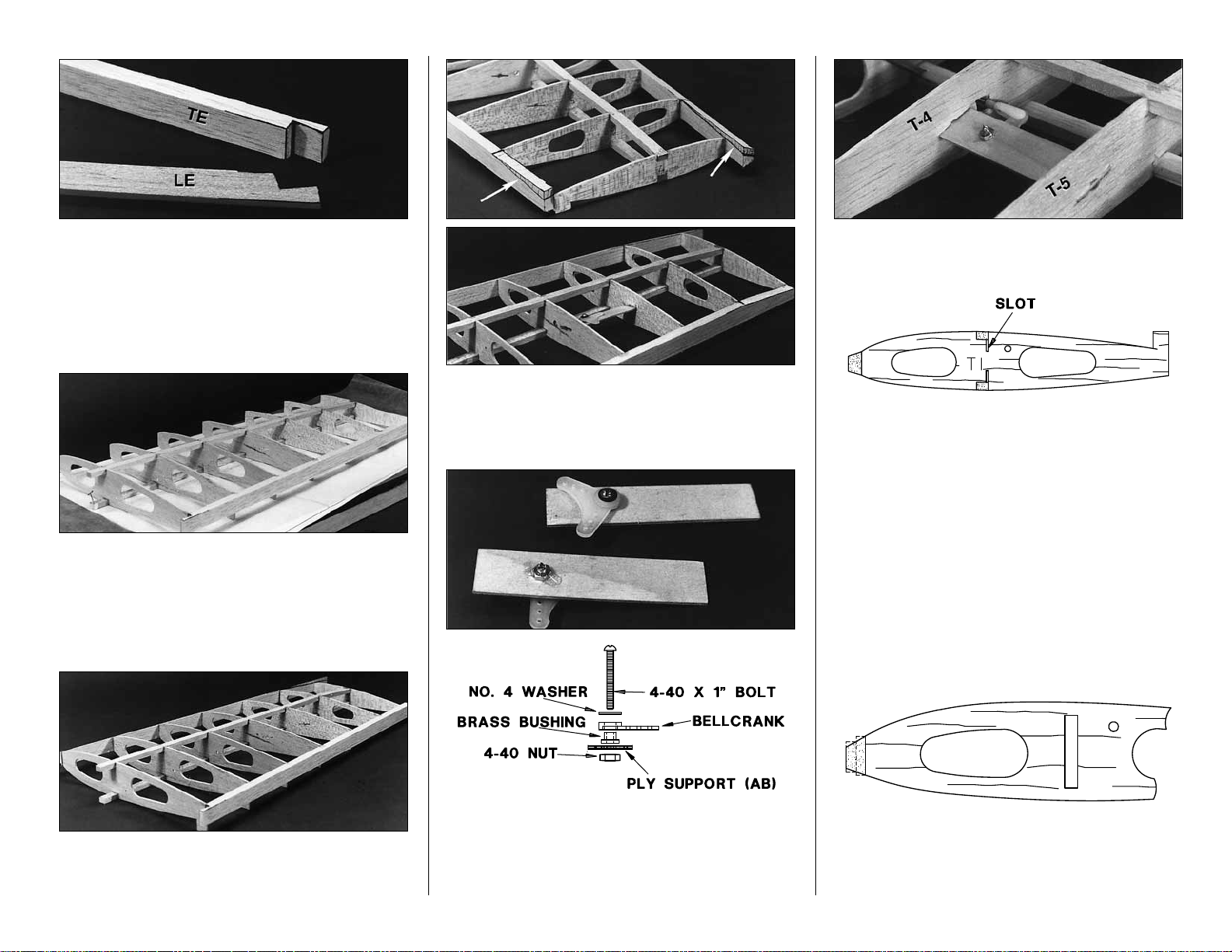

WING JOINING

❏

1. Trim off all tip panel jig tabs except the tabs

on the T-7’s.

❏ 2. Sand the center section LE and TE (using a

block or sanding bar where possible) to approximate

the shape of the outer panel LE and TE. Be careful

13

Page 14

not to alter the shape of the ribs during this process

(masking tape can be used to help protect them).

Final shaping can be done after wing joining.

❏ 3. Trim the tip panel top and bottom spars so

they protrude 11/16" past T-1.

❏ 4. Notch the front of the center section LE to

accept the tip panel LE. Notch the back of the

center section TE to accept the tip panel TE.

❏ 5. Make any small adjustments necessary to

allow you to mate the tip panel with the center

section. Use a small ruler to check that ribs R-1

and T-1 can be positioned parallel and 11/16"

apart. Adjust if necessary to obtain a good fit.

NOTE: The 3/8" wide tip spar should be

centered over the 1/4" wide center spar.

❏ 6. Place the wing upside down on a flat table

with the balsa 5/8" x 2" x 6" dihedral jig block under

the center section. This sets the proper dihedral

when the tips are on the table surface.

❏ 7. Apply small weights to the tips of the wing. The

T-7 jig tabs and the spar tips should contact the table.

Adjust the LE and TE junctions of the tip and center

sections to align them and relieve any stresses.

❏ 8. Check again to see that R-1 and T-1

are parallel.

❏ 9. Tack glue the TE and spar joints with CA.

❏ 10. Carefully remove the tip weights and look at

the entire wing. Make sure there are no twists in

the wing. If there are any problems, pop loose the

wing joints and realign them.

❏ 11. Replace the wing tip weights and apply

30-minute epoxy to all joints involved. Use

30-minute epoxy to glue the die-cut 1/16" ply spar

joiners in place before the glue cures.

WING STRUCTURE COMPLETION

❏❏

1. Cut a piece of the outer pushrod guide

tube to 18". Roughen the outside of it with coarse

sandpaper. Carefully slide it in place through the

wing ribs. Glue it to all ribs it touches.

❏❏2. Cut a 20" piece of inner pushrod tube and

screw a 1" piece of threaded rod and a nylon clevis

into one end.

❏❏3. Use a sharp knife to cut a 5/16" sq.

window in T-4 where the pushrod passes through.

This will allow the pushrod to move slightly as the

bellcrank rotates.

❏❏4. Slide the inner pushrod tube into place

and connect the clevis to the bellcrank.

REPEAT STEPS 1-4 FOR THE OTHER SIDE OF

THE WING

❏ 5. If you have your aileron servo available it is

easiest to install it now. This will allow you to

confidently zero the bellcranks when the servo is in

its centered position. See plan for proper location

and mounting of the aileron servo. The aileron

servo is mounted on 3/16" x 3/8" plywood rails.

NOTE: The servo may protrude about 5/16" below the

bottom of R-6 into the belly-pan if necessary.

Skip steps 6 to 8 if you are using standard

sport ailerons and no flaps.

14

Page 15

❏ 6. If you are installing functioning flaps, install

the hinge reinforcement blocks shown on the wing

plan. These are cut from a 3/8" x 1/2" balsa stick

supplied. The flap reinforcement blocks (for Hinge

Points) rest against the bottom wing skin.

❏ 7. If you wish to use the “scale” type of aileron

hinging (see plan for a typical cross section), using

Hinge Points, install reinforcement blocks now. The

aileron reinforcement blocks are centered on the

TE.

❏ 8. Mark the hinge locations on the outside of the

TE so you can find them after the wing is sheeted.

❏ 9. In preparation for wing skinning, sand any

parts that protrude higher than the surrounding

parts. Any high spots will cause you to sand

through the wing skins after they are applied. It is

important to have a consistent structure if you want

a smooth skin.

❏ 10. Final sand the center section LE and TE to

blend them with the outer panel. The transition from

the LE to all the ribs may be slightly blended to

provide a smooth curve for the sheeting to bend over.

❏ 11. Do any final fitting of retracts at this time. If

you have chosen retracts that require external

actuation, rig them at this time.

❏ 12. Make the aileron pushrods from the 12" long

threaded end rods. Make a Z-bend in one end and

screw a nylon clevis on the other.

WING SHEETING

❏

1. Sort through the 1/16" x 3" x 24" balsa wing

sheeting, separating the best wood with the most

uniform grain for the top wing skins. Use the other

wood for the bottom skins.

❏ 2. True the edges of the wing sheeting by

placing a metal straightedge lengthwise on the

sheet. Position the straightedge about 1/32" from

the sheet edge. With a sharp knife, cut carefully

along the straightedge.

❏ 3. Place waxed paper on a flat smooth table.

You will join the wing skins on this surface.

❏ 4. Edge glue four wing sheets together with thin

CA for each of the four outer panel surfaces.

LIGHTLY sand both sides of the skin over the work

surface with a block and sharp 220-grit sandpaper.

❏❏5. Hold a skin over the bottom of the outer

wing panel. Mark the shape of the wing on the

skin, allowing about 3/16" extra on all sides. On the

wing bottom, the section between T-6 and T-7 is

sheeted separately from the section between T-1

and T-6. Cut off the tip of the skin and save it.

❏❏6. Connect the aileron pushrod to the

bellcrank. Make a small cut in the bottom skin to act

as a pushrod exit. Refer to the plan for its location.

NOTE: Before gluing the bottom wing skin, jig

the wing as before with the 5/8" block under

the center and the tips weighted on the table.

15

Page 16

❏❏7. Test fit the bottom skin. Make any

adjustments necessary for a good fit. Apply

medium or slow CA to all the structure that will

contact the bottom wing skin between T-1 and T-6.

Carefully position the bottom wing skin on the

structure between ribs T-1 and T-6. The skin

should cover half of the rib T-6. Hold the skin in

place until the glue cures (masking tape is often

helpful in holding skins in place while glue sets).

❏❏8. Do any trimming necessary to fit the skin

piece cut off at step 5, over ribs T-6 and T-7. Glue

the tip skin in place.

❏❏9. Make two 1/4" x 1" pushrod exit stiffeners

from leftover 1/16" balsa. Glue them in place around

the aileron linkage exit in the bottom wing skin.

REPEAT STEPS 5 to 9

FOR THE OTHER TIP PANEL

❏❏10. Cut the top outer panel wing skins from 2

remaining blanks made earlier. The top tip panel is

skinned in one piece from the center of T-1 to T-7.

❏❏11. When you are ready to skin the top of the

wing, cut the remaining jig tabs off the T-7’s. Be

careful not to twist the tip panels while

applying the top skin.

❏❏12. Apply medium or slow CA to all structures

that will contact the top wing skin. Position the top

wing skin on the structure and hold it in place until

the glue sets.

REPEAT STEPS 10 to 12

FOR THE OTHER TIP PANEL

❏ 13. Trim and sand the edges of all tip panel

wing skins with a knife and bar sander.

❏ 14. Refer to the photos and plan to see the grain

directions of the sheeting on the top of the wing

center section. All sheeting in the top center section

is applied in prejoined sections as in photos. Study

the photos in this section...when making the skins

with angled grain, cut the sheets at 45 degree

angles to conserve wood. The grain direction shown

for these wing skins represents the best technique

for sheeting the Corsair’s bent wing.

NOTE: You may find it faster and easier to do

both left and right wings at the same time to

avoid having to determine the sheet shapes

twice. Skin sizes given are approximate.

❏ 15. Make a slightly oversize skin to cover the

area forward of the spar from R-3 to T-1. Trim the

wood until it fits well along the edge at T-1.

❏ 16. Wet the outside of the skin with a water

soaked paper towel. Glue the skin in place starting

at T-1. You may apply glue from the underside of

the wing structure.

❏ 17. Trim the skin edges to the middle of the

spar and the middle of R-3.

16

Page 17

❏ 18. Make a skin to cover the area aft of the spar

from R-5 to T-1. Wet the skin and place it over the

structure. Trim it so it fits well at T-1 and at the

spar. Glue the wet skin to the structure.

Photo for steps 19-20

❏ 19. Make a skin for the section forward of the

spar from R-5 to R-3. Glue this piece on dry.

❏ 20. Skin the top of the wing between the two R-5’s.

❏ 21. Add some CA to any questionable center

section top wing skin joints from the bottom side of

the wing.

❏ 22. If you are using flaps, install the servos now.

They are mounted on 3/16" x 3/8" plywood rails

between ribs R-4 and R-5. Notice that one servo is

mounted inboard in the bay and one is mounted

outboard. This allows both pushrods to exit at the

center of the bay. Route the servo leads to the

center as shown. (A Y-harness is used to connect

the two flap servos together. Plug the Y-harness

into the receiver and use it as an extension.)

NOTE: The ribs were changed slightly after the

photos were taken to make it easier to mount the

servo rails.

❏ 23. Make the flap pushrods from two 12"

threaded end wires. Use nylon clevises at one end

of the wires and make Z-bends at the other. When

the servos are centered the clevis pins should line

up with the seam between the two 3/16" TE

laminations.

NOTE 1: If you are using fixed gear, the standard

procedure is to securely screw the fixed gear into

place before proceeding to sheet around the wire

strut. An alternative is to proceed as you would

with the retracts. Sheet the bottom of the wing with

no gear installed and cut out an opening for

installing the fixed/retract gear after sheeting is

completed. A balsa block (not supplied) could be

glued to each fixed gear plate (with holes drilled to

access mounting bolts) and faired into the bottom

of the wing. This technique allows you to remove

the fixed gear for servicing.

NOTE 2: All of the bottom wing sheeting is cut from

the remaining 1/16" x 3" x 24" balsa sheeting. Study

the photos in this section before proceeding. You may

find it faster and easier to do both left and right wings

at the same time to avoid having to determine sheet

shapes twice. Indicated skin sizes are approximate.

NOTE 3: Parts of the center section will be

covered by the belly-pan. Do not fill small misfits in

this area until after the belly-pan is installed.

❏ 24. Cut a 1-1/2" x 10" piece of 1/16" wing skin.

Glue it behind the main spar, starting at the aft half

of the main spar.

❏ 25. Next, glue a 1-1/2" x 7" piece forward from

the center of the main spar. This sheet covers from

R-4B outward to T-1.

17

Page 18

❏ 26. Continue forward until you reach the LE with

narrower strips (3/4" to 1"). It will be necessary to

curve the aft edge of the strips to allow them to

conform to the structure.

❏ 27. Glue a 3" wide sheet over the center section

between two R-5’s. The R-5B’s serve as a shelf to

support this sheet.

❏ 28. Locate the small 1/8" die-cut R-5C sub ribs.

Cut off the small die-cut bump at the narrow end so

the part tapers to a point. Glue it in place at the

outboard end of the oil cooler as shown in the photo.

❏ 29. Make a piece of skin to cover the bottom of

the oil cooler from the center of the spar forward to

the LE. Study the photos. Notice how the sheet

blends into the center of the wing. Cut out a small

piece of wing sheeting between R-3 and R-4 just

forward of the main spar. This will allow the oil

cooler sheeting to blend in smoothly.

❏ 30. Glue the oil cooler skin in place.

❏ 31. Continue sheeting aft in 1-1/4" to 1-1/2"

increments. Allow the flap pushrods (if any) to exit

as shown.

❏ 32. Sheet the rest of the wing center section

between the R-5’s. The rectangular hole shown

allows the aileron servo to protrude into the belly-pan.

❏ 33. Cut out the vacuum formed oil coolers just

below the faint cut line on the inside. Use coarse

sandpaper to sand the part exactly to the line.

❏ 34. Place the oil cooler on the wing. Trace its

location onto the LE of the wing. Cut away balsa

under the oil cooler until it will blend nicely into the

wing. You will need to remove a fair amount

of wood.

❏ 35. Glue the oil cooler to the wing. Shape the

surrounding area to blend into the formed oil coolers.

Lightweight filler may be used to fill any gaps.

❏ 36. Use a portion of the provided 3/8" x 1/2" x 24"

stick to fair the outboard ends of the oil coolers.

The wing will be completed after the

Fuselage Construction.

18

Page 19

FUSELAGE TOP

NOTE: The 1/8" die-cut plywood formers are

stamped only with the necessary portion of their

name (F-3B is stamped 3-B).

IMPORTANT: All formers should be installed with

the STAMPED IDENTIFICATION NUMBER

FACING FORWARD. This is necessary to line up

the pushrod holes.

❏ 1. Cut out the Top View of the fuselage. Tape it

to the building board and cover it with waxed paper.

❏ 2. Pin the 1/8" die-cut forward frame accurately

over the plan. Be sure the outline fits the plan

exactly as this establishes the engine offset

thrust angle.

NOTE: Use a small triangle to hold all formers

vertical while gluing. Any small warps or twists in

the formers can be taken out when the 3/16" sq.

stringers are glued in place.

❏ 3. Glue F-3 into the forward half of the slot in

the middle of the forward frame.

❏ 4. Glue F-2 to the forward edge of the forward

frame. It is centered by the interlocking tab.

❏ 5. Separate the two 42" long shaped balsa

main fuselage stringers by running a knife

vertically against the edge where they are joined.

Sand the edges if necessary.

❏ 6. Position the main fuselage stringers in the

former notches so the ends protrude about 1/16"

forward of F-2. Notice that the 1/8" slots in the

main fuselage stringers are more toward the

bottom of the fuse (toward the table). Glue the

stringers to F-2, F-3 and the forward frame

❏ 7. Glue F-4 in place at the aft end of the forward

frame. The notch at the center of F-4 engages the

tab on the forward frame (see photo at step 10).

❏ 8. Drill 3/16" holes where indicated by punch

marks in F-5, F-7, F-8 and F-10. The pushrods will

be installed through these holes later. Check that

all pushrod holes are offset slightly to the plane’s

left. These holes should line up for a virtually

straight shot.

❏ 9. Check your servos for fit in the 1/8" die-cut

servo tray. Make modifications if necessary. Glue

the 1/8" die-cut plywood servo tray doubler strips

to one side of the servo tray as shown. These will

stiffen the tray and give the servo mounting screws

extra material to bite into.

❏ 10. Position F-5 over the plan. Key the servo tray

in place as in the photo. Notice that the servo tray

doublers are facing up. Glue F-5 to the main stringer.

Remove the servo tray and apply medium CA to the

mating surfaces. Put the servo tray back in position.

❏ 11. Glue the two halves of the die-cut 1/8" balsa

cockpit deck (CD) together.

19

Page 20

❏ 12. If you are installing the optional cockpit kit,

glue F-7 and the cockpit deck in position as

indicated in the photo. Otherwise, trim off both edges

of the cockpit deck along the precut lines and install it

in the notches in the upper part of the formers.

❏ 13. Glue F-8, F-9 and F-10 to the main stringers

over their location on the plan. Be sure the pushrod

holes are properly oriented.

❏ 14. Trial fit F-11 on the main stringers. Test the fit

of the stab base supports in between F-10 and

F-11. The stab base support should rest flat on the

building board along its entire length. This is very

important as it sets the stab incidence. Remove a

little material from the interlocking joints if necessary

to allow the stab base support to rest on the building

board. Glue the stab base support and F-11 in

position with medium CA.

NOTE: If you are installing the optional cockpit kit,

install the instrument panel as shown in the following

steps. Otherwise, the instrument panel is glued to the

base of the cockpit deck 1-1/16" behind F-5.

❏ 15. Glue all the upper stringers in place as

shown in the photograph. Check the formers with a

90 deg. triangle during this process to make sure

they are vertical.

❏ 16. Fit the Instrument Panel into the stringers

1-1/16" to the rear of F-5. Insure that it is parallel

with F-5 and then glue it into position.

❏ 17. With a sanding block, smooth any glue joints

that will affect the sheeting of the fuselage. Sand the

main stringers slightly to blend with the formers.

❏ 18. Glue the four 1/8" x 1/4" x 24" balsa sub

stringers into the slots in each of the main

stringers. These will provide a shelf for the

sheeting to rest on.

NOTE: It is helpful to put some weight in the cockpit

to hold the fuse firmly on the building board. Leave

the fuse on the building board during sheeting.

❏ 19. Locate the 3/32" x 4" x 36" balsa lower fuse

side sheets. Place the shaped 3/32" balsa upper

fuse side over the lower fuse side sheets. Trace

the “bow” of the bottom edge of the upper fuse

side sheet onto the lower fuse side sheets as

shown in the sketch. Set the lower fuse side sheets

aside until they are needed.

❏❏20. Pin a shaped 3/32" balsa fuse side on

the fuselage frame. Align the rear edge of the fuse

side with the rear of F-12. Notice that the bottom

edge of the fuse side is curved up slightly. This

allows the wood to bend around the fuselage

frame without lifting the center of the fuselage off

the building board.

NOTE: A small amount of water applied to the

outside of the fuse side with a paper towel is

helpful when bending the fuse sides.

20

Page 21

❏❏21. Glue the balsa fuse side to the main

stringer only between F-5 and F-7.

❏❏22. Apply medium CA to the edge of F-5 and

F-7 and the lower edge of the instrument panel.

Bend the fuse side to meet them. Use thin CA to

glue the fuse side to the 3/16" sq. stringer between

F-5 and F-7.

❏❏23. Work your way forward and aft from this

point, one former section at a time. Glue the fuse side

to the main stringer (at bottom edge of sheeting) first,

then to the formers and upper stringer for that

segment. If you notice the center of the fuselage

trying to lift off the building board during this process,

trim a little wood off the bottom edge of the fuse side.

Repeat steps 20 to 23 for the other fuse side.

❏ 24. Keep the fuselage firmly pinned down on

the building board until all glue is cured and the

wood is dry.

❏ 25. Look at the fuselage side view on the plan

and notice F-12’s height off the building board.

Glue F-12 in place. Trim the aft end of the fuse

sides flush with F-12.

❏ 26. Use the pattern provided on the plan to cut

two forward deck sheets out of the

3/32" x 2-1/2" x 36" balsa sheet. Glue one deck

sheet in place starting at the edge of the fuse side.

Apply glue to the former and the top 3/16" sq.

stringer. Wrap the sheet around until it is glued to

the top stringer. Trim the sheet to the center of the

stringer. Repeat this process for the other forward

deck sheet.

NOTE: The sheeting will extend well beyond F-2 to

allow trimming for the engine offset.

❏ 27. Use the pattern on the plan to cut two aft

deck sheets out of the 3/32" x 3" x 24" balsa

sheet. Glue the aft deck sheets in place as shown

in the photo and on the plan.

21

Page 22

❏ 28. Use a sanding block to sand the top of the aft

deck sheeting down to the height of the former tops.

❏ 29. Place the 1/2" x 2" x 17-7/8" top deck block

on top of the fuse. Trace the shape of the fuse

onto the bottom of the block. Roughly cut the block

to shape.

❏ 30. Mark a 1/2" wide slot on the top deck block

that will allow the fin to protrude through. Notice

that the fin LE sweeps back. Cut the slot into the

deck block. Temporarily plug the fin into the slots in

formers F-9 and F-10. Adjust the slot in the deck

block if necessary for a satisfactory fit. Tack glue

the deck block to the fuse but do not glue the fin.

Remove the fin and thoroughly glue the deck block

to the fuse with thin CA.

❏ 31. Shape the deck block to match the cross-

section on the plan. A razor plane is helpful for this

kind of shaping.

❏ 32. Remove the fuselage from the building board.

❏ 33. Inspect the structure from the inside. Add

glue to any open joints.

FUSELAGE BOTTOM

❏

1. Cut two of the 24" outer pushrod guide

tubes to the lengths required for the rudder and

elevator pushrods (see fuse side view).

❏ 2. Roughen the outside of the pushrod tubes

with sandpaper. Slide the tubes through the 3/16"

holes in the formers with reference to the plan.

Securely glue the tubes to all formers they contact.

❏ 3. Cut 10" off the unthreaded end of a threaded

pushrod wire. Cut about eight 5/16" lengths of the

inner pushrod tube from the material left over from

the inner aileron pushrod. Use rubbing alcohol to

remove any residue from the pushrod wire. Slide the

short lengths of inner tube over the pushrod wire,

spacing them approximately 3" apart. These act as

spacers to support the wire pushrod in the guide tube.

The spacers can be shorter than 5/16" if they are to

hard to push on. The spacers must not be near the

end of the outer pushrod tube. Apply a small drop

of thin CA to each spacer if the fit is loose.

❏ 4. Screw the nylon double-ended ball link onto

the threaded end of the .074" x 24" wire. Make a

22

Page 23

1-1/2" threaded rod by cutting off a 4" threaded

end rod and soldering a brass threaded coupler

onto the bare end. Screw this assembly into the

other end of the ball link.

❏ 5. Thread a nylon swivel clevis onto the

exposed end of the 1-1/2" threaded rod. Thread the

nylon parts onto the threaded rod until the center of

the ball and the center of the swivel clevis pivot

are exactly 2-1/4" apart (see photo for step 4).

❏ 6. Cut off the threaded end of the rudder

torque rod so the end is only 3/4" from the center

of the torque rod.

❏ 7. Screw the nylon swivel onto the rudder

torque rod and attach this assembly to the end of

the pushrod (see photo step 4).

❏ 8. Flatten one end of the 1/8" OD brass tube and

solder it onto the top of the tailwheel wire

assembly. Drill a 1/16" hole in the flattened portion

of the brass tube at the top of the tailwheel wire.

Securely screw the ball and nut to the tail wheel

wire. Use two #4 x 1/2" sheet metal screws to

screw the tail wheel wire assembly to the 1/8" die-

cut tail wheel mount plate (T W). Refer to the

photo for proper orientation. Put a drop of 5-minute

epoxy on the threads of each #4 screw and the nut

on the ball link to prevent them from vibrating loose.

❏ 9. Slide the rudder pushrod assembly into its

outer pushrod guide tube from the back of the fuse.

❏ 10. Position the tailwheel assembly and rudder

torque rod as shown on the plan. Check to see if

the tailwheel and rudder rods are both properly

aligned. Make adjustments if required.

❏ 11. Glue the tailwheel assembly to the fuse in

the position indicated on the plan. Use the wheel

collar to position the tailwheel wire so the pushrod

is centered in its passageway through the formers.

Use thread lock on the wheel collar set screw and

tighten it with an allen wrench.

NOTE: Do not glue the rudder torque rod bearing

tube in position until after the fin is attached. The

rudder torque rod may be taped back out of the

way until more work is done in this area.

❏ 12. Glue the die-cut 1/8" plywood F-3C to the

die-cut 1/8" plywood F-3B. Be sure that the 5/16"

punched holes in F-3C and F-3B line up with

each other.

❏ 13. Plug F-3B into the forward frame of the

fuselage just behind F-3. Notice that F-3C is on the

forward side of F-3B.

❏ 14. Slide the die-cut 1/8" plywood wing saddles

(WS) into place along the bottom of the fuse.

23

Page 24

❏ 15. Interlock F-3B and the wing saddles

together on the bottom of the fuse. Glue them to

the fuselage and to each other.

❏ 16. Glue F-4B, F-5B, F-6 and F-7B in place as

indicated on the plan and in the photos.

❏ 17. Glue the wing saddle triplers (ST) to the

inside of the wing saddle just forward of F-6 as

shown on the plan.

❏ 18. Glue F-8B, F-9B and F-10B in position as

shown on the plan.

❏ 19. Drill a 5/32" hole where indicated by the

punch mark in the 1/8" die-cut plywood tailwheel

support. It is helpful to contour the edges of the

tailwheel support slightly to allow the sheeting to

smoothly transition into it. Glue the tailwheel

support in place between F-9 and F-10. Roughen

the lower nylon tailwheel bearing with some fine

sandpaper and glue it to the tailwheel support. Be

careful not to get glue inside the bearing. A little

petroleum jelly applied to both ends will help

protect the inside of the bearing from glue.

❏ 20. Glue in the lower aft 3/16" sq. stringers as

shown in the photo. The center one is notched

slightly to where it engages the tailwheel support.

❏ 21. Trim the upper fuse side sheeting flush with

F-2. Use a bar sander to obtain a smooth

front surface.

❏ 22. Carefully align and glue F-2A to F-2. This

can be accomplished with the fuselage pointing

nose down, resting on F-2 over a waxed paper

covered flat surface.

24

Page 25

❏ 23. Glue the forward 3/16" sq. stringers into

place. These stringers can be used to pull any

slight twists out of F-2A.

❏ 24. In preparation for fuselage sheeting, look

over the structure and use a sanding block to

blend all parts smoothly.

❏ 25. Refer to the photo and plan. Cut oversized

lower fuselage sides from the 3/32" x 4" x 36"

balsa sheets. Cut the bow along the line you

marked earlier on the edge that engages the

main stringer.

❏ 26. Glue the bottom fuse sheet in place using the

same technique used on the upper fuse sheet. Start

at the center of the main stringer and work your way

toward the ends. It will be necessary to wet the

outer surface of the bottom sheet to permit bending.

❏ 27. Trim the ends of the sheeting at F-2A and

F-10B. Trim the edges of the bottom sheeting to the

middle of the 3/16" stringers. Lay a leftover piece of

stiff cardboard or similar thin sheet across the

plywood wing saddle pieces and mark the wing

saddle on the inside of the bottom fuse sheeting. Trim

the sheeting close to the mark along the wing saddle.

❏ 28. Use the 3/32" x 3" x 36" balsa fuse bottom

sheeting to skin the forward and aft fuselage bottom.

❏ 29. Use 30-minute epoxy to glue the 3/8" x 3/4"

x 1" hardwood wing bolt blocks in position. Back

these up with 1" lengths cut from the supplied 1/4"

hard balsa triangle stock.

❏ 30. Place a strip of masking tape over the

plywood wing saddle edges. This will prevent them

from being inadvertently altered. Use a sanding

block to carefully sand the bottom fuse sheeting to

the same height as the wing saddle. (A slightly

rounded sanding block works best for this.)

25

Page 26

❏ 31. Sheet (cross grain) the wing saddle area

with leftover 1/16" balsa wing sheeting. Trim and

block sand edges of the sheeting to blend with the

fuse sides and the wing saddle.

WING MOUNTING

❏

1. Draw an accurate centerline on both the wing

and the fuse to aid you in the wing mounting

process.

❏ 2. Drill a 5/16" hole in the LE of the wing

through the existing hole in the forward dowel plate

(DP) and through the aft dowel plate (ADP).

❏ 3. Round the ends of the 5/16" x 3-3/8" dowel

and install it into the hole you drilled. Trial fit the

wing onto the fuse. Make any adjustments to the

wing and fuse necessary for a good fit. If the dowel

alignment is interfering with the wing fit, “oblong” the

hole in the forward dowel plate using a round file.

❏ 4. Epoxy the dowel into the wing so it protrudes

about 1/2" forward of the LE.

❏ 5. Mark the tapered hardwood bolt plate with

a centerline. Put two lines 1-1/2" outside the

centerline on the non-tapered (square) side of the

block. Drill two 3/16" pilot holes 3/8" behind the

front (thick) edge of the block. Refer to plan for

exact locations.

❏ 6. Cover the aft portion of the wing saddle with

waxed paper. Place the wing in the wing saddle.

Use masking tape to hold the wing securely in

place. Carefully align the wing visually and with the

centerlines you drew.

❏ 7. Cut a piece of 1/16" balsa to fit in the wing

saddle behind the wing. Glue it to the aft edge of

the wing.

❏ 8. Epoxy the tapered hardwood bolt plate to the

aft edge of the wing and the 1/16" balsa sheet (see

photo at step 10).

❏ 9. Push a T-pin into the center of F-12. Tie a

piece of string to the pin. Use the string to check

the distances between the pin and the wingtips.

They should be equal.

26

Page 27

❏ 10. Tape and hold the wing firmly down. Use a

13/64" bit to drill through the pilot holes in the

tapered bolt plate and through the wing bolt blocks.

❏ 11. Remove the wing and tap the wing bolt

blocks in the fuse with a 1/4-20 tap. Drill out the

tapered bolt plate in the wing with a 1/4" drill to

clear the wing bolts.

❏ 12. Keep the saddle covered with waxed paper.

Bolt the wing onto the fuselage with two 1/4-20

nylon bolts.

❏ 13. Bevel the edges of the 1/8" die-cut plywood

F-6B to allow the wing saddle to blend into the

fuselage (see fuse side view). Glue F-6B in place;

the waxed paper must keep the glue off

the fuselage.

❏ 14. Test fit F-3D at the front of the wing saddle.

Trim it if necessary so it matches up nicely with F3B. Use waxed paper to make sure it does not get

glued to the fuselage. Glue F-3D to the wing.

❏ 15. Glue a 3/16" sq. stringer between F-3D and

F-6B. Slide F-4C and F-5C under the stringer. Trim

the height of F-4C and F-5C if necessary to obtain

a smooth profile in the belly-pan area.

❏ 16. Cut the 3/32" x 3" x 30" balsa belly-pan

sheeting using the approximate pattern on the

plan. Fit and glue the sheeting in place as shown

in the photo.

❏ 17. Cut 1/2" access holes in the belly pan

sheeting for the wing bolts. Glue lengths of

cardboard tubes into the access holes, but do not

glue the bolts. Trim their length close with a knife,

then sand flush with a block and sharp sandpaper.

❏ 18. Make two triangles from 1/8" leftover balsa.

Glue them in place behind the wing TE and fair in.

STAB & FIN MOUNTING

❏

1. Notch the bottom of the stab as shown to

allow elevator horn movement.

27

Page 28

❏ 2. Cut off the metal elevator horn so only two

1/16" holes remain. Check the holes in the horn

and remove any sharp edges or burrs that may

damage the clevis pin. Prepare the elevator

pushrod by screwing a nylon clevis onto a .074 x

34" threaded pushrod wire until the threads

protrude slightly into the clevis opening. Slide a

1/4" long piece of medium silicone fuel tubing

down the pushrod to act as a safety sleeve on the

elevator clevis. Slide 5/16" pieces of inner pushrod

tube onto the wire, spacing them about 3" apart.

Hook the nylon clevis to the outside hole on the

elevator control horn and slide the safety sleeve

over the clevis.

❏ 3. Securely glue the die-cut 1/8" plywood stab

base (SB) in flush with the two stab base supports.

Be sure the rudder torque rod is in its proper

upright position.

❏ 4. Position the stab in place on the stab base

and stab base supports. Check the stab alignment

with the wing. If any slant is detected, apply

masking tape to the low side of the stab supports

and block sand the other side of the base until the

stab will sit level.

CAUTION: Do not change the stab incidence

which is set by the stab base supports.

❏ 5. Check the stab alignment visually and with a

string from the top center of F-2 to the stab tips.

Epoxy the stab in place – check the final alignment

before the epoxy cures.

❏ 6. When the stab epoxy has cured, check the fit

and alignment of the fin and adjust if necessary (a

90 deg. triangle placed on the stab will help you

detect any fin tilt). Use 30-minute epoxy to glue the

fin in place.

❏ 7. Taper the fuse side sheeting between F-11

and F-12 as shown on the fuse side view. Look at

the photos and the plan, and note where leftover

3/16" balsa filler is glued on.

❏ 8. Angle the front edge of the 3/8" x 2-1/2" x 7-

3/4" lower aft fuse block. Glue the block to the

bottom of the fuse. Use a razor plane and a bar

sander to shape the block.

28

Page 29

❏ 9. Look at the photo and the plan. Make FWD

and AFT wedges from 3/16" or 1/8" leftover balsa.

Note the clearance holes in the aft wedge for the

elevator torque rods.

❏ 10. Glue the wedges in place. Use masking tape

to protect the stab while you sand the tops of the

wedges flush. Fit the 1/2" x 1" x 7-1/2" upper aft

fuse block. Glue it in place. Rough shape the sides

of the block to a taper but do not round the corners

until after the rudder fillet block is installed.

❏ 11. Move the rudder torque rod through its

range of motion. Make sure it is at an elevation

where it is not binding or striking a former. Mark

the height on the rudder where the torque wire

bends aft. Drill a 3/32" hole in the rudder to engage

the wire. Slot the lower leading edge of the rudder

to accept the remainder of the torque rod.

❏ 12. Refer to the plan to obtain a starting point

for shaping the 3/4" x 1" x 6" rudder fillet block.

Shape the rudder fillet block by trial fitting it

between the rudder and the fuse. Mark the radius

on the side of the fillet block by extending a line off

the bottom of the rudder. When the shape is close,

glue the fillet block in place on the fuselage. Use

the photos to assist you in obtaining the final

shape of the fillets.

❏ 13. Sand the end of the fuselage flat and glue

the shaped balsa aft tip block to the end of the

fuselage. Sand it to shape.

❏ 14. Mark the elevators left and right. Mark the

location of the torque rods on the elevators. Drill

the elevators with a 1/8" bit to accept the torque

rod. Notch the LE of the elevator to accept the

torque rod.

29

Page 30

❏ 15. Cut two 3-1/8" long elevator fillet blocks

from 3/8" x 1/2" stock. Tack glue one to the root

end of each elevator. Carve and sand them to

match the taper of the elevators. Bevel the root

end until the blocks mate to the fuselage when the

elevators are both neutral (make sure the

elevators are both aligned the same). Glue the fillet

blocks to the fuselage while the elevators are both

neutral. When the elevator blocks are properly

glued to the fuselage, break loose or cut through

the tack glue joints, leaving the fillet blocks

attached to the fuselage. Sand the root end of the

elevator to provide clearance between the elevator

and the fillet.

FIREWALL AND ENGINE

INSTALLATION

Read through this entire section

before proceeding!

Depending on your choice of engine, 2-stroke or

4-stroke, you may have to be a little inventive for

engine mounting and throttle, tank and muffler

hookup. The installation of a 2-stroke .60 to .75

size engine with a Top Flite In-Cowl Muffler

(TOPQ7915) is pretty straightforward. Some

4-stroke engines allow the throttle linkage to be

rotated 180 degrees, thereby permitting the same

servo setup as a 2-stroke engine. The O.S. .91

Surpass is one such engine.

This model flies very well on an O.S. .61 SF

2-stroke engine. As the .61SF also allows for the

most “sterile” setup with everything contained in

the cowl, we will detail its installation.

❏ 1. Mark a horizontal and vertical centerline on

the firewall F-1. Mark a line 3/16" to the right of the

centerline. (If the engine mount is centered on this

line, 2 deg. of right thrust starting at the firewall will

cause the prop shaft to be centered in the cowl.

❏ 2. Spread 30-minute epoxy over the entire

firewall. Use multiple strips of masking tape to hold

the firewall to the fuselage while the epoxy cures.

Install the firewall so the reference lines are vertical

and horizontal.

❏ 3. Decide how you will mount the engine. For a

.61 size 2-stroke engine, mounting at a 45 degree

inverted position will allow the cowl to be installed

as shown on the plans. Mounting the engine in

other positions will require the cowl mounting bolts

to be relocated.

❏ 4. Remove the spacer bar from the back of both

engine mount halves and trim off any burrs. Snap

the Engine Mount halves together and place the

engine between the rails, adjusting the width

between the rails accordingly.

❏ 5. Position the engine so that the propeller

backplate is exactly 5-3/4" (146 mm) from the aft

30

Page 31

edge of the engine mount. Mark, drill and tap the

engine mounting holes to accept 8-32 socket head

cap screws.

❏ 6. Center your engine mount over the lines you

drew on the face of the firewall. Mark and drill the

engine mount holes in the firewall. Install the engine

mount on the firewall with four 8-32 x 2" socket head

cap screws, #8 flat washers and #8 lock washers.

Cut off the excess screw length, if any, that

protrudes into the tank compartment.

NOTE: The firewall is already marked for the

45 degree inverted position.

❏ 7. Drill holes in the firewall for the fuel lines and

the throttle pushrod. The location of these holes will

depend on the engine installation you choose.

❏ 8. Before mounting the muffler you will have to

modify the Top Flite Engine Exhaust Header (not

included) and the Top Flite In-Cowl Muffler (not

included). Trim 3/8" from the outlet end of the

Engine Exhaust Header and 1/8" from the Muffler

inlet. Other engine and muffler combinations will

require different modifications. Bolt the Top Flite

Header to the engine. Use the Silicone Sleeve to

attach the Top Flite In-Cowl Muffler to the header.

Mount the Muffler to the firewall with the supplied

screws and silicone washers.

❏ 9. Place the molded plastic aft cowl ring on the

front of the model. The 1/8" mounting holes are

rotated 45 degrees from the horizontal and vertical

axis as shown in the photos. These holes may have

to be relocated depending on how you mount your

engine. Mark and drill these holes with a 5/32" drill.

❏ 10. There are four 1/2" x 1/2" x 11/32" maple

spacer blocks provided for mounting the cowl ring.

Drill a 1/8" hole through two of these blocks on the

face that is 1/2" thick. On the other two blocks drill a

1/8" hole through the face that is 11/32" thick. The

thicker blocks are used on the right side of the ring

and the thinner ones on the left side. You may have

to trim one of the blocks to clear the muffler.

❏ 11. Use 4-40 x 1-1/2" socket head cap screws,

#4 flat washers and #4 lock washers in conjunction

with 4-40 blind nuts inside the firewall to mount the

cowl. Cut off excess screw length, if any, that

protrudes into the tank compartment.

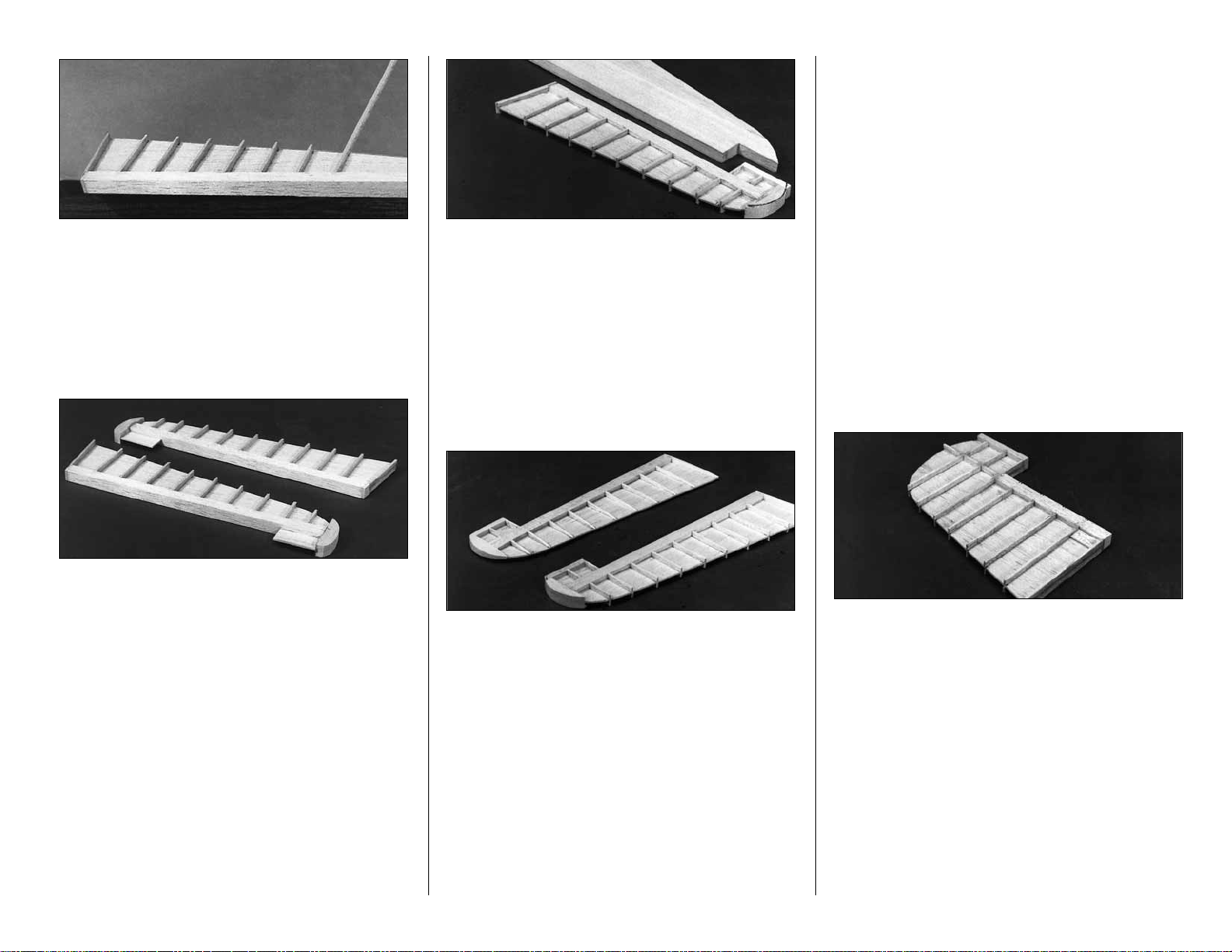

FLAPS

(Fixed and Operating)

❏ 1. Square up the trailing edge of the wing with a

sanding bar.

❏ 2. Put a mark 4-5/8" outside the sheeting

junction at R-5. Refer to the aft view of the wing on

the plan for flap and hinge locations.

❏ 3. Locate the aft (A) flap LE. Check its fit on

the outboard side of the mark you made. Taper (A)

with sandpaper if necessary to allow a 1/16" balsa

top and bottom skin to blend into the wing TE. (The

forward (F) flap LE is not used for fixed flaps; it

will be used later on operating flaps.)

❏ 4. Tack glue (A) in place as shown. (Glue it

solidly for fixed flaps.)

31

Page 32

❏ 5. Cut off a 5" piece of tapered aileron/flap

stock. This is the inner flap. Angle the inboard end

to match the fuse fairing. Trim its length so it fits

just inside of (A).

❏ 6. Tack glue the inboard flap section in place.

(Glue it solidly for fixed flaps.)

❏ 7. Put a mark 11-1/2" inboard of the wing’s tip

rib T-7. This is the outer flap/aileron junction.

❏ 8. Cut off a 7-1/4" length of flap/aileron stock.

This is the outer flap. Trim the inboard end of the

outer flap to match angle on the plan. (100 deg.)

Place the outer flap in position against (A). Trim the

length of the outer flap until it extends just to the

outer flap/aileron junction mark. The cut-off angle at

the outboard end of this flap is 90 degrees.

❏ 9. Tack glue the outer flap in place. (Glue it

solidly for fixed flaps.)

❏ 10. Glue the die-cut balsa flap ribs to A as

shown the photos. (These parts are found in diecut sheets CRS6S03 and CRS6S05. Use the 3/32"

parts at the ends of the middle flaps and the 1/16"

parts in the middle.) Notice that waxed paper is

used to separate the flap ribs from the other flaps if

you are making operational flaps. (Omit the waxed